Brita Platinum Performance, BPF89CB75TO, BPF89CBK100TOK, BPF89CB300TO, BPF89CBK75TOK Installation Manual

...

PLATINUM

TASTE AND ODOR (TO)

MULTIMEDIA (MM)

FILTER

NEXSAND

NEUTRALIZER (NU)

BIRM (BM)

Professional

Installation

MANUAL

Version V1.0F

54565

THROUGHOUT YOUR HOME | THROUGHOUT YOUR LIFE

The Platinum Carbon Filter Series is certified by

IAPMO R&T to NSF/ANSI 42 for chlorine, taste

and odor reduction.

The Platinum Catalytic Carbon Filter Series

is certified by IAPMO R&T to NSF/ANSI 42 for

chloramine, chlorine taste and odor reduction.

The Platinum Neutralizer Filter Series is

certified by IAPMO R&T according to NSF/ANSI

42 for low pH adjustment.

The Platinum Nexsand Filter Series is certified

by IAPMO R&T to NSF/ANSI 42 for Particulate

Class V reduction.

2

2

This control value and pressure tank is Tested

and Certified by NSF International against

NSF/ANSI Standard 44 for material and

structural integrity requirements.

COMPONENT

828.449.2536

BRITA® PRO

www.britapro.com

BRITA®PRO trademark and logo are registered trademarks of Brita LP and are

used under license by Protect Plus, LLC. All rights reserved

420 3rd Avenue NW

Hickory, NC 28601

READ THIS PAGE FIRST

CONTENTS

BEFORE STARTING INSTALLATION 4

BASICS

HOW YOUR FILTER WORKS 5

COMPONENTS & SPECIFICATIONS

SPECIFICATIONS 6

INSTALLATION

UNPACK & INSTALL 8

CHECK VALVE SERIAL NUMBER & VALVE TYPE 10

PREINSTALLATION INSTRUCTIONS 11

ELECTRICAL GROUNDING 11

TOOLS REQUIRED FOR INSTALLATION 14

DETERMINING LOCATION 14

CHECK WATER PRESSURE AND PUMPING RATE 14

FILTER INSTALLATION 15

MEDIA INSTALLATION 16

OPERATION

STARTUP PROCEDURES 20

DIAGNOSTIC CHECKLIST 21

DURING REGENERATION 21

PLUMBING SYSTEM CLEANUP 21

SOFTENERWATER BYPASSOPERATING CONDITIONS 22

MAINTENANCE INSTRUCTIONS 23

BACKWASHING INSTRUCTIONS 24

CALCULATE BACKWASH FREQUENCY 24

SERVICE THE PLATINUM VALVE 24

PROGRAMMING

MASTER PROGRAMMING 25

DIAGNOSTIC SCREEN 27

REPLACEMENT

REPLACE PISTON &/OR BRINE VALVE 28

CLEAN INJECTOR ASSEMBLY 28

REPLACE TIMER 29

REPLACE MOTOR 29

REPLACE METER ASSEMBLY 30

DISPLAY REPLACEMENT 31

REPLACE MICROSWITCHES 31

AFTER SERVICING 31

DRAIN LINE FLOW CONTROL 32

BRINE LINE FLOW CONTROL 32

PARTS

FILTER 33

CONTROLLER ASSEMBLY PARTS LIST 34

STANDARD BYPASS ASSEMBLY PARTS LIST 35

STANDARD VALVE BODY ASSEMBLY PARTS LIST 36

TROUBLE SHOOTING GUIDE 38

PERFORMANCE DATA STATEMENT 41

WARRANTY 47

3

READ THIS

PAGE FIRST

BEFORE STARTING INSTALLATION

You must read and understand the contents of this manual

before installing or operating your water softener. Personal injury

or property damage could result if you fail to follow instructions in

this manual.

This system and its installation must comply with state and

local regulations. Check with your local public works department

for plumbing and sanitation codes. Local codes should be

followed In the event the codes conflict with any content in this

manual.

For installations in Massachusetts, Massachusetts Plumbing

Code 248 CMR shall be adhered to. Consult your licensed plumber

for installation of this system.

This water softener must be operated on pressures

between 30 psi to 125 psi. If the water pressure is higher than 125

PSI, use a pressure reducing valve in the water supply line to the

softener.

This unit must be operated at temperatures between 40°F and

110°F (4°C - 43°C).

Do not use this water softener on hot water supplies.

Do not install this unit where it may be exposed to wet

weather, direct sunlight, or temperatures outside of the

range specified above.

Apply provided NSF certified lubricant to all o-rings during

installation. Do not use pinched or damaged o-rings during

installation.

Softeners are exposed to high levels of iron, manganese,

sulfur, and sediments. Damage to pistons, seals, and or spacers

within the control valve are not covered in this warranty due to the

harsh environment.

It is recommended to annually inspect and service the control

valve. Frequent cleaning and or replacement of piston, seals,

and or spacers may be necessary depending on how harsh the

conditions are. An Annual Maintenance kit (Part # 60010307) is

available for this purpose.

Do not use water that is microbiologically unsafe without

adequate disinfection before or after this system.

This publication is based on information available when

approved for printing. Continuing design refinement could

cause changes that may not be included in this publication.

See page 8 for unpack and inspect system

BRITA®PRO reserves the right to change the specifications

referred to in this literature at any time, without prior notice.

4

INSTALL

NOTES &

SAFETY

MESSAGES

Watch for the

following messages

in this manual:

EXAMPLE:

NOTE

Check and comply with

your state and local

codes. You must follow

these guidelines.

EXAMPLE:

EXAMPLE:

CAUTION

Disassembly while under pressure

can result in flooding.

WARNING

ELECTRICAL SHOCK HAZARD! Unplug the unit before removing

the cover or accessing any internal control parts

BASICS

The success of the installation will depend, to a great

extent, on advanced planning and preparation. Careful

attention to the location of the unit, accessibility to

electrical and drain facilities, and the availability of the

proper tools will ensure a professional-looking installation.

Of utmost importance is the assurance that the filter has

been properly applied and meets all specifications.

APPLICATION:

Correct application is directly associated with the

performance and life expectancy of any water filter. It is

important, therefore, to understand how your Brita® Pro

Water Filter functions and to know its capabilities and

limitations so that a correct application can be made.

By following the guidelines and recommendations set forth

in this manual, you can be certain your filter is applied

correctly.

MM / NEXSAND FILTER

The Automatic Water Filter is capable of removing

particulate matter particle size as small as 30 microns.

It will not remove color, organics, colloidal turbidity or

dissolved solids. Some applications include:

- Removal of suspended matter in any water system

- Removal of particulate matter, such as clay, mud, etc.

- Prefiltration of oxidized iron prior to an automatic or

manual softener

-Removal of light sand

The quality and number of gallons of filtered water

between backwashes will depend upon the amount, type,

and size of the particulate matter being filtered. If a water

sample is sent to a laboratory, where application of a MMF

Type unit is contemplated. The laboratory will test for

Nephelometric Turbidity Units (NTU) and suspended solids

(mg/L). The sample will also be filtered through 10 micron

filter paper and NTU run on a filtered sample. If the NTU

of the raw water exceeds 150, suspended solids exceed

150 mg/L, or the filter water through the 10 micron filter

paper has unacceptable quality, a MMF filter might not

be applicable. As a guide, the U.S. Public Health Drinking

Water standards states the turbidity should not exceed

1 NTU. The exact number of gallons filtered between

backwashes can not be given because of many variables.

