Page 1

Not for

Reproduction

Copyright © Briggs & Stratton Corporation

Milwaukee, WI, USA. All rights reserved.

BRIGGS & STRATTON is a registered

trademark of Briggs & Stratton Corporation.

80006731USCN

Revision: B

Page 2

Not for

Reproduction

1

2

5

6

9

10

11

3

4

7

12

8

2 BRIGGSandSTRATTON.com

Page 3

Not for

Reproduction

13

14

16

15

3

Page 4

Not for

Reproduction

Copyright © Briggs & Stratton Corporation, Milwaukee, WI, USA. All rights reserved.

This manual contains safety information to make you aware of the hazards and risks

associated with engines and how to avoid them. It also contains instructions for the proper

use and care of the engine. Because Briggs & Stratton Corporation does not necessarily

know what equipment this engine will power, it is important that you read and understand

these instructions and the instructions for the equipment. Save these original instructions

for future reference.

Note:

The figures and illustrations in this manual are provided for reference only and may

differ from your specific model. Contact your dealer if you have questions.

For replacement parts or technical assistance, record below the engine model, type, and

code numbers along with the date of purchase. These numbers are located on your engine

(see the

Features and Controls

Date of Purchase

Engine Model - Type - Trim

Engine Serial Number

section).

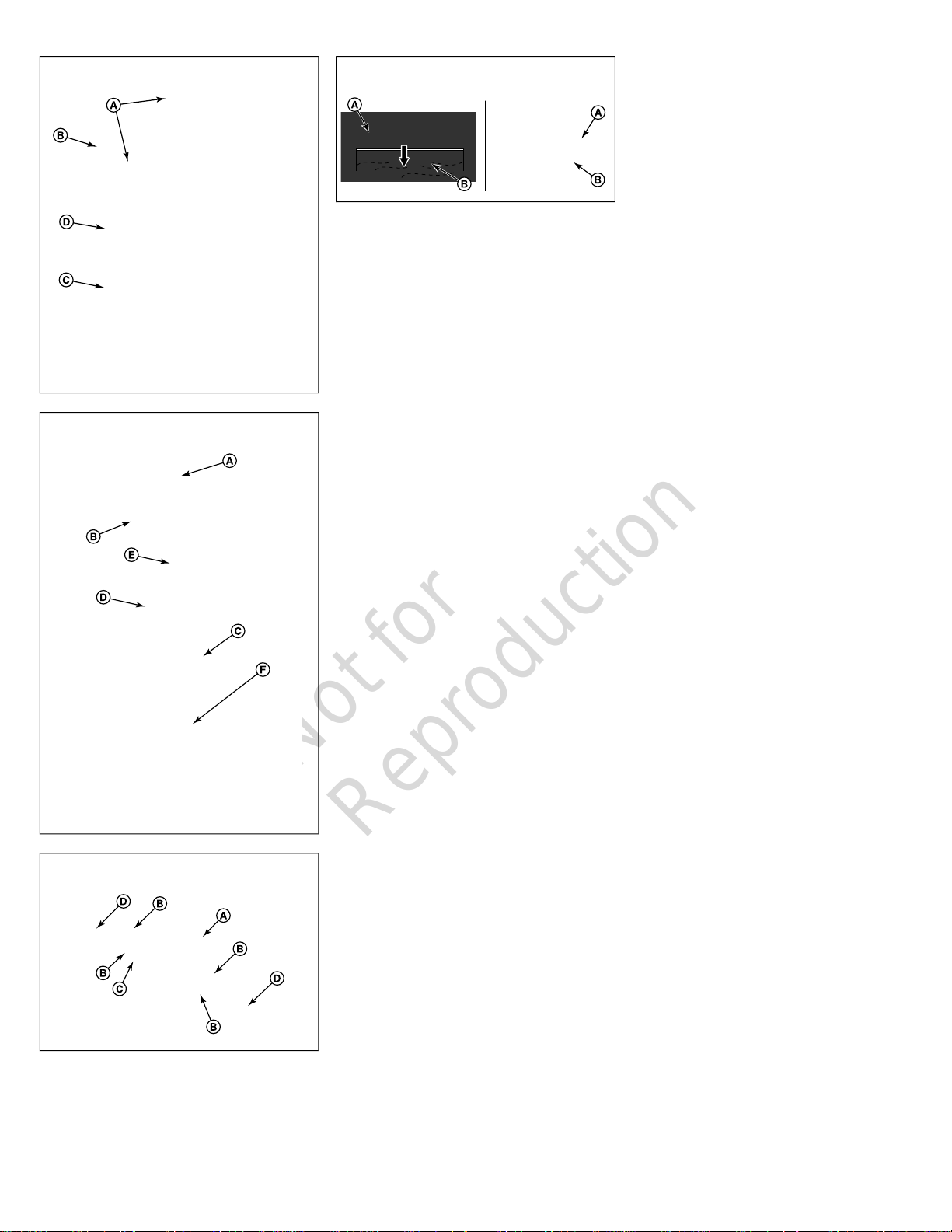

Hot surface hazard

Wear eye protection.

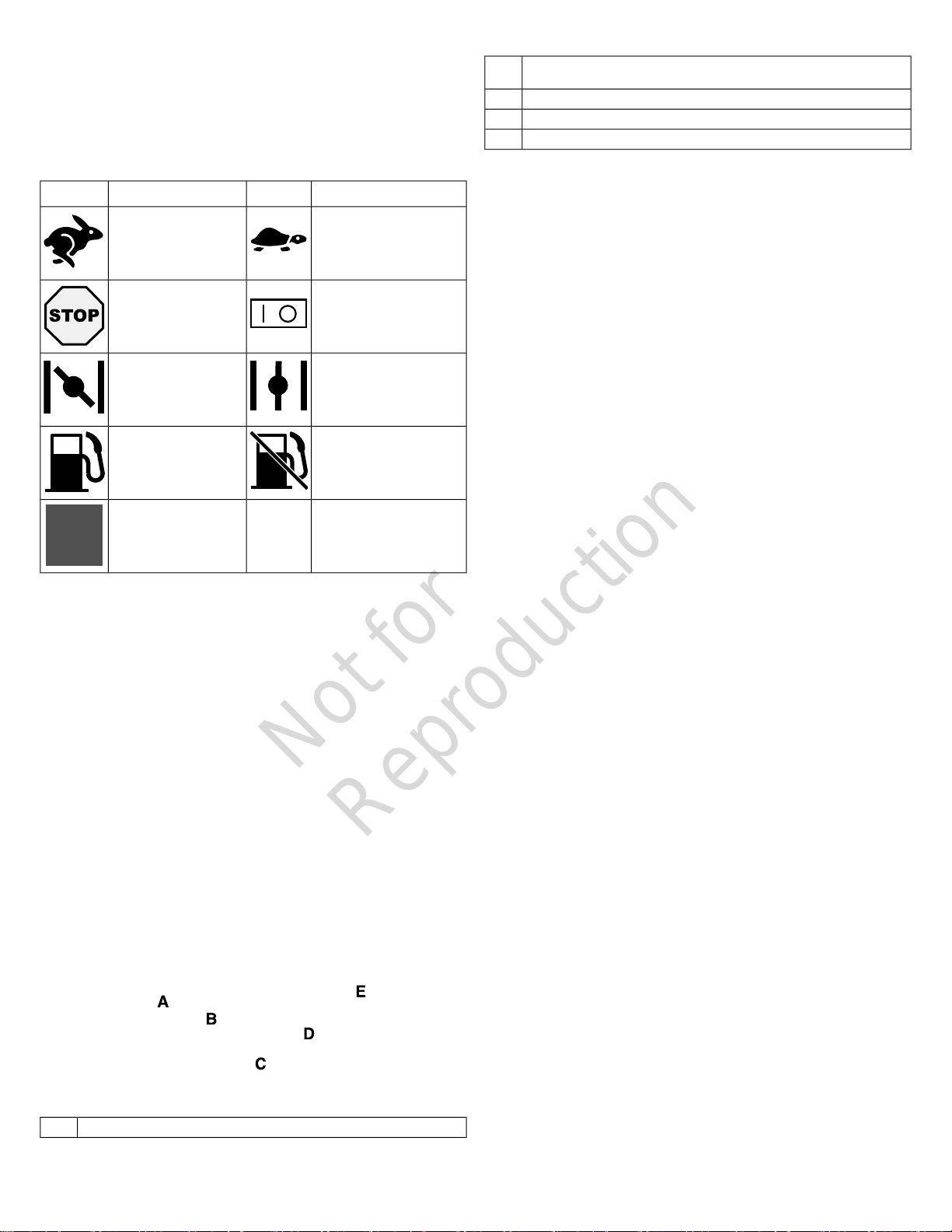

MeaningSymbolMeaningSymbol

Toxic fume hazardShock hazard

Noise hazard - Ear protection

recommended for extended

use.

Explosion hazardThrown object hazard -

Kickback hazardFrostbite hazard

Look for the 2D barcode located on some

engines. When viewed with a 2D-capable

device, the code will bring up our website

where you can access support information

for this product. Data rates apply. Some

countries may not have online support

information available.

Recycling Information

All packaging, used oil, and batteries should be recycled

according to applicable government regulations.

Operator Safety

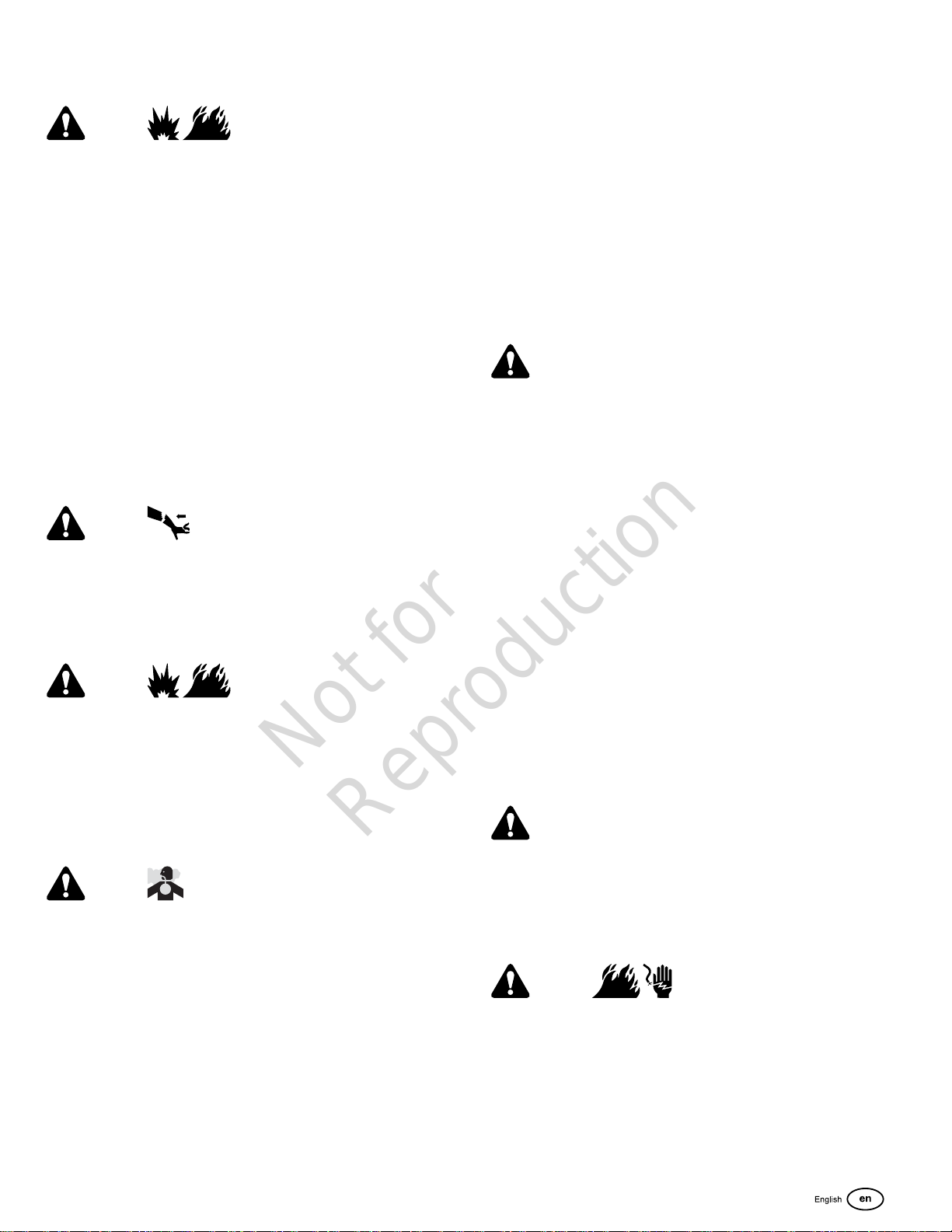

Safety Alert Symbol and Signal Words

The safety alert symbol is used to identify safety information about hazards that can

result in personal injury. A signal word (DANGER, WARNING, or CAUTION) is used with

the alert symbol to indicate the likelihood and the potential severity of injury. In addition, a

hazard symbol may be used to represent the type of hazard.

