Briggs & Stratton Power Built 825, Power Built 850, Power Built 875, Power Built 900, Power Built 1350 Operating And Maintenance Instruction Manual

...Page 1

@

Operating & Maintenance lnstructons

Model 120000

Power Built 825185018751900 Series

lntek

IIC 825185018751900 Series

IIC 82518501875 Series

Model 150000

Power Built 110011125 Series

Model 200000

Power Built 1350/1450 Series

lntek IIC 135011450 Series

IIC 1450 Series

Model 210000

Power Built 150011575 Series

lntek

IIC 1500/1575 Series

O

Copyright

Briggs

&

Stratton Corporation

Form

No.

MS-3790-3107

BRIGGSandSTRATrON.com

Milwaukee,

Wisconsin

53201

U.S.A.

Printed

in

U.S.A.

Page 2

Page 3

hole

Illis note applies orl) lo engines used in tne U SA) Maintenance. replacemenl or rcpir of ihe emisslon comro de-s and syslems

may

be

periorm~l

GB

bv

anv non!oao eno no reoalr estao isrimcnt or ~noivto~a. nolvevcr. lo oblan

10

chdrae rcpalrs ~noer lne terms and pro, slops of tnc Bwqs & Shahorl

0

..

iarr&ty statemen{ any Qervice or emission control part repair or replacement mustke performed by a factory

authorized

dealer.

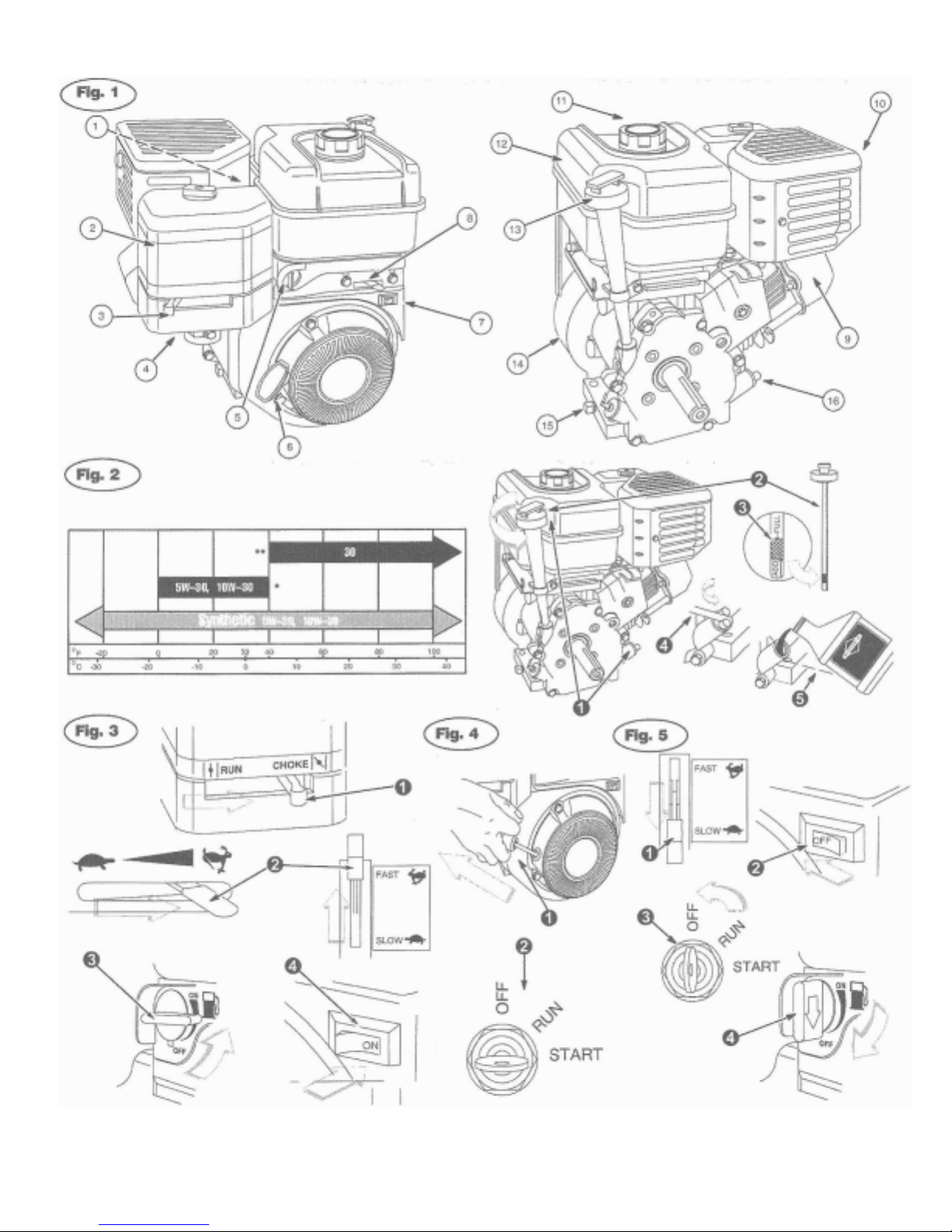

ENGINE COMPONENTS

Symbols Associated

with

this

Engine

@

Spark Plug Wlre

@

Air Cleaner

@

Fuel Shut-on Valve

@

Rope Handle

@

Stop SwitchIOil GardO, if equipped

8

nmle

@

Engine Model ITypelCode number

XXXXXX

m-XX

@

Mufflerispark Arrester,

if

equipped

@

Fuel Fill

@

Fuel Tank

1

Oil FilllDipstick, Requipped

4

Blower Housing

5

Oil Drain Plug

@

Oil Filler Plug

Record your

&

Model,

Type

and Code numbers here for future use

Record your date of purchase here for future use.

