Page 1

Braun Corporation FMVSS No. 403 Quick Reference Installation Sheet 31312

2-3/4"1-7/16"

r

o

o

D

g

n

i

w

S

r

a

e

R

r

o

o

D

g

n

i

w

S

t

n

o

r

F

Wall

Floor

Wall

(ALIGNED) PARALLEL (ALIGNED)

Stepwell

Floor

Inboard

Locator

"RAUN#ORPORATION&-633.O

1UICK2EFE

OEM (

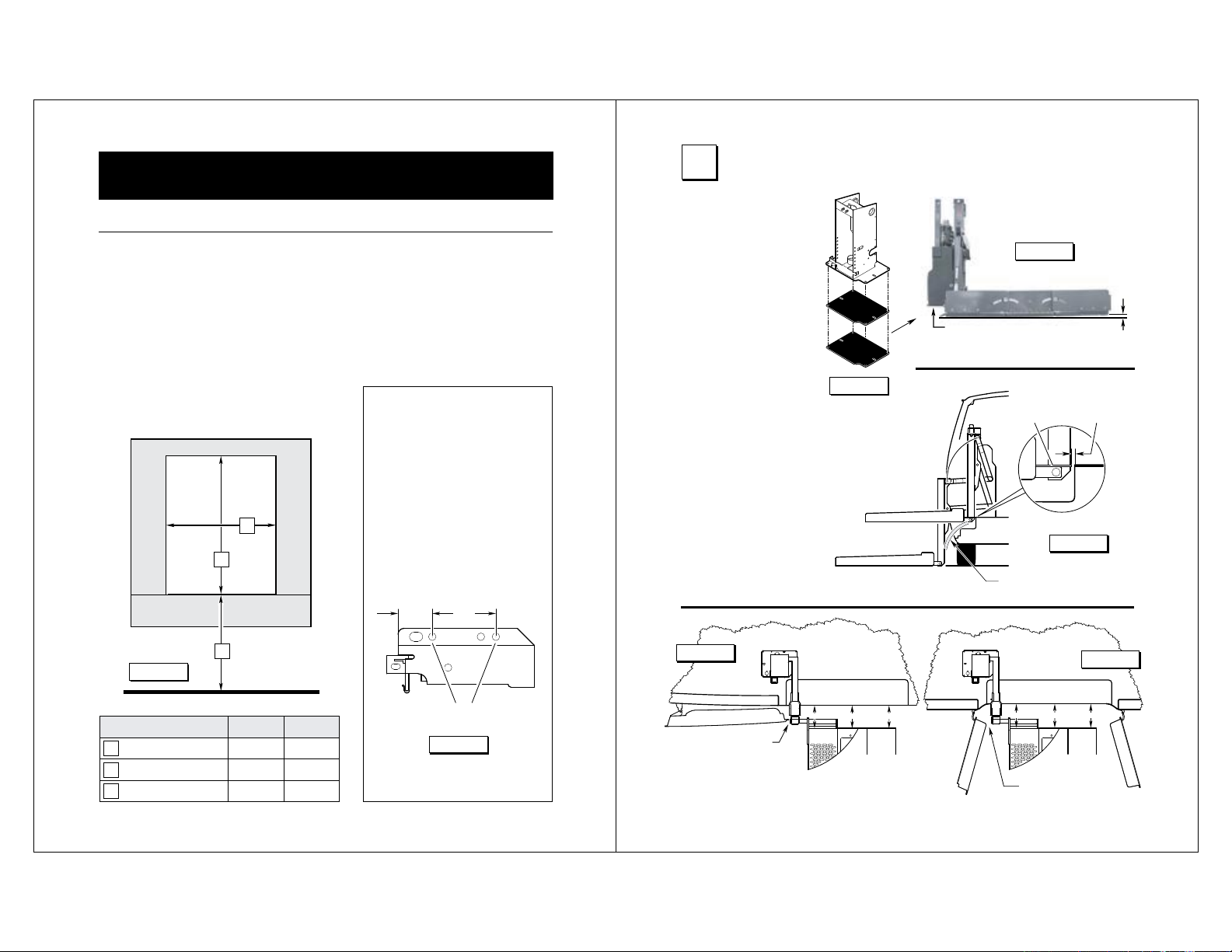

Van) Chassis Floor Requirements

Nonmodi

fied OEM full size van floors meet

all requirements for Vangater II. Nonmodified OEM mini van floors meet all requirements for Mini Vangater II.

Door Opening Dimensions

Vehicle lift access door opening

must meet specified dimensions.

Vehicle

Door

Opening

RENCE)NSTALLATION3HEET

h$/40RIVATE5SE,IFTv

.(43!6EHICLE0HYSICAL2EQUIREMENTS

B

A

Lowered (Drop) Floor Requirements

Must meet or exceed nonmodi

OEM floor section.

fied

“1992” and Newer Ford Slide Door

1. Remove the lower slide door stop.

2. With

Power Door: Door stop not

used.

Without

Power Door: Drill (2) holes

in the lower door stop at dimensions

shown in Figure B.

3. Replace

door stop, locating on the

(2) drilled holes (provides adequate

clearance).

