Page 1

Braun Corporation FMVSS No. 403 Quick Reference Installation Sheet 32494

Braun Corporation FMVSS No. 403

Quick Reference Installation Sheet 32494

“DOT — Private Use Lift”

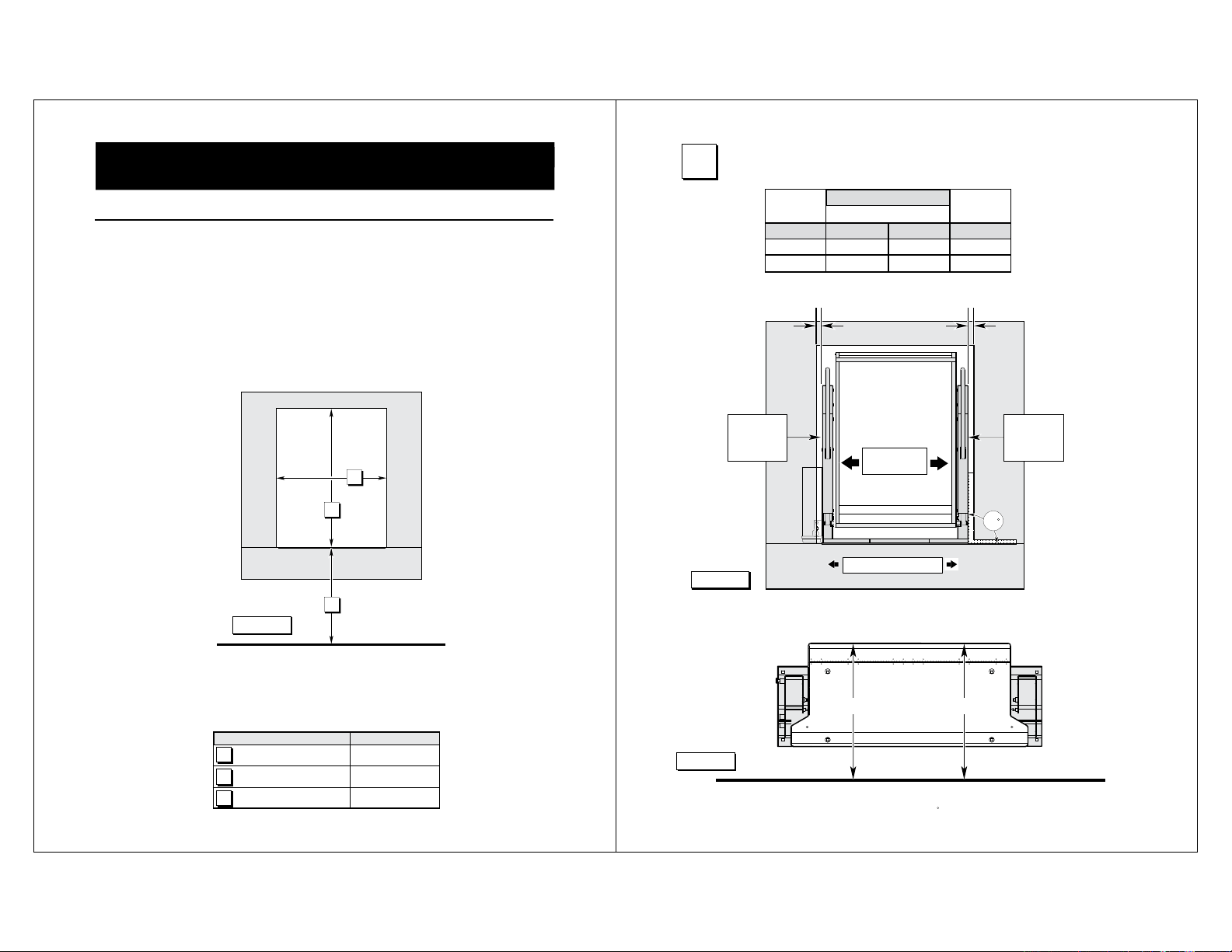

NHTSA Vehicle Physical Requirements

OEM (Van) Chassis

Floor Requirements

Nonmodified OEM full

size floors meet all

requirements.

Alternative floor

structures are allowed

providing the installed lift

system passes all FMVSS 403 requirements.