DANGER indicates a hazard which, if not avoided, will result in death or serious

injury.

parts

Chemical HazardAmputation hazard - moving

CorrosiveThermal heat hazard

Safety Messages

WARNING

Certain components in this product and its related accessories contain chemicals

known to the State of California to cause cancer, birth defects, or other reproductive

harm. Wash hands after handling.

WARNING

The engine exhaust from this product contains chemicals known to the State of

California to cause cancer, birth defects, or other reproductive harm.

WARNING

Briggs & Stratton Engines are not designed for and are not to be used to power: funkarts; go-karts; children's, recreational, or sport all-terrain vehicles (ATVs); motorbikes;

hovercraft; aircraft products; or vehicles used in competitive events not sanctioned by

Briggs & Stratton. For information about competitive racing products, see

www.briggsracing.com. For use with utility and side-by-side ATVs, please contact

Briggs & Stratton Engine Application Center, 1-866-927-3349. Improper engine

application may result in serious injury or death.

WARNING indicates a hazard which, if not avoided, could result in death or serious

injury.

CAUTION indicates a hazard which, if not avoided, could result in minor or

moderate injury.

NOTICE

indicates an situation that could result in damage to the product.

When Adding Fuel

Hazard Symbols and Meanings

MeaningSymbolMeaningSymbol

Safety information about

hazards that can result in

personal injury.

4 BRIGGSandSTRATTON.com

Read and understand the

Operator's Manual before

operating or servicing the unit.

Explosion hazardFire hazard

When Starting Engine

WARNING

Fuel and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

• Turn engine off and let engine cool at least 2 minutes before removing the fuel cap.

• Fill fuel tank outdoors or in well-ventilated area.

• Do not overfill fuel tank. To allow for expansion of the fuel, do not fill above the

bottom of the fuel tank neck.

• Keep fuel away from sparks, open flames, pilot lights, heat, and other ignition

sources.

• Check fuel lines, tank, cap, and fittings frequently for cracks or leaks. Replace if

necessary.

• If fuel spills, wait until it evaporates before starting engine.

Page 5

Not for

Reproduction

• Ensure that spark plug, muffler, fuel cap and air cleaner (if equipped) are in place

and secured.

• Do not crank engine with spark plug removed.

• If engine floods, set choke (if equipped) to OPEN / RUN position, move throttle (if

equipped) to FAST position and crank until engine starts.

When Operating Equipment

• Do not tip engine or equipment at angle which causes fuel to spill.

• Do not choke the carburetor to stop engine.

• Never start or run the engine with the air cleaner assembly (if equipped) or the air

filter (if equipped) removed.

When Changing Oil

• If you drain the oil from the top oil fill tube, the fuel tank must be empty or fuel can

leak out and result in a fire or explosion.

When Tipping Unit for Maintenance

• When performing maintenance that requires the unit to be tipped, the fuel tank, if

mounted on the engine, must be empty or fuel can leak out and result in a fire or

explosion.

When Transporting Equipment

• Transport with fuel tank EMPTY or with fuel shut-off valve in the CLOSED position.

When Storing Fuel Or Equipment With Fuel In Tank

• Store away from furnaces, stoves, water heaters or other appliances that have pilot

lights or other ignition sources because they can ignite fuel vapors.

WARNING

Starting engine creates sparking.

Sparking can ignite nearby flammable gases.

Explosion and fire could result.

• If there is natural or LP gas leakage in area, do not start engine.

• Do not use pressurized starting fluids because vapors are flammable.

WARNING

POISONOUS GAS HAZARD. Engine exhaust contains carbon monoxide, a

poisonous gas that could kill you in minutes. You CANNOT see it, smell it, or

taste it. Even if you do not smell exhaust fumes, you could still be exposed to

carbon monoxide gas. If you start to feel sick, dizzy, or weak while using this

product, get to fresh air RIGHT AWAY. See a doctor. You may have carbon

monoxide poisoning.

• Operate this product ONLY outside far away from windows, doors and vents to

reduce the risk of carbon monoxide gas from accumulating and potentially being

drawn towards occupied spaces.

• Install battery-operated carbon monoxide alarms or plug-in carbon monoxide alarms

with battery back-up according to the manufacturer's instructions. Smoke alarms

cannot detect carbon monoxide gas.

• DO NOT run this product inside homes, garages, basements, crawlspaces, sheds,

or other partially-enclosed spaces even if using fans or opening doors and windows

for ventilation. Carbon monoxide can quickly build up in these spaces and can linger

for hours, even after this product has shut off.

• ALWAYS place this product downwind and point the engine exhaust away from

occupied spaces.

WARNING

Rotating parts can contact or entangle hands, feet, hair, clothing, or accessories.

Traumatic amputation or severe laceration can result.

• Operate equipment with guards in place.

• Keep hands and feet away from rotating parts.

• Tie up long hair and remove jewelry.

• Do not wear loose-fitting clothing, dangling drawstrings or items that could become

caught.

WARNING

Running engines produce heat. Engine parts, especially muffler, become

extremely hot.

Severe thermal burns can occur on contact.

Combustible debris, such as leaves, grass, brush, etc. can catch fire.

• Allow muffler, engine cylinder and fins to cool before touching.

• Remove accumulated debris from muffler area and cylinder area.

• It is a violation of California Public Resource Code, Section 4442, to use or operate

the engine on any forest-covered, brush-covered, or grass-covered land unless the

exhaust system is equipped with a spark arrester, as defined in Section 4442,

maintained in effective working order. Other states or federal jurisdictions may have

similar laws. Contact the original equipment manufacturer, retailer, or dealer to

obtain a spark arrester designed for the exhaust system installed on this engine.

WARNING

Unintentional sparking can result in fire or electric shock.

Unintentional start-up can result in entanglement, traumatic amputation, or

laceration.

Fire hazard

Before performing adjustments or repairs:

• Disconnect the spark plug wire and keep it away from the spark plug.

• Disconnect battery at negative terminal (only engines with electric start.)

• Use only correct tools.

• Do not tamper with governor spring, links or other parts to increase engine speed.

• Replacement parts must be of the same design and installed in the same position

as the original parts. Other parts may not perform as well, may damage the unit,

and may result in injury.

• Do not strike the flywheel with a hammer or hard object because the flywheel may

later shatter during operation.

When testing for spark:

• Use approved spark plug tester.

• Do not check for spark with spark plug removed.

