Brita Platinum Performance, BPF89CB75TO, BPF89CBK100TOK, BPF89CB300TO, BPF89CBK75TOK Installation Manual

...

PLATINUM

TASTE AND ODOR (TO)

MULTIMEDIA (MM)

FILTER

NEXSAND

NEUTRALIZER (NU)

BIRM (BM)

Professional

Installation

MANUAL

Version V1.0F

54565

THROUGHOUT YOUR HOME | THROUGHOUT YOUR LIFE

The Platinum Carbon Filter Series is certified by

IAPMO R&T to NSF/ANSI 42 for chlorine, taste

and odor reduction.

The Platinum Catalytic Carbon Filter Series

is certified by IAPMO R&T to NSF/ANSI 42 for

chloramine, chlorine taste and odor reduction.

The Platinum Neutralizer Filter Series is

certified by IAPMO R&T according to NSF/ANSI

42 for low pH adjustment.

The Platinum Nexsand Filter Series is certified

by IAPMO R&T to NSF/ANSI 42 for Particulate

Class V reduction.

2

2

This control value and pressure tank is Tested

and Certified by NSF International against

NSF/ANSI Standard 44 for material and

structural integrity requirements.

COMPONENT

828.449.2536

BRITA® PRO

www.britapro.com

BRITA®PRO trademark and logo are registered trademarks of Brita LP and are

used under license by Protect Plus, LLC. All rights reserved

420 3rd Avenue NW

Hickory, NC 28601

READ THIS PAGE FIRST

CONTENTS

BEFORE STARTING INSTALLATION 4

BASICS

HOW YOUR FILTER WORKS 5

COMPONENTS & SPECIFICATIONS

SPECIFICATIONS 6

INSTALLATION

UNPACK & INSTALL 8

CHECK VALVE SERIAL NUMBER & VALVE TYPE 10

PREINSTALLATION INSTRUCTIONS 11

ELECTRICAL GROUNDING 11

TOOLS REQUIRED FOR INSTALLATION 14

DETERMINING LOCATION 14

CHECK WATER PRESSURE AND PUMPING RATE 14

FILTER INSTALLATION 15

MEDIA INSTALLATION 16

OPERATION

STARTUP PROCEDURES 20

DIAGNOSTIC CHECKLIST 21

DURING REGENERATION 21

PLUMBING SYSTEM CLEANUP 21

SOFTENERWATER BYPASSOPERATING CONDITIONS 22

MAINTENANCE INSTRUCTIONS 23

BACKWASHING INSTRUCTIONS 24

CALCULATE BACKWASH FREQUENCY 24

SERVICE THE PLATINUM VALVE 24

PROGRAMMING

MASTER PROGRAMMING 25

DIAGNOSTIC SCREEN 27

REPLACEMENT

REPLACE PISTON &/OR BRINE VALVE 28

CLEAN INJECTOR ASSEMBLY 28

REPLACE TIMER 29

REPLACE MOTOR 29

REPLACE METER ASSEMBLY 30

DISPLAY REPLACEMENT 31

REPLACE MICROSWITCHES 31

AFTER SERVICING 31

DRAIN LINE FLOW CONTROL 32

BRINE LINE FLOW CONTROL 32

PARTS

FILTER 33

CONTROLLER ASSEMBLY PARTS LIST 34

STANDARD BYPASS ASSEMBLY PARTS LIST 35

STANDARD VALVE BODY ASSEMBLY PARTS LIST 36

TROUBLE SHOOTING GUIDE 38

PERFORMANCE DATA STATEMENT 41

WARRANTY 47

3

READ THIS

PAGE FIRST

BEFORE STARTING INSTALLATION

You must read and understand the contents of this manual

before installing or operating your water softener. Personal injury

or property damage could result if you fail to follow instructions in

this manual.

This system and its installation must comply with state and

local regulations. Check with your local public works department

for plumbing and sanitation codes. Local codes should be

followed In the event the codes conflict with any content in this

manual.

For installations in Massachusetts, Massachusetts Plumbing

Code 248 CMR shall be adhered to. Consult your licensed plumber

for installation of this system.

This water softener must be operated on pressures

between 30 psi to 125 psi. If the water pressure is higher than 125

PSI, use a pressure reducing valve in the water supply line to the

softener.

This unit must be operated at temperatures between 40°F and

110°F (4°C - 43°C).

Do not use this water softener on hot water supplies.

Do not install this unit where it may be exposed to wet

weather, direct sunlight, or temperatures outside of the

range specified above.

Apply provided NSF certified lubricant to all o-rings during

installation. Do not use pinched or damaged o-rings during

installation.

Softeners are exposed to high levels of iron, manganese,

sulfur, and sediments. Damage to pistons, seals, and or spacers

within the control valve are not covered in this warranty due to the

harsh environment.

It is recommended to annually inspect and service the control

valve. Frequent cleaning and or replacement of piston, seals,

and or spacers may be necessary depending on how harsh the

conditions are. An Annual Maintenance kit (Part # 60010307) is

available for this purpose.

Do not use water that is microbiologically unsafe without

adequate disinfection before or after this system.

This publication is based on information available when

approved for printing. Continuing design refinement could

cause changes that may not be included in this publication.

See page 8 for unpack and inspect system

BRITA®PRO reserves the right to change the specifications

referred to in this literature at any time, without prior notice.

4

INSTALL

NOTES &

SAFETY

MESSAGES

Watch for the

following messages

in this manual:

EXAMPLE:

NOTE

Check and comply with

your state and local

codes. You must follow

these guidelines.

EXAMPLE:

EXAMPLE:

CAUTION

Disassembly while under pressure

can result in flooding.

WARNING

ELECTRICAL SHOCK HAZARD! Unplug the unit before removing

the cover or accessing any internal control parts

BASICS

The success of the installation will depend, to a great

extent, on advanced planning and preparation. Careful

attention to the location of the unit, accessibility to

electrical and drain facilities, and the availability of the

proper tools will ensure a professional-looking installation.

Of utmost importance is the assurance that the filter has

been properly applied and meets all specifications.

APPLICATION:

Correct application is directly associated with the

performance and life expectancy of any water filter. It is

important, therefore, to understand how your Brita® Pro

Water Filter functions and to know its capabilities and

limitations so that a correct application can be made.

By following the guidelines and recommendations set forth

in this manual, you can be certain your filter is applied

correctly.

MM / NEXSAND FILTER

The Automatic Water Filter is capable of removing

particulate matter particle size as small as 30 microns.

It will not remove color, organics, colloidal turbidity or

dissolved solids. Some applications include:

- Removal of suspended matter in any water system

- Removal of particulate matter, such as clay, mud, etc.

- Prefiltration of oxidized iron prior to an automatic or

manual softener

-Removal of light sand

The quality and number of gallons of filtered water

between backwashes will depend upon the amount, type,

and size of the particulate matter being filtered. If a water

sample is sent to a laboratory, where application of a MMF

Type unit is contemplated. The laboratory will test for

Nephelometric Turbidity Units (NTU) and suspended solids

(mg/L). The sample will also be filtered through 10 micron

filter paper and NTU run on a filtered sample. If the NTU

of the raw water exceeds 150, suspended solids exceed

150 mg/L, or the filter water through the 10 micron filter

paper has unacceptable quality, a MMF filter might not

be applicable. As a guide, the U.S. Public Health Drinking

Water standards states the turbidity should not exceed

1 NTU. The exact number of gallons filtered between

backwashes can not be given because of many variables.

TO FILTER

Automatic Water Filter with Activated Media will control

chlorine taste and odor, and it will also remove most

objectional organic colors. It will not remove hydrogen

sulfide. It is important to note that whenever the cause

of an objectional taste or odor has not been established,

Health Authorities should determine if the water is safe

to drink. Do not use with water that is microbiologically

unsafe or of unknown quality without adequate disinfection

before or after the system.

NU FILTER*

Automatic Water Filter with Neutralizing Media will

neutralize slightly acid water (pH 5.2 to >6.8) and thus help

to prevent unsightly brown or green stains due to corrosion

of household plumbing. If the pH is between 5 and 6, one

part of Magnesium Oxide Media should be mixed with five

parts of Calcite Media to provide additional neutralizing

capability. If the water to be treated has a pH less than 5, a

high hardness, or a high carbon dioxide level, NF might not

be applicable; a solution feeder should be used. Because

NF adds hardness, it should be used prior to a softener.

BM FILTER

This media acts as a catalyst for the removal of iron and

manganese from the water but require pre-oxidation. This

media removes the iron and manganese from the water.

This is not recommended to remove hydrogen sulfide from

the water and requires high pH water. The media is not

sacrificial hence no replenishment is required.

NOTE

Under dynamic conditions it might be necessary to mix five parts

Calcite with one part Magnesium Oxide to effectively raise the pH.

In order to size and apply the equipment correctly, a complete

analysis of the water supply should be obtained.

5

COMPONENTS &

SPECIFICATIONS

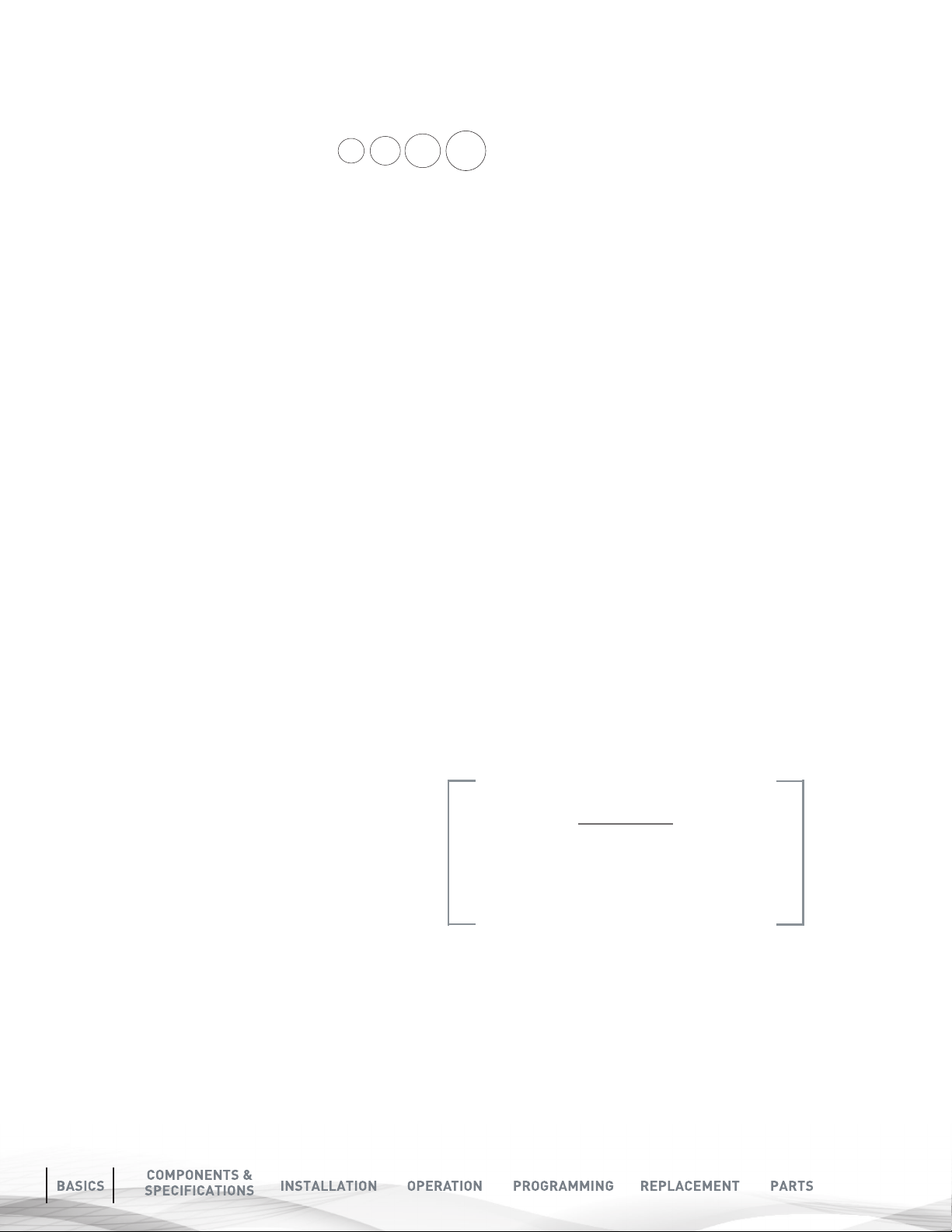

TASTE & ODOR (COCONUT SHELL CARBON) FILTERS

Platinum Series

BPF89CB75TO 0.75 4.0 5.0 3.5 8 x 44 3/4” - 1” 50

BPF89CB100TO 1.00 5.0 7.0 4.0 9 x 48 3/4” - 1” 60

BPF89CB150TO 1.50 7.0 10.0 5.0 10 x 54 3/4” - 1” 78

BPF89CB200TO 2.00 10.0 12.0 7.0 12 x 52 3/4” - 1” 95

BPF89CB300TO 3.00 12.0 15.0 10.0 14 x 65 3/4” - 1” 138

Media Cu

Ft

TASTE & ODOR (COCONUT SHELL CARBON) FILTERS W/KDF

Platinum Series

BPF89CBK75TOK 0.75 4.0 5.0 3.5 8 x 44 3/4” - 1” 50

BPF89CBK100TOK 1.00 5.0 7.0 4.0 9 x 48 3/4” - 1” 60

BPF89CBK150TOK 1.50 7.0 10.0 5.0 10 x 54 3/4” - 1” 78

BPF89CBK200TOK 2.00 10.0 12.0 7.0 12 x 52 3/4” - 1” 95

BPF89CBK300TOK 3.00 12.0 15.0 10.0 14 x 65 3/4” - 1” 138

Media Cu

Ft

Flow Rate USGPM

Flow Rate USGPM

Service Peak Backwash

Mineral

Tank Size

Mineral

Tank Size

Pipe Size

Inches

Pipe Size

Inches

Ship Weight

LbsService Peak Backwash

Ship Weight

Lbs

Working Temperature = 34-110°F

(1-43°C)

(Do not subject the unit to freezing

temperatures)

Working Pressure = 30-125 PSIG

(137-861 kPa)

Voltage = 120V / 60 Hz

Pipe Size = 3/4” and 1”

• At the stated service flow rates, the

pressure drop through these devices

will not exceed 15 psig.