Figure A

“DOT - Private Use Lift” verifies this

platform lift meets only the “private use lift”

requirements of FMVSS No. 403. This lift

may be installed on all vehicles appropriate

for the size and weight of the lift, except for

buses, school buses, and multi-purpose

passenger vehicles other than motor homes

with a gross vehicle weight rating (GVWR)

that exceeds 4,536 kg (10,000 lb).

B

A

C

Position Lift

1

Vehicle Side Door Rear Door Rear Door

Ford 30956K 30957K 30970K-42

GM/Chevy 30958K

Vertical Arm

must clear

door opening.

Figure B

Installation Kits

Standard Length Chassis

*30959K

Align

(Parallel)

Center lift in

door opening.

Side to Side Alignment

Inboard Edge of Threshold Warning (Top) Plate

(with plate folded down)

Extended

Length

Chassis

*30981K

Align

(Parallel)

90

Installation Kit

30955K supplied

in lift parts box.

Detailed instructions

supplied in kits.

* Rear Bumper

Replacement Kit

19395A96 required.

Vertical Arm

must clear

door opening.

Lift towers and

vertical arms must

be parallel (aligned)

with vertical sides

of door jamb and

perpendicular (90˚)

to the vehicle floor.

Door Opening Dimensions

Vehicle lift access door opening

must meet specified dimensions.

Minimum Clear Door

A

Opening Height

B

Clear Door Opening Width

C

Maximum Floor-to-Ground

NVL955IB3144

47"

40"

42"

Figure C

Minimum per

FMVSS No. 403

Edge of Finished Floor or Stepwell Filler

(not outboard edge of vehicle)

18"18"

