Page 1

Home Generator Systems

Installation, Start-Up and Operator’s Manual

7000 Watt

Home Generator System

Manual No. 206484GS Rev. - (04/28/2008)

Page 2

Thank you for purchasing this quality-built Briggs & Stratton home generator. We’re pleased that you’ve placed your

confidence in the Briggs & Stratton brand. When operated and maintained according to the instructions in the operator’s

manual, your Briggs & Stratton home generator will provide many years of dependable service.

This manual contains safety information to make you aware of the hazards and risks associated with home generator systems

and how to avoid them. This home generator system is designed and intended only for use as an optional home standby

system that provides an alternate source of electric power and to serve loads such as heating, refrigeration systems, and

communication systems that, when stopped during any power outage, could cause discomfort or inconvenience. This product

is not intended for any other purpose and does not qualify for emergency standby as defined by NFPA 70 (NEC).

This home generator requires professional installation before use. This installation manual provides full information. Follow

the instructions completely. Save these instructions for future reference.

Where to Find Us

You never have to look far to find Briggs & Stratton support and service for your generator. Consult your Yellow Pages.

There are thousands of Briggs & Stratton authorized service dealers worldwide who provide quality service. You can

also contact Briggs & Stratton Customer Service by phone at (800) 743-4115, or use the Service Center Locator at

BRIGGSandSTRATTON.COM, which provides a list of Briggs & Stratton Authorized Dealers.

Date of Purchase

Generator

Model Number

Model Revision

Serial Number

Engine

Model Number

Briggs & Stratton Power Products Group, LLC

900 North Parkway

Jefferson, WI 53549

Copyright © 2008 Briggs & Stratton Power Products Group, LLC.

All rights reserved. No part of this material may be reproduced or

transmitted in any form by any means without the express written

permission of Briggs & Stratton Power Products Group, LLC.

2 BRIGGSandSTRATTON.COM

Page 3

Table of Contents

Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Hazard Symbols and Meanings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Owner Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Fuel Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Lifting the Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Home Generator Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Essential Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Fuel and Electrical Inlet Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Access Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

The Gaseous Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

System Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Final Installation Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Initial Start-up (No Load). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Features and Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Home Generator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

System Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Automatic Operation Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Automatic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Servicing the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Fault Detection System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Generator Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

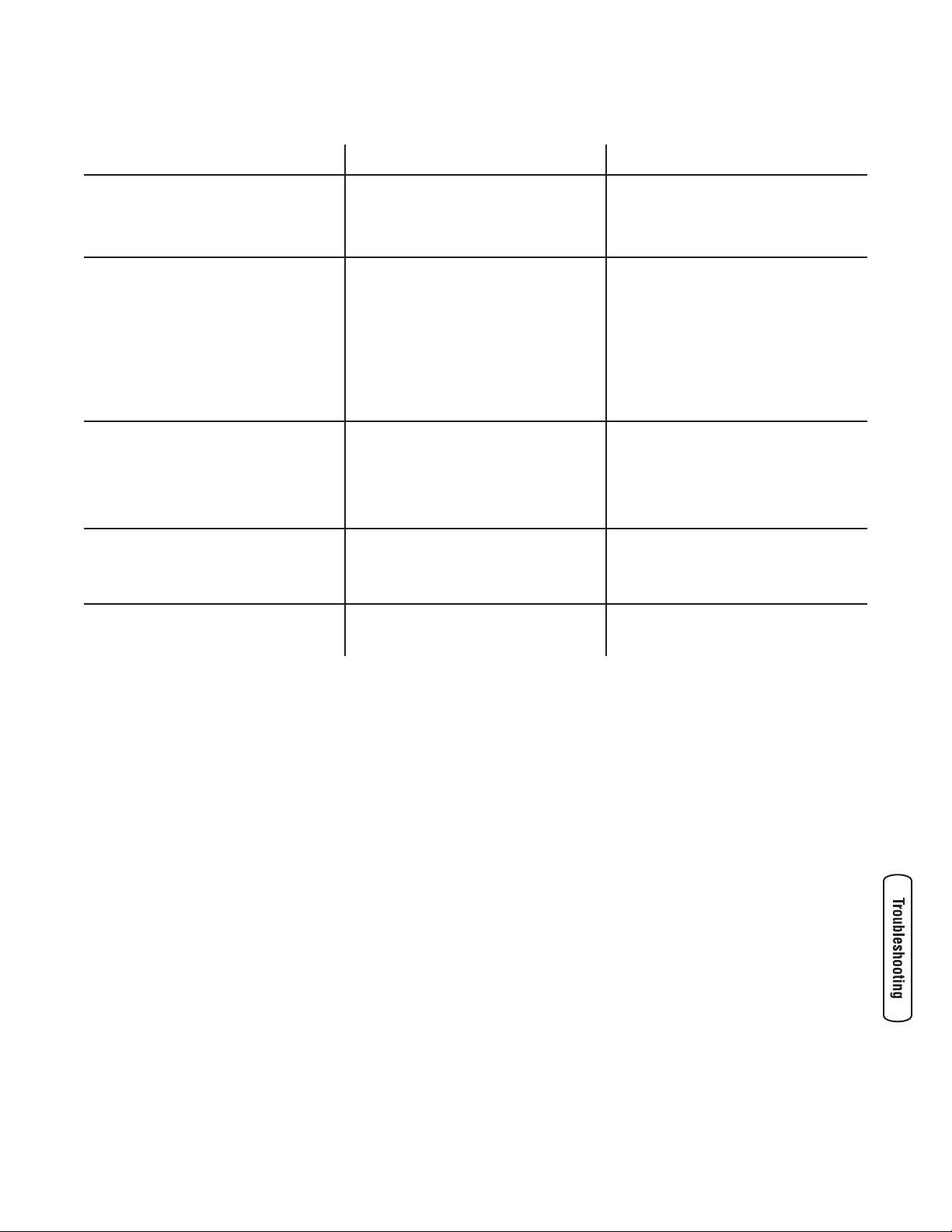

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

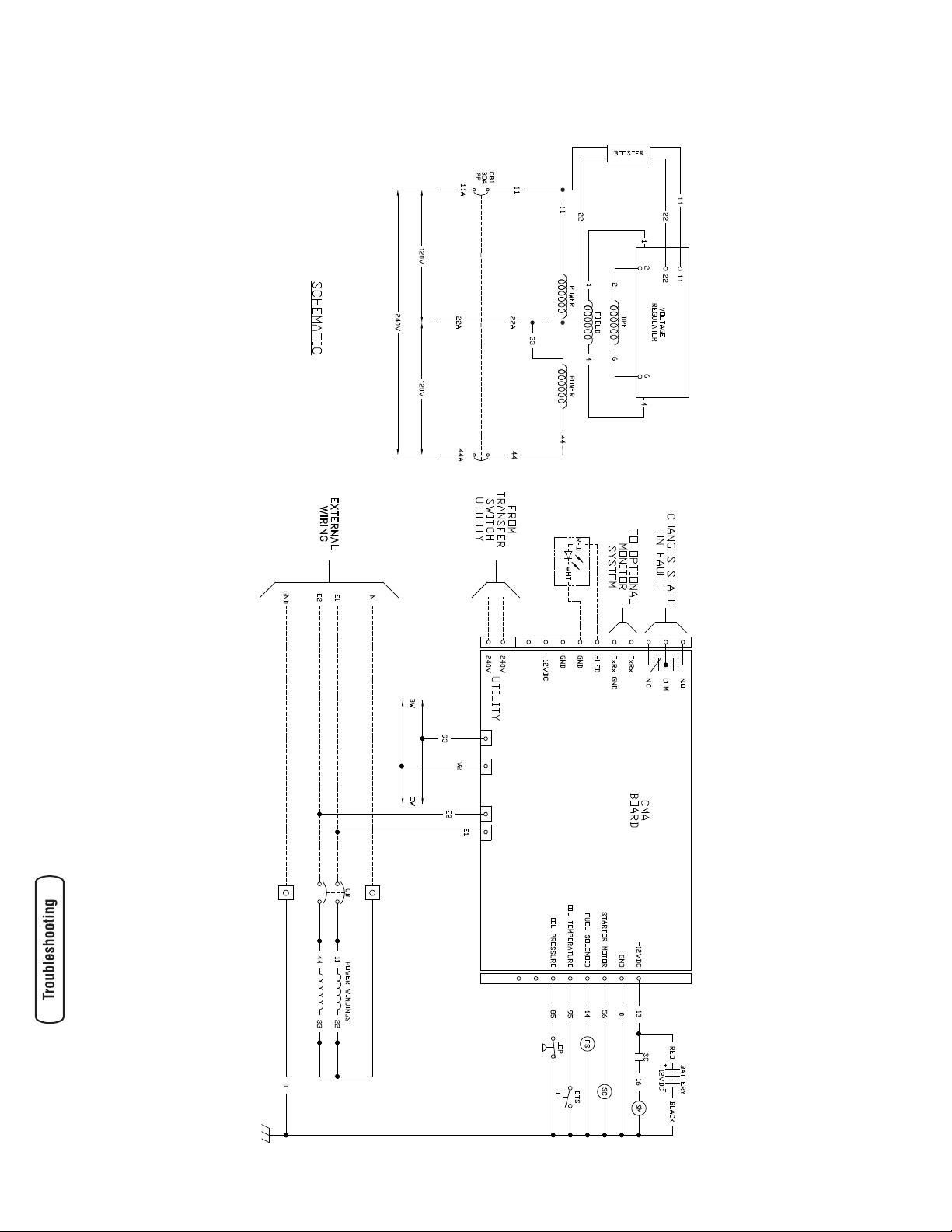

Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Product Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Common Service Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

FrançaisEspañol

3

Page 4

Save These Instructions

Safety Rules

The safety alert symbol ( ) is used with a signal word

(DANGER, CAUTION, WARNING), a pictorial and/or a safety

message to alert you to hazards. DANGER indicates a hazard

which, if not avoided, will result in death or serious injury.

WARNING indicates a hazard which, if not avoided, could

result in death or serious injury. CAUTION indicates a hazard

which, if not avoided, might result in minor or moderate

injury. NOTICE indicates a situation that could result in

equipment damage. Follow safety messages to avoid or

reduce the risk of injury or death.

The manufacturer cannot possibly anticipate every possible

circumstance that might involve a hazard. The warnings in

this manual, and the tags and decals affixed to the unit are,

therefore, not all-inclusive. If you use a procedure, work

method or operating technique that the manufacturer does

not specifically recommend, you must satisfy yourself that

it is safe for you and others. You must also make sure that

the procedure, work method or operating technique that you

choose does not render the generator system unsafe.

NOTE: Your generator is equipped with a spark arrester

muffler. The spark arrester must be maintained in effective

working order by the owner/operator. In the State of

California, a spark arrester is required by law (Section 4442

of the California Public Resources Code). Other states may

have similar laws. Federal laws apply on federal lands.

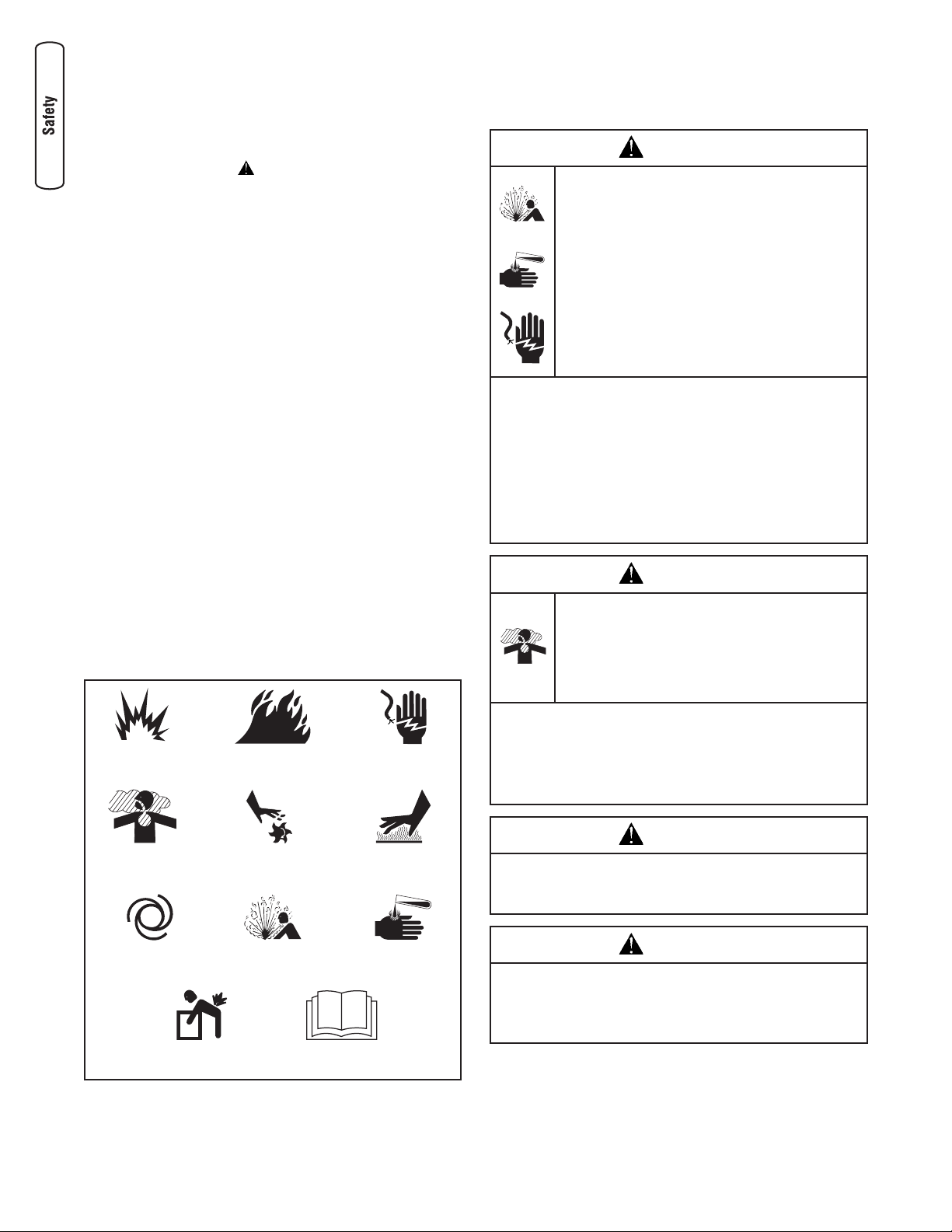

Hazard Symbols and Meanings

WARNING

Storage batteries give off explosive hydrogen

gas during recharging.

