Page 1

IInnssttaallllaattiioonn && OOppeerraattoorr’’ss

MMaannuuaall

Questions? Help is just a moment away!

Call: Transfer Switch Helpline

1-800-743-4115 M-F 8-5 CT

BRIGGSandSTRATTON.COM

Models 071018, 071019, 071020 & 071021

201705GS Rev. - (12/14/06)

100 AMP/200 AMP

Automatic Transfer Switch

with AC Power Control Module™

Page 2

Briggs & Stratton Power Products Group, LLC

900 North Parkway

Jefferson, WI 53549

Copyright © 2006 Briggs & Stratton Power Products Group,

LLC. All rights reserved. No part of this material may be

reproduced or transmitted in any form by any means without

the express written permission of Briggs & Stratton Power

Products Group, LLC.

Thank you for your purchase of this Briggs & Stratton Power Products Automatic Transfer Switch. This product is intended

for use with Briggs & Stratton Home Standby Generator sets ONLY. This is an optional home standby system which provides

an alternate source of electric power and to serve loads such as a gas furnace, refrigeration and communication systems that,

when stopped during any power outage, could cause discomfort or the like. This product DOES NOT qualify for emergency

standby as defined by NFPA 70 (NEC).

This manual contains safety information to make you aware of the hazards and risks associated with transfer switches and

how to avoid them. Briggs & Stratton has made every effort to provide for a safe, streamlined and cost-effective installation.

Each installation is unique, it is impossible to know of and advise of all conceivable procedures and methods by which

installation might be achieved. We do not know all possible hazards and/or the results of each method or procedure. Save

these instructions for future reference.

This transfer switch requires installation before use. Refer to the Installation section of this manual for instructions on

installation procedures. Only licensed electrical contractors should install transfer switches. Installations must strictly

comply with all applicable federal, state and local codes, standards and regulations.

Where to Find Us

You never have to look far to find Briggs & Stratton support and service for your transfer switch. Consult your Yellow Pages.

There are over 30,000 Briggs & Stratton authorized service dealers worldwide who provide quality service. You can also

contact Briggs & Stratton Customer Service by phone at (800) 743-4115, or on the Internet at BRIGGSandSTRATTON.COM.

Transfer Switch

Model Number

Revision

Serial Number

Date Purchased

Page 3

1

FrançaisEspañol

Important Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Owner Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installer Responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Equipment Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Mounting Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Power Wiring Interconnections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Supervisory Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

System Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Testing the Automatic Transfer Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

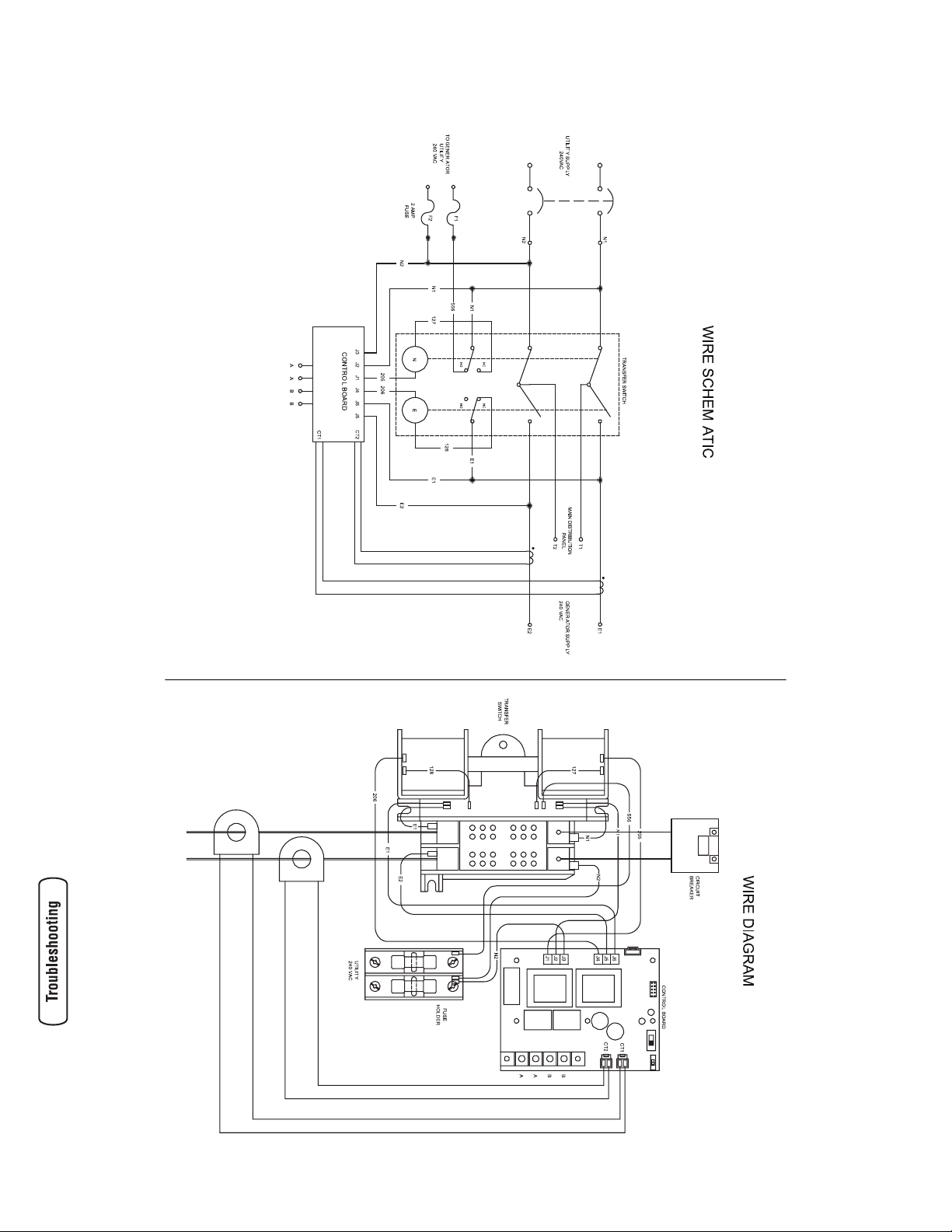

Schematic and Wiring Diagram, Models 071018 and 071019. . . . . . . . . . 11

Schematic and Wiring Diagram, Models 071020 and 071021. . . . . . . . . . 12

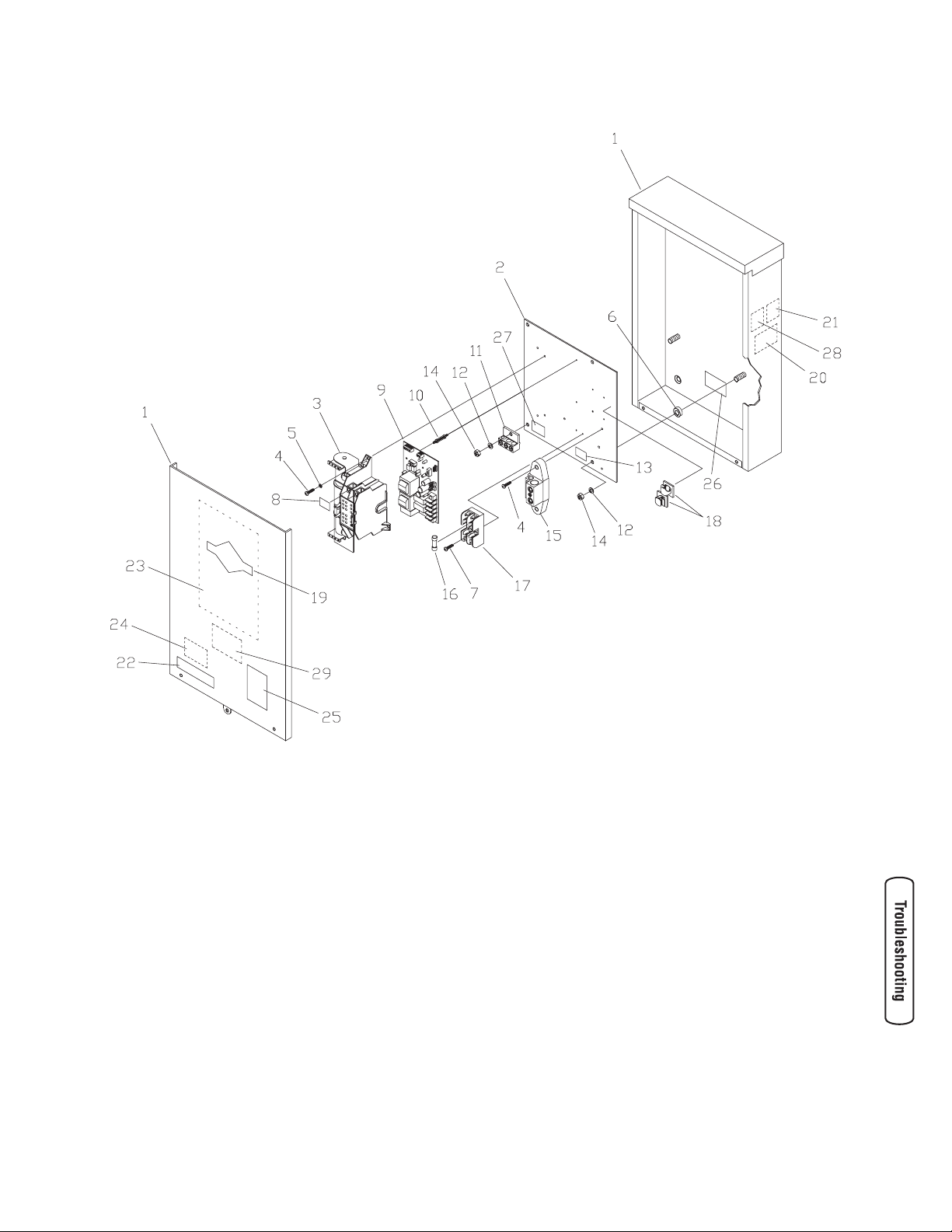

Illustrated Parts List, Model 071018 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Illustrated Parts List, Model 071019 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Illustrated Parts List, Model 071020 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Illustrated Parts List, Model 071021 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table of Contents

Page 4

2 BRIGGSandSTRATTON.COM

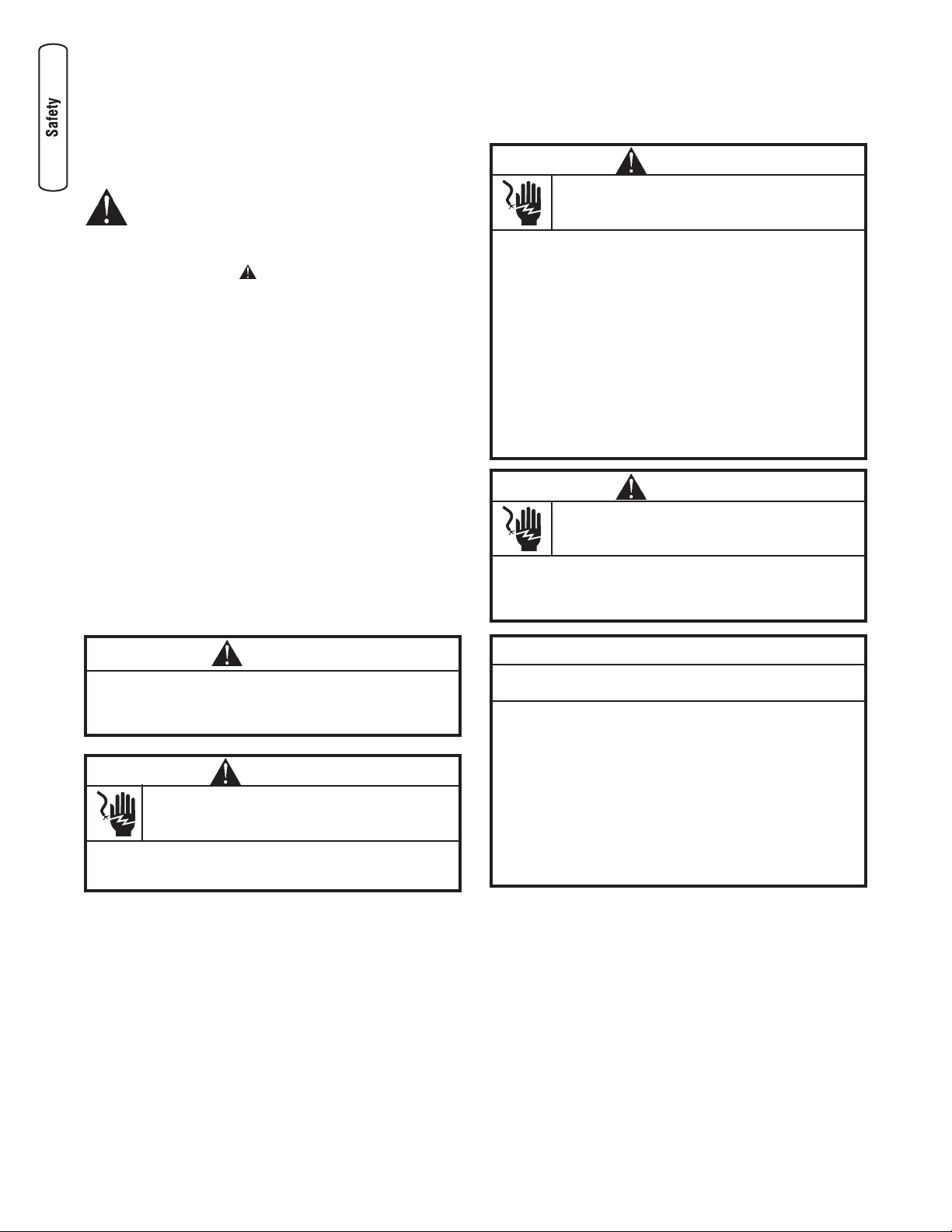

Important Safety Instructions

This is the safety alert symbol. It is used to alert

you to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid

possible injury or death.