Flre

Safety Alert

&

mplosion

a

Read Operator's Manual

Kickback

I

OnOff

28

shock

oil

%

~ot Surface

-

Fuel

e

Slow

d

1x1

Full I Closed Choke

A sional word

IDANGER. WARNING. or CAWIONI is used

wilh

the alert svmbol

lo

c&

cate theirkel noon an0 me potentfa1 se.er ly

01

rn,uty In aoortlon a rnkard

s,rnoo may be

sea

to represent the type of ns7aro

A

DANGER indicates a hazard which,

if

notavoided, will result in death

or serious injury.

A

WARNING indcates a hazard which, if not avoided, could result in

death or

serlous injury.

a

CAUTION indicates a hazard which, if not avoided, might result in

minor or moderate iniurv.

GENERAL INFORMATION

CAUTION, when useiwiihout the alert symbol, indicates a situation

that could result in damage to the engine.

In the U.S.A., the OHV Model 120000 engines covered in this manual are

certified by the California Air Resources Board to meet emissions standards for

125 hours. Models 150000,200000 and 210000 for 250 hours. Such cerlification

does not grant the purchaser, owner or operator of this engine any additional

warranties with resoect to the

oeiformance or ooerational life of this enoine. This

era

ne 1s warranlei so cl, acdarc$ng to !no proo.ct and cmlss ors sarraqttcs

slaleo elsewr~crr tn Ins manual

Note: Engine power ill decrease 3-11Pb

for

each 1,WOfeet

(300

melers)

abwe

sea level and

1%

for each 10"

F

(5.6

"

C)

above

77

"

F

(25

"

C).

H

will operate satisfactorily at

an

angle

up

to 15".

Refer

to the equipment aperator manual

for

safe allowable operating limib

on slopes.

SAFETY SPECIFICATIONS

to avoid them. Because Briggs & Stratton does not necessarily know what

equipment this engine will power, it is important that you read and understand

A

W

A

R

N

I

N

G

The engine exhaust from this product contains chemicals known tothe State

of California to cause cancer, birth defects, or other reproductive harm.

AWARNING

Briggs & Stratton does not approve or authorize the use of these engines on

%wheel All Terrain Vehicles (ANs), motor bikes, funhecreational go.karts,

aircraft products orvehicies intended for use in competitive events. Use of

these engines in such applications could

resuk in property damage, serious

injury (including paralysis), or even death.

Fill iuei tank outdoors or in well.ventilated area.

Do not overfill fuel tank.

Check fuel lines, tank, cap, and Wings frequently for cracks or leaks.

Replace if necessary.

WHEN STARTING ENGINE

.

Make sure spark plug, muffler, fuel cap and air cleaner are in place.

Do not crank engine with spark plug removed.

.

If fuel spills, wait until t evaporates before starting engine.

.

If engine floods, set choke to OPENIRUN position, place throttle in FAST

and crank until engine starls.

WHEN OPERATING EQUIPMENT

Do not choke carburetor to stop engine.

WHEN TRANSPORTING EQUIPMENT

.

Transport with fuel tank EMPTY

ay from furnaces, stoves, water heaters or other appliances that

t light or other ignition source because they can ignite gasoline

Page 4

,

-

~..

.

engine in enclosed area, even if doors or

Install and maintain in working order aspark arrester before using

equipment on forest-covered, grass-covered, brush-covered

unimproved land. The state of California requires this (Secbon 4442 of

the California Public Resources Code). Other states may have similar

laws. Federal laws apply on federal land.

~:ORII?ING

ADJUSTMENTS

QR

REIJAIRS

Disconnect spark plug wire and keep it away from spark plug.

WHEN

TESTING

FOR SPARK

.

Use approved spark plug tester.

Do not check for spark with spark plug removed.

