Page 1

Generator Systems

NOT

for

REPRODUCTION

Operator’s Manual

Liquid-Cooled

Generator System

This generator is rated in accordance with UL (Underwriters Laboratories) 2200 (stationary engine generator assemblies) and CSA

(Canadian Standards Association) standard C22.2 No. 100-4 (motors and generators).

Page 2

Thank you for purchasing this quality-built Briggs & Stratton generator. We’re pleased that you’ve placed your confidence in

NOT

for

REPRODUCTION

the Briggs & Stratton brand. When operated and maintained according to the instructions in this manual, your generator will

provide many years of dependable service.

This manual contains safety information to make you aware of the hazards and risks associated with standby generators and

how to avoid them. Because we do not necessarily know all the applications this equipment could be used for, it is important

that you read and understand these instructions thoroughly before attempting to start or operate this equipment. This product

is only for use as an optional generator system which provides an alternate source of electric power and to serve loads such

as heating, refrigeration systems, and communication systems that, when stopped during any power outage, could cause

discomfort or inconvenience.

Save these original instructions for future reference.

This generator requires professional installation before use. Refer to the separate installation manual for full information.

Your installer should follow the instructions completely.

Where to Find Us

You never have to look far to find Briggs & Stratton support and service for your generator. Consult your Yellow Pages. There

are thousands of Briggs & Stratton authorized service dealers worldwide who provide quality service. You can also contact

Technical Service by phone at 800732-2989, or click on Find a Dealer at BRIGGSandSTRATTON.COM, which provides a list of

authorized dealers.

Generator and engine model and serial numbers should be recorded in the installation manual.

Briggs & Stratton Power Products Group, LLC

P.O. Box 702

Milwaukee, WI 53201-0702

Copyright © 2013. All rights reserved. No part of this material

may be reproduced or transmitted in any form without the express

written permission of Briggs & Stratton Power Products Group, LLC.

2 BRIGGSandSTRATTON.COM

Page 3

Table of Contents

NOT

for

REPRODUCTION

Important Safety Instructions........................4

Installation ....................................7

For the Installing Dealer/Contractor: ..............................7

Owner Orientation ............................................7

Fuel Factors .................................................8

Generator Location............................................8

Delivery Inspection............................................9

Controls ..................................... 10

System Control Panel.........................................12

Access Ports ...............................................13

Operation .................................... 14

Automatic Operation .........................................14

Setting Exercise Timer ........................................15

Maintenance .................................. 15

Fault Detection System .......................................15

Generator Maintenance .......................................17

Engine Maintenance..........................................18

Battery ....................................................21

Storage....................................................22

Maintenance Chart.............................. 23

Troubleshooting................................ 24

Warranty..................................... 25

Product Specifications ........................... 28

3

Page 4

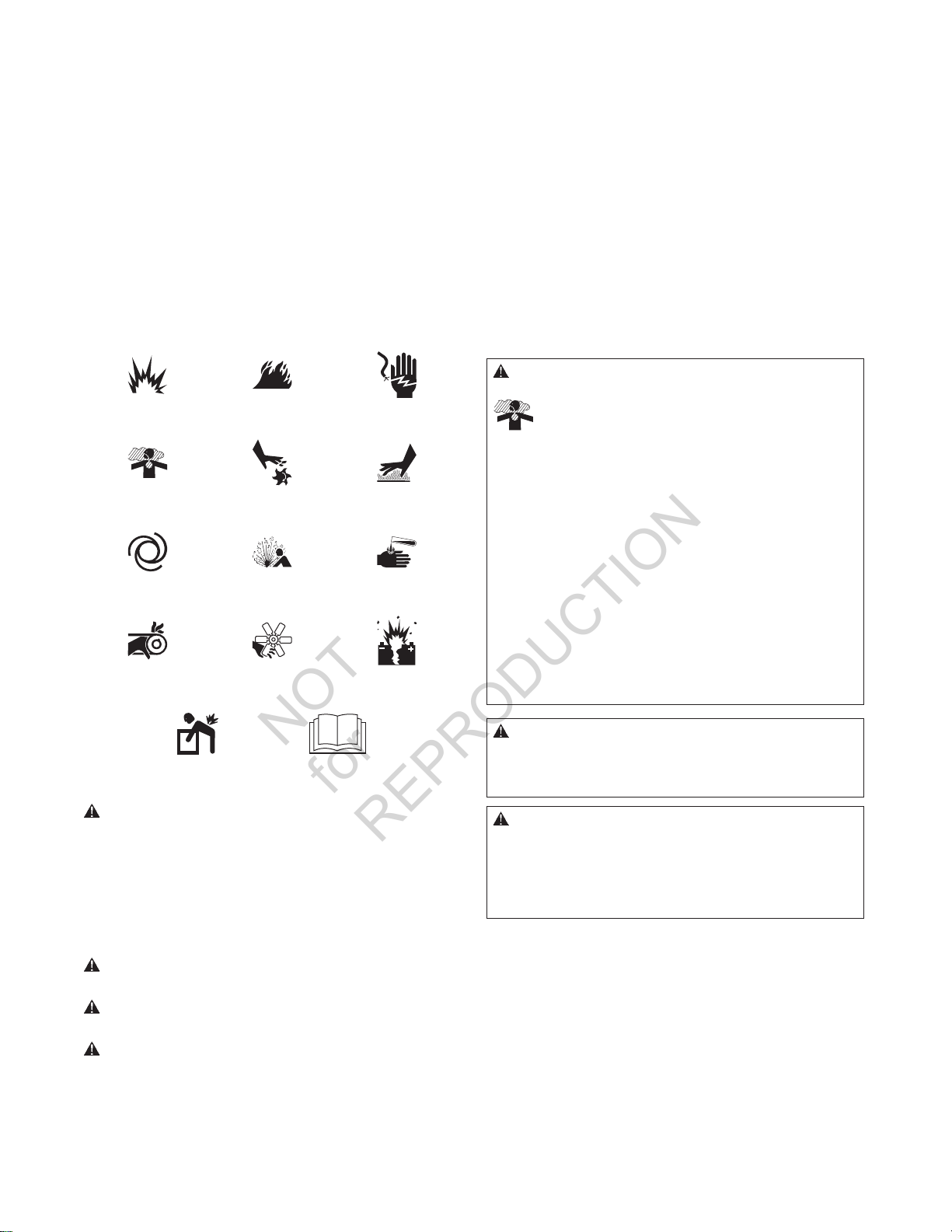

Important Safety Instructions

NOT

for

REPRODUCTION

SAVE THESE INSTRUCTIONS - This manual contains

important instructions that should be followed during

installation and maintenance of the generator and batteries.

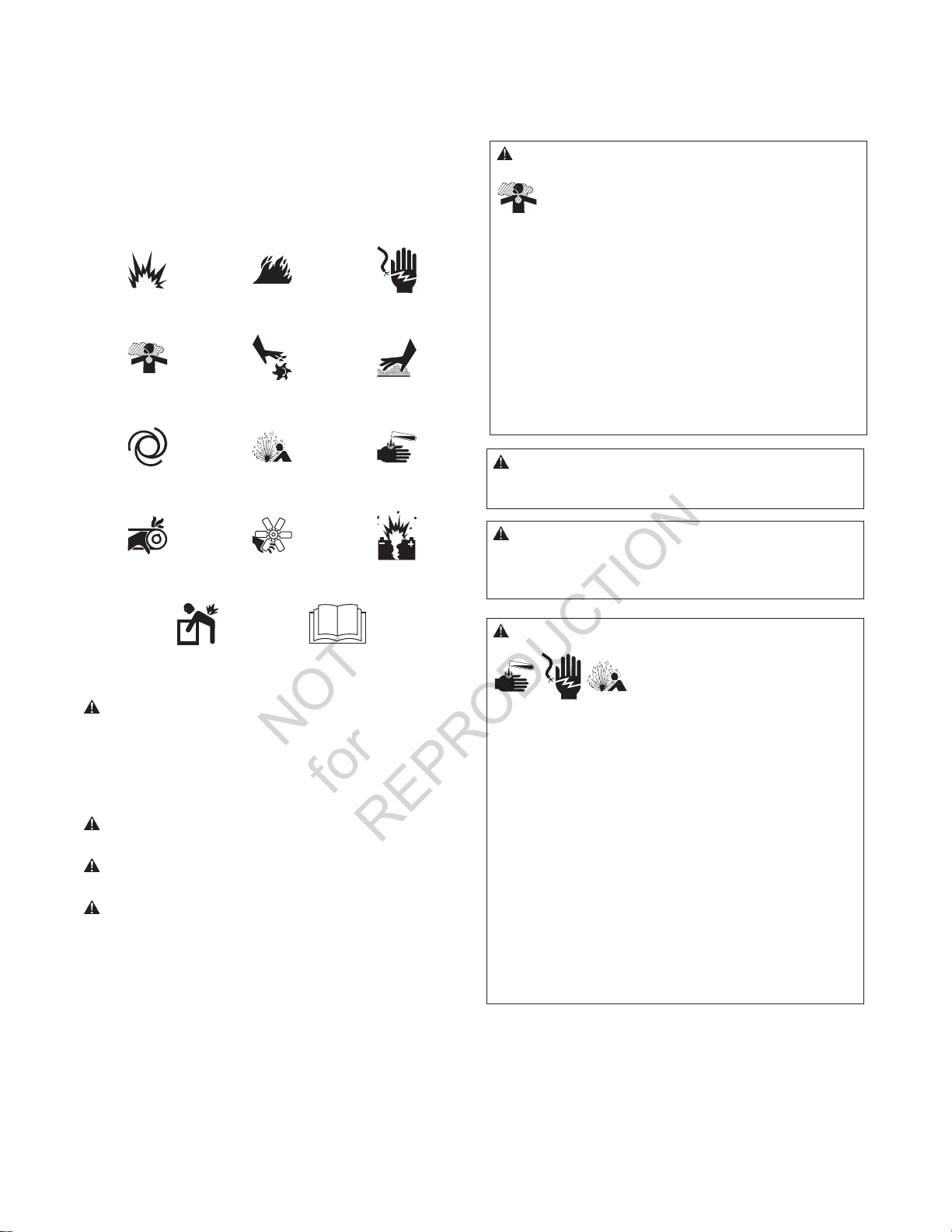

Safety Symbols and Meanings

Fire

Toxic Fumes

Explosive Pressure

Rotating Fan Blade

Electrical ShockExplosion

Hot SurfaceRotating Parts

Chemical BurnAuto Start

Exploding BatteryRotating Belt/Pulley

WARNING Running engine gives off carbon monoxide,

an odorless, colorless, poison gas.

Breathing carbon monoxide could result in death,

serious injury, headache, fatigue, dizziness,

vomiting, confusion, seizures, nausea or fainting.

• Operate this product ONLY outdoors in an area that will

not accumulate deadly exhaust gas.

• Keep exhaust gas away from any windows, doors,

ventailation intakes, soffit vents, crawl spaces, open

garage doors or other openings that can allow exhaust

gas to enter inside or be drawn into a potentially occupied

building or structure.

• Carbon monoxide detector(s) MUST be installed and

maintained indoors according to the manufacturer’s

instructions/recommendations. Smoke alarms cannot

detect carbon monoxide gas.

WARNING The engine exhaust from this product

contains chemicals known to the State of California to

cause cancer, birth defects, or other reproductive harm.