The safety alert symbol ( ) is used with a signal word

(DANGER, CAUTION, WARNING), a pictorial and/or a safety

message to alert you to hazards. DANGER indicates a hazard

which, if not avoided, will result in death or serious injury.

WARNING indicates a hazard which, if not avoided, could

result in death or serious injury. CAUTION indicates a hazard

which, if not avoided, might result in minor or moderate

injury. NOTICE indicates a situation that could result in

equipment damage. Follow safety messages to avoid or

reduce the risk of injury or death.

The manufacturer cannot possibly anticipate every possible

circumstance that might involve a hazard. The warnings in

this manual, and the tags and decals affixed to the unit are,

therefore, not all-inclusive. If you use a procedure, work

method or operating technique that the manufacturer does

not specifically recommend, you must satisfy yourself that it

is safe for you and others. You must also make sure that the

procedure, work method or operating technique that you

choose does not render the transfer switch unsafe.

Save These Instructions

WARNING

Only qualified electricians should attempt installation of

this system, which must strictly comply with applicable

codes, standards and regulations.

WARNING

Failure to properly ground transfer switch can

result in electrocution.

• DO NOT touch bare wires or receptacles.

• DO NOT use transfer switch with worn, frayed, bare or

otherwise damaged wiring.

• DO NOT handle electrical cords while standing in water, while

barefoot, or while hands or feet are wet.

• If you must work around a unit while it is operating, stand on

an insulated dry surface to reduce shock hazard.

• DO NOT allow unqualified persons or children to operate or

service transfer switch.

• In case of an accident caused by electrical shock, immediately

shut down the source of electrical power and contact local

authorities. Avoid direct contact with the victim.

WARNING

Low voltage wire cannot be installed in same

conduit as power voltage wiring.

• Failure to follow above warning could cause personal injury,

damage and/or malfunction of equipment.

WARNING

Transfer Switch contains hazardous voltage that

can cause personal injury or death.

• Despite the safe design of the transfer switch, operating this

equipment imprudently, neglecting its maintenance or being

careless can cause possible injury or death.

NOTICE

Improper treatment of transfer switch can damage it and

shorten its life.

• Use transfer switch only for intended uses.

• If you have questions about intended use, ask dealer or contact

Briggs and Stratton Power Products.

• Do not expose transfer switch to excessive moisture, dust, dirt,

or corrosive vapors.

• Remain alert at all times while working on this equipment.

Never work on the equipment when you are physically or

mentally fatigued.

• If connected devices overheat, turn them off and turn off their

circuit breaker/fuse.

Page 5

3

Introduction

Your Briggs & Stratton Transfer Switch is supplied with this

combined “Installation and Operator’s Manual”. This is an

important document and should be retained by the owner

after the installation has been completed.

Every effort has been expended to make sure that the

information in this manual is both accurate and current.

However, the manufacturer reserves the right to change, alter

or otherwise improve the system at any time without prior

notice.

For the Home Owner

To help you make informed choices and communicate

effectively with your installation contractor(s),

Read and understand the Owner Orientation Section

of this manual BEFORE contracting or starting your

transfer switch installation.

To arrange for proper installation, contact the store at which

you purchased your Briggs & Stratton Transfer Switch, your

dealer, or your utility power provider.

The Transfer Switch Warranty is VOID

unless the system is installed by a

licensed electrical professional.

Owner Orientation

The illustrations are for typical circumstances and are meant

to familiarize you with the installation options available with

your transfer switch.

Local codes, appearance, and distances are the factors that

must be considered when negotiating with an installation

professional. As the distance from the existing electrical

service increases, compensation in wiring materials must be

allowed for. This is necessary to comply with local codes and

overcome electrical voltage drops.

The factors mentioned above will have a direct effect

on the overall price of your transfer switch installation.

NOTE: Your installer must check local codes AND obtain

permits before installing the system.

• Read and follow the instructions given in this manual.

• Follow a regular schedule in caring for and using your

transfer switch, as specified in the manual.

Installer Responsibilities

• Read and observe the safety rules.

• Read and follow the instructions given in this manual.

• Check federal, state and local codes and authority

having jurisdiction, for questions on installation.

• Ensure generator is not overloaded with selected loads.

If you need more information about the transfer switch, call

(800) 743-4115, between 8:00 AM and 5:00 PM CT.

Equipment Description

These transfer switches are intended to transfer the entire

electrical load of normal residential installations when used

with the supervisory contacts provided. The load is

connected either to utility power (normal) or home standby

power (generator). The transfer switch monitors utility and

generator voltages and will automatically connect to the

appropriate source of power.

Major components of the transfer switch are a 2 pole utility

disconnect circuit breaker (models 071020 & 071021 only),

a 2 pole double throw transfer switch, control circuit board,

fused utility terminals and interconnecting wiring. The

control board also has two inputs for current tranformers

used to sense generator current.

The transfer switch is solenoid-operated from utility or

generator inputs and contains suitable mechanical and

electrical interlock switches to eliminate the possibility of

connecting the utility service to the generator output. It has

ratings capable of switching full utility power into the

residence. In addition, a manual override lever is provided

for the transfer function.

The control circuit board has active circuits sensing utility

and generator voltages. It creates a signal for the generator

start-up, switch transfer, and retransfer when utility is

restored. The control board also contains red and green

LED’s indicating the power sources available and two relay

operated contacts that provide supervisory control of

external loads.

Page 6

4 BRIGGSandSTRATTON.COM

Installation

Unpacking

Delivery Inspection

After removing the carton, carefully inspect the transfer

switch components for any damage that may have occurred

during shipment.

IMPORTANT: If loss or damage is noted at time of delivery,

have the person(s) making delivery note all damage on the

freight bill and affix his signature under the consignor's

memo of loss or damage. If loss or damage is noted after

delivery, contact the carrier for claim procedures. Missing or

damaged parts are not warranted.

Shipment Contents

• Automatic Power Transfer Switch

• Two Current Transformers

• Installation and Operator’s Manual

Mounting Guidelines

The Automatic Transfer Switch is enclosed in NEMA Type 3R

enclosures suitable for indoor or indoor/outdoor use.

Guidelines for mounting the Automatic Transfer Switch

include:

• Install the switch on a firm, sturdy supporting

structure.

• The switch must be installed with minimum NEMA 3R

hardware for conduit connections.

• To prevent switch contact distortion, level and plumb

the enclosure. This can be done by placing washers

between the switch enclosure and the mounting

surface.

• Never install the switch where any corrosive substance

might drip onto the enclosure.

• Protect the switch at all times against excessive

moisture, dust, dirt, lint, construction grit and corrosive

vapors.

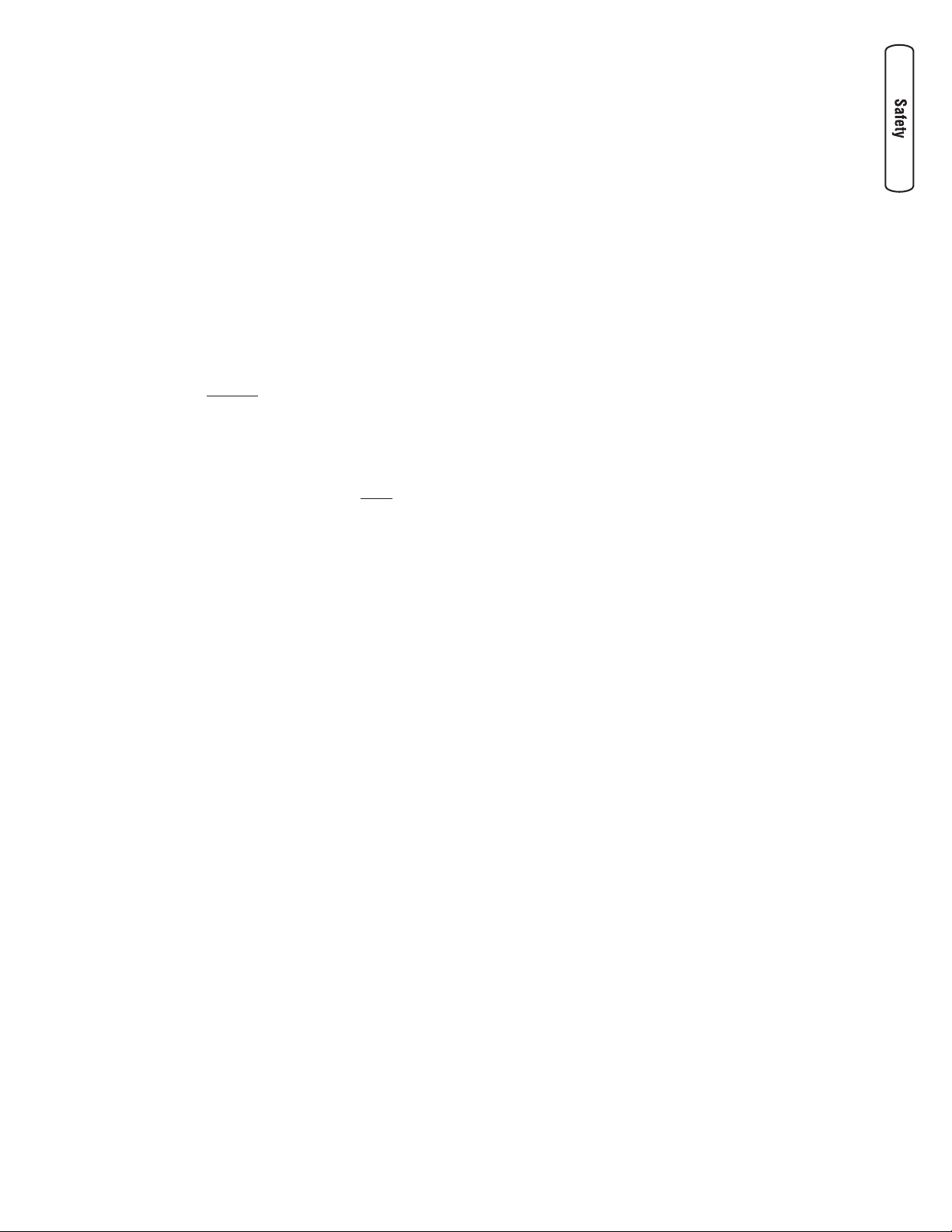

A typical installation of the Automatic Power Transfer Switch

for Models 071018 and 071019 is depicted in Figure 1. An

alternative installation of the Automatic Power Transfer

Switch is depicted in Figure 2.

It is best if the transfer switch is mounted near the utility

watt-hour meter, either inside or outside. Discuss layout

suggestions/changes with the owner before beginning the

system installation process.

