Page 1

Manual No. 206077GS Revision A (04/15/2008)

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC

JEFFERSON, WISCONSIN, U.S.A.

Electric Pressure Washer

Operator’s Manual

This pressure washer is rated in accordance to the Pressure Washer Manufacture Association (PWMA)

standard PW101 (Testing and Rating Performance of Pressure Washers).

Page 2

2 BRIGGSandSTRATTON.COM

Briggs & Stratton Power Products Group, LLC

900 North Parkway

Jefferson, WI 53549

Copyright © 2008 Briggs & Stratton Power Products Group,

LLC. All rights reserved. No part of this material may be

reproduced or transmitted in any form by any means without

the express written permission of Briggs & Stratton Power

Products Group, LLC.

Thank you for purchasing this quality-built Briggs & Stratton pressure washer. We are pleased that you’ve placed your

confidence in the Briggs & Stratton brand. When operated and maintained according to the instructions in this manual, your

Briggs & Stratton pressure washer will provide many years of dependable service.

This manual contains safety information to make you aware of the hazards and risks associated with pressure washers and

how to avoid them. Because Briggs & Stratton does not necessarily know all the applications this pressure washer could be

used for, it is important that you read and understand these instructions thoroughly before attempting to start or operate this

equipment. Save these instructions for future reference.

This pressure washer requires final assembly before use. Refer to the Assembly section of this manual for instructions on

final assembly procedures. Follow the instructions completely.

Where to Find Us

You never have to look far to find Briggs & Stratton support and service for your pressure washer. Consult your Yellow Pages.

There are over 30,000 Briggs & Stratton authorized service dealers worldwide who provide quality service. You can also

contact Briggs & Stratton Customer Service by phone at (800) 743-4115, or on the Internet at BRIGGSandSTRATTON.COM.

Pressure Washer

Model Number

Revision

Serial Number

Date Purchased

Page 3

3

FrançaisEspañol

Table of Contents

Operator Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Equipment Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety Rules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Unpack Pressure Washer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Attach Handle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Connect Hose and Water Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Features and Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

How to Start Your Pressure Washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

How to Stop Your Pressure Washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

How to Use the Adjustable Nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Applying Detergent with the Adjustable Nozzle . . . . . . . . . . . . . . . . . . . . . 11

Pressure Washer Rinsing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

How to Use the Turbo Nozzle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

How to Store Reel Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Other Cleaning Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

How to Store Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Cleaning Detergent Supply System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

General Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Pressure Washer Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Pump and Motor Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Page 4

Operator Safety

Equipment Description

Read this manual carefully and become familiar

with your pressure washer. Know its applications,

its limitations, and any hazards involved.

This pressure washer operates at a maximum of 1800 PSI

and a flow rate of up to 1.6 gallons per minute (6.05 liters

per minute).

Every effort has been made to ensure that information in this

manual is accurate and current. However, we reserve the

right to change, alter, or otherwise improve the product and

this document at any time without prior notice.

Ground Fault Circuit Interrupter Protection

This product must be properly grounded. This electric pressure

washer is equipped with a ground fault circuit interrupter

(GFCI). The device will disconnect both power conductors to

the load circuit in the event of an interruption in either or both

supply circuit power conductors. If a malfunction or breakdown

occurs, the GFCI provides protection.

The plug must be plugged into an appropriate outlet that is

properly installed and grounded in accordance with all local

codes and ordinances. Read the instructions on the plug for

use or see Before Starting Pressure Washer.

Automatic Shut-Off

The pressure washer is equipped with a sensor that will

detect that high pressure water flow has stopped when

releasing or locking the spray gun trigger. The sensor will

cause the motor to shut off for as long as the spray gun

trigger is released or locked.

If the motor continues to run when the spray gun trigger is

released or locked, DO NOT USE THE MACHINE. Call the

pressure washer helpline at (800) 743-4115 for assistance.

IMPORTANT: The pressure washer is equipped with a main

power ON/OFF switch. The switch should always be moved

to the OFF position when the pressure washer is not being

used to prevent possible damage.

Motor Overload

The electric motor in this pressure washer is equipped with

an overload protection device. This device will automatically

shut off the motor if the motor overheats or draws excessive

current. After a period of time, the device will reset and the

pressure washer can resume normal operation.

Extension Cords

We Do Not recommend the use of extension cords with this

device. If it is necessary to use one, however, then you must

use only extension cords that are approved for outside use.

These extension cords are identified by a marking

“ACCEPTABLE FOR USE WITH OUTDOOR APPLIANCES”.

Extension cords are not recommended unless they are

plugged into a ground-fault-protected receptacle. DO NOT

use damaged extension cords. Also observe the following

specifications:

Cable Length: Wire Gauge:

Up to 25 feet (8m) 14 AWG

50 feet (15m) 12 AWG

Always disconnect the extension cord from the receptacle

before disconnecting the GFCI from the extension cord.

Safety Rules

This is the safety alert symbol. It is used to alert

you to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid

possible injury or death.

The safety alert symbol ( ) is used with a signal word

(DANGER, CAUTION, WARNING), a pictorial and/or a safety

message to alert you to hazards. DANGER indicates a hazard

which, if not avoided, will result in death or serious injury.

WARNING indicates a hazard which, if not avoided, could

result in death or serious injury. CAUTION indicates a hazard

which, if not avoided, might result in minor or moderate

injury. NOTICE, indicates a situation that could result in

equipment damage. Follow safety messages to avoid or

reduce the risk of injury or death.

Hazard Symbols and Meanings

A - Electric Shock E - Slippery Surface

B - Explosion F - Flying Objects

C - Fall G - Read Manual

D - Fluid Injection

4 BRIGGSandSTRATTON.COM

WARNING

Risk of electrocution.

• Keep all electrical connections dry and off the ground.

• NEVER touch plug with wet hands.

• NEVER cut or remove grounding blade (round longer pin) on

GFCI attachment plug.

A B C

F

D

G

E

Page 5

5

WARNING

Risk of electrocution.

Contact with power source can cause electric

shock or burn.

• NEVER spray near power source.

• NEVER cut or remove grounding blade (round longer pin) on

GFCI attachment plug.

WARNING

Use of pressure washer can create puddles and

slippery surfaces.

Kickback from spray gun can cause you to fall.

• Operate pressure washer from a stable surface.

• The cleaning area should have adequate slopes and drainage to

reduce the possibility of a fall due to slippery surfaces.

• Be extremely careful if you must use the pressure washer from

a ladder, scaffolding, or any other similar location.

• Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury when spray gun kicks back.

WARNING

Certain components in this product and related

accessories contain chemicals known to the State of

California to cause cancer, birth defects or other

reproductive harm. Wash hands after handling.

WARNING

The high pressure stream of water that this

equipment produces can cut through skin and its

underlying tissues, leading to serious injury and

possible amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected,

which can cause injury.

• DO NOT allow CHILDREN to operate pressure washer.

• NEVER repair high pressure hose. Replace it.

• NEVER repair leaking connections with sealant of any kind.

Replace o-ring or seal.

• NEVER connect high pressure hose to nozzle extension.

• Keep high pressure hose connected to pump and spray gun

while system is pressurized.

• ALWAYS point spray gun in safe direction, press trigger lock

(red button) and squeeze spray gun trigger, to release high

pressure, every time you turn off the pressure washer.

• NEVER aim spray gun at people, animals, or plants.

• DO NOT secure spray gun in open position.

• DO NOT leave spray gun unattended while machine is plugged

in and turned ON.

• NEVER use a spray gun which does not have a trigger lock or

trigger guard in place and in working order.

• Always be certain spray gun, nozzles and accessories are

correctly attached.

NOTICE

High pressure spray may damage fragile items including

glass.

• DO NOT point spray gun at glass when using turbo nozzle.

• NEVER aim spray gun at plants.

WARNING

Risk of eye injury.

Spray can splash back or propel objects,

including incorrectly attached accessories.

• Always wear safety goggles when using this equipment or in

vicinity of where equipment is in use.

• Before starting the pressure washer, be sure you are wearing

adequate safety goggles.

• NEVER substitute safety glasses for safety goggles.

NOTICE

Improper treatment of pressure washer can damage it and

shorten its life.

• If you have questions about intended use, ask dealer or contact

qualified service center.

• NEVER operate units with broken or missing parts, or without

protective housing or covers.

• DO NOT by-pass any safety device on this machine.

• The product warranty is void if grounding blade (round longer

pin) on GFCI attachment plug is removed.

• DO NOT operate pressure washer above rated pressure.

• DO NOT modify pressure washer in any way.

• Before starting pressure washer in cold weather, check all parts

of the equipment to be sure ice has not formed there.

• NEVER move machine by pulling on hoses. Use handle provided

on unit.

• This equipment is designed to be used with Briggs & Stratton

Power Products authorized parts ONLY. If equipment is used

with parts that DO NOT comply with minimum specifications,

user assumes all risks and liabilities.

WARNING

Risk of explosion.

Spraying flammable or combustible liquids can

cause fire or explosion.

• NEVER spray flammable or combustible liquids.

Page 6

Assembly

Read entire operator’s manual before you attempt

to assemble or operate your new pressure washer.

Your pressure washer requires some assembly but is quickly

ready for use. If you have any problems with the assembly of

your pressure washer, please call the pressure washer

helpline at (800) 743-4115.

Tools Needed

• 4mm allen wrench (included)

• Needle nose pliers

Unpack Pressure Washer

1. Remove everything from carton except pressure

washer.

2. If pressure washer is too heavy for you to lift, open

carton completely by cutting each corner from top to

bottom.

Items in the carton include:

• Pressure washer

• Pressure washer handle

• Spray gun

• Nozzle extension with adjustable nozzle

• Nozzle extension with turbo nozzle

• Parts bag (which includes the following):

• Handle attachment allen screws (4)

• Operator’s manual

• Owner’s registration card

• Safety goggles

• Nozzle cleaning tool

Check all contents. If any parts are missing or damaged, call

the pressure washer helpline at (800) 743-4115.

Become familiar with each component before assembling the

pressure washer. Identify contents with the illustration

shown in Features and Controls.

To prepare your pressure washer for operation, you will

need to perform these tasks:

1. Fill out and send in registration card.

2. Attach handle to main unit.

3. Connect high pressure hose to spray gun.

4. Connect water supply to pump.

5. Attach nozzle extension to spray gun.

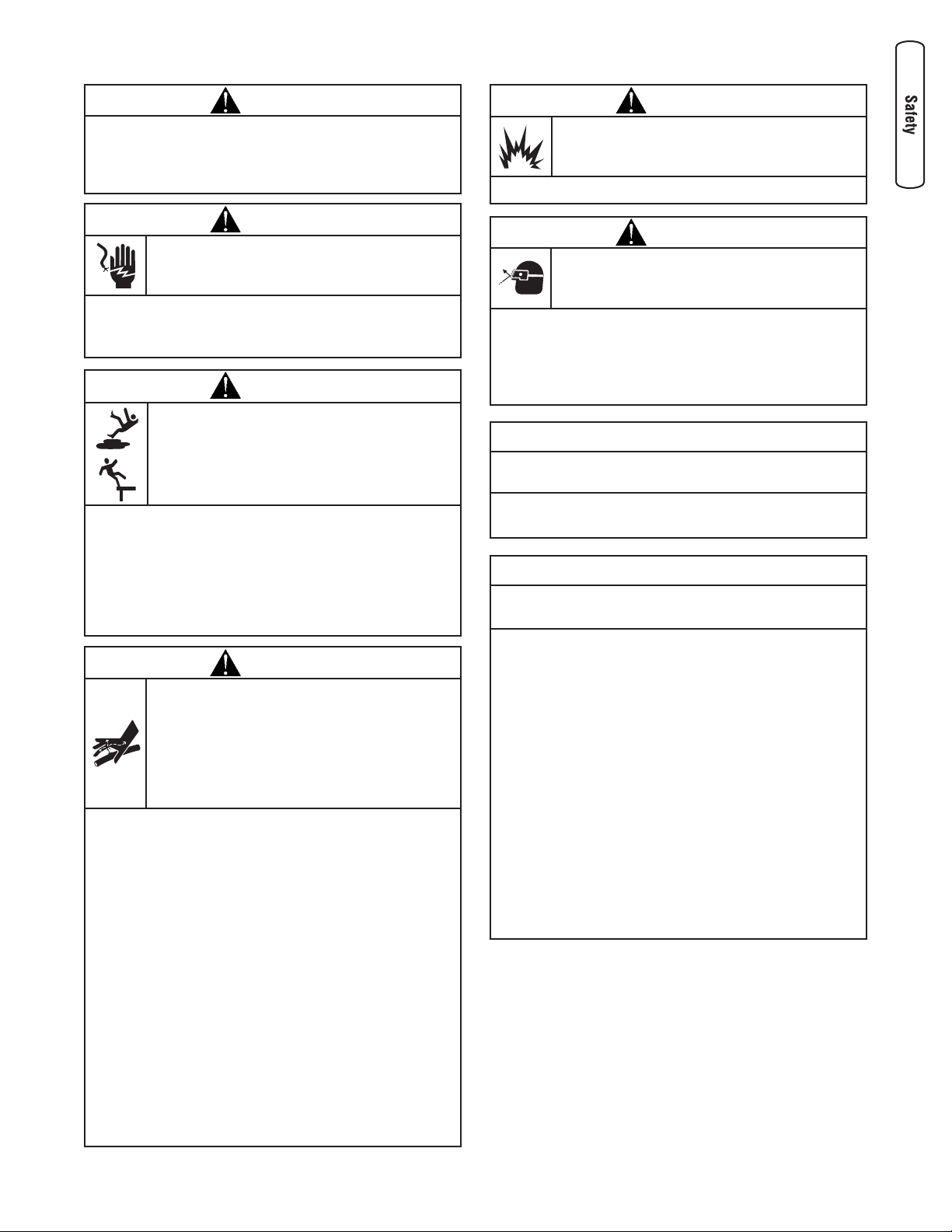

Attach Handle

1. Place handle (A) on top of pressure washer with red

handle above power cord and hole in handle aligned

with the screw holes in the back of the pressure

washer.