Slightest spark will ignite hydrogen and cause

explosion.

Battery electrolyte fluid contains acid and is

extremely caustic.

Contact with battery contents will cause severe

chemical burns.

A battery presents a risk of electrical shock and

high short circuit current.

•

DO NOT dispose of battery in a fire.

•

DO NOT allow any open flame, spark, heat, or lit cigarette

during and for several minutes after charging a battery.

•

DO NOT open or mutilate the battery.

•

Wear protective goggles, rubber apron, and rubber

gloves.

Remove watches, rings, or other metal objects.

•

Use tools with insulated handles.

•

WARNING

Running engine gives off carbon monoxide, an

odorless, colorless, poison gas.

Breathing carbon monoxide can cause

headache, fatigue, dizziness, vomiting,

confusion, seizures, nausea, fainting or death.

Explosion

Toxic Fumes

Lift Hazard

Fire

Rotating Parts

Read Manual

Electrical Shock

Hot Surface

Chemical BurnExplosive PressureAuto Start

•

Operate generator ONLY outdoors.

•

Install a battery operated carbon monoxide alarm near

the bedrooms.

•

Keep exhaust gas from entering a confined area through

windows, doors, ventilation intakes, or other openings.

WARNING

The engine exhaust from this product contains chemicals

known to the State of California to cause cancer, birth

defects, or other reproductive harm.

WARNING

Certain components in this product and related

accessories contain chemicals known to the State

of California to cause cancer, birth defects or other

reproductive harm. Wash hands after handling.

4 BRIGGSandSTRATTON.COM

Page 5

WARNING

WARNING

Generator produces hazardous voltage.

Failure to properly ground generator can result

in electrocution.

Failure to isolate generator from power utility

can result in death or injury to electric utility

workers due to backfeed of electrical energy.

•

When using generator for backup power, notify utility

company.

DO NOT touch bare wires or receptacles.

•

DO NOT use generator with electrical cords which are

•

worn, frayed, bare or otherwise damaged.

DO NOT handle generator or electrical cords while

•

standing in water, while barefoot, or while hands or feet

are wet.

If you must work around a unit while it is operating,

•

stand on an insulated dry surface to reduce shock

hazard.

DO NOT allow unqualified persons or children to operate

•

or service generator.

In case of an accident caused by electrical shock,

•

immediately shut down the source of electrical power

and contact the local authorities. Avoid direct contact

with the victim.

Despite the safe design of the home generator, operating

•

this equipment imprudently, neglecting its maintenance

or being careless can cause possible injury or death.

Remain alert at all times while working on this

•

equipment. Never work on the equipment when you are

physically or mentally fatigued.

Before performing any maintenance on the generator,

•

disconnect the battery cable indicated by a NEGATIVE,

NEG or (-) first. When finished, reconnect that cable last.

After your home generator is installed, the generator

•

may crank and start without warning any time there is a

power failure. To prevent possible injury, always set the

generator’s system switch to OFF, remove the service

disconnect from the disconnect box AND remove the

15 Amp fuse BEFORE working on the equipment.

Propane and Natural Gas are extremely

flammable and explosive.

Fire or explosion can cause severe burns or

death.

Install the fuel supply system according to applicable

•

fuel-gas codes.

Before placing the home generator into service, the fuel

•

system lines must be properly purged and leak tested.

After the generator is installed, you should inspect the

•

fuel system periodically.

NO leakage is permitted.

•

DO NOT operate engine if smell of fuel is present or other

•

explosive conditions exist.

DO NOT smoke around the generator. Wipe up any oil

•

spills immediately. Ensure that no combustible materials

are left in the generator compartment. Keep the area near

the generator clean and free of debris.

WARNING

Hazardous Voltage

Contact with power lines can cause electric

shock or burn.

Lifting Hazard / Heavy Object

Can cause muscle strain or back injury.

If lifting or hoisting equipment is used, DO NOT contact

•

any power lines.

DO NOT lift or move generator without assistance.

•

DO NOT lift unit by roof as damage to generator will

•

occur.

5

Page 6

WARNING

Contact with muffler area can result in serious

burns.

Exhaust heat/gases can ignite combustibles or

structures causing a fire.

•

DO NOT touch hot parts and AVOID hot exhaust gases.

•

Allow equipment to cool before touching.

•

DO NOT install the generator closer than 5 feet (1.5m)

from any combustibles or structures with combustible

walls having a fire resistance rating of less than 1 hour.

•

Keep at least minimum distances shown in

Location Guidelines to insure for proper generator

cooling and maintenance clearances.

Code of Federal Regulation (CFR) Title 36 Parks, Forests,

•

and Public Property require equipment powered by an

internal combustion engine to have a spark arrester,

maintained in effective working order, complying to

USDA Forest service standard 5100-1C or later revision.

In the State of California a spark arrester is required

under section 4442 of the California Public resources

code. Other states may have similar laws.

WARNING

Starter and other rotating parts can entangle

hands, hair, clothing, or accessories.

NEVER operate generator without protective housing or

•

covers.

DO NOT wear loose clothing, jewelry or anything that

•

may be caught in the starter or other rotating parts.

Tie up long hair and remove jewelry.

•

CAUTION

Installing the 15A fuse could cause the engine

to start.

Observe that the 15 Amp fuse has been removed from

•

the control panel for shipping.

DO NOT install this fuse until all plumbing and wiring has

•

been completed and inspected.

General

CAUTION

Excessively high operating speeds increase risk of injury

and damage to generator.

Excessively low speeds impose a heavy load.

•

DO NOT tamper with governed speed. Generator supplies

correct rated frequency and voltage when running at

governed speed.

•

DO NOT modify generator in any way.

NOTICE

Exceeding generators wattage/amperage capacity can

damage generator and/or electrical devices connected to

it.

Essential Circuits.

•

See

Start generator and let engine stabilize before connecting

•

electrical loads.

NOTICE

Improper treatment of generator can damage it and

shorten its life.

•

Use generator only for intended uses.

•

If you have questions about intended use, ask dealer or

contact Briggs & Stratton.

•

Operate generator only on level surfaces.

•

Adequate, unobstructed flow of cooling and ventilating air

is critical to correct generator operation.

•

The Oil Fill, Oil Drain and the Control Panel doors must be

installed whenever the unit is running.

•

DO NOT expose generator to excessive moisture, dust,

dirt, or corrosive vapors.

•

Despite the safe design of the home generator, operating

this equipment imprudently, neglecting its maintenance or

being careless can cause possible injury or death.

•

Remain alert at all times while working on this

equipment. NEVER work on the equipment when you are

physically or mentally fatigued.

•

DO NOT start engine with air cleaner or air cleaner cover

removed.

DO NOT insert any objects through cooling slots.

•

DO NOT use the generator or any of its parts as a step.

•

Stepping on the unit can cause stress and break parts.

This may result in dangerous operating conditions from

leaking exhaust gases, fuel leakage, oil leakage, etc.

If connected devices overheat, turn them off and

•

disconnect them from generator.

Shut off generator if:

•

-electrical output is lost;

-equipment sparks, smokes, or emits flames;

-unit vibrates excessively.

6 BRIGGSandSTRATTON.COM

Page 7

Installation

Save These Instructions

This manual contains important instructions that should be

followed during installation and maintenance of the generator

and battery.

Introduction

Thank you for your purchase of a Briggs & Stratton Home

Generator System. This product is intended for use as

an optional standby system which provides an alternate

source of electric power and to serve loads such as heating,

refrigeration systems, and communication systems that,

when stopped during any power outage, could cause

discomfort or the like. This product does not qualify for

emergency standby as defined by NFPA 70 (NEC).

This manual is an important document and should be

retained by the owner after installation has been completed.

This manual contains installation, startup and adjustment

instructions for a Home Standby Generator that supplies

120/240 Volt, single phase, 60Hz devices. The Home

Standby Generator may be operated on LP vapor or natural

gas fuel.

Every effort has been made to ensure that the information

in this manual is both accurate and current. However, the

manufacturer reserves the right to change, alter or otherwise

improve the generator at any time without prior notice.

Briggs & Stratton has made every effort to provide for a

safe, streamlined and cost-effective installation. Because

each installation is unique, it is impossible to know of and

advise the trade of all conceivable procedures and methods

by which installation might be achieved. Neither could we

know of possible hazards and/or the results of each method

or procedure. For these reasons,

Only current licensed electrical and plumbing contractors

should attempt Home Standby Generator installations.

Installations must strictly comply with all applicable

codes, industry standards and regulations.

Customer Responsibilities

• Read and follow the instructions given in this manual,

especially the section regarding selecting essential

circuits.

• Follow a regular schedule in maintaining, caring for and

using your home generator, as specified in this manual.

Installer Responsibilities

• Read and observe the safety rules.

• Install only an UL approved transfer switches that is

compatible with the home generator.

• Read and follow the instructions given in this

Installation, Start-up and Operator’s Manual.

IMPORTANT: If operating the generator below 40°F, it is

recommended that a battery warmer be installed. If operating

the generator below 32°F, a battery warmer must be

installed. This item is available at your local servicing dealer.

For the Home Owner:

To help you make informed choices and communicate

effectively with your installation contractor(s),

Read and understand Owner Orientation in this manual

before contracting or starting your home generator

installation.

To arrange for proper installation, contact the store at which

you purchased your Briggs & Stratton home generator, your

dealer, a licensed electrician or your utility power provider.

The home generator warranty is VOID unless the

system is installed by licensed electrical and plumbing

professionals.

The Emission Control System for this generator is warranted

for standards set by the U.S. Environmental Protection

Agency and by the California Air Resources Board (CARB).

For the Installing Dealer/Contractor:

For most applications, the Installation manual contains all

the information required to properly install and start the

home generator. This Operator’s Manual describes essential

circuit selection, routine operation and owner maintenance

procedures.

If you need more information, call (800) 743-4115, between

8:00 AM and 5:00 PM CT.

Owner Orientation

This section provides home generator owners with the

information necessary to achieve the most satisfactory and

cost effective installation possible.

The illustrations are for typical circumstances and are meant

to familiarize you with the installation options available with

your home generator. A thorough understanding of these

options will provide fundamental control over the cost of

your installation, as well as ensure your final satisfaction and

security.

Federal and local codes, appearance, noise levels, fuel types,

and distances are the factors that must be considered when

negotiating with an installation professional. Remember

that as the distance from the existing electrical service and

gaseous fuel supply increases, and the number of 90 degree

bends in the fuel supply increases; equal compensations

in piping and wiring materials must be allowed for. This

is necessary to comply with local codes and overcome

electrical voltage drops and gaseous fuel pressure drops.

The factors mentioned above will have a direct affect on

the overall price of your home generator installation.

NOTE: In some areas you may need to acquire electrical

permits for installing the home generator, building permits

for installing gas lines, and permits for noise allowances.

Your installer should check your local codes AND obtain the

permits before installing the system.

7

Page 8

Fuel Factors

An important consideration affecting the entire installation is

the type of fuel used by your home generator. The system

was factory tested and adjusted using either natural gas

or liquid propane (LP vapor). For proper engine function,

factors that are inherent to each of these fuels, your

location and the duration of possible utility interruptions are

important considerations in the following fuel guidelines:

• Use clean, dry fuel, free of moisture or any

particulate material. Using fuels outside the following

recommended values may cause performance problems.

• In engines set up to run on propane (LP), commercial

grade HD5 propane with a minimum fuel energy of

2500 BTUs/ft3 with maximum propylene content of

5% and butane and heavier gas content of 2.5% and

minimum propane content of 90%.

WARNING

Propane and Natural Gas are extremely

flammable and explosive.

Fire or explosion can cause severe burns or

death.

The home generator is equipped with an automatic safety

•

gas “fuel shut-off” valve.

DO NOT operate the equipment if the “fuel shut-off” valve

•

is missing or inoperative.

Power Decrease at High Altitude or High Temperature

Air density is less at high altitudes, resulting in less available

engine power. Specifically, engine power will decrease 3.5%

for each 1,000 feet (300 meters) above sea level and 1% for

each 10° F (5.6°C) above 77°F (25°C). Make sure you and

your installer consider these factors when determining total

generator load.

Unpacking Precautions

The unit is shipped bolted to its mounting pad, ready

for installation. Avoid damage from dropping, bumping,

collision, etc. Store and unpack carton with the proper side

up, as noted on the shipping carton.

CAUTION

Installing the 15A fuse could cause the engine

to start.

Observe that the 15 Amp fuse has been removed from

•

the control panel for shipping.

DO NOT install this fuse until all plumbing and wiring has

•

been completed and inspected.

Delivery Inspection

After removing the carton, carefully inspect the home

generator for any damage that may have occurred during

shipment.

IMPORTANT: If loss or damage is noted at time of delivery,

have the person(s) making delivery note all damage on the

freight bill and affix his signature under the consignor’s

memo of loss or damage. If loss or damage is noted after

delivery, separate the damaged materials and contact the

carrier for claim procedures. Missing or damaged parts are

not warranted.

Shipment Contents

The home generator is supplied with:

• Pre-attached mounting pad

• One flexible hook-up pipe (meets UL 569 and CSA 8.3)

• This installation, start-up and operator’s manual

• Installation checklist

• Oil drain tray

• Touch up paint

• One spare 15A fuse

• Roof hardware bag

• LP conversion kit

• 2 Pole connector - 240V from house

• 10 Pole connector - Sensing and control wires

• Remote LED indicator kit (red LED/plate/screws)

Lifting the Generator

The generator weighs more than 280 pounds. Proper tools,

equipment and qualified personnel should be used in all

phases of handling and moving the generator.

WARNING

Hazardous Voltage

Contact with power lines can cause electric

shock or burn.

Lifting Hazard / Heavy Object

Can cause muscle strain or back injury.

If lifting or hoisting equipment is used, DO NOT contact

•

any power lines.

DO NOT lift or move generator without assistance.