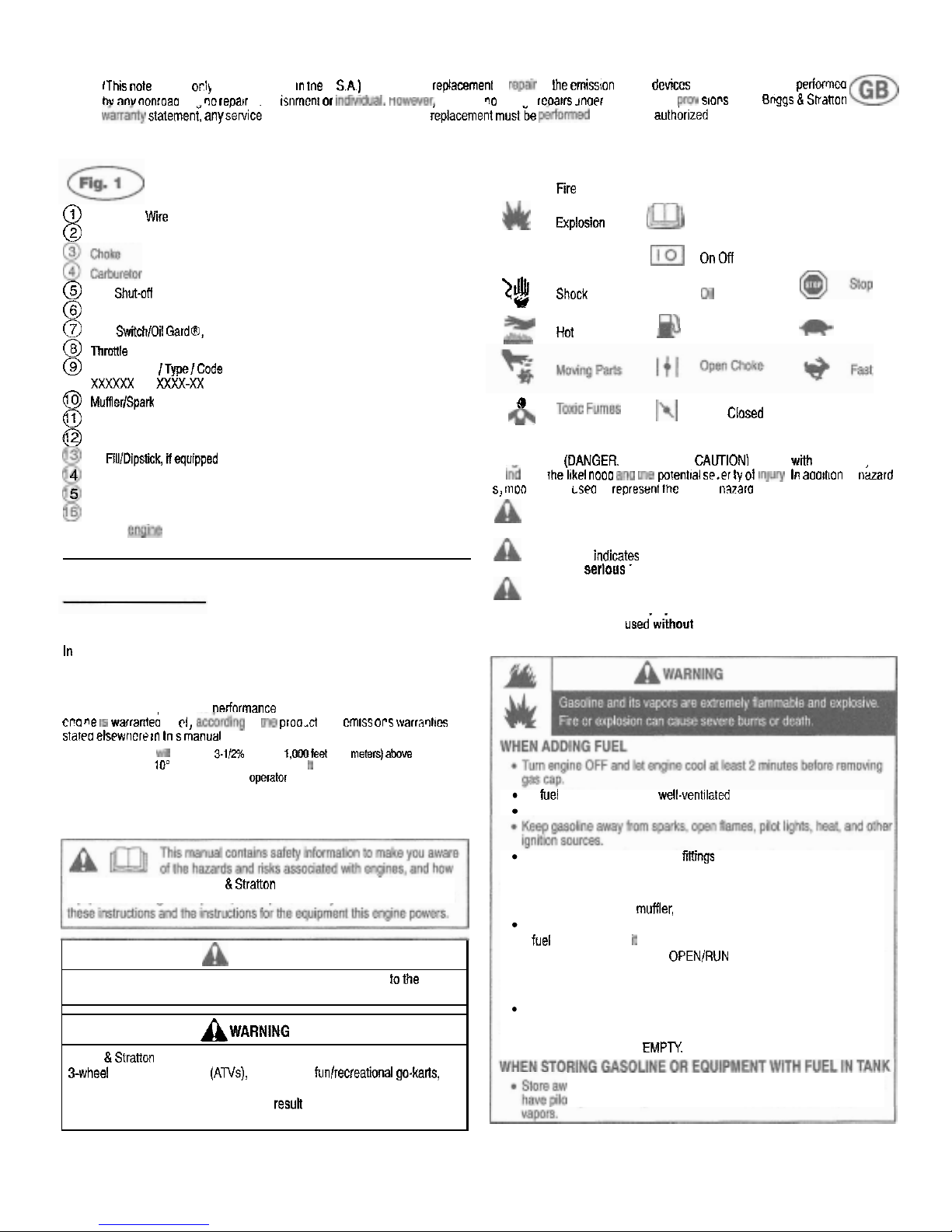

OIL RECOMMENDATIONS

CAUTION:

Engine shipped from Briggs & Stratton !@@&oil. Before stamina engine, fill with

oil. Do not over-fill.

Jse

a

h~gh qua1 ty detergent oli dassltied'for Sew ce SF,

SG,

SH.

SJ"

or nlgner

such as Br~aas & Stradon 30. Part Nlmoer 130005 Use no smd aoall!lcq aft*

rmmmeniid oils. Do not

mix

oil

with

aasoline.

Choose the SAE

viscosih/ grade of oil from this chart that matches the starting

temperature anticipated before the next oil change.

I

CAUTION:

A

r

coo ed englnes run notter tnan automohe englnes Tne

.sc

ol oon ?ynlnetlc mull1 wscosny o Is

(stA:

30, 10W-30, ctc J n temperatJres

doo#e 40

F

14 CI all1 rcs~ll in n

at

er

tbm

normal

01

consumot on When

using a multi-viscosity oil, check

oi lewd more frequently.

*

CAUTION: Synthetic oil must

be

used

when operating engine under

40"

F

(4"

Cl or enoine damaoe will occur.

I

,

,

"

CAUTION: SAE 30 oi.

fused

below 50. F (10'

C),

wll resull

ii

naro stan ng

ano pcssio

c

eoplnr! oore damaqe 0.e to nadequatc lubr~catioo.

Oil Capacity

.

Models 120000 1150000 is 0.6 It (21

02).

Models 200000 i 210000 is 0.8 It

(28

02).

.

Check oil level before starting the engine.

Check oil level before every use.

Keep oil level at FULL.

@

OIL

PROCEDURE

1.

Place engine level and clean around oil

fill

O.

2. Remove dipstick

Q,

wipe with clean cloth, insert and tighten down again.

Remove dipstick and check oil level. Oil should be at FULL mark

O.

If oil is

required, add slowly.

Do

not over fill.

-0R-

3.

Remove oil filler plug

0.

Oil should be full to overRowing

O.

4.

Tighten dipstick or oil filler plug firmly before starting engine.

FUEL RECOMMENDATIONS

Use clean, fresh.

@&keg

gasoline with a minimum of

85

octane. Leaded

gasoline may be used if

it

is commercially available and

it

unleaded is

unavailable.

In U.S.A. leaded gasoline may

not

be used. Some fuels, called oxygenated or

reformulated gasolines, are gasolines blended with alcohols or ethers. Excessive

amounts of these blends can damage the fuel system or cause

performance

problems. If any undesirable operating symptoms occur, use gasoline with a

lower percentage of alcohol or ether.

2

Page 5

This engine is certified to operate on gasoline. Exhaust Emission Control System:

MAINTENANCE

EM (Engine Modifications).

D

O

not use gasoline which contains Methanol. Do not mixoil with gasoline.

-.

Adding Fuel

Clean around

f,e, ti I oefore remoring cap. Fill tank to approximately 1.112 inches

CP

O

W

top of net< lo allow lor l~e sxpanslon. Be carefu not lo 0~e.h

I

a

WAR

N

I

N

G

Before refueling, allow engine to cool 2 minutes.

STARTING

CAUTIOB: Some engines may be equipped with Oil Gard. The Oil Gard is

intended to warn the operator that the engine is low on oil. Always check oil

level

before starting. Engine damage may occur

if

the oil level is not properly

maintained and will void warranty coverage. If the engine will not start, has

stopped running andlor a ligM flickers in the stop switch, add oil (see oil

procedure Fig. 2).

BEFORE

STARTING THE ENGINE

1.

Add oil and fuel as instructed in this manual.

2.

Move choke control 0 to CHOKE wsifion.

3

ito$c lnrotlle ccntro o to

F

A

S

T

pbslt on

4 Tlrll fuel shut.oH valvo

0

ON d eo~ ooed

,

,

,,~~~

5.

Move stop control 0 to

position,

if equipped.

hole OIL GAUD ignl in rocdcr sloo swltch

0

i

eq~tpped, warns ol loiu

011

level.

bght n I O.cder and englne

NII

not start. or realart.

011

mJs1 oe aooed.

