Page 1

Service Manual for:

CA

CA

Millennium

HZg^Zh

HZg^Zh

Public Use Wheelchair Lifts

Series A5

DOT — Public Use Lift

DOT — Public Use Lift

“DOT — Public Use Lift” verifies that this platform lift meets the

“public use lift” requirements of FMVSS No. 403. This lift may be

installed on all vehicles appropriate for the size and weight of the

lift, but must be installed on buses, school buses, and multipurpose passenger vehicles other than motor homes with a gross

vehicle weight rating (GVWR) that exceeds 4,536 kg (10,000 lb).

A5

W

A

R N I N G

Man

ual

"Providing Access to the World"

International Corporate Hdqrs: P.O. Box 310 Winamac, IN 46996 USA

1-800-THE LIFT

33759 Rev. B

January

2008

®

(574) 946-6153 FAX: (574) 946-4670

Patent #6,599,079

Patent #5,261,779

Patent #5,261,779

Patent #5,261,779

Patent #5,261,779

Patent #6,065,924

Patent #6,065,924

Patent #6,065,924

Patent #6,065,924

Patent #6,238,169

Patent #6,238,169

Patent #6,238,169

Patent #6,238,169

Patent #6,464,447

Patent #6,464,447

Patent #6,464,447

Patent #6,464,447

Patent #6,599,079

Patent #6,599,079

Patent #6,599,079

Patent #6,692,217

Patent #6,692,217

Patent #6,692,217

Patent #6,692,217

Patent #6,739,824

Patent #6,739,824

Patent #6,739,824

Patent #6,739,824

Patents Pending

Patents Pending

Patents Pending

Patents Pending

®

®

Read manual

before installing

or servicing lift.

Failure to do so

may result in

serious bodily

injury and/or

property damage.

Braun NL Series

Braun NL Series

Page 2

NL917IB

e5*72/245*95/54*0110*00

1-800-THE LIFT™

BRAUNLIFT.COM™

The Braun Corporation

DOT Public Use Lift MODEL#

Max. Lifting Capacity - 800 lbs.

PATEN T

PENDING-

5,261,779-6,065,924-6,238,169-6,46

4,447-6,599,079-6,692,217-6,739,824

MFG DATE

56 14CG

PUMP CODE CYLINDER

A5-00025

SERIAL NUMBER

10/20/06

OWNER'S WARRANTY REGISTRATION

PURCHASED FROM

DATE INSTALLED

NAME

ADDRESS

CITY

TELEPHONE

TO VALIDATE WARRANTY

REGISTRATION CARDS MUST BE RETURNED TO THE BRAUN CORPORATION.

OWNER

STATE ZIP

Congratulations

We at The Braun Corporation wish to express our fullest appreciation

on your new purchase. With you in mind, our skilled craftsmen have designed and

assembled the finest lift available.

This manual provides service-related material. Refer to the FMVSS No. 403

Quick Reference Installation Sheet for installation instructions, operating instructions

and maintenance procedures.

Braun Millennium Series™ lifts are built for dependability and will provide years

of pleasure and independence as long as the lift is installed and serviced as specified

by a Braun certified technician, and the lift is operated by an instructed person.

Sincerely,

THE BRAUN CORPORATION

Ralph W. Braun

Chief Executive Officer

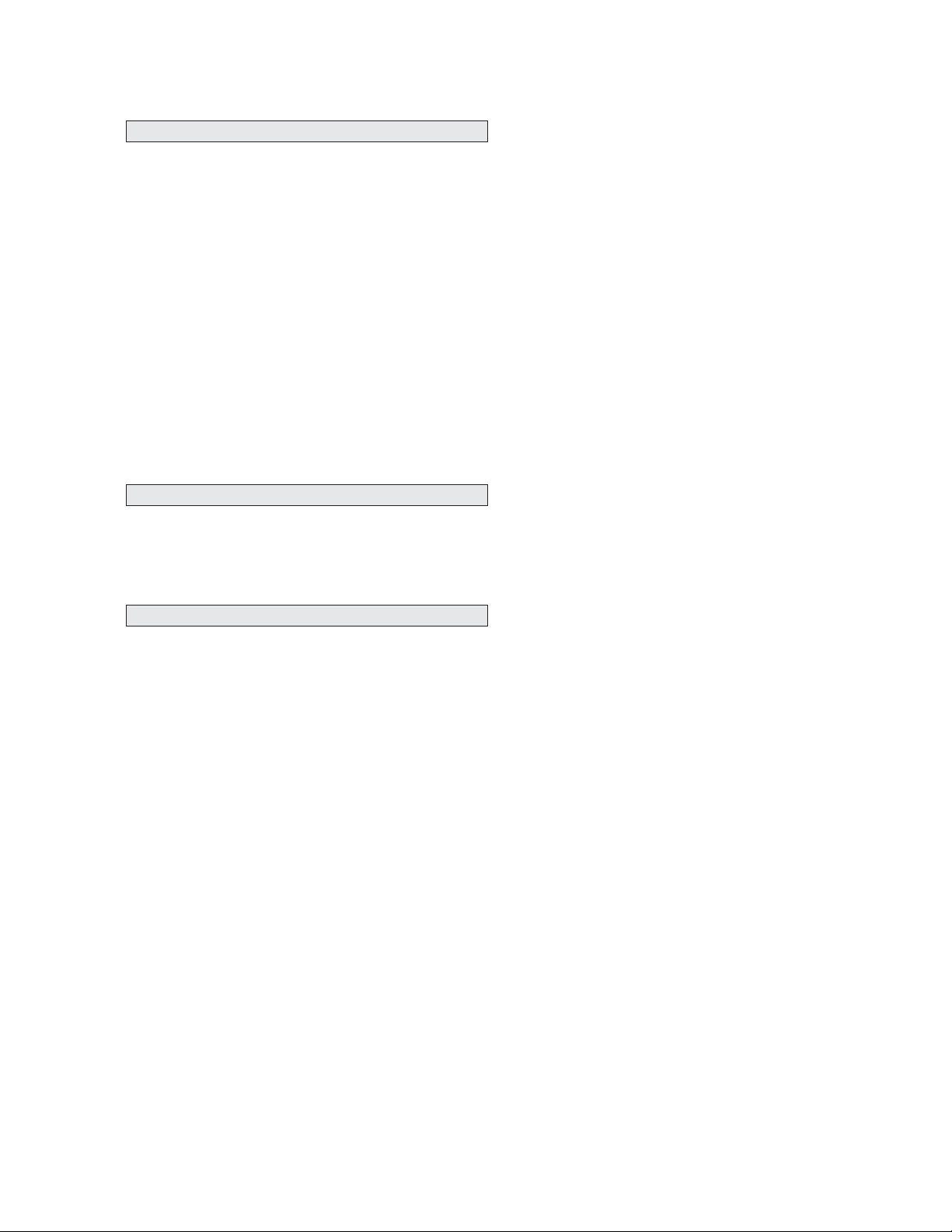

Warranty and Registration Instructions

Immediately upon receiving the lift, examine the

unit for any damage. Notify the carrier at once

Series No. Pump Code

Serial No.Model No. Cylinder Code

with any claims.

NL917IB A5-00025 56 14CG

Two warranty/registration cards (shown right) are

located in the lift-mounted manual storage pouch.

The sales representative must process one of the

cards. The consumer must fill out the other card

and mail it to The Braun Corporation. The warranty is provided on the back cover of this manual.

The warranty cards must be processed to

Sample Warranty/Registration Card

activate the warranty.

Two Braun Serial No./Series No. identification tags (shown below) are posted on the lift.

One I.D. tag is posted on the opposite pump side vertical arm. A second I.D. tag is located

on the opposite pump side tower. Both I.D. tags provide the product identification information provided on the warranty/registration card. Record the information in the space

provided (or document on a copy). This information must be provided when filing

a warranty claim or ordering parts.

Model No.

Sample Serial No./Series No. Identification Tag

Series No.

Serial No.

Pump Code

Cylinder Code

Date of Manufacture

Page 3

Contents

Troubleshooting and Maintenance

Lift Terminology ............................................................ 2

Switch and Sensor Locations ..................................... 3

Certification Checklist Diagnostic Procedures ......... 4

Platform Fold Pressure Adjustment ............................ 5

Outer Barrier Fold Pressure Adjustment .................... 5

Platform Angle Adjustment ......................................6-7

Platform Stop Blocks ................................................... 7

Platform Floor Level Adjustment ................................ 8

Bridging Microswitch Adjustment .............................. 9

LCD Lift Codes ....................................................... 10-11

Lubrication Diagram ................................................... 12

Maintenance and Lubrication Schedule .............. 13-15

Notes ............................................................................ 16

Lift Electrical Schematic ............................................ 17

Lift Wiring Diagram .................................................... 18

Hydraulics

Hydraulic Schematic .................................................. 19

Hydraulics Parts List .................................................. 20

Hydraulics Diagram .................................................... 21

Repair Parts

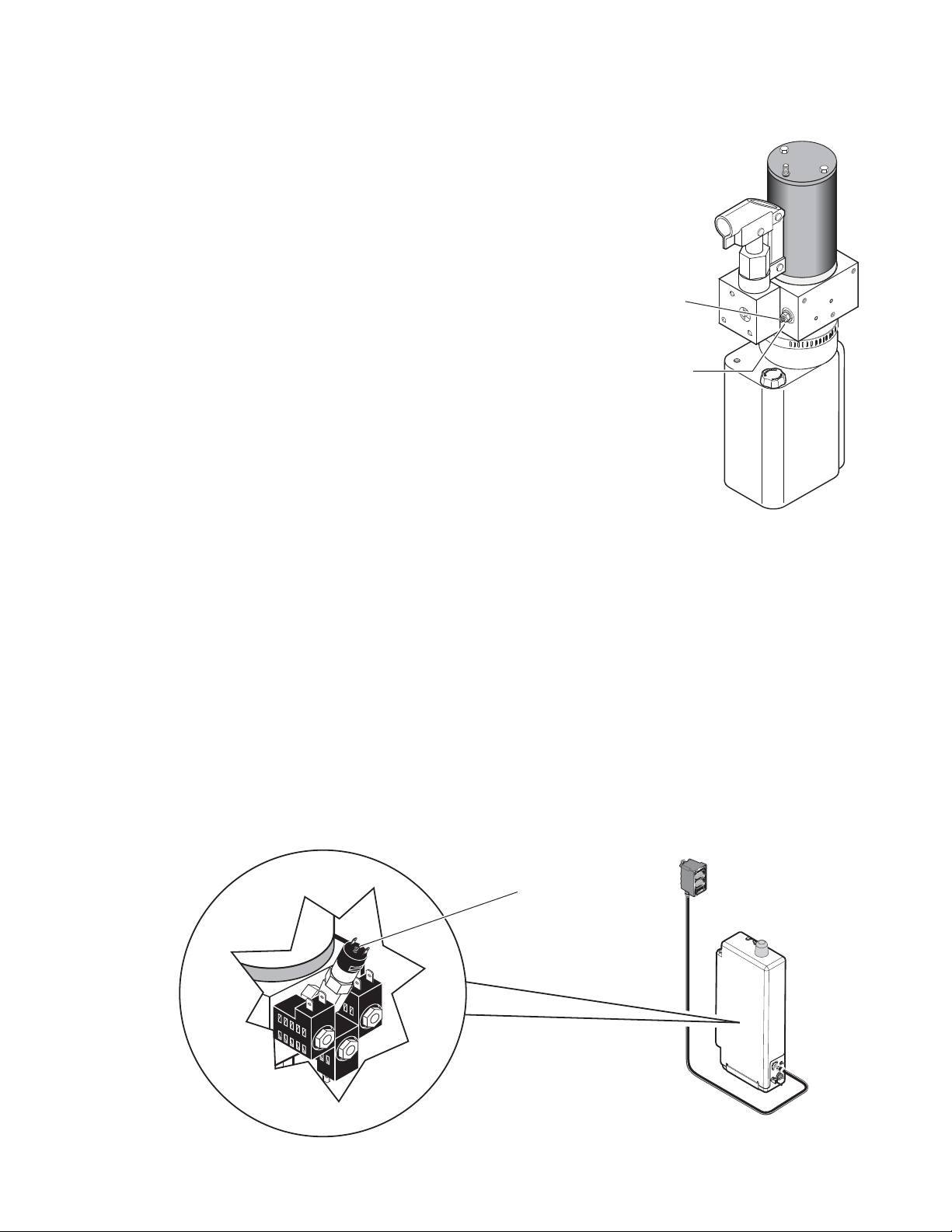

Pump Module

Pump Module Parts List ....................................... 22

Pump Module Diagram ......................................... 23

Lift Exploded Views

42

" Floor-to-Ground Lift Models

(NL915IB, NL915FIB, NL918IB, and NL918FIB)

