Page 1

Not for

Reproduction

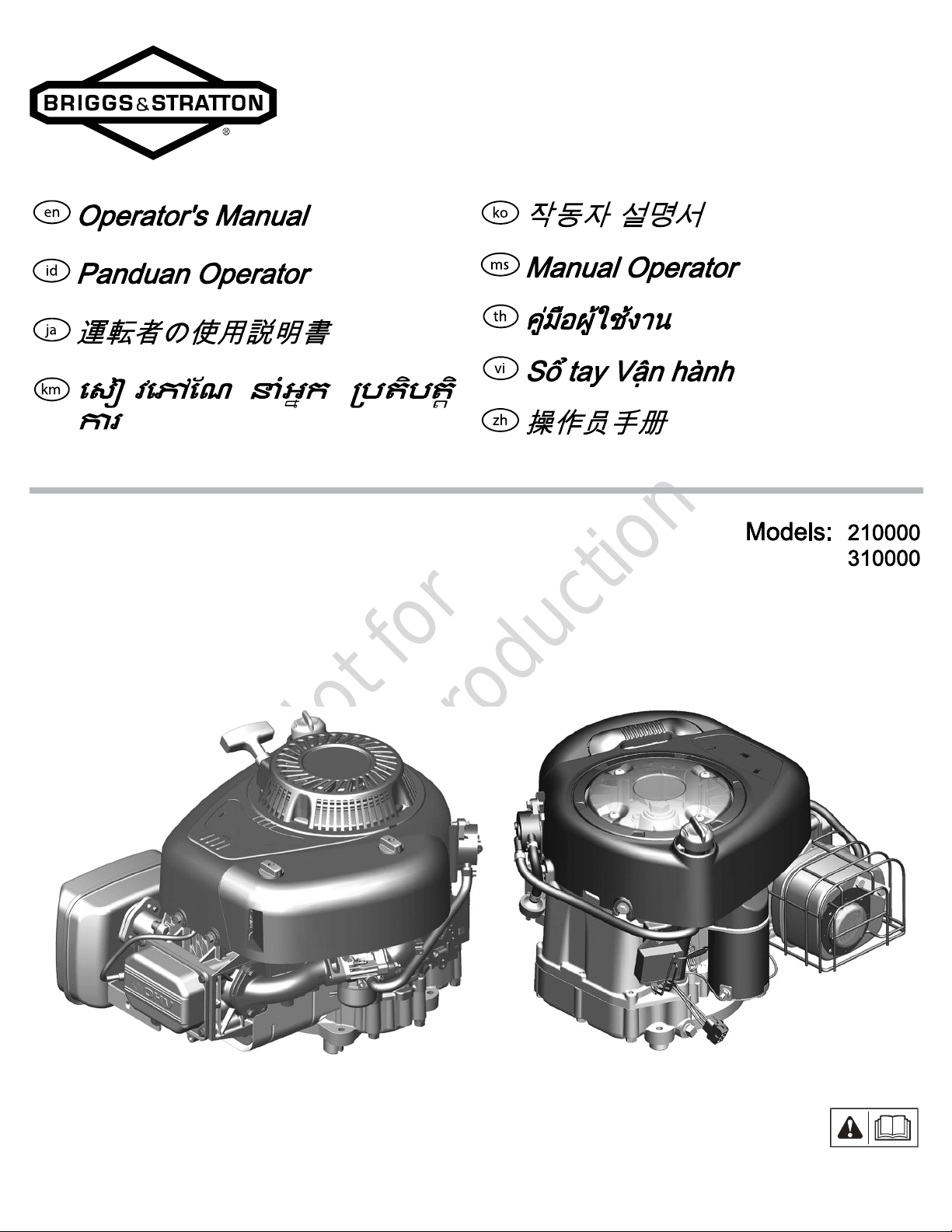

Copyright © Briggs & Stratton Corporation

Milwaukee, WI, USA. All rights reserved.

80030284SEA

Revision: A

Page 2

Not for

Reproduction

1

2

5

6

9

10

3

4

7

11

8

2 BRIGGSandSTRATTON.com

Page 3

Not for

Reproduction

12

13

15

16

14

3

Page 4

Not for

Reproduction

Copyright © Briggs & Stratton Corporation, Milwaukee, WI, USA. All rights reserved.

This manual contains safety information to make you aware of the hazards and risks

associated with enginesand how to avoid them. It also contains instructions for the proper

use and care of the engine. Because Briggs & Stratton Corporation does not necessarily

know what equipment this engine will power, it is important that you read and understand

these instructions and the instructions for the equipment. Save these original instructions

for future reference.

Note:

The figures and illustrations in this manual are provided for reference only and may

differ from your specific model. Contact your dealer if you have questions.

For replacement parts or technical assistance, record below the engine model, type, and

code numbers along with the date of purchase. These numbers are located on your engine

(see the

Features and Controls

Date of Purchase

Engine Model - Type - Trim

Engine Serial Number

Look for the 2D barcode located on some

engines. When viewed with a 2D-capable

device, the code will bring up our website

where you can access support information

for this product. Data rates apply. Some

countries may not have online support

information available.

section).