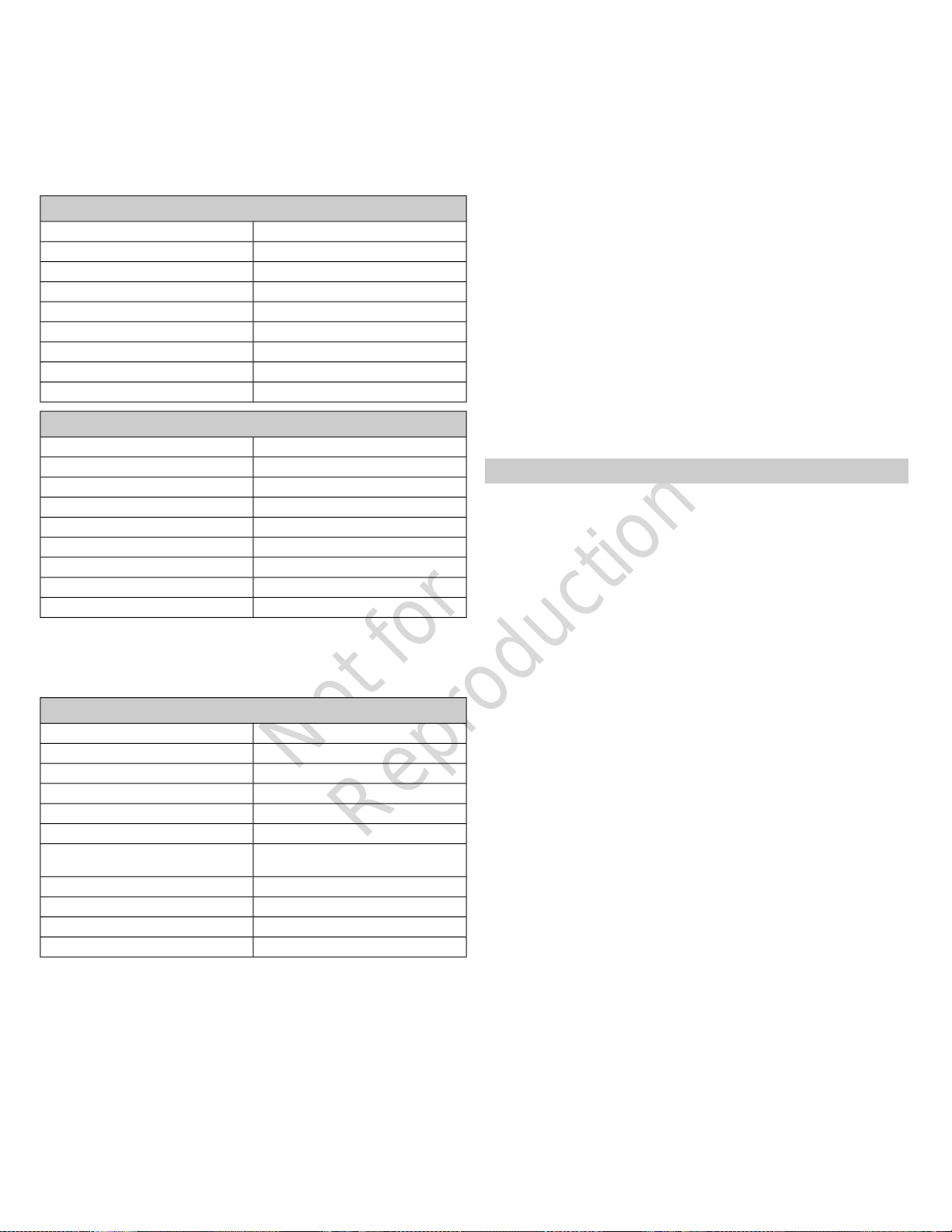

Features and Controls

Engine Controls

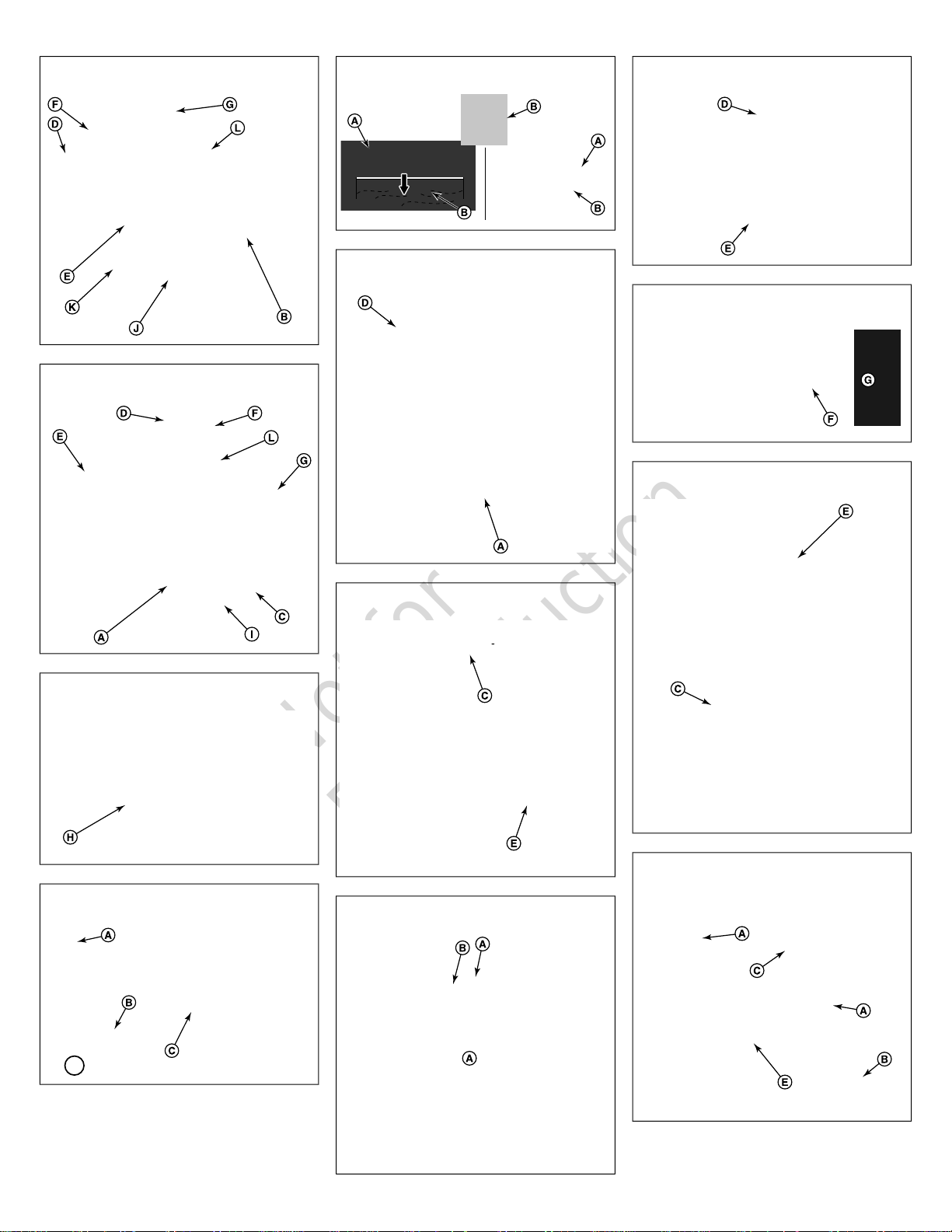

Compare the illustration (Figure: 1, 2, 3) with your engine to familiarize yourself with the

location of various features and controls.

WARNING

Rapid retraction of starter cord (kickback) will pull hand and arm toward engine

faster than you can let go.

Broken bones, fractures, bruises or sprains could result.

• When starting engine, pull the starter cord slowly until resistance is felt and then

pull rapidly to avoid kickback.

• Remove all external equipment / engine loads before starting engine.

• Direct-coupled equipment components such as, but not limited to, blades, impellers,

pulleys, sprockets, etc., must be securely attached.

A. Engine Identification Numbers Model - Type - Code

B. Spark Plug

C. Electric Starter

D. Fuel Tank and Cap

E. Air Cleaner

F. Starter Cord Handle

G. Dipstick

H. Oil Drain Plug

5

Page 6

Not for

Reproduction

I. Muffler, Muffler Guard (if equipped), Spark Arrester (if equipped)

J. Throttle Control (if equipped)

K. Fuel Filter (if equipped)

L. Air Intake Grille

Engine Control Symbols and Meanings

MeaningSymbolMeaningSymbol

Engine speed - SLOWEngine speed - FAST

ON - OFFEngine speed - STOP

Engine start - Choke OPENEngine start - Choke

CLOSED

10W-30 - Above 80 °F (27 °C) the use of 10W-30 may cause increased oil

B

consumption. Check oil level more frequently.

5W-30C

Synthetic 5W-30D

Vanguard™ Synthetic 15W-50E

Check and Add Oil

See Figure: 4

Before checking or adding oil

• Make sure the engine is level.

• Clean the oil fill area of any debris.

• See the

NOTICE

This engine was shipped from Briggs & Stratton without oil. Equipment manufacturers

or dealers may have added oil to the engine. Before you start the engine for the first

time, make sure to check the oil level and add oil according to the instructions in this

manual. If you start the engine without oil, it will be damaged beyond repair and will not

be covered under warranty.

Specifications

section for oil capacity.

Fuel Shut-off - OPEN

Fuel level - Maximum

Do not overfill

Fuel Shut-off - CLOSEDFuel Cap

Operation

Oil Recommendations

Oil Capacity: See the

NOTICE

This engine was shipped from Briggs & Stratton without oil. Equipment manufacturers

or dealers may have added oil to the engine. Before you start the engine for the first

time, make sure to check the oil level and add oil according to the instructions in this

manual. If you start the engine without oil, it will be damaged beyond repair and will not

be covered under warranty.

We recommend the use of Briggs & Stratton Warranty Certified oils for best performance.

Other high-quality detergent oils are acceptable if classified for service SF, SG, SH, SJ or

higher. Do not use special additives.

Outdoor temperatures determine the proper oil viscosity for the engine. Use the chart to

select the best viscosity for the outdoor temperature range expected. Engines on most

outdoor power equipment operate well with 5W-30 Synthetic oil. For equipment operated

in hot temperatures, Vanguard™ 15W-50 Synthetic oil provides the best protection.

Specifications

section.

Check Oil Level

1. Remove the dipstick (A, Figure 4) and wipe with a clean cloth.

2. Install and tighten the dipstick (A, Figure 4).

3. Remove the dipstick and check the oil level. Correct oil level is at the top of the full

indicator (B, Figure 4) on the dipstick.

Add Oil

1. If the oil level is low, slowly add oil into the engine oil fill (C, Figure 4). Do not overfill.

After adding oil, wait one minute and then check the oil level.

2. Reinstall and tighten the dipstick (A, Figure 4).

Low Oil Protection System (if equipped)

Some engines are equipped with a low oil sensor. If the oil is low, the sensor will either

activate a warning light or stop the engine. Stop the engine and follow these steps before

restarting the engine.

• Make sure the engine is level.

• Check the oil level. See the

• If the oil level is low, add the proper amount of oil. Start the engine and make sure

the warning light (if equipped) is not activated.

• If the oil level is not low, do not start the engine. Contact a Briggs & Stratton

Authorized Service Dealer to have the oil problem corrected.

Check Oil Level

section.

Fuel Recommendations

Fuel must meet these requirements:

• Clean, fresh, unleaded gasoline.

• A minimum of 87 octane/87 AKI (91 RON). High altitude use, see below.

• Gasoline with up to 10% ethanol (gasohol) is acceptable.

NOTICE

gasoline or modify the engine to run on alternate fuels. Use of unapproved fuels will

damage the engine components, which will not be covered under warranty.

To protect the fuel system from gum formation, mix a fuel stabilizer into the fuel. See

Storage.

providers or change brands. This engine is certified to operate on gasoline. The emissions

control system for this engine is EM (Engine Modifications).

Do not use unapproved gasolines, such as E15 and E85. Do not mix oil in

All fuel is not the same. If starting or performance problems occur, change fuel

High Altitude

At altitudes over 5,000 feet (1524 meters), a minimum 85 octane/85 AKI (89 RON) gasoline

is acceptable.

For carbureted engines, high altitude adjustment is required to maintain performance.

Operation without this adjustment will cause decreased performance, increased fuel

consumption, and increased emissions. Contact a Briggs & Stratton Authorized Service

Dealer for high altitude adjustment information. Operation of the engine at altitudes below

SAE 30 - Below 40 °F (4 °C) the use of SAE 30 will result in hard starting.A

6 BRIGGSandSTRATTON.com

2,500 feet (762 meters) with the high altitude adjustment is not recommended.

For Electronic Fuel Injection (EFI) engines, no high altitude adjustment is necessary.

Page 7

Not for

Reproduction

Add Fuel

See Figure: 5

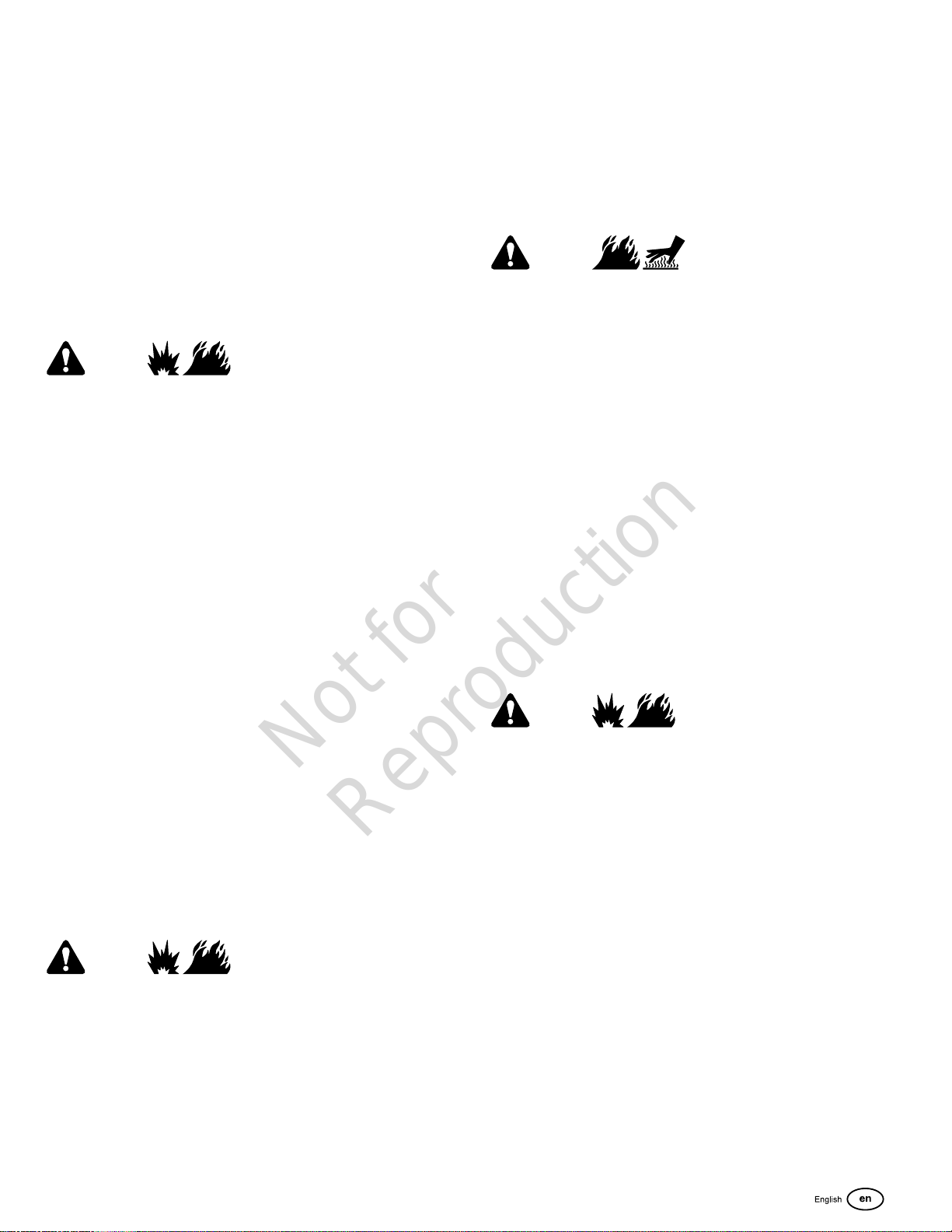

WARNING

Fuel and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

When adding fuel

• Turn engine off and let engine cool at least 2 minutes before removing the fuel cap.

