Brinkmann TSF, BFS User Manual

BAS6960

BRINKMANN PUMPS, Inc.

47060 Cartier Drive

Wixom, MI 48393

USA

Phone: +1 248 926 9400 www.brinkmannpumps.com

Fax.: +1 248 926 9405 sales@brinkmannpumps.com

Subject to change without prior notice. Order - No.: BAS6960 ENGLISH

Operating Instructions

BRINKMANN-Screw Pump

BFS / TFS / FFS / BFS-H / TFS-H / BFG / FFG

© Brinkmann Pumpen Edition 03/2020 Page 1 of 15

BRINKMANN-Screw Pump Type BFS / TFS / FFS

Contents

1 Indication to the manual .................................... 2

2 Description of product and working principle .. 2-3

3 Safety instructions .......................................... 4-5

4 Transport, and Temporary storage .................... 5

5 Installation / Connection ................................. 6-8

6 Start up / Shut down ....................................... 8-9

7 Operation ........................................................... 9

1 Indication to the manual

This operating manual gives basic instructions which

are to be observed during installation, opera-tion and

maintenance of the pump. It is therefore imperative

that this manual be read by the respon-sible personnel and operator prior to assembly and commissioning. It is always to be kept available at the installation

site.

1.1 Identification of safety instructions in the

operating manual

Safety instructions given in this manual noncompliance with which would affect safety are identified by the following symbol

Safety sign according with ISO 3864–B.3.1

or where electrical safety is involved, with

Safety sign according with ISO 3864–B.3.6

Where non-compliance with the safety instructions

may cause a risk to the machine and it’s function the

word

ATTENTION

is inserted.

8 Servicing and Maintenance ............................. 10

9 Trouble shooter’s guide ................................... 11

10 Spare part ....................................................... 12

11 Repair Instructions ..................................... 12-13

12 Disposal .......................................................... 13

13 Terms and Conditions ............................ 14-15

• The medium moves continuously and without

noticeable pulsation toward the pump discharge.

• Proper clockwise rotation must be ensured at all

times. Incorrect counterclockwise rotation will result in dry running and pump damage. Catastrophic failure is possible!

• Screw pumps are self-priming, however, dry

running must be avoided under any circumstances

as it will almost instantly damage the pump and it

might result in catastrophic failure.

• Screw pumps are positive displacement pumps

and must therefore always be used in combination

with a pressure limiting valve or pressure relief

valve.

2.4 Type code structure (example)

High pressure screw pump: BFS 250 S 80 -G

Pump series designation

BFS, TFS or FFS

Pump size

Maximum pressure in bar

Special features

(e.g. with mechanical seal)

