Page 1

Not for

Reproduction

GS2500/GS4000/GS6500/GS6500E

Portable Generator/ Gerador Portátil/Generador portátil/

可擕式發電機

Operator’s Manual/ Manual do Operador/Manual de instrucciones/

操作員手冊

/휴대용 발전기

/작동 설명서

BRIGGS & STRATTON CORPORATION

MILWAUKEE, WISCONSIN, U.S.A.

Manual No. 381491 Revision C

Page 2

Not for

Reproduction

1

L

G

S

T

H

F

K

J

U

B

D

C

P

E

N A

R

M

2

B

4

A

A

3

5

A

B

C

A

2 BRIGGSandSTRATTON.COM

Page 3

Not for

Reproduction

6

87

9

10

A

A

B

A

C

A

11

3 3

Page 4

Not for

Reproduction

Thank you for purchasing this quality-built Briggs & Stratton® generator. We are pleased that you’ve placed your confidence in the Briggs & Stratton brand. When operated and

maintained according to the instructions in this manual, your Briggs & Stratton generator will provide many years of dependable service.

This manual contains safety information to make you aware of the hazards and risks associated with generators and how to avoid them. This generator is designed and intended only

for supplying electrical power for operating compatible electrical lighting, appliances, tools and motor loads, and is not intended for any other purpose. It is important that you read

and understand these instructions thoroughly before attempting to start or operate this equipment. Save these original instructions for future reference.

This generator requires final assembly before use. Refer to the Assembly section of this manual for instructions on final assembly procedures. Follow the instructions completely.

Where to Find Us

You never have to look far to find Briggs & Stratton support and service for your generator. There are thousands of Briggs & Stratton authorized service dealers worldwide who

provide quality service. You can also find the nearest Authorized Service Dealer in our dealer locator map on the Internet at BRIGGSandSTRATTON.COM.

Generator

Model Number

Revision

Serial Number

Date Purchased

Table of Contents

Operator Safety . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .5

Assembly ...........................................7

Features and Controls. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .7

Operation ...........................................8

Maintenance .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. .11

Troubleshooting .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . 14

Specifications ......................................15

Warranties. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. .16

Engine

Model Number

Type Number

Code Number

Copyright © 2017 Briggs & Stratton Corporation

Milwaukee, WI, USA. All rights reserved.

BRIGGS & STRATTON is a registered trademark of Briggs & Stratton Corporation

4 BRIGGSandSTRATTON.COM4 BRIGGSandSTRATTON.COM

ORIGINAL INSTRUCTIONS

Page 5

Not for

Reproduction

Operator Safety

Equipment Description

Read this manual carefully and become familiar with your generator.

Know its applications, its limitations and any hazards involved.

Every effort has been made to ensure that the information in this manual is both

accurate and current. However, the manufacturer reserves the right to change, alter

or otherwise improve the generator and this documentation at any time without prior

notice.

Important Safety Information

The manufacturer cannot possibly anticipate every possible circumstance that might

involve a hazard. The warnings in this manual, and the tags and decals affixed to the

unit are, therefore, not all-inclusive. If you use a procedure, work method or operating

technique that the manufacturer does not specifically recommend, you must satisfy

yourself that it is safe for you and others. You must also make sure that the procedure,

work method or operating technique that you choose does not render the generator

unsafe.

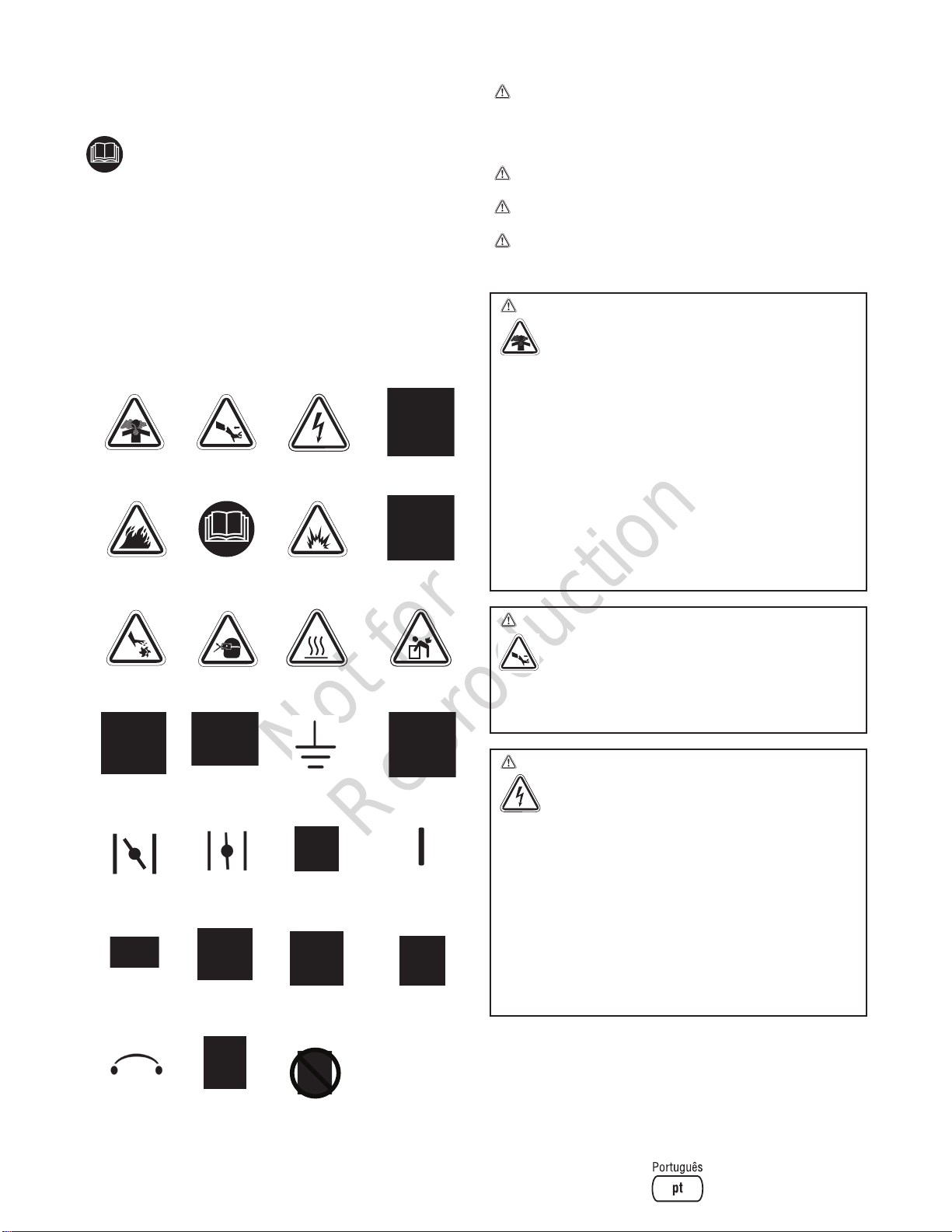

Safety Symbols and Meanings

Toxic Fumes

Fire

Kickback

Operator’s

Manual

Electrical

Shock

Explosion

Suffocation

Suffocation

The safety alert symbol indicates a potential personal injury hazard. A signal word

(DANGER, WARNING, or CAUTION) is used with the alert symbol to designate a

degree or level of hazard seriousness. A safety symbol may be used to represent the

type of hazard. The signal word NOTICE is used to address practices not related to

personal injury.

DANGER indicates a hazard which, if not avoided, will result in death or serious

injury.

WARNING indicates a hazard which, if not avoided, could result in death or

serious injury.

CAUTION indicates a hazard which, if not avoided, could result in minor or

moderate injury.

NOTICE address practices not related to personal injury.

WARNING POISONOUS GAS HAZARD. Engine exhaust contains carbon

monoxide, a poisonous gas that could kill you in minutes. You CANNOT

see it, smell it, or taste it. Even if you do not smell exhaust fumes, you

could still be exposed to carbon monoxide gas. If you start to feel sick,

dizzy or weak while using this product, shut it off and get to fresh air

RIGHT AWAY. See a doctor. You may have carbon monoxide poisoning.

• Operate this product ONLY outside far away from windows, doors and vents to

reduce the risk of carbon monoxide gas from accumulating and potentially being

drawn towards occupied spaces.

• Install battery-operated carbon monoxide alarms or plug-in carbon monoxide

alarms with battery back-up according to the manufacturer’s instructions. Smoke

alarms cannot detect carbon monoxide gas.

• DO NOT run this product inside homes, garages, basements, crawlspaces,

sheds, or other partially-enclosed spaces even if using fans or opening doors and

windows for ventilation. Carbon monoxide can quickly build up in these spaces

and can linger for hours, even after the product has shut off.

• ALWAYS place this product downwind and point the engine exhaust away from

occupied spaces.

Moving Parts Flying Objects

Carbon

Monoxide Alarm

Choke Run

Volt Meter Oil Level Fuel Start

Circuit Breaker Engine Control Do Not Start

Alarm Bonded to

Hot Surface

Ground

Engine

Heavy Objects

Ground

Terminal

Off On

!

WARNING Starter cord kickback (rapid retraction) will pull hand and arm

toward engine faster than you can let go which could cause broken

bones, fractures, bruises, or sprains resulting in serious injury.

• When starting engine, pull cord slowly until resistance is felt and then pull rapidly

to avoid kickback.

• NEVER start or stop engine with electrical devices plugged in and turned on.

WARNING

• Use approved transfer equipment to prevent backfeed by isolating generator from

electric utility workers.

• When using generator for backup power, notify utility company.

• Use a residual-current device (RCD) in any damp or highly conductive area, such

as metal decking or steel work.

• DO NOT touch bare wires or receptacles.

• DO NOT use generator with electrical cords which are worn, frayed, bare or

otherwise damaged.

• DO NOT operate generator in the rain or wet weather.

• DO NOT handle generator or electrical cords while standing in water, while

barefoot, or while hands or feet are wet.

• DO NOT allow unqualified persons or children to operate or service generator.

Generator voltage could cause electrical shock or burn resulting

in death or serious injury.

5 5

Page 6

Not for

Reproduction

WARNING Exhaust heat/gases could ignite combustibles, structures or

damage fuel tank causing a fire, resulting in death, serious

injury and/or property damage.

Contact with muffler area could cause burns resulting in

serious injury.

• DO NOT touch hot parts and AVOID hot exhaust gases.

• Allow equipment to cool before touching.

• Keep at least 1.5m (5ft.) of clearance on all sides of generator including overhead.

• Contact the original equipment manufacturer, retailer, or dealer to obtain a spark

arrester designed for the exhaust system installed on this engine.

• Replacement parts must be the same and installed in the same position as

the original parts.

WARNING Unintentional sparking could cause fire or electric shock resulting

in death or serious injury.

WHEN ADJUSTING OR MAKING REPAIRS TO YOUR GENERATOR

• Disconnect the spark plug wire from the spark plug and place the wire where it

cannot contact spark plug.

WHEN TESTING FOR ENGINE SPARK

• Use approved spark plug tester.

• DO NOT check for spark with spark plug removed.

WARNING Starter and other rotating parts could entangle hands, hair,

clothing, or accessories resulting in serious injury.

• NEVER operate generator without protective housing or covers.

• DO NOT wear loose clothing, jewelry or anything that could be caught in the

starter or other rotating parts.

• Tie up long hair and remove jewelry.

CAUTION Excessively high operating speeds could result in minor injury

and/or generator damage.

Excessively low speeds impose a heavy load.

• DO NOT tamper with governor spring, links or other parts to increase engine

speed.

• DO NOT modify generator in any way.

NOTICE

Exceeding generators wattage/amperage capacity could damage generator

and/or electrical devices connected to it.

• DO NOT exceed the generator’s wattage/amperage capacity. See Don’t Overload

Generator in the Operation section.

• Start generator and let engine stabilize before connecting electrical loads.