Page 2

Braun Corporation FMVSS No. 403 Quick Reference Installation Sheet 32494

W

A

RNING

CAUTION

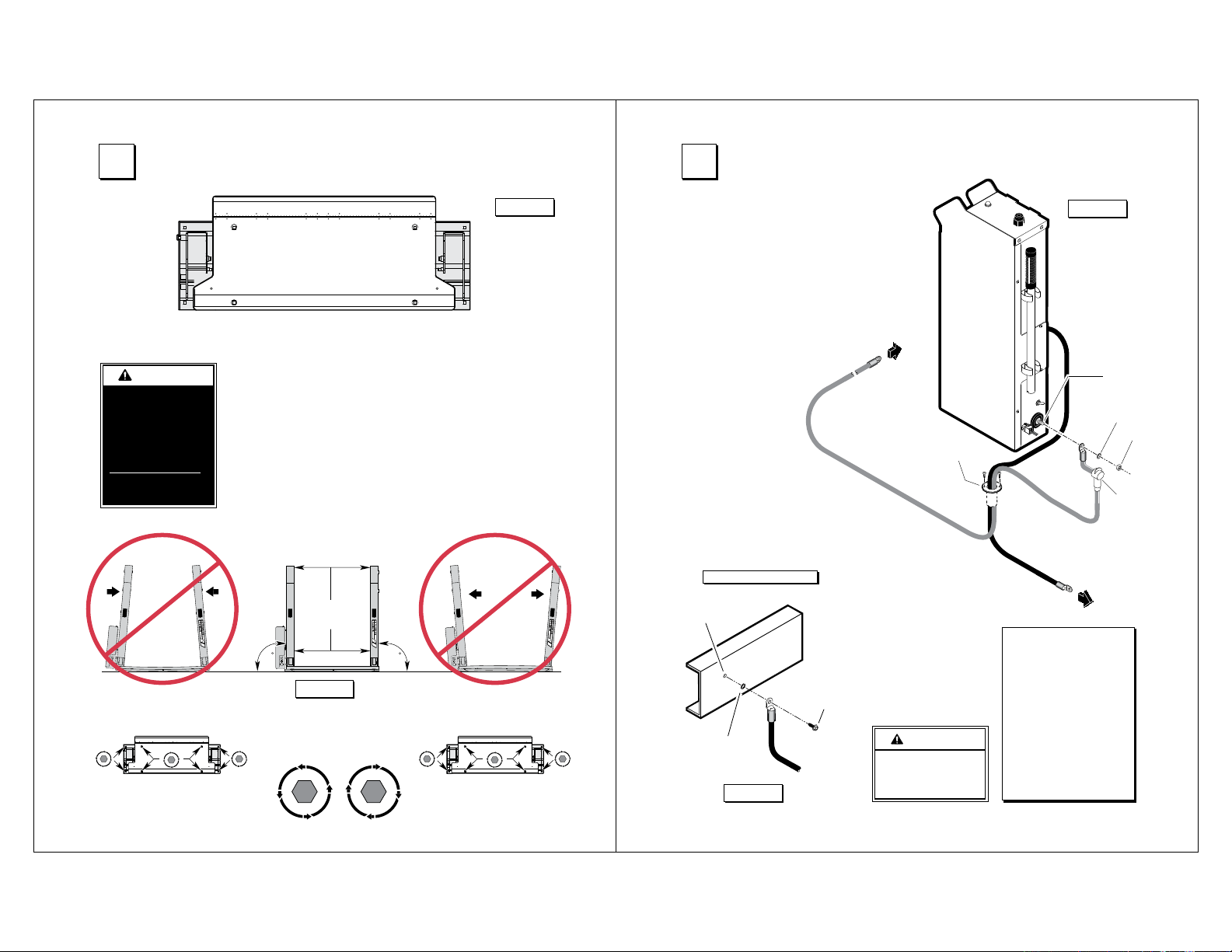

Secure Lift

2

7 6

5

Check for obstructions such as gas

lines, wires, exhaust,

etc. before drilling

or cutting. Failure to

do so may result in

serious bodily injury

and/or property

damage.

1

3

2

9

8

2

3

®

To Correct:

T

H

E

G

I

N

T

Tighten Tighten

S

O

O

L

Loosen

E

N

T

H

E

G

I

T

Note. All fasteners must meet

FMVSS 571.403 Section 6.3.

1. Drill two mounting holes

(holes 6 and 7).

2. Temporarily secure lift

using two mounting bolts

(holes 6 and 7).

3. Manually deploy lift and

check lift clearance. Drill

remaining mounting holes.

Dimensions

MUST

be Equal

Figure E

N

S

O

E

O

N

L

4

2

4. Install below floor mounting

hardware per instructions

supplied in kit.

5. Tighten mounting bolts per

sequence detailed above.

Note deflection detail below.

Mounting Bolt Torque

Target: 30 foot pounds.

29823

®

9090

S

O

E

O

N

L

T

H

E

G

I

N

T

Loosen Loosen

Figure D

8

To Correct:

T

H

E

G

I

N

T

Tighten

Attach Power and Ground Cables

3

1. Drill 1-1/8" diameter

grommet access

hole. Check under

the vehicle for

obstructions.

2. Insert grommet.

Secure grommet

with two self-tap

screws.

3. Route ground

and power cables

through grommet.

Route cables clear

of exhaust, other

hot areas and

moving parts.

4. Connect ground

and power cables.

Battery Cable

to Circuit Sentry

Floor

Grommet

Ground Cable Mounting

9/32" Diameter

3

2

8

9

2

®

S

O

E

O

N

L

Pilot Hole

5/16"

External Tooth

Star Washer

Chassis

5/16-18 x 3/4"

Thread Cutting

Screw

Figure G

Ground Cables

Pump mounted ground

cable must be routed

and mounted directly to a

vehicle framing member.

Failure to do so will

void warranty of certain

electrical components.

Position and secure

ground cable clear

of lift operation.

Ground Cable Corrosion:

When mounting ground

cables, remove undercoating, dirt, rust, etc. from

framing member around

mounting holes (minimum

5/8” diameter area). Apply protective coating to

mounting holes to prevent

corrosion. Failure to do

so will void warranty of

certain electrical components.

