Page 1

Model / Modèle / Modelo

074001

Operator’s Manual

Manuel d’utilisation

Manual del Operario

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC

JEFFERSON,WISCONSIN, U.S.A.

Manual No. 198815GS

Revision 0 (11/04/2005)

Before using this product, read this

manual and follow all Safety Rules and

Operating Instructions.

CAUTION

Antes de utilizar el producto, lea este

manual y siga todas las Reglas de

Seguridad e Instrucciones de Uso.

PRECAUCIÓN

Avant d’utiliser ce produit, veuillez lire

le manuel et suivre toutes les directives

relatives à la sécurité et à l’utilisation.

MISE EN GARDE

Questions? Help is just a moment away!

Vous avez des questions? Vous n'avez pas besoin d'aller

loin pour trouver de l'aide!

Preguntas? La ayuda es justa un momento lejos!

Call: Helpline

Appelez: Ligne d'assistance

Llame: Línea Directa

1-800-743-4115 M-F 8-5 CT

web: www.briggsandstratton.com

Page 2

TABLE OF CONTENTS

Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Features and Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-13

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Glossary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Français. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-37

Espanõl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38-56

EQUIPMENT DESCRIPTION

This manual contains operation and maintenance information

for a twin tank single-stage air compressor that produces

5.1 CFM at 40 PSI (2.8 bars) and 4.0 CFM at 90 PSI (6.2 bars)

using an 120 Volt A.C. electric motor.This high quality system

features a direct drive oil lube pump with cast iron sleeve, an

easy start valve, and two air outlets.This unit also features a

motor overload protection feature with manual restart.

Every effort has been made to ensure that information in this

manual is accurate and current. However, we reserve the right

to change, alter or otherwise improve the product and this

document at any time without prior notice.

Statement of Use

This air compressor has been manufactured to provide an

adequate volume of compressed air for operating a variety of

light-duty air tools (hand grinders, nailers, ratchets,staplers),

spraying equipment, and inflators requiring less than 5.1 CFM

air flow for operation. Operate this compressor ONLY in an

ambient temperature range from 32° to 95°F (0° to 35°C).

This compressor is designed for a maximum of 70% duty per

hour at full load.

SAFETY RULES

This is the safety alert symbol. It is used to

alert you to potential personal injury hazards.

Obey all safety messages that follow this

symbol to avoid possible injury or death.

The safety alert symbol ( ) is used with a signal word

(DANGER, CAUTION,WARNING), a pictorial and/or a

safety message to alert you to hazards. DANGER indicates a

hazard which, if not avoided, will result in death or serious

injury.WARNING indicates a hazard which,if not avoided,

could result in death or serious injury. CAUTION indicates a

hazard which, if not avoided, might result in minor or

moderate injury. CAUTION, when not used with the safety

alert symbol ( ), indicates a situation that could result in

equipment damage. Follow safety messages to avoid or reduce

the risk of injury or death.

Hazard Symbols and Meanings

2

SAFETY RULES

Copyright © 2005 Briggs & Stratton Power Products Group, LLC.All

rights reserved. No part of this material may be reproduced or

transmitted in any form by any means without the express written

permission of Briggs & Stratton Power Products Group, LLC.

SAVE THESE INSTRUCTIONS

Fire

Auto-start

Explosion

Compressed Air

InhalationHot Surface

Electrical Shock

Flying Objects

Air Injection

Page 3

3

SAFETY RULES

• Before using this product, read this Operator’s Manual and

follow all Safety Rules and Operating Instructions listed.

• Make this manual available to other users of this equipment.

Failure to read and follow instructions in manual

can result in death, bodily injury and / or property

damage.

WARNING

• DO NOT use grounding adapters.Inspect cord before each use.

• DO NOT operate with protective covers / guards removed or

damaged.

• DO NOT operate in wet conditions. Store unit indoors.

• Disconnect from power source and drain pressure from tank

when not in use or before servicing.

• DO NOT modify the plug provided. If it does not fit the

available outlet, a qualified electrician should install a proper

outlet.

• A qualified electrician MUST make repairs to the cord set or

plug.

Contact with compressor or its cord can cause

electric shock or burn.

Improper grounding can result in electrical shock.

Contact with components under protective cover

can cause electric shock or burn.

WARNING

• DRAIN TANK after every 4 hours of use or daily by opening

drain fitting(s) and tilting compressor to empty accumulated

water.

• DO NOT modify or repair tank in any way.

• DO NOT adjust pressure greater than maximum rating of

attachments or inflatables.

• DO NOT tamper with or remove ASME safety valve. Check

ASME safety valve by pulling ring before each use.ASME safety

valve has been set to maximum safe rating.

Hidden internal tank corrosion can cause violent

explosion leading to severe injury and / or

property damage.

Exceeding pressure rating of attachments or

inflatables can cause severe injury and / or

property damage.

Tampering with or removing ASME safety valve

can cause explosion leading to severe injury

and / or property damage.

WARNING

• DO NOT spray flammable or combustible liquids while smoking,

near sparks, open flames, pilot lights, any ignition source, or in

confined areas.

• Spray in an open, well ventilated area at least 20 feet

(6.1 meters) away from compressor or other ignition source.

Spraying flammable or combustible liquids can

cause fire or explosion.

Compressor produces sparks during operation,

which can ignite flammable or combustible vapors.

WARNING

Page 4

SAFETY RULES

4

• This procedure is required before the air compressor is put into

service and when the check valve or a complete compressor

pump has been replaced.

Serious damage may result if the break-in instructions are

not closely followed.

CAUTION

• Damage to equipment resulting from failure to follow this

instruction will void warranty.

Serious damage may result if operating the unit with

insufficient oil. Check oil level daily or with each use.

CAUTION

• DO NOT touch compressor or tubing.

• Allow compressor to cool before servicing.

Operating air compressor and tubing are HOT

and can cause burns.

WARNING

• STAY CLEAR

• Disconnect from power source and drain pressure from tank

when not in use or before servicing.

Compressor can start any time when plugged in.

WARNING

• DO NOT direct air stream at self or others.

• DO NOT attempt to repair air hose(s).

• Always wear ANSI Z87.1 approved safety glasses with side

shields.

Compressed air stream from hose or tank drain

can cause soft tissue damage to exposed skin and

can propel objects leading to severe injury

and / or property damage.

WARNING

• DO NOT use compressed air for breathing.

• Always use NIOSH respirator approved for your application

when spraying.

• Read all instructions with respirator so you are certain it will

provide necessary protection against inhaling harmful vapors.

Compressed air is not breathable and can cause

bodily injury.

Some paints or solvents may be harmful if inhaled

or ingested, causing severe nausea, fainting or

poisoning.

WARNING

Page 5

5

ASSEMBLY

Carton Contents

• Air Compressor

• Operator’s Manual

• Bottle of Compressor Pump Oil

• Oil Dipstick

If any parts are missing, call the air compressor helpline at

1-800-743-4115.

Your compressor is ready for use after it has been:

Properly serviced with supplied oil

Connected to a suitable power source

Completed the Break-In Procedure

Unpacking

1. Remove accessories and packing from carton.

2. Lift unit out of carton.

Also Recommended for Use:

• Safety Glasses (ANSI Z87.1 approved safety glasses with

side shields)

• Air Hose - 25 ft (7.6M), 3/8 inch diameter

• Quick Connector fittings - Use type I/M quick connect

fittings that attach to 1/4 inch NPT thread

• Hearing protection (ANSI S3.19-1974) in noisy

environments

• Respirator (NIOSH-approved) in dusty environments

ASSEMBLY

Page 6

FEATURES AND CONTROLS

6

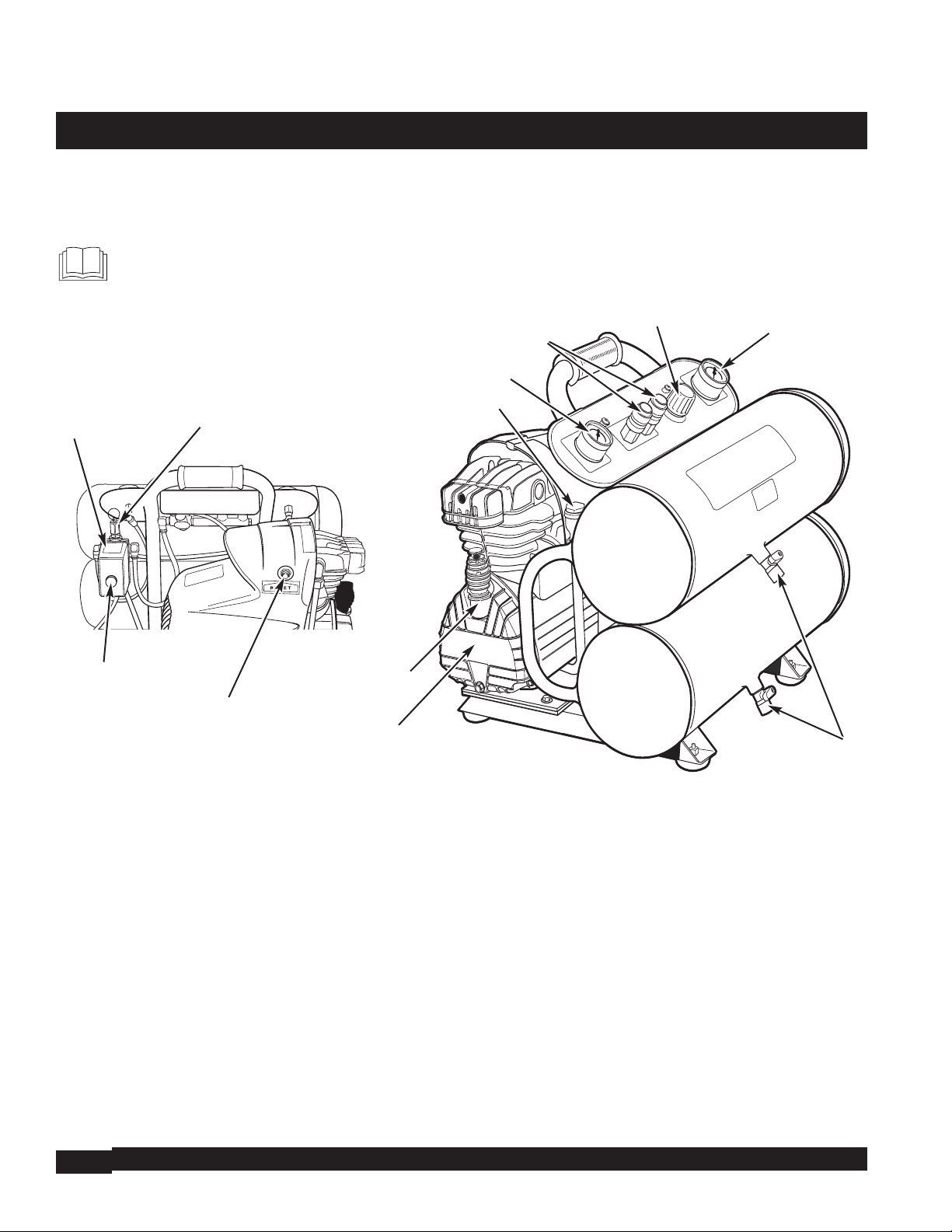

Air Compressor Pump: Pump compresses air into tanks.

Check Valve: When unit is operating, check valve is “open”,

allowing air to enter tank.At “cut-out” pressure, check valve

closes, preventing air from flowing back into pump.

Data Tag: (not shown) The data tag contains serial number,

model number, and revision number information.

Drain Valves: Valves are located near bottom of each air

tank and are used to drain condensation.

Overload Protector: If motor overheats, overload

protector shuts motor off. See TROUBLESHOOTING.