• Connect electrical loads in OFF position, then turn ON for operation.

• Turn electrical loads OFF and disconnect from generator before stopping

generator.

NOTICE

Improper treatment of generator could damage it and shorten its life.

• Use generator only for intended uses.

• If you have questions about intended use, ask dealer or contact local service

center.

• Operate generator only on level surfaces.

• DO NOT expose generator to excessive moisture, dust, dirt, or corrosive vapors.

• DO NOT insert any objects through cooling slots.

• If connected devices overheat, turn them off and disconnect them from

generator.

• Shut off generator if:

-electrical output is lost;

-equipment sparks, smokes, or emits flames;

-unit vibrates excessively.

WARNING Fuel and its vapors are extremely flammable and explosive which

WHEN ADDING OR DRAINING FUEL

• Turn generator engine OFF and let it cool at least 2 minutes before removing fuel

cap. Loosen cap slowly to relieve pressure in tank.

• Fill or drain fuel tank outdoors.

• DO NOT overfill tank. Allow space for fuel expansion.

• If fuel spills, wait until it evaporates before starting engine.

• Keep fuel away from sparks, open flames, pilot lights, heat, and other ignition

sources.

• Check fuel lines, tank, cap and fittings frequently for cracks or leaks. Replace if

necessary.

• DO NOT light a cigarette or smoke.

WHEN STARTING EQUIPMENT

• Ensure spark plug, muffler, fuel cap, and air cleaner are in place.

• DO NOT crank engine with spark plug removed.

WHEN OPERATING EQUIPMENT

• DO NOT operate this product inside any building, carport, porch, mobile

equipment, marine applications, or enclosure.

• DO NOT tip engine or equipment at angle which causes fuel to spill.

• DO NOT stop engine by moving choke control to “Choke” position (

WHEN TRANSPORTING, MOVING OR REPAIRING EQUIPMENT

• Transport/move/repair with fuel tank EMPTY or with fuel shutoff valve OFF.

• DO NOT tip engine or equipment at angle which causes fuel to spill.

• Disconnect spark plug wire.

WHEN STORING FUEL OR EQUIPMENT WITH FUEL IN TANK

• Store away from furnaces, stoves, water heaters, clothes dryers, or other

appliances that have pilot light or other ignition source because they could ignite

fuel vapors.

could cause burns, fire or explosion resulting in death,

serious injury and/or property damage.

).

6 BRIGGSandSTRATTON.COM6 BRIGGSandSTRATTON.COM

Page 7

Not for

Reproduction

Assembly

Your generator is ready for use after it has been properly serviced with the

recommended fuel and oil.

If you have any problems with the servicing of your generator, contact your local Briggs

& Stratton service center. If you need assistance, please have the model, revision, and

serial number from the identification label available. See Features and Controls for

identification label location.

Unpack Generator

1. Set the carton on a rigid, flat surface.

2. Remove everything from carton.

3. Open carton completely by cutting each corner from top to bottom.

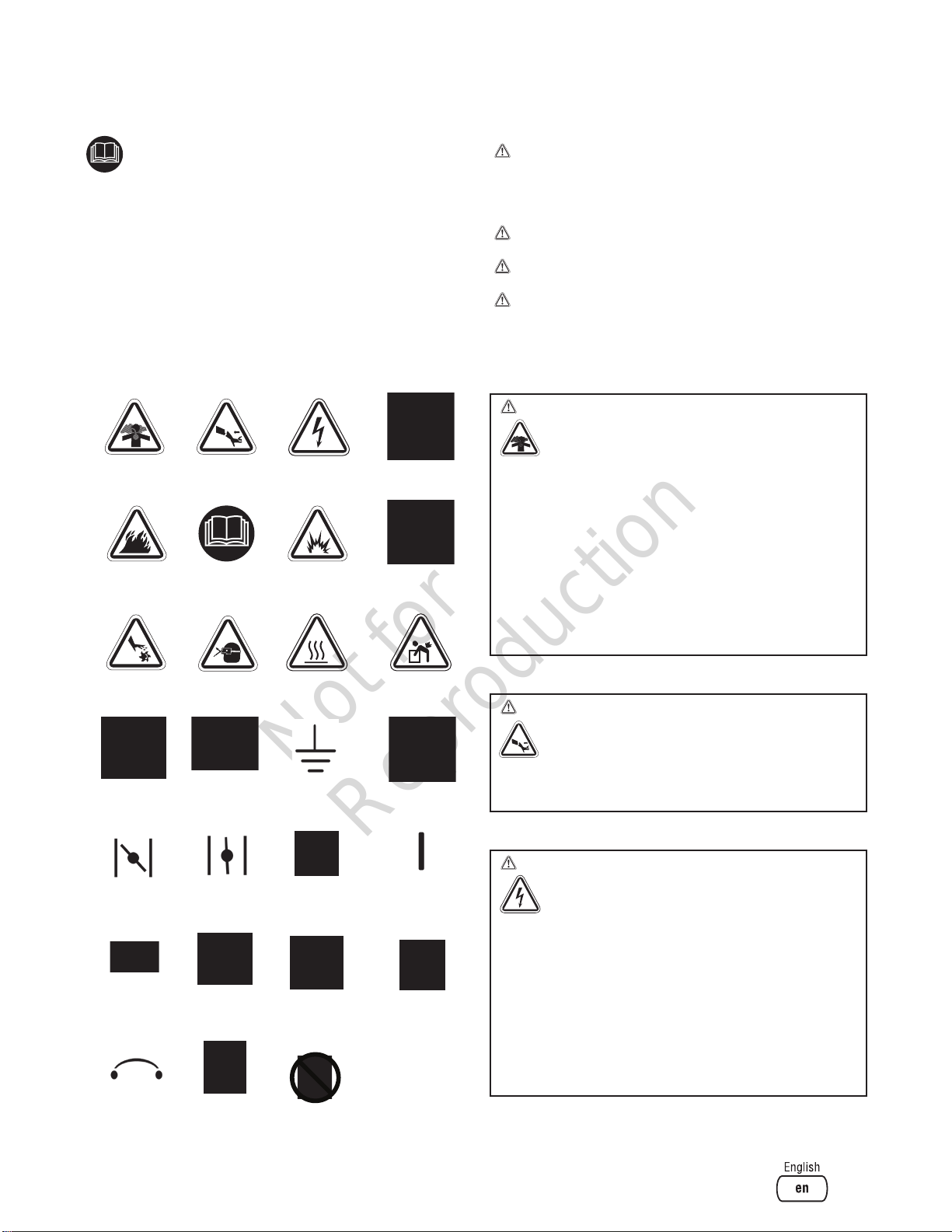

Add Oil Figure 2

1. Place generator on a level surface.

2. Clean the oil fill area of any debris.

3. To add oil, pour the oil slowly into the engine oil fill (4,A).

4. Remove the dipstick (2,A) and wipe with a clean cloth.

5. Insert the dipstick but do not screw in. Oil level should be at FULL mark (2,B).

Add oil if needed to reach FULL mark.

6. Replace and tighten the dipstick.

NOTICE

Improper treatment of generator could damage it and shorten its life.

• DO NOT attempt to crank or start the engine before it has been properly

serviced with the recommended oil. This could result in an engine failure.

Add Fuel Figure 1

Fuel must meet these requirements:

• Clean, fresh, unleaded petrol.

• A minimum of 87 octane/87 AKI (91 RON). For high altitude use, see High Altitude.

• Petrol with up to 10% ethanol (gasohol) is acceptable.

NOTICE Do not use unapproved gasolines, such as E15 and E85. Do not mix oil in

gasoline or modify the engine to run on alternate fuels. Use of unapproved fuels will

damage the engine components and void the engine warranty.

To protect the fuel system from gum formation, mix a fuel stabilizer into the fuel. See

Storage. All fuel is not the same. If starting or performance problems occur, change

fuel providers or change brands. This engine is certified to operate on gasoline. The

emissions control system for this engine is EM (Engine Modifications).

WARNING Fuel and its vapors are extremely flammable and explosive which

WHEN ADDING FUEL

• Turn generator engine OFF and let it cool at least 2 minutes before removing fuel

cap. Loosen cap slowly to relieve pressure in tank.

• Fill fuel tank outdoors.

• DO NOT overfill tank. Allow space for fuel expansion.

• If fuel spills, wait until it evaporates before starting engine.

• Keep fuel away from sparks, open flames, pilot lights, heat, and other ignition sources.

• Check fuel lines, tank, cap and fittings frequently for cracks or leaks. Replace if

necessary.

• DO NOT light a cigarette or smoke.

4

3

could cause burns, fire or explosion resulting in death, serious

injury and/or property damage.

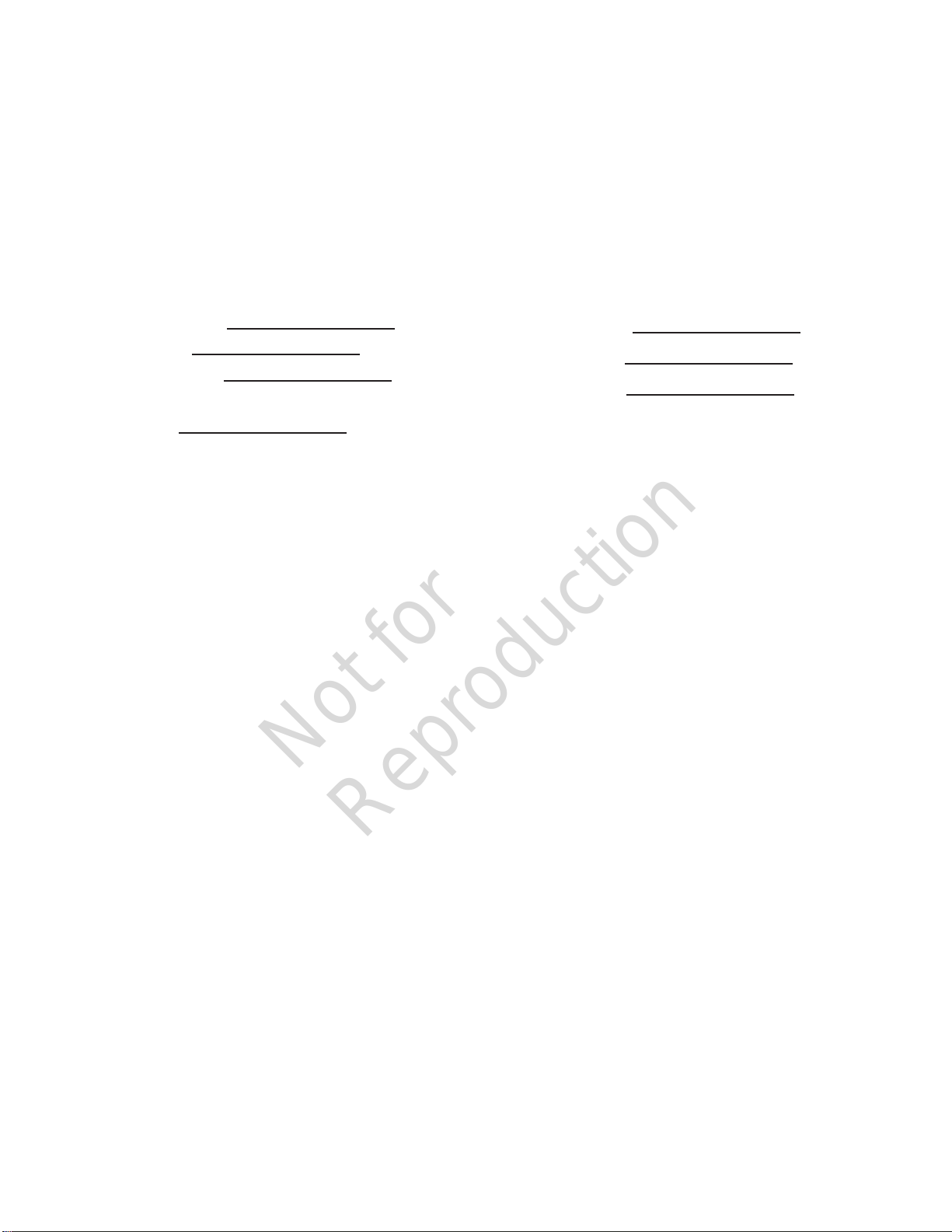

Attach Negative Battery Cable Figure

On models with electric start engines, attach the negative battery cable to the battery

as follows:

1. Cut off tie wrap securing loose end of negative (black) cable.

2. Using an 8 mm socket wrench, remove screw (C), lock washer (C) and flat

washer (C) on negative battery terminal (A).

