ADVANCE PRODUCT SERVICE INFORMATION

Not for Reproduction

APSI #:

DATE:

SUBJECT:

MODELS:

Briggs & Stratton has recently introduced the new E Series™ engine family, which includes the 550e Series™ and

550ex Series™ OHV engines.

This APSI provides basic servicing information in advance of the repair manual currently in development. System

tests and component removal/installation procedures are common with most other Briggs & Stratton engines. See

the Illustrated Parts List for service part numbers. The specifications, part numbers and/or procedures provided

here are PRELIMINARY and subject to change.

85

JULY 2012

INTRODUCTION OF E SERIES™ ENGINES

09P600, 09P700 OHV VERTICAL SHAFT ENGINES

Figure 1

BRIGGS & STRATTON

Distribution Sales & Customer Support

Copyright© 2012 Briggs & Stratton Corporation

All language translations of this document are

derived from the original English source le.

Rev.-

Page 1 of 12

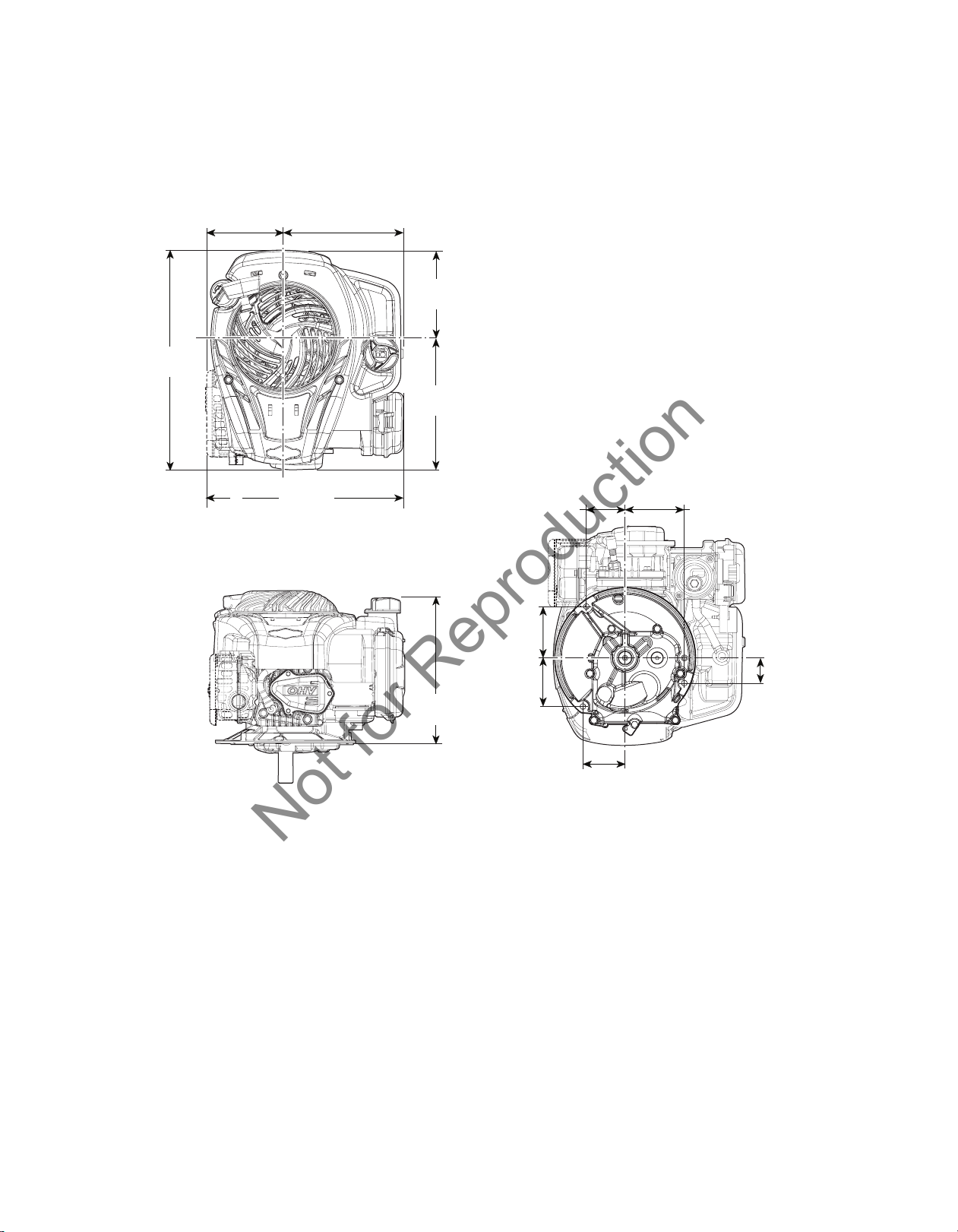

ENGINE DIMENSIONS

4.746

7.442

(345.96)

(39.7)

Not for Reproduction

Dimensions are shown in inches (millimeters).