• Fill fuel tank outdoors or in well-ventilated area.

• Do not overfill fuel tank. To allow for expansion of the fuel, do not fill above the bottom

of the fuel tank neck.

• Keep fuel away from sparks, open flames, pilot lights, heat, and other ignition sources.

• Check fuel lines, tank, cap, and fittings frequently for cracks or leaks. Replace if

necessary.

• If fuel spills, wait until it evaporates before starting engine.

• ALWAYS place this product downwind and point the engine exhaust away from

occupied spaces.

NOTICE

the engine, make sure you add oil according to the instructions in this manual. If you

start the engine without oil, it will be damaged beyond repair and will not be covered

under warranty.

Note:

operation of remote controls.

1. Check the engine oil. See the

2. Make sure equipment drive controls, if equipped, are disengaged.

3. Move the throttle control (A, Figure 6), if equipped, to the FAST position. Operate

4. If the product is equipped with an engine stop lever (C, Figure 7), hold the engine

5. Rewind Start, if equipped: Firmly hold the starter cord handle (D, Figure 6). Pull

This engine was shipped from Briggs & Stratton without oil. Before you start

Equipment may have remote controls. See the equipment manual for location and

Check Oil Level

the engine in the FAST position.

stop lever against the handle.

the starter cord handle slowly until resistance is felt, then pull rapidly.

section.

1. Clean the fuel cap area of dirt and debris. Remove the fuel cap.

2. Fill the fuel tank (A, Figure 5) with fuel. To allow for expansion of the fuel, do not fill

above the bottom of the fuel tank neck (B).

3. Reinstall the fuel cap.

Start and Stop Engine

See Figure: 6, 7

Start Engine

WARNING

Rapid retraction of starter cord (kickback) will pull hand and arm toward engine

faster than you can let go.

Broken bones, fractures, bruises or sprains could result.

• When starting engine, pull the starter cord slowly until resistance is felt and then pull

rapidly to avoid kickback.

WARNING

Fuel and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

When Starting Engine

• Ensure that spark plug, muffler, fuel cap and air cleaner (if equipped) are in place

and secured.

• Do not crank engine with spark plug removed.

• If engine floods, set choke (if equipped) to OPEN / RUN position, move throttle (if

equipped) to FAST position and crank until engine starts.

WARNING

POISONOUS GAS HAZARD. Engine exhaust contains carbon monoxide, a

poisonous gas that could kill you in minutes. You CANNOT see it, smell it, or taste

it. Even if you do not smell exhaust fumes, you could still be exposed to carbon

monoxide gas. If you start to feel sick, dizzy, or weak while using this product,

shut it off and get to fresh air RIGHT AWAY. See a doctor. You may have carbon

monoxide poisoning.

• Operate this product ONLY outside far away from windows, doors and vents to reduce

the risk of carbon monoxide gas from accumulating and potentially being drawn

towards occupied spaces.

• Install battery-operated carbon monoxide alarms or plug-in carbon monoxide alarms

with battery back-up according to the manufacturer's instructions. Smoke alarms

cannot detect carbon monoxide gas.

• DO NOT run this product inside homes, garages, basements, crawlspaces, sheds,

or other partially-enclosed spaces even if using fans or opening doors and windows

for ventilation. Carbon monoxide can quickly build up in these spaces and can linger

for hours, even after this product has shut off.

WARNING

Rapid retraction of the starter cord (kickback) will pull your hand and arm toward the

engine faster than you can let go. Broken bones, fractures, bruises or sprains could

result. When starting engine, pull the starter cord slowly until resistance is felt and then

pull rapidly to avoid kickback.

6. Electric Start, if equipped: Turn the electric start switch to the ON or START position.

NOTICE

maximum). Wait one minute between starting cycles.

Note:

to BRIGGSandSTRATTON.com or call 1-800-233-3723 (in USA).

To extend the life of the starter, use short starting cycles (five seconds

If the engine does not start after repeated attempts, contact you local dealer or go

Stop Engine

Engine Stop Lever, if equipped: Release the engine stop lever (E, Figure 7).

Throttle Control, if equipped: Move the throttle control (A, Figure 6) to the STOP position.

Electric Start, if equipped: Turn the electric start switch to the OFF or STOP position.

See the equipment manual for the location and operation of the switch. Remove the key

and keep in a safe place out of the reach of children.

Maintenance

NOTICE

engine, must be empty and the spark plug side must be up. If the fuel tank is not empty

and if the engine is tipped in any other direction, it may be difficult to start due to oil or

gasoline contaminating the air filter and/or the spark plug.

When performing maintenance that requires the unit to be tipped, the fuel tank, if mounted

on the engine, must be empty or fuel can leak out and result in a fire or explosion.

We recommend that you see any Briggs & Stratton Authorized Service Dealer for all

maintenance and service of the engine and engine parts.

NOTICE

operation.

Unintentional sparking can result in fire or electric shock.

Unintentional start-up can result in entanglement, traumatic amputation, or

laceration.

Fire hazard

Before performing adjustments or repairs:

• Disconnect the spark plug wire and keep it away from the spark plug.

• Disconnect battery at negative terminal (only engines with electric start.)

• Use only correct tools.

If the engine is tipped during maintenance, the fuel tank, if mounted on

WARNING

All the components used to build this engine must remain in place for proper

WARNING

7

Page 8

Not for

Reproduction

• Do not tamper with governor spring, links or other parts to increase engine speed.

• Replacement parts must be of the same design and installed in the same position

as the original parts. Other parts may not perform as well, may damage the unit, and

may result in injury.

• Do not strike the flywheel with a hammer or hard object because the flywheel may

later shatter during operation.

When testing for spark:

• Use approved spark plug tester.

• Do not check for spark with spark plug removed.

Emissions Control Service

Maintenance, replacement, or repair of the emissions control devices and systems

may be performed by any off-road engine repair establishment or individual. However,

to obtain "no charge" emissions control service, the work must be performed by a factory

authorized dealer. See the Emissions Control Statements.

Maintenance Schedule

First 5 Hours

• Change oil

Every 8 Hours or Daily

• Check engine oil level

• Clean area around muffler and controls

• Clean air intake grille

Every 25 Hours or Annually

• Service air filter

Every 50 Hours or Annually

• Change engine oil

• Service exhaust system

Annually

• Replace spark plug

• Replace air filter

• Replace pre-cleaner (if equipped)

• Replace fuel filter (if equipped)

• Service fuel system

• Service cooling system

• Check valve clearance

1

In dusty conditions or when airborne debris is present, clean more often.

2

Not required unless engine performance problems are noted.

1

1

2

Carburetor and Engine Speed

Never make adjustments to the carburetor or engine speed. The carburetor was set at the

factory to operate efficiently under most conditions. Do not tamper with the governor spring,

linkages, or other parts to change the engine speed. If any adjustments are required contact

a Briggs & Stratton Authorized Service Dealer for service.

NOTICE

as installed on the equipment. Do not exceed this speed. If you are unsure what the

equipment maximum speed is, or what the engine speed is set to from the factory,

contact a Briggs & Stratton Authorized Service Dealer for assistance. For safe and

proper operation of the equipment, the engine speed should be adjusted only by a

qualified service technician.

The equipment manufacturer specifies the maximum speed for the engine

Service Exhaust System

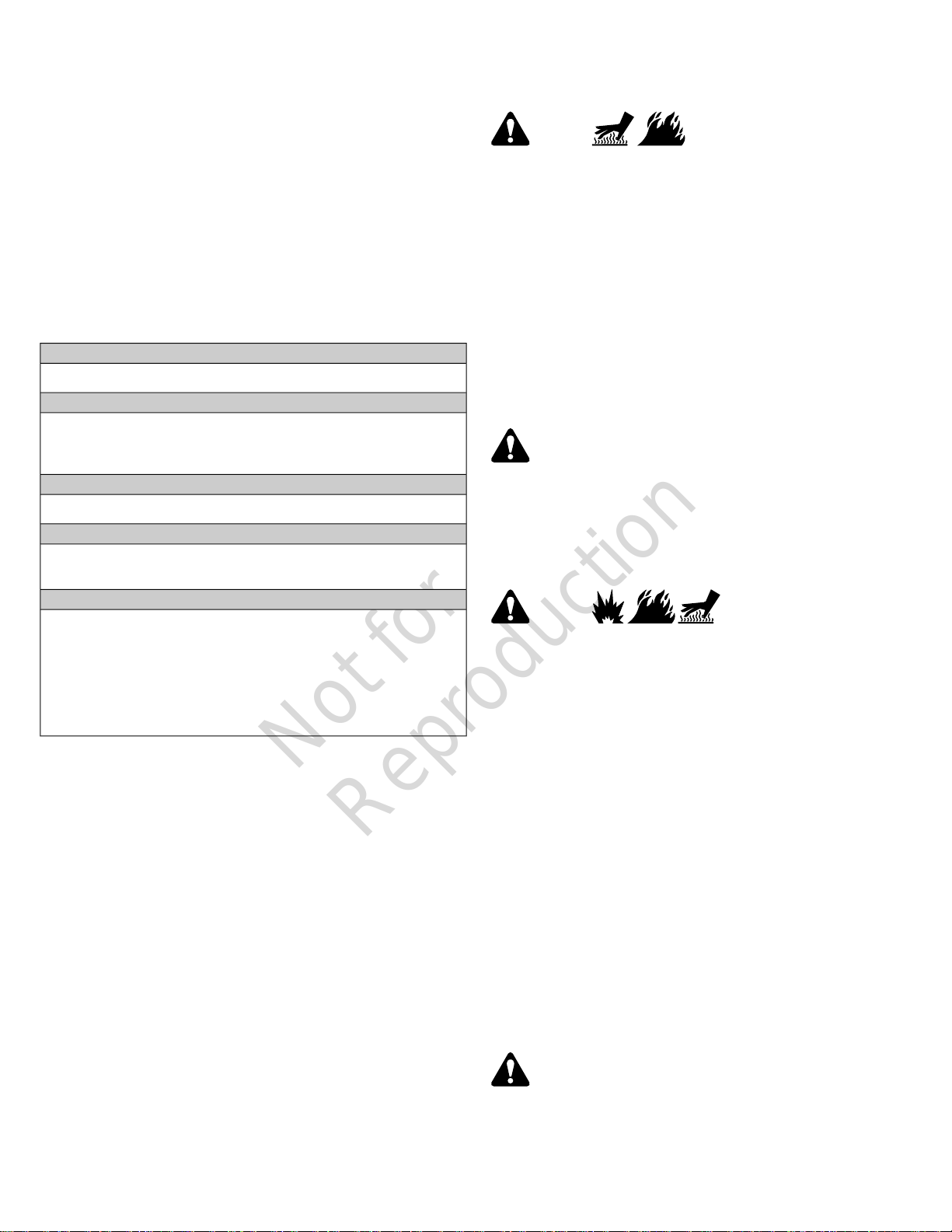

WARNING

Running engines produce heat. Engine parts, especially muffler, become extremely

hot.