Main

Circuit

Breaker

Panel

Transfer

Switch

Hot Water

Heater

Air

Conditioner

Contactor

Generator

Watt -

Hourmeter

Branch Circuits

— — — — — — Control Wiring

Disconnect Switch

Service

Disconnect

Figure 1 - Typical Transfer Switch Mounting for Models 071018 and 071019

Page 7

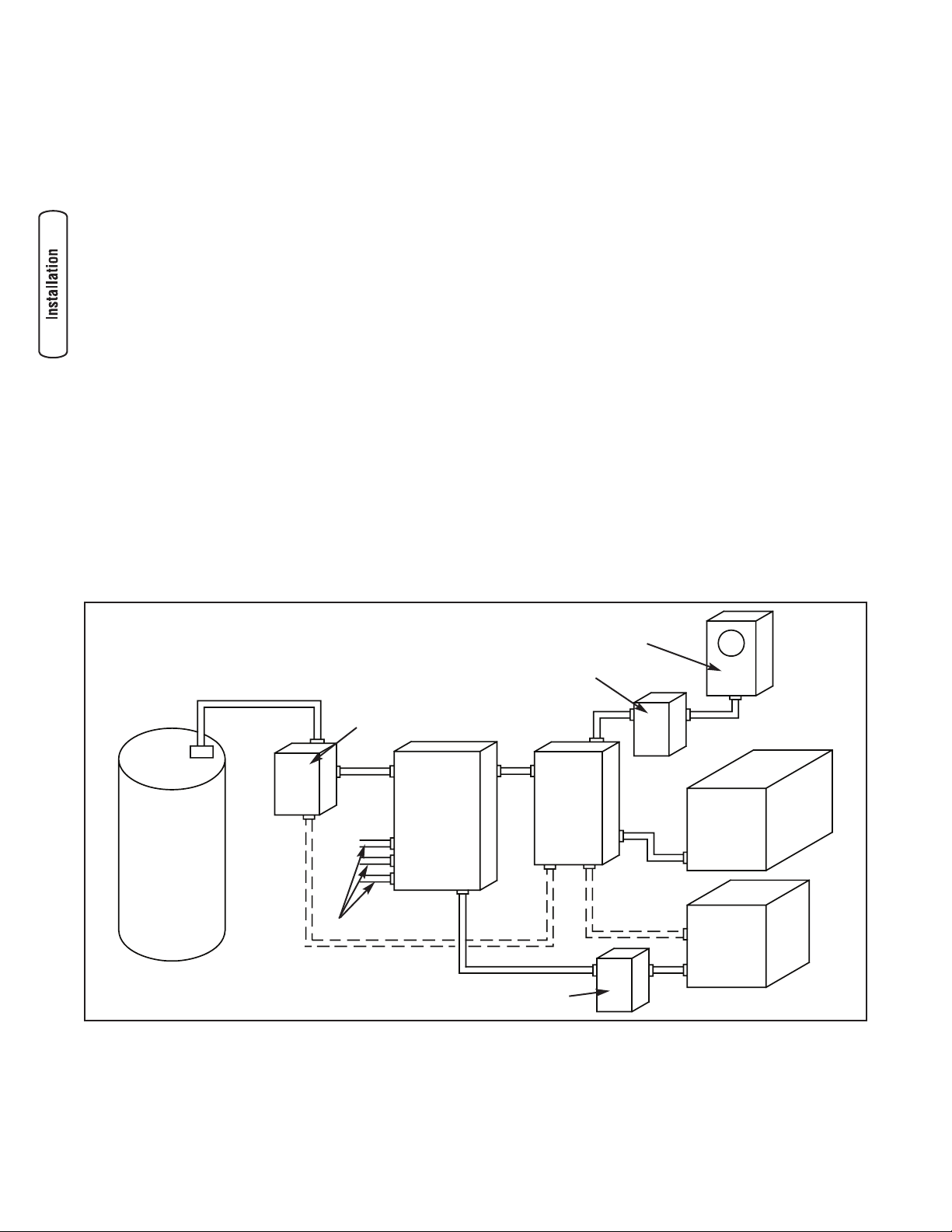

5

Main

Circuit

Breaker

Panel

Transfer

Switch

Hot Water

Heater

Air

Conditioner

Contactor

Disconnect Switch

Generator

Watt -

Hourmeter

Branch

Circuits

Emergency

Branch Circuits

— — — — — — Control Wiring

Emergency

Load Center

Figure 2 - Alternate Transfer Switch Mounting

Figure 3 - Typical Installation Diagram for Model 071018 & 071019 Transfer Switches

Main

Main Breaker Panel

Ground Bus

Neutral

Bus

To Generator

Neutral

Terminal

To Utility Meter

Supervisory

Contacts

Load

Connection

Ground Lug

Generator

Connection

Utility

Connection

Page 8

6 BRIGGSandSTRATTON.COM

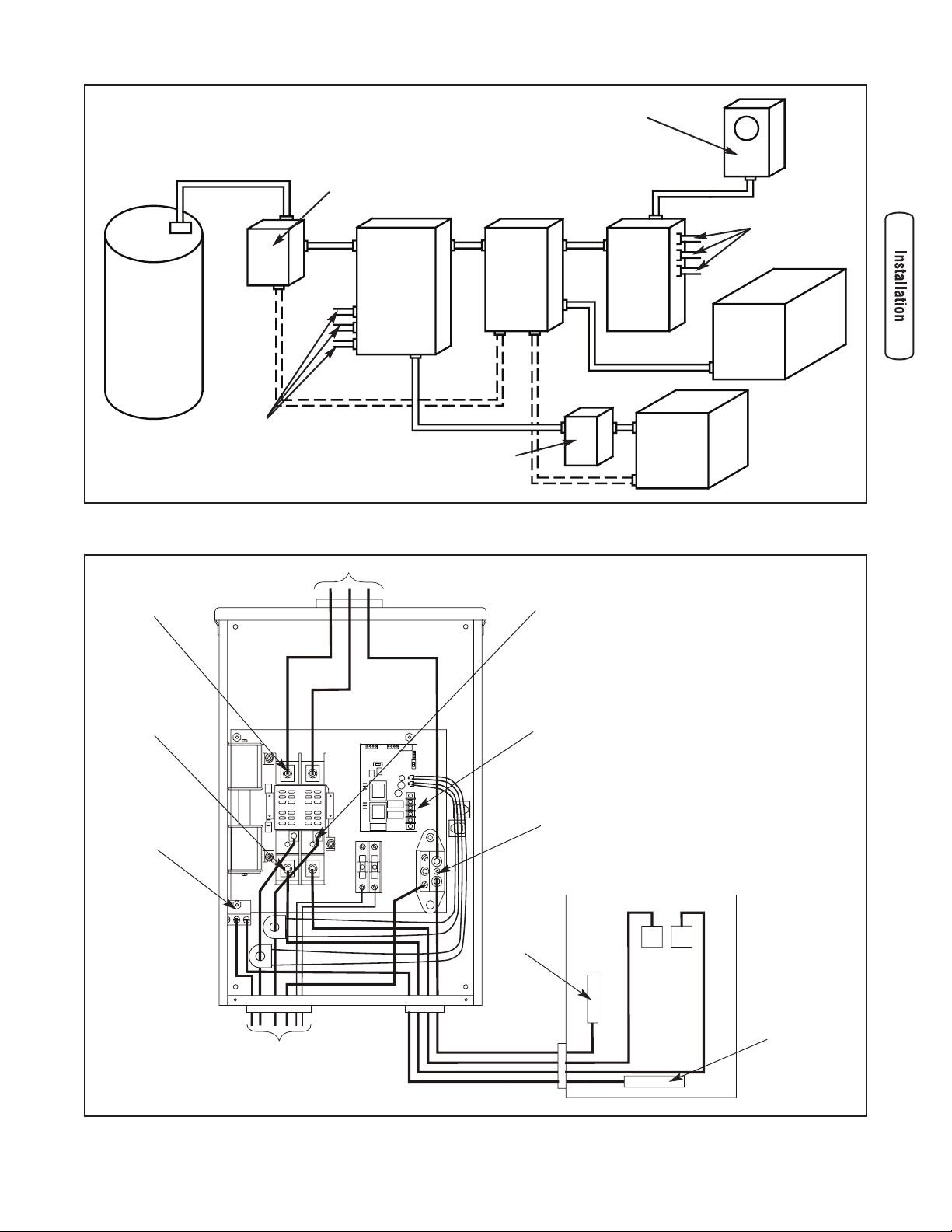

Power Wiring Interconnections

All wiring must be the proper size, properly supported and

protected by conduit.

Complete the following connections between the transfer

switch, main distribution panel, utility power and generator,

as shown in Figures 3 and 4.

1. Ensure utility power is turned OFF. Connect utility

feeder conductors to transfer switch terminals marked

“UTILITY CONNNECTION”.

2. Connect utility Neutral conductor to the transfer switch

“NEUTRAL” terminal.

3. Connect main breaker panel feeder conductors to

transfer switch terminals marked “LOAD

CONNECTION”.

4. Connect main breaker panel Neutral conductor to

transfer switch “NEUTRAL” terminal.

5. Connect main breaker panel Ground conductor to the

transfer switch “GND” terminal.

NOTE: Assure grounding electrode conductor is connected

and bonded per applicable federal, state and local codes,

standards and regulations.

6. Connect generator feeder conductors from the

generator control panel to transfer switch terminals

marked “GENERATOR CONNECTION” Each conductor

should pass through hole of current transformer before

making connection.

7. Plug in current transformer leads into “CT1” and “CT2”

on control module.

WARNING

Low voltage wire cannot be installed in same

conduit as power voltage wiring.

• Failure to follow above warning could cause personal injury,

damage and/or malfunction of equipment.

Figure 4 - Typical Installation Diagram for Model 071020 and 071021 Transfer Switches

Main

Main Breaker Panel

Ground Bus

Neutral

Bus

To Generator

Neutral

Terminal

To Utility Meter

Supervisory

Contacts

Generator

Connection

Ground Lug

CT2

CT1

Load

Connection

Utility

Connection

Page 9

7

8. Connect Neutral conductor from the generator control

panel to the transfer switch “NEUTRAL” terminal.

9. Connect generator Ground conductor from the control

panel to the transfer switch “GND” terminal.

NOTE: Assure generator equipment grounding conductor is

connected per applicable federal, state and local codes,

standards and regulations.

10. Connect generator “UTILITY 240 VAC” terminals to

transfer switch “UTILITY 240 VAC” terminals. Use

minimum #14 AWG conductors.

11. Tighten all wire connections/fasteners to proper torque.

See inside transfer switch enclosure for proper torque

values.

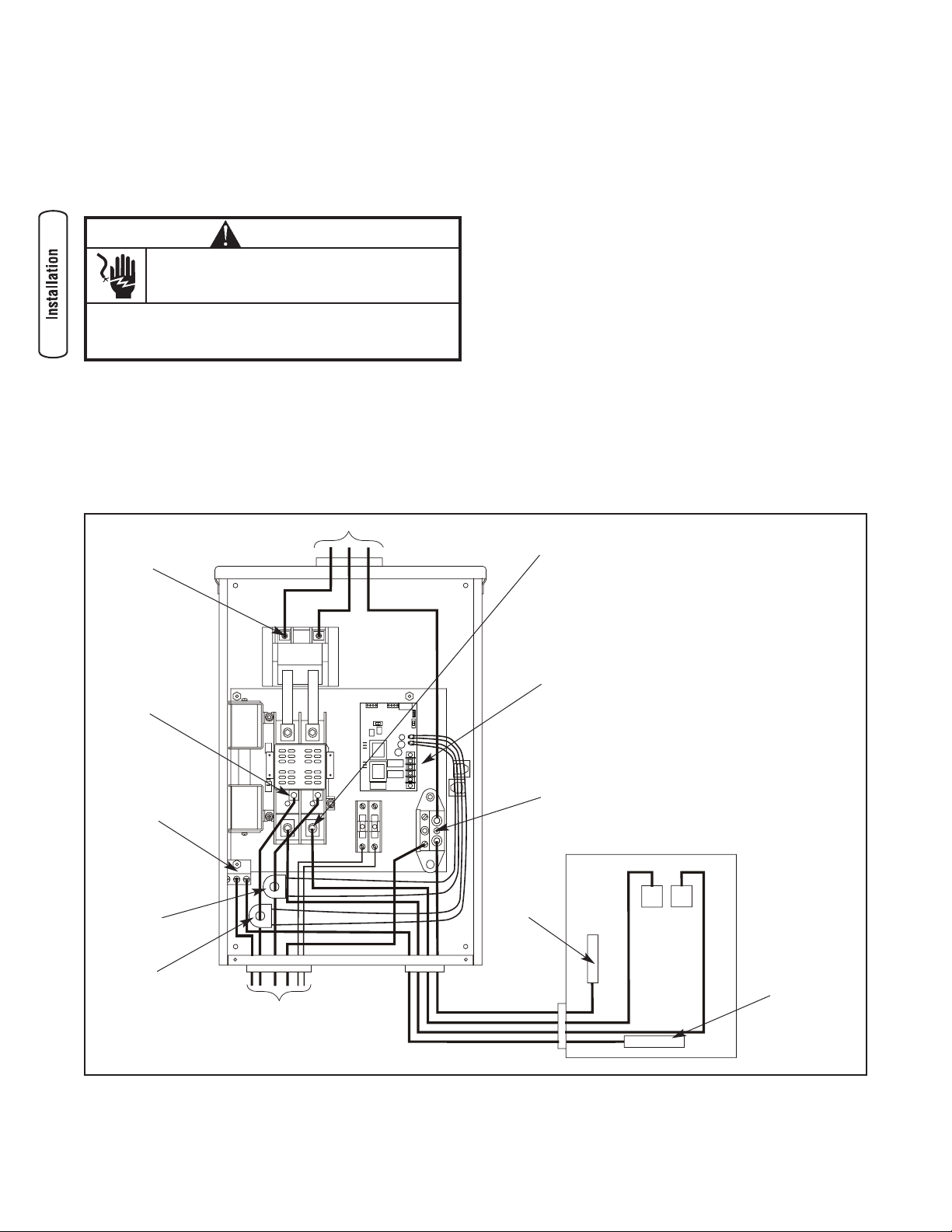

Supervisory Control Wiring

1. Terminal strip on control module in transfer switch has

four connections for customer use. There are two sets

of “Normally Closed” contacts available. They will be

activated when generator power is required. These can

be used for supervisory control of large connected

loads on generator. Loads will be allowed to operate if

there is enough generator power available.