•

DO NOT lift unit by roof as damage to generator will

•

occur.

Lifting pockets are provided at each corner between the base

of the generator and its mounting pad. Retouch any chipped

paint with supplied touch-up paint.

8 BRIGGSandSTRATTON.COM

Page 9

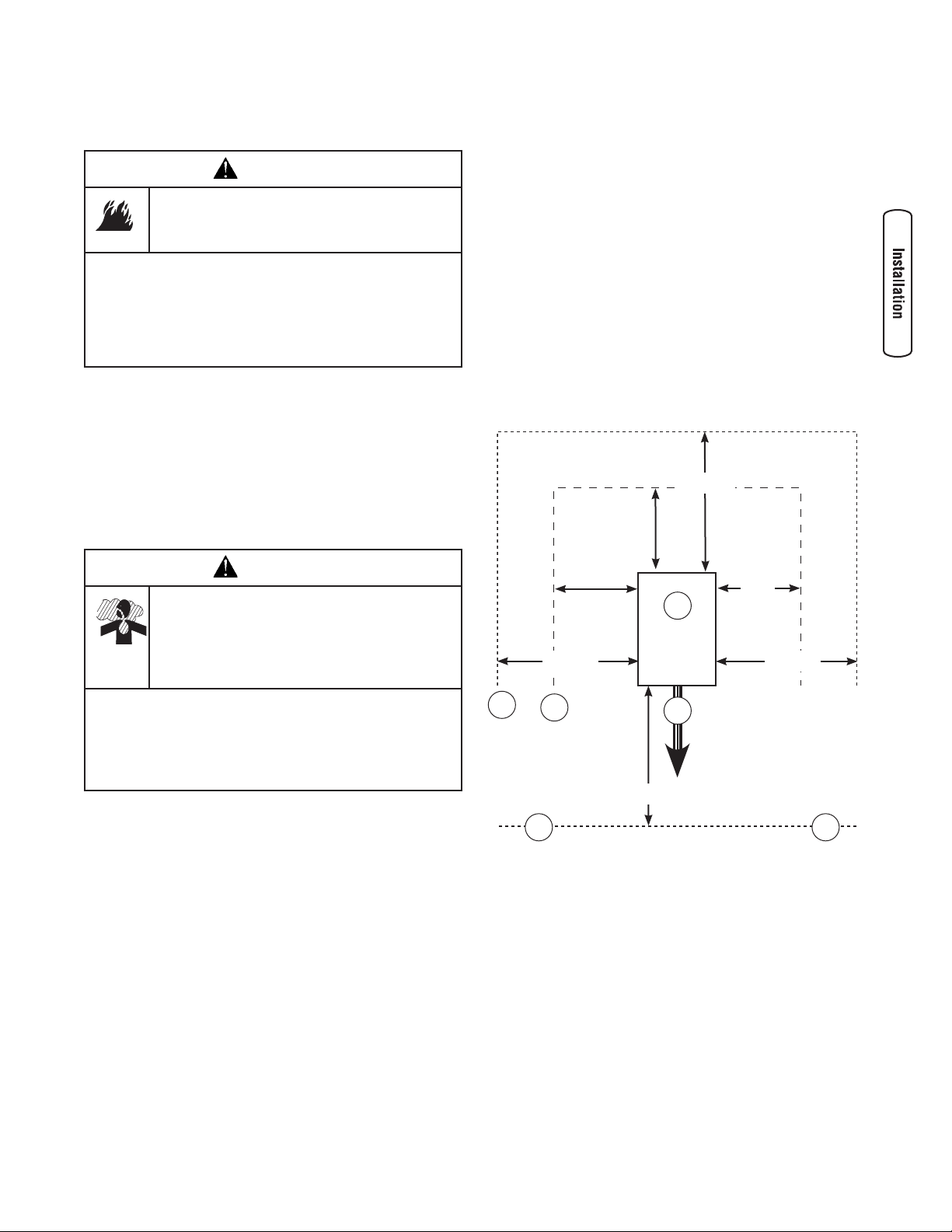

Home Generator Location

Before installing generator, consult with homeowner and convey

the following guidelines which may affect the desired location.

WARNING

Exhaust heat / gasses can ignite combustibles

or structures causing a fire.

•

DO NOT install the generator closer than 5 feet (1.5m)

from any combustibles or structures with combustible

walls having a fire resistance rating of less than 1 hour.

•

Keep at least minimum distances shown in

Location Guidelines to insure for proper generator

cooling and maintenance clearances.

Generator Location

Install generator outdoors in an area which will not

accumulate deadly exhaust gas. DO NOT install generator

where exhaust gas could accumulate and enter inside or be

drawn into a potentially occupied building. Ensure exhaust

gas is kept away from any windows, doors, ventilation intakes

or other openings that can allow exhaust gas to collect in a

confined area. Prevailing winds and air currents should be

taken into consideration when positioning generator.

WARNING

Running engine gives off carbon monoxide, an

odorless, colorless, poison gas.

Breathing carbon monoxide can cause

headache, fatigue, dizziness, vomiting,

confusion, seizures, nausea, fainting, or death.

•

Operate generator ONLY outdoors.

•

Install a battery operated carbon monoxide alarm near

the bedrooms.

•

Keep exhaust gas from entering a confined area through

windows, doors, ventilation intakes, or other openings.

General Location Guidelines

• Install the unit outdoors ONLY.

• Place the unit in a prepared location that is flat and has

provisions for water drainage.

• Install the unit in a location where sump pump

discharge, rain gutter down spouts, roof run-off,

landscape irrigation, or water sprinklers will not flood

the unit or spray the enclosure and enter any air inlet

our outlet openings.

• Install the unit where the location of any services such

as phone, electrical, fuel, air conditioning, irrigation,

including covered, concealed and underground services

will not be affected or obstructed.

• Install the unit where air inlet and outlet openings will

not become obstructed by leaves, grass, snow, etc. If

prevailing winds will cause blowing or drifting, you may

need to construct a windbreak to protect the unit.

General

• Install the generator as close as possible to the

Transfer Switch and fuel supply to reduce the length of

wiring, conduit, and piping.

IMPORTANT: Laws or local codes may regulate the distance

to the fuel supply.

The Minimum (MIN) clearances from aerial view of generator

(B) to combustible (D), and non-combustible (A) materials is

shown below.

• These distances are provided to give generator location

guidance relative ONLY to combustibles, generator

cooling, and maintenance.

• The minimum distances in the figure are as shown.

All four sides of the generator cannot be enclosed

or restricted, even if the minimum distances are

maintained. DO NOT connect (A) and/or (D) to (E)

• A roof cannot be used.

• Exhaust (C) must not be allowed to accumulate.

5’ (1.5m)

3’

(1m)

3’

B

5’ (1.5m) 5’ (1.5m)

D

A

5’ (1.5m)

E

C

(1m)

E

A Non-Combustible material with Fire Resistant Rating of

1 hour or greater

B Home Generator System

C Engine Exhaust

D Combustible Material or Structure with a Fire

Resistance Rating of less than 1 hour.

E Any structure or material. DO NOT connect (A) and/or

(D) to (E).

The home generator is shipped already attached to its

mounting pad. Unless mandated by local code, a concrete

slab is not required.

If mandated by local code, construct a concrete slab at least

3 inches thick and 6 inches longer and wider than the unit.

Attach unit to slab with 1/4” diameter (minimum) masonry

anchor bolts long enough to retain the unit.

9

Page 10

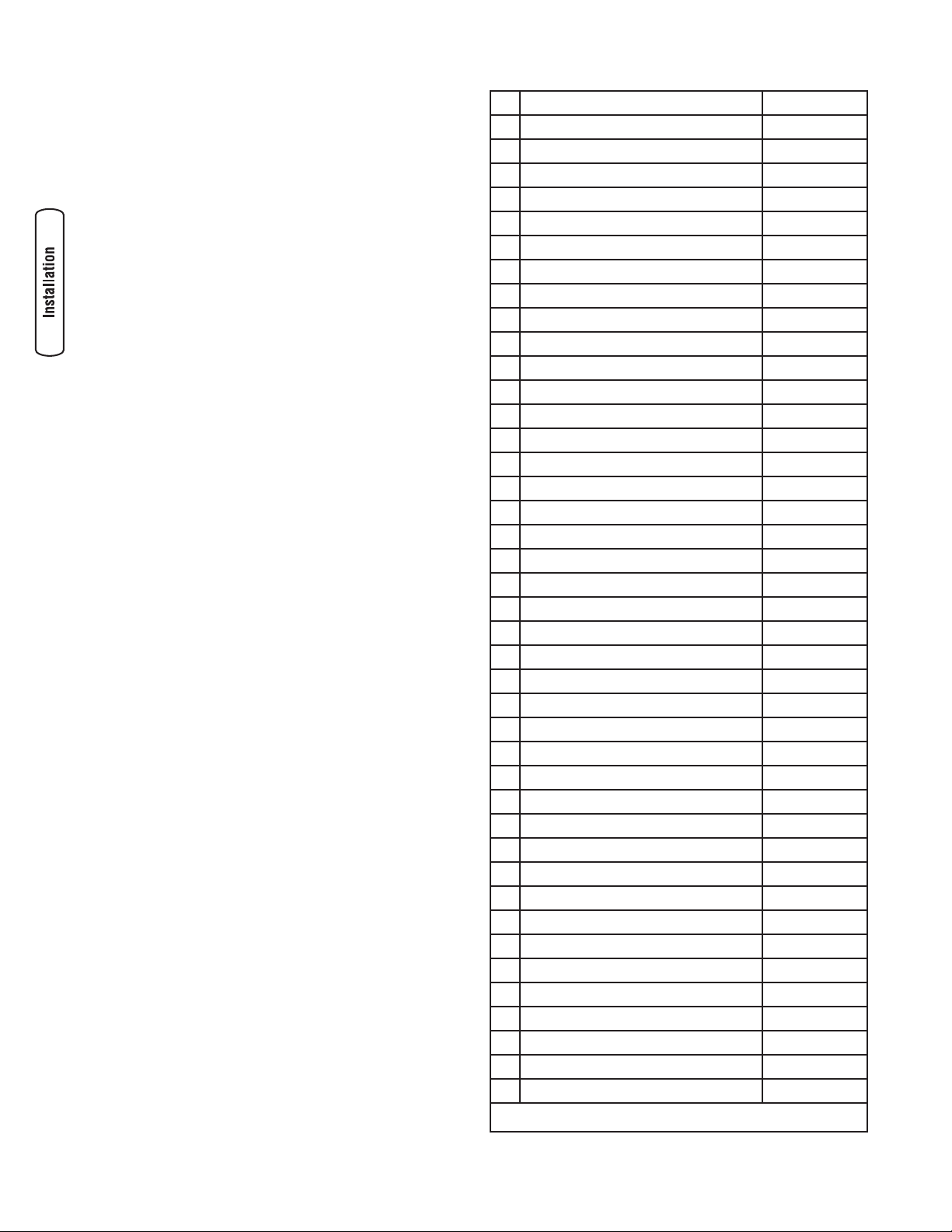

Essential Circuits

As a home generator owner, it is important that you clearly

identify the circuits in your building that are “essential” to

you.

It is also important that your installer understand which

circuits you want to include as “Essential Circuits”.

Depending on the power consumed by these circuits, most

or all of them can be switched to the home generator for the

duration of normal power interruption.

The wattage reference table that follows will assist you with

your decision-making process. It provides the wattage used

by many ordinary household devices. Use it as a guide when

selecting your essential circuits. Review this information with

your installer and ask about any technical considerations that

might affect your installation. This chart serves as a guide

only. For exact wattage use an appropriate wattage meter.

Essential Circuit Selection

When selecting the essential circuits that will be switched

to “Standby Power,” it is important that the sum of the

combined circuit loads does not exceed the wattage/

amperage capacity of the generator. To help you with your

selection of essential circuits, please consider the following:

• Add up the total wattage of all electrical devices to be

connected at one time. This total should NOT be greater

than the generator’s wattage capacity.

The rated wattage of lights can be taken from light

bulbs. The rated wattage of tools, appliances and

motors can usually be found on a data plate or decal

affixed to the device.

• If the appliance, tool or motor nameplate does not

list wattage, multiply volts times the ampere rating to

determine watts (Volts x Amps = Watts).

Some electric motors (induction types) require about

three times more watts of power for starting than for

running. This surge lasts for only a few seconds. Be

sure you allow for this high starting wattage when

selecting electrical devices that will be energized by the

home generator:

• Figure the watts required to start the largest motor.

• Add that to the total running watts of all other

connected loads.

This Briggs & Stratton home generator complies with the

following “stationary standby power rating”:

The standby power rating is applicable for supplying

power for the duration of normal power interruption.

No sustained overload capability is available for this

rating.

Device

q

Air Conditioner (12,000 Btu)* 1700

q

Air Conditioner (24,000 Btu)* 3800

q

Air Conditioner (40,000 Btu)* 6000

q

Battery Charger (20 Amp) 500

q

Circular Saw (6-1/2”) 800 to 1000

q

Clothes Dryer (Electric)* 5750

q

Clothes Dryer (Gas)* 700

q

Clothes Washer* 1150

q

Coffee Maker 1750

q

Compressor (1 HP)* 2000

q

Compressor (1/2 HP)* 1400

q

Compressor (3/4 HP)* 1800

q

Curling Iron 700

q

Dehumidifier* 650

q

Electric Blanket 400

q

Electric Range (per element) 1500

q

Electric Skillet 1250

q

Freezer* 700

q

Furnace Fan (1/2 HP)* 800

q

Garage Door Opener* 500 to 750

q

Hair Dryer 1200

q

Hand Drill 250 to 1100

q

Iron 1200

q

Jet Pump* 800

q

Light Bulb 100

q

Microwave Oven 700 to 1000

q

Milk Cooler* 1100

q

Oil Burner on Furnace 300

q

Oil Fired Space Heater (140,000 Btu) 400

q

Oil Fired Space Heater (30,000 Btu) 150

q

Oil Fired Space Heater (85,000 Btu) 225

q

Radio 50 to 200

q

Refrigerator 700

q

Slow Cooker 200

q

Submersible Pump (1 HP)* 2000

q

Submersible Pump (1/2 HP)* 1500

q

Submersible Pump (1-1/2 HP)* 2800

q

Sump Pump* 800 to 1050

q

Table Saw (10”)* 1750 to 2000

q

Television 200 to 500

q

Toaster 1000 to 1650

Running Watts

*Allow three (3) times listed watts for starting device

10 BRIGGSandSTRATTON.COM

Page 11

This rating is applicable to installations served by a

reliable normal utility source. This rating is only applicable

to variable loads with an average load factor of 80% of

the standby rating. The standby rating is only applicable

for optional standby power where the generator set

serves as the backup to the normal utility source.

