Page 1

Edition 2/05

Transfer Printer

THT-BP Precision

Operator’s Manual

Page 2

2 Transfer Printer THT-BP Precision

W.H. Brady

Lindestraat 21

Industriepark C3

9240 Zele Belgium

Tel.: +32 52 457 811

e-mail: support@brady.be

All specifications about delivery, design, performance and weight are given to the best of our current knowledge and are subject

to change without prior notice.

Page 3

3Transfer Printer THT-BP Precision

Transfer Printer

Operator's Manual

Transfer Printer

Operator's Manual

All rights reserved, including those of the translations.

No part of this manual nor any translation may be reproduced or transmitted in any

form or by any means, for any purpose other than the purchaser's personal use,

without the express written permission of W.H. Brady Co.

Edition 2/05

Printed in Germany

THT-BP Precision

Page 4

4 Transfer Printer THT-BP Precision

Table of Contents

Trademarks .................................................................................................................................... 6

A General Guide to the Documentation ........................................................................................ 7

1. Product Description ................................................................................................................ 8

General Information .................................................................................................................. 8

Printer Types ............................................................................................................................. 8

Particular Features BP Precision 200P / 300P ......................................................................... 9

Characteristics of the Thermal Printhead .................................................................................. 9

Compliances ........................................................................................................................... 10

Instructions for the Lithium Battery .......................................................................................... 10

Technical Specifications ........................................................................................................... 11

Options ................................................................................................................................... 15

External Media Unwinder/Rewinder .................................................................................. 15

Present Sensors ............................................................................................................... 15

Rewind Guide Plate .......................................................................................................... 15

Cutter Unit ........................................................................................................................ 15

Memory Card ................................................................................................................... 15

External Keyboard ............................................................................................................ 15

Interface Extensions ......................................................................................................... 15

Print Media .............................................................................................................................. 16

Print Media for Direct Thermal Printing ............................................................................. 17

Print Media for Thermal Transfer Printing ......................................................................... 17

Label / Tag Media Specifications ...................................................................................... 18

Transfer Ribbon ................................................................................................................ 19

Software .................................................................................................................................. 20

2. General Safety Instructions .................................................................................................. 21

3. Unpacking .............................................................................................................................. 21

Delivery Contents .................................................................................................................... 21

Removing the Securing Devices ............................................................................................. 22

4. Printer Component Location ................................................................................................ 23

5. Connecting the Printer ......................................................................................................... 27

Connection to Power Supply ................................................................................................... 27

Connection to a Computer ...................................................................................................... 28

Switch on the Printer ............................................................................................................... 29

6. Control Panel ......................................................................................................................... 30

Use of the Control Panel ......................................................................................................... 30

Structure of the Control Panel ................................................................................................. 31

Functions of the Control Panel during Printing ........................................................................ 32

Functions of the Control Panel in the Offline Menu.................................................................. 35

7. Media Loading ....................................................................................................................... 38

General Information ................................................................................................................ 38

Preparation for Rewind Mode .................................................................................................. 39

Loading Labels ........................................................................................................................ 40

Loading Labels from Roll ........................................................................................................40

Adjustment of the Printhead Support ....................................................................................... 45

Loading Fanfold Labels ........................................................................................................... 46

Loading Transfer Ribbon .........................................................................................................48

Adjustment of the Transfer Ribbon .......................................................................................... 50

Table of Contents

Page 5

5Transfer Printer THT-BP Precision

8. Printer Configuration ............................................................................................................ 52

Overview ................................................................................................................................. 52

Local Settings ......................................................................................................................... 54

Machine Parameters ............................................................................................................... 56

Print Parameters ..................................................................................................................... 60

Interfaces ................................................................................................................................ 64

Security ................................................................................................................................... 66

9. Test Options .......................................................................................................................... 68

Overview ................................................................................................................................. 68

Short Status ............................................................................................................................ 70

Status Print .............................................................................................................................. 72

Font List .................................................................................................................................. 74

Device List .............................................................................................................................. 76

Printhead Profile ..................................................................................................................... 78

ASCII Dump (Monitor) Mode ................................................................................................... 80

Test Grid ................................................................................................................................. 82

Label Profile ............................................................................................................................ 84

10. Memory Cards ....................................................................................................................... 86

Installation and Removing the Memory Card ........................................................................... 87

Preparing the Memory Card .................................................................................................... 88

Writing to the Memory Card .................................................................................................... 88

Memory Card Options in the Offline Menu ............................................................................... 89

Overview .......................................................................................................................... 89

Label from Card ............................................................................................................... 90

Print Directory .................................................................................................................. 91

Copy Memory Card .......................................................................................................... 92

Format Card .....................................................................................................................94

ASCII Dump (Card) .......................................................................................................... 95

11. External Keyboard ................................................................................................................ 96

Connecting the External Keyboard .......................................................................................... 96

Key Assignment ...................................................................................................................... 97

Special Key Functions ............................................................................................................. 97

