Page 1

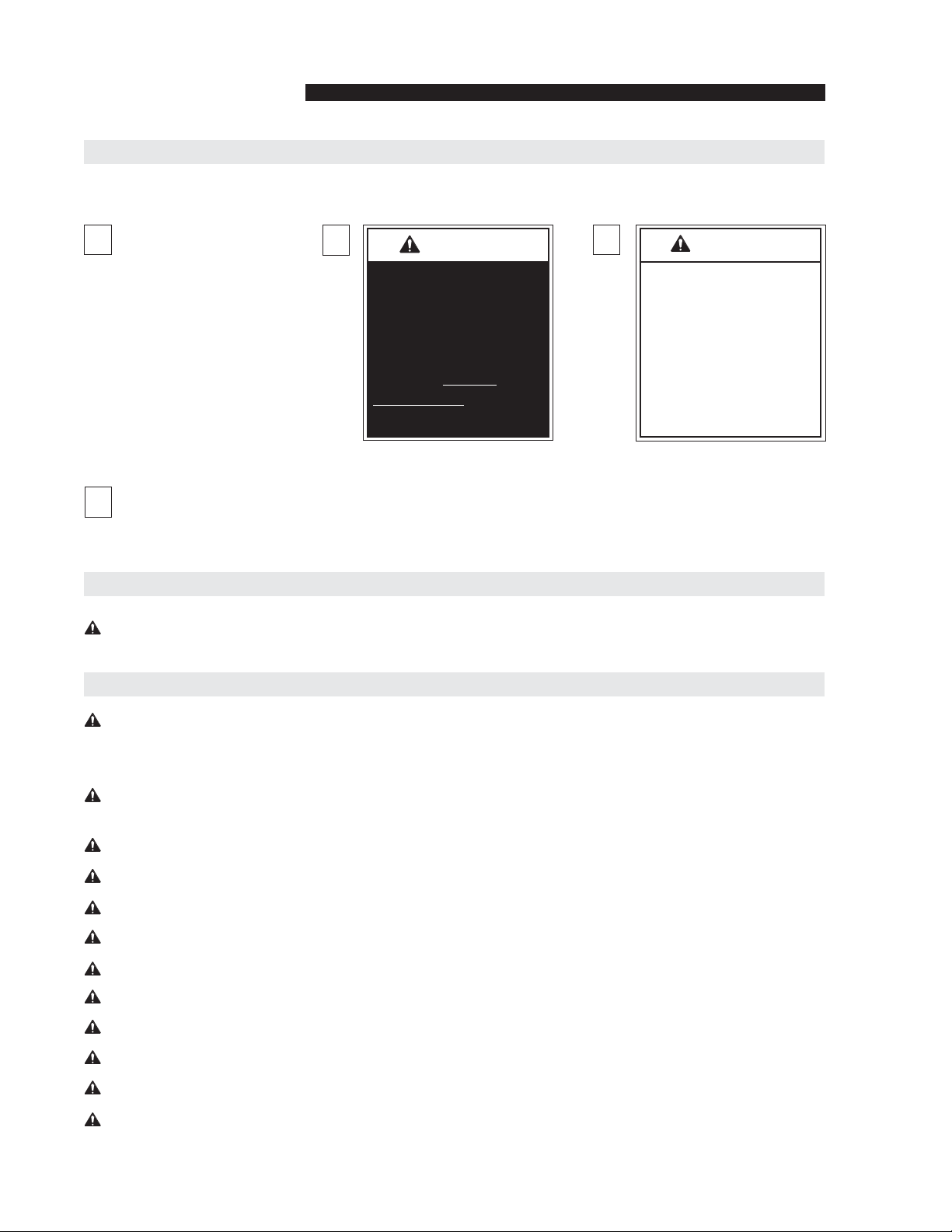

l^i]LZ^\]iHZchdgHZch^i^k^in:Y\Z

"Providing Access to the World"

International Corporate Hdqrs: P.O. Box 310 Winamac, IN 46996 USA

1-800-THE LIFT (574) 946-6153 FAX: (574) 946-4670

A

RNING

W

Man

ual

®

®

Read manual

before operating,

installing or

servicing ramp.

RA200 Transit Ramp

RA200 Transit Ramp

Failure to do so

may result in

serious bodily

injury and/or

property damage.

34952

July 2008

Patent 7,264,433

Owner's/Service Manual

Owner's/Service Manual

Page 2

Congratulations

We at The Braun Corporation wish to express our fullest appreciation

on your new purchase.

With you in mind, our skilled craftsmen have designed and assembled

the finest ramp available.

This manual includes operating instructions, installation instructions,

servicing instructions and instructions for troubleshooting, if needed.

Braun ramps are built for dependability and will provide years of service

and mobility independence, as long as the ramp is installed and maintained as

specified, and the ramp is operated by an instructed person.

THE BRAUN CORPORATION

Ralph W. Braun

Chief Executive Officer

Sincerely,

Page 3

Terminology

ER1301WS Terminology Illustration ....................... 2

Introduction .............................................................. 3

Ramp Components..................................................3

Ramp Actions and Functions ...................................3

Contents

Cable-Activated Manual Release System ............10

Manual Release System Security Sensor ............10

Self-Locking Release Pin .................................... 10

To Manually Extend or Retract Ramp ...................10

Reengage Carriage Assembly Drive Chains .. 10, 11

To Manually Raise or Lower Ramp ....................... 11

Safety Precautions

Safety Symbols .......................................................4

Safety Precautions ..............................................4, 5

Installation Instructions

Installation Procedures ...........................................6

User Inputs/Outputs.................................................7

Operation

Pre-Operation Notes

Operation Procedure Review .................................8

Preventative Maintenance .....................................8

Cold Climate Recommendations ............................8

Ramp Operating Instructions

Before Operating Ramp ..........................................8

Customer Interlock .................................................8

Operator Input Switches .........................................8

Two-Way Toggle Operation .....................................8

Halt Conditions ....................................................... 8

Obstructions ...................................................... 8, 9

Operation Functionality

One-Touch Operation .............................................9

Ramp Enable .......................................................... 9

"Close All Doors" Input ...........................................9

Opening Door .......................................................... 9

Obstruction Sensing ............................................... 9

Pressure Mat Detection ..........................................9

Ramp Alarm ............................................................ 9

Electrical Method

Control Box Manual Input (Override Switches) .... 11

Maintenance, Lubrication and Adjustments

Exterior Maintenance and Lubrication ............ 12, 13

Exterior Adjustments .......................................13-15

Interior Maintenance and Lubrication ................... 16

Interior Adjustments .........................................17-20

Inspection List

Exterior Inspection ........................................... 21,22

Interior Inspection .................................................23

Troubleshooting

Troubleshooting Guide ................................... 24, 25

Repair Parts

Parts List - ER1301WS Overall Exploded View ...26

Exploded View - ER1301WS Overall ........ 27A, 28A

Exploded View - ER1301WS Carriage

& Ramp Assembly ...............................27B, 28B

Parts List - ER1301WS Carriage

& Ramp Assembly ..........................................29

Parts List - ER1301WS Frame Assembly .............30

Exploded View - ER1301WS Frame

Assembly ............................................ 31A, 32A

Exploded View - ER1301WS Ramp

Subassemblies .................................... 31B, 32B

Parts List - ER1301WS Ramp Subassemblies .....33

Schematics

Manual Operating Instructions

Mechanical Method

Electrical Schematic - ER1301WS Ramp

Caradap Controller .........................................35

Electrical Schematic - ER1301WS Ramp Wiring

Harness (Caradap Controller) ........................ 36

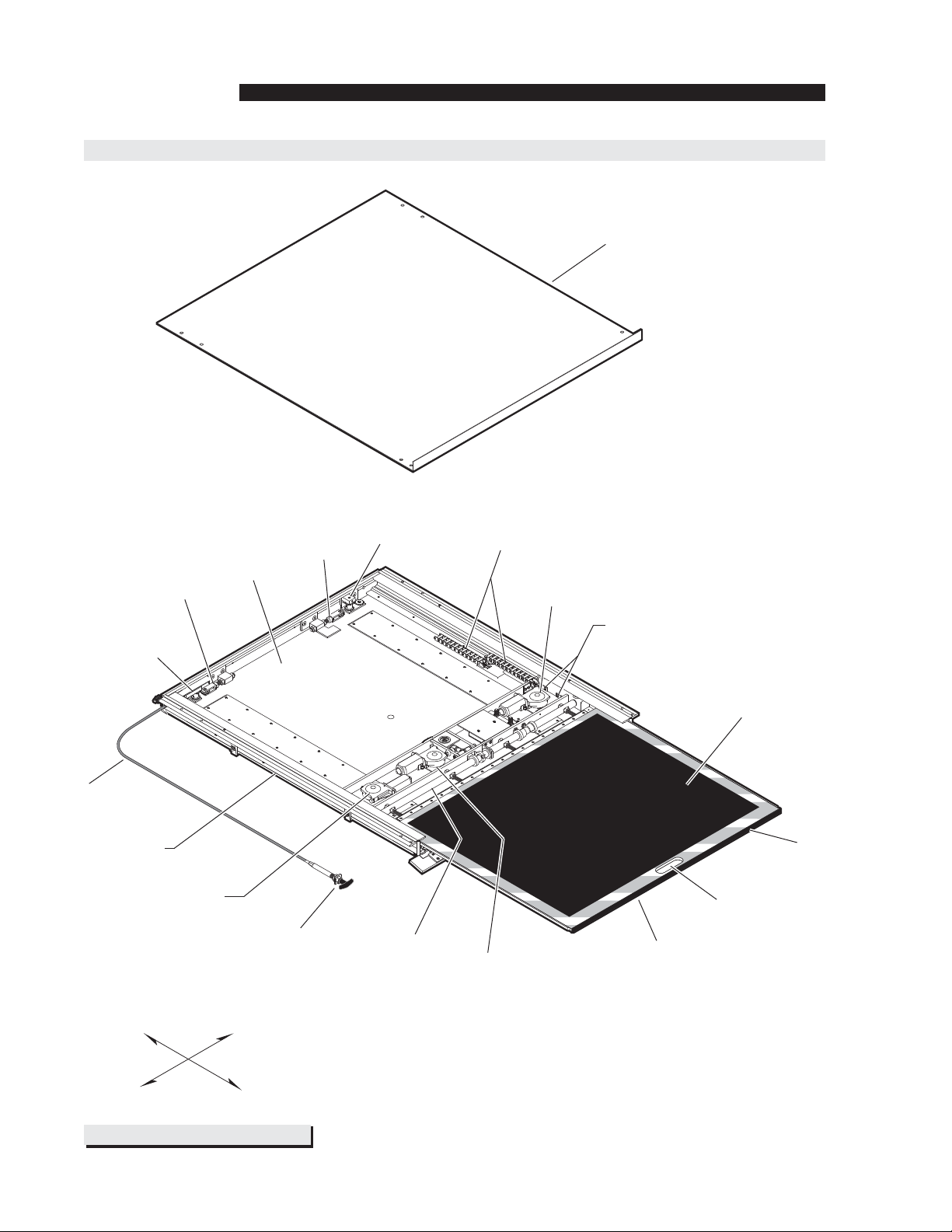

Page 1

Page 4

Terminology

ER1301WS Terminology Illustration

Top Panel

(Cover)