Fill

to FULL

mark on

n nshck or ovedlflokina al oil I ler o~uo Do not over fill 0.- GARD hov~ever.

will not stop a running engine"if the engitie Gns low on oil.

-

STARTING THE ENGINE

Rewind Starter

1 Grasp rope nandle

0

an0

~LI

slowly unl, res stance ts fcH Tnen pull cold

rap ol/ lo overcome

compression,

prevenl ntcheack ano start cnglne

2

Rspe3t

11

necessarf sin choke n R.h postlon nno fhrottlo tn FAST Wncn

engine starts,

operie in FAST position

WARNI

N

G

Rapid retraction of staiter cord (kickback) will pun hand and

arm

toward

engine faster than you can let go.

Electric Starter

1.

On engines equipped with

12

volt starting systems, turn key to START

position

O.

2.

Repeat if necessary wiTh thronle conbol In FAST position. When engine

starts, operate in FAST

podion.

Not?

11

equ oment mandaclurcr has supp lea oaltery charge n oeforo tyng to stan

engtne as equtprnctil manufacturs reconmends

Note: Use short starting cycles

(15

sec. per minute) to prolong starter life. ExTended

cranking can damage starter motor.

STOPPING

1.

Move throttle control lever to IDLE or SLOW position

0,

if equipped.

2.

Then move stop control to OFF position O or turn key to OFF

O.

3. Close fuel shut-off valve

0.

CAUTION: DO NOT move choke control to CHOKE poslon to stop engine.

BacMire or engine damage may occur.

Note: Always remove key from switch when equipment is not in use or left unattended.

Note: When engine is transported, dose

fuel shut-off valve to prevent leakage.

I

WARNING,

1

To prevent acc~dental

starting,

remove spark plug

*

wire 0 and keeD awav from soark Dlua before

,

."

I

servicing.

Regw.ar maintrnance improves petlotmance and extends elqine

I'tp

Uore

freq lent sewlce

is

required whe~i operattng In adverse cor Uilions.

may shatter during operation.

Follow the hourly or calendar

intewals, whichever occur first. More frequent

service is required when

operating in adverse conditions noted below.

First

5

HOU~

-

Change oil

Every

8

Hoh

or

Daily

Check oil level

Clean around muffler

Every

25

Hours

or

Every Season

Change oil

if

operating under heavy load or high ambient temperature

Setvice air clean8 pre-cleaner

Every

50

Hours

or

Every Season

Changeoil

Clean and inspect spark arrester, if equipped

Every

100

Hours

or

Every Season

Service oil foam air cleaner or cartridge*

Cleanlreplace spark plug

Change gear reduction oil, if equipped

Clean cooling system*

Every

Season

Check valve clearance

Clean more onen under dusty conditions, or when airborne

debris

is

present or afier

prolonged operatbn

ciming

fail,

dry

grass

Check oil level regularly.

Be sure

cotrecl o I&

IS

rnartatned Check elery 8 hours or dal, oel~re starby

epglne See o I B'tng procm.re ~ndw

Od

Recommendairons DO rot

ow

6

Changing Oil

Cnange

om aher firs! 5 hours of operailon Changc o I cnlle en9 ne 1s warm Refill

wltn ncn o I

01

recornmenoel SAk wscoslh/ vaac (see

fig.

2)

.

. .

.

Changlng Oil

In

Gear Reduction, if equipped

Remove oil fill plug

0

and oil level plug

Q.

Drain oil every

100

hours of operation

or every season. To refill, pour SAE

30

oil into oil fill hole until

it

runs out level

check hole. Replace both plugs. Oil fill plug has a vent hole Q and must be

installed on top of gear case cover.

a

AIR CLEANER MAINTENANCE

Dual Element

Air

Cleaners

Reolace orecleaner 0 andlor mrtridae Q if vew dirtv or damaaed

.

.

To kewlce prec ea:ler,

tl

cqutppeo nisn :n lhquld delergent andwaler. Sq~ec~c

oq in a clean clotn and allov, lo av lharouqhly DO hOT oil pre c~eaner.

~o.service cartridge, clean by tapping

in a #at surface. DO NOToil

camidae.

CAUT~N:

Do not use pressurized air or solvents to dean. Pressurized air can damage filter;

solvents will dissolve finer

Page 6

Rectangular Dual Element Air Cleaner

1. Loosen screw and tilt cover down. Remove

precieaner

(il

equipped) and

canridoe assemblv from cover.

2.

Alter Scrvciiq pie-ceancr and caririoge, place pre cleaner.

II

eq~:ppea

(a~ows

J~J

ow cartnage plcnts (pre-cleaner lio v.i.1 or!

31

bonom of plealsl.

3.

lrislal p:e-c eaner ano canlioqe assembly n cover.

4.

insert tabs on cover into slot& in bottom of base.

5. Tilt cover upand tighten screw securely.

Oval Dual Element Air Cleaner

1. Remove knob and cover.

bit

air deanw d stud

2. After cleaning, reassemble

precleaner on cartridge. Push air cleaner firmly

down on stud

O

to seat in base.

3.

Push cover squarely onto base. Tighten knob securely.

Oil Foam Air Cleaner

To service foam

element

€9,

wash in liquid detergent and water. Squeeze dry in a

clean cloth. Saturate in engine oil. Squeeze in clean, absorbent cloth to remove

ALL EXCESS oil.

1.

Lwsen screw and tilt cover down. Remove bracket O and foam dement from

cover.

2.

Clean 013~664, mer an0 oase.

3.

Insk orackd and loa

II

e ement In cover.

4 Insert labs on cover inlo slots in oonom of oase.

5. Tilt cover up and fasten securely with screw.

SPARK PLUG MAINTENANCE

Cleanheplace spark plug every 100 hours or

every

season, whichever occurs

first. Spark plug wrench is available from any Authorized Briggs

&

Stratton

Setvice Dealer.