Oil Fill Location: Oil level dipstick indicates pump oil level.

ON - OFF Switch: Pull to ON position to power air

compressor. Push to OFF position to remove power.

Pressure Release Valve: (not shown) Located near

pressure switch, valve automatically releases air from internal

compressor components at “cut-out” pressure or when unit

is shut off.

Pressure Switch: Automatically starts motor when tank

pressure drops below “cut-in” pressure and stops motor

when pressure rises to “cut-out” pressure.

Pressure Control:Regulator controls air pressure delivered

to quick connect fittings.

Quick Connect Fittings: Connect air tools here.

Regulated Pressure Gauge: Indicates air pressure at quick

connect fittings.

Safety Valve: Valve protects against excessive tank pressure

by ‘popping out’ at its factory setting, thus relieving pressure.

Tank Pressure Gauge: Gauge indicates air pressure within

air tanks.

NOTE:See GLOSSARY on page 17 for definitions.

Air Compressor Pump

Pressure Control

Quick Connect Fittings

Oil Fill Location

FEATURES AND CONTROLS

Read this Operator’s Manual and safety rules before operating your compressor.

Compare this illustration with your air compressor to familiarize yourself with the locations of various controls and

adjustments. Save this manual for future reference.

ON - OFF Switch

Safety Valve

Check Valve

Overload Protector

Pressure Switch

Tank Pressure Gauge

Regulated Pressure Gauge

Drain Valves

Page 7

OPERATION

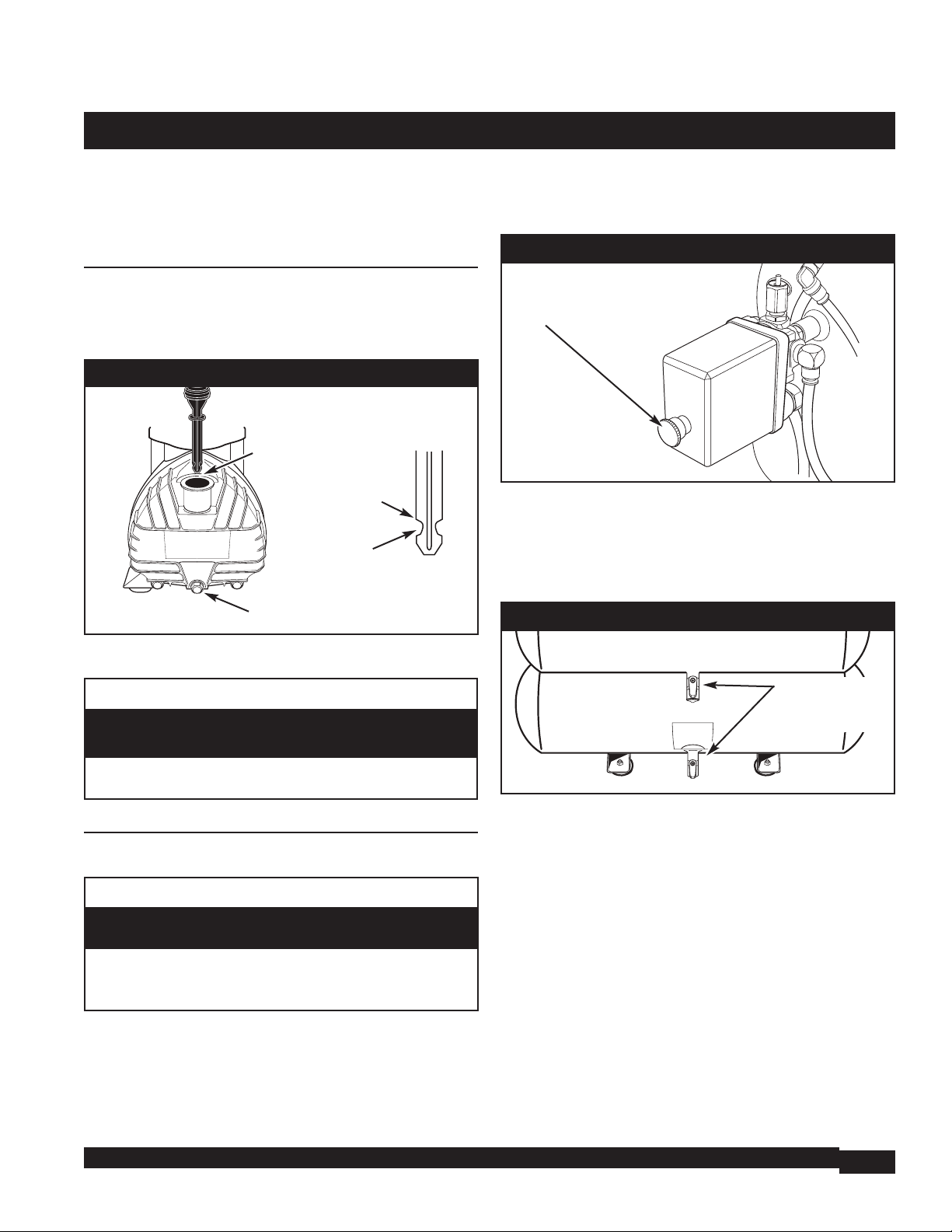

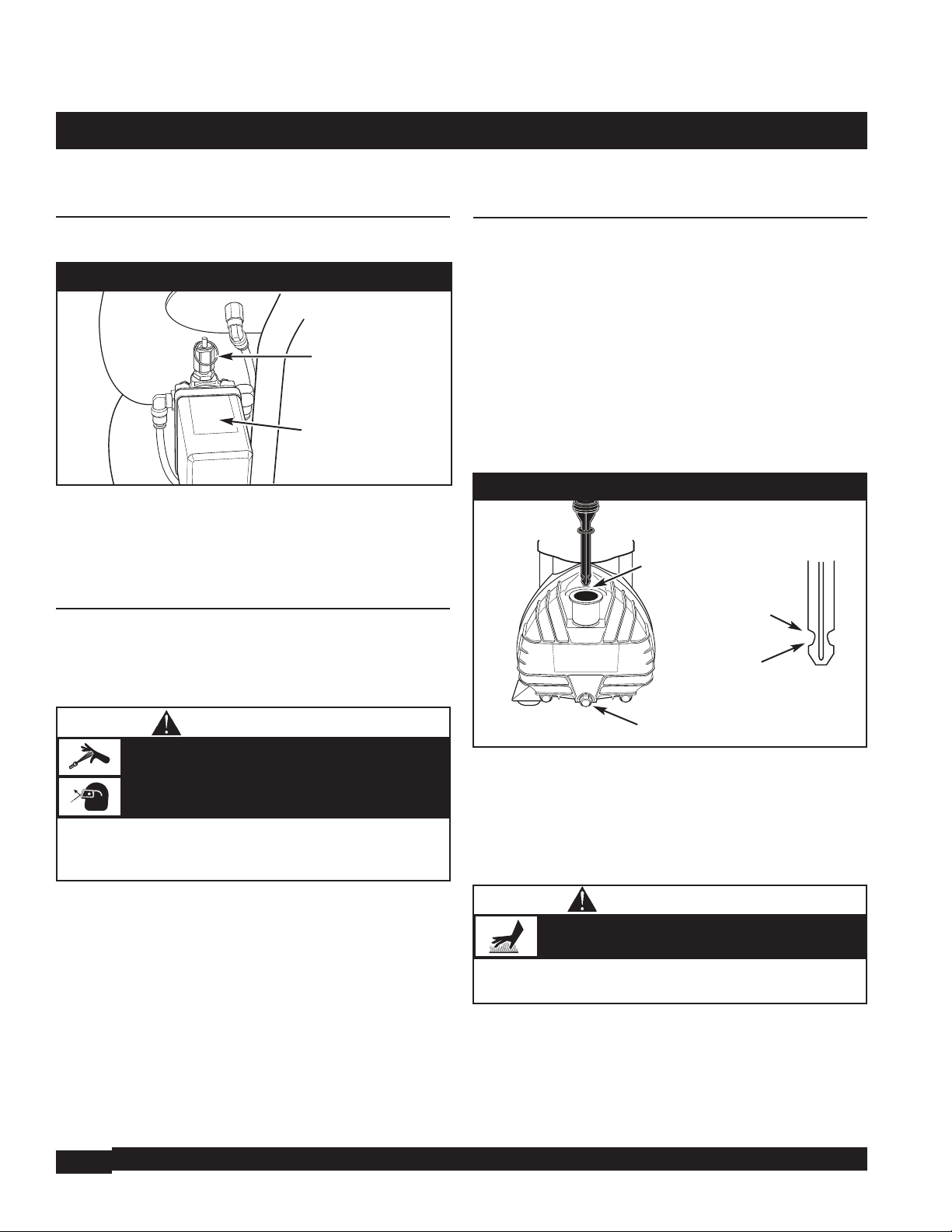

Add Oil

1. Place the compressor on a flat, level surface.

2. Remove and discard the shipping cap. Using an oil funnel,

slowly fill pump with oil to notch on dipstick (See

Figure 1).

3. Insert the dipstick. and check oil level. Oil level should be

at the notch in the dipstick. Replace dipstick.

Break-In Procedure

Before first use of this equipment, the system must undergo a

break-in operation, as described in this section.

1. Make sure ON - OFF switch is in OFF position (see

Figure 2).

2. Plug power cord into grounded 120 Volt AC outlet (see

Grounding Instructions on page 8).

3. Open both drain valves (rotate fully counterclockwise) to

prevent air pressure build-up in air tank during break-in

period (see Figure 3).

NOTE:Always drain air tank over a washable surface or in a

suitable container to prevent damaging or staining surfaces.

4. Pull ON - OFF switch to ON position. Compressor will

start.

NOTE: If you hear leaking air, pull quick connect coupler(s)

back until it clicks to reset coupler valve.

5. Run compressor for 15 minutes. Make sure both drain

valves remain open.

6. After 15 minutes, close both drain valves (rotate fully

clockwise).Air tank will fill to “cut-out” pressure and

compressor will stop.

NOTE: Check oil level in compressor after break-in.

The compressor has completed the break-In procedure and is

ready for normal use.

7

OPERATION

Figure 2 - Pressure Switch with ON/AUTO - OFF Switch

• This procedure is required before air compressor is put into

service and when check valve or a complete compressor pump

has been replaced.

Serious damage may result if the described break-in

instructions are not closely followed.

CAUTION

CAUTION

• Damage to equipment resulting from failure to follow this

instruction will void warranty.

Serious damage may result if operating the unit with

insufficient oil. Check oil level daily or with each use.