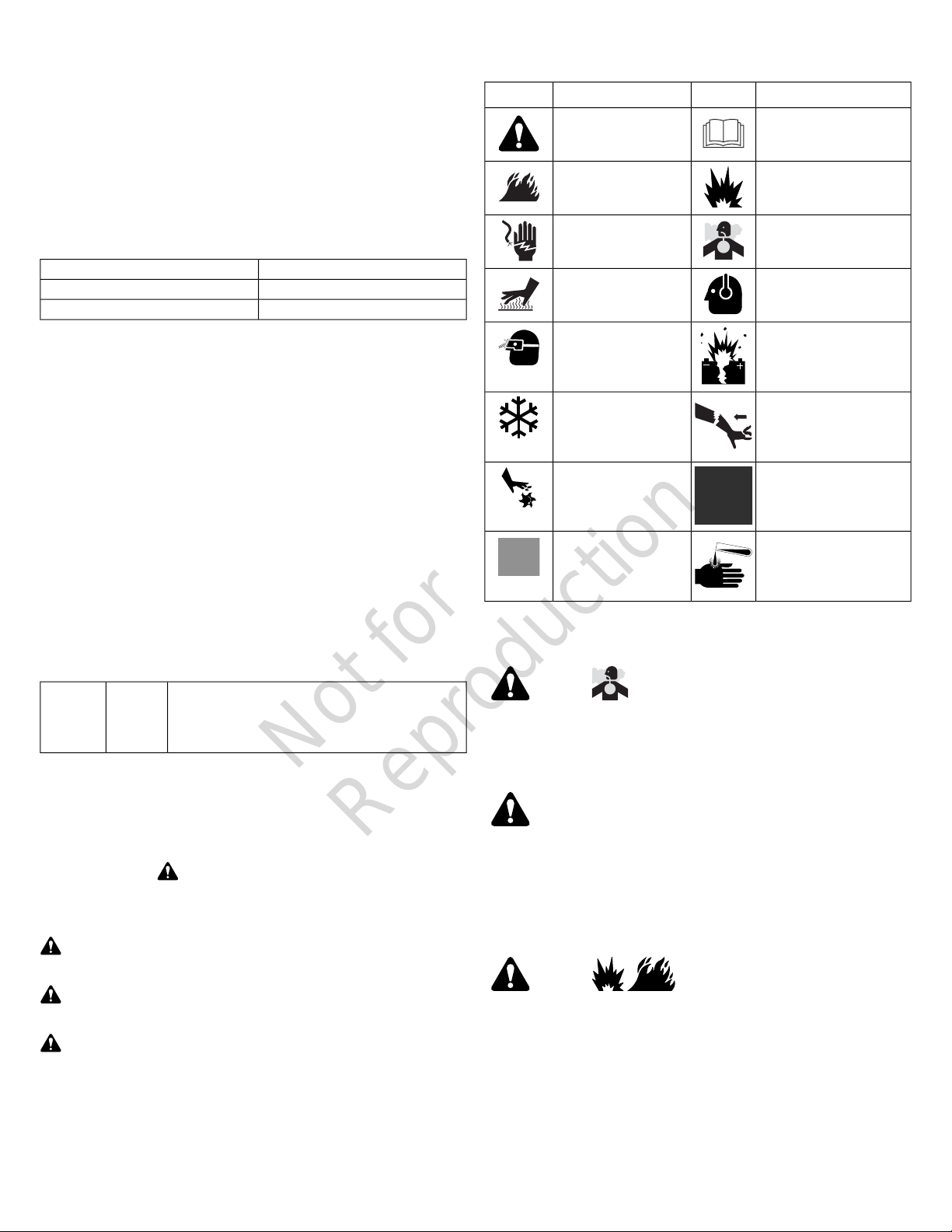

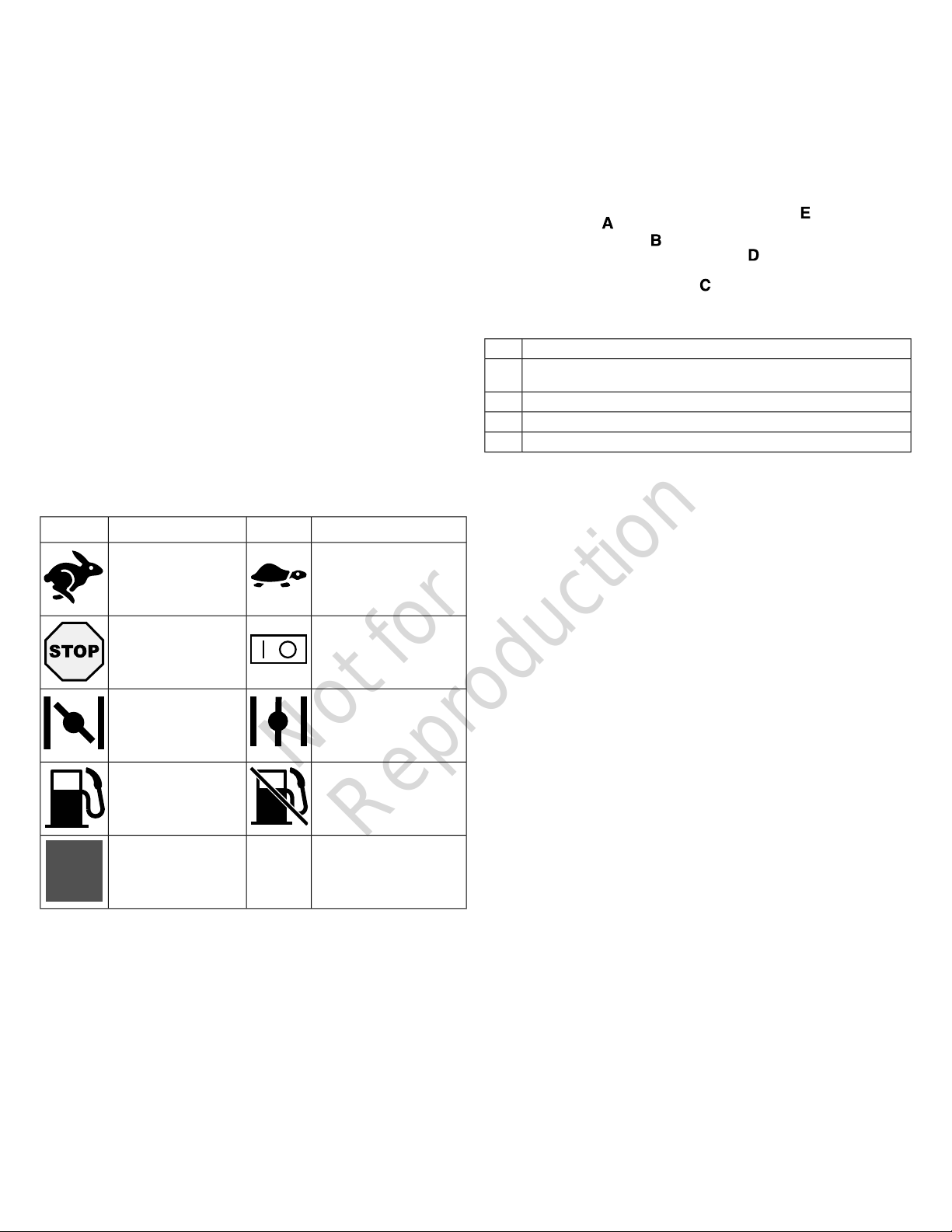

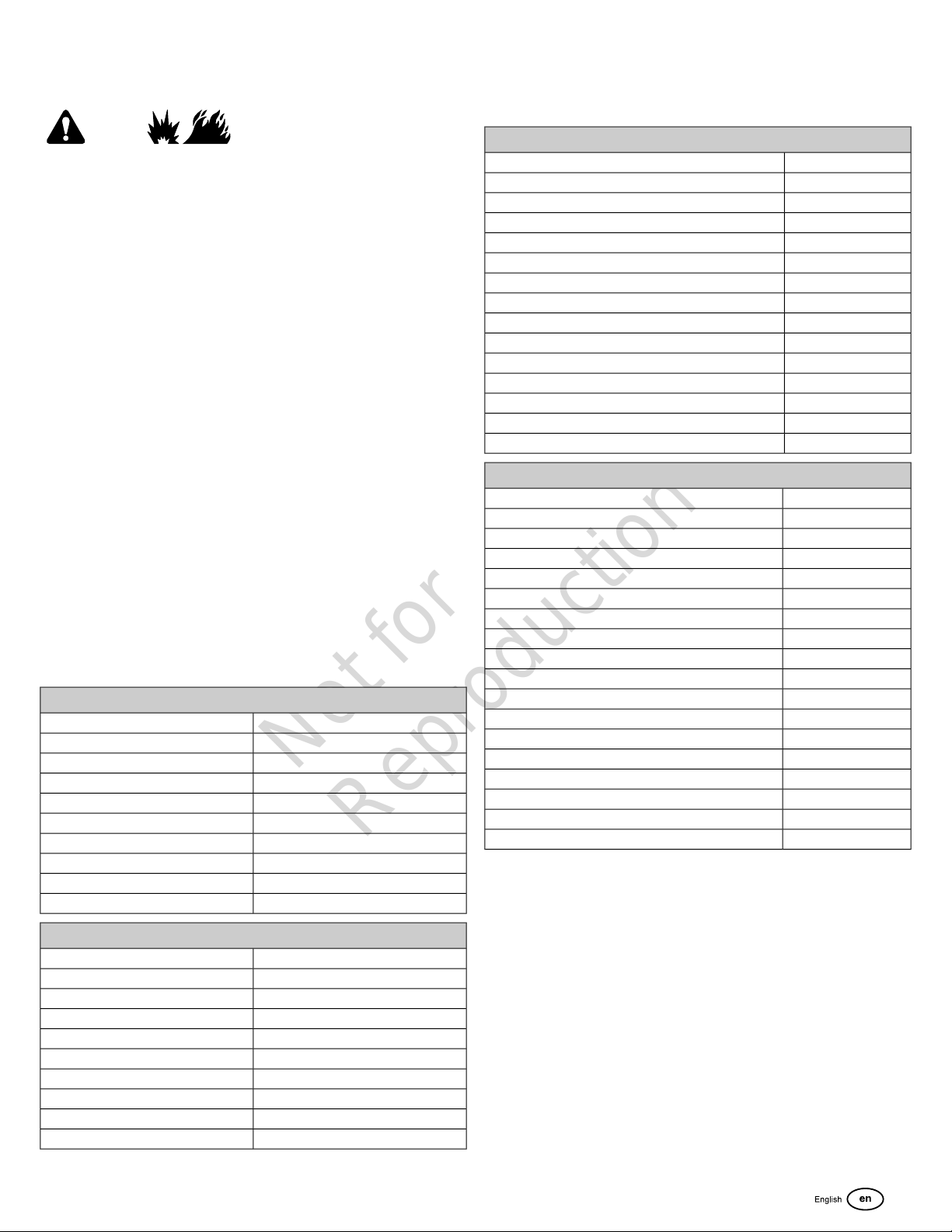

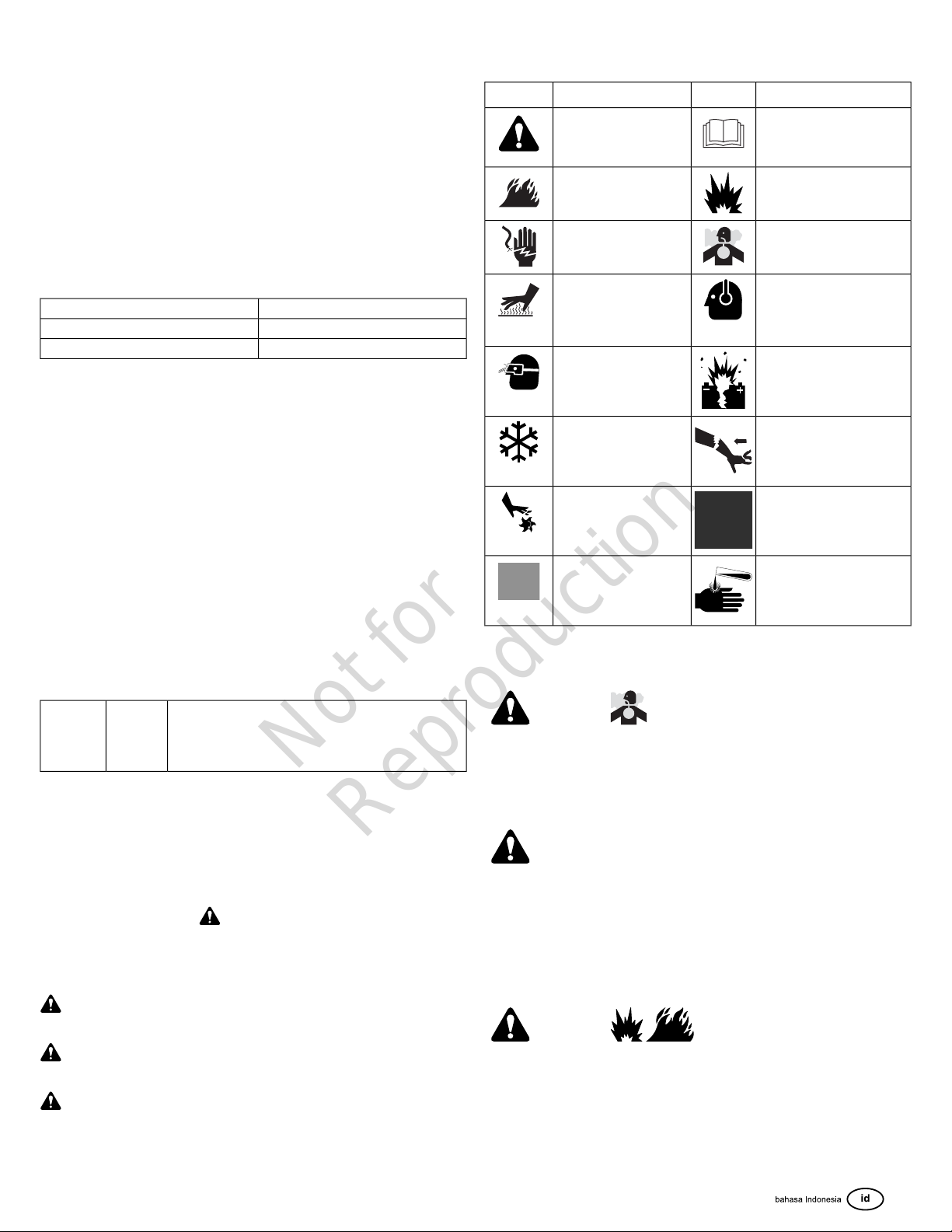

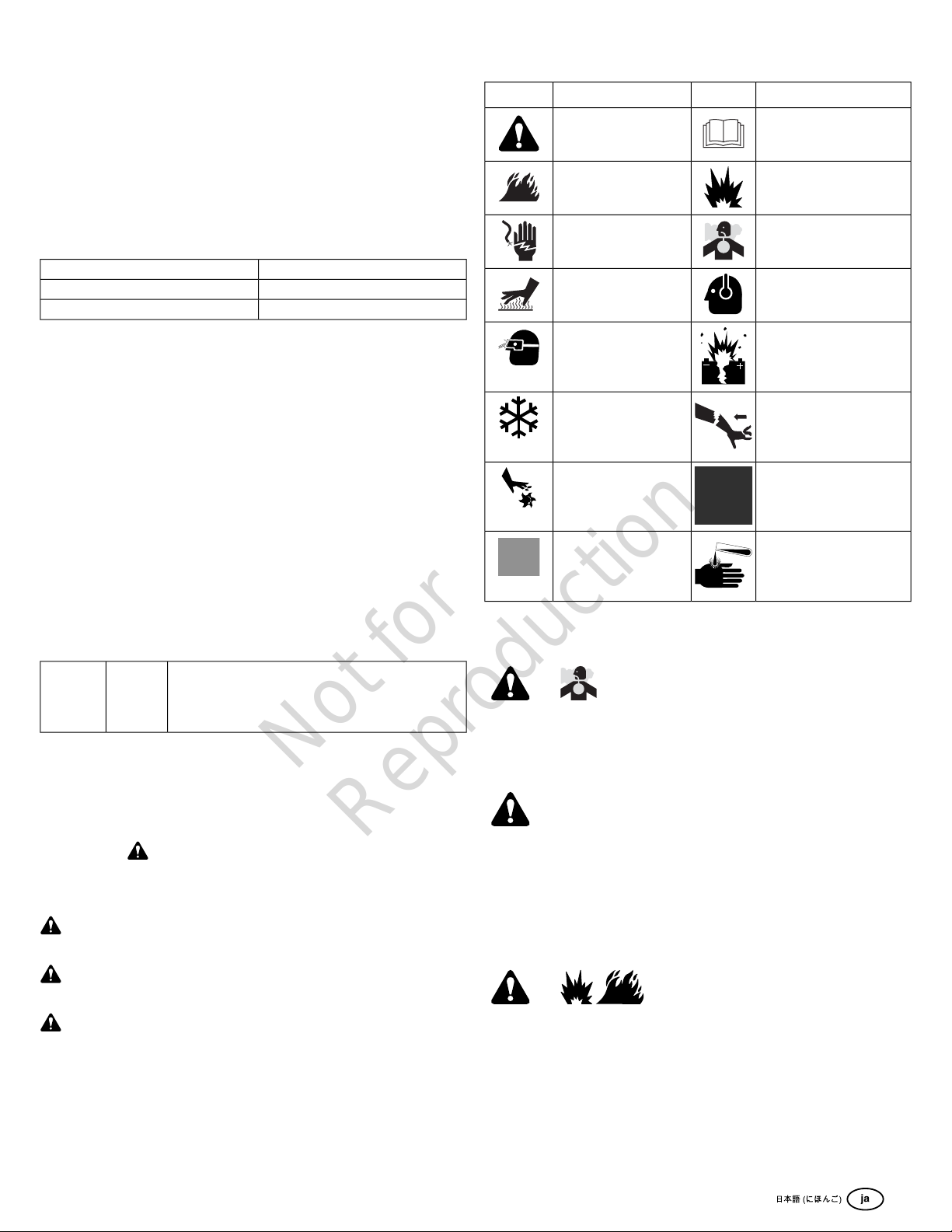

Hazard Symbols and Meanings

Safety information about

hazards that can result in

personal injury.

Hot surface hazard

Wear eye protection.

Read and understand the

Operator's Manual before

operating or servicing the unit.

Explosion hazardFire hazard

Toxic fume hazardShock hazard

Noise hazard - Ear protection

recommended for extended

use.

Explosion hazardThrown object hazard -

Kickback hazardFrostbite hazard

MeaningSymbolMeaningSymbol

European Office Contact

Information

For questions regarding European emissions, please contact our European office at:

Max-Born-Straße 2, 68519 Viernheim, Germany.

Recycling Information

All packaging, used oil, and batteries should be recycled

according to applicable government regulations.

Operator Safety

Safety Alert Symbol and Signal Words

The safety alert symbol ( ) is used to identify safety information about hazards that can

result in personal injury. A signal word (DANGER, WARNING, or CAUTION) is used with

the alert symbol to indicate the likelihood and the potential severity of injury. In addition, a

hazard symbol may be used to represent the type of hazard.

parts

Chemical HazardAmputation hazard - moving

CorrosiveThermal heat hazard

Safety Messages

WARNING

This product can expose you to chemicals including gasoline engine exhaust, which is

known to the State of California to cause cancer, and carbon monoxide, which is known

to the State of California to cause birth defects or other reproductive harm. For more

information go to www.P65Warnings.ca.gov.

WARNING

Briggs & Stratton® Engines are not designed for and are not to be used to power: funkarts; go-karts; children's, recreational, or sport all-terrain vehicles (ATVs); motorbikes;

hovercraft; aircraft products; or vehicles used in competitive events not sanctioned by

Briggs & Stratton. For information about competitive racing products, see

www.briggsracing.com. For use with utility and side-by-side ATVs, please contact Briggs

& Stratton Power Application Center, 1-866-927-3349. Improper engine application may

result in serious injury or death.

DANGER indicates a hazard which, if not avoided, will result in death or serious

injury.

WARNING indicates a hazard which, if not avoided, could result in death or serious

injury.

CAUTION indicates a hazard which, if not avoided, could result in minor or moderate

injury.

NOTICE

indicates a situation that could result in damage to the product.

When Adding Fuel

4 BRIGGSandSTRATTON.com

WARNING

Fuel and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

• Turn engine off and let engine cool at least 2 minutes before removing the fuel cap.

• Fill fuel tank outdoors or in well-ventilated area.

• Do not overfill fuel tank. To allow for expansion of the fuel, do not fill above the bottom

of the fuel tank neck.

• Keep fuel away from sparks, open flames, pilot lights, heat, and other ignition sources.

Page 5

Not for

Reproduction

• Check fuel lines, tank, cap, and fittings frequently for cracks or leaks. Replace if

necessary.

• If fuel spills, wait until it evaporates before starting engine.

When Starting Engine

• Ensure that spark plug, muffler, fuel cap and air cleaner (if equipped) are in place

and secured.

• Do not crank engine with spark plug removed.

• If engine floods, set choke (if equipped) to OPEN / RUN position, move throttle (if

equipped) to FAST position and crank until engine starts.

When Operating Equipment

• Do not tip engine or equipment at angle which causes fuel to spill.

• Do not choke the carburetor to stop engine.

• Never start or run the engine with the air cleaner assembly (if equipped) or the air

filter (if equipped) removed.

When Changing Oil

• If you drain the oil from the top oil fill tube, the fuel tank must be empty or fuel can

leak out and result in a fire or explosion.

When Tipping Unit for Maintenance

• When performing maintenance that requires the unit to be tipped, the fuel tank, if

mounted on the engine, must be empty or fuel can leak out and result in a fire or

explosion.

When Transporting Equipment

• Transport with fuel tank EMPTY or with fuel shut-off valve in the CLOSED position.

WARNING

Rapid retraction of starter cord (kickback) will pull hand and arm toward engine

faster than you can let go.

Broken bones, fractures, bruises or sprains could result.

• When starting engine, pull the starter cord slowly until resistance is felt and then pull

rapidly to avoid kickback.