3. Slide lock washer, flat washer and negative battery cable (B) over screw as shown.

4. Reattach screw to negative battery terminal and tighten.

5. Verify that connections to battery and generator are tight and secure.

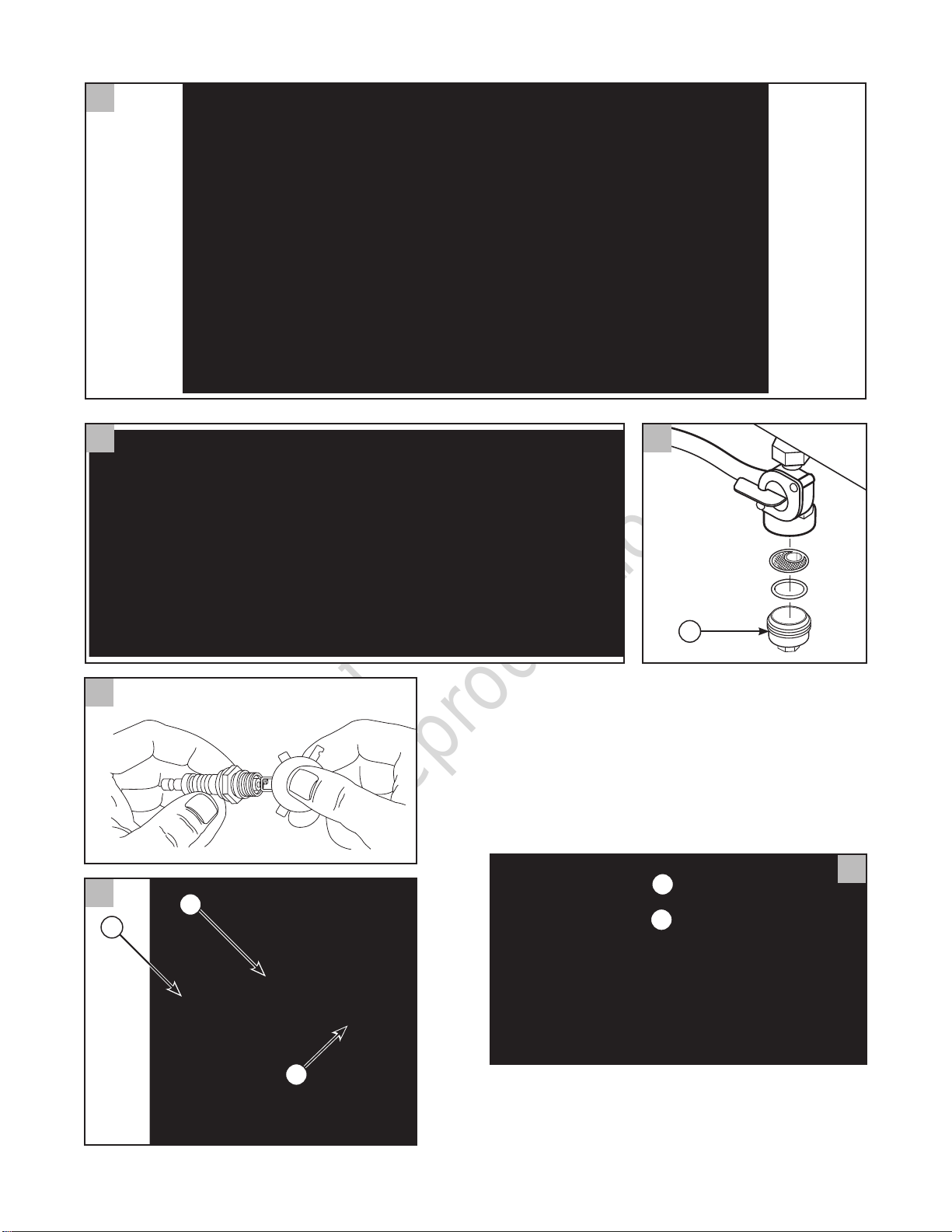

Features and Controls Figure

Read this Operator’s Manual and safety rules before operating your

generator. Compare the illustrations with your generator, to familiarize

yourself with the locations of various controls and adjustments. Save this

manual for future reference.

A - Engine Identification Number — Provides model, type and code of engine. Please

have these readily available if calling for assistance.

B - Generator Identification Number — Provides model and serial number of

generator. Please have these readily available if calling for assistance.

C - Fuel Tank — Check and add unleaded fuel here.

D - Grounding Fastener — Consult your local agency having jurisdiction for grounding

requirements in your area.

E - Fuel Gauge — Displays amount of fuel available in fuel tank.

F - AC Outlet — May be used to supply electrical power for the operation of AC, single

phase, electrical, lighting, appliance, tool, and motor loads.

G - Circuit Breaker — The receptacles are provided with circuit breakers to protect the

generator against electrical overload.

H - Voltmeter — Used for measuring electrical potential.

J - Oil Fill Cap/Dipstick — Check and add engine oil here.

K - Oil Drain Plug — Drain engine oil here.

L - Fuel Valve — Used to turn fuel supply on and off to engine.

M - Recoil Starter — Used to start the engine manually.

N - Air Cleaner — Protects engine by filtering dust and debris out of intake air.

P - Spark Arrester Muffler — Exhaust muffler lowers engine noise and is equipped

with spark arrester screen.

R - Spark Plug — A device in the cylinder head of engine that ignites the fuel mixture

by means of an electric spark.

S - Choke Control — Used when starting a cold engine.

T - Electric Start Switch (Electric Start) — Turn key to start (

engine. Turn key to off (O) position to switch off engine.

U - Low Oil Warning Light — The low oil warning light is designed to prevent engine

damage caused by not enough engine oil.

5

1

) position to start the

1. Clean area around fuel fill cap, remove cap.

2. Slowly add unleaded fuel to fuel tank (1,C). Be careful not to fill above the red

indicator line (3,A). This allows adequate space for fuel expansion as shown.

3. Install fuel cap and let any spilled fuel evaporate before starting engine.

High Altitude

At altitudes over 5,000 feet (1524 meters), a minimum 85 octane / 85 AKI (89 RON)

gasoline is acceptable. To remain emissions compliant, high altitude adjustment

is required. Operation without this adjustment will cause decreased performance,

increased fuel consumption, and increased emissions. Contact a Briggs & Stratton

Authorized Service Dealer for high altitude adjustment information.

Operation of the engine at altitudes below 2,500 feet (762 meters) with the high

altitude kit is not recommended.

7 7

Page 8

Not for

Reproduction

Operation

System Ground

The generator is provided with a grounding fastener. The generator has a system

ground that connects the generator frame components to the ground terminals on the

AC output receptacles. The system ground is connected to the AC neutral wire (the

neutral is bonded to the generator frame).

Special Requirements

There may be Federal, local codes, or ordinances that apply to the intended use of the

generator. Please consult a qualified electrician, electrical inspector, or the local agency

having jurisdiction:

• In some areas, generators are required to be registered with local utility

companies.

• If the generator is used at a construction site, there may be additional

regulations which must be observed.

Connecting to a Building’s Electrical System

Connections for standby power to a building’s electrical system must use a listed

transfer switch installed by a current licensed electrician. The connection must isolate

the generator power from the utility power and must comply with all applicable laws

and electrical codes.

WARNING

• Use approved transfer equipment to prevent backfeed by isolating generator from

electric utility workers.

• When using generator for backup power, notify utility company.

• Use a residual-current device (RCD) in any damp or highly conductive area, such

as metal decking or steel work.

• DO NOT touch bare wires or receptacles.

• DO NOT use generator with electrical cords which are worn, frayed, bare or

otherwise damaged.

• DO NOT operate generator in the rain or wet weather.

• DO NOT handle generator or electrical cords while standing in water, while

barefoot, or while hands or feet are wet.

• DO NOT allow unqualified persons or children to operate or service generator.

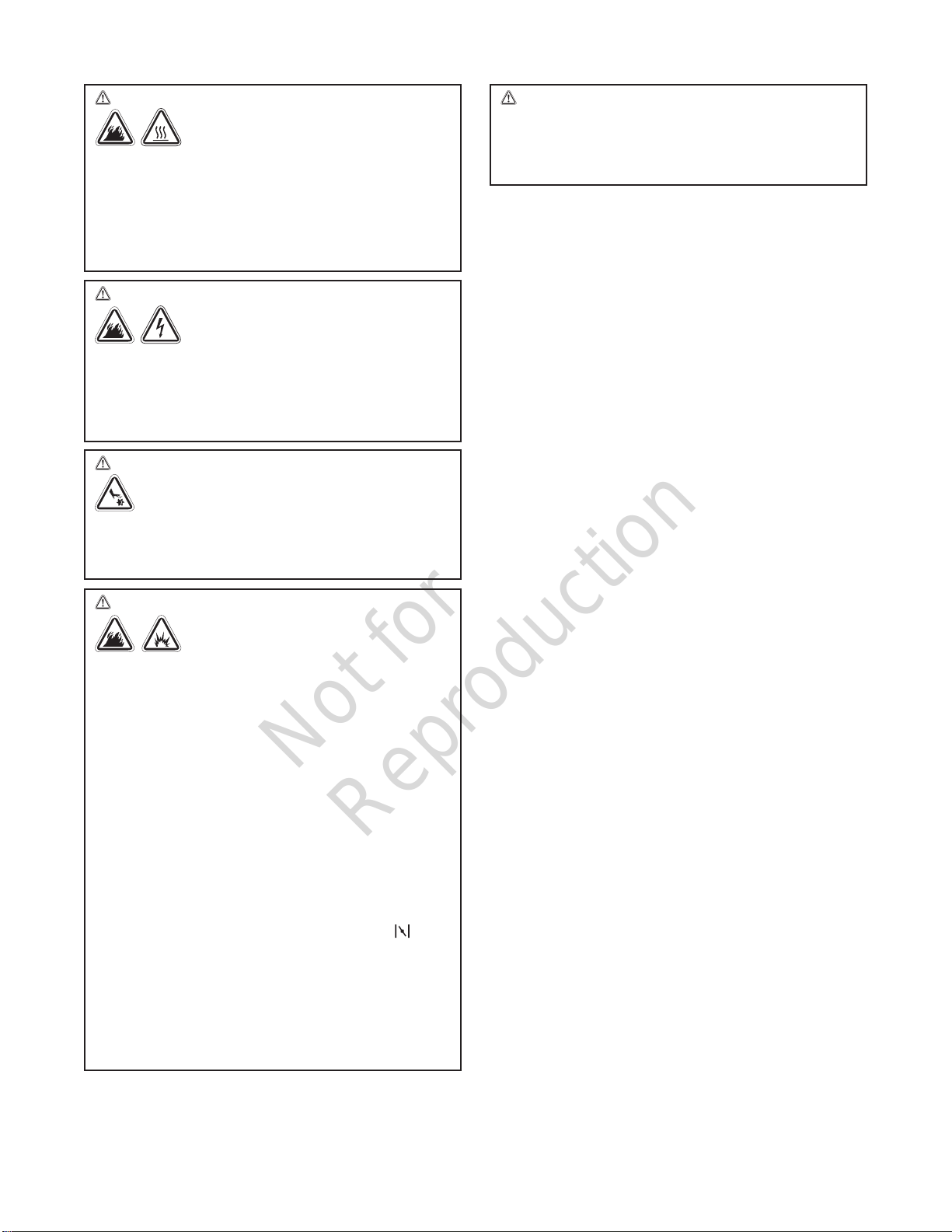

Generator Location Figure 6

WARNING POISONOUS GAS HAZARD. Engine exhaust contains carbon

RIGHT AWAY. See a doctor. You may have carbon monoxide poisoning.