Special Characters Available with an External Keyboard ......................................................... 98

Appendices

Appendix A - Operation in Peel-off Mode .................................................................................. A-1

Components for the Peel-off Mode ......................................................................................... A-1

Preliminary Tests .................................................................................................................... A-2

Present Sensors ..................................................................................................................... A-2

Appendix B - Pin Assignment of the Interface Connectors ..................................................... B-1

Pin Assignment of the RS-232 Interface ................................................................................. B-1

Interface Cable for RS-232 .................................................................................................... B-2

Pin Assignment of the Parallel Interface Connector ................................................................ B-3

Parallel Interface Cable .......................................................................................................... B-3

Table of Contents

Page 6

6 Transfer Printer THT-BP Precision

Trademarks

Centronics ® is a registered trademark owned by Centronics Data Computer

Corporation.

Macintosh-Computer is a product of Apple Computer, Inc.

Microsoft ® is a registered trademark owned by Microsoft Corporation.

Bitstream ® is a registered trademark owned by Bitstream Inc.

TrueType ™ is a registered trademark owned by Apple Computer Inc.

Table of Contents / Trademarks

Appendix C - Error Messages / Problem Solution .................................................................... C-1

Error Messages ...................................................................................................................... C-1

Recoverable Errors ......................................................................................................... C-1

Non-Recoverable Errors .................................................................................................. C-2

Errors during System Test ............................................................................................... C-2

List of Error Messages ..................................................................................................... C-3

Problem Solution .................................................................................................................... C-7

Appendix D - Maintenance / Cleaning ....................................................................................... D-1

General Cleaning ................................................................................................................... D-1

Cleaning the Print Roller ........................................................................................................ D-1

Cleaning the Printhead ........................................................................................................... D-2

Cleaning the Label Edge Sensor ............................................................................................ D-3

Appendix E - Replacing Assembly Units ................................................................................... E-1

Replacing the Prinhead .......................................................................................................... E-1

Replacing the Print Roller and the Rewind Assist Roller ......................................................... E-4

Appendix F - Firmware Updates ................................................................................................ F-1

General Information ............................................................................................................... F-1

Firmware Update Using the Parallel Interface ........................................................................ F-1

Firmware Update from Memory Card ..................................................................................... F-2

Error Messages During the Firmware Update ........................................................................ F-3

Index

EU - Conformity Declaration

Page 7

7Transfer Printer THT-BP Precision

A General Guide to the Documentation

This manual contains the description and usage instructions for the Transfer

Printer THT-BP Precision.

For detailed technical information on programming of the printer a separate

Programming Guide is available on request. For specific information on

maintenance and repair of the printer, a separate Service/Maintenance

Manuals is available.

The first few chapters cover general information which is necessary for

unpacking and setup of the printer, including ribbon and media loading. Further

chapters cover the connection and usage of optional equipment that may be

attached to the printer.

In the appendices, additional information such as cabling specifications, error

messages and problem resolution, and maintenance/cleaning instructions are

included.

Please take special note of the specifications for suggested print media and

the references to cleaning the printer, to prevent damage, poor quality printing

and avoidable failures of your printer.

Every effort has been made in the creation of this manual to provide as much

information as possible in a form that is both understandable and useful.

We welcome your comments and suggestions regarding additions or

corrections to improve future editions of this manual.

NOTICE !

The figures in this manual normally show the Transfer Printer THT-BP

Precision 600 !

If there are important differences between the printer types you will find a

notice !

A General Guide to the Documentation

Page 8

8 Transfer Printer THT-BP Precision

1. Product Description

General Information

The devices of the BP Precision familiy are innovative printers which may be

used in either direct thermal or thermal transfer mode. They offer a high

resolution with virtually an unlimited variety of printout designs.

The center mounting plate is made of die-cast aluminum which makes it very

robust and resistant to bending.

By using 32 bit-processors from Motorola and the internal memory of 8 MB

(BP Precision 200 / 300) or 16 MB (Precision 600), very long large labels (up

to a length of 39 in / 1000 mm) can be printed quickly. As standard equipment,

the printers have a bi-directional parallel and a serial RS-232-interface. An

optional RS-422/485-interface, USB-interface or ethernet-interface can be

installed. The printers auto-sense which interface is actually used.

Furthermore the printers have a keyboard interface to connect a standard

keyboard as well as a bar code scanner. By using a memory card it is possible

to print and to enter variable data without any connection to a computer.

The ranging power supply (100-240VAC) allows the printers to be used around

the world without re-configuration.

The operation and usage of the printers is simple and comfortable. All printer

settings can be carried out with the Navigator Pad. To ease the operation the

active key is marked in the several operating modes.

The graphic LCD display keeps the operator constantly informed about the

current status of the printer.

The modular design of the printers guarantees efficient service.

A special feature of the BP Presicion 200 / 300 printers is the possibility to

change between the 203 dpi-printhead and the 300 dpi-printhead easily, with a

minimum amount of time and effort.