Use the wattage reference table provided and mark those

circuits you consider “critical” or “essential”. Make sure you

and your installer consider the system’s altitude above sea

level and the ambient temperature range when determining

total generator load.

IMPORTANT: When using the 100 Amp or 200 Amp transfer

switch with the home generator, you must turn off any non

essential loads. Failure to turn off non essential loads could

overload the generator causing it to shut down.

Some examples of non essential loads are as follows:

• Pool pump

• Hot tub

• Electric hot tub and/or pool heaters

• Central air conditioners

• Electric hot water heaters

• Electric range and/or oven

• Arc welder

• Non essential electric heaters

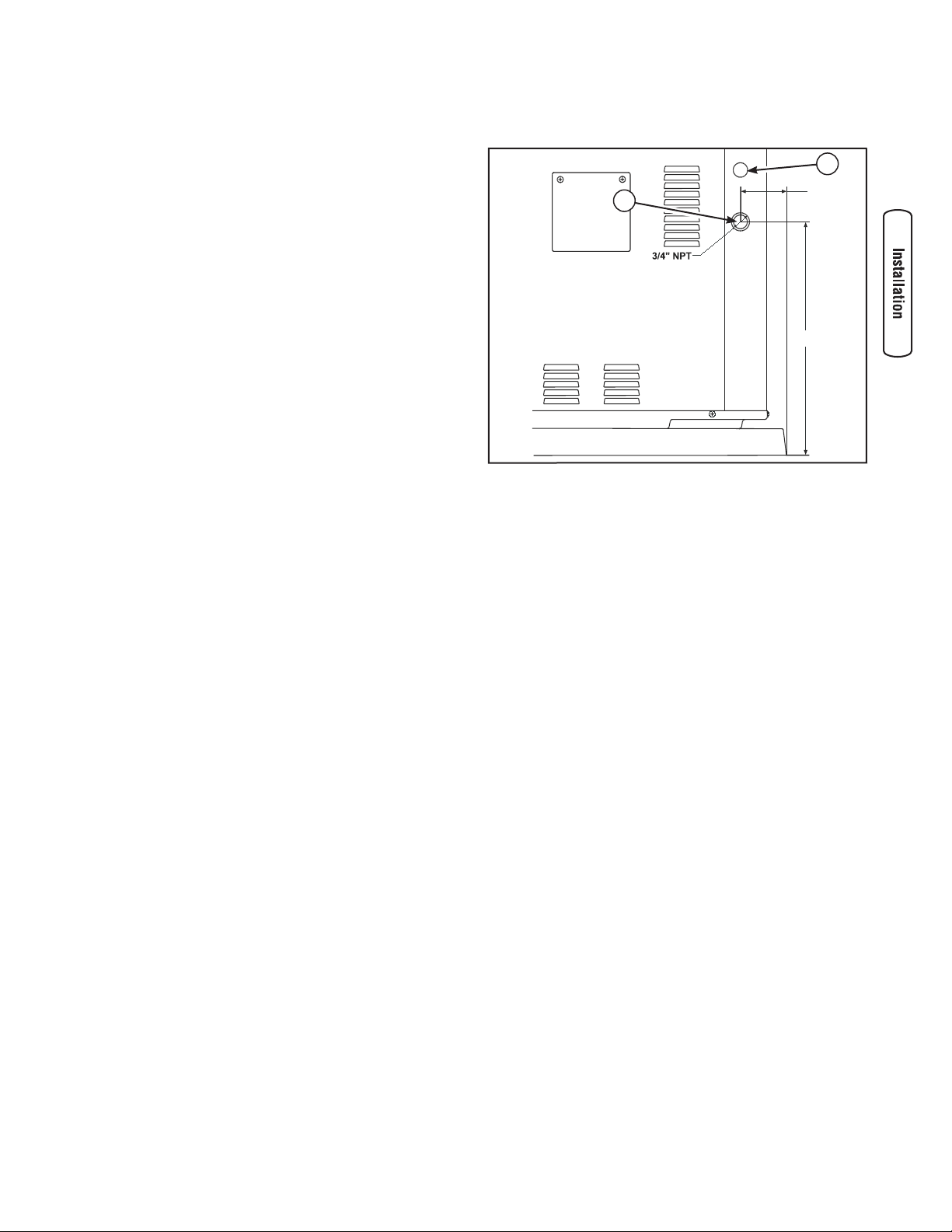

Fuel and Electrical Inlet Locations

The fuel inlet connector (A) and electrical inlet (B) is shown

below.

B

A

4.5”

13.5”

Access Covers

The home generator is equipped with an enclosure that has a

removable roof and an access cover for the control panel.

To Remove Roof:

Remove the four screws and lift off.

To Remove Access Cover:

1. Remove roof as described above.

2. Remove screw at top of access cover.

3. Pull access cover outward (away) from unit while pulling

cover upward and out of base. Cover will come free.

To Install Access Cover and Roof:

1. Guide bottom of access cover into base.

2. Push access cover until it is flush with sides.

3. Replace cover screw.

4. Replace roof and screws.

11

Page 12

The Gaseous Fuel System

WARNING

Propane and Natural Gas are extremely

flammable and explosive.

Fire or explosion can cause severe burns or

death.

• Installed piping must be properly purged and leak

tested, in accordance with applicable codes and

standards.

WARNING

Propane and Natural Gas are extremely

flammable and explosive.

LP gas is heavier than air and will settle in low areas.

•

Natural gas is lighter than air and will collect in high

•

areas.

The slightest spark can ignite these fuels and cause an

•

explosion.

DO NOT light a cigarette or smoke.

•

The information provided below is to assist gaseous fuel

system technicians in planning installations. In no way

should this information be interpreted to conflict with

applicable fuel gas codes. Consult with your local fuel

supplier or Fire Marshall if questions or problems arise.

TO THE INSTALLER: Consult with the home generator

owner(s) and convey any technical considerations that might

affect their installation plans before applying these general

guidelines.

The following general rules apply to gaseous fuel system

piping:

• The piping should be of a material that conforms to

federal and local codes, rigidly mounted and protected

against vibration.

• Piping should be protected from physical damage

where it passes through flower beds, shrub beds, and

other cultivated areas where damage could occur.

• Install the flexible, gaseous hose (supplied) between

the home generator Fuel Inlet port and rigid piping to

prevent thermal expansion or contraction from causing

excessive stress on the piping material.

NOTE: Where local conditions include earthquake, tornado,

unstable ground, or flood hazards, special consideration

shall be given to increase strength and flexibility of piping

supports and connections.

CAUTION

The supplied flexible gaseous pipe is not to be installed

underground or in contact with the ground.

•

The entire flexible gaseous pipe must be visible for

periodic inspection and must not be concealed within,

contact, or run through any wall, floor, or partition.

• Piping must be of the correct size to maintain the

required supply pressures and volume flow under

varying generator load conditions with all gas appliances

connected to the fuel system turned on and operating.

• Use an approved pipe sealant or joint compound on all

threaded fittings to reduce the possibility of leakage.

Fire or explosion can cause severe burns or

death.

Before placing the home generator into service, the fuel

•

system lines must be properly purged and leak tested.

NO leakage is permitted.

•

Consider the following factors when planning to install the

fuel supply system:

The home generator engine is fitted with a fuel mixer system

that meets the specifications of the California Air Resources

Board for “tamper-proof” fuel systems.

• A minimum of one accessible, approved manual shutoff

valve shall be installed in the fuel supply line within

6 ft (1.8 m) of the home generator. A union or flanged

connection shall be provided downstream from this

valve to permit removal of controls.

• Natural gas fuel supply pressure at the generator’s fuel

inlet port should be between 5 to 7 inches of water (in.

W.C.) at full load with all gas appliances turned on and

operating.

• LP gas fuel supply pressure should be 11 to 14 inches

of water (in. W.C.) at full load with all gas appliances

turned on and operating.

The Home Generator has been factory set to run on natural

gas. If you need to change from natural gas to LP gas,

the unit will need to be reconfigured, as described in Fuel

System Selection.

It is recommended that the fuel connection incorporate the

following components:

• A manual fuel shut-off valve located in the interior of

the building.

• A manual fuel shut-off valve located outside the

building, just before the generator unit.

• Where the formation of hydrates or ice is known to

occur, piping should be protected against freezing. The

termination of hard piping should include a sediment

trap where condensate is not likely to freeze.

• A manometer port should be provided.

12 BRIGGSandSTRATTON.COM

Page 13

The manometer port permits temporary installation of a

manometer to ensure that the engine receives the correct

fuel pressure to operate efficiently throughout its operating

range.

NOTE: A digital manometer, P/N 19495, is available at your

local Briggs & Stratton service center.

When the initial test runs are completed, the manometer

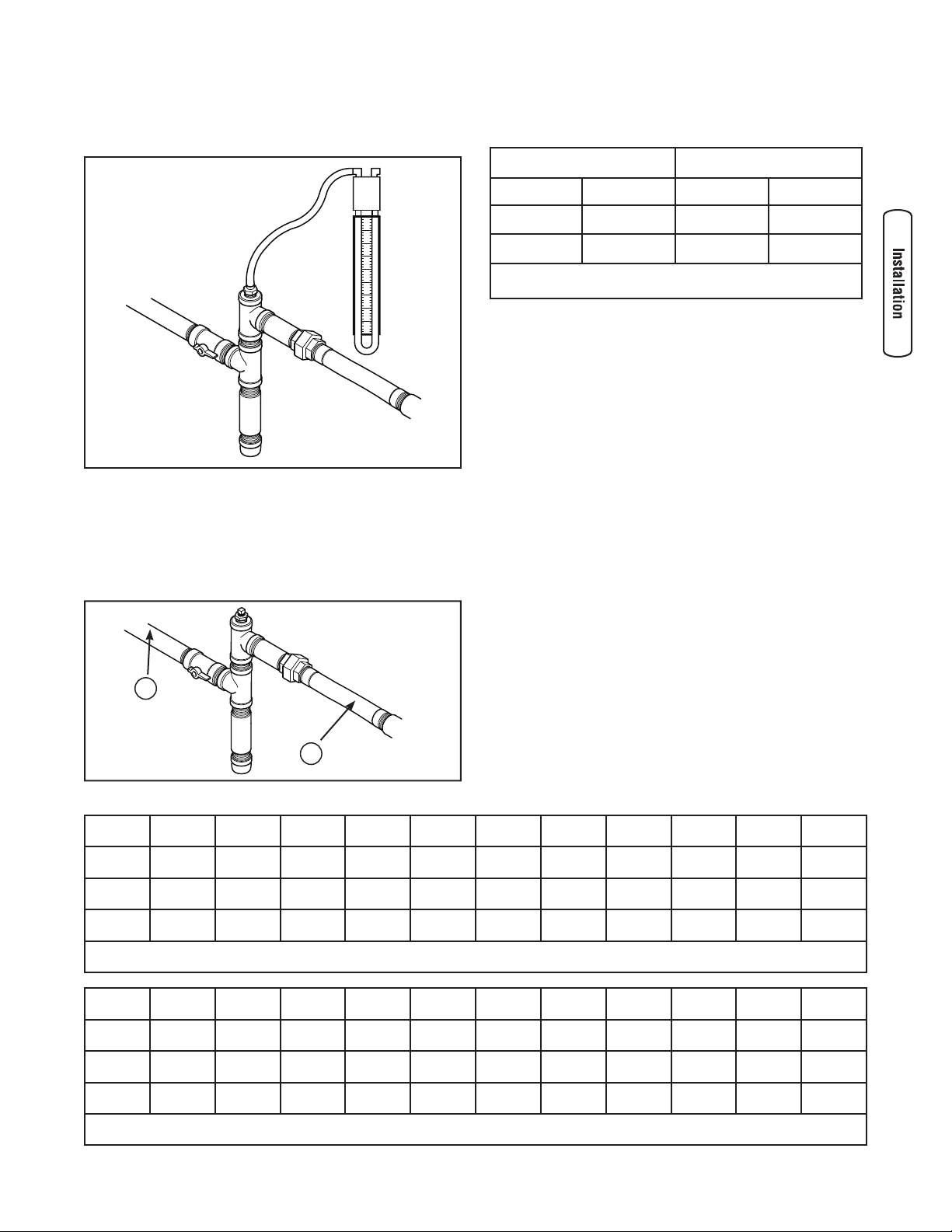

is removed and the port is plugged. A typical final fuel

connection assembly is shown here, where (A) is the fuel

supply and (B) goes to the home generator.

A

B

Fuel Consumption

Estimated fuel supply requirements at half and full load for

natural gas and LP vapor fuels are shown below.

Natural Gas LP Vapor

1/2 Load Full Load 1/2 Load Full Load

80 C 137 C 33 C 56 C

80,000 B 137,000 B 82,500 B 140,000 B

C = Cubic feet per hour

B = BTU’s per hour

Fuel Pipe Sizing

The tables below provide the maximum capacity of pipe in

cubic feet of gas per hour for gas pressures of 0.5 psi or

less and a pressure drop of 0.3 in. water column. Specific

gravity of gas is shown.

Listed values compensate for a nominal amount of

restriction from bends, fittings, etc. If an unusual number of

fittings, bends, or other restrictions are used, please refer to

federal and local codes.