0OSITION,IFT

1

Place lift in approximate

position. Note: Hoist

or other lifting device is

recommended.

Position wedge plate(s)

to achieve a 1/2" preload at right inboard

corner of platform. See

Figures C and D.

Clearances

Minimum 1" clearance

between lift and vehicle.

See Figure E.

Maximum 1/2" between

inboard locator and

when locator is deployed.

See Figure E.

Minimum 3/4" clearance

between door and vertical arm. See Figures F

and G.

floor

e

m

ar

F

e

b

u

T

W

e

d

P

g

l

e

a

t

e

W

e

d

P

g

l

e

a

t

e

&IGURE#

&IGURE$

Position wedges as

needed for 1/2" preload.

Minimum 1" Clearance

Maximum

1/2"

&IGURE%

1/2"

C

&IGURE!

Ground Level

Drill (2) 5/16" diameter holes.

Dimen- Minivan Full Size

Minimum Clear

A

Clear Door Opening

B

Maximum Floor-to-

C

42"

31-1/2"

29"

48"

39-1/2"

29"

&IGURE"

&IGURE&

Slide Door

Minimum 3/4"

Wall

Clearance

Floor

(ALIGNED) PARALLEL (ALIGNED)

Minimum 3/4"

Clearance

&IGURE'

Page 2

Docking

Bumper

Outer Pivot

Platform

Docking

Bumper

Stepwell

Floor

Trim

5/16" Flat

Washer

3/8" Lock

Washer

3/8-16 Hex Nut

3/8-16 x 2"

Hex Bolt

(Qty: 2)

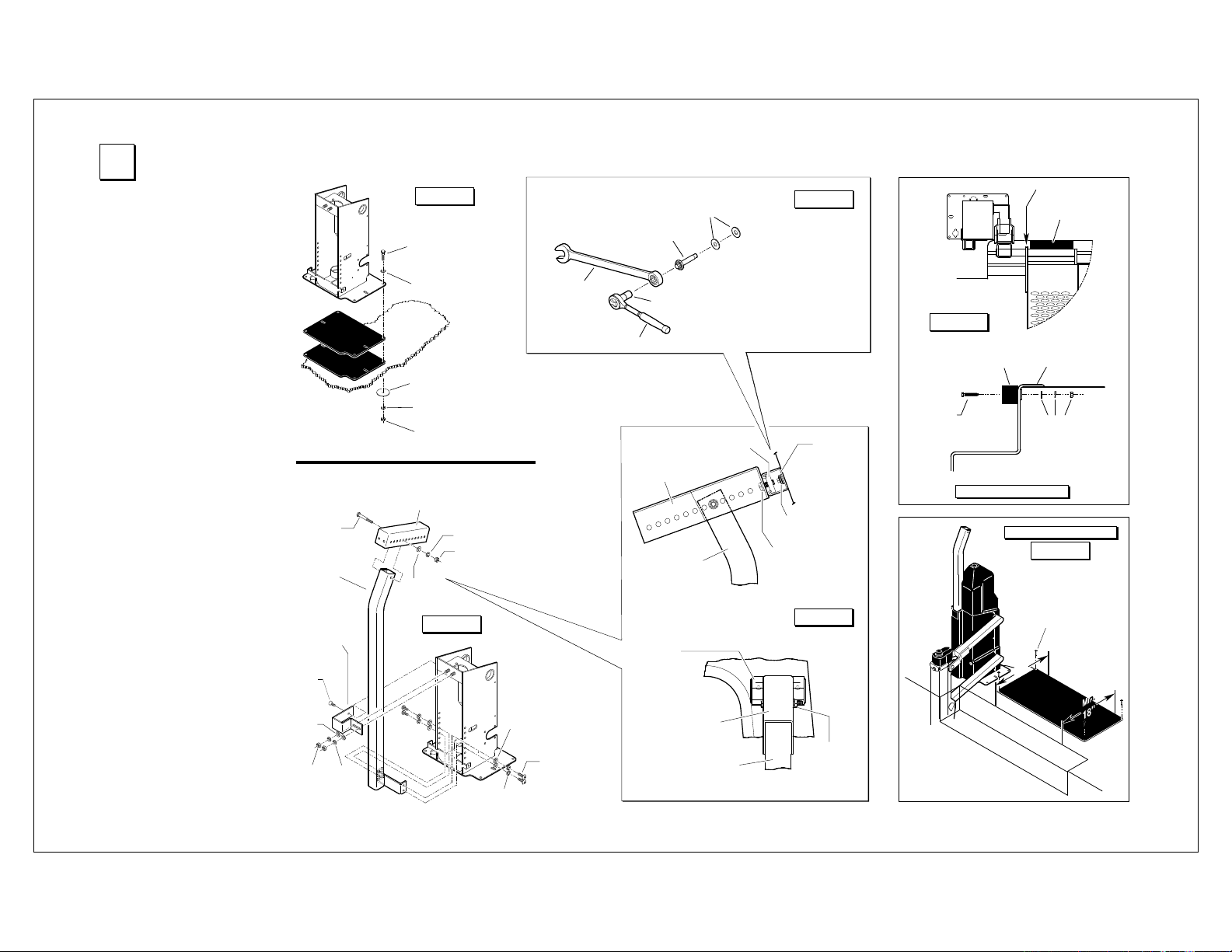

3ECURE,IFT

2

1. Temporarily secure base plate by

installing sheet metal screws in

base plate slots.