For the printers a wide range of optional accessories like external un- and

rewinders, label/tag cutters, different peel-off modules and a tamp applicator is

available.

1. Product Description

Printer Types

BP Precision printers are available in different equipment variations:

Printhead Basic Devices P-Versions

203 dpi BP Precision 200 BP Precision 200P

300 dpi BP Precision 300 BP Precision 300P

600 dpi BP Precision 600 BP Precision 600P

Basic Devices : Printer types for tearing-off the labels

P-Versions : Printer types with internal rewinder and dispense plate

for peeling-off the labels

Page 9

9Transfer Printer THT-BP Precision

1. Product Description

Particular Features BP Precision 200P / 300P

The P-versions of the printers are specificly developed for operation in the

peel-off mode and they are equipped with dispense edge as standard. In the

peel-off mode the labels are removed from the silicon liner immediately after

printing, and then available in a dispense position ready for further processing.

A peel-off module, for example an optional present sensor, which is attached to

the printer by the peripheral connector, indicates the presence of a label, and

pauses the printing process until the label is removed. After taking the label

from the dispense position the next label will be printed. To guarantee a

maximum of reliability in the peel-off mode the printers are additionally

equipped with a pair of rollers to cause the dispense tension.

NOTICE !

In the delivery state, BP Precision 200P and 300P are configured in such a

way, that the print speed in the peel-off mode is limited to maximum

100mm/s. When using smaller labels or supply rolls with a small outside

diameter it is possible to increase the print speed for the peel-off mode.

We recommend to carry out preliminary tests with speed limitation

switched off (see printer configuration) !

For the other P-version printers there is no limitation of the print speed in the

peel-off mode.

Characteristics of the Thermal Printhead

CAUTION !

The thermal printhead is the most sensitive part of your printer. Please

pay special attention to the following guidelines:

1) The glass cover on the printhead must not be touched with the hand. Also,

do not use sharp objects (knives, screwdrivers, etc) to clean the printhead.

2) Ensure that the printhead is properly adjusted at all times.

3) Make sure that there are no high spots or debris on your media to lodge on

or damage the printhead. The label surface must be smooth. Lower grade

direct thermal paper is very rough and will act like sandpaper on the head,

reducing the head's lifetime. Do not use low grade stock.

4) Clean the head at each change of ribbon, or with each new roll of direct

thermal media, with a special cleaning pen, or a cotton swab with isopropyl

alcohol.

5) Print with the lowest possible head temperature to increase the life of the

printhead.

6) When changing the printhead, first turn the power off and disconnect the

power cord. Then, place a clean paper towel or tissue under the head to

provide a clean surface for it to rest on. When removing the head, hold it

on the sides only.

Failure to observe the instructions above can lead to a reduced printhead life.

Page 10

10 Transfer Printer THT-BP Precision

Compliances

The device complies with the following safety regulations :

CE : The printer complies with the following safety requirements

- EC Low Voltage Directive (73/23/EEC)

- EC Machinery Directive (98/37/EEC)

- EC Electromagnetic Compatibility Directive

(89/336/EEC)

FCC : The device complies with the requirements of the FCC

regulations part 15 for class A computers. Under

disadvantageous circumstances, the operation of these

devices may cause interference with radio or TV reception,

which has to be eliminated by the operator.

Instructions for the Lithium Battery

The PCB of the printer is equipped with a Lithium battery.

Take necessary precautions against a possible short circuit if the battery is not

fully discharged. Properly remove the battery should the printer be scrapped.

WARNING !

This is a Class A product. In a domestic environment this product may cause

radio interference in which case the user may be required to take adequate

measures.

1. Product Description

Page 11

11Transfer Printer THT-BP Precision

1. Product Description

Technical Specifications

Printhead

Printhead Type : Direct thermal or thermal transfer

Printhead Model : BP Precision 200/300: Thick film transfer printhead

BP Precision 600: Thin film transfer printhead

Printhead Resolution : BP Precision 200 : 203 dpi = 8 Punkte / mm

BP Precision 300 : 300 dpi = 11,8 Punkte / mm

BP Precision 600 : 600 dpi = 23,6 Punkte / mm

Number of dots/line : BP Precision 200 : 832

BP Precision 300 : 1280

BP Precision 600 : 1920

Print Speed : BP Precision 200 :

2,3,4,5,6,7,8 ips (50,75,100,125,150,175,200 mm/s)

BP Precision 300 :

2,3,4,5,6 ips (50,75,100,125,150 mm/s)

BP Precision 600 :

2,3,4 ips (50,75,100 mm/s)

for peel-off mode : print speed limited to maximum 4 ips (100mm/s) as standard

Print Width : BP Precision 200 : up to 4.1 in (104 mm)

BP Precision 300 : up to 4.25 in (108.4 mm)

BP Precision 600 : up to 4.15 in (105.6 mm)

Media

Material : Standard Labels and Cardboard / Tags

Direct Thermal, Thermal Transfer and various Synthetics including: thermal

transfer plaincoated papers, vinyl, Mylar, metalized paper, non-woven

fabric, fine woven fabric, thermal visible light scannable paper, infrared

scannable paper, thermal ticket/tag stock, thermally sensitive plastic stock.