• Operate this product ONLY outside far away from windows, doors and vents to

reduce the risk of carbon monoxide gas from accumulating and potentially being

drawn towards occupied spaces.

• Install battery-operated carbon monoxide alarms or plug-in carbon monoxide

alarms with battery back-up according to the manufacturer’s instructions. Smoke

alarms cannot detect carbon monoxide gas.

• DO NOT run this product inside homes, garages, basements, crawlspaces,

sheds, or other partially-enclosed spaces even if using fans or opening doors and

windows for ventilation. Carbon monoxide can quickly build up in these spaces

and can linger for hours, even after the product has shut off.

• ALWAYS place this product downwind and point the engine exhaust away from

occupied spaces.

Generator voltage could cause electrical shock or burn resulting

in death or serious injury.

7

monoxide, a poisonous gas that could kill you in minutes. You CANNOT

see it, smell it, or taste it. Even if you do not smell exhaust fumes, you

could still be exposed to carbon monoxide gas. If you start to feel sick,

dizzy or weak while using this product, shut it off and get to fresh air

Starting the Engine Figure

NOTICE This engine was shipped without oil. Before you start the engine, make sure

you add oil according to the instructions in this manual. If you start the engine without

oil, it will be damaged beyond repair and will not be covered under warranty.

NOTICE Before you start the engine, make sure that all electrical devices are

disconnected from the generator outlets.

1. Make sure unit is on a flat, level surface.

NOTICE Failure to start and operate the unit on a flat, level surface will cause the unit

not to start or shut down during operation.

2. Turn fuel valve (L) to on position (I).

3. Pull choke control (S) out to close choke (

4A. For electric starting, turn and hold key in start switch (T) to start (

until generator starts. To prolong the life of starter components, DO NOT hold key

in start (

between starting attempts.

• If engine starts, proceed to step 6.

• If engine fails to start, proceed to step 5.

NOTICE If battery is discharged, use manual starting instructions.

WARNING Starter cord kickback (rapid retraction) will pull hand and arm

• When starting engine, pull cord slowly until resistance is felt and then pull rapidly

to avoid kickback.

• NEVER start or stop engine with electrical devices plugged in and turned on.

4B. For manual starting, turn key in start switch to run (I) position, grasp recoil

handle (M) and pull slowly until slight resistance is felt. Then pull rapidly one

time only to start engine.

• If engine starts, proceed to step 6.

• If engine fails to start, proceed to step 5.

5. Push in the choke handle half way, turn key in start switch to run (I) position

and pull recoil handle twice or turn and hold key in start switch to start (

position as described in step 4A.

• If engine fails to start, repeat steps 3 thru 4.

6. Open the choke gradually as the engine warms up by pushing in on the choke

handle.

NOTICE If engine floods, push choke handle all the way in and crank until engine starts.

NOTICE If engine starts after 3 pulls but fails to run, or if unit shuts down during

operation, make sure unit is on a level surface and check for proper oil level in

crankcase. This unit is equipped with a low oil protection device. If so, oil must be at

proper level for engine to start.

WARNING Exhaust heat/gases could ignite combustibles, structures or

serious injury.

• DO NOT touch hot parts and AVOID hot exhaust gases.

• Allow equipment to cool before touching.

• Keep at least 1.5m (5ft.) of clearance on all sides of generator including overhead.

• Contact the original equipment manufacturer, retailer, or dealer to obtain a

spark arrester designed for the exhaust system installed on this engine.

• Replacement parts must be the same and installed in the same position as

the original parts.

) position for more than 15 seconds, and pause for at least 1 minute

toward engine faster than you can let go which could cause broken

bones, fractures, bruises, or sprains resulting in serious injury.

damage fuel tank causing a fire, resulting in death, serious

injury and/or property damage.

Contact with muffler area could cause burns resulting in

1

).

) position

)

8 BRIGGSandSTRATTON.COM

8 BRIGGSandSTRATTON.COM

Page 9

Not for

Reproduction

Connecting Electrical Loads Figure

WARNING

• Use approved transfer equipment to prevent backfeed by isolating generator from

electric utility workers.

• When using generator for backup power, notify utility company.

• Use a residual-current device (RCD) in any damp or highly conductive area, such

as metal decking or steel work.

• DO NOT touch bare wires or receptacles.

• DO NOT use generator with electrical cords which are worn, frayed, bare or

otherwise damaged.

• DO NOT operate generator in the rain or wet weather.

• DO NOT handle generator or electrical cords while standing in water, while

barefoot, or while hands or feet are wet.

• DO NOT allow unqualified persons or children to operate or service generator.

Use only high quality, well-insulated extension cables with the generator’s AC outlets.

Inspect extension cables before each use. Check that all extension cables are suitably

rated and are not damaged.

WARNING Damaged or overloaded electrical cables could overheat, arc, and

• ONLY use suitably rated extension cables.

• Follow all safety instructions on extension cables.

• Inspect cables before each use.

Generator voltage could cause electrical shock or burn resulting

in death or serious injury.

burn resulting in death, serious injury, and/or property damage.

1

Oil Level Switch and Warning Light Figure 1

If the oil level is too low, a switch will stop the engine and activate a warning light (U)

on the generator. If the oil level is too low when starting the engine, the switch will

activate the warning light. If the warning light is activated, make sure the unit is on a

level surface and check for proper oil level. See the How to Check/Add Oil section.

If the oil level is below the ADD mark, add oil until it reaches the FULL mark. Start the

engine and check for oil leaks before continuing to operate.

If the oil level is between the ADD and FULL marks, do not start the engine. See a

Briggs & Stratton Authorized Dealer to have the engine inspected.

1. Let engine stabilize and warm up for a few minutes after starting.

2. Check the voltmeter (H) for proper voltage.

3. Make sure the load of the electrical device is within the generator’s rated output.

NOTICE Receptacles may be marked with rating value greater than generator output

capacity.

• NEVER attempt to power a device requiring more amperage than the generator or

receptacle can supply.

• DO NOT overload the generator. See Generator Capacity.

4. Make sure the electrical device is turned off. Then connect the electrical device

to the generator’s AC outlet (F). After the electrical device is connected, turn on

the electrical device.

5. When connecting additional electrical devices, make sure the total load does

not exceed the generator’s wattage capacity. See Specifications section.

NOTICE Do not exceed the generator’s wattage capacity. Exceeding the wattage

capacity could damage generator and/or connected electrical devices.

6. Before stopping the engine, turn off and then disconnect all electrical devices.

Stopping the Engine Figure 8

1. Before stopping the engine, turn off and then disconnect all electrical devices.

2. Let engine run at no-load for several minutes to stabilize internal temperatures

of engine and generator.

3. Turn fuel valve to the off (

4. Electric Start: Turn the electric start switch (T) to the off ( ) position.

WARNING Fuel and its vapors are extremely flammable and explosive which

could cause burns, fire or explosion resulting in death,

serious injury and/or property damage.

• DO NOT stop engine by moving choke control to “Choke” position (

9

) position.

).

9 9

Page 10

Not for

Reproduction

Circuit Breaker Figure

The circuit breaker(s) (G) will automatically open if the load exceeds the generator’s

rated output. If the circuit breaker opens, then reduce the output load and reset the

circuit breaker before resuming operation. To determine maximum output load, see the

Generator Capacity section.

1

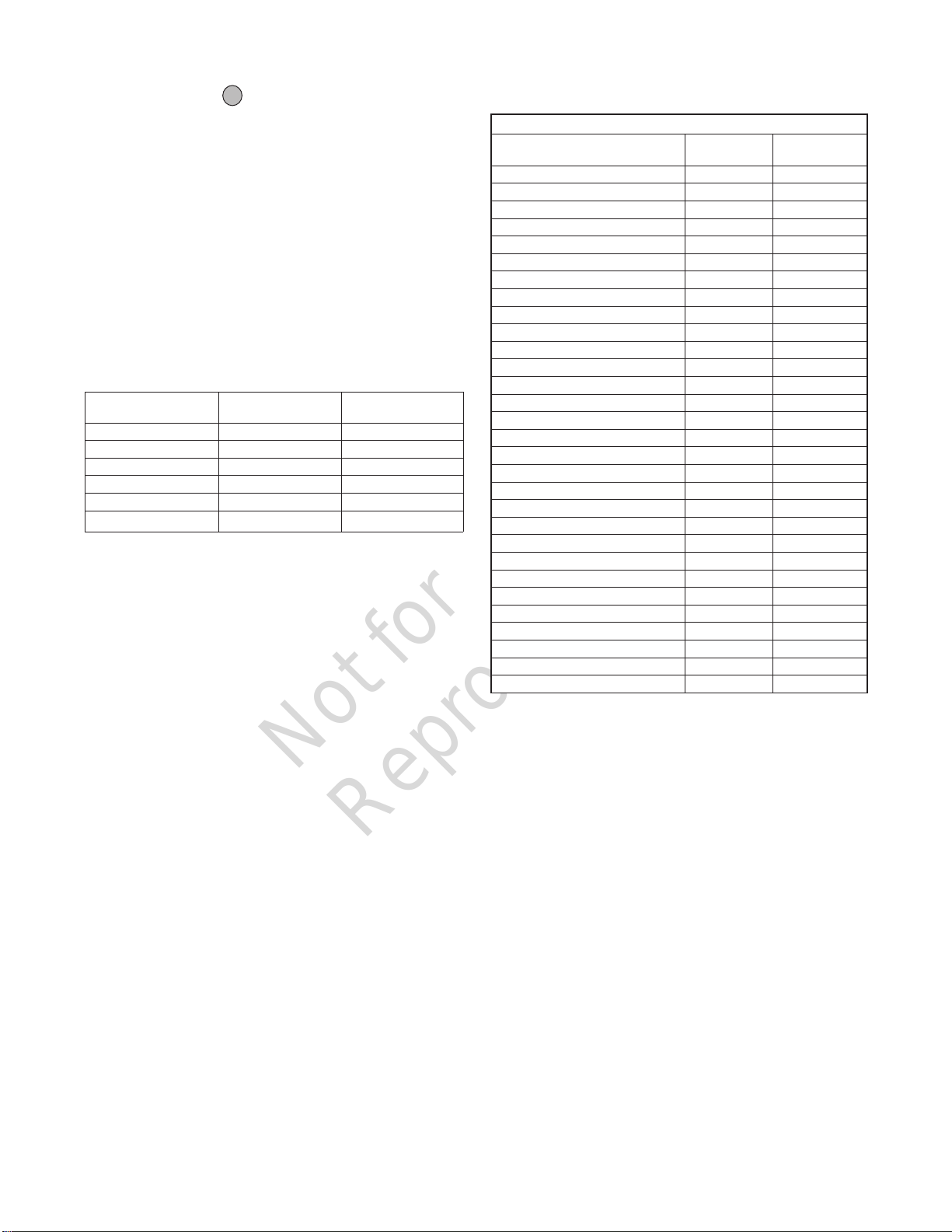

Don’t Overload Generator

Capacity

Make sure the generator’s Starting Wattage* meets or exceeds the Rated (Operating) and

Additional Surge (Starting) Watts of the electrical devices.

1. Select the items you will power at the same time.

2. Total the rated (running) watts of these items. This is the amount of power your

generator must produce to keep your items running. See Wattage Reference

Guide.

3. Estimate how many surge (starting) watts you will need. Surge wattage is the

short burst of power needed to start electric motor-driven tools or appliances

such as a circular saw or refrigerator. Because not all motors start at the same

time, total surge watts can be estimated by adding only the item(s) with the

highest additional surge watts to the total rated watts from step 2.

