Briggs & Stratton 146400 User Manual

Briggs & Sfr?Je*©iii!

mo AND MA^NTlfsiAWCl

INSTRUCTIONS

MODELS

146400 to 146457

170400 to 170457

190400 to 190457

IN THE INTEREST OF SAFETY, 00 NOT RUN ENGINE AT EXCESSIVE SPEEDS

Operating an engine at excessive speeds increases the hazard of personal injury. DO NOT TAMPER WITH PARTS WHICH MAY

INCREASE THE GOVERNED SPEED.

For rotary lawnmower safety, USA Standard Safety Specifications for Power Lawn Mowers specify a maximum blade tip speed

of 19,000 feet per minute, primarily to reduce the hazard from thrown objects.

Rotary lawnmower manufacturers select the governed top speed of the engine based on the length and design of the cutter

blade and design of other mower parts.

All rotary lawnmowers should be checked for conformance to the USA Standard Safety Specifications for Power Lawn Mowers

on blade tip speed, if the engine is repaired or replaced, or if mower parts are changed.

Dirt and grass clippings, or other debris, in cooling fins or governor parts can affect engine speed. See cleaning instruc

tions in Section 3.

TO PREVENT ACCIDENTAL STARTING always remove the spark plug before working on the engine or equipment driven by the

engine or remove cable from spark plug and insert terminal in V-notch in cylinder head cover.

DO NOT RUN THE ENGINE IN AN ENCLOSED AREA. Exhaust gases contain carbon monoxide, an odorless and deadly poison.

DO NOT FILL GASOLINE TANK WHILE ENGINE IS RUNNING. Spilling gasoline on a hot engine may cause a fire or explosion.