Repair Parts List ................................................... 24

Exploded View ........................................................ 25

48

" Floor-to-Ground Lift Models

(NL916IB, NL916FIB, NL917IB, NL917FIB,

NL919IB and NL919FIB)

Exploded View .. ..................................................... 26

Repair Parts List .................................................... 27

Notes ....................................................................... 28

Page 1

Page 4

Hand-Held

Pendant

Control

9

1

8

2

3

OWN

D

P

U

D

L

O

F

N

U

0

LD

2

8

2

3

FO

Visual

Threshold

Warning

Threshold

(not visible)

Audible

Warning

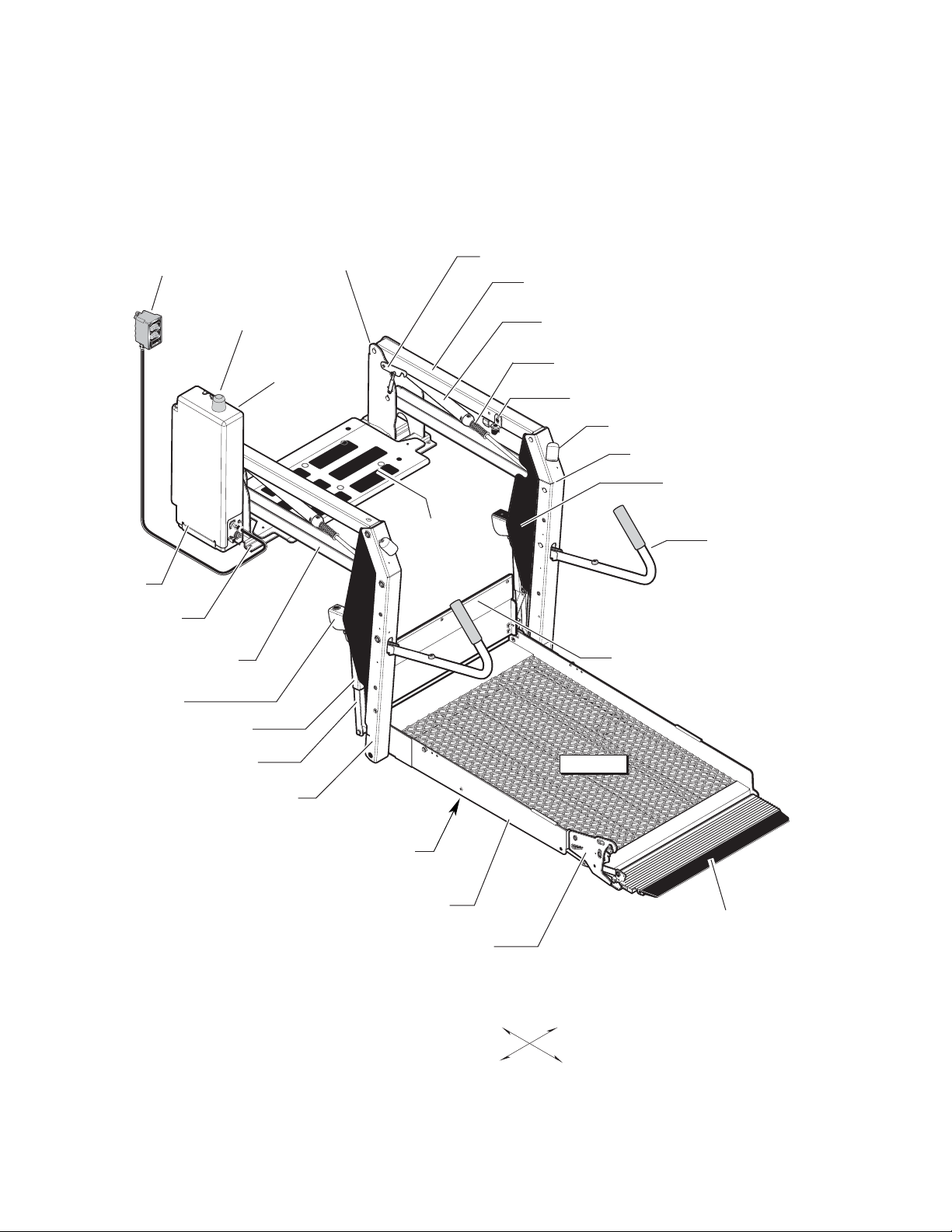

Lift Terminology

Towers (2)

Lift-Tite™ Latches (2)

Top Parallel Arms (2)

Main Cylinders (2)

Unfold Assist Compression Springs (2)

Adjustable Quiet-Ride Stow Blocks (2)

Platform Lights

Opposite Pump Side Vertical Arm

Vertical Arm Covers (4)

Pump

Module

(Rear)

Base

Plate

Bottom Parallel Arm (2)

Saddle (2)

Upper Fold Arm (2)

Lower Fold Arm (2)

Pump Side Vertical Arm

Threshold

Warning

Plate

Outer Barrier Cylinder

(not visible - underside of platform)

Platform Side Plates (2)

Outer Barrier Latch

Handrails (2)

Inner Roll Stop

Platform

Outer Barrier

(Automatic Outboard Roll Stop)

Page 2

Inboard

Left

Right

Outboard

Page 5

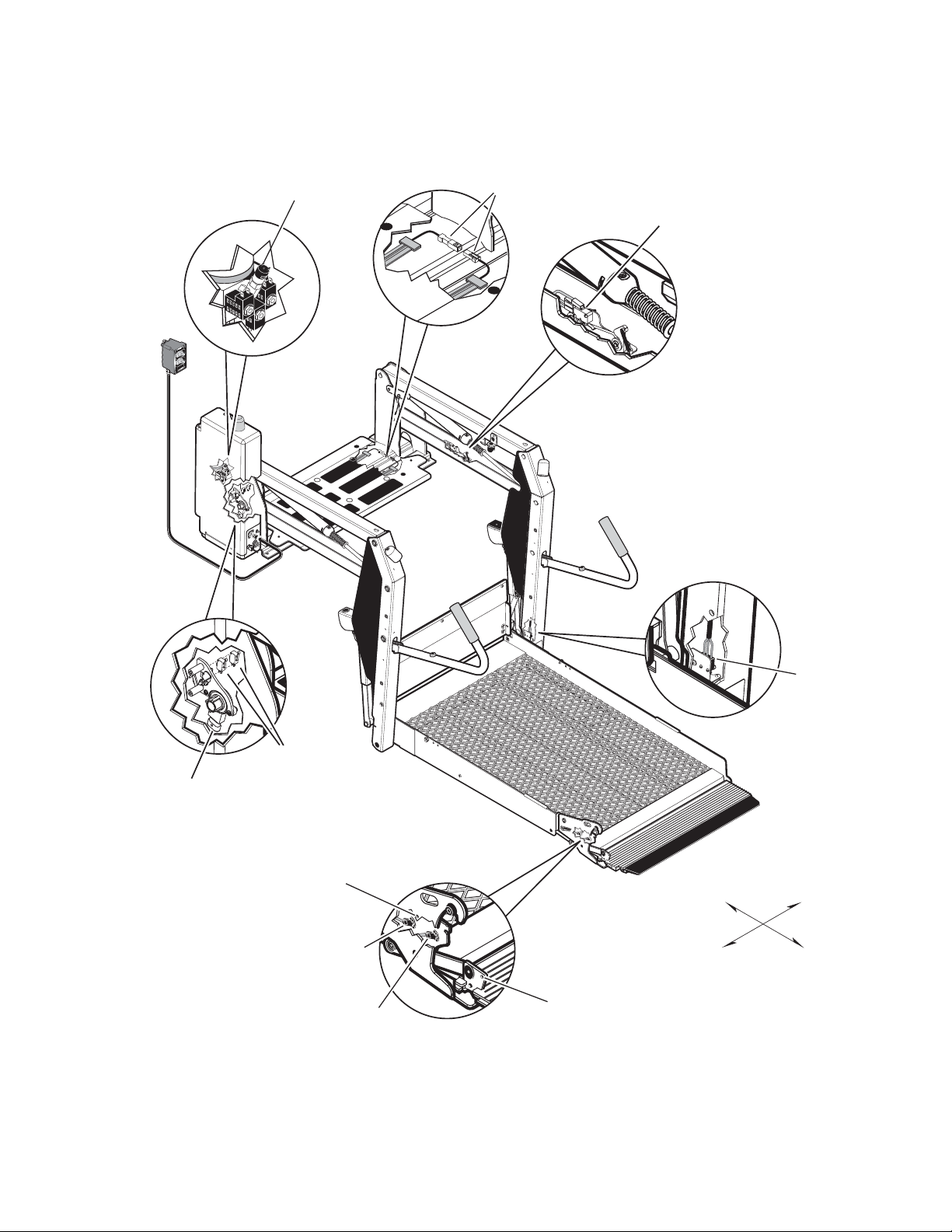

Switch and Sensor Locations

Threshold Strip Switch

Pressure Switch

31199

9

1

N

8

2

3

W

O

D

P

U

D

L

O

F

N

U

D

0

L

2

8

2

3

®

FO

31221A (Qty. 2)

*IB Occupancy

Microswitch Assy.

32642A

*Rotary

Position

Sensor

31094A

Outer Barrier Latched

Magnetic Sensor

32645NA60

*Note: Mirror image for

right (front) pump lifts.

*Stow

Microswitch

23184 (Qty. 2)

Outer Barrier Latched

Magnet

31664

Outer Barrier Raised

Magnetic Sensor

32645NA60

Outer Barrier Raised

Magnet

31664

Inboard

Left

*Bridging

Microswitch

31010FA

Right

Outboard

Page 3

Page 6

Certification Checklist Diagnostic Procedures

The following operations and conditions must be functionally verified in order for the lift to be FMVSS

403/404 compliant. If an operation does not function as described or a condition is not met, follow the referenced procedures to correct the problem or contact a Braun Corporation Product Support representative at

1-800-THE LIFT

• Vehicle movement is prevented unless lift door is closed, ensuring the lift is stowed.

1. Verify lift stowed signal - pin 7 on the pump module has a +12 volt signal OR pin 9 has a ground

signal (depends on interlock used).

2. Refer to the interlock installation instructions.

• Lift operation shall be prevented unless the vehicle is stopped and vehicle movement is prevented.

1. Verify vehicle secure signal (pin 6) has a +12 volt signal.

2. Refer to the interlock installation instructions.

• The platform will not fold/stow if occupied.

- Refer to Platform Fold Pressure Adjustment procedures.

®

.

• The inner roll stop will not raise if occupied.

- Call Product Support

• The outer barrier will not raise if occupied.

- Refer to Outer Barrier Fold Pressure Adjustment

• Verify platform lighting when lift is deployed and pendant illumination when lift is powered.

1. Replace bulb(s) in the light housing.

2. Check fuse (5 amp fuse on circuit board; F13)

• A visual and audible warning will activate if the threshold area is occupied when the platform is a least one

inch below floor level.

1. Remove the threshold warning plate

2. Verify the threshold strip switch connectors are connected (see illustration on Page 3)

3. Replace the threshold strip switch

4. Reinstall the threshold warning plate

• Platform movement is prohibited beyond the position where the inner roll stop is fully deployed (up).

- Call Product Support.

• Lift platform movement shall be interrupted unless the outer barrier is deployed (up).

- Call Product Support.

Page 4

Page 7

Platform Fold Pressure Adjustment

1. Position the platform at the floor level loading

position.

2. Loosen the hex nut on the adjustment screw (do

not remove hex nut).

3. Turn the adjustment screw counter clockwise

until the platform does not fold when the Fold

button is pressed.

4. Turn the adjustment screw clockwise in 1/4 turn

increments and press the Fold button until the

platform folds completely (Note: Return the

platform to floor level position after each attempt to fold the platform).

5. Turn the adjustment screw an additional 1/8 turn

after the platform folds successfully.

6. Tighten the hex nut without moving the adjustment screw.

7. Verify the platform will not stow while occupied.

Platform Fold

Adjustment

Allen Screw

Note: Secure adjustment

screw and tighten hex

nut following adjustment.