TO FILTER

Automatic Water Filter with Activated Media will control

chlorine taste and odor, and it will also remove most

objectional organic colors. It will not remove hydrogen

sulfide. It is important to note that whenever the cause

of an objectional taste or odor has not been established,

Health Authorities should determine if the water is safe

to drink. Do not use with water that is microbiologically

unsafe or of unknown quality without adequate disinfection

before or after the system.

NU FILTER*

Automatic Water Filter with Neutralizing Media will

neutralize slightly acid water (pH 5.2 to >6.8) and thus help

to prevent unsightly brown or green stains due to corrosion

of household plumbing. If the pH is between 5 and 6, one

part of Magnesium Oxide Media should be mixed with five

parts of Calcite Media to provide additional neutralizing

capability. If the water to be treated has a pH less than 5, a

high hardness, or a high carbon dioxide level, NF might not

be applicable; a solution feeder should be used. Because

NF adds hardness, it should be used prior to a softener.

BM FILTER

This media acts as a catalyst for the removal of iron and

manganese from the water but require pre-oxidation. This

media removes the iron and manganese from the water.

This is not recommended to remove hydrogen sulfide from

the water and requires high pH water. The media is not

sacrificial hence no replenishment is required.

NOTE

Under dynamic conditions it might be necessary to mix five parts

Calcite with one part Magnesium Oxide to effectively raise the pH.

In order to size and apply the equipment correctly, a complete

analysis of the water supply should be obtained.