13.62

(120.54)

(189.04)

7.442

(189.04)

6.21

(157.7)

7.41

(188.3)

9.13

(231.98)

3.19

(81.15)

3.02

(76.68)

2.41

(61.15)

3.68

(93.54)

1.56

Figure 2

Page 2 of 12

SERVICE NOTES

Not for Reproduction

Flywheel

The flywheel overlaps the governor crank at the top of the cylinder. There are two openings in the flywheel casting

to allow access to the governor nut, after the blower housing has been removed.

To remove the flywheel nut, remove the ignition armature and slip a flywheel strap wrench through the armature

opening in the flywheel guard (blower scroll). The flywheel can be removed from the crankshaft using Flywheel

Puller 19069.

Carburetor

For draining the bowl, there is a 1/4-turn hex plug with o-ring installed in the bottom of the float bowl. (CAUTION: Do

not attempt to unscrew the plug, as it is not threaded.)

The float bowl installs in the carburetor in only one direction. There is a cavity molded into the bowl that provides

clearance for the emulsion tube and jet. If the bowl cannot be fully seated into the carburetor by hand, turn it 180

degrees and then reinstall.

Note that the bowl screws are self-tapping. To avoid cross-threading when installing the screws, turn them

counterclockwise until the screw threads drop into place, then tighten clockwise.

The needle valve seat can be removed by threading in a screw, then clamping the screw head in a vise. Carefully

twist and pull on the carburetor body to extract the seat. When installing a replacement seat, make sure the

rounded edge is pressed into the opening in the carburetor body and the flat edge is facing the bowl.

Oil Capacity

This engine requires a reduced oil capacity of just 15 oz (.44 L). A new oil bottle has been designed for service

under part number 100113. The bottle contains the correct amount for this engine in support of our message to

consumers to “pour in the entire bottle”.

Please make sure to remind customers that this engine requires only 15 oz (.44 L) and not the higher capacity of

our other engines.

We anticipate that overfilling could be an issue until customers become accustomed to the difference. Typical

symptoms of overfilling would be white smoke from the exhaust, sparkplug fouling, oil contamination of the air filter

and/or oil leaking from the air filter area.

Blower Housing Barcode Label

In the event that the engine blower housing must be replaced, the barcode label can be transferred to the new

blower housing as follows:

1. After installation, clean the surface of the new blower housing to remove any traces of dust, oil, or grease.

2. Wash hands thoroughly to remove dirt and oils from the skin.

3. Carefully peel off the label from the original blower housing and reposition it in the same location on the new

blower housing.