Severe thermal burns can occur on contact.

Combustible debris, such as leaves, grass, brush, etc. can catch fire.

• Allow muffler, engine cylinder and fins to cool before touching.

• Remove accumulated debris from muffler area and cylinder area.

• It is a violation of California Public Resource Code, Section 4442, to use or operate

the engine on any forest-covered, brush-covered, or grass-covered land unless the

exhaust system is equipped with a spark arrester, as defined in Section 4442,

maintained in effective working order. Other states or federal jurisdictions may have

similar laws. Contact the original equipment manufacturer, retailer, or dealer to obtain

a spark arrester designed for the exhaust system installed on this engine.

Remove accumulated debris from muffler and cylinder area. Inspect the muffler for cracks,

corrosion, or other damage. Remove the deflector or the spark arrester, if equipped, and

inspect for damage or carbon blockage. If damage is found, install replacement parts before

operating.

WARNING

Replacement parts must be of the same design and installed in the same position as

the original parts. Other parts may not perform as well, may damage the unit, and may

result in injury.

Change Engine Oil

See Figure: 9, 10, 11, 12

WARNING

Fuel and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

Running engines produce heat. Engine parts, especially muffler, become extremely

hot.

Severe thermal burns can occur on contact.

• When you drain the oil from the top oil fill tube, the fuel tank must be empty or fuel

can leak out and result in a fire or explosion.

• Allow muffler, engine cylinder and fins to cool before touching.

Used oil is a hazardous waste product and must be disposed of properly. Do not discard

with household waste. Check with your local authorities, service center, or dealer for safe

disposal/recycling facilities.

Remove Oil

You can drain the oil from the bottom drain hole or from the top oil fill tube.

1. With engine off but still warm, disconnect the spark plug wire (D, Figure 9) and keep

it away from the spark plug (E).

2. Remove the oil drain plug (F, Figure 10). Drain the oil into an approved container.

Note:

Any of the oil drain plugs (G, Figure 10) may be installed in the engine.

3. After the oil has drained, install and tighten the oil drain plug (F, Figure 10).

Service Spark Plug

See Figure: 8

Check the gap (A, Figure 8) with a wire gauge (B). If necessary, reset the gap. Install and

tighten the spark plug to the recommended torque. For gap setting or torque, see the

Specifications

Note:

In some areas, local law requires using a resistor spark plug to suppress ignition

signals. If this engine was originally equipped with a resistor spark plug, use the same type

for replacement.

section.

4. When you drain the oil from the top oil fill tube (C, Figure 11), keep the spark plug

(E) end of the engine up. Drain the oil into an approved container.

WARNING

When you drain the oil from the top oil fill tube, the fuel tank must be empty or fuel can

leak out and result in a fire or explosion. To empty the fuel tank, run the engine until it

stops from lack of fuel.

8 BRIGGSandSTRATTON.com

Page 9

Not for

Reproduction

Add Oil

• Make sure the engine is level.

• Clean the oil fill area of any debris.

• See the

1. Remove the dipstick (A, Figure 12) and wipe with a clean cloth.

2. Slowly pour oil slowly into the engine oil fill (C, Figure 12). Do not overfill. After

3. Install and tighten the dipstick (A, Figure 12).

4. Remove the dipstick and check the oil level. Correct oil level is at the top of the full

5. Reinstall and tighten the dipstick (A, Figure 12).

6. Connect the spark plug wire (D, Figure 9) to the spark plug (E).

Specifications

adding oil, wait one minute and then check the oil level.

indicator (B, Figure 12) on the dipstick.

section for oil capacity.

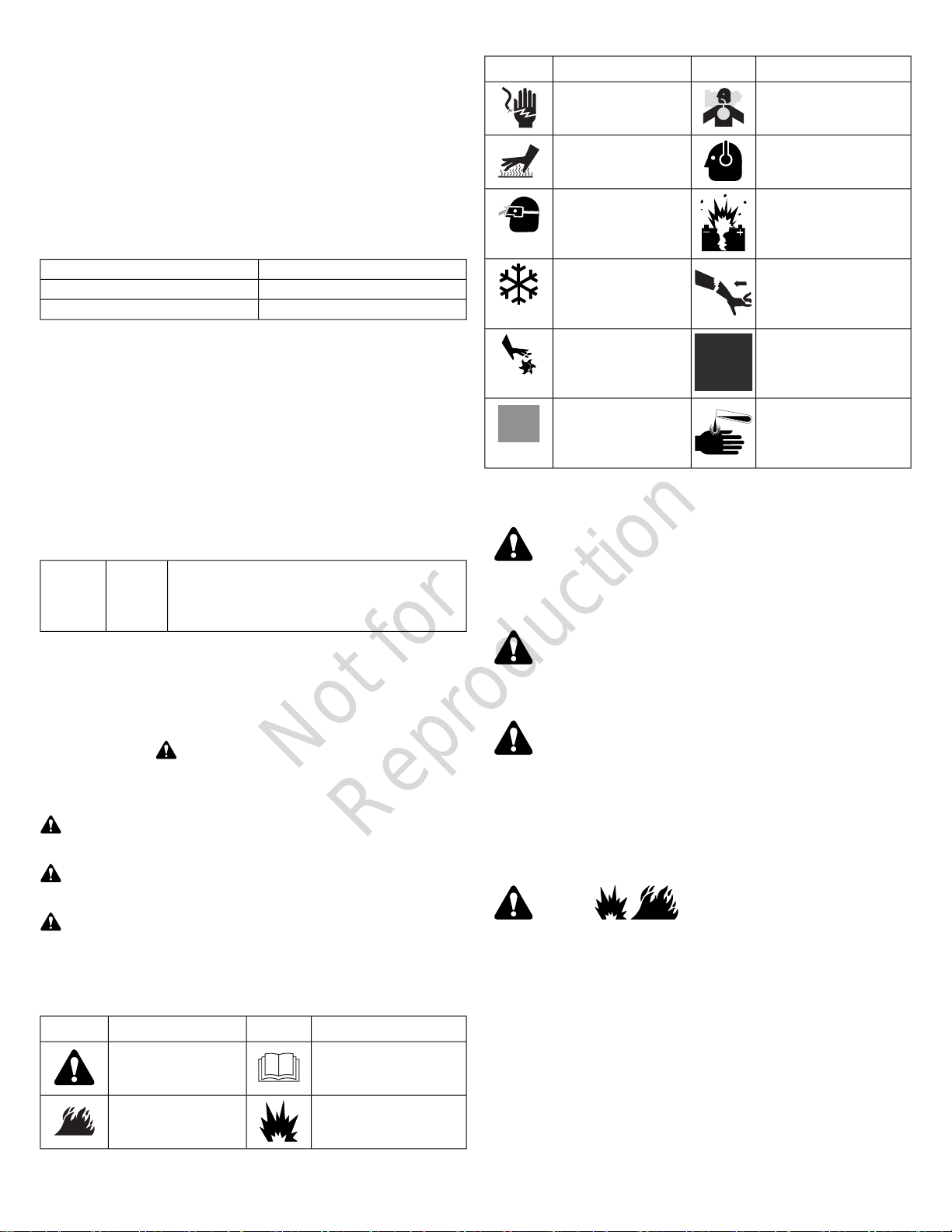

Service Air Filter

See Figure: 13, 14

Fuel Filter, if equipped

1. Before cleaning or replacing the fuel filter (A, Figure 15), drain the fuel tank or close

the fuel shut-off valve. Otherwise, fuel can leak out and cause a fire or explosion.

2. Use pliers to squeeze tabs (B, Figure 15) on the clamps (C), then slide the clamps

away from the fuel filter (A). Twist and pull the fuel lines (D) off of the fuel filter.

3. Check the fuel lines (D, Figure 15) for cracks or leaks. Replace if necessary.

4. Replace the fuel filter (A, Figure 15) with an original equipment replacement filter.

5. Secure the fuel lines (D, Figure 15) with clamps (C) as shown.

Service Cooling System

WARNING

Running engines produce heat. Engine parts, especially muffler, become extremely

hot.

Severe thermal burns can occur on contact.

Combustible debris, such as leaves, grass, brush, etc., can catch fire.

WARNING

Fuel and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

• Never start and run the engine with the air cleaner assembly (if equipped) or the air

filter (if equipped) removed.

NOTICE

damage the filter and solvents will dissolve the filter.

See the

Various models use either a foam or a paper filter. Some models may also have an optional

pre-cleaner that can be washed and reused. Compare the illustrations in this manual with

the type installed on your engine and service as follows.

1. Loosen the fastener(s) (A, Figure 13, 14).

2. Remove the cover (B, Figure 13, 14).

3. Remove the fastener(s) (E, Figure 14), if equipped.

4. To prevent debris from falling into the carburetor, carefully remove the pre-cleaner

5. To loosen debris, gently tap the filter (C, Figure 13, 14) on a hard surface. If the filter

6. Remove the pre-cleaner (D, Figure 13, 14) from the filter (C).

7. Wash the pre-cleaner (D, Figure 13, 14) in liquid detergent and water. Allow the pre-

8. Assemble the dry pre-cleaner (D, Figure 13, 14) to the filter (C).

9. Install the filter (C, Figure 13, 14) and the pre-cleaner (D). Make sure the filter fits

10. Make sure the gasket (F, Figure 14), if equipped, is in correct position under the filter

11. Install the cover (B, Figure 13, 14) and secure with the fastener(s) (A). Make sure

Do not use pressurized air or solvents to clean the filter. Pressurized air can

Maintenance Schedule

(D, Figure 13, 14) and the filter (C) from the air filter base.

is excessively dirty, replace with a new filter.

cleaner to throughly air dry. Do not oil the pre-cleaner.

securely on the air filter base.

(C). Secure filter (C) with fastener(s) (E), if equipped.

the fastener(s) is tight.

for service requirements.

Service Fuel System

See Figure: 15

WARNING

Fuel and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

• Keep fuel away from sparks, open flames, pilot lights, heat, and other ignition sources.

• Check fuel lines, tank, cap, and fittings frequently for cracks or leaks. Replace if

necessary.

• Before cleaning or replacing the fuel filter, drain the fuel tank or close the fuel shutoff valve.

• If fuel spills, wait until it evaporates before starting engine.

• Replacement parts must be the same and installed in the same position as the original

parts.

• Allow muffler, engine cylinder and fins to cool before touching.

• Remove accumulated debris from muffler area and cylinder area.

NOTICE

system. Use a brush or dry cloth to clean the engine.

This is an air cooled engine. Dirt or debris can restrict air flow and cause the engine to

overheat, resulting in poor performance and reduced engine life.

1. Use a brush or dry cloth to remove debris from the air intake grille.

2. Keep linkage, springs and controls clean.

3. Keep the area around and behind the muffler, if equipped, free of any combustible

4. Make sure the oil cooler fins, if equipped, are free of dirt and debris.

After a period of time, debris can accumulate in the cylinder cooling fins and cause the

engine to overheat. This debris cannot be removed without partial disassembly of the

engine. Have a Briggs & Stratton Authorized Service Dealer inspect and clean the air

cooling system as recommended in the

Do not use water to clean the engine. Water could contaminate the fuel

debris.

Maintenance Schedule.

Storage

WARNING

Fuel and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

When Storing Fuel Or Equipment With Fuel In Tank

• Store away from furnaces, stoves, water heaters or other appliances that have pilot

lights or other ignition sources because they can ignite fuel vapors.

Fuel System

See Figure: 16

Store the engine level (normal operating position). Fill fuel tank (A, Figure 16) with fuel.

To allow for expansion of fuel, do not overfill above the fuel tank neck (B).

Fuel can become stale when stored over 30 days. Stale fuel causes acid and gum deposits

to form in the fuel system or on essential carburetor parts. To keep fuel fresh, use Briggs

& Stratton Advanced Formula Fuel Treatment & Stabilizer, available wherever Briggs

& Stratton genuine service parts are sold.