Figure F

Power

Feed Stud

Star Washer

Rubber

Ground Cable

to Chassis

3/8" Hex Nut

Boot

Page 3

Braun Corporation FMVSS No. 403 Quick Reference Installation Sheet 32494

W

A

RNING

W

A

RNING

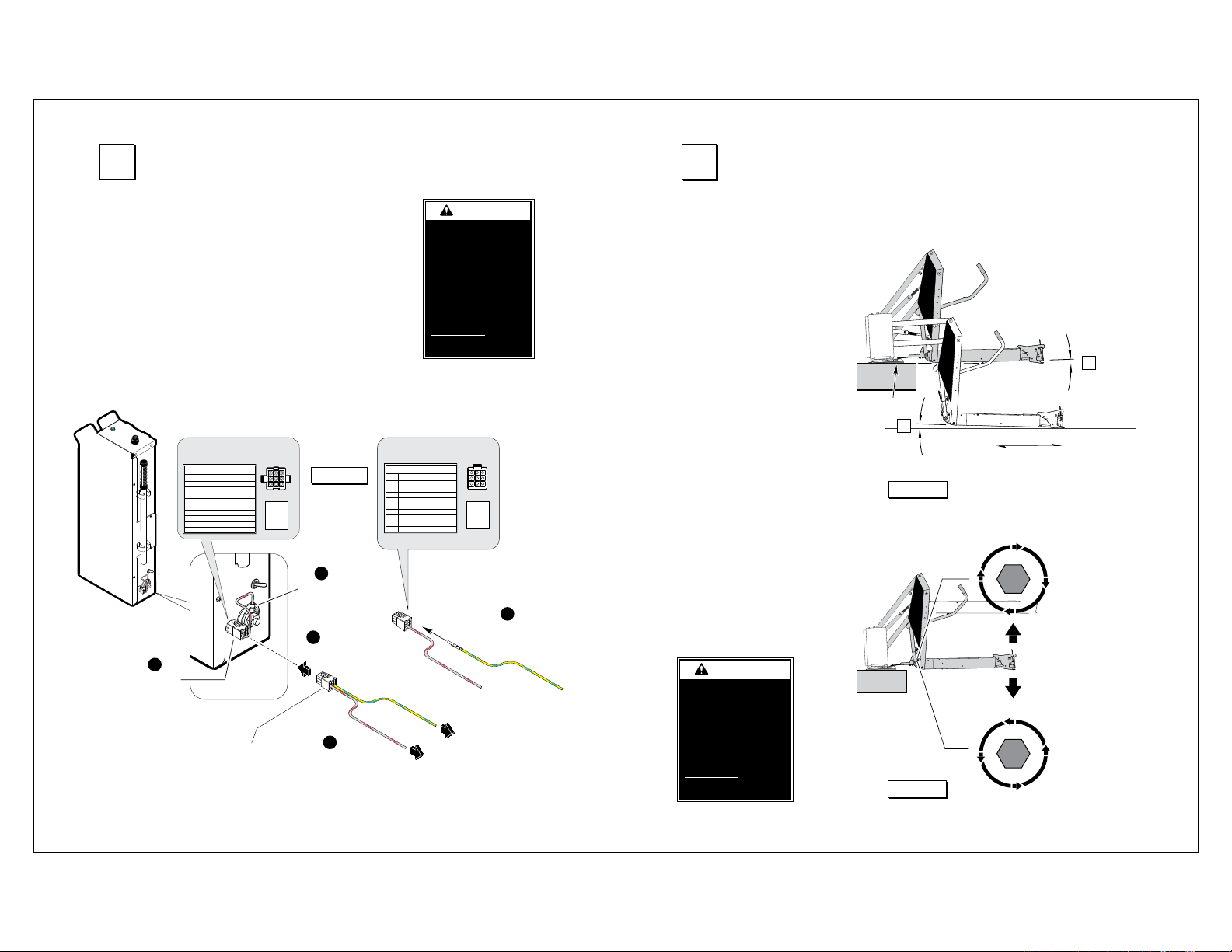

Connect Interlocks

4

Vehicle and Lift Interlocks

The pump module is equipped

with a lift interface 9-circuit connector (female socket). A mating

9-circuit connector (male plug) is

supplied.

To meet minimum NHTSA

requirements, connect to vehicle

interlock harness as outlined

below (Steps 1-5)

PUMP MODULE

CONNECTOR - J21

9-COND WIRE CODE

SIGNAL DEFINITION NO.

1

2

Lift

Pump

Module

Disconnect

3

4

5

VEHICLE SECURE (INPUT)

6

7

8

9

2

Manufacturer’s Part Numbers

Connector: AMP 172169

Terminal:TYCO 770904-3

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

LIFT STOWED (+12V)

NOT USED

LIFT STOWED (GND)

Shipped

Optional Interlock Kits

Universal Interlock Kit 30940K is

available for easy interface with

vehicle OEM electronic signals.

Instrument Panel Display Kit

30938K provides an LED

Panel Display that interfaces

with Braun Universal Interlock Kit

30940K.

Detailed installation instructions

are supplied with interlock kits.

Note: All Braun Corporation interlocks require a positive (+12V)

Lift Stowed signal (Pin 7).