WARNING Certain components in this product and

related accessories contain chemicals known to the State

of California to cause cancer, birth defects, or other

reproductive harm. Wash hands after handling.

Lift Hazard Read Manual

The safety alert symbol indicates a potential personal

injury hazard. A signal word (DANGER, WARNING, or

CAUTION) is used with the alert symbol to designate a degree

or level of hazard seriousness. A safety symbol may be used

to represent the type of hazard. The signal word NOTICE is

used to address practices not related to personal injury.

DANGER indicates a hazard which, if not avoided, will

result in death or serious injury.

WARNING indicates a hazard which, if not avoided, could

result in death or serious injury.

CAUTION indicates a hazard which, if not avoided, could

result in minor or moderate injury.

NOTICE addresses practices not related to personal injury.

The manufacturer cannot possibly anticipate every possible

circumstance that might involve a hazard. The warnings in

this manual, and the tags and decals affixed to the unit are,

therefore, not all-inclusive. If you use a procedure, work

method or operating technique that the manufacturer does

not specifically recommend, you must satisfy yourself that

it is safe for you and others. You must also make sure that

the procedure, work method or operating technique that you

choose does not render the generator system unsafe.

WARNING Storage batteries give off explosive

hydrogen gas during recharging.

Slightest spark will ignite hydrogen

and cause explosion, resulting in

death or serious injury.

Battery electrolyte fluid contains

acid and is extremely caustic.

Contact with battery contents could cause severe

chemical burns.

A battery presents a risk of electrical shock and high short

circuit current.

• DO NOT dispose of battery in a fire. Recycle battery.

• DO NOT allow any open flame, spark, heat, or lit cigarette

during and for several minutes after charging a battery.

• DO NOT open or mutilate the battery.

• Wear protective goggles, rubber apron, rubber boots and

rubber gloves.

• Remove watches, rings, or other metal objects.

• Use tools having insulated handles.

4 BRIGGSandSTRATTON.COM

Page 5

WARNING Generator produces hazardous voltage.

NOT

for

REPRODUCTION

Failure to properly ground generator could result

inelectrocution.

Failure to isolate generator from utility power could

result in death or serious injury to electric utility

workers due to backfeed of electrical energy.

• DO NOT touch bare wires or bare receptacles.

• DO NOT use generator with electrical cords which are

worn, frayed, bare or otherwise damaged.

• DO NOT handle generator or electrical cords while

standing in water, while barefoot, or while hands or feet

are wet.

• If you must work around a unit while it is operating,

stand on an insulated dry surface to reduce the risk of a

shock hazard.

• DO NOT allow unqualified persons or children to operate

or service generator.

• In case of an accident caused by electrical shock,

immediately shut down the source of electrical power and

contact the local authorities. Avoid direct contact with

the victim.

• Despite the safe design of the generator, operating this

equipment imprudently, neglecting its maintenance or

being careless could cause possible injury or death.

• Remain alert at all times while working on this equipment.

Never work on the equipment when you are physically or

mentally fatigued.

• Before performing any maintenance on the generator,

disconnect the battery cable indicated by a NEGATIVE,

NEG or (-) first. When finished, reconnect that cable last.

• After your system is installed, the generator may crank

and start without warning any time there is a power

failure. To prevent possible injury, always set the

generator’s system switch to OFF, remove the service

disconnect from the disconnect box AND remove the

15 Amp fuse BEFORE working on the equipment.

WARNING Hazardous Voltage - Contact with power

• If lifting or hoisting equipment is used, DO NOT contact

any power lines.

• DO NOT lift or move generator without assistance.

• DO NOT lift unit by roof as damage to generator

will occur.

lines could cause electric shock or burns,

resulting in death or serious injury.

Lifting Hazard / Heavy Object - Could result

in serious injury.

WARNING Propane and Natural Gas are extremely

flammable and explosive, which could cause

burns, fire or explosion resulting in death or

serious injury.

• Install the fuel supply system according to NFPA 37 and

other applicable fuel-gas codes.

• Before placing the generator into service, the fuel system

lines must be properly purged and leak tested.

• After the generator is installed, you should inspect the fuel

system periodically.

• NO leakage is permitted.

• DO NOT operate engine if smell of fuel is present or other

explosive conditions exist.

• DO NOT smoke around the generator. Wipe up any oil

spills immediately. Ensure that no combustible materials

are left in the generator compartment. Keep the area near

the generator clean and free of debris.

WARNING Exhaust heat/gases could ignite

combustibles or structures resulting in

death or serious injury.

Contact with muffler area could cause

burns resulting in serious injury.

• DO NOT touch hot parts and AVOID hot exhaust gases.

• Allow equipment to cool before touching.

• Exhaust outlet side of weatherproof enclosure must

have at least 5 ft. (1.5m) minimum clearance from any

structure, shrubs, trees or any kind of vegetation.

• Standby generator weatherproof enclosure must be at

least 5 ft. (1.5m) from windows, doors, any wall opening,

shrubs or vegetation over 12 inches (30.5 cm) in height.

• Standby generator weatherproof enclosure must have a

minimum of 5 ft. (1.5 m) overhead clearance from any

structure, overhang, or trees.

• DO NOT place weatherproof enclosure under a deck or

other type of structure that may confine airflow.

• Use only flexible fuel line provided. Connect provided fuel

line to generator. DO NOT use with or substitute any other

flexible fuel line.

• Smoke detector(s) MUST be installed and maintained

indoors according to the manufacturer’s instructions/

recommendations. Carbon monoxide alarms cannot

detect smoke.

• Keep at least minimum distances shown in General

Location Guidelines to insure for proper generator cooling

and maintenance clearances.

• Replacement parts must be the same and installed in the

same position as the original parts.

5

Page 6

WARNING Moving parts could crush and cut.

NOT

for

REPRODUCTION

Starter and other rotating parts could

entangle hands, hair, clothing, or

accessories resulting in serious injury.

• NEVER operate generator without protective housings,

covers, or guards in place.

• DO NOT wear loose clothing, jewelry or anything that

could be caught in the starter or other rotating parts.

• Tie up long hair and remove jewelry.

• Before servicing, remove 15 Amp fuse from control panel

and disconnect Negative (NEG or -) battery cable.

WARNING Hot pressurized coolant could cause serious

injury.

• DO NOT open radiator cap when hot.

• Before servicing, allow coolant to cool.

CAUTION Installing the 15A fuse could cause the

engine to start at any time without warning

resulting in minor or moderate injury.

• Observe that the 15 Amp fuse has been removed from the

control panel for shipping.

• DO NOT install this fuse until all plumbing and wiring has

been completed and inspected.

NOTICE Improper treatment of generator could damage it

and shorten its life.

• Use generator only for intended uses.

• If you have questions about intended use, contact your

authorized dealer.

• Operate generator only on level surfaces.

• Adequate, unobstructed flow of cooling and ventilating air

is critical to correct generator operation.

• The access panels/door must be installed whenever the

unit is running.

• DO NOT expose generator to excessive moisture, dust,

dirt, or corrosive vapors.

• Remain alert at all times while working on this equipment.

Never work on the equipment when you are physically or

mentally fatigued.

• DO NOT start engine with air cleaner or air cleaner

cover removed.

• DO NOT insert any objects through cooling slots.

• DO NOT use the generator or any of its parts as a step.

Stepping on the unit could cause stress and break parts.

This may result in dangerous operating conditions from

leaking exhaust gases, fuel leakage, oil leakage, etc.

• If connected devices overheat, turn them off and

disconnect them from generator.

• Shut off generator if:

-electrical output is lost;

-equipment sparks, smokes, or emits flames;

-unit vibrates excessively.

-unit makes unusual noises.

CAUTION Excessively high operating speeds could

result in minor injury and/or equipment damage.

Excessively low speeds impose a heavy load on generator.

• DO NOT tamper with governed speed. Generator supplies

correct rated frequency and voltage when running at

governed speed.

• DO NOT modify generator in any way.

6 BRIGGSandSTRATTON.COM

Page 7

Installation

NOT

for

REPRODUCTION

We sincerely appreciate your patronage. For this reason, we

have made every effort to provide for a safe, streamlined

and cost-effective installation. Because each installation is

unique, it is impossible to know of and advise the trade of all

conceivable procedures and methods by which installation

might be achieved. Neither could we know of possible

hazards and/or the results of each method or procedure.

For these reasons, only current licensed electrical and

plumbing professionals should attempt generator system

installations. Installations must strictly comply with all

applicable codes, industry standards andregulations.

Your generator is supplied with this “Operator’s Manual”

and a separate “Installation Manual”. These are important

documents and should be retained by the owner after the

installation has been completed.

This product is only for use as an optional generator system

which provides an alternate source of electric power and

to serve loads such as heating, refrigeration systems, and

communication systems that, when stopped during any power

outage, could cause discomfort or inconvenience.

NOTICE This product does NOT qualify for either an

emergency standby or legally required standby system as

defined by NFPA 70 (NEC).

• Emergency generator systems are intended to

automatically supply illumination, power, or both, to

designated areas and equipment in the event of failure

of the normal supply. Emergency systems may also

provide power for such functions as ventilation where

essential to maintain life, where current interruption of

the normal supply would produce serious life safety or

health hazards.

• Legally Required standby generator systems are

intended to automatically supply power to selected

loads in the event of failure of the normal source

which could create hazards or hamper rescue or firefighting operations.

Every effort has been made to ensure that information in this

manual is accurate and current. However, we reserve the right

to change, alter, or otherwise improve the product and this

document at any time without prior notice.

Only current licensed electrical and plumbing professionals

should attempt generator system installations. Installations

must strictly comply with all applicable codes, industry

standards, laws and regulations.

For the Owner:

To help you make informed choices and communicate

effectively with your installation contractor(s), read and

understand Owner Orientation in this manual before

contracting or starting your generatorinstallation.

To arrange for proper installation, contact the store at which

you purchased your generator, your dealer, a licensed

electrician or your utility power provider.

The generator warranty is VOID unless the system is

installed by licensed electrical and plumbingprofessionals.

Every effort has been made to ensure that information in this

manual is accurate and current. However, we reserve the

right to change, alter, or otherwise improve the product and

this document at any time without prior notice.

The Emission Control System for this generator is warranted

for standards set by the U.S. Environmental Protection

Agency and by the California Air Resources Board (CARB).

For the Installing Dealer/Contractor:

For most applications, the Installation manual contains all

the information required to properly install and start the

generator. This operator’s manual describes routine operation

and owner maintenanceprocedures.

If you need more information in this matter, please call

800732-2989, between 8:00 AM and 5:00 PM CT.

Owner Orientation

This section provides generator owners with the information

necessary to achieve the most satisfactory and cost effective

installation possible.

The illustrations are for typical circumstances and are meant

to familiarize you with the installation options available

with your generator. A thorough understanding of these

options will provide fundamental control over the cost of

your installation, as well as ensure your final satisfaction

andsecurity.

Federal and local codes, appearance, noise levels, fuel types,

and distances are the factors that must be considered when

negotiating with an installation professional. Remember

that as the distance from the existing electrical service and

gaseous fuel supply increases, and the number of 90 degree

bends in the fuel supply increases, compensations in piping

and wiring materials must be made. This is necessary to

comply with local codes and overcome electrical voltage

drops and gaseous fuel pressure drops.

The factors mentioned above will have a direct affect on

the overall price of your generator installation.