Note:

In some areas, local law requires using a resistor spark piug to suppress

ignition signals. If this engine wasoriginally equipped with resistor spark plug, use

same type of spark plug for replacement.

Spark plug gap

€9

should be 0.76 mm (0.030 in)

A

WAR

NIN

G

DO NOTattempt to start engine with spark plug removed. Fuel can ignite

and cause afire or explosion. If you need to check for spark, use only Briggs

&

Stratton Spark Tester, to check for spark.

KEEPING ENGINE CLEAN

Periodically remove grass and

chaff build-up from engine. Clean finger guard. Do

not spray engine with water to clean because water could contaminatefuel.

Clean with a brush or compressed air.

If muffler is equipped with spark arrester screen

O,

remove spark arrester screen

for cleaning and inspection every 50 hours or every season. Replace if damaged.

To assure smooth operation, keep governor linkage, springs and controls

0

free

of debris.

Clean cooling system. Chaff or debris may clog engine's air cooling system,

especially

after prolonged operation. Remove blower housing and clean as

shown

O.

STORAGE

Engines stored over

30

days need to be protected or drained of fuel to prevent

gum from forming in fuel system or on essential carburetor parts.

For

engine protection, we recommend use of Briggs & Stratton Fuel Stabilizer.

Note:

Hstabiiizer

is

not used or if engine is operating on gasoline containing alcohol,

e.g. gasohol, remove all fuel from tankand run engine until

it

stopsfrom lack of fuel.

1. Change oil. See Oil service.

2. Remove

soark olua and wur about 15 ml

HI2

ozl of enaine oil into cvlinder.

Replaw spwr 61,iand crann s~oniy lo dlsinb~te

c,

I

"

3

Clean

cnafl

ano oeons from cy noer and cylinder nead

fim,

under lnqer g~iard

and behind muHter.

4.

When removing the unit tmm storage, only use fresh gasoline. Perfom

operation checks, see maintenance schedule, before starting engine.

a

WARNI

N

G

Store in a clean, dry ma. DO NOT store near a stove, furnace or water

heater which uses a pilot light or any device that can create a spark.

SERVICE

See an A~tnsrized Br~ggs 8 Stratton Se~ce Dealer tach one carr es a stock of

Cen~.ne Br qqs & Stranon Pans and 1s equ ppeo

rr

rh specla servlce to0.s

Need ~ssisiance?

GO

to tne websile or &I., 1-800-233-3723

(U

SA

and

Canada) to

lear

a

n

enJ of prerecorded mcssaqcs olfer~nq enptne

maintenance

. .

information.

Partial List of Genuine Briggs & Stratton Parts

part

&j&L

Oil (20 or)

...............................................

100005

Oil

(48

oz)

...............................................

100028

Oil pump kit (uses standard electric drill

............................

5056

to remove oil from engine quickly)

Fuel stabilizer

(I oz.,

30

ml single use pouch)

.................

992030 (5041)

Fuel filter

................................................

604485

Flat

air cleaner caflridge

................................

491588 (5043)

flat air

cleanerpwleaner

...................................

493537

Oval air deanw

callridge (Model 11,12)

..........................

690610

Oval air deaner pre

-

cleaner (Model 11,12)

........................

273356

Oval air cleaner cartridge (Model

20,21)

..........................

692484

Uva air cieaner precleaner (Model 20.21)

........................

273930

Resistor spark plug

........................................

802592E

Standard spark plug

.......................................

492167E

Long life platlnum spark plug

....................................

5066

(used on most OHV engines)

Spark tester

...............................................

19368

Spark plug wrench

..........................................

19374

Use

our web site at

~~~.briggsandstratt~n.com

to find a dealer nearest

you,

or check the "Yellow Pages'M".

TUNE-UP SPECIFICATIONS

Model 120000

Bore

...............................................

2-11/16 in. (68 mm)

Stroke

............................................

.2-13/64 in. (56 mm)

Displacement.

......................................

12.48 cu. In. (206 cc)

Model

1500W

Bore..

..............................................

75 mm (2.970 in.)

Stmke

..............................................

56mm(2.2Win.)

Displacement

.......................................

249 cc (15.22 win.)

Model 200000

Bore.

.............................................

3.120in. (79.23 mm)

Stroke

............................................

2.438in. (6167mm)

Displacement

.......................................

18.64 cu. in. (305 cc)

Model 210000

Bore..

............................................

3.300 in. (83.81 mm)

............................................

Stroke 2.438 In. (61.67 mm)

Displacement..

.....................................

.20.85

nr.

in. (342 cc)

Spark plug gap

.......................................

0.030 in, (0.76 mm)

Models lZOOOOI 1SOWO

...........................

Armature air

gap

0.010 - 0.014 in. (0.25 -056mm)

.......................................

Spark plug gap

0.030 in. (0.76

mm)

...............................

Intake.. .0.004 -0.006in. (0.10-0.15 mm)*

................................

Exhaust

0.009

-

O.OH in. (0.23 - 0.28 mm)"

Models 20W00 1210000

Armature air gap

...........................

0.008- 0.012 in. (0.20 -0.30mm)

................................

Intake.. 0.004-0.006in. (0.10- 0.15mm)"

................................

Exhaust

0.004

-

0.006 in. (0.10 - 0.15 mm)"

"

Valve dearance with valve springs installed and piston

114

in.

(6

mm) past top dead

center (check when engine is cold). See Repair Manual

PIN

272147.

Page 7

Briggs a Stranon Corporation (B&S),

Ihe Calilomls Air Resources Board (CARE)

an0 the Unhed States

Envlmnmental Protection Agcncy (US. €PA)

Emissions Contml Syslcrn Warranly Statemenl

(Owner's Delcct \Varranly Rights and Obligations)

California, United

States and Canada Emis

-

sions Control Defects Warranty Statement

The

California Air Resources Board (CARE),

U.S.

EPA and 88s are pleased to explain the Emissions

Control System Wamanty

on

your

small off-mad

engine (SORE).

In Calilorna. new smali &-road

enoines model

vear

2006 and later must be de-

,

~~

,~~

~~

~

-

~

~~

~

sic,*

I

,,..

'

nno eqL.

,,GO

'o meet

lhr

S1a.e 5 iw-

(;crl

in.

sllnq stancy

.s

I:

sewnere

0

're

Jrced

.,tales niw ro7roe.l .,.am-$on iof'

i.1:

.-2s cen

-

lied for model year

1997

and rater musimeet simi

-

lar standards set fonh bv the

II

S. EPA.

B&S

must

~~ ~ ~

~,