Figure 3 - Drain Valves in OPEN Position

ON - OFF Switch shown

in OFF position

Drain Valves

shown in OPEN

position

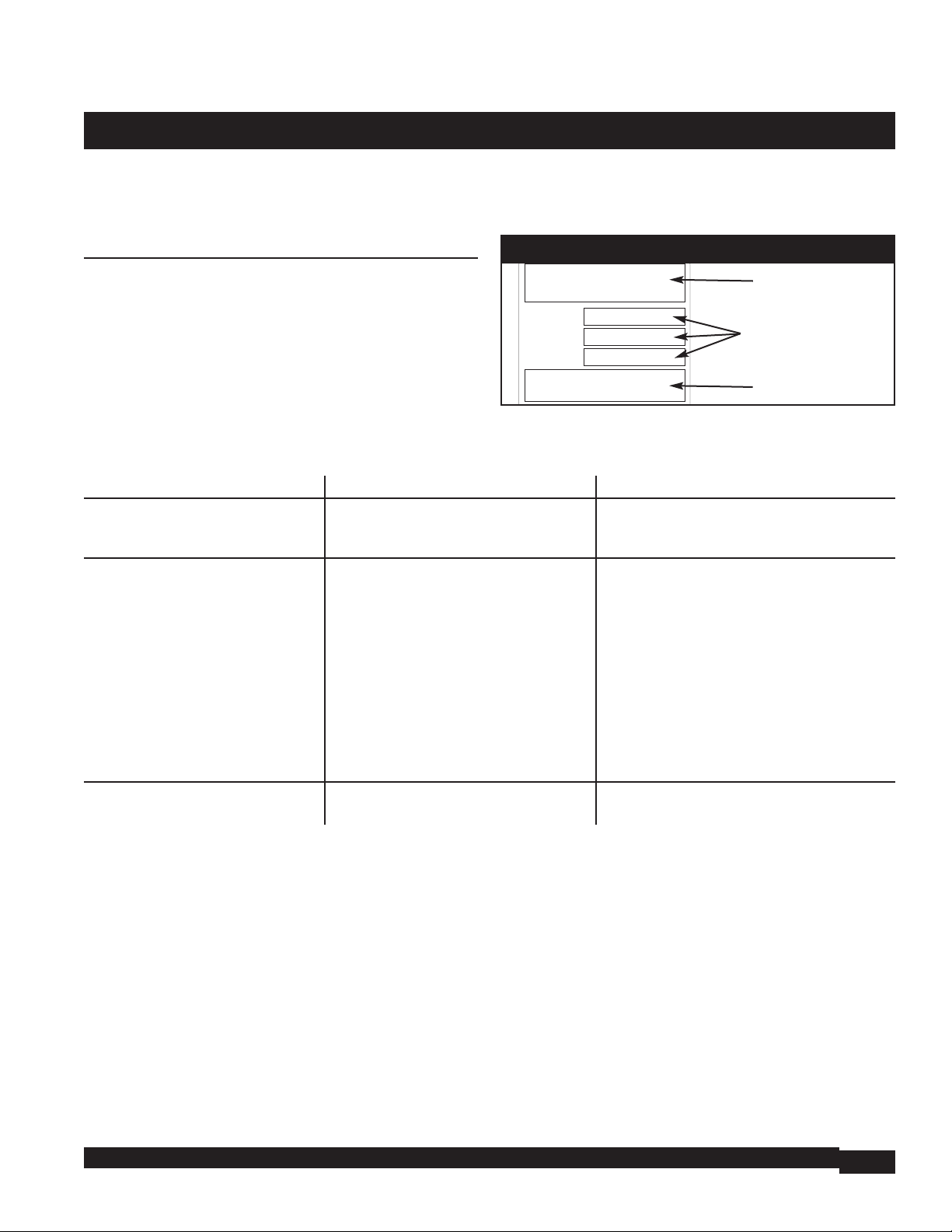

Figure 1 - Oil Fill Information

Drain Plug

Oil Fill

Location

MAXIMUM

Oil Level

PROPER

Oil Level

Inset of

Dipstick

Page 8

OPERATION

8

Air Compressor Operating Location

Locate the air compressor in a clean, dry and well-ventilated

area for operation.The air compressor should be placed at

least 12 inches (30 cm) away from walls or other

obstructions that could interfere with airflow.

The air compressor pump and shroud are designed to allow

for proper cooling.The ventilation openings on the

compressor are necessary to maintain proper operating

temperature. DO NOT place rags or containers on or near

these openings.The air filter must be kept clear of

obstructions that could reduce airflow to the air compressor.

If you have any problems with the operation of your air

compressor, call the air compressor helpline at

1-800-743-4115. If calling for assistance, please have the

model, revision, and serial number from the data tag available.

Grounding Instructions

1. The cord set and plug supplied with this unit contains a

grounding pin.This plug MUST be used with a grounded

outlet.

2. Make sure power outlet being used has same

configuration as air compressor’s plug (see Figure 4).

DO NOT USE A GROUND ADAPTER!

3. Inspect plug and cord before each use. DO NOT use

compressor if there are signs of damage.

4. If these grounding instructions are not completely

understood, or if in doubt that air compressor is

correctly grounded,have installation checked by a

qualified electrician.

• DO NOT use grounding adapters.

• DO NOT modify the plug provided. If it does not fit the

available outlet, a qualified electrician should install a proper

outlet.

• A qualified electrician MUST make repairs to the cord set or

plug.

Improper grounding can result in electrical shock.

WARNING

Figure 4 - Correctly Rated 15 AMP Power Duplex Outlet

Page 9

9

OPERATION

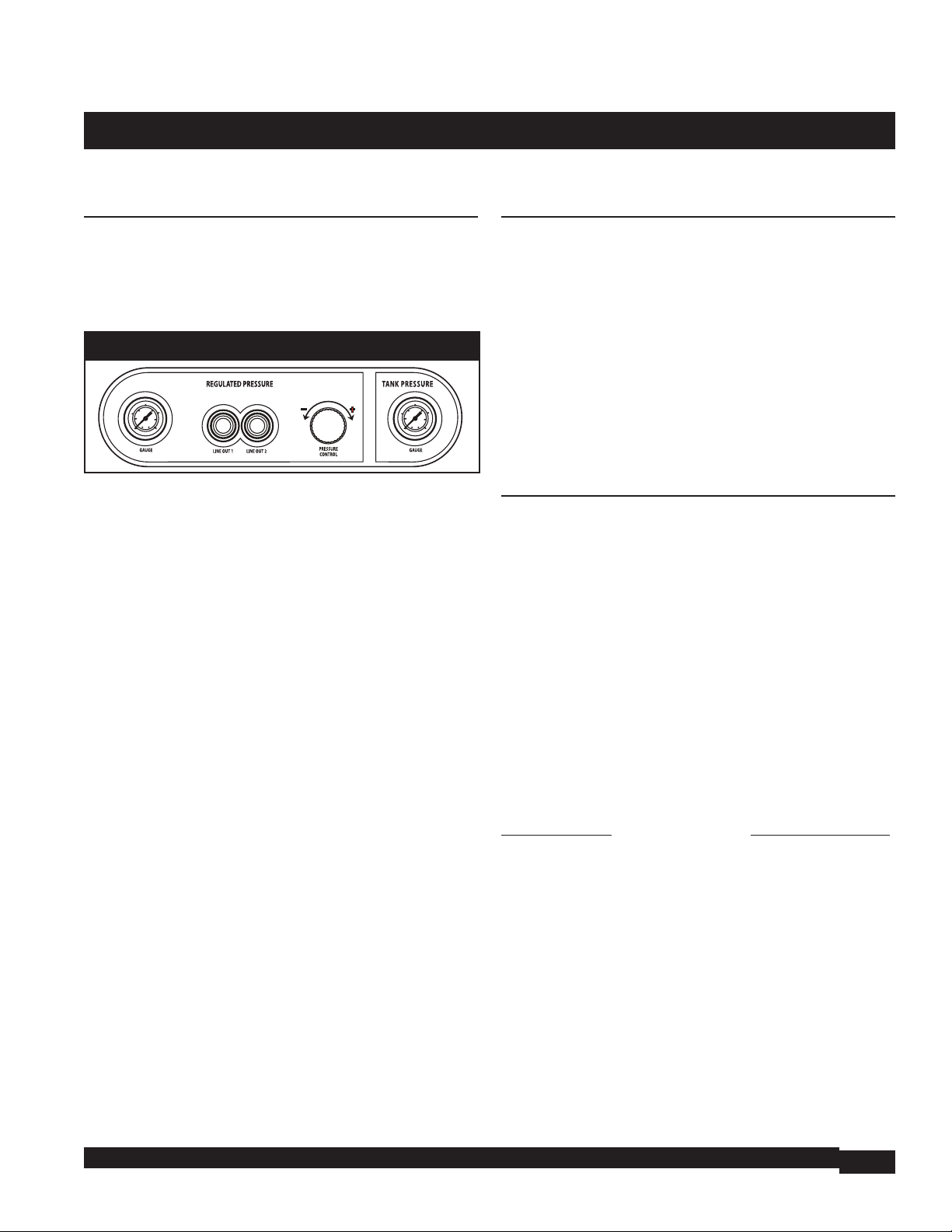

Starting Your Air Compressor

1. Make sure ON - OFF switch is in OFF position.

2. Plug power cord into grounded 120 Volt A.C. outlet (see

Figure 4).

3. Turn PRESSURE CONTROL knob counterclockwise until

knob turns without resistance (see Figure 5).

4. Pull ON - OFF switch to ON position. Compressor will

start.

NOTE: If the motor fails to start, refer to

TROUBLESHOOTING on page 15.

NOTE: If you hear air leaking, pull quick connect coupler(s)

back until it clicks to reset coupler valve.

The air compressor is fully automatic and is controlled by the

pressure switch.The compressor will run until pressure in the

air tank reaches cut-out pressure.The compressor will restart

when pressure in the air tank falls below the cut-in pressure.

See the Glossary on page 17 for definitions.

NOTE:Always operate the air compressor in well-ventilated

areas free of gasoline or other flammable / combustible

vapors. If the compressor is being used to spray volatile

chemicals (such as paint), locate the compressor at least

20 feet (6.1 meters) away from the spray area.

Stopping Your Air Compressor

1. Push ON - OFF switch to OFF position. Compressor

motor will stop.

2. If you are finished using the compressor, unplug the

compressor’s power cord from the outlet.

3. Pull the safety valve ring to release most of the tank’s

compressed air. Release valve.

4. Open both drain valves to fully drain the air tanks.

NOTE:The compressor generates condensation water that

accumulates in the air tank(s).The water condensate must be

drained every 4 hours or daily.

5. Close both drain valves.

Extension Cords

NOTE:Avoid use of extension cords!

The air compressor should be located where it can be

directly plugged into a grounded outlet. DO NOT use an

extension cord unless absolutely necessary. Instead, increase

the working reach of the air hose by attaching one or more

air hoses together.

If the use of an extension cord cannot be avoided, use these

guidelines:

• Use only a 3-wire extension cord that has a 3-blade

grounding plug, and a 3-slot outlet that will accept the plug

from the air compressor.

• Make sure the cord is in good condition.

• When compressor is used outdoors, use only extension

cords marked “Intended for Outdoor Use”.

• Follow these length restrictions:

Distance Needed

. . . . . . . . . . . . . . . . . . Recommended Gauge

Less than 25 ft. (7.5 M) . . . . . . . . . . . . . . . . . . . . . . . . 12 AWG

25 to 50 ft. (7.5 to 15 M) . . . . . . . . . . . . . . . . . . . . . . 10 AWG

More than 50 ft. (15 M) . . . . . . . . . . . . . . Not Recommended

Figure 5 - Air Compressor Control Panel

Page 10

Compressor Operation

You do not have to use the maximum operating pressure at

all times as the pneumatic tool being used often requires less

pressure. Here are general guidelines for setting pressure.

1, With air compressor connected to proper power and

turned ON, attach desired air tool or accessory to

either LINE OUT 1 or LINE OUT 2 quick connect

fittings. Use recommended air hose and quick connect

fittings.

2. Activate air tool and turn PRESSURE CONTROL knob

clockwise to increase outlet pressure.

3. Observe REGULATED PRESSURE GAUGE and adjust

pressure to recommended setting of accessory tool.

NOTE:You must adjust regulated air pressure while tool is

operating or activated.

4. Up to two tools or accessories may be connected to the

air compressor at the same time. Each will receive air at

the same regulated pressure.

5. Always operate this unit on a level surface to avoid

lubrication problems.

Observe these safety precautions when operating air

compressor:

OPERATION

10

• DO NOT use grounding adapters.Inspect cord before each use.

• DO NOT operate with protective covers / guards removed or

damaged.

• DO NOT operate in wet conditions. Store indoors.

• Disconnect from power source and drain pressure from tank

when not in use or before servicing.