2. Secure vertical mounting brace

and upper mounting bracket to

frame tube. See Figure I.

3.

Temporarily assemble upper ad

justment bracket and upper mount

ing channel. See Figure K. Position assembly and mark mounting

holes on van wall (C pillar).

Carefully drill 5/16" diameter wall

mounting holes. Secure upper

mounting channel to wall (C pillar)

using expanding Fab-Lock bolts

(minimum 2). See Figure J.

4. Secure upper adjustment bracket

and upper mounting channel assembly to vertical mounting brace.

5. Carefully operate lift through all

functions checking for clearances

(specified in Figures D-I).

lift position and/or upper mounting

hardware as needed.

6. Drill 3/8" diameter holes through

floor using the corner holes in the

base plate as a template. Refer to

Figure H. Insert 3/8"-16 hex bolts

and secure below

fied in Figure H (bolt lengths as

required per application).

Tighten all mounting hardware

securely.

FMVSS 571.403 Section 6.3.

7. Cut upper adjustment bracket off

flush with mounting brace and

install foam padded cover using

cable ties. Note: Cover power

unit before cutting bracket.

8. Position and secure docking bum

per. See Figure L.

9. Position and secure warning sen

sor mat as specified in Figure M.

Connect wiring harness to lift as

shown in Figure

Braun Corporation FMVSS No. 403 Quick Reference Installation Sheet 31312

-

Adjust

floor as speci-

All fasteners must meet

P.

-

-

-

Position

wedges

as needed.

All Positions

3/8-16 x 3"

Mounting

5/16-18 x 3/4"

Flat Head

Screw

5/16"

Flat

Washer

5/16"

Hex

Nut

P

P

Hardware

Typical

Hex Bolt

Vertical

Brace

Upper

Mounting

Bracket

Washer

W

l

a

t

W

l

a

t

5/16"

Lock

&IGURE(

• One in each corner.

• Lengths as required

o

o

l

F

Adjustment

Bracket

5/16" Flat

Washer

e

c

a

r

B

g

n

i

t

n

u

o

M

l

a

c

i

t

r

e

V

3/8-16 Hex Bolt

(Minimum 4)

per application.

Washer

5/16" Flat

r

3/8" Body Washer

3/8" Lock Washer

3/8-16 Hex Nut

Upper

3/8" Lock

Washer

3/8" Hex

&IGURE)

Nut

e

m

a

r

F

e

b

u

T

5/16" Lock

Washer

5/16" Flat

Washer

e

m

a

r

F

e

b

u

T

e

d

g

e

e

e

d

g

e

e

Fab-Lock Bolt Installation

1. Remove rubber

washer and install

1/4" flat washers.

5/8" Wrench

3. Place a 5/8"

wrench onto

bolt head and

secure tightly

Hardware

typical

opposite side

5/16-18 x 7/8"

Button Head

Cap Screw

1/4" Flat

Fab-Lock Bolt

5/16" Socket

Ratchet Wrench

Upper

Adjustment

Bracket

Vertical

Mounting

Brace

Note: Cut bracket o

mounting brace and install foam

padded cover using cable ties.

Upper

Mounting

Channel

Adjustment

Bracket

Washers

2. Insert Fab-Lock bolts (minimum

2) fully through mounting channel

r.

and C pilla

4. Place a 5/16" socket onto the inner

screw and tighten (turn clockwise).

Turn socket until Fab-Lock has

5.

expanded against metal surface.

3/8-16 Slide Nut

Fab-Lock Bolt

3/8-16 x 1"

Hex Cap Screw

Lock

(Qty: 2)

ff flush with

Wall (C Pillar)

Upper

Vertical

Mounting

Brace

&IGURE*

Upper

Mounting

Channel

with

Washer

RE+

&IGU

3/8-16 x 3"

Hex Bolt

with

Lock

and Hex Nut

Washer

&IGU

RE,

Docking Bumper

E

d

g

e

o

Threshold Warning

&IGU

#10-16 x 1-1/2"

Wafer Head Phillips

Self-Drilling Screw

(Qty: 4)

.

n

i

M

"

8

1

T

h

r

e

W

s

a

r

n

i

n

f

g

F

i

n

i

s

h

e

d

F

l

o

RE-

h

o

o

l

d

r

Page 3

Braun Corporation FMVSS No. 403 Quick Reference Installation Sheet 31312

s

i

s

s

a

h

C

R/YG

UB .TL/Y

KB

NB

W

K

B

Cut

wire.

Install butt

connecto

r.

Threshold

Warning

Sensor Harness

Door Cut-Out

Switch Harness

Connect vehicle

interlock signal wires.

Disconnect

and discard.

R

/

Y

G

)

l

a

n

g

i

S

e

r

u

c

e

S

e

l

c

i

h

e

V

(

)

l

a

n

g

i

S

d

e

w

o

t

S

t

f

i

L

(

U

B

.

