Page 1

Page 2

Copyright

This manual is copyrighted with all rights reserved. No portion of this manual

may be copied or reproduced by any means without the prior written consent of

Brady Worldwide, Inc.

While every precaution has been taken in the preparation of this document, Brady

assumes no liability to any party for any loss or damage caused by errors or

omissions or by statements resulting from negligence, accident, or any other

cause. Brady further assumes no liability arising out of the application or use of

any product or system described, herein; nor any liability for incidental or

consequential damages arising from the use of this document. Brady disclaims all

warranties of merchantability of fitness for a particular purpose.

Trademarks

TM

TLS PC Link

is a trademark of Brady Worldwide, Inc.

DPL (Datamax Programming Language) is a trademark of Datamax Corp.

Brady reserves the right to make changes without further notice to any product or

system described herein to improve reliability, function, or design.

© 2001 Brady Worldwide, Inc. All Rights Reserved

Revision 0

Firmware Version 1.0

Brady Worldwide, Inc.

6555 West Good Hope Road

P.O. Box 2131

Milwaukee, WI 53201

Main Switchboard: (800) 541-1686

(414) 358-6600

FAX: (800) 292-2289

Sales/Customer Support: (800) 537- 8791

TLS PC LinkTM Programmer’s Guide

I

Page 3

Table of Contents

Introduction................................................................................................................. 1

Scope....................................................................................................................... 1

Programming Overview.............................................................................................. 2

Basic print language overview ................................................................................ 2

Control Codes.......................................................................................................... 3

Power up Conditions ............................................................................................... 3

Generating and Printing a Label With the TLS PC Link Programming Language.4

Determining Printer Status......................................................................................5

COM Port Settings...................................................................................................... 6

Immediate Commands <SOH>................................................................................... 7

Summary of Immediate Commands........................................................................ 7

Reset (SOH #) ......................................................................................................... 7

Send ASCII Status String (SOH A)......................................................................... 8

Toggle Pause (SOH B)............................................................................................ 9

Cancel (SOH C)..................................................................................................... 10

Disable SOH (SOH D) .......................................................................................... 10

Send Batch Quantity (SOH E)............................................................................... 10

System-Level Commands <STX> ............................................................................ 11

Summary of System Level Commands ................................................................. 11

Disable Feedback Characters (STX A) ................................................................. 12

Enable Feedback Characters (STX a).................................................................... 12

Enter Heat Setting Offset (STX b) ........................................................................ 13

Disable Feeding to Cut Position after Print (STX C) ............................................ 13

Enable Feeding to Cut Position after Print and Perform a Feed to Cut (STX c)...14

Set Quantity for Stored Label (STX E).................................................................14

Form Feed (STX F)............................................................................................... 15

Set Form Stop Position (STX f) ............................................................................ 15

Print Last Label Format (STX G).......................................................................... 16

Enable SOH Commands (STX H)......................................................................... 16

Input Image Data (STX I)...................................................................................... 17

Extended System Commands (STX K)................................................................. 18

Enter Label Formatting Command (STX L) ......................................................... 18

Set Printer to Metric (STX m)............................................................................... 18

Set Printer to Inches (STX n) ................................................................................ 19

Set Start of Print Offset (STX O)..........................................................................19

Horizontal Alignment Offset (STX o)................................................................... 20

Set Continuous Label Length (STX P).................................................................. 20

Clear All Memory (STX Q) .................................................................................. 21

Set Continuous Label Spacing (STX S)................................................................ 21

Printhead Dot Pattern Test Label (STX T)............................................................ 22

Send Binary Touch Cell Data (STX t)................................................................... 22

II

TLS PC LinkTM Programmer’s Guide

Page 4

Label Format Field Replacement (STX U) ........................................................... 24

Send ASCII Touch Cell Data (STX V).................................................................25

Printer’s Firmware Version Information (STX v)................................................. 25

Request Memory Information (STX W) ............................................................... 25

Delete File (STX x)............................................................................................... 26

Pack Memory (STX z) .......................................................................................... 27

Extended-System Commands <STX>K.................................................................... 28

Label-Formatting Commands ................................................................................... 29

Set Format Attribute (A) ....................................................................................... 30

Set Column Offset Amount (C)............................................................................. 31

Terminate Label Formatting Mode and Print Label (E)........................................ 31

Set Row Offset Amount (R).................................................................................. 31

Terminate Label-Formatting Mode (X)................................................................. 32

+ (-) Make Last Field Entered Increment (Decrement) Numeric..........................33

> (<) Make Last Field Entered Increment (Decrement) AlphaNumeric................ 34

Set Count By Amount (^)...................................................................................... 35

Generating Label Formats.........................................................................................36

The structure of a record........................................................................................ 37

Examples of a Label Format:....................................................................................38

Example 1 (1.5” x 1.5” Label, PTL-32):............................................................... 38

Example 2 (1.9” x 4.0” Label, PTL-38):............................................................... 40

Example 3 (0.24” continuous terminal block material, PTLTB-400-240):........... 42

Troubleshooting ........................................................................................................ 44

Common Problems and Corrective Action............................................................ 44

Appendix A: Feedback Characters............................................................................ 47

Appendix B: Image File Definitions.........................................................................48

Image Type U:....................................................................................................... 48

Record Types:........................................................................................................ 48

Data Format...........................................................................................................49

Appendix C: ASCII Control Chart............................................................................ 51

ASCII Control Chart ............................................................................................. 51

Appendix D: List of Commands ............................................................................... 53

Appendix E: Fonts .................................................................................................... 55

TLS PC Link

TM

Printer Fonts................................................................................55

Font Symbol Set.................................................................................................... 57

Appendix F: Barcodes Summary .............................................................................. 58

Appendix G: Mini-DIN 6-Pin to 9-Pin Cable Pinouts .............................................. 59

TLS PC LinkTM Programmer’s Guide

III

Page 5

Page 6

Introduction

Scope

The TLS PC LinkTM Programmer’s Guide is intended for technical personnel

who have basic programming knowledge and intend to create their own programs

to send controls down to the printer for printing labels (design their own labelcreation software). A programming language allows the printer to be integrated

with a piece of equipment such as a portable data terminal (PDT), scanner, wire

tester, electrical meter, or medical device. Operators without programming

experience may prefer to use a label-creation software package such as

LabelMark

detailed information on the Brady Programming Language (based off of the

Datamax programming Language (DPL)), specifically regarding the writing,

loading, and storing of programs for the control and production of label formats

(designs) using the TLS PC Link Printer. The Brady Programming Language

(BPL) provides a built-in communication language with every printer.

Note: The TLS PC Link Printer is referred to as “the printer” in this

programmer’s guide.

Be sure to check the Brady web site www.tls2200.com for the latest updates.

TM

(included with every printer) or CODESOFTTM. This guide offers

TLS PC LinkTM Programmer’s Guide

1

Page 7

Programming Overview

Basic print language overview

The TLS PC Link Printer control language is based on Datamax DPL, revision

D2.

The print language can be implemented as completely 7-bit ASCII characters.

The ASCII table is shown in Appendix C: ASCII Control Chart. All commands

and responses are sent as printable ASCII characters with a few exceptions:

1. Some control codes (non-printable ASCII characters) are sent to inform the

printer that a command is to be received or terminated. Refer to table of

Control Codes on page 3.

2. 8-bit binary image files can be sent. These include BMP and PCX files.

Also, there is special download format based on Datamax’s image load file

and Windows’ print drivers. This file can be sent as an 8-bit binary file or a

7-bit ASCII hex file.

3. International characters and symbols are sent as extended-ASCII or 8-bit

characters.

Throughout the examples in the book, all characters are ASCII unless otherwise

noted. Control characters are shown by their symbol in brackets. For example,

the SOH control character is shown as <SOH>. The brackets are not symbols to

be sent. Only the decimal value of 1 is sent. All hex values are shown with a

preceding 0x. For example, 3D hex is shown as 0x3D. Whenever a value is sent

as ASCII Hex, this means the hex value is sent as two ASCII characters. For

example, 0x3D sent as ASCII Hex will send two ASCII characters ‘3’ and ‘D’.