NOTE: There are two wireways provided to keep the

supervisory loads separated from each other.

2. Terminals “A-A” on control module are rated for 24 VAC

and air conditioner contactor control. Contacts are

connected in series with the air conditioner contactor

control circuit (Figure 5).

3. Terminals “B-B” on control module are rated for 1 Amp

125 VAC and installer supplied contactor to control a

large load. Example: electric hot water heater. Contacts

are connected in series with the contactor control

circuit (Figure 6).

4. Tighten all wire connections/fasteners to proper torque.

See inside transfer switch enclosure for proper torque

values.

System Setup

You must perform the following on the control module

before operating the system:

• If generator is installed in an area regularly subjected to

temperatures below 40°F (4°C), select a 50 second

warm up time by moving jumper installed on JP2

(Figure 7) from ‘20’ position to ‘50’ position.

• Place 2 position switch (Figure 7) in ‘NG’ or ‘LP’

position, whichever is appropriate for your system.

• Place 3 position switch (Figure 7) to match KW rating

of installed generator.

Controls

Other than a Manual Override lever, there are no operator

controls because this is an automatic transfer switch. The

manual override is to be used only by licensed professionals.

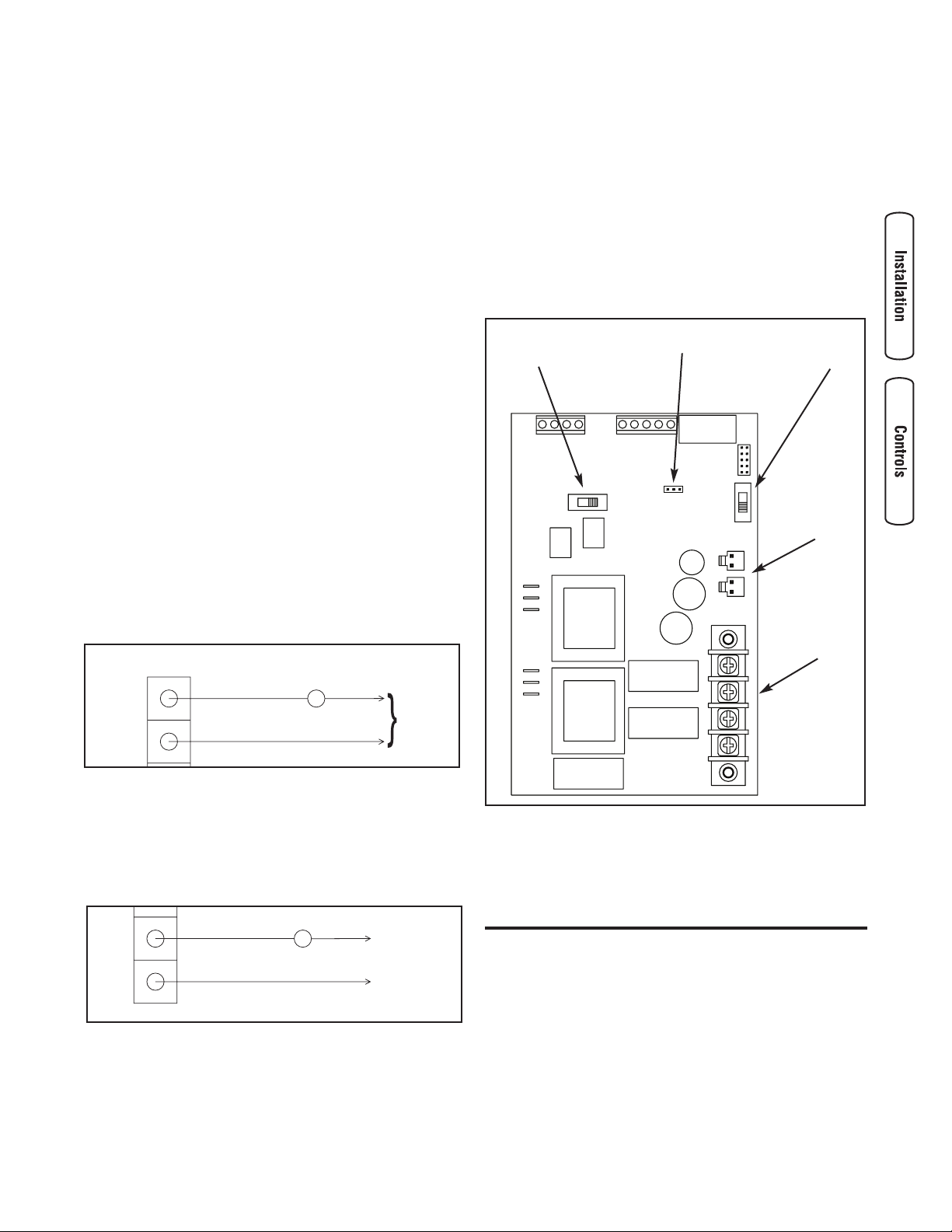

Figure 7 — Control Module

Figure 6 — Terminals “B-B”

B

B

Figure 5 — Terminals “A-A”

Contactor

Neutral

120 VAC

2 Position

Switch

3 Position

Switch

JP2

CT1 & CT2

Connectors

Supervisory

Contacts

Air Conditioner Contactor

24 VAC

A

A

Page 10

8 BRIGGSandSTRATTON.COM

Operation

To select automatic transfer operation, do the following:

1A. For models 071018 & 071019, set disconnect switch

that sends utility power to transfer switch to “On”

position. This switch is probably located in the main

breaker panel.

1B. For models 071020 & 071021, set utility breaker in

transfer switch “On” position.

2. Set generator main circuit breaker to its “On” position.

3. Install 15 Amp fuse in generator control panel.

4A. If generator is equipped with a system ON/OFF switch,

set switch to “On” position.

4B. If generator is equipped with a AUTO/OFF/MANUAL

switch, set switch to “AUTO” position.

The system will now be in automatic operation mode.

When the generator is providing power to the transfer

switch, the control module is constantly monitoring

generator power. If the air conditioner is called to run, and

there is sufficient generator power available, the control

module will close contacts “A-A” to air conditioner contactor.

Contacts “B-B” will open before contacts A-A close. If loads

are too great for generator, contacts A-A and/or B-B will

open. When air conditioning is not needed, A-A will open. If

enough power is available, B-B will close.

Testing the Automatic Transfer Switch

Turn the disconnect switch feeding the transfer switch

contactor to the “Off” position. The Automatic Sequence of

the system will follow. To go back to utility power, turn the

disconnect to the “On” position.

Automatic Sequence

Utility Fail

The Home Standby Generator set senses when utility voltage

is below 70 percent of nominal. Engine start sequence is

initiated after 6 second time delay.

Engine Warm-Up

Time delay to allow for engine warm-up before transfer fixed

at 20 seconds or 50 seconds with removal of jumper on

control board (see System Setup).

Transfer

Transfer from utility to generator supply occurs after voltage

is above set levels. Minimum engine run time is 5 minutes

after transfer.

Utility Pickup

Voltage pickup level is 80 percent of nominal voltage.

Retransfer

Retransfer from generator to utility supply is approximately

10 seconds after utility voltage supply is above utility pickup

level and minimum run time is completed.

Engine Cool Down

Engine will run for 60 seconds after retransfer.

When Calling the Factory

Before contacting Briggs and Stratton Power Products

regarding service or repair of this transfer switch, obtain the

Model Number and Serial Number from the unit data decal

located on or inside the enclosure.

To contact Briggs and Stratton Power Products call

1-800-743-4115, between 8:00 AM and 5:00 PM CT.

Page 11

9

Specifications

UL® 1008 Listed Transfer Switch

Model 071018

Maximum Load Current . . . . . . . . . . . . . . . . . . . . .100 Amps

Rated AC Voltage . . . . . . . . . . . . . . . . . . . . . . . . . .250 Volts

Poles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50/60 Hz

Fault Current Rating . . . .22,000 RMS Symmetrical Amperes

Supervisory Contacts Rating:

A-A Terminals . . . . . . . . . . . . . . . . . . . . . . . . . .24 Volt AC

B-B Terminals . . . . . . . . . .1 Amp, 125 Volt AC, Pilot Duty

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 lbs.

Model 071019

Maximum Load Current . . . . . . . . . . . . . . . . . . . . .200 Amps

Rated AC Voltage . . . . . . . . . . . . . . . . . . . . . . . . . .250 Volts

Poles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50/60 Hz

Fault Current Rating . . . .25,000 RMS Symmetrical Amperes

Supervisory Contacts Rating:

A-A Terminals . . . . . . . . . . . . . . . . . . . . . . . . . .24 Volt AC

B-B Terminals . . . . . . . . . .1 Amp, 125 Volt AC, Pilot Duty

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34 lbs.

Model 071020

Maximum Load Current . . . . . . . . . . . . . . . . . . . . .100 Amps

Rated AC Voltage . . . . . . . . . . . . . . . . . . . . . . . . . .250 Volts

Poles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50/60 Hz

Fault Current Rating . . . .22,000 RMS Symmetrical Amperes

Supervisory Contacts Rating:

A-A Terminals . . . . . . . . . . . . . . . . . . . . . . . . . .24 Volt AC

B-B Terminals . . . . . . . . . .1 Amp, 125 Volt AC, Pilot Duty

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32 lbs.

Model 071021

Maximum Load Current . . . . . . . . . . . . . . . . . . . . .200 Amps

Rated AC Voltage . . . . . . . . . . . . . . . . . . . . . . . . . .250 Volts

Poles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50/60 Hz

Fault Current Rating . . . .25,000 RMS Symmetrical Amperes

Supervisory Contacts Rating:

A-A Terminals . . . . . . . . . . . . . . . . . . . . . . . . . .24 Volt AC

B-B Terminals . . . . . . . . . .1 Amp, 125 Volt AC, Pilot Duty

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44 lbs.

Maintenance

The transfer switch is designed to be maintenance free under

normal usage. However, inspection and maintenance checks

should be made on a regular basis. Maintenance will consist

mainly of keeping the transfer switch clean.

Visual inspections should be done at least once a month.

Access to transfer switch must not be obstructed. Keep

3 feet (1 m) clearance around transfer switch. Check for an

accumulation of dirt, moisture and/or corrosion on and

around the enclosure, loose parts/hardware, cracks and/or

discoloration to insulation, and damaged or discolored

components.

Exercise the transfer switch at least once every three months

as described in section Testing the Automatic Transfer

Switch unless a power outage occurs and home generator

system has gone through an automatic sequence. Allow

generator to run for at least 30 minutes.

Contact a licensed electrical professional to inspect and clean

the inside of your transfer switch at least once a year.