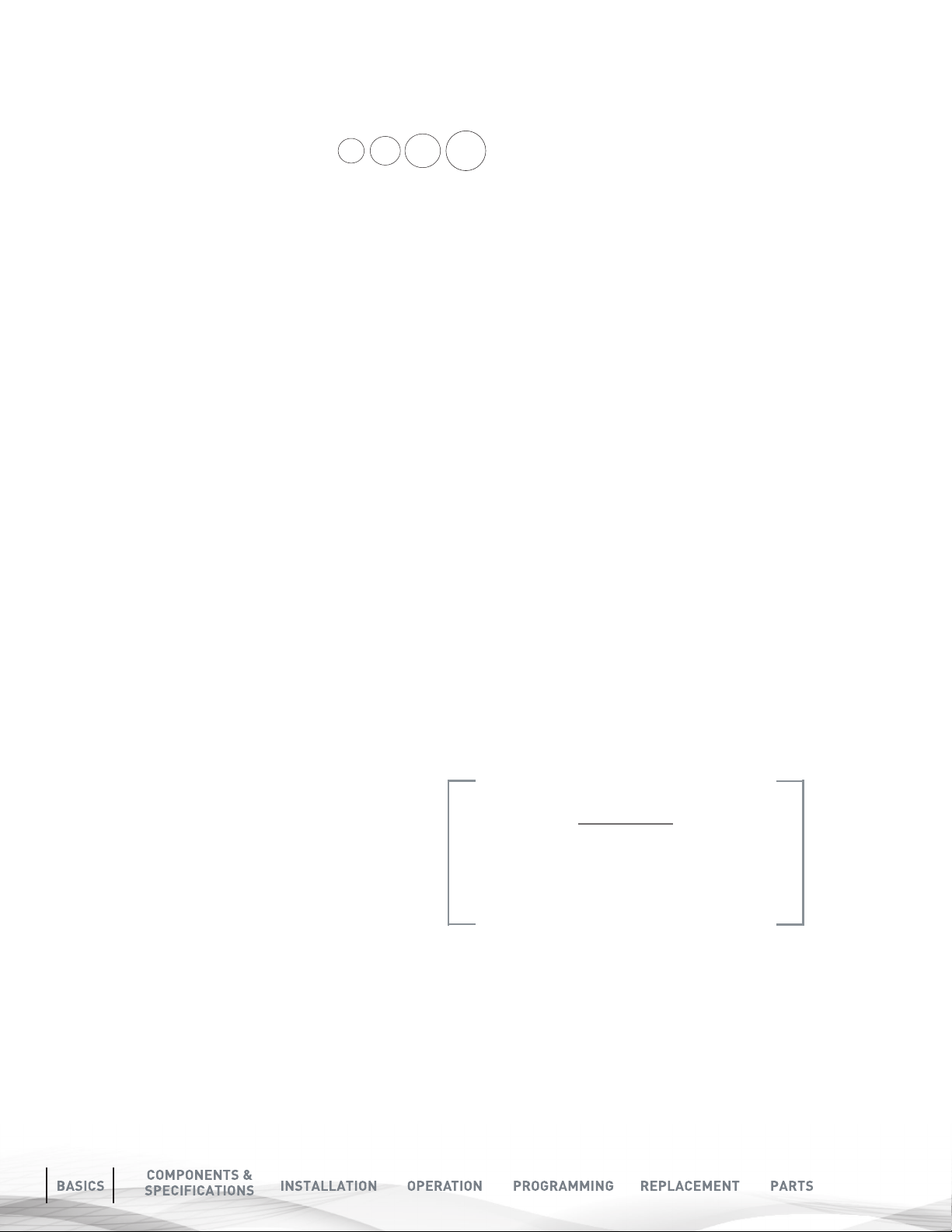

5

COMPONENTS &

SPECIFICATIONS

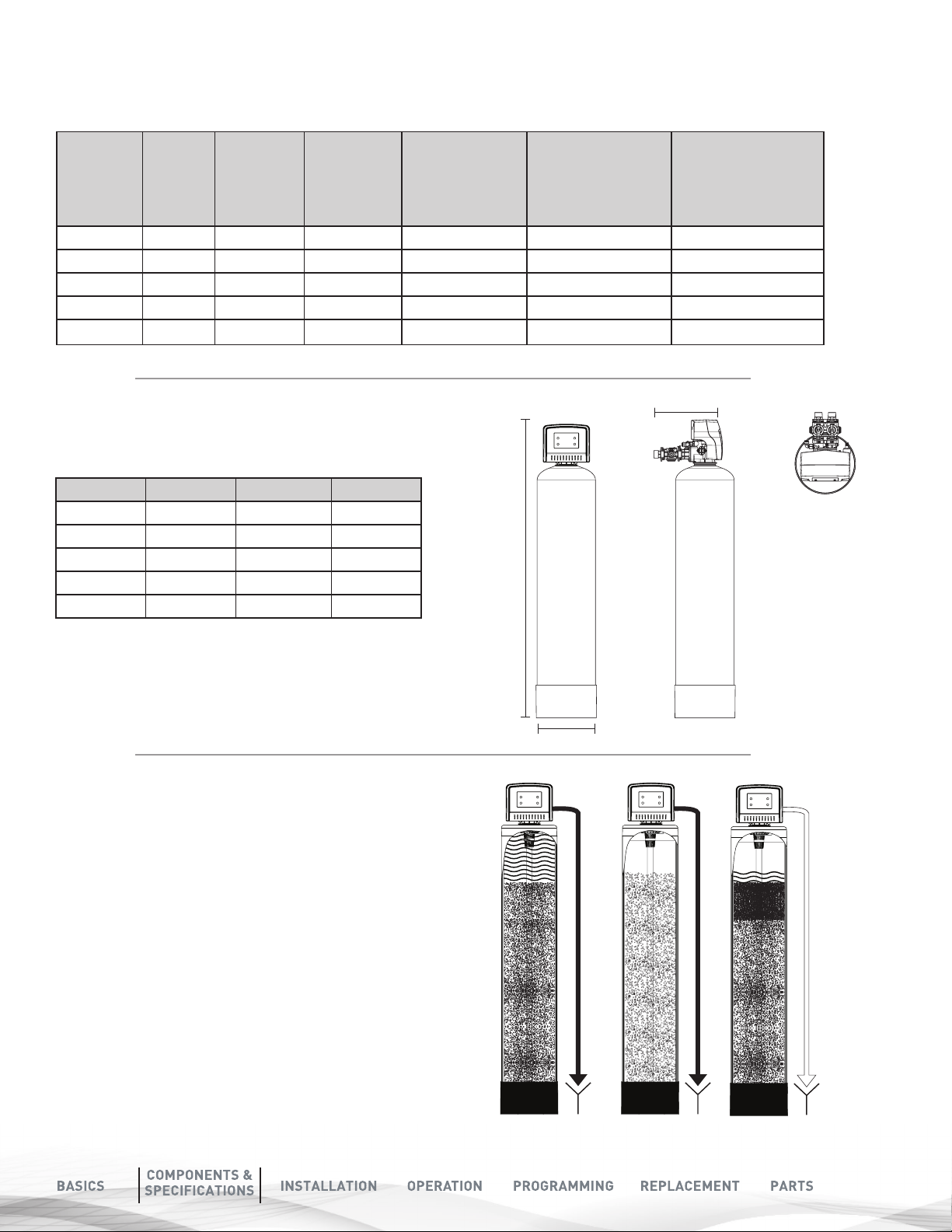

TASTE & ODOR (COCONUT SHELL CARBON) FILTERS

Platinum Series

BPF89CB75TO 0.75 4.0 5.0 3.5 8 x 44 3/4” - 1” 50

BPF89CB100TO 1.00 5.0 7.0 4.0 9 x 48 3/4” - 1” 60

BPF89CB150TO 1.50 7.0 10.0 5.0 10 x 54 3/4” - 1” 78

BPF89CB200TO 2.00 10.0 12.0 7.0 12 x 52 3/4” - 1” 95

BPF89CB300TO 3.00 12.0 15.0 10.0 14 x 65 3/4” - 1” 138

Media Cu

Ft

TASTE & ODOR (COCONUT SHELL CARBON) FILTERS W/KDF

Platinum Series

BPF89CBK75TOK 0.75 4.0 5.0 3.5 8 x 44 3/4” - 1” 50

BPF89CBK100TOK 1.00 5.0 7.0 4.0 9 x 48 3/4” - 1” 60

BPF89CBK150TOK 1.50 7.0 10.0 5.0 10 x 54 3/4” - 1” 78

BPF89CBK200TOK 2.00 10.0 12.0 7.0 12 x 52 3/4” - 1” 95

BPF89CBK300TOK 3.00 12.0 15.0 10.0 14 x 65 3/4” - 1” 138

Media Cu

Ft

Flow Rate USGPM

Flow Rate USGPM

Service Peak Backwash

Mineral

Tank Size

Mineral

Tank Size

Pipe Size

Inches

Pipe Size

Inches

Ship Weight

LbsService Peak Backwash

Ship Weight

Lbs

Working Temperature = 34-110°F

(1-43°C)

(Do not subject the unit to freezing

temperatures)

Working Pressure = 30-125 PSIG

(137-861 kPa)

Voltage = 120V / 60 Hz

Pipe Size = 3/4” and 1”

• At the stated service flow rates, the

pressure drop through these devices

will not exceed 15 psig.

CATALYTIC CARBON FILTERS (CHLORAMINES REDUCTION)

Platinum Series

BPF89CATCB75TOC 0.75 4.0 5.0 3.5 8 x 44 3/4” - 1” 50

BPF89CATCB100TOC 1.00 5.0 7.0 4.0 9 x 48 3/4” - 1” 60

BPF89CATCB150TOC 1.50 7.0 10.0 5.0 10 x 54 3/4” - 1” 78

BPF89CATCB200TOC 2.00 10.0 12.0 7.0 12 x 52 3/4” - 1” 95

BPF89CATCB300TOC 3.00 12.0 15.0 10.0 14 x 65 3/4” - 1” 138

Media Cu

Ft

Flow Rate USGPM

Mineral

Tank Size

Pipe Size

Inches

Ship Weight

LbsService Peak Backwash

CATALYTIC CARBON FILTERS (CHLORAMINES REDUCTION) W/ KDF

Platinum Series

BPF89CATCBK75TOCK 0.75 4.0 5.0 3.5 8 x 44 3/4” - 1” 50

BPF89CATCBK100TOCK 1.00 5.0 7.0 4.0 9 x 48 3/4” - 1” 60

BPF89CATCBK150TOCK 1.50 7.0 10.0 5.0 10 x 54 3/4” - 1” 78

BPF89CATCBK200TOCK 2.00 10.0 12.0 7.0 12 x 52 3/4” - 1” 95

BPF89CATCBK300TOCK 3.00 12.0 15.0 10.0 14 x 65 3/4” - 1” 138

Media Cu

Ft

Flow Rate USGPM

Mineral

Tank Size

Pipe Size

Inches

Ship Weight

LbsService Peak Backwash

NEUTRALIZING FILTERS

Platinum Series

BPF89NEU75PH 0.75 2.0 3.5 3.5 8 x 44 3/4” - 1” 93

BPF89NEU100PH 1.00 3.0 5.0 4.0 9 x 48 3/4” - 1” 120

BPF89NEU150PH 1.50 5.0 8.0 5.0 10 x 54 3/4” - 1” 164

BPF89NEU200PH 2.00 6.0 10.0 7.0 12 x 52 3/4” - 1” 207

BPF89NEU300PH 3.00 7.0 12.0 10.0 14 x 65 3/4” - 1” 330

Media Cu

Ft

Flow Rate USGPM

Mineral

Tank Size

Pipe Size

Inches

Ship Weight

LbsService Peak Backwash

• The manufacturer reserves the right

to make product improvements which

may deviate from the specifications

and descriptions stated herein,

without obligation to change previously

manufactured products or to note the

change.

* Do not use water that is

microbiologically unsafe without

adequate disinfection before or after

the system.

Peak flow rates intended for intermittent

use only (10 minutes or less) and are

for residential applications only. Do

not use peak flow rate for commercial

applications or for a continuous

rate when treated water supplies are

geothermal heat pump, swimming

pool, etc.

For satisfactory operation, the pumping

rate of the well system must equal or

exceed indicated backwash flow rate.

All units come with plastic bypass.