Left Manual

Release

Assembly

Manual Release

Cable Assembly

Ramp Cassette

(Housing)

Rear (In)

Left Chain

Tension

Assembly

Carriage

Assembly

Drive Motor

Lower

Panel

(Pan)

Right

Right Chain

Tension

Assembly

Manual

Release

Handle

Right Manual

Release As-

sembly

Main

Elevation

(Rotation)

Axle

Electrical Harness

Energy Chain

Carriage

Assembly

Drive Motor

Carriage

Elevation

Motor

Carriage

Track

Rollers

Pressure

Mat

Sensitivity

Edge

Hand Hold

Platform

(Ramp)

and

Carriage

Assembly

Left

As viewed from outside the vehicle

Page 2

Front (Out)

Page 5

Terminology

Introduction

The RA200 provides fully automatic operation of all ramp

functions. Basic ramp operation

procedures are identical for all

RA200 models. The operating

instructions contained in this manual address the operator input

switches and the corresponding

ramp functions. Instructions are

provided for manual operation of

the ramp in the event of power or

equipment failure.

Terminology: Become familiar

with the terminology that will be

used throughout this manual.

Become familiar with the identification of RA200 components

and their functions. Contact your

ramp sales representative or call

The Braun Corporation at 1-800THE LIFT if any of this information is not fully understood.

Direction: The terms “left”,

“right”, “front” and “rear” will be

used throughout this manual to

indicate direction (as viewed from

the outside of the vehicle looking

directly at the ramp’s front cover).

Refer to the Ramp Terminology

Illustrations for clarification to

direction terms.

Ramp Components

Refer to the Ramp Terminology

Illustrations and discriptions on

pages 2 and 3.

Control Box (Electronic Controller): The remote mounted

control box provides the logic

to manage the inputs in order

to produce the desired outputs

in terms of ramp function and

performance. In general terms of

abilities and features, the control

box is commonly referred to as

the “controller.”

Ramp Cassette (Housing):

The ramp cassette is the metal

structure (casing) mounted under

the vehicle which contains and

protects the platform and carriage

assemblies. The cassette contains all ramp components except

the control box when the ramp is

in the stowed position.

Carriage Assembly: The carriage assembly consists of the

steel weldment that contains the

four track rollers, the main rotation

axle and the electric drive motors.

The carriage assembly powers the

platform assembly in and out of

the housing during operation.

Platform Assembly: The platform assembly consists of the flat

aluminum laminate upon which the

wheelchair travels, the sensitivity

edge, the supporting hinge, the

associated skid pads, and pressure mat.

Cable-activated Manual Release

System: A cable-activated man-

ual release system disengages or

“unlocks” the carriage assembly

drive chains to allow the platform

and carriage assemblies to be

manually moved out (extended) or

moved in (retracted), should it be

necessary. Complete details and

manual operating procedures are

provided on page 10 and 11.

Ramp Actions and Functions

Extend: Extend is the action of

the platform and carriage assembly moving out of the ramp cassette (housing).

Retract: Retract is the action of

the platform and carriage assembly moving into the ramp cassette.

Deploy: Deploy is the action of

the platform and carriage assembly extending and raising (elevating) to floor level when the DEPLOY (OUT) switch is activated.

Stow: Stow is the action of the

platform and carriage assembly

lowering to stow level, and fully

retracting when the STOW (IN)

switch is activated.

Stow Level: Stow level is the

height at which the platform and

carriage assembly extends and

retracts.

Floor Level: Floor level is the

height that the platform assembly

raises (elevates) to in order for

the wheelchair to enter or exit the

vehicle.

Obstruction Sensing: An obstruction sensing feature is standard with the RA200. The controller monitors the instantaneous

current of all the electric motors,

and calculates a ‘real time’ running average of the current. It

then compares programmed peak

(maximum vs. instantaneous) and

delta (instantaneous minus running average) limits to determine if

an obstruction has been encountered. The programmed limits for

the different models of the RA200

are selected while configuring the

controller during ramp installation procedures (see Installation

Instructions for detailed information).

Obstruction Force: The obstruction force is the maximum allowable force (pounds or Newtons)

the ramp exerts on a object during

a specific movement. There is a

different force for each of the four

movements (extend, retract, raise,

lower). This force is a direct result

of the obstruction sensing current

limits, usually specified by the

customer.

Note: Further details regarding

ramp control switches and the

corresponding ramp functions are

provided in the Ramp Operating

Instructions below and on page 8

and 9.

Page 3

Page 6

CAUTION

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

Safety Precautions

Safety Symbols

SAFETY FIRST! Know That....

All information contained

A

in this manual and

supplements (if included), is provided for your safety. Familiarity

with proper operation instructions

as well as proper maintenance

procedures are necessary to ensure safe, troublefree operation.

Safety precautions are provided

to identify potentially hazardous

situations and provide instruction

on how to avoid them.

Note: Additional information provided to help clarify or detail a specific subject.

D

These symbols will appear throughout this manual. Recognize the seriousness of this information.

Safety Precautions

Read this manual and supplement(s) before performing installation, operation or service

procedures.

B

This symbol indicates

important safety information regarding a

potentially hazardous

situation that could

result in serious

bodily injury and/or

property damage.

C

This symbol indicates

important information

regarding how to

avoid a hazardous

situation that could

result in minor personal injury or property damage.

RA200 Operation Safety Precautions

Read manual and supplement(s) before operating ramp. Read and become familiar with

all safety precautions, pre-operation notes, operating instructions and manual operating

instructions before operating the ramp.

Inspect ramp before operation. Do not operate ramp if you suspect lift damage, wear or

any abnormal condition.

Load and unload clear of vehicular traffic.

Load and unload on level surface only.

Engage vehicle parking brake before operating ramp.

Provide adequate clearance outside the vehicle to accommodate the ramp.

Keep operator and bystanders clear of area in which the ramp operates.

Do not overload or abuse. The load rating capacity is 300 kilograms (660 pounds).

Ramp must be positioned at floor level when loading or unloading in and out of vehicle.

Do not activate control switches when anyone is near the area in which ramp operates.

Do not operate or board the ramp if you or your ramp attendant are intoxicated.

Wheelchair passengers must position and secure (buckle, engage, fasten, etc.) the wheelchair-equipped occupant seat belt before loading onto the ramp.

Page 4

Page 7

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

RA200 Operation Safety Precautions (continued)

Be aware of the ramp slope (angle).

Do not raise front wheelchair wheels (pull wheelie) when loading (boarding) the platform.

The wheelchair must be positioned in the center of the ramp when loading and unloading.

After manually releasing ramp, stow ramp and push manual release T-handle in fully and

move ramp in and out to engage ramp lock before driving vehicle. Failure to lock ramp may

result in unintended ramp deployment.

Keep owner’s manual in ramp-mounted vehicle at all times.

Never modify (alter) a Braun Corporation ramp.

Do not use accessory devices not authorized by The Braun Corporation.

Do not remove any guards or covers.

If the information contained in this manual is not fully understood, contact The Braun Corporation immediately.

Safety Precautions

Failure to follow these safety precautions may result in serious bodily injury and/or property

damage.

Installation and Service Safety Precautions

Read this manual, supplement(s) before performing installation, operation or service procedures.

Check for obstructions such as gas lines, wires, exhaust, etc. before drilling or cutting during installation procedures.

Route all cables clear of exhaust system, other hot areas, moving parts, wet areas, etc.

Risk of electrical shock or fire! Use extra care when making electrical connections. Con-

nect and secure as outlined in Installation Instructions and Wiring Schematics.

Maintenance and lubrication procedures must be performed as specified in this manual by

authorized (certified) service personnel.

Disconnect the power cable at the battery prior to servicing.

Replacement parts must be Braun authorized replacements.

Never install screws or fasteners (other than factory equipped).

Failure to follow these safety precautions may result in serious bodily injury and/or property

damage.