2. Using 4 supplied allen screws (B), attach handle to

pressure washer with provided 4mm allen wrench.

Tighten until screws are snug.

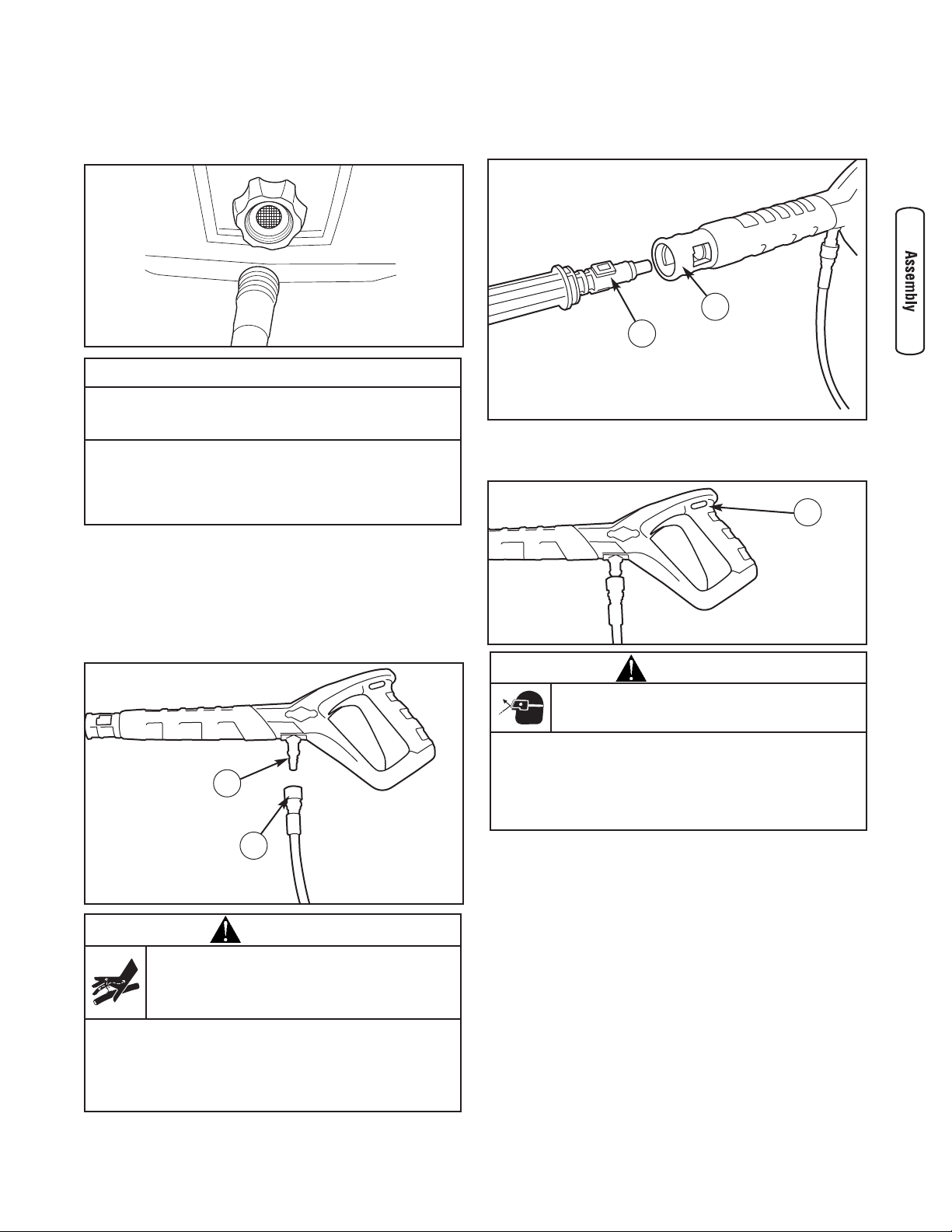

Connect Hose and Water Supply

1. Remove and discard shipping cap from the unit’s water

inlet using a needle nose pliers.

2. Confirm water inlet screen (C) is installed.

NOTE: If inlet screen is damaged or missing, DO NOT use

pressure washer. Call (800) 743-4115 for assistance.

6 BRIGGSandSTRATTON.COM

A

B

C

NOTICE

DO NOT run the pump without the water supply connected

and turned on.

• Damage to equipment resulting from failure to follow this

instruction will void warranty.

Page 7

3. Run water through garden hose for 30 seconds to flush

the hose of debris. Turn off water.

4. Attach garden hose to water inlet coupling. Tighten by

hand.

IMPORTANT: DO NOT siphon standing water for the water

supply. Use ONLY cold water (less than 100°F).

5. Uncoil high pressure hose and attach quick connect

end of hose (A) to spray gun (B). Pull down on collar of

quick connect, slide on to spray gun and let go of

collar. Tug on hose to be sure of tight connection.

6. Attach nozzle extension to spray gun by aligning the

locking tabs (C) into the grooves in the gun (D). Push

extension inward and twist clockwise to lock in place.

Tug on connection to be sure it is securely attached.

7. Turn ON water, point gun in a safe direction, press

trigger lock (red button) (E) and squeeze trigger to

purge pump system and spray gun of air.

Checklist Before Starting Engine

Review the unit’s assembly to ensure you have performed all

of the following.

1. Be sure to read the Operator Safety section and How to

Use Your Pressure Washer in Operation section before

using pressure washer.

2. Make sure handle is in place and secure.

3. Check for properly tightened hose connections.

4. Check to make sure there are no kinks, cuts, or damage

to high pressure hose.

5. Provide a proper water supply at an adequate flow.

7

B

A

C

D

E

NOTICE

Damage to pump or water inlet connector will occur if a

One Way Valve (vacuum breaker or check valve) is

connected to pump.

• There MUST be at least ten feet (3M) of unrestricted garden

hose between the pressure washer inlet and any device, such as

a One Way Valve.

• Damage to equipment caused by attaching a One Way Valve to

pump will void warranty.

WARNING

Risk of eye injury.

Spray can splash back or propel objects.

• Always wear safety goggles when using this equipment or in

vicinity of where equipment is in use.

• Before starting the pressure washer, be sure you are wearing

adequate safety goggles.

• NEVER substitute safety glasses for safety goggles.

WARNING

The high pressure stream of water that this

equipment produces can cut through skin and its

underlying tissues, leading to serious injury and

possible amputation.

• NEVER connect high pressure hose to nozzle extension.

• Keep high pressure hose connected to pump and spray gun

while system is pressurized.

• Always be certain spray gun, nozzles and accessories are

correctly attached.

Page 8

8 BRIGGSandSTRATTON.COM

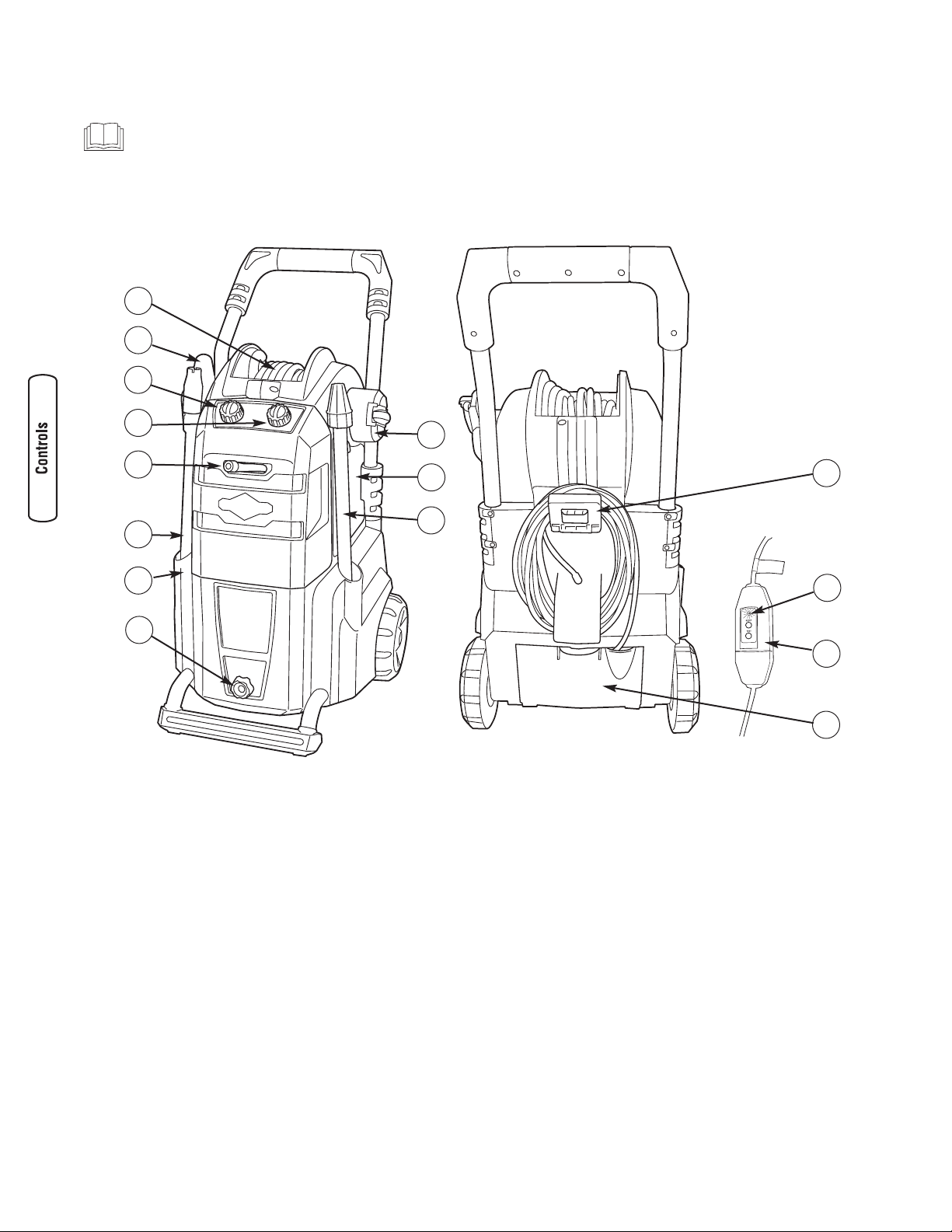

Features and Controls

Read the Operator’s Manual and safety rules before operating your pressure washer.

Compare the illustrations with your pressure washer to familiarize yourself with the locations

of various controls and adjustments. Save this manual for future reference.

A - High Pressure Hose Reel — High pressure connection

between pump and spray gun. Permanently attached to

hose reel.

B - Spray Gun — Controls the application of water onto

cleaning surface with trigger device. Includes trigger

lock.

C - Master ON/OFF Switch — ON is fully clockwise. OFF is

fully counter-clockwise.

D - Variable Dual Soap Tank Selector Knob — Controls the

concentration of detergent into low pressure stream

from either of two tanks.

E - High Pressure Hose Quick Connect — High pressure

connection between hose and spray gun.

F - Adjustable Nozzle — Always attached to nozzle

extension. Adjustable nozzle allows you to adjust spray

pressure and spray pattern.

G - Accessory Storage — On both sides of unit. Used to

store spray gun and nozzle extensions.

H - Garden Hose Water Inlet — Connect garden hose here.

J - Hose Reel w/Crank Handle — Hose reel permits clean

and convenient hose storage. Handle folds away.

K - Cleaning Tanks — Used to hold pressure-washer-safe

detergents.

L - Turbo Nozzle Extension — Attaches to the spray gun and

allows you to clean or rinse surfaces at high pressure.

You cannot apply detergent using the turbo nozzle.

M - Quick Release Cord Storage — Allows quick and easy

release of the stored power cord.

N - GFCI Indicator — When RED, the GFCI device is working

properly. See OPERATION.

P - Electric Cord with GFCI — Pressure washer and

operator is protected by a ground fault circuit

interrupter (GFCI).

R - Accessory Door — Provides safe storage of GFCI and

plug end of power cord.