T

L

/

Y

KB

Y

G

F1

R17

+

C7

+

U11

+

C1

C53

R64

U8

W9

J8

4

3

2

R73

1

J5

29

18

7

R43

R32

1

21W

R28

2

1

D14

C19

C17

R37

1

W20

R5

R63

1

K5

1

U7

R20

R59

C54

D12

D1

Q6

C43

Q4

R65

C52

C37

R53

R67

C23

R1

R9

C4

3

W10

2

1

W8

R22

2

1

R54

R70

R19

D32

C45

C29

R10

Q3

R25

R49

D8

C21

C18

D2

R71

D15

R14

K3

D9

C36

R38

R6

D18

D16

C38

R72

31W

D19

Q7

21

J6

C15

W6

2

1

Y1

01C

D27

C35

C25

R66

C33

D4

7R

+

R18

C31

D10

R13

C51

06R

D24

C20

C34

L3

C39

D28

C26

C9

D22

C8

C24

R15

D3

R35

C32

C41

K2

R50

C30

1

R47

R57

R4

D23

R46

40

+

R42

R12

R39

D7

C42

K6

C28

R24

D6

U3

D5

C27

J9

D29

R68

R55

R34

C14

R29

R44

R33

C6

R27

R40

R45

R11

C13

R2

R41

R31

5W

Q2

R69

R51

R8

R48

Q1

W16

3

W11

D30

2

1

R58

R16

R21

R30

K1

321

ON

ON

ON

S1

+

+

C46

D21

R26

11

C

R3

K4

C5

C12

U10

D26

D17

7 6 5

4

3

2

D13

U9

+

1

71W

C16

Q5

R56

D11

C47

C22

W7

D31

+

C40

2

1

+

C3

+

R36

R52

R23

D20

U5

1

41W

+

100024-001

ESD HAZARD

CAUTION!

REVISION

MED-LO

LOW

SPEED

ON

OFF ON

ON

OFFON

OFF OFF

1 2

ENABLEONTRIFOLD

3

ON

BUZZER

12V

GND

GND

12V

12V

MED-HI

HIGH

1

U

21U

+

C2

+

C50

4W

3W

1

W

1

2W

U4

L2

L1

J4

COUNTER

BARRIER

LIFT

K

C

O

LR

ET

N

I

rosn

eS

dl

o

h

ser

hT

t

imiL

dlofn

U

timi

L

dloF

timi

L

nwoD

timi

L

r

e

i

rraB

t

i

miL

yol

peD

ti

mi

L

wotS

ti

m

iL ro

ol

F

ti

miL

p

U

timiL rooD

J2

U6

2 3

1

2

3

1

2

3

1

2

3

1

2

3

4

5

J1

J1

J3

1

3

4

2

W

A

RNING

!TTACH0OWERAND'ROUND#ABLE

3

&IGURE.

d

e

m

a

r

t

e

m

mo

r

G

d

n

u

or

G

C

9/32" Diameter

Pilot Hole

F

eb

uT

e

l

b

a

1. Drill 1-1/8” diameter grom-

met access hole. Check

under the vehicle for

obstructions.

2. Insert grommet. Secure

grommet with two self-tap

screws.

5/16"

External Tooth

Washer

Star

Ground Cable Mounting

&IGURE/

Thread Cutting

Screw

P

o

w

e

r

C

a

b

3. Route ground and power

cables through grommet.

Route cables clear of

exhaust, other hot areas

and moving parts.

4. Connect ground cable to

vehicle framing member

(see detail below).

Attach power cable to

5.

Auxiliary terminal of

Circuit Sentr

end of 18" lead cable to

the Battery Circuit Sentry

terminal.

Ground Cable

Lift mounted ground

cable ground cable must

be mounted to a vehicle

framing member to pro

vide optimum ground.

l

e

y. Attach one

a

e

el

L

b

a

C

t

i

u

c

y

ri

r

t

C

n

e

t

a

S

B

.

x

u

A

x

"

4

x

"

8

a

/

l

1

P

Locate Circuit Sentry within

12" of positive (+) battery

terminal. Mount Circuit

Sentry with four self-tap

screws. Sandwich 1/8"

x 4" x 4" plastic between

Circuit Sentry and mount

ing surface.

6. Carefully connect opposite

end of lead cable to Posi-

tive (+) post of battery.

Ground Cable Corrosion:

When mounting ground

cables, remove undercoat

ing, dirt, rust, etc. from

framing member around

mounting holes (minimum

5/8” diameter area).

ply protective coating to

mounting holes to prevent

corrosion. Failure to do

so will void warranty of

certain electrical compo

nents.

P

so

.

N

e

g

.

.