2

3

1

Figure H

4

6

5

8

9

7

31 2

64 5

97 8

As

1

Disconnect

and remove

eye terminal

5

Connect

4

Connect vehicle

interlock signal wires

INTERLOCK

CONNECTOR - P21

9-COND WIRE CODE

1

2

3

4

5

6

7

8

9

T

o Interlock

Install and verify

proper operation of

all NHTSA mandated

interlocks as

specified. Failure

to do so will result

in a non-compliant

installation and may

result in serious

bodily injury and/or

property damage.

SIGNAL DEFINITION NO.

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

VEHICLE SECURE (INPUT)

LIFT STOWED (+12V)

NOT USED

LIFT STOWED (GND)

Note: Pins 7 and 9

300mA maximum.

(

Yellow/Light Blue)

VEHICLE SECURE

SIGNAL

(Grey/Red)

132

465

9 8

7

13 2

46 5

79 8

3

Install 31798A

in cavity 7 (+) or 9 (-)

LIFT S

SIGNAL

T

OWED

Adjust Platform Angle

5

Adjustments to platform

angle may be required

if base plate wedges

are used. See Figures I

and J.

Floor Level Positioning:

Reset floor level positioning

if wedges are used. See

Floor Level Adjustment

panel.

Reset floor level

position as specified

in Floor Level

Adjustment Instructions if wedges are

used. Failure to do so

may result in serious

bodily injury and/or

property damage.

Wedges

B

Approximately

1” Clearance

Figure I

Figure J

Inboard

Angle A

equals

Angle B.

✓

A

Outboard

T

H

E

G

N

I

T

S

E

O

N

O

L

Turn

clockwise

to

raise

outboard end

of platform

Turn

counterclockwise

to

lower

outboard end

of platform

Page 4

Braun Corporation FMVSS No. 403 Quick Reference Installation Sheet 32494

6

Platform Floor Level Adjustment

6

FMVSS 403/404 Certification Checklist

7

Platform Floor Level Position Adjustment:

1. Position platform at desired floor level position

(passenger loading/unloading height).

Note: Position platform such that:

a. the inner roll stop is laying flat on the threshold

plate

b. platforrm has not begun to fold

2. Turn Lift Power switch Off.

3. Press Floor Level Set button (located between

pump housing and lift tower).

4. While pressing the Floor Level Set button, turn the

Lift Power switch On.

5. Continue pressing the Floor Level Set button until

the lift sounds three “beeps.”

6. Release the Floor Level Set button.

7. Cycle lift to verify that platform stops at the set

floor level position.

Diagnostic codes have been established in event the

lift platform floor position does not set (the lift does not

sound three “beeps” - see Step 5 above). The control

board located inside the pump housing is equipped

with an LCD screen. Remove the pump cover to access the LCD screen. The following diagnostic codes

will help resolve floor position setting problems:

91 – The platform position is out of a prede-

termined acceptable range

92 – The Bridge Microswitch is not activated

(adjust switch or lower the platform)

94 – The Outer Barrier Up switch is not

activated (adjust switch)

95 – The Outer Barrier Latched sensor is not

activated.

Floor Level Set Button

LCD Screen

UP

U

N

F

O

L

D

L

O

F

N

W

O

D

Lift Ready

Green LED

D

Audible

Threshold

Warning

Threshold

Area

Figure K

The following operations must be

functionally verified.

Vehicle movement is prevented unless the

lift door is closed, ensuring the lift is stowed.

Lift operation shall be prevented unless the

vehicle is stopped and vehicle movement is

prevented.

The platform will not fold/stow if occupied.

The inner roll stop will not raise if occupied.

DOT — Private Use Lift

Inboard

Locator

Platform

Inboard

Platform

Outboard

Platform

The outer barrier will not raise if occupied.

A warning will activate if the threshold area is

occupied when the platform is at least one inch

below floor level.

Lift platform movement shall be interrupted

unless the outer barrier is raised and the

outer barrier latch is positively engaged.

Outer Barrier

Page 5

Braun Corporation FMVSS No. 403 Quick Reference Installation Sheet 32494

Lift Operating Instructions

A

C

E

DOWN

G

To Open Door(s):

Automatic Door Operator(s):

Press yellow OPEN switch until

door(s) are fully open. Release

switch.

Manual Door(s):

Manually open door(s) fully and

secure.

To Unfold Platform (Out):

Press UNFOLD (orange OUT)

switch (see Photo B) until platform

stops (unfolds fully – reaches

floor level). See Photos C and D.

Release switch.