A

H

D

B

E

F

G

M

P

N

L

J

R

C

K

Page 9

Operation

How to Start Your Pressure Washer

Follow the instructions below in the order presented. If you

have any problems operating your pressure washer, please

call the pressure washer helpline at (800) 743-4115.

1. Place pressure washer near an outside water source

capable of supplying water at a flow rate greater than

2.6 gallons per minute (9.8 l) and no less than 20 PSI

(1.38 BARS) at pressure washer end of garden hose.

DO NOT siphon supply water.

2. Check that high pressure hose is tightly connected to

spray gun. See Assembly for illustrations.

3. Make sure unit is in a vertical position.

4. Connect garden hose to water inlet.

5. Turn ON water, point gun in a safe direction, press

trigger lock (red button) and squeeze trigger to purge

pump system of air.

6. Remove any dirt or foreign matter from spray gun

outlet and attach desired nozzle extension to spray gun.

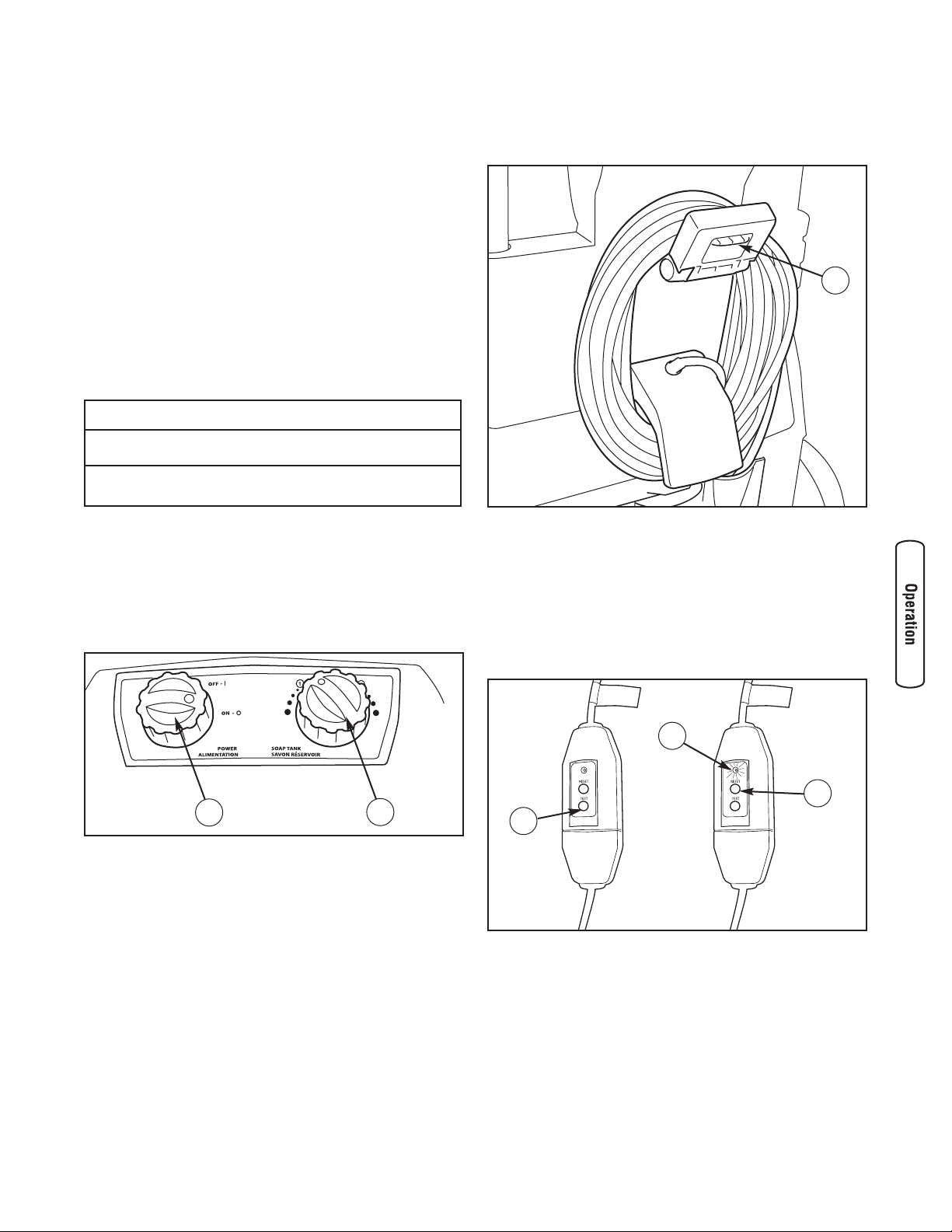

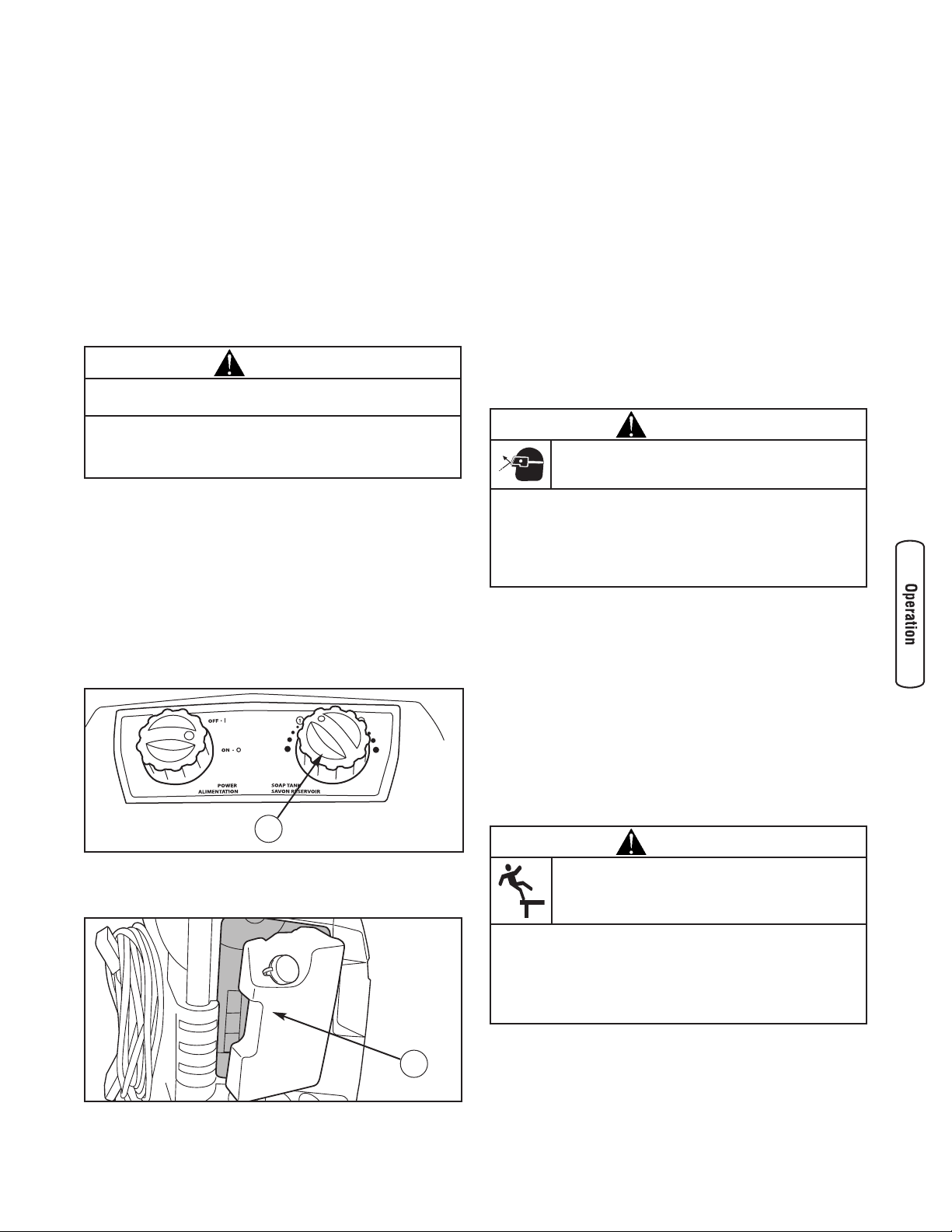

7. Rotate the ON/OFF switch (A) to the OFF position (fully

counterclockwise).

8. Rotate the dual soap tank control knob (B) to the center

position (no soap application).

9. Release stored power cord from the yoke on the back

of the pressure washer by pulling upward on the red

sliding lock (C) and then folding down the upper arm of

the yoke.

10. Plug power cord into an electrical circuit rated for

120 Volts AC at 15 Amps that has been installed in

accordance with local safety regulations. The red

indicator on the GFCI should appear.

NOTE: The red indicator must be visible for the pressure

washer to operate.

11. Press TEST button (D). The red indicator should

disappear.

12. Press RESET button (E). The red indicator (F) should

illuminate.

IMPORTANT: DO NOT use electric pressure washer if above

test fails.

9

NOTICE

DO NOT run the pump without the water supply connected

and turned on.

• Damage to equipment resulting from failure to follow this

instruction will void warranty.

B

A

C

D

E

F

Page 10

13. Move master ON/OFF switch (A) to the ON position

(turn knob fully clockwise).

14. Point gun in a safe direction, press trigger lock (red

button) and squeeze trigger. Pressure washer motor

will start and stop as spray gun trigger is depressed

and released.

The pressure washer is now ready for use. Instructions for

use of the supplied accessories are given later in this

section.

How to Stop Your Pressure Washer

The pressure washer motor runs only when the trigger is

engaged. To stop the pressure washer and turn off the

motor:

1. Release spray gun trigger.

2. Move unit’s master ON/OFF switch to OFF position.

IMPORTANT: Releasing the trigger will shut off the motor

but does not shut off electrical power to the unit.

3. Turn off water supply.

4. ALWAYS point spray gun in a safe direction, press

trigger lock (red button) and squeeze spray gun trigger

to relieve built up pressure in the unit.

NOTE: Spray gun traps high water pressure, even when

motor is stopped and water is disconnected.

5. Disconnect GFCI plug from outlet and coil power cord.

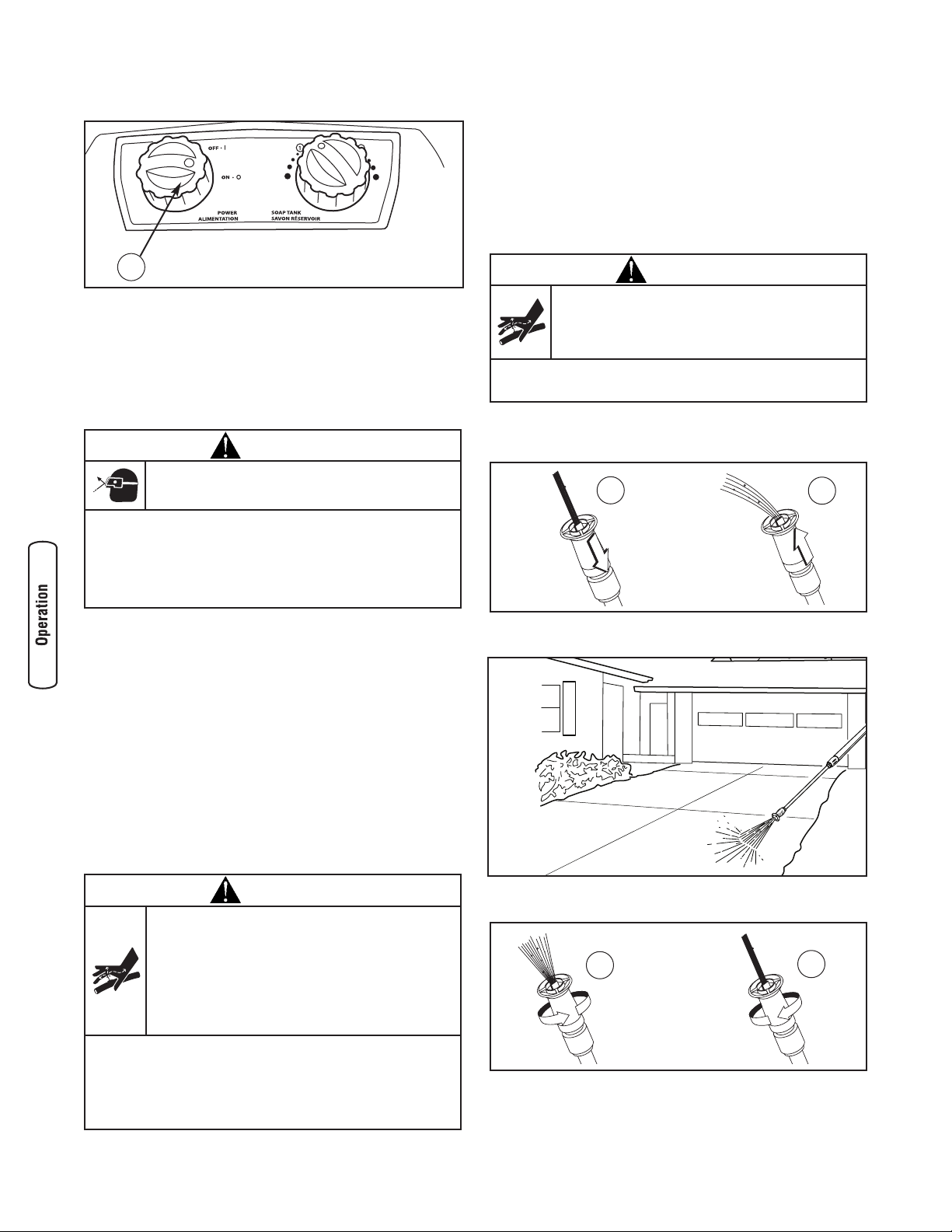

How to Use the Adjustable Nozzle

You should now know how to START and STOP your

pressure washer. The information in this section will tell you

how to adjust the spray pattern and to apply pressure

washer specific detergents.