Outer Barrier Fold Pressure Adjustment

1. Lower the platform to the ground level loading position.

2. Remove the pump cover.

3. Turn the adjustment screw (shown below) counter clockwise until the outer barrier does not raise

when the Up button is pressed.

4. Turn the adjustment screw clockwise in 1/4 turn increments until the outer barrier raises and fully

locks in position when the Up button is pressed. DO NOT turn the adjustment screw beyond this

position.

5. Verify the outer barrier will not raise when occupied.

6. Reattach the pump cover.

9

281

3

WN

O

D

Outer Barrier

Fold Adjustment

Allen Screw

UP

FOLD

UN

0

2

8

2

3

®

FOLD

Page 5

Page 8

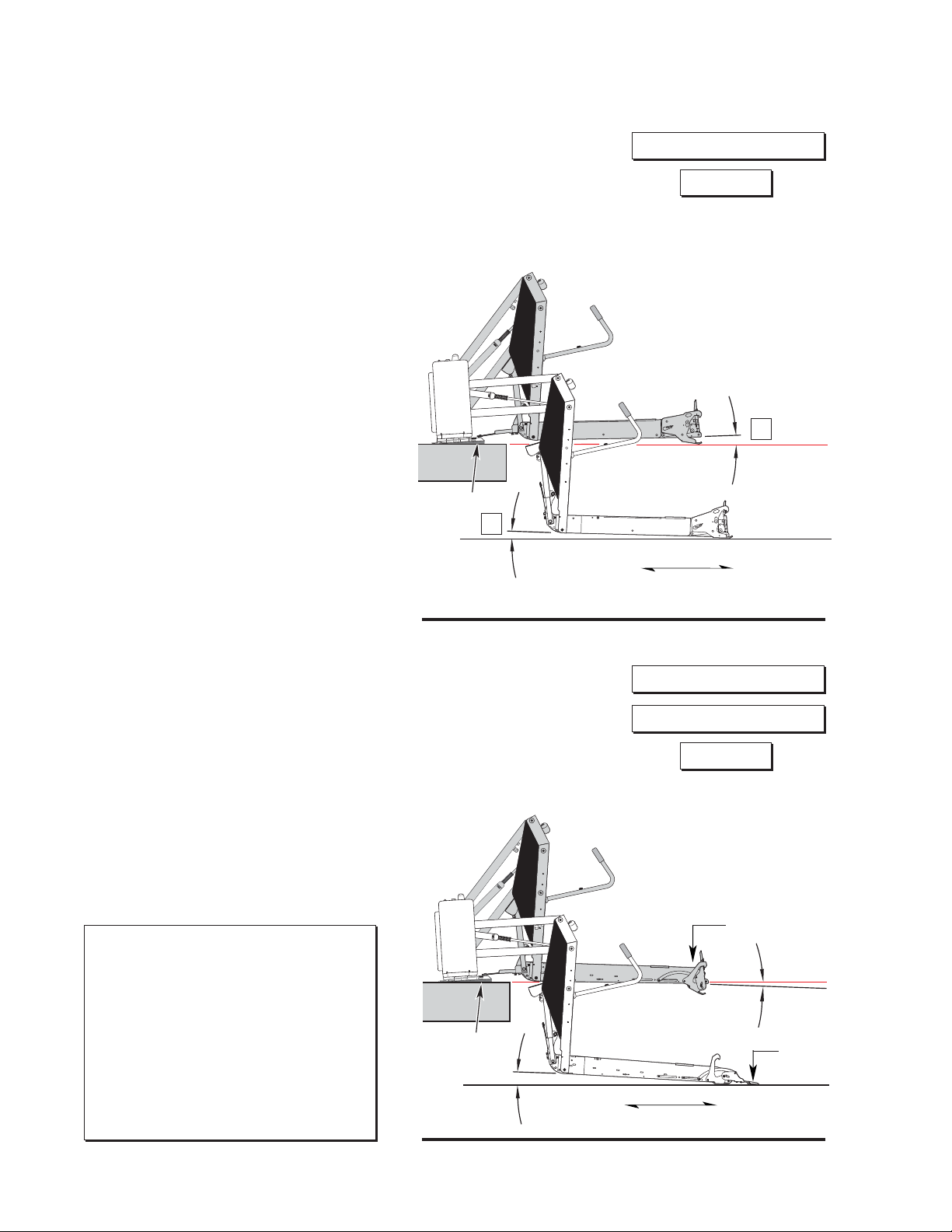

Platform Angle Adjustment

Adjusting the platform angle based on the

relationship of the platform at ground level

directly affects the angle of the platform

when positioned at floor level.

Unfold the lift and visually examine the

angle of the platform when positioned at

floor level. Lower the platform fully and

note the angle of the platform when it

reaches ground level also. The outboard

end of the platform (toe) must contact

the ground first when the platform is

lowered (all lift models).

Millennium “NL” Series:

The platform angle should be adjusted so

there is a balance between the angle at

both positions (equal amount of angle).

Angle A should equal angle B as shown

in Figure C.

Century “NCL” Series:

Vista “NVL” Series:

The platform angle must be adjusted so

the outboard end of the platform (toe) is

angled down slightly when positioned at

floor level. See Figure D. The outboard

end of the platform must contact the

ground first to ensure the spring-loaded

outer barrier unfolds fully.

Adjustment Procedures: Adjustment

Allen screws are provided on each side of

the lift platform for adjusting the platform

angle. Details and photos are provided

on the opposite page.

Wedges

B

Approximately

1” Clearance

Inboard

Millennium “NL” Series

Figure C

Angle A

equals

Angle B.

✓

Floor

A

Level

Outboard

Century “NCL” Series

Vista “NVL” Series

Figure D

Base Plate Wedges: Installations where

base plate wedges are used require more

platform angle adjustment than normal.

Platform Stop Blocks: When adjusting platform angle, ensure both

stop blocks are making full contact

with the vertical arms (details on

opposite page).

Floor Level Adjustment: Following platform angle adjustment, set

floor level positioning as detailed in

Platform Floor Level Adjustment

(details on page 8).

Page 6

Wedges

Inboard

Toe must

angle

down

slightly.

Floor

Level

Barrier

must

unfold

fully.

Outboard

Page 9

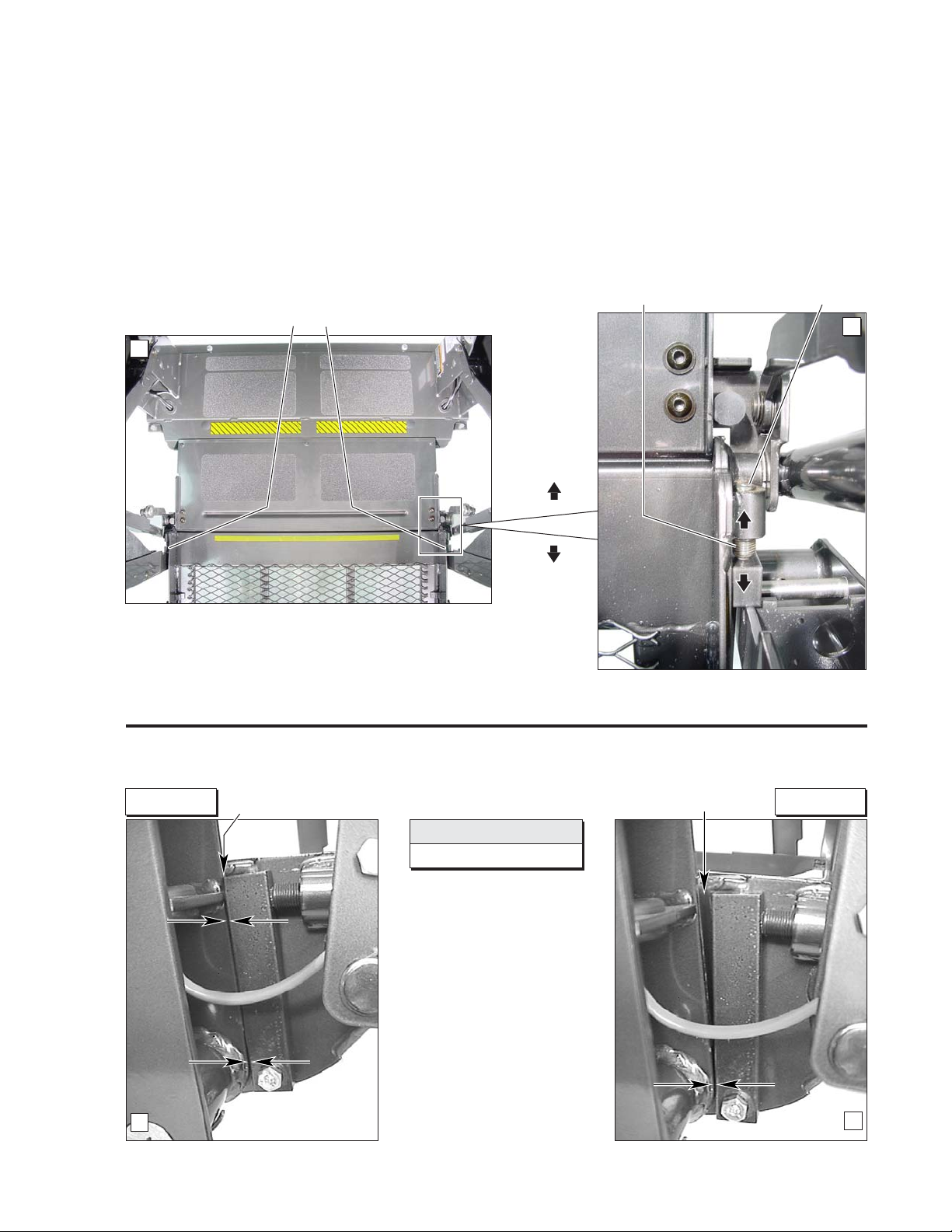

Platform Angle Adjustment

Adjustment Allen screws are

provided on each side of the lift

platform for adjusting the platform

angle. Adjust platform angle as

specified on previous page.

Platform Angle

Adjustment Screws

A

To raise the outboard end

of platform - turn adjustment

screw clockwise.

To lower the outboard end

of platform - turn adjustment

screw counterclockwise.

Turn

counter-

clockwise

to lower

outboard

end of

platform

Turn

clockwise

to raise

outboard

end of

platform

Note: Both adjustment screws

must be adjusted equally.

®

Apply Loctite

to adjustment

screws following adjustment.

Adjustment Screw Allen Head

B

Platform Stop Blocks

Right Wrong

C

Must make full contact.Gap not permitted.

Stop Block Guideline

All Lift Models

Both stop blocks must

make full contact with

Vertical

Arm

Stop

Block

the edge of vertical arms.

Vertical

Arm

When adjusting platform

angle, setting floor level

position or adjusting

bridging microswitch -

ensure both stop blocks

are making full contact

with the vertical arms.

Stop

Block

D

Page 7

Page 10

Platform Floor Level Adjustment

Before setting floor level position:

• Adjust platform angle as detailed

on page 6.

• Ensure both stop blocks are

making full contact with vertical arms (details on page 7).

Floor Level Adjustment:

1. Position platform at desired

floor level position (passenger

loading/unloading height).

Position platform such that:

a. the inner roll stop is laying

flat on the threshold plate

b. platform has not begun to

fold

Note: Use hand pump to position platform at proper posi-

tion if unable to stop platform

when powering lift.

2. Turn Lift Power switch Off.

3. Press Floor Position Set button (located between pump

housing and lift tower).

4. While pressing the Floor Position Set button, turn the Lift

Power switch On.

5. Continue pressing the Floor

Position Set button until the

lift sounds three “beeps.”

6. Release the Floor Position

Set button.

7. Cycle lift to verify that platform stops at the set floor

level position. Note: If

platform does not stop at

E

Floor Level Set Button

the intended position - repeat

adjustment procedures. If repeating procedures fails - refer

to Diagnostics section below.