To Unload Passenger:

1. Read notes below! Load passen-

ger onto platform facing outward

and lock wheelchair brakes.

Note: Outer barrier must be UP

and outer barrier latch must be

fully engaged before loading passenger onto platform. Lower head

to clear vehicle door jamb header.

2. Press red DOWN switch until the

entire platform reaches ground

level (stops) and outer barrier

unfolds fully (see Photos H and I).

Release switch.

Switch Arm Switch: Slide knob in

to DOWN position. See Photo G.

B

D

F

H

I

3. Unlock wheelchair brakes and

unload passenger from platform.

Note: Outer barrier must be fully

unfolded (ramp position) until the

entire wheelchair has crossed the

outer barrier. See Photos K and L.

K

To Load Passenger:

M

UP

O

1. Load passenger onto platform facing outward and lock wheelchair

brakes.

Note: Outer barrier must be fully

unfolded (ramp position) until the

entire wheelchair has crossed the

outer barrier. See Photos K and L.

2. Press red UP switch until platform

stops (reaches floor level). Release switch.

Switch Arm Switch: Slide knob out

to UP position.

Note: Outer barrier must be

UP and outer barrier latch must

be fully engaged before raising

platform. Platform will raise above

ground level approximately two

inches before latch engages fully.

approximately 2”

J

L

N

P

Page 6

Braun Corporation FMVSS No. 403 Quick Reference Installation Sheet 32494

O

P

E

N

C

L

O

S

E

Lift Operating Instructions

Q

To Load Passenger (continued):

3. Unlock wheelchair brakes and load

passenger from platform into vehicle. Note: Lower head to clear

door jamb header.

R

A

Release Valve

Note: Close backup

pump release valve

securely before operating

electric pump.

maximum

30 inch lbs

minimum

15 inch lbs

seats

(stops)

approximate

1/16” intervals

Release Valve

Valve Tightening

Specification:

Once valve seats

(stops), tighten 15

to 30 inch pounds

as shown.

To Fold Platform (In):

Press FOLD (orange IN) switch

until platform stops (fully folded).

Release switch.

S

T

Open

(Down)

Close

(Up/Stop)

To Close Door(s):

U

Automatic Door Operator(s):

Press yellow CLOSE switch until

door(s) are fully closed. Release

switch.

Manual Door(s):

Manually close door(s) fully.

B

To Unfold Platform (Out):

Using hand pump handle:

a. Place slotted end of pump handle onto

back-up pump release valve and turn

counterclockwise (open — 1/2 turn

only) until the platform reaches floor

level (fully unfolded). See Photo B.

b. Turn the release valve clockwise

(close) to stop the platform. See Photo

B.

Note: Valve must be tight, but do not

overtighten.

UP (To Fold Outer Barrier and

Raise Platform):

Using hand pump handle:

a. Place slotted end of pump handle

onto back-up pump release valve

and turn clockwise to close securely. See Photo B.

Note: Valve must be tight, but do

not overtighten.

b. Insert handle into back-up pump and

stroke until platform reaches floor

level (see Photo C).

C

Manual Operating Instructions

If you experience power or equipment failure, refer to the Manual

Operating Instructions to operate

the lift. Instructions and photos

are provided for all steps that

differ from standard lift operation

procedures. Manual Instructions

Decal 31894 (posted on pump

cover) provides manual operating instructions also. Refer to the

Lift Operating Instructions for all

normal lift operation procedures

(such as loading and unloading

passengers). Follow all Lift

Operation Safety Precautions!

DOWN (To Lower Platform and Unfold

Outer Barrier):

Place slotted end of pump handle onto

back-up pump release valve and turn

counterclockwise (open — 1/2 turn only)

until the platform reaches ground level

and/or outer barrier unfolds. See Photo B.

To Fold Platform (In):

Insert handle into back-up pump and

stroke until platform stops (folds fully).

See Photo C.

Note: Close back-up pump release

valve securely before operating electric pump.

Page 7

Braun Corporation FMVSS No. 403 Quick Reference Installation Sheet 32494

W

A

RNING

Maintenance and Lubrication

Lubrication Diagram

P

U

U

N

OF

LD

D

L

O

F

N

W

DO

UHMW Bearing (4)

DE

Rotating Pivot

Slide Arm Pivot Pins

LO

Platform Fold Axles (2)

LO

Platform Pivot Pin (2 Points)

Parallel Arm

Pivot Pins (8)

LO

LO

Platform Fold Link Roller/Pin (4)

LO

Outer Barrier Hinge Pivot Points

Outboard Platform Pivot Pins (2)

See the Maintenance/Lubrication Schedule for recommended applications per number of cycles.