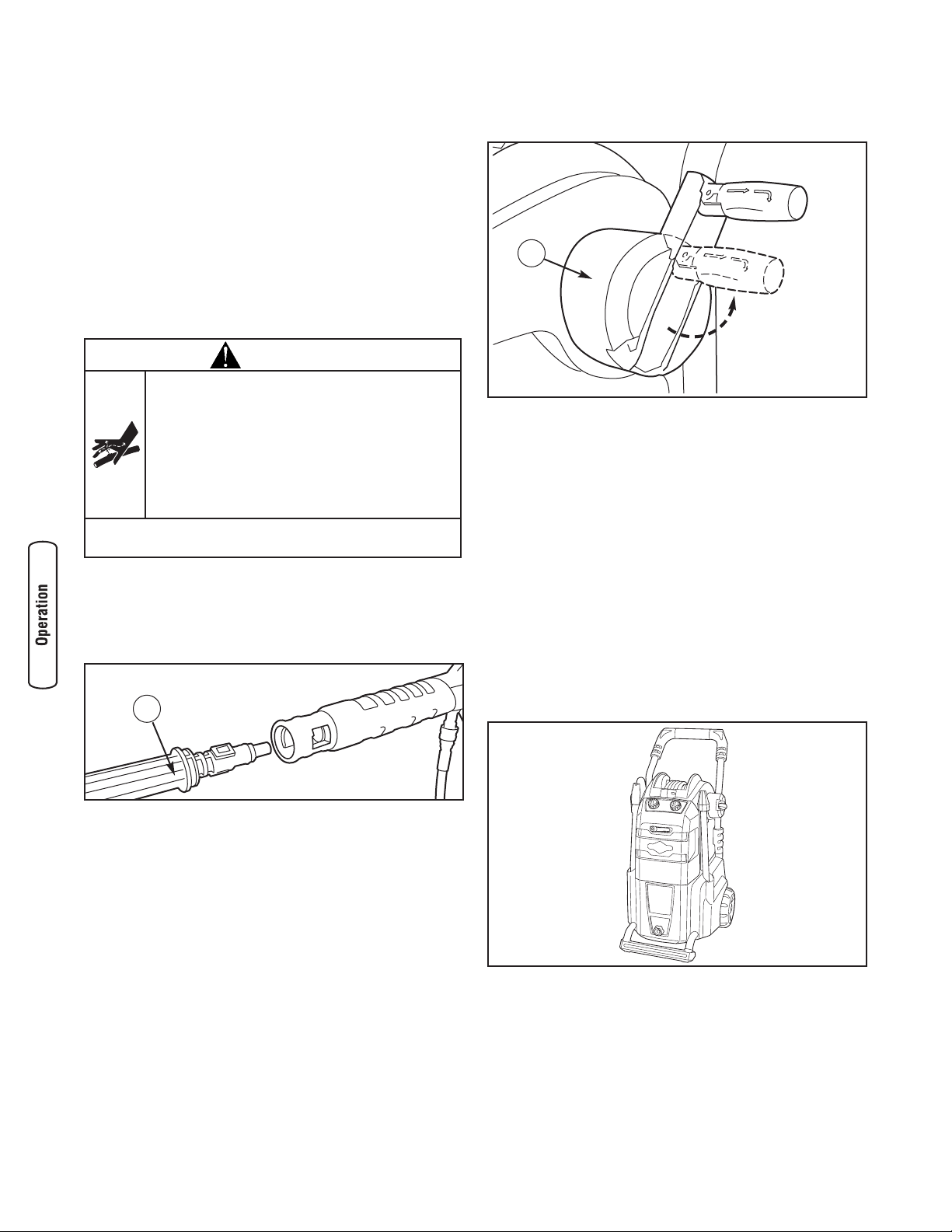

1. Slide nozzle backward (B) to achieve high pressure.

Slide nozzle forward (C) when you wish to adjust spray

to low pressure mode.

2. Point nozzle down towards a firm surface and press

trigger to test pattern.

3. Twisting nozzle adjusts spray pattern from a fan pattern

(D) to a narrow pattern (E).

10 BRIGGSandSTRATTON.COM

D

E

B

C

A

WARNING

Risk of eye injury.

Spray can splash back or propel objects.

• Always wear safety goggles when using this equipment or in

vicinity of where equipment is in use.

• Before starting the pressure washer, be sure you are wearing

adequate safety goggles.

• NEVER substitute safety glasses for safety goggles.

WARNING

The high pressure stream of water that this

equipment produces can cut through skin and its

underlying tissues, leading to serious injury and

possible amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected,

which can cause injury.

• Keep high pressure hose connected to pump and spray gun

while system is pressurized.

• ALWAYS point spray gun in safe direction, press trigger lock

(red button) and squeeze spray gun trigger, to release high

pressure, every time you turn off motor.

WARNING

The high pressure stream of water that this

equipment produces can cut through skin and its

underlying tissues, leading to serious injury and

possible amputation.

• NEVER adjust spray pattern when spraying.

• NEVER put hands in front of nozzle to adjust spray pattern.

Page 11

11

Usage Tips

• For most effective cleaning, keep spray nozzle from 8 to

24 inches (20 to 61 cm) away from cleaning surface.

• If you get spray nozzle too close, especially using high

pressure mode, you may damage surface being

cleaned.

• DO NOT get closer than 6 inches (15 cm) when

cleaning tires.

Applying Detergent with the Adjustable Nozzle

Your pressure washer is equipped with dual cleaning tanks

and a variable soap tank control knob to control the

concentration of soap dispensed from either tank.

To apply detergent, follow these steps:

1. Review use of adjustable nozzle.

2. Prepare detergent solution as required by job.

3. Turn the variable control knob (A) to the right to

increase the concentration of soap from the right tank

into the pressure spray. Turn the variable control knob

to the left to increase the concentration of soap mixed

into the pressure spray from the left tank. Center the

control knob to prevent the flow of soap into the

pressure spray.

4. Pull a cleaning tank (B) out from the side of the unit by

grasping the formed handle in the tank and pulling out

the handle side.

NOTE: DO NOT disconnect hose attached to bottom of

cleaning tank.

5. Open snap-fit cap on cleaning tank and fill the tank with

prepared detergent solution. A small funnel may help

with this task.

6. Press cleaning tank lid back down onto tank opening.

7. Fit cleaning tank back into opening. First, fully insert the

side that is attached to the pressure washer. Second,

press in the handle side until it snaps in place.

8. Slide adjustable nozzle forward to low pressure mode.

Detergent cannot be applied with nozzle in high

pressure position.

9. Turn the variable soap control knob to the tank and

level of soap concentration desired.

10. Press trigger lock (red button), pull spray gun trigger

and apply detergent to a dry surface, starting at lower

portion of area to be washed and work upward, using

long, even, overlapping strokes.

11. Allow detergent to "soak in" for 3-5 minutes before

washing and rinsing. Reapply as needed to prevent

surface from drying. DO NOT allow detergent to dry on

(prevents streaking).

Pressure Washer Rinsing

For Rinsing:

1. Slide the nozzle backward to high pressure, press the

trigger and wait for the detergent to clear.

2. Keep the spray gun a safe distance from the area you

plan to spray.

3. Apply a high pressure spray to a small area, then check

the surface for damage. If no damage is found, it is

okay to continue cleaning.

4. Start at the top of the area to be rinsed, working down

with same overlapping strokes as you used for washing

and applying detergent.

CAUTION

Chemicals can cause bodily injury, and/ or property

damage.

• NEVER use caustic liquid with pressure washer.

• Use ONLY pressure washer safe detergents/soaps. Follow all

manufacturers instructions.

A

B

WARNING

Risk of eye injury.

Spray can splash back or propel objects.

• Always wear safety goggles when using this equipment or in

vicinity of where equipment is in use.

• Before starting the pressure washer, be sure you are wearing

adequate safety goggles.

• NEVER substitute safety glasses for safety goggles.

WARNING

Kickback from spray gun can cause you to fall.

• Operate pressure washer from a stable surface.

• Be extremely careful if you must use the pressure washer from

a ladder, scaffolding, or any other similar location.

• Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury when spray gun kicks back.

Page 12

12 BRIGGSandSTRATTON.COM

How to Use the Turbo Nozzle

The turbo nozzle spins a 0° nozzle stream in a circular

pattern, providing an intense wide-spray pattern for scouring

large surface areas fast and efficient.

A turbo nozzle can easily cut through heavy oil and grease

stains on concrete, brick and plastic and strip paint from

various surfaces. DO NOT use the turbo nozzle on delicate

materials, especially wood. Always start the turbo nozzle at a

distance, gradually getting closer to the surface until you get

the cleaning force you want. Always keep the turbo nozzle in

a constant motion. NEVER dwell on a single spot. Pass over

stubborn stains repeatedly until they are gone using even

strokes.

To attach the turbo nozzle to the spray gun:

1. Remove any accessories attached to the spray gun.

2. Attach turbo nozzle extension (A) to spray gun. Tug on

the connection to be sure it is securely attached.

3. For most effective cleaning, keep turbo nozzle from 8 to

24 inches away from cleaning surface. If you get turbo

nozzle too close, you may damage cleaning surface.

NOTE: Detergent cannot be applied with the turbo nozzle.

How to Store Reel Handle

The hose reel is equipped with a folding and retracting space

saving handle. To retract the high pressure hose, lift the

handle knob until it snaps in place. Then slide the arm of the

handle out from the housing until it snaps in place.

To store the crank (B), first pull outward and then fold down

the handle knob completely to unlock the arm. Then slide the

arm back into the reel housing.

Other Cleaning Tips

• NEVER leave the pressure washer unattended while it is

plugged into an electrical outlet and while water is

supplied to the equipment.

• NEVER use the garden hose inlet to siphon detergent or

wax.

• If you have the nozzle too far away from the surface

being washed, the cleaning will not be as effective.

IMPORTANT: DO NOT get closer than 6 inches when

cleaning tires.

How to Store Accessories

The unit is equipped with an accessory tray with places to

store your spray gun and nozzle extensions. Identify all

accessories with the illustrations in Features and Controls.

Cleaning Detergent Supply System

If you use the cleaning tank to dispense detergents, it is

important to flush the system with clean water before storing

the pressure washer. See Maintenance for details.

A

WARNING

The high pressure stream of water that this

equipment produces can cut through skin and its

underlying tissues, leading to serious injury and

possible amputation.

The turbo nozzle produces an extremely high

pressure spray which is capable of removing

paint and cutting holes through surfaces if held

too close.

• Always make sure the surface you will clean will not be damaged

by the high pressure spray by testing in a hidden area.

B

Page 13

13

Maintenance

General Recommendations

Regular maintenance will improve the performance and

extend the life of the pressure washer. See any qualified

dealer for service.

The pressure washer’s warranty does not cover items that

have been subjected to operator abuse or negligence. To

receive full value from the warranty, the operator must

maintain the pressure washer as instructed in this manual,

including proper storage.

NOTE: Should you have questions about replacing

components on your pressure washer, please call

(800) 743-4115 for assistance.

Some adjustments will need to be made periodically to

properly maintain your pressure washer.

Before Each Use

1. Clean debris.

2. Check water inlet screen for damage.

3. Check high pressure hose for leaks.

4. Check cleaning tanks for damage.

5. Check spray gun and nozzle extension assembly for

leaks.

6. Rinse out garden hose to flush out debris.

Pressure Washer Maintenance

Clean Debris

Daily or before use, clean accumulated debris from pressure

washer. Inspect cooling air slots and openings on the

pressure washer. These openings must be kept clean and

unobstructed.

Pressure washer parts should be kept clean to reduce the

risk of overheating and ignition of accumulated debris.

• Use a damp cloth to wipe exterior surfaces clean.

• Use a soft bristle brush to loosen caked on dirt, oil, etc.

• Use a vacuum cleaner to pick up loose dirt and debris.