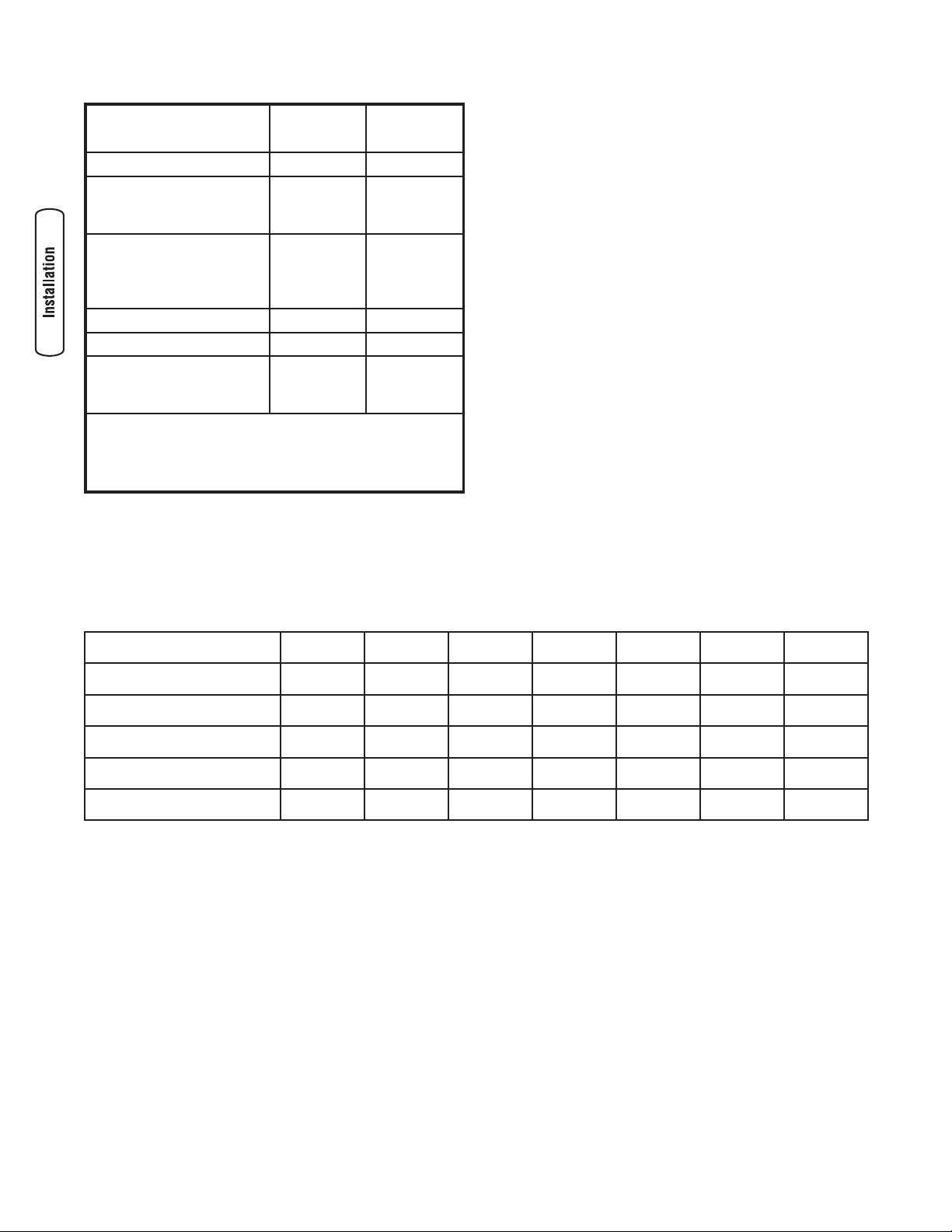

NPT 10ft 15ft 20ft 30ft 40ft 50ft 60ft 70ft 80ft 90ft 100ft

1/2” 168 146 115 93 79 70 63 59 55 51 48

3/4” 346 293 240 192 163 145 132 120 113 106 99

1” 653 549 446 360 307 274 250 230 211 197 187

Natural Gas Pipe Size - Gas Flow chart, in cubic feet per hour, specific gravity=0.65

NPT 10ft 15ft 20ft 30ft 40ft 50ft 60ft 70ft 80ft 90ft 100ft

1/2” 110 96 76 61 52 46 42 38 36 33 32

3/4” 277 192 158 126 107 95 87 79 74 69 65

1” 428 360 293 236 202 180 164 151 139 129 123

Liquid Propane (LP) Gas Pipe Size - Gas Flow chart, in cubic feet per hour, specific gravity=1.50

13

Page 14

Fuel Comparison Chart

Physical Properties LP Vapor Natural

Gas

Normal Atmospheric State Gas Gas

Boiling Point (in °F):

Initial

End

Heating Value:

BTU per gallon (Net LHV*)

BTU per gallon (gross**)

Cubic feet (gas)

Density*** 36.39 57.75

Weight† 4.24 2.65

Octane Number:

Research

Motor

* LHV (Low Heat Value) is the more realistic rating.

** Gross heat value does not consider heat lost in the form of water

during combustion.

*** Density is given in “Cubic Feet of Gas per Gallon of Liquid”.

† Weight is given in “Pounds per Gallon of Liquid”.

Required Propane Tank Size

The required size of the propane tank at various

temperatures when kept at least half full is shown below

in the chart. Given the gas withdrawal rate and the lowest

average winter temperature, an installer can specify the

required LP storage tank size.

-44

-44

83,340

91,547

2,500

110+

97

-259

-259

63,310

1,000

110+

Withdrawal Rate 32° F 20° F 10° F 0° F -10° F -30° F -40° F

50 CFH 115 115 115 250 250 400 600

100 CFH 250 250 250

150 CFH

200 CFH

300 400 500 500 1000 1500 2500

400 500 750 1000 1200 2000 2500

400 500 1000 1500

300 CFH 750 1000 1500 2000 2500 4000 5000

14 BRIGGSandSTRATTON.COM

Page 15

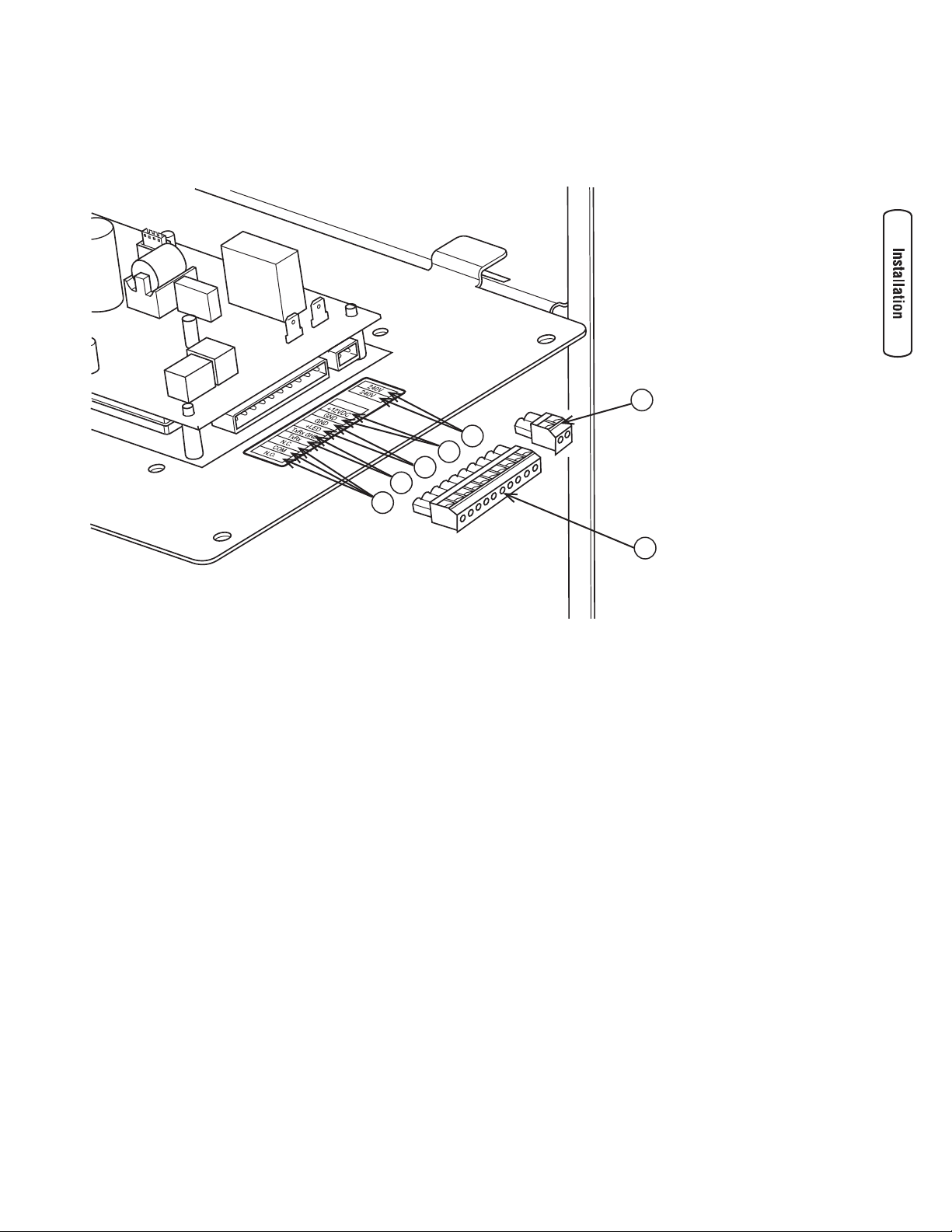

System Connectors

Low voltage connections to signal fault contacts, transfer switch communication, remote LED and auxiliary 12VDC power are

made to a removable ten-pin connector plug. Compare this illustration with your generator to familiarize yourself with the

location of these important connections:

A

B

C

D

E

F

A - 2 Pole Connector Plug

B - 240 Volt Utility — Use to hook up the 240V utility leads

from the transfer switch to the generator.

C - +12 Volt DC, .5 Amp Output — Internal auxiliary power

supply.

D - Remote LED Output — Used to connect to the remote

LED supplied with the generator. The remote LED will

turn on and off in a series of blinks if certain faults are

detected in the generator.

G

E - Transfer Switch Communication — Connect TxRx and

TxRx GND to transfer switch to monitor transfer switch

functions.

F - Fault Contacts — Use NO, COM and NC for operating a

siren, light, optional GenAlert, etc. to alert you in case

of a fault. Contacts reverse state (NO goes to NC and

vice versa) upon a fault condition.

G - 10 Pole Connector Plug

15

Page 16

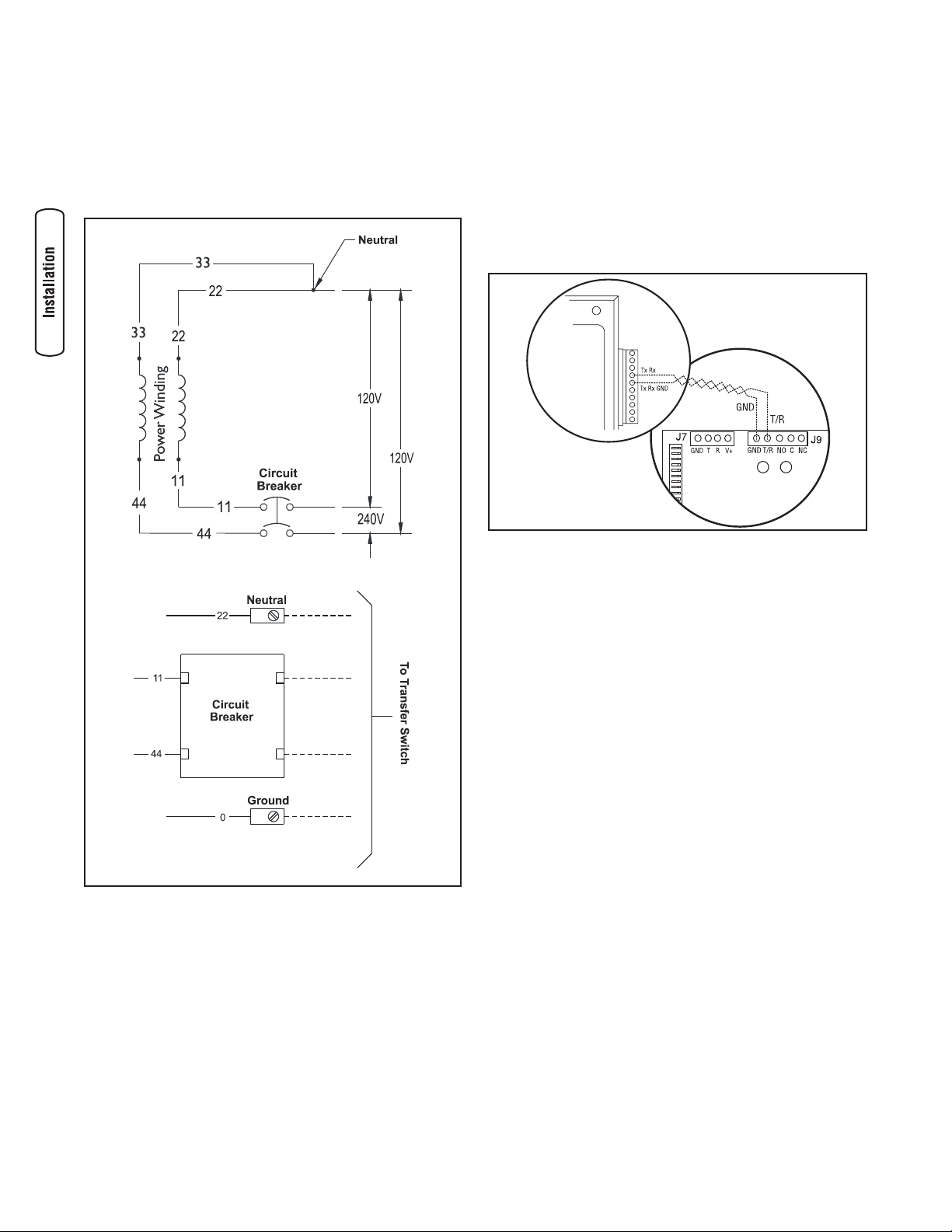

Generator AC Connection System

A single-phase, three-wire AC connection system is used in

the home generator. The stator assembly consists of a pair

of stationary windings with two leads brought out of each

winding. The junction of leads 22 and 33 forms the neutral

lead. Keep field wiring to a minimum. A complete schematic

and wiring diagram can be found later in this manual.