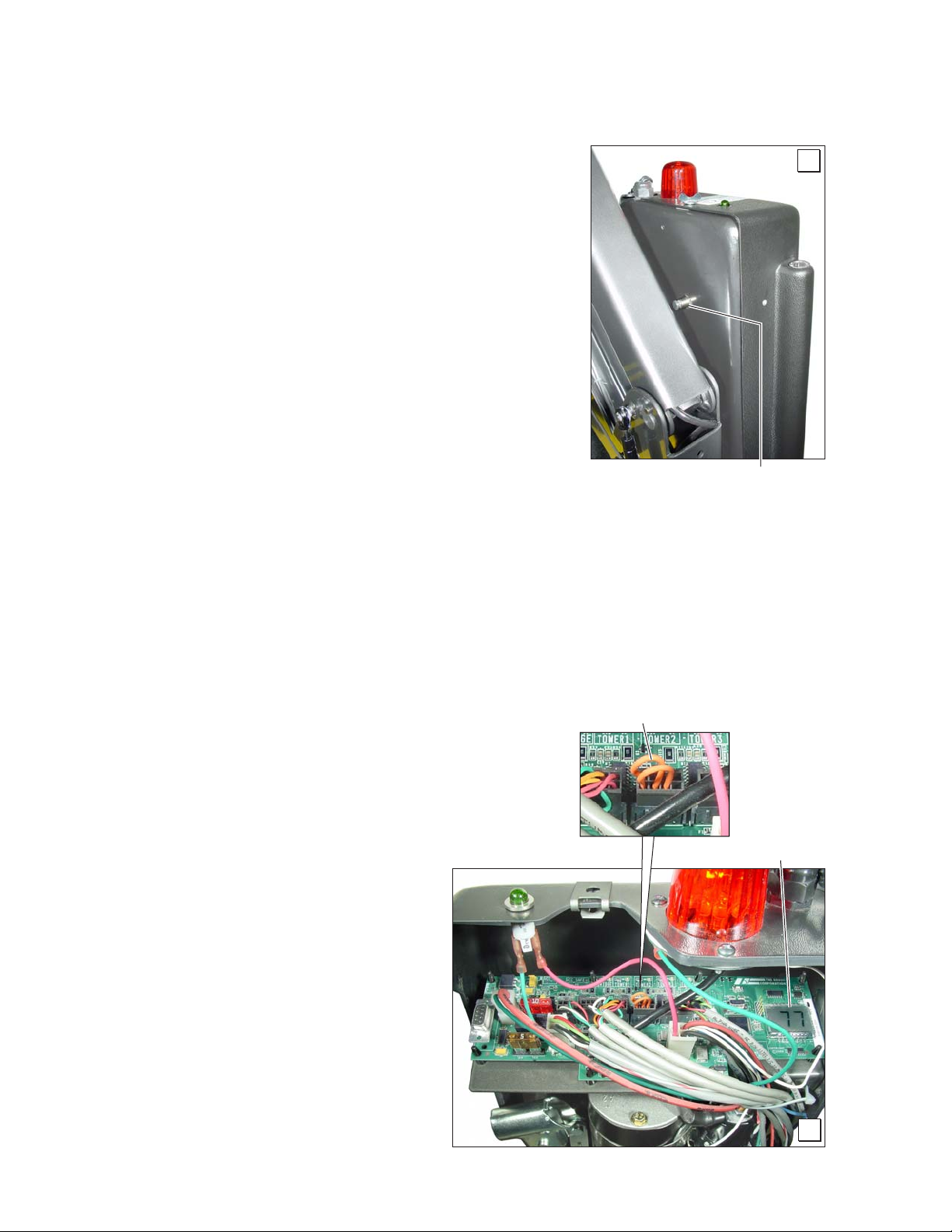

Diagnostics: Diagnostic codes

have been established in event

the lift platform floor position

does not set (the lift does not

sound three “beeps” - see Step

5 above). The control board

located inside the pump hous-

91 – The platform position is out of a prede-

termined acceptable range

92 – The Bridging Microswitch is not activat-

ed (adjust switch or lower the platform)

93 – The Inner Roll Stop Occupied switch is

not activated (adjust switch)

94 – The Outer Barrier Up switch is not acti-

vated (adjust switch)

95 – The Outer Barrier Latched sensor is

not activated (Century and Vista: Verify

jumper is installed on the outboard

barrier latch switch – see photo at right;

Millennium: Check latch)

ing is equipped with an LCD

screen. Remove the pump

cover to access the LCD

screen. The following diagnostic codes will help resolve floor

position setting problems:

Century/Vista Jumper

LCD Screen

F

Page 8

Page 11

Bridging Microswitch Adjustment

Bridging Microswitch:

The bridging microswitch is

located at the bottom of the

right (front) vertical arm. See

Photos A and B. An adjustment screw is built into the

platform stop block.

The bridging microswitch will

be deactivated if the outboard

end of the platform contacts

the unloading surface before

the inboard end while the

DOWN switch is pressed.

The deactivated bridging microswitch interrupts power to

the DOWN switch circuit and

stops the down travel of the

platform (while allowing the

outer barrier to deploy).

Inboard Vertical

Edge of Vertical Arm

Adjustment Screw

Platform

Stop Block

Bridging Microswitch

HG

Switch

Activation Lever

Adjustment Guidelines:

Caution: This adjustment is

factory set and typically should

not require adjustment.

Before adjusting the bridging

microswitch:

• Adjust platform angle as

detailed on page 6.

Bridging Microswitch Adjustment

1. Position the platform at floor

level (or slightly below).

Ensure the platform is not

partially folded. From the

stowed position, press the

UNFOLD switch until the

pump stops running and the

platform comes to a full stop.

From below floor level, press

the UP switch until the pump

stops running and the platform

comes to a full stop.

• Adjust floor level position as

detailed on page 8.

• Ensure platform is in the fully

unfolded position.

• Ensure both stop blocks are

making full contact with vertical

arms (details on page 7).

2. Check both platform stop

blocks to ensure there is no

gap between the stop blocks

and the vertical arms. See

Photos B, C and D on page

7. A gap may indicate that the

platform is not fully unfolded or

the platform angle adjustment

bolts are not adjusted equally

on both sides.

Failure to follow these

guidelines will result in an

overtight adjustment that

will bend the adjustment

screw, break the bridging

switch and/or result in lift

operation failure.

3. Loosen the two jam nuts on

the bridging switch activation

screw (see Photo G). Tighten

the screw until the activation

lever is fully depressed. Verify

that there is no play in the

activation lever and tighten the

jam nuts.

4. Test lift for proper operation.

Page 9

Page 12

LCD Lift Codes

To better understand the Braun LCD Trouble shooting display you must first understand the numbers that

appear on the screen. There are Flashing Codes, Solid Error Codes, and Solid Normal Operational Codes.

Flashing Codes #65-89: About 10 seconds after an operation has stopped there are a set of scrolling

flashing numbers that indicate whenever a particular sensor or switch has been activated. These numbers

will start at number 65 and scroll up to number 89, then start the sequence over. Remember they are not

error codes. Keep in mind that the lift will display codes for different positions and certain flashing codes

must be present for that position, you will not always get an error code.

Solid Error Codes #50-64: These are the numbers that will come on the screen when the audible and

visual alarm goes off, and will direct you to where the problem exists. These numbers will only stay on the

screen for about 10 seconds and then the flashing codes will scroll indicating what sensors are active. This

sequence of codes will keep repeating. It is important to be looking at the screen when trying to get the lift

to fail.

Solid Normal Operational Codes: There are also solid numbers that will appear while and after the lift is

moving that indicate the lift operation and platform position.

Troubleshooting Procedures

1. While looking at the LCD screen, operate the lift until the failure occurs. Read the number that comes

on the display the moment the alarm goes off and the light starts to flash. This code will only stay on the

screen for 10 seconds.

2. Look up the number on the correct error code sheet and determine what part on the lift is causing the

failure. Go to the part on the lift that is suspected of causing the failure and look for anything obvious like

magnets missing, broken wires etc. If nothing is found, the next step is to determine if that sensor is sending a signal to the board.

3. Bring the platform to the level that the sensor should be activated using the backup pump if needed. At

this point, look up the flashing code that corresponds to that sensor in the error code sheet, look at the LCD

screen and wait for the flashing scrolling numbers to appear. If the number is not included in the scrolling

numbers, you know that sensor is the problem. You should then check the harness or try another magnet

with the south side of the magnet facing the sensor and see if the number will come up on the display.

4. If the problem is still not found or the harness is suspected, the voltages should to be checked to and

from the sensor to find the exact location of the problem. First determine the 3 wire colors for this sensor at

the board and understand the 3 voltage readings needed to operate the sensor, the 12V power, 8V power,

and the 8V input signal to the PC board when activated by a magnet. First check for a 8V input signal

coming from the sensor to the wire going into the PC board, if there is 11V on this wire, the sensor is not

being activated by the magnet. Next check the 12V and 8V wires at the PC board plug leading to the sensor. Once verified at the plug on the PC board, the voltages should then be checked at the next plug down

on the harness going to the sensor until the location of the problem is found.

Anytime you see the code for that specific switch you will have 8 volts on that colored wire on the 8 or 18

pin connector from that switch. IE: Outboard Barrier is closed “72” will appear on the screen and also 8V

will be present on the signal wire from that switch, if no code is present the voltage will be 11V.

Page 10

Page 13

LCD Lift Codes

Listed below are codes that the lift controller outputs

during lift operation. The codes will be displayed

on an LCD screen located on the lift control board

inside the pump module. See the Manual Operating

Instructions in the operator's manual for pump cover

removal instructions.

Non-Flashing Numbers

01 – Platform stowed

02 – Platform unfolding

03 – Platform unfolding paused

04 – Platform at floor level

05 – Platform beginning to lower

06 – Platform lowering (threshold cannot be occu-

pied from this point down)

07 – Outer barrier moving to horizontal position

08 – Platform at ground level

09 – Outer barrier moving to vertical position

10 – Platform raising

11 – Platform raising paused at floor

12 – Platform folding (limited pressure)

13 – Platform folding (full pressure)

™

14 – Timed fold (cinching Lift-Tite

) or (anti-rattle state)

15 – Platform folding stopped

16 – Paused fold

17 – Platform between ground and 3” above ground

18 – Platform above 3”

19 – Outer barrier moving to horizontal position

23 Outer barrier going back down after occupant

detected

28 – Illegal function/not defined

29 – Interlock fault not recognized (or has been

cleared but a motion button is still pressed)

30 – Platform location unknown

31 – Platform location transition state; attempting to

locate position

35 – Two or more motion buttons are being pressed

36 – The retention belt cannot be buckled while try-

ing to fold or unfold

37 – Motion button being pressed is not a valid mo-

tion

50 – Outer barrier is not up above inboard barrier

locked position

51 – Threshold is occupied when platform is 1” or

more below floor level

52 – Inner roll stop is not up and locked below inner

roll stop locked position

53 – Inner roll stop occupied sensor is not activated

between floor and inner roll stop up position

54 – Outer barrier is occupied before it is up

55 – Outer barrier is not latched when above the in-

ner roll stop locked position (Millennium only)

56 – Outer barrier is not up and latched and bridge

switch did not deactivate

57 – Outer barrier is not up and latched and

ground detect switch did not deactivate (Century

and Vista only)

58 – Outer barrier is not up and latched and the plat-

form is 3” above the ground

59 – Outer barrier is not up after pausing platform

travel

60 – The kick out gas springs are worn, replace be-

fore using

75 – Low voltage detected; must turn off power switch

to reset LCD

77 – Vehicle secure interlock has not been activated

90 – Position will be set if you keep holding the button

until it beeps

91 – Position is out of a predetermined acceptable

range of floor position

92 – Bridge switch is not made, needs adjusting

93 – Inner roll stop occupied switch is not made,

position needs to be moved or switch should be

adjusted

94 – Outer barrier is not made, fix and try again

95 – Outer barrier latch is not made (check for jumper

on Century and Vista lifts, check latch on Millen-

nium lifts)

99 – Controller program is not valid; replace controller

Flashing Numbers

Flashing 65 – Unfold button is pressed

Flashing 66 – Fold button is pressed

Flashing 67 – Down button is pressed

Flashing 68 – Up button is pressed

Flashing 69 – Bridge switch is activated

Flashing 70 – Outer barrier latch switch is activated

Flashing 71 – Ground detect switch is activated

Flashing 72 – Outer barrier up switch is activated

Flashing 73 – Inner roll stop up switch is activated

Flashing 74 – Inner roll stop occupied switch is acti-

vated

Flashing 76 – Outboard barrier occupied switch is

activated

Flashing 78 – Threshold tape switch “A” is activated

Flashing 79 – Threshold tape switch “B” is activated

Flashing 80 – Position set button is pressed

Page 11

Page 14

Pivot Pin Bearings (16)

19

N

8

2

3

W

DO

P

U

D

L

UNFO

D

0

82

2

OL

3

F

Saddle Bearing

Buttons (2)

DE

Upper Fold Arm

Cam Followers (4)

LO

Saddle Support

Bearings (8)

LO

Upper/Lower Fold Arm

Contact Area (2)

LG

Lower Fold Arm

Bearings (8)

LO

Platform Pivot Pin

Bearings (4)

LO

™

Lift-Tite

Latch Rollers (2)

LO

Maintenance and Lubrication

Parallel Arm

LO

Lubrication Diagram

™

Lift-Tite

(Tower Pivot Points - 2)

Latches

LO

Lift-Tite™ Latch Dampening Spring

Outer Barrier

Latch Pivot

LO

Outer Barrier

Lever Guide Slot

(Both Sides)

LG

(2 springs - 4 Points)

LO

Hydraulic Cylinder

Pivot Bushings (8)

Saddle

Bearing

DE

Pivot Pin Bearings (16)

Inner Roll Stop

Pivot Bearings (2)

Outer Barrier

Lever Bearings

LO

Parallel Arm

LO

Handrail Pivot Pin

Bearings (4)

LO

Inner Roll Stop

Lever Bearings (2)

and Slots (2)

LO

LO

Outer Barrier

Pivot Bearings (2)

LO

Outer Barrier

Latch Slot

(Both Sides)

LG

LO

See the Maintenance/Lubrication Schedule for recommended applications per number of cycles.