CATALYTIC CARBON FILTERS (CHLORAMINES REDUCTION)

Platinum Series

BPF89CATCB75TOC 0.75 4.0 5.0 3.5 8 x 44 3/4” - 1” 50

BPF89CATCB100TOC 1.00 5.0 7.0 4.0 9 x 48 3/4” - 1” 60

BPF89CATCB150TOC 1.50 7.0 10.0 5.0 10 x 54 3/4” - 1” 78

BPF89CATCB200TOC 2.00 10.0 12.0 7.0 12 x 52 3/4” - 1” 95

BPF89CATCB300TOC 3.00 12.0 15.0 10.0 14 x 65 3/4” - 1” 138

Media Cu

Ft

Flow Rate USGPM

Mineral

Tank Size

Pipe Size

Inches

Ship Weight

LbsService Peak Backwash

CATALYTIC CARBON FILTERS (CHLORAMINES REDUCTION) W/ KDF

Platinum Series

BPF89CATCBK75TOCK 0.75 4.0 5.0 3.5 8 x 44 3/4” - 1” 50

BPF89CATCBK100TOCK 1.00 5.0 7.0 4.0 9 x 48 3/4” - 1” 60

BPF89CATCBK150TOCK 1.50 7.0 10.0 5.0 10 x 54 3/4” - 1” 78

BPF89CATCBK200TOCK 2.00 10.0 12.0 7.0 12 x 52 3/4” - 1” 95

BPF89CATCBK300TOCK 3.00 12.0 15.0 10.0 14 x 65 3/4” - 1” 138

Media Cu

Ft

Flow Rate USGPM

Mineral

Tank Size

Pipe Size

Inches

Ship Weight

LbsService Peak Backwash

NEUTRALIZING FILTERS

Platinum Series

BPF89NEU75PH 0.75 2.0 3.5 3.5 8 x 44 3/4” - 1” 93

BPF89NEU100PH 1.00 3.0 5.0 4.0 9 x 48 3/4” - 1” 120

BPF89NEU150PH 1.50 5.0 8.0 5.0 10 x 54 3/4” - 1” 164

BPF89NEU200PH 2.00 6.0 10.0 7.0 12 x 52 3/4” - 1” 207

BPF89NEU300PH 3.00 7.0 12.0 10.0 14 x 65 3/4” - 1” 330

Media Cu

Ft

Flow Rate USGPM

Mineral

Tank Size

Pipe Size

Inches

Ship Weight

LbsService Peak Backwash

• The manufacturer reserves the right

to make product improvements which

may deviate from the specifications

and descriptions stated herein,

without obligation to change previously

manufactured products or to note the

change.

* Do not use water that is

microbiologically unsafe without

adequate disinfection before or after

the system.

Peak flow rates intended for intermittent

use only (10 minutes or less) and are

for residential applications only. Do

not use peak flow rate for commercial

applications or for a continuous

rate when treated water supplies are

geothermal heat pump, swimming

pool, etc.

For satisfactory operation, the pumping

rate of the well system must equal or

exceed indicated backwash flow rate.

All units come with plastic bypass.

NEXSAND PARTICULATE FILTERS

Platinum Series Media Cu

Ft

BPF89NEX75TUR 0.75 4.0 6.0 5.0 3 - 5 µ 8 x 44 3/4” - 1” 90

BPF89NEX100TUR 1.00 5.0 8.0 7.0 3 - 5 µ 9 x 48 3/4” - 1” 135

BPF89NEX150TUR 1.50 8.0 10.0 10.0 3 - 5 µ 10 x 54 3/4” - 1” 205

BPF89NEX200TUR 2.00 10.0 12.0 14.0 3 - 5 µ 12 x 52 3/4” - 1” 255

Flow Rate USGPM

Micron

Rating

Mineral

Tank Size

Pipe Size

Inches

6

Ship

Weight

LbsService Peak Backwash

WATER AND TIME CONSUMED

DURING REGENERATION

Models Backwash

Minutes

75 10 10 20 70 80 100

100 10 10 20 80 100 140

150 10 10 20 100 140 200

200 10 10 20 140 200 280

300 10 10 20 200 280 340

Rapid Rinse

Minutes

Total

Time of

Regeneration

Total Water

Consumed during

Regeneration (GAL)

(Birm, TO, Neu)

Total Water Consumed

during Regeneration

(GAL) (MM)

Total Water Consumed

B

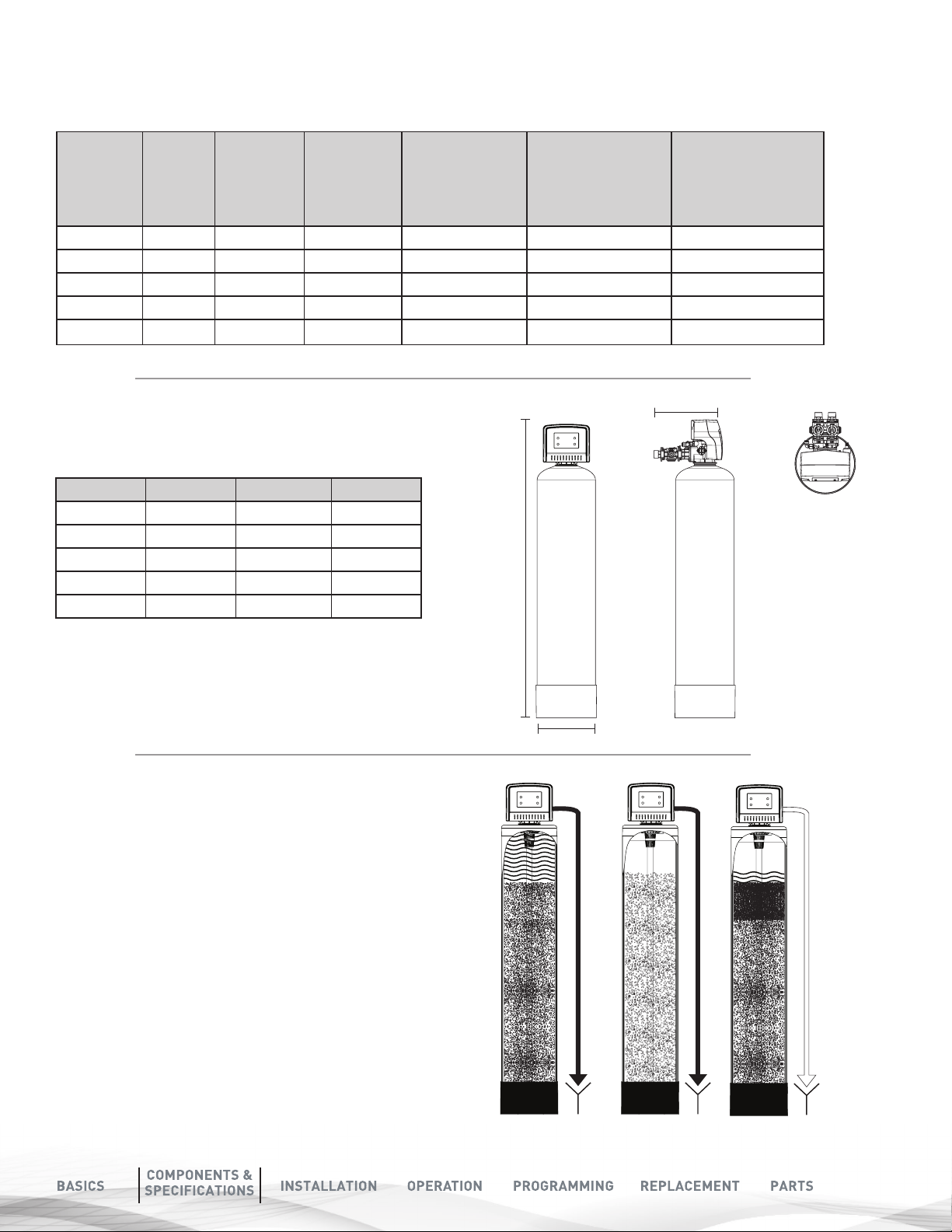

SYSTEM DIMENSIONS

Models A (Inches) B (Inches) C (Inches)

75

100

150

200

300

51.5 13" 8"

55.5 15" 9"

61.5 16" 10"

59.5 17" 12"

72.5 18" 14"

A

during Regeneration

(GAL) (Nexsand)

CONTROL VALVE

REGENERATION

SEQUENCE

The regeneration cycle goes through 3 steps.

1. BACKWASH (MINIMUM 30 PSI INLET

PRESSURE REQUIRED): During the backwash cycle, water

flows upwards through the bed, expanding the media and

carrying any contaminants trapped within it to the drain.

2. RAPID RINSE: During the rapid rinse cycle, water flows

downwards through the bed, settling the media and carrying

any precipitated contaminants trapped within it to the drain.

3. INSERVICE POSITION: The unit then returns to the In-Service

position. While this happens water continues to enter the tank.

C

Step1 Step 2

Step 3

7

INSTALLATION

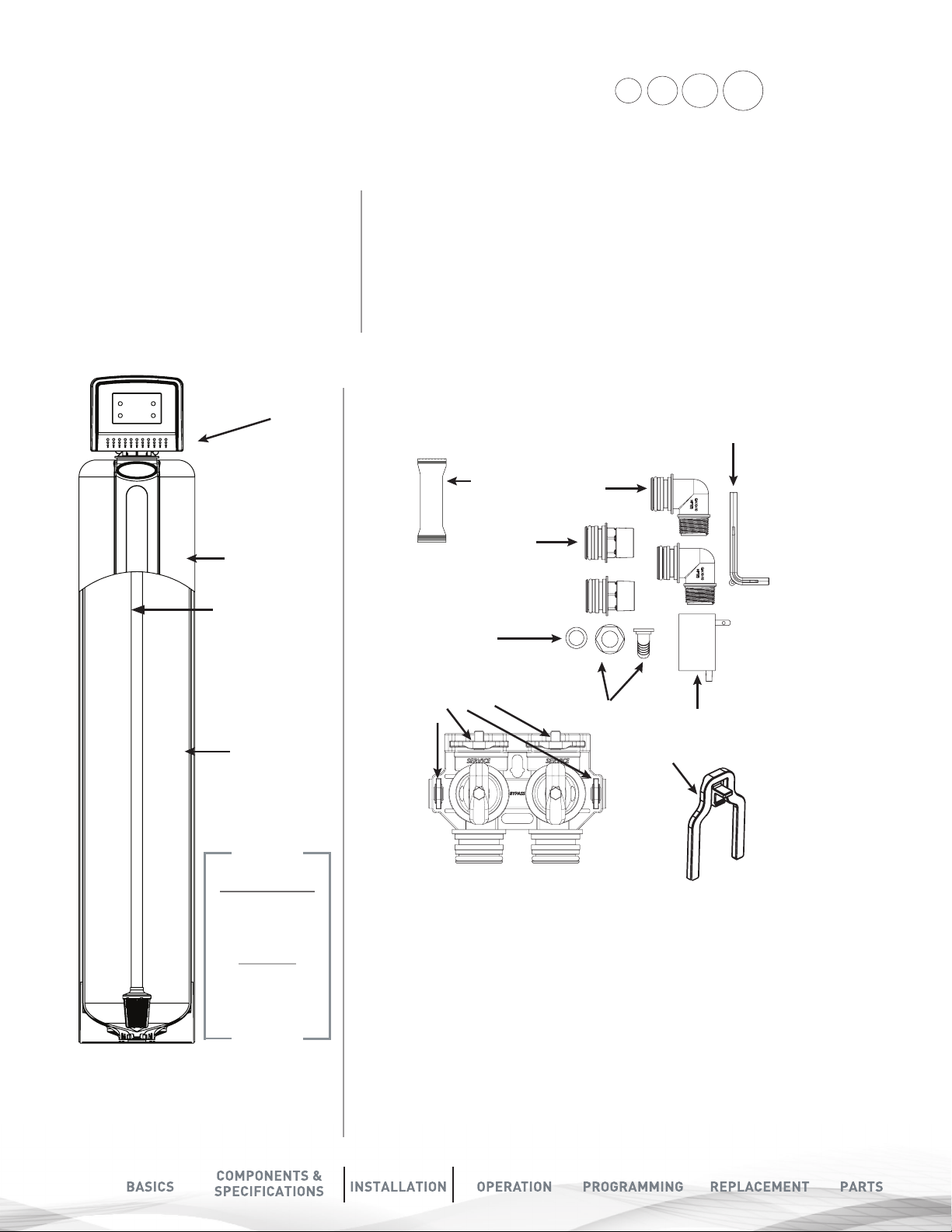

UNPACK & INSPECT PLATINUM FILTER

PLATINUM FILTER CONTENTS:

FOR MODELS 75,100,150, TO200, BIRM200,

YOU WILL EXPECT THE FOLLOWING.