In some areas you may need to acquire electrical permits

for installing the generator, building permits for installing

gas lines, and permits for noise allowances. Your installer

should check your local codes AND obtain the permits before

installing the system.

7

Page 8

Fuel Factors

NOT

for

REPRODUCTION

An important consideration affecting the entire installation

is the type of fuel used by your generator. The system was

factory tested and adjusted using either natural gas or liquid

propane (LP vapor). For proper engine function, factors

that are inherent to each of these fuels, your location and

the duration of possible utility interruptions are important

considerations in the following fuel guidelines:

• Use clean, dry fuel, free of moisture or any

particulate material. Using fuels outside the following

recommended values may cause performanceproblems.

• In engines set up to run on propane (LP), commercial

grade HD5 propane with a minimum fuel energy of 2500

BTUs/ft3 with maximum propylene content of 5% and

butane and heavier gas content of 2.5% and minimum

propane content of 90%.

Natural gas rating will depend on specific fuel but typical

derates are between 10 to 20% off the LP gas rating.

WARNING

• The generator is equipped with an automatic safety gas

“fuel shut-off” valve.

• DO NOT operate the equipment if the “fuel shut-off” valve

is missing or inoperative.

Power Decrease at High Altitude or High Temperature

Air density is less at high altitudes, resulting in less available

engine power. Specifically, engine power will decrease 3%

for each 1,000 feet (300 meters) above sea level and 1% for

each 10° F (5.6°C) above 77°F (25°C). Make sure you and

your installer consider these factors when determining total

generator load.

Propane and Natural Gas are extremely

flammable and explosive, which could cause

burns, fire or explosion resulting in death or

serious injury.

Delivery Inspection

Carefully inspect the generator for any damage that may have

occurred during shipment.

If loss or damage is noted at time of delivery, have the

person(s) making delivery note all damage on the freight bill

and affix his signature under the consignor’s memo of loss

or damage. If loss or damage is noted after delivery, separate

the damaged materials and contact the carrier and your

installer for claim procedures. Missing or damaged parts are

not warranted.

The generator is supplied with:

• Fully-serviced coolant system

• Fully-serviced oil/lubricating system

• Flexible fuel hook-up hose

• Installation and start-up manual

• Operator’s manual

• Spare access door keys

• Spare 15A fuse

• Touch up paint

To be supplied by installer:

• Carbon monoxide detector(s)

• Smoke detector(s)

• Starting battery

• Reinforced concrete mounting pad

• Connecting wire and conduit

• Fuel supply valves/plumbing

• Various specialty tools/equipment

8 BRIGGSandSTRATTON.COM

Page 9

Generator Location

NOT

for

REPRODUCTION

The actual physical location of your generator has a direct

affect on:

1. The amount of plumbing required to fuel your generator.

2. The amount of wiring required to control and connect

your generator.

Specific location guidelines are discussed in the installation

manual. Acquaint yourself with that information and confer

with your installer. Be sure to ask how your site might

affect installation costs and compliance with local codes

andstandards.

• Install generator outdoors in an area that will not

accumulate deadly exhaust gas.

• DO NOT install generator where exhaust gas could

accumulate and enter inside or be drawn into a

potentially occupied building or structure.

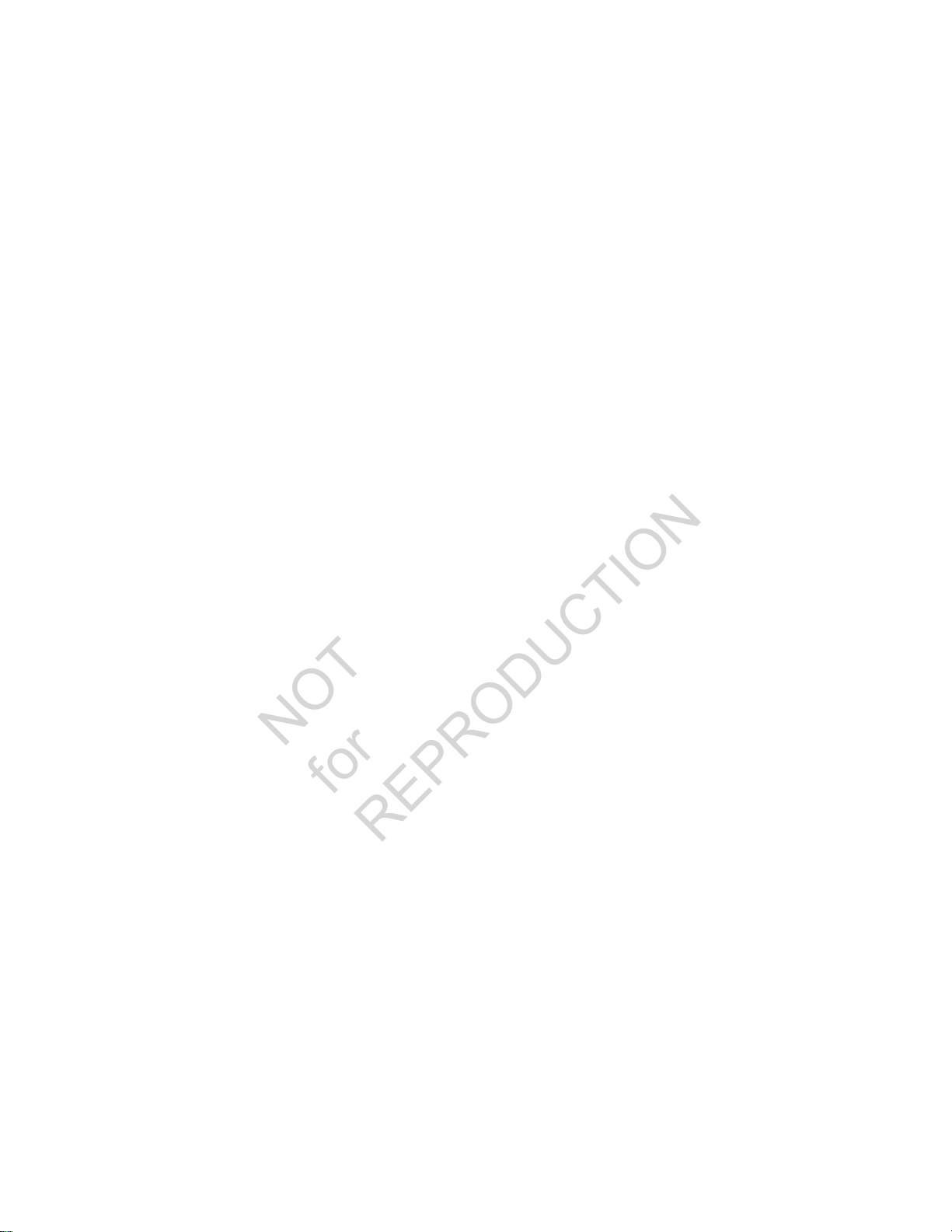

• By law it is required in many states to have a Carbon

Monoxide (CO) detector in operating condition in your.

Carbon monoxide detector(s) (A) MUST be installed

and maintained indoors according to the manufacturer’s

instructions/recommendations. A CO monitor is an

electronic device that detects hazardous levels of CO.

When there is a buildup of CO, the monitor will alert the

occupants by flashing visual indicator light and alarm.

Smoke alarms cannot detect CO gas.

A

WARNING Running engine gives off carbon monoxide,

an odorless, colorless, poison gas.

Breathing carbon monoxide could result in death,

serious injury, headache, fatigue, dizziness,

vomiting, confusion, seizures, nausea or fainting.

• Operate this product ONLY outdoors in an area that will

not accumulate deadly exhaust gas.

• Keep exhaust gas away from any windows, doors,

ventilation intakes, soffit vents, crawl spaces, open garage

doors or other openings that can allow exhaust gas

to enter inside or be drawn into a potentially occupied

building or structure.

• Carbon monoxide detector(s) MUST be installed and

maintained indoors according to the manufacturer’s

instructions/recommendations. Smoke alarms cannot

detect carbon monoxide gas.

WARNING Exhaust heat/gases could ignite

combustibles or structures resulting in death or serious

injury.

• Exhaust outlet side of weatherproof enclosure must

have at least 5 ft. (1.5 m) minimum clearance from any

structure, shrubs, trees, or any kind of vegetation.

• Standby generator weatherproof enclosure must be at

least 5 ft. (1.5 m) from windows, doors, any wall opening,

shrubs or vegetation over 12 in. (30.5 cm) in height.

• Standby generator weatherproof enclosure must have a

minimum of 5 ft. (1.5 m) overhead clearance from any

structure, overhang or trees.

• DO NOT place weatherproof enclosure under a deck or

other type of structure that may confine airflow.

• USE ONLY flexible steel fuel line provided. Connect

provided fuel line to generator. DO NOT use with or

substitute any other flexible fuel line.

• Smoke detector(s) MUST be installed and maintained

indoors according to the manufacturer’s instructions/

recommendations. Carbon monoxide alarms cannot

detect smoke.

• DO NOT place weatherproof enclosure in manner other

than shown in illustrations.

• Ensure exhaust gas is kept away from any windows,

doors, ventilation intakes, soffit vents, crawl spaces,

open garage doors or other openings that can

allow exhaust gas to enter inside or be drawn into a

potentially occupied building or structure. Neighboring

structures may be exposed to the engine exhaust from

your standby generator and must be considered when

installing your standby generator.

• Wind and air currents should be taken into

consideration when positioning generator.

9

See the installation manual for full details on safe generator

location.