NEXSAND PARTICULATE FILTERS

Platinum Series Media Cu

Ft

BPF89NEX75TUR 0.75 4.0 6.0 5.0 3 - 5 µ 8 x 44 3/4” - 1” 90

BPF89NEX100TUR 1.00 5.0 8.0 7.0 3 - 5 µ 9 x 48 3/4” - 1” 135

BPF89NEX150TUR 1.50 8.0 10.0 10.0 3 - 5 µ 10 x 54 3/4” - 1” 205

BPF89NEX200TUR 2.00 10.0 12.0 14.0 3 - 5 µ 12 x 52 3/4” - 1” 255

Flow Rate USGPM

Micron

Rating

Mineral

Tank Size

Pipe Size

Inches

6

Ship

Weight

LbsService Peak Backwash

WATER AND TIME CONSUMED

DURING REGENERATION

Models Backwash

Minutes

75 10 10 20 70 80 100

100 10 10 20 80 100 140

150 10 10 20 100 140 200

200 10 10 20 140 200 280

300 10 10 20 200 280 340

Rapid Rinse

Minutes

Total

Time of

Regeneration

Total Water

Consumed during

Regeneration (GAL)

(Birm, TO, Neu)

Total Water Consumed

during Regeneration

(GAL) (MM)

Total Water Consumed

B

SYSTEM DIMENSIONS

Models A (Inches) B (Inches) C (Inches)

75

100

150

200

300

51.5 13" 8"

55.5 15" 9"

61.5 16" 10"

59.5 17" 12"

72.5 18" 14"

A

during Regeneration

(GAL) (Nexsand)

CONTROL VALVE

REGENERATION

SEQUENCE

The regeneration cycle goes through 3 steps.

1. BACKWASH (MINIMUM 30 PSI INLET

PRESSURE REQUIRED): During the backwash cycle, water

flows upwards through the bed, expanding the media and

carrying any contaminants trapped within it to the drain.

2. RAPID RINSE: During the rapid rinse cycle, water flows

downwards through the bed, settling the media and carrying

any precipitated contaminants trapped within it to the drain.

3. INSERVICE POSITION: The unit then returns to the In-Service

position. While this happens water continues to enter the tank.

C

Step1 Step 2

Step 3

7

INSTALLATION

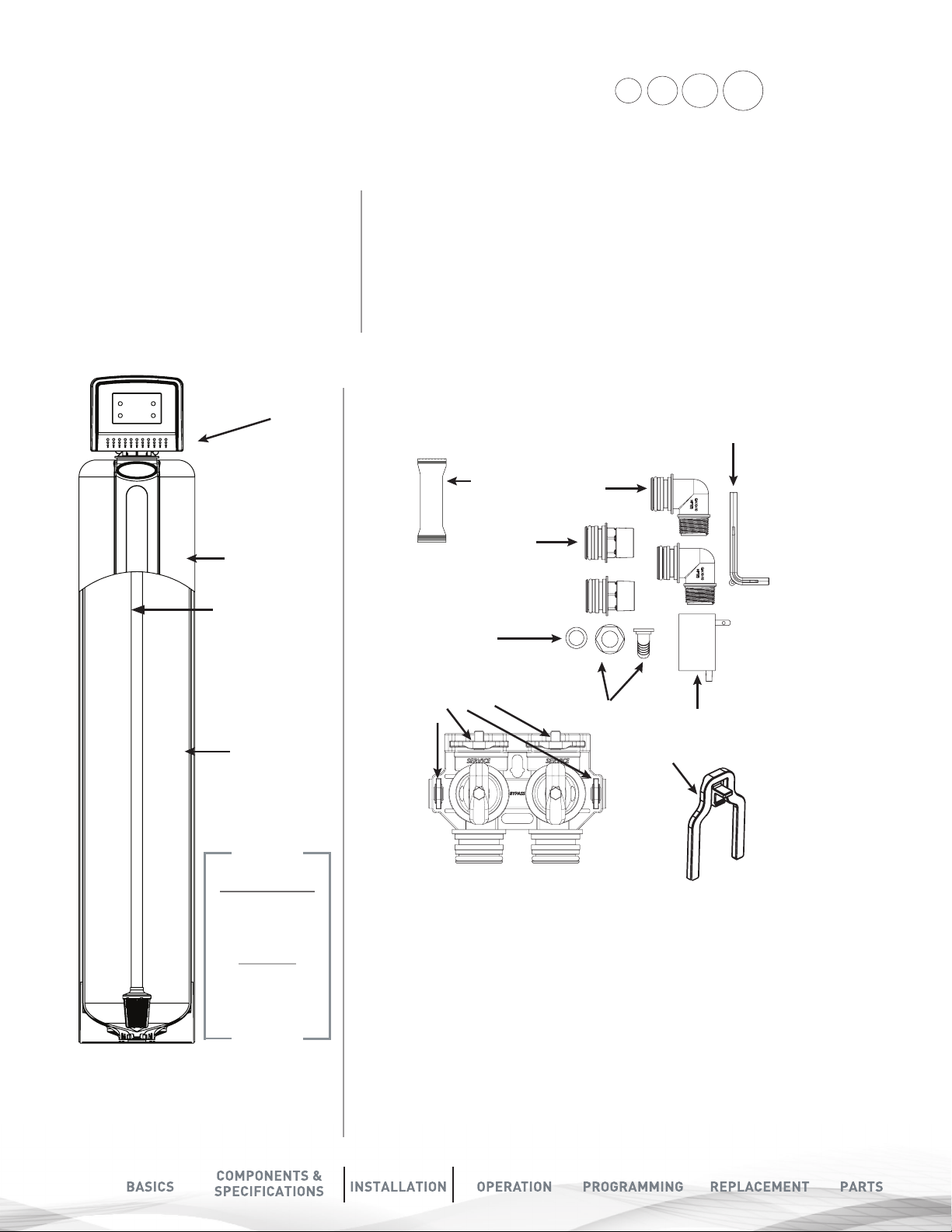

UNPACK & INSPECT PLATINUM FILTER

PLATINUM FILTER CONTENTS:

FOR MODELS 75,100,150, TO200, BIRM200,

YOU WILL EXPECT THE FOLLOWING.

SHIPPING CARTON QUANTITY 1

1. Control Valve

2. Pressure Tank

3. Parts Box

4. Owners Manual

5. Drain Hose & Clamp

(Not included in some brands)

1. CONTROL

VALVE

2. TANK

Distributor

Tube Inside

the Tank

• Check the entire unit for any shipping damage or lost parts.

• Note any damage to the shipping cartons.

• Contact the transportation company for all damage and loss claims.

• The manufacturer is not responsible for damages in transit.

• Small parts needed to install the softener are in a parts box.

• To avoid loss of the small parts keep them in the parts bag until you are ready to install.

• Handle the softener unit with care.

• Do not drop the unit or set on sharp uneven projections on the floor.

• Do not turn the softener unit upside down.

3. PARTS BOX

Grease

Packet

2X 1”

Straight

Adapter

Drain Line

Gasket

2 X 1”

Elbow

Adapter

(Not

Included)

Bypass Tool

Media Inside

the Tank.

Media Type will

depend on what

models were

purchased

NOTE

Only 8”, 9” & 10”

Pressure tanks

have plastic

sleeves.