~~~

~~

~iitn9111

:ie er5sor)s conVo

s,s:cn

on

o

.,en-

grr:

I.:,

I

o

wralcol tne sled

i,~:rrr

"'0.

,:I,:

InPrC.

Pii4

!M"

liU

9.

.CP

nWWi

r

,

T3'03L.'

maintenance of your small o%iaad engine.

Your

emissions contmi svstem includes

Darts

such

as

ire

cnrc,.retor

ir

r

pane, QWII& sys-

t~.nl. 1.e

.?c

t~wtle'an

l

r-13

,.ccon\

..ilcr

As0

IIC

-;LO

may

1%-

cLllectcrs

nntl

otre

er

ss

ons

related asseimblies.

Where a warrantabie condition exists. B&S will

repair your small ofl-mad engine at

no

cost lo you

including diagnosis, parts and labor.

BriaQs & Straton Emissions Control

DeGts Warnnty Coverage

;TI

oY-'oR(.

(PC

~RS

are ,rsnanleo mattr 10

e . son5 to--ru

.,;i%

co'r

::n

iur n perocl

ul

iro

Owner's Warranty Responsibllltics

A5

the Sm; 1'1-road eogl.,c? Jxner

lot6

;,re

ro

-

swns

~e

10.''

3

oertona?~~

o'

Ine

reuL

r?o

maintenance lisgd in yaur Operating arid Main*

nance instructions. B&S recommends that vou

retain all your receipts coveting maintenande

on

your Small off-road engine, but E&S cannot deny

warranty solely for the lack of receipts

orfor your

failure to ensure the performance of all scheduled

maintenance.

As the smali of

-

road engine owner, you should

however be aware that

B&S may deny you war

ranty coverage if your small off-road engine or a

part has

failed due

to

abuse, neglect, improper

maintenance or unapproved modilications.

You are responsible for presenting

yaur small off-

road engine to

an

Authorized B&S Sewice Dealer

as

swn

as a pioblem exists. The undisputed war

-

ranty repairs shouid be completed in a reasonable

amount of time, not to exceed 30 days.

If

you have any questions regarding your warranty

rights and

responsibillties, you should contact a

B&S Service Representative at 1

-

414-259-5262.

The emissions warranty is

a

defects warranty.

Defects are judged

on

normal engine perior-

mance. The warranty is not related to an in-use

emissions test.

Brlggs 8 Stranon Emissions Control

Defects Warranty Pmvisions

The following are specific provisions relative to your

Emissions

Control Defects Warranty Coverage. It is

in addition to the

B&S engine warranty for non-reg-

ulated engines found in the Operating and Mainte

-

nance

Instructions.

~~~~~

1. Warranted

Parts

Coverase underthis warranty exlends oniy to

the

pans listed below [the emissions contmi

systems pans) to the extent these patis were

present

on

the engine purchased.

a. Fuel

Metering System

Cold stan enrichment system (soft choke)

Carburetor and internal parts

.

Fuel pump

Fuel iine, fuel line fittings, clamps

. Fuel tank, capand tether

.

Carbon canister

b. Air

Induction System

Aircleaner

Intake manifold

Purge and vent line

c, Ignition System

spa* PlUQ(S)

Magneto ignition system

d. Catalyst System

Catalyticconverier

Exhaust manifold

Air injection system or pulse valve

e.

Miscelianeous Items Used in Above Systems

. Vacuum, temperature, position, time sen

sitive valves and switches

Connectors and assemblies

2.

LengVI ol Coverage

ranted

harts

for a per~od of two years from the

date the englne is

delivered

to a retali purchaser

3

NoChsioe

"

5

Maintenance

Anv Warranted Part whlch

is

not scheduled fol

':u:eraqe hcr: .lcri slall extcw to

lntl

lallure

o'any

eng

ne corvlonents ir-sec oy ltce

I?

.'6

of

arfy

Aarranteo Pni

s

:

ILI

warrant,

Look For Relevant Emissions

Durability Period and

Air Index

Information On

Your Engine Emissions

Label

Engines that are cenified to meet the California

Air Resources Board

(CARE) Tier2 Emission

Standards must display

informalion regarding the

Emissions Durability Period and the Air Index.

Eriggs & Stratton makes this information availabie

to the consumer on

our

emission labels.

The

enqine emission label will indicate certification

information.

The Emissions Durability Period

desciibes the

number of

hours of actual running time for which

the engine is

cetiified to be emissions compliant,

assuming

proper maintenance

in

accordance kith

the Operating &Maintenance Instructions. The

foliowing categories

are

used:

Moderate:

Engine is

cenified to be emission compliant for

125 hours of adual engine running time.

Intermediate:

Engine is certified

lo

be

emission compliant for

250 hours

of

actual engine running time.

Extended:

Engine is

cerlified to be emission compliant for

500 hours of

actuai engine running time. For

example. a typical walk

-

behind lawn mower is

used 20 to 25 hours per year

Therefare, the

Emissions Durability Period of an engine with

an

Intermediate rating would equate to 10 to 12

years.

Certain

Briggs & Stmtton engines will

be

ceflified

lo meet the United States Environmental

Protection Agency

(USEPA) Phase 2 emission

standards.

Far Phase 2 cerliiied engines, the

Emissions Compiiance Period referred to

on

the

Emissions

Comp1,ance label indicates the number

of operating hours for whlch the engine has been

shown lo meet

Federal emission requirements.

For

engines less than 225 ccdisplacement.

Category C = 125 hours

Category B = 250 hours

Category A

=

500 hours

For

engines01 225 cc or more displacement

Category C

=

250 hours

Category B

=

500 hours

Category A

=

1000 hours.

TECHNICAL INFORMATION

Engine Power Rating Information

megrass power rating tor ~ndividual gas engine models is

labeled in accordance with

SAE

(Society of Automo$ve

En

-

gineers) code 51940 (Small Engine

Power

&Torque Rating

Procedilrel, and rating oeiiormance has

been

obtained and

-.

coueflro

n

.ccrlswe

u

1h

?nE

.lsij

nmulclon

700705

1:0

re

.a

,erdli

cer coal

3CM

RP:I -olre

pr

$a areoernec

;I'JC?C

RPU

A:IJ..

11

59

elq.ns

power will be lower and is anected by, among other thmngs.

ambient operating conditions and engine-tc-engine mriabiii-

ty

Giin

both the widemy of products on which engines

a#ep irticnc!?e anen/alel.

1011~8~1181

~s_esi'p

CI

ble

I:

oier?

~g

lnee2.

y!

zr

me gas

~'lln'

I

ncI

09-

..

~pm~ntmip~oss~3n~~

!.I*,

2%.

li

pvn

POCPO~

:;.el

eqLIFni?l'

~r.b'on-sne"?!

net pcrc. .

Th5o

Wc-

PnCe

IS

n

el0

a

..

:.

41,

01

IPfl,r?

.lr

..2

PO.

hl

not

ir

'el

~