Media Type : die cut labels, continuous paper

Media Winding : face-in or face-out on the roll

Supply roll Diameter : up to 7.9 in (200 mm)

Core Diameter : 1 to 3 in (25.4-76 mm)

Material thickness : 0.003-0.01 in (0,07-0,25 mm)

Weight : 60-250 g/sqm

Page 12

12 Transfer Printer THT-BP Precision

Material Width : 4.7 in (120 mm)

Media Width : .5 to 4.6 in (12-116 mm)

for peel-off mode : 1 to 4.6 in (25-116 mm)

Media Height : BP Precision 200/300: .2 to 39 in (5-1000 mm)

BP Precision 600 : .2 to 9.8 in (5-250 mm)

for peel-off mode : .5 to 7.9 in (12-200 mm)

Internal Rewinder : to rewind media or the liner in peel-off mode

Core Diameter : 1.5 (38.1mm)

Rewind Diameter : up to 5.7 in (145 mm)

Label side : out

Transfer Ribbon

Inkside : in or out

Outer Diameter : up to 3.1 in (80 mm)

Core Diameter : 1 in (25 mm)

Length : up to 1650 in (500 m)

Width : up to 4.5 in (114 mm)

Media Edge Sensor

Distance to paper edge : .16-2.3 in (4-57,5 mm)

Material recognition : Gap sensor ("see-through"),

Bottom-reflective sensor for black marks

Electronics

Processor : BP Precision 200/300: 32 Bit Motorola Coldfire / 64 MHz

BP Precision 600: 32 Bit Motorola Coldfire / 144 MHz

Internal Memory (RAM) : BP Precision 200/300: 8 MB

BP Precision 600: 16 MB

Slot for memory card : CompactFlash Type 1 up to 512 MB

Real time clock : Printout of time and date

Control panel :

Navigator Pad with the active key illuminated indicating operating mode

Lighted graphic LCD display

LCD can be set to display in different languages

1. Product Description

Page 13

13Transfer Printer THT-BP Precision

1. Product Description

Interfaces

Standard :

serial : RS-232 8 Bit; 1,200-230,400 Baud

parallel : Centronics bi-directional (IEEE 1284 Nibble mode)

USB (Master) : for keyboard / scanner / external control panel

peripheral connection : for cutter / present sensor / peel-off adapter, pause adapter /

Optional :

serial : RS-422/485 8 Bit; 1,200-230,400 Baud

USB (Slave) : for PC connection

Ethernet : 10/100 Base T

Twinax/Coax Converter : for IBM connection

Contents of the Print Image

Text Fields : max. 250

Graphic Elements : max. 200

Bitmap Graphics : max. 128 (100 several graphics in memory)

Barcode Fields : max.100

Fonts

Available Fonts : 5 Bitmap fonts incl. OCR-A and OCR-B

3 scaleable fonts (TrueType™) internal

Additional TrueType™ fonts may be downloaded

Character Sets : Windows : 1250 bis 1257

DOS 437, 737, 775, 850, 852, 857, 862, 864, 866, 869

EBCDIC 500, ISO 8859-1 bis -10, ISO 8859-13 bis -16, Macintosh

Roman, DEC MSC, KOI8-R, Win OEM 720, UTF-8

Font Size :

Bitmap fonts : Width and height .04 to .1 in (1 - 3 mm)

Width and height are selectable up to 10.

Scaleable fonts : Width and height .035 to 5 in (.9 - 128 mm)

Width and height are individually changeable.

Font style : reverse, bold, italic, underlined, outlined, grey, vertical

Font rotation :

Bitmap fonts : 0°, 90°, 180°, 270°

Scaleable fonts : 360° in 1° increments

Graphics

Graphic elements : line, box, circle, ellipse, fill-in segment, arrow

Graphic file types : .PCX, .IMG, .BMP, .TIF, .GIF and .MAC Graphic files

Page 14

14 Transfer Printer THT-BP Precision

Barcodes

Lineare Codes : Code 39, Code 93, Code 128 A,B,C, Codabar, EAN 8, EAN 13, EAN

128, EAN/UCC 128, EAN/UPC Anhang 2, EAN/UPC Anhang 5, FIM,

HIBC, Interleaved 2/5, Ident-/Leitcode der Deutschen Post AG, Jan 8,

Jan 13, MSI, Plessey, Postnet, RSS 14, UPC A, UPC E

2-D Codes : Aztec, Codablock, Data Matrix, PDF417, Micro PDF, UPS Maxicode,

QR-Code

Bar code height, module width and ratio are variabe, with/without

check digit, human readable character, start/stop character

Control / Test

Control : Ribbon available

Paper / fanfold available

Printhead closed

Test options : System test when powering on including a printhead test

short status, status print, font list, device list,

printhead profile, label profile, test grid, ASCII dump mode

Status messages : Counter of the printed length, counter of the operating hours

Software

Windows driver : 95, 98, ME, 2000, XP, NT from Version 4.0

Others

Dimensions : H: 10.8 in (274mm) W: 9.5 in (242mm) D: 17.6 in (446mm)