Page 5

Page 8

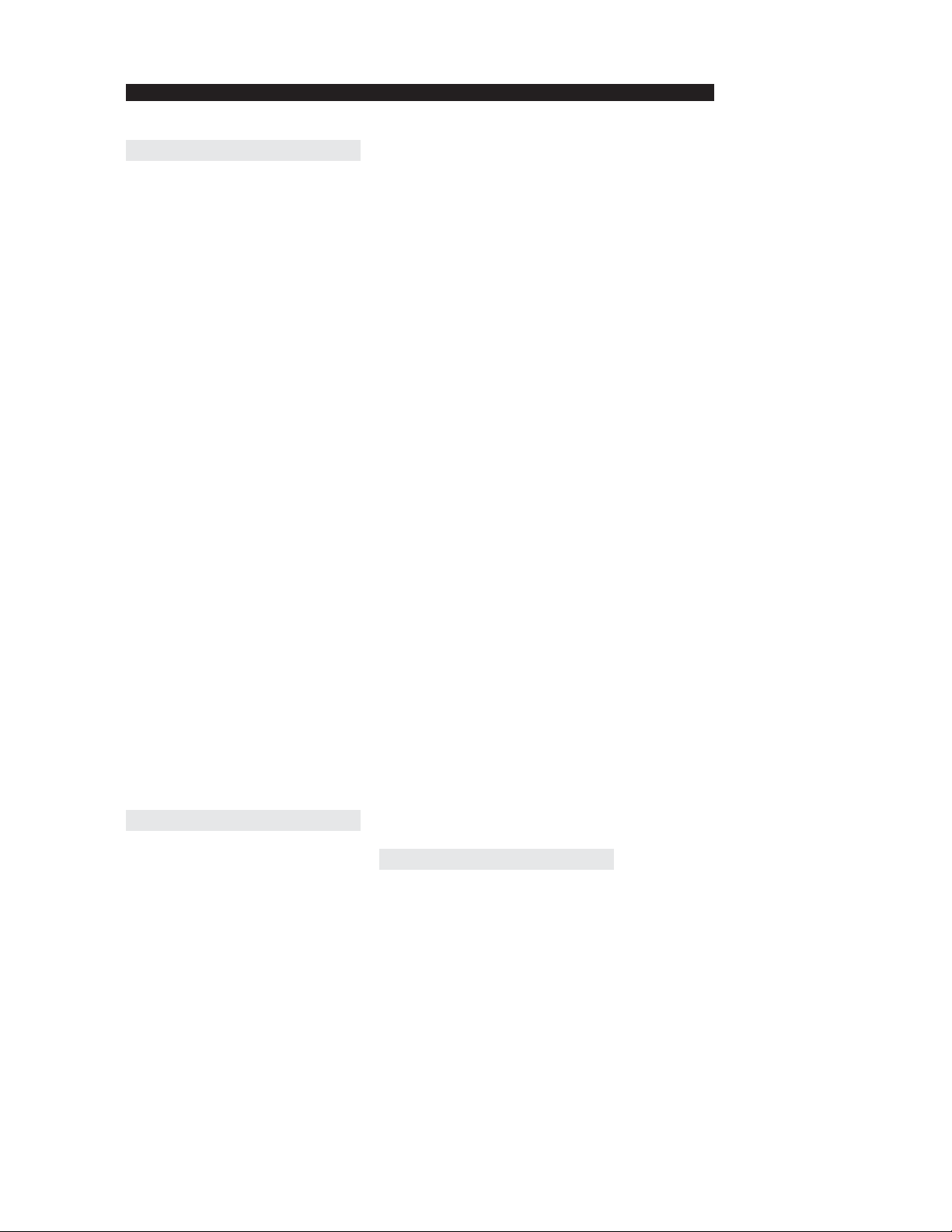

Installation Instructions

ER1301WS Installation:

Braun ER1301WS electronic controller

100465-002 is exclusive for Weight Sensor ramps. Install Weight Sensor RA200

models as outlined in this section.

Installation Procedures:

1. Mount ramp assem-

bly using the eight

holes shown in Photo

C. Mounting hardware

must be minimum 7/16"

or 12mm diameter.

Position the ramp, with

top cover lip flush with

vehicle door threshold.

Level the unit front-toback and side-to-side.

Mounting procedures

other than those specified here must be pre-

approved by a Braun

representative.

Parts List (ER1319):

Item Qty. Description Part No.

1 1 Control Box - ER1301WS 100465-002

Ramp

Mounting

Holes

Photo C

2. Route free end of

ER1317WSA harness

through vehicle floor

structure to desired

mounting location of control box.

Photo D

Ramp

Mounting

Holes

Ramp

Connection

Page 6

Page 9

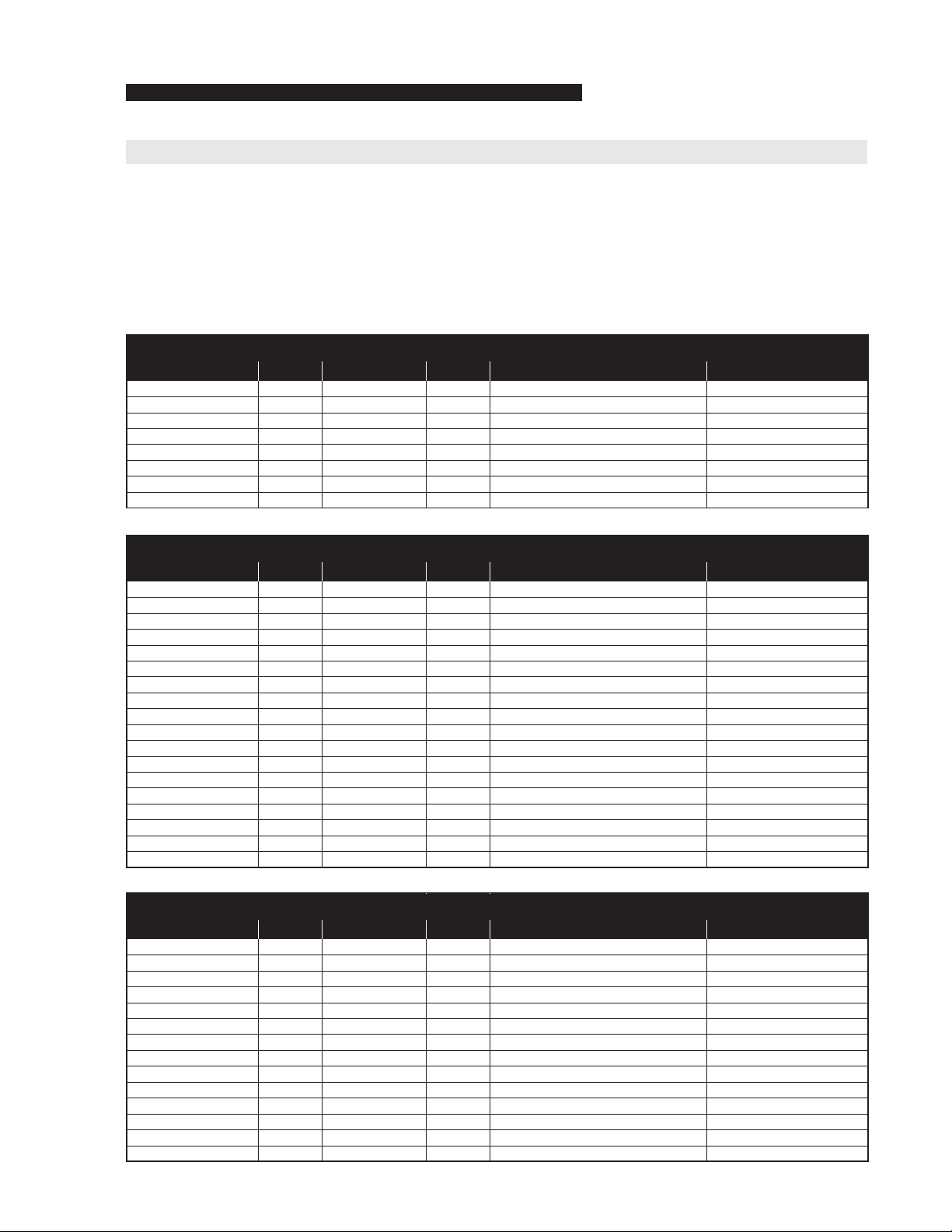

Installation Instructions

User Inputs/Outputs

The weight sensor controller has five required user inputs and five optional user outputs. At least four user

inputs are required to be connected in order for the ramp to function, whereas none of the user outputs

must be connected (optional).

Below is a list of the user inputs and outputs, including the designated connector pin number, wire color,

and description. Please note the optional user outputs have maximum limitations as specified in the

“Restrictions” column below.

Controller to Vehicle Connections (929.505-3 Amp Connector)

Function Pin # Wire Color LED Description Restrictions

Input (Pulse) 1 Black LD10 Ramp Enable Required

Input (Pulse) 2 Brown LD11 Ramp Operate Required

Input (Continuous) 3 Red LD12 Door Full Open Required

Input (Pulse) 4 Orange Reset Controller Optional

Power Supply 5 Yellow +24 V Supply 10 A Time Delay Fuse

Power Ground 6 Blue Ground Required

Input (Pulse) 7 Violet/Yellow LD13 Close All Doors Required

Input 8 Violet/Green LD14 Extra Optional

All Connections on this Connector Optional (929.505-6 Amp Connector)

Function Pin # Wire Color LED Description Restrictions

Input 1 Green Relay Power (+24 V) 10 A Time Delay Fuse

Output 2 Purple N.C. Ramp Enabled

Output 3 Grey LD17 N.O. Ramp Enabled Required

Output 4 White N.C. Open Door

Output 5 Black/White LD18 N.O. Open Door Required

Output 6 Black N.C. Ramp Malfunction

Output 7 Red/White LD19 N.O. Ramp Malfunction

Output 8 Orange/Red N.C. Clear Signal

Output 9 Yellow/White LD20 N.O. Clear Signal Required

Output 10 Blue/White N.C. Manual Release Unlocked

Output 11 Green/White LD21 N.O. Manual Release Unlocked

Output 12 Red/Black LD22 N.O. Ramp alarm

Power Ground 13 Gray/Pink Ramp alarm ground

Not Used 14

Not Used 15

Not Used 16

Not Used 17

Not Used 18

Ramp to Controller Connections (T1730-S14 Thomas & Betts Connector)

Function Pin # Wire Color LED Description Restrictions

Power 2 Green/Black Ramp + 24 V

Power 3 Orange/Black Ramp Ground

Input 4 Orange LD1 Ramp full out sensor

Input 5 Green/Black LD2 Ramp full in sensor

Output 6 Red/White LD29 Drive Motor +

Output 7 Yellow LD30 Drive Motor -

Input 8 Blue LD3 Ramp full up sensor

Input 9 Yellow LD4 Ramp full down sensor

Not Used 10

Not Used 11

Input 12 Brown LD5 Ramp manual release sensor

Output 13 Black/Red LD27 Elevate motor +

Output 14 Orange/Red LD28 Elevate motor -

Input 1 Yellow/Red LD6 Pressure Mat Return

Page 7

Page 10

Operation

Pre-Operation Notes

Operation Procedure Review:

The RA200 operator should review all safety precautions and all

operation procedures appearing

in this manual prior to attempting

to operate ramp. Failure to do so

may result in serious bodily injury

and/or property damage.