Contact with compressor or its cord can cause

electric shock or burn.

Compressor must be grounded.

WARNING

• DO NOT adjust pressure greater than maximum rating of

attachments or inflatables.

Exceeding pressure rating of attachments or

inflatables can cause severe injury and/or property

damage.

WARNING

• DO NOT touch compressor or tubing.

• Allow compressor to cool before servicing.

Operating air compressor and tubing are HOT

and can cause burns.

WARNING

• STAY CLEAR

• Disconnect from power source and drain pressure from tank

when not in use or before servicing.

Compressor can start any time when plugged in.

WARNING

• DO NOT use compressed air for breathing.

• Always use NIOSH respirator approved for your application

when spraying.

• Read all instructions with respirator so you are certain it will

provide necessary protection against inhaling harmful vapors.

Compressed air is not breathable and can cause

bodily injury.

Some paints or solvents may be harmful if inhaled

or ingested, causing severe nausea, fainting or

poisoning.

WARNING

• DO NOT direct air stream at self or others.

• Always wear ANSI Z87.1 approved safety glasses with side

shields.

Compressed air stream from hose or tank drain

can cause soft tissue damage to exposed skin and

can propel objects leading to severe injury

and / or property damage.

WARNING

Page 11

SPECIFICATIONS / MAINTENANCE

11

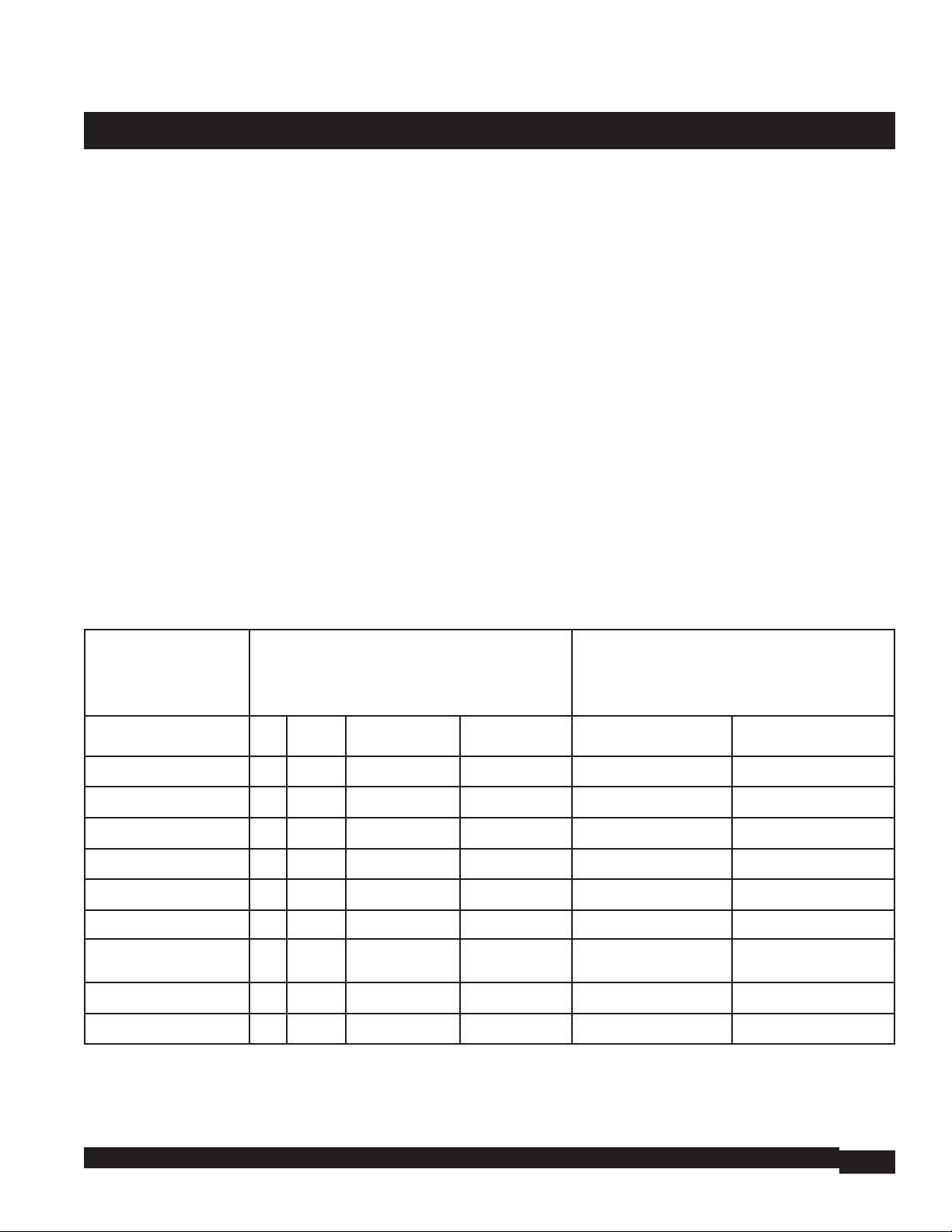

PRODUCT SPECIFICATIONS

MAINTENANCE

To ensure efficient operation and longer life of the air

compressor, prepare and follow a routine maintenance

schedule.The routine described in this section is intended for

an air compressor used under normal daily working

conditions. If necessary, modify the schedule to suit the

conditions under which you use your compressor.

Modifications will depend upon hours of operation and

working environment. Operating air compressors in

extremely dirty or hostile environments will require more

frequent maintenance checks.

NOTE:See Operation section for control locations.

Follow the hourly or calendar intervals, whichever occurs

first:

Maintenance

Schedule

Service Intervals

Service Dates

Fill in as you complete

regular service

Maintenance Task Daily Weekly

Every 50 Hours

or Yearly

Every 100 Hours

or Yearly

Check Safety Valve X

Check Fittings/Valves X

Check Oil Level X

Clean Unit X

Check Air Filter X

Change Pump Oil X*

Check Intake and

Exhaust Valves

X**

Check Safety Labels X***

Overload RESET X**

* Change oil after first 100 hours of operation, then every 300 hours thereafter.

** Inspect annually. Return unit to approved repair center if part requires replacement.

*** Inspect annually, replace as necessary

AC Frequency: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60Hz

Rated AC Voltage: . . . . . . . . . . . . . . . . . 120 volts, single phase

Running Horsepower: . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 HP

Pump Type: . . . . . . . . . . . . . . . . . . Oil Lubricated Direct Drive

Lubricant:. . . . . . . . . . . . . . . . . . . . . . . . . SAE 5W50 Synthetic

Oil Capacity: . . . . . . . . . . . . . . . . . . . . . . . . . 7.168 oz. (200ml)

Air Delivery:

at 40 psi:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.1 CFM

at 90 psi:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.0 CFM

Cut-In Pressure Setting: . . . . . . . . . . . . . . . . . 80 psi (5.6 bars)

Cut/Out Pressure Setting: . . . . . . . . . . . . . . 125 PSI (8.7 bars)

Tank capacity: . . . . . . . . . . . . . . . . . . . . . . . . . 4 Gallons (15 L)

Tank Style: . . . . . . . . . . . . . . . . . . . . . . . . . . Twin Stack Vertical

Recommended Air Hose Size: . . . . . . . . . 3/8 inch ID (14mm)

Air Fittings: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/4 inch NPT

Quick Connect Fitting Type: . . . . . . . . . . . . . . . . . . . . . . . . I/M

Operating Temperature Range: . . . . 32° to 97°F (0° to 35°C)

Shipping Weight:. . . . . . . . . . . . . . . . . . . . . . . . . 62 lbs. (28 Kg)

Page 12

Check Safety Valve

1. Pull ring on safety valve (see Figure 6) and observe that

safety valve operates freely.

2. If valve is stuck or does not operate smoothly, it must be

replaced with same type of valve.Take unit to authorized

service facility for repair.

Check Quick Connect Fittings and

Tank Drain Valves

1. Push ON - OFF switch to OFF and unplug unit.

2. Disconnect air tool or accessory from unit.

3. Pull ring on safety valve to reduce air pressure. Release

safety valve ring.

4. Open both drain valves (turn fully counterclockwise, see

Figure 3, earlier) and permit accumulated water to be

discharged.Valves should operate smoothly and have full

range of operation.

5. After water has drained, close drain valves fully

clockwise.

NOTE:If drain valves are plugged, pull safety valve ring to

fully drain air from tank. Remove, clean and reinstall drain

valve.

Check / Change Pump Oil

Checking Oil Level

Use these steps to check oil level:

1. Push ON - OFF switch to OFF and unplug unit.

2. Place unit on a flat, level surface.

3. Remove oil dipstick and wipe dipstick with clean cloth.

4. Reinstall dipstick into oil fill opening.

5. Carefully remove dipstick and verify that oil level is at

proper level (see Figure 7).

6. If oil level is too low, add recommended oil to proper

level (see Figure 7). If oil is above MAXIMUM oil level,

remove excess oil, as described in next section.

7. Reinstall oil dipstick.

Changing Oil

At recommended oil change interval, follow these steps:

1. Push ON - OFF switch to OFF and unplug unit.

2. Place unit on a flat, level surface.

3. Remove oil dipstick and wipe dipstick with clean cloth.

4. Position a suitable container under oil drain plug to

collect drain oil.

5. Use an adjustable wrench to remove hex head drain plug.

MAINTENANCE

12

Figure 7 - Oil Fill Information

Drain Plug

Oil Fill

Location

MAXIMUM

Oil Level

PROPER

Oil Level

Inset of

Dipstick

Figure 6 - Safety Valve

Pressure Switch

• DO NOT touch compressor or tubing.

• Allow compressor to cool before servicing.

Operating air compressor and tubing are HOT

and can cause burns.

WARNING

• DO NOT direct air stream at self or others.

• Always wear ANSI Z87.1 approved safety glasses with side

shields.

Compressed air stream from hose or tank drain

can cause soft tissue damage to exposed skin and

can propel objects leading to severe injury

and / or property damage.

WARNING

Safety Valve Ring

Page 13

6. Fully drain oil into container. Install drain plug and tighten

using adjustable wrench. Dispose of used oil properly.

7. Using oil funnel, slowly add recommended oil. Check oil

level frequently with dipstick to avoid overfilling pump

(see Figure 7).

8. When oil is at proper level, reinstall oil dipstick and wipe

up any spilled oil.

Cleaning Unit

To prolong compressor life, perform these steps weekly. If the

operating environment is particularly dirty, perform daily.

1. Push ON - OFF switch to OFF and unplug unit.

2. Use a soft cloth and a small brush for cleaning

accumulated dirt and debris from following locations:

• Oil fill and adjacent area on air pump housing

• Oil drain on air pump housing

• Instrument panel gauges, quick connect fittings, and

regulator

• Louvers on left hand end of motor shroud (when

viewed from rear of unit (see Figure 8).

• Cooling fins on top and sides of air compressor pump.

• Cooling fins on sides of air compressor pump, especially

between sides of pump, shroud and tanks on left side.

General Maintenance

Keep your air compressor clean and dry, by placing it in a

location far away from sources of contamination. Make sure

the unit is kept in a well-ventilated area. Protect hoses,

connectors, quick connects, and accessories from damage.

IMPORTANT: DO NOT use jets of water or flammable

liquids to clean unit.

Check / Clean Air Filter

Use the following steps to check and clean the compressor’s

internal air filter.

1. With air tank fully pressurized (ON - OFF switch in

ON position and motor stopped), push ON - OFF

switch to OFF position. Disconnect power cord from

outlet.

2. Use phillips screwdriver to remove screw holding air

filter cover and remove air filter cover (see Figure 9).

3. Remove air filter media.

IMPORTANT: DO NOT operate compressor with air filter

media removed.

