Braun Under-Vehicle Lift NUVL603C Service Manual

Service Manual for:

CJKA+%(8

CJKA+%(8

Under-Vehicle Lift

®

Private Use Wheelchair Lifts

www.braunlift.com

Series 02

DOT — Private Use Lift

DOT — Private Use Lift

“DOT — Private Use Lift” verifies that this platform lift meets only

the “private use lift” requirements of FMVSS No. 403. This lift may

be installed on all vehicles appropriate for the size and weight of

the lift, except for buses, school buses, and multi-purpose

passenger vehicles other than motor homes with a gross vehicle

weight rating (GVWR) that exceeds 4,536 kg (10,000 lb).

02

W

A

R N I N G

Man

ual

"Providing Access to the World"

International Corporate Hdqrs: P.O. Box 310 Winamac, IN 46996 USA

1-800-THE LIFT

35033

November

2008

®

(574) 946-6153 FAX: (574) 946-4670

®

®

Patent #5,305,486

Patent #5,305,486

Read manual

before installing

or servicing lift.

Failure to do so

may result in

serious bodily

injury and/or

property damage.

Braun UVL SeriesTM

Braun UVL SeriesTM

OWNER'S WARRANTY REGISTRATION

PURCHASED FROM

DATE INSTALLED

NAME

ADDRESS

CITY

TELEPHONE

TO VALIDATE WARRANTY

REGISTRATION CARDS MUST BE RETURNED TO THE BRAUN CORPORATION.

OWNER

STATE ZIP

Congratulations

We at The Braun Corporation wish to express our fullest appreciation

on your new purchase. With you in mind, our skilled craftsmen have designed and

assembled the finest lift available.

This manual provides service-related material. Refer to the FMVSS No. 403

Quick Reference Installation Sheet for installation instructions, operating instructions

and maintenance procedures.

Braun UVL Series™ lifts are built for dependability and will provide years of pleasure and independence as long as the lift is installed and serviced as specified by a

Braun certified technician, and the lift is operated by an instructed person.

Sincerely,

THE BRAUN CORPORATION

Ralph W. Braun

Chief Executive Officer

Warranty and Registration Instructions

Immediately upon receiving the lift, examine the

unit for any damage. Notify the carrier at once

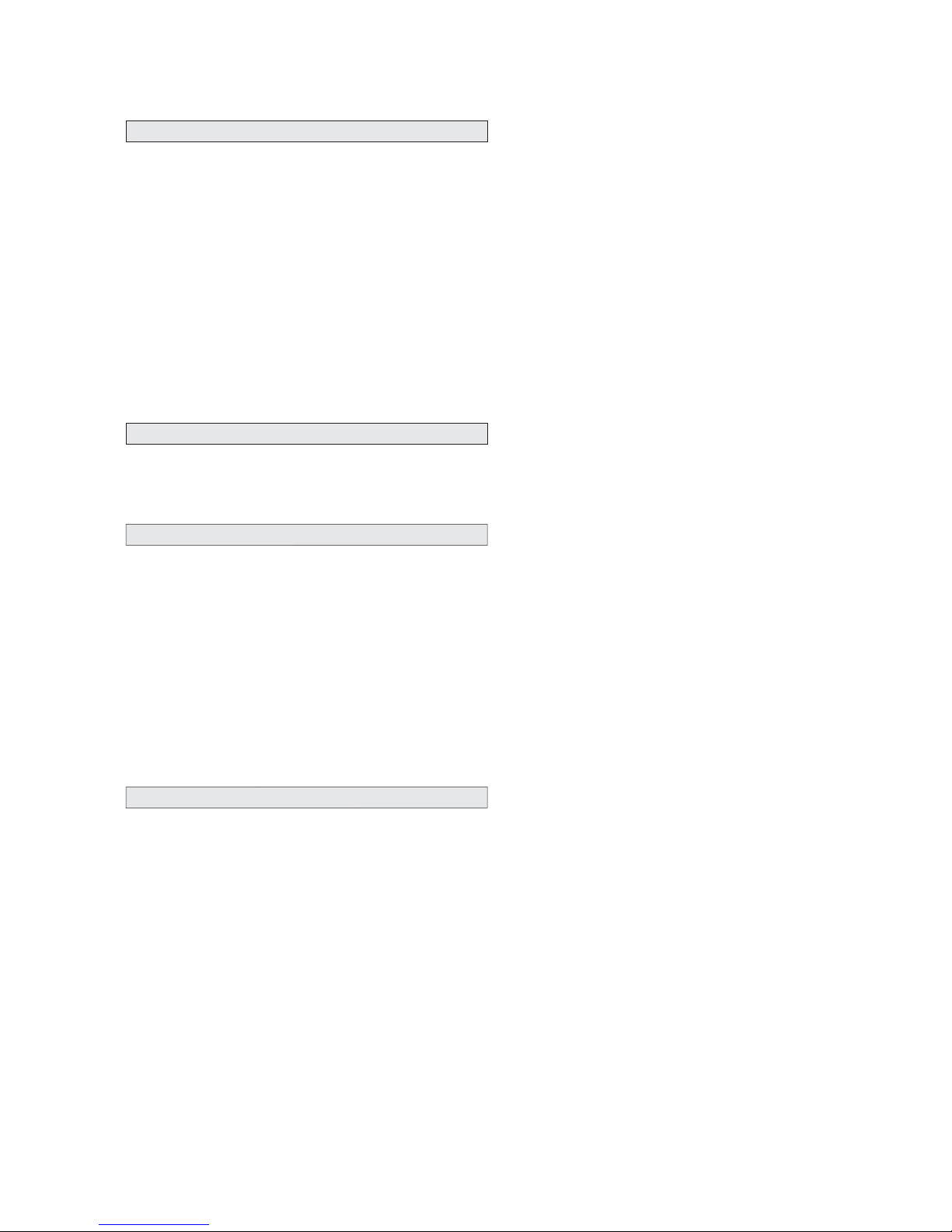

Series No.

Serial No.Model No.

with any claims.