4. Press firmly to remove any air bubbles and ensure good adhesion.

Page 3 of 12

ASSEMBLY INFORMATION

Not for Reproduction

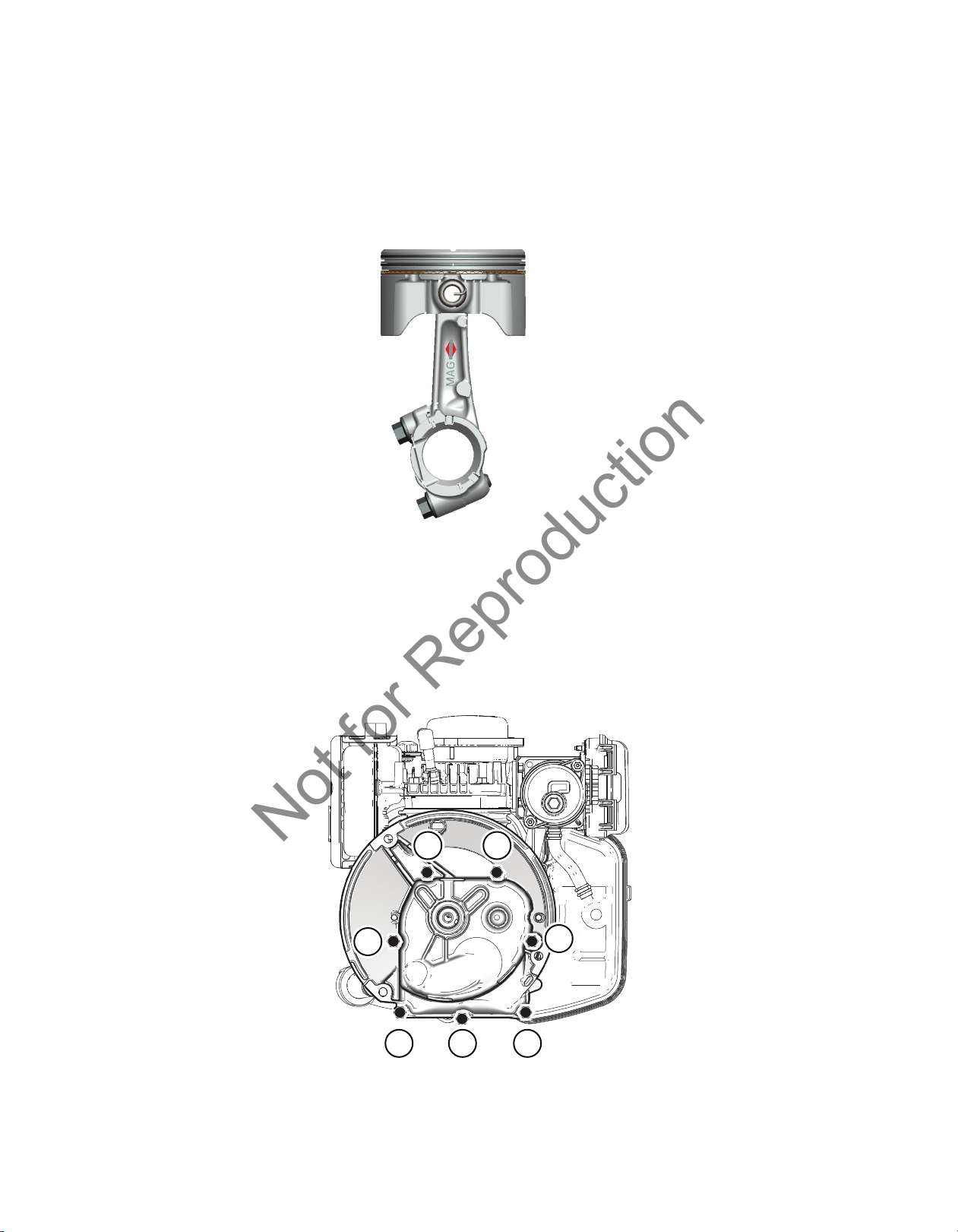

Piston Assembly and Orientation

The notch in the piston, the piston pin clip, and the MAG identification on the connecting rod all face the flywheel

side (mag side) of the engine (Figure 3). When installing replacement piston rings, the paint stripes on the rings

must be to the right side of the ring gaps.

Figure 3

Sump and Seals

Install the sump bolts in positions 1 through 6 (Figure 4). Install the self-tapping sump screw in position 7. Do not

use the self-tapping screw in any other hole location. Using the sequence shown, tighten the bolts to the torque

specification provided in this APSI.

53

6

2

1

7

Figure 4

4

Page 4 of 12

Cylinder Head

Not for Reproduction

Engines built before Date of Manufacture FEB 02 12 (or 120201xx) were equipped with sealant under the rocker

cover. The cover cannot be removed without damaging it. If servicing the cylinder head on these early units, plan

on replacing the rocker cover, and cylinder head plate. Current production engines are equipped with a gasket for

the rocker cover.

The valve guides and the valve seats are not replaceable. If the guides are worn beyond reject size, replace the

head. If the seats are slightly worn, they can be resurfaced to the extent possible with lapping compound; otherwise

replace the cylinder head.

Tighten the four bolts in the sequence shown (Figure 5) to the specification provided in this APSI.

1

3

Figure 5

Apply a bead of sealant to the cylinder head plate before placing it on the head. To set the valve clearance, rotate

the crankshaft PTO counterclockwise four turns to seat the valve train parts, then continue turning until the piston

reaches Top Dead Center (TDC) on the compression stroke. Both valves will be closed. Slowly turn the crankshaft

again until the piston is .250” (6.35 mm) past TDC. Adjust the valve clearance and tighten the rocker ball set screws

to the specification provided in this APSI.

Using a new gasket, install the rocker cover on the cylinder head plate.

Carburetor and Air Cleaner

Make sure the o-ring is installed on the cylinder side of the carburetor spacer, then fit the spacer into the mounting

bracket. Place the bracket and spacer on the cylinder head with the bracket flange to the top (Figure 6). Install and

tighten the two mounting screws to the specification provided in this APSI.

