Bras QUARK 1, QUARK 2, QUARK 3 Operator's Manual

QUARK

MANUALE D’ISTRUZIONI

OPERATOR’S MANUAL

CARNET D’INSTRUCTIONS

GEBRAUCHSANWEISUNG

MANUAL DE INSTRUCCIONES

11

1 ELECTRICAL SAFETY INSTRUCTIONS

1

Before connecting the dispenser to the mains, check that

the voltage shown on the rating plate matches your electricity

su pply. C onnec t the dispense r to a sing le-phase supply

through an earthed socket as required by current regulations. If

the dispenser is to be disconnected from the power supply

using a single pole switch, the gap between the contacts on this

switch must be sufficiently wide to guarantee full disconnection

under category III overload conditions.?

2 Do not use extension cables to connect the appliance.

3 To avoid any risks, if the power cable is damaged, it must

be replaced by the manufacturer, by an authorised technician

or by a similarly qualified person.

4 The dispenser is not suitable for outdoor use.

5 The dispenser must be installed in the upright position.

6 Before cleaning, always disconnect the dispenser by

removing the plug from the socket.

7 Always disconnect the dispenser before removing any of

the panels for cleaning or maintenance work.

8 Do not use a water jet to clean the dispenser.

9 This appliance must not be operated by children.

10 Do not let children play with the appliance.

11 This appliance must not be used by persons with reduced

physi cal , sen sory or me nta l cap abilities or with a lack of

experience and knowledge unless they have supervision or

have been trained regarding the safe use of the appliance and

understand the risks involved.

12 Only persons who know and have practical experience of

the appliance are permitted access to the inner components of

the dispenser, especially when dealing with issues regarding

safety and hygiene.

2 HYGIENIC SAFETY INSTRUCTIONS

1

This appliance is intended exclusively for domestic and

similar use.

2 For the appliance to operate correctly, room temperature

must be between +5° and +32°C.

3 Use the appliance to cool the indicated liquids only.

4 Do not introduce dangerous or toxic liquids to the appliance.

3 TECHNICAL CHARACTERISTICS

The electric diagram of the dispenser is located in the inner

part of the dispensing side panel.

Specifications are subject to change without notice.

4 INTRODUCTION

It is necessary to read all sections of this manual thoroughly to

familiarize yourself with all aspects of the unit.

Like all mechanical products, this machine will require cleaning

an d maintenance. Be si de s, di sp en se r working can be

compromised by operator’s mistakes during disassembly and

cleaning. It is strongly recommended that personnel in charge to

the equipment’s daily operations, disasse mbly, cleaning,

sanitizing and assembly, go through these procedures in order

t o be p r oper l y trai n e d and t o make s u re th a t no

misunderstandings exist.

5 INSTALLATION

1

Remove the corrugate container and packing materials and

keep them for possible future use.

Transparent removable bowls n 1 2 3

Capacity of each bowl, approx. l 6 6 6

Dimensions:

width cm 18 36 54

depth cm 47 47 47

height cm 65 65 65

Net weight, approx. kg 22 36 48

Gross weight, approx. kg 24 39 51

Adjustable thermostats n 1 2 3

Hermetic compressor

Air-cooled condenser

Overload protector

Noise level lower than 70 dB (A)

IMPORTANT

Read electrical ratings written on the data plate of the

individual units; the data plate is adhered on the dispensing side panel of the unit, just behind the drip tray (the

right side drip tray in multiple bowl models). The serial

number of the unit (preceded by the symbol #) is adhered

inside the left switch box. In the ETC model the serial

numbers are located underneath the machine or on the

evaporator holder level when the side panels are removed. Data plate specifications will always supersede the

information in this manual.

IMPORTANT

When handling the machine never grasp it by the bowls

or by the evaporator cylinders. The manufacturer refuses

all responsibilities for possible damages which may

occur through incorrect handling.

QUARK 2

QUARK 1

QUARK 3

Q U A R K

E NG LI S H

12

2 Inspect the uncrated unit for any possible damage. If

damage is found, call the delivering carrier immediately to file a

claim.

3 Install the unit on a counter top that will support the

combined weight of dispenser and product bearing in mind

wh at i s st at ed i n th e pr ec eding point 1 IMPORTA NT

warning.

4 A minimum of 15 cm (6”) of free air space all around the unit

should be allowed to guarantee adequate ventilation.

5 Ensure that the legs are screwed tightly into the base of the

machine.

Replace the standard legs originally installed with the 100 mm

(4”) legs whenever they are provided with the unit.