Weight : 20 lb. (9 kg)

Operating Voltage : 100-240 V A.C. / 50-60 Hz

Maximum Power Input : 250 W

Environment :

Operation : at 50° to 95° F (10 to 35°C) at a humidity of 30 to 85%

Transport : at -13° to 158° F (-25 to +70°C) at a max. humidity of 95%

non-condensing

Storage : at 41° to 104° F (5 to 40 °C) at a humidity of 5 to 85%

1. Product Description

Page 15

15Transfer Printer THT-BP Precision

1. Product Description

Options

External Media Unwinder/Rewinder

For operating large print jobs, external unwinders and rewinders are available

to handle big label rolls :

- Ext. Rewinder ER1 (up to diam. 8.3in/210mm)

- Ext. Rewinder ER4 (up to diam. 11.8in/300mm)

- Ext. Unwinder EU4 (up to diam. 11.8in/300mm)

Present Sensors (for P-version printers only)

The Present Sensor PS8 is a see-through sensor, which indicates the label in

the peel-off position and stopp the print job. After removing of the label, the

next one is printed. The Present Sensor PS6 has additionally a peripheral

interface to control the peel-off process by an external application.

Rewind Guide Plate (for P-version printers only)

The Rewind Guide Plate RG4 offers to rewind small print jobs internally. The

maximum rewind diameter depends on the size of the remaining media roll.

Cutter Unit

With the CU4 installed, labels or continuous media may be cut when desired.

Cutter options include a choice of: after each label, after a specific quantity of

labels, or at the end of a print job. For cutter operation, the printer firmware will

extend the label for cutting based on specified displacements, then

automatically backfeed the label, so that after making a cut, the label roll will be

repositioned and ready for printing the next label.

The cutter is powered directly by the printers peripheral connector.

Memory Card

The printer includes an option for using memory cards in order to permanently

store graphics, fonts or whole label formats. The data can be downloaded via

any of the printers data interfaces. CompactFlash Type 1 cards with a

maximum capacity of 512 MB are accepted. Using a memory card, the printer

can be operated without being connected to a computer which represents a

great advantage regarding the flexibility.

External Keyboard

The keyboard connector allows you to connect your printer to an USB

keyboard. This will allow you to input variable data to a format stored on a

memory card.

Interface Extensions

The printer is equipped with a slot to connect an additional interface.

It is possible to install an USB interface or an ethernet interface allowing the

printer to be connected to several different types of interfaces and networks.

Page 16

16 Transfer Printer THT-BP Precision

1. Product Description

Print Media

The BP Precision printers can be run in a direct thermal or thermal transfer

mode.

For direct thermal mode, the label material must be specifically designed for

this use. The printout is created directly on the paper, as the paper reacts with

the heat of the printhead and results in the darkening of the material.

Driving the printer in thermal transfer mode requires standard paper labels and

the addition of thermal transfer ribbons. The printout is created by heating the

ribbon with the printhead, resulting in a transfer of color from the ribbon onto

the labels.

The printers allow for regulating the required heat setting through the software,

which offers a wide range of printing possibilities.

The BP Precision printers are able to print on labels and continuous media,

with a maximum supply roll diameter of 7.9" (200 mm). The minimum core

diameter is 1" (25.4 mm).

Top of form (label edge) detection is accomplished with a moveable photocell,

which is driven by the internal processor of the printer. The photocell does an

automatic measurement of the used material. No additional adjustments are

required.

The following pages contain more detailed information and specifications which

apply depending on the print method to be used.

For information of specific materials you may wish to use, check with your local

distributor. Not every material is suitable for quality direct thermal or thermal

transfer printing. The surface of the material is very often the main factor, but

not the only factor determining suitability. There are many materials available

for labeling and your local distributor can offer suggestions to meet your

particular needs.

Page 17

17Transfer Printer THT-BP Precision

1. Product Description

Print Media for Direct Thermal Printing

The material to be printed must comply with certain important specifications to

ensure a quality print image and to avoid damage or extra wear to the

printhead.

Using the label stock which we have tested and recommended ensures the

best treatment of the printhead. In the event that your label stock will be

supplied by another manufacturer, the following points should be noted with

regard to the use of thermal paper:

1. The surface coating/quality must sufficiently cover the thermo-reactive

coating to ensure that the printhead does not become damaged. If the

surface coating is too thin, the printhead can become pitted due to

microscopically small "explosions" resulting when the chemical reaction of

the thermal coating takes place. The result is that the printhead can rapidly

become damaged.

2. The surface of the label should be very smooth to avoid a "sandpaper" type

effect on the printhead.