Page 10

Controls

NOT

for

REPRODUCTION

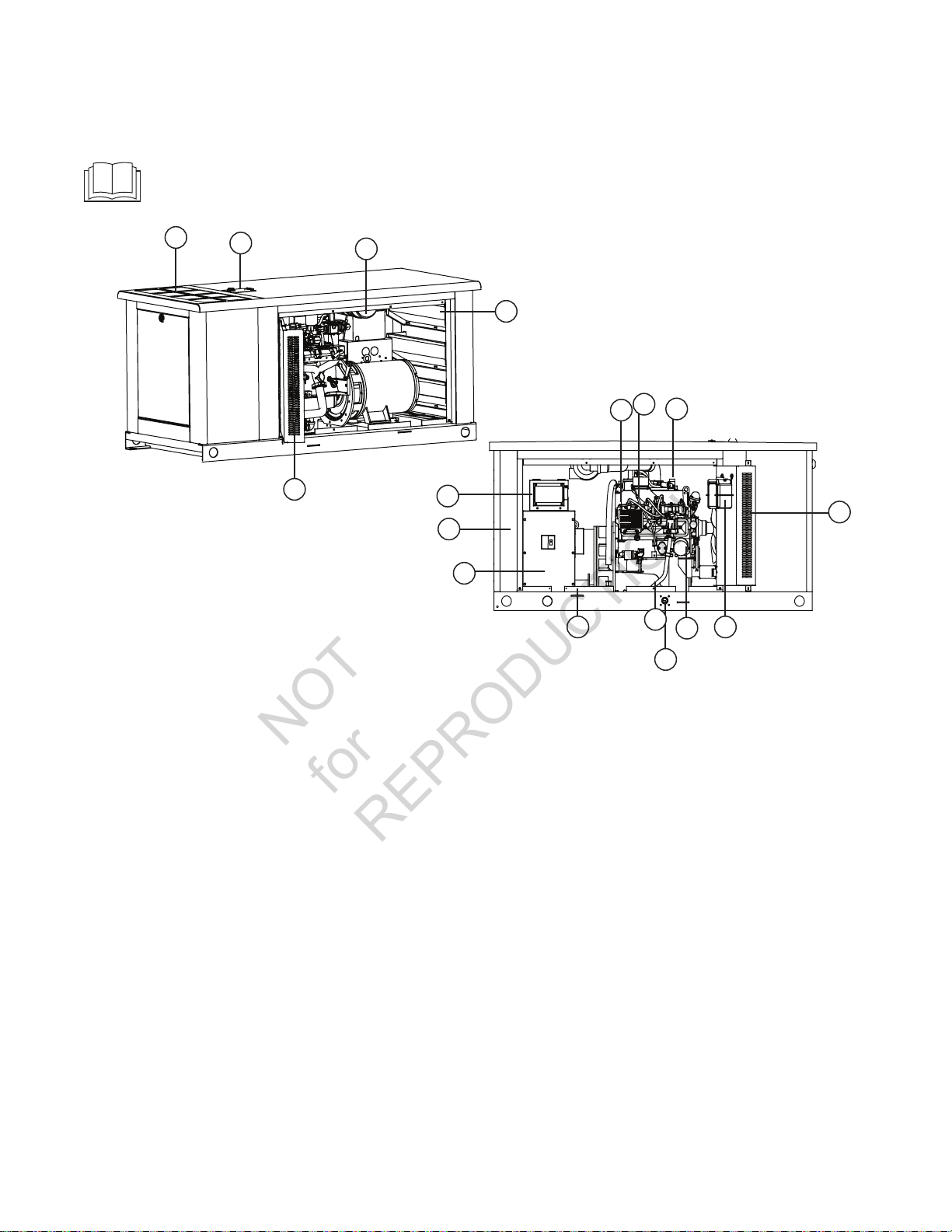

60 kW Generator

Read this operator’s manual and Important Safety Instructions before operating your generator.

Compare the illustrations of this model with your generator to familiarize yourself with the locations of various

controls and adjustments. Save this manual for future reference.

A

B

A

C

D

F

E

S

R

P

N

G

H

M

L

J

K

Generator is pictured with access doors removed for clarity

and screen guard open for clarity.

A - Exhaust Port — High-performance muffler lowers engine

sound level to comply with most residential codes.

B - Coolant Fill Door — Provides access for servicing engine

with coolant.

C - Air Cleaner — Protects engine by filtering dust and

debris out of intake air.

D - Battery Door opening — Provides access to starting

battery and air cleaner.

E - Engine Label — Identifies engine model and type.

F - Oil Dip Stick — Used to check the engine oil level.

G - Oil Fill Cap — Remove to service the engine with

recommended oil.

H - Screen Guard — Prevents fingers from touching radiator

fan and houses the coolant recovery bottle. Must stay

closed while generator is in use.

J - Coolant Recovery Bottle — Located on inside of screen

guard. Provides visual indicator of engine coolant level.

K - Oil Filter — Filters engine oil to prolong system life.

L - Fuel Inlet — Fuel supply is connected here.

M - Oil Drain Hose — Provided to facilitate oil changing.

N - ID Label (located on base) — Identifies unit by

serial number.

P - Circuit Breaker Enclosure — Equipped with removable

bottom to assist with conduit connection.

R - Control Panel Door opening — Provides access to

control panel, oil filter, etc.

S - Control Panel — Used for various test, operation and

maintenance functions. See System Control Panel.

10 BRIGGSandSTRATTON.COM

Page 11

System Control Panel

NOT

for

REPRODUCTION

The system control panel is a printed circuit board that is

integrated with the control panel of the generator. It contains

all the logic circuits, operator controls, and system displays

necessary to operate, program, and protect the generator. The

system control panel interprets and monitors electrical inputs

from related circuits throughout the unit.

Please refer to the supplied Control Panel Application Guide

for detailed information about the control panel.

Each generator is supplied with a set of identical keys. These

keys fit the locks that secure the access doors.

To open access door:

1. Insert key into lock of access door handle and turn key

one quarter turn counterclockwise.

2. Grasp door’s handle and turn one quarter turn

counterclockwise to open. Remove key.

3. Coolant Fill door is unlocked in the same manner. It can

be used for adding coolant or oil.

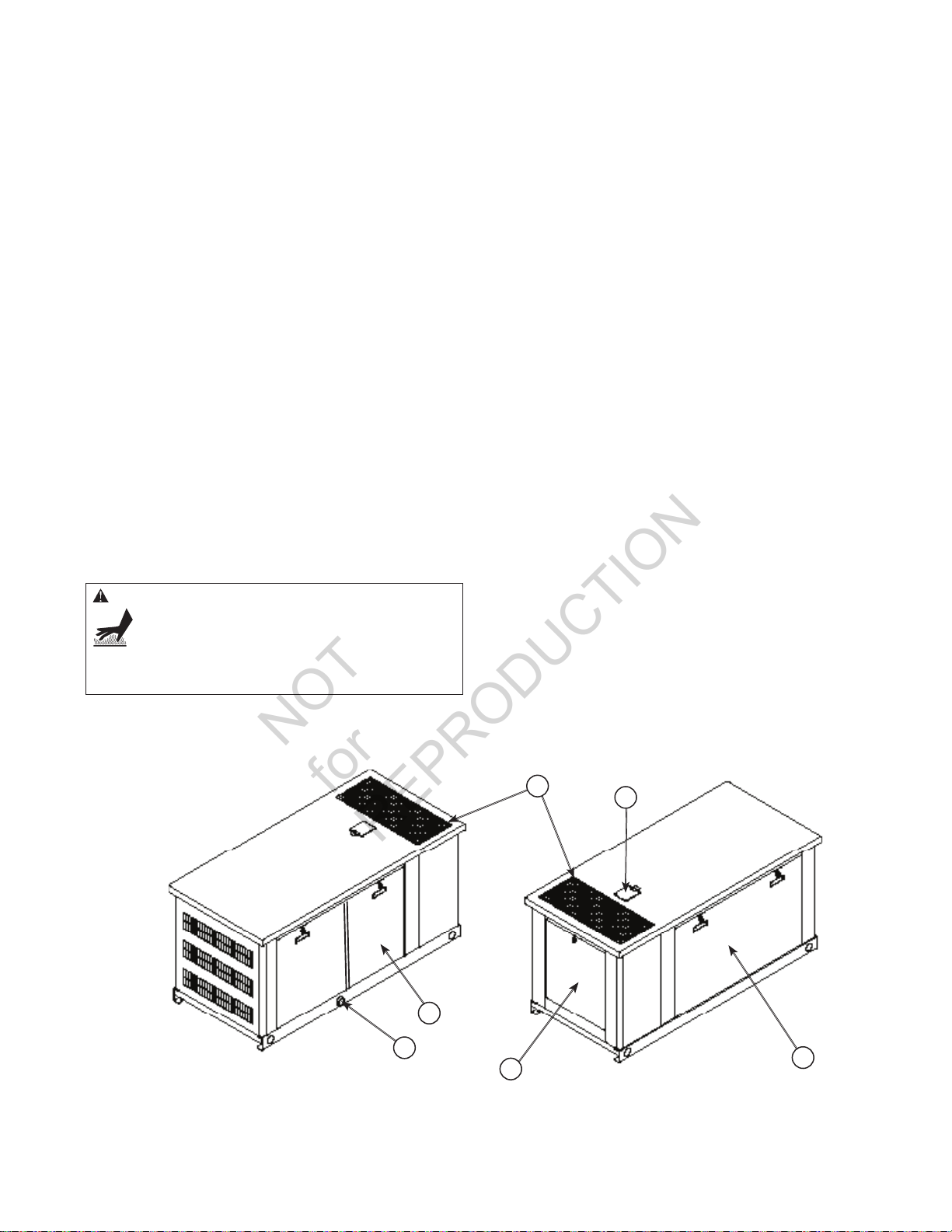

Access Ports

The generator is equipped with an enclosure that has

several access doors. The doors are named for a significant

component located behind them, as follows::

A - Fuel Inlet port (shown for reference)

B - Control Panel door

C - Exhaust opening (shown for reference)

D - Coolant Fill door

E - Battery door

F - Muffler door

WARNING Contact with muffler area could cause burns

resulting in serious injury.

• DO NOT touch hot parts and AVOID hot exhaust gases.

• Allow equipment to cool before touching.

To close access door:

1. Close door and turn door’s handle one quarter

turnclockwise.

2. Insert key into lock of door handle and turn key one

quarter turn clockwise. Remove key.

The enclosure also includes muffler and radiator access

panels, used for cleaning those components. Those panels

should remain closed at all other times to assure proper

cooling, reduce noise, and for added safety.

C

B

A

F

D

11

E

Page 12

Operation

NOT

for

REPRODUCTION

Important Owner’s Considerations

Engine Oil

NOTICE Any attempt to crank or start the engine before it

has been properly serviced with the recommended coolant

or oil will result in equipment failure.

• Refer to the Maintenance section for coolant and oil fill

information.

• Damage to equipment resulting from failure to follow this

instruction will void engine and generator warranty.

This engine is shipped from the factory pre-run and filled

with non-synthetic oil (API SL 10W-30W). This allows

for system operation in a wide range of temperature and

climate conditions. Before starting the engine, check oil

level and ensure that engine is serviced as described in the

Maintenance section.

Coolant System

This engine is shipped from the factory filled with a

50-50 mix of automotive (ethylene glycol) anti-freeze and

water. This will provide optimum year round protection

against freezing, boiling and corrosion.

Battery

The installer must supply a valve-regulated, rechargeable

12 volt DC starting battery. See Battery in Final Installation

Considerations in the installation manual.

WARNING Battery posts, terminals and related

accessories contain lead and lead compounds - chemicals

known to the State of California to cause cancer and

reproductive harm. Wash hands after handling.

15 Amp Fuse

The generator’s 15 Amp fuse is critical to correct system

operation. The 15 Amp fuse was removed at the factory to

prevent the unit from starting during shipping. Your installer

will ensure the fuse is properly installed upon completion of

the installation.

Automatic Operation

The generator’s control board constantly monitors utility

voltage. Should utility voltage drop below a preset level, the

control board will signal the engine to crank and start.

When utility voltage is restored above a preset voltage level,

the engine is signaled to shut down.

The actual system operation is not adjustable and is

sequenced by sensors and timers on the control board,

as follows:

Utility Voltage Dropout Sensor

• This sensor monitors utility source voltage.

• If utility source voltage drops below about 70 percent

of the nominal supply voltage, the sensor energizes

a 3 second timer. The timer is used to ‘sense’

brown-outs.

• Once the timer has expired, the engine will crank

and start.

Utility Voltage Pickup Sensor

This sensor monitors utility voltage. When utility voltage is

restored above 80 percent of the nominal source voltage, a

time delay starts timing and the engine will go to engine cooldown.

Engine Cool-down Timer

When utility power is sensed and the load transfers back to

the utility source, the engine will go into a cool down period

as described below:

• If the generator has run for MORE than 5 minutes,

once the utility transfer occurs, the engine will

continue to run for about 1 minute before shutting

down.

• If the generator has run for LESS than 5 minutes, once

the utility transfer occurs, the engine will continue to

run until 5 minutes has elapsed before shutting down.