"

2

1

.

xa

M

"

4

c

i

ts

-

-

Ap-

-

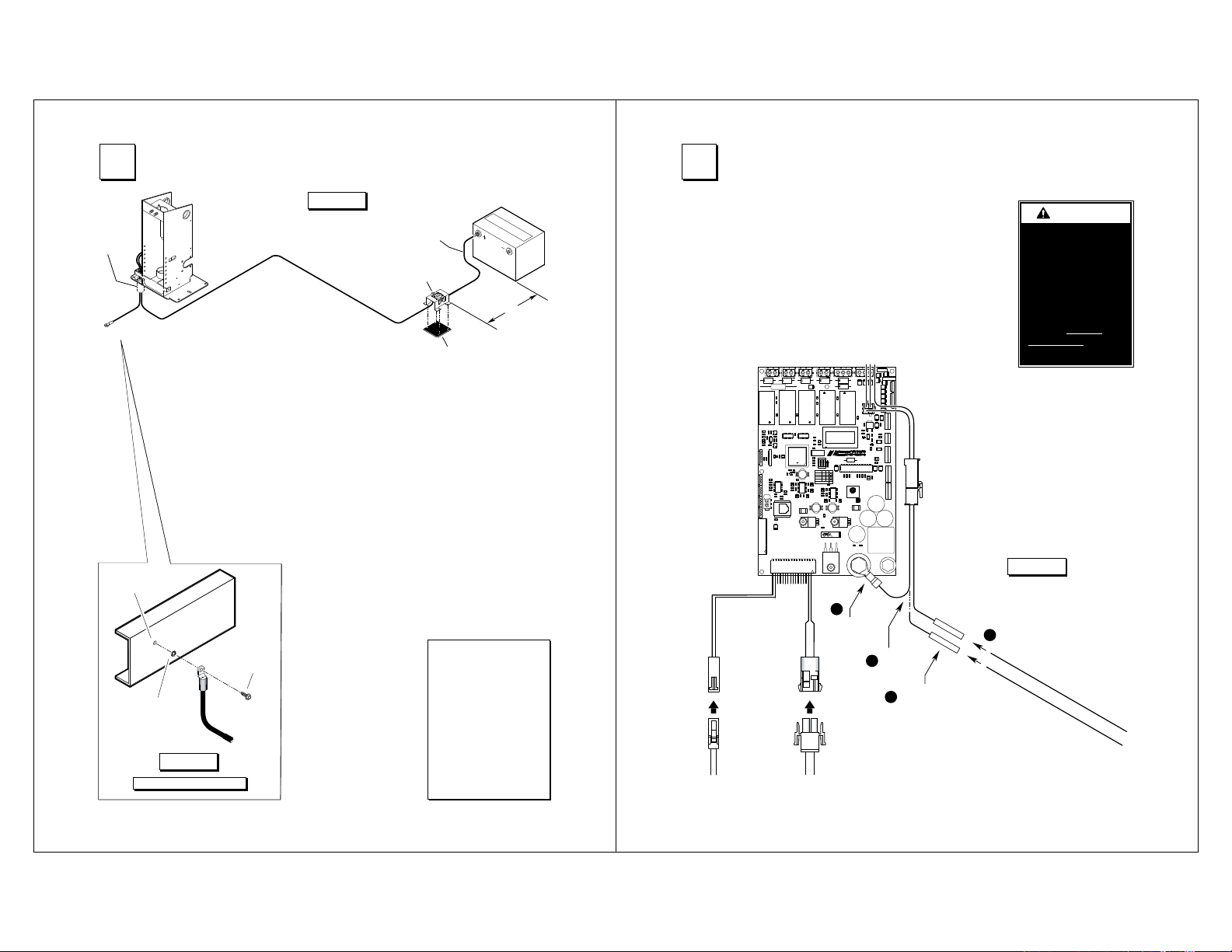

#ONNECT)NTERLOCK

4

Vehicle and Lift Interlock

A 2-circuit lift/vehicle interlock

interface harness is provided inside

the tower cove

is connected to the battery power

stud. A butt connector is provided

on the

To meet minimum NHTSA requirements, connect vehicle interlock

signal wires as detailed in Figure

(Steps 1-4):

r. The Grey/Red wire

Yellow/Light Blue wire.

P

Optional Interlock Kits

Universal Interlock Kit 30940K

is available for easy interface

with vehicle OEM electronic

signals.

Note: Detailed installation

instructions are supplied with

interlock kit(s).

Install and verify

proper operation of

A mandated

all NHTS

interlocks as

specified. Failure

to do so will result

in a non-compliant

installation and may

result in serious

bodily injury and/or

property damage.

&IGURE0

Page 4

Braun Corporation FMVSS No. 403 Quick Reference Installation Sheet 31312

Cam

Switch

Screws

Inner

Cam

C

A B

Outer

Cam

Switch

,IMIT3WITCH!DJUSTMENT

5

Floor Level Cam Adjustment:

The floor level cam(s) are located on the lower drive

arm shaft, on the rear side of the frame tube (under

Adjust per application.

the cover).

• Stepwell Application (Figure Q)

1. Position platform at floor level.

2. Loosen the two cam screws.

Adjust the cam for proper switch activation.

3.

Tighten the two cam screws.

4.

Stepwell Application

&IGURE1

2%15)2%$"9&%$%2!,,!7

&-633#ERTIlCATION#HECKLIST

6

-USTBE#OMPLETEDAND3IGNED

Audible

Threshold

DOT — Private Use Lift

The operations listed below must be

functionally veri

for use unless these operations have been

verified by the installe

fied. This lift is not available

rʼs signature below.