SHIPPING CARTON QUANTITY 1

1. Control Valve

2. Pressure Tank

3. Parts Box

4. Owners Manual

5. Drain Hose & Clamp

(Not included in some brands)

1. CONTROL

VALVE

2. TANK

Distributor

Tube Inside

the Tank

• Check the entire unit for any shipping damage or lost parts.

• Note any damage to the shipping cartons.

• Contact the transportation company for all damage and loss claims.

• The manufacturer is not responsible for damages in transit.

• Small parts needed to install the softener are in a parts box.

• To avoid loss of the small parts keep them in the parts bag until you are ready to install.

• Handle the softener unit with care.

• Do not drop the unit or set on sharp uneven projections on the floor.

• Do not turn the softener unit upside down.

3. PARTS BOX

Grease

Packet

2X 1”

Straight

Adapter

Drain Line

Gasket

2 X 1”

Elbow

Adapter

(Not

Included)

Bypass Tool

Media Inside

the Tank.

Media Type will

depend on what

models were

purchased

NOTE

Only 8”, 9” & 10”

Pressure tanks

have plastic

sleeves.

8”, 9” & 10” tanks

come filled with

media & control

value attached

Bypass with 4

Red Clips

Drain Hose Barb

2 x Clips

Transformer

8

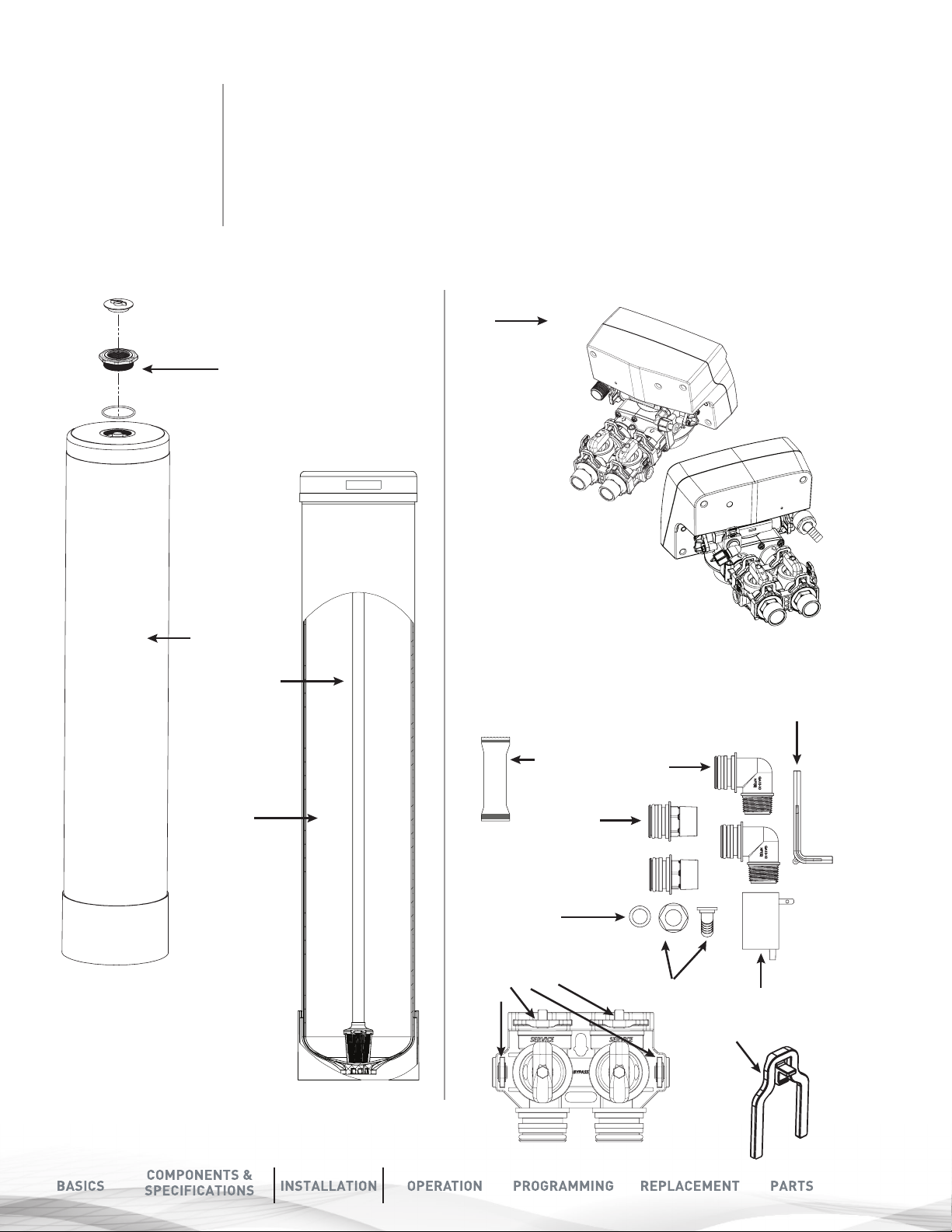

FOR MODELS 200, 300

THE MEDIA AND

CONTROL VALVE

IS PACKAGED

SEPARATELY IN

CARTON AND BAGS

Model 300 will get

Adaptor and O-ring

PLATINUM FILTER CONTENTS :

200, 300

1. Tank

(Model 30 will get an Adaptor and O-ring attached to the tank)

2. Control Valve with Parts Box

3. Media Boxes (Qty 2 for 200, Qty 3 for 300

4. Drain Line and Hose Clamp (Not Included) with some models

2. CONTROL

VALVE

Shown

1. TANK

Distributor

Tube Inside

the Tank

Media Inside

the Tank.

Media Type will

depend on what

models were

purchased

3. PARTS BOX

Grease

Packet

2X 1”

Straight

Adapter

Drain Line

Gasket

Bypass with 4

Red Clips

2 X 3/4”

Elbow

Adapter

(Not

Included)

Drain Hose Barb

2 x Clips

Bypass Tool

Transformer

9

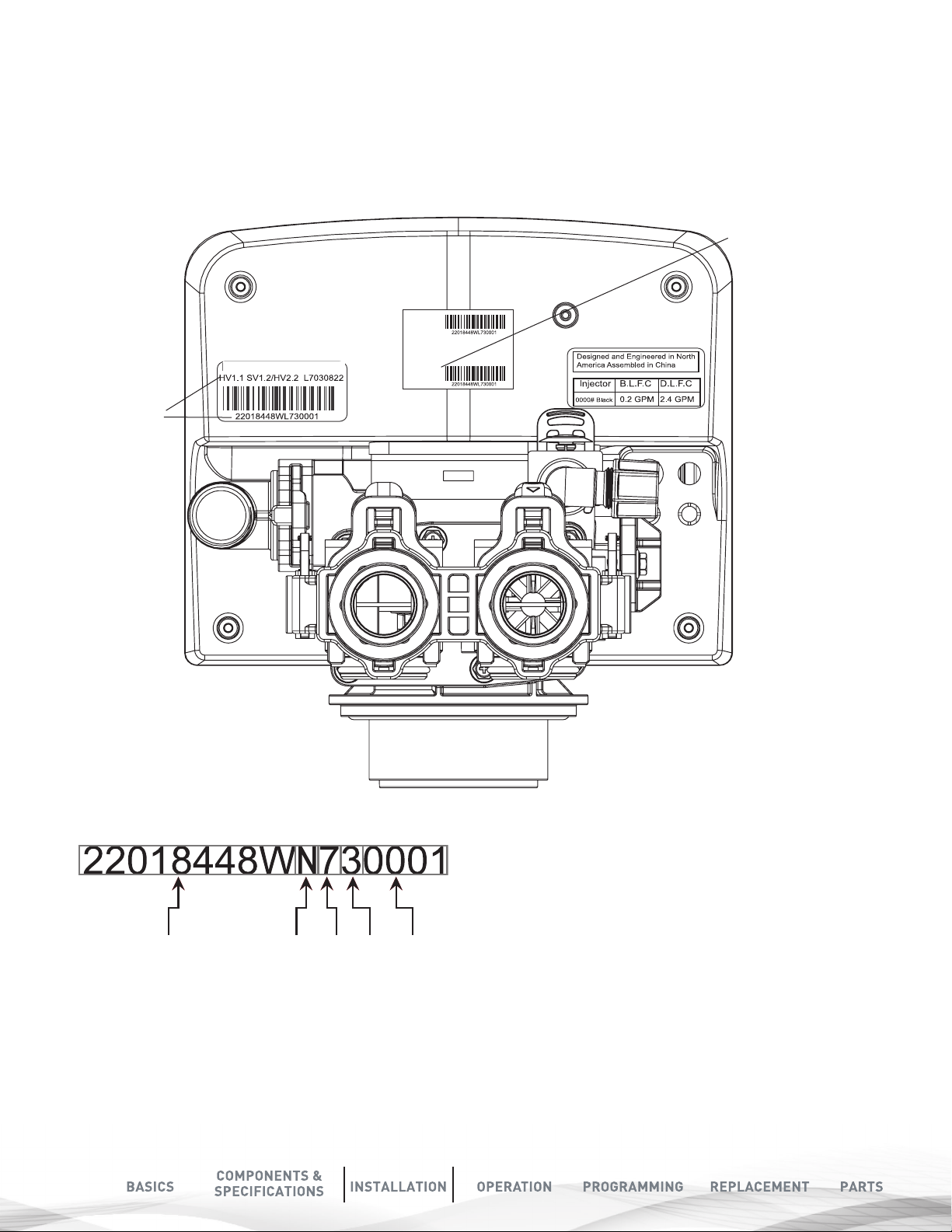

CHECK THE VALVE SERIAL NUMBER

AND VALVE TYPE

Check to make sure the valve type matches what you ordered.

The serial # label on the left will show BPCVPLATUF for Upflow valve

The right Sticker shows the serial # of the control valve.

The middle Sticker is dataplate which provides information of Serial # and Date of Manufacture of complete system.

Both Serial # labels are important for troubleshooting.

COMPLETE SYSTEM

SERIAL NUMBER

Item #

Desc

Date of Manufacture

BPCVPLATUF

VALVE SERIAL

NUMBER

Serial #

VALVE SERIAL NUMBER:

10

(22018448W): Part #

(L)YEAR : ’’ N’’ stand for 2017 year,’’ M’’ stand for 2016

year,’’ L’’ stand for 2015, ’’K’’ stand for 2014, ’’J’’ stand for

2013

Year Month Date Batch #Part #

(7)MONTH: 1 (JAN) 2(FEB) 3(MAR) 4(APRIL) 5(MAY)

6(JUNE) 7(JULY) 8(AUG) 9(SEP) A(OCT) B(NOV) C(DEC)

(3)DATE: 1 2 3 4 5 6 7 8 9 A(10) B(11) C(12) D(13) E(14)

F(15) G(16) H(17) I(18) J(19) K(20) L(21) M(22) N(23) O(24)

P(25) Q(26) R(27) S(28) T(29) U(30) V(31)

(0001): Batch code

PRE-INSTALLATION INSTRUCTIONS

CHECK YOUR WATER HARDNESS

Use test strips (Part # 2793828-20) to get an estimation of water hardness. Contact your local BRITA®PRO dealer to use a

BRITA®PRO laboratory for a complete water analysis free of cost and no obligation to you.

ELECTRICAL GROUNDING

An approved grounding

strap must be used in all

cases where metal pipe was

originally used and is later

interrupted by poly pipe,

the Noryl bypass valve or

by physical separation. The

grounding clamp used for

continuity, must be no less

than #6 copper conductor

to maintain proper metallic

pipe bonding.

8QILOWHUHG:DWHU%\SDVV

/RRS&XW&DSSHG

)LOWHUHG:DWHU/LQHLQ+RPH

*URXQG6WUDS5HTXLUHG%HFDXVH

RI%UHDNLQ&RQWLQXLW\

NOTE

Check your local

electrical code for

the correct strap.