Using provided 2 pole connector plug and installer-supplied

minimum 300V, 14 AWG copper wire, connect each control

circuit terminal in the generator to the two-amp fuse

terminals in the automatic transfer switch.

Transfer Switch Communication

Using #18 AWG twisted pair conductors, no greater than

200 ft in length, connect Tx Rx and Tx Rx Ground from the

generator control panel to the GND and T/R on the transfer

switch control board.

Generator

Transfer

Switch

NOTE: Neutral is not bonded to ground at generator.

Grounding the Generator

Ground the home generator per applicable codes, standards,

and regulations. The generator GND lug is located in the

control panel box.

Fault Detection System

The generator may have to run for long periods of time with

no operator present. For that reason, the system is equipped

with sensors that automatically shut down the generator

in the event of potentially damaging conditions, such as

low oil pressure, high temperature, over speed, and other

conditions. Refer to Fault Detection System in Maintenance

for more detailed information.

The owner will use the remote LED indicator to observe the

status of the home generator system. Consult with the owner

for a convenient location. Locate the electrical box in an

area visible by the home owner such as near a garage door

opener or security control panel.

To install the remote LED indicator:

1. Push the LED through the mounting plate from the

front until it snaps in place.

IMPORTANT: The LED is polarity sensitive.

2. Using provided 10 pole connector and installer-supplied

minimum 18AWG wire, connect the remote LED to the

generator control board +LED and GND connection.

Use wire nuts to attach wire to LED leads.

3. Attach mounting plate to installer-supplied electrical box.

Utility Circuit Connection

“240V Utility” leads must be routed in conduit. The

“240V Utility” leads deliver power to the generator’s circuit

board, optional battery warmer and oil warmer. This power

also charges the battery. When power on these leads is lost,

the generator will start.

16 BRIGGSandSTRATTON.COM

Page 17

Final Installation Considerations

Engine Oil

NOTICE

Any attempt to crank or start the engine before it has been

properly serviced with the recommended oil will result in

equipment failure.

•

Refer to

information.

Damage to equipment resulting from failure to follow this

•

instruction will void engine and generator warranty.

This engine is shipped from the factory pre-run and filled

with synthetic oil (API SJ/CF 5W-30W). This allows for

system operation in the widest range of temperature and

climate conditions. Before starting the engine, check oil level

and ensure that engine is serviced as described in the engine

operator’s manual.

NOTE: The use of synthetic oil does not alter the required oil

change intervals described in the engine operator’s manual.

Battery

The home generator is supplied with a sealed, lead-acid,

rechargeable, 12 Volt DC 33 Amp-Hour, 350 cold cranking

amps (CCA), valve regulated battery. It is installed in the unit

and the battery cables are connected at the factory.

With the battery installed, all wiring to transfer switch and

home generator completed, utility power supplied to the

Automatic Transfer Switch, and the system switch in the

AUTO position, the battery receives a trickle charge while the

engine is not running. The trickle charge cannot be used to

recharge a battery that is completely discharged.

15 Amp Fuse

The generator’s 15 Amp fuse was removed at the factory to

prevent the unit from starting during shipping. Your installer

will ensure the fuse is properly installed upon completion of

the installation.

Fuel Supply System

Ensure that all fuel pipe connections are tight, secure and

without leaks.

Ensure that all gas line shutoff valves are OPEN and that

adequate fuel pressure is available whenever automatic

operation is desired.

Fuel System Selection

The engine of your Home Generator System is factory

calibrated to run on natural gas (NG). It may also be

operated on liquid propane (LP) vapor.

To configure the fuel system for LP use:

1. LP fuel inlet pressure must be between 11 and 14

2. Set AUTO/OFF switch to OFF.

3. Turn OFF the main distribution panel circuit breaker

Maintenance and engine manual for oil fill

inches water column.

sending power to the automatic transfer switch.

4. Remove 15 Amp fuse.

5. Change main jet in fuel mixer following instruction

sheet provided in LP conversion kit.

6. Reinstall 15 Amp fuse.

7. Turn

8. Set AUTO/OFF switch to AUTO.

9. Reset exercise timer following instructions Setting

The generator is now ready to operate automatically using

LP fuel. With a fixed main jet for LP gas, there is no need to

perform any engine adjustments for LP operation.

ON the main distribution panel circuit breaker that

supplies utility power to the automatic transfer switch.

Exercise Timer.

Initial Start-up (No Load)

Before operating the home generator or placing it into

service, inspect the entire installation carefully.

Then begin testing the system without any electrical loads

connected, as follows:

1. Set generator’s main circuit breaker to its ON (closed)

position.

2. Install 15 Amp fuse in control panel.

3. Set generator’s system switch to AUTO.

4. Push MANUAL OVER-RIDE button on control panel.

NOTE: When the home generator is started for the very

first time, it will require that air in the gaseous fuel lines be

purged. This may take a few minutes.

5. DO NOT crank engine for more than 10 seconds, then

pause for 10 seconds to reduce heat in the starter.

6. Repeat process until engine starts.

7. Listen for unusual noises, vibration or other indications of

abnormal operation. Check for oil leaks while engine runs.

8. Let engine warm up for about five minutes to allow

internal temperatures to stabilize.

9. Connect an RMS AC voltmeter and a frequency meter

to check generator output at load side of circuit

breaker. Voltage should be 230-240 Volts, frequency

should be 62.0 - 62.5 Hz.

10. Check generator output between one of the generator

connection lugs and the neutral lug, then between the

other generator connection lug and the neutral lug.

In both cases, voltage reading should be between

115-120 Volts.

11. Push and hold MANUAL OVER-RIDE button on control

panel again until engine stops.

Installation Inspection

Complete the ”Installation Checklist” as you make the

inspection. Ensure all items have been filled-in and all

signatures have been obtained. Instruct the owner to mail

the white copy to:

Briggs & Stratton Power Products

Warranty Registration

P. O. Box 239

Jefferson, WI 53549-0239

17

Page 18

Features and Controls

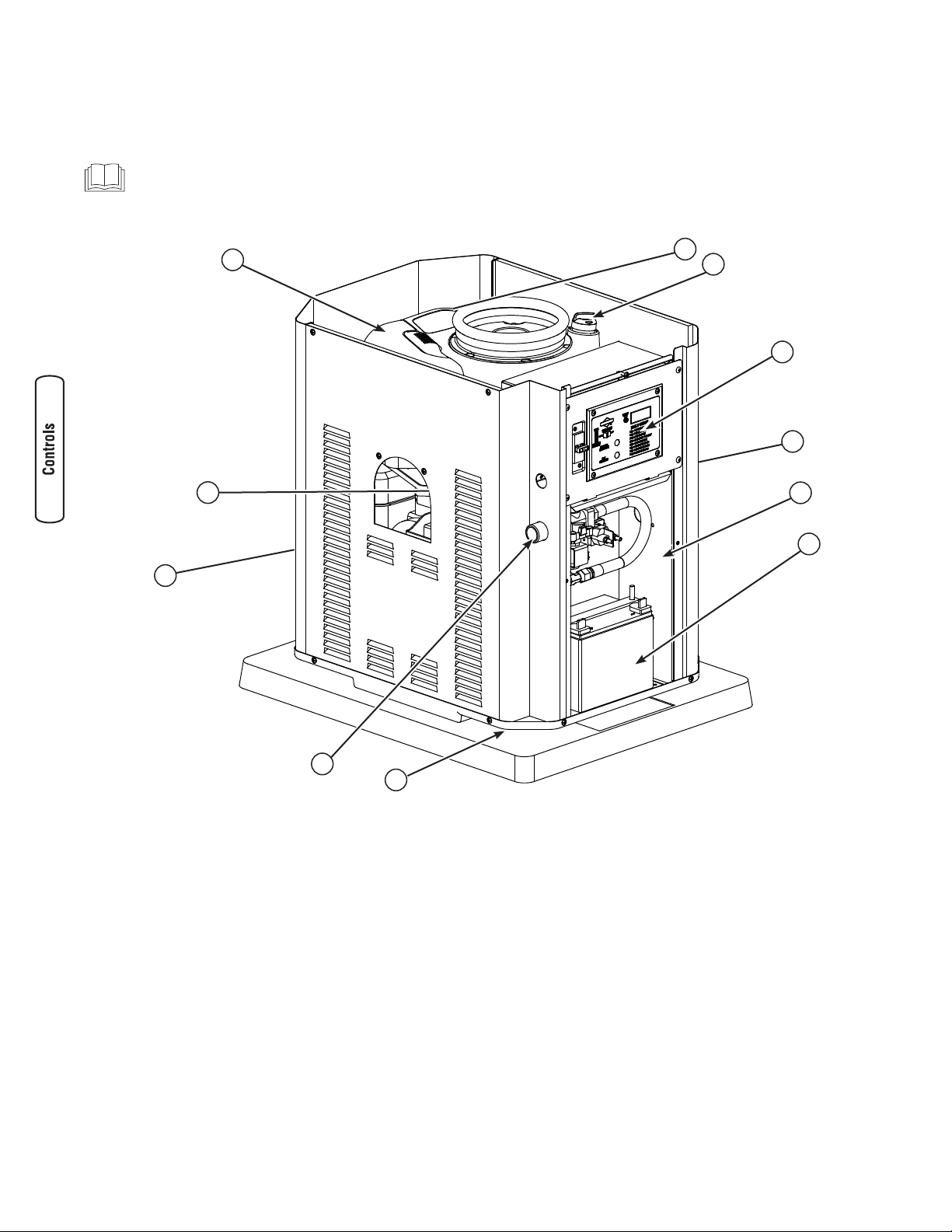

Home Generator

Read this Operator’s Manual and Safety Rules before operating your generator.

Compare the illustrations with your generator to familiarize yourself with the locations of various controls and

adjustments. Save this manual for future reference.

A

L

K

B

C

D

E

F

G

J

H

Generator is shown with roof, plastic access cover and

control panel cover removed for clarity.

A - Air Cleaner — Uses a dry type filter element and foam

precleaner to protect engine by filtering dust and debris

out of intake air.

B - Engine Label — Identifies engine model and type.

C - Oil Fill Cap/Dipstick — Check and add recommended

engine oil here.

D - Control Panel — Used for various test, operation and

maintenance functions. See System Control Panel on the

next page.

F - Unit Identification Label — Identifies unit by serial

number.

G - Battery — 12 Volt DC, sealed battery provides power to

start the engine.

H - Lifting Pocket — Provided at each corner for lifting

generator.

J - Fuel Inlet — Attach appropriate fuel supply to generator

here.

K - Exhaust Port — High-performance muffler lowers engine

noise to comply with most residential codes.

L - Oil Filter — Filters engine oil to prolong generator life.

E - Oil Drain Hose — Located inside access cover on side

panel. Provided to facilitate oil changing.

18 BRIGGSandSTRATTON.COM

Page 19

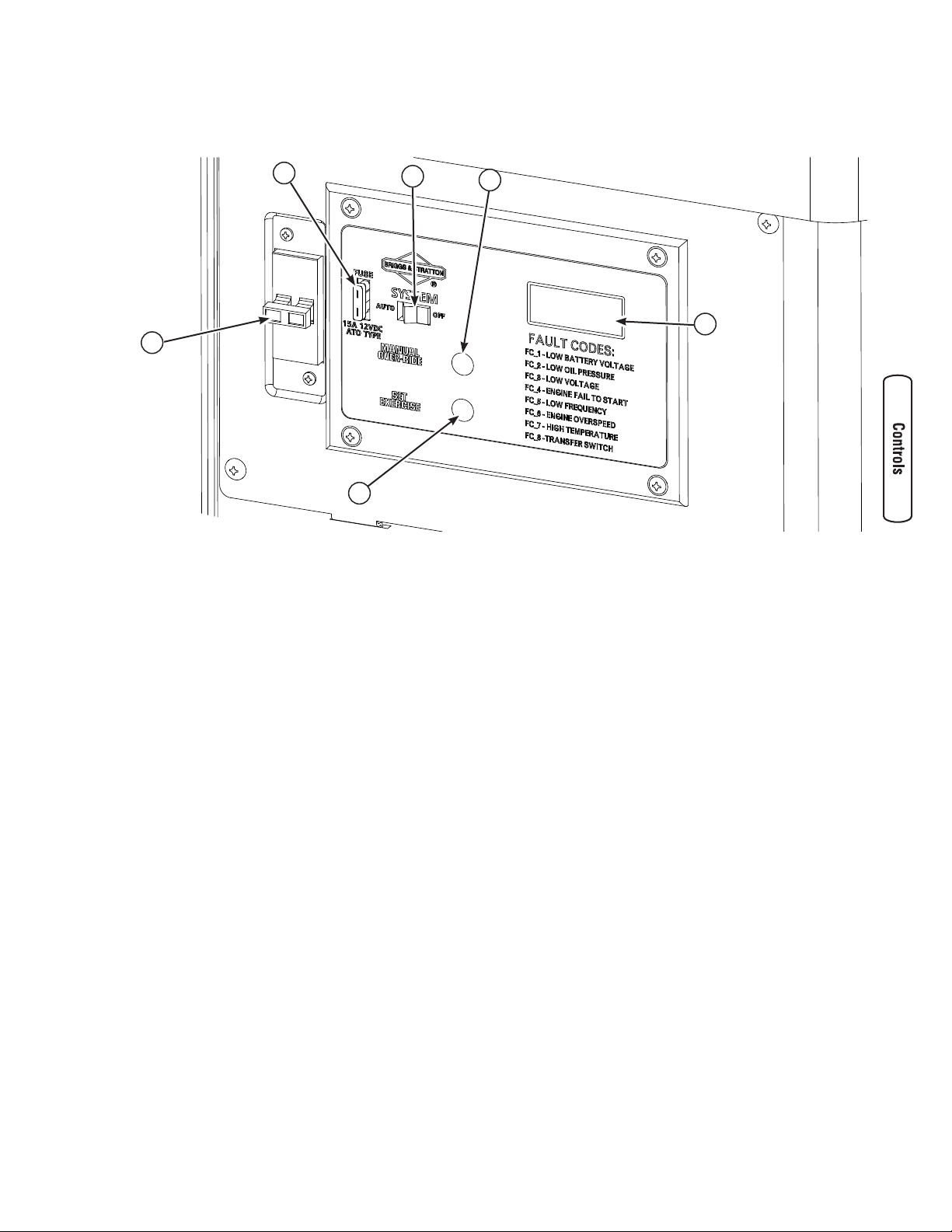

System Control Panel

Compare this Control Panel illustration with your generator to familiarize yourself with the location of these important controls:

C

B

A

D

A - Set Exercise Switch — Used to set the exercise cycle

start time and day-of-the-week. Exercise cycle only

occurs in AUTO mode.