Warning

Threshold

Warning Sensor

• Dropped Floor

• Up-Stop Adjustment (inner cam and switch):

• Floor Level Adjustment (outer cam and

switch):

Activated when the platform switches from the

up/down positions to the stow/deploy positions.

Deploy Limit Switch

This switch adjusts the angle of the platform when

positioned at

level with the van floor. The switch is located on the

vertical arm where the switch arm pivots.

1. Position platform at floor level.

2. Loosen the screw that secures the cam to the

vertical arm.

3. Level platform using a level (or as needed).

Adjust cam so the deploy limit switch activates.

4.

Tighten screw.

5.

Verify position and check level.

6.

Application (Figure R)

1. Position platform at original

(full up position).

2. Loosen screws A, B and C.

Adjust the inner cam for proper switch

3.

activation.

Tighten screw B.

4.

1. Position platform at lowered

2. Loosen screws A and C.

3. Adjust the outer cam until the floor level

switch activates.

Tighten screws

4.

floor level. The platform should be

A and C.

Adjustment (Figure S)

floor height

floor level.

Dropped Floor Application

&IGU

RE2

Deploy Limit Switch

&IGURE3

Switch

Arm

Vertical

Arm

Deploy Limit Switch

Screw

Cam

Switch

Arm

Inboard

Locator

Platform

Verified:

Vehicle movement is prevented unless the

platform is fully stowed.

Lift operation shall be prevented unless the

vehicle is stopped and vehicle movement is

prevented.

The platform will not fold/stow when at least

50 pounds is on the platform.

Lift Model: Series No: Serial No:

Verified By:

Signature Required

Outer Barrier

The outer barrier will not raise if occupied by at

least 25 pounds.

An audible warning will activate if at least 25

pounds is on the threshold area when the plat

form is at least one inch below floor level.

Raising the platform more than 3” off of the

ground is prevented unless the outer barrier is

raised.

Process, fold and insert completed document in

the lift-mounted operato

2%15)2%$"9&%$%2!,,!7

-

rʼs manual storage pouch.

Page 5

Braun Corporation FMVSS No. 403 Quick Reference Installation Sheet 31312

W

A

RNING

,IFT/PERATING)NSTRUCTIONS

Whenever a

passenger is on the

platform, the:

• Passenger must

face outward

• Wheelchair brakes

must be locked

• Inboard locator and

outer barrier must

P.

be U

Failure to do so may

result in serious

bodily injury and/or

property damage.

A

A

C

Before lift operation, park the

vehicle on a level surface, away

from vehicular traffic. Place the

vehicle transmission in “Park”

and engage the parking brake.

Photos appearing in the Lift

Operating Instructions depict lift

functions being activated by liftmounted control switches onl

TO OPEN DOOR(S):

Power Door Operator(s):

Press the DEPLOY switch until

door(s) are fully open. Release

switch.

Manual Door(s):

Manually open door(s) fully and

secure.

TO DEPLOY PLATFORM:

1. Press DEPLOY switch until plat-

form sections open (rotate) to

full width. See Photos D and E.

Release switch.

y.

Lift-posted Warnings and Lift

Operating Instructions decal

31185 provides lift operating in-

structions. Replace any missing, worn or illegible decals.

Follow the Manual Operating

Instructions in event of power

or equipment failure. Do not

use electrical override to oper

ate the lift when a passenger is

on the platform.

B

D

G

-

I

K

LEVEL

Switch

TO UNLOAD PASSENGER:

1. Load passenger onto platform

facing outward and lock wheelchair brakes

Note: Outer barrier must be U

before loading passenger onto

platform.

2. If necessar

arm LEVEL switch until platform

is level.

3. Press DOWN switch until the

entire platform reaches ground

level and outer barrier unfolds

fully. Release switch. See

Photo K.

TO UNLOAD PASSENGER:

4. Unlock wheelchair brakes and

unload passenger from platform.

Note: Outer barrier must be

fully unfolded until entire wheel

chair has crossed the barrier.

See Photos M and N.

.

y, press the switch

H

P

DOWN

Switch

J

L

-

E

2. Press DEPLO

form until platform stops (reaches

floor level) and the inboard loca

tor unfolds. See Photos C and

Release switch.

Y switch until plat-

F.

F

M N

Page 6

Braun Corporation FMVSS No. 403 Quick Reference Installation Sheet 31312

,IFT/PERATING)NSTRUCTIONS

TO LOAD PASSENGER:

1. Load passenger onto platform facing outward and lock wheelchair

brakes. See Photos Q and R.

O

UP

Switch

S

Note: Outer barrier must be fully

unfolded until entire wheelchair

has crossed the barrier. See Photos O and P.

2. Press UP switch until platform

raises just above ground level.

Release switch.

3. If necessar

LEVEL switch until platform is level.

y, press the switch arm

LEVEL

Switch

P

RQ

T

W

Y

AA

Inboard Locator

(unfolded)

5.

Unlock wheelchair brakes and unload

passenger from platform.