NOTE

CAUTION

The ground from the electrical panel or breaker box to the water meter or underground

copper pipe is tied to the copper water lines. If these lines are cut during installation

of the Noryl bypass valve and/or poly pipe, an approved grounding strap must be used

between the two lines that have been cut. This will maintain continuity. The length of the

grounding strap will depend upon the number of units being installed and/or the amount

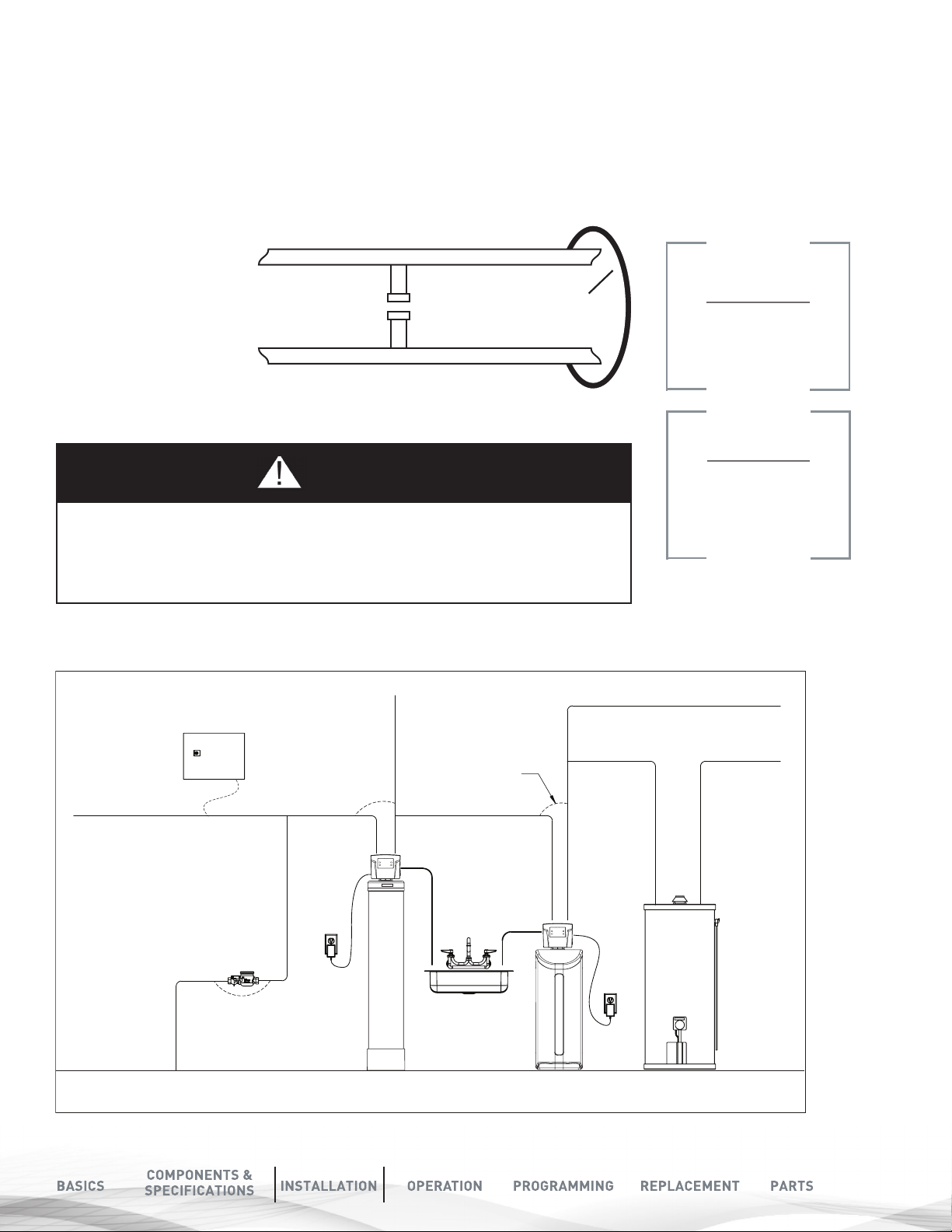

FIGURE 1A: TASTE AND ODOR FILTER (TO)

TYPICAL INSTALLATION:

Raw Water

To Outdoors

of copper pipe being replaced with plastic pipe. See drawing below.

Hard

Electrical Panel

Filtered

Water

Ground Strap

Drain

Drain

You must follow all

government codes and

regulations governing

the installation of

these devices.

Cold Soft Water

Hard Soft Water

Water Meter

Taste and Odor

(TO) Filter

Softener

Water Heater

11

FIGURE 1B: BIRM (BM) TYPICAL INSTALLATION:

Raw Water

To Outdoors

Electrical Panel

Water Meter

Birm

(BM) Filter

Hard

Filtered

Water

Drain

Ground Strap

Drain

Softener

Cold Soft Water

Hard Soft Water

Water Heater

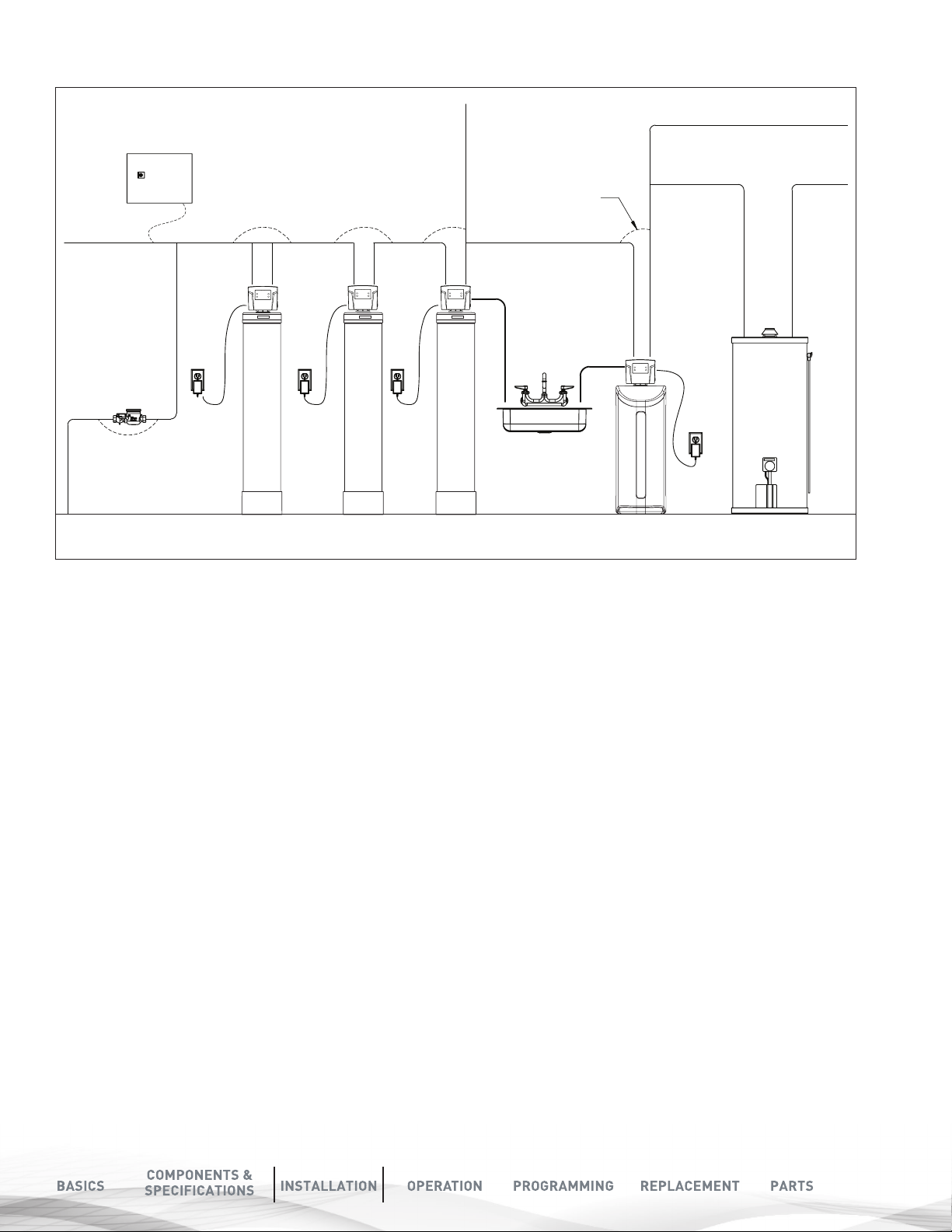

FIGURE 1C: MULTI MEDIA FILTER (MM OR NEXSAND) TYPICAL INSTALLATION:

Raw Water

To Outdoors

Electrical Panel

Water Meter

Hard

Filtered

Water

Ground Strap

Drain

Drain

Cold Soft Water

Hard Soft Water

12

Multi Media

Filter (MM or nextSand)

Taste and Odor

(TO) Filter

Softener

Water Heater

FIGURE 1D: NEUTRALIZING FILTER (NF) TYPICAL INSTALLATION:

Raw Water

To Outdoors

Water Meter

Electrical Panel

Multi Media

Filter (MM or neXtSand)

Multi Media

Filter (NU)

Hard

Filtered

Water

Drain

Taste and Odor

(TO) Filter

Ground Strap

Drain

Softener

Cold Soft Water

Hard Soft Water

Water Heater

13

TOOLS REQUIRED FOR

CHECK WATER

INSTALLATION:

Two adjustable wrenches

Additional tools may be required if modifications to home

plumbing are required.

Plastic inlet and outlet fittings are included with the softener. 3/4”

or 1” pipes to and from the softener fittings are recommended to

maintain full valve flow. You should maintain the same or larger

water supply pipe sizes as the softener inlet and outlet pipe sizes.

Use copper, brass, or PEX pipe and fittings.

Some codes may also allow PVC plastic pipe. Refer to local codes.

ALWAYS INSTALL THE INCLUDED BYPASS VALVE, OR 3 SHUT-OFF

VALVES. Bypass valves let you turn off water to the softener for

repairs, but still have water in the house pipes.

5/8” OD drain line is needed for the valve drain. A 10’ length of

hose is not included with some brands

NOTE

If the plumbing system is used as the ground leg of

the electric supply, continuity should be maintained

by installing ground straps around any nonconductive

plastic piping used in installation.

PRESSURE AND

PUMPING RATE

Two water system conditions must be checked carefully

to avoid unsatisfactory operation or equipment damage:

1. Minimum water pressure required at the softener

tank inlet is 30 psi.

2. The pumping rate of your home’s well pump must at

least equal to the required backwash flow rate of your

model (see Specifications on Page 6 for backwash

flow rates).

TO MEASURE THE PUMPING RATE OF YOUR

PUMP, FOLLOW THESE INSTRUCTIONS:

A. Determine the cycle time. Make certain no water is

being drawn. Open spigot nearest pressure tank.

When pump starts, close spigot and measure time (in

seconds) to refill pressure tank (when pump shuts

off). This figure represents cycle time.

B. Determine drawn-down time. With the pressure tank

full, draw water into a container of known volume and

measure the number of gallons drawn until the pump

starts again. This is draw-down.

C. Determine drawn cycle time. Divide the draw down

time by cycle time and multiply the result by

60 to arrive at the pumping rate in gallons per

minute (gpm).

DETERMINE THE CORRECT

LOCATION OF THE WATER

CONDITIONING EQUIPMENT

Determine the best location for your water softener, bearing in mind the

location of your water supply lines, drain line and 120 volt AC electrical

outlet. Subjecting the softener to freezing or temperatures above 43°C

(110°F) will void the warranty. Review the various conditions below to

determine a proper location:

1. Locate as close as possible to the water supply source.

2. Locate as close as possible to a floor or laundry tub drain.

3. Locate in correct relationship to other water conditioning

equipment (see Fig. 1 on Page 10)

4. Softener should be located in the supply line before the water heater.

Temperatures above 120°F damage softeners.

5. Do not install a softener in a location where freezing temperatures

occur. Freezing may cause permanent damage to this type of

equipment and will void the factory warranty.

6. Allow sufficient space around the unit for easy servicing.

7. Determine if additional plumbing is required if your water source is a

community water supply, a public water supply or you wish to bypass

water used for a geothermal heat pump, lawn sprinkling,

out-buildings or other high demand applications, refer to Fig. 1.

8. Keep the softener out of direct sunlight. Heat build up from direct

sunlight may soften and distort plastic parts.

To aid in your calculation, insert the data in the

following formula:

DRAW-DOWN________ (gals)

÷ CYCLE TIME______________x 60 (seconds)

= PUMPING RATE______________ (gpm)

EXAMPLE:

DRAWDOWN is 6 gals; CYCLE TIME is 53 secs; then,

PUMPING RATE equals: 6 gals ÷ 53 secs x 60 = 6.8 gpm

SEE SPECIFICATIONS ON PAGE 6

FOR MINIMUM FLOW RATES.

.

NOTE

If there is a severe loss in water pressure when the

softener unit is initially placed in service, the softener

tank may have been laid on its side during transit. If this

occurs, backwash the softener to “reclassify” the media.