NUVL603C 02-00025

Two warranty/registration cards (shown right) are

protected in a clear envelope and attached to the

lift protective shipping wrap. The sales representative must process one of the cards. The consumer

must fill out the other card and mail it to The Braun

Corporation. A detailed warranty section is provided

in this manual. The warranty cards must be

Sample Warranty/Registration Card

processed to activate the warranty.

Two Braun Serial No./Series No. identification tags (shown below) are posted on the lift. One

I.D. tag is posted on the left platform side plate (outboard end). A second I.D. tag is located

inside of the pump module. Both I.D. tags provide the product identification information

provided on the warranty/registration card. Record the information in the space provided (or

document on a copy). This information must be provided when filing a warranty

claim or ordering parts.

The Braun Corporation

1-800-THE-LIFT

BRAUNMOBILITY.COM

DOT Private Use Lift MODEL#

NUVL603C

Max. Lifting Capacity - 750Lbs.

SERIAL NUMBER

02-00025

®

®

Model No.

Series No.

Serial No.

MFG DATE

11/12/2007

e5*72/245*95/54*0102*00

Sample Serial No./Series No. Identification Tag

PATENT

5,305,486

Pump Code

Cylinder Code

Date of Manufacture

Contents

Troubleshooting and Maintenance

Lift Terminology ............................................................ 2

Switch and Sensor Locations ..................................... 3

Certification Checklist .................................................. 4

Adjustments and Calibration ....................................... 5

LCD Diagnostic Codes ................................................. 6

Floor Level and Inboard Locator Adjustments ..... 7-10

Lubrication Diagram ....................................................11

Maintenance and Lubrication Schedule ............... 12-14

Troubleshooting Diagnosis Chart ......................... 15-18

Notes ............................................................................ 19

Lift Wiring Schematic - Main ..................................... 20

Lift Wiring Schematic - Accessories ........................ 21

Hydraulics

Hydraulics Parts List .................................................. 22

Hydraulics Diagram .................................................... 23

Repair Parts

Pump Module

Pump Module Parts List ....................................... 24

Pump Module Diagram ......................................... 25

Lift Exploded Views

Complete Lift .......................................................... 26

Repair Parts List ................................................... 27

Housing Detail ........................................................ 28

Carriage Detail........................................................ 29

Platform Detail ........................................................ 30

Warranty

®

Braun

Limited Warranty .......................................31-33

Notes ............................................................................ 34

Page 1

Hand-Held Attendant's

Control Box

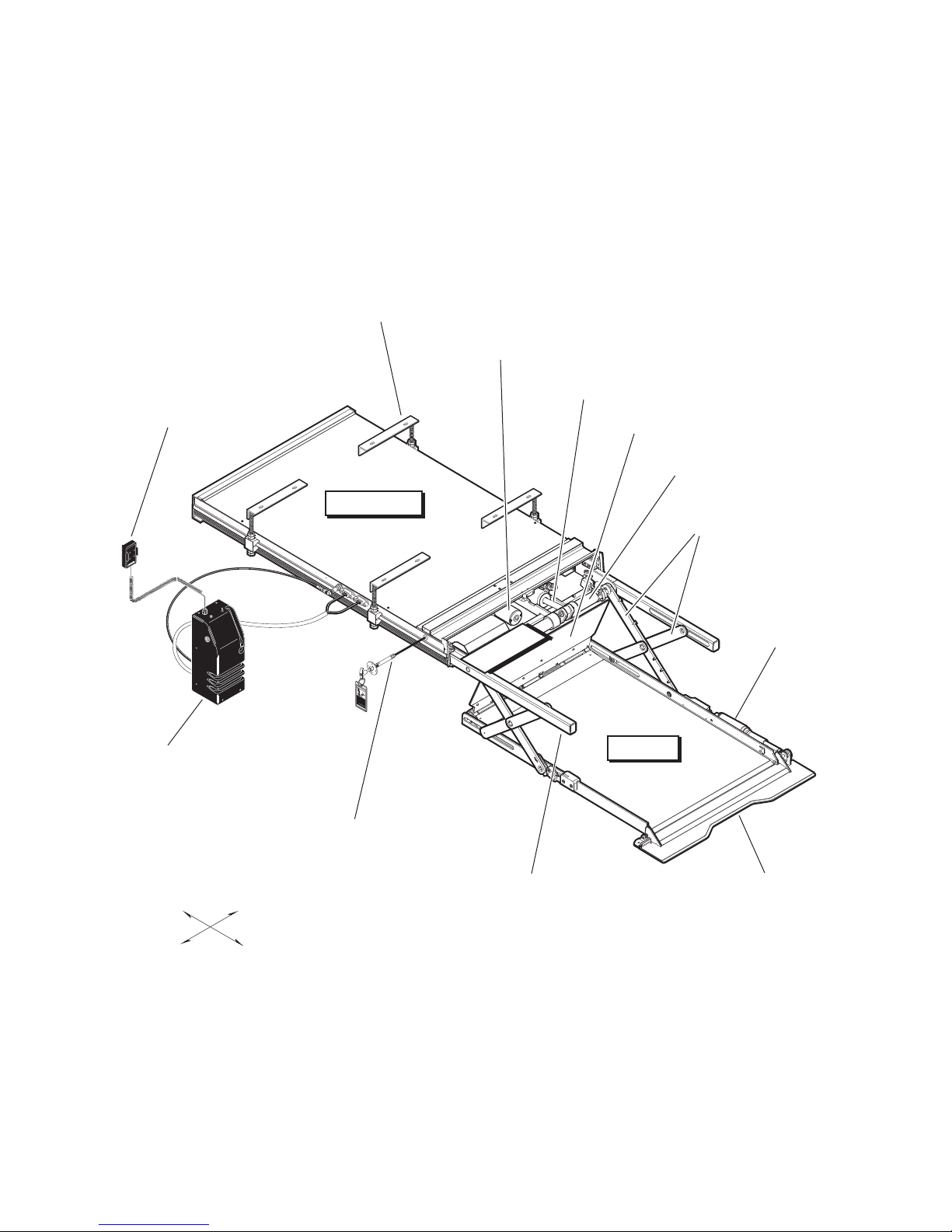

Lift Terminology

Lift Mounting

Brackets (4)