• Remove all external equipment / engine loads before starting engine.

• Direct-coupled equipment components such as, but not limited to, blades, impellers,

pulleys, sprockets, etc., must be securely attached.

WARNING

Rotating parts can contact or entangle hands, feet, hair, clothing, or accessories.

Traumatic amputation or severe laceration can result.

• Operate equipment with guards in place.

• Keep hands and feet away from rotating parts.

• Tie up long hair and remove jewelry.

• Do not wear loose-fitting clothing, dangling drawstrings or items that could become

caught.

When Storing Fuel Or Equipment With Fuel In Tank

• Store away from furnaces, stoves, water heaters or other appliances that have pilot

lights or other ignition sources because they can ignite fuel vapors.

WARNING

Starting engine creates sparking.

Sparking can ignite nearby flammable gases.

Explosion and fire could result.

• If there is natural or LP gas leakage in area, do not start engine.

• Do not use pressurized starting fluids because vapors are flammable.

WARNING

POISONOUS GAS HAZARD. Engine exhaust contains carbon monoxide, a

poisonous gas that could kill you in minutes. You CANNOT see it, smell it, or taste

it. Even if you do not smell exhaust fumes, you could still be exposed to carbon

monoxide gas. If you start to feel sick, dizzy, or weak while using this product,

get to fresh air RIGHT AWAY. See a doctor. You may have carbon monoxide

poisoning.

• Operate this product ONLY outside far away from windows, doors and vents to reduce

the risk of carbon monoxide gas from accumulating and potentially being drawn

towards occupied spaces.

• Install battery-operated carbon monoxide alarms or plug-in carbon monoxide alarms

with battery back-up according to the manufacturer's instructions. Smoke alarms

cannot detect carbon monoxide gas.

• DO NOT run this product inside homes, garages, basements, crawlspaces, sheds,

or other partially-enclosed spaces even if using fans or opening doors and windows

for ventilation. Carbon monoxide can quickly build up in these spaces and can linger

for hours, even after this product has shut off.

• ALWAYS place this product downwind and point the engine exhaust away from

occupied spaces.

WARNING

Running engines produce heat. Engine parts, especially muffler, become extremely

hot.

Severe thermal burns can occur on contact.

Combustible debris, such as leaves, grass, brush, etc. can catch fire.

• Allow muffler, engine cylinder and fins to cool before touching.

• Remove accumulated debris from muffler area and cylinder area.

• It is a violation of California Public Resource Code, Section 4442, to use or operate

the engine on any forest-covered, brush-covered, or grass-covered land unless the

exhaust system is equipped with a spark arrester, as defined in Section 4442,

maintained in effective working order. Other states or federal jurisdictions may have

similar laws. Contact the original equipment manufacturer, retailer, or dealer to obtain

a spark arrester designed for the exhaust system installed on this engine.

WARNING

Unintentional sparking can result in fire or electric shock.

Unintentional start-up can result in entanglement, traumatic amputation, or

laceration.

Fire hazard

Before performing adjustments or repairs:

• Disconnect the spark plug wire and keep it away from the spark plug.

• Disconnect battery at negative terminal (only engines with electric start.)

• Use only correct tools.

• Do not tamper with governor spring, links or other parts to increase engine speed.

• Replacement parts must be of the same design and installed in the same position

as the original parts. Other parts may not perform as well, may damage the unit, and

may result in injury.

• Do not strike the flywheel with a hammer or hard object because the flywheel may

later shatter during operation.

When testing for spark:

• Use approved spark plug tester.

• Do not check for spark with spark plug removed.

5

Page 6

Not for

Reproduction

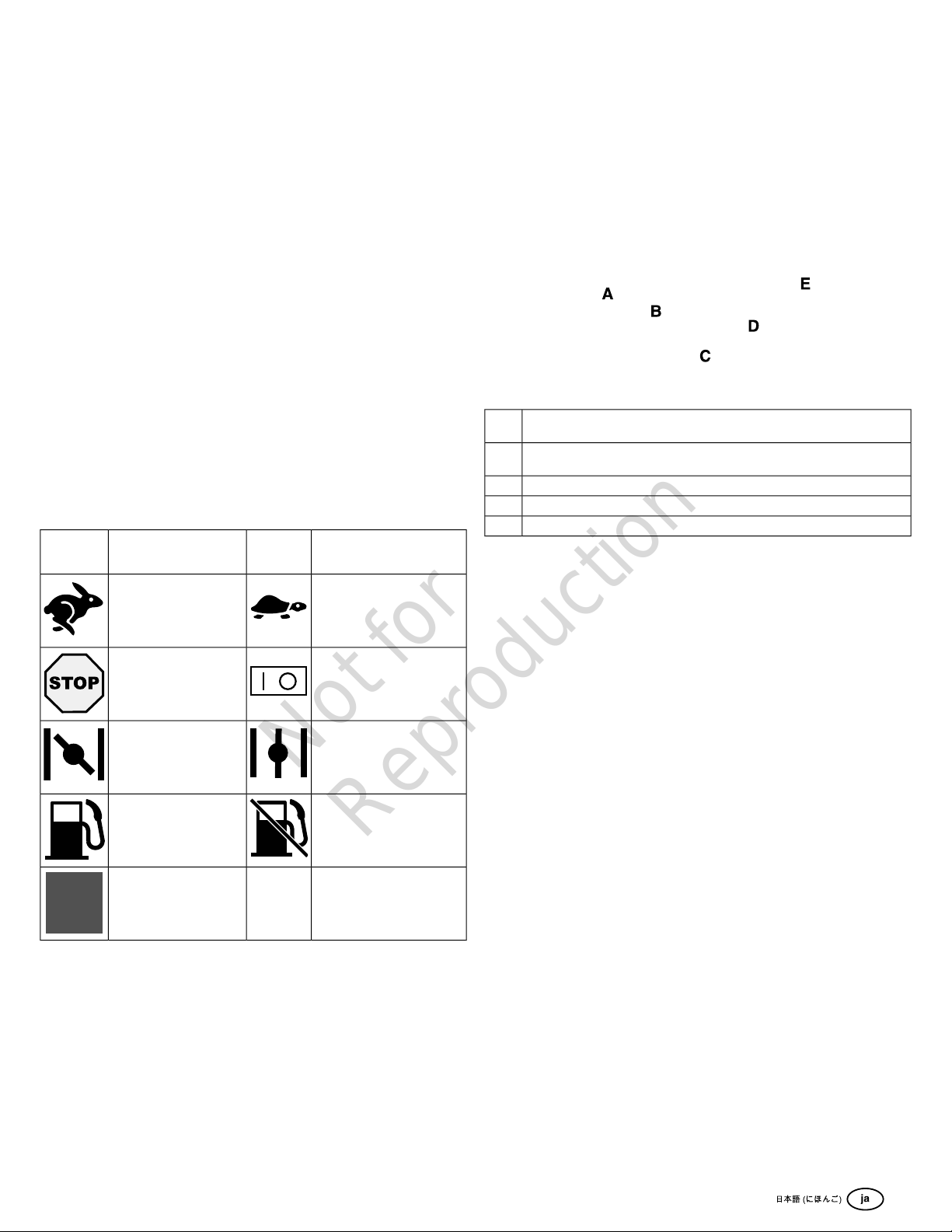

Features and Controls

Engine Controls

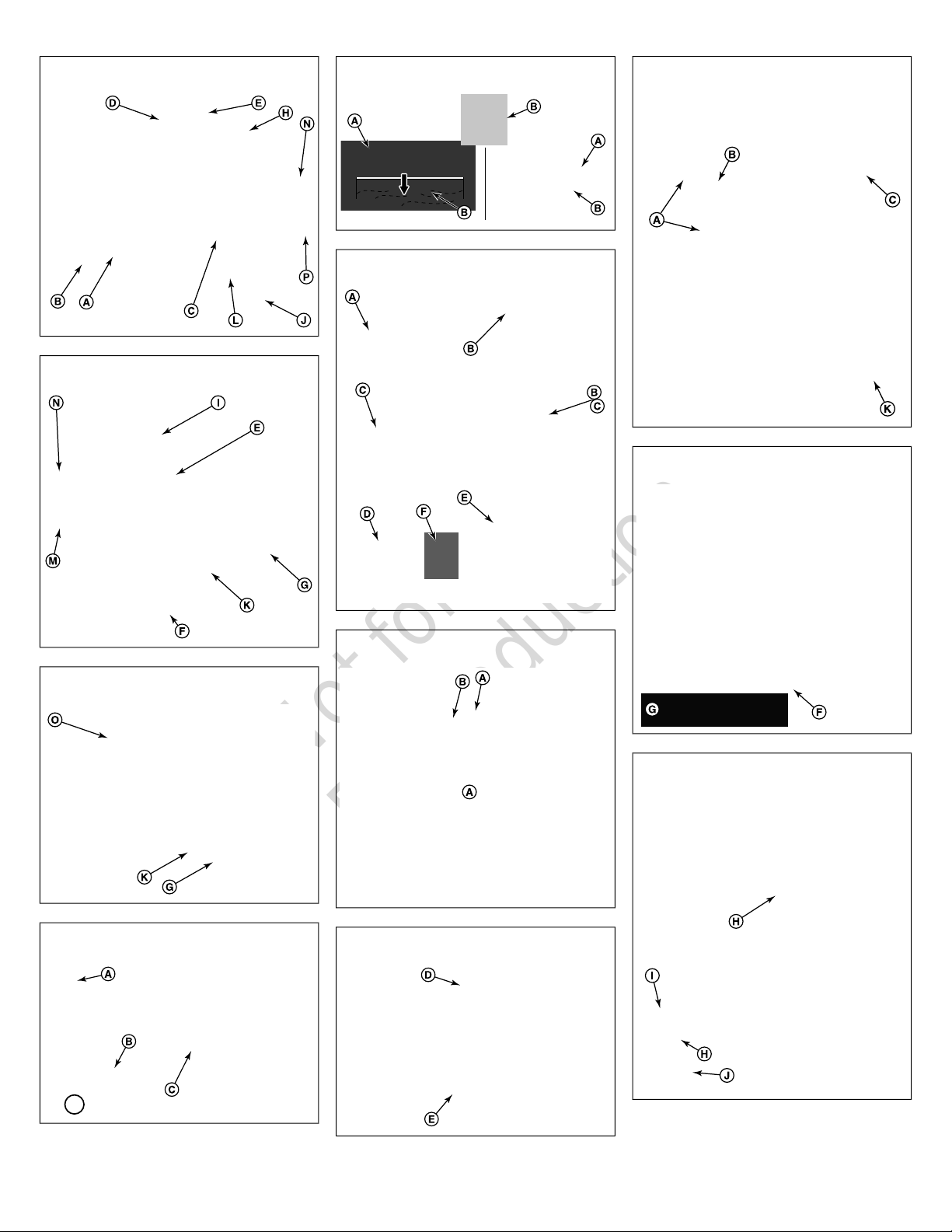

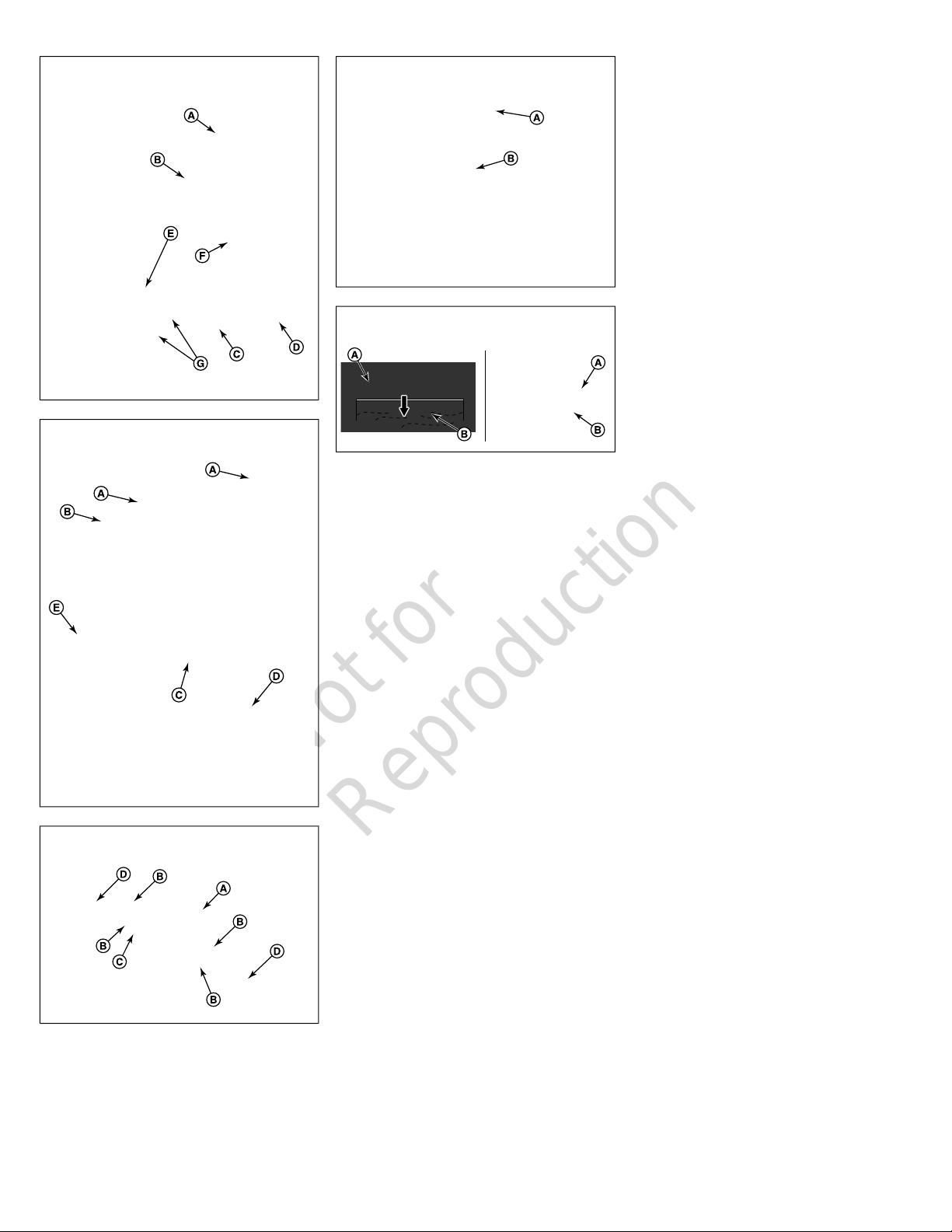

Compare the illustration (Figure: 1, 2, 3) with your engine to familiarize yourself with the

location of various features and controls.