3. Choose label stock which can be printed with the lowest possible thermal

value. The greater the thermal value required, the greater wear on the

printhead. Additionally, when the thermal value is high, the time required

for the printhead to heat up and cool down can have an adverse effect on

the quality of print, especially when a fast print speed is desired.

Print Media for Thermal Transfer Printing

The thermal transfer process makes possible the use of many different

materials for printing, such as normal paper, cardboard, polyester film, etc.

NOTICE !

The print results depend to a great degree on a suitable combination of

label material and transfer ribbon. The label surface dictates which

transfer ribbon will provide the best print results, and which ribbon

cannot. An unsuitable match of label material to ribbon type can be

responsible for an extremely poor print quality.

Your Dealer can give you expert advice as to which combination of materials

will best meet your requirements. Your Dealer can also assist you by testing

the different materials you may be considering for your labeling needs.

Page 18

18 Transfer Printer THT-BP Precision

Item BP Precision 200 BP Precision 300 BP Precision 600

A Label width .5 - 4.6 (12-116)

Peel-off mode 1 - 4.6 (25-116)

B Backing width 1 - 4.7 (25-120)

C Label length .2 - 39 (5-1000) .2 - 9.8 (5-250)

Peel-off mode .5 - 7.9 (12-200)

D Gap between labels .08 - 39 (2-1000)

E Label thickness .003 - .01 (0.07-0.25)

F Thickness of backing material .003 - .01 (0.07-0.25)

G Distance of the first printing position

from the edge of the backing paper .08 (2)

H Distance of the label sensor

from the edge of the backing paper .16 - 2.3 (4-57.5)

I Width of the perforation mark >.2 (>5)

K Height of the perforation mark .08 - .4 (2-10)

L Width of the reflective mark (black) >.2 (>5)

M Height of the reflective mark (black) .08 - .4 (2-10)

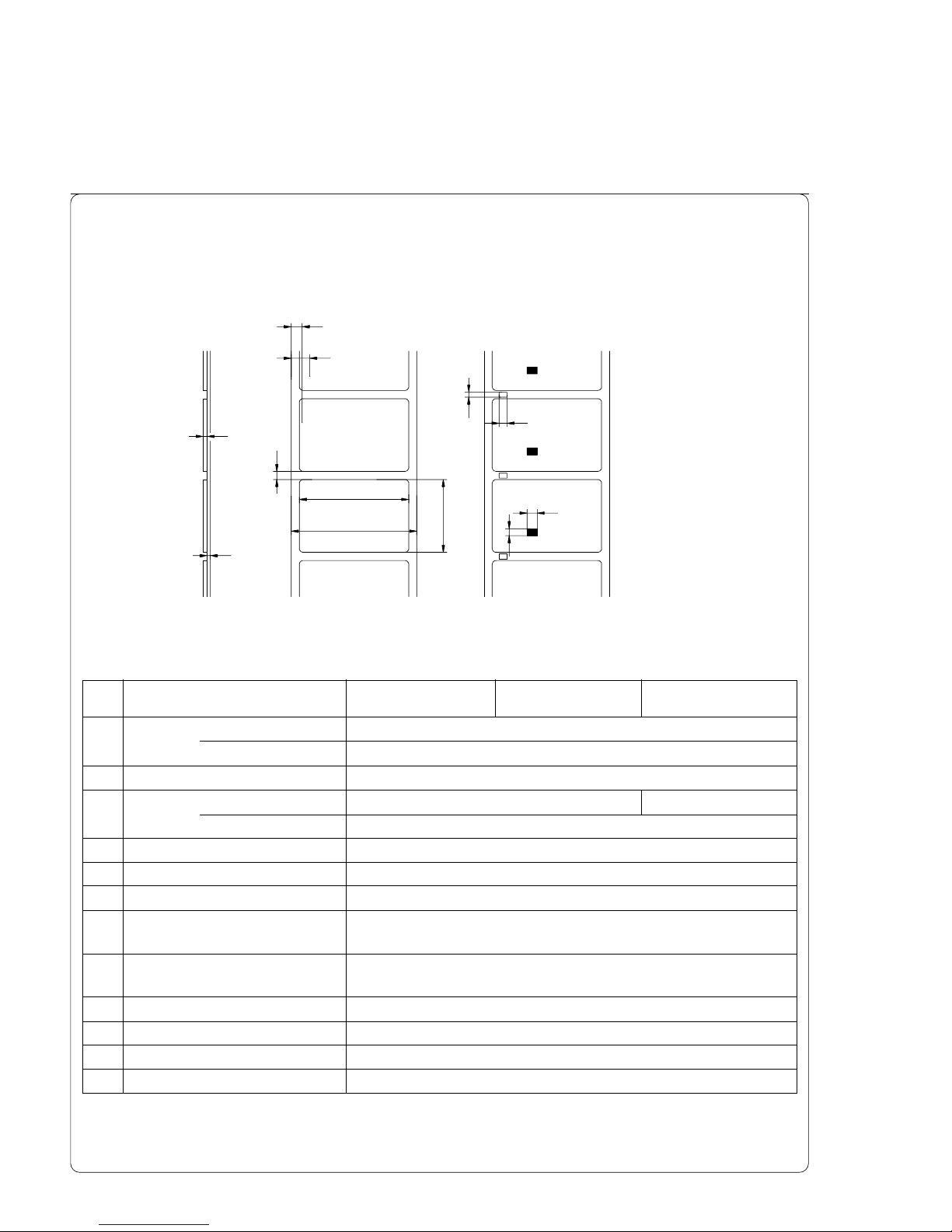

Label / Tag Media Specifications

Label and tag media to be used by the printer must conform to the following

specifications:

Fig. 1 Media Specifications

Table 1 Media values are displayed in inches (values in brackets are mm)

E

F

D

A

B

K

I

C

G

H

L

M

1. Product Description

Page 19

19Transfer Printer THT-BP Precision

1. Product Description

Transfer Ribbon

The choice of transfer ribbon plays an important role in the quality of print

image that can be produced, and it also directly affects the longevity of the

printhead.

CAUTION !

Poor quality transfer ribbon can lead to premature deterioration of the

printhead !

The ribbon material must be as anti-static as possible. This is because the

extremely thin surface coating on the printhead can be damaged by a build up

of electrostatic charges. The temperature tolerance of the material must be

extremely high in order to avoid the transfer ribbon melting directly onto the

printhead. The temperature increase which results from the printing cycle must

be dissipated over the label and the transfer ribbon. Poor quality transfer

ribbon often has only a limited ability to dissipate the heat. This can contribute

to overheating of the printhead, despite electronic protection against

overheating

Poor quality transfer ribbon also tends to partially shed its ink coating, causing

the printhead and sensors to accumulate dirt. In addition, with some transfer

ribbons, the back coating can flake or smudge, leaving traces on the

printhead. All of these effects contribute to lowering the print quality to below

desired standards.

Numerous tests have been conducted with a very large number of different

transfer ribbons and we recommend only ribbons supplied by reputable

manufacturers. A variety of different transfer ribbons can sometimes be used

for a particular type of label stock. The quality of print is determined by the

correct combination of these materials.

NOTICE !

When choosing material, make sure the transfer ribbon is slightly wider

than the width of the label backing.

The presence of transfer ribbon is sensed by the rotational movement control

of the transfer ribbon unwinder, rather than with photocell sensors. As a result,

ribbons that have a thinner coating or those with a colored coating can be used

without problems.

The possiblity of printing labels up to the absolute end of the ribbon is restricted

by the length of the uncoated "trailer", which attaches the end of the ribbon to

the core.

NOTICE !

Make certain before purchasing transfer ribbon that the "trailer" (see

above) is not more than 2.3in (60mm) long.

Page 20

20 Transfer Printer THT-BP Precision

1. Product Description

Software

There are several methods to create formats and to send them to the printer.

Below, a short explanation of the most common methods is given.

Direct Programming

The printer is equipped with an internal command set. The command set is

designed to program all functions of the printer. To create a label format, use

any ASCII editor to combine the necessary commands. Save the commands

to a file, then copy the file to the printer using the connected interface and

HyperTerminal or the DOS COPY command.

Direct programming requires a minimum knowledge of programming logic.

The printer commands are designed logically and structured clearly. However

it is necessary to carry out several test prints when creating a label using the

command set since no image of the label is displayed on the monitor.

The complete description of the command set and sample programs is

available in the "Programming Guide".

Windows Printer Driver

Windows Printer drivers are available for the different Windows versions.

The printer can be operated from any Windows Application that supports

Windows Printer drivers. The graphical user interface allows for easier creation

of label formats. However, the functionality depends on the choosen

application and how each product supports Windows Printer drivers. There

could be restrictions depending on the application you are using. A help file is

included with the drivers to explain the usage and limitations when using

certain Windows applications.

Label Software

There are several Windows Applications that are designed to create labels.

These programs are more suited to the requirements of label printing than

standard Windows Applications. In some cases these programs use the

Windows Printer Driver.

Some applications have integrated internal drivers to operate the BP Precision

printers. These applications offer the best solution for creating and printing

labels.

Page 21

21Transfer Printer THT-BP Precision

2. General Safety Instructions

CAUTION !

- The printer is built exclusively to print die-cut labels, continuous media, and

similar materials as listed in Technical Specifications in Chapter 1.

- Connect the printer to an outlet with the correct voltage!

The printer is configured for voltages of 100 to 240 V.

Connect only to a power outlet with a grounded contact.

- The printer must only be connected to devices which have extra low voltage.

- Power must be OFF before plugging in any accessory, connecting to a

computer and before performing any maintenance on the printer. Also turn

the power off on all appliances before disconnecting from the printer.

- Do not expose the printer to any moisture, or use in damp or wet areas.

- The printer will operate with the cover open if necessary. This is not

recommended, as it might allow debris to collect on the printhead surface. If

the printer must be operated with the cover open, extra care must be taken

to avoid allowing hair, jewelry, clothing, etc. near the moving parts.