4. If dirty, use compressed air to dislodge dirt from air filter

media.Also, blow debris out of air filter cover and

compressor filter housing (see Figure 9).

NOTE: DO NOT use liquid solvents to clean filter media.

MAINTENANCE

13

Figure 9 - Servicing Air Filter

Air Filter Media

Compressor

Filter Housing

Figure 8 - Cooling Fins

Shroud Louvers

• DO NOT touch compressor or tubing.

• Allow compressor to cool before servicing.

Operating air compressor and tubing are HOT

and can cause burns.

WARNING

• DO NOT direct air stream at self or others.

• Always wear ANSI Z87.1 approved safety glasses with side

shields.

Compressed air stream from hose or tank drain

can cause soft tissue damage to exposed skin and

can propel objects leading to severe injury

and / or property damage.

WARNING

Cooling Fins

Page 14

MAINTENANCE / STORAGE

14

5. Replace air filter media in compressor filter housing.

6. Position air filter cover over air filter media. Use phillips

screwdriver to secure cover with screw.

NOTE:Replace air filter media if it is extremely dirty.

Check Pump Intake and Exhaust

Valves

Once each year, certain internal compressor components

must be inspected. Have a trained service technician perform

this check, to include the air compressor pump intake and

exhaust valves.

Check Safety Labels

As often as desired or at least yearly, inspect all labels applied

to the air compressor.All safety labels should be present and

readable. Should any safety label be missing or illegible, obtain

a replacement from an authorized service center or call the

air compressor helpline at 1-800-743-4115.

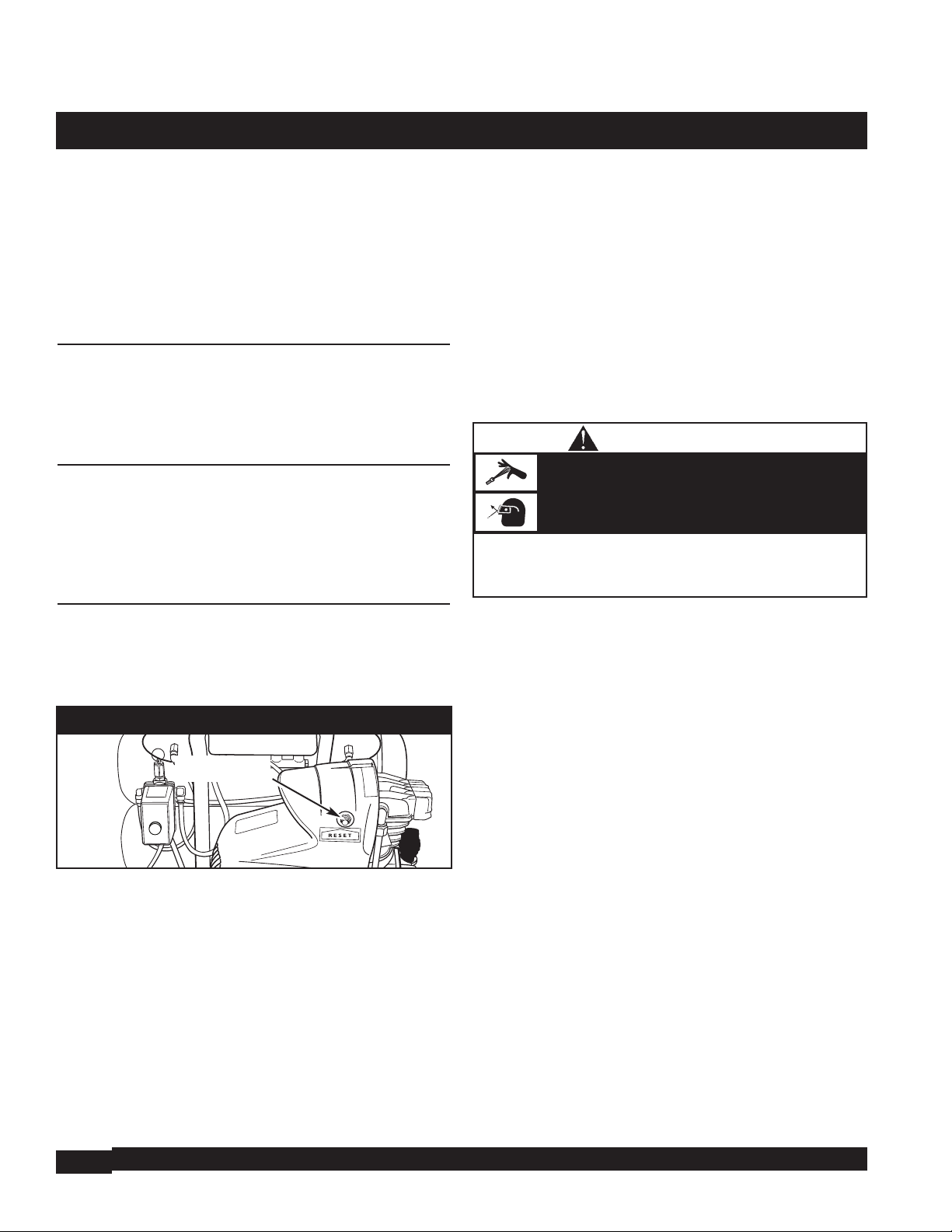

Overload Protection Reset

This compressor is equipped with an overload protection

feature that protects the motor if it overheats. If the

compressor motor overheats and ‘trips’ this circuit breaker,

wait 15 minutes for the motor to cool.Then push the RESET

button located on the motor shroud (see Figure 10).

Also see the Troubleshooting section on page 15 for more

information.

STORAGE

Before you store your air compressor, make sure you

perform the following:

1. Review “Maintenance” beginning on page 11 and perform

scheduled maintenance as necessary.

2. Push ON - OFF switch to OFF and unplug unit.

3. Turn pressure control knob counterclockwise until knob

turns freely.

4. Remove air tool or accessory.

5. Pull ring on safety valve and drain air from air tank to

reduce air pressure. Release safety valve ring.

6. Drain remaining air and water from tank by opening

drain valves fully counterclockwise.

7. Rock unit forward and back to agitate condensate as it

drains to obtain a more thorough emptying action.

8. After water has been drained, close drain valves fully

clockwise.

9. Protect electrical cord and air hose from damage (such

as being stepped on or driven over).

10. Store air compressor in clean, dry, indoor location.

Figure 10 - Overload Protection RESET Button

RESET Button

• DO NOT direct air stream at self or others.

• Always wear ANSI Z87.1 approved safety glasses with side

shields.

Compressed air stream from hose or tank drain

can cause soft tissue damage to exposed skin and

can propel objects leading to severe injury

and / or property damage.

WARNING

Page 15

TROUBLESHOOTING

15

Before You Call

If you have any problems with the operation of your air

compressor, please call the air compressor helpline at

1-800-743-4115. If calling for assistance, please have the

model, revision, and serial number information printed on the

data tag available (see Figure 11).

TROUBLESHOOTING

MODEL

REV NO

SERIAL NO

Figure 11 - Data Tag Information

Barcode

Barcode

Unit Information

PROBLEM CAUSE CORRECTION

Excessive tank pressure - safety

valve pops off.

Pressure switch does not shut off motor

when compressor reaches “cut-off”

pressure or “cut-out” setting too high.

Move ON/AUTO - OFF switch to OFF

position. If unit does not shut off, contact

trained service technician.

Air losses

1. Fitting cracked.

2. Check valve seat dirty or damaged.

3. Defective pressure switch release

valve.

4. Defective air tank.

5. Leaking seal.

6. Damaged regulator.

1. Tighten fittings where air can be heard

escaping. Replace fittings.

2. Replace check valve. Contact a trained

service technician.

3. Contact a trained service technician.

4. Air tank must be replaced. DO NOT

REPAIR TANK.

5. Contact a trained service technician.

6. Contact a trained service technician.

Knocking noise

Safety valve dirty or defective. Operate safety valve manually by pulling on

ring. If valve still leaks, have it replaced.

Page 16

TROUBLESHOOTING

16

PROBLEM CAUSE CORRECTION

Compressor is not

supplying enough air to

operate accessories.

1. Prolonged excessive use of air.

2. Compressor is not large enough for air

requirement.

3. Hole in hose.

4. Check valve restricted or leaks air.

5. Restricted air intake filter.

1. Decrease amount of air used.

2. Check the accessory requirement. If it is

higher than the CFM or pressure supplied by

your air compressor, you need a larger

capacity air compressor.

3. Check and replace if required.

4. Remove and clean or replace check valve.

5. Tighten fittings. Clean or replace air intake

filter (see page 13).

Motor will not run.

1. Motor overload protection switch has

tripped.

2. Tank pressure exceeds pressure switch

“cut-in” pressure.

3. Loose electrical connections.

4. Possible defective motor or starting

capacitor.

5. Pressure release valve on pressure

switch has not unloaded head pressure.

6. Fuse blown, circuit breaker tripped.

1. Let motor cool for 15 minutes. Press RESET

to reset overload switch.

2. Motor will start automatically when tank

pressure drops below “cut-in” pressure

setting.

3. Check wiring connection inside pressure

switch and terminal box area.

4. Have checked by a trained service technician.

5. Drain pressure by setting ON/AUTO - OFF

switch to OFF. If the valve does not open,

replace pressure switch.

6A. Check fuse box for blown fuse and replace as

necessary. Reset circuit breaker. DO NOT use

a fuse or circuit breaker with higher rating

than that specified for that branch circuit.

B. Check for proper fuse. Use a time delay fuse.

C. Check for low voltage conditions and/or

proper extension cord.

D. Disconnect all other electrical loads from

circuit used by air compressor OR operate

air compressor on dedicated branch circuit.

Page 17

GLOSSARY

17

GLOSSARY

Becoming familiar with these terms will help you understand

and operate most air compressors:

Air Delivery – A combination of psi and CFM.The air

delivery required by a tool or accessory is stated as

“’number’ (S)CFM at ‘number’ psi”. For example “5.1 CFM at

90 psi”.The combination of these values dictates the required

air compressor capacity.

Air Tank Capacity – The volume of air stored in the tank

and available for immediate use.

Alternating Current (AC) - Voltage that increases to a

maximum positive value (+) and falls back to zero and then

continues to a maximum negative value (-) and back to zero.

This cycle is repeated 60 times each second for 60 hertz AC

power.

ASME Certified - Indicates that the pressure vessel (air

tank) and related components are manufactured, tested, and

inspected to the specifications set by the American Society of

Mechanical Engineers.

ASME Safety Valve - A protection device that automatically

releases tank air if the air contained within exceeds a preset

maximum rating.

Cast Iron Sleeve - A thin iron cylinder cast into the

cylinder head, producing a harder surface between the

aluminum cylinder walls and steel piston rings, thus extending

the life of the compressor.

CFM or SCFM (Standard Cubic Feet per Minute). SCFM is

the volume of air, in cubic feet, that the compressor can pump

in one minute at a specific working pressure.The term CFM

is used in this manual.

Circuit Breaker - A thermal switch that opens a circuit if

too much current is passing through it.The air compressor

motor is protected by this resettable device.

Cut-In Pressure – As air is taken from the air tank, the tank

air pressure drops.At a certain low level, the pressure switch

senses this low pressure and turns-on the compressor motor,

thus refilling the air tank.The level at which the motor

switches ON is called the Cut-In Pressure.

Cut-Out Pressure – While the compressor is running, air is

being produced and stored in the air tank. If no air is being

used, air pressure will build in the tank.The pressure switch

senses this high pressure and at a certain high level, it turns

the compressor motor off.The level at which the motor

switches OFF is called the Cut-Out Pressure.

Duplex Receptacle - Two 120 volt AC receptacles that are

tied together. Similar to common household outlets.