A. Engine Identification Numbers Model - Type - Code

B. Spark Plug

C. Air Cleaner

D. Starter Cord Handle (if equipped)

E. Dipstick

F. Oil Drain Plug

G. Muffler, Muffler Guard (if equipped), Spark Arrester (if equipped)

H. Air Intake Grille

I. Air Intake Grille

J. Oil Filter (if equipped)

K. Electric Starter (if equipped)

L. Carburetor

M. Fuel Filter (if equipped)

N. Fuel Pump (if equipped)

O. Quick Oil Drain (if equipped)

P. Electronic Control Unit (if equipped)

Outdoor temperatures determine the proper oil viscosity for the engine. Use the chart to

select the best viscosity for the outdoor temperature range expected. Engines on most

outdoor power equipment operate well with 5W-30 Synthetic oil. For equipment operated

in hot temperatures, Vanguard™ 15W-50 Synthetic oil provides the best protection.

SAE 30 - Below 40 °F (4 °C) the use of SAE 30 will result in hard starting.A

10W-30 - Above 80 °F (27 °C) the use of 10W-30 may cause increased oil

B

consumption. Check oil level more frequently.

5W-30C

Synthetic 5W-30D

Vanguard™ Synthetic 15W-50E

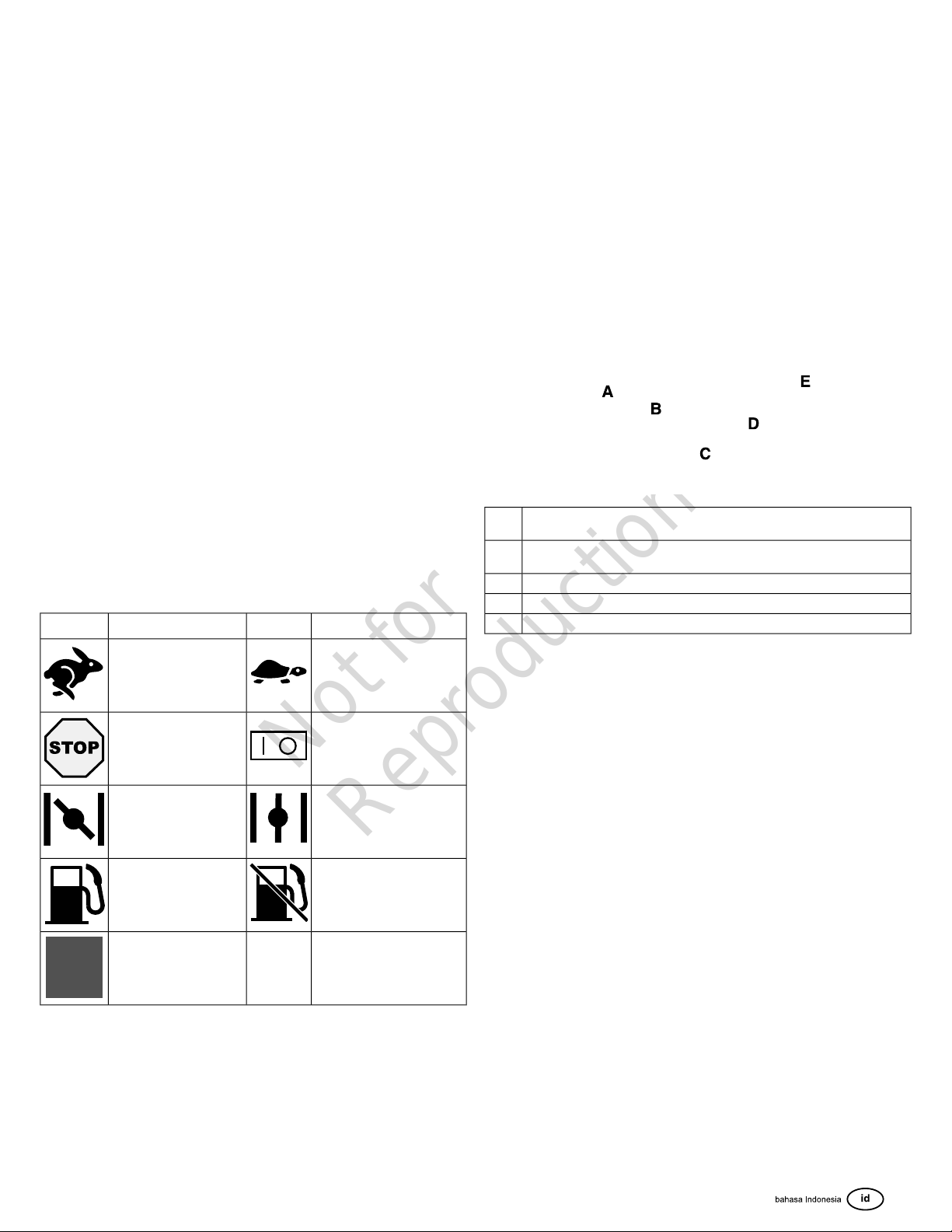

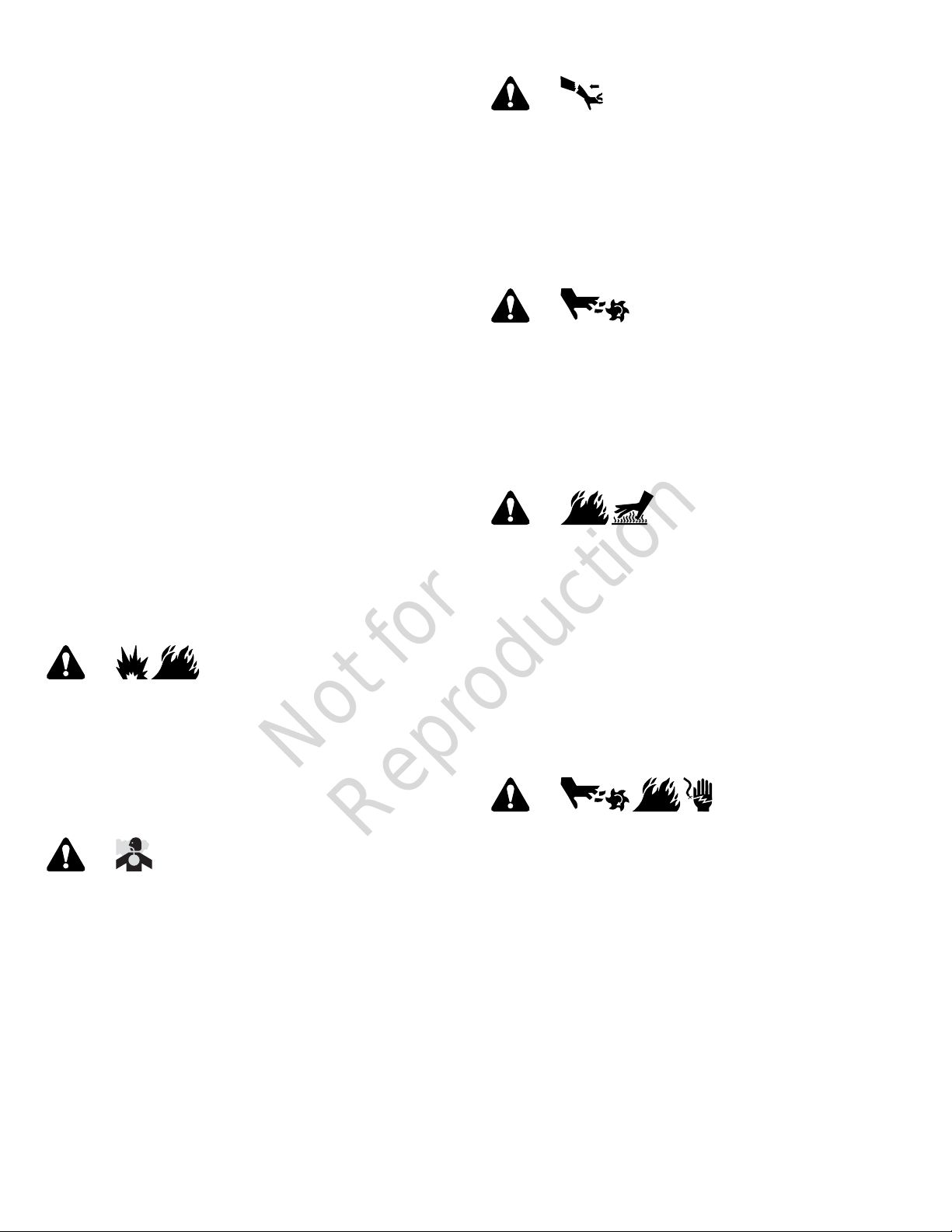

Engine Control Symbols and Meanings

MeaningSymbolMeaningSymbol

Engine speed - SLOWEngine speed - FAST

ON - OFFEngine speed - STOP

Engine start - Choke OPENEngine start - Choke

CLOSED

Fuel Shut-off - CLOSEDFuel Cap

Fuel Shut-off - OPEN

Fuel level - Maximum

Do not overfill

Operation

Check Oil Level

See Figure: 4

Before adding or checking the oil

• Make sure the engine is level.

• Clean the oil fill area of any debris.

1. Remove the dipstick (A, Figure 4) and wipe with a clean cloth.

2. Install and tighten the dipstick (A, Figure 4).

3. Remove the dipstick and check the oil level. Correct oil level is at the top of the full

indicator (B, Figure 4) on the dipstick.

4. If oil level is low, slowly add oil into the engine oil fill (C, Figure 4). Do not overfill.

After adding oil, wait one minute and then recheck the oil level.

Note:

Do not add oil at the quick oil drain , if equipped. For location, see

Controls.

5. Reinstall and tighten the dipstick (A, Figure 4).

Features and

Low Oil Protection System (if equipped)

Some engines are equipped with a low oil sensor. If the oil is low, the sensor will either

activate a warning light or stop the engine. Stop the engine and follow these steps before

restarting the engine.

• Make sure the engine is level.

• Check the oil level. See the

• If the oil level is low, add the proper amount of oil. Start the engine and make sure

the warning light (if equipped) is not activated.

• If the oil level is not low, do not start the engine. Contact a Briggs & Stratton

Authorized Service Dealer to have the oil problem corrected.

Check Oil Level

section.

Oil Recommendations

Oil Capacity: See the

NOTICE

This engine was shipped from Briggs & Stratton without oil. Equipment manufacturers

or dealers may have added oil to the engine. Before you start the engine for the first

time, make sure to check the oil level and add oil according to the instructions in this

manual. If you start the engine without oil, it will be damaged beyond repair and will not

be covered under warranty.

We recommend the use of Briggs & Stratton® Warranty Certified oils for best performance.

Other high-quality detergent oils are acceptable if classified for service SF, SG, SH, SJ or

higher. Do not use special additives.

6 BRIGGSandSTRATTON.com

Specifications

section.

Fuel Recommendations

Fuel must meet these requirements:

• Clean, fresh, unleaded gasoline.

• A minimum of 87 octane/87 AKI (91 RON). High altitude use, see below.

• Gasoline with up to 10% ethanol (gasohol) is acceptable.

NOTICE

gasoline or modify the engine to run on alternate fuels. Use of unapproved fuels will

damage the engine components, which will not be covered under warranty.

To protect the fuel system from gum formation, mix a fuel stabilizer into the fuel. See

Storage.

Do not use unapproved gasolines, such as E15 and E85. Do not mix oil in

All fuel is not the same. If starting or performance problems occur, change fuel

Page 7

Not for

Reproduction

providers or change brands. This engine is certified to operate on gasoline. The emissions

control system for this engine is EM (Engine Modifications).

High Altitude

At altitudes over 5,000 feet (1524 meters), a minimum 85 octane/85 AKI (89 RON) gasoline

is acceptable.

For carbureted engines, high altitude adjustment is required to maintain performance.

Operation without this adjustment will cause decreased performance, increased fuel

consumption, and increased emissions. Contact a Briggs & Stratton Authorized Service

Dealer for high altitude adjustment information. Operation of the engine at altitudes below

2,500 feet (762 meters) with the high altitude adjustment is not recommended.

For Electronic Fuel Injection (EFI) engines, no high altitude adjustment is necessary.

Add Fuel

See Figure: 5

WARNING

Fuel and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

When adding fuel

• Turn engine off and let engine cool at least 2 minutes before removing the fuel cap.

• Fill fuel tank outdoors or in well-ventilated area.

• Do not overfill fuel tank. To allow for expansion of the fuel, do not fill above the bottom

of the fuel tank neck.

• Keep fuel away from sparks, open flames, pilot lights, heat, and other ignition sources.

• Check fuel lines, tank, cap, and fittings frequently for cracks or leaks. Replace if

necessary.