Chain Drive

Motor

Hydraulic

Cylinder

Inboard

Locator

Torque

Tube

STOW

R

DOO

P

U

N

DOW

Module

Pump

Inboard

Lift Housing

Platform Cable-activated

Manual Release System

Right

Lifting

Arms

Outer Barrier

Actuator

Carriage

W

A

R

N

I

N

G

P

u

sh

ma

T

h

n

a

ual

n

and ou

dl

l

y m

e in

lock b

ove

t t

f

u

o

lly

Fa

platform in

e

ef

n

a

ilure to lock platfo

nd

o

gage pla

re dr

re

s

u

i

vi

l

t

deploy

n

t

i

f

n

g

o

vehi

u

r

m

nint

platform d

m

cl

e

e

e.

nt. Unintended

n

rm

r

d

e

sult

ed pla

ma

eployment

a

y

i

n

n

d/or p

t

se

f

o

rm

riou

roper

s

m

bo

a

ty da

y

dil

y

injury

Do not remove!

m

a

g

e

.

8

1

8

23

Platform

Rolling

Horizontal Arms

Outer

Barrier

Left

Outboard

Page 2

Switch and Sensor Locations

Lift Out

Cam

73774

Lift Out

Limit Switch

73950A

Full Out

Limit Switch

73950A

Full Out

Cam

73775

Below Stow

Limit Switch

73950A

Floor Level

Limit Switch

73950A

Floor Level

Cam

73712

Below Stow

Cam

73712

Outer Barrier

Limit Switch

73950A

STOW

DOOR

UP

OWN

D

Inboard

Left

Right

Outboard

W

A

R

N

I

N

G

Pu

sh

Tm

a

h

n

a

uall

n

an

dle

d

y

o

m

i

n

l

ut to

o

o

f

c

ve

u

k

l

l

b

pl

y a

Fa

en

ef

a

i

nd

o

g

l

tf

u

re

a

o

r

result in

g

e to

rm

e plat

d

r

i

i

v

n

l

d

i

o

n

ep

c

f

g

o

k pl

unin

r

l

ve

o

m

plat

yment

hi

a

t

t

cle.

f

e

o

f

o

n

r

r

r

m

ded

e

m

.

sult in

Uni

m

de

a

p

an

y

p

lat

n

l

d/o

t

o

e

se

fo

yment may

n

r

r

d

r

m

i

pr

ed

o

u

o

s

p

bo

e

r

t

d

y

ily

d

amage

Do

inju

not rem

ry

.

81

8

2

3

ov

e!

Pressure

Transducer

30426

Page 3

Certification Checklist

The following operations and conditions must be functionally verified in order for the lift to be FMVSS

403/404 compliant. If an operation does not function as described or a condition is not met, follow the referenced procedures to correct the problem or contact a Braun Corporation Product Support representative.

• Vehicle movement is prevented unless the lift door is closed, ensuring the lift is stowed.

1. Verify lift stowed signal (pin 9) in the 9 conductor plug on the side of the pump module has a +12 volt

signal.

2. Refer to the interlock installation instructions.

• Lift operation shall be inhibited unless the vehicle is stopped and vehicle movement is prevented.

1. Verify vehicle secure signal (pin 6) in the 9 conductor plug on the side of the pump module has a +12

volt signal.

2. Refer to the interlock installation instructions.

• The platform will not fold/stow when occupied.

- Refer to Platform Sense Calibration.

• The outer barrier will not raise if occupied.

- Refer to Outer Barrier Occupied Calibration procedure

• An audio warning (and visual warning for public use lifts) will activate if the threshold area is occupied

when the platform is a least 1" below floor level.

1. Make sure connectors to threshold mat are properly connected.

2. Call Product Support.

• Lift platform movement shall be interrupted unless the outer barrier is deployed (up).

- Check Barrier Down limit switch, wires and connector.

- Diagnostic LCD should display a value of “1” for OBAR SW when outer barrier is deployed (up).

Page 4

Adjustment Procedures

Adjustments and Calibration

Lift Out Switch: The Lift Out Switch stops inward

travel of the carriage/platform during Stow function

(activated by the housing-mounted Lift Out Cam).

Move cam in to increase inward travel. Move cam

out to decrease inward travel.

Full Out Switch: The Full Out Switch stops outward travel of the carriage/platform during Deploy

(Up/Down) functions (activated by the housingmounted Full Out Cam). Move cam in to decrease

outward travel. Move cam out to increase outward

travel. Carriage rollers must be inside housing a

minimum 1/2". The platform will not raise or lower

until this switch is activated.

Floor Level Switch: See page 6 for procedures.

Stow Switch: The Stow Switch controls the height

of the carriage/platform before it moves inward during the Stow function (activated by the torque tubemounted Stow Cam). Rotate the cam in to decrease

platform height. Rotate the cam out to increase platform height. Adjust cam so lifting arms are aligned.

View the platform position in the housing.

Barrier Down Switch: This platform-mounted

switch prohibits the platform from raising unless the

outer barrier is in the full up position. The Up function is prohibited if the outer barrier detent pin is not

fully engaged also.