Page 12

10 BRIGGSandSTRATTON.COM

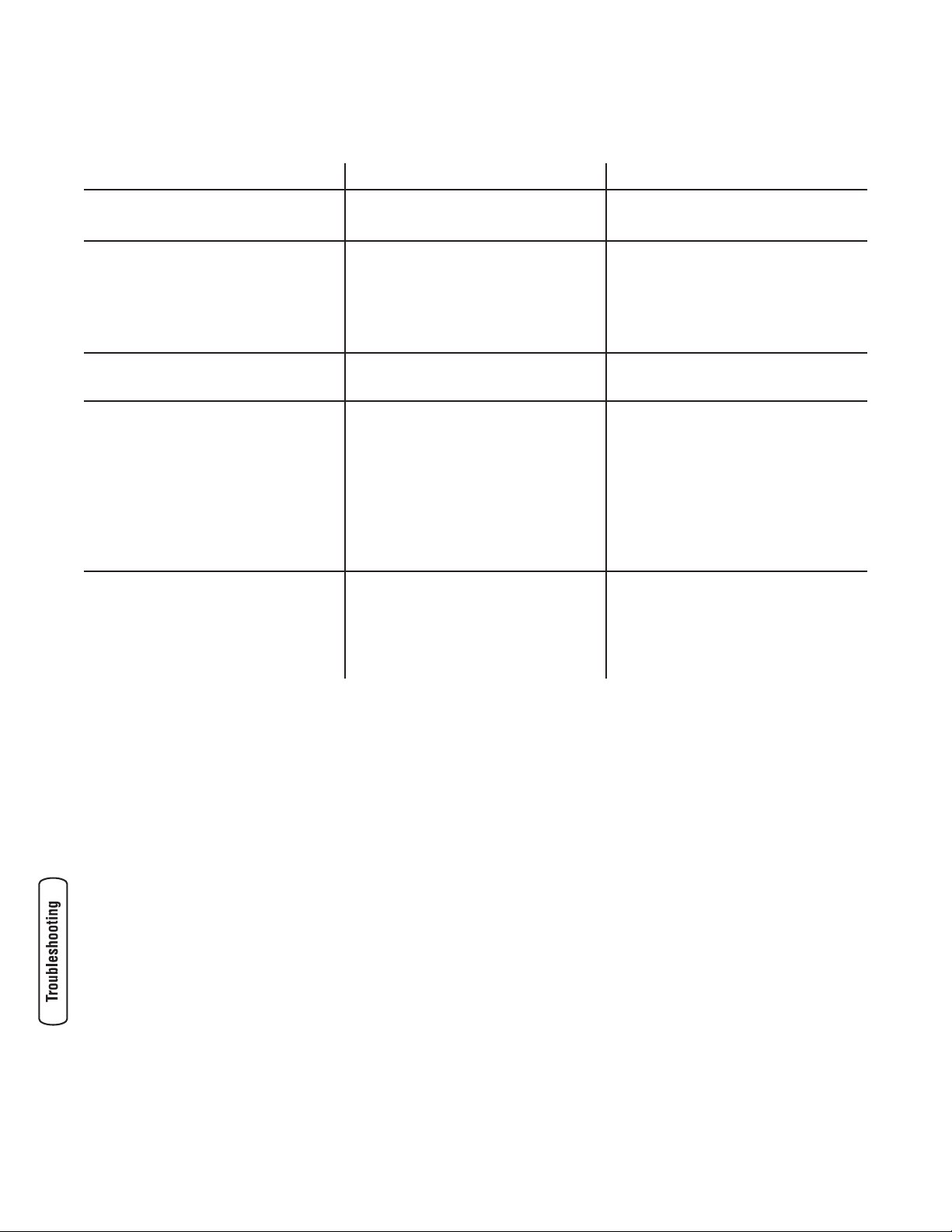

Troubleshooting

Problem Cause Correction

Automatic transfer switch does not

transfer to generator

1. Generator breaker open.

2. Generator voltage not acceptable.

1. Reset generator circuit breaker.

2. Refer to generator manual.

Automatic transfer switch does not

transfer to utility

1. Utility disconnect breaker open

(Models 071020 & 071021 only).

2. Service disconnect breaker open.

3. Utility voltage not acceptable.

1. Reset utility disconnect breaker

(Models 071020 & 071021 only).

2. Reset service disconnect breaker.

3. Wait for utility voltage to return to

normal.

Generator is still running after switch

transfers to utility power

Engine cool down period. Engine should stop after 1 minute.

Supervised loads (air conditioner, etc.)

are not operating when generator is

supplying power

1. A-A or B-B contacts not operating

correctly.

2. Too much load on generator.

3. Current transformer not connected.

4. Broken current transformer.

1. Check A-A or B-B contacts for

proper operation and/or check

control wiring to external load.

2. Decrease load to generator.

3. Plug CT connectors into control

board.

4. Contact local Briggs & Stratton

Power Products service center.

Generator is still running after utility

power is restored

1. Minimum engine run time has not

elapsed.

2. Fuse(s) in transfer switch is

defective.

1. Wait five minutes for transfer

switch to retransfer to utility power.

2. Check fuse(s) and replace if

necessary.

Page 13

11

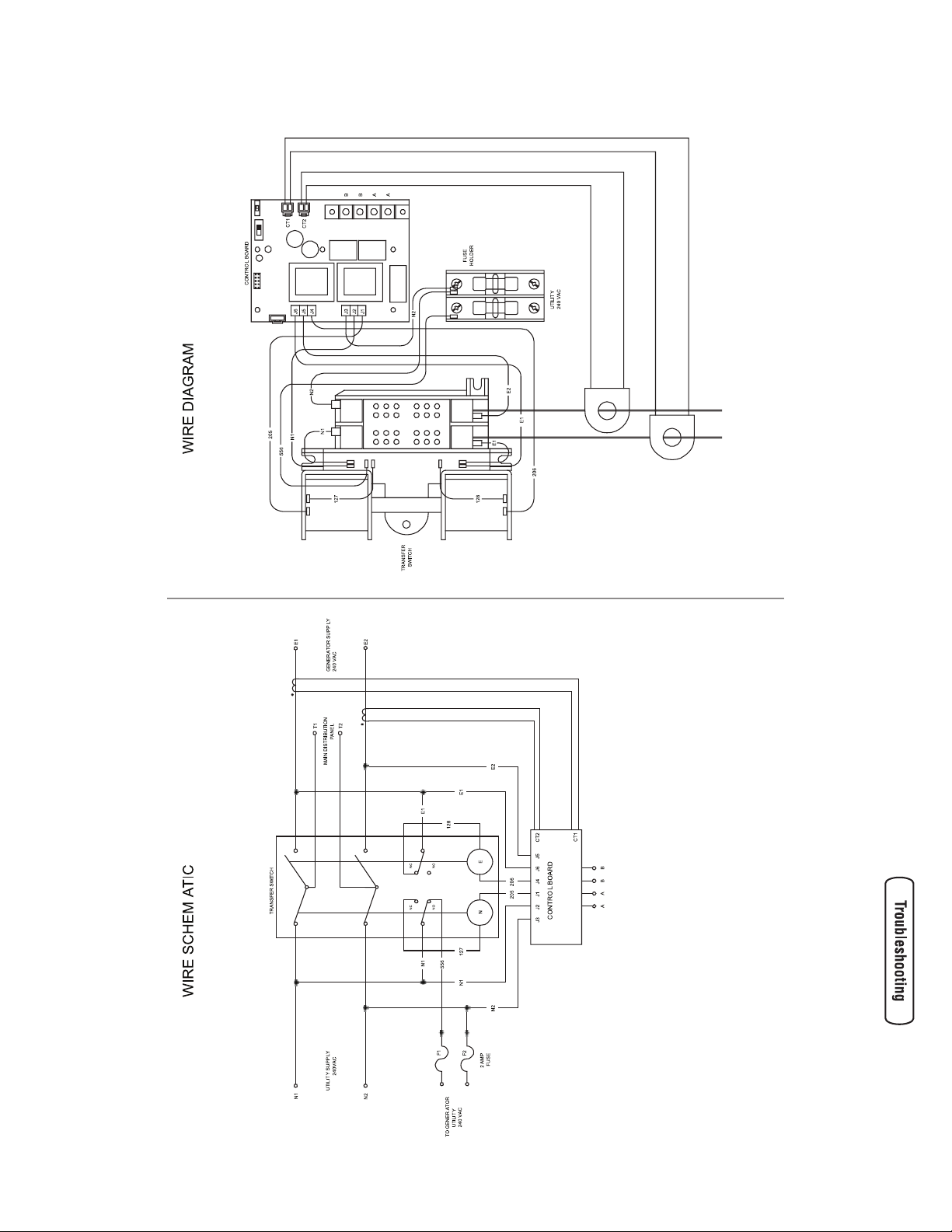

Schematic and Wiring Diagram, Models 071018 and 071019

Page 14

12 BRIGGSandSTRATTON.COM

Schematic and Wiring Diagram, Models 071020 and 071021

Page 15

13

Item Part # Description

1 NSP ENCLOSURE, 16" x 12" x 6"

2 NSP BACK PANEL

3 195667GS TRANSFER SWITCH, 100A, with

Cover & Handle

4 * PPHMS, #10 - 32 x 1/2"

5 * WASHER, Ext. Tooth, #10

6 192150GS SPACER

7 * PPHMS, #6-32 x 3/8"

8 193159GS DECAL, Reinstall After

9 197279GS CONTROL, Board

10 201685GS SPACER

11 196094GS GROUND LUG

12 * WASHER, Lock 1/4"

13 192597GS DECAL, Utility, 240 VAC

14 * NUT, 1/4" - 20

15 192696GS TERMINAL, Neutral

16 B4857GS FUSE

17 192151GS FUSE HOLDER

Item Part # Description

18 197355GS CLIP, Latching Wire

19 198136GS DECAL, B & S Logo

20 196355GS DECAL, CT Warning

21 197294GS DECAL, Contacts Rating

22 198615GS DECAL, Intelligen Logo

23 196522GS DECAL, 100A, ATS

24 NSP DECAL, UL Listed, ATS

25 190992GS DECAL, Warning Shock

26 190984GS DECAL, Fuse

27 B4986GS DECAL, Ground

28 197198GS DECAL, Wire Circuits

29 192165GS DECAL, APPVD CB

Items Not Illustrated

195728GS CURRENT TRANSFORMER

* - Items without part numbers are common fasteners and

are available at local hardware stores.

Illustrated Parts List, Model 071018

Page 16

14 BRIGGSandSTRATTON.COM

Item Part # Description

1 NSP ENCLOSURE, 22” x 16” x 7”

2 NSP BACK PANEL

3 195668GS TRANSFER SWITCH, 200A, with

Cover & Handle

4 * PPHMS, #10 - 32 x 1/2"

5 * WASHER, Ext. Tooth, #10

6 192150GS SPACER

7 * PPHMS, #6- 32 x 3/8"

8 193159GS DECAL, Reinstall After

9 197279GS CONTROL, Board

10 201685GS SPACER

11 196094GS GROUND LUG

12 * WASHER, Lock 1/4"

13 190984GS DECAL, Fuse

14 * NUT, 1/4” - 20

15 192696GS TERMINAL, Neutral

16 B4857GS FUSE

17 192151GS FUSE HOLDER

Item Part # Description

18 197355GS CLIP, Latching Wire

19 198136GS DECAL, B & S Logo

20 196355GS DECAL, CT Warning

21 197294GS DECAL, Contacts Rating

22 198615GS DECAL, Intelligen Logo

23 196523GS DECAL, 200A, ATS

24 NSP DECAL, UL Listed, ATS

25 190992GS DECAL, Warning Shock

26 197198GS DECAL, Wire Circuits

27 B4986GS DECAL, Ground

28 192597GS DECAL, Utility 240VAC

29 192166GS DECAL, APPVD CB

Items Not Illustrated

195728GS CURRENT TRANSFORMER

* - Items without part numbers are common fasteners and

are available at local hardware stores.

Illustrated Parts List, Model 071019

Page 17

15

Item Part # Description

1 NSP ASSY, Enclosure

2 NSP BACK PANEL

3 195667GS TRNSFR SWTCH, 100A, w/ Hdle

4 * PPHMS, #10 - 32 x 1/2"

5 * WASHER, Ext. Tooth, #10

6 193689GS WIRE, Copper

7 * PPHMS, #6- 32 x 3/8"

8 193664GS INSULATION, Dead Front

9 197279GS CONTROL, Board

10 201685GS SPACER

11 196094GS GROUND LUG

12 * WASHER, Lock 1/4"

13 192882GS BREAKER Circuit, 100A

14 * NUT, 1/4” - 20

15 192696GS TERMINAL, Neutral

16 B4857GS FUSE

17 192151GS FUSE HOLDER

18 197355GS CLIP, Latching Wire

19 198136GS DECAL, B & S Logo

20 196355GS DECAL, CT Warning

21 B5106GS DECAL, Connection, Utility

22 198615GS DECAL, Intelligen, Logo

Item Part # Description

23 196520GS DECAL, 100A, ATS

24 NSP) DECAL, UL Listed

25 190992GS DECAL, Warning Shock

26 190984GS DECAL, Fuse

27 B4986GS DECAL, Ground

28 192597GS DECAL, Sensing, Utility

29 193450GS DECAL, Breaker, Circuit

30 197294GS DECAL, Contacts Rating

31 192150GS SPACER

32 197198GS DECAL, Wire Circuits

33 192770GS BRACKET, Circuit Breaker

34 * PPHMS, 8-32x 3/8"

35 * PPHMS, 10-32 x 3/8"

36 * LOCKWASHER, #10

37 * PPHMS, #10 - 32 x 1/4"

38 193159GS DECAL, Reinstall Barrier

Items Not Illustrated

195728GS CURRENT TRANSFORMER

* - Items without part numbers are common fasteners and

are available at local hardware stores.