Operate the ramp through all

functions to ensure the proper

use and operation of the ramp is

clearly understood. Be sure to

review the manual operation procedures, particularly the proper

re-engagement procedure of the

manual cable release system

(see page 10). Any questions or

concerns should be forwarded to

your Braun representative.

Do not operate the ramp if it is

suspected to be damaged, have

excessive wear, or any abnormal

condition. Discontinue use immediately and contact an authorized

Braun representative.

Preventative Maintenance:

Maintenance is necessary to

ensure safe and trouble-free

ramp operation. General preventative maintenance consisting of

inspecting, cleaning and lubricating procedures should be part

of a scheduled routine. Simple

inspections can detect potential ramp operational problems.

Adjustments can be made as

needed (details in Maintenance

and Adjustments section).

Regular preventative maintenance will reduce potential ramp

operation downtime and increase

the service life and reliability of

the ramp, as well as enhancing safety. Exposure to harsh

weather elements, environmental

conditions or heavy usage may

require more frequent mainte-

nance and lubricating procedures.

See the Maintenance and Adjustments section for more detailed

information.

Cold Climate Recommendations: The vehicle in which the

ramp has been installed should

be stored in a garage or other

sheltered place if possible, especially during inclement weather

conditions. When the ramp is not

in use, it should be in the stowed

position to prohibit rain, snow, ice,

dirt, mud, or other foreign materials from entering the ramp opening or building up on the platform

surface.

Ramp Operating Instructions

Ramp Operating Instructions

address the required controller

inputs and the corresponding

ramp functions. Instructions for

customer specific display panels

and interlock options will not be

addressed due to the boundless variations in application and

installation of the ramp. Manual

Operating Instructions are addressed in the event of power or

equipment failure.

Before Operating Ramp: Always park the vehicle on a level

area, away from vehicle traffic.

Place the vehicle transmission

in “Park” and engage the park or

emergency brake.

Customer Interlock: The ramp

controller requires a (+) 24V signal be supplied which interlocks

the ramp functions with a customer supplied vehicle signal. If

this interlock signal is not present,

the controller will not provide any

outputs necessary to operate the

ramp. If the interlock signal is lost

during ramp operation, the platform assembly will automatically

complete the ‘full stow’ sequence,

and the controller will not function any further until the interlock

signal is present once again.

Operator Input Switches: The

RA200 electronic controller provides fully automatic operation of

all ramp functions, which are protected by the obstruction sensing

feature. Ramp functions can be

performed from any position the

platform assembly happens to be

in at the time the operator input

switch is activated.

Two-Way Toggle Operation:

In two-way toggle mode, there

are separate switches for deploy

and stow functions. One of the

switches must be pressed and

held or locked into position (continuous input signal required) for

the RA200 to operate. The ramp

will move in the selected direction

until the switch is released (signal

interrupted), the unit reaches the

end of the travel, or a “halt condition” occurs (details follow).

Halt Conditions: Several conditions can cause a normal sequence to terminate (stop):

• Obstructions (details below)

• Customer Interlock signal lost

(see Customer Interlock)

• Manual Release System ‘unlocked’ signal present (see

Manual Operating Instructions:

Mechanical Method)

• Control Box Manual Input Switch

pressed (see Manual Operating

Instructions: Electrical Method)

• Weight sensed on platform

Obstructions: The controller

performs obstruction sensing (see

RA200 Terminology: Obstruction

Sensing) on all stow and deploy

movements of the ramp (in, out,

up, down), whether operated normally or with the manual override

switches. The selected obstruction response mode configured

Page 8

Page 11

Operation

in the controller during installation immediately stops movement when obstructed. Once an

obstruction has halted the ramp,

the controller automatically resets

and awaits operator input for

further operation.

Note: The ramp will sense an

obstruction and halt with any

substantial weight on the platform

(built-in safety feature). The ramp

will continue when the weight is

removed from platform.

Operation Functionality

The 100465-002 easy ramp control box incorporates a Microchip

PIC microcontroller that executes

a sequential program from a

built-in flash memory. This sec-

tion gives a brief overview of the

operational functionality that the

firmware provides in the operation

of the ramp.

“Close All Doors” Input: An

optional input, “Close All Doors,”

may be used to cause a stow

sequence. This input is also a

momentary pulse input. At the

completion of a stow cycle, the

control box will de-activate the

“Open Door” output. The door

should then automatically close.

Opening Door: The control box

opens the door using the “Open

Door” output. For the duration of

the ramp deployment and stow

cycle, the door shall never be allowed to close. At the completion

of a stow cycle, the control box

will de-activate the “Open Door”

output. The door may automatically close or close after the driver

signals the door to close.

If the door fails to open after an 8

second timeout period, the “Open

Door” output will be deactivated

and the ramp will not be deployed.

The leading edge ovstruction strip

would be wired with the pressure

mat and therefore behave similarly.

Ramp Alarm: Prior to any motion of the ramp, an alarm output

is activated for a few seconds.

The alarm output sounds for the

duration that the ramp platform is

not fully deployed or fully stowed.

This continuous output is used to

power an audible alarm and/or

lights. For the lights to flash, a

special harness (ER1320A) is

used with a built-in flashing unit.

One-Touch Operation: A momentary pulse input from an operate button will start an automated

deployment sequence. The user

does not have to continue to

press the operate button for the

ramp to complete its motion. In

a similar manner, the user need

only push the operate button once

again to start a stow sequence.

Ramp Enable: The ramp must

first be enabled by applying a momentary pulse signal to the ramp

enable input (momentary pushbutton switch). Once enabled,

the “Ramp Enabled” normally

open (N.O.) output is activated.

Then, the ramp may be operated

using the “Ramp Operate” button.

The ramp is automatically disabled when the platform becomes

fully stowed at the end of a cycle.

The ramp may also be disabled if

the enable push-button is pressed

again.

Obstruction Sensing: The

control box can sense if the ramp

platform is obstructed during

movement using a pressure mat

and over-current circuitry. If one

of these detection techniques occurs, the ramp is halted. If three

consecutive obstructions during

the deployment cycle occur, the

auto-stow feature described in

Section 3.10 will execute.

Pressure Mat Detection: The

top surface of the ramp platform

is covered with a weight or pressure sensitive mat. If a passenger is on top of the platform,

the ramp will not move when

activated. If the ramp is already

in motion and weight is applied to

the platform, the ramp will halt its

motion. Additionally, the platform

may be equipped with a pressure

sensitive edge strip that senses

obstructions at the leading edge.

Page 9

Page 12

Do not remove!

81823

Push T-handle in fully and

manually move platform in

and out to engage platform

lock before driving vehicle.

Failure to lock platform may

result in unintended platform

deployment. Unintended

platform deployment may

result in serious bodily injury

and/or property damage.

W

A

RNING

Manual Operating Instructions

The RA200 has the capability of

being manually operated (mechanical or electrical methods). If

you experience power or equipment failure, refer to the stepby-step instructions to manually

operate the ramp. Always use extreme caution when operating the

ramp manually. Read all Manual

Operating Instructions carefully

and thoroughly prior to performing manual operating procedures.

Follow all Ramp Operation Safety

Precautions at all times.

Mechanical Method

Cable-Activated Manual Release System: A cable activated

manual release system disengages (unlocks) the carriage assembly drive chains to allow the

platform assembly to be manually

extended or retracted as required.

A T-handle is provided on the

release cable for activation of the

manual release system (details

follow).

After manually extending or

retracting the platform assembly,

it is extremely important that the

cable-activated manual release

is positively reengaged to secure

(lock) the platform assembly

before loading a passenger or

continuing vehicle use (details

provided). Failure to reengage

and secure the platform may

result in unintended ramp

movement, which may result

in serious bodily injury and/or

property damage.

injury. The unlocked signal may

also be used to supply a visual

display to the operator that the

ramp is unlocked and must be

secured prior to any additional

operation of the ramp or vehicle.

Note: The unlocked sensor

LED is not supplied (customer

installed).

Self-Locking Release Pin: A

self-locking release pin allows

the platform assembly to be

disconnected from the elevation

mechanism, allowing a raised

platform to be manually lowered

in the event of a power failure.

See Photo below. The release

pin should only be used when

the platform will not lower under

electric power, as stated in the

Electrical Method section (next).

To Manually Extend or Retract

Ramp:

1. Turn (loosen) the manual

release “T” handle 90°.

2. Pull the “T” handle fully outward (3" to 4").

3. Turn (tighten) the “T” handle

90° to secure handle in the

disengaged (unlocked) position.

Self-Locking Release Pin

4. Verify mechanism is disengaged (unlocked). View

customer installed sensor LED.

5. Carefully move the platform

in or out to desired location

using the platform Hand Hold.

Reengage Carriage Assembly

by Drive Chains:

1. Position the ramp platform

manually so that only 15 cm

is extended out of the cassette.

2. Turn (loosen) the manual

release “T” handle 90°.

3. Push the “T” handle fully

inward until handle contacts

shaft shoulder (3" to 4").

4. Grasp the platform Hand Hold

and move the platform slightly

outward until platform locks

into position (secured by

reengaging the carriage assembly with the drive chains).

Note: Do not push platform

inward to lock as it may then

create a binding condition in

the release mechanism and

will not release easily in the

future

Manual Release System Security Sensor: A proximity sensor

detects when the cable-activated

manual release system is disengaged (unlocked) and provides a

ground (-) "unlocked" signal to the

controller. The unlocked signal

disables all controller functions so

that the mechanism can be manually operated without the risk of

Page 10

Page 13

Manual Operating Instructions

5. Turn (tighten) the “T” handle

90° to secure handle in the

engaged (locked) position.