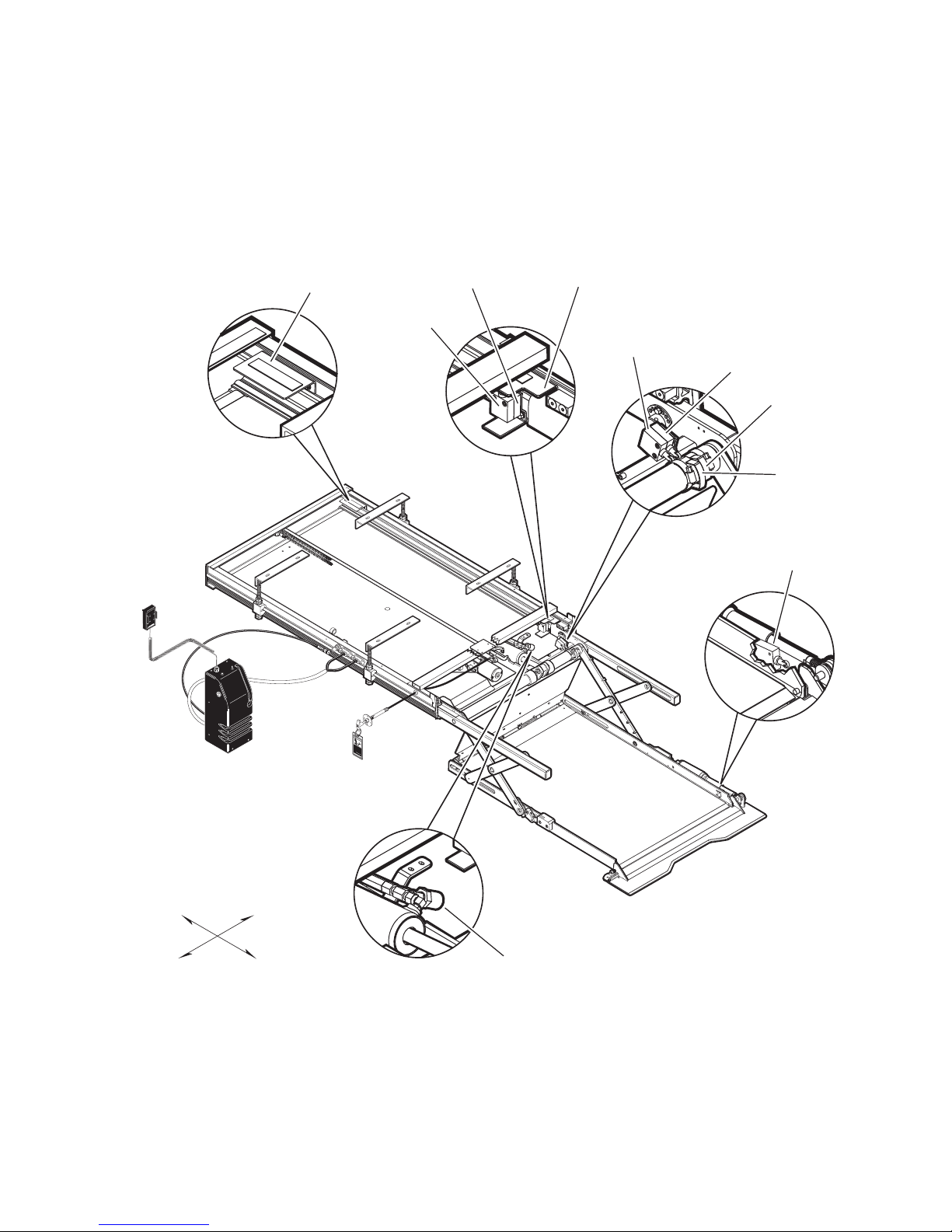

Remove eccentric plate mounting screw. Using

screwdriver or small rod, rotate the shaft clockwise to

increase carriage height. Rotate the shaft counterclockwise to decrease carriage height. Reinstall

mounting screw in nearest retainer hole. Adjust

left and right side eccentric shafts (screw positions

may vary from side to side). Adjust height such that

horizontal arms do not contact top or bottom of tracks

(align center).

Calibration Procedures

Platform Sense Calibration

1. Place 20 lbs. in the center of the platform.

2. Press UP button on the hand-held pendant to raise

the platform a minimum of 3" above stow level.

3. Press and hold 50# CAL button on control board.

While pressing the 50# CAL button, press and

hold the STOW button on the hand-held pendant.

The platform will lower to stow level, raise slightly,

lower to stow level, and begin inward travel.

Release the 50# CAL button when the platform

begins moving inward. The platform sensing is

now calibrated.

4. After calibration, the LCD screen should read “PF

OCCUPIED” when 50 lbs., or more, are present

on the platform. If 50 lbs. does not activate the

“platform occupied” signal readout, recalibrate with

less weight to lower the “occupied” setting or more

weight to increase the “occupied” setting.

Drive Chain Adjustment

In event the drive chain sags 1/2" or more, adjust

tension as detailed. Tighten to eliminate visible sag

but do not overtighten.

1. Remove bottom pan.

2. Pull the manual release cable and lock.

3. Remove adjustment bolt (tensioner) access

cover.

4. Loosen inside jam nut. Secure tensioner and

tighten outside jam nut. Tighten to eliminate visible chain sag but do not overtighten.

5. Lock jam nuts together making sure the tensioner roller is horizontal. Release and push the

manual cable in fully. Ensure platform is locked

by moving the platform in and out until chain

release assembly engages chain.

Carriage Ride Height Adjustment

The carriage horizontal arms move (roll) in and out

of the housing tracks on roller bearings. Following installation or extensive lift operation, clearance

between horizontal arms and tracks may diminish.

The eccentric shaft mounting plate allows height

adjustment.

Ground Sense Calibration

1. Press hand-held pendant DOWN switch to lower

platform fully to ground level.

2. While continuing to press the pendant DOWN

switch, press and then release the control board

O_BAR/GROUND LVL button.

3. Release the pendant DOWN switch. Ground

Level sensing is now calibrated.

4. After calibration, the outboard roll stop should

not unfold (down) until the platform is fully on the

ground.

Outer Barrier Occupied Calibration

1. Press hand-held pendant DOWN switch to lower

platform fully to ground level.

2. Once outer barrier is fully unfolded (ramp position),

release the pendant DOWN switch.

3. Press and hold the control board O_BAR/

GROUND LVL button. While holding O_BAR/

GROUND LVL button, press hand-held pendant

UP switch to raise the outer barrier. Be sure to

release O_BAR/GROUND LVL button when outer

barrier reaches approximately half full up (vertical)

position.

4. After calibration, the LCD screen should read

“OUT-BAR OCCUPIED” whenever there is weight

present on the outer barrier.