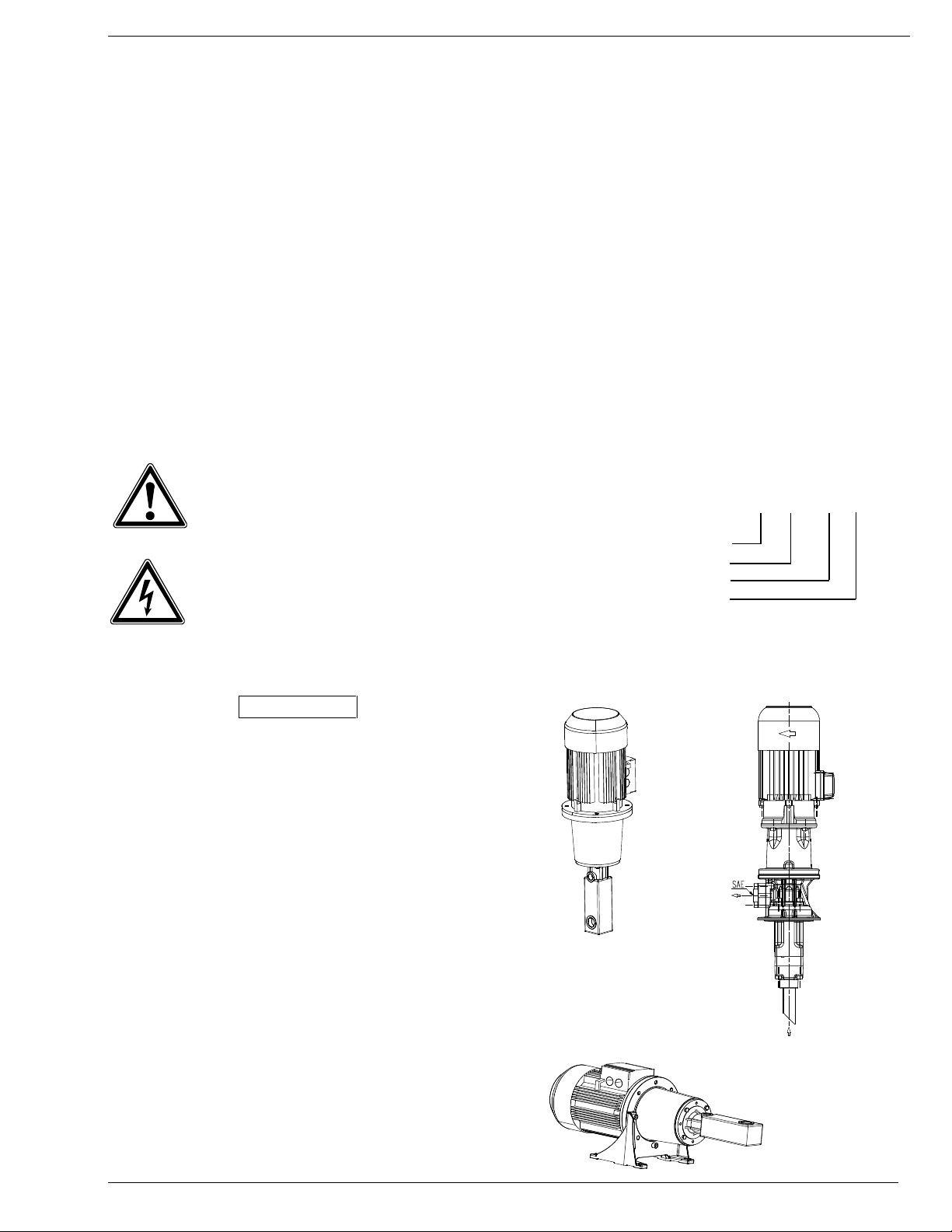

2.5 Pump Models

Immersion style

BFS, TFS (-H) pressure outlet above tank plate

2 Description of product and working prin-

ciple

2.1 Scope

Pumping of fluids at high backpressure. The discharge pressure needs to be at least 2 bar higher

than the inlet pressure.

2.2 Application range

• Screw pumps are designed for pumping filtered,

lubricating fluids (Please consult with the manufacturer for specific applications).

• Screw pumps are used in applications where high

pressures and constant flow rates are required

(e.g. general machine design, machine tool industry, etc.)

Operate pump within the design limititations and in

accordance with section 2.6.

2.3 Working principle

• The intermeshing threads of three screw spindles

generate liquid holding chambers.

• The center spindle is driven and all three screw

spindles rotate.