14

2XWOHW

,QOHW

tI

T

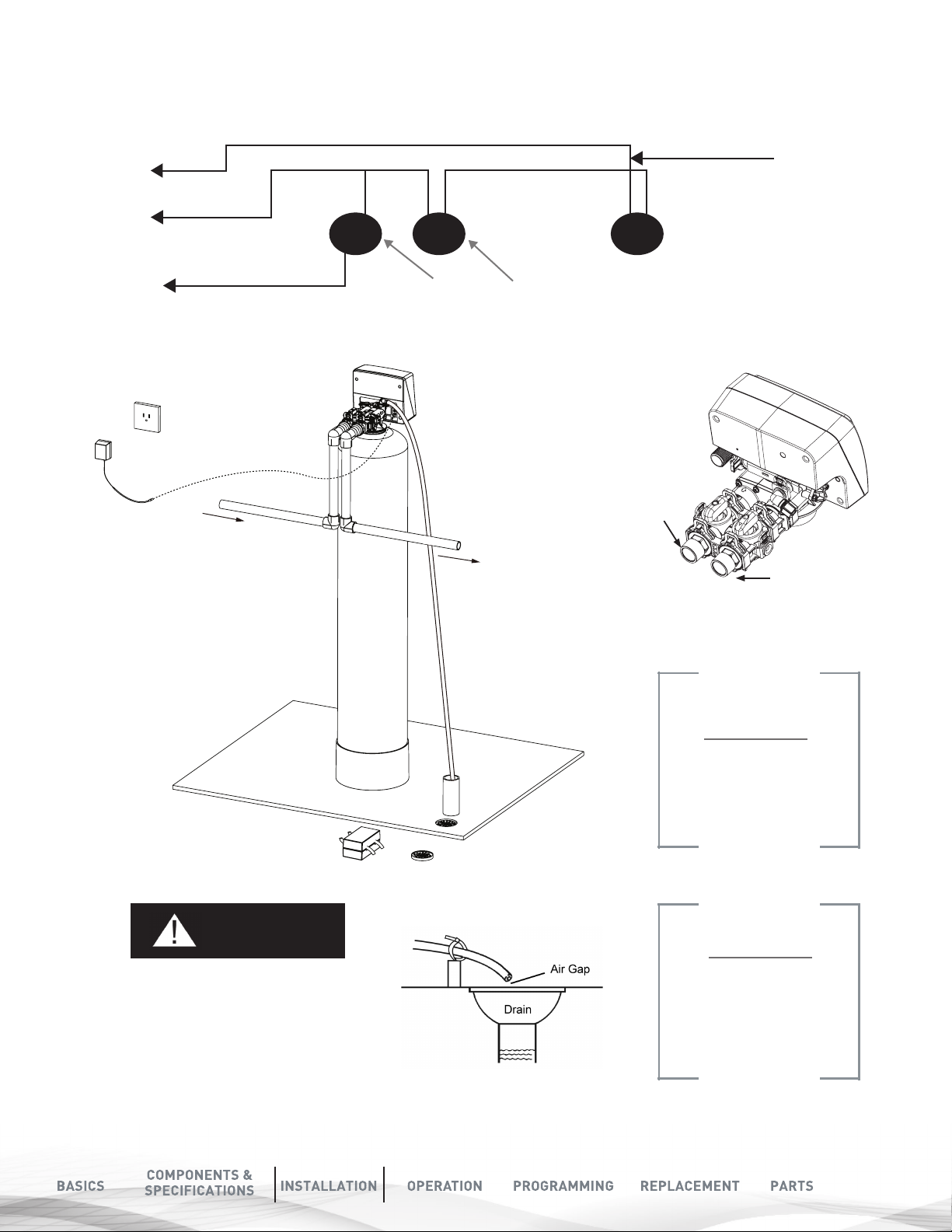

FILTER INSTALLATION

Cold (Raw water)

o Outside Faucet

Cold (Soft Water)

Cold (Filtered water)

InIn Ou

Cold (Raw water)

nOut

Filter

Hot (Soft Water)

Out

Water Heater

Water Softener

Inlet

Outlet

Opposite Most

Standard Softeners

NOTE

The valves are labeled

inlet and outlet on the

vale. Please make sure

to plumb as shown here

CAUTION

Never insert the drain line directly

into a drain, sewer line, or trap.

Always allow an air gap between

the drain line and the wastewater.

This will prevent the possibility of

sewage being back-siphoned

into the conditioner.

NOTE

The waste connection or drain

outlet shall be designed and

constructed to provide an

air-gap to the sanitary waste

system of 2 pipe diameters or

1 inch (22 mm).

(whichever is larger)

15

MEDIA INSTALLATION

1. MEDIA INSTALLATION (WHEN NECESSARY).

Models 250 or 300 media are shipped with separate media in pails or

boxes. Models lower than 2 CF of media come loaded

with media and this step can be skipped for new installation.

NOTE

The 8”, 9” and 10: tank

media is pre-installed.

Go to Step 4

CAUTION

The unit should be

de-pressurized before

installing or replacing media

A) Remove cap to Pressure Tank

PLUG

THE

RISER

TUBE

B) Temporarily plug the open end of the riser tube. This

ensures that no resin or gravel falls down into the

distribution. The riser (distributor) remains inside the

tank seated in the depression at the bottom.

Plug tube with a tape. Remove after media is loaded.

THE RISER

(DISTRIBUTOR)

REMAINS

INSIDE THE

TANK SEATED

IN THE

DEPRESSION

AT THE

BOTTOM

C) Fill support bed first. The media will not always

spill down inside the tank and may need to be

swept inside.

The large funnel makes filling the tank easier and

neater. (Or an empty 1 gallon or 4 liter container

with the bottom cut out makes a good funnel.)

16

D) Fill tank one quarter full of water

to protect distribution during gravel

installation.

Place the media into the tank in the

order indicated above. Slowly and

carefully add the gravel support bed

and the filtration media leveling each

layer as it is placed into the tank.

Fill support bed (if supplied) first.

During the filling process, ensure the

distributor tube stays on the bottom of

the tank, reasonably centered. Remove

the tape from the distributor once

media is loaded. Whenever possible,

fill the tank outdoors to avoid problems

with dust. If filling indoors, a dust mask

should be worn.

NEUTRALIZING

FILTER (NF)

MEDIA BED

Calcium

Carbonate &

Magnesium Oxide

Mixed

(Grey / White)

Support Bed

(when supplied)

Fine, Medium

and/or Coarse

Gravel

MULTI MEDIA

FILTER (MMF)

MEDIA BED

Anthrafilt /

Anthracite

(Black)

Fine Sand

Fine Garnet

(Purple)

Coarse Garnet

(Purple)

Support Bed

(when supplied)

Fine, Medium

and/or Coarse

Gravel

2. MEDIA INSTALLATION

ACTIVATED

CARBON FILTER

(ACF) MEDIA

BED

Carbon

(Black)

Support Bed

(when supplied)

Fine, Medium

and/or Coarse

Gravel

Unscrew Spill Cap

D-Tube

Attach

Upper

Basket

BIRM FILTER

(BM) MEDIA

BED

Birm

(Black)

Support Bed

(when supplied)

Fine, Medium

and/or Coarse

Gravel

MULTI MEDIA FILTER

(MM OR NEXSAND)

MEDIA BED

Nexsand

(Black)

Support Bed

(when supplied)

Fine, Medium

and/or Coarse

Gravel

NOTE

Grease port O-rings using brush

(not included) or your finger

(Make sure to wear protective

gloves)

Some medias like those used in NU

Models are sacrificial and deplete faster

depending on inlet water conditions and

usage. The media replenishment is more

frequent in high water usage and more

acidic water cases. The dome hole models

are available and supplied in which the

dome hole is available for a quick addition

or replenishment of media in the tank.

Unplug the riser tube, carefully position the valve over it and turn the valve into the threads

in the fiberglass tank, tightening securely into tank. Note: Ensure that the internal O-ring in

the valve fits securely over the riser tube. Silicone grease (part # 92360) or other food grade

lubricant may be applied to the O-ring to ease installation of the riser tube.

17

Dome Hole Cap Dome Hole Cap

Removed

CAUTION

Make sure the O-Ring is free of

defects. Use silicone based lubrication

(part # 92360) if necessary.

The filter is now

charged with media.

NOTE

CAUTION

Make sure that the unit is

de-pressurized before

conducting this task.

DO NOT use petroleum based lubricants as they

will cause swelling of O-ring seals.

18

3. MEDIA INSTALLATION

Outside faucets used to water lawns and gardens should not

supply untreated water. A new water line is often required

to be connected to supply untreated water to the inlet of the

water filter and to the outside faucets.

(CARBON UNITS MODEL TO)

Open the inlet on the bypass valve slightly and very slowly allow

water to enter the unit. (If the water enters too quickly it will

push the media or carbon up into the control valve and get

plugged).

Cut the water line between where it enters the house and

before any lines that branch off to feed the hot water heater or

other fixtures in the house and as near the desired location of

the water filter as possible. Install a tee fitting on the feed end

of the cut pipe, and an elbow fitting on the other end. Install

piping from the tee to the inlet of the water filter and from

the elbow to the outlet of the filter. To sever the water lines

which branch off to feed any outside faucets, cut the branch

lines approximately two inches from the fitting on the main

water line. Install an elbow on the end of the pipe nearest the

outside faucet and a cap on the end connected to the existing

water line. Install piping from the tee installed on the inlet

line to the water filter to the elbow installed on the pipe to the

outside faucet. Following this procedure will result in all lines

in the house, with the exception of the outside faucets, but

including the water heater and therefore the hot water lines,

being supplied with treated water.

Make sure the bypass is attached well to the control valve.

Connect the straight or elbow connectors to the bypass with

red clips. Connect the inlet and outlet of the water filter to

the plumbing of the house. The control valve must not be

submitted to temperatures above 43°C (110°F). When sweat

fittings are used, to avoid damaging the control valve, solder

the threaded copper adaptors to the copper pipe and then,

using Teflon tape, screw the assembly into the bypass valve.

Do not use pipe thread compound as it may attack the

material

in the valve body.

Once the unit has filled sufficiently that water is at least equal to

the height of the top of the media shut down the water for 15 – 20

minutes for the carbon to soak. Unplug the power cable. After the

carbon has soaked for the recommended time continue by plugging

the power cable back in.

4b. (Other Models) Open the inlet on the bypass valve slowly and

allow water to enter the unit. (The outlet of the bypass should

remain closed to prevent any fines or debris from entering the

plumbing system. Allow all air to escape from the unit before

turning the water on fully then allow water to run to drain for 3-4

minutes.

5. Unplug the power cord from the power supply, open inlet. Check

the drain line flow. Allow the water to run for 30 minutes.

6. Plug in the valve and the valve will automatically advance to the

SERVICE position. Open the outlet valve on the bypass, then slowly

open the nearest treated water faucet and allow the water to run

until clear, close the tap and replace the faucet screen.

7. The Valve is already programmed from factory for AIO Models.

Please set up date and time of day as shown on next page.

Clips

Make sure both

brass and plastic

nuts are tightened

well

Inspect and check that the brine line plug is

Ensure that the brass and plastic nut connected

4. CONNECT DRAIN LINE:

A) Using plumbers tape, screw the 1/2” hose barb and attach

o-ring into the drain port in the valve.

B) Attach 1/2” drain hose to the hose barb. and tighten

securely with a hose clamp.

C) Run the drain line to a floor drain or a laundry drain.

Complete any necessary plumbing.

NOTICE

connected to the valve.

NOTICE

to the air check assembly is tight.

19

OPERATION

MENU

175/225/275

salt grid system

salt tank body

salt tank

lid

brine well and brine valve

STARTUP PROCEDURES

1. CONNECT THE TRANSFORMER TO THE VALVE.

Plug the 12-volt transformer into a 120 VAC 60 Hz outlet.

Power

Connector

2. ADD WATER TO BRINE TANK

Open the brine tank lid and add 3 gallons of water. Do not

add salt to the brine tank at this time.

3. SCREEN DISPLAY

When power is supplied to the

control, the screen will display

“INITIALIZING WAIT PLEASE”

while it finds the service position.

FAMILIARIZE WITH BUTTON

CONFIGURATION:

Date and Time

MENU

SET

KEY PAD CONFIGURATION

18-Apr-2016 10:35AM

Gal Remain 1400

Flow Rate 3 gpm/min

The controller will show the

following on the screen: Time,

Date and Gallons Remaining for

Regeneration

This function enters the basic set

up information required at the

MENU

time of installation.

This function accepts the values if

changed and advance to the next

SET

page in the menu

These buttons increase or decrease

the value of the settings while in the

programming mode.

System initializing

Please wait

4. SET THE VALUE TO MANUALLY REGENERATE

If screen is locked, press Menu Key for 5 seconds to unlock.

Manually Regenerate the Valve and move it

to backwash position. Press Menu Key and

Scroll down using Up and Down Arrow buttons

to “Manual Regen”. Press “SET” Select “Regen Now”

20

Skip this cycle by

pressing any key for 3

seconds

Complete

the Backwashing cycle to

let the air out of the

system

Date and Time

Hardness

Manual Regen.

Dealer Information

Main Menu

Regen. Now?

Regen. Tonight?

Press

To Cancel

To Conrm

Press

Brine Drawing

Any Key 3s To Next

13:59

Backwashing

Any Key 3S to Next

18%

18%

Rinsing

Any Key 3S to Next

Brine Rell

Any Key 3S to Next

18%

18%

Complete this cycle to

settle the media

Complete this cycle to let

the air out of the injector

system

SYSTEM DIAGNOSTICS

DURING REGENERATION

CHECK LIST

More than 90% of problems affecting the efficiency of

a softener system can be identified in 9 minutes or less. Follow

this diagnostic schedule below.

Start with Step 1, then follow each step in sequence to ensure

proper diagnostic procedures.

1. CHECK FOR PROPER INSTALLATION

A. Is the pipe from the pressure tank to the softener

unit attached to the inlet port of the control valve?

B. Is the pipe from the softener unit to the water heater

attached to the outlet port of the control valve?