Illustrated Parts List, Model 071020

Page 18

16 BRIGGSandSTRATTON.COM

Illustrated Parts List, Model 071021

Item Part # Description

1 NSP ASSY, Enclosure

2 NSP BACK PANEL

3 195668GS TRANSFER SWITCH, 200A, with

Handle

4 * PPHMS, #10 - 32 x 1/2"

5 * WASHER, Ext. Tooth, #10

6 * PPHMS, 1/4-20x 3/4"

7 * PPHMS, #6- 32 x 3/8"

8 193664GS INSULATION, Dead Front

9 197279GS CONTROL, Board

10 201685GS SPACER

11 196094GS GROUND LUG

12 * WASHER, Lock 1/4"

13 192065GS BREAKER Circuit, 200A

14 * NUT, 1/4” - 20

15 192696GS TERMINAL, Neutral

16 B4857GS FUSE

17 192151GS FUSE HOLDER

18 197355GS CLIP, Latching Wire

19 198136GS DECAL, B & S Logo

20 196355GS DECAL, CT Warning

21 B5106GS DECAL, Connection, Utility

22 198615GS DECAL, Intelligen Logo

Item Part # Description

23 196521GS DECAL, 200A, ATS

24 NSP DECAL, UL LIsted

25 190992GS DECAL, Warning Shock

26 190984GS DECAL, Fuse

27 B4986GS DECAL, Ground

28 192597GS DECAL, Sensing, Utility

29 193450GS DECAL, Breaker, Circuit

30 * PPHMS, #10 - 32 x 3/4"

31 192150GS SPACER

32 197198GS DECAL, Wire Circuits

33 192879GS INSULATION, Circuit Breaker

34 197294GS DECAL, Contacts Rating

35 192881GS BUS BAR

36 * LOCKWASHER, #10

37 * PPHMS, #10 - 32 x 1/4"

38 193159GS DECAL, Reinstall Barrier

Items Not Illustrated

195728GS CURRENT TRANSFORMER

* - Items without part numbers are common fasteners and

are available at local hardware stores.

Page 19

17

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC TRANSFER SWITCH OWNER WARRANTY POLICY

LIMITED WARRANTY

Briggs & Stratton Power Products Group, LLC will repair or replace, free of charge, any part(s) of the equipment that is defective in material or

workmanship or both. Transportation charges on product submitted for repair or replacement under this warranty must be borne by purchaser. This

warranty is effective for the time periods and subject to the conditions stated below. For warranty service, find the nearest Authorized Service Dealer in

our dealer locator map at BRIGGSandSTRATTON.COM.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, ARE LIMITED TO ONE YEAR FROM PURCHASE, OR TO THE EXTENT PERMITTED BY LAW. ANY AND ALL IMPLIED WARRANTIES ARE

EXCLUDED. LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES ARE EXCLUDED TO THE EXTENT EXCLUSION IS PERMITTED BY LAW. Some

states or countries do not allow limitations on how long an implied warranty lasts, and some states or countries do not allow the exclusion or limitation

of incidental or consequential damages, so the above limitation and exclusion may not apply to you. This warranty gives you specific legal rights and

you may also have other rights which vary from state to state or country to country.

3 years

None

Consumer Use

Commercial Use

The warranty period begins on the date of purchase by the first retail consumer or commercial end user, and continues for the period of time stated in the

table above. “Consumer use" means personal residential household use by a retail consumer. “Commercial use" means all other uses, including use for

commercial, income producing or rental purposes. Once equipment has experienced commercial use, it shall thereafter be considered as commercial use for

purposes of this warranty. Equipment used for prime power in place of utility are not applicable to this warranty.

NO WARRANTY REGISTRATION IS NECESSARY TO OBTAIN WARRANTY ON BRIGGS & STRATTON PRODUCTS. SAVE YOUR PROOF OF PURCHASE

RECEIPT. IF YOU DO NOT PROVIDE PROOF OF THE INITIAL PURCHASE DATE AT THE TIME WARRANTY SERVICE IS REQUESTED, THE MANUFACTURING

DATE OF THE PRODUCT WILL BE USED TO DETERMINE THE WARRANTY PERIOD.

ABOUT YOUR WARRANTY

We welcome warranty repair and apologize to you for being inconvenienced. Any Authorized Service Dealer may perform warranty repairs. Most warranty

repairs are handled routinely, but sometimes requests for warranty service may not be appropriate. For example, warranty service would not apply if

equipment damage occurred because of misuse, lack of routine maintenance, shipping, handling, warehousing or improper installation. Similarly, the

warranty is void if the manufacturing date or the serial number on the equipment has been removed or the equipment has been altered or modified. During

the warranty period, the Authorized Service Dealer, at its option, will repair or replace any part that, upon examination, is found to be defective under normal

use and service. This warranty will not cover the following repairs and equipment:

• Normal Wear: Outdoor Power Equipment, like all mechanical devices, needs periodic parts and service to perform well. This warranty does not cover

repair when normal use has exhausted the life of a part or the equipment.

• Installation and Maintenance: This warranty does not apply to equipment or parts that have been subjected to improper or unauthorized installation or

alteration and modification, misuse, negligence, accident, overloading, improper maintenance, repair or storage so as, in our judgment, to adversely

affect its performance and reliability. This warranty also does not cover normal maintenance such as adjustments, cleaning and fuse replacement.

• Other Exclusions: This warranty excludes wear items or damage or malfunctions resulting from accidents, abuse, modifications, alterations, or

improper servicing. Accessory parts are excluded from the product warranty. This warranty excludes failures due to acts of God and other force

majeure events beyond the manufacturers control. Also excluded is used, reconditioned, and demonstration equipment.

198180E, Rev. C, 12/14/2006

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC

JEFFERSON, WI, USA

Effective November 1, 2005 replaces all undated Warranties and all Warranties dated before November 1, 2005

WARRANTY PERIOD

Page 20

Reserved

Page 21

MMaannuuaall ddee IInnssttaallaacciióónn

yy ddeell OOppeerraarriioo

Preguntas? La ayuda es justa

un momento lejos!

Llamada: Línea Directa de

Interruptor de Transferencia

1-800-743-4115 M-F 8-5 CT

Web: BRIGGSandSTRATTON.COM

100 AMP/200 AMP

Automatic Transfer Switch

con AC Power Control Module™

Page 22

Gracias por comprar este conectador automático Briggs & Stratton Power Products. Este producto SÓLO es adecuado para

utilización con grupos electrógenos domésticos de reserva de Briggs & Stratton. Este producto es un sistema doméstico de

reserva opcional y proporciona una fuente alternativa de energía eléctrica con capacidad para alimentar cargas tales como

calderas de gas y sistemas de refrigeración y de telecomunicaciones, que cuando dejan de funcionar a causa de una

interrupción de la alimentación eléctrica de la red pueden producir incomodidades o problemas. Este producto no pertenece a

la categoría de reserva de emergencia según lo definido por la norma NFPA 70 (NEC).

Este manual contiene información de seguridad sobre los riesgos asociados con los conectadores y sobre cómo evitarlos.

Briggs & Stratton ha realizado el máximo esfuerzo para que la instalación resulte segura, sencilla y económica. Cada

instalación es única, lo que hace imposible conocer y recomendar todos los procedimientos y métodos posibles para

efectuarla. No conocemos todos los riesgos y/o resultados posibles de cada método o procedimiento. Guarde estas

instrucciones para futuras consultas.

Antes de utilizar el conectador, es necesario instalarlo. Consulte en la sección Instalación de este manual las instrucciones

o procedimientos de instalación. Los conectadores sólo deben ser instalados por electricistas cualificados. Las instalaciones

deben cumplir estrictamente la totalidad de la normativa vigente.

Dónde puede encontrarnos

Nunca tendrá que buscar mucho para poder obtener soporte y servicio técnico para su conectador Briggs & Stratton. Consulte

las páginas amarillas. Hay más de 30.000 distribuidores de servicio autorizados en todo el mundo que le ofrecerán un servicio

de calidad. También puede dirigirse al departamento de servicio al cliente de Briggs & Stratton llamando al (800) 743-4115 o

por Internet, en el sitio web BRIGGSandSTRATTON.COM.

Conectador Automático

Número de Modelo

Revisión

Número de Serie

Fecha de compra

Briggs & Stratton Power Products Group, LLC.

900 North Parkway

Jefferson, WI 53549

Copyright © 2006 Briggs & Stratton Power Products Group, LLC.

Reservados todos los derechos. Queda prohibida la reproducción o

transmisión total o parcial de este material, sea cual sea la forma y

el medio empleados para ello, sin el permiso previo y por escrito

de Briggs & Stratton Power Products Group, LLC.

Page 23

1

Español

Instrucciones importantes de seguridad . . . . . . . . . . . . . . . . . . . . . . . . . 2

Orientación para el Propietario . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Responsabilidades del Instalador . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Descripción del Equipo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Instalacion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Desempaque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Pautas de Montaje . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Interconexiones de Cableado de Energía . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Cableado de Control de Supervisión . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Configuración del Sistema . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Mandos. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Sistema Funcionamiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

El sistema estará entonces en el modo de funcionamiento automático. . . . 8

Mantenimiento. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Especificaciones. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Reparacion de Averias . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Garantía . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

TABLA DE CONTENIDO

Page 24

2 BRIGGSandSTRATTON.COM

Instrucciones importantes de

seguridad

Éste es el símbolo de alerta de seguridad. Sirve para

advertir al usuario de un posible riesgo para su integridad

física. Siga todos los mensajes de seguridad que figuren

después de este símbolo para evitar lesiones o incluso la

muerte.

El símbolo de alerta de seguridad ( ) es usado con una palabra

(PELIGRO, ADVERTENCIA, PRECAUCIÓN), un mensaje por escrito o

una ilustración, para alertarlo acerca de cualquier situación de

peligro que pueda existir. PELIGRO indica un riesgo el cual, si no se

evita, causará la muerte o una herida grave. ADVERTENCIA indica un

riesgo el cual, si no se evita, puede causar la muerte o una herida

grave. PRECAUCIÓN indica un riesgo, el cual, si no se evita, puede

causar heridas menores o moderadas. PRECAUCIÓN, cuando se usa

sin el símbolo de alerta, indica una situación que podría resultar en

el daño del equipo. Siga los mensajes de seguridad para evitar o

reducir los riesgos de heridas e inclusive la muerte.

El fabricante no puede prever todas las posibles

circunstancias que pueden implicar riesgos. Por lo tanto, las

advertencias que aparecen en este manual y las etiquetas y

calcomanías adheridas a la unidad no incluyen todas las

posibilidades. Si aplica un procedimiento, método de trabajo

o técnica de operación no recomendada específicamente por

el fabricante, debe estar seguro de que se trata de una

práctica segura para usted y para otras personas. También

debe asegurarse de que el procedimiento, método de trabajo

o técnica de operación que elija, no haga que el conmutador

de transferencia se torne inseguro.

Únicamente los electricistas capacitados pueden intentar

instalar este sistema. Dicha instalación debe cumplir

estrictamente con los códigos, las regulaciones y las normas

correspondientes.

ADVERTENCIA

• No toque los alambres pelados o receptáculos.

• No use un conmutador de transferencia con cables eléctricos

que estén malgastados, rotos, pelados o dañados de cualquier

forma.

• No maneje el cables eléctricos mientras esté parado en agua,

descalzo o cuando las manos y los pies estén mojados.

• Si fuera necesario realizar trabajos en cercanías de la unidad

mientras está en funcionamiento, párese sobre una superficie

seca y aislada para reducir los riesgos de una descarga.

• No permita que personas descalificadas o niños operen o sirvan

al conmutador de transferencia.

• En caso de que se produzca un accidente causado por una

descarga eléctrica, cierre inmediatamente la fuente de energía

eléctrica y contacta administración local. Evite el contacto directo

con la víctima.

Si no hace tierra apropiadamente con un conmutador de

transferencia, puede hacer que ocurra un

electrocutamiento.

ADVERTENCIA

• Use el conmutador de transferencia solamente con la finalidad

para el cual fue diseñado.

• Si usted tiene alguna pregunta acerca de las finalidades de uso

del generador, pregúntele a su concesionario o contacte a Briggs

and Stratton Power Products.

• No exponga al conmutador de transferencia a una humedad

excesiva, polvo, suciedad o vapores corrosivos.

• Permanezca siempre alerta cuando trabaje con este equipo.

Nunca trabaje con este equipo si se siente cansado física o

mentalmente.

• Si se calientan excesivamente los dispositivos conectados,

apáguelos y abra sus interruptores o quite sus fusibles.

El tratamiento inadecuado del conmutador de transferencia

puede dañarlo y acortar su vida productiva.

PRECAUCIÓN

• Si no se respeta esta indicación pueden producirse lesiones,

daños y/o fallos de funcionamiento del equipo.

Los cables de baja tensión no se pueden instalar en el

mismo conducto que los cables de suministro de

energía.

ADVERTENCIA

• A pesar del diseño seguro del conmutador de transferencia, si se

opera este equipo en forma imprudente, si no se cumple con el

mantenimiento o si se actúa con descuido, se pueden producir

lesiones o la muerte.