Specified (recommended) Available Braun

Lubricant Type Lubricant Amount Part No.

LO - Light Oil

DE - Door-Ease

LG - Light Grease

Light Penetrating Oil LPS2, General Purpose 11 oz.

(30 weight or equivalent) Penetrating Oil Aerosol Can

Stainless Stick Door-Ease 1.68 oz.

Style (tube) Stick (tube)

Light Grease Lubriplate 14 oz.

(Multipurpose) Can

15807

15806

15805

Page 12

Page 15

Maintenance and Lubrication Schedule

W

A

RNING

Proper maintenance is necessary to ensure safe,

troublefree operation. Inspecting the lift for any wear,

damage or other abnormal conditions should be a part

of all transit agencies’s daily service program. Simple

inspections can detect potential problems.

The maintenance and lubrication procedures specified

in this schedule must be performed by a Braun authorized service representative at the scheduled intervals

according to the number of cycles.

Braun dual parallel arm lifts are equipped with hardened pins and self-lubricating bushings to decrease

wear, provide smooth operation and extend the service

life of the lift.

When servicing the lift at the recommended intervals,

inspection and lubrication procedures specified in

the previous sections should be repeated. Clean the

components and the surrounding area before apply-

ing lubricants. LPS2 General Purpose Penetrating

Oil is recommended where Light Oil is called out.

Use of improper lubricants can attract dirt or other

contaminants which could result in wear or damage

to the components. Platform components exposed to

contaminants when lowered to the ground may require

extra attention.

following the scheduled

“4500 Cycles” maintenance. These intervals

are a general guideline

for scheduling maintenance procedures and

will vary according to

lift use and conditions.

Lifts exposed to severe

conditions (weather, environment, contamination, heavy usage, etc.)

may require inspection

and maintenance proce-

Maintenance and

lubrication procedures

must be performed as

specified by an

authorized service

technician. Failure to

do so may result in

serious bodily injury

and/or property

damage.

dures to be performed

more often than specified.

Maintenance Indicator: The Lift Ready green LED

mounted on top of the pump cover will begin to blink

after every 750 cycles. The blinking LED will not affect

the functions of the lift, but is a reminder to complete

necessary maintenance and lubrication.

Once the lift has been serviced, fully stow the lift. Once

stowed, press the UP button on the hand pendant and

the Floor Level Set button on the back side of the pump

cover until the Lift Ready green LED stops blinking.

Lift components requiring grease are lubricated during

assembly procedures. When these components are

replaced, grease must be applied during installation

procedures. Specified lubricants are available from

The Braun Corporation (part numbers provided above).

All listed inspection, lubrication and maintenance

procedures should be repeated at “750 cycle” intervals

Outer barrier pivot points (2)

Outer barrier latch pivot point

Outer barrier latch slot

750

Cycles

continued

Outer barrier lever bearings (2)

™

Lift-Tite

Lift-Tite

points (2 springs - 4 points)

Inspect Lift-Tite

or damage (bent, deformed or misaligned), positive securement (external snap rings) and proper

operation

Inspect outer barrier for proper operation

Inspect outer barrier latch for proper operation,

positive securement, and detached or missing

spring

latches (tower pivot points - 2)

™

latch gas (dampening) spring pivot

™

latches and gas springs for wear

Discontinue lift use immediately if maintenance and

lubrication procedures are not properly performed, or if

there is any sign of wear, damage or improper operation. Contact your sales representative or call The

Braun Corporation at 1-800-THE LIFT

®

. One of our

national Product Support representatives will direct you

to an authorized service technician who will inspect your

lift.

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Grease to both sides of slot.

See Lubrication diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Resecure, replace damaged parts or otherwise

correct as needed. Note: Apply Light Grease to

™

Lift-Tite

Correct or replace damaged parts.

Correct or replace damaged parts and/or relubricate. See Lubrication Diagram

latch tower pivot point if replacing latch.

Page 13

Page 16

Maintenance and Lubrication Schedule

750

Cycles

Inspect lift for wear, damage or any abnormal

condition

Inspect lift for rattles

Perform all procedures listed in previous section also

Upper/lower fold arms (2)

Platform pivot pin bearings (4)

Lower fold arm bearings (8)

Inner roll stop pivot bearings (2)

Inner roll stop lever bearings (2)

Inner roll stop lever slot (2)

Saddle support bearings (8)

Upper fold arm cam followers (4)

Parallel arm pivot pin bearings (16)

Handrail pivot pins (2)

Correct as needed.

Correct as needed.

Apply grease (synthetic) to contact areas between

upper/lower fold arms. See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

1500

Cycles

Hydraulic cylinder pivot bushings (8)

Outer barrier lever guide slot

Inspect Lift-Tite

positive securement and proper operation (2)

Inspect inner roll stop for:

• Wear or damage

• Proper operation. Roll stop should just rest on top

surface of the threshold plate.

• Positive securement (both ends)

Inspect handrail components for wear or damage,

and for proper operation

Inspect microswitches for securement and proper

adjustment.

Make sure lift operates smoothly

Inspect external snap rings:

• Lower fold arm (6)

• Lift-Tite

• Lift-Tite

• Upper fold arm cam followers (4)

• Outer barrier hydraulic cylinder mounting pin (2)

• Inner roll stop lever bracket pins (2)

™

latch rollers for wear or damage,

™

latch roller (2)

™

latch gas (dampening) spring (4)

Apply Light Oil - See Lubrication Diagram

Apply Light Grease to both sides of slot.

See Lubrication Diagram

Correct, replace damaged parts and/or relubricate.

Resecure, replace or correct as needed. See Platform Angle Adjustment and Platform Floor Level

Adjustment Instructions.

Replace damaged parts.

Resecure, replace or adjust as needed. See

Microswitch Adjustment Instructions.

Realign towers and vertical arms. Lubricate or

correct as needed.

Resecure or replace if needed.

continued

Page 14

Inspect inner roll stop lock and torsion spring for

wear or damage and for proper operation.

Replace damaged parts. Apply Light Oil to inner

roll stop lock pivot point.

Page 17

Maintenance and Lubrication Schedule

1500

Cycles

Inspect lower fold arm pins (2), axles (2) and

bearings (8) for wear or damage and positive

securement

Remove pump module cover and inspect:

• Hydraulic hoses, fittings and connections for wear

or leaks

• Harness cables, wires, terminals and connections

for securement or damage

• Control board, circuit breaker, power switch and

lights for securement or damage

Perform all procedures listed in previous section also

Inspect cotter pins on platform pivot pin (2)

Hydraulic Fluid (Pump) - Check level. Note: Fluid

should be changed if there is visible contamination.

Inspect the hydraulic system (cylinder, hoses, fit-

tings, seals, etc.) for leaks if fluid level is low.

Inspect cylinders, fittings and hydraulic connections

for wear, damage or leaks

Inspect outer barrier cylinder hose assembly (hose,

fasteners, connections, etc.) for wear, damage or

leakage

Replace damaged parts and resecure as needed.

Apply Light Oil.

Resecure, replace or correct as needed.

Resecure, replace or correct as needed

Use Braun 32840-QT (Exxon® Univis HVI 26)

hydraulic fluid (do not mix with Dextron III or other

hydraulic fluids). Check fluid level with platform

lowered fully and roll stop unfolded fully. Fill

to within 1/2” of the bottom of the 1 1/2” fill tube

(neck).

Tighten, repair or replace if needed.

Tighten, repair or replace if needed.

4500

Cycles

Inspect parallel arms, bearings and pivot pins for

visible wear or damage

Inspect parallel arm pivot pin mounting bolts (8)

Inspect platform pivot pins, bearings and vertical

arms for wear, damage and positive securement

Inspect upper/lower fold arms, saddle, saddle

support and associated pivot pins and bearings for

visible wear or damage

Inspect gas springs (cylinders - 4) for wear or damage, proper operation and positive securement

Inspect saddle bearing (1) and saddle bearing buttons (2)

Inspect vertical arm plastic covers

Inspect power cable

Mounting

Decals and Antiskid

Replace if needed.

Tighten or replace if needed.

Replace damaged parts and resecure as needed.

Apply Light Grease during reassembly procedures.

Replace if needed.

Tighten, replace or correct as needed

Apply Door-Ease or replace if needed. See Lubrication Diagram.

Resecure or replace if needed.

Resecure, repair or replace if needed.

Check to see that the lift is securely anchored to

the vehicle and there are no loose bolts, broken

welds, or stress fractures.

Replace decals if worn, missing or illegible. Replace antiskid if worn or missing.

Consecutive

750 Cycle

Intervals

Repeat all previously listed inspection, lubrication and maintenance procedures at 750 cycle

intervals.

Page 15

Page 18

NOTES

This page intentionally left blank.

Page 16

Page 19

Lift Electrical Schematic

NL917-05-025.ai

BK(6)

BK(4)

GN(20)

BU / WH(20)

BU / WH(20)

RD / WH(20)

RD / WH(20)

BU / BK(20)

RD / BK(20)

GN / WH(20)

GN / WH(20)

BU(20)

GN(20)

GN(20)

GN(20)

PK(20)

OR(20)

OR(20)

GN(20)

GN(20)

GN(20)

GN(20)

GN(20)

GN(14)

BK(20)

UP/FOLD

SOLENOID

IN-LINE

FUSE

RD (2)

PUMP

RD(14)

CIRCUIT

SENTRY

(CIRCUIT BREAKER)

PLATFORM LIGHTS (OPTION)

RD(4)

RD(2)

HYDRAULIC

(UP)

M

POWER

STUD

PUMP BODY

GROUND

PUMP BODY

GROUND

VT(20)

YL(20)

DOWN

SOLENOID

BRIDGE

SOLENOID

M

BATTERY

CHASSIS GROUND

CIRCUIT BREAKER / FUSE

CONNECTORS

JUNCTION

MOTOR

MICROSWITCH

PRESSURE SWITCH

DIODE

SWITCH

SOLENOID

SYMBOL DESCRIPTION

SOLENOID

NOTE: ALL WIRES ARE 22 GA.

UNLESS OTHERWISE NOTED.