Tool or Appliance Rated (Running) Watts

Window Fan 300 600

Deep Freezer 500 500

Television 500 —

Security System 180 —

Light (75 Watts) 75 —

1555 Total Running Watts 600 Highest Surge Watts

Example:

Total Rated (Running) Watts 1555

Highest Additional Surge Watts + 600

Total Generator Output Required =2155

NOTICE If total generator output required does not contain additional surge watts, DO

NOT exceed generator’s rated wattage.**

*See Starting Wattage in the Specifications section.

**See Rated Wattage in the Specifications section.

Power Management

Failure to properly connect electrical devices can result in damage to the generator or

to connected electrical devices. The correct and safe way to manage generator power is

to sequentially add electrical devices (loads) as follows:

1. Before you start the engine, make sure that all electrical devices are

disconnected from the generator outlets.

2. Start the engine (see the How to Start the Engine section).

3. Connect the electrical device that requires the most watts (load).

4. Let the generator output stabilize (engine runs smoothly).

5. Connect the next electrical device.

6. Again, let the generator output stabilize.

7. Continue following the above steps to add electrical devices. Make sure the

total watts (load) of all electrical devices does not exceed the generator’s

wattage capacity (see the Specifications section).

NOTICE

Exceeding generators wattage/amperage capacity could damage generator

and/or electrical devices connected to it.

• DO NOT exceed the generator’s wattage/amperage capacity.

• Start generator and let engine stabilize before connecting electrical loads.

• Connect electrical loads in OFF position, then turn ON for operation.

• Turn electrical loads OFF and disconnect from generator before stopping generator.

Additional Surge

(Starting) Watts

Wattage Reference Guide

Tool or Appliance

Essentials

Light Bulb - 75 watt 75 —

Deep Freezer 500 500

Sump Pump 800 1200

Refrigerator/Freezer - 18 cf 800 1600

Water Well Pump - 1/3 hp 1000 2000

Heating/Cooling

Window AC - 10,000 BTU 1200 1800

Window Fan 300 600

Furnace Fan Blower - 1/2 hp 800 1300

Kitchen

Microwave Oven - 1000 Watt 1000 —

Coffee Maker 1500 —

Electric Stove - Single Element 1500 —

Family Room

DVD/CD Player 100 —

VCR 100 —

Stereo Receiver 450 —

Color Television - 27 in 500 —

Personal Computer w/17 in monitor 800 —

Other

Security System 180 —

AM/FM Clock Radio 300 —

Garage Door Opener - 1/2 hp 480 520

DIY/Job Site

Quartz Halogen Work Light 1000 —

Airless Sprayer - 1/3 hp 600 1200

Reciprocating Saw 960 960

Electric Drill - 1/2 hp 1000 1000

Circular Saw - 7-1/4 in 1500 1500

Rated* (Running)

Watts

Additional Surge

(Starting) Watts

10 BRIGGSandSTRATTON.COM

Page 11

Not for

Reproduction

Maintenance

Maintenance Schedule

Follow the hourly or calendar intervals, whichever occurs first. More frequent service is

required when operating in adverse conditions noted below.

First 5 Hours

• Change engine oil

Every 8 Hours or Daily

• Clean debris

• Check engine oil level

Every 25 Hours or Yearly

• Service engine air cleaner†

Every 50 Hours or Yearly

• Change engine oil

Every 100 Hours or Yearly

• Service fuel valve

• Service spark plug

• Inspect muffler and spark arrester

• Clean cooling system

† Service more often under dirty or dusty conditions.

General Recommendations

Regular maintenance will improve the performance and extend the life of the generator.

See any authorized dealer for service.

The generator’s warranty does not cover items that have been subjected to operator

abuse or negligence. To receive full value from the warranty, the operator must

maintain the generator as instructed in this manual.

NOTICE

Improper treatment of generator could damage it and shorten its life.

• NEVER operate generator without protective housing or covers to assure proper

cooling.

Some adjustments will need to be made periodically to properly maintain your generator.

All service and adjustments should be made at least once each season. Follow the

requirements in the Maintenance Schedule chart above.

NOTICE Once a year you should clean or replace the spark plug and replace the air

filter. A new spark plug and clean air filter assure proper fuel-air mixture and help your

engine run better and last longer.

Generator Maintenance

Generator maintenance consists of keeping the unit clean and dry. Operate and store

the unit in a clean dry environment where it will not be exposed to excessive dust, dirt,

moisture, or any corrosive vapors. Cooling air slots in the generator must not become

clogged with snow, leaves, or any other foreign material.

NOTICE DO NOT use water or other liquids to clean generator. Liquids can enter

engine fuel system, causing poor performance and/or failure to occur. In addition, if

liquid enters generator through cooling air slots, some of the liquid will be retained in

voids and cracks of the rotor and stator winding insulation. Liquid and dirt buildup on

the generator internal windings will eventually decrease the insulation resistance of

these windings.

†

†

Cleaning

Daily or before use, look around and underneath the generator for signs of oil or fuel

leaks. Clean accumulated debris from inside and outside the generator. Keep the linkage,

spring and other engine controls clean. Keep the area around and behind the muffler free

from any combustible debris. Inspect cooling air slots and openings on generator. These

openings must be kept clean and unobstructed.

Engine parts should be kept clean to reduce the risk of overheating and ignition of

accumulated debris:

• Use a damp cloth to wipe exterior surfaces clean.

NOTICE

Improper treatment of generator could damage it and shorten its life.

• DO NOT expose generator to excessive moisture, dust, dirt, or corrosive vapors.

• DO NOT insert any objects through cooling slots.

• Use a soft bristle brush to loosen caked on dirt or oil.

• Use a vacuum cleaner to pick up loose dirt and debris.

Fuel System Maintenance Figure 8

WARNING Fuel and its vapors are extremely flammable and explosive which

could cause burns, fire or explosion resulting in death,

serious injury and/or property damage.

• Keep fuel away from sparks, open flames, pilot lights, heat, and other ignition

sources.

• Check fuel lines, tank cap, and fittings frequently for cracks or leaks. Replace if

necessary.

• If fuel spills, wait until it evaporates before starting engine.

How to Clean/Replace the Debris Strainer

1. Remove the fuel cap (11,A).

2. Remove the debris strainer (11,B).

3. If the debris strainer is dirty, clean it. If the debris strainer is torn or otherwise

damaged, replace it. If you replace the debris strainer, make sure to use an

original equipment replacement debris strainer.

How to Clean the Fuel Sediment Cup

The fuel valve is equipped with a fuel sediment cup that can be cleaned as follows:

1. Move the fuel valve to the off position.

2. Remove the sediment cup (8,A) from the fuel valve.

3. Wash the sediment cup in a nonflammable solvent. Dry thoroughly.

4. Install the sediment cup and tighten securely.

5. Move the fuel valve to the on position and check for leaks. If the fuel valve

leaks, replace with an original equipment replacement fuel valve.

11

Battery Maintenance

There is no required maintenance for the starting battery, if equipped. Keep battery and

terminals clean and dry.

NOTICE The starting battery charges only while the generator is operating.

11

Page 12

Not for

Reproduction

Engine Maintenance

WARNING Unintentional sparking could cause fire or electric shock resulting

WHEN ADJUSTING OR MAKING REPAIRS TO YOUR GENERATOR

• Disconnect the spark plug wire from the spark plug and place the wire where it

cannot contact spark plug.

WHEN TESTING FOR ENGINE SPARK

• Use approved spark plug tester.

• DO NOT check for spark with spark plug removed.

Carburetor and Engine Speed Adjustment

Never make adjustments to the carburetor or engine speed. The carburetor was set at

the factory to operate efficiently under most conditions. Do not tamper with governor

spring, linkages, or other parts to change the engine speed. If adjustment is required,

see a Briggs & Stratton authorized dealer.

CAUTION Excessively high operating speeds could result in minor injury

and/or generator damage.

Excessively low speeds impose a heavy load.

• DO NOT tamper with governor spring, links or other parts to increase engine speed.

• DO NOT modify generator in any way.

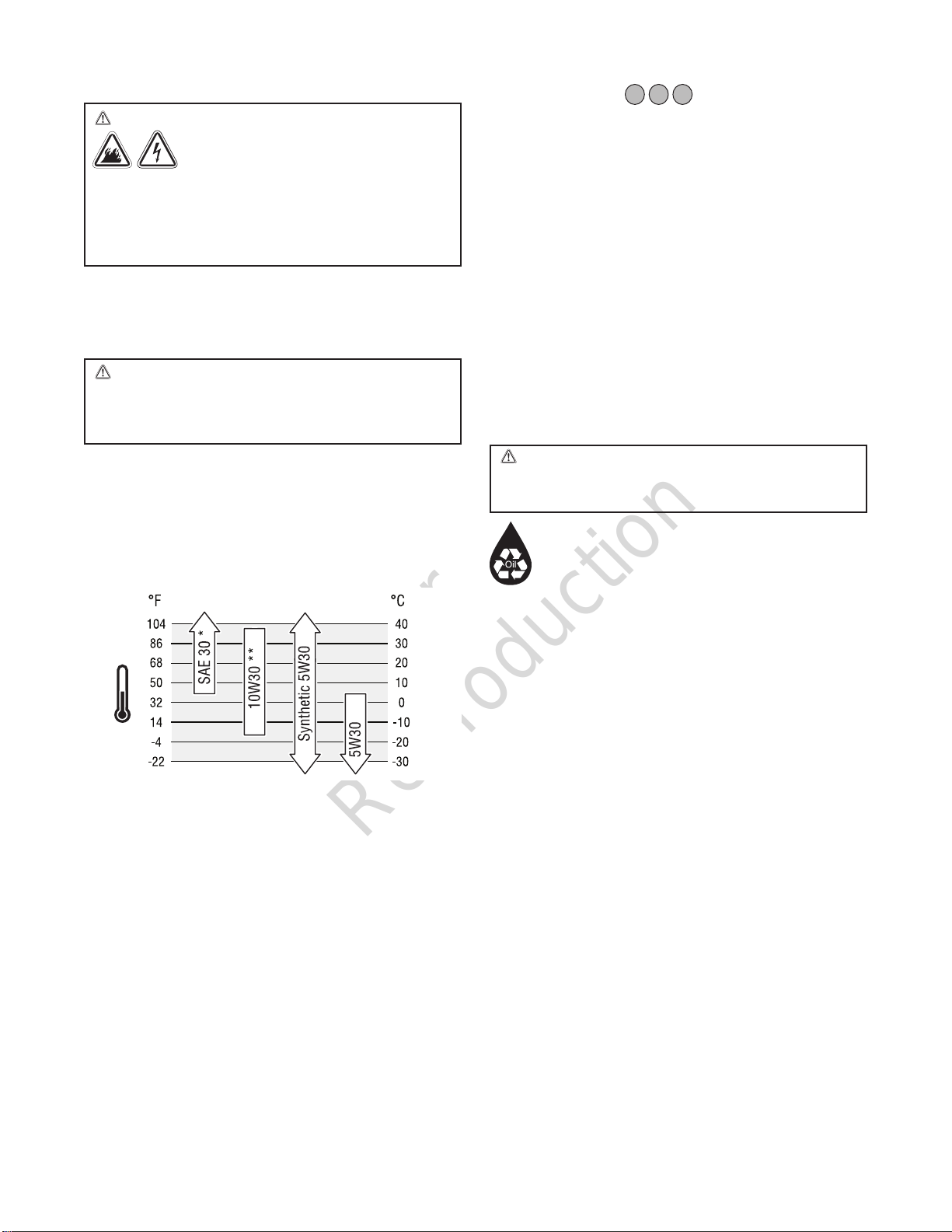

Oil

Oil Recommendations

We recommend the use of Briggs & Stratton Warranty Certified oils for best

performance. Other high-quality detergent oils are acceptable if classified for service

SF, SG, SH, SJ or higher. DO NOT use special additives.