6. Verify mechanism is reengaged (locked). View customer installed sensor LED,

or pull on the Hand Hold to

ensure no movement occurs.

7. Stow the remaining portion

of the platform by using the

electrical system.

To Manually Raise or Lower

Ramp:

1. Raise and hold platform assembly up to gain access to

the self-locking release pin.

2. Carefully remove release pin,

using caution as the platform

assembly may now move

freely (unhindered).

3. Manually raise or lower the

platform assembly as desired.

Note: The release pin will

only be able to be reinstalled

when the platform assembly

is returned to the original

position in which the pin was

removed.

allow normal ramp operation).

The switches can also be used

in event of an electrical problem

remote from the ramp electrical

system (such as a problem with a

vehicle installed control switch or

interlock circuit).

Note: There must be power to

the ramp system (electronic controller) in order to use the manual

input (override) switches.

Each respective override switch

can be used to move the ramp

platform in the stated direction

(as labeled); OUT (extend), IN

(retract), UP (raise or elevate) or

DOWN (lower). The IN and OUT

switches use the control logic to

limit the travel to the maximums

as set by the respective sensor

pickups. Caution! The UP and

DOWN switches are not limited

to the sensor pickups, and thus

manual over travel can occur.

Over travel may result in damage

to ramp components or serious

bodily injury if not used with

extreme caution.

Electrical Method

Control Box Manual Input

(Override) Switches: Manual

input switches are located inside

the electronic control box. Do

not use manual input switches

to operate the ramp when load-

ing or unloading a passenger.

These momentary contact switches are provided as an override

for maintenance and service

purposes only. Manual input

switches should be activated by

qualified technicians only.

A service technician can use the

manual input (override) switches

to move the carriage assembly

with problems due to debris build

up, wear or mechanical binding (obstruction sensing will not

Note: A ramp operating under normal conditions via an

operator’s input switch will halt in

the event a manual input override switch is pressed. Once

released, the controller will

automatically reset and function

normally when the next operator’s

input switch signal is received.

Page 11

Page 14

Maintenance, Lubrication & Adjustments

Exterior Maintenance and Lubrication

Note: In order to ensure proper and consis-

tent performance of the Braun RA200, routine

maintenance in the form of cleaning, lubricating,

inspecting, and adjusting is essential.

frame. A de-greasing agent and brush may be

used if necessary to remove large buildups. Do

not spray water directly into cassette or at the

electrical connectors . Clean away debris that

may be built up in beeper that may reduce or

The following items can be accessed after de-

prohibit audibility.

ploying the platform, and without the removal of

either the top or bottom cover.

Ramp Platform Hinge: Clean and lubricate the

ramp platform hinge. A light oil may be used on

Cleaning/Lubrication: All exterior parts of the

ramp, accessible during stow or deploy, may be

cleaned with high pressure water, with exception of being pointed directly into the cassette

the hinge, but should be limited to reduce the

possible buildup of debris. See Photos C and

D. Allow hinge to dry before applying lubricant

(light oil).

or at the electrical connectors along the exterior

Photo A Photo B

Do not

spray

water

in this

area!

Overall View of Deployed RA200

Photo C Photo D

Ramp

Platform

Hinge

Clean

and

Apply

Light Oil

Electrical Connector

Page 12

Do not spray water directly into cassette!

Page 15

Maintenance, Lubrication & Adjustments

Exterior Maintenance and Lubrication (continued)

Front Cover Hinge: The front cover opens and

closes via a spring loaded hinge. See Photo

E. Clean and lubricate the front cover hinge. A

light oil may be used on the front cover hinge but

should be limited to reduce the possible buildup

of debris. Allow hinge to dry before applying

lubricant (light oil).

Manual Release Handle: The manual release

handle locks in position via a quarter turn of

the handle. Clean exterior then unlock and pull

handle out to apply lubricant (light oil) to shaft.

Cycle handle in and out to distribute lubricant

throughout mechanism.

Front Cover Seals: The front cover seals

are important in order to reduce the amount of

debris which enters the cassette during nonoperation of the ramp. Inspect seals, clean and

replace if necessary.

Exterior Adjustments

Photo E

Manual

Release

Handle

Front Seals

Front

Cover

Clean and Apply Light Oil

Spring

Loaded

Hinge

Stow Level

Sensor

Floor Level

Sensor

Photo F

Floor Level/Stow Level Position of Platform:

Vital to ramp performance is proper platform

position before, after and during deploying and

stowing cycles. Proximity sensors (see Photo F)

use a magnetic field to switch on and off as the

Top Cover LipPlatform

Adjustable

Pick-Ups

Photo G

metallic pick-up passes in front of the sensor head.

Distance from the sensor head to the pick-up must

be approximately 2 mm and should be checked to

ensure sensor switching (sensor LED lights when

switched on). See Photos H and I.

Page 13

Page 16

Maintenance, Lubrication & Adjustments

Exterior Adjustments (continued)

Floor Level Sensor Stow Level Sensor

Photo H Photo I

2 MM

2 MM

Set ScrewFloor Level Pick-Up Set ScrewStow Level Pick-Up

1. The floor level (up) sensor pick-up (see Photo

H) should be adjusted (via the set screw)

so that the elevation motor stops once the

platform has gently touched against the

top cover lip (see Photo G on page 13 ), or

vehicle threshold if further from the center of

the vehicle. Incorrect setting of this pickup could result in a large gap between the

platform and the threshold (too low) or in the

ramp retracting into the stowed position due

to obstruction sensing (too high).

Ramp Skid Pad Guide Rail Slide Tube Ramp Skid Pad Contacting Top of Guide Rail

2. The stow level (down) sensor pick-up (see Photo

I) should be set (via the set screw) to allow a

smooth transition of the ramp platform into the

cassette. Ramp skid pads, located on the back

corners of the ramp (see Photo J), reduce friction

at the point where the ramp corners contact the

top of the guide rail. See Photo K. Carefully observe the ramp skid pads when adjusting the stow

level sensor pick-up. Note: An incorrect setting

of the stow level could result in excessive wear,

premature failure, or the shearing off of the ramp

skid pads (pads are replaceable).

Photo J Photo K

Page 14

Page 17

Exterior Adjustments (continued)

Maintenance, Lubrication & Adjustments

Floor Height: Variable height adjustments are

made by screwing the four threaded bar ramp

supports in/out to achieve the desired floor level

height. Once initially set during installation, this

height should not require altering. Two items to

note.

1. When increasing the height, the maximum

is achieved when the ramp toe contacts the

inside of the front cover (see Photo M). If the

maximum is surpassed, the front cover will

remain partially open when the ramp is in the

fully stowed position, thus allowing foreign

material and debris to enter the cassette.

2. When decreasing the height, the non-used

portion of the threaded studs must be cut off

to maintain proper clearance for main axle

rotation (see Photo N). Failure to do so may

result in the inability of the platform to lower

to stow level due to a binding condition of the

main axle, possibly causing damage to the

elevation motor.

Photo L

Lift ramp to access bolts.

Front Cover Ramp Toe

Maximum Setting

Toe of Ramp

Contacts Cover

Cut off excess threads.

Photo NPhoto M

Page 15

Page 18

Maintenance, Lubrication & Adjustments

Interior Maintenance and Lubrication

The following items can be accessed through the interior

of the ramp by removing either the top or bottom cover.

Bottom Cover: The snap-on bottom cover can be

removed for easy access. The bottom cover is easily

removed via two draw latches on each side (see Photo

P), along with four bolts across the front (see Photo O).

When replacing, make sure to install a new tie wrap on

the latches in order to secure the bottom cover. Inspect

the bottom cover seals and replace when necessary.

Top Cover: Only remove the top cover when deemed

absolutely necessary to obtain access to specific parts

not available via the bottom cover. Remove the ramp

mounting hardware and lower the ramp assembly in

order to remove the top cover. Replace the double sided

foam tape seal whenever the top cover is removed.

Cleaning and Lubrication: All interior parts

of the ramp, accessible via the top or bottom

cover, may be cleaned with high pressure

air only. Use a cleansing cloth to wipe away

debris deposits and large buildups.

Ensure guide rails are clean and free of all

debris. Carriage track rollers are sealed and

do not require lubrication.

Note: Ramp controller includes an Obstruction Sensing Feature. Debris build

up or obstructions (rocks, sand, dirt) in the

guide rails can result in the ramp stopping

or reversing direction during in-out functions

(if obstructed). Again, ensure the guide rails

are clean.

Bolts Securing

Front Cover

Draw Latch

Tie Wrap

Photo O Photo P

Page 16

Page 19

Interior Adjustments

Photo Q

Maintenance, Lubrication & Adjustments

Overall View

Full Out/Deployed

Positional

Sensor

Pick-Up

Photo R Photo S

Plate

Full In/Full Out Position of Carriage: The carriage

houses two sensors that provide positional feedback

of full out (see Photo R) or full in/stowed (see Photo

S) for the carriage and platform assembly. The proximity sensors switch on and off as the sensor head

passes over a metallic pick-up plate mounted on the

cassette frame. Distance from the sensor head to

the pick-up plate must be approximately 4 mm and

should be checked (due to possible loosening) to

Full In/Stowed

Positional

Sensor

Pick-Up

Plate

ensure sensor switching (sensor LED lights when

switched on). Note: Verify the full out sensor is

distanced properly to remain lit (switched on) during

the entire elevation cycle. If the sensor light should

be intermittent during the elevation cycle, reposition

the sensor to reduce the distance between the sensor head and pick-up plate, while confirming there is

no interference of the sensor head and pick-up plate

during the in/out movement. See Photo R.

Page 17

Page 20

Maintenance, Lubrication & Adjustments

Interior Adjustments (continued)

Photo T

Cable Compression Sensor Pick-Up Stop Pin Slider Axle

Spring .

(dotted lines represent deployment)

4 MM

Manual Release

Manual Release System: If the

release cable is difficult to pull to

unlock the system, inspect the

guide and slider shown in Photo T.

Confirm no dirt, metal shavings,

or other foreign debris are present and restricting the slider. Also,

check compression spring to verify

the open end of the spring is not

binding the movement of the slider.