TO STOW PLATFORM:

1. Press STOW switch until platform

stops (fully stowed - vertical). Re

lease switch.

TOW switch (Photo Y) until

2. Press S

platform sections close (rotate) to

locked position. See Photos

AA-CC.

X

-

Z

BB

V

U

UP

Switch

4. Press UP switch until platform stops

(reaches floor level) and inboard

locator unfolds (see Photo W). Re-

lease switch.

CC

TO CLOSE DOOR(S):

Power Door Operator(s):

Press the STOW switch until door(s)

are fully closed. Release switch.

Manual Door(s):

Manually close door(s) fully.

DD

Page 7

Braun Corporation FMVSS No. 403 Quick Reference Installation Sheet 31312

W

A

RNIN

G

W

A

RNING

-ANUAL/PERATING)NSTRUCTIONS

If you experience power or equipment

failure, refer to the Manual Operating

Do not use electrical

override to operate

lift when a passenger

is on the platform.

Doing so may result

in serious bodily

injury and/or property

damage.

PLATFORM LATCH

Locked

I

L

Unlocked

&IGURE! &IGURE" &IGURE# &IGURE$

TO OPEN DOOR(S):

Manually open door(s) fully and

secure.

TO DEPLOY PLATFORM:

1. Unlock (disengage) latch

under middle platform section.

See Figure A.

2. Manually open (rotate) the

three platform sections to full

width.

3. Engage latch under middle

platform section to lock plat

form sections at full width. See

Figure A.

4. Remove cap from top of vertical arm actuator. See Figure

C.

5. Place crank handle on actuator

shaft and turn counterclock

wise until platform reaches

floor level. See Figure C.

Remove crank handle.

Instructions to operate the lift. Do not

use electrical override to operate lift

when a passenger is on the platform.

Refer to the Lift Operating Instructions

for all normal lift operation procedures

(such as loading and unloading passengers). Follow all Lift Operation

Safety Precautions!

INBOARD LOCATOR

Hairpin

n

b

o

a

r

d

o

c

a

t

o

r

Link

TO DEPLOY INBOARD

LOCATOR:

1. Remove hairpin cotter from

inboard locator link pin. See

Figure B.

2. Remove link from inboard locator pin. See Figure B.

3. Lower (unfold) inboard locator

to vehicle floo

TO STOW INBOARD LOCATOR:

1. Raise (fold) inboard locator to

-

vertical position.

2. Place link on inboard locator

pin. See Figure B.

3. Insert hairpin cotter into inboard

locator link pin. See Figure B.

TO LOWER PLATFORM:

-

1. Remove plug from top of motor

cove

r. See Figure D.

2. Place crank handle on motor

shaft and turn clockwise until

platform reaches ground level.

See Figure D. Remove crank

handle.

ACTUATOR

Cap

Stow

r.

Hand Crank Note:

For easier operation

of the hand crank,

press and hold the

electrical override

MANUAL/BRAKE

RELEASE switch in

the MANUA

while turning crank.

Deploy

Down

TO RAISE PLATFORM:

1. Remove plug from top of motor

cove

r. See Figure D.

2. Place crank handle on motor

shaft and turn counterclockwise

until platform reaches floor

level. See Figure D. Remove

crank handle.

TO STOW PLATFORM:

1. Remove cap from top of vertical

arm actuator. See Figure C.

2. Place crank handle on actuator

shaft and turn clockwise until

platform stops (reaches full

vertical position). See Figure C.

Remove crank handle.

3. Unlock (disengage) latch under

middle platform section. See

Figure A.

4. Manually close (rotate) the

three platform sections

5. Engage latch under middle

platform section to lock platform

sections. See Figure

TO CLOSE DOOR(S):

Manually close door(s).

L position

MO

TOR

Plug

A.

%LECTRICAL/VERRIDE)NSTRUCTIONS

The Electrical Override feature

is provided as a diagnostic

procedure to reset the system

and as an alternative method

of operating the lift without

• Do not use electrical

override to operate

lift when a passenger

is on the platform.

• Override switches

must be released to

stop lift at desired

position.

Up

Failure to follow these

rules may result in

serious bodily injury

and/or property dam

age.

TO OPEN DOOR(S):

Manually open door(s) fully and secure.

TO DEPLOY PLATFORM:

1. Unlock (disengage) latch under middle platform

section. See Figure A.

2. Manually open (rotate) the three platform sections to full width (unfolded).

3. Engage latch under middle platform section to

lock platform sections at full width. See Figure

A.

4. Rotate the access cover to expose the override

switches. See above photo.

5. Press the two override rocker switches to

OVERRIDE.

6. Press the left toggle switch to DEPLO

platform reaches floor level. Release switch.

7. Press the right toggle switch to DOWN until

platform reaches ground level. Release switch.

8. To deploy (unfold) the outer barrier, press

the left toggle switch to DEPLOY until barrier

unfolds fully. Release switch.

-

passenger onl

the electrical override to operate the lift when a passenger is

on the platform. Lift functions

a

operate at higher rate of speed

when using the electrical over

ride. When using the electrical

override, the operator must stop

pressing the applicable override

switch when the lift reaches the

desired position (limit switches

Y until

&IGURE!

y. Do not use

Locked

Unlocked

TO OPEN DOOR(S):

Manually open door(s) fully and secure.