CAUTIOIM

Section

1

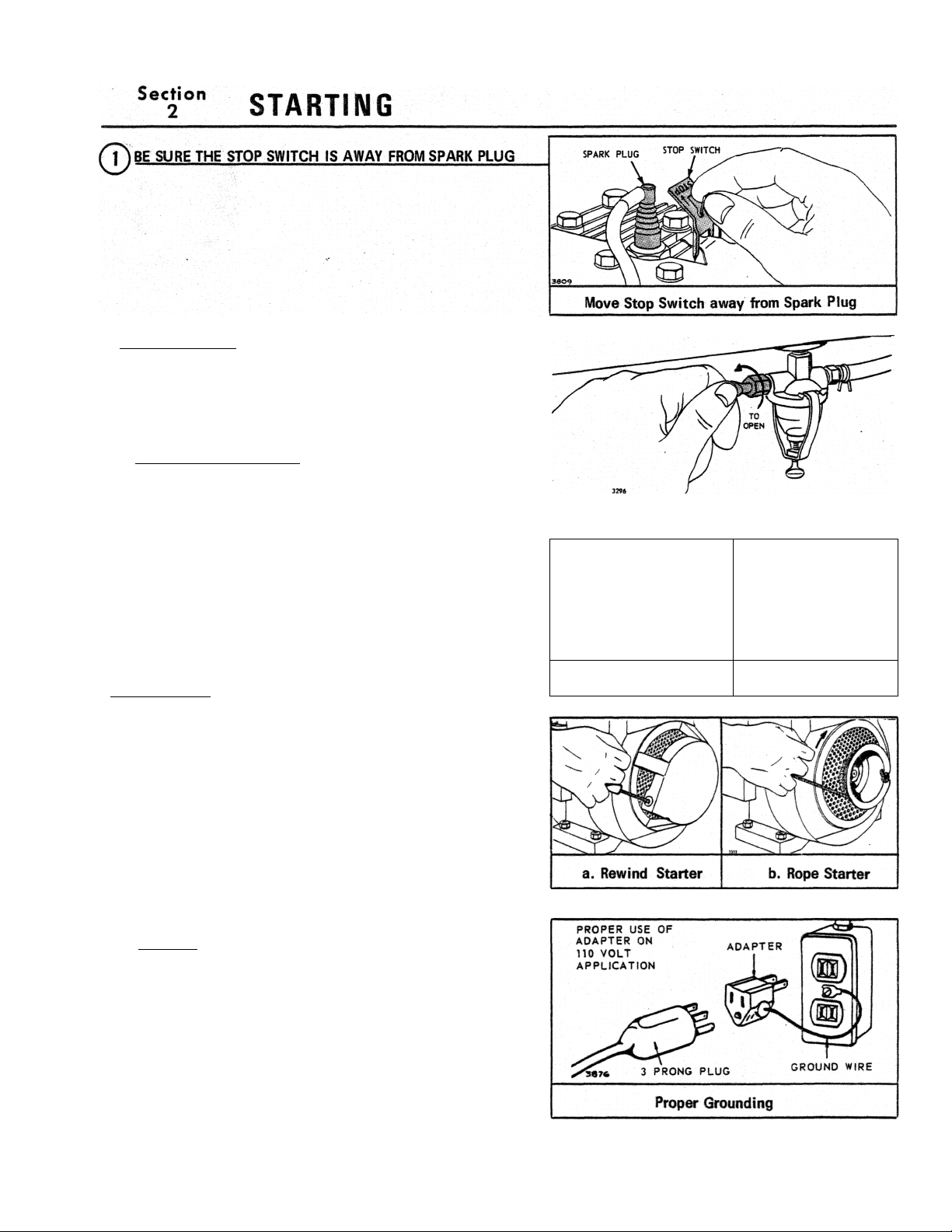

FILL CRANKCASE WITH OIL-Use a high quality de

tergent oil classified "For Service SCorSD or MS".

©

Nothing should be added to the recommended oil.

Summer Winter

(Above 40® F.) (Under 40® f.)

Use SAE 30 Use SAE 5W-20 or SAE 5W-30

If not available. If not available.

Use SAE 10W-30 Use SAE 10W or SAE 10W-30

CAP 1 oW-40 Below 0® F,

DIRECTIONS: Place the engine level. FILL THE OIL

SUMP TO OVERFLOWING or to the FULL mark on dip

stick. Pour slowly. Capacity 2-3/4 pints.

EXTENDED OIL FILL (Optional). Remove cap and dip

stick and fill to full mark on dipstick. When checking

oil level push dipstick assembly firmly but slowly until

cap bottoms on tube. Do not overfill. Dipstick assem

bly must be pushed fully into tube at all times when

engine is operating.

FILL FUEL TANK — Use clean, fresh, lead-free or

leaded "regular" grade automotive gasoline. Fill

©

tank completely !

DO NOT MIX OIL WITH GASOLINE.

BEFORE STARTING

Use SAE 10W or SAE 10W-30

Diluted 10% with Kerosene

READ THE OPERATING INSTRUCTIONS OF

THE EQUIPMENT THIS ENGINE POWERS

AIR CLEANER

OIL DRAIN PLUG

OIL FILLER PLUG

FORM NO. 270367-71

PRINTED !N U.S.A.

BRIGGS & STRATTON CORP.

Milwaukee, Wisconsin 53201

(T) OPEN FUEL VALVE

CHOKE THE CARBURETOR

a. (Vlanual Type

Move lever in direction of arrow to fully closed choke

position. Set governor control in normal operating po

sition.

b. Choke-A-Matic

Move lever to 'Tull Choke" or "Start" position.

Mote: This should fully close choke on carburetor. If

it does not, remote control must be re-adjusted. See

"Choke-A-Matic Carburetor" Adjustments, Section 4.

Note: A warm engine requires less choking than a

cold engine.

(j^START ENGINE

a. Rewind Starter Grasp starter grip as Illustrated and

pull out cord two to three feet. Repeat If necessary

with choke opened slightly. When engine starts open

choke gradually.

Opening Fuel Valve

a.- Manual Type

b. Choke-A-Matic

b. Rope Starter Wind the starter rope around the pulley

in direction shown by arrow. Pull the rope with a

quick full arm stroke. Repeat if necessary with choke

opened slightly. When engine starts open choke grad

ually.

c. Electric. Starter Press starter button on powered

equipment. When engine starts open choke gradually.

CAUTION: The 110 volt electric starter is equipped

with a three prong plug for your safety. If a longer

extension cord is used it should also have three-prong

and three hole plugs. If the outlet or receptacle is the

two-hole type, an adapter must be used. To get the

proper grounding, fasten the ground lead on the adapter

to something electrically grounded, such as the metal

box on the end of a grounded metal conduit.

FORM NO. 270367-71

Loading...

Loading...