Manual Release Sensor Adjustment: Inspect manual release

sensor to confirm LED is lit when

slider is precisely released from

axle. The distance from the sensor head to the pick-up must be

approximately 4mm or less at this

precise point to ensure Manual

Release Locked/Unlocked signal is

accurate. Adjust distance by moving sensor in/out via the sensor’s

two locknuts. Operate several

times after adjustment to confirm

new setting is correct.

Connecting or “Timing”

Rear Chain

Photo U Photo V

Right Drive ChainLeft Drive Chain

Light Oil can be applied

to chains (small amount)

Chain System: The ramp utilizes a 3 chain system.

Two drive chains, left and right, provide the means

for the carriage to travel along. The third chain, in

the rear of the cassette, interlocks the left and right

drive chain to rotate in sequence (or equal time).

During normal operation, none of the 3 chains move.

However, during manual operation of the ramp, all 3

chains travel equal distances. To lubricate, a light oil

may be used on the chains, but should be limited to

reduce the possible buildup of debris.

Page 18

Page 21

Interior Adjustments (continued)

Maintenance, Lubrication & Adjustments

Chain Tension: Equal tension on the left and right

drive chains is necessary to reduce binding effects on the carriage bearings and allow for smooth

movement throughout the in/out cycle. An exces-

during manual operation. Each respective side’s

chain tension can easily be modified by moving the

threaded rod in or out to the desired position via a

pair of locknuts (see Photos W and X).

sively loose chain may enable the drive sprocket

to “jump” teeth, thus providing a binding situation. Conversely, an excessively tight chain may

increase the drag on the drive sprockets, and thus

Note: The rear timing chain tension is not adjust-

able. If problems arise due to the rear timing chain

tension, contact your Braun representative.

increase the force necessary to move the platform

LocknutsThreaded Rod Locknuts Threaded Rod

Photo W Photo X

Drive Chain Drive Chain

Inspection and Adjustment: Braun specifies a

drive chain tension that requires a force gauge and

metric tape measure for accurate setting, inspecting, or adjusting on all models of RA200 ramps.

Braun recommends the Wagner Force Dial gauge

model FDK 20 or FDN 100. These gauges can be

found at www.wagnerforce.com.

1. Remove the bottom cover of the ramp assembly.

2. Position the ramp in the fully deployed position.

3. Measuring from the back of the carriage the

distance L1 = 200mm (for all models), hook the

force gauge to the outside edge of the drive

chain (photo Y).

4. Pull the force gauge inward until the center of

the drive chain linkage measures approximately

85mm from the edge of the extruded housing (L2

in photo Y). The nominal chain tension (on the

force gauge) should read 5.5 kg ± 0.5 kg (55N ±

5N). Adjust the tension by tightening the respective locknuts as required. Note: Improper chain

tension may result in poor ramp performance,

difficult ramp operation or excessive wear/ pre-

mature failure of respective drive components.

5. Repeat steps 3-4 for the opposite drive chain,

again ensuring the tension force is within the

recommended range.

6. Proceed with the Carriage "Full Out" Alignment to

ensure proper chain tension and alignment.

Photo Y

L

1

L2 = 85mm

Page 19

Page 22

Maintenance, Lubrication & Adjustments

Interior Adjustments (continued)

Carriage “Full Out” Alignment: When the

carriage is deployed to the “Full Out” position, the front bar of the carriage should align

parallel with the union bar of the housing.

This alignment will help ensure that a fully

deployed and elevated platform will properly

align with the bus threshold. Properly maintaining this carriage alignment will also help

provide optimal performance during the in/out

movement of the carriage and platform.

Locknuts

L

3

L

4

Accurate inspection of the carriage alignment can be done by measuring the distance

behind each drive motor from the rear carriage

bar to the rear housing (L3 and L4 in Photo

Z). Comparing the two distances, increase

the chain tension on the side of the longest

distance, via the tension locknut, 1/2 turn

for each 1mm difference. Cycle the ramp

several times, observing the full out alignment of the ramp with the bus threshold.

Stopping once again at the fully deployed

position re-measure the distance behind each

drive motor from the rear carriage bar to the

rear housing and adjust the chain tension accordingly until the full out alignment from side

to side is within ±1mm. Note: If the chain

tension of one side is overly increased, it may

result in a binding condition of the track rollers in the guide rail and lead to obstructions

sensed by the control box.

Photo Z

Page 20

Page 23

Exterior Inspection

Inspection List

Below is a list of routine inspections which should

be done to ensure optimal ramp performance and

prevent excessive wear leading to poor operation

and possible component failure. Refer to the specified pages within this manual for further details.

These ramp inspections should be performed if the

ramp has unusual malfunctions, the bus is undergo-

See Manual

Inspect For What Action/Adjustment Page No.

Torn or detached tape

Proper floor level height

Platform

Ramp

Skid Pads

Front

Cover

Proper floor level rotation

Proper stow level

Proper floor threshold alignment

Excessive wear

Loose rivet

Proper closure

Excessive interference during

stowing cycles

ing routine service, or after every 500 completed

cycles, whichever comes first. If the ramp fails to

operate at a satisfactory level after performing these

inspections and the accompanying adjustment or

course of action, please contact your local Braun

distributor or The Braun Corporation’s Product Support Department for further assistance.

Replace tape

Floor height per ramp support

Floor level sensor pick-up

Stow level sensor pick-up

Carriage “full out” alignment

Replace pad

Replace rivet, pad

Inspect front cover hinge (next item)

Check platform position for

clearance.

See Troubleshooting Guide

15

13, 14

13, 14

20

12

13

24, 25

Front

Cover

Hinge

Front

Cover

Seals

Front

Cover

Skid pads

Ramp Hinge

Electrical

Connectors

Debris buildup

Pin fatigue

Spring fatigue/failure

Debris build up

Damage, fatigue & adhesion

Excessive wear

Uncharacteristic marks

Debris buildup

Pin fatigue

Debris buildup

Positive lock engagement

Clean, lubricate

Replace hinge

Replace hinge

Clean

Replace seals

Replace pads

Identify marking item and correct

Clean, lubricate

Replace

Clean

Re-engage

12, 13

13

13

12

12

Page 21

Page 24

Inspection List

Exterior Inspection

See Manual

Inspect For What Action/Adjustment Page No.

Beeper

Manual

Release

Cable

Manual

Release

Sensor

Bottom

Cover

Bottom Cover

Latches

Top Cover

Top Cover

Seal

Debris buildup

Proper audible level

Smooth, easy operation

Debris buildup

Cut or damaged lead wire

Damage resulting in ramp

interference

Secured with tie-wrap

Proper compression of bottom

cover seal

Debris buildup

Damage resulting in ramp inter ference

Proper adhesion/seal

Clean

Replace beeper

Clean, lubricate cable

See Troubleshooting Guide

Clean

Repair or replace sensor

Replace bottom cover

Add tie-wrap if missing

Adjust latch “draw” hook

Clean

Replace top cover

Replace double-faced adhesive

tape

12

13

24, 25

18

16

16

16

14, 16

RA200

Label

Damage or lack of adhesion

Replace label

Page 22

Page 25

Inspection List

Interior Inspection (with snap-on bottom cover removed)

See Manual

Inspect For What Action/Adjustment Page No.

Fully

Deployed

Carriage

Extruded

Guide Rails

Chain

Manual

Release

Assembly

Electrical

Wiring

Full In/Out

Sensor

Pick-ups

Bottom Cover

Seals

Proper alignment

Debris buildup

Debris buildup

Loose chain

Debris buildup

Restricted movement

Proper sensor switching

Cut/worn wire/jacket

Corroded terminal

Debris buildup

Debris buildup

Damage, fatigue and lack of

adhesion

Carriage “full out” alignment

Clean

Clean, lubricate

Chain tension

Clean, lubricate

See Troubleshooting Guide (back

page)

Reset sensor position

Repair or replace

Clean or replace

Clean

Clean

Replace seals

20

16

18

19

18

18

12

17

16

Page 23

Page 26

Troubleshooting

Troubleshooting Guide

Problem Possible Cause Possible Solution

Carriage and ramp

misalignment during

in/out movement

Deployed platform

misalignment with bus

threshold

Repeating obstruction

sensed during in/out

movement

Repeating obstruction

sensed during up/down

movement

Grinding/rubbing sound

during in/out movement

Front cover remains open

when platform is stowed

Manual release cable

pulls too hard

Manually released platform pulls too hard

Designed allowable tolerances

Chain tension or position with

carriage sprockets

Misalignment of carriage

Differential in chain tension

Debris on extruded guide rails

Mechanical interferences

Low/high supply voltage

Exceeded current draw limits of

control box

Loss of full out sensor signal

Threaded bar ramp supports

interfere with carriage

Platform contacting floor level

edge

Platform contacting union bar

during inward movement

Threaded bar ramp support

rubbing on front cover skid pad

Debris on extruded guide rails

Hinge springs fractured

Carriage/platform misalignment

Slider binding in guide

Left/right drive chain tension

excessively high

No action required unless other problems

observed.

Inspect/check carriage “full out alignment”

Inspect/check carriage “full out alignment”

Inspect drive chains

Inspect extruded guide rails

Check for identifying marks on all skid pads, etc.

Check supply voltage

Place controller in ‘service’ mode and cycle ramp.

If no obstructions occur, return controller to

‘operating’ mode and clean and lubricate

platform assembly. If obstructions do occur in

‘service’ mode, discontinue use and contact

authorized Braun representative.

Inspect sensor LED during up/down movement. If

LED is intermittent, reposition sensor as

required to ensure sensor remains lit during up/

down movement.

Cut off excess threaded bar ramp supports to

allow proper clearance

Reposition floor level sensor pick-up

Reposition stow level sensor pick-up

Grind leading edges of threaded bar if noise

intolerable

Inspect extruded guide rails

Replace hinge

Inspect/check carriage “full out” alignment

Remove slider. Check for foreign debris, metal

shavings, or spring interference. Clean and

lubricate.