~~~

~

,

~~

".

to, accessories

(ar

cleaner, exhaust charging, moiing.

car

-

buretor fuel oumo. etcl. aoolication limitations, ambient

,

,.

,

,.

operating mdiiions (temperature, humidihi, aitude), and

eogine.to-engine variabiiiiy

Due

lo manufacturing and ca-

pacify limita6ons, Btiggs

8

Siranon

may subs6Iute

an

engine

af

higher rated power for this Series engine.

Page 8

BRIGGS & STRATON ENGINE OWNER WARRANTY POLICY

Eifectlve

12106

. . .

-

..

~.

..,

.

...

~p

-

,..

-~

..

-

..

....

LIMITED WARRANTY

:

Briggs & Stratton Corporation will repair or replace, free of charge, any part(s) ofthe engine that is defective

in

material orworkmanship or

,

both. Transportation charges on parts submitted for repair or replacement underthis warranty must be borne by purchaser. This warranty Is

/

effectivebrand issubjectto the time periods and conditions stated below. Forwarranty service,find the nearest Authorized Service Dealer

in

,

our dealer locator map at

www.brioasandstratton.com_,

or by calling 1-800-233-3723,

or

as listed in the 'Yellow PagesT"

'.

1

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS

FORAPARTICULAR PURPOSE, ARE LIMITEDTOONE YEAR FROM PURCHASE, ORTOTHE EXTENTPERMITTED BY LAW ANY AND

ALLIMPLIED WARRANTIES ARE EXCLUDED. LIABILITY FOR

INCIDENTALORCONSEQUENTIALDAMAGESARE

EXCLUDEDTOTHE

EXTENT EXCLUSION IS PERMITTED BY LAW.

Somestatesorcountriesdonotailow

limitationson how long animplied warranty lasts, and

I

some states or countriesdo

notaliowtheexclusionorlimitationofincidentaiorconsequential

damages, solheabove limitationand exclusion

,

may not apply to you. This warranty gives you specificlegal tightsand you may also haveotherrights which vary fromstate to stateand country

to country.

-

,..

.

..

~

.~

.~

~

-

.

~ . ~~

.

...

WARRANTY

TERMS

**

Brand

/Product

Type Consumer

Use

Commercial Use

Vanguard

"

2

years

2

years

Extended

LifeSeries"", I/CO, lntek

I/CO,

lntek Pro'

"

2

years

1

year

Kerosene

Fuel

Operated Engines 1 year

90

days

All Other Briggs

&

Stratton Engines

2

years 90 days

"

Engines used

an

Home Standby Generator applications are warranted under consumer use ontv

Thie warranty does not apply to engineson equipment used for prime power in place

of

a

utility.

Engines

used

in competitive racing

or

on

commercial

or

rental

tasks

are

not warranted.

The

warramy

period begins

on

the date

GI

purchase by the first reiaii consumer

or

commercial end

user,

and continues

for

the perhd of time sfated in the table

above.

'Consumer

usen

means

personal residential household use

by

a retail consumer "Commercial use" means all other

uses.

including

use for mmmercial, inme producing

or

rental purposes.

Once

an

engine

has

experienced commercial use,

fi

shall thereafter be considered

as

a commercial use engine

fw

purposes of this

wairanly

NO WARRANTY SEGISTRATIONISNECESSARV TO OBTAlh WARRANTY ON BRIGGS

STRATTOh PRODUCTS SAVE YOUR PROOF OFPURCHASE RECEIPT. IF

YOU DO NOT PROVIDE

PROOFOF THE INITiA- PURChASE DATE AT ThE TIME WARRAhlTY SERVICE (S REQUESTED. THE tJANUFACT-RING DATE OFTHE

PRODUCT WILL BE USEDTO DETERMINE THE WARRAhTV PEHIOD.