C. Is the drain line of adequate diameter? Drain line

must be sized to prevent back pressure from

reducing backwash flow rate below minimum for the

model installed.

D. Has the drain line been “kinked”? A kinked drain line

must be replaced.

E. Is the drain line installed in a way that it will freeze in

cold weather?

F. If the system incorporates a standard air-to-water

pressure tank, does it have the required deep well air

volume control (air release valve) and is it functioning?

(Proper installation of this type of pressure tank should

have inlet from pump higher than outlet to service.)

NOTE

Typical examples of minimum drain line diameters are:

5/8” ID when drain is up to 15 ft from unit and backwash water

discharge point is slightly higher than the control valve

3/4” ID when drain is 25 ft away and/or drain is installed overhead

2. CHECK PH, IRON AND MANGANESE CONTENT

OF TREATED WATER

Is the treated water pH reading less than 6.7 (8.2 when

manganese is present)?

AUTOMATIC BYPASS

The regeneration cycle lasts approximately 60 minutes, after

which treated water service will be restored. During regeneration,

untreated water is automatically bypassed for use in the

household. Hot water should be used as little as possible during

this time to prevent hard water from filling the water heater.

IMPORTANT: This is why the automatic regeneration is set for

sometime during the night and manual regenerations should be

performed when little or no water will be used in the household.

NEW SOUNDS DURING REGENERATION

You may notice new sounds as your water softener operates.

The regeneration cycle lasts approximately 2-1/2 hours.

During this time, you may hear water running intermittently

to the drain.

PLUMBING SYSTEM

CLEAN-UP

The following procedures are guidelines only but have proven

successful in most instances. Under no circumstances should any

procedure outlined below be followed if contrary to the appliance

manufacturer’s instructions. Should there be any questions

concerning the advisability of performing a procedure, it is

strongly recommended your local BRITA®PRO dealer be

consulted prior to performing the procedure.

The plumbing system and water using appliances that have been

exposed, even for a short time, to iron-fouled water need to be

cleaned of the precipitated iron that has collected in them. If not

cleaned, the iron bleed (staining) will continue to be a problem.

Depending on the amount of iron in the water and the length of

time the water system has been exposed to iron fouling, select

from the following procedures those that apply to the type of

system and appliances that need to be cleaned to assure

iron-free water at the point of use.

If yes, replenish the media with MpH adder and check the

bed for “channelling”.

3. CHECK PUMPING RATE

Do not refer to a pumping rate curve for this data. Follow the

instructions found on Page 7. Is the measured pumping rate

less than the backwash rate of the softener? If yes, increase

the pumping rate by first reducing the system operating

pressure. If the pumping rate is still too low, replace the pump.

4. REVIEW OTHER USES OF WATER IN ADDITION

TO NORMAL DOMESTIC PURPOSES

(e.g. geothermal heating/cooling, swimming pool, lawn

irrigation, farm animal watering, etc.)

Have any high demand water uses been added subsequent

to the installation of the softener system or overlooked when

originally sizing the system? If a high demand situation exists,

resize the system using continuous service flow rate data.)

21

SOFTENER

1. Disconnect brine draw line from the brine cabinet. Place the loose end into a

five gallon plastic pail filled with a solution of warm water and 4 oz. of resin

mineral cleaner.

2. Manually advance control timer to brine draw position (refer to page 16

step 4 chart). Allow all the warm mineral cleaner solution to be drawn into

mineral bed.

Then immediately...

3. Close main water supply valve or turn power off to pump and proceed with

softener installation. During time required to install softener system,

iron- fouled softener resin will be chemically cleaned.

4. After softener installation is completed and final adjustments are made

with the water turned on and brine draw tube reconnected, manually

reprogram timer on softener to backwash setting. Allow timer to perform

an automatic regeneration cycle. During backwash of softener all iron

cleaned from the resin will be washed down the drain. It is advisable after

chemically cleaning softener to regenerate system twice to fully restore

capacity lost due to iron fouling.

WATER BYPASS

MANUAL BYPASS

In case of an emergency such as softener maintenance, you can isolate your

water softener from the water supply using the bypass valve located at the

back of the control.

In normal operation the bypass is open with the ON/OFF knobs in line with

the INLET and OUTLET pipes. To isolate the softener, simply rotate the knobs

clockwise (as indicated by the word BYPASS and arrow) until they lock.

You can use your water related fixtures and appliances as the water supply is

bypassing the softener. However, the water you use will be hard. To resume

treated service, open the bypass valve by rotating the knobs counterclockwise.

Please make sure bypass knobs are completely open otherwise the

unsoftened water could bypass through the valve.

Sample

Connection

SERVICE

BYPASS

BYPASS

Sample

Connection

OPERATING CONDITIONS

WATER HEATER

After completing the installation of the chemical free iron softener

system, clean the water heater by following these instructions:

1. Shut off energy supply to water heater and close heater inlet water

valve.

2. Drain hot water tank completely. Open inlet water valve allowing

heater tank to be refilled with conditioned water. Continue flushing

until water runs clear to drain.

3. If, after approximately 30 minutes flushing, water does NOT clear,

terminate flushing operation. Refill hot water heater with water and

pour approximately 1/2 gallon of household bleach into top of heater

tank. Allow bleach solution to stand in tank for 20 to 30 minutes.

Flush tank again until water is clear at drain. Turn energy supply on.

4. If the water heater has been exposed to both iron and hardness for a

long period of time, replacement of the heater tank may be the only

practical solution to prevent continued staining originating from this

source.

22

TOILET FLUSH TANKS

Prior to commencing installation of the Softener

system, pour 4 to 6 ounces of resin mineral cleaner

Pro-Rust Out or inhibited muriatic acid into flush tanks

and bowls and let stand. When installation is completed,

flush toilets several times with iron-free water. If iron

deposits or stains remain, repeat procedure until clear.

NOTE

If water does not become clear in approximately

10 minutes, water heater should probably

be replaced.

MAINTENANCE INSTRUCTIONS

Your chem free iron filter requires some minor maintenance to ensure optimum

performance and years of trouble-free clean water. The following steps should be

performed once or twice a year (more often under harsh conditions):

1. Verify the pumping rate of the system - do not refer to a

pumping curve for this data. Follow the instructions found

on page 7. If the measured pumping rate is less than the

backwash rate of the filter, see page 39, Trouble Shooting.

2. Have your water tested - for pH, iron and manganese on both

the treated and raw water to ensure your water conditions

haven’t changed.

3. Inspect the Control Valve and the piping between the iron filter

and the pressure tank to ensure they are not plugged with

raw iron. If the line becomes plugged, the flow of water to the

home will be reduced. This will result in a reduction of water

available for backwashing the unit which will inhibit operation

of the system.

4. Air-to-water pressure tank - periodically drain and flush your

tank to prevent a build-up of precipitated iron from forming in

the bottom of the tank.

5. Bladder tank - periodically check that the bladder air pressure

remains at 2 psi lower than the cut-in pressure of your pump.

6. For applications with low pH, manganese or hydrogen sulfide,

consult your local dealer for specific instructions to maintain

the efficiency and operation of your filter.

7. Periodic cleaning of the air vent assembly with mild acid

or vinegar will ensure that it continues to vent excess air

properly.

8. The filter tank can be cleaned with a mild soap solution.

9. Never subject the unit to freezing

REPLACING MEDIA BED

The media bed in a neutralizing Model NU filter is slowly

dissolved and has to be replaced. The frequency of replacement

varies, depending on water quality - consult your dealer to

determine the expected life of your media bed.

NU - the media bed in a neutralizing filter is slowly dissolved

and has to be replaced. The frequency of replacement varies,

depending on water quality - consult your dealer to determine

the expected life of your media bed.

TO - under normal operating conditions the effective life of the

filter media is approximately one to three years depending

on the water quality, after which, taste and odor problems

may return. When this happens contact your dealer for a

replacement media bed.

MM / Nexsand - under normal operating conditions, the media

should never need to be replaced. If you experience pressure

loss and cannot correct it with a manual regeneration, your

media bed may need replacing - contact your dealer.

BM - Depending on the raw water iron content.

CARE OF YOUR FILTER

To retain the attractive appearance of your new water filter,

clean occasionally with a mild soap solution. Do not use abrasive

cleaners, ammonia or solvents. Never subject your filter to

freezing or to temperatures above 43°C (110°F).

SERVICING COMPONENTS-

The seals and cartridge should be inspected/cleaned or

replaced every year depending on the inlet water quality

and water usage.

The media should be replenished or replaced depending

of inlet water quality and water consumption. Check with

your water treatment expert on the media bed change

frequency.

BELOW ARE SOME GUIDELINES:

Piston assembly, seal and spacers, injectors should be

replaced on an annual basis.

Please refer to the servicing section of this manual for step by

step procedure.

Not following the above will void all warranty on the control

valve.

Maintenance of your new water filter requires very little time

or effort but it is essential. Regular maintenance will ensure

many years of efficient and trouble free operation.

Maintenance Kit

(60010307)

23

BACKWASHING

TO CALCULATE BACK-

INSTRUCTIONS

TO CALCULATE BACKWASH FREQUENCY

- NORMAL APPLICATIONS

Backwash frequency for households with average water

use can be determined using the following guide. The guide

cannot be used if the filtered water supplies a swimming

pool, geothermal pump, outside spigots or other high water

demand devices or activities. If your application includes

any of the foregoing refer to the paragraph on “Special

Applications” below:

PEO-

PLE

IN

FAMI-

LY

1 1 1 1 1 1 1 1 1 1 1

2 1 1 1 1 1 2 2 2 2 2

3 1 1 1 2 2 2 3 3 3 3

4 1 1 2 2 2 3 3 4 4 4

5 1 1 2 2 3 3 4 4 6 6

6 1 2 2 3 3 4 6 6 6 6

1. Locate the box intersected by the number of people

in your family and the parts per million (ppm) of

iron in your water (if your ppm is between two

numbers on the guide, use the higher number).

2. The number in the box represents how many

times your filter has to backwash in a twelve day

schedule.

2 4 6 8 10 12 14 16 18 20

IRON CONTENT (PPM)

WASH FREQUENCY SPECIAL APPLICATIONS

To ensure adequate reserve capacity and prevent loss of

water pressure between backwashes the figure of 15,000 (not

the full 30,000 ppm capacity) is used to calculate backwash

frequency. Determine your backwash frequency as follows:

1. Estimate daily iron removal requirements using the

following calculation:

No. of people in family

x 75 gallons of water per person

+ No. of gallons of water for special use

= No. of gallons of water required per day

x Iron concentration (ppm)

= Daily iron removal requirements (ppm)

2. Establish backwash frequency using daily iron removal

requirements to complete the following calculation:

15,000 iron removal capacity (ppm)

÷ Daily iron removal requirements (ppm)

= No. of backwashes required in 12 day schedule

Example: You have four in the family, 8 ppm of iron and a

swimming pool requiring 46 gallons of water per day.

4 People in the family

x 75 Gallons of water per person

300 Gallons of water for family

+ 46 Gallons of water for the pool

346 Gallons of water required per day

x 8 Iron concentration

2,768 Daily iron removal requirements (ppm)

15,000 Iron removal capacity (ppm)

÷ 2,768 Daily iron removal requirements (ppm)

5.4 Backwash frequency (days)

The calculation indicates the need to backwash every 5.4

days. The control can only be programmed to backwash

at intervals of two, three, four, six and twelve days.

The control would be programmed to the closest more

frequent setting i.e. every four days.

24

CAUTION

Disassembly while under pressure can result

in flooding. Always follow these steps prior to

servicing the valve.

WARNING

Electrical shock Hazard!

unplug the unit before

removing the cover or

accessing any internal

control parts.

SERVICE THE PLATINUM VALVE

BEFORE SERVICING

1. Turn off water supply to conditioner :

A. If the conditioner installation has a 3 valve bypass system

first open the valve in the bypass line, then close the valves at the

conditioner inlet & outlet.

B. If the conditioner has an integral bypass valve, put it in the

bypass position.

C. If there is only a shut-off valve near the conditioner inlet, close it.

2. Relieve water pressure in the conditioner by stepping the control

into the backwash position momentarily. Return the control to the

In Service position.