El conectador contiene alta tensión que puede provocar

lesiones o la muerte.

ADVERTENCIA

Conserve estas instrucciones

Page 25

3

Español

Introduccion

Su conectador BSPP se suministra con este "Manual de

Instalación y del Operario" combinado. Se trata de un

documento importante que debe ser conservado por el

propietario después de haber terminado la instalación.

Se han tomado todos los recaudos posibles para asegurar

que la información incluida en este manual sea correcta y

esté actualizada. Sin embargo, los fabricantes se reservan el

derecho de cambiar, alterar o mejorar el sistema de cualquier

otra manera y en cualquier momento, sin previo aviso.

Para el Propietario Doméstico

Para que pueda tomar decisiones fundamentadas y lograr

una comunicación efectiva con el o los contratistas de

instalación,

Lea y comprenda la sección de este manual denominada

Orientación para el Propietario ANTES de contratar o

iniciar la instalación de su conmutador de transferencia.

Para coordinar y organizar una instalación adecuada,

consulte al comercio en el cual adquirió su conmutador de

transferencia Briggs & Stratton Power Products, a su agente

de ventas o a la compañía proveedora de electricidad.

La garantía del conmutador de transferencia se ANULA si

la instalación del sistema no está a cargo de

profesionales especializados en electricidad certificados.

Para el Agente de Ventas/Contratista que Realiza

la instalación

Consulte los aspectos de la instalación con un inspector.

Si necesita más información en conectador, llame al

1-800-743-4115, entre las 8:00 AM y las 5:00 PM hora

del centro.

Orientación para el Propietario

Las ilustraciones se aplican a circunstancias típicas y están

destinadas a que usted se familiarice con las opciones de

instalación disponibles con su conmutador de transferencia.

Los códigos locales, la apariencia y las distancias son los

factores fundamentales a tener en cuenta cuando se realiza

la negociación con el profesional que tendrá a su cargo la

instalación. Recuerde que a medida que la distancia del

servicio de electricidad existente aumenta, se debe tener en

cuenta una compensación igual en los materiales de

cableado. Esto es necesario para cumplir con los códigos

locales y solucionar caídas en la tensión eléctrica.

Los factores antes mencionados tendrán un efecto directo

sobre el precio general de la instalación del conmutador

de transferencia.

NOTA: El instalador debe verificar los códigos locales Y

obtener los permisos correspondientes antes de instalar el

sistema.

• Lea y cumpla las instrucciones incluidas en el manual.

• Siga un programa regular para cuidar y utilizar el

conmutador de transferencia, según se especifica en el

manual.

Responsabilidades del Instalador

• Lea y observe las reglas de seguridad que se

encuentran en el manual.

• Lea y siga las instrucciones que se encuentran en este

manual.

• Consulte la normativa vigente en caso de dudas sobre

la instalación.

• Asegúrese de que las cargas seleccionadas no

sobrecargan el generador.

Si necesita más información sobre el conectador, llame al

(800) 743-743-4115, de 08:00 a 17:00 CT.

Descripción del Equipo

Estos conectadores pertenecen a una nueva generación

destinada a transferir toda la carga de instalaciones

residenciales normales cuando se utilizan con los contactos

de supervisión previstos. La carga se conecta a la red

pública (normal) o a la alimentación doméstica de reserva

(generador). El conectador monitoriza las tensiones de la red

pública y del generador y conecta automáticamente la carga

a la fuente de alimentación apropiada.

Los componentes principales del conectador son un utilidad

desconecta cortacircuitos bipolar (sólo modelos 071020 y

071021), un interruptor bipolar de 2 posiciones de contacto,

una tarjeta de circuito impreso del módulo de control,

terminales con fusibles de detección de tensión de la red

pública y cableado de interconexión. La tarjeta de control

también tiene dos entradas para transformadores de

corriente que detectan la corriente del generador.

El conectador es accionado por un solenoide alimentado

desde las entradas de la red pública o del generador y tiene

interruptores de enclavamiento mecánicos y eléctricos,

adecuados para eliminar la posibilidad de conectar la red

pública a la salida del generador. Sus valores nominales son

suficientes para conectar toda potencia de la red pública a la

residencia. Para la función de transferencia hay una palanca

de cancelación manual.

La tarjeta de circuito impreso del módulo de control tiene

circuitos activos que detectan las tensiones de la red pública

y del generador. Genera una señal para el arranque del

generador, el conectador, la retransferencia cuando se

restablece la tensión en la red pública y los períodos de

enfriamiento del generador. La tarjeta de control contiene

también luces rojas y verdes que indican las fuentes de

alimentación disponibles y dos contactos accionados por

relé que proporcionan el control de supervisión de cargas

críticas externas.

Page 26

4 BRIGGSandSTRATTON.COM

Instalacion

Desempaque

Inspección al Momento de la Entrega

Luego de retirar la caja, inspeccione cuidadosamente el los

componentes del conmutador de transferencia de energía

automático para detectar cualquier daño que pudiera haber

ocurrido durante el traslado.

IMPORTANTE: Si en el momento de la entrega se detecta

alguna pérdida o daño, solicite a la persona o personas

encargadas de la entrega que dejen debida constancia en la

nota de entrega y que firmen debajo de la nota del

consignador donde se informa acerca de la pérdida o daño.

Si la pérdida o el daño se detecta después de la entrega,

separe los materiales dañados y póngase en contacto con el

transportista para llevar a cabo los procedimientos de

reclamo. Las piezas perdidas o dañadas no están

garantizadas.

Contenido de la Caja

• Conmutador de transferencia de energía automático

• Dos transformadores de corriente

• Manual de instalación y operario

Pautas de Montaje

El conectador automático está encerrado en una caja tipo

3R NEMA, que es adecuada para uso en interiores y a la

intemperie. Las directrices para el montaje de conectador

automático incluyen:

• Instale el conmutador sobre una estructura de soporte

firme y resistente.

• El interruptor se debe instalar con conexiones mínimas

de conduit de fo de hardware de NEMA 3R.

• Para evitar distorsiones en el conmutador, nivele la

unidad si es necesario. Puede hacerlo colocando

arandelas entre el compartimiento del conmutador y la

superficie de montaje.

• Nunca instale el conmutador en un lugar en el cual

pueda producirse el goteo de alguna sustancia

corrosiva en el compartimiento.

• Proteja permanentemente al conmutador contra

humedad excesiva, polvo, suciedad, pelusas, arenilla

para construcción y vapores corrosivos.

La Figura 1 ilustra la instalación habitual del conectador

automático, modelos 071018 y 071019. En la Figura 2, se

muestra una instalación alternativa del conectador

automático. Lo mejor es montarlo cerca del contador de la

compañía eléctrica en el interior o en el exterior. Antes de

iniciar el proceso de instalación del sistema, analice los

cambios y sugerencias de diagramación con el propietario de

la unidad.

— — — — — — Cableado de control

Contactor

Conmutador

de

Transferencia

Seccionador de servicio

Generador

Acondicionador

de aire

Contador de

vatios hora

Seccionador

Circuitos derivados

Panel del

Disyuntor

Principal

Calentador

de agua

Figura 1 — Montaje Habitual de un Conectador para los Modelos 071018 y 071019

Page 27

5

Español

Contactor

Figura 2 — Montaje de un Conectador Alternativo

Panel del

Disyuntor

Principal

Conmutador de

Transferencia

Calentador de

agua

Seccionador

Generador

Contador de

vatios hora

Circuitos derivados

— — — — — — Cableado de control

Centro de

carga de

emergencia

Acondicionador

de aire

Figura 3 — Schéma d'Installation Typique du Commutateur de Transfert Modele 071018 o 071019

Principal

Panel de Distribución Principal

Barra conductora

Ground (tierra)

Barra

conductora

NEUTRAL

(neutro)

Al Generador

Terminales NEUTRAL

(neutro)

A la Red Pública

Contactos de supervisión

Conexión de la Carga

Orejetas de conexión a

tierra (GND)

Conexión al generador

Conexión de la

compañía

proveedora de

electricidad

Page 28

6 BRIGGSandSTRATTON.COM

CT2

CT1

Figura 4 — Schéma d'Installation Typique du Commutateur de Transfert Modele 071020 o 071021

Principal

Panel de Distribución Principal

Barra conductora

Ground (tierra)

Barra

conductora

NEUTRAL

(neutro)

Al Generador

Terminales

NEUTRAL

(neutro)

A la Red Pública

Contactos de supervisión

Conexión de la Carga

Orejetas de

conexión a

tierra (GND)

Conexión al

generador

Conexión de la

compañía

proveedora de

electricidad

Interconexiones de Cableado de Energía

Todo el cableado debe tener el tamaño adecuado y debe

estar correctamente soportado. También debe estar

protegido mediante un conducto.

Realice las conexiones siguientes entre el conectador, el

panel principal de distribución, la red pública y el generador

(Figura 3 o 4).

1. Asegúrese de que la tensión de la red pública no esté

aplicada. Conecte los conductores de alimentación a los

terminales del conectador, con la marca “UTILITY

CONNECTION” (conexión a la red pública).

2. Conecte el neutro de la red pública al terminal del

conectador con la marca "NEUTRAL" (neutro).

3. Conecte los terminales de alimentación de la red

pública a los terminales del conectador, con la marca

"LOAD CONNECTION" (conexión de la carga).

4. Conecte el neutro del panel principal de distribución al

terminal del conectador con la marca "NEUTRAL"

(neutro).

5. Conecte el conductor de conexión a tierra del panel del

disyuntor principal al terminal “GND” (tierra) del

conectador.

NOTA: Compruebe que el conductor del electrodo de

conexión a tierra está conectado conforme a la normativa

vigente.

6. Conecte los conductores de alimentación del panel de

control del generador a los terminales del conectador

con la marca “GENERATOR CONNECTION” (conexión

del generador). Los conductores se deben pasar por el

orificio del transformador de corriente antes de realizar

la conexión.

• Si no se respeta esta indicación pueden producirse lesiones,

daños y/o fallos de funcionamiento del equipo.

Los cables de baja tensión no se pueden instalar

en el mismo conducto que los cables de

suministro de energía.

ADVERTENCIA

Page 29

7

Español

7. Conecte los cables secundarios del transformador de

corriente a los terminales “CT1” y “CT2” del módulo de

control.

8. Conecte el conductor neutro del panel de control del

generador al terminal del conectador con la marca

“NEUTRAL” (neutro).

9. Conecte el conductor de tierra del panel de control al

terminal del conectador con la marca “GND” (tierra).

NOTA: Compruebe que el conductor de conexión a tierra del

equipo generador está conectado conforme a la normativa

vigente.

10. Conzecte los terminales “UTILITY 240 VAC” (240 VCA

de servicio) del generador a los terminales “UTILITY

240 VAC” del conectador. Utilice cables 14 AWG, como

mínimo.

11. Apriete de todas las conexiones de los cables y

elementos de fijación al par adecuado. Consulte los

valores de par correctos en el interior de la caja del

conectador.

Cableado de Control de Supervisión

1. La regleta de terminales del módulo de control del

conectador dispone de cuatro conexiones para uso del

cliente. Hay dos conjuntos de contactos "Normalmente

Cerrados" que se activarán cuando sea necesario

utilizar la electricidad del generador. Se pueden utilizar

para el control de supervisión de grandes cargas

conectadas al generador. Ejemplo: acondicionador de

aire, calentador de agua, etc. Las cargas podrán

funcionar siempre que la potencia del generador sea

suficiente.

NOTA: Hay dos conductos para cables que permiten

mantener separadas las cargas de supervisión.

2. Los terminales “A-A” del módulo de control se utilizan

para controlar el contactor del acondicionador de aire.

Los contactos se conectan en serie con el circuito de

control del contactor del aire acondicionado (Figura 5).

3. Los terminales “B-B” del módulo de control permiten

que el instalador conecte un contactor para controlar

una carga importante. Ejemplo: calentador eléctricos de

agua. Los contactos se conectan en serie con el circuito

de control del contactor (Figura 6).

4. Apriete de todas las conexiones de los cables y

elementos de fijación al par adecuado. Consulte los

valores de par correctos en el interior de la caja del

conectador.

Configuración del Sistema

Deberá llevar a cabo las siguientes operaciones en el módulo

de control antes de poner el sistema en funcionamiento:

• Si el generador está instalado en una zona

normalmente expuesta a temperaturas inferiores a 4 °C

(40 °F), seleccione un tiempo de calentamiento de

50 segundos moviendo el puente instalado en JP2

(Figura 7) de la posición ‘20’ a la posición ‘50’.

• Ponga el conmutador de 2 posiciones (Figura 7) en la

posición adecuada para su sistema, ‘NG’ o ‘LP’.