BAS6960 Edition 03/2020 Page 2 of 15

FFS foot mounted inline style

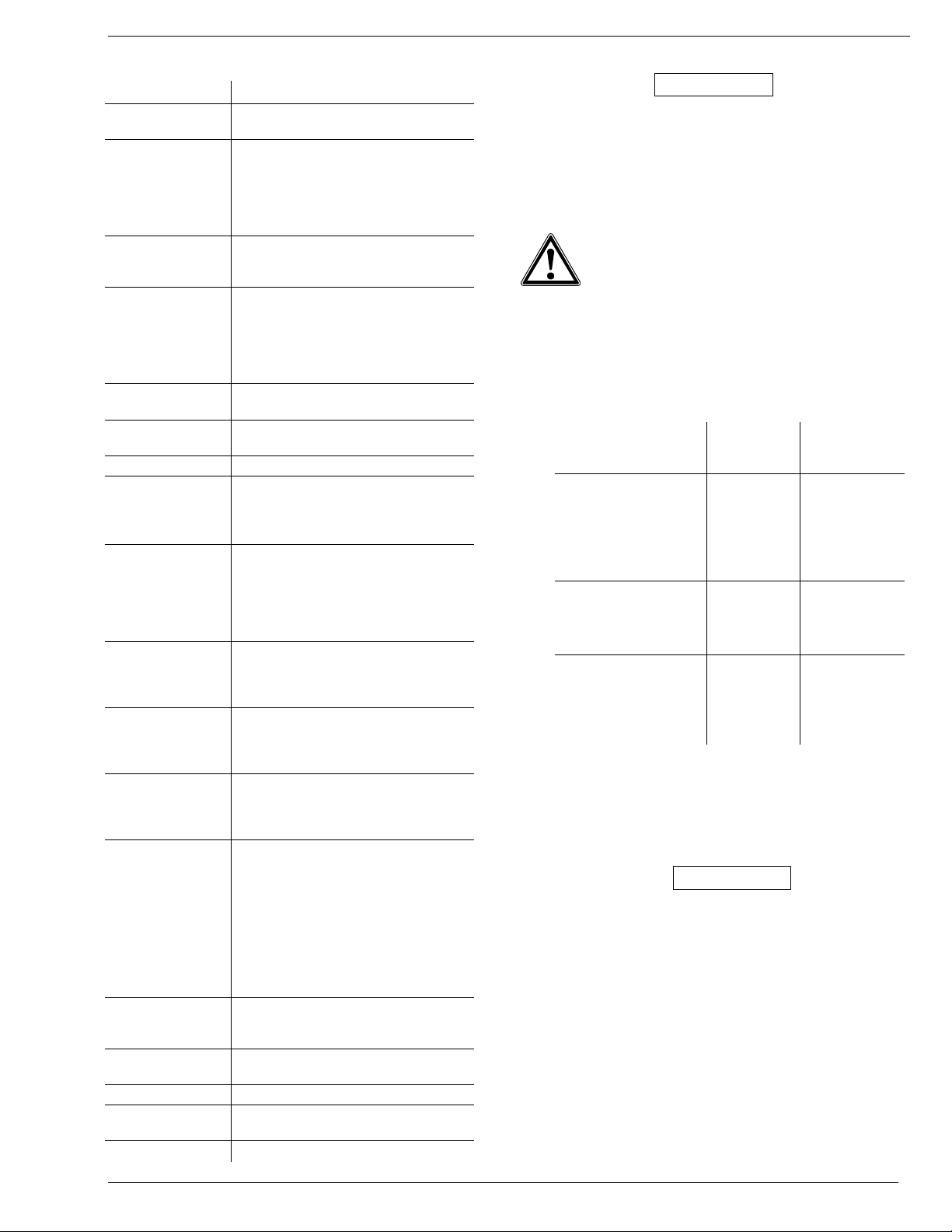

2.6 Limit of Application

Materials

Particle

size

Particle

concentration:

Steel / Forgeable

aluminium alloys

(without Si content) /

GG25

BFG, FFG, BFS,

FFS

< 60 m

< 177 mg/l

Grey cast iron with

hard additives

(e.g. GGV)

BFS, FFS

< 50 m

< 63 mg/l

Ceramic/ corundum

/ hard metal / glass /

CBN Aluminium

alloy with Si parts

BFS, FFS

< 20 m

< 19 mg/l

The particle concentration refers to standardized test.

For additional information please refer to the

filtration diagram in the screw pump catalogue.

ATTENTION

If high pressure screw pumps are to be used

outside of the recommended ranges, a suitable

filter system (e.g. filter bags) must be installed

upstream from the pump or pumps with special

features must be used (e.g., with coated spindles).

If pump failure is caused by excessive wear due

to foreign particles, the warranty is void!

In applications where hard or abrasive particles

are present, the use of coated spindles is highly

recommended.

2.8 Technical data

Detailed technical data can be found in the

screw spindle pump catalogue.

Type

BFS, TFS, FFS

Mediums

Oils, cooling / cutting oils

coolants

Max. delivery

pressure

870 PSI (60 bar) (BFG, FFG with cast

iron spindle housing)

2175 PSI (150 bar) (2900 PSI (200 bar)

for BFS/FFS1, BFS/FFS2 and

TFS/BFS/FFS3 upon request)

1740 PSI (120 bar) (-H)

Minimum discharge

pressure

Ensure that the discharge pressure is

at least 29 PSI (2 bar) higher than the

inlet pressure

Minimum inlet

pressure

In order to prevent

damage from

cavitation

12 PSI (0.8 bar) absolute, with increased fluid temperature also more,

(Pumps with a flow rate of greater than

210 GPM (800 l/min) have to be

operated in conjunction with a feed

pump > 14.5 PSI (1 bar)).