3. Unplug electrical cord from outlet.

4. Disconnect drain line connection.

PROGRAMMING

MASTER PROGRAMMING

BELOW IS HOW THE SETTINGS ARE SET AT FACTORY:

PRESS MENU KEY

PRESS ‘+’ AND ‘-’ FOR 8 SECONDS

MODELS LANGUAGE REGION VALVE METER

BM-75 ENGLISH US GALLONS FILTER 1.364 DONT TOUCH OFF DAY S 10 10 12:00AM 3 DAYS #1 White 0 3.5 2S

BM-100 ENGLISH US GALLONS FILTER 1.364 DONT TOUCH OFF DAYS 10 10 12:00AM 3 DAYS #1 White 0 4.0 3S

BM-150 ENGLISH US GALLONS FILTER 1.364 DONT TOUCH OFF DAYS 10 10 12:00AM 3 DAYS #1 White 0 5.0 4S

BM-200 ENGLISH US GALLONS FILTER 1.364 DONT TOUCH OFF DAYS 10 10 12:00AM 3 DAYS #1 White 0 7.0 1

BM-300 ENGLISH US GALLONS FILTER 1.364 DONT TOUCH OFF DAYS 10 10 12:00AM 3 DAYS #1 White 0 10.0 2

MM-75 ENGLISH US GALLONS FILTER 1.364 DONT TOUCH OFF DAYS 10 10 12:00AM 3 DAYS #1 White 0 5.0 4S

MM-100 ENGLISH US GALLONS FILTER 1.364 DONT TOUCH OFF DAYS 10 10 12:00AM 3 DAYS #1 White 0 7.0 1

MM-150 ENGLISH US GALLONS FILTER 1.364 DONT TOUCH OFF DAYS 10 10 12:00AM 3 DAYS #1 White 0 10.0 2

MM-200 ENGLISH US GALLONS FILTER 1.364 DONT TOUCH OFF DAYS 10 10 12:00AM 3 DAYS #1 White 0 12.0 2

MM-300 ENGLISH US GALLONS FILTER 1.364 DONT TOUCH OFF DAYS 10 10 12:00AM 3 DAYS #1 White 0 15.0 3

NU-75 ENGLISH US GALLONS FILTER 1.364 DONT TOUCH OFF DAYS 10 10 12:00AM 3 DAYS #1 White 0 3.5 2S

NU-100 ENGLISH US GALLONS FILTER 1.364 DONT TOUCH OFF DAY S 10 10 12:00AM 3 DAYS #1 White 0 4.0 3S

NU-150 ENGLISH US GALLONS FILTER 1.364 DONT TOUCH OFF DAY S 10 10 12:00AM 3 DAYS #1 White 0 5.0 4S

NU-200 ENGLISH US GALLONS FILTER 1.364 DONT TOUCH OFF DAY S 10 10 12:00AM 3 DAYS #1 White 0 7.0 1

NU-300 ENGLISH US GALLONS FILTER 1.364 DONT TOUCH OFF DAY S 10 10 12:00AM 3 DAYS #1 White 0 10.0 2

TO-75 ENGLISH US GALLONS FILTER 1.364 DONT TOUCH OFF DAYS 10 10 12:00AM 3 DAYS #1 White 0 3.5 2S

TO-100 ENGLISH US GALLONS FILTER 1.364 DONT TOUCH OFF DAY S 10 10 12:00AM 3 DAYS #1 White 0 4.0 3S

TO-150 ENGLISH US GALLONS FILTER 1.364 DONT TOUCH OFF DAY S 10 10 12:00AM 3 DAYS #1 White 0 5.0 4S

TO-200 ENGLISH US GALLONS FILTER 1.364 DONT TOUCH OFF DAY S 10 10 12:00AM 3 DAYS #1 White 0 7.0 1

TO-300 ENGLISH US GALLONS FILTER 1.364 DONT TOUCH OFF DAY S 10 10 12:00AM 3 DAYS #1 White 0 10.0 2

NEX-75 ENGLISH US GALLONS FILTER 1.364 DONT TOUCH OFF DAYS 10 10 12:00AM 3 DAYS #1 White 0 5.0 4S

NEX-100 ENGLISH US GALLONS FILTER 1.364 DONT TOUCH OFF DAYS 10 10 12:00AM 3 DAYS #1 White 0 7.0 1

NEX-150 ENGLISH US GALLONS FILTER 1.364 DONT TOUCH OFF DAYS 10 10 12:00AM 3 DAYS #1 White 0 10.0 2

NEX-200 ENGLISH US GALLONS FILTER 1.364 DONT TOUCH OFF DAYS 10 10 12:00AM 3 DAYS #1 White 0 14.0 3

RATIO

SALT VS

EFFICIENCY

AUTO

CALCULA-

TION

REGEN.

MODE

BACK WASH

DURATION

RINSE

DURATION

AND SCROLL TO

‘MAIN MENU’. THEN

PRESS ‘SET’ TILL IT

BEEPS

REGEN

REGEN

TIME

SETTING

DAY

SETTING

Injector Injector

Color

VALVE SETTINGS

BLFC

Washer

DLFC

Washer

DLFC

Washer

Code

MENU

SET

Flow Rate: 24.5 GPM

18-Apr-2015 10:35AM

Days Remain 03

KEY PAD CONFIGURATION:

MENU - This function is to enter the basic

set up information required at the time of

installation.

SET/REGEN - This function is to accept the

values if changed and advance to the next

page in the menu.

to increase or decrease the value of the

settings while in the programming mode.

UP/DOWN - These buttons are used

25

STEP A - REGION SETTING

Press + and —. Hold until you hear a beep (8 seconds).

Press + or — to choose menu option. Press SETTINGS to enter.

Press + or — to change option. Press SETTINGS to accept.

STANDBY INTERFACE

= = Initial Setup interface = =

n

Language

n

Region

n

Valve

n

Meter Ratio

n

Salt vs Eciency Setting

n

Calculation

= Language =

n

English

Setting Complete

Press ¨ T o Return

= = Initial Setup interface = =

n

Language

n

Region

n

Valve

n

Meter Ratio

n

Salt vs Eciency Setting

n

Calculation

= Region =

n

U.S. Gallon

Setting Complete

Press ¨ To Return

STEP B - ADVANCED MENU

Press Menu key. Press — to advance to Advanced Menu

Press + or — to choose menu option. Press SET to enter

Press + or — to change option. Press SET to accept

Press Menu key. Press — to advance to Main Menu

Press SET or until you hear a beep.

Press — to advance to Advanced Menu

Press and hold SET 5 seconds or until you hear

= Main Menu =

Regen. Time Setting

System Capacity

Salt Mode Setting

Advanced Menu

= Advanced Menu =

Regen. Mode

Regen. Cycles

History Values

= Regen. Mode =

Calendar

Meter Immediate

Meter Delay

Meter Override

Setting Complete

Press To Return

a beep.

Press + or — to choose menu option. Press SET

to enter.

Press + or — to change option. Press SET to

accept.

= Advanced Menu =

Regen. Mode

Regen. Cycles

History Values

= Regen. Cycles =

Backwash Duration

Rinse Duration

= Backwash Duration =

10 Minutes

Press ¨ To Cancel

Press To Confirm

= Rinse Duration =

10 Minutes

Press To Cancel

Press To Confirm

Setting Complete

Press To Return

= = Initial Setup interface = =

n

Language

n

Region

n

Valve

n

Meter Ratio

n

Salt vs Eciency Setting

n

Calculation

= Valve Setting =

n

Filter

n

DownFlow

n

UpFlow

Setting Complete

Press ¨ To Return

= = Initial Setup interface = =

n

Language

n

Region

n

Valve

n

Meter Ratio

n

Salt vs Eciency Setting

n

Calculation

Meter Ratio

1.364

Press ¨ To Cancel

PressnTo Conrm

Setting Complete

Press ¨ To Return

= = Initial Setup interface = =

n

Language

n

Region

n

Valve

n

Meter Ratio

n

Salt vs Eciency Setting

n

Calculation

= Salt Vs Eciency =

Don’t Touch

n

E: 03.0 lbs Vs 5000 Grs

n

S: 06.0 lbs Vs 4150 Grs

n

H: 12.0 lbs Vs 2500 Grs

Setting Complete

Press ¨ To Return

STEP C - MAIN MENU

Press Menu key. Press — to advance to Advanced Menu

Press SET or until you hear a beep

Press + or — to choose menu option. Press SET to enter

Press + or — to change option. Press SET to accept

Date and Time

Hardness

Manual Regen.

Dealer Information

Main Menu

= Main Menu =

Regen. Time Setting

Regen. Days Setting

Advanced Menu

= = Regen. Time = =

12:00 AM

Press To Cancel

Press To Confirm

Setting Complete

Press ¨ To Return

Main Menu

Regen. Time Setting

Regen. Day Setting

Advanced Menu

= Main Menu =

Regen. Time Setting

Regen. Days Setting

Advanced Menu

= = Regen. Day = =

03 Days

Press ¨ To Cancel

Press To Confirm

Setting Complete

Press ¨ To Return

STEP D - USER SETTING

Press Menu key

Press SET or until you hear a beep

Press + or — to choose menu option. Press SET to enter

Press + or — to change value. Press SET to accept

Standby

Interface

Date and Time

Manual Regen.

Dealer Information

Main Menu

Date and Time

Manual Regen.

Dealer Information

Main Menu

= = Initial Setup interface = =

n

Language

n

Region

n

Valve

n

Meter Ratio

n

Salt vs Eciency Setting

n

Calculation

== Auto Calculation ==

ON OFF

Press ¨ To Cancel

PressnTo Conrm

Setting Complete

Press ¨ To Return

26

= = Date and Time = =

17 - Feb - 2016

12:25PM

Press To Cancel

Press To Confirm

Setting Complete

Press ¨ To Return

= = Dealer Informa-

tion = =

Quality Water

666 3 Ave

Chicago IL

Tel 12345678

Press To Cancel

Press To Confirm

Setting Complete

Press ¨ To Return

DIAGNOSTIC SCREEN

PRESS “MENU” KEY AND SCROLL TO “MAIN MENU”. THEN PRESS “SET” TILL IT

BEEPS. SCROLL TO ADVANCED MENU

Press “Menu” key . Press - to advance to Main Menu

Press “SET”

or until you hear a beep.

Press - to advance to Advanced Menu

Press and hold “SET” 5 seconds or until you hear a beep.

= Advanced Menu =

Resin Volume

Rell Rate

Regen. Mode

Backwash Override

Emergency Regen.

Regen. Cycles

History Values

= History Values =

General Diagnostics

Reserve

Usage History

Last Regen. On:

17-Feb-2016, 02:00AM

Used Since Regen.

0051 Gallons

Current Flow Rate:

15.22 gpm

Used Since Regen.

85.22 gpm

Peak Flow Rate on:

17-Feb-2016, 12:25PM

Software Version

1.10

= History Values =

General Diagnostics

Reserve

Usage History

Sunday: 5800 Gal

Monday: 5801 Gal

Tuesday: 5802 Gal

Wednesday: 5803 Gal

Thursday: 5804 Gal

Friday: 5805 Gal

Saturday: 5806 Gal

Highest record in

last 4 weekdays

Press - to advance to History Values

Press“SET”

Press “+” or “-”

Press “+” or “-”

or until you hear a beep.

to choose menu option. Press “SET”

to change option. Press “SET” to accept.

PARAMETER DESCRIPTION

LAST REGEN ONDate of last system

USED SINCE

REGEN

CURRENT

FLOW RATE

PEAK FLOW

= History Values =

General Diagnostics

Reserve

Usage History

RATE

SOFTWARE

VERSION

RESERVE The calculated reserve

28 DAYS

HISTORY

USAGE

HISTORY

TOTAL USED The total volume used.

TOTAL REGENS The total quantity of

TOTAL DAYS The total days in operation.

to enter.

regeneration.

Volume used since last

regeneration.

The current system

flow rate.

The peak or highest flow

rate since last regeneration.

The software version

programmed on the PCB.

for each day based on the

highest days usage over the

past 4 weeks.

The volume used for each

of the last 28 days.

The usage since system

start up and from the last

reset.

regenerations.

= 28 Days Reset =

NO YES

Press To Cancel

To Conrm

Press

= 28 Days History =

Sun Dec 01: 5800 Gal

Mon Dec 02: 5801 Gal

Sat Dec 28: 5806 Gal

= Usage History =

28 Days History

History Since Startup

History Since Reset

= 28 Days Reset =

NO YES

Press To Cancel

To Conrm

Press

= 28 Days Reset =

Reset Conrm?

Press To Cancel

Press

To Conrm

= 28 Days History =

Sun Dec 01: 5800 Gal

Mon Dec 02: 5801 Gal

Sat Dec 28: 5806 Gal

Page by page

display

= Usage History =

28 Days History

History Since Startup

History Since Reset

= History Since Startup =

Peak Flow Rate:

85.22 gpm

Total Used:

123456789 Gallons

Total Regen.s:

0088

Total Days:

0325

= Usage History =

28 Days History

History Since Startup

History Since Reset

= History Since Reset =

Peak Flow Rate:

85.22 gpm

Total Used:

123456789 Gallons

Untreated water:

2123456 Gallons

Total Regen.s:

0088

Total Days:

0325

Conrm and return

One by One

= History Since Reset =

Reset Conrm?

Press To Cancel

To Conrm

Press

27

REPLACEMENT

REPLACE PISTON AND/OR BRINE VALVE ASSEMBLY

Remove 4 X

Screws

1. Follow steps 1 to 6 of

timer /Powerhead replacement.

2. Remove four screws from the plate

on the valve body.

Plate

Brine Valve

Assembly

3. Remove the plate from the valve body and

pull the Piston Assembly from the valve.

The brine valve assembly can also be

removed in this stage.

4. Remove the seal spacer assembly,

grease it with silicone lubricant and

put back in.

Piston

Assembly

5. Replace piston assembly followed

by timer assembly.

6. Replace the piston

assembly and reverse

following steps

in this section

Seal and

Spacer

CLEAN INJECTOR ASSEMBLY

1.

Injector

Cap

2X Screws

4.

3.

Screen

5.

2.

Injector

Assembly

Gasket

1.