• If fuel spills, wait until it evaporates before starting engine.

1. Clean the fuel cap area of dirt and debris. Remove the fuel cap.

2. Fill the fuel tank (A, Figure 5) with fuel. To allow for expansion of the fuel, do not fill

above the bottom of the fuel tank neck (B).

3. Reinstall the fuel cap.

Start and Stop Engine

See Figure: 6

Start Engine

WARNING

Rapid retraction of starter cord (kickback) will pull hand and arm toward engine

faster than you can let go.

Broken bones, fractures, bruises or sprains could result.

• When starting engine, pull the starter cord slowly until resistance is felt and then pull

rapidly to avoid kickback.

WARNING

POISONOUS GAS HAZARD. Engine exhaust contains carbon monoxide, a

poisonous gas that could kill you in minutes. You CANNOT see it, smell it, or taste

it. Even if you do not smell exhaust fumes, you could still be exposed to carbon

monoxide gas. If you start to feel sick, dizzy, or weak while using this product,

shut it off and get to fresh air RIGHT AWAY. See a doctor. You may have carbon

monoxide poisoning.

• Operate this product ONLY outside far away from windows, doors and vents to reduce

the risk of carbon monoxide gas from accumulating and potentially being drawn

towards occupied spaces.

• Install battery-operated carbon monoxide alarms or plug-in carbon monoxide alarms

with battery back-up according to the manufacturer's instructions. Smoke alarms

cannot detect carbon monoxide gas.

• DO NOT run this product inside homes, garages, basements, crawlspaces, sheds,

or other partially-enclosed spaces even if using fans or opening doors and windows

for ventilation. Carbon monoxide can quickly build up in these spaces and can linger

for hours, even after this product has shut off.

• ALWAYS place this product downwind and point the engine exhaust away from

occupied spaces.

NOTICE

the engine, make sure you add oil according to the instructions in this manual. If you

start the engine without oil, it will be damaged beyond repair and will not be covered

under warranty.

Determine The Starting System

Before starting the engine, you must determine the type of starting system that is on your

engine. Your engine will have one of the following types.

• ReadyStart®System: This features a temperature controlled automatic choke. This

• Electronic Fuel Management System: This features an Electronic Control Unit that

• Choke System: This features a choke to be used for starting in cool temperatures.

To start your engine, follow the instructions for your type of starting system.

Note:

operation of remote controls.

This engine was shipped from Briggs & Stratton without oil. Before you start

type does not have a primer.

monitors engine and temperature conditions. This type does not have a manual

choke or a primer.

Some models will have a separate choke control while others will have a combination

choke / throttle control. This type does not have a primer.

Equipment may have remote controls. See the equipment manual for location and

ReadyStart®System

1. Check the engine oil. See the

2. Make sure equipment drive controls, if equipped, are disengaged.

3. Move the fuel shut-off (A, Figure 6), if equipped, to the OPEN position.

4. Move the throttle control (B, Figure 6), if equipped, to the FAST position. Operate

the engine in the FAST position.

Note:

For starting in cold weather temperatures (below 32° F), move the combination choke

/ throttle lever (B C, Figure 6) to the CHOKE position.

Check Oil Level

section.

WARNING

Fuel and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

When Starting Engine

• Ensure that spark plug, muffler, fuel cap and air cleaner (if equipped) are in place

and secured.

• Do not crank engine with spark plug removed.

• If engine floods, set choke (if equipped) to OPEN / RUN position, move throttle (if

equipped) to FAST position and crank until engine starts.

5. Key Switch, if equipped: Turn the key switch (D, Figure 6) to the ON / START

position.

Start / Stop Button, if equipped: Push the start / stop button (F, Figure 6).

NOTICE

maximum). Wait one minute between starting cycles.

Note:

to BRIGGSandSTRATTON.com or call 1-800-233-3723 (in USA).

To extend the life of the starter, use short starting cycles (five seconds

If the engine does not start after repeated attempts, contact you local dealer or go

Electronic Fuel Management System

1. Check the engine oil. See the

2. Make sure equipment drive controls, if equipped, are disengaged.

3. Move the fuel shut-off (A, Figure 6), if equipped, to the OPEN position.

4. Move the throttle control (B, Figure 6), if equipped, to the FAST position. Operate

the engine in the FAST position.

Check Oil Level

section.

7

Page 8

Not for

Reproduction

5. Rewind Start, if equipped: Turn the key switch (D, Figure 6) to the ON / START

position.

6. Rewind Start, if equipped: Firmly hold the starter cord handle (E, Figure 6). Pull

the starter cord handle slowly until resistance is felt, then pull rapidly.

WARNING

Rapid retraction of the starter cord (kickback) will pull your hand and arm toward the

engine faster than you can let go. Broken bones, fractures, bruises or sprains could

result. When starting engine, pull the starter cord slowly until resistance is felt and then

pull rapidly to avoid kickback.

7. Electric Start, if equipped: Turn the key switch (D, Figure 6) to the ON / START

position.

NOTICE

maximum). Wait one minute between starting cycles.

Note:

to BRIGGSandSTRATTON.com or call 1-800-233-3723 (in USA).

To extend the life of the starter, use short starting cycles (five seconds

If the engine does not start after repeated attempts, contact you local dealer or go

2. After the engine stops, move the fuel shut-off (A, Figure 6), if equipped, to the

CLOSED position.

Maintenance

NOTICE

engine, must be empty and the spark plug side must be up. If the fuel tank is not empty

and if the engine is tipped in any other direction, it may be difficult to start due to oil or

gasoline contaminating the air filter and/or the spark plug.

When performing maintenance that requires the unit to be tipped, the fuel tank, if mounted

on the engine, must be empty or fuel can leak out and result in a fire or explosion.

We recommend that you see any Briggs & Stratton Authorized Service Dealer for all

maintenance and service of the engine and engine parts.

NOTICE

operation.

If the engine is tipped during maintenance, the fuel tank, if mounted on

WARNING

All the components used to build this engine must remain in place for proper

Choke System

1. Check the engine oil. See the

2. Make sure equipment drive controls, if equipped, are disengaged.

3. Move the fuel shut-off (A, Figure 6), if equipped, to the OPEN position.

4. Move the throttle control (B, Figure 6), if equipped, to the FAST position. Operate

the engine in the FAST position.

5. Move the choke control (C, Figure 6) to the CLOSED position. For models with a

combination choke / throttle control (B C), move the control to the CHOKE position.

Note:

Choke is usually unnecessary when restarting a warm engine.

6. Rewind Start, if equipped: Turn the key switch (D, Figure 6) to the ON / START

position.

7. Rewind Start, if equipped: Firmly hold the starter cord handle (E, Figure 6). Pull

the starter cord handle slowly until resistance is felt, then pull rapidly.

WARNING

Rapid retraction of the starter cord (kickback) will pull your hand and arm toward the

engine faster than you can let go. Broken bones, fractures, bruises or sprains could

result. When starting engine, pull the starter cord slowly until resistance is felt and then

pull rapidly to avoid kickback.

8. Electric Start, if equipped: Turn the key switch (D, Figure 6) to the ON / START

position.

NOTICE

maximum). Wait one minute between starting cycles.

9. As the engine warms up, move the choke control (C, Figure 6) to the OPEN position.

Note:

to BRIGGSandSTRATTON.com or call 1-800-233-3723 (in USA).

To extend the life of the starter, use short starting cycles (five seconds

For models with a combination choke / throttle control (B C), move the control to the

FAST position.

If the engine does not start after repeated attempts, contact your local dealer or go

Check Oil Level

section.

WARNING

Unintentional sparking can result in fire or electric shock.

Unintentional start-up can result in entanglement, traumatic amputation, or

laceration.

Fire hazard

Before performing adjustments or repairs:

• Disconnect the spark plug wire and keep it away from the spark plug.

• Disconnect battery at negative terminal (only engines with electric start.)

• Use only correct tools.

• Do not tamper with governor spring, links or other parts to increase engine speed.

• Replacement parts must be of the same design and installed in the same position

as the original parts. Other parts may not perform as well, may damage the unit, and

may result in injury.

• Do not strike the flywheel with a hammer or hard object because the flywheel may

later shatter during operation.

When testing for spark:

• Use approved spark plug tester.

• Do not check for spark with spark plug removed.

Emissions Control Service

Maintenance, replacement, or repair of the emissions control devices and systems

may be performed by any off-road engine repair establishment or individual. However,

to obtain "no charge" emissions control service, the work must be performed by a factory

authorized dealer. See the Emissions Control Statements.

Maintenance Schedule

First 5 Hours

• Change oil

Every 8 Hours or Daily

3

Stop Engine

WARNING

Fuel and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

• Do not choke the carburetor to stop the engine.

1. Key Switch, if equipped: With the throttle control in the FAST position, turn the key

switch (D, Figure 6) to the OFF position. Remove the key and keep in a safe place

out of the reach of children.

Start / Stop Button, if equipped: With the throttle control in the FAST position, push

the START / STOP button (F, Figure 6).

8 BRIGGSandSTRATTON.com

• Check engine oil level

• Clean area around muffler and controls

• Clean air intake grille

Every 25 Hours or Annually

• Clean air filter

• Clean pre-cleaner (if equipped)

Every 50 Hours or Annually

• Change engine oil

• Replace oil filter (if equipped)

• Service exhaust system

1

1

4

4

Page 9

Not for

Reproduction

Every 100 Hours or Annually

• Change engine oil

• Replace oil filter (if equipped)

5

5

Service Exhaust System

Annually

• Replace spark plug

• Replace air filter

• Replace pre-cleaner (if equipped)

• Replace fuel filter (if equipped)

• Service fuel system

• Service cooling system

• Check valve clearance

1

In dusty conditions or when airborne debris is present, clean more often.

2

Not required unless engine performance problems are noted.

3

Only engines without oil filter.

4

Engine without oil filter or with standard black oil filter (see

for part number).

5

Engines with high-efficiency yellow or orange oil filter (see

for part number).

1

2

Specifications

Specifications

page

page

Electronic Fuel Management System

The Electronic Fuel Management System monitors engine temperature, engine speed,

and battery voltage to adjust the choke during engine starting and warm up. There are no

adjustments on the system. If starting or operation problems occur, contact an Authorized

Briggs & Stratton Dealer.

NOTICE

System could be damaged.

• Never start the engine if the battery cables are loose.

• Turn the key to the off position before disconnecting, removing and / or installing the

• Never use a battery charger to start the engine.

• Never disconnect the battery cables while the engine is running.

• When connecting the battery cables, first connect the positive (+) cable and then

• When charging the battery, turn the ignition switch to the off position and disconnect

• Do not spray water directly on the Electronic Control Unit.

Make sure to follow the steps below or the Electronic Fuel Management

battery.

connect the negative (-) cable to the battery.

the negative (-) battery cable from the battery.

WARNING

Running engines produce heat. Engine parts, especially muffler, become extremely

hot.

Severe thermal burns can occur on contact.

Combustible debris, such as leaves, grass, brush, etc. can catch fire.

• Allow muffler, engine cylinder and fins to cool before touching.

• Remove accumulated debris from muffler area and cylinder area.

• It is a violation of California Public Resource Code, Section 4442, to use or operate

the engine on any forest-covered, brush-covered, or grass-covered land unless the

exhaust system is equipped with a spark arrester, as defined in Section 4442,

maintained in effective working order. Other states or federal jurisdictions may have

similar laws. Contact the original equipment manufacturer, retailer, or dealer to obtain

a spark arrester designed for the exhaust system installed on this engine.

Remove accumulated debris from muffler and cylinder area. Inspect the muffler for cracks,

corrosion, or other damage. Remove the deflector or the spark arrester, if equipped, and

inspect for damage or carbon blockage. If damage is found, install replacement parts before

operating.

WARNING

Replacement parts must be of the same design and installed in the same position as

the original parts. Other parts may not perform as well, may damage the unit, and may

result in injury.

Change Engine Oil

See Figure: 8, 9, 10, 11

Used oil is a hazardous waste product and must be disposed of properly. Do not discard

with household waste. Check with your local authorities, service center, or dealer for safe

disposal/recycling facilities.

Remove Oil

1. With engine off but still warm, disconnect the spark plug wire (D, Figure 8) and keep

it away from the spark plug (E).

2. Remove the dipstick (A, Figure 9).

Carburetor and Engine Speed

Never make adjustments to the carburetor or engine speed. The carburetor was set at the

factory to operate efficiently under most conditions. Do not tamper with the governor spring,

linkages, or other parts to change the engine speed. If any adjustments are required contact

a Briggs & Stratton Authorized Service Dealer for service.

NOTICE

as installed on the equipment. Do not exceed this speed. If you are unsure what the

equipment maximum speed is, or what the engine speed is set to from the factory,

contact a Briggs & Stratton Authorized Service Dealer for assistance. For safe and

proper operation of the equipment, the engine speed should be adjusted only by a

qualified service technician.

The equipment manufacturer specifies the maximum speed for the engine

Service Spark Plug

See Figure: 7

Check the gap (A, Figure 7) with a wire gauge (B). If necessary, reset the gap. Install and

tighten the spark plug to the recommended torque. For gap setting or torque, see the

Specifications

Note:

In some areas, local law requires using a resistor spark plug to suppress ignition

signals. If this engine was originally equipped with a resistor spark plug, use the same type

for replacement.

section.

Oil Drain Plug, if equipped

1. Remove the oil drain plug (F, Figure 10). Drain the oil into an approved container.

Note:

Any of the oil drain plugs (G, Figure 10) may be installed in the engine.

2. After the oil has drained, install and tighten the oil drain plug (F, Figure 10).

Quick Oil Drain, if equipped

1. Disconnect the quick oil drain hose (H, Figure 11) from the side of the engine.

2. Turn and remove the oil drain cap (I, Figure 11). Carefully lower the quick oil drain

(H) into an approved container (J).