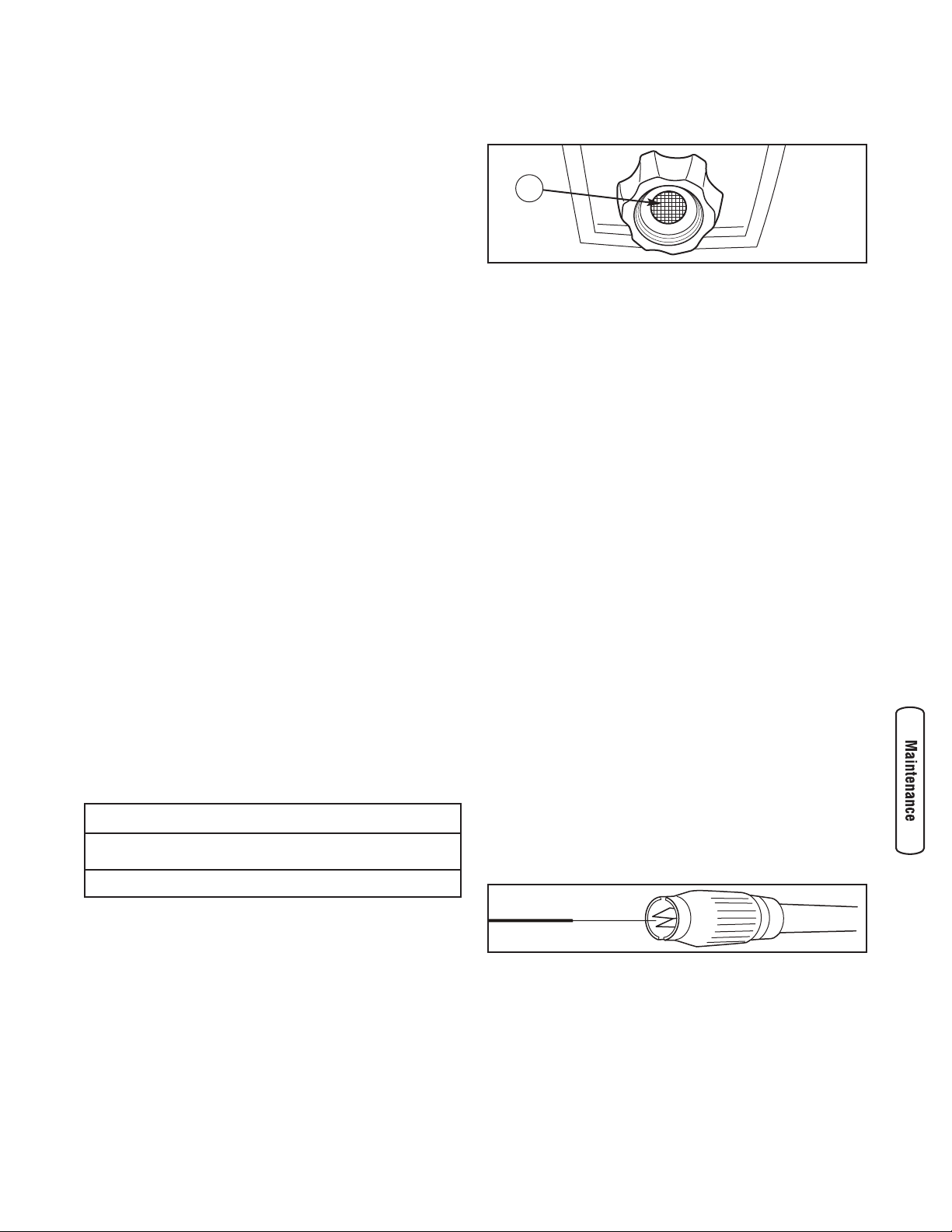

Check and Clean Water Inlet Screen

Examine water inlet screen (A). Clean if it is clogged or

replace if it is torn.

Check High Pressure Hose

High pressure hoses can develop leaks from wear, kinking,

or abuse. Inspect hose before each use. Check for cuts,

leaks, abrasions, bulging of cover, or damage or movement

of couplings.

Check Gun and Nozzle Extension

Examine hose connection to spray gun and make sure it is

secure. Test trigger lock (red buttion) by pressing it and

making sure it springs back into place when you release it.

With trigger lock in latched position, test gun by squeezing

trigger. You should not be able to press trigger. Replace

spray gun immediately if it fails any of these tests.

The nozzle extensions use o-rings to prevent water leaks.

Normal usage will cause wear on these rings and mating

surfaces.

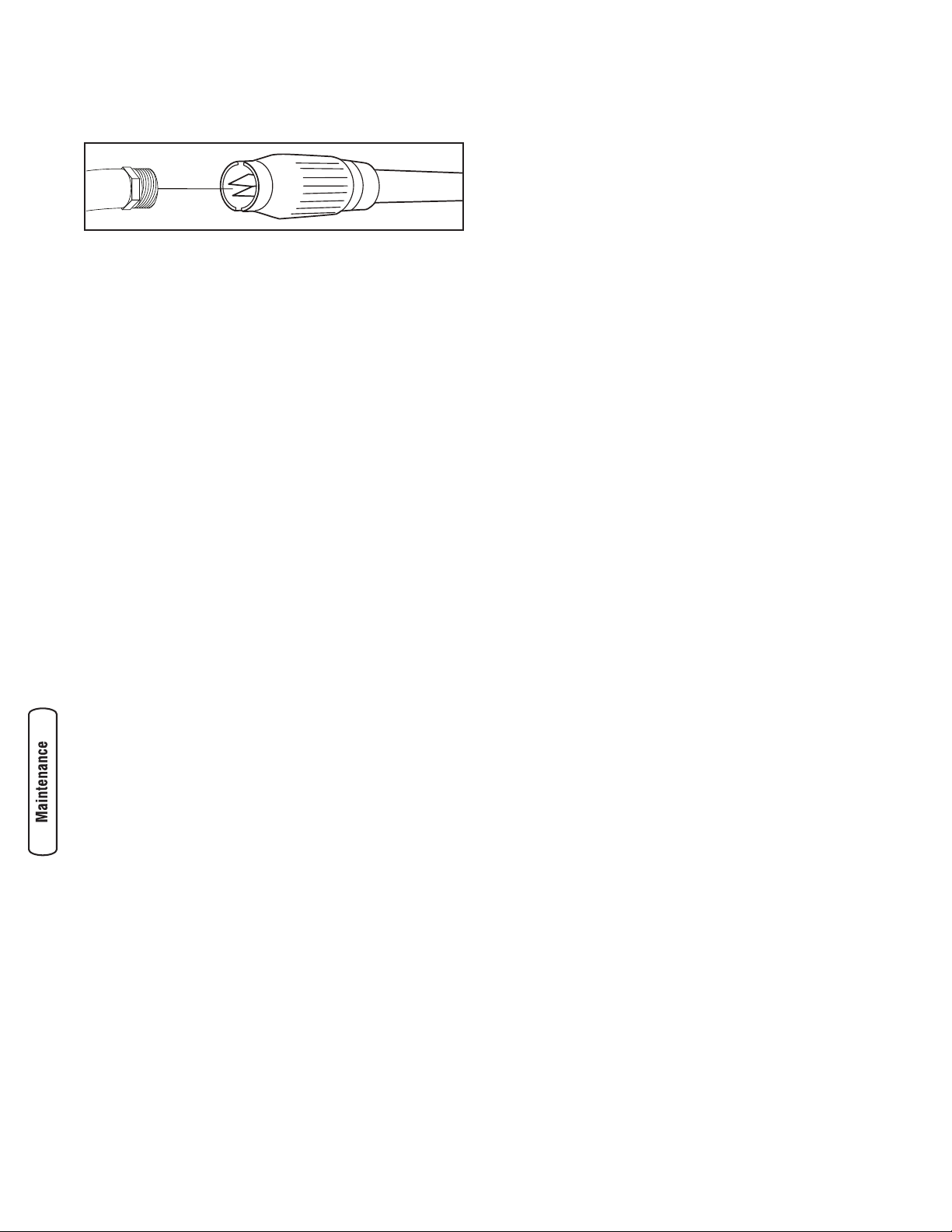

Nozzle Maintenance

A pulsing sensation felt while squeezing the spray gun

trigger may be caused by excessive pump pressure. The

principal cause of excessive pump pressure is a nozzle

clogged or restricted with foreign materials, such as dirt, etc.

To correct the problem, immediately clean the nozzle

following these instructions:

1. Turn master ON/OFF switch to OFF.(Turn knob fully

counter-clockwise.) Disconnect water supply.

2. Press trigger lock (red button), pull spray gun trigger to

relieve pressure.

3. Remove nozzle extension from spray gun.

4. Use supplied cleaning wire or bent paper clip to free

any foreign material clogging or restricting nozzle.

NOTICE

Improper treatment of pressure washer can damage it and

shorten its life.

• DO NOT insert any objects through cooling slots.

A

Page 14

14 BRIGGSandSTRATTON.COM

5. Using a garden hose, remove additional debris by back

flushing water through nozzle extension. Back flush

between 30 to 60 seconds.

6. Reconnect nozzle extension to spray gun.

7. Reconnect water supply, turn on water, and move

master ON/OFF switch to ON.

8. Test pressure washer by operating with nozzle in every

available position.

Pump and Motor Maintenance

This pressure washer does not require any maintenance on

the pump or motor. Both assemblies are pre-lubricated and

sealed, requiring no additional lubrication ever.

Storage

Water should not remain in the unit for long periods of time.

Sediments or minerals can deposit on pump parts and

“freeze” pump action.

1. Flush detergent system by lifting cleaning tank lid,

removing tank from pressure washer and dumping

solution from tank.

2. Rinse cleaning tank out with fresh clean water. Fill tank

with clean water.

3. Run pressure washer with adjustable nozzle set for low

pressure. Flush for one or two minutes.

4. Dump remaining water out of cleaning tank. Push tank

back into pressure washer base. Reinsert detergent

hose and secure tank lid on tank.

5. Turn master ON/OFF switch to OFF and turn off water

supply. Point gun in a safe direction, press trigger lock

(red button) and squeeze trigger to relieve trapped

pressure. After a few moments, release trigger on spray

gun.

6. Disconnect hose from spray gun. Drain water from

hose, gun, and nozzle extension. Use a rag to wipe off

the hose.

7. Rewind high pressure hose onto hose reel.

8. Store unit in a clean, dry area that is protected from

freezing temperatures.

9. Cover unit with a suitable protective cover that does not

retain moisture.

Page 15

15

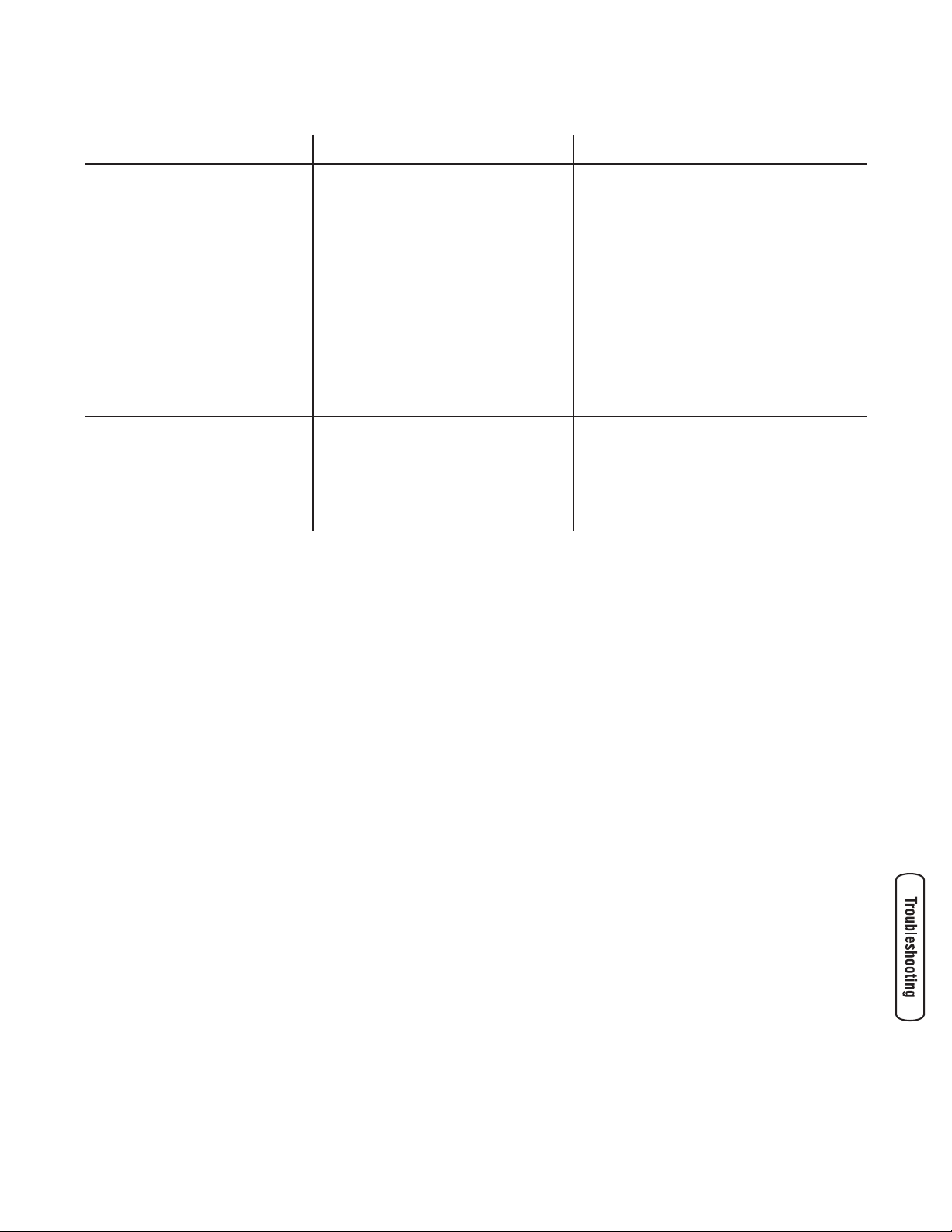

Troubleshooting

Problem Cause Correction

Pump has following problems:

failure to produce pressure,

erratic pressure, chattering, loss

of pressure, low water volume.