4

2

Page 5 of 12

Figure 6

Not for Reproduction

Both the primer system and the ReadyStart® system have options for a foam element or paper cartridge air

cleaner. The primer systems are shown with foam element version (Figure 7a) and paper cartridge (Figure 7b).

Figure 7a Figure 7b

Install a new gasket in the carburetor flange and a new o-ring and ring retainer into the cylinder side of the venturi.

Assemble the air cleaner base to the carburetor and install two screws and tighten to the specification provided in

this APSI.

Rotate the carburetor to fit the governor link into the throttle lever, then insert the primer hose barb into the slot of

the mounting bracket, and then press the carburetor on the tube of the carburetor spacer. Secure the air cleaner

base to the mounting bracket with two screws and tighten to the specification provided in this APSI. Attach the

primer hose to the primer hose barb (paper cartridge version only).

Page 6 of 12

Control Bracket, Governor Lever, and Governor Spring

Not for Reproduction

Either a fixed speed bracket with a single screw (Figure 8a) or a variable speed bracket with two screws (Figure 8b)

is installed.

Attach the governor spring first to the tab of the fixed or the variable speed bracket, then attach it to the governor

lever from the cylinder side, as shown (Figure 8a or 8b).

Figure 8a Figure 8b

Governor Adjustment Procedure

Static Adjustment

1. Loosen the governor nut.

2. Rotate the throttle linkage from idle to wide open throttle. Note the direction of rotation of the governor lever.

3. Rotate the governor shaft in the direction noted until it stops.

4. While holding the linkage and governor shaft, tighten the governor lever nut to the specification provided in this

APSI.

Dynamic Adjustment

1. Start the engine and allow it to warm up at idle for 3-5 minutes.

2. Move the throttle control (if equipped) to high speed. Using a tang bender, adjust the top no load speed by

bending the tang to obtain the equipment manufacturer’s top no load speed specification.

Spring Color Top No Load Speed

Blue 2600 - 2700

Purple 2800 - 3200

Orange 3200 - 3600

Yellow 3600 - 4000

3. Verify that all speeds meet specifications before returning the engine to service.

Page 7 of 12

Flywheel Brake and Stop Switch Wire

Not for Reproduction

Position the flywheel brake on the cylinder mounting bosses behind the governor crank (Figure 9). Install the long

screw into the hole next to the brake pad. Install the short screw into the hole next to the stop switch. Tighten the

screws to the specification provided in this APSI.

Figure 9

Flywheel Guard (Blower Scroll)

Ensure that the breather tube is fully installed at the back of the air cleaner base and against the cylinder casting

at the breather chamber. Apply a thin bead of sealant (p/n 100106) around the breather (Figure 10). Position the

flywheel guard on the cylinder and install the five screws. Tighten the screws to the specification provided in this

APSI.

Figure 10

Page 8 of 12

Fuel Tank and Fuel Hose

Not for Reproduction

Slide the two mounting tabs of the fuel tank into the slots of the flywheel guard (Figure 11). Press down until the

tank snaps into the metal bosses of the flywheel guard.

Figure 11

Oil Dipstick and Dipstick Tube

The short oil dipstick screws directly into the cylinder. The extended dipstick tube is pressed into the cylinder

and hooks over the edge of the flywheel guard (Figure 12). The tube is held in place when the blower housing is

installed.

Figure 12

Page 9 of 12

Rewind Starter and Blower Housing

Not for Reproduction

The starter rope and the rope handle are the only serviceable parts of the rewind assembly. Place the rewind

assembly inside the blower housing with the handle in the required position (Figure 13a). Align the tabs in the

housing and the rewind and press together until all tabs snap into place. Line up the tabs of the retaining ring

(Figure 13b) with the slots on the rewind and snap it into position.