Remove the two screws from the

injector cap

2. Pull the injector cap and gasket

3. Pull the injector assembly

and screen

4. Replace/clean screen and injector

assembly and put it back in the valve

in appropriate location as shown

5. Put back the injector cap. Grease the

injector assembly o-rings and injector

cap gasket. Care should be taken to

put all o-rings and gaskets in place

and grease them so that they

don’t pinch

28

REPLACE TIMER

Meter Cable

1. Disconnect the meter cable from the

meter. (If flow meter is attached)

Piston Screw 2 X Screws from Powerhead

Washer

4 X Screws

2. Remove four screws from the back of

the valve cover

Front Cover

3. Remove the front cover of the valve.

Powerhead

Assembly

4. Remove the piston screw and

washer from the piston rod.

REPLACE MOTOR

1. Remove Screws from the back of the valve

and pull the cover

2. Remove all connections from the

circuit board

3. Remove the two screws from the motor.

Remove the motor and watch for the pin

under the motor.

4. Replace the motor, connections and cover

5. Remove the two screws from the powerhead as shown

6. Life the powerhead from the valve body assembly

7. Replace the powerhead by reverse following the steps in this section

1.

Cover 4X Screws

3.

4.

Front Cover

2.

Valve Body

Assembly

2X Screws

Motor

29

REPLACE METER ASSEMBLY

1.

Meter

Cable

2.

2X Clips

3.

Coupling Adaptor

5.

4.

1. Disconnect the meter cable from the meter.

2. Disconnect the valve from bypass by removing clips

3. Remove the coupling adaptor from the valve

4. Remove the meter support and then the impeller out from

the coupling and clean it

5. Replace meter with the help of special tool and

re-assemble the removed components back in the section

30

DISPLAY

REPLACE

REPLACEMENT

MICROSWITCHES

1.

4X Screws

3.

2X Screws

1. Remove Screws from the back of the valve

and pull the cover

2. Remove all connections from the circuit board

3. Remove the two screws from the microswitch

4. Replace the microswitch, connections and cover

2.

4.

Front Cover

Microswitches

1. Remove the screws from the back of the valve and

pull the front cover

2. Remove all connections from the circuit board

3. Remove the four screws from the

circuit board and pull it out

AFTER SERVICING

1. Reconnect drain line

2. Return bypass or inlet valve to normal in service

position. Water pressure will automatically build

in the softener

3. Check for leaks at all sealed areas. Check drain seal

with the control in the backwash position

4. Plug electrical cord into outlet

5. Set Time of Day and cycle the control valve manually to

assure proper function. Make sure control valve is

returned to the In Service position

NOTE

Be sure to shut off any bypass line.

31

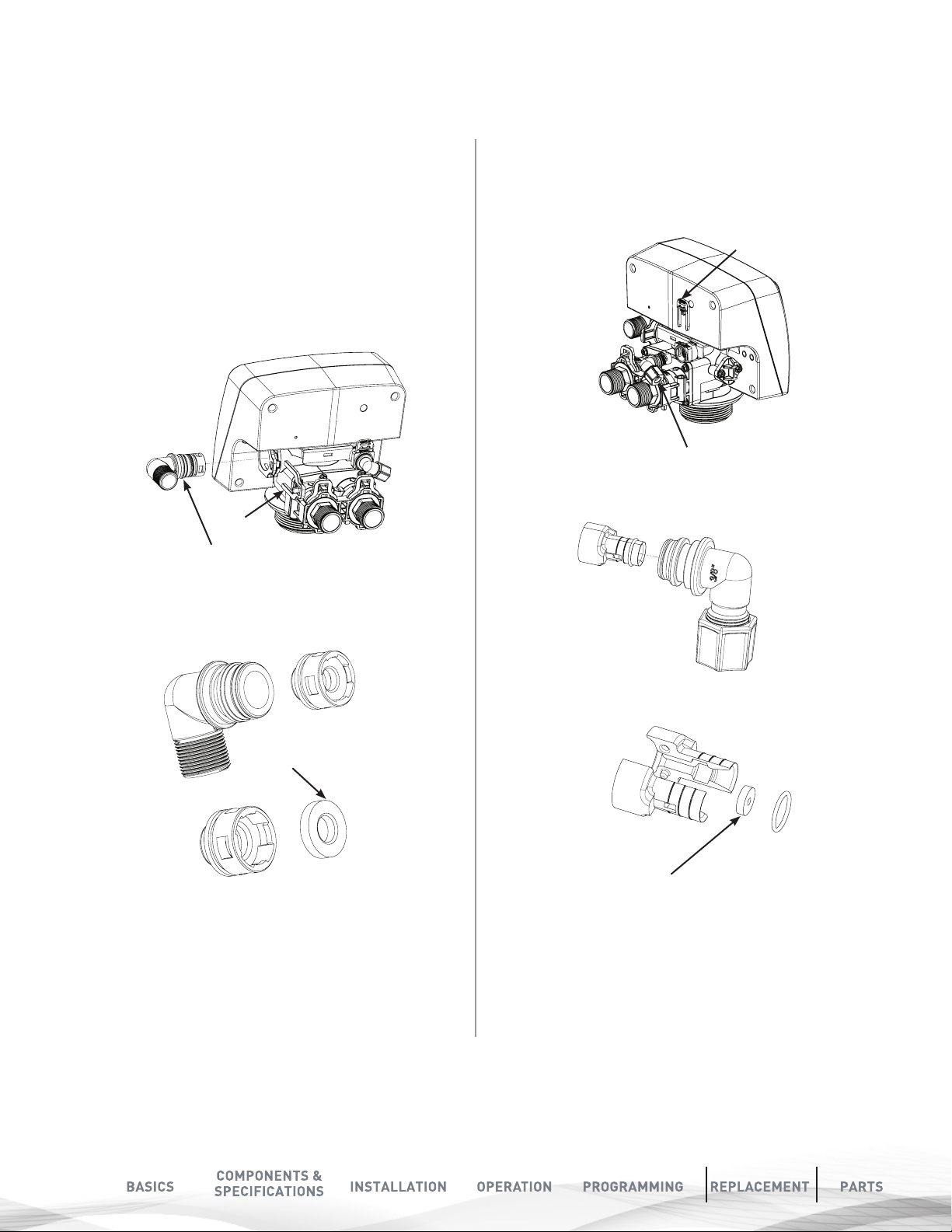

REPLACE DRAIN

REPLACE BRINE LINE

LINE FLOW

CONTROL

1.

Clip

Drain Line Elbow

FLOW CONTROL

1.

Brine Line Elbow

2.

Clip

2.

Drain Line Washer

1. Pull the drain line clip and remove the

drain line elbow and washer

2. Clean/replace drain line washer

Brine Line Washer

1. Pull the brine line clip and remove

the brine line elbow and washer

2. Clean/replace brine line washer

32

PARTS

PLATINUM FILTER PARTS LIST

Upper Cone

(18280)

Bypass

60010004

Distributor

Control Valve

SYSTEM

MODEL

TP-75 8 x 44 25010025 25010027 25010026 50010005 10010043 95401

TO-100 9 x 48 25010034 25010036 25010035 50010005 10010043 95402

TO-150 10 x 54 25010049 25010051 25010050 50010005 10010043 95403

TO-200 12 x 52 25010058 25010060 25010059 50010005 10010043 95404

TO-300 14 x 65 25030001 and 50040039 Not Available Not Available 50010010 10010043 XXXXx

TO-400 16 x 65 25030002 ad 50040039 Not Available Not Available 50010010 10010043 XXXXX

NU-75 8 x 44 25010025 25010027 25010026 50010005 10010043 93500

NU-100 9 x 48 25010034 25010036 25010035 50010005 10010043 93501

NU-150 10 x 54 25010049 25010051 25010050 50010005 10010043 93502

NU-200 12 x 52 25010058 25010060 25010059 50010005 10010043 93503

NU-300 14 x 65 25030001 and 50040039 Not Available Not Available 50010010 10010043 xxxxx

NU-400 16 x 65 25030002 and 50040039 Not Available Not Available 50010010 10010043 xxxxx

MM-75 8 x 44 25010025 25010027 25010026 50010005 10010043 95418

MM-100 9 x 48 25010034 25010036 25010035 50010005 10010043 95415

MM-150 10 x 54 25010049 25010051 25010050 50010005 10010043 95416

MM-200 12 x 52 25010058 25010060 25010059 50010005 10010043 95417

MM-300 14 x 65 25030001 and 50040039 Not Available Not Available 50010010 10010043 XXXXX

MM-400 16 x 65 25030002 and 50040039 Not Available Not Available 50010010 10010043 XXXXX

BM-75 8 x 44 25010025 25010027 25010026 50010005 10010043 95435

BM-100 9 x 48 25010034 25010036 25010035 50010005 10010043 95449

BM-150 10 x 54 25010049 25010051 25010050 50010005 10010043 95436

BM-200 12 x 52 25010058 25010060 25010059 50010005 10010043 95437

BM-300 14 x 65 25030001 and 50040039 Not Available Not Available 50010010 10010043 95438

BM-400 16 x 65 25030002 and 50040039 Not Available Not Available 50010010 10010043 XXXXX

Nexsand-758 x 44 25010025 25010027 25010026 50010005 10010043 95632

MINERAL

TANK SIZE

TANK # TANK #

(BLACK

COLOR)

TANK #

(BLUE

COLOR)

DISTRIBUTOR #

VALVE # MEDIA

BED #

Nexsand-

100

Nexsand-

150

Nexsand-

200

Nexsand-

300

Nexsand-

400

9 x 48 25010034 25010036 25010035 50010005 10010043 95633

10 x 54 25010049 25010051 25010050 50010005 10010043 95644

12 x 52 25010058 25010060 25010059 50010005 10010043 95645

14 x 65 25030001 and 50040039 Not Available Not Available 50010010 10010043 XXXXX

16 x 65 25030002 and 50040039 Not Available Not Available 50010010 10010043 XXXXX

33

CONTROLLER ASSEMBLY PARTS LIST

%

%

%

%

%

NO. PART # PART DESCRIPTION QTY

B29 DNR Micro Switch Cable 1

B28 60010115 Meter Cable 1

B27 60010124 Power Cable 1

B26 60095092 Meter Cable Clip 1

B25 60095091 Power Cable Clip 1

B24 92393 Motor 12VAC 3W 1

B23 60010574 Screw on Mounting Plate 8

B22 60010573 Mounting Plate 1

B21 60010660 Motor Pin 1

B20 60010099 Screw on Main Gear 1

B19 60010100 Washer on Main Gear 1

B18 92391 Main Gear 1

B17 92389 Drive Gear 1

B16 DNR Screw on Back Cover 4

B15 DNR Washers on Screw 4

B14 DNR Platinum Back Cover 1

B13 92392 Brine Gear 1

B12 60010577 Locating wheel(UF) 1

B11 60010661 Washer on Locating Wheel 1

B10 DNR Screw 2.2×13 1

B9 60010575 Screw on Locating Wheel 1

B8 60010580 Micro Switch 2

B7 60010579 Screws on Micro Switch 2

B6 DNR Platinum Front Cover 1

B5 60010572 Screws on PCB 4

B4 92388 Platinum PCB 1

B3 60010571 PCB Absorb Shock Foam 1

B2 DNR Platinum Controller Cover 1

B1 DNR Controller Touch Panel 1

34

STANDARD BYPASS ASSEMBLY PARTS LIST

NO. PART #

WATER GROUP

C14 DNR O-ring on Shaft Top 2

C13 DNR Platinum Bypass Shaft Seal 2

C12 60095614 O-ring on Shaft Bottom 2

C11 60010069 Secure Clip of Plug 2

C10 92387 Secure Clip Inlet and Oulet 2

C9 DNR Steel Retainer Ring 2

C8 60010252 Elbow 1“ NPT Inlet and Oulet 2

C7 60010592 Straight 1“ NPT Inlet and Oulet 2

C6 60010590 O-ring on Inlet

C5 DNR Platinum Bypass Body 1

C4 DNR O-ring on Plug 2

C3 60010209 Plug 2

C2 DNR Shaft of Platinum Bypass 2

C1 DNR Knob on Platinum Bypass 2

PART DESCRIPTION QTY

and Oulet Adaptor

4

35

STANDARD VALVE BODY ASSEMBLY PARTS LIST

$

$

$

$

NO. PA RT # PART DESCRIPTION QTY

A51 60010184 Brine Line Elbow Nut 1

A50 60010172 Brine Line Elbow 1

A49 60010044 O-ring of Brine Line Elbow 1

A48 60010188 O-ring of BLFC Holder 1

A47 60010173 BLFC Holder 2

A46 60010128 BLFC(0.2GPM)(Optional) 1

A45 DNR Brine Line Connector 1

A44 DNR O-ring of Brine Line Connector 1

A43 60010099 Screw on Valve Bottom Connector 2

A42 60010599 Valve Bottom Connector 1

A41 60010080 Distributor O-ring 1

A40 60010598 Central Pipe Adaptor 1

A39 60010597 O-ring of Central Pipe Adaptor 1

A38 60010077 Tank Mouth O-ring 1

A37 60010715 Screen Platinum Valve 1

A36 60010595 Injector Cover 1

A35 DNR O-ring of Injector Cover 1

A34 60010186 Big O-ring of Injector Holder 1

A33 Check Page 23 #0000 Black Injector Nozzle

A32 60010174 Injector Holder 1

A31 Check Page 23 #0000 Black Injector Throat

A30 60010187 Small O-ring of Injector Holder 1