12 BRIGGSandSTRATTON.COM

Page 13

Setting Exercise Timer

NOT

for

REPRODUCTION

It is recommended to have the generator go through an

excercise cycle once every seven days. During this exercise

period, the unit runs for approximately 20 minutes and then

shuts down.

Refer to the Control Panel Application Guide supplied with this

generator for more detailed information on the exercise timer.

OR, refer to the Automatic Transfer Switch Application Guide

for more detailed information on the exercise timer.

Maintenance

The generator warranty does not cover items that have been

subjected to operator abuse or neglect. To receive full value

from the warranty, the operator must maintain the system as

instructed in the Maintenance section.

Servicing the System

Before performing any generator maintenance, always

perform the following steps:

1. Set generator’s circuit breaker to its OFF position.

2. Turn the generator off.

3. Remove 15 Amp fuse from control board.

4. Utility voltage is present at generator control board.

Disconnect power before servicing control board by

removing the fuses from the transfer switch.

5. After all servicing has been completed, replace fuses in

transfer switch, replace 15 Amp fuse in control board,

set circuit breaker ON and turn the generator on.

Shutdown Alarm Detection System

The generator may have to run for long periods of time with

no operator present. For that reason, the system is equipped

with sensors that automatically shut down the generator in

the event of potentially damaging conditions, such as low oil

pressure, high temperature, over speed, and other conditions.

The generator’s control board shows possible shutdown

alarms descriptions on the digital display.

The possible shutdown alarms are listed below:

• Overspeed

• Underspeed

• Low Oil Pressure

• High Coolant Temperature

• External Shutdown 1

• External Shutdown 2

• External Shutdown 3

• GCB (Generator Circuit Breaker) Fail

• Generator Overvoltage

• Generator Undervoltage

• Generator Overfrequency

• Generator Underfrequency

• Generator CCW Rotation

• Start Fail

• Stop Fail

• Battery Flat

• Voltage Autodetect

Reset Shutdown Alarm Detection System

The operator must reset the shutdown alarm detection system

each time it activates.

Refer to the Control Panel Application Guide supplied with

this generator for more detailed information on resetting the

Shutdown Alarm Detection System.

Overspeed

This shutdown alarm is indicated by Overspeed showing on

the digital display. This condition occurs if the engine speed in

greater than 115% of nominal engine RPM, which is derived

from generator frequency.

To remedy the problem, contact your installer or an

authorized dealer.

Underspeed

This shutdown alarm is indicated by Underspeed showing on

the digital display. This condition occurs if the engine speed

drops under the nominal engine RPM.

13

To remedy the problem, contact your installer or an

authorized dealer.

Page 14

Low Oil Pressure

NOT

for

REPRODUCTION

This shutdown alarm is indicated by Low Oil Pressure on

the digital display. The unit is equipped with an oil pressure

switch that uses normally closed contacts held open by

engine oil pressure during operation. Should oil pressure drop

below the 8 psi range, switch contacts close and the engine

will shut down.

To remedy the low oil pressure condition, add the

recommended oil to the FULL mark on the dipstick or contact

your installer or an authorized dealer.

High Coolant Temperature

This shutdown alarm is indicated by High Coolant

Temperature on the digital display. This condition occurs

when the temperature of the coolant exceeds the shutdown

threshold.

To remedy the problem, contact your installer or an

authorized dealer.

External Shutdown 1,2 or 3

This shutdown alarm is indicated by External Shutdown on

the digital display.

To remedy the problem, contact your installer or an

authorized dealer.

Generator Circuit Breaker (GCB) Fail

This shutdown alarm is indicated by GCB Fail on the digital

display. This condition occurs when the generator circuit

breaker trips or becomes non-functional.

To remedy the problem, contact your installer or an

authorized dealer.

Generator Overvoltage

This shutdown alarm is indicated by Generator Overvoltage

on the digital display. This condition occurs when the output

voltage exceeds the preset threshold.

To remedy the problem, contact your installer or an

authorized dealer.

Generator CCW Rotation

This shutdown alarm is indicated by Generator CCW on the

digital display. This condition occurs when the generator

phase is out of sequence.

To remedy the problem, contact your installer or an

authorized dealer.

Start Fail

This shutdown alarm is indicated by Start Fail on the digital

display. This condition occurs when the generator does not

start.

To remedy the problem, contact your installer or an

authorized dealer.

Stop Fail

This shutdown alarm is indicated by Stop Fail on the digital

display. This condition occurs when the generator fails to

stop.

To remedy the problem, contact your installer or an

authorized dealer.

Battery Flat

This shutdown alarm is indicated by Battery Flat on the digital

display. This condition occurs if the controller loses power

during starting sequence due to a bad battery condition. It will

not try to start again until the battery is functioning properly.

To remedy the problem, contact your installer or an

authorized dealer.

Voltage Autodetect

This shutdown alarm is indicated by Voltage Autodetect on

the digital display. This condition occurs if the controller

loses power during starting sequence due to a bad battery

condition. It will not try to start again until the battery is

functioning properly.

To remedy the problem, contact your installer or an

authorized dealer.

Generator Undervoltage

This shutdown alarm is indicated by Generator Undervoltage

on the digital display. This condition occurs when the output

voltage drops below the preset threshold.

To remedy the problem, contact your installer or an

authorized dealer.

Generator Overfrequency

This shutdown alarm is indicated by Generator Overfrequency

on the digital display. This condition occurs when the

generator frequency is out of limits given by setpoints.

To remedy the problem, contact your installer or an

authorized dealer.

Generator Underfrequency

This shutdown alarm is indicated by Generator

Underfrequency on the digital display. This condition occurs

when the generator frequency is out of limits given by

setpoints.

To remedy the problem, contact your installer or an

authorized dealer.

14 BRIGGSandSTRATTON.COM

Page 15

Generator Maintenance

NOT

for

REPRODUCTION

Generator maintenance consists of keeping the unit

clean. Operate the unit in an environment where it will

not be exposed to excessive dust, dirt, moisture or any

corrosive vapors. Cooling air louvers on the enclosure

must not become clogged with snow, leaves, or any other

foreign material. To prevent generator damage caused by

overheating, keep the enclosure cooling inlets and outlets

clean and unobstructed at all times.

Check the cleanliness of the unit frequently and clean when

dust, dirt, oil, moisture or other foreign substances are visible

on its exterior/interior surface. Inspect the air inlet and outlet

openings inside and outside the enclosure to ensure air flow

is not blocked.

DO NOT use direct spray from a garden hose to clean generator.

Water can enter the engine and generator and cause problems.

Cleaning the Generator

NOTICE Improper treatment of generator can damage it

and shorten its life.

• DO NOT expose generator to excessive moisture, dust,

dirt, or corrosive vapors.

• DO NOT insert any objects through cooling slots.

1. Turn the generator off.

2. Remove 15 Amp fuse from control board.

3. Clean generator as desired.

• Use a damp cloth to wipe exterior surfaces clean.

• Use a soft, bristle brush to loosen caked on dirt, etc.

• Use a vacuum cleaner to pick up loose dirt and debris.

• Use low pressure air (not to exceed 25 psi) to blow

away dirt. Inspect cooling air slots and openings on

the generator. These openings must be kept clean and

unobstructed.

4. Reinstall 15 Amp fuse in control board.

5. Turn the generator on and place in AUTO mode.

Engine Maintenance

The maintenance of an engine and related components are

critical to its operating performance and lifespan. Industrial

engines operate in an environment that often include hot

and cold temperatures and extreme dust. The recommended

maintenance schedule is listed in this section, however,

environmental operating conditions and additional installed

equipment may require more frequent inspection and

servicing. The owner and/or authorized service technician

should review the operating conditions of the equipment to

determine the inspection and maintenance intervals. Proper

engine cooling and lubrication are very important, so pay

particular attention to these matters.

Engine Oil

The engine is shipped from the factory pre-run and filled

with non-synthetic oil (API SL 10W-30). This allows for

system operation in a wide range of temperature and

climateconditions.

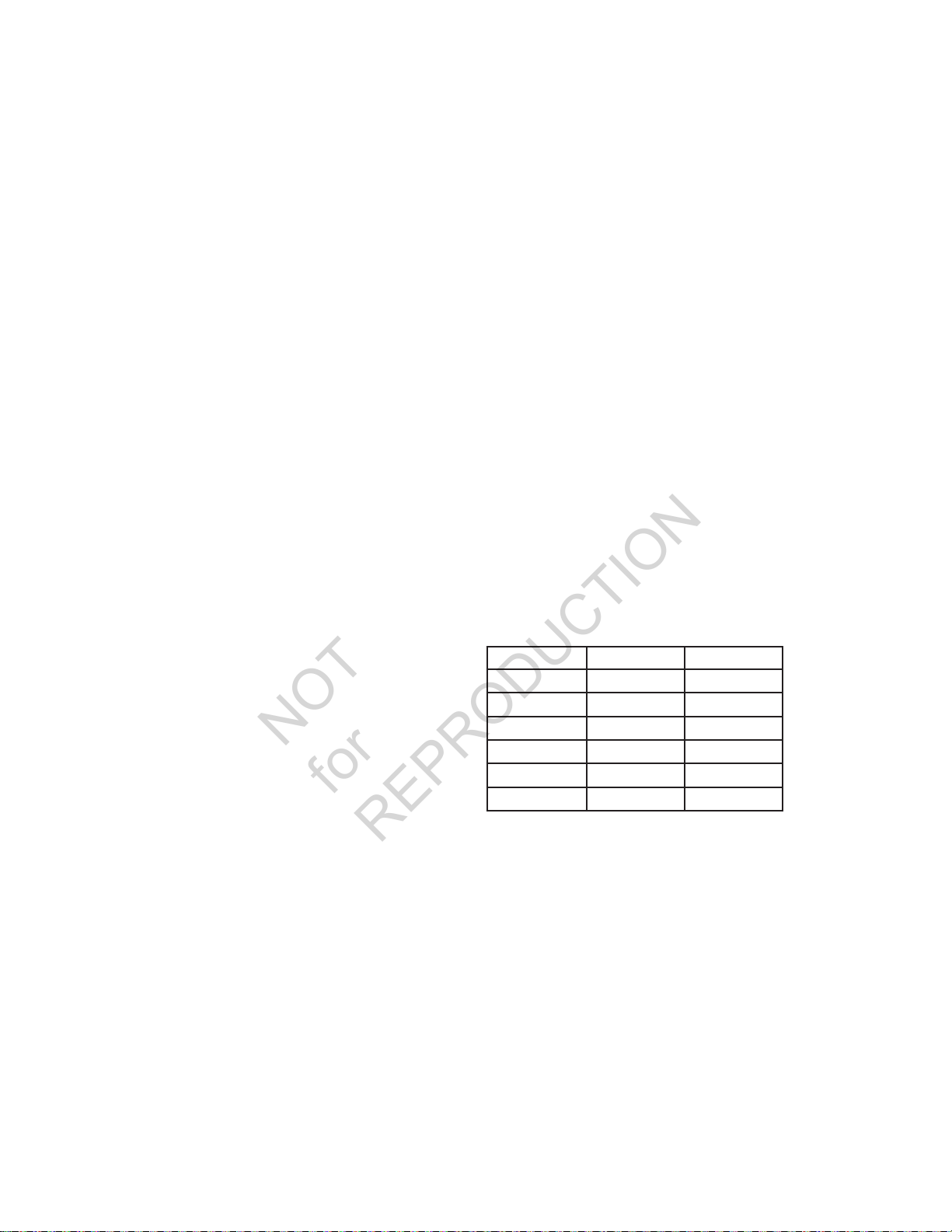

RECOMMENDED SAE VISCOSITY GRADE ENGINE OILS

FOR THE BEST FUEL ECONOMY AND COLD STARTING, SELECT THE LOWEST

SAE VISCOSITY GRADE OIL FOR THE EXPECTED TEMPERATURE RANGE

HOT WEATHER

COLD WEATHER

SAE 10W-30

PREFERRED

SAE 15W-40

IF NEITHER SAE 10W-30

NOR SAE 15W-40 GRADE

OILS ARE AVAILABLE, SAE

30 GRADE MAY BE USED AT

TEMPERATURES ABOVE 4

DEGREES C (40F), SAE 40

GRADE AY BE USED AT

TEMPERATURES ABOVE 27

DEGREES C (80F).