B - Circuit Breaker — Protects the generator from shorts

and other over-current conditions. Must be ON to

supply power to the Automatic Transfer Switch.

C - 15 Amp Fuse — Protects the home generator DC control

circuits. If the fuse has ‘blown’ (melted open) or was

removed, the engine cannot crank or start. Replace the

fuse using only an identical ATO 15A fuse.

D - System Switch — This two-position switch is the most

important control on the system and is used as follows:

• “AUTO” position is the normal operating position. If a

utility power outage is sensed, the system will start the

generator. When utility power is restored, AUTO lets

the engine stabilize internal temperatures, shuts off the

generator, and waits for the next utility power outage.

E

F

• “OFF” position turns off running generator, prevents

unit from starting and resets any detected faults.

E - Manual Over-Ride Switch — With system switch in

AUTO position, push the manual over-ride switch to

start the generator. To turn off the generator, push and

hold the manual over-ride switch again until engine

stops.

F - Digital Display — Displays the total number of hours

the generator has been running and fault codes. Used

to schedule maintenance tasks and for troubleshooting

operational problems with the home generator. All fault

conditions are described in Fault Detection System.

19

Page 20

Operation

Automatic Operation Sequence

The generator’s control panel houses a logic control circuit

board. This control board constantly monitors utility power

source voltage. Should that voltage drop below a preset level,

control board action will signal the engine to crank and start.

When utility source voltage is restored above a preset

voltage level, the engine is signaled to shut down.

The actual system operation is not adjustable and is sequenced

by sensors and timers on the control board, as follows:

Utility Voltage Dropout Sensor

• This sensor monitors utility source voltage.

• If utility source voltage drops below about 70 percent

of the nominal supply voltage, the sensor energizes a

10 second timer. The timer is used to ‘sense’ brown-outs.

• Once the timer has expired, the engine will crank and

start.

Utility Voltage Pickup Sensor

This sensor monitors utility power supply voltage. When that

voltage is restored above 80 percent of the nominal source

voltage, a time delay starts timing and the engine will go to

engine cool-down.

Engine Cool-down Timer

• When the load is transferred back to the utility power

source, the engine cool-down timer starts timing.

• The timer will run for about one minute, then the

generator will stop.

• Minimum engine run time is 5 minutes.

Automatic Operation

To select automatic operation, do the following:

1. Set the main distribution panel circuit breaker that

sends utility voltage to the transfer switch to ON.

2. Set the generator’s main circuit breaker to its ON

position.

3. Set the system switch to AUTO.

CAUTION

With the system switch set to AUTO, the engine

may crank and start at any time without warning.

Such automatic starting normally occurs when

utility source voltage drops below a preset level

or during the normal exercise cycle.

•

To prevent possible injury that may be caused by such

sudden starts, always set the system switch to OFF.

•

Remove the 15 Amp fuse before working on or around

the generator or transfer switch.

Checking Automatic Operation

To check the system for proper automatic operation, proceed

as follows:

1. Turn OFF the main distribution panel circuit breaker

sending power to the automatic transfer switch.

The engine will crank and start when the utility voltage drops

out and the sensor has timed out. Let the system go through

its entire automatic operation sequence.

2. With the generator output supplying its loads, turn ON

the main distribution panel circuit breaker that supplies

utility power to the automatic transfer switch.

3. The automatic transfer switch will transfer loads back

to the utility power after 5 minute minimum run time

and utility is restored.

4. The generator will run for an additional one minute for

engine cool down, then shut down.

NOTE: If utility is restored and generator does not shut down

after 10 minutes, set system switch to OFF and contact your

installer or local service center.

This completes the test procedures for automatic operation.

The home generator will now start automatically when utility

power is lost and will supply power to the transfer switch.

20 BRIGGSandSTRATTON.COM

Page 21

Setting Exercise Timer

The home generator is equipped with an exercise timer that

will start and exercise the system once every seven days.

During this exercise period, the unit runs for approximately

20 minutes and then shuts down. Electrical load transfer

DOES NOT occur during the exercise cycle (unless an utility

power outage occurs).

A button on the control panel is labeled “Set Exercise” (see

System Control Panel). The specific day and the specific

time of day this button is pressed is programmed into the

control board memory. This date and time is then used to

automatically initiate the system exercise cycle. The “SET

EXERCISE” legend on the control panel will flash until the set

exercise cycle is set.

To perform the Set Exercise procedure:

1. Choose the day and time you want your home

generator to exercise.

2. On that day and time, press and hold down the “Set

Exercise” button for three seconds.

NOTE: “SET EXERCISE” will flash until the button is pressed

for three seconds, then “SET EXERCISE” will illuminate for

5 seconds, and finally turn off.

3. The unit will then start and run it’s 20 minute exercise

cycle.

For example, if you press the “Set Exercise” button on

Sunday morning at 10:00 AM, the unit will run an immediate

exercise cycle and then the following Sunday at 10:00 AM

(+/- 1/2 hour).

NOTE: “Set Exercise” will only work if the unit is in the

Automatic mode and this exact procedure is followed.

The exerciser will need to be re-set if the 15 Amp fuse

is removed or changed, or if the 12 Volt DC battery is

disconnected.

If you want to change the day and time the unit exercises,

simply perform the “Set Exercise” procedure at the exact

weekday and time you want it to take place.

21

Page 22

Maintenance

Servicing the System

To service system:

1. Set the system switch to OFF.

2. Set the generator’s main circuit breaker to its OFF position.

3. Utility voltage is present. Disconnect power before

servicing by removing the two 2 Amp fuses from the

transfer switch.

Fault Detection System

The generator may have to run for long periods of time with

no operator present. For that reason, the system is equipped

with sensors that automatically shut down the generator

in the event of potentially damaging conditions, such as

low oil pressure, high temperature, over speed, and other

conditions.

The generator’s control panel has a digital display that shows

fault codes, like “FC_1”. The table below lists the detected

fault, the fault code as displayed on the control panel, and

the number of blinks seen on the remote LED indicator.

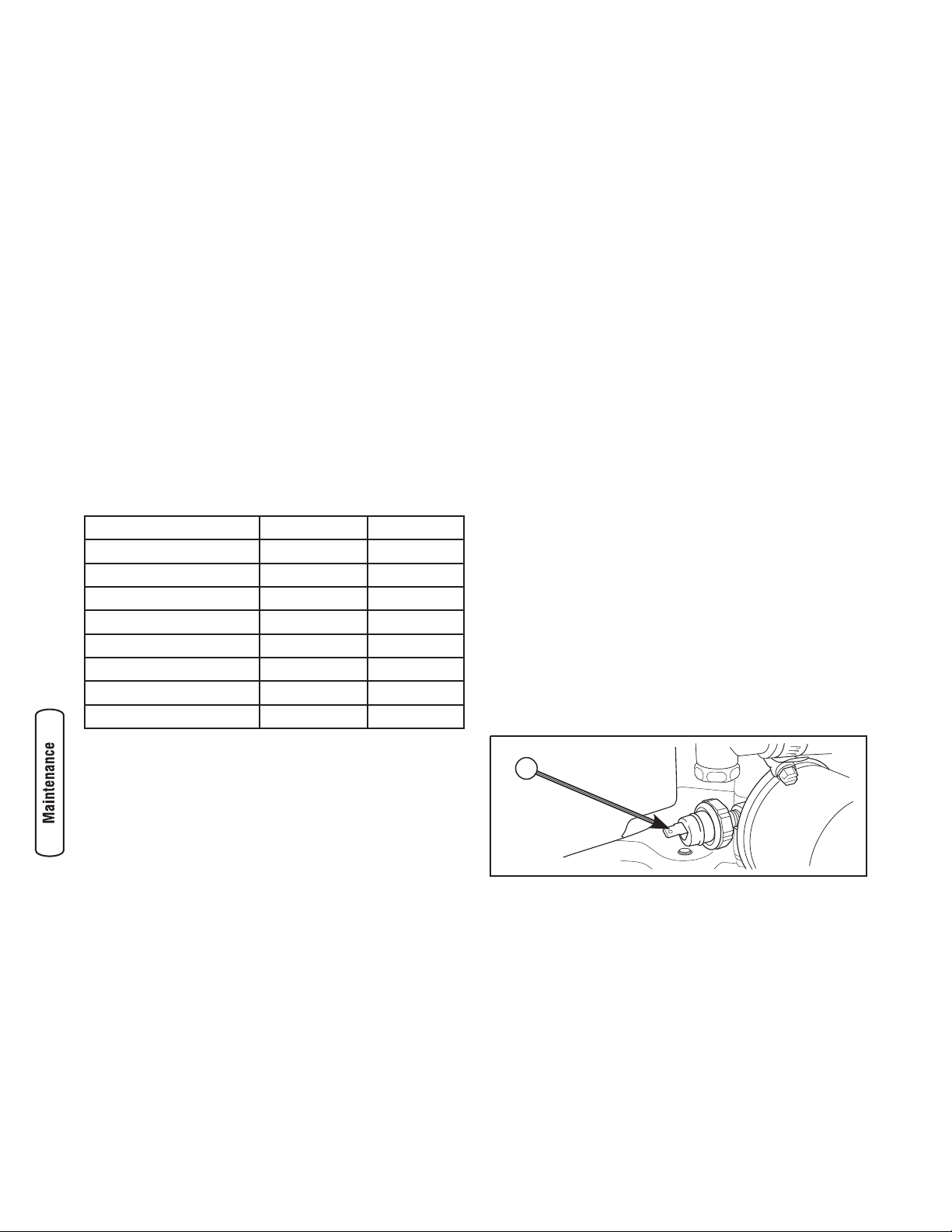

Fault Description Fault Codes LED Flashes

Low battery voltage

Low oil pressure FC_2

Low voltage

Engine fails to start

Low frequency

Engine overspeed

High temperature

Transfer switch fault

The remote LED indicator is installed at a convenient inside

location. The LED will remain lit when the generator is in

AUTO. The LED will turn on and off in a series of blinks that

correspond to the fault detected in your home generator. The

blink pattern is repeated with a brief pause between each

series of blinks.

FC_1 1

2

FC_3 3

FC_4 4

FC_5 5

FC_6 6

FC_7 7

FC_8 8

No LED - Discharged Battery

If there is a detected fault condition but the LED is

not blinking, this is because the battery is completely

discharged. To remedy the problem, remove the 15 Amp

fuse and disconnect the battery from the generator. Take

the battery to a local battery store for analysis. Replace the

battery after it has been fully recharged, connecting the

NEGATIVE cable last. Then install the 15 Amp fuse in the

control panel.

NOTE: With the battery installed, all wiring to transfer switch

and home generator completed, utility power supplied to

the Automatic Transfer Switch, and the system switch in

AUTO position, the battery receives a trickle charge while

the engine is not running. The trickle charge is not able to

recharge a battery that is completely discharged. See Battery

in Maintenance.

Low Battery Voltage

This fault is indicated by fault code FC_1 and one blink on

the LED indicator. This condition occurs if the generator

cannot start because the starting battery output power is

below that needed to crank the engine. Causes for this

problem may be a faulty battery or battery charge circuit.

To remedy the problem, contact your local service center to

check the battery charge output. Remove the 15 Amp fuse

and disconnect the battery from the generator. Take the

battery to a local battery store for analysis. Replace ONLY

with same type battery as described in Battery in Installation.

Replace the battery after it has been fully recharged, connecting

the NEGATIVE cable last. Then install the 15 Amp fuse.

Low Oil Pressure

This fault is indicated by fault code FC_2 and two blinks on

the remote LED indicator. The unit is equipped with an oil

pressure switch (A).

A

Reset Fault Detection System

The operator must reset the fault detection system each time

it activates. To do so, place the system switch in the OFF

position for 5 seconds or more. Remedy the fault condition,

then return the home generator to service by placing the

system switch in the AUTO position.

A description of each fault and suggested remedies are as

follows:

22 BRIGGSandSTRATTON.COM

The oil pressure switch uses normally closed contacts that

are held open by engine oil pressure during operation.

Should oil pressure drop below the 8 psi range, switch

contacts close and the engine is shut down.

To remedy the low oil pressure condition, add the

recommended oil to the FULL mark on the dipstick.

If the low oil pressure condition still exists, the engine will

start, then shut down after about 20 seconds. The fault code

will appear and the LED will flash. In this case, contact a

Briggs & Stratton Authorized Dealer.

Page 23

Low Voltage (Generator)

This fault is indicated by fault code FC_3 and three blinks on

the LED indicator. This condition is caused by a restriction in

the fuel flow, a broken or disconnected signal lead, a failed

alternator winding, the control panel circuit breaker is open,

or the generator is overloaded.

To remedy the problem, contact your installer or a Briggs &

Stratton Authorized Dealer.

Engine Fail To Start

This fault is indicated by fault code FC_4 and four blinks on

the LED indicator. This feature prevents the generator from

damaging itself if it continually attempts to start in spite

of another problem, such as no fuel supply. Each time the

system is directed to start, the unit will crank for 10 seconds,

pause for 10 seconds, and repeat. If the system does not

begin producing electricity after approximately 2 minutes,

the unit will stop cranking and the LED will blink.

Check to make sure the generator’s main circuit breaker is in

the ON position in order for the sensing leads to verify that

the unit is running.

The most likely cause of this problem is no fuel supply.

Check the inside and outside fuel shut off valves to ensure

they are fully open. Other causes could be failed spark

plug(s), failed engine ignition, or the engine air filter

is clogged. You may need to contact your installer for

assistance if you can’t remedy these problems.

Engine Overspeed

This fault is indicated by fault code FC_6 and six blinks on

the LED indicator. This feature protects devices connected

to the transfer switch by shutting the generator down if

the engine happens to run faster than the preset limit. The

overspeed fault is detected as follows:

• If the generator output frequency is 65-70 Hz, after

three seconds, the generator will shut down.