LIFT SHOWN IN STOWED POSITION

LIFT CONTROL MODULE

LED

COUNTER

MAGNETIC SWITCH

LIGHT

BEEPER

DUAL RELIEF

SOLENOID

INTERLOCK

LED

THRESHOLD

WARNING

LIGHT

THRESHOLD

WARNING

BEEPER

OUTER BARRIER

RAISED

SENSOR

OUTER BARRIER

LATCHED

SENSOR

NO

NC

C

WH(26)

BU(26)

BK(26)

YL(26)

RD(26)

GN(26)

GN(20)

RD(14)

J3

+

E

SN

-

00000

OR(18)

BK(18)

GN(26)

RD(26)

GN(18) YL(26)

RD(18) BK(26)

BU(18) BU(26)

WH(18) WH(26)

6

1

5

2

J2-A

6

1

5

2

P2

44

3

77

3

4

3

J4

4

3

P4

5

2

5

2

11

66

1

2

J9

1

2

P9

212

1

121

2

BK(20)

BU(20)

VT(20)

YL(20)

OR(20)

OR(20)

PK(20)

1

6

J8

1

6

P8

2

3

2

3

44

55

2

1

P6

2

1

J6

J13

4

3

4

3

55

66

5

6

8

3

4

2

GN(20)

RD(18)

RD(20)

BK(18)

BK(18)

BK(18)

WH(20)

BK(18)

RD(18)

BK(18)

BK(24 GA COPPER)

BK(24 GA COPPER)

BK/WH(24 GA SILVER)

BK/WH(24 GA SILVER)

BK(18)

GY/RD(18)

BK(20)

BN(20)

2

1

J7

2

1

P7

3

44

3

1

2

1

2

1

2

1

2

BK(18)

RD(18)

BK(20)

RD(20)

RD(18)

BK(18)

WH(20)

GN(20)

13

154147111012178

9

18

J5

13

154147111012

17

8

9

18

P5

P28J28

P16

J20P20

J20P20

J16

P16

J16

1

2

1

2

P32

J32

665 5

16 16

3 3

1 1

2 2

2

3

1

2

31

RD / BK(20)

BU / BK(20)

GN / BK(20)

3

2

1

J25

P25

P26

YL(26)

RD(26)

GN(26)

P27

2

1 3

P26

J27

YL(26)

RD(26)

GN(26)

BRIDGE

MICROSWITCH

MAGNET

N S

N S

MAGNET

GN(20)

BU(20)

RD(20)

PK

PK

IB JUMPER

THRESHOLD

SENSOR

232

3

11

OR / BK(20)

OR / BK(20)

OR(20)

OR(20)

GN / BK(20)

RD(20)

OR

BU(20)

GN(20)

2

1

2

1

NO

NC

C

BU(16)

BU(16)

BU(16)

RD

RD

BK

BK

GN

GN

WH

WH

BK

RD

WH

GN

MAGNET

LIFT POWER SWITCH

1

2

1

2

J15

P15

121

2

P15

J15

5

6

7 7

8

3

4

2

1 1

P13

BK / WH(20)

WH / BK(20)

PRESSURE

SWITCH

GN

YL(20)

OR(20)

VT(20)

BK

BU(20)

WH(20)

RD

ROTARY

POSITION

SENSOR

FLOOR LEVEL

MEMORY SET

PUSH BUTTON

COUNTER

GN

RD

VT(20)

J30

BK YL(20)

RD

POS.+

E

NEG. -

BU(20)

BK

WH(20)

GN

OR(20)

3

12

2

6

541

7

8

9

10

11

3122

65417891011

P3

C

E

F

C

DD

A A

BB

E

F

00000

C1

WH(20)

BK(20)

IB OCCUPANCY

MICROSWITCH

WH(20)

BK(20)

NO

NC

C

FUSE HOLDER(16)

NC

GN(20)

INTERLOCK

J21

8

9

P21

6

7

5

2

3

4

1

8

9

6

7

5

2

3

4

1

GY/RD(18)

BK(20)

BN(20)

BK(20)

WH(20)

WH(20)

BK(20)

RD(20)

FUSE HOLDER(16)

GN(20)

VEHICLE SECURE SIGNAL GY/RD(18)

LIFT STOWED SIGNAL YL/LT. BU(18)

LIFT NOT STOWED SIGNAL YL/LT. BU(18)

121

2

343

4

565

6

J31P31

C5

STOW INTERLOCK (+)

MICROSWITCH

NO

NC

C

GN(20)

WH(20)

BN(20)

C6

STOW INTERLOCK (-)

MICROSWITCH

NO

C

BN(20)

OR(18)

BK(18)

GN(18)

RD(18)

BU(18)

WH(18)

WH(18)

(+12V OUTPUT)

(GROUND)

(GROUND)

OR

(+12V INPUT)

ROTARY POSITION SENSOR

UP

DOWN

UNFOLD

FOLD

SWITCH BOX

L

G

LIFT

E

Page 17

Page 20

Lift Wiring Diagram

Unfold for:

Lift Electrical

Schematic

9-COND WIRE CODE

COLORNO.

NOT USED

1

2

NOT USED

3

NOT USED

NOT USED

4

5

LIFT NOT STOWED GROUND SIGNAL

GY / RD(18) VEHICLE SECURE +12V INPUT

6

7

LIFT STOWED +12V OUTPUT

8

NOT USED

9

LIFT STOWED GROUND SIGNAL

GY/RD(18)

VEHICLE SECURE SIGNAL +12V INPUT

32638A

(Located in cavity #5, #7 or #9 - see chart above)

YL/LT. BU(18)

LIFT STOWED / NOT STOWED SIGNAL

123

456

789

32639A

915-4530RNA

6-COND WIRE CODE

1

2

FUSE HOLDER(16)

3

4

5

6

9-COND WIRE CODE

1

2

3

4

5

6

7

8

9

Connection

J21P21

1

23

4

6

5

COLORNO.

BLACK(20)

GREEN(20)

WHITE(20)

BROWN(20)

NOT USED

GN(20)

Up/Fold

Solenoid

1

23

4

6

5

9

8

7

COLORNO.

NOT USED

NOT USED

NOT USED

NOT USED

BROWN(20)

GRAY / RED(18)

BLACK(20)

NOT USED

WHITE(20)

Interlock

BK(20)

Platform Lights (Option)

915-4539NA

J31

P31

321

546

6-COND WIRE CODE

COLORNO.

BLACK(20)

1

2

RED(20)

3

GREEN(20)

WHITE(20)

4

5

BROWN(20)

NOT USED

6

RL2

RL7

or

RL1

Connects to

Vehicle Battery

(+) Positive Post

Lead Wire

13362A

RD(2)

)

)81(KB

8

1

(KB

2

1

P20

J20

2

1

RD(20)

BK(20)

(31033A96)

NL915IB/FIB

NL918IB/FIB

(31033A99)

NL916IB/FIB

NL917IB/FIB

NL919IB/FIB

BK(20)

RD(20)

GN(20)

WH(20)

BN(20)

RD(14)

Pump Module

Power Feed

26082A-4

RD(4)

Note polarity of diode. It

must be oriented as shown.

Detail at left shows two different

styles of diode identification.

Circuit Sentry

(Circuit Breaker)

Bat.

B

A

T

Motor Power Feed Wire

A

U

Aux.

915-4534NA

Note: All wires 22 GA.

)81(KB

)81(KB

unless otherwise noted.

2

1

P20

J20

2

1

RD(20)

BK(20)

4

5A

3

3

0

1

3

P16

RD(20)

1

2

BK(20)

RD(20)

1

2

BK(20)

P16 J16

COM.

Stow Interlock (+)

COM

NO

N.O.

NC

Microswitch

C-H

N.C.

C5

COM.

Stow Interlock (-)

COM

NO

N.O.

NC

Microswitch

C-H

N.C.

C6

WH

OR

GN

WH

E

WH

G

BU

BK

RD

L

Switch

Box

Up/Down

Fold/Unfold

32832A

546

321

6-COND WIRE CODE

COLORNO.

RED

1

2

BLACK

3

WHITE

GREEN

4

NOT USED

5

NOT USED

6

J16

1

2

GN(20)

1

2

GY/RD(18)

Switch

Switch

Position

Sensor

In-Line

Fuse

RD(20)

BK(20)

WH(20)

Rotary

Floor Level

Memory Set

Push Button

FS5

P6

BN(20)

FS6

Lift Power

Switch

A

B

C

D

E

F

321

J9

J6

100245-001

A

BCDE F

6-COND WIRE CODE

COLORNO.

NOT USED

NOT USED

NOT USED

ORANGE(20)

YELLOW(20)

BLUE(20)

J30

FS20

VT(20)

WH(20)

FS21

65748

8-COND WIRE CODE

1

2

3

4

J7

P9

1

2

RD(14)

BK(20)

COLORNO.

RD / BK(20)

BU / BK(20)

WH / BK(20)

GN / BK(20)

J5

GN(20)

COLORNO.

NOT USED

5

6

NOT USED

7

NOT USED

BK / WH(20)

8

J13

J3

J4

Lift

Control

Module

J8

P13

P5

18-COND WIRE CODE

COLORNO.

RED / WHITE(20)

1

2

BLUE / WHITE(20)

3

GREEN / WHITE(20)

NOT USED

4

ORANGE JUMPER

5

ORANGE JUMPER

6

NOT USED

7

ORANGE(20)

8

ORANGE / BLACK(20)

9

P7

21

78910

12

11

COLORNO.

ORANGE(20)

BLUE(20)

NOT USED

NOT USED

WHITE(20)

VIOLET(20)

NOT USED

NOT USED

RED(20)

BLACK(20)

GREEN(20)

YELLOW(20)

123456

P4

P3

12-COND WIRE CODE

1

2

3

4

5

6

7

8

9

10

11

12

43

4-COND WIRE CODE

COLORNO.

NOT USED

1

2

RED(20) & GREEN(20)

3

BLACK(20) & WHITE(20)

BROWN(20)

4

985-4532NA

BK(20)

RD(20)

FS13 FS14

+

FS12

-

E

GN(20)

BK(20)

Counter

OR(20)

Beeper

FS1

+

-

FS9

FS8

GN(20)

GN(20)

Threshold

Warning

Light

FS5

OR(20)

GN(20)

FS17

YL(20)

FS16

Bridge

BK / WH(20)

WH / BK(20)

15161718

P8

915-4533NA

FS19

FS18

131214

11 1 0

214356789

COLORNO.

10

11

12

GREEN(20)

NOT USED

13

WHITE(20)

14

BLACK(20)

15

NOT USED

16

NOT USED

17

NOT USED

18

6-COND WIRE CODE

1

2

3

4

5

6

Bridge

Microswitch

Pressure

Switch

RED(20)

BLUE(20)

321

546

COLORNO.

OR(20) & OR(20)

YELLOW(20)

VIOLET(20)

BLUE(20)

BLACK(20)

PINK(20)

IB Occupancy

Microswitch

3-COND WIRE CODE

1

2

3

IB Jumper

Harness

COM

NO

NC

917-4535RNA-33 REAR PUMP LIFTS

917-4535FNA-33 FRONT PUMP LIFTS

.

M

OC

COM

NO

N.O.

4

NC

C-H

N.C.

C1

123

COLORNO.

PINK

NOT USED

PINK

3-COND WIRE CODE

1

2

3

32929A

J28 P28

31010FA

BU(16)

BU(16)

3-COND WIRE CODE

1

2

3

PK(20)

GN(20)

1

2

321

COLORNO.

YELLOW(26)

RED(26)

GREEN(26)

Interlock LED

FS4

FS7

BK(20)

WH(20)

321

COLORNO.

BLUE(20)

RED(20)

GREEN(20)

J25 P25

+

-

OR / BK(20)

1

2

OR(20)

123

3-COND WIRE CODE

COLORNO.

BLUE / WHITE(20)

1

2

RED / WHITE(20)

3

GREEN / WHITE(20)

VT(20)

Hydraulic

Pump

Ground

4L

R

Lift

Power Cable

205-0712-37

RD(2)

X

Power

Stud

BK(20)

GN(14)

Down

Dual

Relief

Bridge

RL3

BK(4)

22166A

Pump Ground

Back

Plate

FS3

GN(20)

(Side view of

solenoids removed

from pump.)

FS10

Down

Dual Relief

BU(20)

FS2

FS11

BK(20)

BK(6)

GN(20)

Outer Barrier

Raised Sensor

32645NA60

Outer Barrier

Latched Sensor

1

2

BK(24) COPPER

BK / WH(24) SILVER

P32J32

BK / WH(24) SILVER

BK(24) COPPER

1

2

P27

J26

123

3-COND WIRE CODE

COLORNO.

YELLOW(26)

1

2

RED(26)

3

GREEN(26)

Threshold Sensors

31221A

31221A

J27

P26

321

3-COND WIRE CODE

COLORNO.