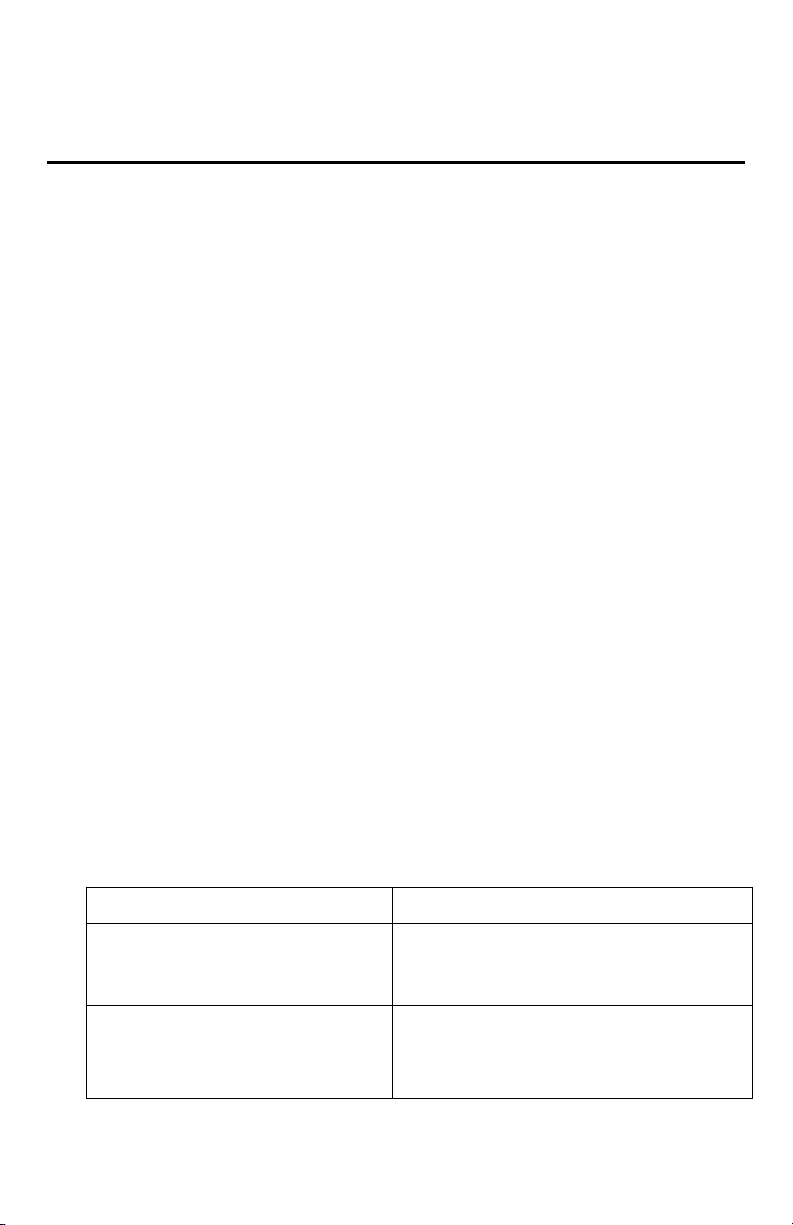

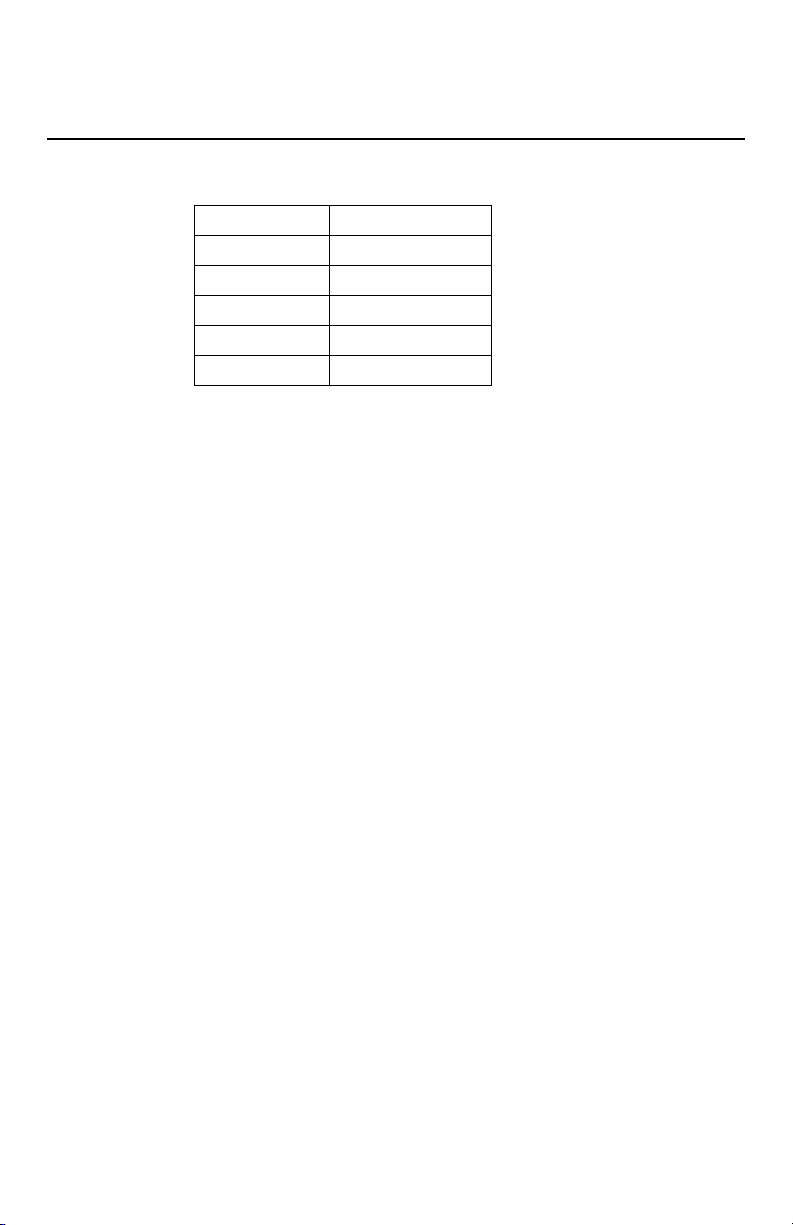

Command Types

There are three main command types used to create labels and control the printer.

These are:

Command Type Description

Immediate Commands Interrupts the printer to perform a

particular action. The printer then

resumes normal operations.

System-Level Commands Performed in the sequence that they are

received and generally control the

printer’s hardware. In addition, systemlevel commands allow memory

2

TLS PC LinkTM Programmer’s Guide

Page 8

Command Type Description

configuration and image downloading.

Label-Formatting Commands Used to control the position of text and

images. The label format termination

commands can selectively store and print

the label and end the formatting process.

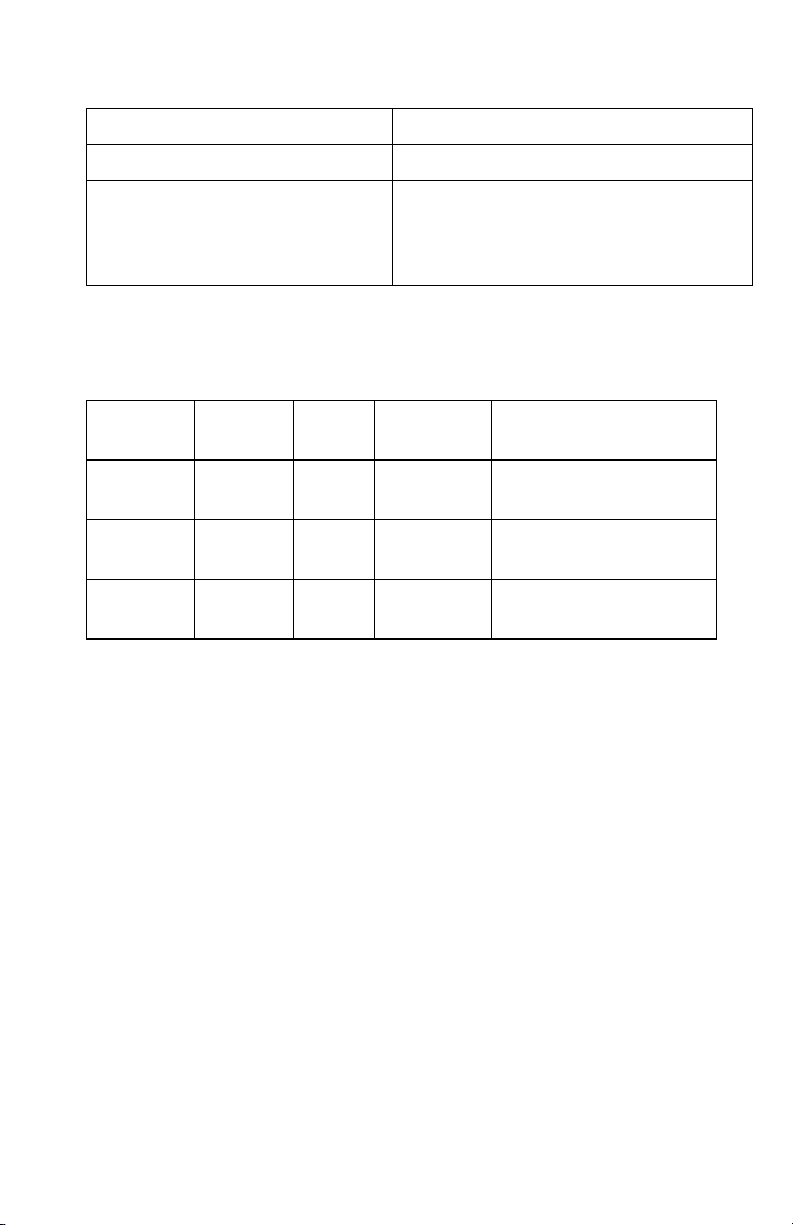

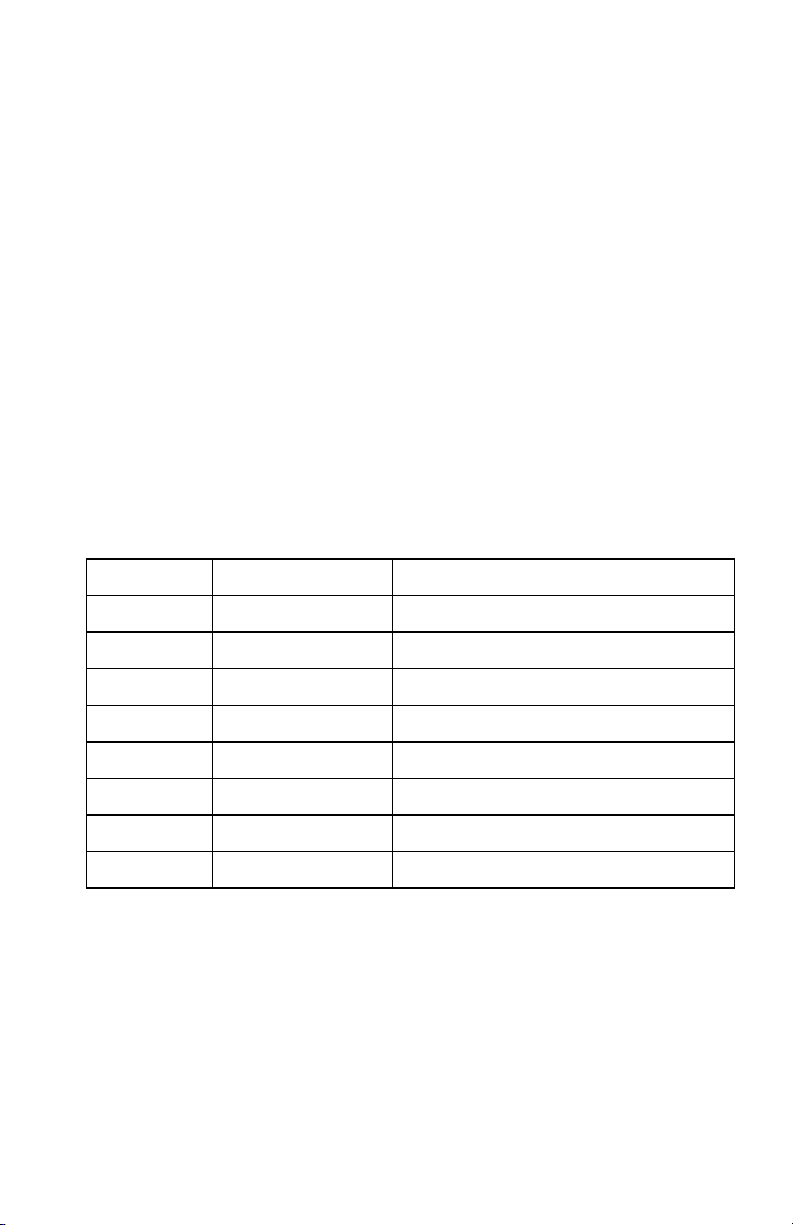

Control Codes

Control codes are used to inform the printer that a command is to be received or

terminated. The control codes used are:

ASCII

Char

SOH 1 0x01 ^A Start of Immediate

STX 2 0x02 ^B Start of System

CR 13 0x0D ^M Termination of many

Decimal

Value

HEX

Value

Printer

Dump

Control Code for

Commands

Commands

commands

Power up Conditions

On power up, the unit is in the following modes:

! System Level Commands are accepted

! Immediate Commands are turned off

! Feedback Characters are turned off

The unit will never accept System Level Commands and Label Formatting

Commands at the same time. When Label Formatting mode is entered, System

Level Commands are disabled. After Label Formatting Mode is exited, System

Level Commands can be received again.

Immediate Commands can be turned on and off. When turned on, they can be

received in both Label Formatting Mode and System Level Mode. They are

turned off with an Immediate Command, but turned back on with a System Level

command.

Feedback Characters can be turned on and off with System Level Commands.

When turned on, all System Level and Label Formatting Commands will reply

TLS PC LinkTM Programmer’s Guide

3

Page 9

with a feedback character denoting success or an error. Feedback characters are

defined in Appendix A. Each command lists the possible feedback characters.