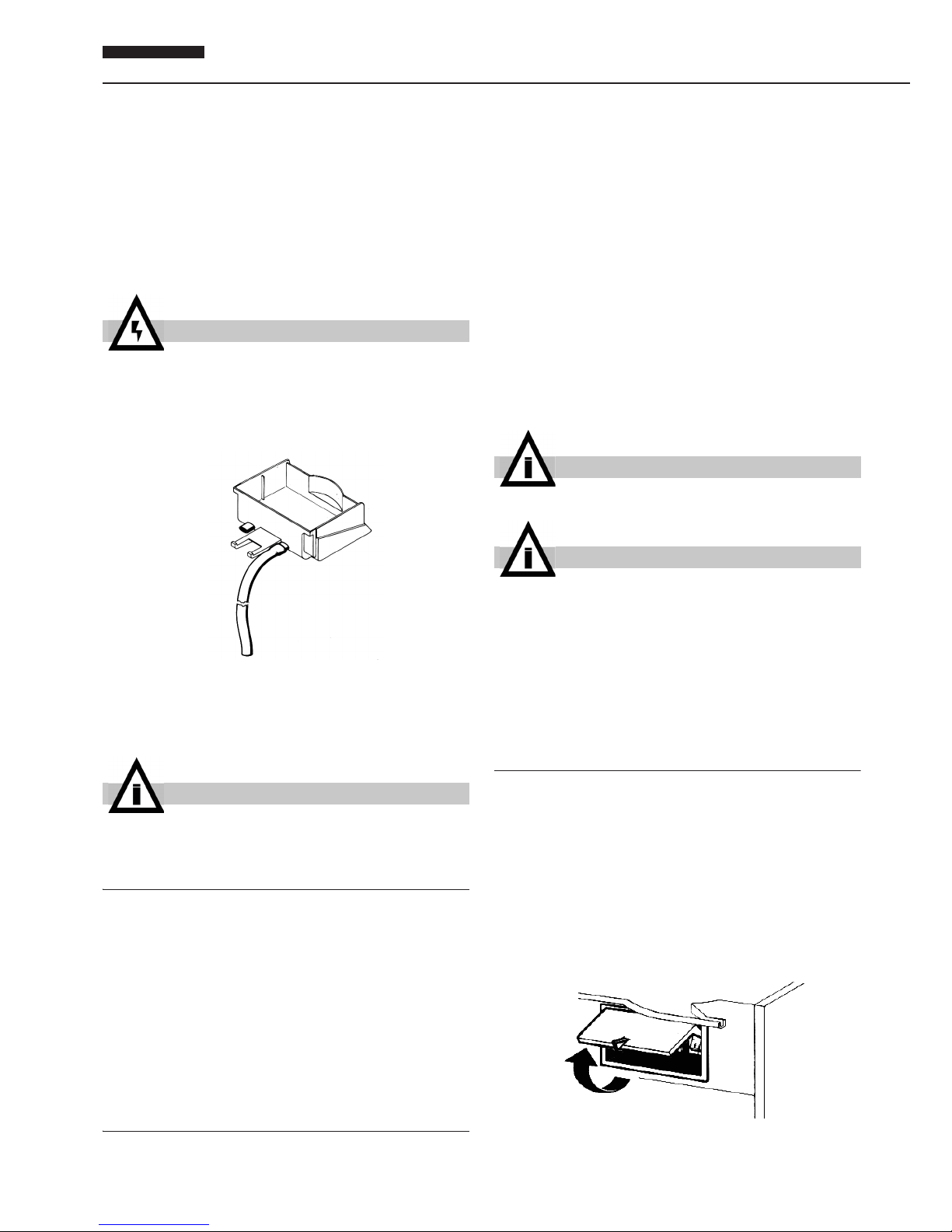

6 Each drip tray has two diaphragm plugs: if a continuous

drain is needed, perforate one of the drain plugs and connect it

to a flexible drain line (see figure 1).

figure 1

7 The unit doesn’t come presanitized from the factory. Before

se rving pro ducts, th e dispens er m ust be disa ssemble d,

cleaned and sanitized according to this handbook instructions

(chapter 5.3 CLEANING AND SANITAZING PROCEDURES).

6 TO OPERATE PROPERLY AND SAFELY

1

Do not operate the dispenser without reading this

operator’s manual.

2 Do not operate the dispenser unless it is properly

grounded.

3 Do not operate the dispenser unless all panels are

restrained with screws.

4 Do not put objects or fingers in panels louvers and faucet

outlet.

5 Do not remove bowls, augers and panels for cleaning or

routine maintenance unless the dispenser is disconnected from

its power source.

6 The cover must be always closed.

7 OPERATING PROCEDURES

1 Clean and sanitize the unit according to the instructions in

this manual. See chapter 5.3 CLEANING AND SANITIZING

PROCEDURES.

2 Fill the bowls with product to the maximum level mark. Do

not overfill.

The exact quantity of product (expressed as liters and gallons)

is shown by marks on the bowl.

3 In case of products to be diluted with water, pour water into

bowl first, then add correct quantity of product . In case of

natural squashes, it is advisable to strain them, in order to

prevent pulps from obstructing the faucet outlet.

4 To obtain the best performance and result, use bases

designed to be run in Granita freezers. Such bases have a

sugar content of 34 degrees B aum é correspondin g to 64

degrees Brix .

For soft drinks the bases are to be diluted with more water, on a

1 plus 5/5.5 basis.

In any case follow the syrup manufacturer’s instructions for

both Granita and soft drink recipes.

If natural juices (e.g. lemon, o range) as well as s ugarless

products (e.g. coffee) are used, dissolve 150 - 200 grams of

sugar per liter.

5 Set the control switches as shown in chapter

5.1 DESCRIPTION OF CONTROLS.

6 Always leave the dispenser on, as the refrigeration stops

automatically when Granita reaches the proper thickness. The

mixers will continue to turn.

7. 1 DESCRIPTION OF CONTROLS

The dispenser is equipped with a power switch. In addition each

bowl is individually operated by a mixer/refrigeration switch. In

fact it is possible to dispense both soft drinks and Granita.

When a bowl is in Soft Drink mode the beverage temperature is

controlled by the corresponding thermostat.

When a bowl is in Granita mode the mix viscosity is controlled

by the corresponding adjustment screw located in the rear wall

of each container (for temperature and viscosity setting make

reference to chapter 5.2 OPERATION HELPFUL HINTS).

All the switches are located on the faucet side of the dispenser

in switch panels protected by switch covers (see figure 2).

figure 2

With reference to figure 3 dispenser controls functions are as

ATTENTION

Failure to provide proper electrical ground according to

applicable electrical codes could result in serious shock

hazard.

IMPORTANT

Install the dispenser so that the plug is easily accessible.

IMPORTANT

Operate the dispenser with food products only.

IMPORTANT

However Granita mix may be done, its Brix (sugar percent content) must be at least 13.

Loading...

Loading...