1. Water inlet is blocked.

2. Inadequate water supply.

3. Inlet hose is kinked or leaking.

4. Clogged inlet hose strainer.

5. Water supply is over 100°F.

6. High pressure hose is blocked or

leaks.

7. Gun leaks.

8. Nozzle is obstructed.

9. Pump is faulty.

1. Clear inlet.

2. Provide adequate water flow.

3. Straighten inlet hose, patch leak.

4. Check and clean inlet hose strainer.

5. Provide cooler water supply.

6. Clear blocks in high pressure hose or

replace hose.

7. Replace gun.

8. Clean nozzle.

9. Contact Briggs & Stratton service

facility.

Detergent fails to mix with spray.

1. Adjustable nozzle is not in low

pressure position.

2. In-line detergent filter is dirty.

3. Turbo nozzle extension installed.

1. Pull adjustable nozzle back to low

pressure position.

2. Flush detergent filter with clean water.

3. Replace with adjustable nozzle

extension.

Page 16

16 BRIGGSandSTRATTON.COM

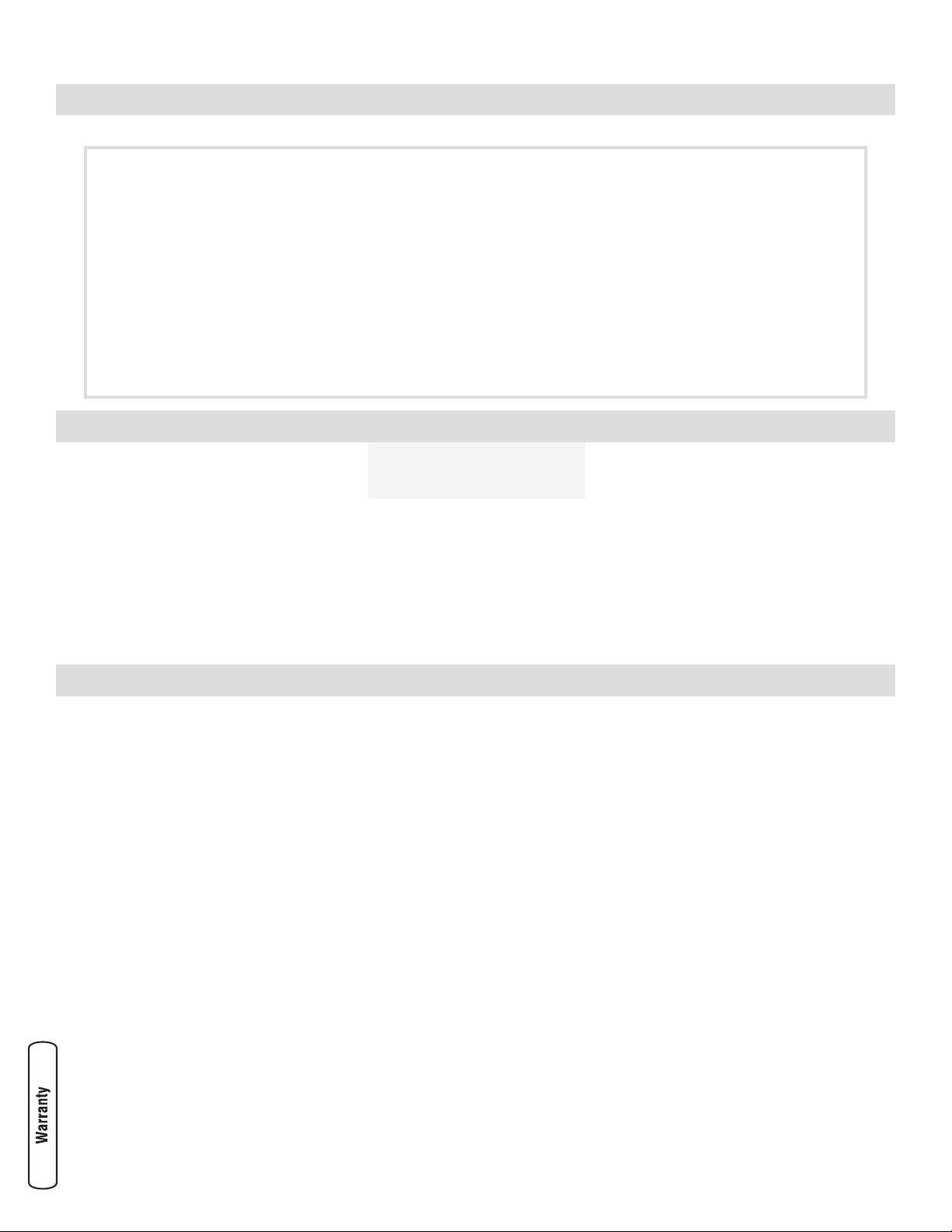

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC PRESSURE WASHER OWNER WARRANTY POLICY

LIMITED WARRANTY

Briggs & Stratton Power Products Group, LLC will repair or replace, free of charge, any part(s) of the pressure washer that is defective in material or

workmanship or both. Transportation charges on product submitted for repair or replacement under this warranty must be borne by purchaser. This

warranty is effective for the time periods and subject to the conditions stated below. For warranty service, find the nearest Authorized Service Dealer in

our dealer locator map at BRIGGSandSTRATTON.COM.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, ARE LIMITED TO ONE YEAR FROM PURCHASE, OR TO THE EXTENT PERMITTED BY LAW. ANY AND ALL IMPLIED WARRANTIES ARE

EXCLUDED. LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES ARE EXCLUDED TO THE EXTENT EXCLUSION IS PERMITTED BY LAW. Some

states or countries do not allow limitations on how long an implied warranty lasts, and some states or countries do not allow the exclusion or limitation

of incidental or consequential damages, so the above limitation and exclusion may not apply to you. This warranty gives you specific legal rights and

you may also have other rights which vary from state to state or country to country.

1 year

30 days

Consumer Use

Commercial Use

The warranty period begins on the date of purchase by the first retail consumer or commercial end user, and continues for the period of time stated above.

“Consumer use” means personal residential household use by a retail consumer. “Commercial use” means all other uses, including use for commercial,

income producing or rental purposes. Once equipment has experienced commercial use, it shall thereafter be considered as commercial use for purposes of

this warranty.

NO WARRANTY REGISTRATION IS NECESSARY TO OBTAIN WARRANTY ON BRIGGS & STRATTON PRODUCTS. SAVE YOUR PROOF OF PURCHASE

RECEIPT. IF YOU DO NOT PROVIDE PROOF OF THE INITIAL PURCHASE DATE AT THE TIME WARRANTY SERVICE IS REQUESTED, THE MANUFACTURING

DATE OF THE PRODUCT WILL BE USED TO DETERMINE THE WARRANTY PERIOD.

ABOUT YOUR WARRANTY

We welcome warranty repair and apologize to you for being inconvenienced. Any Authorized Service Dealer may perform warranty repairs. Most warranty

repairs are handled routinely, but sometimes requests for warranty service may not be appropriate. For example, warranty service would not apply if

equipment damage occurred because of misuse, lack of routine maintenance, shipping, handling, warehousing or improper installation. Similarly, the

warranty is void if the manufacturing date or the serial number on the pressure washer has been removed or the equipment has been altered or modified.

During the warranty period, the Authorized Service Dealer, at its option, will repair or replace any part that, upon examination, is found to be defective under

normal use and service. This warranty will not cover the following repairs and equipment:

• Normal Wear: Outdoor Power Equipment, like all mechanical devices, needs periodic parts and service to perform well. This warranty also does not

cover normal maintenance such as filters, adjustments, cleaning and obstruction (due to chemical, lime, dirt, and so forth).

• Installation and Maintenance: This warranty does not apply to equipment or parts that have been subjected to improper or unauthorized installation or

alteration and modification, misuse, negligence, accident, overloading, overspeeding, improper maintenance, repair or storage so as, in our judgment,

to adversely affect its performance and reliability. This warranty also does not cover normal maintenance such as filters, adjustments, chemical system

cleaning and obstruction (due to chemical, lime, dirt, and so forth).

• Other Exclusions: This warranty excludes wear items such as quick couplers, seals, o-rings, pumps that have been run without water supplied or

damage or malfunctions resulting from accidents, abuse, modifications, alterations, or improper servicing or freezing or chemical deterioration.

Accessory parts, such as guns, hoses, nozzle extensions (wands), and nozzles, are excluded from the product warranty. This warranty excludes used,

reconditioned, and demonstration equipment and failures due to acts of God and other force majeure events beyond the manufacturers control.

206457E, Rev. -, 1/17/2008

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC

JEFFERSON, WI, USA

Effective January 1 replaces all undated Warranties and all Warranties dated before January 1, 2008

WARRANTY PERIOD

Page 17

17

Reserved

Page 18

18 BRIGGSandSTRATTON.COM

Briggs & Stratton Power Products Group, LLC

900 N. Parkway

Jefferson, Wisconsin, 53549 U.S.A.

Pressure Washer

This pressure washer is rated in accordance to the Pressure Washer Manufacture Association (PWMA) standard PW101

(Testing and Rating Performance of Pressure Washers).

Product Specifications

Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1800 PSI

Flow Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.6 GPM

Detergent Mix . . . . . . . . . . . . . . . . .See mfr’s instructions

Water Supply Temperature . . . . . . . .Not to exceed 100°F

Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Induction Type

Rated Voltage . . . . . . . . . . . . . . . . . . . . . . . .120 Volts AC

Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13 Amps

(800) 743-4115

Page 19

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC

JEFFERSON, WISCONSIN, U.S.A.

Limpiadora a presión

Manual del Operario

Esta limpiadora a presión está clasificada conforme a la norma PW101 (comprobación

y clasificación de rendimiento de limpiadoras a presión) de la Asociación de fabricantes

de bombas a presión (Pressure Washer Manufacture Association, PWMA).

Page 20

2 BRIGGSandSTRATTON.COM

Briggs & Stratton Power Products Group, LLC.

900 North Parkway

Jefferson, WI 53549

Copyright © 2008 Briggs & Stratton Power Products Group,

LLC. Reservados todos los derechos. Queda prohibida la

reproducción o transmisión total o parcial de este material,

sea cual sea la forma y el medio empleados para ello, sin el

permiso previo y por escrito de Briggs & Stratton Power

Products Group, LLC.

Muchas gracias por comprar este limpiadora a presión Briggs & Stratton de gran calidad. Nos alegra que haya depositado su

confianza en la marca Briggs & Stratton. Siempre que sea utilizado de acuerdo con las instrucciones de este manual, su

limpiadora a presión Briggs & Stratton le proporcionará muchos años de buen funcionamiento.

Este manual contiene información sobre seguridad para hacerle consciente de los riesgos asociados a los limpiadora a

presións y mostrarle cómo evitarlos. Briggs & Stratton no conoce necesariamente todas las aplicaciones que este limpiadora

a presión puede tener; por ello es importante que lea y entienda estas instrucciones. Conserve este manual para futuras

consultas.

Este limpiadora a presión requiere montaje final antes de ser usado. Consulte la sección Montaje de este manual, donde

encontrará instrucciones para el montaje final. Siga las instrucciones al pie de la letra.

Dónde encontrarnos

Usted no tendrá que ir muy lejos para encontrar el servicio técnico de Briggs & Stratton para su limpiadora a presión.

Consulte las Páginas Amarillas. Hay más de 30.000 proveedores de Briggs & Stratton autorizados en todo el mundo,

proporcionando un servicio de calidad. También puede ponerse en contacto con Atención al Cliente de Briggs & Stratton

llamando al (800) 743-4115 o por Internet en BRIGGSandSTRATTON.COM.