There is no need to drain gasoline from the engine if a fuel stabilizer is added according

to instructions. Run the engine for two (2) minutes to circulate the stabilizer throughout the

fuel system before storage.

If gasoline in the engine has not been treated with a fuel stabilizer, it must be drained into

an approved container. Run the engine until it stops from lack of fuel. The use of a fuel

stabilizer in the storage container is recommended to maintain freshness.

Engine Oil

While the engine is still warm, change the engine oil. See the

Change Engine Oil

section.

9

Page 10

Not for

Reproduction

Troubleshooting

For assistance, contact your local dealer or go to BRIGGSandSTRATTON.com or call

1-800-233-3723 (in USA).

pump, etc.), application limitations, ambient operating conditions (temperature, humidity,

altitude), and engine-to-engine variability. Due to manufacturing and capacity limitations,

Briggs & Stratton may substitute an engine of higher rated power for this engine.

Warranty

Specifications

Model: 90000

8.53 ci (140 cc)Displacement

2.349 in (59,67 mm)Bore

1.968 in (49,99 mm)Stroke

18 - 20 oz (,54 - ,59 L)Oil Capacity

.020 in (,51 mm)Spark Plug Gap

180 lb-in (20 Nm)Spark Plug Torque

.006 - .014 in (,15 - ,36 mm)Armature Air Gap

.004 - .006 in (,10 - ,15 mm)Intake Valve Clearance

.014 - .016 in (,36 - ,41 mm)Exhaust Valve Clearance

Model: 100000

9.82 ci (161 cc)Displacement

2.520 in (64,01 mm)Bore

1.968 in (49,99 mm)Stroke

18 - 20 oz (,54 - ,59 L)Oil Capacity

.020 in (,51 mm)Spark Plug Gap

180 lb-in (20 Nm)Spark Plug Torque

.006 - .014 in (,15 - ,36 mm)Armature Air Gap

.004 - .006 in (,10 - ,15 mm)Intake Valve Clearance

.014 - .016 in (,36 - ,41 mm)Exhaust Valve Clearance

Engine power will decrease 3.5% for each 1,000 feet (300 meters) above sea level and

1% for each 10° F (5.6° C) above 77° F (25° C). The engine will operate satisfactorily at

an angle up to 15°. Refer to the equipment operator's manual for safe allowable operating

limits on slopes.

Service Parts - Model: 90000, 100000

Part NumberService Part

792038Plastic Air Filter

793676Plastic Air Filter Pre-cleaner

590601Metal Air Filter and Pre-cleaner

590602Metal Air Filter Pre-cleaner

100005Oil - SAE 30

Stabilizer

We recommend that you see any Briggs & Stratton Authorized Dealer for all maintenance

and service of the engine and engine parts.

Power Ratings: The gross power rating for individual gasoline engine models is labeled

in accordance with SAE (Society of Automotive Engineers) code J1940 Small Engine

Power & Torque Rating Procedure, and is rated in accordance with SAE J1995. Torque

values are derived at 2600 RPM for those engines with “rpm” called out on the label and

3060 RPM for all others; horsepower values are derived at 3600 RPM. The gross power

curves can be viewed at www.BRIGGSandSTRATTON.COM. Net power values are taken

with exhaust and air cleaner installed whereas gross power values are collected without

these attachments. Actual gross engine power will be higher than net engine power and

is affected by, among other things, ambient operating conditions and engine-to-engine

variability. Given the wide array of products on which engines are placed, the gasoline

engine may not develop the rated gross power when used in a given piece of power

equipment. This difference is due to a variety of factors including, but not limited to, the

variety of engine components (air cleaner, exhaust, charging, cooling, carburetor, fuel

100117, 100120Advanced Formula Fuel Treatment &

298090, 5018Fuel Filter

692051, 692720Resistor Spark Plug

89838, 5023Spark Plug Wrench

19368Spark Tester

Briggs & Stratton Engine Warranty

Effective January 2017

Limited Warranty

Briggs & Stratton warrants that, during the warranty period specified below, it will repair or

replace, free of charge, any part that is defective in material or workmanship or both.

Transportation charges on product submitted for repair or replacement under this warranty

must be borne by purchaser. This warranty is effective for and is subject to the time periods

and conditions stated below. For warranty service, find the nearest Authorized Service

Dealer in our dealer locator map at BRIGGSandSTRATTON.COM. The purchaser must

contact the Authorized Service Dealer, and then make the product available to the

Authorized Service Dealer for inspection and testing.

There is no other express warranty. Implied warranties, including those of

merchantability and fitness for a particular purpose, are limited to the warranty

period listed below, or to the extent permitted by law. Liability for incidental or

consequential damages are excluded to the extent exclusion is permitted by law. Some

states or countries do not allow limitations on how long an implied warranty lasts, and

some states or countries do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitation and exclusion may not apply to you. This

warranty gives you specific legal rights and you may also have other rights which vary

from state to state and country to country4.

Standard Warranty Terms

Brand / Product Name

1

These are our standard warranty terms, but occasionally there may be additional

warranty coverage that was not determined at time of publication. For a listing of

current warranty terms for your engine, go to BRIGGSandSTRATTON.com or contact

your Briggs & Stratton Authorized Service Dealer.

2

There is no warranty for engines on equipment used for prime power in place of a

utility or for standby generators used for commercial purposes. Engines used in

competitive racing or on commercial or rental tracks are not warrantied.

3

Vanguard installed on standby generators: 24 months consumer use, no warranty

commercial use. Vanguard installed on utility vehicles: 24 months consumer use, 24

months commercial use. Commercial Series with manufacturing date before July

2017, 24 months consumer use, 24 months commercial use.

4

In Australia - Our goods come with guarantees that cannot be excluded under the

Australian Consumer Law. You are entitled to a replacement or refund for a major

failure and for compensation for any other reasonably foreseeable loss or damage.

You are also entitled to have the goods repaired or replaced if the goods fail to be

of acceptable quality and the failure does not amount to a major failure. For warranty

service, find the nearest Authorized Service Dealer in our dealer locator map at

BRIGGSandSTRATTON.COM, or by calling 1300 274 447, or by emailing or writing

to salesenquiries@briggsandstratton.com.au, Briggs & Stratton Australia Pty Ltd, 1

Moorebank Avenue, Moorebank, NSW , Australia, 2170.

The warranty period begins on the original date of purchase by the first retail or commercial

consumer. "Consumer use" means personal residential household use by a retail consumer.

"Commercial use" means all other uses, including use for commercial, income producing

or rental purposes. Once an engine has experienced commercial use, it shall thereafter

be considered as a commercial use engine for purposes of this warranty.

Save your proof of purchase receipt. If you do not provide proof of the initial purchase

date at the time warranty service is requested, the manufacturing date of the product

will be used to determine the warranty period. Product registration is not required

to obtain warranty service on Briggs & Stratton products.

About Your Warranty

This limited warranty covers engine-related material and/or workmanship issues only, and

not replacement or refund of the equipment to which the engine may be mounted. Routine

maintenance, tune-ups, adjustments, or normal wear and tear are not covered under this

warranty. Similarly, warranty is not applicable if the engine has been altered or modified

or if the engine serial number has been defaced or removed. This warranty does not cover

engine damage or performance problems caused by:

1. The use of parts that are not original Briggs & Stratton parts;

2. Operating the engine with insufficient, contaminated, or an incorrect grade of

lubricating oil;

1, 2, 3

Consumer

Use

Commercial

Use

36 months36 monthsVanguard™; Commercial Series

12 months24 monthsEngines Featuring Dura-Bore™ Cast Iron Sleeve

3 months24 monthsAll Other Engines

10 BRIGGSandSTRATTON.com

Page 11

Not for

Reproduction

3. The use of contaminated or stale fuel, gasoline formulated with ethanol greater than

10%, or the use of alternative fuels such as liquefied petroleum or natural gas on

engines not originally designed/manufactured by Briggs & Stratton to operate on

such fuels;

4. Dirt which entered the engine because of improper air cleaner maintenance or reassembly;

5. Striking an object with the cutter blade of a rotary lawn mower, loose or improperly

installed blade adapters, impellers, or other crankshaft coupled devices, or excessive

v-belt tightness;

6. Associated parts or assemblies such as clutches, transmissions, equipment controls,

etc., which are not supplied by Briggs & Stratton;

7. Overheating due to grass clippings, dirt and debris, or rodent nests which plug or

clog the cooling fins or flywheel area, or by operating the engine without sufficient

ventilation;

8. Excessive vibration due to over-speeding, loose engine mounting, loose or unbalanced

cutter blades or impellers, or improper coupling of equipment components to the

crankshaft;

9. Misuse, lack of routine maintenance, shipping, handling, or warehousing of equipment,

or improper engine installation.

Warranty service is available only through Briggs & Stratton Authorized Service

Dealers. Locate your nearest Authorized Service Dealer in our dealer locator map

at BRIGGSandSTRATTON.COM or by calling 1-800-233-3723 (in USA).

80004537 (Rev. C)

Briggs & Stratton Emissions Warranty

California, U.S. EPA, and Briggs & Stratton Corporation Emissions

Control Warranty Statement - Your Warranty Rights and

Obligations

For Briggs & Stratton Engine Models with "F" Trim Designation (Model-Type-Trim

Representation xxxxxx xxxx Fx)

The California Air Resources Board, U.S. EPA, and Briggs & Stratton (B&S) are pleased

to explain the emissions control system warranty on your Model Year 2017-2019

engine/equipment. In California, new small off-road engines and large spark ignited engines

less than or equal to 1.0 liter must be designed, built, and equipped to meet the State's

stringent anti-smog standards. B&S must warrant the emissions control system on your

engine/equipment for the periods of time listed below provided there has been no abuse,

neglect, or improper maintenance of your engine/equipment.

Your exhaust emissions control system may include parts such as the carburetor or fuel

injection system, ignition system, and catalytic converter. Also included may be hoses,

belts, connectors, sensors, and other emissions-related assemblies. Your evaporative

emission control system may include parts such as: carburetors, fuel tanks, fuel lines, fuel

caps, valves, canisters, filters, vapor hoses, clamps, connectors, and other associated

components.

Where a warrantable condition exists, B&S will repair your engine/equipment at no cost

to you including diagnosis, parts, and labor.

Manufacturer’s Warranty Coverage:

Small off-road engines and large spark ignited engines less than or equal to 1.0 liter, and

any related emissions components of the equipment, are warranted for two years, or for

the time period listed in the respective engine or product warranty statement, whichever

is greater. If any emissions-related part on your B&S engine/equipment is defective, the

part will be repaired or replaced by B&S.

Owner’s Warranty Responsibilities:

• As the engine/equipment owner, you are responsible for the performance of the

required maintenance listed in your Operator's Manual. B&S recommends that you

retain all receipts covering maintenance on your engine/equipment, but B&S cannot

deny warranty solely for the lack of receipts or your failure to ensure the performance

of all scheduled maintenance.

• As the engine/equipment owner, you should however be aware that B&S may deny

you warranty coverage if your engine/equipment or a part has failed due to abuse,

neglect, improper maintenance, or unapproved modifications.

• You are responsible for presenting your engine/equipment to a B&S distribution

center, servicing dealer, or other equivalent entity, as applicable, as soon as a problem

exists. The warranty repairs should be completed in a reasonable amount of time,

not to exceed 30 days. If you have any questions regarding your warranty rights and

responsibilities, you should contact B&S at 1-800-444-7774 (in USA) or

BRIGGSandSTRATTON.COM.

Briggs & Stratton Emissions Control Warranty Provisions

The following are specific provisions relative to your Emissions Control Warranty Coverage.

It is in addition to the B&S engine warranty for non-regulated engines found in the Operator's

Manual.