Lubricant Type Lubricant Amount Part No.

LO - Light Oil

DE - Door-Ease

LG - Light Grease

Light Penetrating Oil LPS2, General Purpose 11 oz.

(30 weight or equivalent) Penetrating Oil Aerosol Can

Stainless Stick Door-Ease 1.68 oz.

Style (tube) Stick (tube)

Light Grease Lubriplate 14 oz.

(Multipurpose) Can

Lift-Tite Latches

(Tower Pivot Points - 2)

LO

Lift-Tite Latch Dampening

Spring (2 springs - 4 Points)

LO

Pivot Pins (8)

Inboard

Platform

Outboard

Platform

(2) and

LO

Specified (recommended) Available Braun

Parallel Arm

LO

Switch Arm Pivot Pins (2)

Inboard Locator

Pivot Points

Outer Platform Pivot Pins (2)

LO

LO

LO

Outer Barrier Activation

Foot Pivot Point (2)

Outer Barrier

Arm Slots (2)

LO

15807

15806

15805

Maintenance and Lubrication Schedule

Proper maintenance is necessary to ensure safe,

troublefree operation. Inspecting the lift for any

wear, damage or other abnormal conditions should

be a part of a regular service program. Simple

inspections can detect potential problems.

The maintenance and lubrication procedures specified in this schedule must be performed by a Braun

authorized service representative at the scheduled

intervals according to the number of cycles.

Braun dual parallel arm lifts are equipped with hardened pins and self-lubricating bushings to decrease

wear, provide smooth operation and extend the

service life of the lift.

When servicing the lift at the recommended inter-

vals, inspection and lubrication procedures specified

in the previous sections should be repeated. Clean

the components and the surrounding area before

applying lubricants. LPS2 General Purpose

Penetrating Oil is recommended where Light Oil is

called out. Use of improper lubricants can attract

dirt or other contaminants which could result in wear

or damage to the components. Platform components exposed to contaminants when lowered to the

ground may require extra attention.

Lift components requiring grease are lubricated during assembly procedures. When these components

are replaced, grease must be applied during instal-

lation procedures. Specified lubricants are available

from The Braun Corporation (part numbers provided

above).

LO

All listed inspection, lubrication and maintenance

procedures should be repeated at “750 cycle”

Outer barrier hinge pivot points (2)

Outer barrier arm slots (2)

Outboard platform pivot pins (2)

Outer barrier activation foot pivot pins (2)

750

Cycles

Platform fold link rollers and pins (4 sets)

Outer platform pivot pins (2)

Lift-Tite™ latches (tower pivot points - 2)

Lift-Tite™ latch gas (dampening) spring pivot

points (2 springs - 4 points)

Inspect Lift-Tite™ latches and gas springs for wear

or damage (bent, deformed or misaligned), positive securement (external snap rings) and proper

operation

intervals following the

scheduled “4500 Cycles”

maintenance. These

intervals are a general

guideline for scheduling

maintenance procedures

and will vary according

to lift use and conditions.

Lifts exposed to severe

conditions (weather, environment, contamination,

heavy usage, etc.) may

require inspection and

maintenance procedures

to be performed more

often than specified.

Maintenance Indicator: The Lift Ready green LED

mounted on top of the pump cover will begin to blink

after every 750 cycles. The blinking LED will not affect

the functions of the lift, but is a reminder to complete

necessary maintenance and lubrication.

Once the lift has been serviced, fully stow the lift. Once

stowed, press the UP button on the hand pendant and

the Floor Level Set button on the back side of the pump

cover until the Lift Ready green LED stops blinking.

Discontinue lift use immediately if maintenance

and lubrication procedures are not properly performed,

or if there is any sign of wear, damage or improper

operation. Contact your sales representative or call

The Braun Corporation at 1-800-THE LIFT. One of our

national Product Support representatives will direct you

to an authorized service technician who will inspect

your lift.

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Resecure, replace defective parts or otherwise

correct as needed. Note: Apply Light Grease to

Lift-Tite™ latch tower pivot point if replacing latch.

Maintenance and

lubrication procedures

must be performed as

specified by an authorized service technician. Failure to do so

may result in serious

bodily injury and/or

property damage.