BLUE / BLACK(20)

1

2

RED / BLACK(20)

3

GREEN / BLACK(20)

RD

BKGNWH

1

2

P15J15

1

22

BK(24 GA COPPER)

BK / WH(24 GA SILVER)

2

J15P15

BK / WH(24 GA SILVER)

1

1

BK(24 GA COPPER)

Page 18

Page 21

Hydraulic Schematic

Opposite

Pump

Cylinder

Orifice

1900

PSI

BACKUP

PUMP

Down

Valv e

PUMP

Bridging

Valve

.50 GPM

Lifting

Relief Valve

2500

PSI

M

Secondary

Valve

Folding

Relief Valve

800

PSI

Roll Stop Fold

Pressure Switch

Outer Barrier

Cylinder

Orifice

Pump Side

Cylinder

Description Symbol Description Symbol

Fixed Displacement

Pump

Pump Motor

Backup Pump

Single Acting Cylinder

Check Valve

Unfold Orifice

Manual

Shutoff Valve

M

Hydraulic Port

2 Way 2 Position

Solenoid Valve

Pressure Compensated

Flow Control

Relief Valve

Filter Screen

Vented Reservoir

Orifice

Pressure Switch

Page 19

Page 22

Hydraulics Parts List

Part Numbers of Items Dedicated per Lift Model (Front and Rear Pump Models)

Item Qty. Description NL915 NL916 NL917 NL918 NL919

1 1 Hose Assembly, 1/8” (Opposite Pump Side) 16004A-081 16004A-079 16004A-086 16004A-084 16004A-087

2 1 Hose Assembly, 1/8” (Pump Side) 16004A-046 16004A-046 16004A-046 16004A-046 16004A-046

3 2 Cylinder ✓

4 1 (Rear Pump)

5 1 (Front Pump)

6 1 (Front Pump)

Hose Assembly, 3/16” w/Two Guards

Hose Assembly, 3/16” w/Two Guards 915-5602-82 915-5602-92.5 915-5602-92.5 915-5602-82 915-5602-92.5

Hose Assembly, 3/16” 915-5603-80.5 915-5603-83.5 915-5603-86.5 915-5603-83.5 915-5603-86.5

Part Numbers of Items Identical on all Lift Models (Front and Rear Pump Models)

Item Qty. Description Part No.

7 1 Pump Assembly (M268-0113)12V - with Reservoir/with Backup Pump) 31038-12V

8 1 Solenoid, Up - 4-Post - Trombetta (Flat Mount) 31374

9 1 Power Cable, Up Solenoid to Motor 29049

10 1 Motor, Pump - 12 Volt - Low RPM 31350

11 1 Elbow, 65° - Male 7/16-20 SAE O-Ring to 7/16-20 SAE O-Ring Boss 26578

12 2 Valve Assembly, “Down / Bridge” (complete) 31348K

13 3 Coil (only), “Down / Bridge” Valve - (shown below) 31122

14 2 Cartridge (only), “Down / Bridge” Valve - (shown below) 26078

15 1 Valve Assembly, “Duel Relief” (complete) 31120K

16 1 Cartridge (only), “Duel Relief” Valve - (shown below) 31121

17 1 Cap, Reservoir Filler 16935

18 4 O-Ring (only), Hand Pump Mounting 17351

19 1 Hand Pump (Backup) with O-Rings (Item 18) 26074

20 3 Screw, 1/4-20 x 2-1/4”, Allen Head 26080

21 1 Clamp, Reservoir - H-48 (M259) 17069

22 1 Reservoir, Hydraulic Fluid 16934

23 1 Fitting, 90° - 1/8” NPT x 1/8” Barb - Plastic 87563

24 1 Switch, Pressure, 7/16-20 SAE O-Ring Male 31199

25 2 Fitting, Male 7-16-20 SAE O-Ring to Male 7/16-20 JIC 37° 24504

26 1 Elbow, (1) Female 7/16-20 JIC 37 Swivel - (2) Male 7/16-20 JIC 37° 26579

27 2 Elbow, 90°, 7/16-20 SAE O-Ring Male - 7/16-20 JIC 37° Male, Orifice 26667

28 2 Elbow, 90°, 1/4” NPT Male to 1/4” Barbed 15150

29 1 Hose, Thermal Plastic - Black, 1/8” I.D. 23742R*

30 1 Connector, Plastic “Y”, 1/8” O.D. 18877

31 1 Fitting, 90° - Male 9/16-18 SAE O-Ring to Male 7/16-20 JIC 37° 87622

32 1 Cylinder, Roll Stop (915-3318NA Contains Items 31,32 &35) 25309NA

33 1 Handle with Grip 17206A

34 1 Diode Assembly, Up Solenoid 73906A

35 1 Breather Vent, 1/4” NPT 26200-2

36 1 Kit, Hydraulic Port Service Cap 27049K

C1514.3-9407 C1514.3-9408 C1514.3-9408 C1514.3-9407 C1514.3-9408

915-2601-123 915-2601-139 915-2601-139 915-2601-123 915-2601-139

✓ Seal Kits: If repairing a cylinder, order Seal Kit #1500-0500P.

* Raw material items ordered and priced per inch (order specified length).

Hydraulic Fluid

When adding or changing

hydraulic fluid, use Braun

32840-QT (Exxon® Univis

HVI 26) hydraulic fluid (do

not mix with Dextron III or

other hydraulic fluids).

Page 20

“Down and Bridge”

12

Valve (complete)

13

Coil

#31122

14

Cartridge

#26078

15

Cartridge

“Duel Relief”

Valve (complete)

13

Coil

#31122

16

#24612

Page 23

Hydraulics Diagram

7

36

3

Hydraulic

Repair

For repair of a

hydraulic hose

or cylinder, read

this.

Service

Bulletin

27049

9

3

6

FRONT PUMP

27

33

25

17

18

19

20

Manual

Backup

Pump

23

Opposite Pump Side Cylinder

28

34

10

22

29

21

Hydraulic

Pump

30

5

4

8

24

11

12

27

32

FRONT PUMP

REAR PUMP

15

31

25

Roll Stop Cylinder

35

26

1

2

Pump Side Cylinder

28

29

29

Page 21

Page 24

Pump Module Parts List

NL915IB, NL916IB,

Part Numbers of Items Dedicated per Lift Model

Item Qty. Description

1 Pump Module (complete), 12 Volt, Rear 917-5516RNA 917-5516FNA

1 1 Plate, Backing / Mounting - Rear 985-2501RN 985-2501FN

2 1 Cover, Pump, 2-Piece - Back / Bottom

3 1 Cover, Pump - 2-Piece - Top / Front

Part Numbers of Items Identical on all Lift Models

Item Qty. Description Part No.

4 1 Pump Assembly (M268-0113) 12V-120G - Dual Relief / ARS (Includes Items 5 & 6) 31038-12V

5 1 Power Cable, Up Solenoid to Motor 29049

6 1 Solenoid, Up - 4-Post - Trombetta (Flat Mount) 31374

7 1 Diode Assembly, Up Solenoid 73906A

8 2 Nut, #10-32, Serrated Flange 83080

9 2 Fitting, Male 7/16-20 O-Ring to Male 7/16-20 JIC 37° 24504

10 1 Elbow, Female Swivel 7/16-20 JIC 37° to (2) Male 7/16-20 JIC 37° 26579

11 1 Switch, Pressure 31199

12 1 Control, Hand Pendant Assembly (See below for available options)

12a - Control, Hand Pendant Assembly - Non-Shielded Cable - Straight tSee note below 32832A

12b - Control, Hand Pendant Assembly - Shielded Cable - Straight tSee note below 32833A

12c - Control, Hand Pendant Assembly - Shielded Cable - Coiled tSee note below 32421A

13 1 Control Board Assembly 100159-001

14 8 Standoff, Snap-In 31011

15 1 Switch, Push Button 31753

16 1 Recepticle, Clip On 28803

17 1 Lens, Threshold Warning - Red 30704

18 1 Decal, Warning / Pressure Relief Valve (Not shown) 22249

19 1 Spacer, Lens - NHTSA 31386

20 1 Metal Ring Base - Lamp 30971

21 1 Socket, Lamp 30703

22 3 Screw, #8-32 x 1/2” Pan Head Phillips - Thread Cut 30974

23 1 Bulb, Light 19841

24 1 Diode, Green LED, Panel Mount 29545

25 4 Rivet, Snap - .124” Hole x .197”/.236” Thick 29874

26 2 Washer, 5/16” Flat 10063

27 2 Bolt, 5/16-18 x 3/4”, Nylock, Hex * See note below 29608

28 2 Bolt, 5/16-18 x 1/2”, Nylock, Hex * See note below 10012

29 1 Cable, Ground 22166A

30 1 Washer, 5/16” External Tooth 16368

31 1 Beeper, Constant - High Output 33251

32 1 Switch, Toggle 31787

33 1 Decal, Lift Power - On/Off (Not shown) 21494

34 1 Stud, Power Feed 26084

35 1 Rubber Boot, Red tSee note below 82046

36 1 Harness, Lift Interlock Connection 32639A

37 1 Wire Assembly, Lift Stowed Connection tSee note below 32638A

38 1 Pump Handle with Grip 17206A

39 3 Rivet, Pop, SD43BS - 1/8” - .13”/.19” 12954

40 1 Plug, Window - Clear 30443

41 1 Stud, Wing Head - 1/4 Turn 28804

42 1 Retainer, Push On 28805

43 1 Washer, Nylon, 1/4” I.D. x 11/16” O.D. x .030” 12690

44 1 Clip, Pump Handle - Top 915-5517

45 1 Clip, Pump Handle - Bottom 915-5518

46 1 Decal, Manual Instructions - Public (Not shown) 31412

47 1 Decal, Removal / Installaton - Pump Cover (Not shown) 29051

48 1 Decal, Warning - Control Board Damage - ESD (Not shown) 30787

49 1 Decal, Removal / Installation Pump Handle (Not shown) 29052

50 1 Decal, Installation & Warning - Hydraulic Pressure Switch (Not shown) 27154

51 1 Decal, Dual Relief Adjustment (Not shown) 32201

52 1 Decal, LCD Lift Codes (Not shown) 32410

53 1 Cable, Pump Module Power Hookup (Not shown - see Wiring Diagram) 26082A-4

54 1 Harness, Power - Stow Interlock (Not shown - see Wiring Diagram) 915-4530RNA

55 1 Harness, Interlock / Lighting (Not shown - see Wiring Diagram) 915-4533NA

56 1 Harness, Up / Down Solenoid (Not shown - see Wiring Diagram) 915-2533NA

57 1 Harness, Threshold Switch Extension (Not shown - see Wiring Diagram) 915-4534NA

58 1 Harness, Hand Control - Pump Housing to Circuit Board (Not shown - see Wiring Diagram) 100245-001

(915-0513RNAPT or 915-0513FNAPT Includes Items 2 and 16 - 22)

(915-0519RNAPT or 915-0519FNAPT Includes Items 3 and 39 - 52) 915-0519RNPT 915-0519FNPT

NL917IB, NL918IB

and NL919IB

915-0513RNPT 915-0513FNPT

NL915FIB, NL916FIB,

NL917FIB, NL918FIB

and NL919FIB

* Apply red #271 Thread Locker Loctite® to the four hex bolts (items 27 and 28) if a blue nylon patch is not present on

the bolts when retrofitting an M268-0113 pump assembly. Loctite® is available from The Braun Corporation under part

number 11522-1.

t Indicates items available for replacement part purposes only. These items are not included with replacement pump

modules.

Page 22

Page 25

Pump Module Diagram

Pump Mounting Bolts

Apply red #271 Thread Locker Locktite®

to the three pump mounting bolts (items

27 and 28) if a blue nylon patch is not

present on the bolts when retrofitting an

M268 pump assembly. Loctite® is

available from The Braun Corporation

under part number 11522-1.

12a

9

1

N

8

2

3

DOW

UP

LD

FO

UN

0

2

8

32

®

FOLD

12b

9

1

N

8

2

3

DOW

P

U

LD

NFO

U

D

20

8

2

3

®

FOL

12c

UNFOLD

OLD

F

DOWN

UP

3

5

3

2

3

43

40

39

41

44

42

38

3

45

39

17

23

19

24

20

2

16

22

21

13

14

27

26

28

29

15

30

31

32

1

4

28

9

5

25

35

34

11

8

37

36

7

6

9

8

10

Note: Rear pump shown,

front pump mirror image.