Kinetic viscosity of

the medium

4.6...200 SSU (1...45 mm2/s (cSt))

higher viscosities upon request

Max. temperature

of medium

140 °F (60°C)

higher temperatures upon request

Max. air content

3 – 5 vol. %

Max. inlet pressure

with mechanical

seal

Execution -G4

< 100 PSI (7 bar)

290 PSI (20 bar)

Concentration of

coolant lubricants

and water soluble

coolants

The fluid must have a minimum lubricity in accordance with industry standards. This corresponds to an approx.

4% concentration equivalent to mineral

oil. A laboratory analysis is available at

the factory.

Minimum flow rate

The minimum flow rate must be large

enough to protect the pump from

overheating. If necessary, consult with

the manufacturer on exact flow rate.

Minimum rpm

25 Hz (1500 rpm), lower rpm are

available upon request. The minimum

rpm depends on the pressure and

medium.

Dry running

The pump MUST never be run dry

without fluid. When testing for the

direction of rotation, bump the pump for

not longer than 1 second.

Cycle times per

hour

Motors less 4.0 HP / 3 kW: up to 200

times per hour.

Motors from 4.0 HP (3 kW) to 5.4 HP

(4.0 kW): up to 40 times per hour.

Motors from 6.7 HP (5.0 kW) to 12 HP

(9 kW): up to 20 times per hour.

Motors from 13.4 HP (10 kW) to 29.5

HP (22 kW): up to 15 times per hour

Increased cycle times are available

upon request.

Maximum fluid

velocity at pump

suction

2 m/s

Installation positions

(Pump must not be installed with motor

facing down)

Piping / Fittings

Pay attention to max. pressure ratings

Ambient temperature

104 °F (40 °C)

Set-up altitude

3280 ft (1000 m)

ATTENTION

The pumps are to be operated within their design

limits. Applications outside of these limits are not

approved. The manufacturer is not responsible for

any damages resulting from use of the pumps in such

applications.

2.7 Important instructions for screw pumps

• Never allow screw pumps to run dry!

• Incorrect rotation will lead to pump dam-

age!

• Sufficient fluid supply must always be ensured!

• Large particles in the coolant fluid may

damage the screw pump!

• The limits for size and concentration of

foreign particles depends on their hardness!

BAS6960 Edition 03/2020 Page 3 of 15

3 Safety instructions

When operating the pump, the safety instructions

contained in this manual, the relevant national accident prevention regulations and any other service

and safety instructions issued by the plant operator

are to be observed.

3.1 Hazards in the event of non-compliance with

the safety instructions

Non-compliance with the safety instructions may

produce a risk to the personnel as well as to the

environment and the machine and results in a loss of

any right to claim damages. For example, noncompliance may involve the following hazards:

• Failure of important functions of the ma-

chines/plant

• Failure of specified procedures of maintenance

and repair

• Exposure of people to electrical, mechanical and

chemical hazards

• Endangering the environment due to hazardous

substances being released

3.2 Unauthorized modes of operation

3.5 Safety instructions relevant for operation

• If hot or cold machine components involve hazards, they must be guarded against accidental

contact.

• Guards for moving parts (e.g. coupling) must not

be removed from the machine while in operation.

• Never subsequently alter any safety devices (e.g.

pressure relief valves)!

• It is necessary to ensure that all safety devices

always work properly!

• Any leakage of hazardous (e.g. explosive, toxic,

hot) fluids (e.g. from the shaft seal) must be

drained away so as to prevent any risk to per-sons

or the environment. Statutory regulations are to be

complied with.

• Hazards resulting from electricity are to be prevented (see for example, the VDE Specifications

and the bye-laws of the local power supply utilities).

• The pumps’ stability against falling over is not

ensured unless it is properly mounted onto the

tank or to the floor.