Adjust drive chain tension.

Manual release will not

reengage properly

Page 24

Spring failed/has interference

Slider binding in guide

Manual release giving false

signal

Inspect spring and correct as needed

Inspect, clean and lubricate slider and guide

Inspect and adjust manual release sensor

position

Page 27

Troubleshooting

Troubleshooting Guide

Problem Possible Cause Possible Solution

Ramp/controller will not

respond or function to

inputs properly

Controller not configured

properly

Jumpers loose or fallen off

controller terminals

Interlocks not installed/con nected correctly (Park,

Manual Release)

Re-configure controller

Inspect and replace jumpers in proper

configuration

Verify interlock signals are present as required

Panel binds on front

cover during stowing

sequence

Pressure mat will not

respond or function

properly

Sensitivity edge will

not respond or function

properly

Controller relay failure

Electrical harness failure

Front cover edge is hitting the

screws/nuts of the platform

hinge assembly

Controller not configured

properly

Electrical harness failure

Controller not configured

properly

Electrical harness failure

Inspect relays and replace if failed

Inspect harness and replace if failed

Adjust stow height lower

Grind clearance for nuts

Re-configure controller

Inspect harness and replace if failed

Re-configure controller

Inspect harness and replace if failed

Page 25

Page 28

Repair Parts

Parts List - ER1301WS Overall Exploded View

Item Qty. Description ER1301WS

1 1 Carriage and Ramp Assembly Pages 27B, 28B & 29

2 1 Frame Assembly Pages 30, 31A & 32A

3 1 Panel, Upper ER1265-1300

4 10 Screw, M5 x 20, Hex Head Cap 27452

5 12' Tape 1/16" x 3/4" Double Face 82033R

6 1 Panel Assembly, Lower ER1369A-1300GS

7 4 Washer, M6 Fender 27759

8 4 Screw, M6 x 16MM, Hex, Cap 28785

9 1 Chain, Roller, 8MM Pitch 28532R101.00

10 1 Chain, Roller, 8MM Pitch 28532R98.4375

11 1 Chain, Roller, 8MM Pitch 28532R63.625

12 3 Master Link, 8MM Pitch 27428

13 1 Sponge Strip, 1/2" x 1/4" x 40" 82062R040

14 1 Decal, Logo, Cover, Easy Ramp 28223

15 1 Decal, Upper Panel, Easy Ramp 28224

16 10 Nut, M5 Nylock 83038

17 4 Washer, M6 Lock 28787

18 10' Tape, Cap, 1 1/2" 10416R

19 1 Control Box, Main Ramp (Not Shown) ER1319

20 1 Harness, Main (Not Shown) ER1318A-WS1300

21 1 Harness, Alarm (Not Shown) ER1320A

22 1 Harness, Control Box ER1317WSA

23 1 Alarm, 24V - Acoustic with Connection (Not Shown) 27493A

Page 26

Page 29

Exploded View - ER1301WS Overall

Repair Parts

15

4

3

13

4

5

2

9

16

10

12

14

16

12

11

12

1

Page 27A

18

18

7

17

8

6

Page 28A

Page 30

Unfold for:

Exploded View

ER1301WS Overall

Repair Parts

Exploded View - ER1301WS Carriage & Ramp Assembly

55

55

43

55

55

55

55

20

54

2

3

4

17

16

16

31

18

10

13

11

11

18

12

55

37

36

35

39

38

40

33

53

2

7

22

14

16

16

19

21

57

54

55

55

1

57

55

8

9

55

55

55

55

Page 27B

52

48

49

47

50

45

53

52

45

48

49

50

47

46

51

41

45

42

15

43

32

30

56

24

25

6

23

29

56

Note:

Typical Both Ends

5

34

44

28

27

26

Page 28B

Page 31

Repair Parts

Parts List - ER1301WS Carriage & Ramp Assembly

Item Qty. Description ER1301WS

1 1 Ramp Sub Assembly ER1405A-WS1300

2 12 Screw, M4 x 16, Flat Socket Head, Cap - SS 33278

3 11 Locknut, M4, Nylon Insert 83037

4 1 Support Weldment, Adjustable Ramp, Carriage ER1035W

5 4 Pin Weldment, Bearing, Carriage ER1179W

6 4 Bearing, UHMW, 1 1/2", Flat PS1006

7 2 Screw, M5 x 10 Hex, Cap 27449

8 1 Tag, Serial No. / Series No. 18548M

9 2 Rivet, Pop, 3/16" 11512

10 2 Guide, Elevation, Main Axle ER1086

11 2 Screw, M6 x 8, Cup Point, Socket, Set 27460

12 1 Bracket, Support, Main Axle ER1087

13 4 Screw, M6 x 12, Flat Socket Head Cap 27458

14 1 Bearing, Plain Plastic, 1" I.D. X 1 1/4" O.D. 27777

15 4 Screw, M6 x 16, Hex 28785

16 8 Locknut, M12, Nylon Insert 22876

17 1 Axle Weldment, Main Elevation, Carriage ER1030W

18 2 Motor, Drive Assembly, Carriage ER1121A

19 1 Screw, M8 x 100, Hex, Cap 27465

20 1 Pin, 5/16" O.D. X 2" Grip, Self Locking 27840

21 1 Spacer, Elevation, Carriage ER1093

22 1 Screw, M8 x 20, Socket Low Head, Cap 27762

23 1 Pin, Clevis, 5/16" O.D. X 12-3/64" Grip 27841

24 8 Bearing, Plain Plastic, 8MM I.D. X 10MM O.D. 27497

25 2 Link, Elevation, Carriage ER1084

26 1 Yoke, Elevation, Carriage ER1083

27 2 Joint, Ball Rod End, Elevation Linkage 27494

28 1 Spacer, Ball Joint, Carriage ER1081

29 1 Stud, M8 x 50, Threaded 27485

30 4-8 Washer, .328" x .562" x .042" (Qty. varies) 83583

31 1 Motor, Elevation Assembly, Carriage ER1122A

32 8 E-Clip, 7/16" Shaft, 11/32" Groove 27796

33 1 Holder, Cable Tie, 2 Way 27510

34 4 Roller, Track, 38MM OD x 12MM ID 27788

35 1 Screw, M6 x 16, Button, Socket Head, Cap 82691

36 1 Washer, M6, Fender 27759

37 2 Bearing, Ball, Elevation 27495

38 1 Screw, M8 x 35, Hex, Cap 27468

39 2 Bearing, Ball, Top Panel Support 27496

40 2 Washer, M8, Flat 27462

41 4 Locknut, M8, Nylon Insert 83042

42 2 Bearing, Plain Plastic, 16mm ID x 18mm OD 27500

43 2 Screw, M10 x 16, Socket Head, Cap 27434-SS

44 2 Plug, End Cap, 1.5" Square Tube 27843

45 9 Screw, M6 x 10, Flat Head Socket, Cap 27722

46 1 Carriage Drive Weldment ER1225W

47 2 Bearing, Plastic Disc, 10mm ID x 18mm OD 27502

48 2 Sprocket, Drive Position, Carriage 27490

49 2 Bearing, Plain Plastic, 10mm ID x 12mm OD 27498

50 2 Axle, M8, Sprocket, Carriage ER1085

51 1 Gear, Elevation Reduction, Carriage 27487

52 1 Harness, Electrical, Ramp ER1318A-WS1300

53 4 Sensor, 24V, M12 x 42, Proximity 32323

54 2 Pad, Skid, Ramp, Top ER1239

55 16 Rivet, Pop, M4 x 10, Countersunk Blind 27441

56 4 Washer, M6 Lock 28787

57 2 Pad, Alignment Skid ER1263

Page 29

Page 32

Repair Parts

Parts List - ER1301WS Frame Assembly

Item Qty. Description ER1301WS

1 8 Rivet, 5/32" .188" x .250" Grip 28583

2 1 Plate, Skid, Frame, Right ER1292

3 1 Plate, Skid, Frame, Left ER1293

4 2 Ring, 5/16", External Snap 24570

5 2 Sprocket, Fixed Guide, Manual Release 27491

6 2 Bearing, Plain Plastic, 8MM I.D. X 10MM O.D. 27497

7 1 Cover, Front, Cassette ER1370

8 8 Screw, M4 X 10MM, Hex Head, Cap 27706

9 1 Union, Exterior Frame, Weldment ER1210W

10 22 Rivet, Pop, SD64BS 3/16" x 13/.25 11513

11

12 8 Screw, M8 X 25MM, Flat Socket Head, Cap 27466

13 1 Slide, Manual Release ER1245W

14 1 Assembly, Manual Release, Left ER1041A

15 1 Assembly, Chain Tension, Left ER1056A

16 11 Screw, M5 X 20MM, Flat Socket Head, Cap 27451

17 1 Assembly, Chain Tension, Right ER1061A

18 1 Assembly, Manual Release, Right ER1051A

19 25 Locknut, M5, Nylon Insert 83038

20 1 Harness, Electrical, Ramp ER1318A-WS1300

21 3 Strap, M12, Rubber Cushioned, Steel, Loop 27435

22 7 Strap, M6, Rubber Cushioned, Steel. Loop 27456

23 8 Locknut, M8, Nylon Insert 83042

24 8 Washer, M8, Fender 27738

25 6 Screw, M5 x 10MM, Flat Socket Head, Cap 27448

26 4 Latch ER1301

27 1 Spring, Compression 27478

28

29 1 Cable, Manual Release, ER1301WS 34383

30

31

32 1 Frame, Weldment, Exterior, Aluminum ER1305W-1300

33 2 Sponge Strip, 1/2" x 1/4" x 4" 82062R004.00

34 2 Screw, M5 x 20MM, Hex Head, Cap 27452

35 1 Cover, Plate, Manual Release Slide ER1251

36 2 Tape, Cap, 1.5" x 2.0" 10416R002.00

37 2 Washer, .328" x .562" x .042" 83583

38 3 Plate, Skid, Front Cover ER1072

39 1 Hinge, Cover, 1.5" x 41.5" 27425

40 1 Wire, Cover, UHMW ER1241

41 5 Rivet, Pop, SD66BS, 3/16" x .25/.38 14993

Page 30

Page 33

Exploded View - ER1301WS Frame Assembly

Repair Parts

10

38

10

41

2

38

19

24

21

19

19

19

20

19

36

22

23

19

22

19

19

19

21

19

22

23

19

26

41

3

7

8

39

Note: Cover Assembly

ER1375A includes items 7, 38,

33

25

1

29

39 and applicable fasteners.