8”, 9” & 10” tanks

come filled with

media & control

value attached

Bypass with 4

Red Clips

Drain Hose Barb

2 x Clips

Transformer

8

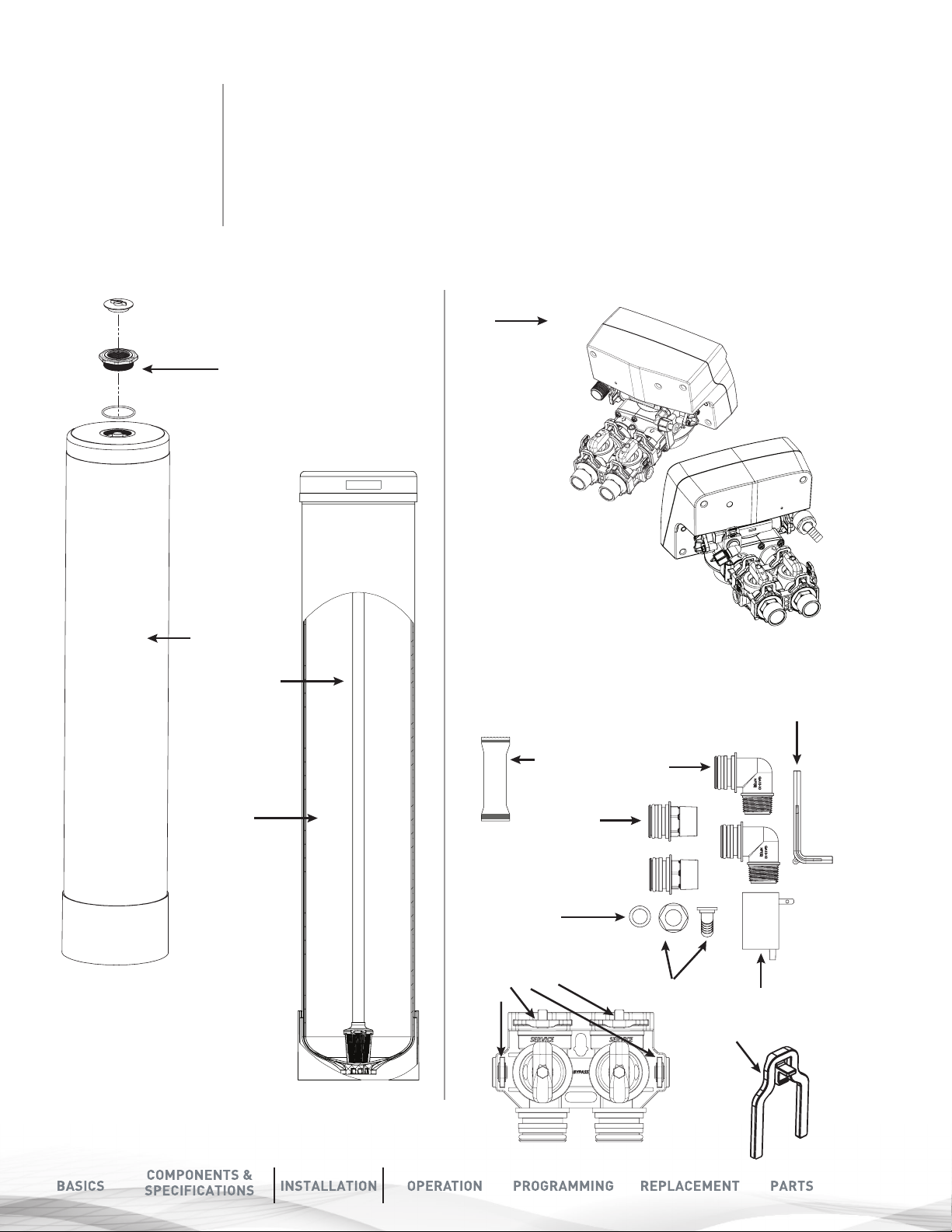

FOR MODELS 200, 300

THE MEDIA AND

CONTROL VALVE

IS PACKAGED

SEPARATELY IN

CARTON AND BAGS

Model 300 will get

Adaptor and O-ring

PLATINUM FILTER CONTENTS :

200, 300

1. Tank

(Model 30 will get an Adaptor and O-ring attached to the tank)

2. Control Valve with Parts Box

3. Media Boxes (Qty 2 for 200, Qty 3 for 300

4. Drain Line and Hose Clamp (Not Included) with some models

2. CONTROL

VALVE

Shown

1. TANK

Distributor

Tube Inside

the Tank

Media Inside

the Tank.

Media Type will

depend on what

models were

purchased

3. PARTS BOX

Grease

Packet

2X 1”

Straight

Adapter

Drain Line

Gasket

Bypass with 4

Red Clips

2 X 3/4”

Elbow

Adapter

(Not

Included)