GFCI - Ground fault current interrupter.A device that will

sense current flow in the milliamp range in a power circuit to

ground conductor and activate a relay to open both line

conductors.

Ground - A connection, either intentional or accidental,

between an electric circuit and the earth or some conducting

body serving in place of the earth.

Pressure Control – Often called a regulator, this device is

used to adjust the air compressor’s pressure output.The

Pressure Control is adjusted to supply the psi value required

by certain air tools, as monitored on the Regulated Pressure

Gauge.

psi - pounds per square inch.The measure of air pressure

delivered by the air compressor system.

Single Stage - Single stage refers to an air compressor with

one or more cylinders that take air in each cylinder at the

down stroke and compresses the air into the air tank on the

up stroke.

Tank Pressure Gauge – A device used to indicate the air

pressure contained in the air tank, in psi

Two Stage - A two-stage compressor always has a minimum

of two cylinders - a low pressure (LP) cylinder (largest) and

an high pressure (HP) cylinder (smallest).As the LP piston

goes downward, air is taken in at atmospheric pressure;on

the upward stroke the LP piston discharges the air through

an intercooler and into the HP cylinder on its downward

stroke. On the upward stroke of the HP piston the air is

discharged into the air tank.Two-stage compressors are

recommended when tool usage is continuous.

Vibration Isolators – When installed, are designed to

minimize vibrations produced by the air compressor.

Page 18

NOTES

18

Page 19

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC AIR COMPRESSOR OWNER WARRANTY POLICY

LIMITED WARRANTY

Briggs & Stratton Power Products Group, LLC will repair or replace, free of charge, any part(s) of the air compressor that is defective in

material or workmanship or both. Transportation charges on parts submitted for repair or replacement under this warranty must be borne

by purchaser. This warranty is effective for the time periods and subject to the conditions stated below. For warranty service, find the

nearest Authorized Service Dealer in our dealer locator map at www.briggspowerproducts.com.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM PURCHASE, OR TO THE EXTENT PERMITTED BY LAW ANY

AND ALL IMPLIED WARRANTIES ARE EXCLUDED. LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES ARE EXCLUDED

TO THE EXTENT EXCLUSION IS PERMITTED BY LAW. Some states or countries do not allow limitations on how long an implied

warranty lasts, and some states or countries do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation and exclusion may not apply to you. This warranty gives you specific legal rights and you may also have other rights which vary

from state to state or country to country.

2 years

90 days

WARRANTY PERIOD

Consumer Use

Commercial Use

The warranty period begins on the date of purchase by the first retail consumer or commercial end user, and continues for the period of time

stated above. “Consumer use" means personal residential household use by a retail consumer. “Commercial use" means all other uses,

including use for commercial, income producing or rental purposes. Once equipment has experienced commercial use, it shall thereafter be

considered as commercial use for purposes of this warranty.

NO WARRANTY REGISTRATION IS NECESSARY TO OBTAIN WARRANTY ON BRIGGS & STRATTON PRODUCTS. SAVE YOUR PROOF

OF PURCHASE RECEIPT. IF YOU DO NOT PROVIDE PROOF OF THE INITIAL PURCHASE DATE AT THE TIME WARRANTY SERVICE IS

REQUESTED, THE MANUFACTURING DATE OF THE PRODUCT WILL BE USED TO DETERMINE THE WARRANTY PERIOD.

ABOUT YOUR WARRANTY

We welcome warranty repair and apologize to you for being inconvenienced. Any Authorized Service Dealer may perform warranty repairs.

Most warranty repairs are handled routinely, but sometimes requests for warranty service may not be appropriate. For example, warranty

service would not apply if equipment damage occurred because of misuse, lack of routine maintenance, shipping, handling, warehousing or

improper installation. Similarly, the warranty is void if the manufacturing date or the serial number on the air compressor has been removed or

the equipment has been altered or modified. During the warranty period, the Authorized Service Dealer, at its option, will repair or replace any

part that, upon examination, is found to be defective under normal use and service. This warranty will not cover the following repairs and

equipment:

• Normal Wear: Outdoor Power Equipment, like all mechanical devices, needs periodic parts and service to perform well. This warranty does

not cover repair when normal use has exhausted the life of a part or the equipment.

• Installation and Maintenance: This warranty does not apply to equipment or parts that have been subjected to improper or unauthorized

installation or alteration and modification, misuse, negligence, accident, overloading, overspeeding, improper maintenance, repair or storage

so as, in our judgment, to adversely affect its performance and reliability. This warranty also does not cover normal maintenance such as air

filters, adjustments, and so forth.

• Other Exclusions: This warranty excludes wear items such as seals and o-rings, etc.This warranty also excludes air compressors that

have been run without oil or subjected to freezing with water in the tank(s). This air compressor is warranted for non-continuous use and

should not be subjected to continuous operation. Accessory parts, such as hoses or air tools not supplied with the compressor are excluded

from the product warranty. This warranty excludes failures due to acts of God and other force majeure events beyond the manufacturers

control.

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC

JEFFERSON, WI, USA

Effective October 1, 2005 replaces all undated Warranties and all Warranties dated before October 1, 2005

198183E, Rev 0, 09/30/2005

Page 20

RÈGLES DE SÉCURITÉ

20

TABLE DES MATIÈRES

Règles de sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-22

Assemblage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Fonctions et commandes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Fonctionnement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-28

Spécifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Entretien. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29-32

Entreposage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Dépannage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33-34

Glossaire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Remarques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Garantie. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Anglais . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Espagnol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38-56

DESCRIPTION DE L ÉQUIPEMENT

Ce manuel renferme des renseignements sur le fonctionnement et la

maintenance d’un compresseur d’air muni de deux réservoirs qui

produit 5,1 pi3/min à 40 lb/po2) (2,8 bars) et 4.0 pi3/min 90 lb/po2)

(6,2 bars) en utilisant un moteur électrique de 120 volts C.A. Ce

système résidentiel de haute qualité est doté d’une pompe à

entraînement direct lubrifiée à l’huile avec un manchon de fonte, une

soupape de démarrage facile et deux sorties d’air. Cette unité

comporte également une protection de surcharge du moteur avec

redémarrage manuel.

Tout a été fait pour s’assurer que les renseignements contenus dans

ce manuel soient exacts et à jour.Toutefois, nous nous réservons le

droit de changer, de modifier ou d’améliorer le produit et ce

document en tout temps, et ce, sans préavis.

Énoncé d’utilisation

Ce compresseur d’air a été fabriqué pour fournir un volume adéquat

d’air compressé pour assurer le fonctionnement d’une variété de

petits outils pneumatiques (rectifieurs à main ou clés à rochet) des

dispositifs de pulvérisation et de soufflerie requérant moins de

5,2 pi3/min de débit d’air pour fonctionner. Ne pas faire fonctionner

l’unité si la moyenne de température ne se situe pas entre 32° et

95° F (0° et 35° C). Ce compresseur est conçu pour fonctionner à

un maximum de 70 % de charge par heure à pleine capacité.

RÈGLES DE SÉCURITÉ

Ceci est la sûreté le symbole vif. Il est utilisé pour vous

alerter aux dangers de blessure personnels potentiels.

Obéir tous messages de sûreté qui suivent ce symbole

éviter la blessure ou la mort possibles.

Le symbole indiquant un message de sécurité

() est accompagné

d'un mot indicateur (DANGER,ATTENTION,AVERTISSEMENT),

d'un message illustré et/ou d'un message de sécurité visant à vous

avertir des dangers.DANGER indique un danger qui, s'il n'est pas

évité, provoquera des blessures graves,voire fatales.

AVERTISSEMENT indique un danger qui,s'il n'est pas évité, peut

provoquer des blessures graves,voire fatales. ATTENTION indique

un danger qui, s'il n'est pas évité, peut provoquer des blessures

mineures ou légères.Le mot ATTENTION, lorsqu'il est utilisé sans

le symbole d'alerte, indique une situation pouvant endommager

l'équipement. Suivez les messages de sécurité

() pour éviter ou

réduire les risques de blessures ou de mort.

Symboles de Danger et Moyens

VEUILLEZ CONSERVER CES INSTRUCTIONS

Feu

Auto-démarrage

Explosion

Air comprimé

InhalationSurface chaude

Choc electrique

Objets volants

Injection

pneumatique

Page 21

RÈGLES DE SÉCURITÉ

21

• Avant d’utiliser ce produit, veuillez lire le Manuel d’utilisation et suivre

toutes les directives relatives à la sécurité et à l’utilisation énumérées.

• Laissez ce manuel à la disposition des autres utilisateurs de cet

équipement.

L’omission de lire et de suivre les directives de ce

manuel pourrait entraîner la mort, des blessures

corporelles ou des dommages matériels.

AVERTISSEMENT

• N’utilisez PAS d’adaptateur de mise à la terre. Inspectez le cordon

d’alimentation avant chaque utilisation.

• N’utilisez PAS le compresseur sans les couvercles protecteurs ou si les

gardes sont manquants ou endommagés.

• Ne faîtes PAS fonctionner dans un milieu détrempé.Entreposez l’unité à

l’intérieur.

• Débranchez la source d’alimentation de courant et libérez la pression du

réservoir lorsque l’unité n’est pas utilisée ou avant d’effectuer

l’entretien.

• NE modifiez PAS la fiche fournie. Si elle ne s’adapte pas à la prise murale

disponible, demandez à un électricien qualifié d’installer une prise murale

appropriée.

• Un électricien qualifié DOIT effectuer la réparation du cordon ou de la

fiche.

Tout contact avec le compresseur ou son cordon

d’alimentation peut causer un choc électrique

dangereux ou des brûlures.

Une mise à la terre inadéquate peut causer un choc

électrique.

Tout contact avec les composants situés sous un

couvercle protecteur peut causer un choc électrique ou

des brûlures.

AVERTISSEMENT

• VIDANGEZ LE RÉSERVOIR à chaque 4 heures d’utilisation ou

quotidiennement, en ouvrant le ou les robinets de vidange et en inclinant

le compresseur pour évacuer l’eau accumulée.

• NE modifiez PAS ou ne réparez pas le réservoir, d’aucune façon.

• N’ajustez PAS la pression à un niveau supérieur aux valeurs nominales

maximum des outils pneumatiques ou des accessoires de gonflement.

• NE modifiez PAS ou n’enlevez pas la soupape de sûreté ASME.Vérifiez la

soupape de sûreté ASME en tirant sur l’anneau avant chaque utilisation.

La soupape de sûreté ASME a été réglée à une valeur nominale

maximum de protection.

La corrosion non visible à l’intérieur du réservoir peut

causer une violente explosion et entraîner des blessures

graves ou des dommages à la propriété.

Excéder la pression nominale des outils pneumatiques

ou accessoires de gonflement pourrait entraîner des

blessures corporelles ou des dommages matériels.

L’altération ou l’enlèvement de la soupape de sûreté

ASME peut causer une explosion et entraîner des

blessures graves ou des dommages à la propriété.

AVERTISSEMENT

• NE pulvérisez PAS de liquides inflammables ou de combustibles alors

que vous fumez, près d’étincelles, de flammes nues, de veilleuses, de

toutes sources d’allumage ou dans des espaces restreints.

• Pulvérisez dans un espace ouvert et bien ventilé à au moins 20 pieds

(6,1 m) du compresseur ou d’autres sources d’allumage.

La vaporisation de liquides inflammables ou de

combustibles peut causer un incendie ou une explosion.

Le compresseur produit des étincelles lors de son

fonctionnement qui peuvent enflammer des vapeurs

inflammables ou de combustibles.

AVERTISSEMENT

Page 22

RÈGLES DE SÉCURITÉ

22

• Cette procédure doit être exécutée avant d’utiliser le compresseur d’air

pour la première fois et après le remplacement de la soupape de

retenue ou de la pompe complète du compresseur.