• Ponga el conmutador de 3 posiciones (Figura 7) de

forma que coincida con el valor nominal de kW del

generador instalado.

Figura 7 — Módulo de control

JP2

CT1 & CT2

Contactos de

supervisión

Conmutador de

3 posiciones

Conmutador de

2 posiciones

Figura 6— Terminales “B-B”

B

B

Contactor

Neutro

120 V CA

Figura 5 — Terminales “A-A”

A

A

Alimentación

Contactor del

acondicionador de aire

Page 30

8 BRIGGSandSTRATTON.COM

Mandos

Aparte de la palanca de cancelación manual, el conectador no

tiene ningún otro mando, ya que es automático. La

cancelación manual es para uso exclusivo de profesionales

cualificados.

Sistema Funcionamiento

Para seleccionar el funcionamiento automático del

conectador, haga lo siguiente:

1A. En los modelos 071018 y 071019, ponga el seccionador

que envía tensión de la red pública al conectador en la

posición “On” (cerrado). El seccionador puede estar

situado en el panel del disyuntor principal.

1B. En los modelos 071020 y 071021, ponga el interruptor

de la red pública del conectador en la posición “On”

(cerrado).

2.. Ponga el disyuntor principal del generador en la

posición "On" (conectado).

3. Instale el fusible de 15 A en el panel de control del

generador.

4A. Si el generador se equipa con un conmutador ON/OFF

del sistema, conjunto el conmutador en la posición

"On".

4B. Si el generador se equipa con un interruptor

AUTO/OFF/MANUAL

(automático/desconectado/manual), conjunto el

interruptor en la posición "AUTO".

El sistema estará entonces en el modo de

funcionamiento automático.

Cuando el generador suministra energía al conectador, el

módulo de control supervisa permanentemente la potencia

del generador. Si se intenta activar el acondicionador de aire

y de que la potencia disponible del generador es suficiente, el

controlador cierra los contactos “A-A” de conexión al

contactor del acondicionador de aire. Los contactos “B-B” se

abren antes del cierre de los contactos “A-A”. Si las cargas

son excesivas para el generador, los contactos A-A y/o B-B

se abren. Cuando no es necesario utilizar el aire

acondicionado, el contacto A-A se abre. Si la potencia

disponible es suficiente, el contacto B-B se cierra.

Prueba del conectador automático

Ponga el seccionador de servicio que alimenta el contactor

del conectador en la posición “Off” (abierto). Se realizará la

secuencia automática correspondiente. Para volver a la

alimentación desde la red pública, ponga el seccionador de

servicio en la posición "On" (conectado).

Secuencia Automática

Fallo de la Red Pública

El sensor de tensión de la red pública detecta cuándo esta

tensión está por debajo del 70% de la nominal. Tras un

retardo de 6 segundos, se inicia la secuencia de arranque del

motor.

Calentamiento del Motor

Retardo de tiempo para permitir el calentamiento del motor

antes de la transferencia fijado en 20 segundos o 50

segundos si se ha retirado el puente de la tarjeta de control.

Transferencia

La transferencia de la alimentación de la red pública a la del

generador se produce cuando la tensión supera los niveles

especificados. El tiempo mínimo de funcionamiento del

motor después de la transferencia es de 5 minutos.

Recuperación de la Red Pública

El nivel de recuperación de la tensión es el 80% de la tensión

nominal.

Retransferencia

La retransferencia de la alimentación del generador a la de la

red pública se produce aproximadamente 10 segundos

después de que la tensión de la red pública supera el nivel de

recuperación y de que transcurre el tiempo mínimo de

funcionamiento.

Enfriamiento del Motor

El motor funcionará durante 60 segundos después de

producirse la retransferencia.

Si Necesita Llamar a Fábrica

Antes de ponerse en contacto con Briggs and Stratton Power

Products en relación con el servicio o reparación de este

conectador, tome nota del número de modelo y del número

de serie que figuran en la etiqueta adhesiva de datos de la

unidad situada en el interior de la caja.

A contacto Briggs and Stratton Power Products, llame al

(800) 743-4115, entre las 8:00 AM y las 5:00 PM hora del

centro.

Page 31

9

Español

Mantenimiento

En condiciones normales de uso, el conectador no requiere

mantenimiento. No obstante, se recomienda examinar el

conectador y realizar comprobaciones de forma periódica.

Principalmente, el mantenimiento consiste en la limpieza del

conectador.

Lleve a cabo un examen visual al menos una vez al mes. La

vía de acceso al conectador debe permanecer libre de

obstáculos. Deje un espacio mínimo de 92 cm (3 pies)

alrededor del conectador. Compruebe la presencia de polvo

acumulado, humedad o corrosión sobre la caja o a su

alrededor, piezas flojas, grietas o pérdida de color del

aislamiento y componentes dañados o descoloridos.

Ponga en funcionamiento el conectador al menos una vez

cada tres meses siguiendo las instrucciones de la sección

“Prueba del conectador automático”, a menos que el sistema

generador doméstico se haya activado automáticamente

como resultado de un corte de suministro eléctrico. Deje

funcionar el generador durante un mínimo de 30 minutos.

Póngase en contacto con un electricista cualificado para

examinar y limpiar el interior del conectador al menos una

vez al año.

Especificaciones

UL® 1008 Listó Conectador

Modelo 071018

Carga máxima/circuito

desde el centro de carga . . . . . . . . . . . . . . . . . . . . . .100 A

Tensión nominal c.a. . . . . . . . . . . . . . . . . . . . . . . . . . .250 V

Polos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Frecuencia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50/60 Hz

Valor nominal de la corriente

conexión a tierra . . .22,000 Amperios Eficaces, Simétrica

Valor nominal de los

contactos de supervisión A-A . . . . . . . . . . . . . . 24 V CA

contactos de supervisión B-B . . . 1A, 125 V CA, régimen

de piloto

Peso . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 lbs.

Modelo 071019

Carga máxima/circuito

desde el centro de carga . . . . . . . . . . . . . . . . . . . . . .200 A

Tensión nominal c.a. . . . . . . . . . . . . . . . . . . . . . . . . . .250 V

Polos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Frecuencia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50/60 Hz

Valor nominal de la corriente

conexión a tierra . . .25,000 Amperios Eficaces, Simétrica

Valor nominal de los

contactos de supervisión A-A . . . . . . . . . . . . . . 24 V CA

contactos de supervisión B-B . . . 1A, 125 V CA, régimen

de piloto

Peso . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34 lbs.

Modelo 071020

Carga máxima/circuito:

desde el centro de carga . . . . . . . . . . . . . . . . . . . . . .100 A

Tensión nominal c.a. . . . . . . . . . . . . . . . . . . . . . . . . . .250 V

Polos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Frecuencia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50/60 Hz

Valor nominal de la corriente

conexión a tierra . . .22,000 Amperios Eficaces, Simétrica

Valor nominal de los

contactos de supervisión A-A . . . . . . . . . . . . . . 24 V CA

contactos de supervisión B-B . . . 1A, 125 V CA, régimen

de piloto

Peso . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32 lbs.

Modelo 071021

Carga máxima/circuito:

desde el centro de carga . . . . . . . . . . . . . . . . . . . . . .200 A

Tensión nominal c.a. . . . . . . . . . . . . . . . . . . . . . . . . . .250 V

Polos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Frecuencia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50/60 Hz

Valor nominal de la corriente

conexión a tierra . . .25,000 Amperios Eficaces, Simétrica

Valor nominal de los

contactos de supervisión A-A . . . . . . . . . . . . . . 24 V CA

contactos de supervisión B-B . . . 1A, 125 V CA, régimen

de piloto

Peso . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44 lbs.

Page 32

10 BRIGGSandSTRATTON.COM

Problemo Causa Accion

El conectador automático no transfiere

la conexión al generador

1. El disyuntor del generador está

abierto.

2. La tensión del generador no es

aceptable.

1. Rearme el disyuntor del generador.

2. Consulte el manual del generador.

El conectador automático no transfiere

la conexión a la red pública

1. El disyuntor de desconexión de

servicio está abierto.

2. La tensión de la red pública no

es aceptable.

1. Rearme el disyuntor de desconexión de

servicio.

2. Espere a que se restablezca la normalidad

en la tensión de la red pública.

El generador sigue funcionando

después de que el conectador

transfiera la conexión a la red pública

El período de enfriamiento del

motor.

El motor debería detenerse después de

1 minutos.

Las cargas supervisadas

(acondicionador de aire, etc.) no

funcionan cuando el generador

suministra energía

1. Los contactos A-A o B-B no

funcionan correctamente.

2. La carga del generador es

excesiva.

3. El transformador de corriente

no conectado.

4. El transformador de corriente

está averiado.

1. Compruebe si los contactos A-A y B-B

funcionan correctamente y verifique el

cableado de control de la carga externa.

2. Reduzca la carga del generador.

3. Conecte los conectores CT a la tarjeta de

control.

4. Póngase en contacto con su centro de

servicio técnico de Briggs & Stratton

Power Products.

El generador sigue funcionando

cuando se restablece la alimentación

eléctrica de la red

1. No ha transcurrido el tiempo de

funcionamiento mínimo del

motor.

2. El o los fusibles del conectador

son defectuosos.

1. Espere cinco minutos a que el conectador

vuelva a utilizar la tensión de la red

pública.

2. Compruebe los fusibles y sustitúyalos si

fuera necesario.

Reparacion de AveriasGarantía

Page 33

11

Español

POLÍTICA DE GARANTÍA PARA EL PROPIETARIO DEL CONECTADOR DE BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC

GARANTÍA LIMITADA

Briggs & Stratton Power Products Group, LLC reparará o sustituirá sin cargo alguno cualquier componente del equipo que presente defectos de

materiales y/o mano de obra. Los gastos de transporte de las producto enviadas para reparar o sustituir conforme a los términos de esta garantía

correrán a cargo del comprador. El periodo de vigencia y las condiciones de esta garantía son los que se estipulan a continuación. Para obtener servicio

en garantía, localice el distribuidor de servicio autorizado más próximo en nuestro mapa de distribuidores, en www.BRIGGSandSTRATTON.COM.

NO EXISTE NINGUNA OTRA GARANTÍA EXPLÍCITA. LAS GARANTÍAS IMPLÍCITAS, INCLUIDAS LAS DE COMERCIABILIDAD O IDONEIDAD PARA UN FIN

CONCRETO, SE LIMITAN A UN AÑO DESDE LA FECHA DE COMPRA O AL LÍMITE DE TIEMPO PERMITIDO POR LA LEY. QUEDAN EXCLUIDAS TODAS

LAS GARANTÍAS IMPLÍCITAS QUEDA EXCLUIDA LA RESPONSABILIDAD POR DAÑOS SECUNDARIOS Y DERIVADOS HASTA EL LÍMITE PERMITIDO

POR LA LEY. Algunos países o estados no permiten limitar la duración de una garantía implícita ni excluir o limitar los daños secundarios y derivados.

Por tanto, es posible que las limitaciones y exclusiones mencionadas no sean aplicables en su caso. Esta garantía le otorga determinados derechos

legales y es posible que tenga otros derechos que pueden variar de un país o estado a otro.

El período de garantía comienza en la fecha de compra del primer consumidor o usuario comercial final y se prolonga durante el tiempo especificado en la

siguiente tabla. "Uso del consumidor" significa uso doméstico personal por parte de un consumidor final. "Uso comercial" significa cualquier otro uso,

incluidos los usos con fines comerciales, de generación de ingresos o alquiler. Una vez que el equipo se haya usado con fines comerciales, se considerará

como equipo de uso comercial a efectos de esta garantía. Los equipos utilizados para suministrar energía en sustitución de un servicio público no pueden

acogerse a esta garantía.

NO ES NECESARIO REGISTRAR LA GARANTÍA PARA OBTENER SERVICIO DE BRIGGS & STRATTON PRODUCTS. GUARDE SU RECIBO DE COMPRA. SI NO

APORTA LA PRUEBA DE LA FECHA DE COMPRA INICIAL, SE UTILIZARÁ LA FECHA DE FABRICACIÓN DEL PRODUCTO PARA DETERMINAR EL PERÍODO DE

GARANTÍA.

ACERCA DE LA EQUIPO GARANTÍA

Esperamos que disfrute de nuestra garantía y le pedimos disculpas por las molestias causadas. Cualquier distribuidor de servicio autorizado puede llevar a

cabo reparaciones en garantía. La mayoría de las reparaciones en garantía se gestionan normalmente, pero algunas veces la solicitud de servicio en garantía

puede no ser procedente. Por ejemplo, la garantía no será válida si el equipo presenta daños debidos al mal uso, la falta de mantenimiento, el transporte, la

manipulación, el almacenamiento o la instalación inadecuados. De manera similar, la garantía quedará anulada si se ha borrado la fecha de fabricación o el