Outdoor temperatures determine the proper oil viscosity for the engine. Use the chart

to select the best viscosity for the outdoor temperature range expected.

in death or serious injury.

Checking Oil Level

Oil level should be checked prior to each use or at least every 8 hours of operation.

Keep oil level maintained.

1. Make sure generator is on a level surface.

2. Clean area around oil fill (4,A), remove oil cap/dipstick and wipe dipstick with

clean cloth. Replace dipstick. Remove and check oil level.

NOTICE DO NOT screw in dipstick when checking oil level.

3. Verify oil is at full mark (2,B) on dipstick. Replace and tighten oil cap/dipstick.

Adding Engine Oil

1. Make sure generator is on a level surface.

2. Check oil level as described in Checking Oil Level.

3. If needed, slowly pour oil into oil fill opening to the full mark on dipstick. DO

NOT overfill.

NOTICE Overfilling with oil could cause the engine to not start, or hard starting.

• DO NOT overfill.

• If over the full mark on dipstick, drain oil to reduce oil level to full mark on dipstick.

4. Replace and tighten oil cap/dipstick.

Changing Engine Oil

If you are using your generator under extremely dirty or dusty conditions, or in

extremely hot weather, change the oil more often.

CAUTION Avoid prolonged or repeated skin contact with used motor oil.

• Used motor oil has been shown to cause skin cancer in certain laboratory

animals.

• Thoroughly wash exposed areas with soap and water.

Change the oil while the engine is still warm from running, as follows:

1. Make sure unit is on a level surface.

2. Disconnect the spark plug wire from the spark plug and place the wire where it

cannot contact spark plug.

3. Clean area around oil drain plug (1,K). The oil drain plug is located at base of

engine, opposite carburetor.

4. Remove oil drain plug and drain oil completely into a suitable container.

5. Reinstall oil drain plug and tighten securely. Remove oil fill cap/dipstick.

6. Repeat steps 3 and 4 to add engine oil as described in Adding Engine Oil.

7. Wipe up any spilled oil.

Figure 1 2 4

KEEP OUT OF REACH OF CHILDREN. DON’T POLLUTE. CONSERVE

RESOURCES. RETURN USED OIL TO COLLECTION CENTERS.

* Below 4°C (40°F) the use of SAE 30 will result in hard starting.

** Above 27°C (80°F) the use of 10W30 may cause increased oil consumption. Check

oil level more frequently.

12 BRIGGSandSTRATTON.COM

12 BRIGGSandSTRATTON.COM

Page 13

Not for

Reproduction

Service Spark Plug Figure

Changing the spark plug will help your engine to start easier and run better.

1. Clean area around spark plug.

2. Remove and inspect spark plug.

3. Check electrode gap with wire feeler gauge and reset spark plug gap to

recommended gap if necessary (see Specifications).

4. Replace spark plug if electrodes are pitted, burned or porcelain is cracked. Use

the recommended replacement spark plug. See Specifications.

5. Install spark plug and tighten firmly.

NOTICE In some areas, local law requires using a resistor spark plug to suppress

ignition signals. If the engine was originally equipped with a resistor spark plug, use

the same type for replacement.

Inspect Muffler and Spark Arrester

Inspect the muffler for cracks, corrosion, or other damage. Remove the spark arrester,

if equipped, and inspect for damage or carbon blockage. If replacement parts are

required, make sure to use only original equipment replacement parts.

WARNING Contact with muffler area can result in serious burns.

• DO NOT touch hot parts and AVOID hot exhaust gases.

• Allow equipment to cool before touching.

• Keep at least 1.5 m (5feet) of clearance on all sides of generator including

overhead.

• Contact the original equipment manufacturer, retailer, or dealer to obtain a spark

arrester designed for the exhaust system installed on this engine.

• Replacement parts must be the same and installed in the same position as the

original parts.

Service Air Cleaner

Your engine will not run properly and may be damaged if you run it with a dirty air

cleaner. Service more often if operating under dirty or dusty conditions.

To service the air cleaner, follow these steps:

1. Unlatch air cleaner cover on top and bottom and remove cover (A).

2. Carefully remove air cleaner (B) to prevent debris from falling into carburetor.

3. Wash foam air cleaner in liquid detergent and water. Squeeze dry in a clean

cloth.

4. SATURATE foam air cleaner in engine oil and squeeze in a clean cloth to

remove excess oil.

5. Reinstall clean or new foam air cleaner in base (C).

6. Assemble air cleaner cover onto base and latch.

Exhaust heat/gases can ignite combustibles, structures or

damage fuel tank causing a fire.

Figure

9

10

Clean Cooling System

Over time debris may accumulate in cylinder cooling fins and cannot be observed

without partial engine disassembly. For this reason, we recommend you have a Briggs

& Stratton authorized dealer clean the cooling system per recommended intervals (see

Maintenance Schedule in the Maintenance section). Equally important is to keep top of

engine free from debris. Also see Cleaning.

Storage

If you will not be using the generator for more than 30days, use the following

guidelines to prepare it for storage.

Generator Storage

• Clean the generator as outlined in Cleaning.

• Check that cooling air slots and openings on generator are open and unobstructed.

Long Term Storage Instructions

Fuel can become stale when stored over 30 days. Stale fuel causes acid and gum

deposits to form in the fuel system or on essential carburetor parts. To keep fuel

fresh, use Briggs & Stratton® Advanced Formula Fuel Treatment & Stabilizer, available

wherever Briggs & Stratton genuine service parts are sold.

There is no need to drain gasoline from the engine if a fuel stabilizer is added

according to instructions. Run the engine for 2 minutes to circulate the stabilizer

throughout the fuel system before storage. If gasoline in the engine has not been

treated with a fuel stabilizer, it must be drained into an approved container. Run

the engine until it stops from lack of fuel. The use of a fuel stabilizer in the storage

container is recommended to maintain freshness.

WARNING Fuel and its vapors are extremely flammable and explosive which

could cause burns, fire or explosion resulting in death, serious

injury and/or property damage.

WHEN STORING FUEL OR EQUIPMENT WITH FUEL IN TANK

• Store away from furnaces, stoves, water heaters, clothes dryers or other

appliances that have pilot light or other ignition source because they could ignite

fuel vapors.

WHEN DRAINING FUEL

• Turn generator engine OFF and let it cool at least 2 minutes before removing fuel

cap. Loosen cap slowly to relieve pressure in tank.

• Drain fuel tank outdoors.

• Keep fuel away from sparks, open flames, pilot lights, heat, and other ignition

sources.

• Check fuel lines, tank, cap and fittings frequently for cracks or leaks. Replace if

necessary.

• DO NOT light a cigarette or smoke.

Change Engine Oil

While engine is still warm, drain oil from crankcase. Refill with recommended grade.

See Changing Engine Oil.

Other Storage Tips

1. DO NOT store fuel from one season to another unless it has been treated as

described in Long Term Storage Instructions.

2. Replace fuel container if it starts to rust. Rust and/or dirt in fuel can cause

problems if it’s used with this unit.

3. Cover unit with a suitable protective cover that does not retain moisture.

WARNING Storage covers could cause a fire resulting in death, serious

injury and/or property damage.

• DO NOT place a storage cover over a hot generator.

• Let equipment cool for a sufficient time before placing the cover on the equipment.

4. Store generator in clean, dry area.

13 13

Page 14

Not for

Reproduction

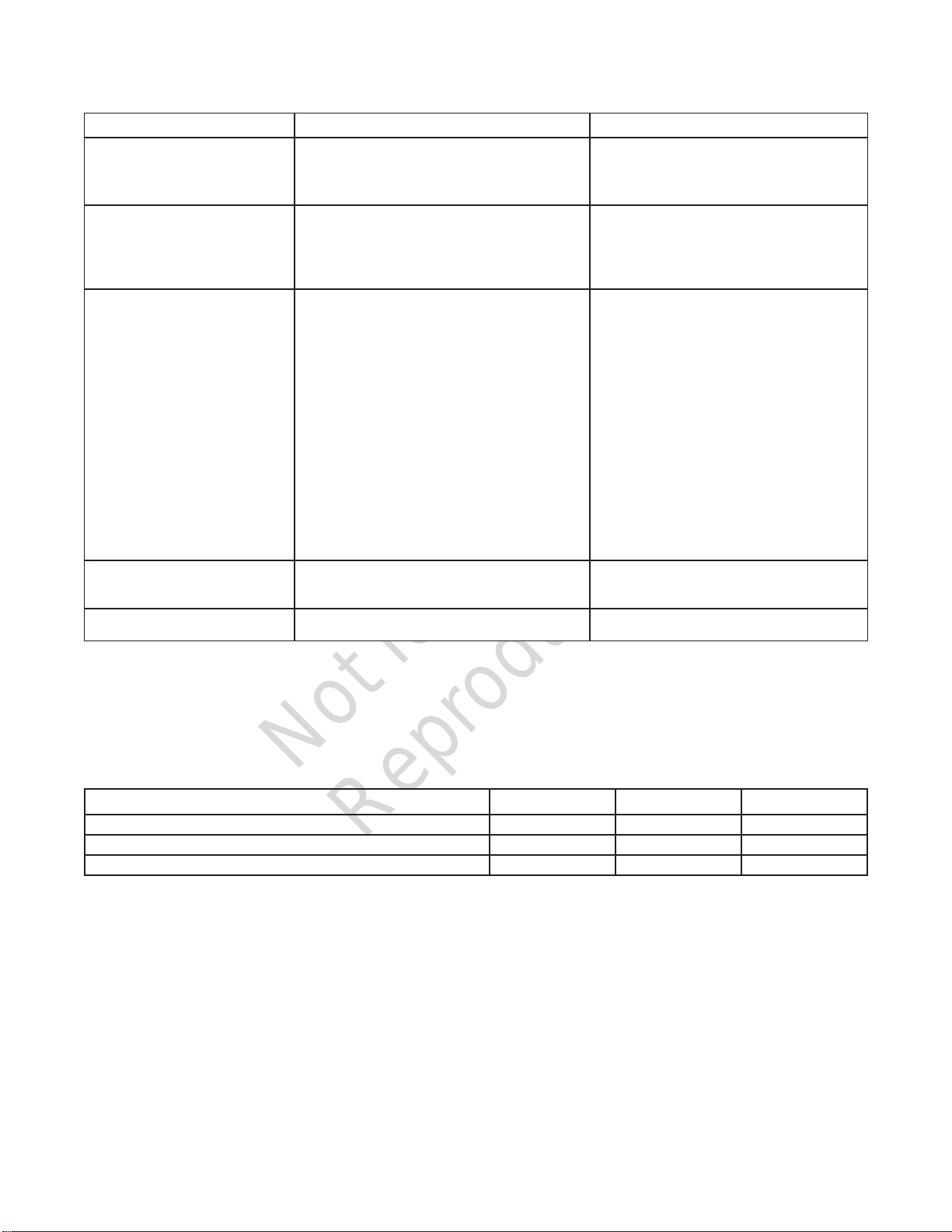

Troubleshooting

Problem Cause Correction

1. Reset circuit breaker.

2. Contact authorized service facility.

3. Check and repair.

4. Connect another device that is in good condition.

1. Disconnect shorted electrical load.

2. Contact authorized service facility.

3. See Don’t Overload Generator in Operation section.

4. Contact authorized service facility.

5. Clean or replace fuel filter.

1. Turn fuel valve to on (I) position.

2. Fill crankcase to proper level or place generator on

level surface.

3. Clean or replace air cleaner.

4. Clean or replace fuel filter.

5. Fill fuel tank.

6. Drain fuel tank and carburetor; fill with fresh fuel.

7. Connect wire to spark plug.

8. Replace spark plug.

9. Drain gas tank and carburetor; fill with fresh fuel.

10. Wait 5 minutes and re-crank engine.

11. Contact authorized service facility.

12. Contact authorized service facility.

13. Contact authorized service facility.

14. Turn electric stop switch to run position.

15. Charge or replace battery.

1. See Don’t Overload Generator.

2. Replace air filter.

3. Clean or replace fuel filter.

1. Contact authorized service facility.

2. Clean or replace fuel filter.

Engine is running, but no AC output is

available.