• If the generator output frequency is greater than 70 Hz,

the generator will shut down immediately.

This condition is caused by a failed engine governor.

To remedy the problem, contact your installer or a

Briggs & Stratton Authorized Dealer.

High Temperature

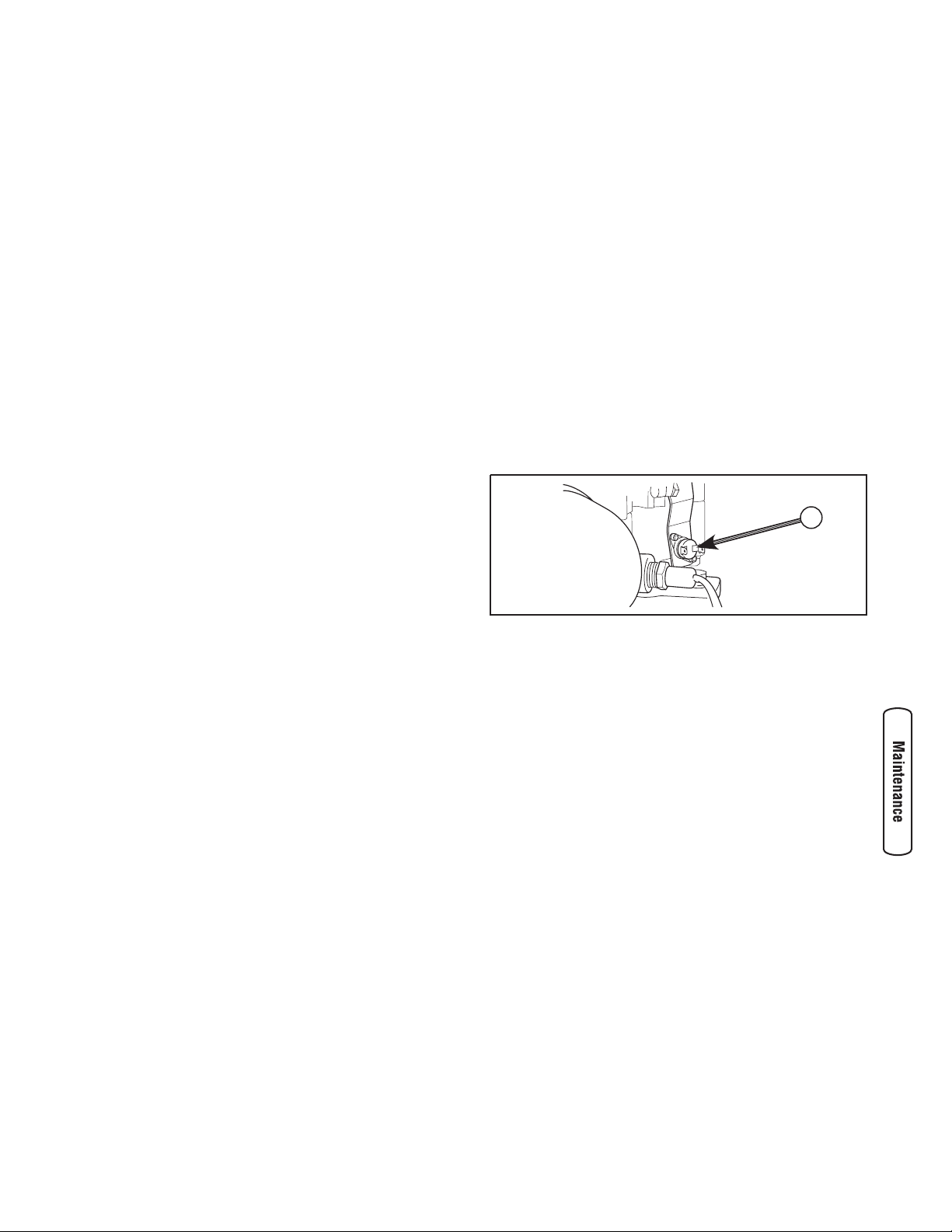

This fault is indicated by fault code FC_7 and seven blinks

on the LED indicator. The contacts of the temperature switch

(A) are normally open. If the engine oil temperature exceeds

approximately 148.9°C (300°F), the fault is detected and the

engine shuts down.

A

Low Frequency

This fault is indicated by fault code FC_5 and five blinks on

the LED indicator. This feature protects devices connected

to the transfer switch by shutting the generator down

if the engine runs slower than 55 Hz for three seconds.

This condition is caused by a failed engine governor or by

excessive loads on the generator. To remedy the problem,

contact your installer or a Briggs & Stratton Authorized

Dealer.

Common causes for this condition include running the

unit with all access covers removed, obstructed air inlet or

exhaust port, low oil level, or debris in the engine cylinder

cooling fins.

To resolve the problem, let the engine cool down and remove

any accumulated debris and obstructions. Ensure that the

access covers are installed whenever the unit is running.

Transfer Switch Fault

This fault is indicated by fault code FC_8 and eight blinks on

the LED indicator (if transfer switch is equipped with fault

detection). The most likely cause of this fault is a blown fuse

in the transfer switch.

To remedy the problem, contact your installer or a Briggs &

Stratton Authorized Dealer.

23

Page 24

Generator Maintenance

The generator warranty does not cover items that have been

subjected to operator abuse or neglect. To receive full value

from the warranty, the operator must maintain the system as

instructed in the engine operator’s manual.

All adjustments should be made at least once each season.

Follow the requirements in the engine operator’s manual.

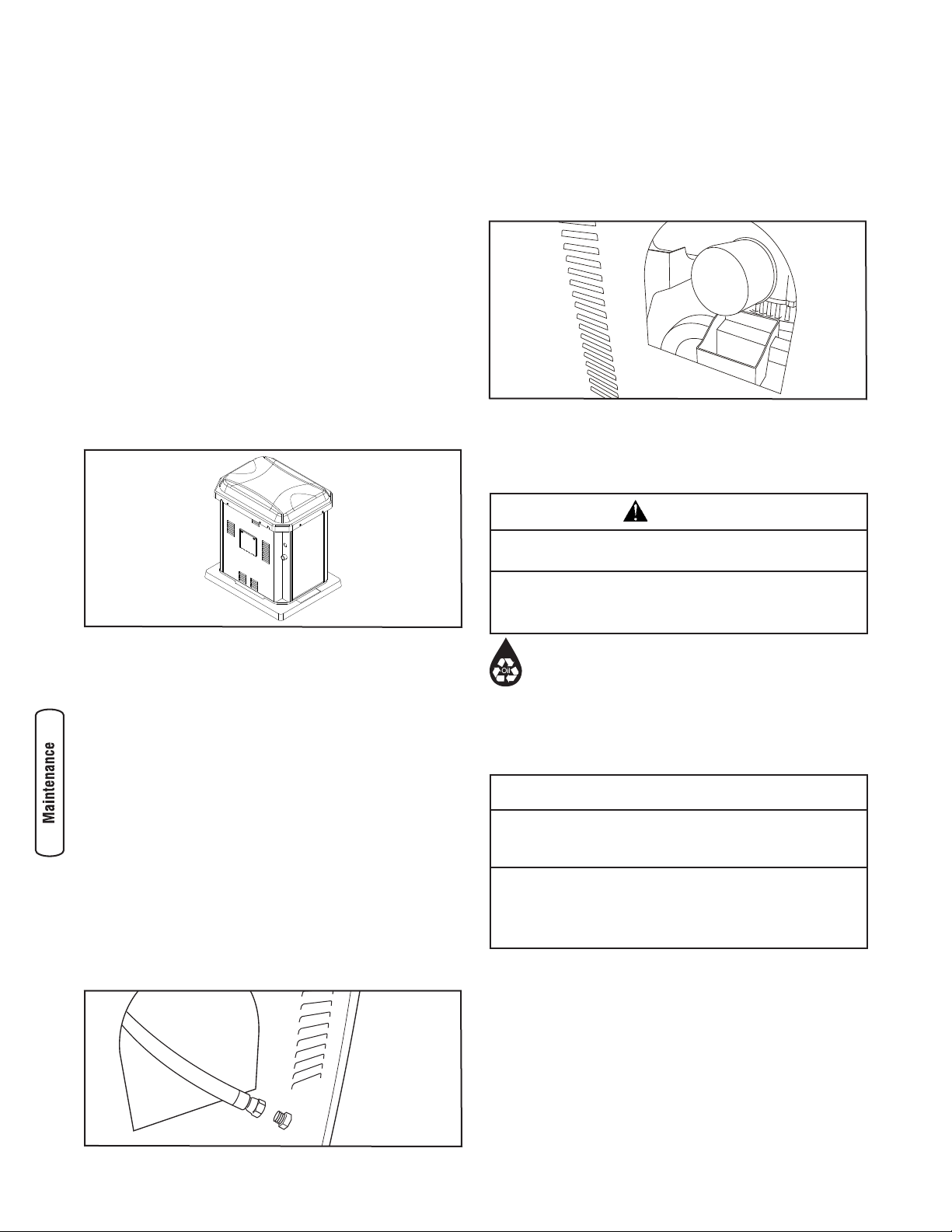

Generator maintenance consists of keeping the unit

clean. Operate the unit in an environment where it will

not be exposed to excessive dust, dirt, moisture or any

corrosive vapors. Cooling air louvers on the enclosure

must not become clogged with snow, leaves, or any other

foreign material. To prevent generator damage caused by

overheating, keep the enclosure cooling inlets and outlets

clean and unobstructed at all times.

Check the cleanliness of the unit frequently and clean when

dust, dirt, oil, moisture or other foreign substances are

visible on its exterior/interior surface. Inspect the air inlet

and outlet openings inside and outside the enclosure to

ensure air flow is not blocked.

3. When the oil has drained, replace brass plug into tube.

4. Slide the oil drain tube up into the beaded tie wrap on

the fuel hose.

Changing Oil Filter

1. Place oil drain tray over tubing and slide it under oil

filter.

2. Follow instructions given in engine operator’s manual

for changing oil filter.

3. Remove oil drain tray from under oil filter and clean up

any spilled oil.

CAUTION

NOTE: DO NOT use direct spray from a garden hose to clean

generator. Water can enter the engine and generator and

cause problems.

Engine Oil

The system is filled with synthetic oil (API SJ/CF 5W-30W).

This allows for system operation in the widest range of

temperature and climate conditions.

NOTE: The use of synthetic oil does not alter the required oil

change intervals described in the engine operator’s manual.

Changing Engine Oil and Filter

Remove the two screws from each plastic access cover

and remove both access covers from the two sides of the

generator enclosure.

Changing Oil

1. Place the oil drain tube into an approved container.

2. Remove brass plug from tube opposite of engine.

Avoid prolonged or repeated skin contact with used motor

oil.

•

Used motor oil has been shown to cause skin cancer in

certain laboratory animals.

•

Thoroughly wash exposed areas with soap and water.

KEEP OUT OF REACH OF CHILDREN. DON’T POLLUTE.

CONSERVE RESOURCES. RETURN USED OIL TO

COLLECTION CENTERS.

To fill your engine with oil:

Follow the synthetic oil grade recommendation and oil fill

instructions given in the engine operator’s manual.

NOTICE

Any attempt to crank or start the engine before it has been

properly serviced with the recommended oil will result in

equipment failure.

•

Refer to

information.

Damage to equipment resulting from failure to follow this

•

instruction will void engine and generator warranty.

Air Filter

The engine for this generator is equipped with a UL

recognized air filter. When servicing the air filter, follow the

instructions given in the engine operators manual. Replace

ONLY with same type UL recognized air filter, P/N 790263.

Maintenance and engine manual for oil fill

24 BRIGGSandSTRATTON.COM

Page 25

Battery

WARNING

Battery posts, terminals and related accessories contain

lead and lead compounds, chemicals known to the State

of California to cause cancer and reproductive harm.

Wash hands after handling.

Charging the Battery

If it is necessary to charge the battery, proceed as follows:

1. Set generator’s system switch to OFF.

2. Remove 15 Amp fuse from control panel.

3. Disconnect negative battery cable to negative battery

terminal (indicated by NEGATIVE, NEG, or (-).

NOTICE

NOTE: With the battery installed and utility power available

to the transfer switch, the battery receives a trickle charge

whenever the engine is not running. It may take up to

72 hours to fully charge a battery with the trickle charge.

The trickle charge is not able to recharge a battery that is

completely discharged.

5. Connect negative battery cable to negative battery

terminal (indicated by NEGATIVE, NEG, or (-)).

6. Ensure hardware on both positive and negative battery

terminals is secure.

7. Reinstall 15 Amp fuse in control panel.

CAUTION

Installing the 15A fuse could cause the engine

to start.

Failure to disconnect negative battery cable will result in

equipment failure.

•

DO NOT attempt to jump start the battery.

•

Damage to equipment resulting from failure to follow this

instruction will void warranty.

4. Charge battery with battery charger at 2 Amps until

battery holds 12 Volts.

NOTE: DO NOT exceed 13.7 Volts charging.

WARNING

Storage batteries give off explosive hydrogen

gas during recharging.

Slightest spark will ignite hydrogen and cause

explosion.

Battery electrolyte fluid contains acid and is

extremely caustic.

Contact with battery contents will cause severe

chemical burns.

A battery presents a risk of electrical shock and

high short circuit current.

•

DO NOT dispose of battery in a fire.

•

DO NOT allow any open flame, spark, heat, or lit cigarette

during and for several minutes after charging a battery.

•

DO NOT open or mutilate the battery.

•

Wear protective goggles, rubber apron, and rubber

gloves.

Remove watches, rings, or other metal objects.

•

Use tools with insulated handles.

•

DO NOT install this fuse until all plumbing and wiring has

•

been completed and inspected.

8. Set generator’s system switch to AUTO.

Servicing the Battery

If it is necessary to service the battery, proceed as follows:

1. Remove “Control Panel” access cover.

2. Set generator’s system switch to OFF.

3. Remove 15 Amp fuse from control panel.

4. Service or replace battery as required.

NOTE: Replace ONLY with same type battery as described in

Battery in Installation.

5. Connect red battery cable to battery positive terminal

(indicated by POSITIVE, POS, or (+)).

6. Connect negative battery cable to negative battery