DO NOT USE SAE 10W-40

GRADE OIL OR ANY OTHER

GRADE NOT RECOMMENDED

40°F (4°C)

Oil Recommendation

Select and engine oil viscosity that will best match the

prevailing daytime temperature.

The oil must meet GM specification 9986231. Motor oils

meeting this spec receive the API (American Petroleum

Institure) starburst symbol:

It is noted that the GF-4 oils are also “backward compatible”

and are equal or better than previous grades of oil in all

aspects.

Synthetic Oils

Synthetic Oils have been available for use in industrial

engines for a relatively long period of time and may offer

advantages in cold and hot temperatures. However, it is not

known if synthetic oils provided operational or economic

benefits over conventional petroleum-based oils in industrial

engines. Use of synthetic oils does not permit the extension

15

of oil change intervals.

Page 16

Checking Engine Oil Level

NOT

for

REPRODUCTION

NOTICE: It is important to be careful when checking engine

oil level. Oil must be maintained between the “ADD” and

the “FULL” mark on the dipstick. To ensure that you are not

getting a false reading, make sure the following steps are

taken before checking the oil level.

1. Stop engine.

2. Turn the generator off.

3. Remove 15 Amp fuse from control panel.

4. Allow approximately five minutes for the oil to drain

back into the oil pan.

5. Remove the dipstick. Wipe with a clean cloth or paper

towel and reinstall. Push the dipstick all the way into the

dipstick tube.

6. Remove the dipstick and note the amount of oil on the

dipstick. The oil level must be between the “ADD” and

“FULL” marks.

7. If the oil level is below the “ADD” mark, reinstall the

dipstick and proceed to step 6.

8. Remove the oil filler cap from the valve cover.

9. Add the required amount of oil to bring the level up to,

but not over, the “FULL” mark on the dipstick. Reinstall

the oil filler cap to the valve rocker arm cover and wipe

any excess oil clean.

Changing Engine Oil

KEEP OUT OF REACH OF CHILDREN. DON’T

POLLUTE. CONSERVE RESOURCES. RETURN

USED OIL TO COLLECTION CENTERS.

Change oil while the engine is still warm from running.

1. Turn the generator off.

2. Remove 15 Amp fuse from control panel.

3. Place oil drain hose (B) into an approved container.

4. Open valve (A) located on bottom of oil pan.

5. When oil has drained, replace brass fitting on hose.

6. Remove oil filter and dispose of properly.

7. Before installing a new oil filter, lightly lubricate the oil

filter gasket with fresh, clean oil.

8. Install the oil filter by hand until the gasket contacts the

oil filter adapter, then tighten the oil filter ½ to ¾ turn.

9. Add the required amount of oil to bring the level up to,

but not over the “FULL” mark on the dipstick. Reinstall

the oil filler cap to valve rocker arm cover and wipe any

excess oil clean.

10. If all engine servicing is complete, replace 15 Amp fuse

in control panel and and turn the generator on and place

in AUTO mode.

To make the task of adding oil more convenient, we

recommend use of a funnel attached to a length of tubing

long enough to reach from the Coolant Fill door to the oil fill

opening on the engine valve cover.

Engine V-Belts

The engine installed in this equipment uses drive belt(s) that

drive the water pump and alternator. The drive belt(s) are an

integral part of the cooling and charging system and should

be inspected according to the maintence schedule. When

inspecting the belts, check for:

• Cracks

• Chunking of the belt

• Splits

• Material hanging loose from the belt

• Glazing, hardening

If any of these conditions exist, the belt should be replaced.

16 BRIGGSandSTRATTON.COM 16

Page 17

Engine Coolant System

NOT

for

REPRODUCTION

It is important that the cooling system of the engine be

maintained properly to ensure proper performance and

longevity.

WARNING Hot pressurized coolant could cause serious

injury.

• DO NOT open radiator cap when hot.

• Before servicing, allow coolant to cool.

NOTICE: Alcohol or methanol based anti-freeze or plain

water are not recommended for use in the cooling system at

any time.

The cooling system must be maintained according to the

recommended maintenance schedule and inspection should

include:

• The regular removal of dust, dirt, and debris from the

radiator core and fan shroud.

• Inspection of coolant hoses and components for leaks,

especially at the radiator hose connections. Tighten

hose clamps if necessary.

• Check radiator hoses for swelling, separation,

hardening, cracks, or any type of deterioration.

• Inspect the radiator cap to ensure proper sealing.

Coolant

With the engine cold, check the coolant level in the coolant

recovery bottle (see Controls). Specifications for the coolant

system can be found in the Maintenance chart of this manual.

Coolant Specification - ethylene glycol 50-50 mixture w/

distilled water.

Engine Air Cleaner

Once each year service the air cleaner, as follows. If

operating in a dusty environment, service more often.

1. Turn the generator off.

2. Remove 15 Amp fuse from control panel.

3. Remove filter cartridge - Remove the service cover by

disengaging three clips and detaching cover, starting

with the bottom two clips and the top clip last. Gently

move the end of the filter back and forth, then rotate

while pulling straight out.

4. Clean outlet tube and check Vacuator™

valve - Use a clean cloth to wipe the

filter sealing surface and the outlet tube

surfaces. Make sure that all contaminant

is removed before the new filter is

inserted. Be careful to not damage the sealing area on

the tube.

Visually check and physically squeeze Vacuator valve

attached to service cover to make sure it is flexible and

not inverted, damaged orplugged.

5. Clean filter - Use a soft bristle brush to loosen dirt

and a vacuum cleaner to remove dirt and debris. Low

pressure air (not to exceed 25 psi) may also be used to

blow away dirt. Replace filter cartridge if any holes are

detected in filter media.

6. Install clean filter properly - Insert the filter carefully.

Seat the filter by hand, making certain it is completely

into the air cleaner housing before securing the cover

in place. To complete a tight seal, apply pressure by

hand at the outer rim of the filter, not the flexible center.

(Avoid pushing on the center of the urethane end cap.)

No cover pressure is required to hold the seal.

NEVER use the service cover to push the filter into

place! Using the cover to push the filter in could cause

damage to the housing, cover, or fasteners and will void

the warranty. If the service cover hits the filter before

it is fully in place, remove the cover and push the filter

(by hand) further into the air cleaner and try again. The

cover should go on with no extra force.

7. Reinstall service cover - Once the filter is in place,

reinstall the service cover, positioning the cover with

the arrow and the word TOP to the top. Fasten the top

clip first, the bottom two clips last. Make sure that all

mounting bands, clamps, bolts, and connections in the

entire air cleaner system are tight and verify absence of

holes in piping - repair if needed.

8. Replace 15 Amp fuse in control panel.

9. Turn the generator on.

17

Page 18

Generator Electrical System Maintenance

NOT

for

REPRODUCTION

The generator’s electrical system incorporates computers to

control various related components. The electrical system

connections and ground circuits require good connections.

Follow the recommended maintenance schedule located in

the Maintenance section of this manual.

When inspecting the electrical system, check the following:

• Check positive (+) and negative (-) battery cables for

corrosion, rubbing, chafing, burning, and ensure tight

connections at both ends.

• Check battery for cracks or damage to the case. Replace

as necessary.

• Inspect engine wire harness for rubbing, chafing,

pinching, burning, and cracks or breaks in the wiring.

• Verify that the engine harness connectors are correctly

locked in.

• Inspect ignition coil wire for hardening, cracking,

chafing, burning, separation, and split boot covers.

• Inspect spark plug wires for hardening, cracking,

chafing, burning, separation, and split boot covers.

• Replace spark plugs at the required intervals per the

recommended maintenance schedule.

• Verify that all electrical components are securely

mounted to the engine or chassis.

• Verify that any additional electrical services installed by

the owner are properly installed in the system.

5. Connect black battery cable to negative battery terminal

(indicated by NEGATIVE, NEG, or (-)).

6. Ensure hardware on both positive and negative battery

terminals is secure.

7. Reinstall 15 Amp fuse in control panel.

8. Turn the generator on.

9. Reset exercise timer. See Setting Exercise Timer.

DON’T POLLUTE. CONSERVE RESOURCES,

RETURN USED BATTERY TO RECYCLING

COLLECTION CENTER.

Charging the Battery

If it is necessary to charge the battery, proceed as follows:

1. Turn the generator on.

2. Remove 15 Amp fuse from control panel.

3. Disconnect negative battery cable from negative battery

terminal (indicated by NEGATIVE, NEG, or (-)).

NOTICE Failure to disconnect negative battery cable will

result in equipment failure.

• DO NOT attempt to jump start the generator.

• Damage to equipment resulting from failure to follow this

instruction will void engine and generator warranty.

Battery

Servicing of batteries is to be performed or supervised

by personnel knowledgeable of batteries and the

required precautions. Keep unauthorized personnel away

frombatteries.

WARNING Battery posts, terminals and related

accessories contain lead and lead compounds - chemicals

known to the State of California to cause cancer and

reproductive harm. Wash hands after handling.

Servicing the Battery

If it is necessary to service the battery, proceed as follows:

1. Turn the generator off.

2. Remove 15 Amp fuse from control panel.

3. Service or replace battery as required. See Battery

in Final Installation Considerations in the installation

manual for specific battery needed.

4. Connect red battery cable to battery positive terminal

(indicated by POSITIVE, POS, or (+)).

4. Charge battery with battery charger at 2 Amps until

battery holds 12 Volts. DO NOT exceed 13.7 volts when

charging battery.

5. Connect negative battery cable to negative battery

terminal (indicated by NEGATIVE, NEG, or (-)).

6. Ensure hardware on both positive and negative battery

terminals is secure.

7. Reinstall 15 Amp fuse in control panel.

8. Turn the generator off.

9. Reset exercise timer. See Setting Exercise Timer.

18 BRIGGSandSTRATTON.COM

Page 19

Fuel System Inspection and Maintenance

NOT

for

REPRODUCTION

Natural Gas/Propane Fuel System

The fuel system installed on this industrial engine has been

designed to various standards to ensure performance and

reliability. To ensure compliance to these standards, follow

the recommended maintenance schedule contained in this

section.

Pressure Regulator Maintenance and Inspection

NOTICE: The pressure regulator components have been

specifically designed and calibrated to meet the fuel system

requirements of the engine.

If the regulator fails to operate or develops a leak, it should

be repaired or replaced with the OEM recommended

replacement parts. When inspecting the regulator, check for

the following items:

• Check for any fuel leaks at the inlet and outlet fittings.