Engine runs good at no-load but “bogs

down” when loads are connected.

Engine will not start; shuts down when

running or starts and runs rough.

Engine lacks power.

Engine “hunts” or falters.

1. Circuit breaker open.

2. Fault in generator.

3. Poor connection or damaged extension cable.

4. Inoperative electrical device.

1. Short circuit in connected electrical device.

2. Engine speed too slow.

3. Generator overloaded.

4. Shorted generator circuit.

5. Clogged or dirty fuel filter.

1. Fuel shut off valve in off (O) position.

2. Low oil level.

3. Dirty air filter.

4. Clogged or dirty fuel filter.

5. Out of fuel.

6. Stale fuel.

7. Spark plug wire not connected to spark plug.

8. Damaged spark plug.

9. Water in fuel.

10. Carburetor flooded.

11. Excessively rich fuel mixture.

12. Intake valve stuck open or closed.

13. Engine has lost compression.

14. Electric start switch in off position.

15. Battery discharged.

1. Generator overloaded.

2. Dirty air filter.

3. Clogged or dirty fuel filter.

1. Carburetor is running too rich or too lean.

2. Clogged or dirty fuel filter.

Energy Consumption

Energy consumption (gasoline) in normal operation at 50% of load 1.12 l/h 1.63 l/h 2.04 l/h

Energy consumption (gasoline) in idle mode Does not apply Does not apply Does not apply

Product or service delivered per energy consumed units Does not apply Does not apply Does not apply

2,300 Watt 3,500 Watt 6,000 Watt

14 BRIGGSandSTRATTON.COM

Page 15

Not for

Reproduction

Product Specifications

Model(s) 030566, 030596

Starting Wattage ..............................................2,500 Watts

Rated Wattage* ...............................................2,300 Watts

AC Output Voltage ...............................................230 Volts

Load Current at 230 Volts AC .....................................10.0 Amps

Frequency ........................................................60 Hz

Phase .....................................................Single Phase

Fuel Capacity ................................................4.0 gal (15 L)

Engine Displacement ........................................9.95 ci (163 cc)

Oil Capacity ....................................... 18 - 20 oz (0.54 - 0.59 L)

Spark Plug Gap .........................................0.030 in (0.76 mm)

Spark Plug Torque ........................................180 lb-in (20 Nm)

Intake Valve Clearance ........................ 0.004 - 0.006 in (0.10 - 0.15 mm)

Exhaust Valve Clearance ...................... 0.006 - 0.008 in (0.15 - 0.20 mm)

Model(s) 030570, 030597

Starting Wattage ..............................................4,000 Watts

Rated Wattage* ...............................................3,500 Watts

AC Output Voltage ...............................................230 Volts

Load Current at 230 Volts AC .....................................15.2 Amps

Frequency ........................................................60 Hz

Phase .....................................................Single Phase

Fuel Capacity ................................................6.6 gal (25 L)

Engine Displacement .......................................16.48 ci (270 cc)

Oil Capacity ....................................... 35 - 37 oz (1.05 - 1.09 L)

Spark Plug Gap .........................................0.030 in (0.76 mm)

Spark Plug Torque ........................................275 lb-in (31 Nm)

Intake Valve Clearance ........................ 0.005 - 0.007 in (0.13 - 0.18 mm)

Exhaust Valve Clearance ...................... 0.005 - 0.007 in (0.13 - 0.18 mm)

Model(s) 030576, 030583, 030598, 030599

Starting Wattage ..............................................6,500 Watts

Rated Wattage* ...............................................6,000 Watts

AC Output Voltage ...............................................230 Volts

Load Current at 230 Volts AC .....................................26.0 Amps

Frequency ........................................................60 Hz

Phase .....................................................Single Phase

Fuel Capacity ................................................6.6 gal (25 L)

Engine Displacement .......................................25.63 ci (420 cc)

Oil Capacity ....................................... 35 - 37 oz (1.05 - 1.09 L)

Spark Plug Gap .........................................0.030 in (0.76 mm)

Spark Plug Torque ........................................275 lb-in (31 Nm)

Intake Valve Clearance ........................ 0.005 - 0.007 in (0.13 - 0.18 mm)

Exhaust Valve Clearance ...................... 0.005 - 0.007 in (0.13 - 0.18 mm)

Model(s) 030588

Starting Wattage ..............................................2,500 Watts

Rated Wattage* ...............................................2,300 Watts

AC Output Voltage ...............................................115 Volts

Load Current at 115 Volts AC .....................................20.0 Amps

Frequency ........................................................60 Hz

Phase .....................................................Single Phase

Fuel Capacity ................................................4.0 gal (15 L)

Engine Displacement ........................................9.95 ci (163 cc)

Oil Capacity ....................................... 18 - 20 oz (0.54 - 0.59 L)

Spark Plug Gap .........................................0.030 in (0.76 mm)

Spark Plug Torque ........................................180 lb-in (20 Nm)

Intake Valve Clearance ........................ 0.004 - 0.006 in (0.10 - 0.15 mm)

Exhaust Valve Clearance ...................... 0.006 - 0.008 in (0.15 - 0.20 mm)

Model(s) 030589

Starting Wattage ..............................................4,000 Watts

Rated Wattage* ...............................................3,500 Watts

AC Output Voltage ..........................................115 / 230 Volts

Load Current at 115 Volts AC .....................................30.4 Amps

Load Current at 230 Volts AC .....................................15.2 Amps

Frequency ........................................................60 Hz

Phase .....................................................Single Phase

Fuel Capacity ................................................ 6.6 gal (25 L

Engine Displacement .......................................16.48 ci (270 cc)

Oil Capacity ....................................... 35 - 37 oz (1.05 - 1.09 L)

Spark Plug Gap .........................................0.030 in (0.76 mm)

Spark Plug Torque ........................................275 lb-in (31 Nm)

Intake Valve Clearance ........................ 0.005 - 0.007 in (0.13 - 0.18 mm)

Exhaust Valve Clearance ...................... 0.005 - 0.007 in (0.13 - 0.18 mm)

Model(s) 030590, 030591

Starting Wattage ..............................................6,500 Watts

Rated Wattage* ...............................................6,000 Watts

AC Output Voltage ..........................................115 / 230 Volts

Load Current at 115 Volts AC .....................................52.1 Amps

Load Current at 230 Volts AC .....................................26.0 Amps

Frequency ........................................................60 Hz

Phase .....................................................Single Phase

Fuel Capacity ................................................6.6 gal (25 L)

Engine Displacement .......................................25.63 ci (420 cc)

Oil Capacity ....................................... 35 - 37 oz (1.05 - 1.09 L)

Spark Plug Gap .........................................0.030 in (0.76 mm)

Spark Plug Torque ........................................275 lb-in (31 Nm)

Intake Valve Clearance ........................ 0.005 - 0.007 in (0.13 - 0.18 mm)

Exhaust Valve Clearance ...................... 0.005 - 0.007 in (0.13 - 0.18 mm)

Common Service Parts

Air Cleaner - Engine Model 106200 ................................... 591717

Air Cleaner - Engine Model 160000 ................................... 591778

Air Cleaner - Engine Model 250000 ................................... 591778

Spark Plug - Engine Model 106200 ................................... 491055

Spark Plug - Engine Model 160000 ................................... 797235

Spark Plug - Engine Model 250000 ................................... 797235

Power Ratings: The gross power rating for individual gas engine models is labeled in accordance with SAE (Society of Automotive Engineers) code J1940 (Small Engine Power &

Torque Rating Procedure), and rating performance has been obtained and corrected in accordance with SAE J1995 (Revision 2002-05). Torque values are derived at 3060 RPM;

horsepower values are derived at 3600 RPM. The gross power curves can be viewed at www.BRIGGSandSTRATTON.COM. Net power values are taken with exhaust and air cleaner

installed whereas gross power values are collected without these attachments. Actual gross engine power will be higher than net engine power and is affected by, among other

things, ambient operating conditions and engine-to-engine variability. Given the wide array of products on which engines are placed, the gas engine may not develop the rated gross

power when used in a given piece of power equipment. This difference is due to a variety of factors including, but not limited to, the variety of engine components (air cleaner,

exhaust, charging, cooling, carburetor, fuel pump, etc.), application limitations, ambient operating conditions (temperature, humidity, altitude), and engine-to-engine variability. Due to

manufacturing and capacity limitations, Briggs & Stratton may substitute an engine of higher rated power for this Series engine.

* This generator is rated in accordance with ISO 8528 G1.

15

Page 16

Not for

Reproduction

BRIGGS & STRATTON PORTABLE GENERATOR OWNER WARRANTY POLICY

Effective September 1, 2012; replaces all undated Warranties and all Warranties dated before September 1, 2012.

LIMITED WARRANTY

Briggs & Stratton warrants that, during the warranty period specified below, it will repair or replace, free of charge, any part that is defective in material or workmanship or

both. Transportation charges on product submitted for repair or replacement under this warranty must be borne by purchaser. This warranty is effective for and is subject to

the time periods and conditions stated below. For warranty service, find the nearest Authorized Service Dealer in our dealer locator map at BRIGGSandSTRATTON.com. The

purchaser must contact the Authorized Service Dealer, and then make the product available to the Authorized Service Dealer for inspection and testing.

There is no other express warranty. Implied warranties, including those of merchantability and fitness for a particular purpose, are limited to one year from purchase,

or to the extent permitted by law. All other implied warranties are excluded. Liability for incidental or consequential damages are excluded to the extent exclusion

is permitted by law. Some states or countries do not allow limitations on how long an implied warranty lasts, and some states or countries do not allow the exclusion or

limitation of incidental or consequential damages, so the above limitation and exclusion may not apply to you. This warranty gives you specific legal rights and you may also

have other rights which vary from state to state or country to country.**

WARRANTY PERIOD

ITEM CONSUMER USE COMMERCIAL USE

EQUIPMENT

Models: 030588, 030589, 030590, 030591

Models: 030566, 030576, 030570, 030583

030596, 030597, 030598, 030599

Engine 2 year 1 year

Battery (if equipped) 1 year 1 year

** In Australia - Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled to a replacement or refund for a major failure and

for compensation for any other reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality

and the failure does not amount to a major failure. For warranty service, find the nearest Authorized Service Dealer in our dealer locator map at BRIGGSandSTRATTON.COM, or by

calling 1300 274 447, or by emailing or writing to salesenquires@briggsandstratton.com.au, Briggs & Stratton Australia Pty Ltd, 1 Moorebank Avenue, NSW, Australia, 2170.

The warranty period begins on the date of purchase by the first retail end user, and continues for the period of time stated above. “Consumer Use” means personal residential

household use by a retail consumer. “Commercial Use” means all other uses, including use for commercial, income producing or rental purposes. Once equipment has experienced

commercial use, it shall thereafter be considered as commercial use for purposes of this warranty. Equipment used for prime power in place of utility are not applicable to this

warranty.

NO WARRANTY REGISTRATION IS NECESSARY TO OBTAIN WARRANTY ON BRIGGS & STRATTON PRODUCTS. SAVE YOUR PROOF OF PURCHASE RECEIPT. IF YOU DO NOT

PROVIDE PROOF OF THE INITIAL PURCHASE DATE AT THE TIME WARRANTY SERVICE IS REQUESTED, THE MANUFACTURING DATE OF THE PRODUCT WILL BE USED TO

DETERMINE THE WARRANTY PERIOD.

2 year

1 year

1 year

1 year

ABOUT YOUR WARRANTY

We welcome warranty repair and apologize to you for being inconvenienced. Any Authorized Service Dealer may perform warranty repairs. Most warranty repairs are handled

routinely, but sometimes requests for warranty service may not be appropriate. For example, warranty service would not apply if equipment damage occurred because of misuse,

lack of routine maintenance, shipping, handling, warehousing or improper installation. Similarly, the warranty is void if the manufacturing date or the serial number on the portable

generator has been removed or the equipment has been altered or modified. During the warranty period, the Authorized Service Dealer, at its option, will repair or replace any part

that, upon examination, is found to be defective under normal use and service. This warranty will not cover the following repairs and equipment:

• Normal Wear: Outdoor Power Equipment, like all mechanical devices, needs periodic parts and service to perform well. This warranty does not cover repair when normal

use has exhausted the life of a part or the equipment.

• Installation and Maintenance: This warranty does not apply to equipment or parts that have been subjected to improper or unauthorized installation or alteration and

modification, misuse, negligence, accident, overloading, overspeeding, improper maintenance, repair or storage so as, in our judgment, to adversely affect its performance

and reliability. This warranty also does not cover normal maintenance such as adjustments, fuel system cleaning and obstruction (due to chemical, dirt, carbon, lime, etc.).

• Other Exclusions: This warranty excludes wear items such as o-rings, filters, etc., or malfunctions resulting from accidents, abuse, modifications, alterations, or improper

servicing or freezing or chemical deterioration. Accessory parts such as generator adapter cord sets and storage covers are excluded from the product warranty. This

warranty excludes failures due to acts of God and other force majeure events beyond the manufacturers control. Also excluded is used, reconditioned, and demonstration

equipment; equipment used for prime power in place of utility power and equipment used in life support applications. 198195E, Rev. D, 08/24/2012

BRIGGS & STRATTON CORPORATION

MILWAUKEE, WI, USA

16 BRIGGSandSTRATTON.COM

Page 17

Not for

Reproduction

17

Page 18

Not for

Reproduction

Obrigado por adquirir este excelente gerador produzido pela Briggs & Stratton®. Ficamos felizes por você depositar sua confiança na marca Briggs & Stratton. Quando operado e

mantido de acordo com as instruções dente manual, o seu gerador Briggs & Stratton fornecerá muitos anos de funcionamento confiável.

Este manual contém informações de segurança para informá-lo sobre os perigos e riscos associados aos geradores e como evitá-los. Este gerador foi desenvolvido apenas para o

fornecimento de alimentação elétrica para iluminação, utensílios, ferramentas e cargas de motor elétricos, e não deve ser utilizado para qualquer outro propósito. O usuário deve ler

e compreender totalmente estas instruções antes de tentar ligar ou operar este equipamento. Guarde estas instruções originais para referência futura.

Este gerador exige uma montagem final antes do uso. Consulte a seção Montagem deste manual de instruções para obter os procedimentos da montagem final. Siga as

instruções completamente.

Onde nos encontrar

Você nunca terá que procurar muito para encontrar assistência e manutenção Briggs & Stratton para o seu gerador. Há milhares de centros de serviço autorizados Briggs & Stratton

ao redor do mundo, prontos para lhe atender com qualidade. Você pode localizar o Centro de Serviço Autorizado mais próximo através do nosso mapa localizador na Internet em

BRIGGSandSTRATTON.COM.

Gerador

Número de Modelo

Revisão

Número de série

Data de aquisição

Índice

Segurança do operador. .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .5

Montagem ..........................................7

Recursos e controles..................................7

Operação .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .8

Manutenção. .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. .11

Solução de problemas ...............................14

Especificações .....................................15

Garantias ..........................................16

Motor

Número de modelo

Número de tipo

Número de código

Copyright © 2017 Briggs & Stratton Corporation

Milwaukee, WI, USA. Todos os direitos reservados.

BRIGGS & STRATTON é uma marca comercial registrada

da Briggs & Stratton Corporation

4 BRIGGSandSTRATTON.COM4 BRIGGSandSTRATTON.COM

Page 19

Not for

Reproduction

Segurança do operador

Descrição do equipamento

Leia este manual atentamente e se familiarize com o seu gerador.

Conheça as suas aplicações, seus limites e todos os perigos envolvidos.

Empregamos grande esforço para assegurar a precisão e atualidade das informações

deste manual. Contudo, o fabricante mantém o direito de mudar, alterar ou aprimorar

de qualquer outra maneira o gerador e a respectiva documentação, a qualquer

momento, sem aviso prévio.

Importantes informações de segurança

O fabricante não tem como prever todas as circunstâncias possíveis que possam

envolver perigo. Os alertas deste manual, e as etiquetas e adesivos afixados à unidade

não são, portanto, absolutamente inclusivos. Se você usa um procedimento, um

método de trabalho ou uma técnica de operação não recomendada especificamente

pelo fabricante, ficará a seu critério julgar se é seguro para você e para outrem. Você

também deve garantir que o procedimento, a técnica de operação ou o método de

trabalho que você escolher não torna o uso do gerador perigoso.

Símbolos de segurança e significados

Vapores tóxicos

Fogo

Rebote

Manual do

Operador

Choque elétrico

Explosão

Sufocamento

Sufocamento

O símbolo de alerta de segurança indica o perigo de ferimento pessoal potencial.

Uma palavra de sinalização (PERIGO, ADVERTÊNCIA ou CUIDADO) é usada com o

símbolo de alerta para designar um grau ou nível de gravidade para o perigo. Um símbolo

de segurança pode ser usado para representar o tipo de perigo. A palavra de sinalização

AVISO é usada em referência a práticas sem relação com ferimentos pessoais.

PERIGO indica um perigo que, se não evitado,resultará em morte ou ferimentos

graves.

ADVERTÊNCIA indica um perigo que, se não evitado,poderá resultar em morte

ou ferimentos graves.

CUIDADO indica um perigo que, se não evitado,pode resultar em ferimentos

leves a moderados.

AVISO trata de práticas não relacionadas a ferimentos pessoais.

ADVERTÊNCIA PERIGO DE GÁS VENENOSO. A exaustão do motor contém

monóxido de carbono, um gás venenoso que pode causar sua morte em

minutos. NÃO é possível identificar esse gás visualmente, pelo cheiro ou

pelo sabor. Não sentir o cheiro dos vapores de exaustão não significa

que você não está exposto ao gás monóxido de carbono. Se você

começar a se sentir mal, tonto ou fraco durante o uso deste produto, desligue-o e

vá para o ar livre IMEDIATAMENTE. Procure atendimento médico. Você corre risco

de envenenamento por monóxido de carbono.

• Opere este produto APENAS ao ar livre, longe de janelas, portas e passagens de

ventilação para evitar o risco de acúmulo de monóxido de carbono e sua entrada

em áreas ocupadas.

• Instale alarmes de monóxido de carbono operados por bateria ou alarmes de

monóxido de carbono adaptados para encaixe, com back-up de bateria, de acordo

com as instruções do fabricante. Alarmes de fumaça não são capazes de detectar

gás carbônico.

• NÃO opere este produto dentro de residências, garagens, porões, vãos, abrigos ou

outros espaços parcialmente fechados, mesmo com o uso de ventiladores ou de

portas e janelas abertas para ventilação. O monóxido de carbono pode se acumular

rapidamente e perdurar por horas, mesmo após o desligamento do produto.

• SEMPRE posicione este produto a favor do vento e aponte a exaustão para longe

de áreas ocupadas.

Peças móveis Objetos

Alarme de monóxido

de carbono

Afogador RUN

Voltímetro Nível do óleo Combustível Partida

lançados no ar

Alarme Ligado à terra Terminal de

(em funcionamento)

Superfície

quente

OFF ON

Objetos pesados

aterramento

ADVERTÊNCIA A retração rápida (rebote) da corda de partida puxará sua

mão e braço na direção do motor antes que você consiga soltá-la,

oquepoderá causar fraturas ósseas, cortes, distensões, contusões ou

ferimentos graves.

• Ao dar partida no motor, puxe a corda lentamente até sentir resistência e, então,

puxe rapidamente para evitar o rebote.

• NUNCA dê partida ou desligue o motor com dispositivos elétricos conectados

eligados.

ADVERTÊNCIA A voltagem do gerador pode causar choques elétricos ou

queimaduras graves e até mesmo fatais.

• Use equipamentos de transferência aprovados para evitar retroalimentação

isolando o gerador dos trabalhadores de serviço elétrico.

• Ao usar o gerador para energia de emergência, notifique a companhia prestadora

do serviço.

• Use um dispositivo de corrente residual (DCR) em qualquer área úmida ou altamente

condutora como, por exemplo, superfícies metálicas ou estruturas de aço.

• NÃO toque em fios desencapados ou soquetes.

• NÃO use o gerador com cabos elétricos desgastados, desfiados ou danificados

dequalquer outra maneira.

• NÃO opere o gerador na chuva ou em clima úmido.

• NÃO opere ou toque no gerador ou nos cabos elétricos enquanto estiver na água,

descalço ou com as mãos ou os pés molhados.

• NÃO permita que pessoas não qualificadas ou crianças operem ou façam a

manutenção do gerador.

!

Disjuntor Controle do motor Não dê partida

no motor

5 5

Page 20

Not for

Reproduction

ADVERTÊNCIA O calor e os gases da exaustão podem provocar a ignição

O contato com a área de escapamento e exaustão pode causar queimaduras e

ferimentos graves.

• NÃO toque em partes quentes e MANTENHA DISTÂNCIA dos gases quentes

daexaustão.

• Espere o equipamento esfriar antes de tocá-lo.

• Mantenha ao menos 1,5 m (5 ft) de distância de todos os lados do gerador,

incluindo acima dele.

• Contate o fabricante de equipamento original, varejista ou concessionário para

obter um protetor de faísca projetado para o sistema de escapamento instalado

neste motor.

• As peças de reposição deverão ser iguais e instaladas na mesma posição que as

peças originais.

ADVERTÊNCIA Fagulhamento acidental pode causar incêndios ou choques

decombustíveis e estruturas ou danificar o tanque de

combustível provocando incêndios, o que pode resultar em

mortes, ferimentos graves e/ou danos a propriedades.

elétricos, que podem provocar morte ou ferimentos graves.

CUIDADO

em pequenos ferimentos e/ou danos ao gerador.

Velocidades excessivamente baixas impõem uma sobrecarga.

• NÃO altere a mola mestra, as ligações ou outras peças para aumentar o giro

domotor.

• NÃO modifique o gerador de nenhuma forma.

AVISO

ogerador e/ou dispositivos elétricos conectados a ele.

• NÃO exceda a capacidade de vatagem/amperagem do gerador. ConsulteNão

sobrecarregue o gerador na seção Operação.

• Dê partida no gerador e deixe o motor se estabilizar antes de conectar cargas

elétricas.

• Conecte cargas elétricas na posição desligada (OFF) e, somente então, mude para

aposição ligada (ON) para operação.

• DESLIGUE as cargas elétricas e, então, desconecte-as do gerador antes de parar

ogerador.

Velocidades de operação excessivamente elevadas podem resultar

Exceder a capacidade de vatagem/amperagem do gerador pode danificar

AO AJUSTAR OU REPARAR O SEU GERADOR

• Desconecte o cabo da vela de ignição da vela de ignição e coloque o cabo onde

ele não possa entrar em contato com a vela de ignição.

AO TESTAR A VELA DE IGNIÇÃO

• Use um testador de vela de ignição aprovado.

• NÃO teste a existência de ignição com a vela de ignição removida.

ADVERTÊNCIA O mecanismo de partida ou outras partes que giram podem

prender suas mãos, cabelos, roupas ou adornos, o que pode causar

ferimentos graves.

• NUNCA opere o gerador sem alojamento ou coberturas de proteção.

• NÃO use roupas largas, joias ou qualquer coisa que possa ser aprisionada na

partida ou em peças rotativas.

• Se tiver cabelo longo ou usar joias, prenda o cabelo e retire as joias.

ADVERTÊNCIA Os combustíveis e seus vapores são extremamente

AO ACRESCENTAR OU DRENAR COMBUSTÍVEL