Limpiadora a Presión

Número de Modelo

Revisión

Número de Serie

Fecha de compra

Page 21

3

Español

Tabla de Contenido

Seguridad de Operario . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Derscripción del equipo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Reglas de seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Montaje . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Desembalaje de la limpiadora a presión . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Montaje del asa . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Conecte la manguera y el suministro de agua. . . . . . . . . . . . . . . . . . . . . . . 6

Características y mandos . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operando . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Puesta en funcionamiento la limpiadora a presión . . . . . . . . . . . . . . . . . . . 9

Parada de la limpiadora a presión . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Uso de la boquilla regulable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Aplicación del detergente usando la boquilla ajustable . . . . . . . . . . . . . . . 11

Enjuage de la máquina limpiadora a presión . . . . . . . . . . . . . . . . . . . . . . . 11

Cómo utilizar la boquilla turbo. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Cómo guardar la manivela del carrete . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Otras sugerencias para la limpieza . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Almacenamiento de los accesorios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Sistema de suministro de detergente . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Mantenimiento. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Recomendaciones generales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Mantenimiento de la limpiadora a presión. . . . . . . . . . . . . . . . . . . . . . . . . 13

Mantenimiento de la bomba y motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Almacenamiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Resolución de problemas . . . . . . . . . . . . . . . . . . . . . . . . . 15

Garantía . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Especificaciones. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Page 22

4 BRIGGSandSTRATTON.COM

Seguridad de Operario

Derscripción del equipo

Lea este manual de manera cuidadosa y

familiarícese con su limpiadora a presión.

Conozca sus usos, sus limitaciones y cualquier

peligro relacionado con el mismo.

Esta limpiadora a presión funciona a un máximo de

1.800 PSI con un caudal de hasta 6,05 litros por minuto

(1,6 galones por minuto).

Se ha realizado el máximo esfuerzo para reunir en este

manual la información más precisa y actualizada. No

obstante, nos reservamos el derecho de modificar, alterar o

mejorar de cualquier otra forma el producto y este

documento en cualquier momento y sin previo aviso.

Protección mediante interruptor de circuito de fallo de

conexión a tierra

Este producto se debe conectar a tierra correctamente. Esta

limpiadora a presión eléctrica está equipada con un

interruptor de circuito de fallo de conexión a tierra (GFCI). El

dispositivo desconectará los dos conductores eléctricos del

circuito de carga en caso de interrupción de uno o ambos

conductores de alimentación del circuito. En caso de fallo o

avería, el GFCI aporta la protección necesaria.

El enchufe debe introducirse en una toma adecuada,

correctamente instalada y conectada a tierra conforme a toda

la normativa vigente. Lea las instrucciones del enchufe o

consulte la sección Antes de encender la limpiadora a presión.

Parada automática

La limpiadora a presión dispone de un sensor que detecta

que el agua a alta presión deja de circular cuando se suelta o

bloquea el gatillo de la pistola rociadora. El sensor provocará

la parada del motor y lo mantendrá parado mientras el gatillo

no esté pulsado o permanezca bloqueado.

NO UTILICE LA MÁQUINA si el motor sigue funcionando

cuando no se aprieta el gatillo o cuando éste está bloqueado.

Llame a la línea de asistencia de la limpiadora a presión,

(800) 743-4115.

IMPORTANTE: La limpiadora a presión dispone de un

interruptor principal de encendido ON/OFF. Para evitar

posibles daños, el interruptor debe permanecer siempre en

la posición OFF cuando no se utilice la limpiadora a presión.

Sobrecarga del motor

El motor eléctrico de la limpiadora a presión dispone de un

dispositivo de protección contra sobrecarga. El dispositivo

parará automáticamente el motor en caso de recalentamiento

o de consumo excesivo de corriente. Al cabo de un tiempo,

el dispositivo se rearmará y la limpiadora a presión podrá

seguir funcionando normalmente.

Cables prolongadores

No se recomienda el uso de cables prolongadores con este

dispositivo. No obstante, si fuera necesario utilizarlos, utilice

cables aprobados para uso en exteriores. Este tipo de cables

prolongadores se identifica mediante la indicación “APTO

PARA USO CON EQUIPOS DE EXTERIOR”. No se recomienda

utilizar cables prolongadores a menos que estén enchufados

a una toma con protección contra fallo de conexión a tierra.

NO utilice cables prolongadores que no estén en perfecto

estado. Respete igualmente las siguientes especificaciones:

Longitud del cable: Calibre del cable:

Hasta 8 m 14 AWG

15 m 12 AWG

Desconecte siempre el cable prolongador de la toma antes

de desconectar el GFCI del cable prolongador.

Reglas de seguridad

Éste es el símbolo de alerta de seguridad. Sirve

para advertir al usuario de un posible riesgo para

su integridad física. Siga todos los mensajes de

seguridad que figuren después de este símbolo

para evitar lesiones o incluso la muerte.

El símbolo de alerta de seguridad ( ) se utiliza con una

palabra de señalización (PELIGRO, PRECAUCIÓN,

ADVERTENCIA), una imagen y/o un mensaje de seguridad

para advertir al usuario de un riesgo. PELIGRO indica un

riesgo que, de no evitarse, provocará la muerte o lesiones de

gravedad. ADVERTENCIA indica un riesgo que, de no evitarse,

puede provocar la muerte o lesiones de gravedad.

PRECAUCIÓN indica un riesgo que, de no evitarse, puede

provocar lesiones moderadas. AVISO indica una situación que

podría producir daños en el equipo. Siga en todo momento

los mensajes de seguridad para evitar o reducir el riesgo de

lesiones y de muerte.

Símbolos de Peligro y Significados

A - Descarga Eléctrica E - Superficies Resbalosas

B - Explosión F - Objetos Voladores

C - Caer G - Manual del Operario

D - Inyección Líquida

ADVERTENCIA

Riesgo de electrocución.

• Mantenga todas conexiones eléctricas secan y del suelo.

• NUNCA toque el enchufe con las manos mojadas.

• NUNCA corte ni quite la clavija de conexión a tierra (clavija

redonda de mayor longitud) del enchufe del GFCI.

A B C

F

D

G

E

Page 23

5

Español

ADVERTENCIA

Riesgo de electrocución.

El contacto con los cables eléctricos puede

provocar electrocución y quemaduras.

• NUNCA rocíe cerca de una fuente de energía eléctrica.

• NUNCA corte ni quite la clavija de conexión a tierra (clavija

redonda de mayor longitud) del enchufe del GFCI.

ADVERTENCIA

Determinados componentes en este producto y los

accesorios relacionados contienen sustancias químicas

declaradas cancerígenas, causantes de malformaciones y

otros defectos congénitos por el Estado de California.

Lávese las manos después de manipular estos elementos.

ADVERTENCIA

El uso de limpiadora a presión puede crear los

charcos y superficies resbalosas.

El retroceso de la pistola rociadora puede

provocar caídas.

• Utilice la limpiadora a presión desde una superficie estable.

• El área de limpieza deberá tener inclinaciones y drenajes

adecuados para disminuir la posibilidad de caídas debido a

superficies resbalosas.

• Extreme las precauciones si necesita utilizar la limpiadora a

presión desde una escalera, un andamio u otro lugar similar.

• Sujete firmemente la pistola rociadora con ambas manos

cuando aplique un rociado a alta presión para evitar lesiones

cuando se produzca el retroceso de la pistola.

ADVERTENCIA

El chorro de agua a alta presión que este equipo

produce, puede atravesar la piel y los tejidos

subcutáneos, provocando lesiones de gravedad

que podrían dar lugar a la amputación de un

miembro.

La pistola rociadora contiene agua a alta presión

incluso con el motor parado y el agua

desconectada, que puede causar la herida.

• NO permita en ningún momento que NIÑOS operen la máquina

limpiadora a presión.

• NUNCA repare la manguera de alta presión. Remplacela.

• NUNCA utilice ningún tipo de sellador para reparar una fuga en

una conexión. Sustituya la junta tórica o la junta.

• NUNCA conecte la manguera de alta presión al prolongador de

la boquilla.

• Mantenga conectada la manguera a la máquina o a la pistola de

rociado cuando el sistema esté presurizado.

• SIEMPRE que pare el motor, apunte con la pistola rociadora

hacia una dirección segura, pulse el botón rojo y apriete el

gatillo para descargar la presión.

• NUNCA apunte la pistola a la gente, animales o plantas.

• NO fije la pistola rociadora en la posición abierta.

• NO abandone la pistola rociadora cuando la máquina esté en

funcionamiento.

• NUNCA utilice una pistola rociadora cuyo seguro o protección

para el gatillo no esté en perfecto estado de funcionamiento.

• Asegúrese en todo momento de conectar correctamente la

pistola rociadora, las boquillas y los accesorios.

ADVERTENCIA

Riesgo de explosión.

Rociar líquidos inflamables o combustibles

pueden causar el fuego o la explosión.

• NO rocíe líquidos inflamables o combustibles.

ADVERTENCIA

Riesgo de lesiones oculares.

El agua rociada puede salpicar o propulsar

objetos.

• Utilice siempre gafas de protección cuando utilice este equipo o

si se encuentra cerca de donde se está utilizando.

• Antes de poner en marcha la limpiadora a presión, asegúrese de

llevar gafas de protección adecuadas.

• Utilice SIEMPRE las gafas de seguridad apropiadas.

AVISO

El rociado de alta presión puede dañar elementos frágiles,

incluyendo el vidrio.

• NO dirija la pistola rociadora hacia un cristal cuando utilice la

boquilla de turbo.

• NUNCA apunte la pistola a plantas.

AVISO

El tratamiento inadecuado del limpiadora a presión puede

dañarlo y acortar su vida productiva.

• Si usted tiene alguna pregunta acerca de las finalidades de uso

del generador, pregúntele a su concesionario o contacte a

Briggs & Stratton Power Products.

• NUNCA deberán ser operadas las unidades con partes rotas o

ausentes, o sin la caja o cubiertas de protección.

• NO eluda ningún dispositivo de seguridad de esta máquina.

• La garantía del producto es vacío si molió hoja (redondea alfiler

más largo) en el tapón de la fijación de GFCI es quitado.

• NO utilice la limpiadora a presión por encima de su presión

nominal.

• NO haga ninguna modificación en la limpiadora a presión.

• Antes de poner en marcha la máquina limpiadora a presión en

clima frío, revise todas las partes del equipo y asegúrese de que

no se haya formado hielo sobre ellas.

• NUNCA mueva la máquina halando la manguera de alta presión.

Utilice la manija que viene con la unidad.

• El equipo de alta presión está diseñado para ser utilizado

UNICAMENTE con las partes autorizadas Briggs & Stratton

Power Products. Si utiliza este equipo con partes que no

cumplan con las especificaciones mínimas, el usuario asume

todos los riesgos y responsabilidades.

Page 24

6 BRIGGSandSTRATTON.COM

Montaje

Lea totalmente el manual del operario antes que

intente ensamblar u operar su limpiadora a presión.

Su limpiadora a presión requiere de ciertos procedimientos

de montaje y solo estará listo para ser utilizado después de

haberle suministrado servicio con el combustible y aceite

recomendados.

Antes de utilizar la limpiadora a presión, es necesario

motarla, pero esta operación requiere poco tiempo. En caso

de problemas durante el montaje de la unidad, llame a la línea

de asistencia de la limpiadora a presión, (800) 743-4115.

Herramientas necesarias

• Llave allen de 4 mm (incluida)

• Alicates de punta fina

Desembalaje de la limpiadora a presión

1. Saque todo el contenido de la caja de cartón, a

excepción de la limpiadora a presión.

2. Si la limpiadora a presión le resulta demasiado pesada,

abra completamente la caja de cartón cortando cada

una de sus esquinas de arriba abajo.

Los artículos que se encuentran en la caja son:

• Limpiadora a presión

• Asa de la limpiadora a presión

• Pistola rociadora

• Prolongador de la boquilla con boquilla regulable

• Prolongador de la boquilla con boquilla turbo

• Bolsa de piezas con el siguiente contenido:

• Tornillos allen de fijación del asa (4)

• Manual del operario

• Tarjeta de registro del propietario

• Máscara de seguridad

• Herramienta de limpieza de la boquilla

Compruebe todo el contenido. Si falta alguno de los

componentes o si está dañado, llame a la línea de asistencia

de la limpiadora a presión, (800) 743-4115.

Familiarícese con cada uno de los componentes antes de

montar la limpiadora a presión. Identifique los componentes

con la ilustración de la sección Características y mandos.

A prepara su arandela de la presión para la operación,

usted necesitará a realiza estas tareas:

1. Llene y mande en tarjeta de matrícula.

2. Conecte manubrio a unidad principal.

3. Conecte manguera a alta presión a pistola rociadora.

4. Conecte el suministro de agua a bomba.

5. Conecte boquilla la extensión al pistola rociadora.

Montaje del asa

1. Coloque el asa (A) sobre la limpiadora a presión, con el

asa roja sobre el cable de alimentación y el orificio del

asa alineado con los orificios de los tornillos de la parte

trasera de la limpiadora a presión.

2. Utilice los 4 tornillos allen (B) y la llave allen que se

suministran para fijar el asa a la limpiadora a presión.

Apriete hasta que los tornillos queden bien ajustados.

Conecte la manguera y el suministro de agua

1. Quite y deseche el tapón de transporte de la entrada de

agua de la unidad con unos alicates de punta fina.

2. Confirme que el filtro de la entrada de agua (C) está

instalado.

NOTE: NO utilice la limpiadora a presión si el filtro de

entrada de agua está dañado o falta. Llame al

(800) 743-4115 para solicitar ayuda.