3. After the oil has drained, install the quick oil drain cap (I, Figure 11). Attach the quick

oil drain hose (H) to the side of the engine.

Change Oil Filter, if equipped

Some models are equipped with an oil filter. For replacement intervals, see the

Maintenance Schedule.

1. Drain the oil from the engine. See

2. Remove the oil filter (K, Figure 9) and dispose of properly.

3. Before you install the new oil filter, lightly lubricate the oil filter gasket with fresh,

clean oil.

4. Install the oil filter by hand until the gasket contacts the oil filter adapter, then tighten

the oil filter 1/2 to 3/4 turns.

Remove Oil

section.

9

Page 10

Not for

Reproduction

5. Add oil. See

6. Start and run the engine. As the engine warms up, check for oil leaks.

7. Stopthe engine and check the oil level. Correct oil level is at the top of the full indicator

(B, Figure 9) on the dipstick.

Add Oil

section.

Add Oil

• Make sure the engine is level.

• Clean the oil fill area of any debris.

• See the

1. Remove the dipstick (A, Figure 9) and wipe with a clean cloth.

2. Slowly pour oil into the engine oil fill (C, Figure 9). Do not overfill. After adding oil,

Note:

3. Install and tighten the dipstick (A, Figure 9).

4. Remove the dipstick and check the oil level. Correct oil level is at the top of the full

5. Reinstall and tighten the dipstick (A, Figure 9).

6. Connect the spark plug wire (D, Figure 8) to the spark plug (E).

Specifications

wait one minute and then check the oil level.

Do not add oil at the quick oil drain (H, Figure 11), if equipped.

indicator (B, Figure 9) on the dipstick.

section for oil capacity.

Service Air Filter

See Figure: 12, 13

WARNING

Fuel and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

8. Install the filter (C, Figure 13) on the intake (D). Push the end of the filter down into

the engine base. Make sure filter fits securely in the engine base.

9. Install the air filter cover (B, Figure 13) and secure with fastener(s) (A).

Service Fuel System

See Figure: 14, 15

WARNING

Fuel and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

• Keep fuel away from sparks, open flames, pilot lights, heat, and other ignition sources.

• Check fuel lines, tank, cap, and fittings frequently for cracks or leaks. Replace if

necessary.

• Before cleaning or replacing the fuel filter, drain the fuel tank or close the fuel shutoff valve.

• If fuel spills, wait until it evaporates before starting engine.

• Replacement parts must be the same and installed in the same position as the original

parts.

Fuel Filter, if equipped

1. Before cleaning or replacing the fuel filter (A, Figure 14), drain the fuel tank or close

the fuel shut-off valve. Otherwise, fuel can leak out and cause a fire or explosion.

2. Use pliers to squeeze tabs (B, Figure 14) on the clamps (C), then slide the clamps

away from the fuel filter (A). Twist and pull the fuel lines (D) off of the fuel filter.

3. Check the fuel lines (D, Figure 14) for cracks or leaks. Replace if necessary.

4. Replace the fuel filter (A, Figure 14) with an original equipment replacement filter.

5. Secure the fuel lines (D, Figure 14) with clamps (C) as shown.

• Never start and run the engine with the air cleaner assembly (if equipped) or the air

filter (if equipped) removed.

NOTICE

damage the filter and solvents will dissolve the filter.

See the

Various models use either a foam or a paper filter. Some models may also have an optional

pre-cleaner that can be washed and reused. Compare the illustrations in this manual with

the type installed on your engine and service as follows.

Do not use pressurized air or solvents to clean the filter. Pressurized air can

Maintenance Schedule

for service requirements.

Paper Air Filter

1. Pullup on the cover handle (A, Figure 12). Rotate the cover handle toward the engine

and then remove the cover (B).

2. Remove the pre-cleaner (C, Figure 12), if equipped, and the filter (D).

3. To loosen debris, gently tap the filter (D, Figure 12) on a hard surface. If the filter is

excessively dirty, replace with a new filter.

4. Wash the pre-cleaner (C, Figure 12) in liquid detergent and water. Allow the precleaner (C) to thoroughly air dry. Do not oil the pre-cleaner.

5. Assemble the dry pre-cleaner (C, Figure 12) and the filter (D) to the engine base (E).

6. Align the tabs (F, Figure 12) on the cover (B) with the slots (G) in the blower housing.

7. Rotate the cover handle (A, Figure 12) back and push down to lock in place.

Paper Air Filter

1. Loosen the fastener(s) (A, Figure 13).

2. Remove the cover (B, Figure 13).

3. To remove the filter (C, Figure 13), lift the end of the filter and then pull the filter off

the intake (D).

4. To loosen debris, gently tap the filter (C, Figure 13) on a hard surface. If the filter is

excessively dirty, replace with a new filter.

5. Remove the pre-cleaner (E, Figure 13), if equipped, from the filter (C).

6. Washthe pre-cleaner (E, Figure 13), if equipped, in liquid detergent and water. Allow

the pre-cleaner to thoroughly air dry. Do not oil the pre-cleaner.

7. Assemble the dry pre-cleaner (E, Figure 13), if equipped, to the filter (C).

Fuel Strainer, if equipped

1. Remove the fuel cap (A, Figure 15).

2. Remove the fuel strainer (B, Figure 15).

3. If the fuel strainer is dirty, clean or replace it. If you replace the fuel strainer, make

sure to use an original equipment replacement fuel strainer.

Service Cooling System

WARNING

Running engines produce heat. Engine parts, especially muffler, become extremely

hot.

Severe thermal burns can occur on contact.

Combustible debris, such as leaves, grass, brush, etc., can catch fire.

• Allow muffler, engine cylinder and fins to cool before touching.

• Remove accumulated debris from muffler area and cylinder area.

NOTICE

system. Use a brush or dry cloth to clean the engine.

This is an air cooled engine. Dirt or debris can restrict air flow and cause the engine to

overheat, resulting in poor performance and reduced engine life.

1. Use a brush or dry cloth to remove debris from the air intake grille.

2. Keep linkage, springs and controls clean.

3. Keep the area around and behind the muffler, if equipped, free of any combustible

4. Make sure the oil cooler fins, if equipped, are free of dirt and debris.

After a period of time, debris can accumulate in the cylinder cooling fins and cause the

engine to overheat. This debris cannot be removed without partial disassembly of the

engine. Have a Briggs & Stratton Authorized Service Dealer inspect and clean the air

cooling system as recommended in the

Do not use water to clean the engine. Water could contaminate the fuel

debris.

Maintenance Schedule.

10 BRIGGSandSTRATTON.com

Page 11

Not for

Reproduction

Storage

Engine power will decrease 3.5% for each 1,000 feet (300 meters) above sea level and

1% for each 10° F (5.6° C) above 77° F (25° C). The engine will operate satisfactorily at

an angle up to 15°. Refer to the equipment operator's manual for safe allowable operating

limits on slopes.

WARNING

Fuel and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

When Storing Fuel Or Equipment With Fuel In Tank

• Store away from furnaces, stoves, water heaters or other appliances that have pilot

lights or other ignition sources because they can ignite fuel vapors.

Fuel System

See Figure: 16

Store the engine level (normal operating position). Fill fuel tank (A, Figure 16) with fuel.

To allow for expansion of fuel, do not overfill above the fuel tank neck (B).

Fuel can become stale when stored over 30 days. Stale fuel causes acid and gum deposits

to form in the fuel system or on essential carburetor parts. To keep fuel fresh, use Briggs

& Stratton® Advanced Formula Fuel Treatment & Stabilizer, available wherever Briggs

& Stratton genuine service parts are sold.

There is no need to drain gasoline from the engine if a fuel stabilizer is added according

to instructions. Run the engine for two (2) minutes to circulate the stabilizer throughout the

fuel system before storage.

If gasoline in the engine has not been treated with a fuel stabilizer, it must be drained into

an approved container. Run the engine until it stops from lack of fuel. The use of a fuel

stabilizer in the storage container is recommended to maintain freshness.

Engine Oil

While the engine is still warm, change the engine oil. See the

Change Engine Oil

section.

Troubleshooting

For assistance, contact your local dealer or go to BRIGGSandSTRATTON.com or call

1-800-233-3723 (in USA).

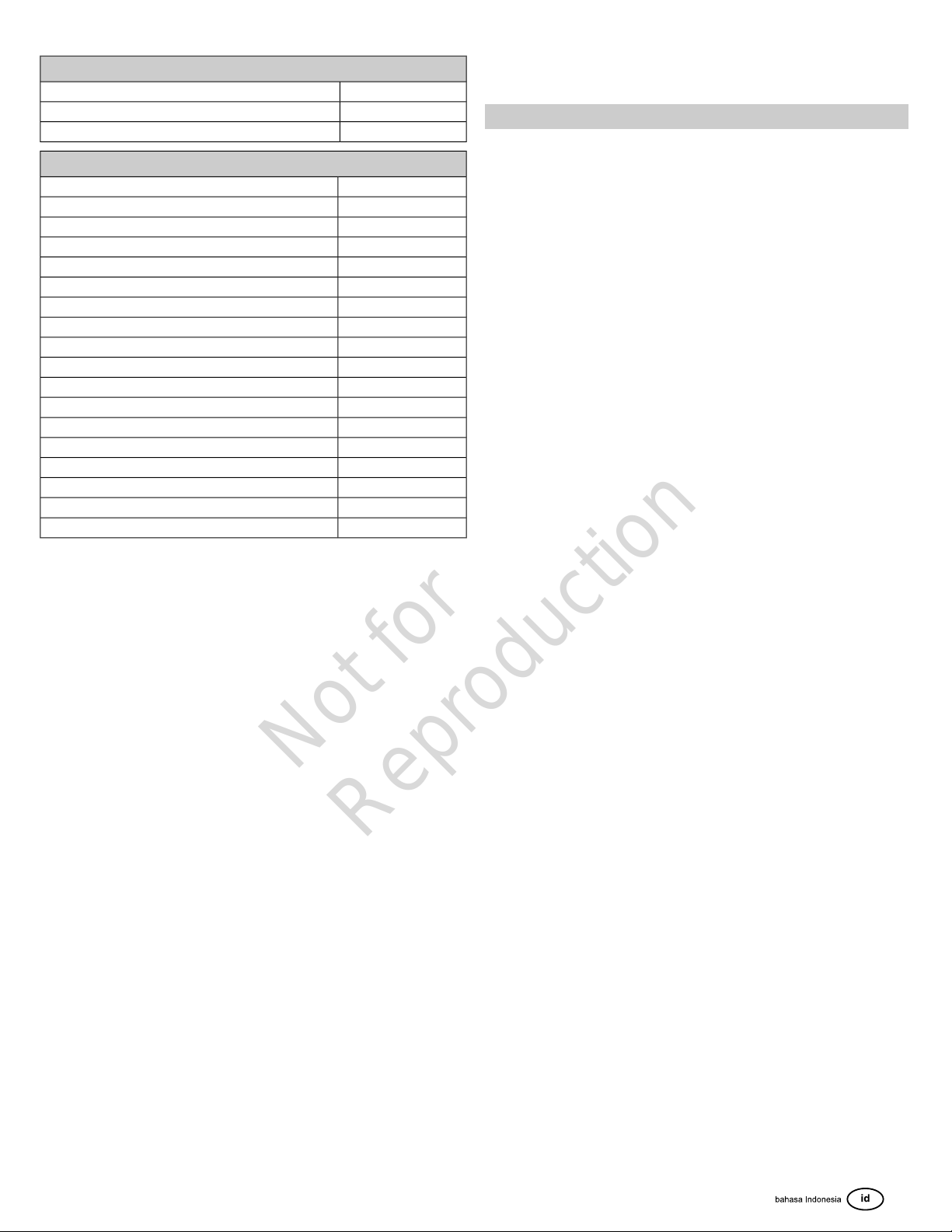

Specifications

Model: 210000

21.01 ci (344 cc)Displacement

3.437 in (87,30 mm)Bore

2.264 in (57,51 mm)Stroke

42 - 44 oz (1,24 - 1,30 L)Oil Capacity - without filter

46 - 48 oz (1,36 - 1,40 L)Oil Capacity - with filter

0.030 in (0,76 mm)Spark Plug Gap

180 lb-in (20 Nm)Spark Plug Torque

0.010 - 0.014 in (0,25 - 0,36 mm)Armature Air Gap

0.003 - 0.005 in (0,08 - 0,13 mm)Intake Valve Clearance

0.005 - 0.007 in (0,13 - 0,18 mm)Exhaust Valve Clearance

Model: 310000

30.59 ci (501 cc)Displacement

3.563 in (90,49 mm)Bore

3.062 in (77,77 mm)Stroke

42 - 44 oz (1,24 - 1,30 L)Oil Capacity - without filter

46 - 48 oz (1,36 - 1,40 L)Oil Capacity - with filter

0.030 in (0,76 mm)Spark Plug Gap

180 lb-in (20 Nm)Spark Plug Torque

0.010 - 0.014 in (0,25 - 0,36 mm)Armature Air Gap

0.003 - 0.005 in (0,08 - 0,13 mm)Intake Valve Clearance

0.005 - 0.007 in (0,13 - 0,18 mm)Exhaust Valve Clearance

Service Parts - Model: 210000

Part NumberService Part

796032Air Filter, Paper (see Figure 13)

798911Air Filter Pre-cleaner, Foam (see Figure 13)

698413, 5079Air Filter, Paper (see Figure 12)

697292, 5079Air Filter Pre-cleaner, Foam (see Figure 12)

100005Oil - SAE 30 (20 oz, 0,6 L)

100028Oil - SAE 30 (48 oz, 1,4 L)

492932Oil Filter

100117, 100120Advanced Formula Fuel Treatment & Stabilizer

394358, 5098Fuel Filter - engine without fuel pump

691035, 5065Fuel Filter - engine with fuel pump

491055Resistor Spark Plug

5066Long Life Platinum Spark Plug

89838, 5023Spark Plug Wrench

19368Spark Tester

Service Parts - Model: 310000

Part NumberService Part

796031Air Filter, Paper (see Figure 13)

797704Air Filter Pre-cleaner, Foam (see Figure 13)

698083, 5077Air Filter, Paper (see Figure 12)

697015, 5077Air Filter Pre-cleaner, Foam (see Figure 12)

697153, 5078Air Filter, Flat Washable

100005Oil - SAE 30 (20 oz, 0,6 L)

100028Oil - SAE 30 (48 oz, 1,4 L)

492932Oil Filter, Standard - Black

795890Oil Filter, High Efficiency - Yellow

798576Oil Filter, High Efficiency - Orange

100117, 100120Advanced Formula Fuel Treatment & Stabilizer

394358, 5098Fuel Filter - engine without fuel pump

691035, 6065Fuel Filter - engine with fuel pump

491055Resistor Spark Plug

5066Long Life Platinum Spark Plug

89838, 5023Spark Plug Wrench

19368Spark Tester

We recommend that you see any Briggs & Stratton Authorized Dealer for all maintenance

and service of the engine and engine parts.