1. Warranted Emissions Parts

Coverage under this warranty extends only to the parts listed below (the emissions

control systems parts) to the extent these parts were present on the B&S engine

and/or B&S supplied fuel system.

a. Fuel Metering System

• Cold start enrichment system (soft choke)

• Carburetor or fuel injection system

• Oxygen sensor

• Electronic control unit

• Fuel pump module

• Fuel line, fuel line fittings, clamps

• Fuel tank, cap and tether

• Carbon canister

b. Air Induction System

• Air cleaner

• Intake manifold

• Purge and vent line

c. Ignition System

• Spark plug(s)

• Magneto ignition system

d. Catalyst System

• Catalytic converter

• Exhaust manifold

• Air injection system or pulse value

e. Miscellaneous Items Used in Above Systems

• Vacuum, temperature, position, time sensitive valves and switches

• Connectors and assemblies

2. Length of Coverage

Coverage is for a period of two years from date of original purchase, or for the time

period listed in the respective engine or product warranty statement, whichever is

greater. B&S warrants to the original purchaser and each subsequent purchaser that

the engine is designed, built, and equipped so as to conform with all applicable

regulations adopted by the Air Resources Board; that it is free from defects in material

and workmanship that could cause the failure of a warranted part; and that it is

identical in all material respects to the engine described in the manufacturer's

application for certification. The warranty period begins on the date the engine is

originally purchased.

The warranty on emissions-related parts is as follows:

• Any warranted part that is not scheduled for replacement as required

maintenance in the Operator's Manual supplied, is warranted for the warranty

period stated above. If any such part fails during the period of warranty

coverage, the part will be repaired or replaced by B&S at no charge to the

owner. Any such part repaired or replaced under the warranty will be warranted

for the remaining warranty period.

• Any warranted part that is scheduled only for regular inspection in the Operator's

Manual supplied, is warranted for the warranty period stated above. Any such

part repaired or replaced under warranty will be warranted for the remaining

warranty period.

• Any warranted part that is scheduled for replacement as required maintenance

in the Operator's Manual supplied, is warranted for the period of time prior to

the first scheduled replacement point for that part. If the part fails prior to the

first scheduled replacement, the part will be repaired or replaced by B&S at no

charge to the owner. Any such part repaired or replaced under warranty will

be warranted for the remainder of the period prior to the first scheduled

replacement point for the part.

• Add-on or modified parts that are not exempted by the Air Resources Board

may not be used. The use of any non-exempted add-on or modified parts by

the owner will be grounds for disallowing a warranty claim. The manufacturer

will not be liable to warrant failures of warranted parts caused by the use of a

non-exempted add-on or modified part.

3. Consequential Coverage

Coverage shall extend to the failure of any engine components caused by the failure

of any warranted emissions parts.

4. Claims and Coverage Exclusions

Warranty claims shall be filed according to the provisions of the B&S engine warranty

policy. Warranty coverage does not apply to failures of emissions parts that are not

original equipment B&S parts or to parts that fail due to abuse, neglect, or improper

maintenance as set forth in the B&S engine warranty policy. B&S is not liable for

warranty coverage of failures of emissions parts caused by the use of add-on or

modified parts.

11

Page 12

Not for

Reproduction

Look For Relevant Emissions Durability Period and Air Index

Information On Your Small Off-Road Engine Emissions Label

Engines that are certified to meet the California Air Resources Board (CARB) small offroad Emissions Standard must display information regarding the Emissions Durability

Period and the Air Index. Briggs & Stratton makes this information available to the consumer

on our emissions labels. The engine emissions label will indicate certification information.

The Emissions Durability Period describes the number of hours of actual running time

for which the engine is certified to be emissions compliant, assuming proper maintenance

in accordance with the Operator's Manual. The following categories are used:

Moderate:

Engines at or less than 80 cc displacement are certified to be emissions compliant for 50

hours of actual engine running time. Engines greater than 80 cc displacement are certified

to be emissions compliant for 125 hours of actual engine running time.

Intermediate:

Engines at or less than 80 cc displacement are certified to be emissions compliant for 125

hours of actual engine running time. Engines greater than 80 cc displacement are certified

to be emissions compliant for 250 hours of actual engine running time.

Extended:

Engines at or less than 80 cc displacement are certified to be emissions compliant for 300

hours of actual engine running time. Engines greater than 80 cc displacement are certified

to be emissions compliant for 500 hours of actual engine running time.

For example, a typical walk-behind lawn mower is used 20 to 25 hours per year. Therefore,

the Emissions Durability Period of an engine with an intermediate rating would equate

to 10 to 12 years.

Briggs & Stratton engines are certified to meet the United States Environmental Protection

Agency (USEPA) Phase 2 or Phase 3 emissions standards. The Emissions Compliance

Period referred to on the Emissions Compliance label indicates the number of operating

hours for which the engine has been shown to meet Federal emissions requirements.

For engines at or less than 80 cc displacement:

Category C = 50 hours, Category B = 125 hours, Category A = 300 hours

For engines greater than 80 cc displacement and less than 225 cc displacement:

Category C = 125 hours, Category B = 250 hours, Category A = 500 hours

For engines of 225 cc or more displacement:

Category C = 250 hours, Category B = 500 hours, Category A = 1000 hours

80008256 (Rev F)

California, U.S. EPA, and Briggs & Stratton Corporation Emissions

Control Warranty Statement - Your Warranty Rights and

Obligations

For Briggs & Stratton Engine Models with "B" or "G" Trim Designation (Model-TypeTrim Representation xxxxxx xxxx Bx or xxxxxx xxxx Gx)

The California Air Resources Board, U.S. EPA, and Briggs & Stratton (B&S) are pleased

to explain the emissions control system warranty on your Model Year 2017-2019 engine.

In California, new small off-road engines and large spark ignited engines less than or equal

to 1.0 liter must be designed, built, and equipped to meet the State's stringent anti-smog

standards. B&S must warrant the emissions control system on your engine for the periods

of time listed below provided there has been no abuse, neglect, or improper maintenance

of your engine.

Your exhaust emissions control system may include parts such as the carburetor or fuel

injection system, ignition system, and catalytic converter. Also included may be hoses,

belts, connectors, sensors, and other emissions-related assemblies.

Where a warrantable condition exists, B&S will repair your engine at no cost to you including

diagnosis, parts, and labor.

Manufacturer’s Warranty Coverage:

Small off-road engines and large spark ignited engines less than or equal to 1.0 liter, and

any related emissions components of the equipment, are warranted for two years, or for

the time period listed in the respective engine or product warranty statement, whichever

is greater. If any emissions-related part on your B&S engine is defective, the part will be

repaired or replaced by B&S.

Owner’s Warranty Responsibilities:

• As the engine owner, you are responsible for the performance of the required

maintenance listed in your Operator's Manual. B&S recommends that you retain all

receipts covering maintenance on your engine, but B&S cannot deny warranty solely

for the lack of receipts or your failure to ensure the performance of all scheduled

maintenance.

• As the engine owner, you should however be aware that B&S may deny you warranty

coverage if your engine or a part has failed due to abuse, neglect, improper

maintenance, or unapproved modifications.

• You are responsible for presenting your engine to a B&S distribution center, servicing

dealer, or other equivalent entity, as applicable, as soon as a problem exists. The

warranty repairs should be completed in a reasonable amount of time, not to exceed

30 days. If you have any questions regarding your warranty rights and responsibilities,

you should contact B&S at 1-800-444-7774 (in USA) or

BRIGGSandSTRATTON.COM.

Briggs & Stratton Emissions Control Warranty Provisions

The following are specific provisions relative to your Emissions Control Warranty Coverage.

It is in addition to the B&S engine warranty for non-regulated engines found in the Operator's

Manual.

1. Warranted Emissions Parts

Coverage under this warranty extends only to the parts listed below (the emissions

control systems parts) to the extent these parts were present on the B&S engine.

a. Fuel Metering System

• Cold start enrichment system (soft choke)

• Carburetor or fuel injection system

• Oxygen sensor

• Electronic control unit

• Fuel pump module

b. Air Induction System

• Air cleaner

• Intake manifold

c. Ignition System

• Spark plug(s)

• Magneto ignition system

d. Catalyst System

• Catalytic converter

• Exhaust manifold

• Air injection system or pulse value

e. Miscellaneous Items Used in Above Systems

• Vacuum, temperature, position, time sensitive valves and switches

• Connectors and assemblies

2. Length of Coverage

Coverage is for a period of two years from date of original purchase, or for the time

period listed in the respective engine or product warranty statement, whichever is

greater. B&S warrants to the original purchaser and each subsequent purchaser that

the engine is designed, built, and equipped so as to conform with all applicable

regulations adopted by the Air Resources Board; that it is free from defects in material

and workmanship that could cause the failure of a warranted part; and that it is

identical in all material respects to the engine described in the manufacturer's

application for certification. The warranty period begins on the date the engine is

originally purchased.

The warranty on emissions-related parts is as follows:

• Any warranted part that is not scheduled for replacement as required

maintenance in the Operator's Manual supplied, is warranted for the warranty

period stated above. If any such part fails during the period of warranty

coverage, the part will be repaired or replaced by B&S at no charge to the

owner. Any such part repaired or replaced under the warranty will be warranted

for the remaining warranty period.

• Any warranted part that is scheduled only for regular inspection in the Operator's

Manual supplied, is warranted for the warranty period stated above. Any such

part repaired or replaced under warranty will be warranted for the remaining

warranty period.

• Any warranted part that is scheduled for replacement as required maintenance

in the Operator's Manual supplied, is warranted for the period of time prior to

the first scheduled replacement point for that part. If the part fails prior to the

first scheduled replacement, the part will be repaired or replaced by B&S at no

charge to the owner. Any such part repaired or replaced under warranty will

be warranted for the remainder of the period prior to the first scheduled

replacement point for the part.

• Add-on or modified parts that are not exempted by the Air Resources Board

may not be used. The use of any non-exempted add-on or modified parts by

the owner will be grounds for disallowing a warranty claim. The manufacturer

will not be liable to warrant failures of warranted parts caused by the use of a

non-exempted add-on or modified part.

3. Consequential Coverage

12 BRIGGSandSTRATTON.com

Page 13

Not for

Reproduction

Coverage shall extend to the failure of any engine components caused by the failure

of any warranted emissions parts.

4. Claims and Coverage Exclusions

Warranty claims shall be filed according to the provisions of the B&S engine warranty

policy. Warranty coverage does not apply to failures of emissions parts that are not

original equipment B&S parts or to parts that fail due to abuse, neglect, or improper

maintenance as set forth in the B&S engine warranty policy. B&S is not liable for

warranty coverage of failures of emissions parts caused by the use of add-on or

modified parts.

Look For Relevant Emissions Durability Period and Air Index

Information On Your Small Off-Road Engine Emissions Label

Engines that are certified to meet the California Air Resources Board (CARB) small offroad Emissions Standard must display information regarding the Emissions Durability

Period and the Air Index. Briggs & Stratton makes this information available to the consumer

on our emissions labels. The engine emissions label will indicate certification information.

The Emissions Durability Period describes the number of hours of actual running time

for which the engine is certified to be emissions compliant, assuming proper maintenance

in accordance with the Operator's Manual. The following categories are used:

Moderate:

Engines at or less than 80 cc displacement are certified to be emissions compliant for 50

hours of actual engine running time. Engines greater than 80 cc displacement are certified

to be emissions compliant for 125 hours of actual engine running time.

Intermediate:

Engines at or less than 80 cc displacement are certified to be emissions compliant for 125

hours of actual engine running time. Engines greater than 80 cc displacement are certified

to be emissions compliant for 250 hours of actual engine running time.

Extended:

Engines at or less than 80 cc displacement are certified to be emissions compliant for 300

hours of actual engine running time. Engines greater than 80 cc displacement are certified

to be emissions compliant for 500 hours of actual engine running time.