Le compresseur d’air peut subir d’importants dommages, si les

procédures de rodage ne sont pas suivies à la lettre.

MISE EN GARDE

• La garantie sera annulée si des dommages à l’équipement sont entraînés

par le non-respect de cette directive.

Le compresseur d’air peut subir d’importants dommages, si l’unité

fonctionne alors que le niveau d’huile est insuffisant.Vérifiez le

niveau d’huile quotidiennement ou à chaque utilisation.

MISE EN GARDE

• NE touchez PAS au compresseur et aux tubes.

• Laissez refroidir le compresseur avant d’effectuer l’entretien.

Lors du fonctionnement, le compresseur d’air et les tubes

de sortie sont CHAUDS et peuvent causer des brûlures.

AVERTISSEMENT

• ÉLOIGNEZ-VOUS

• Débranchez la source d’alimentation de courant et libérez la pression du

réservoir lorsque l’unité n’est pas utilisée ou avant d’effectuer l’entretien.

Le compresseur peut démarrer en tout temps lorsqu’il

est en opération.

AVERTISSEMENT

• NE dirigez PAS le jet d’air vers vous-même ou quelqu’un d’autres.

• NE tentez PAS de réparer un boyau d’air.

• Portez toujours des lunettes de sécurité avec protection latérale

approuvées ANSI Z87.1.

Le jet d’air comprimé du boyau ou du robinet de

vidange peut causer des lésions aux tissus de la peau

exposée et peut projeter des objets entraînant des

blessures graves et / ou des dommages à la propriété.

AVERTISSEMENT

• N’utilisez PAS l’air comprimé pour l’inhalation.

• Portez toujours un respirateur homologué par la NIOSH et conçu pour

votre application.

• Lisez toujours les directives d’utilisation du respirateur de façon à vous

assurer qu’il fournit la protection nécessaire contre l’inhalation de

vapeurs nocives.

L’inhalation de l’air comprimé n’est pas sécuritaire et

peut causer de graves blessures.

Certains produits de peinture ou solvants peuvent être

nocifs en cas d’ingestion ou d’inhalation et peuvent

provoquer des nausées, un évanouissement ou un

empoisonnement.

AVERTISSEMENT

Page 23

ASSEMBLAGE

23

ASSEMBLAGE

Contenu de la boîte

• Compresseur d’air

• Manuel d’utilisation

• Bouteille d’huile pour la pompe du compresseur

• Jauge d’huile

Si une pièce est manquante, veuillez joindre le service de dépannage

du compresseur d’air au numéro sans frais 1-800-743-4115.

Votre compresseur d’air est prêt pour l’utilisation après:

l’avoir correctement rempli d’huile (fournie)

l’avoir branché à une source d’alimentation appropriée

la procédure de rodage

Déballage

1. Enlevez tous les accessoires et composants de la boîte

d’expédition.

2. Retirez l’unité de la boîte.

Accessoires également recommandés:

• Lunettes de sécurité (lunettes de sécurité avec protection

latérale approuvées ANSI Z87.1)

• Boyau d’air – 25 pieds (7,6 m) 3/8 po de diamètre

• Raccords à connexion rapide – Utiliser les raccords à connexion

rapide de type I/M qui se raccordent à un filetage NPT de 1/4 po.

• Protecteurs des oreilles (ANSI S3.19-1974) dans les

environnements bruyants

• Respirateur (approuvés NIOSH) dans les environnements

poussiéreux

Page 24

FONCTIONS ET COMMANDES

24

Commande de pression: Le régulateur contrôle la pression d’air

transmis aux raccords de connexion rapide.

Emplacement pour le remplissage d’huile: La jauge d’huile

indique le niveau d’huile de la pompe.

Étiquette de données: (non illustrée) L’étiquette de données

contient le numéro de série, le numéro de modèle ainsi que les

renseignements du numéro de révision.

Jauge du régulateur de pression: Indique la pression d’air

disponible aux raccords de connexion rapide.

Interrupteur Marche - Arrêt (ON - OFF): Poussez vers le bas

l’interrupteur à Marche (ON) pour démarrer le compresseur d’air.

Poussez vers le haut l’interrupteur Arrêt (OFF) pour couper

l’alimentation.

Manomètre du réservoir: Indique la pression d’air en réserve

dans les réservoirs.

Manostat: Démarre automatiquement le moteur lorsque la

pression dans le réservoir d’air chute à une valeur inférieure à la

“pression d’enclenchement” et arrête le moteur lorsque la pression

atteint la “pression de déclenchement”.

Pompe du compresseur d’air: La pompe compresse l’air dans les

réservoirs.

Protecteur de surcharge: Le protecteur de surcharge arrête le

moteur en cas de surchauffe du moteur.Voir DÉPANNAGE.

Raccords de connexion rapide: Connectez ici les outils

pneumatiques.

Robinets de vidange: Les robinets sont situés à la base de chacun

des réservoirs d’air et sont utilisés pour vidanger la condensation.

Soupape de relâchement de surpression: (non illustrée) Située

au-dessus du manostat, cette soupape libère automatiquement l’air

de la tête du compresseur et du tube de sortie à la “pression de

déclenchement” ou lorsque l’unité est fermée.

Soupape de retenue: Lorsque l’unité est en opération, la soupape

de retenue est “ouverte”, permettant à l’air d’entrer dans le réservoir.

Lorsque la pression de déclenchement est atteinte, la soupape de

retenue se ferme, pour empêcher le retour d’air dans la pompe.

Soupape de sûreté: La soupape protège contre toute surpression

en “sautant” à la valeur de pression établie à l’usine et libère la

pression.

REMARQUE: Voir GLOSSAIRE à la page 35 pour obtenir les

définitions.

Robinets de

vidange

Pompe du

compresseur d’air

Commande de pression

Raccords de

connexion rapide

Manomètre du réservoir

Emplacement pour le

remplissage d’huile

FONCTIONS ET COMMANDES

Lisez ce manuel d’utilisation et les règles de sécurité avant d’utiliser votre compresseur d’air.

Comparez ces illustrations à votre compresseur d’air pour vous familiariser avec l’emplacement des diverses commandes et

réglages. Conservez ce manuel pour référence future.

Protecteur

de surcharge

Jauge du régulateur

de pression

Interrupteur Marche - Arrêt

(ON - OFF)

Manostat

Soupape de sûreté

Soupape de

retenue

Page 25

OPÉRATION

25

OPÉRATION

Ajoutez de l’huile

1. Placez le compresseur sur une surface plane et de niveau.

2. Enlevez et rangez le bouchon d’expédition. À l’aide d’un

entonnoir, versez lentement l’huile dans la pompe jusqu’au

repère sur la jauge d’huile (Figure 12).

3. Insérez la jauge et vérifiez le niveau d’huile. Le niveau d’huile

doit être situé au repère sur la jauge d’huile. Replacez la jauge

d’huile.

Procédure de rodage

Avant la première utilisation de cet équipement,le système doit se

soumettre à une procédure de rodage, tel que décrite dans cette

section.

1. Assurez-vous que l’interrupteur Marche - Arrêt (ON - OFF)

est à la position Arrêt (OFF) (voir Figure 13).

2. Branchez le cordon d’alimentation dans une prise murale mise à

la terre de 120 volts C.A. ( voir Directives de mise à la terre à

la page 26).

3. Ouvrez les deux robinets de vidange (dévissez complètement

dans le sens contraire des aiguilles d’une montre) pour

empêcher une accumulation de pression dans le réservoir d’air

lors de la période de rodage (voir Figure 14).

REMARQUE: Vidangez toujours le réservoir d’air au-dessus d’une

surface lavable ou dans un contenant approprié pour éviter des

dommages ou abîmer les surfaces.

4. Déplacez l’interrupteur Marche - Arrêt (ON - OFF) à la

position Marche (ON). Le compresseur démarrera.

REMARQUE: Si vous entendez une fuite d’air, tirez les

connecteurs rapides vers l’arrière jusqu’à ce qu’ils se déclenchent

pour réamorcer le raccord à manchon.

5. Faites fonctionner le compresseur pendant 15 minutes.Assurezvous que les deux robinets de vidange demeurent ouverts.

6. Après 15 minutes fermez les robinets de vidange (en tournant

complètement dans le sens des aiguilles d’une montre). Les

réservoirs d’air s’empliront jusqu’à la “pression de

déclenchement” et le compresseur s’arrêtera.

REMARQUE:Vérifiez le niveau d’huile après la procédure de rodage.

Le compresseur a terminé la procédure de rodage et est maintenant

prêt pour l’utilisation.

• Cette procédure doit être exécutée avant d’utiliser le compresseur d’air

pour la première fois et après le remplacement de la soupape de

retenue ou de la pompe complète du compresseur.

Le compresseur d’air peut subir d’importants dommages, si les

procédures de rodage ne sont pas suivies à la lettre.

MISE EN GARDE

• La garantie sera annulée si des dommages à l’équipement sont entraînés

par le non-respect de cette directive.

Le compresseur d’air peut subir d’importants dommages, si l’unité

fonctionne alors que le niveau d’huile est insuffisant.Vérifiez le

niveau d’huile quotidiennement ou à chaque utilisation.

MISE EN GARDE

Figure 13 - Manostat avec interrupteur ON - OFF

Figure 14 - Robinets de vidange en position “Open (Ouvert)”

L’interrupteur Marche - Arrêt

(ON - OFF) est à la position

Arrêt (OFF)

Robinets de

vidange

Figure 12 - Renseignements sur le remplissage d’huile

Bouchon de vidange d’huile

Orifice de

remplissage d’huile

Niveau d’huile

MAXIMUM

Niveau

APPROPRIÉ

d’huile

Ouverture de

la jauge d’huile

Page 26

OPÉRATION

26

Emplacement du compresseur d’air lors de

l’utilisation

Le compresseur d’air doit être situé dans un endroit propre, sec et

bien aéré. Il doit être situé à une distance d’au moins 12 pouces

(30 cm) ou de toute autre obstruction qui pourrait nuire au débit

d’air.

La pompe et la tôle de protection du compresseur d’air sont

conçues pour permettre un refroidissement approprié. Les

ouvertures d’aération du compresseur sont nécessaires pour

maintenir la température de fonctionnement appropriée. Ne placez

pas de chiffons ou de contenants sur ou à proximité de ces

ouvertures. Le filtre à air doit être libre d’obstructions pouvant

réduire le débit d’air au compresseur d’air.

Si vous éprouvez des problèmes avec l’utilisation de votre

compresseur d’air, veuillez appeler le service de dépannage du

compresseur d’air au 1-800-743-4115. Si vous appelez pour obtenir

de l’assistance, ayez en main le numéro de modèle, le numéro de

série et de révision que vous trouverez sur l’étiquette de données.

Directives de mise à la terre

1. Le cordon fourni avec cet appareil comprend une fiche avec

broche de mise à la terre. La fiche DOIT être insérée dans une

prise de courant mise à la terre.

2. Assurez-vous que la prise de courant utilisée a la même

configuration que la fiche de mise à la terre (voir Figure 15).

N’UTILISEZ PAS UN ADAPTATEUR DE MISE À LA TERRE!

3. Inspectez la fiche et le cordon avant chaque utilisation.

N’utilisez PAS le compresseur s’il y a des signes de dommages.

4. Si vous ne comprenez pas tout à fait ces directives de mise à la

terre, ou si vous avez des doutes que le compresseur soit mis à

la terre de manière appropriée, faites vérifier l’installation par

un électricien qualifié.

• N’utilisez PAS un adaptateur de mise a la terre.