3. Deje correr el agua por la manguera de riego durante

30 segundos para limpiar cualquier posible resto.

Cierre el agua.

A

B

C

AVISO

NO haga funcionar la bomba si no tiene el suministro

conectado y abierto.

• El daño a la limpiadora a presión, resultado de la desatención a

esta precaución, no será cubierto por la garantía.

Page 25

7

Español

4. Conecte la manguera de riego al acoplamiento de la

entrada de agua. Apriete a mano.

IMPORTANTE: No inyecte agua estancada para alimentar la

bomba. Utilice SÓLO agua fría (con una temperatura inferior

a 38 ºC).

5. Retroceda la manguera a alta presión y conecte el

extremo de conexión rápida de la manguera (A) a la

base de la pistola rociadora (B). Jale el collar de

conexión rápida, deslícelo por la pistola rociadora y

suéltelo. Jale la manguera para asegurarse de que está

conectada firmemente.

6. Conecte el prolongador de la boquilla a la pistola

rociadora alineando las lengüetas de bloqueo (C) en las

ranura de la pistola (D). Empuje hacia dentro el

prolongador y gírelo hacia la derecha para bloquearlo.

Tire de la conexión para asegurarse de que sea firme.

7. Abra el agua, apunte con la pistola hacia una dirección

segura, presione el seguro del gatillo (botón rojo) (E) y

apriete el gatillo para eliminar el aire del sistema de

bombeo y de la pistola rociadora.

Lista de revision previa al arranque del motor

Revise la unidad para asegurarse que ha llevado a cabo los

siguientes procedimientos:

1. Asegúrese de leer las secciones Reglas de seguridad y

Cómo usar su máquina limpiadora a presión antes de

usar la máquina limpiadora a presión.

2. Cerciórese el manecilla es seguro.

3. Revise que todas las conexiones de las mangueras (alta

presión y suministro de agua) estén apretadas

correctamente y que no existan dobleces, cortes o daño

de la manguera de alta presión.

4. Proporcione el suministro de agua adecuado.

B

A

C

D

E

AVISO

El uso de una válvula unidireccional (igualador de presión

o válvula de retención) en la entrada de la bomba puede

producir daños en la bomba o en el conector de entrada.

• DEBE haber un mínimo de 3 metros (10 pies) de manguera de

riego libre entre la entrada de la limpiadora a presión y cualquier

dispositivo, como un igualador de presión o una válvula de

retención).

• El daño a la limpiadora a presión, resultado de la desatención a

esta precaución, no será cubierto por la garantía.

ADVERTENCIA

El chorro de agua a alta presión que este equipo

produce, puede atravesar la piel y los tejidos

subcutáneos, provocando lesiones de gravedad

que podrían dar lugar a la amputación de un

miembro.

• NUNCA conecte la manguera de alta presión al prolongador de

la boquilla.

• Mantenga conectada la manguera a la máquina o a la pistola de

rociado cuando el sistema esté presurizado.

• Asegúrese en todo momento de conectar correctamente la

pistola rociadora, las boquillas y los accesorios.

ADVERTENCIA

Riesgo de lesiones oculares.

El agua rociada puede salpicar o propulsar

objetos.

• Utilice siempre gafas de protección cuando utilice este equipo o

si se encuentra cerca de donde se está utilizando.

• Antes de poner en marcha la limpiadora a presión, asegúrese de

llevar gafas de protección adecuadas.

• Utilice SIEMPRE las gafas de seguridad apropiadas.

Page 26

8 BRIGGSandSTRATTON.COM

Características y mandos

Lea el Manual del Operario y las reglas de seguridad antes de poner en marcha su máquina limpiadora a presión.

Compare las ilustraciones con su máquina limpiadora a presión para familiarizarse con las ubicaciones de los

diferentes controles y ajustes. Guarde este manual para referencias futuras.

A - Carrete de manguera de alta presión: conexión de alta

presión entre la bomba y la pistola rociadora. Está

siempre conectada al carrete de la manguera.

B - Pistola rociadora: permite controlar la aplicación de

agua con un gatillo. Incluye seguro.

C - Interruptor principal ON/OFF: las posiciones ON y OFF

se obtienen girando a tope a derecha o izquierda,

respectivamente.

D - Pomo selector variable del doble depósito de

detergente: controla la concentración de detergente del

circuito de baja presión a partir de uno o dos depósitos.

E - Conector rápido de la manguera de alta presión:

conexión de alta presión entre la manguera y la pistola

rociadora.

F - Boquilla regulable: conecte siempre el prolongador de la

boquilla. La boquilla regulable permite regular la

presión y el patrón de rociado.

G - Almacenamiento de accesorios: en ambos lados de la

unidad. Permite almacenar la pistola rociadora y los

prolongadores de la boquilla.

H - Entrada de agua de la manguera de riego: permite

conectar la manguera de riego.

J - Carrete de la manguera con manivela: el carrete permite

enrollar de forma ordenada y práctica la manguera. La

manivela es plegable.

K - Depósitos de limpieza: contienen detergentes: se utilizan

para contener detergentes aptos para la limpiadora a

presión.

L - Prolongador de la boquilla turbo: se conecta a la pistola

rociadora y permite limpiar o aclarar superficies a alta

presión. No es posible aplicar detergente con la

boquilla turbo.

M - Almacenamiento de extracción rápida del cable de

alimentación: permite extraer de forma rápida y fácil el

cable de alimentación almacenado.

N - Indicador GFCI: cuando su color es rojo, el dispositivo

GFCI funciona correctamente. Consulte la sección

Funcionamiento.

P - Cable eléctrico con GFCI: un interruptor con circuito de

fallo de conexión a tierra (GFCI) protege tanto a la

limpiadora a presión como al usuario.

R - Puerta de accesorios: permite guardar con seguridad el

GFCI y la clavija del cable de alimentación.

A

H

D

B

E

F

G

M

P

N

L

J

R

C

K

Page 27

9

Español

Operando

Puesta en funcionamiento la limpiadora a

presión

Siga estas instrucciones en el orden indicado. En caso de

problemas durante el uso de la unidad, llame a la línea de

asistencia de la limpiadora a presión, (800) 743-4115.

1. Coloque la limpiadora a presión cerca de un grifo

exterior capaz de suministrar un caudal de agua

superior a 9,8 l (2.6 gallons) por minuto y a una

presión no inferior a 20 PSI (1,38 bar) en el extremo de

la manguera conectado a la limpiadora a presión. NO

inyecte agua en la unidad.

2. Compruebe que la manguera de alta presión está bien

conectada a la pistola rociadora. Consulte las

ilustraciones de la sección Montaje.

3. Asegúrese de que la unidad está en posición vertical.

4. Conecte la manguera de riego a la entrada de agua.

5. Abra el agua, apunte con la pistola hacia una dirección

segura, presione el seguro del gatillo (botón rojo) y

apriete el gatillo para eliminar el aire del sistema de

bombeo.

6. Elimine cualquier suciedad o material extraño que

pueda encontrarse en la salida de la pistola rociadora y

conecte el prolongador de la boquilla deseado a la

pistola.

7. Gire el conmutador ON/OFF (A) hasta la posición OFF (a

tope hacia la izquierda).

8. Gire el pomo de control del doble depósito de

detergente (B) hasta la posición central (sin aplicación

de detergente).

9. Extraiga el cable de alimentación almacenado en la

estructura de la parte trasera de la limpiadora a

presión. Para ello, tire hacia arriba del cierre deslizante

rojo (C) y pliegue el brazo superior de la estructura.

10. Enchufe el cable de alimentación a un circuito eléctrico

regulado para 120 V CA a 15 A instalado conforme a la

normativa de seguridad vigente. Debe encenderse el

indicador rojo del GFCI.

NOTA: Si el indicador rojo está apagado, la limpiadora a

presión no podrá funcionar.

11. Pulse el botón TEST (D). El indicador rojo debe

apagarse.

12. Pulse el botón RESET (E). El indicador rojo (F) debe

encenderse.

IMPORTANTE: Si esta prueba no funciona, no utilice la

limpiadora a presión eléctrica.

AVISO

NO haga funcionar la bomba si no tiene el suministro

conectado y abierto.

• El daño a la limpiadora a presión, resultado de la desatención a

esta precaución, no será cubierto por la garantía.

B

A

C

D

E

F

Page 28

10 BRIGGSandSTRATTON.COM

13. Sitúe el interruptor ON/OFF principal (A) en la posición

ON (gire a tope hacia la derecha).

14. Apunte con la pistola a una dirección segura, presione

el seguro del gatillo (botón rojo) y apriete el gatillo. El

motor de la limpiadora a presión arrancará y se parará

conforme se apriete y suelte el gatillo.

La limpiadora a presión ya está lista para su uso. Las

instrucciones de uso de los accesorios suministrados con la

unidad se indican más adelante, en esta misma sección.

Parada de la limpiadora a presión

El motor de la limpiadora a presión sólo funciona cuando se

aprieta el gatillo. Para detener la limpiadora a presión y parar

el motor:

1. Suelte el gatillo de la pistola rociadora.

2. Sitúe el interruptor ON/OFF principal de la unidad en la

posición OFF.

IMPORTANTE: Al soltar el gatillo, el motor se parará, pero la

unidad seguirá recibiendo alimentación eléctrica.

3. Cierre la alimentación de agua.

4. Apunte SIEMPRE con la pistola rociadora hacia una

dirección segura, pulse el botón rojo y apriete el gatillo

para descargar el agua a alta presión restante.

NOTA: La pistola rociadora retiene agua a alta presión

incluso con el motor parado y el agua desconectada.

5. Desconecte el enchufe GFCI de la toma y enrolle el

cable de alimentación.

Uso de la boquilla regulable

Ya sabe como poner en funcionamiento y detener la

limpiadora a presión. En esta sección aprenderá a regular el

patrón de rociado y a aplicar detergente apto para la

limpiadora a presión.

1. Deslice la boquilla hacia atrás (B) para incrementar la

presión. Deslice la boquilla hacia delante (C) cuando

desee rociar en modo de baja presión.

2. Apunte con la boquilla hacia abajo hacia una superficie

firme y apriete el gatillo para probar el patrón.

3. Gire la boquilla para regular el patrón de rociado,

pasando desde la forma de abanico (D) a la forma

estrecha (E).

D

E

B

C

A

ADVERTENCIA

Riesgo de lesiones oculares.

El agua rociada puede salpicar o propulsar

objetos.

• Utilice siempre gafas de protección cuando utilice este equipo o

si se encuentra cerca de donde se está utilizando.

• Antes de poner en marcha la limpiadora a presión, asegúrese de

llevar gafas de protección adecuadas.

• Utilice SIEMPRE las gafas de seguridad apropiadas.

ADVERTENCIA

El chorro de agua a alta presión que este equipo

produce, puede atravesar la piel y los tejidos

subcutáneos, provocando lesiones de gravedad

que podrían dar lugar a la amputación de un

miembro.

La pistola rociadora contiene agua a alta presión

incluso con el motor parado y el agua

desconectada, que puede causar la herida.

• Mantenga conectada la manguera a la máquina o a la pistola de

rociado cuando el sistema esté presurizado.

• SIEMPRE que pare el motor, apunte con la pistola rociadora

hacia una dirección segura, pulse el botón rojo y apriete el

gatillo para descargar la presión.

ADVERTENCIA

El chorro de agua a alta presión que este equipo

produce, puede atravesar la piel y los tejidos

subcutáneos, provocando lesiones de gravedad

que podrían dar lugar a la amputación de un

miembro.

• NUNCA ajuste el patrón de rociado cuando esté rociando.

• NUNCA coloque las manos en frente de la boquilla para ajustar

el patrón de rociado.

Page 29

11

Español

Uso inclina

• Para una limpieza más efectiva, mantenga la boquilla de

8 a 24 pulgadas de la superficie de limpieza.

• Si coloca la boquilla de rociado demasiado cerca podría

dañar la superficie, especialmente cuando esté usando

el modo de alta presión.

• NO coloque la boquilla a menos de 6 pulgadas cuando

esté limpiando llantas.

Aplicación del detergente usando la boquilla

ajustable

La limpiadora a presión está equipada con un doble depósito

de limpieza y un pomo de control variable del depósito de

detergente que permite regular la concentración de

detergente dispensado desde cualquiera de los depósitos.

Para aplicar el detergente, siga los siguientes pasos:

1. Revise el uso de la boquilla ajustable.

2. Prepare la solución detergente siguiendo las

instrucciones del fabricante.

3. Gire el pomo de control variable (A) hacia la derecha para

aumentar la concentración de detergente procedente del

depósito derecho al chorro de rociado de alta presión. Gire

el pomo de control variable hacia la izquierda para

aumentar la concentración de detergente procedente del

depósito izquierdo al chorro de rociado de alta presión.

Centre el pomo de control para evitar la entrada de

detergente en el chorro de rociado de alta presión.

4. Para extraer un depósito de limpieza (B) del lateral de la

unidad, agarre el asa moldeada en el depósito y tire de ella

hacia fuera.