ABOUT YOUR ENGINE WARRANTY

Briggs & Stranon welmmer warrany repair

and

apolognes to

~OU

for being inconvenknced. Any Aulhoiired Sewice Dealer

may

petlorn warranty repairs. Most warranty repairs are han

-

dled routinely, but sometimes requests for warranty service

may not be

epprnpnate.

For

example, harrany would

n4

apply

it engine damage

occurred

because of misuse, lack

of

routine

maintenance, shipping, handiing, warehousing or improper

instaliation.

Similarhi, warranty is void

if

the

serial

number afme

engine has been removed

or

the engine has been altered or

rn"iih.lil

,....,,

la

:,iimroH.?c

wmtneorrsondlkSe%lcei)e;leran

0.~11~7.

I

OC

m70e '0 *lrie!mfne

hwnzr

me

r..,

any

aoc

.r

A,.

Ine

Ze?

..

')el

P.

$0

r

jmn'

a

90cll10

trlrs

10

underslanding which might occur between

he

customer and

the Dealer

l'sled below are same ofthecauses of anoine Ulure

that the warranty does not

mver.

Normal wear:

Engines, Ike ail

m&anioai device$ wed peMc parts

se-

and

repiacement lo perion well. Warranty dl! not cover repair

vhen

normal

use

has exhausled

be

life

ol

a

part

or

an

mine.

Improper maintenance:

The

lileof an enginedepends upon

he

cond'lhnsunder which*

Ooerates. and the care it

receives.

Someaaolicalions, such

as

~llers, pimps

and

roiarymowars, are very $en used in dusyor

orymndl?ns.*mba~

ca.ie wnatsp~-ir~obep~cml'.ie

wears. 9 bear,nmen .a~seaoyc? 0.~1 sp8np.g

:caring

C'

1

3,

PI,

el

abmc

e

lnalcllrl

m,l

I

a

eoleu.

?

o

Prolfle

I

e-

Eause

of

Improper maintenance,is noicoviid by waGanty.

This warranty coven engine related defective material and1

of warkmanshlp~ and

not

replacement

or

refund of the

equfpmentto which the engine may be mounted. Nordoee

the warranly extend to repsirs required because of:

1.

PROBLEMS CAUSED BY PARTS THAT ARE NOT

ORIGINAL

BRiGGS & STRATTON PARTS.

2.

Equipmentcontrols or installations that prevent Ming,

cause

unsatistactnry englne perlormance, or shaten en

-

gine iife. (Contact equipment manufacturer.)

3.

Leaking carburetors, clogged fuei plpes, stickin valuer.

orolherdamage, cawed

by

Using eantaminate#or stale

fuei. (Use ciean, !lash, iaad-bee gasoilne and 8"Qgs

&

Stranon Fuel Stabilizer, Part

No.

5041

)

4.

Pads Which are swred or broken because an enoine was

operaledwith insuffiaent

or

contaminated iubrliing oil.

or an

incorrectorade

oi

lubticabnaoii. OILGAR0 mav not

shul down runhg engine. ~ngi<ie damagemay

occur

it

oil lwei is not orooerlv mainhined.

5.

Repair

or

adiust&en<of associated paits or assemblies

such

as

clutches, transmissions, remote conlrois,

eic,

which

are

not mamifadured

by

Briggs 8 Stranon.

6.

Damage or wear to

park

caused by dirt. which entered

the engine because of improper air

deaner

maintenance,

Snugs6

Shmn

EngineMe

Mae

UMerOneO1Mare01TheFollovnng

Patens:

Oeiign

0247,177 j0Vler

Pat-

Pending)

5,691,683 6,520,141 6.325.036 6.145.487 6,012,420 5,803035 5,548,955

6,647,942 6,495,267 6,311,663 6.142.257 5992.367 5.765.713 5,546,901

8,622,683

6,494,175 6,284,123 6,135,426 5.904.124 5,732,555 5,445,014

6,615,787 6,472,790 6,253,852 6,116,272 5,894715 5,645,025 5,503,725

6.617.725 6,460,502 6,260.529 6,105,548 5,687,678 5,642,701 5,501,203

6,603,227 6,456,515 6,242,828 6.37.614 5,852,951 5.626352 5,437,679

6,595,897 6,362,166 8239,709 6,082,323 5,64335 5,619,845 5,320,795

6,595.176 6,369,532 6,237,555 6,077,063 5,623,153 5,606,946 5,30i,M3

6,584,964 6355,003 6,230,676 60M.027 5,619,513 5,606,651 5.271.363

6,557,633 6.349688 5,213,083 6040,767 5,813,384 5,605,130 5,269.71 3

6,542,074 6,347614 6202,616 6014,806 5,609,958 5,4997,579 5,265,700

re-assembly, or

use

of a non-oi@nd air cleaner ekment

w

cartridge.

7.

Pans damaged by over.speeding, or omheating caused

by

grass, debris, or din, which pugs or clogs the cooling

fins, or flywheel area, or damage caused by operating the

engine in

a

dined

area

without sufficienlvenilation.

8.

EnOine or eauioment Darts broksn bv excessive vibration

over

-

speeding or other abke n operalion.

9.

A bent

or

broken crankshafi, caused bvstrikino

asoli

11.

Engine

or

engine cohponenl faiiure, Ce., combustion

chamber, valves,

vaive seats, valve guides,

or

burned

starter motor windings,

caused

by the use of alternate

fuels such as,

iiquified petroleum, natural gas, altered

gasol~nes,etc.

Warram is aveilabfe only lhrough service dealers whlch

have been alrthorized

hy

Briggs & Stranon

Corporation.

your

nearest Authorized Service Dealer is listed In the'%

low PagesT"' of your telephone directov under "Engines,

Gasoline

"

or "Gasoline Engines," "

Lawn

Mowew"

or simi-

iar category

Loading...

Loading...