Page 5

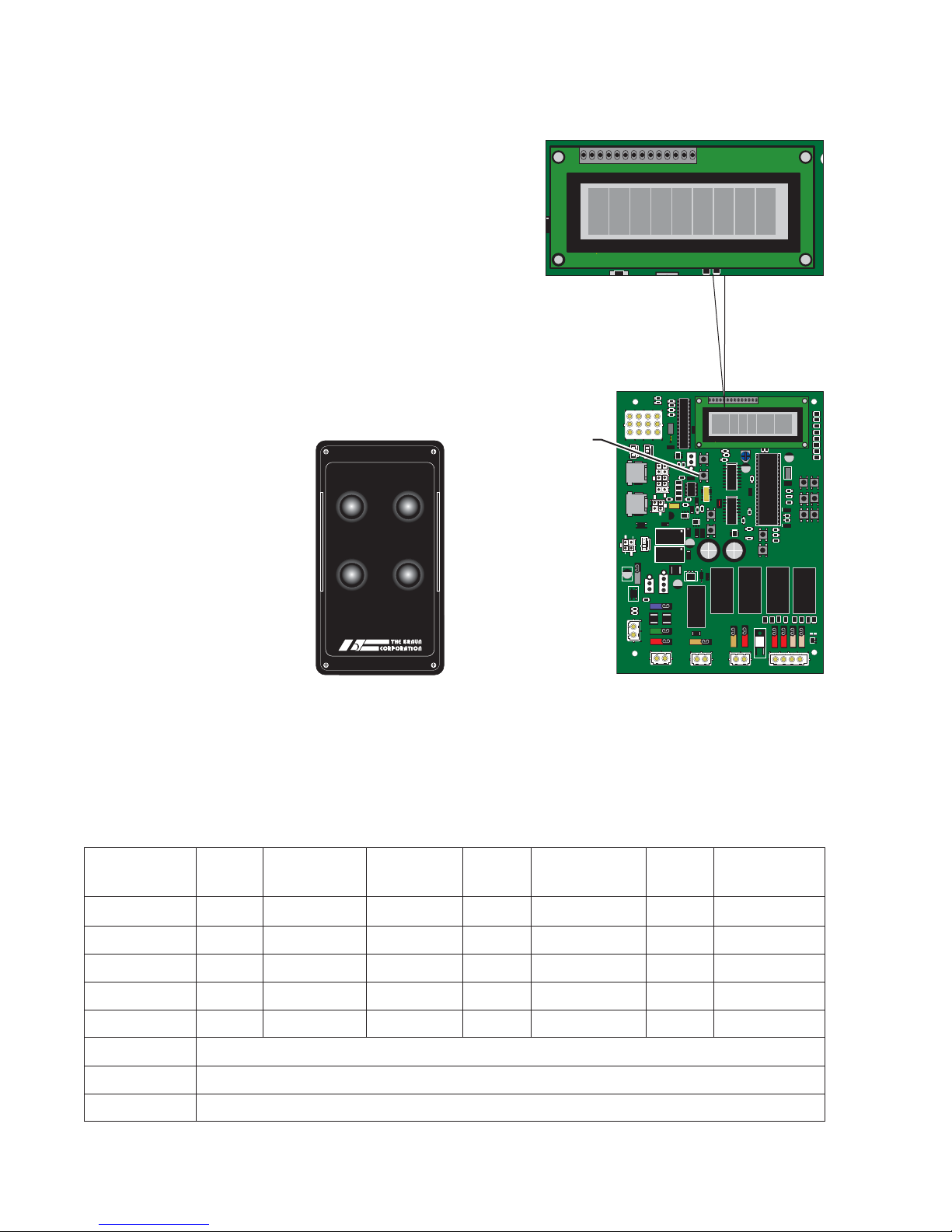

LCD Diagnostic Codes

2

C

To change the LCD display from cycle count to diagnostic

mode, press the “diag” button on the control board (see

illustration at right). When finished, press button again to

return to cycle count mode. When all of the harnesses

are correctly connected to the control board, the values

shown in the chart below will display when the corresponding action is taken. “1” will appear to the right of the switch

or sensor name on the LCD module when activated as

shown. If any other value appears on the LCD screen

during the specific diagnostic procedure, verify that the

correct harness is properly connected to both the control

board and the associated lift harness. Repeat the harness

diagnostic procedure. If an incorrect value is still present

after checking the harness and connections, contact The

Braun Corporation Product Support Department.

All basic functions (UP,

DOWN, STOW and

DOOR) should show a

value of 1 when activated

via a controlled input

(Hand-held Pendant,

Magnetic, Remote Entry

or 3rd Station Controls).