• NE modifiez PAS la fiche fournie. Si elle ne s’adapte pas à la prise murale

disponible, demandez à un électricien qualifié d’installer une prise murale

appropriée.

• Un électricien qualifié DOIT effectuer la réparation du cordon ou de la

fiche.

Une mise à la terre inadéquate peut causer un choc

électrique.

AVERTISSEMENT

Figure 15 - Prise de courant de 15 ampères de tension nominale

appropriée

Page 27

OPÉRATION

27

Démarrage de votre compresseur d’air

1. Assurez-vous que l’interrupteur Marche - Arrêt (ON - OFF)

est à la position Arrêt (OFF).

2. Branchez le cordon d’alimentation dans une prise murale mise à

la terre de 120 volts C.A.

3. Tournez le bouton Commande de pression (PRESSURE

CONTROL) dans le sens contraire des aiguilles d’une montre

jusqu’à ce qu’il n’y ait plus de résistance (voir Figure 16).

4. Déplacez l’interrupteur Marche - Arrêt (ON - OFF) à la

position Marche (ON). Le compresseur démarrera.

REMARQUE: Si le moteur ne démarre pas, veuillez-vous référer à

Dépannage à la page 34.

REMARQUE: Si vous entendez une fuite d’air, tirez les

connecteurs rapides vers l’arrière jusqu’à ce qu’ils déclenchent pour

réamorcer le raccord à manchon.

Le compresseur d’air est entièrement automatique et contrôlé par

le manostat. Le compresseur fonctionnera jusqu’à ce la pression du

réservoir d’air atteigne la “pression de déclenchement”. Le

compresseur redémarrera quand la pression dans les réservoirs d’air

chutera sous la “pression d’enclenchement”.Voir GLOSSAIRE à la

page 35 pour obtenir les définitions.

REMARQUE: Utilisez toujours le compresseur d’air dans des

espaces bien aérés sans vapeurs d’essence ni d’autres combustibles.

Si le compresseur est utilisé pour pulvériser des substances

chimiques volatiles (comme de la peinture), placez le compresseur à

au moins 20 pieds (6.1 mètres) de l’endroit de pulvérisation.

Arrêt de votre compresseur d’air

1. Déplacez l’interrupteur Marche - Arrêt (ON - OFF) à la

position Arrêt (OFF). Le moteur du compresseur s’arrêtera.

2. Si vous avez terminé d’utiliser le compresseur, débranchez le

cordon d’alimentation de la prise murale.

3. Tirez sur la soupape de sûreté pour vidanger la plus grande

partie de l’air comprimé du réservoir d’air. Relâchez la

soupape.

4. Ouvrez complètement les deux robinets de vidange pour

vidanger entièrement les réservoirs d’air.

REMARQUE: Le compresseur génère de la condensation d’eau qui

s’accumule dans les réservoirs d’air. L’eau condensée doit être

vidangée à toutes les 4 heures ou quotidiennement.

5. Fermez les deux robinets de vidange.

Rallonges

REMARQUE: Évitez d’utiliser des rallonges!

Le compresseur d’air devrait être situé dans un endroit où il peut

directement être branché dans une prise murale. N’utilisez PAS de

rallonges, sauf si c’est absolument nécessaire.Augmentez plutôt la

longueur du boyau d’air en connectant un ou plusieurs des boyaux.

Si une rallonge doit être utilisée, veuillez suivre ces directives:

1. Utilisez seulement une rallonge à trois conducteurs, munie

d’une fiche à trois lames avec mise à la terre et une prise de

courant à trois fentes qui accepte la fiche du compresseur d’air.

2. Assurez-vous que la rallonge est en bon état.

3. Lorsque le compresseur est utilisé à l’extérieur, n’utilisez que

des rallonges identifiées “Conçues pour usage à l’extérieur”.

4. Suivez les instructions suivantes concernant les longueurs de

rallonges:

Distance r

equise . . . . . . . . . . . . . . . . . . . . . . . . .Calibre recommandé

Moins de 25 pieds (7,5 m) . . . . . . . . . . . . . . . . . . . . . . . . . . .12 AWG

(25 à 50 pieds (7,5 à 15 m) . . . . . . . . . . . . . . . . . . . . . . . . . .10 AWG

Plus de 50 pieds (15 m) . . . . . . . . . . . . . . . . . . . . .Non recommandé

Figure 16 - Tableau de commande de compresseur d’air

Page 28

OPÉRATION

28

Utilisation du compresseur

Vous n’aurez pas à utiliser le maximum de pression de

fonctionnement en tout temps étant donné que les outils

pneumatiques utilisés requièrent souvent moins de pression.Voici

donc des lignes directrices générales pour l’ajustement de la

pression.

1. Alors que le compresseur est connecté à une source

d’alimentation appropriée et qu’il est en position Marche (ON),

connectez les outils pneumatiques ou accessoires désirés soit

aux raccords de connexion rapide de RACCORD DE SORTIE

1 ou RACCORD DE SORTIE 2. Utilisez le boyau d’air et les

raccords de connexion rapide recommandés.

2. Activez l’outil pneumatique et tournez le bouton Commande

de pression (PRESSURE CONTROL) dans le sens des aiguilles

d’une montre pour augmenter la pression de sortie.

3. Observez la JAUGE DU RÉGULATEUR DE PRESSION et

ajustez la pression selon les recommandations d’ajustement

pour l’outil pneumatique.

REMARQUE: Vous devrez ajuster l’air régulé alors que l’outil est

utilisé ou activé.

4. Vous pouvez connecter jusqu’à deux outils ou accessoires en

même temps au compresseur d’air. Chacun recevra le même air

régulé.

5. Avant d’utiliser l’appareil, assurez-vous qu’il se trouve sur une

surface de niveau afin d’éviter tout problème de lubrification.

Observez ces consignes de sécurité lors de l’utilisation du

compresseur d’air:

• ÉLOIGNEZ-VOUS

• Débranchez la source d’alimentation de courant et libérez la pression du

réservoir lorsque l’unité n’est pas utilisée ou avant d’effectuer l’entretien.

Le compresseur peut démarrer en tout temps lorsqu’il

est en opération.

AVERTISSEMENT

• NE touchez PAS au compresseur et aux tubes.

• Laissez refroidir le compresseur avant d’effectuer l’entretien.

Lors du fonctionnement, le compresseur d’air et les tubes

de sortie sont CHAUDS et peuvent causer des brûlures.

AVERTISSEMENT

• NE dirigez PAS le jet d’air vers vous-même ou quelqu’un d’autres.

• Portez toujours des lunettes de sécurité avec protection latérale

approuvées ANSI Z87.1.

Le jet d’air comprimé du boyau ou du robinet de

vidange peut causer des lésions aux tissus de la peau

exposée et peut projeter des objets entraînant des

blessures graves et / ou des dommages à la propriété.

AVERTISSEMENT

• N’utilisez PAS l’air comprimé pour l’inhalation.

• Portez toujours un respirateur homologué par la NIOSH et conçu pour

votre application.

• Lisez toujours les directives d’utilisation du respirateur de façon à vous

assurer qu’il fournit la protection nécessaire contre l’inhalation de

vapeurs nocives.

L’inhalation de l’air comprimé n’est pas sécuritaire et

peut causer de graves blessures.

Certains produits de peinture ou solvants peuvent être

nocifs en cas d’ingestion ou d’inhalation et peuvent

provoquer des nausées, un évanouissement ou un

empoisonnement.

AVERTISSEMENT

• N’utilisez PAS d’adaptateur de mise à la terre. Inspectez le cordon

d’alimentation avant chaque utilisation.

• N’utilisez PAS le compresseur sans les couvercles protecteurs ou si les

gardes sont manquants ou endommagés.

• Ne faîtes PAS fonctionner dans un milieu détrempé.Entreposez l’unité à

l’intérieur.

• Débranchez la source d’alimentation de courant et libérez la pression du

réservoir lorsque l’unité n’est pas utilisée ou avant d’effectuer

l’entretien.

Tout contact avec le compresseur ou son cordon

d’alimentation peut causer un choc électrique

dangereux ou des brûlures.

Le compresseur doit être mis à la terre.

AVERTISSEMENT

• N’ajustez PAS la pression à un niveau supérieur aux valeurs nominales

maximum des outils pneumatiques ou des accessoires de gonflement.

Excéder la pression nominale des outils pneumatiques

ou accessoires de gonflement pourrait entraîner des

blessures corporelles ou des dommages matériels.

AVERTISSEMENT

Page 29

SPÉCIFICATIONS / ENTRETIEN

29

SPÉCIFICATIONS

Fréquence C.A.: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 Hz

Tension nominale C.A.: . . . . . . . . . . . . . . . . . . .120 volts, monophasé

Puissance d’opération: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1,5 HP

Type de pompe: . . . . . . . . . . . . .Entraînement direct lubrifié à l’huile

Lubrifiant: . . . . . . . . . . . . . . . . . . . . . . . .Huile synthétique SAE 5W50

Capacité du carter d’huile: . . . . . . . . . . . . . . . . . . . .7.168 oz. (200ml)

Sortie d’air:

A 40 lb/po2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5,1 pi3/min

A 90 lb/po2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4,0 pi3/min

Ajustement de la pression d’enclenchement: . . .80 lb/po2 (5,6 bars)

Ajustement de la pression de déclenchement: .125 lb/po2 (8,7 bars)

Taille du réservoir: . . . . . . . . . . . . . . . . . . . . . . . . . . .4 Gallons (15 L)

Style de réservoir: . . . . . . . . . . . . . . . . .Deux réservoirs superposés

Dimension recommandée de boyau d’air: . . .3/8 pouces (14mm) DI

Raccords d’air: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1/4 pouce NPT

Type de raccords à connexion rapide: . . . . . . . . . . . . . . . . . . . . . .I/M

Plage d’utilisation de température: . . . . . 32° à 97° F (0° à + 35° C)

Poids à l’expédition: . . . . . . . . . . . . . . . . . . . . . . . . . . . .62 lb. (28 Kg)

Pour assurer un fonctionnement efficace et une longue durée de vie

au compresseur d’air, préparez et conformez-vous à un calendrier

d’entretien de routine. La routine décrite dans cette section est

conçue pour un compresseur d’air utilisé quotidiennement dans des

conditions normales de travail.Au besoin, modifiez le calendrier

pour vous adapter aux conditions d’utilisation de votre compresseur.

Les modifications seront sujettes aux heures d’utilisation et à

l’environnement de travail. L’utilisation des compresseurs d’air dans

des environnements extrêmement hostiles et sales nécessitera des

vérifications d’entretien plus fréquentes.

REMARQUE: Voir la section “Opération” au sujet de

l’emplacement des commandes.

Respectez le calendrier d’entretien selon le nombre d’heures de

fonctionnement ou le temps écoulé, le premier des deux prévalant:

ENTRETIEN

CALENDRIER

D’ENTRETIEN

INTERVALLE DE FONCTIONNEMENT

SELON LES HEURES D’UTILISATION

DATES D’ENTRETIEN

INSCRIVEZ LES DATES AU FUR ET À

MESURE QUE VOUS EFFECTUEZ

L’ENTRETIEN RÉGULIER

TÂCHE D’ENTRETIEN Quotidiennement Semaine

Aux 50 heures

ou1 fois l’an

Aux 100 heures

ou1 fois l’an

Vérifiez la soupape de sûreté X

Vérifiez les raccords et robinets X

Vérifiez le niveau d’huile X

Nettoyez l’unité X

Vérifiez le filtre à air X

Changer l’huile de la pompe X*

Vérifiez les soupapes d’admission

et d’échappement

X**

Vérifiez les étiquettes de sécurité X***

Réarmement de surcharge X**

* Changez l’huile après les 100 premières heures d’opération et par la suite aux 300 heures d'opération.