TO STOW PLATFORM:

1. Rotate the access cover to expose the override

switches. See above photo.

2. Press the two override rocker switches to

OVERRIDE.

3.

To raise (fold) the outer barrier to vertical posi-

tion, press the left toggle switch to STOW until

barrier folds full

4. Press the right toggle switch to UP until plat-

form reaches floor level. Release switch.

5. Press the left toggle switch to S

form reaches vertical position. Release switch.

6. Unlock (disengage) latch under middle platform

section. See Figure A.

7. Manually close (rotate) the three platform sections to closed position (folded).

8. Engage latch under middle platform section to

lock platform sections. See Figure A.

will not function).

Note: Following electrical

override procedures, press the

two override rocker switches to

-

NORMAL. Close access cover

and press the main control

switch to S

through one full cycle to ensure

proper operation.

Electrical Override Switches

y. Release switch.

TOW. Function lift

TOW until plat-

Page 8

Braun Corporation FMVSS No. 403 Quick Reference Installation Sheet 31312

W

A

RNING

-AINTENANCEAND,UBRICATION

Proper maintenance is necessary to ensure

safe, troublefree operation. Inspecting the lift for

r, damage or other abnormal conditions

any wea

should be a part of your daily routine. Simple

inspections can detect potential problems.

The maintenance and lubrication procedures

specified in this schedule must be performed by

a Braun authorized service representative at the

scheduled intervals according to the number of

cycles.

Vangater II is equipped with hardened pins

The

and self-lubricating bushings to decrease wear,

provide smooth operation and extend the service

life of the lift.

When servicing the lift at the recommended intervals, inspection and lubrication procedures speci-

fied in the previous sections should be repeated.

Clean the components and the surrounding area

before applying lubricants. LPS2 General

Purpose Penetrating Oil is recommended where

Light Oil is called out. Use of improper lubricants

can attract dirt or other contaminants which could

result in wear or damage to the components.

Platform components exposed to contaminants

when lowered to the ground may require extra

attention.

Lift components requiring grease are lubricated

during assembly procedures. When these com

Main Drive Ballscrew

(in Frame Tube - hidden)

ponents are replaced,

grease must be

applied during instal

lation procedures.

Specified lubricants

are available from

The Braun Corpora

tion (part numbers

provided below).

All listed inspection,

lubrication and main

tenance procedures

should be repeated at

“750 cycle” intervals

following the scheduled “4500 Cycles” maintenance.

These intervals are a general guideline for scheduling

maintenance procedures and will vary according to

lift use and conditions. Lifts exposed to severe condi

tions (weather, environment, contamination, heavy

usage, etc.) may require inspection and maintenance

procedures to be performed more often than speci-

fied.

Discontinue lift use immediately if maintenance

and lubrication procedures are not properly performed, or if there is any sign of wear, damage or

improper operation. Contact your sales representative or call

One of our national Product Support representatives

will direct you to an authorized service technician who

will inspect your lift.

-

-

Maintenance and lubrication procedures

must be performed

as specified by an

-

authorized service

technician. Failure

to do so may result

in serious bodily

injury and/or prop

-

erty damage.

The Braun Corporation at 1-800-THE LIFT.

Drive Arms

Specified (recommended) Available Braun

Lubricant Type Lubricant Amount Part No.

Light Oil

Door-Ease

Light Grease

-

#YCLES

-

#YCLES

#YCLES

Light Penetrating Oil LPS2, General Purpose 11 oz.

(30 weight or equivalent) Penetrating Oil Aerosol Can

Stainless Stick Door-Ease 1.68 oz.

Style (tube) Stick (tube)

Light Grease Lubriplate 14 oz.

(Multipurpose) Can

Downstop pivot points (2)

Upper lift rod pin

Lower lift rod pin

Kickout spring (located in switch arm)

Platform hinges (6)

Outboard barrier latch

Perform all procedures listed in previous section also

Inboard locator latch mechanism

Check mounting hardware

Check all fasteners (snap rings, nuts, hairpins, etc.)

Check all pivot points for excessive wear

Perform all procedures listed in previous sections also

Platform fold mechanism

Ballscrew / main drive

Clean ground cable at battery and frame

Check power cables

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Grease - See Lubrication Diagram

Tighten, repair or replace if needed.

Tighten, resecure or replace if needed.

Resecure, replace damaged parts or otherwise

correct as needed. Note: Apply lubricant during

reassembly procedures.

Apply Light Grease - See Lubrication Diagram

Add Lucas Heavy Duty Oil Stabilizer

15807

15806

15805

Downstop

(hidden)

Lift Rod

Switch Arm

Inboard Locator

Latch Mechanism

Platform

Hinges (6)

Outer Barrier Latch

Platform Fold

Mechanism

(Under Cover)

#ONSECUTIVE

#YCLE

RVALS

)NTE

Repeat all previously listed inspection, lubrication and maintenance procedures at 750 cycle

intervals.

Loading...

Loading...