Immediate Commands never send these feedback characters. They will send a

response if the Immediate Command requires one, such as Read Status String.

Generating and Printing a Label With the TLS PC Link

Programming Language

The printer is capable of storing only one label format at a time. A label format

specifies what is to be placed on the label. It specifies the text, fonts, barcodes, or

image files to use. Some barcodes and fonts are resident in the printer. Fonts and

barcodes that are not resident in the printer can only be printed by downloading a

bitmap image file of the desired label or portion of the label containing these

fonts and barcodes.

It is possible to store multiple image files in the unit. These image files will be

lost if the unit is powered down. These files are stored with an 8 character name.

When a label format is created, it can contain any number of images. These are

specified in the label format by the image file name. The actual image file is not

part of the label format. Therefore, an image only needs to be downloaded once,

but can be used in multiple label formats.

The basic procedure to create and print a label follows:

1. Power up printer.

2. Enable feedback characters if they are to be used.

3. Download any image files.

4. Enter Label Formatting Mode.

5. Enter all label fields. Each field contains the following:

field type: text, barcode, or image

font size or barcode type

location within label to place the object

the text or file name of the object

6. Exit Label Formatting Mode.

7. Set print quantity.

8. Print label.

Each time label formatting mode is entered, it clears out the previous label

format. Therefore, Label Formatting Mode cannot be entered and exited multiple

times while creating the same label. The whole label must be created in one

entry.

4

TLS PC LinkTM Programmer’s Guide

Page 10

Determining Printer Status

There are two methods to determine the printer status:

! Feedback Characters

! Immediate Command to Request Status

If feedback characters are used, a response is given after each System Level or

Label Formatting Command is completed. If an error occurs on a command, it is

known immediately by the response. When a print command is sent, a print

complete character is sent by the printer when the print is done. If an error

occurred during the print such as being out of labels, the feedback character

contains this error.

If feedback characters are not used, the status can be determined by requesting it

with an Immediate Command. After a print command is sent, the printer can be

queried with a Send ASCII Status String Command. This command will tell if

the printer is busy printing or if an error has occurred. If using this method, it is

important to have immediate commands enabled. They must be enabled before a

print command is sent, or they will not be enabled until after the print job is

complete.

TLS PC LinkTM Programmer’s Guide

5

Page 11

COM Port Settings

In order to establish communication between the TLS PC Link printer and your

PC, you must have the correct COM port settings:

Setting Value

BPS 9600

Data Bits 8

Parity None

Stop Bits 1

Flow Control Hardware

6

TLS PC LinkTM Programmer’s Guide

Page 12

Immediate Commands <SOH>

When the printer receives an immediate command it will stop whatever it is

doing and perform that command. After the command is complete, the printer

will resume the operation it interrupted. Immediate commands are turned off on

power up, and can be turned on with the System-Level Command “Enable SOH

Commands (STX H)”. When Immediate Commands are enabled, they may be

issued at any time. Because of this, it is necessary to disable immediate

commands whenever sending image files that contain 8-bit data. The image data

in these files may contain an immediate command start code that will be

misinterpreted. These can be disabled using immediate command <SOH> D.

Immediate commands consist of:

1. Attention Character

2. Command Character

3. Parameters (if any)

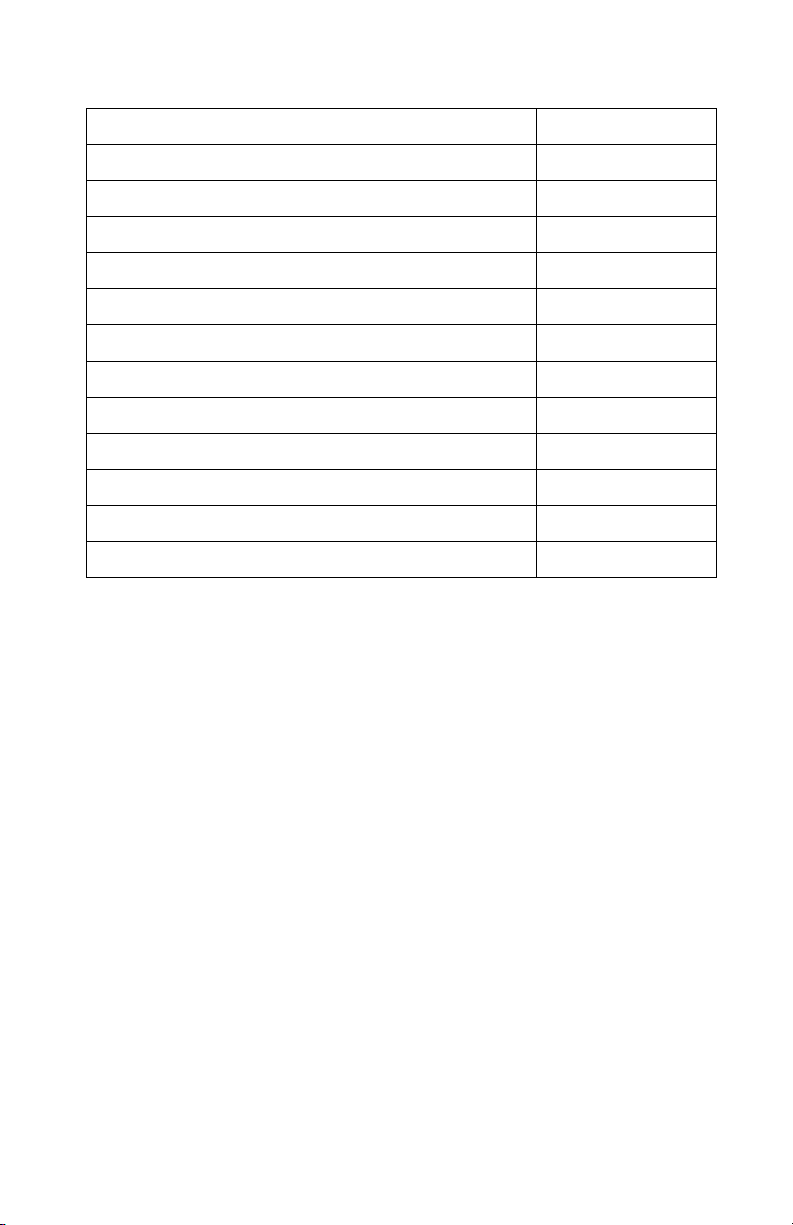

Summary of Immediate Commands

The following immediate commands are discussed in this section. Refer to the

page number listed to the right of each command for more information and a

sample command.

Immediate Command Page

Reset (SOH #) 7

Send ASCII Status String (SOH A) 8

Toggle Pause (SOH B) 9

Cancel (SOH C) 10

Disable SOH (SOH D) 10

Send Batch Quantity (SOH E) 10

Reset (SOH #)

This command resets the printer. Resetting the printer returns all settings to

default and clears both the input and print buffers. The command also clears the

internal RAM memory.

Sample:

<SOH>#

The printer will now reset.

TLS PC LinkTM Programmer’s Guide

7

Page 13

Printer Response: Version 01.01 12/21/00<CR>

The printer always sends out the Version on power up.

Send ASCII Status String (SOH A)

This command allows the host computer to check the printer for its current status.

The printer returns a string of eight characters to the host computer, followed by

a carriage return. Each character is either Y or N indicating whether the associated

condition is true or false (Y = true). Byte 1 is the first character transmitted by

the printer.

Error statuses relating to printer hardware conditions are only updated when

performing a print or feed command. For example, this command does not test

to see if the printhead is open, it only tests if it was open on the last print or feed

command.

Sample:

<SOH>A

Printer Response: abcdefgh<CR>

Byte Character Y/N Condition

1 a = Y/N Y = Printhead open

2 b = Y/N Y = Out of Labels

3 c = Y/N Y = Out of Ribbon

4 d = Y/N Y = Printing Batch

5 e = Y/N Y = Busy Printing

6 f = Y/N Y = Printer Paused

7 g = Y/N Y = Touch Cell Error

8 h = Y/N Y = Low Battery

8

TLS PC LinkTM Programmer’s Guide

Page 14

Toggle Pause (SOH B)

This command toggles the printer’s paused state between on and off.

Sample:

<SOH>B

This command will illuminate the pause/stop light and suspend printing. Printing

will not be suspended in the middle of a label. If a label is being printed, the

printer will finish the label and then pause.

Printing will resume when the SOH B command is sent to the printer again.

TLS PC LinkTM Programmer’s Guide

9

Page 15

Cancel (SOH C)

The stop/cancel function will immediately stop the printer and cancel the current

print job. If currently in the middle of printing a label, it will stop printing and

feed the label to the cut position.

Sample:

<SOH>C

Disable SOH (SOH D)

This command causes the printer to ignore immediate commands (^A). The SOH

shutdown command must be sent before loading graphic images that are sent

using 8-bit data. These image files may contain data sequences that could be

interpreted as an immediate command.

Sample:

<SOH>D

After the SOH shutdown command is sent, immediate commands can be turned

back on by sending the system command <STX> H or by resetting the printer. If

feedback characters are enabled, a code will be sent back to the host when the

SOH commands are enabled. If feedback characters are not used, it is good

practice to check batch quantities <SOH>E to verify that the SOH commands are

working. This test should not occur in label formatting mode. If it is sent during

label formatting mode, and SOH commands are not yet enabled, this command

will be misinterpreted.

Send Batch Quantity (SOH E)

This command causes the printer to send back a 4-digit number indicating the

quantity of labels left to print in the current batch, followed by a carriage return.

Communications latency may cause this value to be higher than actual on some

printers.

Sample:

<SOH>E

Printer Response: 0000<CR>

10

TLS PC LinkTM Programmer’s Guide

Page 16

System-Level Commands <STX>

The most commonly used commands are the system-level commands. These

commands are used to load and store graphic information and to control the

printer. System-level commands may be used before or after immediate

commands but cannot be issued among label-formatting commands. System-level

commands can be used to override default parameter values. System commands

consist of:

1. Attention Character

2. Command Character

3. Parameters (if any).

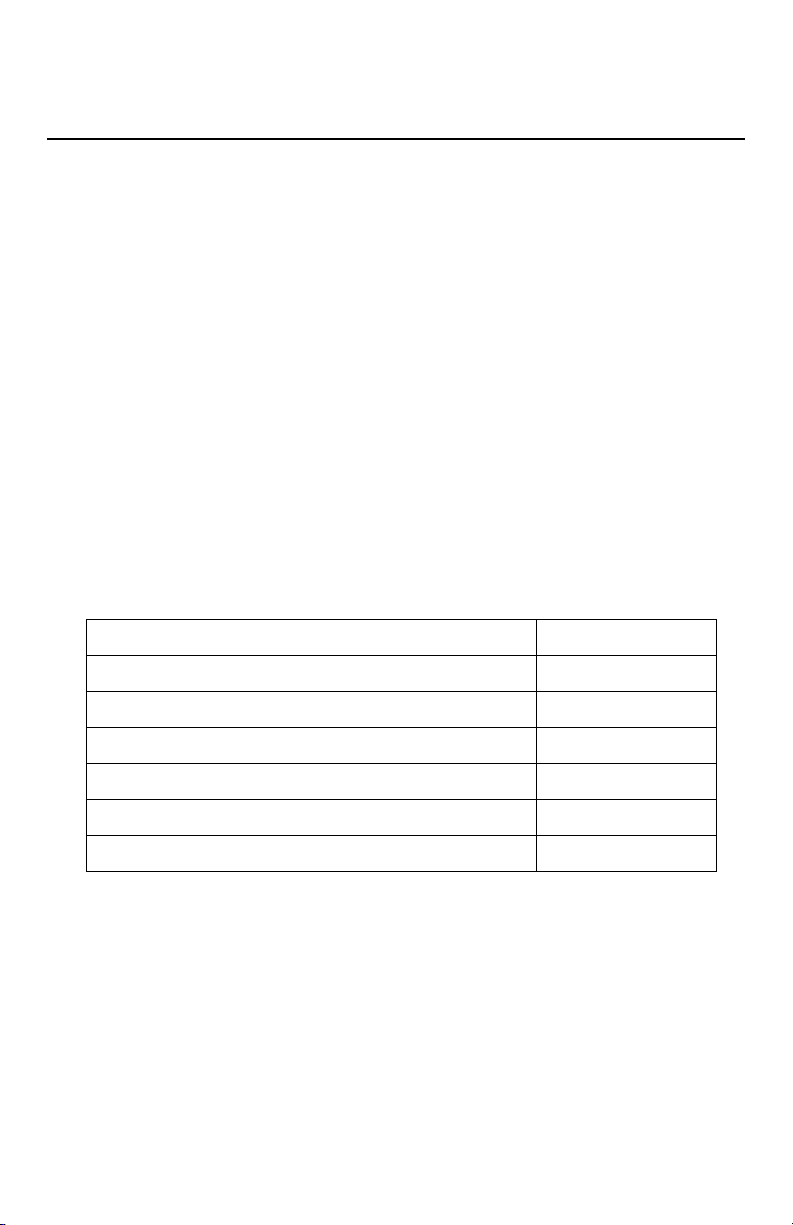

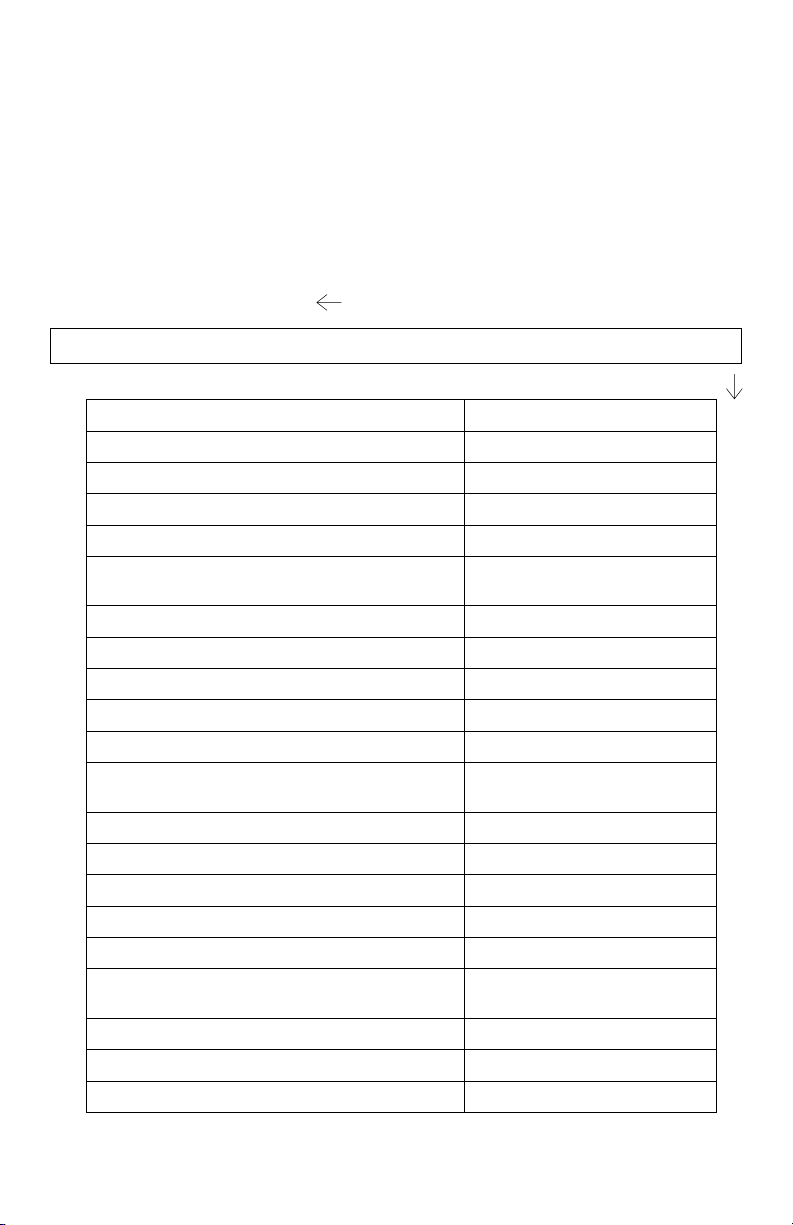

Summary of System Level Commands

The following system level commands are discussed in this section. Refer to the

page number listed to the right of each command for more information and a

sample command.

System Level Command Page

Disable Feedback Characters (STX A) 12

Enable Feedback Characters (STX a) 12

Enter Heat Setting Offset (STX b) 13

Disable Feeding to Cut Position after Print (STX C) 13

Enable Feeding to Cut Position after Print and

Perform a Feed to Cut (STX c)

Set Quantity for Stored Label (STX E) 14

Form Feed (STX F) 15

Set Form Stop Position (STX f) 15

Print Last Label Format (STX G) 16

Enable SOH Commands (STX H) 16

Input Image Data (STX I) 17

Extended System Commands (STX K) 18

Enter Label Formatting Command (STX L) 18

Set Printer to Metric (STX m) 18

TLS PC LinkTM Programmer’s Guide

14

11

Page 17

System Level Command Page

Set Printer to Inches (STX n) 19

Set Start of Print Offset (STX O) 19

Horizontal Alignment Offset (STX o) 20

Clear All Memory (STX Q) 20

Printhead Dot Pattern Test Label (STX T) 21

Send Binary Touch Cell Data (STX t) 22

Label Format Field Replacement (STX U) 24

Send ASCII Touch Cell Data (STX V) 25

Printer’s Firmware Version Information (STX v) 25

Request Memory Information (STX W) 25

Delete File (STX x) 26

Pack Memory (STX z) 26

Disable Feedback Characters (STX A)

This command disables the feedback ASCII characters.

Sample:

<STX>A

No feedback response

Enable Feedback Characters (STX a)

This command enables the feedback ASCII characters. These feedback

characters contain valuable information about system errors, printing completion,

and enabling of immediate commands. These characters are listed in Appendix

A. The printer is initialized with feedback characters turned off. When feedback

characters are enabled, all commands will have a response associated with them.

When there are no errors, the response will be ‘0’. There is no response to the

<STX> a command.

Sample:

<STX>a

No feedback response

12

TLS PC LinkTM Programmer’s Guide

Page 18

Enter Heat Setting Offset (STX b)

This command changes the "on time" of dots on the printhead. The printer

powers up with a default setting determined from the media type installed.

Varying this number changes the amount of time the dots are "turned on" which

in turn changes the amount of heat transferred from the printhead to the media.

The range of valid settings is -5 to +5 that corresponds to an offset of +/- 500

microseconds. This command is helpful when the printer is used with several

different media types. When a label format is sent to the printer and the media

requires more or less heat than the amount set by the default temperature, the host

device can send a command before or after the format to correct the heat setting

for the media being used.

<STX>bsnn

Where:

s ‘+’ or ‘-’ sign, can be either for setting of 0

nn two digit heat offset value (00-05)

Sample:

<STX>b+05

The above sample sets the printer for a heat value of +5.

Feedback possibilities: 0,1,2

Disable Feeding to Cut Position after Print (STX C)

This command will stop the printer from feeding to the cut position after printing.

This command should only be used in conjunction with STX c. This is used to

send multiple print commands without feeding to the cut position after each print.

The STX c command is sent at the end to feed to the cut position and re-enable

feeding to the cut position for all future print commands.

<STX>C

Feedback possibilities (only sent if feedback characters are turned on): 0,1, or 2

TLS PC LinkTM Programmer’s Guide

13

Page 19

Enable Feeding to Cut Position after Print and Perform a Feed to

Cut (STX c)

This command will feed the printer to the cut position. It will also enable feeding

to the cut position after all future print commands. It is to be used in conjunction

with STX C.

<STX>c

Feedback possibilities (only sent if feedback characters are turned on):

1,2,6,7,8,A,B,E,F,J

Set Quantity for Stored Label (STX E)

This command sets the number of labels to print for the label format currently

stored in the print buffer. The most recent label sent to the printer will

automatically remain stored in the buffer until the printer is reset, turned off, or a

batch is canceled. This command is also used in conjunction with the STX G

command, which will print the labels.

<STX>Ennnn

Where:

nnnn- a four-digit quantity, including leading zeros

Sample:

<STX>E0025

<STX>G

The above sample will print 25 labels of the current label format in memory.

Feedback possibilities: 0,1,2

14

TLS PC LinkTM Programmer’s Guide

Page 20

Form Feed (STX F)

This command feeds one label to the top of form.

Sample:

<STX>F

Feedback possibilities: 0,1,2,6,7,8,A,B,E,F

Set Form Stop Position (STX f)

This command is used to adjust the cutter stop position. When a label is printed,

the printer will feed the label to the cut position. This command adjusts the stop

position to allow for desired cutting alignment. When the next label format is

sent to the printer, it will automatically backfeed to the start-of-print position. If a

quantity of more than one label is to be printed (See Set Quantity for Stored

Label (STX E), the printer will operate without feeding to the cut position

between labels. It will feed to the cut position after the last label.

<STX>fsnn

Where:

s- sign of offset, ‘+’ or ‘-’

nn- two digit value of offset

The valid range is -08 to +08.

Sample:

<STX>f+08

The above sample adjusts the stop position 8 pixels from default. The ‘+’ means

that the paper will feed out 8 pixels further.

Feedback possibilities: 0,1,2,6,7,8,A,B,E,F

TLS PC LinkTM Programmer’s Guide

15

Page 21

Print Last Label Format (STX G)

This command prints a previously formatted label. This command is used when

there is a label format in the buffer. The STX E command is used to enter the

quantity. (If the STX E command is not used only one label will print.)

Sample:

<STX>G

Feedback possibilities: 1,2,6,7,8,A,B,C,D,E,F,G,H

Enable SOH Commands (STX H)

This command is used to enable Immediate Commands on power-up or to reenable them if they have been turned off for downloading image data. If feedback

characters are enabled, a code will be sent out from the printer to inform the host

that Immediate Commands are again enabled.

Sample:

<SOH>D

<STX> IBpTest <CR> data...data

<STX>H

The sample above will disable SOH commands, download a PCX image, then reenable SOH commands.

Feedback possibilities: 1,2,5

16

TLS PC LinkTM Programmer’s Guide

Page 22

Input Image Data (STX I)

This command precedes the download of image data from the host to the printer.

The data that immediately follows the command string will be image data. If

Immediate Commands have been enabled and if any of the 8-bit input formats are

to be used, it is necessary to disable the immediate level command interpreter by

executing a SOH D command before issuing this command. To print an image,

select font type Y, (see ‘Generating Label Formats’). Data sent to this field is

also used as the name of the defined graphic image.

<STX>lbfnnnnnnnn<CR>data

Where:

b- Data Type

b Value Image Data Value Range

A ASCII Characters 0-9, A-F, (7bit)

B 00-FF, (8 bit)

f-Format Designation, B,b, P, p, U

Designator

B BMP 8-bit format (image will be flipped), B&W

b BMP 8-bit format (save image as received), B&W

P PCX 8-bit format (image will be flipped), B&W

p PCX 8-bit format (save image as received), B&W

U generic image load file (can be sent as 7- or 8-bit)

Refer to Appendix B: Image File Definitions.

nnnnnnnn-Up to 8 characters used as an image name, must be terminated by

<CR>.

Data—Image data

TLS PC LinkTM Programmer’s Guide

Format

17

Page 23

Sample:

<SOH>D

<STX> IBpTest <CR> data...data

<STX>H

The above sample instructs the printer to receive an 8-bit .PCX image sent by 8bit data, named ‘Test’. It disables immediate commands first, then re-enables

them after.

Feedback possibilities: 0,1,2,3,4

Extended System Commands (STX K)

This command allows for expansion of the DPL-system commands.

Enter Label Formatting Command (STX L)

This command switches the printer to the label-formatting command input mode.

Once in this mode, the printer expects to receive field record definition and labelformatting commands until command E or X is received. System-level

commands will be ignored until the label formatting is terminated with E or X.

Immediate commands will be accepted, but if immediate commands are disabled,

they could get misinterpreted as a label format command. See label-formatting

commands for additional information.

Sample:

<STX>L

Feedback possibilities: 0,1,2

Set Printer to Metric (STX m)

This command sets the printer to measure in metric. When this command is sent,

all measurements will be interpreted as metric values in terms of mm/10, (e.g.,

<STX>M0500 will be interpreted as 50.0mm.). See <STX>n.

Sample:

<STX>m

Default setting: Inches

Feedback possibilities: 0,1,2

18

TLS PC LinkTM Programmer’s Guide

Page 24

Set Printer to Inches (STX n)

This command sets the printer to interpret measurements in inches in terms of

in./100, (e.g., <STX>M0500 will be interpreted as 5.00in.). See STX m.

Sample:

<STX>n

Default setting: Inches

Feedback possibilities: 0,1,2

Set Start of Print Offset (STX O)

This command sets the point where printing starts, relative to the top-of-form

position. Top-of-form is the point where a label edge is detected by the label

edge sensor. The printer will feed from the top-of-form to the offset point

specified in this command, and begin printing there. This offset value is

independent of the STX f, set form stop position command.

<STX>Osnn

Where:

s- sign of offset, ‘+’ or ‘-’

nn- two digit value of offset

The valid range is -05 to +99.

Sample:

<STX>O+05

The above sample sets a start of print position of 5 pixels after the default

position.

Feedback possibilities: 0,1,2

TLS PC LinkTM Programmer’s Guide

19

Page 25

Horizontal Alignment Offset (STX o)

This command sets the point where printing starts relative to the left edge of the

label. This is an offset value from the default position.

<STX>osnn

Where:

s- sign of offset, ‘+’ or ‘-’

nn- two digit value of offset

The valid range is -05 to +99.

Feedback possibilities: 0,1,2

Set Continuous Label Length (STX P)

This command will set the label length for continuous material. The label length

can be set from 0.00 inches to 6.00 inches (0.0mm to 152.4mm). This command

is useful for terminal block labels. It can be used with <STX>S to generate the

correct spacing between the terminals. If the length is set to zero, the printer will

be in banner mode. In banner mode, the label length is determined by the

amount of data on the label. The printer will print until there is no more data up

to 6 inches.

<STX>Pnnnn

Where:

nnnn- a four-digit label length in in/100 or mm/10

Sample:

<STX>L

190000900000000TEST1<CR>

190000901000000TEST2<CR>

X<CR>

<STX>P0100

<STX>G

<STX>P0000

<STX>G

20

TLS PC LinkTM Programmer’s Guide

Page 26

This sample creates a label format with “TEST1” placed at the upper left corner

of the label, and “TEST2” placed 1” below this. The first <STX>P sets the paper

length to 1”. Thus, the following <STX>G will print this label only 1” long and

only “TEST1” will be printed. The second <STX>P command sets the paper

length to 0”, thus putting it in banner mode. The following <STX>G command

will print both text strings and stop printing immediately after “TEST2”.

Feedback Possibilities: 0,1,2

Clear All Memory (STX Q)

This command instructs the printer to clear all images from memory.

Sample:

<STX>Q

Feedback possibilities: 0,1,2

Set Continuous Label Spacing (STX S)

This command will set the label spacing for continuous material. The spacing

can be set down to zero. This command can be used with <STX>P to generate

desired label lengths and spacing for continuous material. If the label length is

set to zero using <STX>P (banner mode), this setting is ignored. A 1/4” spacing

is always used in banner mode. When the label length is set to non-zero, this

spacing is only used when printing batches, or in the special case where the feedto-cut function is disabled (<STX>C). See Examples section for an extensive

terminal block example.

<STX>Snnnn

Where:

nnnn- a four-digit label length in in/100 or mm/10

Sample:

<STX>L

190000900000000TEST01<CR>

+001<CR>

X<CR>

<STX>P0050

<STX>S0000

<STX>E0003

TLS PC LinkTM Programmer’s Guide

21

Page 27

<STX>G

This example will print 3 serialized labels: “TEST01”, “TEST02”, and

“TEST03”. The label length is 0.5” and the spacing between labels is set to zero.

Feedback Possibilities: 0,1,2

Printhead Dot Pattern Test Label (STX T)

This command instructs the printer to print a dot pattern test label. To view the

full test pattern use the media as wide as the print width and at least 1.5-in. (38.1mm) long.

Sending this command will clear the current label format that is stored.

Sample:

<STX>T

Feedback possibilities: 1,2,6,7,8,A,B,C,D,E,F,G

Send Binary Touch Cell Data (STX t)

This command instructs the printer to send the touch cell data from the media as

32 bytes of binary (8-bit) data. A few of these bytes contain useful information

about the print media as follows:

Byte 2,3: Label quantity remaining as a 16-bit value

Byte 6: Bit 0 is set for notched labels and clear for continuous

Byte 7,8: X offset in pixels as a 16-bit value

Byte 9,10: Y offset in pixels as a 16-bit value

Byte 11,12: Width of label in pixels as a 16-bit value

Byte 13,14: Length of label in pixels as a 16-bit value

Sample:

<STX>t

Response:

0x01 0x00 0x78 0x00 0x00 0x1B 0x00 0x00 0x00 0x00 0x01 0x2B 0x01

0x2B 0x11 0xC6

0x32 0x00 0x02 0x00 0x01 0x01 0x00 0x00 0x02 0x94 0x00 0x00 0x00

0x00 0x00 0xF1

This sample read the data from a PTL-32-423 label which is 1.5”x1.5”. This tells

22

TLS PC LinkTM Programmer’s Guide

Page 28

the following:

Byte 2,3: 0x0078 means there are 0x78 or 120 labels remaining.

Byte 6: 0x1B has bit 0 equal to ‘1’, therefore this is notched material

Byte 7,8: 0x0000 means there is no X offset

Byte 9,10: 0x0000 means there is no Y offset

Byte 11,12: 0x012B means this label is 0x12B or 299 pixels wide

Byte 13,14: 0x012B means this label is 0x12B or 299 pixels long

Feedback Possibilities: 0,1,2,E

TLS PC LinkTM Programmer’s Guide

23

Page 29

Label Format Field Replacement (STX U)

This command places new label data into format fields. Format fields are used to

build a label. The new data string must equal the original string length and

contain valid data. To easily keep track of fields put all of the fields to be updated

with the command at the beginning of the label format. A maximum of 99 format

fields can be updated. Fields are numbered consecutively 01 to 99 in the order in

which they are received.

<STX>Unnss..s<CR>

Where:

nn- is the format field number, 2 digits

ss..- is the new string data followed by a <CR>

Sample:

<STX>L

190000501000100data field1<CR>

190000501100110data field2<CR>

190000501200120data field 3<CR>

X<CR>

<STX>E0001

<STX>G

<STX>U01New data F1<CR>

<STX>U02New data F2<CR>

<STX>E0002

<STX>G

The sample above results in three printed labels, the first is formatted with the

commands between <STX>L and X<CR>. The next two labels print with the

replacement data contained in the <STX>U commands, (see <STX>E and

<STX>G).

Feedback possibilities: 0,1,2,I

24

TLS PC LinkTM Programmer’s Guide

Page 30

Send ASCII Touch Cell Data (STX V)

This command causes the printer to send back the touch cell data from the media

in a user-readable 7-bit ASCII Hex format. For interpretation of this data, see

<STX>t.

Sample:

<STX>V

Response:

01007800001B00000000012B012B11C63200020001010000029400000000

00F1

This sample reads the same data as the sample in <STX>t.

Feedback Possibilities: 0,1,2,E

Printer’s Firmware Version Information (STX v)

This command causes the printer to respond by sending a version string. The

version may be different from printer to printer.

Sample:

<STX>v

Printer Response: Version 01.01 12/21/00<CR>

Feedback possibilities: 0,1,2

Request Memory Information (STX W)

This command requests a directory listing of images in the printer memory. It

will list all images stored and the remaining memory available.

<STX>Wa

Where:

a- File Type Identification Code

‘G’ for Graphic (Image) File Type

Sample:

<STX>WG

Printer Response:

LOGO1<CR>

TLS PC LinkTM Programmer’s Guide

25

Page 31

LOGO2<CR>

MEM 8C30<CR>

This shows that there are two images stored called “LOGO1” and “LOGO2”.

The remaining memory is in hex. There are 0x8C30 bytes remaining (35,888

decimal).

Notes on Image Storage:

Image Files are not stored directly. Excess header information is removed.

Following are typical storage sizes for each file type:

File Type B,b:

BMP Files are stored with a reduced header size. Typical size = BMP File size 45 bytes.

File Type P,p:

PCX Files are stored with a reduced header size. Typical size = PCX File Size 111 bytes.

File Type U:

These Files add a header. Typical size = Data Size + 16 bytes.

Feedback possibilities: 0,1,2

Delete File (STX x)

This command removes a specific file from memory. The file name is removed

from the file directory and thus cannot be accessed. The actual storage space

occupied by the file is not released. The pack command can be issued to reclaim

all deleted file storage space, (see STX z).

Sample:

<STX>xtnn...n<CR>

Where:

x ASCII x (0x78)

t the file type identification code

‘G’ for Graphic (Image) file type

nn...n the file name to delete. Up to 8 characters for images

Feedback possibilities: 0,1,2

26

TLS PC LinkTM Programmer’s Guide

Page 32

Pack Memory (STX z)

This command causes the printer to reclaim all storage space associated with all

deleted files.

Sample:

<STX>z

Feedback possibilities: 0,1,2

TLS PC LinkTM Programmer’s Guide

27

Page 33

Extended-System Commands <STX>K

Command Character Command

None Implemented

28

TLS PC LinkTM Programmer’s Guide

Page 34

Label-Formatting Commands

An <STX>L command switches the printer from the system level to the labelformatting command processor. All commands after <STX>L are interpreted as

label-formatting commands. These commands define the format of the label to be

printed.

Label Formatting Command Page

Sets format attribute (A) 30

Sets column offset amount (C) 31

Terminates label formatting mode and print label (E) 31

Sets row offset amount (R) 31

Terminates label formatting mode (X) 32

+ (-) Make Last Field Entered Increment

(Decrement) Numeric

> (<) Make Last Field Entered Increment

(Decrement) Alphanumeric

Sets count by amount (^) 35

33

34

TLS PC LinkTM Programmer’s Guide

29

Page 35

Set Format Attribute (A)

This command specifies the type of format operation and remains in effect until

another format command is specified or another label format has begun

(<STX>L). Each label format defaults to attribute 1 - XOR.

An

Where:

n- is either a 1, 2, 3 or 5

1 = XOR Mode: This is the default mode regions, where text

strings, images, or barcodes intersect will not

be printed, (an odd number of overlapping

objects will print).

2 = Transparent Mode: This optional mode allows the intersection of

text strings, images, and barcodes to print. This

allows the user to print fields on top of one

another. (i.e., the letter I printed on top of a

dash would combine to show a plus).

3 = Opaque Mode: Interacting text is obliterated by the text

formatted last, each character cell is treated as

opaque.

5 = Inverse Mode: This mode allows inverse (white on black)

printing. A proportionally sized border and

background are printed as in a photographic

negative.

Sample:

<STX>L

A2<CR>

190001001000100PCLINK<CR>

190001001100110PCLINK<CR>

E<CR>

The above sample sets the printer to transparent mode and prints one label

showing overlapping text.

Feedback possibilities: 0,1,2

30

TLS PC LinkTM Programmer’s Guide

Page 36

Set Column Offset Amount (C)

This command allows horizontal adjustment of the point where printing begins.

This is a left margin The ‘C’ command instructs the printer to print label formats

nnnn units to the right of the position that the format specifies.

Cnnnn

Where:

nnnn- is a four-digit number for the column offset, in/100 or mm/10—

the printer default is 0 for offset.

Sample:

<STX>L

C0050

190000901000100PCLINK<CR>

The above sample will shift all format data .5 inches to the right, unless the

printer is in metric mode, (see label-formatting command M).

Feedback possibilities: 0,1,2

Terminate Label Formatting Mode and Print Label (E)

When the printer is processing label-formatting commands and receives an ‘E’

command, it will immediately print a label based on the data it has received.

Even if no printable data has been received, the printer will generate and feed a

label, (other termination commands is ‘X’). Commands sent to the printer after a

terminate label command must be of either immediate or system.

E<CR>

Sample:

<STX>L

121100000000000Testing<CR>

E<CR>

The above label format will print a label.

Feedback possibilities: 1,2,6,7,8,A,B,C,D,E,F,G,H

Set Row Offset Amount (R)

This command allows vertical adjustment of the point where printing begins.

This is a top margin. The ‘R’ command instructs the printer to print label formats

TLS PC LinkTM Programmer’s Guide

31

Page 37

nnnn increments above the position the format specifies. Valid input values are

numbers between 0000 and 9999, (refer to the C, Set Column Offset Amount

Command.)

Rnnnn

Where:

nnnn = is a four-digit offset 0000-9999, in/100 or mm/10

Sample:

<STX>L

R0037<CR>

190000901000100SAMPLE LABEL<CR>

E<CR>

The above sample sets the printer's offset row amount to 37 hundredths of an

inch, unless the printer is in metric mode.

Feedback possibilities: 0,1,2

Terminate Label-Formatting Mode (X)

When the printer is in label-formatting mode and receives an X command, it will

immediately switch to the system-command mode and generate a label format

based on whatever data it has already received. However, unlike the ‘E’

command, it will not print a label. (Other termination commands is ‘E’.)

Sample:

<STX>L

190000901000100SAMPLE<CR>

X<CR>

The above sample will result in label formatting, but no label will be printed. The

system command STX G will cause the label to print.

Feedback possibilities: 0,1,2

32

TLS PC LinkTM Programmer’s Guide

Page 38

+ (-) Make Last Field Entered Increment (Decrement) Numeric

The printer is capable of automatically incrementing and decrementing fields on

each label of a batch printed. This command is useful for serializing labels. The

command format is

*pii

Where:

*

-

p -

ii - Is the amount to increment the field by from 01 to 99

Sample:

<STX>L

19000090000000012345<CR>

+001<CR>

X<CR>

<STX>E0003

<STX>G

The above sample will generate a single field label format that prints the initial

label with a value of 12345 and then increments by one for the next two labels.

This command will only affect numbers. If a character other than a number is

inserted, it will affect all numbers to the right of this character. Any numbers to

the left of it will be ignored. If the fill character is a space, leading zeros will be

printed blank. Some examples follow:

Field

Is + for numeric increment, or - for numeric decrement

Is the fill character that is displayed for zeros on the left

Command Label 1 Label 2

Data

0001 +001 0001 0002

0001 + 99 1 100

A9C999 +001 A9C999 A9C000

1000 -001 1000 0999

1000 - 01 1000 999

TLS PC LinkTM Programmer’s Guide

33

Page 39

> (<) Make Last Field Entered Increment (Decrement)

AlphaNumeric

The printer is capable of automatically incrementing and decrementing fields on

each label of a batch printed. This command will increment or decrement an

alphanumeric field. This command is useful for serializing labels. The command

format is

*pii

Where:

*

-

p -

ii - Is the amount to increment the field by from 01 to 99

Sample:

<STX>L

190000900000000ABC<CR>

>001<CR>

X<CR>

<STX>E0003

<STX>G

The above sample will generate a single field label format that prints the initial

label with a value of ABC and then increments by one for the next two labels

(ABD and ABE).

This command will affect numbers and both lowercase and uppercase letters. If a

non-alphanumeric character is inserted, it will affect all alphanumerics to the

right of this character. Any alphanumerics to the left of it will be ignored. The

increment/decrement value is numeric only. Some examples follow:

Field

Is + for numeric increment, or - for numeric decrement

Fill character currently not supported, but must be sent

Command Label 1 Label 2

Data

A9 >001 A9 B0

a9 >019 a9 c8

A$Z9 >001 A$Z9 A$A0

Ba0 <001 Ba0 Az9

Ba0 <099 Ba0 Aq1

34

TLS PC LinkTM Programmer’s Guide

Page 40

Set Count By Amount (^)

An application using incrementing or deincrementing fields (+, -, >, <) will

occasionally require that more than one label be printed with the same values

before the field data is updated. This situation is handled with the ^nn command.

All printers default to 1. This command is set once for the whole label format and

affects all serialized fields in that label format.

^nn

Where:

nn- is a two-digit value that specifies the number of labels to be

generated before the incrementing or deincrementing fields on

the label

Sample:

<STX>L

19000040000000012345<CR>

-001<CR>

^02<CR>

X<CR>

<STX>E0006

<STX>G

The above sample prints two labels with the same field value before

decrementing the field. Six labels are printed.

Feedback possibilities: 0,1,2

TLS PC LinkTM Programmer’s Guide

35

Page 41

Generating Label Formats

Example 1

Example 2

A label format is all the data, in the form of records, that lies between an

<STX>L and either a terminating E<cr> or X<cr>. Other system level

commands may procede the <STX>L command for printer setup.

A record is a data string that contains the information to be printed on the labels.

Every record must end with a termination character (a carriage return <cr>).

A record is made of three parts. (1) A header that is 15 bytes in length, (2) the

data to be printed, and (3) a termination character that marks the end of the field.

The header is used to select the appearance of the data when printed by choosing

rotation, font type, size, and position options. Every header contains similar

information, but this information may be used in different ways by different

record types.

There are currently three types of record currently supported by the TLS PC Link

printer at this time:

1. Bitmapped fonts

2. Barcode

3. Images

36

TLS PC LinkTM Programmer’s Guide

Page 42

The structure of a record

The 15-byte header portion of a record is composed as follows:

a b c d eee ffff gggg

a b c d eee ffff gggg

where: a = rotation*

*Rotation is only supported for fonts and barcodes. Images

cannot be rotated.

b = Font, Barcode, or Image

9 = font (Arial Mono Alternative)

a-c = barcode with no human readable

where a = Code 39

Y = image file ( pcx, bmp, or 7-bit ASCII)

c,d = width and height multiplier (currently not supported and to

be set to 0)

eee = font size identifier (corresponds to TLS code)/ barcode

height. eee is 000 when contained in an image record

(pcx,bmp,etc)

Font Options are 001-019

Refer to Appendix E: Fonts.

ffff = row , the vertical element

gggg = column, the horizontal element

(ffff & gggg are effected by unit of measure set by format

commands m & n)

The header is then followed by the data field. A string of data can be up to 255

characters in length. Characters placed in the data field will be printed as long as

they fall within the physical width of the label being used. It is possible for

characters to “fall” off the sides of a label if the ffff and/or gggg row/column

parameters are inappropriate.

1 = 0° 2 = 90° 3 = 180° 4 = 270°

b = Code 39 w/check character

c = Code 128

When the last record is sent to the printer, the formatting session is ended by

sending one of the terminator label formatting commands, E or X.

TLS PC LinkTM Programmer’s Guide

37

Page 43

Examples of a Label Format:

Example 1 (1.5” x 1.5” Label, PTL-32):

Note: The bitmaps shown are not supplied. For reference to insert your own

bitmaps, the brady.bmp file is 168 pixels x 142 pixels. The logo.bmp bitmap is

139 pixels x 124 pixels.

STX>Q ;clear image memory

<STX>n ;put printer in inches mode

<STX>IBBbrady<CR><brady.bmp> ;Store brady.bmp file

<STX>IBBlogo<CR><logo.bmp> ;Store logo.bmp file

<STX>L ;enter label format mode

1Y0000000250000brady<CR> ;specify brady image at

1Y0000000100082logo<CR> ;specify logo image at

190000600700005PART NUMBER:<CR> ;specify text at X=0.05”,Y=0.70”

190000600950005DESCRIPTION:<CR> ;specify text at X=0.05”,Y=0.95”

190000601200005QUANTITY:<CR> ;specify text at X=0.05”,Y=1.20”

19000060070010012345<CR> ;specify text at X=1.00”,Y=0.70”

190000600950100LABEL<CR> ;specify text at X=1.00”,Y=0.95”

190000601200100100<CR> ;specify text at X=1.00”,Y=1.20”

X<CR> ;exit label format mode

<STX>E0002 ;set print quantity to 2 labels

<STX>G ;print two labels

X=0.00”,Y=0.25”

X=0.82”,Y=0.10”

Change Part Number and Print Again:

38

TLS PC LinkTM Programmer’s Guide

Page 44

Method 1 (New label format):

<STX>L ;enter label format mode

1Y0000000250000brady<CR> ;specify brady image at

1Y0000000100082logo<CR> ;specify logo image at

190000600700005PART NUMBER:<CR> ;specify text at X=0.05”,Y=0.70”

190000600950005DESCRIPTION:<CR> ;specify text at X=0.05”,Y=0.95”

190000601200005QUANTITY:<CR> ;specify text at X=0.05”,Y=1.20”

190000600700100

190000600950100LABEL<CR> ;specify text at X=1.00”,Y=0.95”

190000601200100100<CR> ;specify text at X=1.00”,Y=1.20”

X<CR> ;exit label format mode

<STX>G ;print two labels

56789

<CR>

X=0.00”,Y=0.25”

X=0.82”,Y=0.10”

;specify text at X=1.00”,Y=0.70”

Method 2 (Update Field):

<STX>U06

<STX>G ;print two labels

56789

<CR>

;Replace field*

Note: The new field string “56789” must be the exact same length as the old

string “12345”. This field is number 06 because they are numbered in the order

they were entered in the label format, starting with 01.

TLS PC LinkTM Programmer’s Guide

39

Page 45

Example 2 (1.9” x 4.0” Label, PTL-38):

<STX>n ;put printer in inches mode

<STX>L ;enter label format mode

490000803000030Sample Rotated Label<CR> ;specify text at X=0.30”,Y=3.00”

490000603500090270 Degree<CR> ;specify text at X=0.90”,Y=3.50”

490000601100090Rotate<CR> ;specify text at X=0.90”,Y=1.10”

4a000500255008012345678<CR> ;specify barcode at

49000060225013512345678<CR> ;specify text at X=1.35”,Y=2.25”

X<CR> ;exit label format mode

40

TLS PC LinkTM Programmer’s Guide

X=0.80”,Y=2.55”

Page 46

<STX>Q0002 ;set print quantity to 2 labels

<STX>G ;print two identical labels

Serialize Barcode:

This requires sending the label format again. Since Bar Code “12345678” and

Text “12345678” are separate fields, they must both be serialized in order for the

text to match the bar code.

<STX>L ;enter label format mode

490000803000030Sample Rotated Label<CR> ;specify text at X=0.30”,Y=3.00”

490000603500090270 Degree<CR> ;specify text at X=0.90”,Y=3.50”

490000601100090Rotate<CR> ;specify text at X=0.90”,Y=1.10”

4a000500255008012345678<CR> ;specify barcode at

+001<CR> ;make previous field increment

49000060225013512345678<CR> ;specify text at X=1.35”,Y=2.25”

+001<CR> ;make previous field increment

X<CR> ;exit label format mode

<STX>G ;print two serialized labels

X=0.80”,Y=2.55”

by 1

by 1

;12345678 and 12345679

TLS PC LinkTM Programmer’s Guide

41

Page 47

Example 3 (0.24” continuous terminal block material, PTLTB-400-

240):

To print a terminal block label, it is necessary to set the label size and spacing. In

order to obtain this spacing, the printer must not be fed to the cut position

between terminal block positions on the label. The <STX>C command is used to

disable this function. This example is for a terminal block with a 0.5” pitch.

Y

+5V +5V +5V GND GND GND GND GND GND +12V +12V +12V

<STX>n ;put printer in inches mode

<STX>P0050 ;set label length to 0.5”

<STX>S0000 ;set spacing to zero

<STX>C ;disable feed to cut after print

<STX>L ;enter label format mode

490000700450004+12V<CR> ;place +12V, rotated 270

degrees at

;location X=0.04”, Y=0.45”

X<CR> ;exit label format mode

<STX>E0003 ;set quantity to 3

<STX>G ;print 3 copies of this label

<STX>L ;enter label format mode

490000700400004GND<CR> ;place GND, rotated 270

degrees at

;location X=0.04”, Y=0.40”

X<CR> ;exit label format mode

<STX>E0006 ;set quantity to 6

<STX>G ;print 6 copies of this label

<STX>L ;enter label format mode

490000700400004+5V<CR> ;place +5V, rotated 270 degrees

at

;location X=0.4”, Y=0.40”

X<CR> ;exit label format mode

<STX>E0003 ;set quantity to 3

X

42

TLS PC LinkTM Programmer’s Guide

Page 48

<STX>G ;print 3 copies of this label

<STX>c ;feed to cut position

TLS PC LinkTM Programmer’s Guide

43

Page 49

Troubleshooting

Common Problems and Corrective Action

The best method for troubleshooting development with the TLS PC Link

Programming Language is to use feedback characters. When these are enabled,

all System Level and Label Formatting Commands have a feedback character

sent after them. Looking at these feedback characters is very helpful in

determining where an error has occurred. If a command’s response is an ASCII

‘2’, this means that a bad command was sent. If a command replies with an

ASCII ‘1’, then a serial timeout has occurred. This means the printer was

expecting more data with the command. If the command replies with multiple

characters, such as multiple ‘2’s, this is because the command was bad

somewhere in the middle. All characters that were sent after the invalid character

in the command respond with an error.

The following table lists common programming problems and suggested

corrective action.

If you are having problems with the hardware, refer to the TLS PC Link User’s

Manual.

Problem Possible Cause/Corrective Action

The printer acts sporadically when

downloading an image file.

Unable to read printer status

information while printing.

44

Possible Cause:

If downloading an 8-bit image, it is

likely that Immediate commands are

enabled. Immediate commands will

be detected within the image data.

This will corrupt the data, causing

the printer to see bad information.

Corrective Action:

Make sure immediate commands are

disabled whenever downloading an

8-bit data file.

Possible Cause:

If immediate commands were turned

off to download an image file, they

must be turned back on before

printing an image if it is desired to

send immediate commands (request

status) during the print job. If the

enable immediate commands is sent

after the print command, it will not

TLS PC LinkTM Programmer’s Guide

Page 50

Problem Possible Cause/Corrective Action

be processed until the print job is

complete.

Corrective Action:

When disabling and enabling

immediate commands, it is best to

use feedback characters. With

feedback characters enabled, wait

until an Immediate Commands

Enabled response is sent by the

printer before sending an immediate

command. If it is not desired to have

feedback from all commands, it is

possible to enable and disable

feedback characters around the

command you desire a response

from.

Reading Status String does not

correctly reflect the printer errors.

When sending multiple labels

consecutively to the printer, the

printer acts sporadically.

Possible Cause:

The printer errors Printhead Open,

Out of Labels, Out of Ribbon and

Touch Cell Error are detected when

the printer performs an operation

such as printing. The status is set

during that operation. When a status

is requested, it does not actually test

for these conditions. It just sends the

status from the last print or feed

operation.

Corrective Action:

Test the printer status after a print or

feed operation to see if an error

occurred.

Possible Cause:

When sending data to the printer, it

is stored in a serial buffer until it can

be processed. If the printer is

printing a label, it cannot process the

serial buffer. The serial buffer will

overflow.

TLS PC LinkTM Programmer’s Guide

45

Page 51

Problem Possible Cause/Corrective Action

Corrective Action:

Use hardware flow control. When

the serial buffer fills up, the printer

will stop the host from sending more

data. It will re-enable the serial flow

when it catches up.

Unable to store an image even

though there is enough memory

available.

Possible Cause:

If trying to store an image that

already exists, the printer will only

overwrite that image if it is the only

image that exists.

Corrective Action:

To overwrite an image that already

exists, first delete the image so it can

be re-written. Also, pack image

memory to regain usage of the

memory space that was used by that

file.

Rotation of images does not work. Possible Cause:

Printer does not rotate images, only

bar codes and text.

Corrective Action:

Rotate the image with image

software.

Receive Label Building Error. Possible Cause:

If a label format calls out an image,

but that image is not stored, a label

building error will be given.

Printer does not print. Possible Cause:

Com port settings are not correct.

Corrective Action:

Correct com port settings. Refer to

COM Port Settings on page 6 of this

document.

46

TLS PC LinkTM Programmer’s Guide

Page 52

Appendix A: Feedback Characters

Definition Hex Value Decimal ASCII

No error 0x30 48 0

Serial timeout error 0x31 49 1

Command error 0x32 50 2

Memory full error 0x33 51 3

Image already exists so it was

not stored

Immediate commands enabled 0x35 53 5

Out of labels 0x36 54 6

Printhead open 0x37 55 7

Out of ribbon 0x38 56 8

Battery cell is shorted 0x41 65 A

Low battery 0x42 66 B

Printing is complete 0x43 67 C

Did not print because no label

format has been given

Error reading memory touch

cell on media

Media has changed 0x46 70 F

Printhead is too hot 0x47 71 G

Error Building Label 0x48 72 H

Field Error 0x49 73 I

Feed to cut complete 0x4A 74 J

0x34 52 4

0x44 68 D

0x45 69 E

TLS PC LinkTM Programmer’s Guide

47

Page 53

Appendix B: Image File Definitions

Image Type U:

Record Types:

Dot-Row Record

This record defines the pixel data for one dot-row. After each Dot-Row record,

the Y cursor is incremented so that the next Dot-Row is on the next line.

0x80 ndd...d

where:

n number of data bytes dd...d

dd...d data

Repeat Record

This record will repeat the last Dot-Row Record sent.

0x00 0x00 0xFF n

where: n number of duplicates

X Cursor Record

This record will place the X cursor at an absolute location. All Dot-Row Records

following this command will begin at this X location until a new X Cursor

Record is sent. This pixel location must be a multiple of 8.

0x58 pp

where: pp number of pixels from left edge

represented as 16 bits with low byte

sent first

Y Cursor Record

This record will place the Y cursor at an absolute location to position the next

Dot-Row Record.

0x59 pp

where: pp number of pixels from top edge

represented as 16 bits with low byte

48

TLS PC LinkTM Programmer’s Guide

Page 54

sent first

Terminator

This record must be at the end of the file.

0xFF 0xFF <CR>

Data Format

This image file can be sent as 8-bit data or 7-bit ASCII Hex. The 7-bit version

sends the same data as the 8-bit version, but each byte is sent as two ASCII Hex

characters.

Example:

A 50-pixel by 50-pixel box located 10 pixels down and 10 pixels to the right of

the origin. Note that the X-Cursor is set to pixel 8, and the data starts with the

first two bits equal to zero so the box starts at column 10.

As 8-bit data:

Command Description

0x58 0x08 0x00 X-Cursor at pixel 8

0x59 0x0A 0x00 Y-Cursor at pixel

10

0x80 0x07 0x3F 0xFF 0xFF 0xFF 0xFF 0xFF 0xF0 First line of box

0x80 0x07 0x20 0x00 0x00 0x00 0x00 0x00 0x10 Second line of box

0x00 0x00 0xFF 0x2F Repeat second line

47 times

0x80 0x07 0x3F 0xFF 0xFF 0xFF 0xFF 0xFF 0xF0 Last line of box

0xFF 0xFF 0x0D Terminator

As 7-bit ASCII:

Command Description

580800 X-Cursor at pixel 8

590A00 Y-Cursor at pixel

10

TLS PC LinkTM Programmer’s Guide

49

Page 55

80073FFFFFFFFFFFF0 First line of box

800720000000000010 Second line of box

0000FF2F Repeat second line

47 times

80073FFFFFFFFFFFF0 Last line of box

FFFF 0x0D Terminator

50

TLS PC LinkTM Programmer’s Guide

Page 56

Appendix C: ASCII Control Chart

ASCII Control Chart

(Continued on next page.)

TLS PC LinkTM Programmer’s Guide

51

Page 57

ASCII Control Chart, Continued

52

TLS PC LinkTM Programmer’s Guide

Page 58

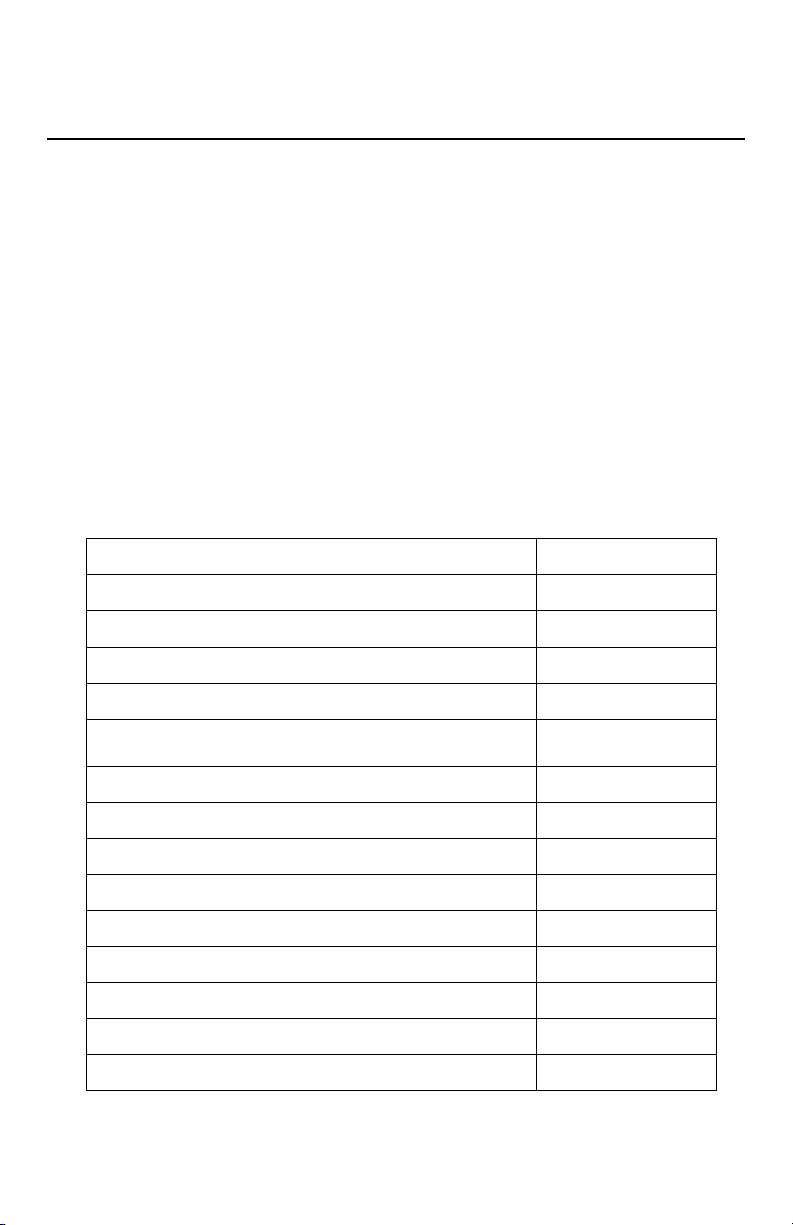

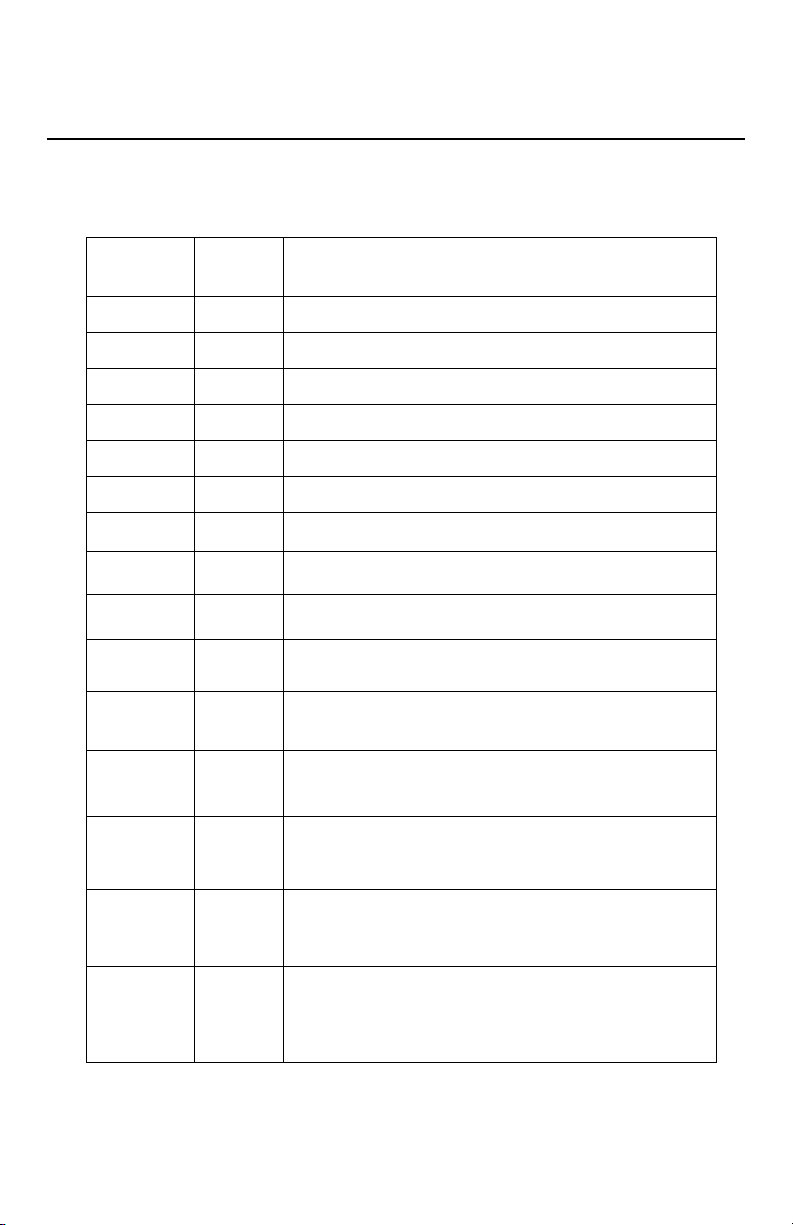

Appendix D: List of Commands

The following table lists all of the commands found in the guide, along with their

description. Refer to the page number listed to the right for detailed information

on each command.

Description Command Page

Reset SOH # 7

Send ASCII Status String SOH A 8

Toggle Pause SOH B 9

Cancel SOH C 10

Disable SOH SOH D 10

Send Batch Quantity SOH E 10

Disable Feedback Characters STX A 12

Enable Feedback Characters STX a 12

Enter Heat Setting Offset STX b 13

Disable Feeding to Cut Position after

Print

Enable Feeding to Cut Position after

Print and Perform a Feed to Cut

Set Quantity for Stored Label STX E 14

Form Feed STX F 15

Set Form Stop Position STX f 15

Print Last Label Format STX G 16

Enable SOH Commands STX H 16

Input Image Data STX I 17

Extended System Commands STX K 18

Enter Label Formatting Command STX L 18

Set Printer to Metric STX m 18

Set Printer to Inches STX n 19

Set Start of Print Offset STX O 19

TLS PC LinkTM Programmer’s Guide

STX C 13

STX c 14

53

Page 59

Description Command Page

Horizontal Alignment Offset STX o 20

Clear All Memory STX Q 20

Printhead Dot Pattern Test Label STX T 21

Send Binary Touch Cell Data STX t 22

Label Format Field Replacement STX U 24

Send ASCII Touch Cell Data STX V 25

Printer’s Firmware Version Information STX v 25

Request Memory Information STX W 25

Delete File STX x 26

Pack Memory STX z 26

Sets format attribute A 30

Sets column offset amount C 31

Terminates label formatting mode and

print label

Sets row offset amount R 31

Terminates label formatting mode X 32

Make Last Field Entered Increment

(Decrement) Numeric

Make Last Field Entered Increment

(Decrement) Alphanumeric

Sets count by amount ^ 35

54

TLS PC LinkTM Programmer’s Guide

E31

+ (-) 33

> (<) 34

Page 60

Appendix E: Fonts

TLS PC LinkTM Printer Fonts

The following fonts are available on the TLS PC Link printer:

FONT

NUMBER

14

25

36

47

59

610

711

813

914

10 17

11 20

POINT

SIZE

PRINT SAMPLE

BRADY 12345

BRADY 12345

BRADY 12345

BRADY 12345

BRADY 12345

BRADY 12345

BRADY 12345

BRADY 12345

BRADY 12345

BRADY 12345

BRADY 12345

12 23

BRADY 12345

13 26

BRADY 12345

14 28

BRADY 12345

15 36

BRADY 123

TLS PC LinkTM Programmer’s Guide

55

Page 61

FONT

NUMBER

16 45

17 51

18 56

19 72

POINT

SIZE

PRINT SAMPLE

BRADY 1

BRADY

BRADY

BRAD

56

TLS PC LinkTM Programmer’s Guide

Page 62

Font Symbol Set

The following characters are supported in all fonts.

0123456789ABCDEF

00

10

20 !“#$%&‘()*+,-./

300123456789: =

40@ABCDEFGHIJKLMNO

50PQRSTUVWXYZ \ _

60 abcdefghijklmno

70pqrstuvwxyz

80 Š‹Œ!

90 ™

A0 ¤ §¨© ª« " ®

B0 ° ± ² ´

C0ÀÁÂÃÄ ЕЖЗИЙКЛМНОП

D0 СТУФ Ц ШЩЪЫЬ

E0абвгдежзийклмноп

F0 стуф ц шщъыь

!

TLS PC LinkTM Programmer’s Guide

57

Page 63

Appendix F: Barcodes Summary

Font Type Length Checksum Valid ASCII

Characters,

decimal

value

a Code 39 Varies No 32,36,37,42,

43,45-57,

65-90

b Code 39 with

check

character

c Code 128 Varies Yes 32-127

Varies Yes 32,36,37,42,

43,45-57,

65-90

58

TLS PC LinkTM Programmer’s Guide

Page 64

Appendix G: Mini-DIN 6-Pin to 9-Pin Cable Pinouts

Mini-DIN-6S

Connector to Printer

DB-9S Connector to

PC

RXD 1 No Connection 1

CTS 2 2

+5V 3 No Connection 3

GND 4 4

TXD 5 5

RTS 6 6

7

8

No Connection 9

SHELL SHELL

Loading...

Loading...