Drain Hose Barb

2 x Clips

Bypass Tool

Transformer

9

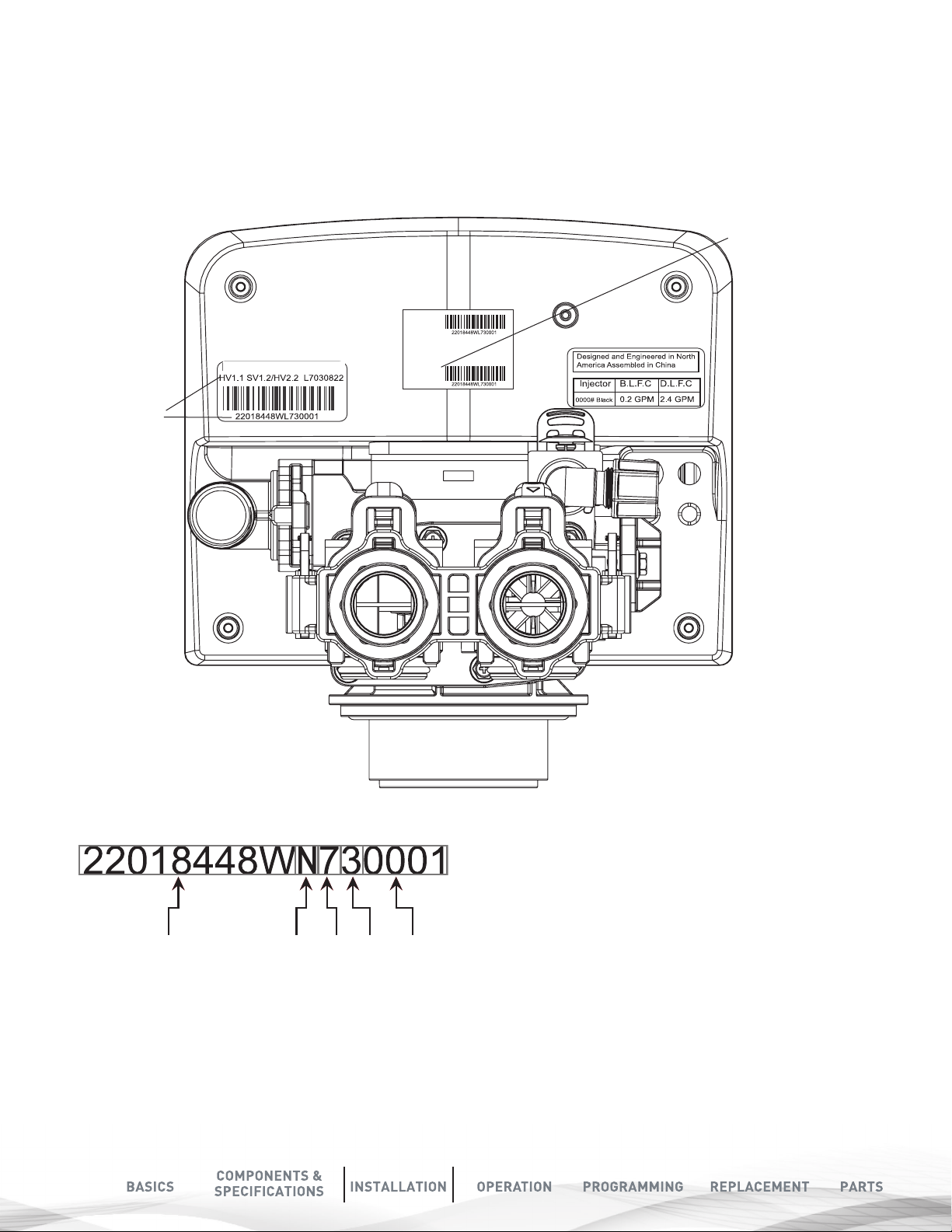

CHECK THE VALVE SERIAL NUMBER

AND VALVE TYPE

Check to make sure the valve type matches what you ordered.

The serial # label on the left will show BPCVPLATUF for Upflow valve

The right Sticker shows the serial # of the control valve.

The middle Sticker is dataplate which provides information of Serial # and Date of Manufacture of complete system.

Both Serial # labels are important for troubleshooting.

COMPLETE SYSTEM

SERIAL NUMBER

Item #

Desc

Date of Manufacture

BPCVPLATUF

VALVE SERIAL

NUMBER

Serial #

VALVE SERIAL NUMBER:

10

(22018448W): Part #

(L)YEAR : ’’ N’’ stand for 2017 year,’’ M’’ stand for 2016

year,’’ L’’ stand for 2015, ’’K’’ stand for 2014, ’’J’’ stand for

2013

Year Month Date Batch #Part #

(7)MONTH: 1 (JAN) 2(FEB) 3(MAR) 4(APRIL) 5(MAY)

6(JUNE) 7(JULY) 8(AUG) 9(SEP) A(OCT) B(NOV) C(DEC)

(3)DATE: 1 2 3 4 5 6 7 8 9 A(10) B(11) C(12) D(13) E(14)

F(15) G(16) H(17) I(18) J(19) K(20) L(21) M(22) N(23) O(24)

P(25) Q(26) R(27) S(28) T(29) U(30) V(31)

(0001): Batch code

PRE-INSTALLATION INSTRUCTIONS

CHECK YOUR WATER HARDNESS

Use test strips (Part # 2793828-20) to get an estimation of water hardness. Contact your local BRITA®PRO dealer to use a

BRITA®PRO laboratory for a complete water analysis free of cost and no obligation to you.

ELECTRICAL GROUNDING

An approved grounding

strap must be used in all

cases where metal pipe was

originally used and is later

interrupted by poly pipe,

the Noryl bypass valve or

by physical separation. The

grounding clamp used for

continuity, must be no less

than #6 copper conductor

to maintain proper metallic

pipe bonding.

8QILOWHUHG:DWHU%\SDVV

/RRS&XW&DSSHG

)LOWHUHG:DWHU/LQHLQ+RPH

*URXQG6WUDS5HTXLUHG%HFDXVH

RI%UHDNLQ&RQWLQXLW\

NOTE

Check your local

electrical code for

the correct strap.

NOTE

CAUTION

The ground from the electrical panel or breaker box to the water meter or underground

copper pipe is tied to the copper water lines. If these lines are cut during installation

of the Noryl bypass valve and/or poly pipe, an approved grounding strap must be used

between the two lines that have been cut. This will maintain continuity. The length of the

grounding strap will depend upon the number of units being installed and/or the amount

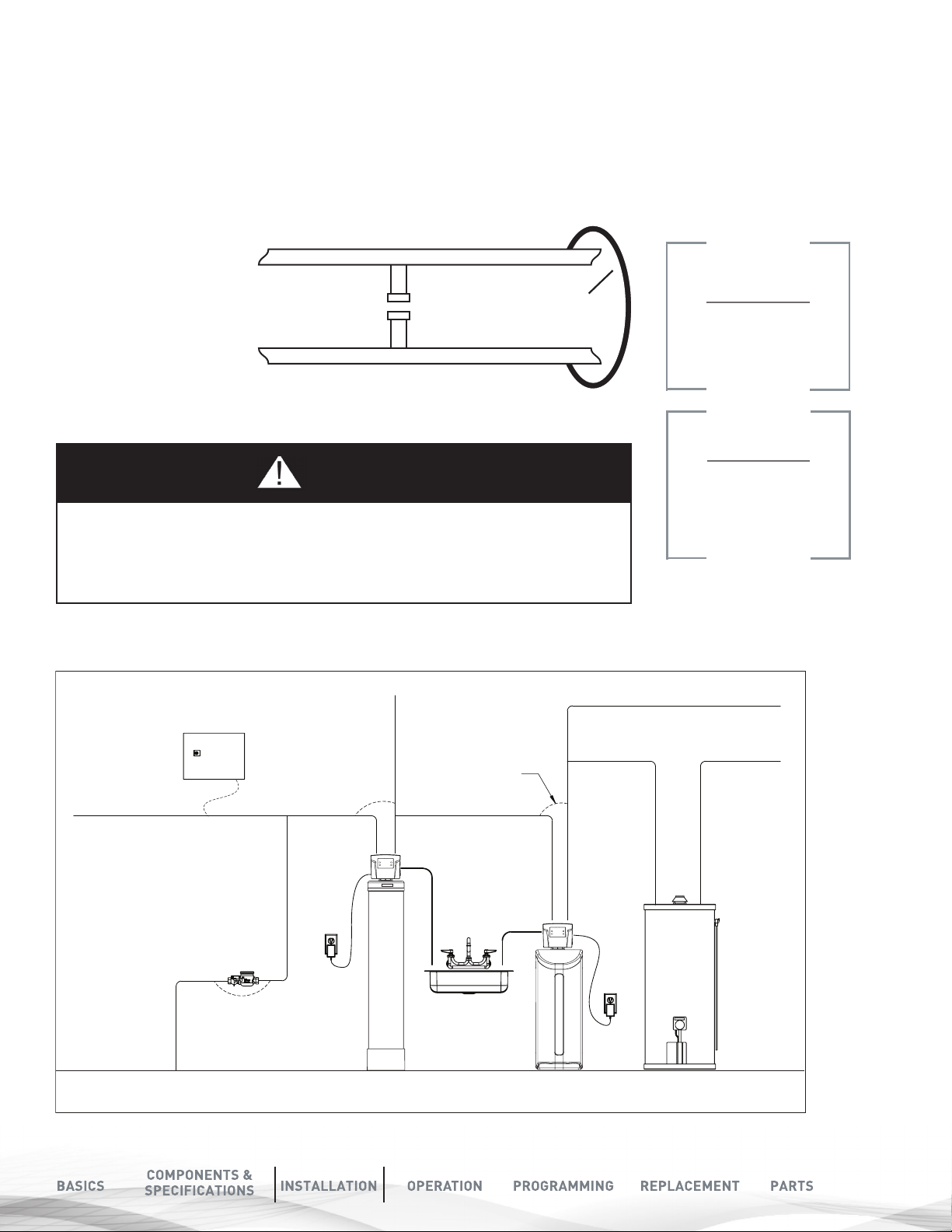

FIGURE 1A: TASTE AND ODOR FILTER (TO)

TYPICAL INSTALLATION:

Raw Water

To Outdoors

of copper pipe being replaced with plastic pipe. See drawing below.