Page 23

Page 26

42” Floor-to-Ground Lift Repair Parts List

Part Numbers of Items Dedicated per Lift Model

Item Qty. Description NL915IB NL915FIB NL918IB NL918FIB

1 1 Base Weldment 915R5142NW30 915F5142NW30 918R5142NW33 918F5142NW33

2 1 Cover, Pump, 2-Piece, Back-Bottom 915-0513RNPT 915-0513FNPT 915-0513RNPT 915-0513FNPT

3 1 Cover, Pump, 2-Piece, Top-Front Assy. 915-0519RNPT 915-0519FNPT 915-0519RNPT 915-0519FNPT

4 1 Platform Weldment 917-53050NW 917-53050NW 917-53350NW 917-53350NW

5 1 Outer Barrier Assembly (inc. 5,14,22,51,168) 915-0312NA30Y 915-0312NA30Y 915R4312A-33Y 915R4312A-33Y

6 1 Inner Rollstop 918-0147NWY-30 918-0147NWY-30 915-0312NA33Y 915-0312NA33Y

7 1 Bridge Switch Assembly 31010FA 31010FA 31010FA 31010FA

8 1 Plate, Backing/Mounting 985-2501RN 985-2501FN 985-2501RN 985-2501FN

9 1 Base Cover (Traction Tape Not Shown) 915-5142CNA30Y 915-5142CNA30Y 915-5142CNA33Y 915-5142CNA33Y

10 1 Parallel Arm Assy., Bottom, w/Bearings - Rear 915-4457NA 915-4456NA 915-4457NA 915-4456NA

11 1 Parallel Arm Assy., Top, w/Bearings - Front 915-0422FA 915-5422FNA 915-0422FA 915-5422FNA

12 1 Parallel Arm Assy., Top, w/Bearings - Rear 915-5422RNA 915-5422RA 915-5422RNA 915-0422RA

13 1 Parallel Arm Assy., Bottom, w/Bearings - Front 915-4458NA 915-4455NA 915-4458NA 915-4455NA

14 1 Rubber Nose 24603-30 24603-30 24603-33 24603-33

Part Numbers of Items Identical on All Lift Models

Item Qty. Description Part No.

15 1 Block, Platform Stop 25778

16 1 Block, Platform Stop 900-0311

17 4 Snap-Ring 5/16" 24570

18 4 O-Ring, 5/16" I.D. x 1/16" O.D. 26614

19 2 Screw, Socket Head, 3/8-16 x 1/2" with 1/2" Shoulder 25929

20 2 Grommet, I.D. .281"/ FR.125" x GD.625"/T.375" 27725

21 1 Pivot, Outer Barrier Lever 24550

22 2 Rivet, Pop, 3/16" x .06"/.13" 11512

23 1 Stud, Wing Head 28804

24 1 Retainer, Push-On 28805

25 1 Grommet, ID .312", FR .250", GD .813" T500" 27726

26 1 Pump Assembly 31038-12V

27 10 Pin, Pivot, Parallel Arm 917-0403

28 10 Screw Drive #8 x 3/16" Long Black 31086BK

29 1 Receptacle, Clip-On 28803

30 1 Cylinder Assy., Outer Barrier 915-3318NA

31 4 Snap-Ring 1/2" 13273

32 1 Latch, Outer Barrier Assy., w/Magnet 915-4343NA

33 2 Bolt, 5/16-18 x 1/2" Nylock, Hex 10012

34 2 Washer, 5/16" Flat 10063

35 2 Bolt, 3/8-16 x 1/2" Nylock, Hex 29729

36 1 Assembly, IB Occupied 32642A

37 1 Assembly, Rotary Position Sensor 31094A

38 2 Bolt, 5/16-18 x 3/4" Nylock, Hex 29608

39 1 Rivet, Pop, SD68 BSLF-3/16" - .38"/.50" 15244

40 5 Rivet, Pop, 1/8"- .25"/.31" 13906

41 4 Bearing, Flange, 1/2" x 1/4" 24442

42 1 Weldment, Latch, Lift/Tite, Rear 27013RW

43 1 Weldment, Latch, Lift/Tite, Front 27013FW

44 2 Screw, #4-40 x 5/8", Round Head 14810

45 2 Screw, 1/4-20 x 3/4", Flat Head, Countersink 28986

46 1 Screw, #8-32 x 1", Mach. Truss Head 19912BK

47 2 Nut, #4-40 w/Lockwasher 19537

48 2 Nut, #8-32, Hex 10777

49 1 Bag, Vinyl - 7" x 10" 31174

50 2 Cylinder, 14.625"/29.146" Retracted C1514.3-9408

51 1 Screw, 10-32 x 5/8" Pan Head Phillips, Thd. Cut 26714

52 4 Washer, 1/4" External Tooth 83588

53 1 Clamp, 5/8" Closed Insulated 84070

54 1 Vertical Channel Weldment, Front, 42" 918-0442FNW

55 1 Cover, Plastic, Parallel Arm, O/S Front-w/Tape 915-0704NA

56 2 Tape, 1" Wide S-Face Foam, x 14" (1 Shown) 82015R014

57 6 Tape, 1" Wide S-Face Foam, x 10" (3 Shown) 82015R010

58 1 Cycle Counter-LCD Without Reset 30547

59 2 Handrail Weldment 985-4618NW

60 8 Rivet, Push In - 8MM 30063

61 4 Bumper, Rubber, 31/32" O.D. 10950

62 2 Screw, #8-18 x 1/2", Self-Tap, Phillips 13583

63 2 Bulb, Light 20-W, Halogen Reflector 31060

64 2 Nut, #10-32 w/Lockwasher 18349

65 2 Screw, 1/4-20 x 3/4", Button Head, Socket Cap 81068-000

66 6 Washer, 3/8" Flat, Black 10064

67 4 Nut, 3/8-16, Hex Lock 13617

68 2 Cotter Pin, 1/4" x 2", Black 15886BK

69 4 Nut, 1/4-20 Hex Lock 10775

70 1 Cover, Plastic, Parallel Arm, I/S Front-w/Tape 975-0701NA

71 2 Threshold Strip Switch 31221A

72 2 Bolt, Shoulder, 5/16" x 5/8"-1/4-20 31816

73 10 Washer, .516" I.D. x 1" O.D. x .0269", Auto BK 15328

74 10 Washer, 1/2" Flat Black Zinc 25346

75 2 Bolt, 3/8-16 x 1", Hex 10025

76 2 Washer, 3/8", Lock, Black 10069BK

77 2 Lever, Inner Rollstop 985-0404N

78 4 Clamp, Insulate, 1 3/8" I.D. 29765

79 2 Washer, 5/16" Lock, Black 10068

80 2 Gas Spring, Fold Arm 29186

81 2 Ball Stud, Gas Spring, 13MM x 3/8-16 F. Thread 29185

82 2 Washer, 3/8", Lock 10069

83 1 Spacer, Flap Cylinder .184" Thick 915-0416

84 2 Clip, Safety, 3/8-16 x 3/4", Flange 12608

85 6 Bolt, 3/8-16 X 3/4", Flange Button Head, Socket Cap 25171

86 2 Bolt, 5/16-18 x 2", Flange, Hex 25130

87 2 Nut, 5/16-18, Serrated Flange 25131

88 2 Arm, Slide Support (Replace In Pairs) 985-6612N

89 2 Slide, Platform, Rotate, Weldment 915-0606N

90 2 Spacer, .5" O.D. x .334" I.D. x 1.515" LG 25132

91 10 Bearing, Flange, 3/4" x 1/4" 24012

92 2 Weldment, Platform Pivot Arm - 42" (Replace In Pairs) 918-2640NW-BKN

93 2 Pin, Pivot, Lower Arm 900-0413N

94 6 Ring, Snap, 3/4", External 18657

95 2 Bearing, UHMW, Flat, 1.226" 205-1760

96 2 Ball Stud, 10MM 21301

97 1 Vertical Channel Weldment, Rear, 42" 918-0442RNW

98 6 Plastic End Cap, 1" I.D. x 1 1/4" O.D. 20474

99 2 Grip, Handle, Yellow 19074

Item Qty. Description Part No.

100 2 Spring, Dampener, Retract 26963

101 2 Bolt, 5/16-18 x 1 1/4" Low Socket Hd., Cap, Bk. 26327

102 2 Bumper, 1" x 1/2" Long 33654

103 2 Screw, 1/2-20 x 1 1/2" Set Lock, Black 18663

104 2 Block, Guide-Platform Stow 28593

105 2 Pin, Platform 975-2325

106 10 Screw, 5/16-18 x 3/4", SHFS 25527

107 2 Spacer, UHMW, Vertical Channel 995-0320

108 1 Position Sensor Collet 31093

109 2 Bracket, Mounting, Quiet Ride 915-0392

110 2 Gas Spring, 12.2" Extended/8.3" Compressed 30550A

111 2 Bolt, 5/16-18 x 3/4", Carriage, Black 15858BK

112 3 Washer, 5/16", External Tooth 16368

113 4 Nut, 5/16-18 Hex 10058

114 2 Bracket, Inner Side Panel Guide 915-0703

115 3 Bearing, UHMW, Flat, Thin, Black 916-5406

116 2 Pivot, Inner Rollstop Lever, Upper, Inside 916-5433

117 4 Bearing, Flange - 3/4" x 1/2" 24027

118 1 Spacer, UHMW, Latch 950-7760

119 1 Spring, 1/4" x 1" Extension w/Hooks 10774

120 1 Tubing, Polyurethane - 1/4" I.D. x 1/2" O.D. x .81" 28630R000.81

121 2 Pin, Clevis, 3/8" x 3", Black 24932BK

122 1 Pin, Platform Cylinder 915-0414

123 2 Ring, Snap, 1/2", External, .035" Thick 20946

124 1 Weldment, Tube-IB Fold Arm-Front 918-0625RNW

125 1 Lever, Outer Barrier Latch (Assembly #915-0345A) 915-0345

126 4 Nut, 3/8-16, Hex Lock Jamb 20926

127 1 Weldment,Tube-IB Fold Arm-Rear 918-0625FNA

128 1 Pivot, Outer Barrier Cylinder, Front 990-0352

129 2 Bolt, 5/16-18 x 1 1/2" Hex Head, Cap 10014

130 2 Bolt, 7/16-20 x 1", SHCS, w/Nylock Patch 28474

131 2 Screw, #10-32 x 3/8", Flat Head, Hex 24537

132 3 Adapter, Cylinder/Outer Barrier Lever-Out 990-0341

133 2 Bolt, 5/16-18 x 3/4", Button Head, Soc Cap Hd 24440

134 7 Rivet, Pop, 3/16"-.25"/.38", Black 14993

135 1 Adapter, Cylinder/Outer Barrier Lever 915-0341N

136 1 Harness, Sensor - Cherry w/Plug 32645NA60

137 4 Screw, #4-40 x 1/4" Phillips Head 11480

138 11 Clip, Cable, 1/2", Plastic 10092

139 2 Nut, 5/16-18, Top Lock, Black 28324BK

140 2 Bolt, 1/4-20 x 1/2", Button Head Socket 15733

141 2 Bolt, 3/8-16 x 2", Hex Head, Cap 10027

142 2 Roller Assembly 1000-2395A

143 2 Roller Retainer 915-5353

144 2 Nut, 5/16-18 Hex, Lock 11387BK

145 2 Pivot, Inner Rollstop Lever, Upper-Outer 916-5434

146 6 Clamp, 1/4" I.D.- Nylon Loop 84396

147 3 Washer, #10, Flat, Auto BK 11541

148 18 Rivet, Snap, .201" x .256"/.295" 26362

149 4 Bearing, Flange, 1" x 1/2-16 FDU08 28031

150 1 Cover, Plastic, Parallel Arm, O/S Rear-w/Tape 915-0702NA

151 1 Weldment, Inner Rollstop Bracket, Front 985-0431FNW

152 4 Spacer, Handrail, .375” Thk. UHMW 995-0301

153 2 Washer, .516" I.D. x .75" O.D. x .250", Black 25336

154 1 Cover, Plastic, Parallel Arm, I/S Rear-w/Tape 975-0703NA

155 1 Weldment, Inner Rollstop Bracket, Rear 985-0431RNW

156 2 Spring, Torsion - .366 I.D. x .05" 30386

157 4 Spacer, IB Lock 30394

158 2 Weldment, IB Lock 985-0630NW

159 4 Bearing, 3/8" I.D. x 1/2" Long 30405

160 4 Roller, .65" O.D. x 1/2" Long 985-0631N

161 4 E-Clip, 3/8" Shaft 84383

162 2 Spacer, Handrail, .230" Thk. UHMW 911-5301

163 1 Adapter, Cylinder/Outer Barrier Lever 915-0344

164 1 Harness, Sensor - Magnetic w/Plug - 15" 30433A15

165 6 Rivet, Pop, 3/16" - .13/.25" - SD64BS 11513

166 2 Bearing, Flange, 3/8" x 1/4" - Plastic 24028

167 2 Light Assy, Vertical Channel 31062A

168 1 Tab, Outer Barrier, Flap Cylinder 915-6367NA

169 1 Washer, .4" I.D. x .810" O.D. x .12" 24536