Page 8

Braun Corporation FMVSS No. 403 Quick Reference Installation Sheet 32494

750

Cycles

1500

Cycles

Maintenance and Lubrication Schedule

Inspect outer barrier for proper operation

Inspect lift for wear, damage or any abnormal

condition

Inspect lift for rattles

Perform all procedures listed in previous section also

Platform pivot pin bearings (2)

Platform fold axles (2)

Inboard locator lever bearings (2)

Inboard locator lever slot (2)

Rotating pivot slide arm pivot pins (2)

Parallel arm pivot bearings (16)

Switch arm pivot pin bearings (4)

Hydraulic cylinder bushings (8)

Inspect Lift-Tite™ latch rollers for wear or damage,

positive securement and proper operation (2)

Inspect inboard locator for:

• Wear or damage

• Proper operation. Inboard locator should just rest

on top surface of the base plate.

Inspect platform fold gear rack and gear weldment

teeth for foreign objects, wear or damage (bent,

deformed or misaligned), positive securement and

proper operation

Inspect switch arm components for wear or damage, and for proper operation

Inspect microswitches for securement and proper

adjustment.

Make sure lift operates smoothly

Inspect external snap rings / e-clips:

• Rotating pivot slide arm pivot pins (2 per pin)

• Rotating pivot slide arm roller axles (2 per axle)

• Platform fold axles (1 per axle)

• Inboard locator lever bracket pins (1 per pin)

• Lift-Tite™ latch gas (dampening) spring (2 per

spring)

Inspect platform fold axles and bearings for wear or

damage and positive securement

Correct or replace defective parts.

Correct as needed.

Correct as needed.

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Correct, replace defective parts and/or relubricate.

Resecure, replace or correct as needed. See

Platform Angle Instructions and Platform Floor

Level Adjustment Instructions.

Remove foreign objects, replace defective parts

and secure as needed.

Replace defective parts.

Resecure, replace or adjust as needed.

Realign towers and vertical arms. Lubricate or

correct as needed.

Resecure or replace if needed.

Replace defective parts and resecure as needed.

Apply Light Oil.

1500

Cycles

4500

Cycles

Consecutive

750 Cycle

Intervals

Maintenance and Lubrication Schedule

Remove pump module cover and inspect:

• Hydraulic hoses, fittings and connections for wear

or leaks

• Harness cables, wires, terminals and connections

for securement or damage

• Control board, circuit breaker, power switch and

lights for securement or damage

Perform all procedures listed in previous section also

Inspect cotter pins on platform pivot pin (2)

Hydraulic Fluid (Pump) - Check level. Note: Fluid

should be changed if there is visible contamination.

Inspect the hydraulic system (cylinder, hoses, fittings, seals, etc.) for leaks if fluid level is low.

Inspect cylinders, fittings and hydraulic connections

for wear, damage or leaks

Inspect parallel arms, bushings and pivot pins for

visible wear or damage

Inspect parallel arm pivot pin mounting bolts (8)

Inspect platform pivot pin, bushings and vertical

arms for wear, damage and positive securement

Inspect upper/lower fold arms, rotating pivot slide

arms, slide support arms and associated pivot pins,

bushings, and bearings for visible wear or damage

Inspect gas springs (cylinders) for wear or damage,

proper operation and positive securement

Inspect rotating pivot slide arm UHMW slide bearings (buttons)

Inspect vertical arm plastic covers

Inspect power cable

Mounting

Decals and Antiskid

Repeat all previously listed inspection, lubrication and maintenance procedures at 750 cycle

intervals.

Resecure, replace or correct as needed.

Resecure, replace or correct as needed

Use Dextron III transmission fluid. Check fluid

level with platform lowered fully and roll stop

unfolded fully. Fill to within 1/2” of the bottom of

the 1-1/2” fill tube (neck).

Tighten, repair or replace if needed.

Replace if needed.

Tighten or replace if needed.

Replace defective parts and resecure as needed.

Apply Light Grease during reassembly procedures.

Replace if needed.

Tighten, replace or correct as needed

Apply Door-Ease or replace if needed. See Lubrication Diagram.

Resecure or replace if needed.

Resecure, repair or replace if needed.

Check to see that the lift is securely anchored to

the vehicle and there are no loose bolts, broken

welds, or stress fractures.

Replace decals if worn, missing or illegible. Replace antiskid if worn or missing.

Loading...

Loading...