Power Ratings: The gross power rating for individual gasoline engine models is labeled

in accordance with SAE (Society of Automotive Engineers) code J1940 Small Engine

Power & Torque Rating Procedure, and is rated in accordance with SAE J1995. Torque

values are derived at 2600 RPM for those engines with “rpm” called out on the label and

3060 RPM for all others; horsepower values are derived at 3600 RPM. The gross power

curves can be viewed at www.BRIGGSandSTRATTON.COM. Net power values are taken

with exhaust and air cleaner installed whereas gross power values are collected without

these attachments. Actual gross engine power will be higher than net engine power and

is affected by, among other things, ambient operating conditions and engine-to-engine

variability. Given the wide array of products on which engines are placed, the gasoline

engine may not develop the rated gross power when used in a given piece of power

equipment. This difference is due to a variety of factors including, but not limited to, the

variety of engine components (air cleaner, exhaust, charging, cooling, carburetor, fuel

pump, etc.), application limitations, ambient operating conditions (temperature, humidity,

altitude), and engine-to-engine variability. Due to manufacturing and capacity limitations,

Briggs & Stratton may substitute an engine of higher rated power for this engine.

11

Page 12

Not for

Reproduction

Warranty

Briggs & Stratton Engine Warranty

Effective January 2018

Limited Warranty

Briggs & Stratton warrants that, during the warranty period specified below, it will repair or

replace, free of charge, any part that is defective in material or workmanship or both.

Transportation charges on product submitted for repair or replacement under this warranty

must be borne by purchaser. This warranty is effective for and is subject to the time periods

and conditions stated below. For warranty service, find the nearest Authorized Service

Dealer in our dealer locator map at BRIGGSandSTRATTON.COM. The purchaser must

contact the Authorized Service Dealer, and then make the product available to the

Authorized Service Dealer for inspection and testing.

There is no other express warranty. Implied warranties, including those of

merchantability and fitness for a particular purpose, are limited to the warranty

period listed below, or to the extent permitted by law. Liability for incidental or

consequential damages are excluded to the extent exclusion is permitted by law. Some

states or countries do not allow limitations on how long an implied warranty lasts, and

some states or countries do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitation and exclusion may not apply to you. This

warranty gives you specific legal rights and you may also have other rights which vary

from state to state and country to country4.

Standard Warranty Terms

Brand / Product Name

1

These are our standard warranty terms, but occasionally there may be additional

warranty coverage that was not determined at time of publication. For a listing of

current warranty terms for your engine, go to BRIGGSandSTRATTON.com or contact

your Briggs & Stratton Authorized Service Dealer.

2

There is no warranty for engines on equipment used for prime power in place of a

utility; standby generators used for commercial purposes, utility vehicles exceeding

25 MPH, or engines used in competitive racing or on commercial or rental tracks.

3

Vanguard installed on standby generators: 24 months consumer use, no warranty

commercial use. Commercial Series with manufacturing date before July 2017: 24

months consumer use, 24 months commercial use.

4

In Australia - Our goods come with guarantees that cannot be excluded under the

Australian Consumer Law. You are entitled to a replacement or refund for a major

failure and for compensation for any other reasonably foreseeable loss or damage.

You are also entitled to have the goods repaired or replaced if the goods fail to be

of acceptable quality and the failure does not amount to a major failure. For warranty

service, find the nearest Authorized Service Dealer in our dealer locator map at

BRIGGSandSTRATTON.COM, or by calling 1300 274 447, or by emailing or writing

to salesenquiries@briggsandstratton.com.au, Briggs & Stratton Australia Pty Ltd, 1

Moorebank Avenue, Moorebank, NSW , Australia, 2170.

The warranty period begins on the original date of purchase by the first retail or commercial

consumer. "Consumer use" means personal residential household use by a retail consumer.

"Commercial use" means all other uses, including use for commercial, income producing

or rental purposes. Once an engine has experienced commercial use, it shall thereafter

be considered as a commercial use engine for purposes of this warranty.

Save your proof of purchase receipt. If you do not provide proof of the initial purchase

date at the time warranty service is requested, the manufacturing date of the product

will be used to determine the warranty period. Product registration is not required

to obtain warranty service on Briggs & Stratton products.

About Your Warranty

This limited warranty covers engine-related material and/or workmanship issues only, and

not replacement or refund of the equipment to which the engine may be mounted. Routine

maintenance, tune-ups, adjustments, or normal wear and tear are not covered under this

warranty. Similarly, warranty is not applicable if the engine has been altered or modified

or if the engine serial number has been defaced or removed. This warranty does not cover

engine damage or performance problems caused by:

1. The use of parts that are not original Briggs & Stratton parts;

2. Operating the engine with insufficient, contaminated, or an incorrect grade of

lubricating oil;

3. The use of contaminated or stale fuel, gasoline formulated with ethanol greater than

10%, or the use of alternative fuels such as liquefied petroleum or natural gas on

engines not originally designed/manufactured by Briggs & Stratton to operate on

such fuels;

1, 2, 3

Consumer

Use

3

Commercial

Use

36 months36 monthsVanguard™; Commercial Series

12 months24 monthsEngines Featuring Dura-Bore™ Cast Iron Sleeve

3 months24 monthsAll Other Engines

4. Dirt which entered the engine because of improper air cleaner maintenance or reassembly;

5. Striking an object with the cutter blade of a rotary lawn mower, loose or improperly

installed blade adapters, impellers, or other crankshaft coupled devices, or excessive

v-belt tightness;

6. Associatedparts or assemblies such as clutches, transmissions, equipment controls,

etc., which are not supplied by Briggs & Stratton;

7. Overheating due to grass clippings, dirt and debris, or rodent nests which plug or

clog the cooling fins or flywheel area, or by operating the engine without sufficient

ventilation;

8. Excessivevibration due to over-speeding, loose engine mounting, loose or unbalanced

cutter blades or impellers, or improper coupling of equipment components to the

crankshaft;

9. Misuse,lack of routine maintenance, shipping, handling, or warehousing of equipment,

or improper engine installation.

Warranty service is available only through Briggs & Stratton Authorized Service

Dealers. Locate your nearest Authorized Service Dealer in our dealer locator map

at BRIGGSandSTRATTON.COM or by calling 1-800-233-3723 (in USA).

80004537 (Rev. D)

Briggs & Stratton Emissions Warranty

California, U.S. EPA, and Briggs & Stratton Corporation Emissions

Control Warranty Statement - Your Warranty Rights and

Obligations

For Briggs & Stratton Engine Models with "F" Trim Designation (Model-Type-Trim

Representation xxxxxx xxxx Fx)

The California Air Resources Board, U.S. EPA, and Briggs & Stratton (B&S) are pleased

to explain the emissions control system warranty on your Model Year 2017-2019

engine/equipment. In California, new small off-road engines and large spark ignited engines

less than or equal to 1.0 liter must be designed, built, and equipped to meet the State's

stringent anti-smog standards. B&S must warrant the emissions control system on your

engine/equipment for the periods of time listed below provided there has been no abuse,

neglect, or improper maintenance of your engine/equipment.

Your exhaust emissions control system may include parts such as the carburetor or fuel

injection system, ignition system, and catalytic converter. Also included may be hoses,

belts, connectors, sensors, and other emissions-related assemblies. Your evaporative

emission control system may include parts such as: carburetors, fuel tanks, fuel lines, fuel

caps, valves, canisters, filters, vapor hoses, clamps, connectors, and other associated

components.

Where a warrantable condition exists, B&S will repair your engine/equipment at no cost

to you including diagnosis, parts, and labor.

Manufacturer’s Warranty Coverage:

Small off-road engines and large spark ignited engines less than or equal to 1.0 liter, and

any related emissions components of the equipment, are warranted for two years, or for

the time period listed in the respective engine or product warranty statement, whichever

is greater. If any emissions-related part on your B&S engine/equipment is defective, the

part will be repaired or replaced by B&S.

Owner’s Warranty Responsibilities:

• As the engine/equipment owner, you are responsible for the performance of the

required maintenance listed in your Operator's Manual. B&S recommends that you

retain all receipts covering maintenance on your engine/equipment, but B&S cannot

deny warranty solely for the lack of receipts or your failure to ensure the performance

of all scheduled maintenance.

• As the engine/equipment owner, you should however be aware that B&S may deny

you warranty coverage if your engine/equipment or a part has failed due to abuse,

neglect, improper maintenance, or unapproved modifications.

• You are responsible for presenting your engine/equipment to a B&S distribution

center, servicing dealer, or other equivalent entity, as applicable, as soon as a problem

exists. The warranty repairs should be completed in a reasonable amount of time,

not to exceed 30 days. If you have any questions regarding your warranty rights and

responsibilities, you should contact B&S at 1-800-444-7774 (in USA) or

BRIGGSandSTRATTON.COM.

Briggs & Stratton Emissions Control Warranty Provisions

The following are specific provisions relative to your Emissions Control Warranty Coverage.

It is in addition to the B&S engine warranty for non-regulated engines found in the Operator's

Manual.

1. Warranted Emissions Parts

12 BRIGGSandSTRATTON.com

Page 13

Not for

Reproduction

Coverage under this warranty extends only to the parts listed below (the emissions

control systems parts) to the extent these parts were present on the B&S engine

and/or B&S supplied fuel system.

a. Fuel Metering System

• Cold start enrichment system (soft choke)

• Carburetor or fuel injection system

• Oxygen sensor

• Electronic control unit

• Fuel pump module

• Fuel line, fuel line fittings, clamps

• Fuel tank, cap and tether

• Carbon canister

b. Air Induction System

• Air cleaner

• Intake manifold

• Purge and vent line

c. Ignition System

• Spark plug(s)

• Magneto ignition system

d. Catalyst System

• Catalytic converter

• Exhaust manifold

• Air injection system or pulse value

e. Miscellaneous Items Used in Above Systems

• Vacuum, temperature, position, time sensitive valves and switches

• Connectors and assemblies

2. Length of Coverage

Coverage is for a period of two years from date of original purchase, or for the time

period listed in the respective engine or product warranty statement, whichever is

greater. B&S warrants to the original purchaser and each subsequent purchaser that

the engine is designed, built, and equipped so as to conform with all applicable

regulations adopted by the Air Resources Board; that it is free from defects in material

and workmanship that could cause the failure of a warranted part; and that it is

identical in all material respects to the engine described in the manufacturer's

application for certification. The warranty period begins on the date the engine is

originally purchased.

The warranty on emissions-related parts is as follows:

• Any warranted part that is not scheduled for replacement as required

maintenance in the Operator's Manual supplied, is warranted for the warranty

period stated above. If any such part fails during the period of warranty

coverage, the part will be repaired or replaced by B&S at no charge to the

owner. Any such part repaired or replaced under the warranty will be warranted

for the remaining warranty period.

• Any warranted part that is scheduled only for regular inspection in the Operator's

Manual supplied, is warranted for the warranty period stated above. Any such

part repaired or replaced under warranty will be warranted for the remaining

warranty period.

• Any warranted part that is scheduled for replacement as required maintenance

in the Operator's Manual supplied, is warranted for the period of time prior to

the first scheduled replacement point for that part. If the part fails prior to the

first scheduled replacement, the part will be repaired or replaced by B&S at no

charge to the owner. Any such part repaired or replaced under warranty will

be warranted for the remainder of the period prior to the first scheduled

replacement point for the part.

• Add-on or modified parts that are not exempted by the Air Resources Board

may not be used. The use of any non-exempted add-on or modified parts by

the owner will be grounds for disallowing a warranty claim. The manufacturer

will not be liable to warrant failures of warranted parts caused by the use of a

non-exempted add-on or modified part.

3. Consequential Coverage

Coverage shall extend to the failure of any engine components caused by the failure

of any warranted emissions parts.

4. Claims and Coverage Exclusions

Warranty claims shall be filed according to the provisions of the B&S engine warranty

policy. Warranty coverage does not apply to failures of emissions parts that are not

original equipment B&S parts or to parts that fail due to abuse, neglect, or improper

maintenance as set forth in the B&S engine warranty policy. B&S is not liable for

warranty coverage of failures of emissions parts caused by the use of add-on or

modified parts.