For example, a typical walk-behind lawn mower is used 20 to 25 hours per year. Therefore,

the Emissions Durability Period of an engine with an intermediate rating would equate

to 10 to 12 years.

Briggs & Stratton engines are certified to meet the United States Environmental Protection

Agency (USEPA) Phase 2 or Phase 3 emissions standards. The Emissions Compliance

Period referred to on the Emissions Compliance label indicates the number of operating

hours for which the engine has been shown to meet Federal emissions requirements.

For engines at or less than 80 cc displacement:

Category C = 50 hours, Category B = 125 hours, Category A = 300 hours

For engines greater than 80 cc displacement and less than 225 cc displacement:

Category C = 125 hours, Category B = 250 hours, Category A = 500 hours

For engines of 225 cc or more displacement:

Category C = 250 hours, Category B = 500 hours, Category A = 1000 hours

80008114 (Rev F)

13

Page 14

Not for

Reproduction

Copyright © Briggs & Stratton Corporation, Milwaukee, WI, EE.UU. Todos los derechos

reservados.

Este manual contiene información de seguridad para advertirle sobre los peligros y riesgos

asociados con motores y cómo evitarlos. También contiene instrucciones para uso y

cuidado correctos del motor. Debido a que Briggs & Stratton Corporation no necesariamente

sabe para qué equipo se utilizará este motor, es importante que usted lea y comprenda

estas instrucciones y las instrucciones de su equipo. Conserve estas instrucciones

originales para consulta futura.

Nota:

Las figuras e ilustraciones en este manual son provistas solo para consulta y pueden

no ser iguales a su modelo específico. Si tiene preguntas, comuníquese con su distribuidor.

Para piezas de repuesto o asistencia técnica, anote a continuación el modelo, tipo y

números de código del motor, junto con la fecha de compra. Estos números están ubicados

en su motor (vea la sección de

Fecha de compra

Modelo del motor - Tipo - Reglaje

Número de Serie del motor

Busque el código de barras 2D que se

encuentra en algunos motores. Cuando se

ve con un dispositivo con capacidad 2D, el

código hará surgir nuestro sitio web donde

puede acceder a información de soporte para

este producto. Corresponden tarifas de datos.

Algunos países pueden no tener información

de soporte en línea disponible.

Características y Controles

).

Peligro de descarga

Peligro de superficie

caliente

utilice protección para los

ojos.

piezas móviles

SignificadoSímboloSignificadoSímbolo

Peligro de explosiónPeligro de incendio

Peligro de emisión de vapores

tóxicos

Peligro de ruido: se recomienda

el uso prolongado de protección

para los oídos.

Peligro de explosiónPeligro de caída de objetos:

Peligro de retroceso violentoPeligro de congelación

Peligro químicoPeligro de amputación:

CorrosivoPeligro de calor

Información de reciclaje

Todos los envases, el aceite usado y las baterías deben

reciclarse de acuerdo con las regulaciones gubernamentales

aplicables.

Seguridad del operador

Símbolo de alerta de seguridad y palabras

de señalización

El símbolo de alerta de seguridad se usa para identificar información de seguridad

sobre riesgos que pueden provocar lesiones personales. Se usa una palabra de

señalización (PELIGRO, ADVERTENCIA o ATENCIÓN) junto con el símbolo de alerta

para indicar la probabilidad y la gravedad potencial de las lesiones. Además, se puede

usar un símbolo de riesgo para representar el tipo de riesgo.

PELIGRO indica un riesgo que, si no se evita, ocasionará la muerte o lesiones

graves.

ADVERTENCIA indica un riesgo que, si no se evita, podría ocasionar la muerte

o lesiones graves.

ATENCIÓN indica un riesgo que, si no se evita, podría ocasionar lesiones menores

o moderadas.

AVISO

indica una situación que podría provocar daños al producto.

Símbolos de peligro y sus significados

SignificadoSímboloSignificadoSímbolo

Información de seguridad

sobre los riesgos que

pueden provocar lesiones

físicas.

Lea y entienda el Manual del

Operador antes de operar o

reparar la unidad.

Mensajes de seguridad

ADVERTENCIA

Ciertos componentes en este producto y sus accesorios correspondientes contienen

químicos considerados para el Estado de California como causantes de cáncer,

defectos de nacimiento u otros daños reproductivos. Lávese las manos después de

manipular estos elementos.

ADVERTENCIA

El escape del motor de este producto contiene sustancias químicas reconocidas en

el estado de California por producir cáncer, defectos de nacimiento u otros daños que

pueden ser perjudiciales para la reproducción.

ADVERTENCIA

Los motores Briggs & Stratton no están diseñados para y no deben utilizarse para

impulsar "karts" recreativos o deportivos; vehículos recreativos para niños o deportivos

todo terreno; motos; aerodeslizadores; productos de aeronaves o vehículos utilizados

en eventos competitivos no sancionados por Briggs & Stratton. Para obtener

información sobre productos para carreras competitivas, vaya a www.briggsracing.com.

Para uso con vehículos utilitarios y side-by-side todo terreno, contáctese con el Centro

de Aplicación de Motores Briggs &Stratton al 1-866-927-3349. El uso del motor para

aplicaciones inadecuadas puede generar lesiones graves o la muerte.

ADVERTENCIA

El combustible y sus vapores son extremadamente inflamables y explosivos.

El fuego o la explosión pueden causar quemaduras graves o la muerte.

Cuando agregue combustible

• Apague el motor y deje que se enfríe por lo menos 2 minutos antes de remover la

tapa del combustible.

• Llene el tanque de combustible en exteriores o en un área bien ventilada.

• No llene excesivamente el tanque de combustible. Para permitir la expansión del

combustible, no llene el tanque por arriba de la parte inferior del cuello.

14 BRIGGSandSTRATTON.com

Page 15

Not for

Reproduction

• Mantenga el combustible alejado de chispas, llamas abiertas, testigos piloto, fuentes

de calor y otras fuentes de encendido.

• Compruebe con frecuencia si existen grietas o fugas en las mangueras de

combustible, el tanque, la tapa y en los accesorios. Reemplace las piezas, si es

necesario.

• Si se derramó combustible, espere hasta que se haya evaporado antes arrancar

el motor.

Cuando encienda el motor

• Asegúrese de que la bujía, el silenciador, la tapa del combustible y el filtro de aire

(si está equipado) estén colocados y fijos en su lugar.

• No haga girar el motor si retiró la bujía.

• Si el motor se ahoga, coloque el estrangulador (si está equipado) en la posición

de apertura/funcionamiento (OPEN/RUN), coloque el acelerador (si está equipado)

en la posición de velocidad (FAST) y arranque el motor hasta que se encienda.

Cuando opere el equipo

• No incline el motor ni el equipo de forma que pueda derramarse el combustible.

• No estrangule el carburador para detener el motor.

• Nunca encienda o haga funcionar el motor sin el conjunto del purificador de aire

(si tiene) o el filtro de aire (si tiene).

Cuando cambie el aceite

• Si drena el aceite desde el tubo superior de llenado de aceite, el tanque de

combustible debe estar vacío o de lo contrario podría presentarse una fuga de

combustible que podría ocasionar un incendio o una explosión.

Cuando incline la unidad para trabajos de mantenimiento

• Al realizar trabajos de mantenimiento que requieran inclinar la unidad, el tanque

de combustible, si está montado en el motor, debe estar vacío o podría haber una

fuga de combustible y generar un incendio o una explosión.

Cuando transporte el equipo

• Transporte con el tanque de combustible VACÍO o con la válvula de cierre de

combustible en la posición CLOSED.

Cuando almacene el combustible o el equipo con combustible en el tanque

• Almacénelo a distancia de hornos, estufas, calentadores de agua u otros aparatos

que utilicen testigos piloto u otras fuentes de encendido ya que estos pueden

encender vapores combustibles.

ADVERTENCIA

Dar arranque al motor crea chispeo.

El chispeo puede encender los gases inflamables cercanos, lo que

podría ocasionar una explosión o un incendio.

ADVERTENCIA

La retracción rápida de la cuerda del arranque (retroceso violento) le halará la

mano y el brazo hacia el motor antes de que pueda soltarla.

Podría causar huesos rotos, fracturas, hematomas o esguinces.

• Cuando arranque el motor, tire lentamente de la cuerda hasta sentir una resistencia

y, a continuación, tire rápidamente de ella para evitar su retroceso.

• Remueva todas las cargas externas del equipo/motor antes de darle arranque al

motor.

• Los componentes del equipo de acoplamiento directo, como cuchillas, impulsores,

poleas, ruedas dentadas, entre otros, se deben colocar firmemente.

ADVERTENCIA

Las partes rotantes pueden tener contacto o atrapar las manos, los pies, el

cabello, la ropa o los accesorios.

podría ocasionar una amputación traumática o una laceración grave.

• Opere el equipo con los protectores en su lugar.

• Mantenga las manos y los pies a distancia de las partes rotantes.

• Recoja el pelo largo y quítese cualquier joya.

• No use ropa floja, tiras que cuelguen ni artículos que puedan ser agarrados.

ADVERTENCIA

El funcionamiento de los motores produce calor. Las piezas de los motores,

especialmente el silenciador, se calientan demasiado.

Pueden ocurrir graves quemaduras al tocarlas.

Los desechos combustibles, tal como hojas, grama, maleza, etc. pueden

prenderse fuego.

• Deje que el silenciador, el cilindro y las aletas del motor se enfríen antes de tocarlos.

• Extraiga los desechos acumulados en el área del silenciador y en el área del cilindro.

• Es una violación del Código de Recursos Públicos de California, Sección 4442,

utilizar u operar el motor en cualquier espacio con árboles, maleza o grama a menos

que el sistema de escape esté equipado con un extintor de chispas, como lo define

la Sección 4442, mantenido en correcto funcionamiento. Otros estados o

jurisdicciones federales pueden tener leyes similares. Póngase en contacto con el

vendedor, el distribuidor o el fabricante del equipo original para obtener un extintor

de chispas diseñado para el sistema de escape instalado en este motor.

• Si hay una fuga de gas natural o gas propano LP en el área, no le de arranque al

motor.

• No use líquidos de arranque presurizados ya que los vapores son inflamables.

ADVERTENCIA

PELIGRO DE GAS TÓXICO. La descarga de escape del motor contiene monóxido

de carbono, un gas tóxico que puede matar en minutos. NO puede verlo, es

inodoro e insípido. Incluso si no huele los gases del escape, puede estar expuesto

al monóxido de carbono. Si comienza a sentirse mareado o débil cuando utiliza

el producto, tome aire fresco inmediatamente y Consulte a un médico. Puede

haberse intoxicado con monóxido de carbono.

• Opere este producto SOLAMENTE al aire libre, lejos de ventanas, puertas y

ventilaciones, para reducir el riesgo de que el monóxido de carbono se acumule y

pueda circular a espacios habitados.

• Instale alarmas de monóxido de carbono con baterías o enchufe (batería de

respaldo) siguiendo las instrucciones del fabricante. Las alarmas de humo no

pueden detectar el monóxido de carbono.

• NO opere este producto dentro de hogares, garajes, sótanos, espacios reducidos,

cobertizos u otros espacios parcialmente cerrados, incluso si usa ventiladores o

deja las puertas y ventanas abiertas. El monóxido de carbono se puede acumular

rápidamente en estos espacios y puede permanecer durante horas, incluso después

de que se apaga este producto.

• SIEMPRE coloque este producto en la dirección del viento y apunte el escape del

motor lejos de espacios habitados.

ADVERTENCIA

Las chispas no intencionales pueden provocar un incendio o una descarga

eléctrica.

El arranque accidental puede provocar enredos, amputaciones traumáticas o

laceraciones.

Peligro de incendio

Antes de hacer ajustes o reparaciones: