2000X aod

Actuator

Instruction Manual

EDP 100-214-282

Rev. 07

Software Version 10.xx and above

BRANSON Ultrasonics Corporation

41 Eagle Road

Danbury, Connecticut 06813-1961 U.S.A.

(203) 796-0400

ii2000X aod Actuator

Manual Change Information

NOTE

i

i

At Branson, we strive to maintain our position as the leader in ultrasonics plastics joining, cleaning

and related technologies by continually improving our circuits and components in our equipment.

These improvements are incorporated as soon as they are developed and thoroughly tested.

Information concerning any improvements will be added to the appropriate technical documentation

at its next revision and printing. Therefore, when requesting service assistance for specific units, note

the Revision information found on the cover of this document, and refer to the printing date which

appears at the bottom of this page.

Copyright

Loctite is a registered trademark of Henkel Corporation U.S.A.

Other trademarks and service marks mentioned herein are held by their respective

owners.

© BRANSON Ultrasonics Corporation Printed in U.S.A. September 2017

2000X aod

Actuator

Instruction Manual

Foreword

Congratulations on your choice of a Branson Ultrasonics Corporation system!

The Branson 2000X-Series system is process equipment for the joining of plastic parts using

ultrasonic energy. It is the newest generation of product using this sophisticated technology for

a variety of customer applications. This Instruction Manual is part of the documentation set for

this system, and should be kept with the equipment.

Thank you for choosing Branson!

Introduction

This manual is arranged into several structured chapters which will help you find the information

you may need to know to safely handle, install, set up, program, operate, and/or maintain this

product. Please refer to the Table of Contents and/or the Index of this manual to find the information you may be looking for. In the event you require additional assistance or information,

please contact our Product Support department (see How to Contact Branson

information on how to contact them) or your local Branson representative.

iv 100-214-282 Rev. 07

on page 1-10 for

2000X aod Actuator

Instruction Manual

Table of Contents

1 Safety and Support

1.1 Safety Requirements and Warnings - - - - - - - - - - - - - 1-2

1.1.1 Symbols Found in this Manual - - - - - - - - - - - - - - - 1-2

1.1.2 Symbols Found on the Product - - - - - - - - - - - - - - - 1-2

1.2 General Precautions - - - - - - - - - - - - - - - - - - - - - 1-3

1.2.1 Intended Use of the System - - - - - - - - - - - - - - - - 1-5

1.2.2 Safety Measures and Guards- - - - - - - - - - - - - - - - 1-5

1.2.3 Emissions - - - - - - - - - - - - - - - - - - - - - - - - - 1-6

1.2.4 Setting up the Workplace- - - - - - - - - - - - - - - - - - 1-6

1.2.5 Regulatory Compliance - - - - - - - - - - - - - - - - - - 1-6

1.3 Warranty Statement, Disclaimer - - - - - - - - - - - - - - - 1-7

1.4 How to Contact Branson - - - - - - - - - - - - - - - - - - 1-10

1.4.1 Before Calling Branson for Assistance - - - - - - - - - - - 1-10

1.5 Returning Equipment for Repair - - - - - - - - - - - - - - 1-11

1.5.1 Get an RGA Number - - - - - - - - - - - - - - - - - - - - 1-12

1.5.2 Record information about the Problem - - - - - - - - - - -1-12

1.5.3 Departments to Contact - - - - - - - - - - - - - - - - - - 1-13

1.5.4 Pack and Ship the Equipment - - - - - - - - - - - - - - -1-14

1.6 Obtaining Replacement Parts- - - - - - - - - - - - - - - - 1-14

2 Introduction to the 2000X aod Actuator

2.1 Models Covered- - - - - - - - - - - - - - - - - - - - - - - - 2-1

2.1.1 Power Supply Manual Set - - - - - - - - - - - - - - - - - 2-2

2.2 Overview of this Model - - - - - - - - - - - - - - - - - - - - 2-3

2.3 Features of the System - - - - - - - - - - - - - - - - - - - - 2-4

2.4 Controls and Indicators- - - - - - - - - - - - - - - - - - - - 2-6

2.5 Welding Systems - - - - - - - - - - - - - - - - - - - - - - - 2-7

2.6 Glossary of Terms - - - - - - - - - - - - - - - - - - - - - - 2-9

100-214-282 Rev. 07 v

3 Delivery and Handling

3.1 Shipping and Handling - - - - - - - - - - - - - - - - - - - - 3-1

3.1.1 Environmental Specifications - - - - - - - - - - - - - - - - 3-1

3.2 Receiving - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

3.3 Unpacking - - - - - - - - - - - - - - - - - - - - - - - - - - 3-3

3.3.1 Actuator Assemblies - - - - - - - - - - - - - - - - - - - - 3-3

3.4 Returning Equipment - - - - - - - - - - - - - - - - - - - - - 3-3

4 Installation and Setup

4.1 About Installation - - - - - - - - - - - - - - - - - - - - - - - 4-2

4.2 Handling and Unpacking - - - - - - - - - - - - - - - - - - - 4-2

4.2.1 Unpack the Stand or Actuator - - - - - - - - - - - - - - - 4-3

4.2.2 Stand (actuator on a base) - - - - - - - - - - - - - - - - - 4-4

4.2.3 Stand (Actuator on a Hub) - - - - - - - - - - - - - - - - - 4-5

4.2.4 Actuator (Alone) - - - - - - - - - - - - - - - - - - - - - - 4-6

4.3 Take Inventory of Small Parts - - - - - - - - - - - - - - - - 4-7

4.3.1 Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-8

4.4 Installation Requirements - - - - - - - - - - - - - - - - - - 4-9

4.4.1 Location - - - - - - - - - - - - - - - - - - - - - - - - - - 4-9

4.4.2 Environmental Specifications - - - - - - - - - - - - - - - - 4-9

4.4.3 Electrical Input Power Ratings - - - - - - - - - - - - - - - 4-10

4.4.4 Air Cylinder Consumption - - - - - - - - - - - - - - - - -4-11

4.4.5 Factory Air - - - - - - - - - - - - - - - - - - - - - - - - - 4-15

4.5 Installation Steps - - - - - - - - - - - - - - - - - - - - - - 4-16

4.5.1 Mounting the Stand (Actuator on Base) - - - - - - - - - -4-16

4.5.2 Mounting the Stand (Actuator on Hub-mounted column)- - - 4-17

4.5.3 Actuator (Alone) - - - - - - - - - - - - - - - - - - - - - - 4-19

4.5.4 Mount the Power Supply - - - - - - - - - - - - - - - - - -4-20

4.5.5 Input Power (Main)- - - - - - - - - - - - - - - - - - - - - 4-21

4.5.6 Output Power (RF Cable) - - - - - - - - - - - - - - - - - 4-21

4.5.7 Interconnect between Power Supply and Actuator - - - - - 4-21

4.5.8 Start Switch Connection (Automation) - - - - - - - - - - - 4-23

4.5.9 Serial (RS-232) Port Connector- - - - - - - - - - - - - - - 4-24

4.5.10 Parallel Printer Connector - - - - - - - - - - - - - - - - - 4-24

4.5.11 User I/O Interface - - - - - - - - - - - - - - - - - - - - -4-25

4.5.12 Input Power Plug- - - - - - - - - - - - - - - - - - - - - - 4-28

4.5.13 User I/O DIP Switch (SW1) - - - - - - - - - - - - - - - - - 4-29

vi 100-214-282 Rev. 07

2000X aod Actuator

Instruction Manual

4.5.14 Module Options DIP Switch - - - - - - - - - - - - - - - - 4-29

4.6 Guards and Safety Equipment - - - - - - - - - - - - - - - 4-30

4.6.1 Emergency Stop Control - - - - - - - - - - - - - - - - - -4-30

4.7 Rack Mount Installation- - - - - - - - - - - - - - - - - - - 4-31

4.8 Assemble the Acoustic Stack - - - - - - - - - - - - - - - 4-32

4.8.1 For a 20kHz System - - - - - - - - - - - - - - - - - - - - 4-32

4.8.2 For a 30kHz System - - - - - - - - - - - - - - - - - - - - 4-33

4.8.3 For a 40kHz System - - - - - - - - - - - - - - - - - - - - 4-33

4.8.4 Assembling the 20kHz Acoustic Stack - - - - - - - - - - - 4-34

4.8.5 Connecting Tip to Horn- - - - - - - - - - - - - - - - - - -4-35

4.8.6 Installing the Stack in the Actuator - - - - - - - - - - - - -4-36

4.9 Mounting the Fixture on the Branson Base- - - - - - - - - 4-38

4.10 Testing the Installation - - - - - - - - - - - - - - - - - - - 4-39

4.11 Still Need Help? - - - - - - - - - - - - - - - - - - - - - - - 4-40

5 Technical Specifications

5.1 Technical Specifications - - - - - - - - - - - - - - - - - - - 5-1

5.1.1 Requirement Specifications - - - - - - - - - - - - - - - - 5-1

5.1.2 Performance Specifications - - - - - - - - - - - - - - - - 5-2

5.2 Physical Description - - - - - - - - - - - - - - - - - - - - - 5-3

5.2.1 Standard Items- - - - - - - - - - - - - - - - - - - - - - - 5-3

6Operation

6.1 Actuator Controls- - - - - - - - - - - - - - - - - - - - - - - 6-1

6.2 Initial Actuator Settings- - - - - - - - - - - - - - - - - - - - 6-2

6.2.1 Regulated Air Pressure and Air Pressure Gauge - - - - - - 6-2

6.2.2 Factory Air Source - - - - - - - - - - - - - - - - - - - - - 6-3

6.2.3 Downspeed Control - - - - - - - - - - - - - - - - - - - - 6-3

6.2.4 Actuator Alignment and Height (Horn travel) - - - - - - - - 6-4

6.2.5 Mechanical Stop - - - - - - - - - - - - - - - - - - - - - - 6-4

6.2.6 Emergency Stop - - - - - - - - - - - - - - - - - - - - - - 6-5

6.3 Operating the Actuator - - - - - - - - - - - - - - - - - - - - 6-5

7 Maintenance

7.1 Calibration - - - - - - - - - - - - - - - - - - - - - - - - - - 7-1

7.2 Periodic and Preventive Maintenance - - - - - - - - - - - - 7-1

7.2.1 Periodically Clean the Equipment - - - - - - - - - - - - - - 7-1

7.2.2 Recondition the Stack (converter, booster, and horn) - - - - 7-2

100-214-282 Rev. 07 vii

7.2.3 Routine Component Replacement - - - - - - - - - - - - - 7-4

7.3 Parts Lists - - - - - - - - - - - - - - - - - - - - - - - - - - 7-5

Index

viii 100-214-282 Rev. 07

2000X aod Actuator

Instruction Manual

List of Figures

fig. 1.1 Connector label on the aod Actuator - - - - - - - - - - - - - - - - - - - - - - - - 1-2

fig. 1.2 Caution label on the aod Actuator for the factory air supply - - - - - - - - - - - - - 1-3

fig. 1.3 Safety Labels on front of the aod Actuator - - - - - - - - - - - - - - - - - - - - - 1-3

fig. 2.1 Right Side View of the 2000Xaod Actuator - - - - - - - - - - - - - - - - - - - - 2-2

fig. 4.1 Linear Encoder is Sensitive; Do Not Handle it! - - - - - - - - - - - - - - - - - - - 4-3

fig. 4.2 Unpacking the Stand (Actuator on a Base); Right-side View of Stand - - - - - - - - 4-4

fig. 4.3 Unpacking the Stand (Actuator on a Hub); Hub Shown Separately - - - - - - - - - 4-5

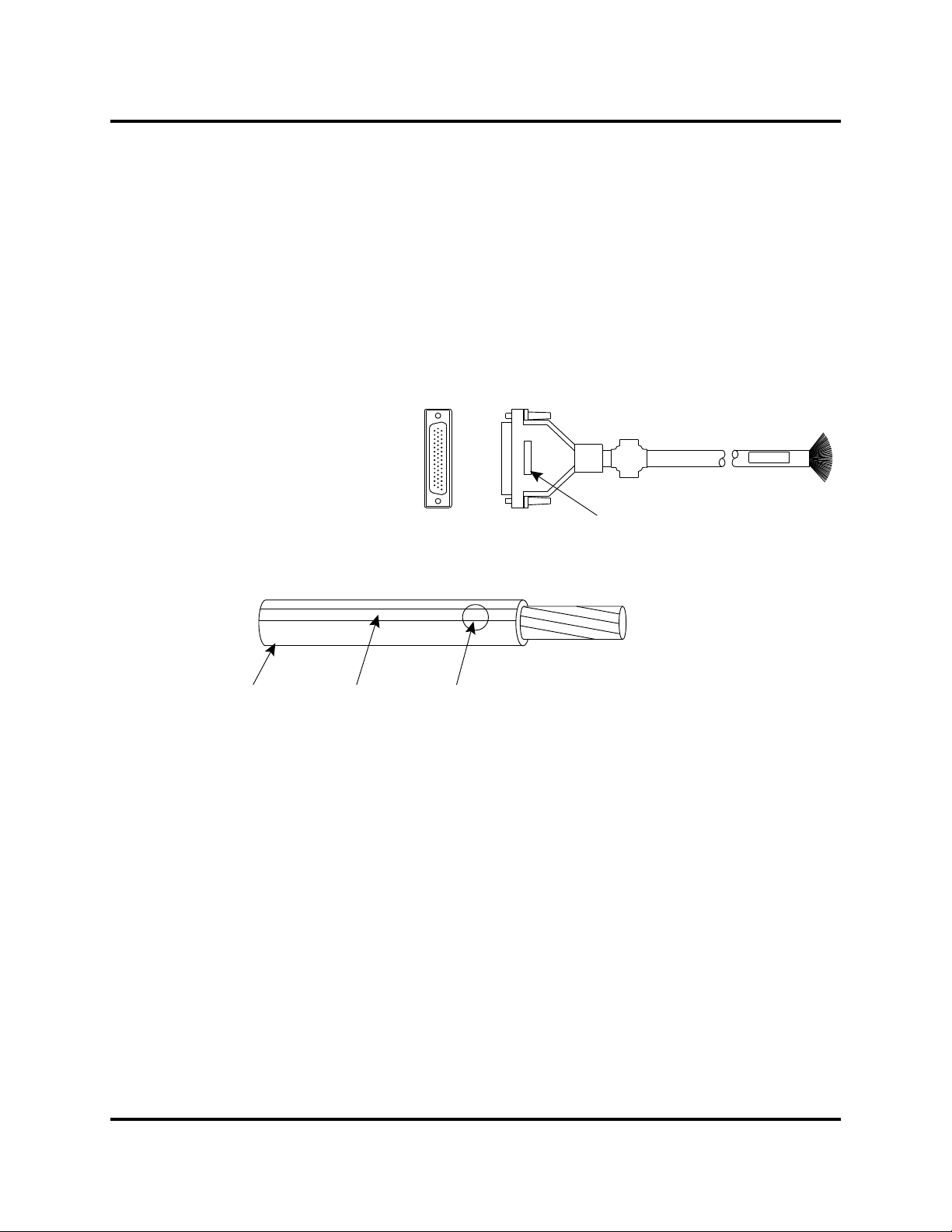

fig. 4.4 Ultrasonic Converter (J-Type for Stand-Alone Use) and Booster - - - - - - - - - - 4-7

fig. 4.5 Power Supply Dimensional Drawing - - - - - - - - - - - - - - - - - - - - - - - - 4-12

fig. 4.6 aod Actuator Dimensional Drawing - - - - - - - - - - - - - - - - - - - - - - - - - 4-13

fig. 4.7 Block Wiring Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-14

fig. 4.8 Base Mounting Centers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-17

fig. 4.9 Mounting Bolt Pattern for the Hub (for Stand on Hub) - - - - - - - - - - - - - - - - 4-18

fig. 4.10 Rear view of Actuator, showing Mounting Surface, Bolt and Guide Pin locations- - 4-19

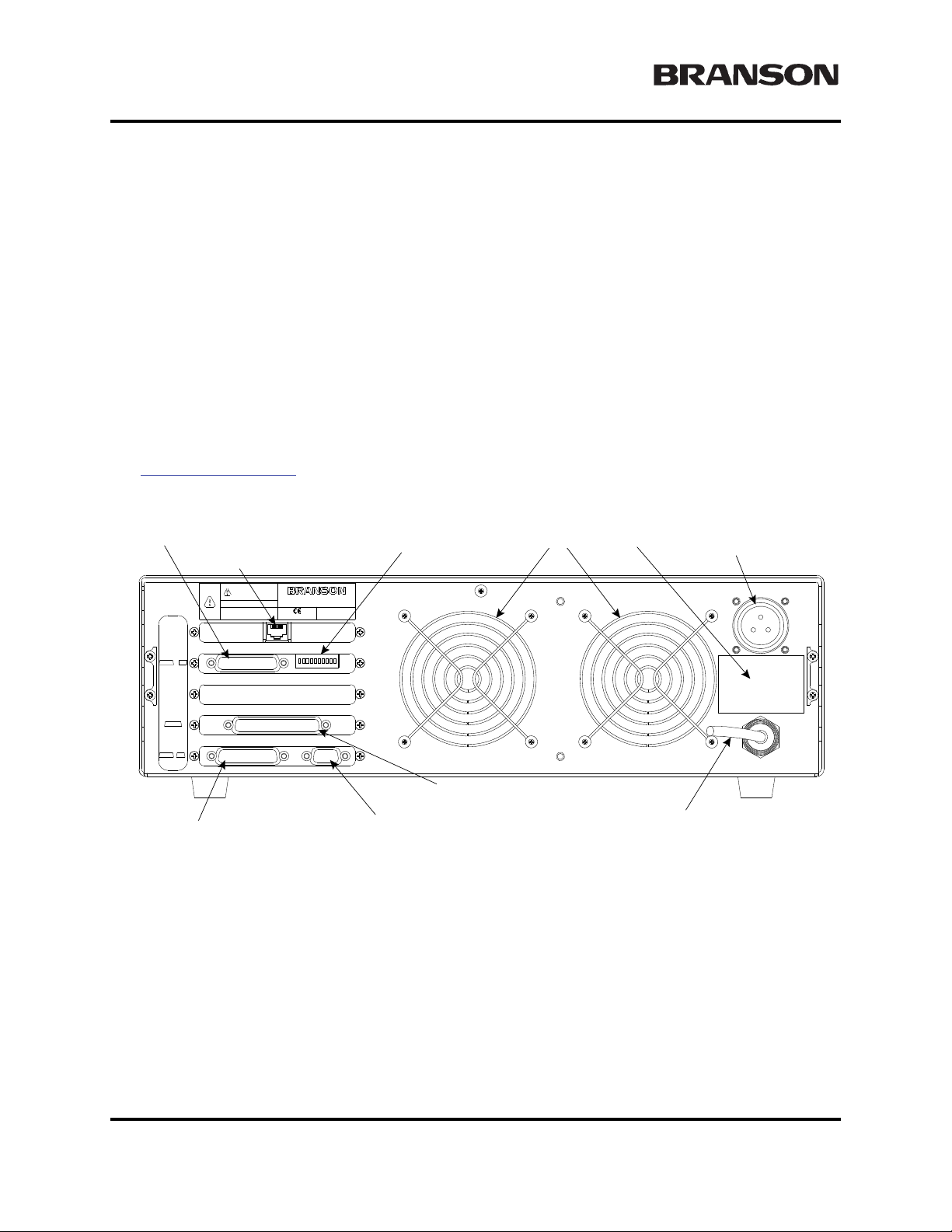

fig. 4.11 Connections on Rear of Power Supply - - - - - - - - - - - - - - - - - - - - - - - 4-20

fig. 4.12 Electrical Connections from Power Supply to a 2000-series Actuator - - - - - - - - 4-22

fig. 4.13 Start Switch Connection Codes - - - - - - - - - - - - - - - - - - - - - - - - - - 4-23

fig. 4.14 User I/O Cable Identification and Wire Color Diagram- - - - - - - - - - - - - - - -4-25

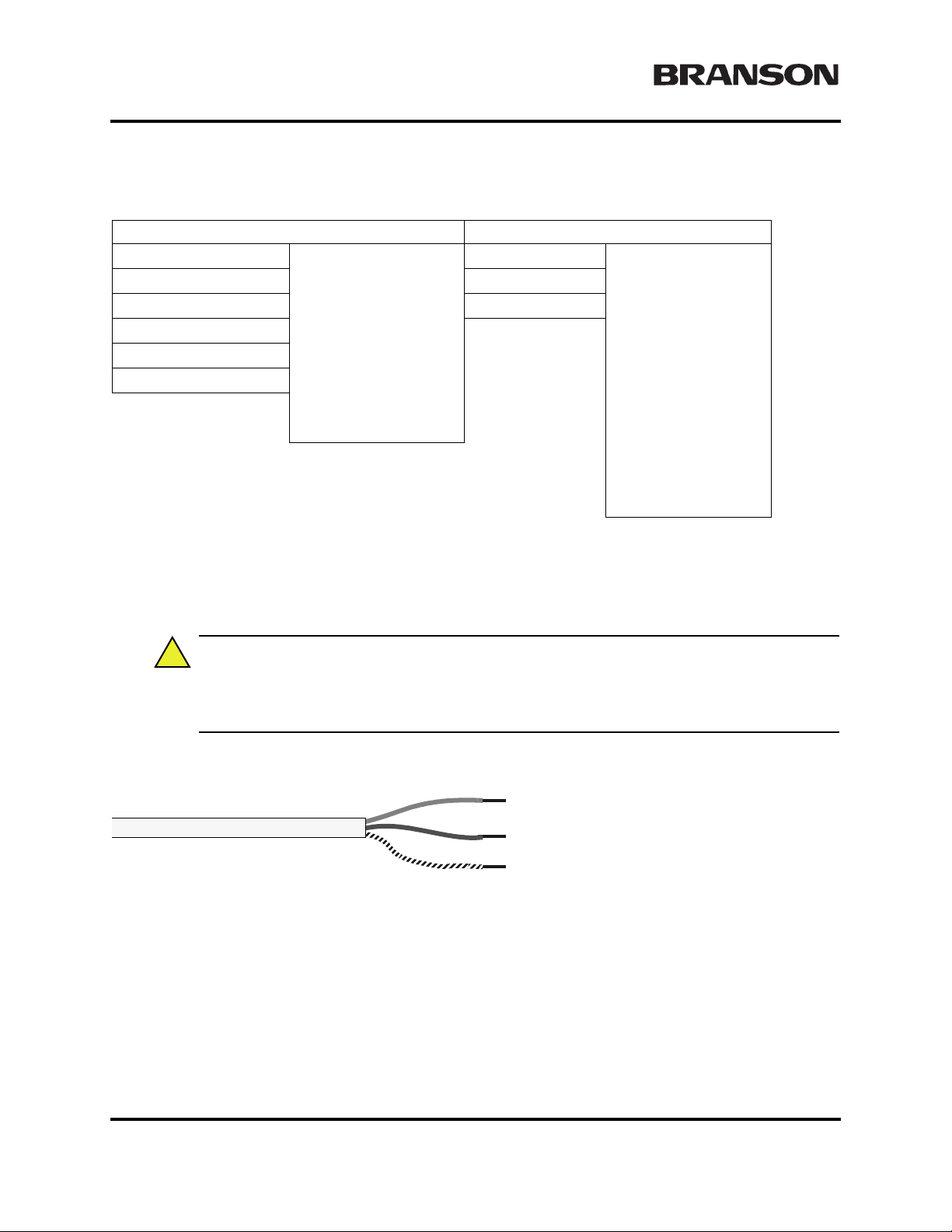

fig. 4.15 Line Cord Color Code - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-28

fig. 4.16 Actuator Emergency Stop Button - - - - - - - - - - - - - - - - - - - - - - - - - - 4-30

fig. 4.17 Detail of Rack Mount Handle Kit Assembly - - - - - - - - - - - - - - - - - - - - -4-31

fig. 4.18 Assembling the 20kHz Acoustic Stack - - - - - - - - - - - - - - - - - - - - - - - 4-34

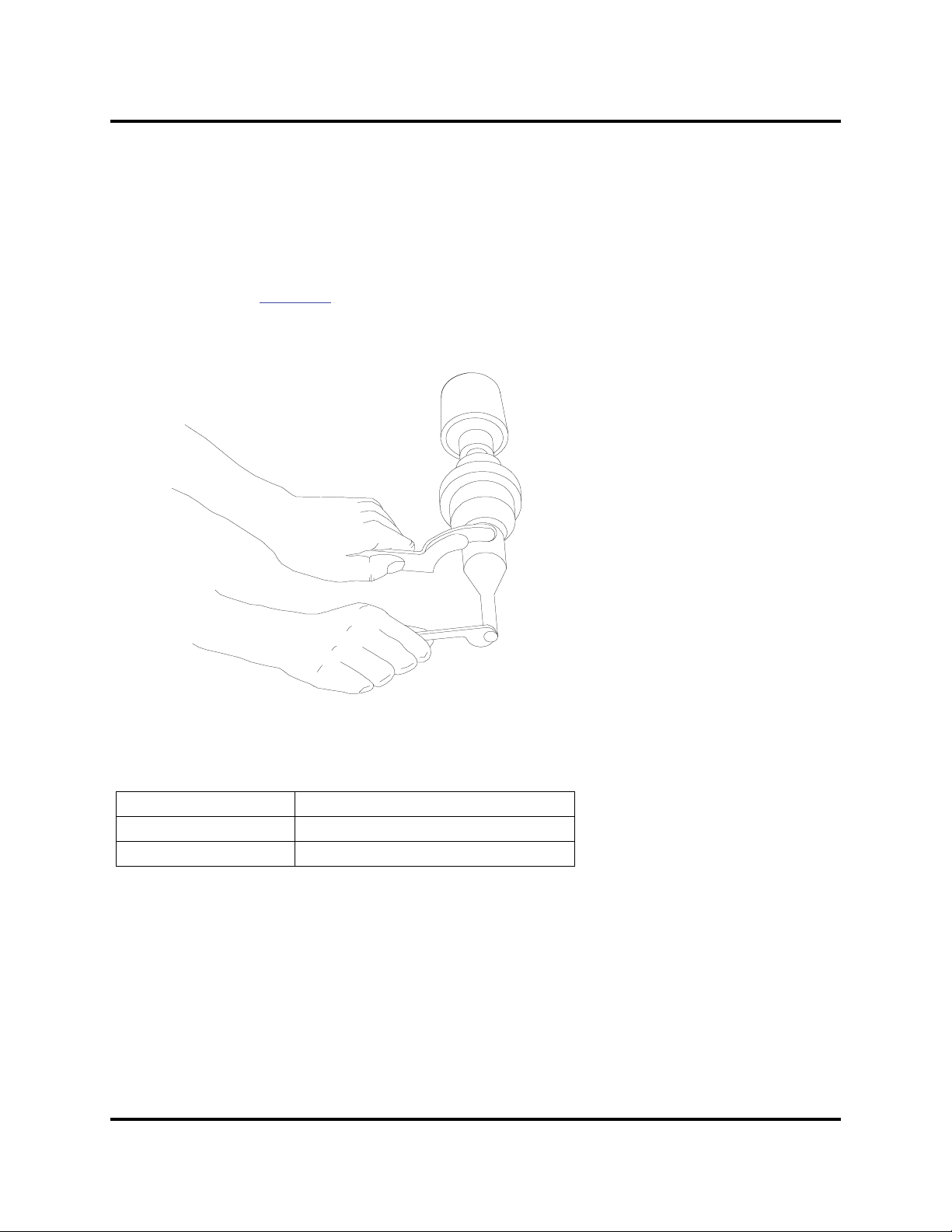

fig. 4.19 Connecting Tip to Horn - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-35

fig. 4.20 Installing a 20kHz Stack in a Branson Actuator - - - - - - - - - - - - - - - - - - - 4-36

fig. 4.21 Installing a 40kHz Stack in a Branson Actuator - - - - - - - - - - - - - - - - - - - 4-37

fig. 4.22 Mounting Circles on Base - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-38

fig. 4.23 Normal Front Panel Display After Power-Up - - - - - - - - - - - - - - - - - - - - 4-39

fig. 5.1 2000X Actuator Pneumatic System- - - - - - - - - - - - - - - - - - - - - - - - - 5-5

100-214-282 Rev. 07 ix

x 100-214-282 Rev. 07

2000X aod Actuator

Instruction Manual

List of Tables

tab. 1 .1 Warranty Period - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-8

tab. 1.2 Branson Contacts - - - - - - - - - - - - - - - - - - - - - - - - - - -1-13

tab. 3.1 Environmental Specifications - - - - - - - - - - - - - - - - - - - - - 3-1

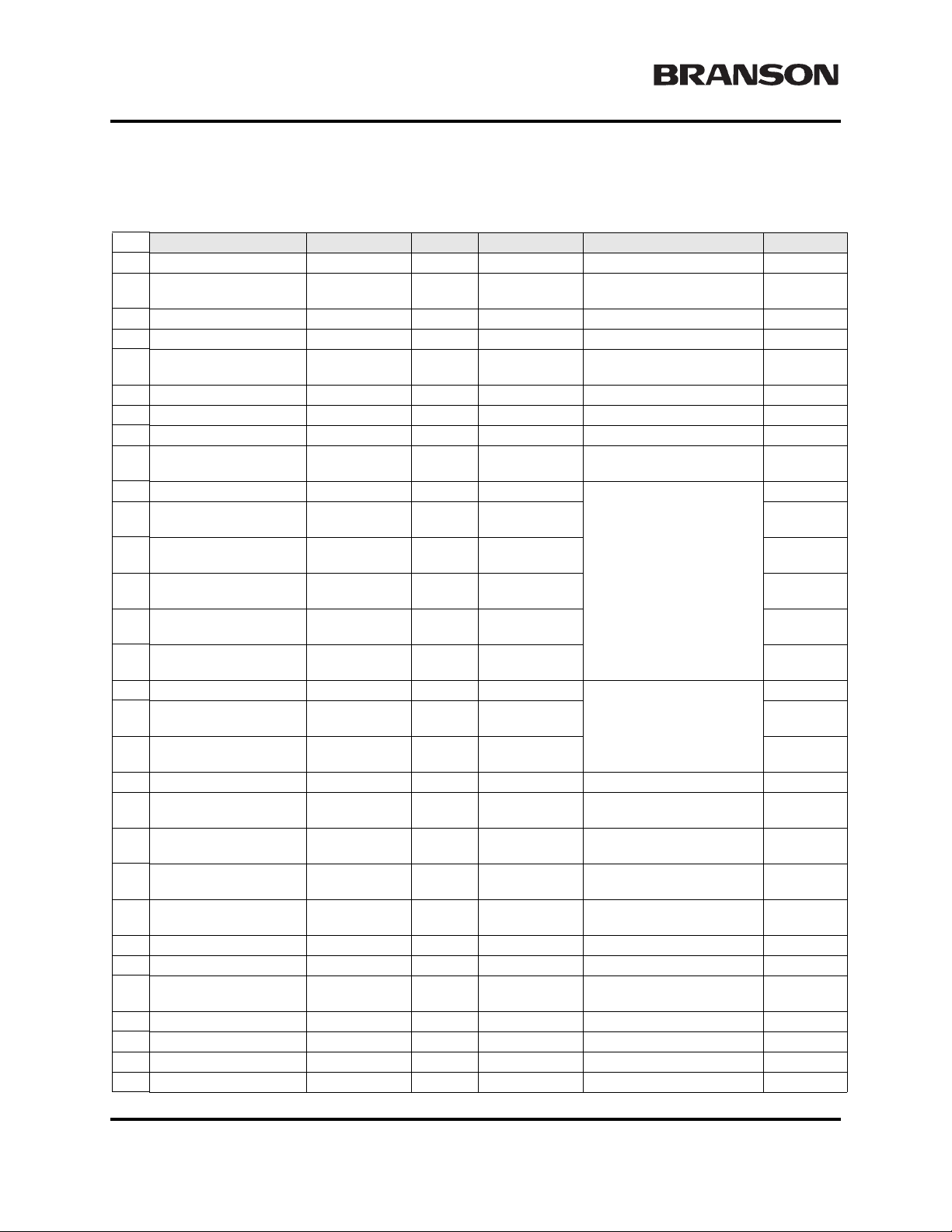

tab. 4.1 Small Parts included (=x) : Power Supply and/or Actuator Assemblies - 4-7

tab. 4.2 List of Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-8

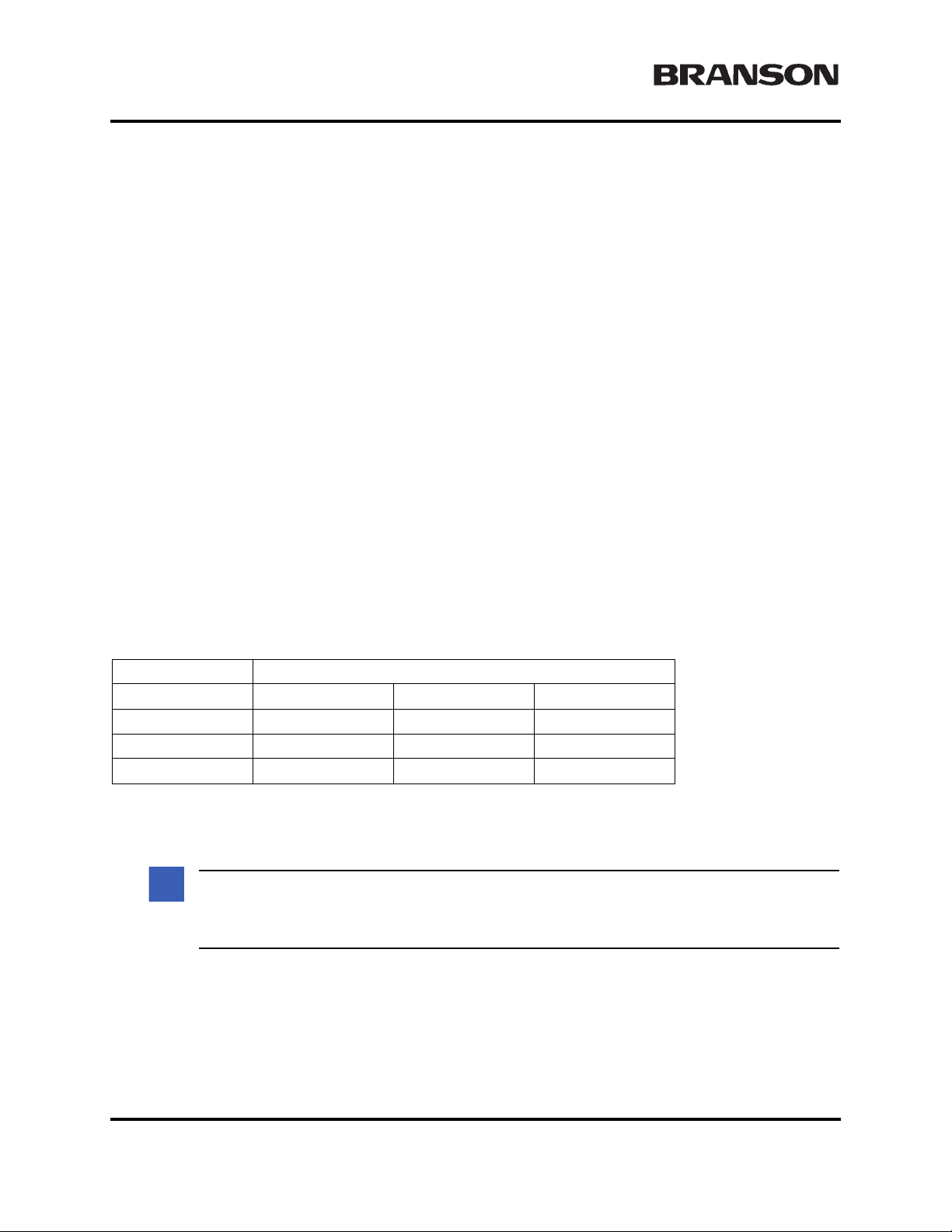

tab. 4.3 Environmental Specifications - - - - - - - - - - - - - - - - - - - - - 4-9

tab. 4.4 Input Power requirements - - - - - - - - - - - - - - - - - - - - - - -4-10

tab. 4.5 Printer Compatibility - - - - - - - - - - - - - - - - - - - - - - - - - - 4-24

tab. 4.6 User I/O Cable Pin Assignments, Alphabetical Order - - - - - - - - - -4-26

tab. 4.7 User I/O Input and Output Function Selection - - - - - - - - - - - - -4-28

tab. 4.8 User I/O DIP Switch Functions - - - - - - - - - - - - - - - - - - - - -4-29

tab. 4.9 Tools - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-32

tab. 4.10 Stud Torque Values - - - - - - - - - - - - - - - - - - - - - - - - - -4-34

tab. 4.11 Tip to Horn Torque Specifications - - - - - - - - - - - - - - - - - - - 4-35

tab. 5.1 Environmental Specifications - - - - - - - - - - - - - - - - - - - - - 5-1

tab. 5.2 Maximum Welding Force (at 100 psig and 4.0” stroke) - - - - - - - - - 5-2

tab. 5.3 Dynamic Trigger Force- - - - - - - - - - - - - - - - - - - - - - - - - 5-2

tab. 5.4 Dynamic Follow-Through - - - - - - - - - - - - - - - - - - - - - - - 5-2

tab. 5.5 Maximum Traverse Speed - - - - - - - - - - - - - - - - - - - - - - - 5-2

tab. 5.6 Description of Controls on Base - - - - - - - - - - - - - - - - - - - - 5-3

tab. 7.1 Component Replacements Based on Cycles Run - - - - - - - - - - - 7-4

tab. 7.2 Accessories List for aod Actuator - - - - - - - - - - - - - - - - - - - 7-5

tab. 7.3 Spare Parts List for the aod Actuator - - - - - - - - - - - - - - - - - - 7-7

tab. 7.4 Suggested Spares - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-9

100-214-282 Rev. 07 xi

xii 100-214-282 Rev. 07

2000X aod Actuator Chapter 1: Safety and Support

Instruction Manual

Chapter 1: Safety and Support

1.1 Safety Requirements and Warnings - - - - - - - - - - - - - 1-2

1.1.1 Symbols Found in this Manual - - - - - - - - - - - - - - - 1-2

1.1.2 Symbols Found on the Product - - - - - - - - - - - - - - - 1-2

1.2 General Precautions - - - - - - - - - - - - - - - - - - - - - 1-3

1.2.1 Intended Use of the System - - - - - - - - - - - - - - - - 1-5

1.2.2 Safety Measures and Guards - - - - - - - - - - - - - - - - 1-5

1.2.3 Emissions - - - - - - - - - - - - - - - - - - - - - - - - - 1-6

1.2.4 Setting up the Workplace - - - - - - - - - - - - - - - - - - 1-6

1.2.5 Regulatory Compliance- - - - - - - - - - - - - - - - - - - 1-6

1.3 Warranty Statement, Disclaimer - - - - - - - - - - - - - - - 1-7

1.4 How to Contact Branson - - - - - - - - - - - - - - - - - - 1-10

1.4.1 Before Calling Branson for Assistance - - - - - - - - - - 1-10

1.5 Returning Equipment for Repair - - - - - - - - - - - - - - 1-11

1.5.1 Get an RGA Number - - - - - - - - - - - - - - - - - - - 1-12

1.5.2 Record information about the Problem - - - - - - - - - - 1-12

1.5.3 Departments to Contact - - - - - - - - - - - - - - - - - 1-13

1.5.4 Pack and Ship the Equipment - - - - - - - - - - - - - - 1-14

1.6 Obtaining Replacement Parts- - - - - - - - - - - - - - - - 1-14

This chapter contains an explanation of the different Safety Notice symbols and icons found both

in this manual and on the product itself and provides additional safety information for ultrasonic

welding. This chapter also describes how to contact Branson for assistance.

100-214-282 Rev. 07 1-1

Chapter 1: Safety and Support

NOTE

i

i

CAUTION

!

WARNING

!

Safety Requirements and Warnings

1.1 Safety Requirements and Warnings

1.1.1 Symbols Found in this Manual

Three symbols used throughout this manual warrant special attention:

A Note contains important information. It does not alert the user to potential injury,

but only to a situation that might eventually require additional work or modification

if you ignore it initially.

A Caution indicates a potentially hazardous situation that, if not avoided, can

result in minor or moderate injury. It might also alert the user to unsafe practices

or conditions that can damage equipment if not corrected.

A Warning indicates a hazardous situation or practice that, if not avoided, can

result in serious injury or death.

1.1.2 Symbols Found on the Product

Familiar graphic warning symbols are used to alert the user to items of concern or hazard. The

following warning symbols appear on the 2000aod Actuator

Figure 1.1 Connector label on the aod Actuator

1-2 100-214-282 Rev. 07

2000X aod Actuator Chapter 1: Safety and Support

Instruction Manual General Precautions

Figure 1.2 Caution label on the aod Actuator for the factory air supply

Figure 1.3 Safety Labels on front of the aod Actuator

1.2 General Precautions

Take the following precautions before servicing the power supply:

• Be sure the power switch is in the Off position before making any electrical connections.

• To prevent the possibility of an electrical shock, always plug the power supply into a

grounded power source.

• Power supplies produce high voltage. Before working on the power supply module, do the

following:

• Turn off the power supply;

• Unplug main power; and

• Allow at least 2 minutes for capacitors to discharge.

• High voltage is present in the power supply. Do not operate with the cover removed.

• High line voltages exist in the ultrasonic power supply module. Common points are tied to

100-214-282 Rev. 07 1-3

Chapter 1: Safety and Support

NOTE

i

i

General Precautions

circuit reference, not chassis ground. Therefore, use only non-grounded, battery-powered

multimeters when testing these modules. Using other types of test equipment can present a

shock hazard.

• Be sure power is disconnected from the power supply before setting a DIP switch.

• Keep hands from under the horn. Down force (pressure) and ultrasonic vibrations can cause

injury.

• Do not cycle the welding system if either the RF cable or converter is disconnected.

• When using larger horns, avoid situations where fingers could be pinched between the horn

and the fixture.

• Be aware that the actuator is "armed" if air pressure is indicated by the pressure indicator on

the actuator front panel and/or the air pressure gauge in the remote box.

• In normal operation, bearing seals will retain an adequate amount of grease for safe bearing

operation. Bearing can leak but contains enough grease for the life of the bearing. Removing

and running without grease will void the warranty. For more information contact product support.

Sound level and frequency of the noise emitted during the ultrasonic assembly

process may depend upon a. type of application, b. size, shape and composition

of the material being assembled, c. shape and material of the holding fixture, d.

welder setup parameters and e. tool design. Some parts vibrate at an audible frequency during the process. Some or all of these factors may result in an uncomfortable noise being emitted during the process. In such cases operators may

need to be provided with personal protective equipment. See 29 CFR (Code of

Federal Regulations) 1910.95 Occupational Noise Exposure.

Manufacturers of Protective Materials and Equipment

Safeware, Inc

9475 Lottsford Rd.

Suite 150

Largo, MD 20774-5351

www.safewareinc.com

Hearing Protectors

David Clark

360 Franklin St.

Box 15054

Worcester, MA 01615-0054

www.davidclark.com

1-4 100-214-282 Rev. 07

2000X aod Actuator Chapter 1: Safety and Support

Instruction Manual General Precautions

Softcomm Products

2310 - T South Airport Blvd.

Chandler, AZ 85224

Sound Absorbing Material

American Acoustical Products

6 October Hill Road

Holliston, MA 01746

Singer Safety Co.

2300 W. Logan Blvd.

Chicago IL 60647-2023

Polymer Technologies, Inc.

420 - T Corporate Blvd.

Newark, DE 19702

Static Protection Equipment

Polygenex

PO Box 4468

Cary, NC 27519

Elvex Corp

13 Trowbridge Drive

Bethel, CT 06801

Tamer Industries

185 Riverside Av.

Somerset MA 02725

Foamex

1501 E. Second St.

Eddystone PA 19022

Soundcoat Company

1 Burt Drive

Deer Park, NY 11729

Electrostatics, Inc.

352D Godshall Dr.

Harleysville, PA 19438-2017

Terra Universal

700 - N Harbor Blvd.

Anaheim, CA 92805

www.terrauni.com

1.2.1 Intended Use of the System

The 2000X-series Power Supply and aod Actuator are components of an ultrasonic welding system. These are designed for a wide variety of welding or processing applications.

1.2.2 Safety Measures and Guards

The2000X aod Actuator, along with its 2000X distance Power Supply, contains software-controlled electronic safety devices intended to prevent the machine from operating in a fashion

harmful to the user. Start Switch and Emergency Stop controls are designed to prevent undesirable startup.

100-214-282 Rev. 07 1-5

Chapter 1: Safety and Support

CAUTION

!

General Precautions

1.2.3 Emissions

When being processed, certain plastic materials can emit toxic fumes, gases or other emissions

that can be hazardous to the operator’s health. Where such materials are processed, proper ventilation of the workstation is required. Check your materials suppliers for recommended protection when processing their materials.

Processing of many materials, such as PVC, can be hazardous to an operator’s

health and could cause corrosion/damage to the equipment. Use proper ventilation and take protective measures.

1.2.4 Setting up the Workplace

Measures for setting up a workplace for safe operation of the ultrasonic welder are outlined in

Chapter 4: Installation and Setup and in the 2000-series Installation Guide.

1.2.5 Regulatory Compliance

The Branson 2000aod actuator and converter receive their power and control from a 2000Xseries power supply, and together make up a system. The 2000d power supply is designed for

compliance with the following domestic (U.S.A.) and other regulatory guidelines.

• ANSI Z535.1 Safety Color Code

• ANSI Z535.3 Criteria for Safety Symbols

• ANSI Z535.4 Product Safety Signs and Labels

• BS EN ISO 12100-1, -2 Safety of Machinery - Basic concepts, general guidelines for design

• EN 55011 Limits and methods of measurement of radio disturbance of industrial, scientific

and medical radio-frequency equipment

• EN 60204-1 Safety of Machinery - Electrical Equipment of machines

• EN 60529 Degrees of protection provided by enclosure

• EN 60664-1 Insulation coordination for equipment within low-voltage systems

• EN 61000-3-3 Electromagnetic Compatibility - Limitations of voltage fluctuations and flicker

in low voltage supply systems (for European products that draw less than 1000 watts from

the line at full rated power)

• EN 61000-6-2 Electromagnetic Compatibility - Generic standards - Immunity for industrial

environments

• EN 61310-2 Safety of Machinery - Indication, marking, actuation

• NFPA 70 National Electrical Code Article 670 Industrial Machinery

• NFPA 79 Electrical Standard for Industrial Machinery

1-6 100-214-282 Rev. 07

2000X aod Actuator Chapter 1: Safety and Support

Instruction Manual Warranty Statement, Disclaimer

• 29 CFR 1910.212 OSHA General Requirements for all machines

• 47 CFR Part 18 Federal Communication Commission

All products with CE Mark require: Same as above plus

• EN 61000-3-2 Electromagnetic Compatibility - Limits for harmonic emissions (for European

products that draw less than 1000 watts from the line at full rated power)

1.3 Warranty Statement, Disclaimer

The following excerpts from the “Terms and Conditions of Sale” (found on the back of your

Invoice) are essential guidelines for the product Warranty issued with your Branson ultrasonic

welding components. The items listed in this section specifically address issues involving the

delivery, shipment, and warranty period provided. If you have any questions, please refer to the

back of the Invoice included with your system, which lists all of the Terms and Conditions of

Sale, or contact your Branson representative.

TERMS AND CONDITIONS OF SALE

Branson Ultrasonics Corporation is herein referred to as the “Seller” and the customer or person

or entity purchasing products (“Products”) from Seller is referred to as the “Buyer.” Buyer’s

acceptance of the Products will manifest Buyer’s assent to these Terms and Conditions.

100-214-282 Rev. 07 1-7

Chapter 1: Safety and Support

Warranty Statement, Disclaimer

ULTRASONIC JOINING EQUIPMENT NORTH AMERICAN WARRANTY POLICY

Each product manufactured by Branson is guaranteed to be free from defects in material and

workmanship for a period of time specified in Table 1 .1

invoice.

Table 1 .1 Warranty Period

Power Supplies 36 months

Actuators 36 months

Actuator, Special 12 months

Integrated Welders 36 months

Accessories 36 months

Warranty Period from the date of

Converters 36 months (limited to one-time replacement)

Non-Branson equipment

(i.e. printers)

Horns 12 months (limited to one-time replacement)

Boosters 36 months

Rental Equipment Same as purchased equipment

Specials and products with EDP prefix

159-xxx-xxx

Specials and products with EDP prefix

125-xxx-xxx

warranted by the manufacturer

12 months

12 months

The warranty does not apply to:

• any product which has been subject to misuse, misapplication, neglect (including

without limitation inadequate maintenance), accident or improper installation, modification or adjustment.

• applications requiring metal-to-metal contact when the ultrasonic exposure time

exceeds 1.5 seconds.

• any product exposed to adverse environments, improper repair or repairs using nonBranson methods or material.

• non-Branson equipment (i.e., horns, boosters, converters) or improperly tuned

horns.

• Set up/installation of equipment and software updates.

1-8 100-214-282 Rev. 07

2000X aod Actuator Chapter 1: Safety and Support

Instruction Manual Warranty Statement, Disclaimer

Warranty Service covers the following:

Repair service at Branson´s main repair facility or a regional office

• Includes parts and labor performed at Branson authorized repair facilities. The customer

must return the equipment properly packed with all shipping charges prepaid.

Repair service at the customer site

• Includes parts and labor at the customer site performed by a Branson technician. The customer is responsible for all travel-related charges.

Module trade-in:

• Includes serialized components for work performed by the customer. The customer

orders the replacement components from the Parts Store and issues a P.O. When

the failed components are returned to Branson the warranty status is verified and a

credit is issued. The customer is responsible for all shipping charges.

Additional Warranty Notes

• Components replaced during in-warranty repair carries the remainder of the original

warranty.

• Serialized assemblies replaced during the repair of out-of-warranty equipment are

warranted for a period of 12 months.

• Travel charges for Branson service personnel will be waived on service calls performed within 30 days of invoice date.

• Non-serialized parts replaced during the repair of out-of-warranty equipment are

warranted for 3 months.

• Trade in allowance: Branson out-of-warranty serialized components are entitled to a

25% trade in allowance regardless of age or condition, however, converters must be

less than 5 years old to qualify for the trade in.

If you have any questions concerning the warranty coverage (including coverage outside of

North America), please contact your Branson representative or Branson Customer Support.

100-214-282 Rev. 07 1-9

Chapter 1: Safety and Support

How to Contact Branson

1.4 How to Contact Branson

Branson is here to help you. We appreciate your business and are interested in helping you successfully use our products. To contact Branson for help, use the following telephone numbers,

or contact the field office nearest you.

• Danbury Main Number (all Departments): (203) 796-0400 (Eastern Time Zone)

• Parts Store (direct number): (877) 330-0406 (Central Time Zone)

• Repair department: (877)-330-0405 (Central Time Zone)

• For emergency after-hours service (5pm-8am Est): (203) 796-0500 (US phone numbers

only).

Tell the operator which product you have and which person or department you need (see Section

1.5.3

Departments to Contact). If you are calling after hours, please leave a voice message with

your name and return telephone number.

1.4.1 Before Calling Branson for Assistance

This manual provides information for troubleshooting and resolving problems that could occur

with the equipment (see Chapter 7). If you still require assistance, Branson Product Support is

here to help you. To help identify the problem, use the following questionnaire which lists the

common questions you will be asked when you contact the Product Support department.

Before calling, determine the following information:

1. Your company name and location.

2. Your return telephone number.

3. Have your manual with you. If troubleshooting a problem, refer to Chapter 7.

4. Know your equipment model and serial numbers (found on a gray data label on the units).

Information about the Horn (part number, gain, etc.) or other tooling may be etched into the

tooling. Software- or firmware-based systems may provide a BOS or software version number, which may be required.

5. What tooling (horn) and booster are being used?

6. What are the setup parameters and mode?

7. Is your equipment in an automated system? If so, what is supplying the “start” signal?

8. Describe the problem; provide as much detail as possible. For example, is the problem intermittent? How often does it occur? How long before it occurs if you are just powering up? If

an error is occurring, which error (give error number or name)?

9. List the steps you have already taken.

10. What is your application, including the materials being processed?

11. Have a list of service or spare parts you have on hand (tips, horns, etc.)

12. Notes: __________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

1-10 100-214-282 Rev. 07

2000X aod Actuator Chapter 1: Safety and Support

NOTE

i

i

Instruction Manual Returning Equipment for Repair

1.5 Returning Equipment for Repair

Before sending equipment for repair, provide as much information with the equipment to help

determine the problem with the system. Fill in any details below or on a separate sheet.

Describe the problem; provide as much detail as possible. For example, is this a new problem?

Is the problem intermittent? How often does it occur? How long before it occurs if you are just

powering up?

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

To return equipment to Branson, you must first obtain an RGA number from a

Branson representative, or the shipment may be delayed or refused.

If you are returning equipment to Branson for repair, you must first call the Repair department

to obtain a Returned Goods Authorization

ment will fax a Returned Goods Authorization form to fill out and return with your equipment.)

Branson Repair Department, C/O Zuniga Logistics, LTD

2013 Sara Road, Killam Industrial Park

Laredo, Texas 78045 U.S.A. direct

telephone number: (877) 330-0405

fax number: (877) 330-0404

• Provide as much information as possible that will help identify the need for repair.

• Carefully pack the equipment in original packing cartons.

• Clearly label all shipping cartons with the RGA number on the outside of cartons as well as

on your packing slip, along with the reason for return.

• Return general repairs by any convenient method. Send priority repairs by air freight.

• You must prepay the transportation charges FOB Laredo, Texas, U.S.A.

(RGA) number. (If you request it, the repair depart-

100-214-282 Rev. 07 1-11

Chapter 1: Safety and Support

Returning Equipment for Repair

1.5.1 Get an RGA Number

RGA# _____________

If you are returning equipment to Branson, please call the Repair Department to obtain a

Returned Goods Authorization (RGA) number. (At your request, the Repair Department will fax

an RGA form to fill out and return with the equipment.)

1.5.2 Record information about the Problem

Before sending equipment for repair, record the following information and send a copy of it with

the equipment. This will greatly increase Branson’s ability to address the problem.

1. Describe the problem; provide as much detail as possible.

For example, is the problem intermittent? How often does it occur? How long before it

occurs after powering up?

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

2. Is your equipment in an automated system? NO / YES

3. If the problem is with an external signal, which signal? ______________________

If known, include plug/pin # (e.g., P29, pin #3) for that signal: _________________

4. What are the Weld Parameters?

________________________________________________________________________

________________________________________________________________________

5. What is your application? (Type of weld, plastic material, etc.)

________________________________________________________________________

6. Name and phone number of the person most familiar with the problem:

________________________________________________________________________

________________________________________________________________________

7. Contact the Branson office prior to shipping the equipment.

8. For equipment not covered by warranty, to avoid delay, include a Purchase Order.

Send a copy of this page with the equipment being returned for repair.

1-12 100-214-282 Rev. 07

2000X aod Actuator Chapter 1: Safety and Support

Instruction Manual Returning Equipment for Repair

1.5.3 Departments to Contact

Call your local Branson Representative, or contact Branson by calling, and asking for the appropriate

department as indicated in Table 1.2:

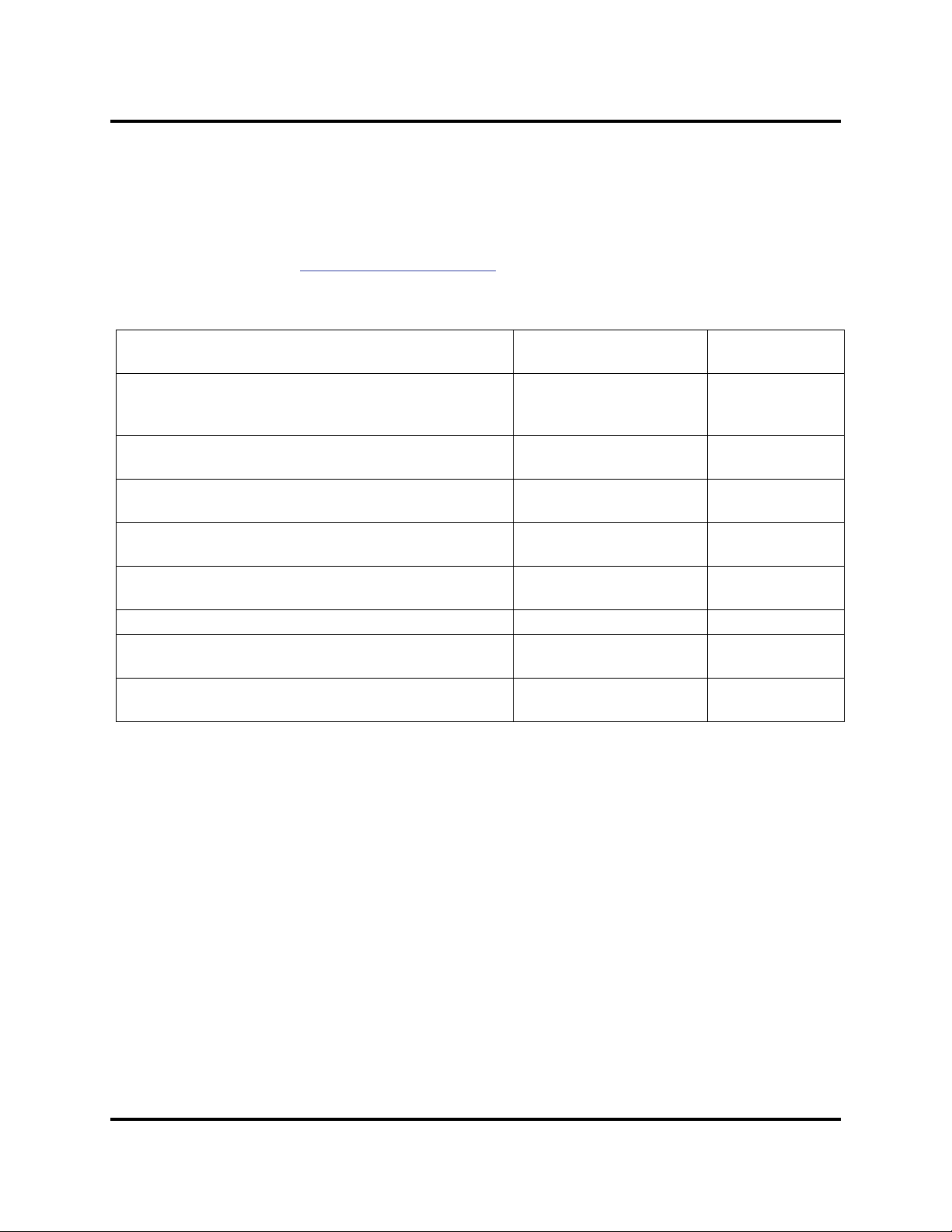

Table 1.2 Branson Contacts

Branson Contacts below.

What you need help with or information about . . . Whom to Call

Your local Branson Rep

Information about new welding systems or components

Application and Setup questions on the

welding system

Application assistance on the Horns and

Tooling

Technical questions about the welding system Welding Product Support

Technical questions about Horns and Tooling ATG Lab

Ordering new parts Parts Store 877-330-0406

RGA’s, Request for Repair, Status of a Repair

System Automation/Hookup Information Product Support

or Branson Customer

Service

Welding Applications Lab

ATG L a b

Welding Repair Department

At this Phone

Number

203-796-0400

Ext 384

203-796-0400

Ext 368

203-796-0400

Ext 495

203-796-0400

Ext 355

203-796-0400

Ext 495

877-330-0405

203-796-0400

Ext 355

My Local Branson Representative’s name is:

__________________________________________________

I can reach this representative at:

___________________________________________________________________

100-214-282 Rev. 07 1-13

Chapter 1: Safety and Support

NOTE

i

i

Obtaining Replacement Parts

1.5.4 Pack and Ship the Equipment

1. Carefully pack the system in original packing material to avoid shipping damage. Plainly show the

RGA number on the outside of cartons as well as inside the carton along with the reason for return.

Make a list of all components packed in the box. KEEP YOUR MANUAL.

2. Return general repairs by any convenient method. Send priority repairs by air freight. Prepay the

transportation charges FOB the repair site.

Items that are sent Freight Collect will be refused.

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

1.6 Obtaining Replacement Parts

You can reach Branson Parts Store at the following telephone numbers:

Branson Part Store

direct telephone number: 877-330-0406

fax number: 877-330-0404

Many parts can be shipped the same day if ordered before 2:30 p.m., Eastern time.

A parts list is found in Chapter 7 of this manual, listing descriptions and EDP part numbers. If

you need replacement parts, coordinate the following with your purchasing agent:

• Purchase order number

• ‘Ship to’ information

• ‘Bill to’ information

• Shipping instructions (air freight, truck, etc.)

• Any special instructions (for example, “Hold at the airport and call”). Be sure to give a name

and phone number

• Contact name information

1-14 100-214-282 Rev. 07

2000X aod Actuator Chapter 2: Introduction to the 2000X aod Actuator

NOTE

i

i

Instruction Manual Models Covered

Chapter 2: Introduction to the 2000X aod

Actuator

2.1 Models Covered- - - - - - - - - - - - - - - - - - - - - - - - 2-1

2.1.1 Power Supply Manual Set - - - - - - - - - - - - - - - - - 2-2

2.2 Overview of this Model - - - - - - - - - - - - - - - - - - - - 2-3

2.3 Features of the System - - - - - - - - - - - - - - - - - - - - 2-4

2.4 Controls and Indicators - - - - - - - - - - - - - - - - - - - - 2-6

2.5 Welding Systems - - - - - - - - - - - - - - - - - - - - - - - 2-7

2.6 Glossary of Terms - - - - - - - - - - - - - - - - - - - - - - 2-9

The 2000X aod Actuator provides motion, force, power (from the power supply), and cooling

air to the ultrasonic stack assembly. The 2000X aod Actuator is designed to work with a Branson

2000X distance Power Supply.

2.1 Models Covered

This manual covers the Branson 2000X aod Actuator. The 2000X aod Actuator may be found in

one of several configurations:

• An Actuator on a Column Support, Column and Ergonomic Base, also called a Stand on Base

(as seen on the following page)

• An Actuator on a Column Support, Column and Mounting Hub, sometimes called a Stand on

Hub

• An Actuator alone (not installed on a Column Support, and so on.). These are often used in

custom or automated systems that provide a means of positioning the Actuator.

This manual covers these configurations. A 2000X-series actuator requires a 2000X-series

power supply to function, and that is covered in separate manuals and user documents.

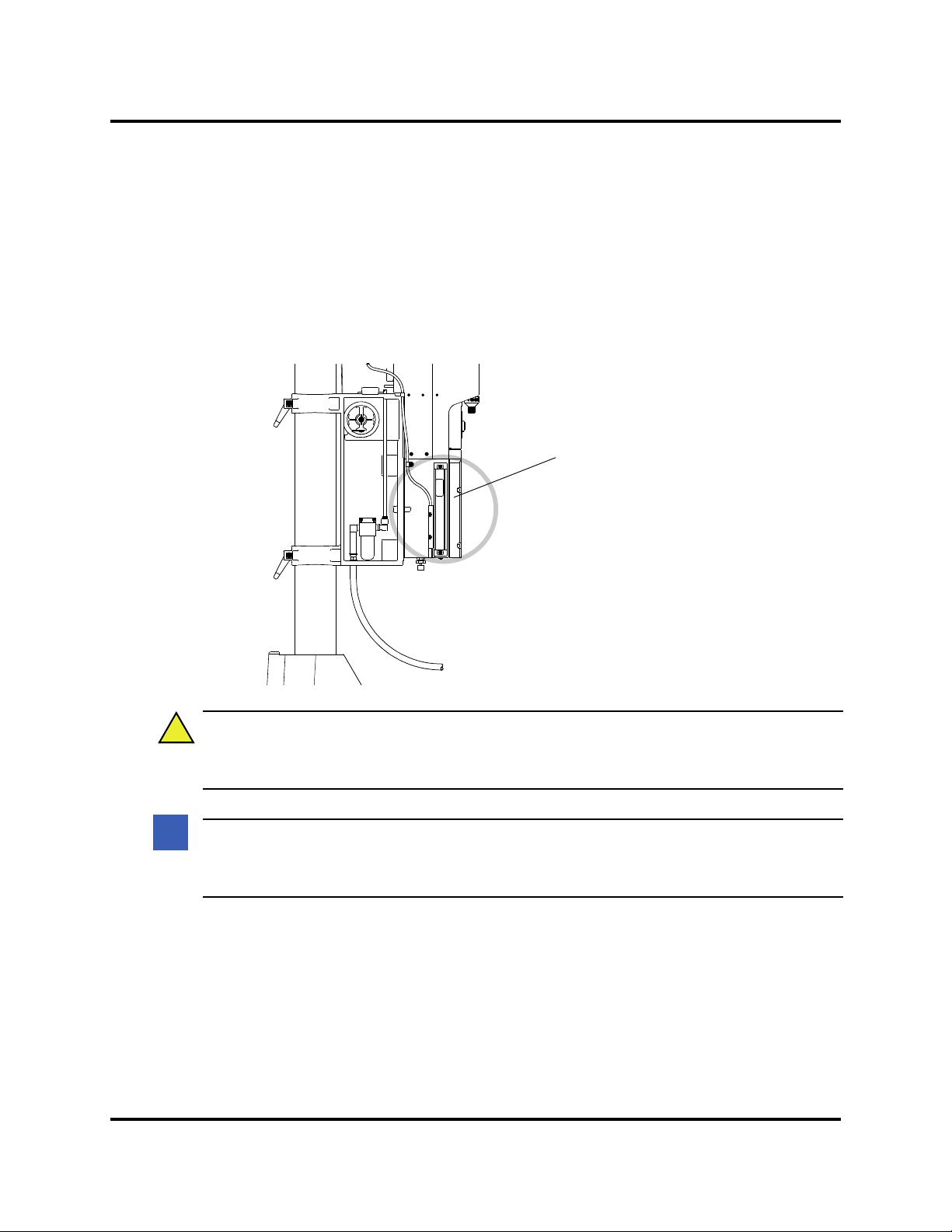

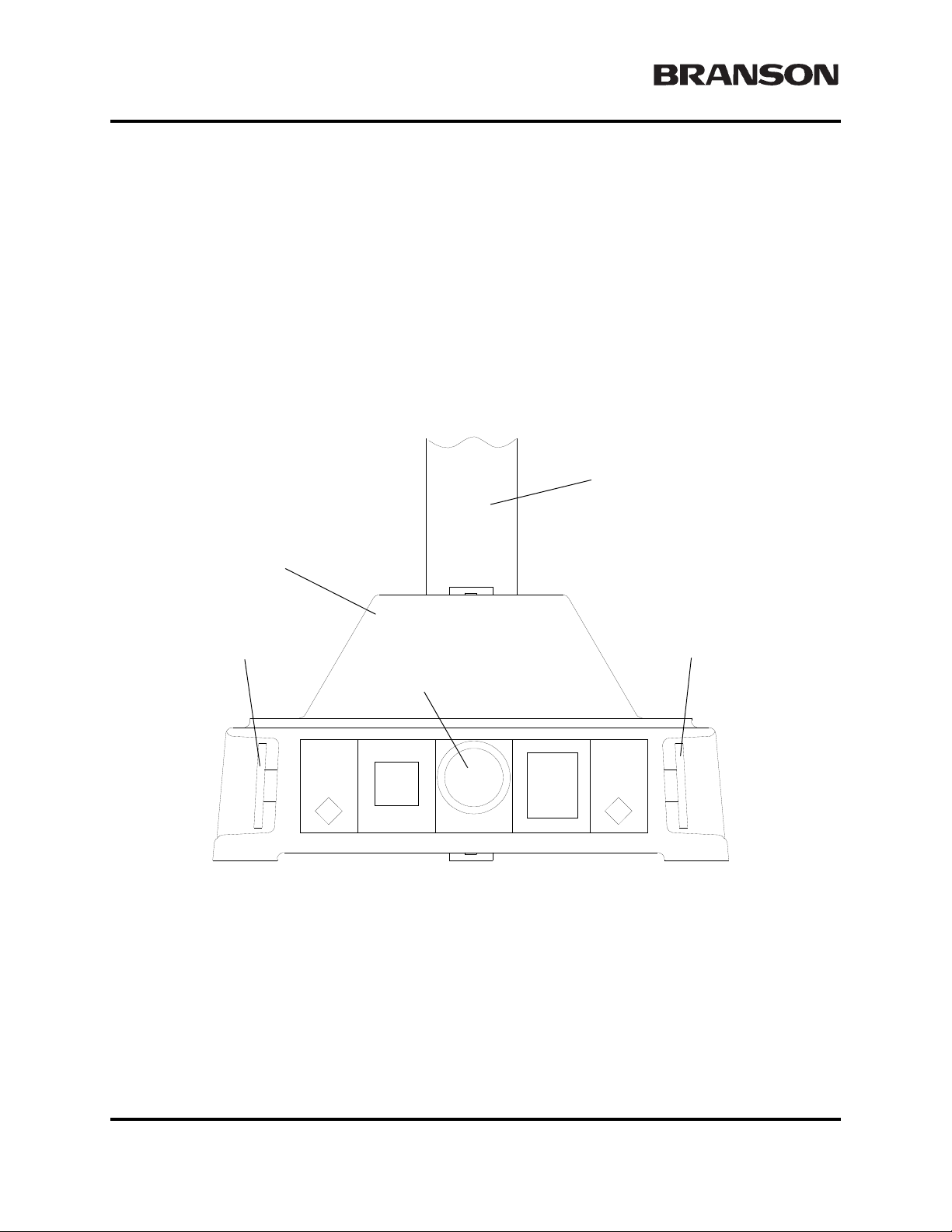

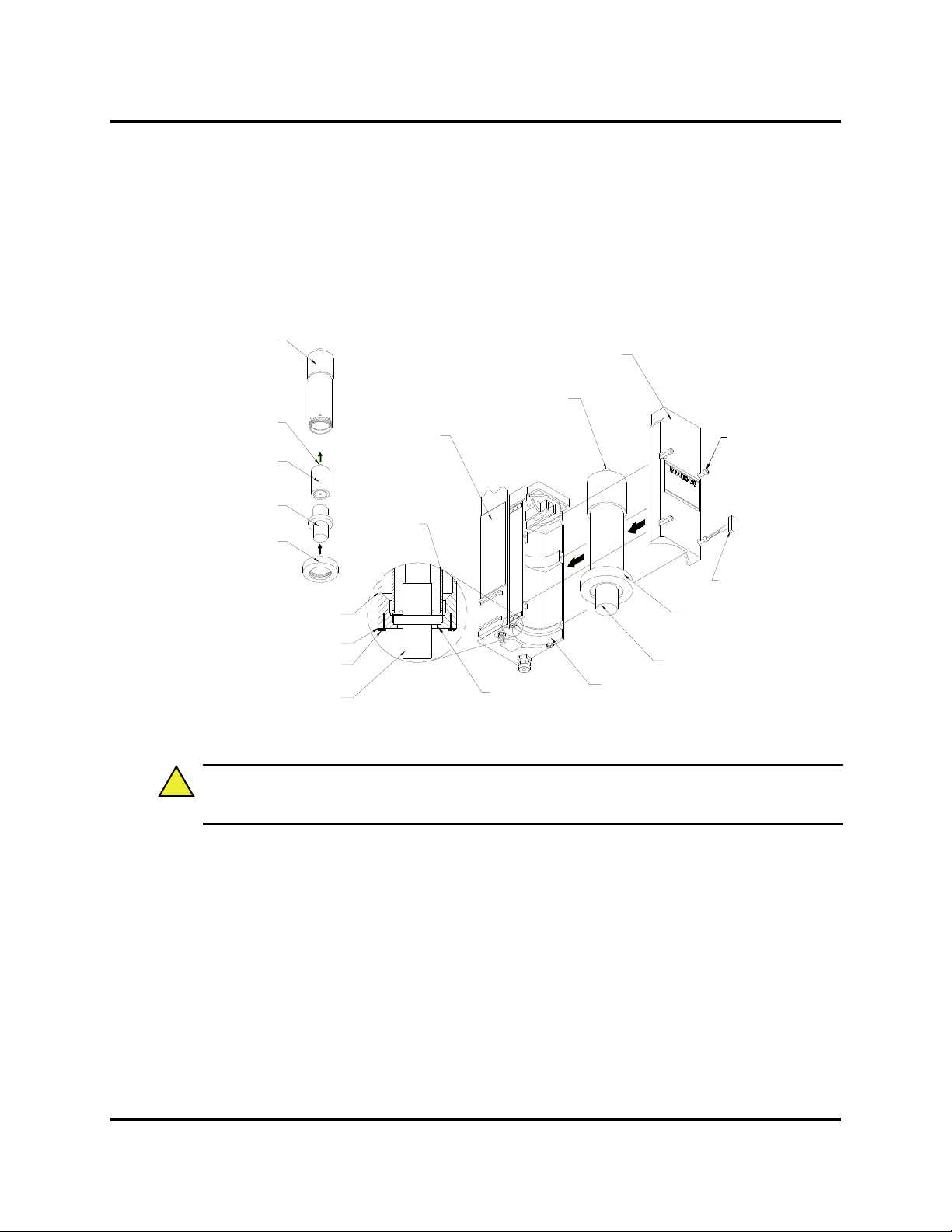

Figure 2-1 shows a Branson 2000X aod Actuator mounted on a column support which, in turn

is mounted on a column, and is supported by the ergonomic base.

Pneumatics are sold separately and referred to as rp as covered by this manual.

100-214-282 Rev. 07 2-1

Chapter 2: Introduction to the 2000X aod Actuator

Base

Column Support Clamps

Actuator Support

(Optional)

Column

2000X aod Actuator

Encoder

Mechanical

Stop Adjust

Models Covered

Figure 2.1 Right Side View of the 2000Xaod Actuator

2-2 100-214-282 Rev. 07

2.1.1 Power Supply Manual Set

The following documentation is available for the Branson 2000X-series Power Supplies that are

compatible with the 2000Xaod Actuator:

• 2000X distance Power Supply Instruction Manual (EDP 100-412-167)

• 2000-Series Installation Guide (EDP 100-214-226)

• 2000X distance Quick Start User’s Guide (EDP 100-412-169)

2000X aod Actuator Chapter 2: Introduction to the 2000X aod Actuator

Instruction Manual Overview of this Model

2.2 Overview of this Model

The 2000X aod Actuator is a compact, rigid unit designed for use in manual, semi-automated,

and automated ultrasonic welding systems. The Actuator can be mounted directly on an I-beam

(or similar machine frame), or it can be mounted on a column and base with start switches and

used in a manual or benchtop system. The Actuator is designed to be operated in an upright position, but is capable of running horizontally or inverted. If you are mounting your equipment in

an inverted position, contact Branson for further recommendations. (See Section 1.5.3, Depart-

ments to Contact, on page 1-13.)

The 2000X aod Actuator requires a 2000X distance Power Supply for power and control of the

Actuator’s operation and to provide ultrasonic power to the Converter in the Actuator.

The 2000X aod Actuator is designed with remotely-mountable pneumatic controls. Operation

of the 2000X aod is controlled by inputs to the 2000X distance Power Supply. Having remote

pneumatic controls allows easier user access to the Actuator settings, often important in automated systems. The pneumatics covered in this manual refer to the remote box package sold by

Branson. Some customers may require custom controls.

The Carriage and Slide System

The 2000X aod Actuator’s carriage is driven by a double-acting air cylinder. It is mounted on a

linear ball-bearing slide. The slide system is based on eight sets of preloaded, permanently

lubricated bearings and provides consistent, precise alignment of the horn, smooth linear

motion, and long-term reliability.

The Pneumatic System

The pneumatic controls on the 2000X aod are contained in the 2000X rp Remote Pneumatics

box, which is connected to the Actuator with three (3)1/4-inch-OD poly tubing lines. The 2000X

aod Actuator’s carriage and sheet-metal enclosure contains the air cylinder, which receives air

pressure and control from the 2000X rp. There is a pressure sensor in the actuator to allow the

power supply to read the regulated air pressure.

The air pressure regulator, solenoid valves, and air pressure gauge are found in the remote box.

Filtered factory air is connected to the 2000Xaod.

The horn’s rate of descent is adjusted by the Downspeed control on the Remote Pneumatics

Box. The rate of return is fixed. For information on setting the Downspeed control, see Section

2.4: Controls and Indicators.

Dynamic Triggering and Follow-Through

Many welding applications require force to be built up on the part before ultrasonic energy is

activated. To achieve this, the Actuator contains a S-Beam load cell, located between the air cylinder and the converter, which initiates (triggers) ultrasonics after a preset force is applied to the

part. Dynamic follow-through maintains a consistent force on the part during the weld collapse.

This system helps provide uniform weld quality.

100-214-282 Rev. 07 2-3

Chapter 2: Introduction to the 2000X aod Actuator

Features of the System

The dynamic triggering and follow-through process operates as follows: upon activation of the

operating cycle, the solenoid valve delivers regulated air to the upper portion of the cylinder, and

exhausts air through the Downspeed control from the bottom of the cylinder, causing the horn

to advance and contact the workpiece. When the load cell measurement of the force on the part

indicates part contact, and the desired trigger force is reached, a signal is sent to the Power Supply, which then starts the weld cycle. At this time, the actuator locks into a cycle, timing begins,

and the palm buttons can be released. As melting of the plastic occurs, the load cell dynamic follow through maintains consistent force on the part, ensuring smooth, efficient transmission of

ultrasonic energy into the part.

2.3 Features of the System

Listed below are many features of the Branson 2000X-series ultrasonic welding system included

in a 2000X aod Actuator and 2000X distance Power Supply.

• Autotuning: Branson Power Supply tuning ensures that the system is running at

peak efficiency.

• Amplitude Stepping: A patented Branson process, controlled by the Power Supply.

At a specified time, energy, peak power, distance, or by external signal you can

change the amplitude during the weld to control the flow of plastic. This feature helps

ensure part consistency, higher strength parts and control of flash.

• Digital Horn Test Diagnostics: In Test mode of the Power Supply, you can view the

Horn Test results in digital form, using digital readouts and bar graphs on the Power

Supply to give you the best picture of the stack’s operation.

• Pretrigger: This feature allows you to set the system weld controls to turn the

ultrasonics on before contact with the part.

• Afterburst: This feature allows you to set the system weld controls to turn the

ultrasonics on after the weld and hold steps to release parts from the horn.

• Control Limits: With some power supply models, these secondary controls are

used in conjunction with the main parameters of the weld parameters. These userprogrammed limits provide for adaptive control of the weld process.

• Process Alarm Display Showing Actual and Set Values: When an alarm

condition has occurred, you can view the value for the last weld and the suspect and

reject settings you programmed into the controls.

• Post Weld Seek: This system feature provides a short burst of energy at the end of

the weld Hold and Afterburst steps to automatically retune the power supply, if

required.

• Frequency Offset: This process feature allows a user to set a frequency value, for

certain specific applications, where the force imparted on the fixture or anvil causes

a frequency shift in the Stack’s operation. You should only use this feature when

advised to do so by Branson.

• English (USCS)/Metric Units: This feature allows the welder to be set up in the

local units in use.

2-4 100-214-282 Rev. 07

2000X aod Actuator Chapter 2: Introduction to the 2000X aod Actuator

Instruction Manual Features of the System

• Startup Diagnostics: At power supply startup, the controls test the major system

components, including the Actuator and its controls.

• Weld Parameter Entry through Digital Keypad: User Setup is direct and easy, by

selecting the menu parameter by name and using the keypad to enter the precise

value. The controls also support entry by incrementing existing values.

• System Information Screen: This is a screen that will give you information about

your welding system (e.g., cylinder size, stroke length, number of cycles). Refer to

this screen when contacting Branson for service and support.

• Ramp Starting: The starting of the 2000X-series power supply and horn is done at

the optimum rate to reduce electrical and mechanical stress on the system. This also

helps make some tough-to-start applications possible.

• True Wattmeter: The controls on the power supply include a true wattmeter for

accurate measurement of power and energy.

• Load Cell/Dynamic Follow Through: c

• S-Beam Load Cell: The load cell allows the ultrasonics to be triggered at a

designated force input into the power supply.

• Encoder: Allows the power supply to monitor the distance the horn has travelled,

enabling the use of distance functions.

• Downspeed: Controls the rate of descent and force build-up on the part.

• Pressure Sensor: Allows the power supply to read the system pressure.

100-214-282 Rev. 07 2-5

Chapter 2: Introduction to the 2000X aod Actuator

NOTE

i

i

CAUTION

!

Controls and Indicators

2.4 Controls and Indicators

The Actuator Controls for the 2000X aod are found in two locations: on the Actuator or on the

Remote Pneumatics Box. The 2000X rp is a separate component of the 2000aod. System controls and Actuator power are provided by the 2000X-series Power Supply.

• Stroke Indicator Provides a quick method of determining relative carriage travel during an

operating cycle. A scale is provided to indicate relative distance.

• S-Beam Load Cell: Provides an indication of the force on a part during a weld. This indica-

tion can be used to determine when to trigger ultrasonics and also to produce a force/distance graph of the operating cycle.

The mechanical stop is not intended for welding by distance.

The front panel controls on the 2000aod Actuator are listed below.

• Pressure Indicator: Indicates that the actuator is receiving pressurized air.

• Power Light: Indicates that the Actuator is connected to the Power Supply and that the

Power Supply’s main power is on.

• Carriage Door: Provides access to the converter-booster-horn stack; secured by four cap-

tive hex screws. Use an M5 T-handle wrench (EDP 109-128-024) to tighten the cap screws.

• Mechanical Stop: Limits the stroke length to prevent the horn from contacting the fixture

when no workpiece is in place; adjustment is approximately 0.04 in. (1 mm) per rotation; a

locking ring keeps the setting from vibrating loose. Turning the knob clockwise increases the

stroke length.

Turning the mechanical stop too far can cause it to come apart.

Controls on the 2000rp Remote Pneumatics Box are listed below.

• Pressure Regulator: Adjust the amount of air pressure applied to the cylinder; range of 5-

100 psig (35-700 kPa). Pull to set; push to lock.

• Downspeed Control: Downspeed knob controls the rate of descent and force buildup on the

part to be welded.

• Pilot Light: Indicates that the actuator is connected to the power supply, that the 2000rp

remote box is electrically connected to the 2000aod actuator, and that the power supply’s

main power is on.

• Pressure Gauge: Indicates the amount of air pressure applied to the cylinder; range of 5-

100psig (35-700 kPa). Pull to set; push to lock.

2-6 100-214-282 Rev. 07

2000X aod Actuator Chapter 2: Introduction to the 2000X aod Actuator

Instruction Manual Welding Systems

2.5 Welding Systems

Ultrasonic Plastics Welding

Thermoplastic parts are welded ultrasonically by applying high-frequency vibrations to the parts

being assembled. The vibrations, through surface and intermolecular friction, produce a sharp

rise in temperature at the welding interface.

When the temperature is high enough to melt the plastic, there is a

parts. When the vibrations stop, the material solidifies under pressure and a weld results.

The Plastics Welding System

The welding system consists of a power supply, an actuator, and a converter-booster-horn stack.

The system can perform a variety of ultrasonic welding operations, including: inserting, staking,

spot welding, swaging, degating, and continuous operations. It is designed for use in automated,

semi-automated, and/or manual production systems.

flow of material between the

Power Supply

The 2000X distance digital Power Supply converts conventional 50/60 Hz line current to high

frequency electrical energy. It also contains all the electronic controls and can be located

remotely from the Actuator. This allows the operator to adjust or reprogram the welding cycle

remotely from the Actuator and related welding, tooling, and parts-handling systems.

The 2000X distance Power Supply also contains a DC power supply for electrical power to operate the electrical components and control circuits in the power supply, and on the Actuator.

Converter

The converter is mounted in the actuator as part of the ultrasonic stack. The ultrasonic electrical

energy from the power supply is applied to the converter (sometimes called the transducer). This

transforms the high frequency electrical oscillations into mechanical vibrations at the same frequency as the electrical oscillations. The heart of the converter are piezoelectric ceramic elements. When subjected to an alternating voltage, these elements alternately expand and contract,

resulting in better than 90% conversion of electrical to mechanical energy.

Booster

Success in ultrasonic assembly depends on the right amplitude of movement at the horn face.

Amplitude is a function of horn shape, which is largely determined by the size and form of the

parts to be assembled. The booster can be used as a mechanical transformer to increase or

decrease the amplitude of vibrations applied to the parts through the horn.

The booster is a resonant half-wave section of aluminum or titanium. It is mounted between the

converter and the horn, as part of the ultrasonic stack. It also provides a clamping point for rigid

stack mounting.

100-214-282 Rev. 07 2-7

Chapter 2: Introduction to the 2000X aod Actuator

Welding Systems

Boosters are designed to resonate at the same frequency as the converter with which they are

used. Boosters are usually mounted at a nodal (minimum vibration) point of axial motion. This

minimizes the loss of energy and prevents vibration from being transmitted into the actuator.

Horn

The horn is selected or designed for a specific application. Each horn is tuned typically as a halfwave section that applies the necessary force and vibration uniformly to the parts to be assembled. It transfers ultrasonic vibrations from the converter to the workpiece. The horn is mounted

to the booster as part of the ultrasonic stack.

Depending on their profile, horns are referred to as stepped, conical, exponential, bar, or catenoidal. The shape of the horn determines the amplitude at the face of the horn. Depending on the

application, horns can be made from titanium alloys, aluminum, or steel. Titanium alloys are the

best materials for horn fabrication due to their high level of strength and low loss. Aluminum

horns are usually chrome- or nickel-plated or hard-coated to reduce wear. Steel horns are for low

amplitude requiring hardness, such as ultrasonic insertion applications.

S-Beam Load Cell and Dynamic Follow Through

The Load Cell measures the force being applied to the part to trigger ultrasonics and record the

welding parameters. The load cell assembly ensures that pressure is applied to the part prior to

the application of ultrasonic energy.

To maintain horn-to-part contact and force as the joint collapses, the load cell assembly provides

dynamic follow-through. As the plastic melts, the load cell assembly ensures smooth transmission of ultrasonic energy into the part.

Encoder

The encoder measures the distance the horn has travelled. Depending on the power supply settings, it can:

• Allow for distance welding in absolute and collapse modes

• Detect improper setup controls

• Monitor the distance data of the weld

2-8 100-214-282 Rev. 07

2000X aod Actuator Chapter 2: Introduction to the 2000X aod Actuator

Instruction Manual Glossary of Terms

2.6 Glossary of Terms

The following terminology may be encountered when using or operating a 2000X-series ultrasonic welding system. Some of these terms may not be available in all Controls (Power Supply

model) configurations:

AB Amplitude: The amplitude at the horn face during the afterburst step.

AB Delay: Time delay between the end of the hold and the start of the afterburst.

AB Time: The duration of the afterburst.

Abort Current Printing: Terminates the current printing request.

Absolute Cutoff: Ends the ultrasonic portion of the cycle when the set absolute distance is

reached.

Absolute Distance: The distance the horn has travelled from home (ULS deactivation).

Absolute Mode: A mode of operation in which the ultrasonic portion of the cycle is terminated

when a user-specified distance from home has been reached.

Absolute Position: The position of the actuator after clearing the Upper Limit Switch.

Actual: A reported value that occurred during the weld cycle. The converse is the set parameter

that was requested during the setup.

Afterburst: Ultrasonic energy applied after the hold step. Used to break away sticking parts

from the tooling.

Alarm Beeper: An audible signal that sounds when a general alarm has occurred.

Amplitude: The peak-to-peak movement at the horn face. Always expressed as a percentage

of the maximum.

Amp A: The amplitude applied to the part from the start of the weld to the step change.

Amp B: The amplitude applied to the part from the step change to the end of the weld.

Amplitude Graph: A graph of amplitude percentage plotted against time.

Amplitude Step: A change in amplitude during the ultrasonic portion of the cycle.

Amp Control: The ability to set amplitude digitally or by an external control.

Automatic: A pretrigger condition indicating that pretrigger engages when the actuator leaves

the upper limit switch.

Baud Rate: The rate of data transmission over the serial communication port.

Beep: An audible signal produced by the Branson control board. Used to alert the operator to an

unexpected condition.

Cold Start: A condition that restores a setup to its default values.

Collapse Distance: The distance the horn has travelled from the trigger point of ultrasonics.

Collapse Mode: A mode in which the ultrasonics portion of the cycle is terminated when a user-

specified distance from the trigger point has been reached.

Control Limits: Additional parameters that determine the end of the ultrasonic portion of the

cycle and the move to the hold state.

Converter: The device that converts electrical energy into mechanical vibrations at a high frequency (an ultrasonic rate). The Converter is a central component of the welding system and is

mounted in the Actuator.

100-214-282 Rev. 07 2-9

Chapter 2: Introduction to the 2000X aod Actuator

Glossary of Terms

Counters: A record of the number of cycles run by category, for example, alarms, good parts,

and so on, recorded in the Controls.

Digital Filter: A smoothing technique used to provide more meaningful data.

Down Speed: The user-definable speed of descent (percentage of maximum speed) during the

down stroke of the Actuator.

Energy Mode: A mode of operation in which ultrasonics are terminated at a user-specified

energy value.

External Amplitude Control: Enables you to access real-time amplitude control directly.

External Frequency Control: Enables you to access real-time frequency control directly.

Form Feed: When using a printer with the 2000Xd Power Supply to capture weld data, you can

insert a form feed after print setup, print graph, or after reaching the number of lines per page.

Frequency: The operating frequency of the ultrasonic stack. The frequency stored is measured

at the end of the ultrasonic portion of the cycle (when ultrasonics are terminated).

Freq End: The frequency at the end of the ultrasonic portion of the welding cycle (when ultrasonics are terminated).

F Actual: The actual running frequency of the acoustic system.

F Memory: The frequency stored in the Power Supply memory.

Frequency Offset: An offset factor applied to the ultrasonic frequency stored in the Power Sup-

ply.

General Alarm: An alarm that occurs due to system fault and/or tripping a limit.

Ground Det. Cutoff: Ground Detect Cutoff. Immediately terminates the weld process, includ-

ing the hold step, when a ground detect has occurred.

Gnd Det. Mode: Ground Detect Mode, available in all models of 2000X power supplies. In this

mode of operation, ultrasonics are terminated after detection of a ground condition between the

horn and fixture or anvil.

Hold Force: The force on the part during the hold portion of the cycle.

Hold Time: The duration of the hold step.

Horn Down: A mode in which ultrasonics are locked out and the user can advance the Actuator

for setup and alignment.

Linear Encoder: Provides carriage (horn) distance measurement during the Actuator cycle.

Lines per Page: When using an optional Printer, the number of welds per printed page.

Load Cell: Provides force measurement for accurate ultrasonic triggering and graphing of force.

Main Menu: The list of categories of features available in the software, as displayed on the front

panel of the Power Supply. Accessible by using a power supply front-panel button.

Max Energy: Maximum Energy. The maximum user-specified energy that produces a part without an alarm.

Min Energy: Minimum Energy. The minimum user-specified energy that produces a part without an alarm.

Minus Limit: The user-defined lower limit, or lower extreme of an acceptable range for a given

parameter. See Control Limits in the Power Supply manual.

2-10 100-214-282 Rev. 07

2000X aod Actuator Chapter 2: Introduction to the 2000X aod Actuator

Instruction Manual Glossary of Terms

Parameter Range: Valid range of parameters accepted for a particular setup.

Parameter Step: Ability to dynamically change amplitude during the weld cycle.

Password: A user-defined access code for the secure areas of the Power Supply’s user controls.

Password Protection: Enables lock-out of the Power Supply’s weld parameter modification by

using a user-defined password.

Peak Power Cutoff: A power value that terminates the ultrasonics when peak power is not the

primary control mode.

Pk Pwr Mode: Peak Power Mode. A mode of operation in which ultrasonics are terminated at

a user-specified power value in percentage of maximum.

Plus Limit: The user-defined upper limit. See Control Limits, Suspect, Reject and Missing

Part Limits in the Power Supply manual.

Post Weld Seek: Used to determine the operating frequency of the Stack, after the Hold and/or

Afterburst portion of the weld cycle. Ultrasonics are run at a low level (5%) amplitude during

this step, and the frequency is stored to memory.

Power Graph: A printed graph of power in percentage of maximum plotted against time.

Preset: A method of saving the power supply’s user-set parameters to memory, for a given

Setup. The Power Supply model may allow multiple presets for easy recall of a Setup’s parameters, for a given part, process or operation. Presets can be labeled by the user or the system.

Preset Name: The ability to name a preset in customer-defined terms. Not available in the

2000Xt Power Supply.

Pretrigger: The setting that causes ultrasonics to start before contact with the part (or, before

the set Trigger Force has been met).

Pretrig Amp: Pretrigger Amplitude. The amplitude at the horn face during pretrigger.

Print on Alarm: Allows the user to set up printing automatically when an alarm occurs.

Print on Sample: Allows the user to set up printing automatically based on the number of cycles

performed.

Ready Position: State in which the welder is retracted to the home position and ready to receive

the start signal, ready to operate.

Recall Preset: Allows a user to activate a preset from memory for purposes of operation or modification.

Reject Limits: User-definable limits at which the violating cycle is identified as having produced a bad part.

Required: State used with limits indicating that a reset will be required when the limit is

exceeded. The reset is accomplished by using the reset key on the front of the Power Supply.

Reset Required: State used with limits indicating that a reset will be required when the limit is

exceeded. The reset is accomplished by using the reset key on the front of the Power Supply.

Run Screen: The screen showing weld status, alarms, weld count, and process information.

Available using a front-panel button on the Power Supply.

Save Preset: Stores a programmed set of weld parameters as a Preset.

Scrub Time: In Ground Detect mode, the amount of time after detection of a ground condition

before the termination of ultrasonics, and end of the cycle.

100-214-282 Rev. 07 2-11

Chapter 2: Introduction to the 2000X aod Actuator

Glossary of Terms

Seek: The activation of ultrasonics at a low-level (5%) amplitude, for the purpose of finding the

resonant frequency of the Stack.

Serial Port: A RS232 port provided to you for external data communications.

Step @ Energy: User-definable point at which AmpA is changed to AmpB.

Step @ Ext Sig: Allows you to shift either force or amplitude based upon an external signal.

Step @ Power: User-definable point at which AmpA is changed to AmpB.

Step @ Time: User-definable point at which AmpA is changed to AmpB.

Suspect Limits: User-definable limits at which the resultant weld in a welding cycle is identi-

fied as potentially bad (suspect).

Tes t Sca l e: The magnification of the power bar on the front panel of the Power Supply, useful

for lower-power applications that want a more accurate (but smaller) scale.

Time Mode: Terminates the ultrasonics at a user-specified time.

Timeout: A time at which the ultrasonic energy terminates if the main control parameter has not

been reached.

Trigger Beeper: An audible signal sounded when the trigger force has been met, and the trigger

switch is made.

Trig Delay: Trigger Delay. A user-programmable time delay between engagement of the trigger

switch and start of ultrasonics and ramping of force to the weld force.

User-defined Limits: for process resultants, where - is the user-defined lower limit, and + is the

user defined upper limit:

-/+ S/R Energy: The energy reached during the weld.

-/+ S/R Freq: The peak frequency reached during a weld.

-/+ S/R Power: The peak power as a percentage of the maximum reached during the weld.

-/+ S/R Abs D: The absolute distance reached during the weld from the Upper Limit

Switch.

-/+ S/R Col D: The collapse distance reached from trigger to end of weld.

-/+ S/R Trg D: The distance at which the trigger occurred.

-/+ S/R Time: The weld time reached during the weld.

Weld Count: Count of acceptable weld cycles.

Weld Energy: The energy specified to be applied to the part during the weld cycle.

Weld History: The last 50 weld summary data lines are saved.

Weld Sca le: The power bar LED scale during weld.

Weld State: A screen message showing the current state of the welder during or before the pro-

cess. The list of messages are shown in the Run Screen section.

Weld Results: A one-line summary of information concerning the last weld cycle.

Weld Time: The time for which ultrasonics are on.

2-12 100-214-282 Rev. 07

2000X aod Actuator Chapter 3: Delivery and Handling

Instruction Manual Shipping and Handling

Chapter 3: Delivery and Handling

3.1 Shipping and Handling - - - - - - - - - - - - - - - - - - - - 3-1

3.1.1 Environmental Specifications - - - - - - - - - - - - - - - - 3-1

3.2 Receiving - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

3.3 Unpacking- - - - - - - - - - - - - - - - - - - - - - - - - - - 3-3

3.3.1 Actuator Assemblies - - - - - - - - - - - - - - - - - - - - 3-3

3.4 Returning Equipment - - - - - - - - - - - - - - - - - - - - - 3-3

3.1 Shipping and Handling

3.1.1 Environmental Specifications

The aod Actuator is a system of cast and electro-pneumatic components that move the ultrasonic

tooling in the ultrasonic welding system and control aspects of the weld process. Many of its

components can be harmed if the unit is dropped, shipped under improper conditions, or otherwise mishandled. The following environmental guidelines should be respected in the shipping

of the aod Actuator unit.

Table 3.1 Environmental Specifications

Environmental Condition Acceptable Range

Humidity 0% to 90% non-condensing

Storage / Shipping Temperature

Shock / Vibration (transit)

-25°C/-13°F to +55°C/+131°F (+70°C/+158°F

for 24 hours)

60 g shock / 0.5 g and (3-100 Hz) vibration per

ASTM 3332-88 and 3580-90

100-214-282 Rev. 07 3-1

Chapter 3: Delivery and Handling

NOTE

i

i

CAUTION

!

Receiving

3.2 Receiving

Branson Actuator units are carefully checked and packed before dispatch. It is recommended,

however, that you follow the procedure below upon receiving your Actuator.

Inspect the Actuator when it is delivered:

Step: Action:

1

2

3

Check the equipment immediately after delivery to ensure that they have

not been damaged during transport.

Verify that all parts are complete according to the delivery note.

Determine if any component has become loose during shipping and, if

necessary, tighten screws.

If the goods delivered have been damaged during shipping, please contact the

forwarding agent immediately. Retain packing material (for possible inspection or

for sending back the unit).

The Actuator and the Power Supply are heavy. Handling, unpacking, and installation may require the assistance of a colleague or the use of lifting platforms or

hoists

3-2 100-214-282 Rev. 07

2000X aod Actuator Chapter 3: Delivery and Handling

NOTE

i

i

Instruction Manual Unpacking

3.3 Unpacking

3.3.1 Actuator Assemblies

Actuator assemblies are heavy and packed in a protective shipping container. The Booster, Converter, and Actuator Toolkit are often packed inside the shipping container.

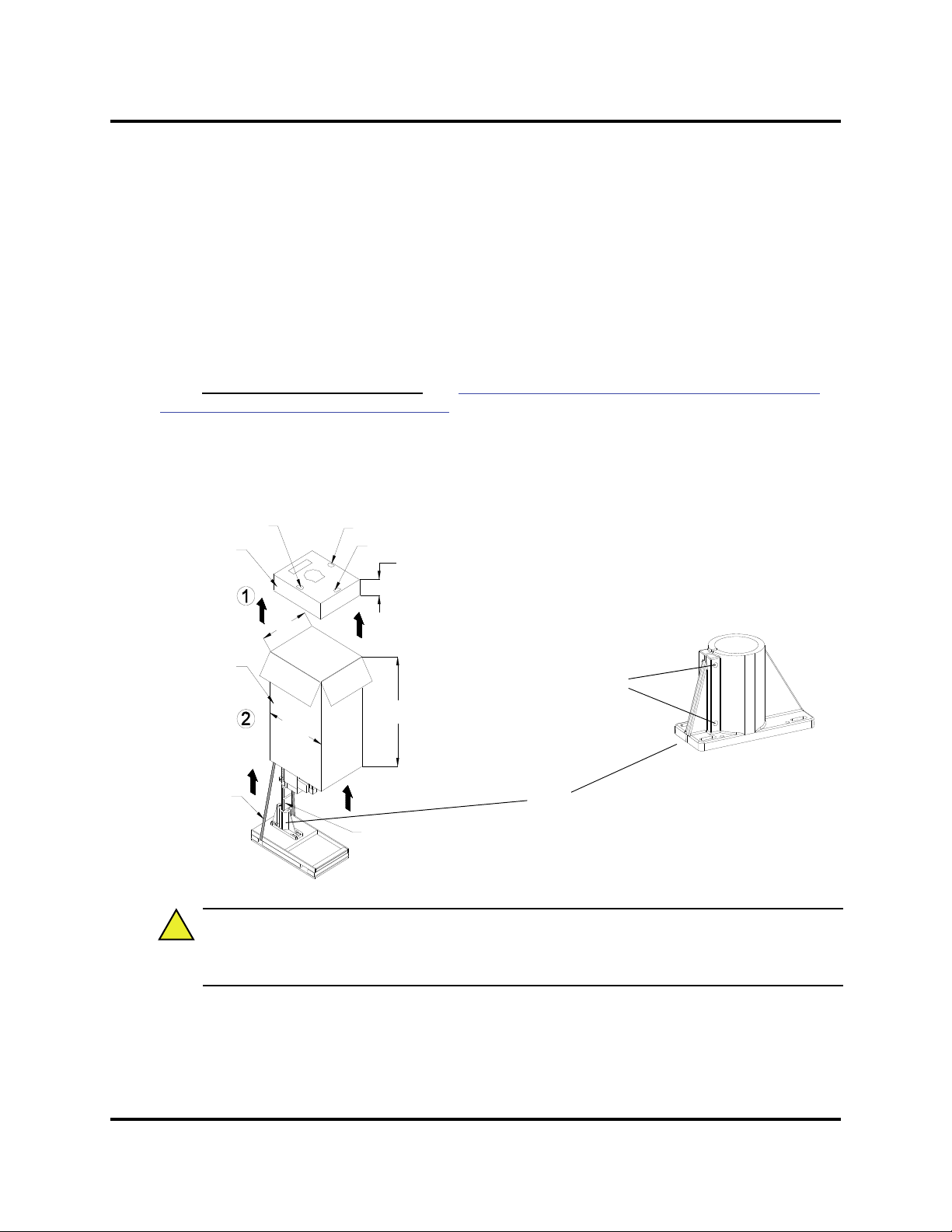

Each Actuator is shipped as one of the three assemblies described below, with its own corresponding unpacking procedure. These assemblies vary in both the materials used for shipping

and the actual components that you will receive when the Actuator is shipped. For complete

Actuator unpacking and installation procedures, refer to Chapter 4: Installation and Setup.

Remote pneumatics are always shipped in a separate box.

• Stand (Actuator on Base): A stand consisting of an Actuator on a Base is shipped on a

wooden pallet with a cardboard box cover. (The packaging for this assembly is similar to that

of an Actuator on Hub-Mounted Column.)

• Stand (Actuator on Hub-Mounted Column): A stand consisting of an Actuator on a hub-

mounted column is shipped on a wooden pallet with a cardboard box cover. (The packaging

for this assembly is similar to that of an Actuator on Base.)

• Actuator (Alone): An Actuator that does not use either type of stand is shipped in a rigid

cardboard box using protective foam shells for support.

3.4 Returning Equipment

If you are returning equipment to Branson Ultrasonic Corporation, please call your Customer

Service Representative to receive approval to return goods to Branson.

If you are returning equipment for repair refer to Chapter 1:

Returning Equipment for Repair, of this manual, for appropriate procedure.

Safety and Support, Section 1.5:

100-214-282 Rev. 07 3-3

Chapter 3: Delivery and Handling

Returning Equipment

3-4 100-214-282 Rev. 07

2000X aod Actuator Chapter 4: Installation and Setup

Instruction Manual

Chapter 4: Installation and Setup

4.1 About Installation- - - - - - - - - - - - - - - - - - - - - - - 4-2

4.2 Handling and Unpacking - - - - - - - - - - - - - - - - - - - 4-2

4.2.1 Unpack the Stand or Actuator - - - - - - - - - - - - - - - 4-3

4.2.2 Stand (actuator on a base) - - - - - - - - - - - - - - - - - 4-4

4.2.3 Stand (Actuator on a Hub) - - - - - - - - - - - - - - - - - 4-5

4.2.4 Actuator (Alone)- - - - - - - - - - - - - - - - - - - - - - 4-6

4.3 Take Inventory of Small Parts - - - - - - - - - - - - - - - - 4-7

4.3.1 Cables - - - - - - - - - - - - - - - - - - - - - - - - - - 4-8

4.4 Installation Requirements - - - - - - - - - - - - - - - - - - 4-9

4.4.1 Location - - - - - - - - - - - - - - - - - - - - - - - - - - 4-9

4.4.2 Environmental Specifications- - - - - - - - - - - - - - - - 4-9

4.4.3 Electrical Input Power Ratings - - - - - - - - - - - - - - - 4-10

4.4.4 Air Cylinder Consumption - - - - - - - - - - - - - - - - - 4-11

4.4.5 Factory Air- - - - - - - - - - - - - - - - - - - - - - - - - 4-15

4.5 Installation Steps - - - - - - - - - - - - - - - - - - - - - - 4-16

4.5.1 Mounting the Stand (Actuator on Base) - - - - - - - - - - 4-16

4.5.2 Mounting the Stand (Actuator on Hub-mounted column) - - 4-17

4.5.3 Actuator (Alone) - - - - - - - - - - - - - - - - - - - - - - 4-19

4.5.4 Mount the Power Supply - - - - - - - - - - - - - - - - - - 4-20

4.5.5 Input Power (Main) - - - - - - - - - - - - - - - - - - - - 4-21

4.5.6 Output Power (RF Cable) - - - - - - - - - - - - - - - - - 4-21

4.5.7 Interconnect between Power Supply and Actuator - - - - - 4-21

4.5.8 Start Switch Connection (Automation) - - - - - - - - - - - 4-23

4.5.9 Serial (RS-232) Port Connector - - - - - - - - - - - - - - 4-24

4.5.10 Parallel Printer Connector - - - - - - - - - - - - - - - - - 4-24

4.5.11 User I/O Interface - - - - - - - - - - - - - - - - - - - - - 4-25

4.5.12 Input Power Plug - - - - - - - - - - - - - - - - - - - - - 4-28

100-214-282 Rev. 07 4-1

Chapter 4: Installation and Setup

CAUTION

!

About Installation

4.5.13 User I/O DIP Switch (SW1) - - - - - - - - - - - - - - - - -4-29

4.5.14 Module Options DIP Switch- - - - - - - - - - - - - - - - -4-29

4.6 Guards and Safety Equipment - - - - - - - - - - - - - - - 4-30

4.6.1 Emergency Stop Control - - - - - - - - - - - - - - - - - -4-30

4.7 Rack Mount Installation- - - - - - - - - - - - - - - - - - - 4-31

4.8 Assemble the Acoustic Stack- - - - - - - - - - - - - - - - 4-32

4.8.1 For a 20kHz System - - - - - - - - - - - - - - - - - - - -4-32

4.8.2 For a 30kHz System - - - - - - - - - - - - - - - - - - - -4-33

4.8.3 For a 40kHz System - - - - - - - - - - - - - - - - - - - -4-33

4.8.4 Assembling the 20kHz Acoustic Stack - - - - - - - - - - -4-34

4.8.5 Connecting Tip to Horn - - - - - - - - - - - - - - - - - - -4-35

4.8.6 Installing the Stack in the Actuator - - - - - - - - - - - - -4-36

4.9 Mounting the Fixture on the Branson Base- - - - - - - - - 4-38

4.10 Testing the Installation - - - - - - - - - - - - - - - - - - - 4-39

4.11 Still Need Help? - - - - - - - - - - - - - - - - - - - - - - - 4-40

4.1 About Installation

This chapter is intended to help the installer with the basic installation and setup of your new 2000aod Actuator.

The Actuator and related components are heavy. Handling, unpacking, and installation can

require help or the use of lifting platforms or hoists.

International safety labels are found on the power supply and actuator. Those that are of importance during