Figure 13a Figure 13b

ENGINE SPECIFICATIONS

Common Specifications SAE Metric

Armature Air Gap .006 - .014 in .15 - .36 mm

Bore and Stroke 2.49 x 1.75 in 63.4 x 44.5 mm

Crankshaft End Play .002 - .028 in .05 - 1.0 mm

Displacement 8.54 ci 140cc

Exhaust Valve Clearance (Cold) .004 - .008 in .10 - .20 mm

Intake Valve Clearance (Cold) .004 - .008 in .10 - .20 mm

Fuel Tank Capacity .8 qt .8 L

Oil Capacity 15 oz .44 L

Spark Plug Gap .020 in .51 mm

Spark Plug Torque 180 lb-in 20.3 Nm

Page 10 of 12

Common Service Parts Service Number

Not for Reproduction

Air Cleaner Gasket 799580

Air Cleaner Gasket 799581

Air Filter (Foam) 799579

Air Filter (Paper) 798452

Armature 799582

Carburetor (Primer) 799583

Carburetor (Ready Start) 799584

Crankcase Cover Gasket 799587

Cylinder Head Gasket 799586

Fuel Cap, Standard 799684

Fuel Cap, Carbon in Cap 799585

Spark Plug 692051

Starter (Rewind) 799685

Fastener Torque Specication SAE Metric

Air Cleaner Base to Carburetor 25 lb-in 2.8 Nm

Air Cleaner Base to Carburetor Bracket 35 lb-in 4.0 Nm

Armature to Cylinder Block 30 lb-in 3.4 Nm

Blower Housing 35 lb-in 4. 0 Nm

Flywheel Brake 35 lb-in 4.0 Nm

Breather Reed 45 lb-in 5.1 Nm

Carburetor Bracket to Cylinder Head 60 lb-in 6.8 Nm

Casing Clamp 3 lb-in .3 Nm

Connecting Rod 100 lb-in 11.3 Nm

Cylinder Head to Cylinder Block 130 lb-in 14.7 Nm

Sump to Cylinder Block 85 lb-in 9.6 Nm

Control Bracket 65 lb-in 7.3 Nm

Flywheel Guard to Cylinder Block 65 lb-in 7.3 Nm

Flywheel Nut 70 lb-ft 94.9 Nm

Governor Lever Nut 30 lb-in 3.4 Nm

High Oil Dipstick n/a n/a

Low Oil Dipstick 30 lb-in 3.4 nm

Muer 65 lb-in 7.3 Nm

Muer Guard 25 lb-in 2.8 Nm

Rocker Arm Stud 50 lb-in 5.6 Nm

Rocker Arm Setscrew or Nut 25 lb-in 2.8 Nm

Rocker Cover 30 lb-in 3.4 Nm

Sparkplug 180 lb-in 20.3 Nm

Page 11 of 12

Component Standard Dimensions Reject Dimensions

Not for Reproduction

SAE Metric SAE Metric

Cylinder

Mag Bearing .877 in 22.27 .879 in 22.33 mm

Mag Oil Seal Depth Flush Flush N/A N/A

Cam Bearing .501 in 12.73 mm .502 in 12.75 mm

Bore Out-of-Round N/A N/A .0015 in .04 mm

Cylinder Head

Intake

Valve Seat Angle 45° 45° N/A N/A

Valve Stem .156 in 3.96 mm .154 in 3.91 mm

Valve Guide .158 in 4.01 mm .160 in 4.07 mm

Exhaust

Valve Seat Angle 45° 45° N/A N/A

Valve Stem .156 in 3.96 mm .154 in 3.91 mm

Valve Guide .158 in 4.01 mm .160 in 4.07 mm

Crankcase Cover/Sump

PTO Bearing .877 in 22.27 mm .879 in 22.33 mm

PTO Oil Seal Depth Flush Flush N/A N/A

Cam Bearing .501 in 12.73 mm .502 in 12.75 mm

Crankshaft

Crankpin Journal .874 in 22.20 mm .872 in 22.15 mm

Mag Journal .874 in 22.20 mm .872 in 22.15 mm

PTO Journal .874 in 22.20 mm .872 in 22.15 mm

Cam Shaft

Mag-Side Journal .500 in 12.71 mm .499 in 12.67 mm

PTO Side Journal .500 in 12.71 mm .499 in 12.67 mm

Connecting Rod

Crankpin Bearing .875 in 22.24 mm .876 in 22.26 mm

Piston Pin Bore .491 in 12.46 mm .493 in 12.52 mm

Piston and Pin

Pin Diameter .490 in 12.45 mm .489 in 12.42 mm

Piston Pin Bore .491 in 12.46 mm .493 in 12.52 mm

Piston Rings

End Gap-Top .005 in .13 mm .025 in .64 mm

End Gap-Middle .028 in .71 mm .045 in 1.14 mm

End Gap-Oil .030 in .76 mm .045 in 1.14 mm

Ring Land Clearance-Top .002 in .05 mm .003 in .08 mm

Ring Land Clearance-Middle .001 in .03 mm .002 in .03 mm

Ring Land Clearance-Oil .001 in .03 mm .002 in .06 mm

Starter Rope

Rope Diameter .125 in (#4) 3.17 mm (#4) N/A N/A

Rope Length 88.62 in 2.25 m N/A N/A

Page 12 of 12

Loading...

Loading...