• The female threads on the motor MUST NOT be

used to lift the entire pump and motor assembly.

• Pump may not be used in potentially explosive

environments!

• Pump and discharge piping are not designed to

hold any weight and may not be used as a step

ladder.

3.3 Remaining Risk

Risk of Injury!

Risk of squeezing or crushing body parts when

installing or removing the pump exists. Proper and

secured lifting tools must be used.

Risk of burns!

The pump must have cooled down sufficiently prior to

commencing any repair, maintenance or installation.

3.4 Qualification and training of operating per-

sonnel

The personnel responsible for operation, maintenance, inspection and assembly must be adequately

qualified. Scope of responsibility and supervision of

the personnel must be exactly defined by the plant

operator. If the staff does not have the necessary

knowledge, they must be trained and instructed,

which may be performed by the machine manufacturer or supplier on behalf of the plant operator.

Moreover, the plant operator is to make sure that the

contents of the operating manual are fully understood

by the personnel.

3.6 Safety instructions relevant for maintenance, inspection and assembly work

Any work on the machine shall only be performed

when it is at a standstill, it being imperative that the

procedure for shutting down the machine described in

this manual be followed.

Pumps and pump units which convey hazardous

media must be decontaminated.

On completion of work all safety and protective

facilities must be re-installed and made operative

again.

Prior to restarting the machine, the instructions listed

under “Start up” are to be observed.

3.7 Signs on the pump

It is imperative that signs affixed to the machine, e.g.

• arrow indicating the direction of rotation

• symbols indicating fluid connections

be observed and kept legible.

BAS6960 Edition 03/2020 Page 4 of 15

3.8 Unauthorized alterations and production of

Drawing 1

spare parts

Any modification may be made to the machine only

after consultation with the manufacturer. Using spare

parts and accessories authorized by the manufacturer is in the interest of safety. Use of other parts may

exempt the manufacturer from any liability.

4 Transport and Temporary Storage

Protect pumps against damage during transportation.

The pumps may only be transported lying flat and

must be secured on the motor side as well as on the

pump side.

Store pumps protected from moisture in an enclosed

location. Prevent foreign bodies from entering the

pump.

Keep the storage temperature above freezing

Pumps are factory preserved.

If storage exceeds 6 months, the preservation should

be checked and reapplied if applicable.

Pumps that have been immersed or have been

running must be cleaned and preserved prior to

storage. This applies especially to water based fluids!

4.1 Pump Preservation

4.1.1 Draining pump

Pumps with mechanical seal –G or axial thrust

–A:

6. Place pump on a work bench (7) horizontally

with the threaded port facing up. The flange (8)

may not touch the surface. See picture 1.

7. Plug outlet port (5) with a sealing plastic cap.

8. Turn the motor shaft as quickly as possible

counterclockwise. This will allow for the remaining fluid to drain from the adjacent cavities

(6).

9. Repeat steps 1-8 until no more fluid drains.

4.1.2 Pump preservation

Interior Preservation

1. Outlet (5) and inlet port (3) should be open.

2. Place pump on a work bench (7) horizontally

with the threaded port facing up. The flange (8)

may not touch the surface.

3. Pour preservation agent (spray oil) into the inlet

port (3) and turn motor (1) shaft clockwise until

it becomes visible at the outlet port and the fluid

level of the oil is above the lowest point of the

labyrinth seal area.

Pumps with mechanical seal –G or axial thrust

–A:

4. Plug outlet port (5) with a sealing plastic cap.

5. Turn motor shaft (1) clockwise as quickly as

possible by hand in order for the preservation

agent to enter into the adjacent cavities (6).

1. Separate pump and motor.

2. Clean the pump body thoroughly

3. Outlet (5) and Inlet port should be open.

4. Stand pump up with the coupling (2) facing up

tilting it in direction of the inlet port (3).

5. Turn motor shaft (1) counterclockwise. Keep

pump tilted until it is completely drained.

Exterior Preservation

6. Preserve all unpainted metal components

Drain excess preserving agent and plug outlet and

inlet ports with plastic caps.

Collect draining coolant and oil and dispose in ac-

cordance with applicable local laws and regulations!

BAS6960 Edition 03/2020 Page 5 of 15

Loading...

Loading...