DOOR

STOW

DOWN UP

cycle

diag Button

OBAR S 1

R31

R39

102

R13

R5

243R

R20

C

D

A

B

R19

R18

Lift Devices

K

L

U14

JIH

G

D/S

U/D

C7

321

321

J1

J2

6H23EM

HAND-1

R28

6H23EM

103

HAND-2

U18

Magnetic

C9

V104

INLK-1

U21

OH

RL11

4 3 2 1

321

RL10

Operator

Door

IN

MAT

VR3

FS11

C16

35A

220

5Q6

IN L H

U20

R25

102

FS1

R43

1802

R41

1002

GND

VR2

VR1

PWR-IN

FS2

12V-B

FS8

LIGHT

U16

103

103

103

103

V104

8.00M

C6

V104

U15

cycle

B LIGHT A

103

103

Remote

R1

R16

R26

103

C105

U12

C14

D23

D24

D25

C15

102

V104

D26

R33

103

R11

R37

C5

R36

106 E

330

C8

103

V104

103

U7

U17

D13

D10D11

C22

6C5

100

VHA

D12

U19

R34

C12

5Q6

220

35A

RL9

D9

FS7

LIGHT

W

102

102

OB AR S 1

R31

diag

U5

SOMC1601

CLOSECLOSE

OPEN

C10

V104

C13

RL4

ALARM

ALARM

W

102

102

CONTRAST

102

102

R29

103

U3

R27

CHA

220

6C5

C21

R32

102

V104

U2

C1

ZD3

R38

102

R42

102

R9

103

50# CAL

SW1

R10

103

U22

103

GROUND LVL

O_BAR

SW2

C11

RL2

RL3

D21

D19

D18

FS10

FS9

MP916

0.010Ω

.5% R

FS5

R40

PUMP

VALVE

B_DN

R4

R2

R1

103

R6

103

R7

D20

D7

D8

D5

D6

D3

D4

D

D7

D8

D5

D6

D3

D4

D2 D1

C20

CHA

220

6C5

U8

8.00M

L_UP

L_DN

C4

V104

R15

102

R14

B_DN

B_UP

103

R8

103

C3

V104

L_IN

L_OUT

103

103

NUVL CONTROLLER REV-3.1-1

The Braun Corporation

C2

V104

RL1

D16

D17

D15

D14

R3

U9

FS6

FS4

FS3

L_IN

L_OUT

B_UP

Hand-held Pendant

LCD Display Moving Out

STLV SW 1 1

Stowed

Of Cassette

Moving Up

From Stow

At Floor

Level

Moving Down

From Stow

NUVL Control Board

Ground

Level

Ground Level

OB Out

LOUT SW 1

FOUT SW 1 1 1 1 1

FLV SW 1

OBAR SW 1 1 1 1 1 1

MAT SW = 1 when mat is activated.

DO SW = 1 when door is full open or pin 3 and pin 4 are jumpered.

*IBAR SW = 1 when inboard locator is activated

*(NUVL855C only)

Page 6

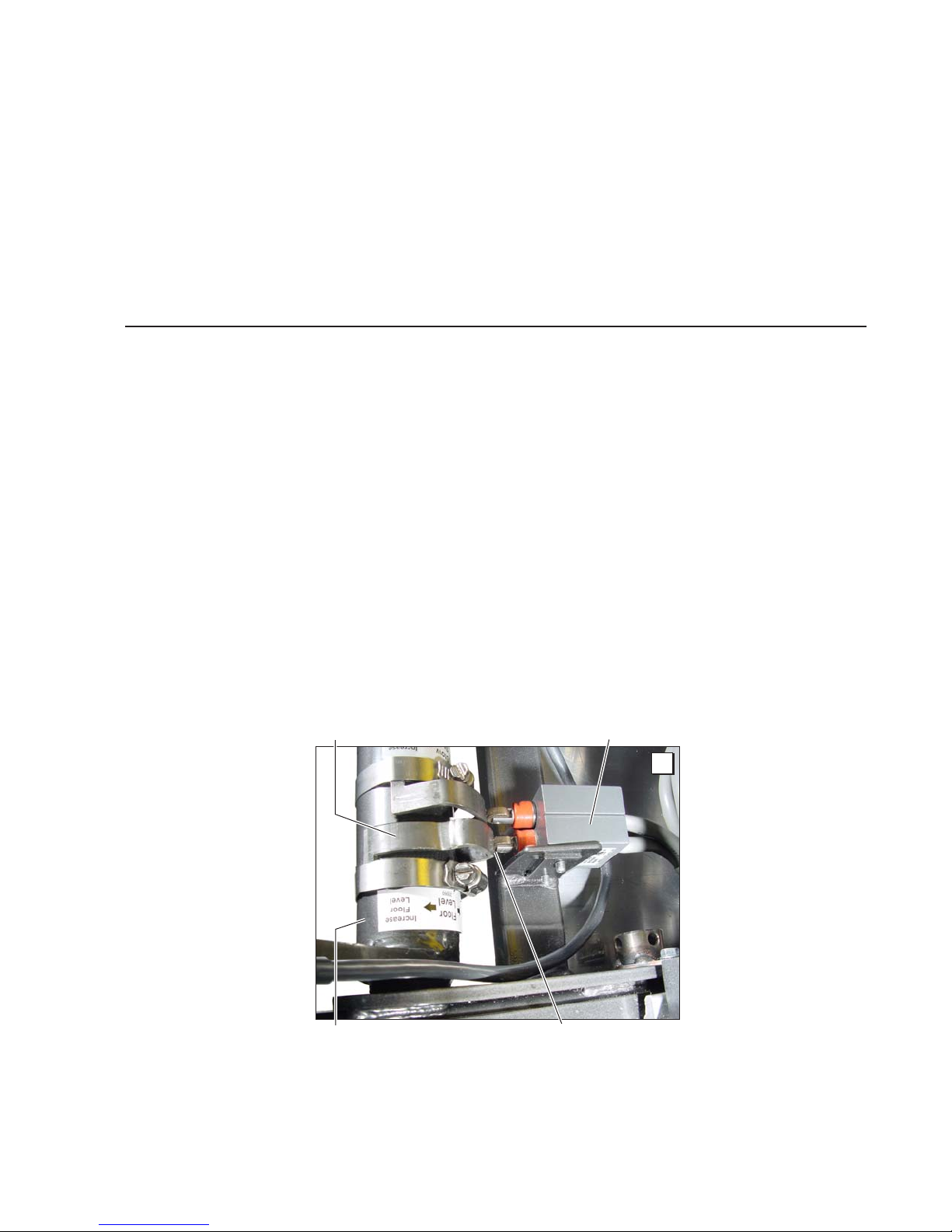

Floor Level and Inboard Locator Adjustments

Achieving proper floor level

positioning of the platform and

inboard locator requires a combination of Floor Level switch

adjustment and inboard locator

adjustment. Both are factory set

but must be inspected during

installation procedures (will vary

per vehicle application).

Floor Level Switch Adjustment

Adjust the Floor Level switch

first! (before adjusting the inboard

locator)!

The Floor Level switch stops upward travel of the platform during

the Up function (activated by the

torque tube-mounted Floor Level

cam).

Position the bottom of the lift plat-

Ensure the lift is positioned and

secured as specified on Quick

Reference Installation Sheet (supplied with lift) panels 1 and 2. Ad-

just the Floor Level switch first

(detailed below). Then, adjust

the inboard locator as detailed

in Inboard Locator Adjustment

Instructions (adjust only if neces-

form 1" above floor level (thresh-

old mat) using the manual op

eration system. Do not operate

the lift with the electric pump during adjustment procedures.

Loosen the clamp securing the

torque tube-mounted Floor Level

cam. Rotate the cam until the

Floor Level switch is activated

(cam depresses switch).

sary). The inboard locator must

rest properly on the vehicle floor

for wheelchair entry and exit.