• Check for any fuel leaks in the regulator body.

• Check to ensure the regulator is securely mounted and

the mounting bolts are tight.

• Check the regulator for external damage.

Exhaust System Maintenance and Inspection

When inspecting the exhaust system, check the following:

• Inspect exhaust manifold at the cylinder head for leaks

and that all retaining bolts and shields (if used) are in

place.

• Inspect manifold to exhaust pipe fasteners to ensure

they are tight and that there are not exhaust leaks.

Repair as necessary.

• Inspect the oxygen sensor electrical connector to ensure

connector is seated and locked, check wires to ensure

there is no cracking, splitting, chaffing, or burning.

Replace or replace if necessary.

• Inspect exhaust pipe connection for leaks. Repair if

necessary.

Engine Exterior

Periodically inspect the engine exterior for contamination

and potential damage from dirt, leaves, rodents, spider webs,

insects, etc. and remove.

Venturi/Throttle Control Device Maintenance and Inspection

NOTICE: The venturi and throttle body components have been

specifically designed and calibrated to met the fuel system

requirements of the engine.

When inspecting the venturi and throttle body, check for the

following items:

NOTICE: A dirty air cleaner may significantly alter the venturi

performance.

• Leaks at all fittings.

• Ensure the venturi and throttle body are securely

mounted.

• Inspect air cleaner element according to the

recommended maintenance schedule found in this

section.

• Inspect air inlet hose connection and clamp. Inspect

hose for cracking, splitting, or chaffing. Replace if any

of these conditions exist.

• Check fuel lines for cracking, splitting, or chaffing.

Replace if any of this conditions exist.

• Check for leaks at the throttle body and intake manifold.

When Calling for Assistance

You must have the following information at hand if it is

necessary to contact a local service center regarding service

or repair of this unit:

1. Obtain the unit Model Number and Serial Number from

the unit ID label. See Controls for location of the label

or refer to the information recorded on the inside front

cover of the installation manual.

2. Obtain the engine identification numbers from the

engine label. See the Installation manual for location of

this information.

Storage

The generator system is designed for long term service as

a backup generator. There is no need to take any storage

precautions. However, if it becomes necessary to take the

system out of service for an extended period, call Technical

Services at 800743-4115, between 8:00 AM and 5:00PMCT

for specific recommendations.

19

Page 20

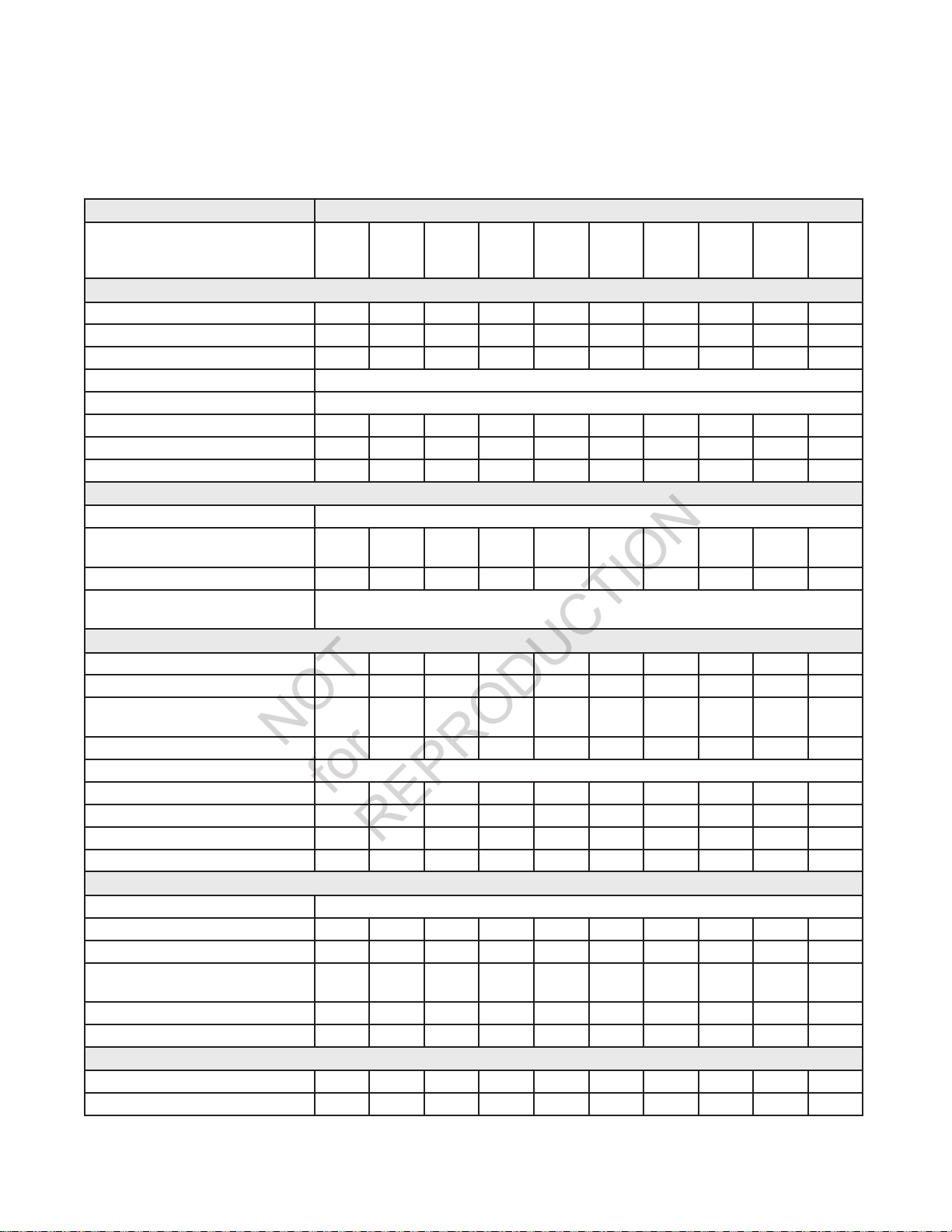

Maintenance Chart

NOT

for

REPRODUCTION

This maintenance schedule represents the manufacturer’s recommended maintenance intervals to maintain proper engine/

equipment function. Federal, State, or Local regulations may require additional or more frequent inspection or maintenance

intervals than those specified above. Check with the authority having jurisdiction for details.

Perform the following maintenance on the engine at the hours indicated and at equivalent hour intervals thereafter.

Maintenance Interval Hours

After

each

use

General Maintenance Section

Visual check for fluid leaks X

Check engine oil level X

Check coolant level X

Change engine oil and oil filter Every 100 hours or Annually

Check fuel system for leaks Before and after any service or maintenance activity

Inspect accessory drive belts X X X X X

Inspect electrical system wiring X X

Inspect all vacuum lines and fitting X X

Engine Coolant Section

Clean debris from radiator core Every 100 hours or 60 days of operation

Change coolant - ethylene glycol 50-50

mixture w/ distilled water

Inspect coolant hoses X X X

Replace coolant hoses and accessory

drive belt

Engine Ignition System

Inspect battery case for leaks/damage X X X X X

Inspect battery cables X X X X X

Inspect all electrical connector retainer

locks

Replace spark plugs X X X

Inspect crank sensor timing wheel Every 100 hours or annually

Replace distributor cap and rotor X X

Clean secondary ignition coil tower X X X X X

Check spark plug wires X

Replace spark plug wires X

Fuel System Maintenance

Inspect air cleaner Every 200 hours (or every 100 hours in severe environments) and Annually

Check fuel shut-off valve function X X

Replace inline LPG filter X X X X X

Check LPG shut-off solenoid valve

function

Check air induction system X X

Check intake manifold X X

Engine Exhaust System

Inspect exhaust manifold and piping X X

Check oxygen sensor connector X X

1000 1500 2000 2500 3000 3500 4000 4500 5000

X X X X X

Every 2,000 Hours or two years, whichever occurs first

X X X X X

X X

20 BRIGGSandSTRATTON.COM

Page 21

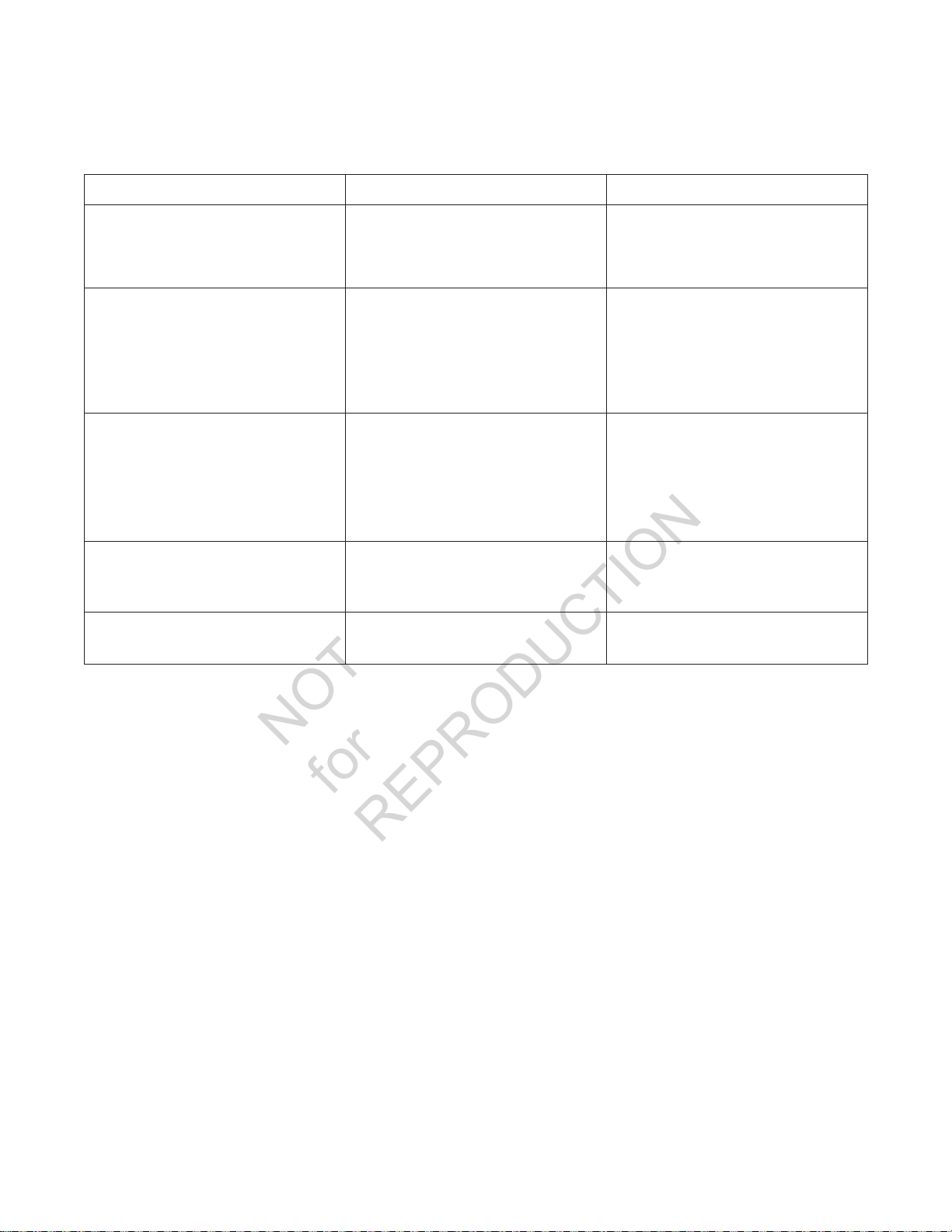

Troubleshooting

NOT

for

REPRODUCTION

Problem Cause Correction

Engine is running, but no AC output

isavailable.