Hard

Electrical Panel

Filtered

Water

Ground Strap

Drain

Drain

You must follow all

government codes and

regulations governing

the installation of

these devices.

Cold Soft Water

Hard Soft Water

Water Meter

Taste and Odor

(TO) Filter

Softener

Water Heater

11

FIGURE 1B: BIRM (BM) TYPICAL INSTALLATION:

Raw Water

To Outdoors

Electrical Panel

Water Meter

Birm

(BM) Filter

Hard

Filtered

Water

Drain

Ground Strap

Drain

Softener

Cold Soft Water

Hard Soft Water

Water Heater

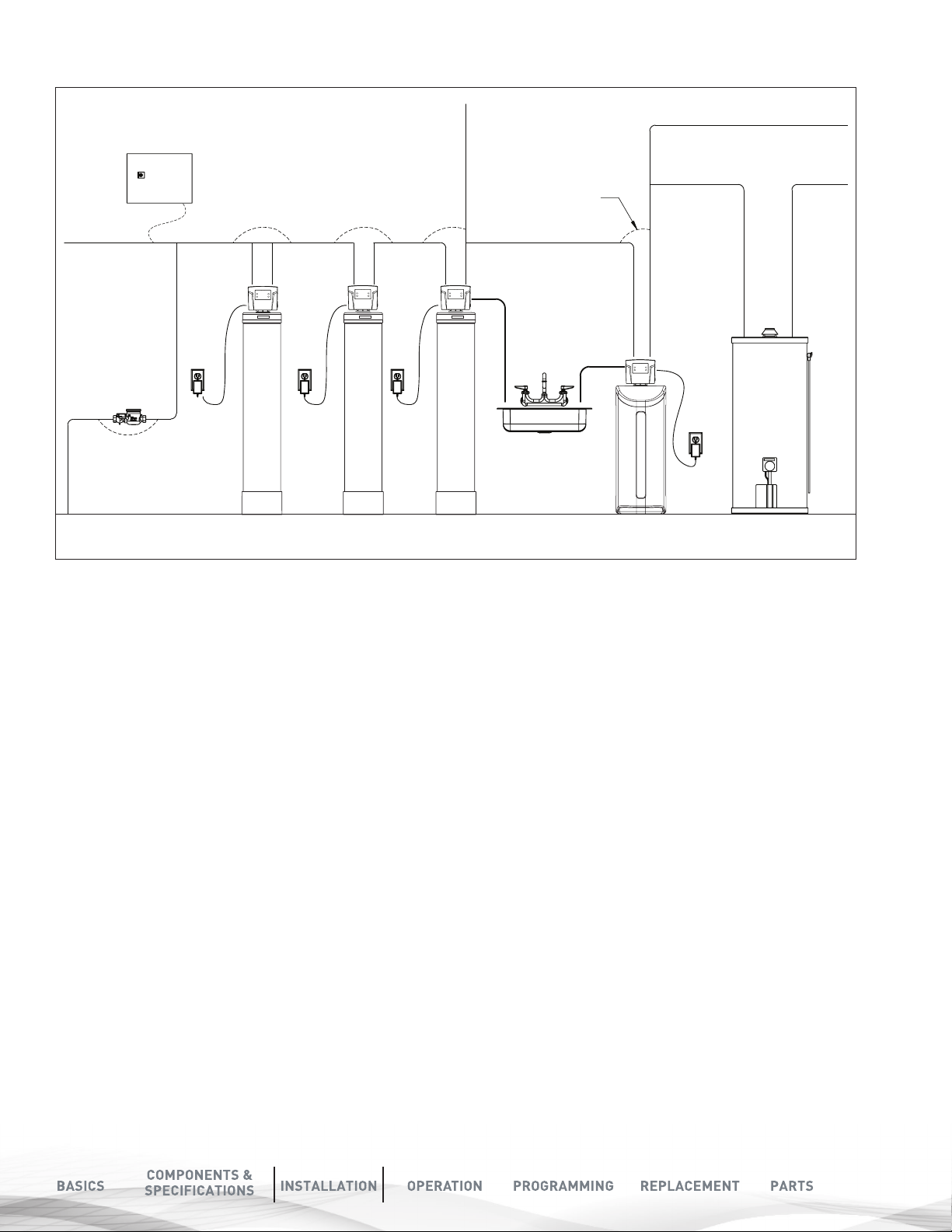

FIGURE 1C: MULTI MEDIA FILTER (MM OR NEXSAND) TYPICAL INSTALLATION:

Raw Water

To Outdoors

Electrical Panel

Water Meter

Hard

Filtered

Water

Ground Strap

Drain

Drain

Cold Soft Water

Hard Soft Water

12

Multi Media

Filter (MM or nextSand)

Taste and Odor

(TO) Filter

Softener

Water Heater

FIGURE 1D: NEUTRALIZING FILTER (NF) TYPICAL INSTALLATION:

Raw Water

To Outdoors

Water Meter

Electrical Panel

Multi Media

Filter (MM or neXtSand)

Multi Media

Filter (NU)

Hard

Filtered

Water

Drain

Taste and Odor

(TO) Filter

Ground Strap

Drain

Softener

Cold Soft Water

Hard Soft Water

Water Heater

13

TOOLS REQUIRED FOR

CHECK WATER

INSTALLATION:

Two adjustable wrenches

Additional tools may be required if modifications to home

plumbing are required.

Plastic inlet and outlet fittings are included with the softener. 3/4”

or 1” pipes to and from the softener fittings are recommended to

maintain full valve flow. You should maintain the same or larger

water supply pipe sizes as the softener inlet and outlet pipe sizes.

Use copper, brass, or PEX pipe and fittings.

Some codes may also allow PVC plastic pipe. Refer to local codes.

ALWAYS INSTALL THE INCLUDED BYPASS VALVE, OR 3 SHUT-OFF

VALVES. Bypass valves let you turn off water to the softener for

repairs, but still have water in the house pipes.

5/8” OD drain line is needed for the valve drain. A 10’ length of

hose is not included with some brands

NOTE

If the plumbing system is used as the ground leg of

the electric supply, continuity should be maintained

by installing ground straps around any nonconductive

plastic piping used in installation.

PRESSURE AND

PUMPING RATE

Two water system conditions must be checked carefully

to avoid unsatisfactory operation or equipment damage:

1. Minimum water pressure required at the softener

tank inlet is 30 psi.

2. The pumping rate of your home’s well pump must at

least equal to the required backwash flow rate of your

model (see Specifications on Page 6 for backwash

flow rates).