Note: Check the floor level posi-

tion of the platform and the inboard locator after powering the

pump. Hydraulic pressure may affect platform height slightly. Fine

tuning adjustment (tweaking) of

the Floor Level switch may be

required.

Floor Level Cam

Torque Tube

Floor Level Switch

A

Cam depressing switch.

Page 7

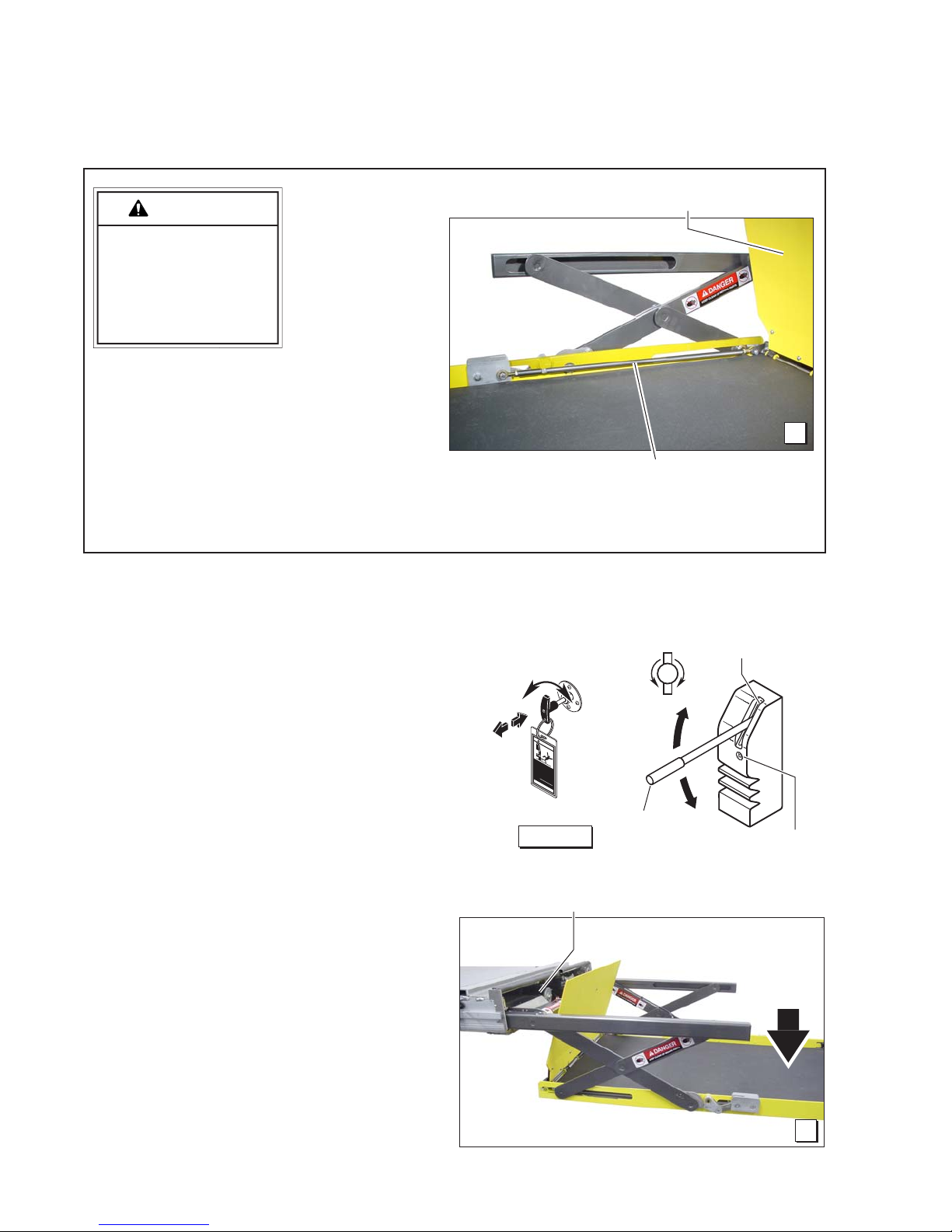

Floor Level and Inboard Locator Adjustments

CAUTION

Inboard Locator Adjustment

Do not adjust

inboard locator linkage rod

Do not adjust inboard locator linkage rod. Linkage

rod adjustment may

result in lift damage.

at this time!

Linkage rod

adjustment is not

required unless

extra usable

platform length

is needed. If

the angle of the inboard locator (when in the

vertical position) restricts the usable platform

length for the wheelchair passenger, adjustment of the linkage rod will change the angle.

With the platform at ground level and the

inboard locator in the vertical position, there

should be a minimum of 1” clearance between

the inboard locator and torque tube.

Adjust the inboard locator as detailed in the

following procedures. Then, adjust the linkage

rod as detailed on page 9 (only if necessary).

1. Raise the lift platform fully (floor level) using the manual operation system (Manual

Operating Instructions detailed on Quick

Reference Installation Sheet). If the inboard

locator rests properly on the floor, do not ad-

just the inboard locator. Lower the platform

to ground level. If the angle of the inboard

locator (when in the vertical position), does

not restrict the usable platform length for the

wheelchair passenger, disregard inboard

locator adjustment procedures. See Photo H

on page 9. Refer to the following procedures

if adjustment is required.

Inboard Locator

Linkage Rod

Manual Operation Systems

T-Handle

Release

Cable

W

A

R

NI

N

G

Push T-handle in fully

manually move platfo

and out to engage platfo

lock before driving

Failure to lock platform may

and

result in unintended platform

rm in

deployment. Unintended

rm

veh

platform deployment

icle.

result in serious bodily injury

and/or property dam

may

Do not remove!

ag

e.

81823

Figure A

N

E

P

O

Pump

Handle

VALV E

Stow Level

B

Hand

Pump

C

L

O

S

E

Val ve

2. Position the lift platform below

stow level using the manual op-

eration system. See Photo C.

Lowering the platform will allow access to the cam bolt

securement nut. See Photo E.