Engine runs good at no-load but “bogs

down” when loads are connected.

Engine will not start; or starts and

runsrough.

Engine shuts down during operation.

Loss of power on circuits.

1. Circuit breaker open or defective.

2. Fault in generator control panel.

3. Poor wiring connections or

defective transfer switch.

1. Short circuit in a connected load.

2. Generator is overloaded.

3. Shorted generator circuit.

4. Fuel pressure or mixture is

incorrect.

5. Kinked fuel line.

1. 15 Amp fuse missing or blown.

2. Fuel supply turned off or depleted.

3. Failed battery.

4. Fuel pressure is incorrect

1. Fuel supply turned off or depleted.

2. Fault indicator blinking.

1. Generator circuit breaker is open.

2. Transfer switch problems.

1. Reset or replace circuit breaker.

2. Contact local service facility.

3. Check and repair.

1. Disconnect shorted electrical load.

2. Turn off one or more loads.

3. Contact local service facility.

4. See Gaseous Fuel System in the

Installation Manual.

5. Remove kink. Replace if necessary.

1. Install (new) 15 Amp fuse. See

System Control Panel.

2. Open fuel valve(s); check

propanetank.

3. Replace battery.

4. See Gaseous Fuel System in the

Installation Manual.

1. Check fuel valves, fill propane tank.

2. Count blinks and refer to Fault

Detection System.

1. Reset circuit breaker.

2. See the transfer switch manual.

21

Page 22

U.S. EPA, and Briggs & Stratton Corporation Emissions Control Warranty Statement for Emergency Standby Engines

NOT

for

REPRODUCTION

Your Warranty Rights And Obligations

September 2010

General Information

The U.S. EPA, and Briggs & Stratton (B&S) are pleased to explain

the emissions control system warranty on your Model Year 2010

and later engine / equipment. In the U.S., new Emergency Standby

Engines greater than 25HP must be designed, built, and equipped

to meet stringent emission standards. B&S must warrant the

emissions control system on your engine / equipment.

See Definition of appropriate use of Emergency Standby below.

The emission-related warranty covers all components whose failure

would increase an engine’s non-evaporative emissions of any

regulated pollutant referenced below.

Manufacturer’s Warranty Coverage:

Briggs & Stratton warrants that the engine is free from defects in

material and workmanship, and is also designed, built, and equipped

to conform to applicable regulations under Section 213 of the Clean

Air Act, from the time the engine is sold, until the expiration of its

warranty period.

This warranty applies to all emission related engine components

whose failure would cause engine exhaust emissions to be out of

EPA compliance. Further, this warranty also applies to other engine

components damaged due to the failure of any of these emissions

related components.

If a warrantable emissions related component on your engine is

defective, the part will be repaired or replaced by B&S at no cost to

you including diagnosis, parts, and labor.

Warranty coverage period is two years from date of original

purchase, and is offered to the original purchaser and each

subsequent purchaser so long as Owner’s Warranty Responsibilities

are adhered to.

Owner’s Warranty Responsibilities:

• Warranty claims shall be filed according to the provisions of

the Briggs & Stratton Warranty Policy.

• An engine may not be warrantable if subjected to abuse,

misuse, neglect, improper maintenance, unapproved

modifications, accidents not caused by Briggs & Stratton

engines or equipment, or by acts of God.

• Only those engines used as an Emergency Stationary Engine,

as defined below, are warrantable.

• You are responsible for presenting your engine / equipment to

a B&S distribution center, servicing dealer, or other equivalent

entity, as applicable, as soon as a problem exists. The warranty

repairs should be completed in a reasonable amount of time,

not to exceed 30 days. If you have any questions regarding your

warranty rights and responsibilities, you should contact B&S at

1-800-233-3723 or BRIGGSandSTRATTON.COM.

• If any components not scheduled for maintenance is repaired

or replaced under this warranty, the new part will be warranted

only for the remaining warranty period.

• If a warrantable component scheduled for maintenance

fails prior to its first scheduled replacement, the part will

be repaired or replaced by B&S at no charge to the owner.

Any such component is only warrantable until the originally

scheduled maintenance period has expired.

• Add on or modified parts that are not exempted by the EPA

may not be used. The use of any non-exempted add on or

modified parts by the owner will be grounds for disallowing a

warranty claim. The manufacturer will not be liable to warrant

failures or warranted parts caused by the use of a nonexempted add on or modified part.

MANUFACTURER OF RECORD

IMPCO is the Manufacturer of Record for all Environmental Protection Agency (EPA) compliance issues related to the manufature and use of the engine.

Please refer to Emissions Warranty for further information.

Emergency Stationary Engine Definition

An Emergency Stationary Engine is defined as any stationary internal combustion engine whose operation is limited to emergency situations

and required testing and maintenance. Examples include stationary engines used to produce power for critical networks or equipment

(including power supplied to portions of a facility) when electric power from the local utility (or the normal power source, if the facility runs on

its own power production) is interrupted, or stationary engines used to pump water in the case of fire or flood, etc. Stationary engines used

for peak shaving are not considered emergency stationary engines. Stationary engines used to supply power to an electric grid or that supply

power as part of a financial arrangement with another entity are not considered to be emergency engines. Emergency stationary ICE may be

operated for the purpose of maintenance checks and readiness testing, provided that the tests are recommended by Federal, State or local

government, the manufacturer, the vendor, or the insurance company associated with the engine. Maintenance checks and readiness testing

of such units is limited to 100 hours per year. There is no time limit on the use of emergency stationary engines in emergency situations. The

owner or operator may petition the Administrator for approval of additional hours to be used for maintenance checks and readiness testing,

but a petition is not required if the owner or operator maintains records indicating that Federal, State, or local standards require maintenance

and testing of emergency ICE beyond 100 hours per year. Emergency stationary ICE may operate up to 50 hours per year in non-emergency

situations, but those 50 hours are counted towards the 100 hours per year provided for maintenance and testing. The 50 hours per year for

non-emergency situations cannot be used for peak shaving or to generate income for a facility to supply power to an electric grid or otherwise

supply power as part of a financial arrangement with another entity. For owners and operators of emergency engines, any operation other

than emergency operation, maintenance and testing, and operation in non-emergency situations for 50 hours per year, as permitted above is

prohibited.

Form NO. 313540 Rev.-

22 BRIGGSandSTRATTON.COM

Page 23

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC

NOT

for

REPRODUCTION

STANDBY GENERATOR OWNER WARRANTY POLICY

Effective September 1, 2010 - replaces all undated Warranties and Warranties dated before September, 2010.

LIMITED WARRANTY

Briggs & Stratton Power Products Group, LLC will repair or replace, free of charge, any part(s) of the equipment that is defective in material or

workmanship or both. Travel expenses are reimbursed as specified under the Briggs & Stratton Warranty Guidelines document to authorized Briggs &

Stratton dealers for performing applicable warranty repair work. This warranty is effective for the time periods and subject to the conditions stated below.

For all warranty service, find the nearest Authorized Service Dealer in our dealer locator map at BRIGGSandSTRATTON.COM.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, ARE LIMITED TO ONE YEAR FROM PURCHASE, OR TO THE EXTENT PERMITTED BY LAW. ANY AND ALL IMPLIED WARRANTIES ARE

EXCLUDED. LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES ARE EXCLUDED TO THE EXTENT EXCLUSION IS PERMITTED BY LAW. Some

states or countries do not allow limitations on how long an implied warranty lasts, and some states or countries do not allow the exclusion or limitation

of incidental or consequential damages, so the above limitation and exclusion may not apply to you. This warranty gives you specific legal rights and you

may also have other rights which vary from state to state or country to country.

WARRANTY PERIOD

Generator 4 years

Engine 2 years

The warranty period begins on the date of purchase by the first retail consumer and continues for the period of time stated above.

NO WARRANTY REGISTRATION IS NECESSARY TO OBTAIN WARRANTY ON BRIGGS & STRATTON PRODUCTS. SAVE YOUR PROOF OF PURCHASE

RECEIPT. IF YOU DO NOT PROVIDE PROOF OF THE INITIAL PURCHASE DATE AT THE TIME WARRANTY SERVICE IS REQUESTED, THE MANUFACTURING

DATE OF THE PRODUCT WILL BE USED TO DETERMINE THE WARRANTY PERIOD.

If you have any questions regarding your warranty rights and responsibilities, you should contact B&S at 1-800-233-3723 or BRIGGSandSTRATTON.COM.

MANUFACTURER OF RECORD

IMPCO is the Manufacturer of Record for all Environmental Protection Agency (EPA) compliance issues related to the use and performance of the engine.

Please refer to Emissions Warranty for further information.

ABOUT YOUR WARRANTY

We welcome warranty repair and apologize to you for being inconvenienced. Any authorized service dealer may perform warranty repairs. Most warranty

repairs are handled routinely, but sometimes requests for warranty service may not be appropriate. For example, warranty service would not apply if

equipment damage occurred because of misuse, lack of routine maintenance, and shipping, handling, warehousing or improper installation. Similarly, the

warranty is void if the manufacturing date or serial number(s) on the equipment has been removed or the equipment has been altered or modified. During the

warranty period, the authorized service dealer, at its option, will repair or replace any part that, upon examination, is found to be defective under normal use

and service. This warranty will not cover the following repairs and equipment:

• Normal Wear: Outdoor Power Equipment and engines, like all mechanical devices, needs periodic parts and service to perform well. This warranty

does not cover repair when normal use has exhausted the life of a part or the equipment.

• Installation and Maintenance: This warranty does not apply to equipment or parts that have been subjected to improper or unauthorized installation or

alteration and modification, misuse, negligence, accident, overloading, overspeeding, improper maintenance, repair or storage so as, in our judgment,

to adversely affect its performance and reliability.

Warranty terms continue on next page.

23

Page 24

Exclusions:

NOT

for

REPRODUCTION

1. Wear items such as engine oil, oil gauges, o-rings, filters, fuses, spark plugs, anti-freeze, starting batteries, etc., or damage or malfunctions resulting from

accidents, freezing, abuse, modifications, alterations, or improper servicing or chemical deterioration.

2. Any costs for adjustments, loose or leaking clamps or connections, installation or start-up operations fuel system cleaning and obstruction (due to chemical, dirt,

carbon, lime, and so forth) and any failures caused by contaminated fuels, anti-freeze or oil, etc.

3. Units sold for primary power applications as defined by the U.S. & Canadian National Electric Codes, whether utility power exists or where utility power does not

normally exist.

* For purposes of this warranty, Prime Power is defined where the generator is a source of power where no electrical power is available from the

UTILITY POWER GRID. If no UTILITY power is available, the generator is considered the prime power source.

4. Used, reconditioned, and demonstration equipment, equipment used in mobile or rental applications, and equipment used in life support applications.

“Rental use” means any use of this product in a temporary or semi-permanently installed rental application. Once equipment has experienced rental