Look For Relevant Emissions Durability Period and Air Index

Information On Your Small Off-Road Engine Emissions Label

Engines that are certified to meet the California Air Resources Board (CARB) small offroad Emissions Standard must display information regarding the Emissions Durability

Period and the Air Index. Briggs & Stratton makes this information available to the consumer

on our emissions labels. The engine emissions label will indicate certification information.

The Emissions Durability Period describes the number of hours of actual running time

for which the engine is certified to be emissions compliant, assuming proper maintenance

in accordance with the Operator's Manual. The following categories are used:

Moderate:

Engines at or less than 80 cc displacement are certified to be emissions compliant for 50

hours of actual engine running time. Engines greater than 80 cc displacement are certified

to be emissions compliant for 125 hours of actual engine running time.

Intermediate:

Engines at or less than 80 cc displacement are certified to be emissions compliant for 125

hours of actual engine running time. Engines greater than 80 cc displacement are certified

to be emissions compliant for 250 hours of actual engine running time.

Extended:

Engines at or less than 80 cc displacement are certified to be emissions compliant for 300

hours of actual engine running time. Engines greater than 80 cc displacement are certified

to be emissions compliant for 500 hours of actual engine running time.

For example, a typical walk-behind lawn mower is used 20 to 25 hours per year. Therefore,

the Emissions Durability Period of an engine with an intermediate rating would equate

to 10 to 12 years.

Briggs & Stratton engines are certified to meet the United States Environmental Protection

Agency (USEPA) Phase 2 or Phase 3 emissions standards. The Emissions Compliance

Period referred to on the Emissions Compliance label indicates the number of operating

hours for which the engine has been shown to meet Federal emissions requirements.

For engines at or less than 80 cc displacement:

Category C = 50 hours, Category B = 125 hours, Category A = 300 hours

For engines greater than 80 cc displacement and less than 225 cc displacement:

Category C = 125 hours, Category B = 250 hours, Category A = 500 hours

For engines of 225 cc or more displacement:

Category C = 250 hours, Category B = 500 hours, Category A = 1000 hours

80008256 (Rev F)

California, U.S. EPA, and Briggs & Stratton Corporation Emissions

Control Warranty Statement - Your Warranty Rights and

Obligations

For Briggs & Stratton Engine Models with "B" or "G" Trim Designation (Model-TypeTrim Representation xxxxxx xxxx Bx or xxxxxx xxxx Gx)

The California Air Resources Board, U.S. EPA, and Briggs & Stratton (B&S) are pleased

to explain the emissions control system warranty on your Model Year 2017-2019 engine.

In California, new small off-road engines and large spark ignited engines less than or equal

to 1.0 liter must be designed, built, and equipped to meet the State's stringent anti-smog

standards. B&S must warrant the emissions control system on your engine for the periods

of time listed below provided there has been no abuse, neglect, or improper maintenance

of your engine.

Your exhaust emissions control system may include parts such as the carburetor or fuel

injection system, ignition system, and catalytic converter. Also included may be hoses,

belts, connectors, sensors, and other emissions-related assemblies.

Where a warrantable condition exists, B&S will repair your engine at no cost to you including

diagnosis, parts, and labor.

Manufacturer’s Warranty Coverage:

Small off-road engines and large spark ignited engines less than or equal to 1.0 liter, and

any related emissions components of the equipment, are warranted for two years, or for

the time period listed in the respective engine or product warranty statement, whichever

is greater. If any emissions-related part on your B&S engine is defective, the part will be

repaired or replaced by B&S.

Owner’s Warranty Responsibilities:

13

Page 14

Not for

Reproduction

• As the engine owner, you are responsible for the performance of the required

maintenance listed in your Operator's Manual. B&S recommends that you retain all

receipts covering maintenance on your engine, but B&S cannot deny warranty solely

for the lack of receipts or your failure to ensure the performance of all scheduled

maintenance.

• As the engine owner, you should however be aware that B&S may deny you warranty

coverage if your engine or a part has failed due to abuse, neglect, improper

maintenance, or unapproved modifications.

• You are responsible for presenting your engine to a B&S distribution center, servicing

dealer, or other equivalent entity, as applicable, as soon as a problem exists. The

warranty repairs should be completed in a reasonable amount of time, not to exceed

30 days. If you have any questions regarding your warranty rights and responsibilities,

you should contact B&S at 1-800-444-7774 (in USA) or

BRIGGSandSTRATTON.COM.

Briggs & Stratton Emissions Control Warranty Provisions

The following are specific provisions relative to your Emissions Control Warranty Coverage.

It is in addition to the B&S engine warranty for non-regulated engines found in the Operator's

Manual.

1. Warranted Emissions Parts

Coverage under this warranty extends only to the parts listed below (the emissions

control systems parts) to the extent these parts were present on the B&S engine.

a. Fuel Metering System

• Cold start enrichment system (soft choke)

• Carburetor or fuel injection system

• Oxygen sensor

• Electronic control unit

• Fuel pump module

b. Air Induction System

• Air cleaner

• Intake manifold

c. Ignition System

• Spark plug(s)

• Magneto ignition system

d. Catalyst System

• Catalytic converter

• Exhaust manifold

• Air injection system or pulse value

e. Miscellaneous Items Used in Above Systems

• Vacuum, temperature, position, time sensitive valves and switches

• Connectors and assemblies

2. Length of Coverage

Coverage is for a period of two years from date of original purchase, or for the time

period listed in the respective engine or product warranty statement, whichever is

greater. B&S warrants to the original purchaser and each subsequent purchaser that

the engine is designed, built, and equipped so as to conform with all applicable

regulations adopted by the Air Resources Board; that it is free from defects in material

and workmanship that could cause the failure of a warranted part; and that it is

identical in all material respects to the engine described in the manufacturer's

application for certification. The warranty period begins on the date the engine is

originally purchased.

The warranty on emissions-related parts is as follows:

• Any warranted part that is not scheduled for replacement as required

maintenance in the Operator's Manual supplied, is warranted for the warranty

period stated above. If any such part fails during the period of warranty

coverage, the part will be repaired or replaced by B&S at no charge to the

owner. Any such part repaired or replaced under the warranty will be warranted

for the remaining warranty period.

• Any warranted part that is scheduled only for regular inspection in the Operator's

Manual supplied, is warranted for the warranty period stated above. Any such

part repaired or replaced under warranty will be warranted for the remaining

warranty period.

• Any warranted part that is scheduled for replacement as required maintenance

in the Operator's Manual supplied, is warranted for the period of time prior to

the first scheduled replacement point for that part. If the part fails prior to the

first scheduled replacement, the part will be repaired or replaced by B&S at no

charge to the owner. Any such part repaired or replaced under warranty will

be warranted for the remainder of the period prior to the first scheduled

replacement point for the part.

• Add-on or modified parts that are not exempted by the Air Resources Board

may not be used. The use of any non-exempted add-on or modified parts by

the owner will be grounds for disallowing a warranty claim. The manufacturer

will not be liable to warrant failures of warranted parts caused by the use of a

non-exempted add-on or modified part.

3. Consequential Coverage

Coverage shall extend to the failure of any engine components caused by the failure

of any warranted emissions parts.

4. Claims and Coverage Exclusions

Warranty claims shall be filed according to the provisions of the B&S engine warranty

policy. Warranty coverage does not apply to failures of emissions parts that are not

original equipment B&S parts or to parts that fail due to abuse, neglect, or improper

maintenance as set forth in the B&S engine warranty policy. B&S is not liable for

warranty coverage of failures of emissions parts caused by the use of add-on or

modified parts.

Look For Relevant Emissions Durability Period and Air Index

Information On Your Small Off-Road Engine Emissions Label

Engines that are certified to meet the California Air Resources Board (CARB) small offroad Emissions Standard must display information regarding the Emissions Durability

Period and the Air Index. Briggs & Stratton makes this information available to the consumer

on our emissions labels. The engine emissions label will indicate certification information.

The Emissions Durability Period describes the number of hours of actual running time

for which the engine is certified to be emissions compliant, assuming proper maintenance

in accordance with the Operator's Manual. The following categories are used:

Moderate:

Engines at or less than 80 cc displacement are certified to be emissions compliant for 50

hours of actual engine running time. Engines greater than 80 cc displacement are certified

to be emissions compliant for 125 hours of actual engine running time.

Intermediate:

Engines at or less than 80 cc displacement are certified to be emissions compliant for 125

hours of actual engine running time. Engines greater than 80 cc displacement are certified

to be emissions compliant for 250 hours of actual engine running time.

Extended:

Engines at or less than 80 cc displacement are certified to be emissions compliant for 300

hours of actual engine running time. Engines greater than 80 cc displacement are certified

to be emissions compliant for 500 hours of actual engine running time.

For example, a typical walk-behind lawn mower is used 20 to 25 hours per year. Therefore,

the Emissions Durability Period of an engine with an intermediate rating would equate

to 10 to 12 years.

Briggs & Stratton engines are certified to meet the United States Environmental Protection

Agency (USEPA) Phase 2 or Phase 3 emissions standards. The Emissions Compliance

Period referred to on the Emissions Compliance label indicates the number of operating

hours for which the engine has been shown to meet Federal emissions requirements.

For engines at or less than 80 cc displacement:

Category C = 50 hours, Category B = 125 hours, Category A = 300 hours

For engines greater than 80 cc displacement and less than 225 cc displacement:

Category C = 125 hours, Category B = 250 hours, Category A = 500 hours

For engines of 225 cc or more displacement:

Category C = 250 hours, Category B = 500 hours, Category A = 1000 hours

80008114 (Rev F)

14 BRIGGSandSTRATTON.com

Page 15

Not for

Reproduction

Hak Cipta Perusahaan Briggs & Stratton, Milwaukee, WI, USA. Hak Cipta dilindungi

Undang-Undang.

Panduan ini menjelaskan informasi keselamatan pada Anda agar sadar akan bahaya dan

resiko yang berhubungan dengan mesin-mesin dan bagaimana menghindarinya. Selain

itu panduan ini juga memberikan petunjuk-petunjuk untuk menggunakan dan merawat

mesin dengan tepat. Perusahaan Briggs & Stratton tidak selalu mengetahui peralatan apa

yang mendukung mesin ini, sehingga penting bila Anda membaca dan memahami petunjukpetunjuk yang ada serta panduan untuk peralatan. Simpan buku panduan yang asli

untuk referensi di masa datang.

Perhatikan:

referensi saja dan mungkin berbeda dari model spesifikasi Anda. Hubungi distributor Anda

jika ada pertanyaan.

Untuk penggantian suku cadang atau bantuan teknis, silakan catat model, tipe, dan kode

nomor mesin beserta tanggal pembeliannya. Nomor-nomor ini ditempatkan di mesin Anda

(lihat

Tanggal Pembelian

Model Mesin - Tipe – Kondisi

Nomor Seri Mesin

Cari barcode 2D yang ditempatkan pada

beberapa mesin. Jika dilihat dari perangkat

dengan sistem 2D, maka kode akan

memunculkan website kami di mana Anda

bisa mengakses informasi dukungan untuk

produk ini. Kecepatan data berlaku. Beberapa

Negara mungkin tidak memiliki dukungan

informasi online.

Gambar-gambar dan ilustrasi pada buku panduan diberikan hanya untuk

bagian

fitur dan kontrol).

Tanda-tanda Bahaya dan Maknanya

MaknaSimbolMaknaSimbol

Informasi Keselamatan

tentang bahaya dapat

menyebabkan cedera

pribadi.

Bahaya Permukaan Panas

Menggunakan penutup

mata.

dingin

kehilangan bagian tubuh

Membaca dan memahamiBuku

Panduan Penggunaan sebelum

menjalankan atau melayani unit

tersebut.

Bahaya LedakanBahaya Kebakaran

Bahaya Asap BeracunBahaya Sengatan

Bahaya Suara –

Direkomendasikan

menggunakan tutup telinga

untuk penggunaan

berkepanjangan.

Bahaya LedakanBahaya Dilempar Benda –

Bahaya BantinganBahaya Frosbite/Radang

Bahaya Bahan KimiaBahaya Amputasi –

Informasi Kontak Kantor Eropa

Untuk pertanyaan mengenai emisi Eropa, silakan hubungi kantor Eropa kami yang

beralamatkan di:

Max-Born-Straße 2, 68519 Viernheim, Germany.

Informasi Daur Ulang

Semua kemasan, oli bekas, dan baterai harus didaur ulang

sesuai aturan pemerintah yang berlaku.

Keselamatan Operator

Simbol Peringatan dan Kata Sinyal

Keselamatan

Simbol peringatan keselamatan ( ) digunakan untuk mengidentifikasi informasi

keselamatan tentang bahaya yang dapat menyebabkan cedera pribadi. Kata sinyal

(BAHAYA, PERINGATAN, atau PERHATIAN) digunakan dengan simbol peringatan untuk

mengindikasikan kemungkinan dan potensi keparahan cedera. Selain itu, simbol bahaya

dapat digunakan untuk menunjukkan jenis bahaya.

BAHAYA menunjukkan bahaya yang, jika tidak dihindari, akan menyebabkan

kematian atau cedera serius.

PERINGATAN menunjukkan bahaya yang, jika tidak dihindari, dapat menyebabkan

kematian atau cedera serius.

PERHATIAN menunjukkan bahaya yang, jika tidak dihindari, dapat menyebabkan

cedera ringan atau sedang.

PEMBERITAHUAN

produk.

menunjukkan situasi yang dapat menyebabkan kerusakan pada

KorosiBahaya Panas

Pesan Keselamatan

PERINGATAN

Produk ini dapat memaparkan Anda pada bahan kimia, termasuk sisa pembakaran

bensin yang menurut Negara Bagian California dapat menyebabkan kanker, dan karbon

monoksida yang menurut Negara Bagian California dapat menyebabkan cacat lahir