Page 8

Platform

below

Stow

Level

C

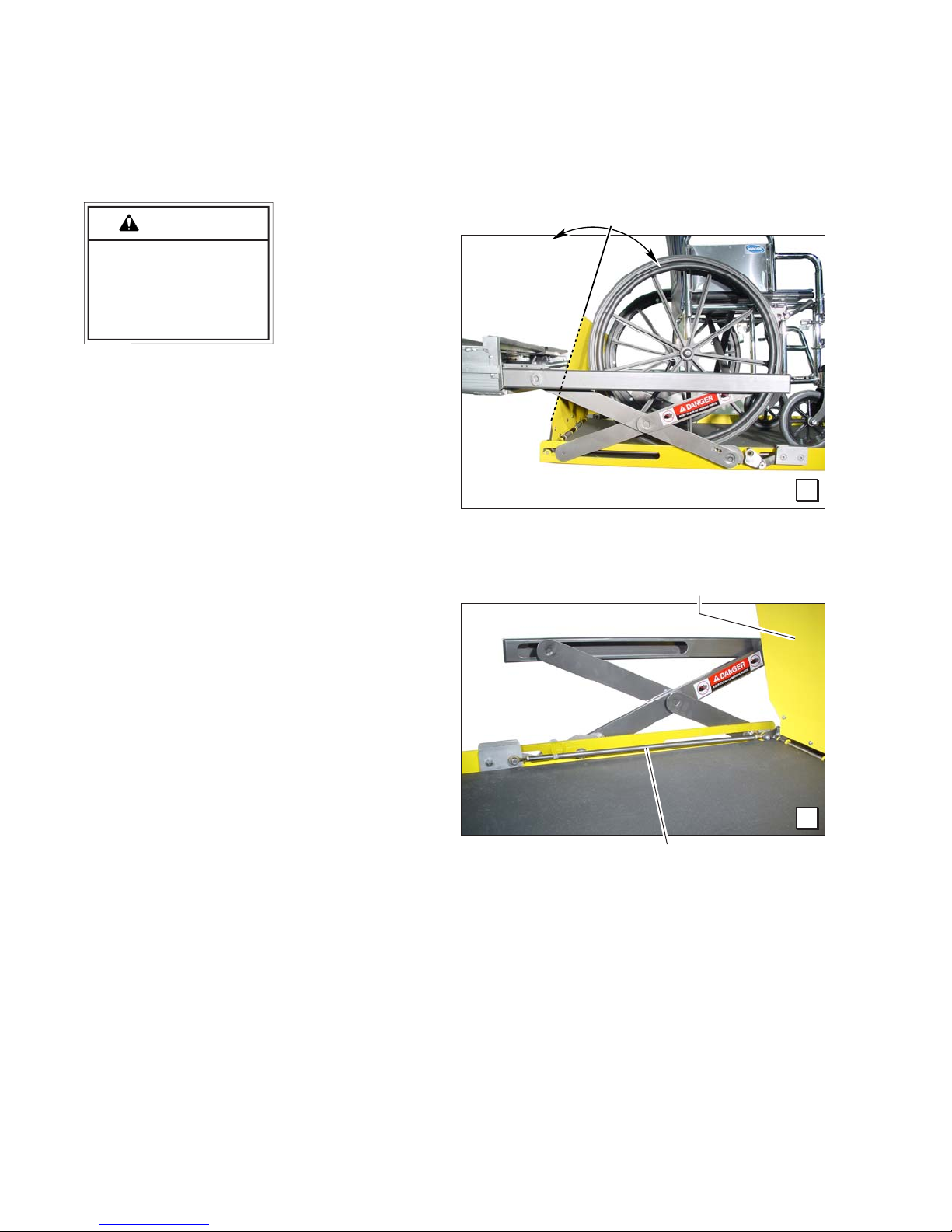

Floor Level and Inboard Locator Adjustments

Inboard Locator Adjustment

3. Remove the 1/4" lock nut se-

curing the lifting arm cam bolt.

See Photos D and E. Do not

remove the bolt.

Raise the platform fully (floor

level) using the manual op-

eration system.

Remove the cam securement

bolt (lift inboard locator to relieve pressure on bolt).

Allow the inboard locator to rest

on the floor.

Rotate the cam so the cam follower bearing engages the cam

notch (saddle). See Photos F

and G.

Reinstall the cam securement

bolt in one of the three lifting

arm holes that best lines up

with one of the nine holes in the

cam. See Photos F and G.

D

Cam Bolt

1/4" Lock Nut

Reposition the securement bolt

lock nut. Note: Lowering the

platform will allow access to

cam bolt. Tighten securely.

Cam Notch (Saddle)

e

t

C

a

t

o

R

a

m

F

Lifting Arm

(3 available holes)

Slider Block

Rocker

Cam

(9 available holes)

E

Cam Notch (Saddle)

Engaging

Cam Follower Bearing

e

t

C

a

t

o

R

a

m

G

Page 9

CAUTION

Floor Level and Inboard Locator Adjustments

Inboard Locator Linkage Rod Adjustment

Do not adjust the

inboard locator

linkage rod un-

Improper inboard

locator linkage rod

adjustment may

result in lift damage.

the vertical position) restricts the usable platform

length for the wheelchair passenger, adjustment

of the linkage rod will change the angle.

Adjust the inboard locator as detailed in the

previous procedures. Then, adjust the linkage

rod as detailed (only if necessary). If the link-

age rod is adjusted too long or too short, it will

exceed the travel of the slider block resulting in

damage to the cam follower bearing, the cam

and/or other components.

less extra usable

platform length

is needed. See

Photo H. If the angle of the inboard

locator (when in

Linkage rod adjustment affects angle

of inboard locator (vertical position).

H

Inboard Locator

1. Position the lift platform below stow level

using the manual operation system. Do

not operate the lift with the electric pump

during adjustment procedures.

2. Loosen the jam nuts at each end. Adjust

rod length as needed. Minimize adjustment. Carefully check the inboard locator

angle and operation using the manual

operation system. Ensure the rod has not

been over adjusted resulting in pressure on

components (damage will result). Tighten

the linkage rod jam nuts.

I

Linkage Rod

Page 10

Loading...

Loading...