37

4

5

41

40

26

23

17

22

12

16

19

23

18

21

19

24

19

16

16

16

19

22

19

22

1

26

24

23

24

23

24

19

1

15

16

16

24

19

22

34

16

16

19

36

35

16

6

33

25

9

12

13

14

32

1

26

27

41

10

Page 31A

Page 32A

Page 34

Unfold for:

Exploded View

Repair Parts

Exploded View - ER1301WS Ramp Subassemblies

ER1301WS Frame Assembly

14

ER1061A

12

17

17

19

ER1051A

16

7

15

7

5

10

11

8

7

18

18

9

ER1056A

13

8

11

12

ER1041A

3

10

1

9

4

2

5

12

12

Page 31B

6

7

6

Page 32B

Page 35

Repair Parts

Parts List - ER1301WS Ramp Subassemblies

Item Qty. Description ER1301WS

1 1 Manual Release, Weldment, Left ER1040W

2 1 Screw, M5 x 10MM, Hex Head, Cap 27449

3 1 Shaft, Left, Manual Release ER1037

4 1 Bearing, Plain Plastic, 15MM I.D. X 17MM O.D. 27499

5 2 Sprocket, Double, Manual Release 27488

6 2 Pin, M2.5 x 20MM, Steel Roll, Plain 27436

7 4 Bearing, Plain Plastic, 8MM I.D. X 10MM O.D. 27497

8 2 Roller, Chain Tension ER1252

9 2 Pin, Clevis, Chain Tension 27511

10 2 Clevis, Chain Tensioner 27513

11 2 Adjustor, Threaded, Chain Tension ER1090

12 4 Locknut, M12, Nylon Insert 22876

13 1 Chain Tension, Weldment, Left ER1055W

14 1 Chain Tension, Weldment, Right ER1060W

15 1 Manual Release, Weldment, Right ER1050W

16 1 Sprocket, Fixed Guide, Manual Release 27491

17 2 Screw, M6 x 8MM, Cup Point Socket, Set 27460

18 2 Shaft, Right, Manual Release ER1047

19 1 Tubing, .5 O.D. x .334 I.D. x 1.06" 15865R001.06

Page 33

Page 36

Blank for Layout / Notes

Page 34

Page 37

Electrical Schematic - ER1301WS Ramp Caradap Controller

Repair Parts

GREEN

GREY

PURPLE

WHITE

BK/W

BLACK

RD/W

OR/RD

Y/W

BU/W

GR/W

RD/BK

GREEN

PURPLE

GREY

WHITE

BK/W

BLACK

RD/W

OR/RD

Y/W

BU/W

GR/W

RD/BK

BK/RD

OR/RD

RD/W

YELLOW

J6

1

K1

2

3

4

K2

5

6

K3

7

8

9

K4

10

K5

J7

1

K6

2

3

4

5

6

7

8

9

10

11

12

K9

J4

K10

1

2

K11

3

4

K12

LD17

LD18

LD19

LD20

LD21

LD22

LD32

LD28

LD27

LD30

LD29

OR/BK

GR/BK

U15

MICROPROCESSOR

POT 1

POT 2

POT 3

POT 4

J1

1 2 3 4

BLUE

S5 S1

YELLOW

LD1

LD2

LD3

LD4

LD5

LD6

LD7

LD8

LD9

LD10

LD11

LD12

LD13

LD14

LD15

LD16

SERIAL NO.

XXXXXXXXX

J2

1

2

3

4

5

6

7

8

9

10

J3

1

2

3

4

5

6

7

8

9

10

11

12

S2

S3

S4

ORANGE

GR/BK

BLUE

YELLOW

BROWN

Y/RD

BLACK

BROWN

RED

V/Y

V/GN

GRAY/PINK

ORANGE

GRAY/PINK

GR/BK

ORANGE

BLUE

BROWN

YELLOW

Y/RD

Page 35A

CN3

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

AMP CONNECTOR

929.505-6

OUTPUT SIGNALS

GRAY/PINK

BK/RD

RD/W

OR/RD

YELLOW

ORANGE

OR/BK

GR/BK

Y/RD

CN1

1 2 3 4 5 6 7 8 9 10 11 12 13 14

THOMAS & BETTS CONNECTOR

T1730-S14

RAMP SIGNALS

GR/BK

RD/W

BLUE

YELLOW

YELLOW

BROWN

BK/RD

OR/RD

GRAY/PINK

BLACK

CN2

1 2 3 4 5 6 7 8

AMP CONNECTOR

929.505-3

INPUT SIGNALS

RED

BROWN

ORANGE

YELLOW

BLUE

V/Y

V/GN

Page 36A

Page 38

Unfold for:

Repair Parts

Electrical Schematic

ER1301WS Ramp

Caradap Controller

LEFT

DRIVE

MOTOR

+-

M

ELEVATE

MOTOR

+

-

M

IN

PROXIMITY

SENSOR

RIGHT

DRIVE

MOTOR

+

-

M

GN (16GA)

W (16GA)

Y (16GA)

BN (16GA)

BN (22GA)

BK (22GA)

BU (22GA)

W (16GA)

GN (16GA)

Electrical Schematic - ER1301WS Ramp Wiring Harness (Caradap Controller)

HARNESS #ER1318A-WS1300

CARRIAGE JUNCTION BOX

TO TERMINAL #11

DRIVE MOTOR (-)

DRIVE MOTOR (+OUT)

ELEVATE MOTOR (-)

ELEVATE MOTOR (+UP)

RAMP IN (+)

RAMP IN SIGNAL (-)

RAMP IN (-)

DRIVE MOTOR (+OUT)

DRIVE MOTOR (-)

TO TERMINAL #7

TO TERMINAL #8

TO TERMINAL #10

TO TERMINAL #9

TO TERMINAL #6

TO TERMINAL #2

TO TERMINAL #5

TO TERMINAL #8

TO TERMINAL #7

TERMINAL STRIP

1

2

3

4

5

6

7

8

9

10

11

12

TO TERMINAL #5

TO TERMINAL #6

TO TERMINAL #3

TO TERMINAL #5

TO TERMINAL #6

TO TERMINAL #1

TO TERMINAL #5

TO TERMINAL #6

TO TERMINAL #4

TO TERMINAL #5

PRESSURE MAT

PRESSURE MAT

RAMP DOWN (+)

RAMP DOWN SIGNAL (-)

RAMP DOWN (-)

RAMP OUT (+)

RAMP OUT SIGNAL (-)

RAMP OUT (-)

RAMP UP (+)

RAMP UP SIGNAL (-)

RAMP UP (-)

BN (22GA)

BK (22GA)

BU (22GA)

BN (22GA)

BK (22GA)

BU (22GA)

BN (22GA)

BK (22GA)

BU (22GA)

PRESSURE

MAT

DOWN

PROXIMITY

SENSOR

OUT

PROXIMITY

SENSOR

UP

PROXIMITY

SENSOR

SYMBOL DESCRIPTION

JUNCTION

M

BN

(+)

LOAD

BK

BU

(-)

MOTOR

PROXIMITY SENSOR

CONNECTORS

TO TERMINAL #9

TO TERMINAL #4

TO TERMINAL #3

TO TERMINAL #10

MANUAL RELEASE

PROXIMITY

SENSOR

HARNESS #ER1317WSA

TO TERMINAL #8

TO TERMINAL #11

PK (20GA) PRESSURE MATY (18GA)

BN (20GA)

BU (20GA)

GN (20GA)

Y (20GA)

GN (16GA)

W (16GA)

GY (20GA)

WH (20GA)

Y (16GA)

BN (16GA)

PRESSURE MAT

PRESSURE MAT

GROUND

RAMP OUT SIGNAL (-)

RAMP IN SIGNAL (-)

DRIVE MOTOR (-)

DRIVE MOTOR (+OUT)

RAMP UP SIGNAL (-)

RAMP DOWN SIGNAL (-)

ELEVATE MOTOR (-)

ELEVATE MOTOR (+UP)

BK (22GA)

GN (22GA)

123

123

RD (22GA)

PK (20GA)

BN (20GA)

BU (20GA)

GN (20GA)

Y (20GA)

GN (16GA)

W (16GA)

GY (20GA)

WH (20GA)

NOT USED

NOT USED

GN (22GA)

Y (16GA)

BN (16GA)

NOT USED

NOT USED

P/J 8

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

R (18GA)

2

BK (18GA)

3

OR (18GA)

4

BU (18GA)

5

R (14GA)

6

W (14GA)

7

W (18GA)

8

GN (18GA)

9

10

11

BN (18GA)

12

BK (14GA)

13

BN (14GA)

14

15

16

PRESSURE MAT

GROUND

RAMP OUT SIGNAL (-)

RAMP IN SIGNAL (-)

DRIVE MOTOR (-)

DRIVE MOTOR (+OUT)

RAMP UP SIGNAL (-)

RAMP DOWN SIGNAL (-)

MANUAL RELEASE SIGNAL (-)

ELEVATE MOTOR (-)

ELEVATE MOTOR (+UP)

Y (18GA)

R (18GA)

BK (18GA)

OR (18GA)

BU (18GA)

R (14GA)

W (14GA)

W (18GA)

GN (18GA)

BN (18GA)

BK (14GA)

BN (14GA)

1

2

3

4

5

6

7

8

9

10

11

12

13

TO CN1 ON CARADAP

14

CONTROLLER #100465-002

15

16

TO TERMINAL #6

TO TERMINAL #5

TO TERMINAL #1

TO TERMINAL #2

TO TERMINAL #7

HARNESS #32323A

BU (26GA)

BK (26GA)

BN (26GA)

BU (26GA)