TO MEASURE THE PUMPING RATE OF YOUR

PUMP, FOLLOW THESE INSTRUCTIONS:

A. Determine the cycle time. Make certain no water is

being drawn. Open spigot nearest pressure tank.

When pump starts, close spigot and measure time (in

seconds) to refill pressure tank (when pump shuts

off). This figure represents cycle time.

B. Determine drawn-down time. With the pressure tank

full, draw water into a container of known volume and

measure the number of gallons drawn until the pump

starts again. This is draw-down.

C. Determine drawn cycle time. Divide the draw down

time by cycle time and multiply the result by

60 to arrive at the pumping rate in gallons per

minute (gpm).

DETERMINE THE CORRECT

LOCATION OF THE WATER

CONDITIONING EQUIPMENT

Determine the best location for your water softener, bearing in mind the

location of your water supply lines, drain line and 120 volt AC electrical

outlet. Subjecting the softener to freezing or temperatures above 43°C

(110°F) will void the warranty. Review the various conditions below to

determine a proper location:

1. Locate as close as possible to the water supply source.

2. Locate as close as possible to a floor or laundry tub drain.

3. Locate in correct relationship to other water conditioning

equipment (see Fig. 1 on Page 10)

4. Softener should be located in the supply line before the water heater.

Temperatures above 120°F damage softeners.

5. Do not install a softener in a location where freezing temperatures

occur. Freezing may cause permanent damage to this type of

equipment and will void the factory warranty.

6. Allow sufficient space around the unit for easy servicing.

7. Determine if additional plumbing is required if your water source is a

community water supply, a public water supply or you wish to bypass

water used for a geothermal heat pump, lawn sprinkling,

out-buildings or other high demand applications, refer to Fig. 1.

8. Keep the softener out of direct sunlight. Heat build up from direct

sunlight may soften and distort plastic parts.

To aid in your calculation, insert the data in the

following formula:

DRAW-DOWN________ (gals)

÷ CYCLE TIME______________x 60 (seconds)

= PUMPING RATE______________ (gpm)

EXAMPLE:

DRAWDOWN is 6 gals; CYCLE TIME is 53 secs; then,

PUMPING RATE equals: 6 gals ÷ 53 secs x 60 = 6.8 gpm

SEE SPECIFICATIONS ON PAGE 6

FOR MINIMUM FLOW RATES.

.

NOTE

If there is a severe loss in water pressure when the

softener unit is initially placed in service, the softener

tank may have been laid on its side during transit. If this

occurs, backwash the softener to “reclassify” the media.

14

2XWOHW

,QOHW

tI

T

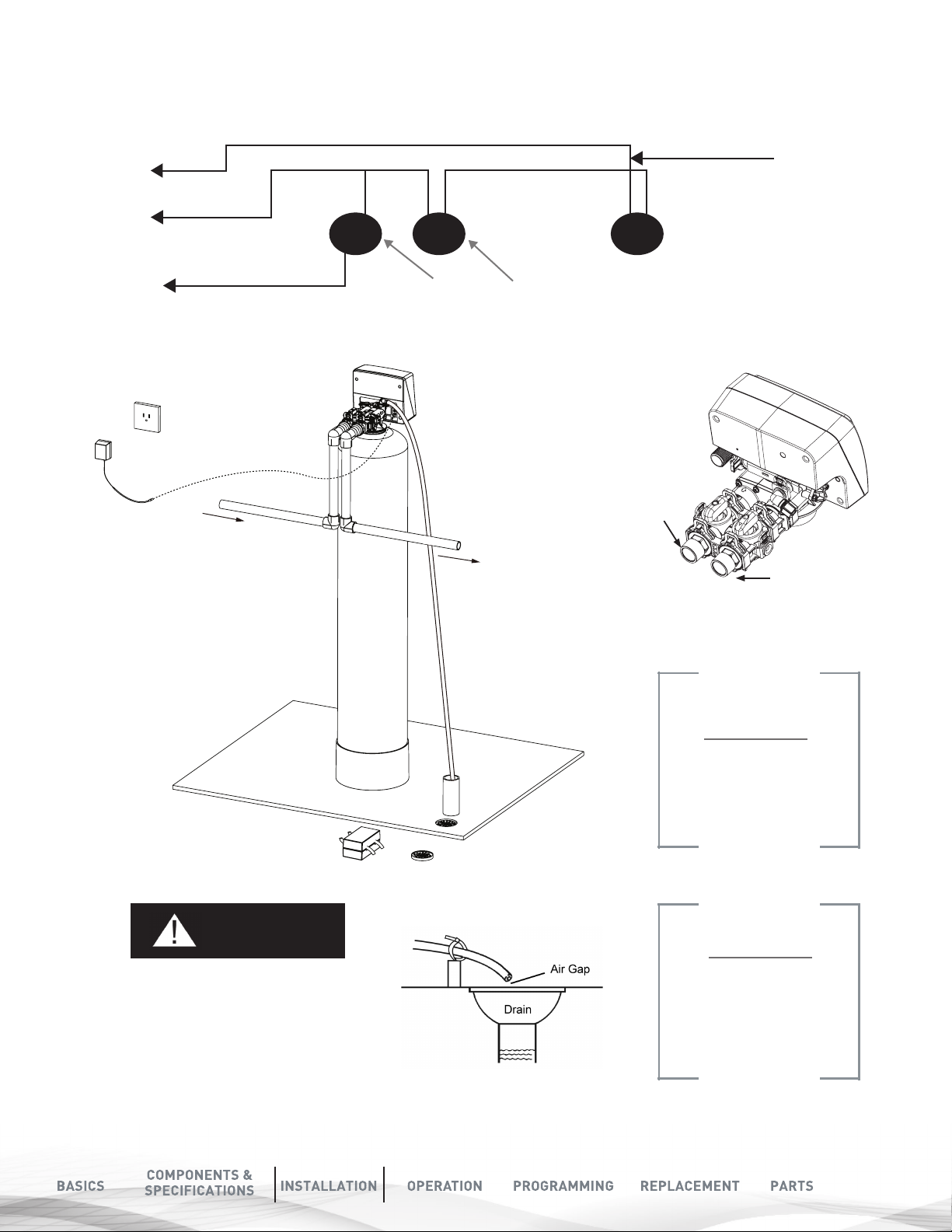

FILTER INSTALLATION

Cold (Raw water)

o Outside Faucet

Cold (Soft Water)

Cold (Filtered water)

InIn Ou

Cold (Raw water)

nOut

Filter

Hot (Soft Water)

Out

Water Heater

Water Softener

Inlet

Outlet

Opposite Most

Standard Softeners

NOTE

The valves are labeled

inlet and outlet on the

vale. Please make sure

to plumb as shown here

CAUTION

Never insert the drain line directly

into a drain, sewer line, or trap.

Always allow an air gap between

the drain line and the wastewater.

This will prevent the possibility of

sewage being back-siphoned

into the conditioner.

NOTE

The waste connection or drain

outlet shall be designed and

constructed to provide an

air-gap to the sanitary waste

system of 2 pipe diameters or

1 inch (22 mm).

(whichever is larger)

15

Loading...

Loading...