- During the print process the printhead will become hot. Use extra caution

when touching the printhead. Do not touch the printing surface of the

printhead with you hand!

- Any adjustments or repairs which are not described in this manual, should

only be carried out by an authorized service technician.

WARNING !

To avoid possible electric shock, do not open the backside cover!

3. Unpacking

Delivery Contents

Please inspect the printers packaging and contents immediately after receipt for

possible damage during shipment.

NOTICE !

Be sure to preserve the original packaging for possible later shipment!

The shipping container will contain the following standard components:

- Thermal Transfer Printer

- Cardboard Core for the transfer ribbon rewinder

- Tear-off Plate (Basic devices only)

- Dispense Plate (P-Versions only)

- Power Cord

- Documentation

2. General Safety Instructions / 3. Unpacking

Page 22

22 Transfer Printer THT-BP Precision

1

2

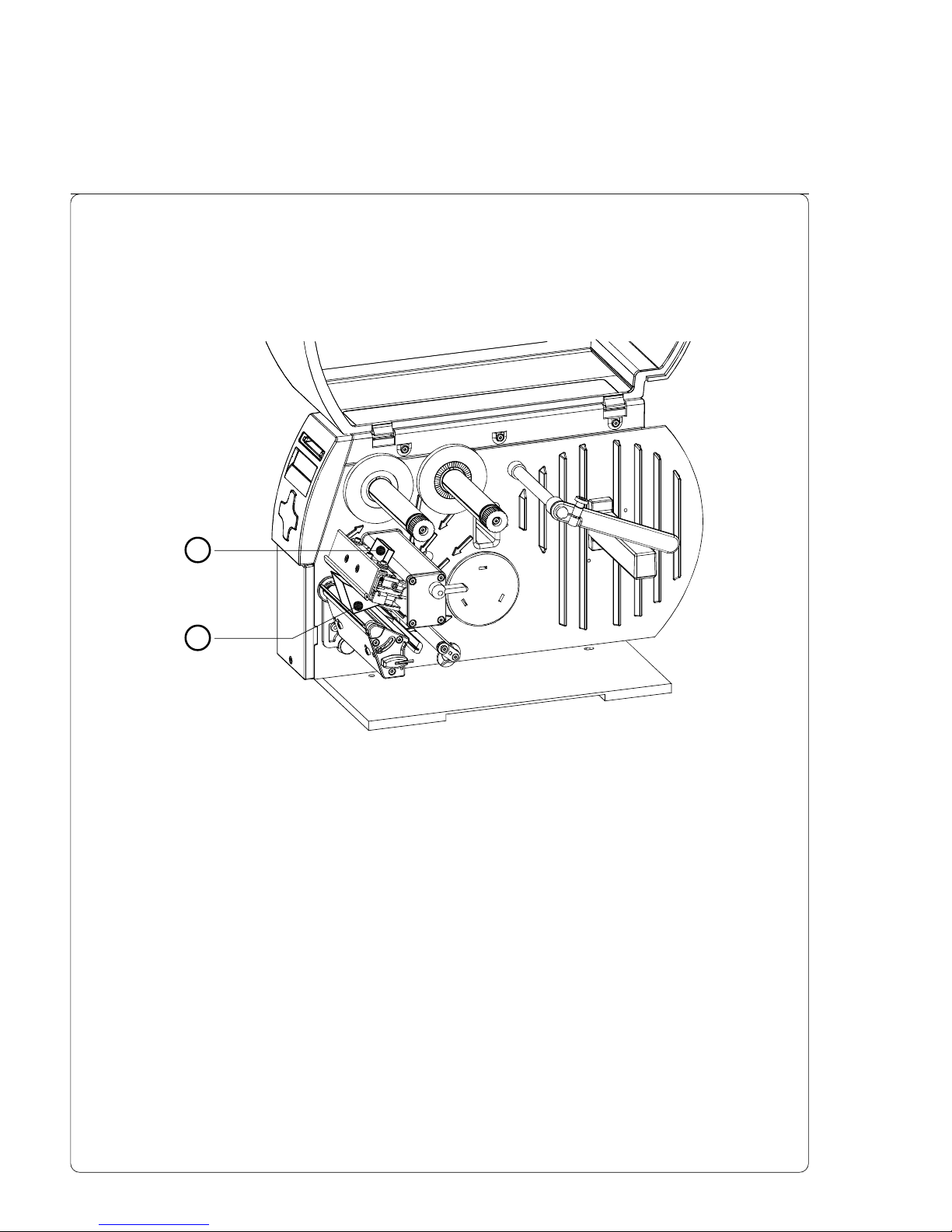

3. Unpacking

Fig. 3 Removing the securing devices

Removing the Securing Devices

1. Place the printer on a solid flat surface.

2. Open the cover.

3. Remove the securing devices (1, 2).

Page 23

23Transfer Printer THT-BP Precision

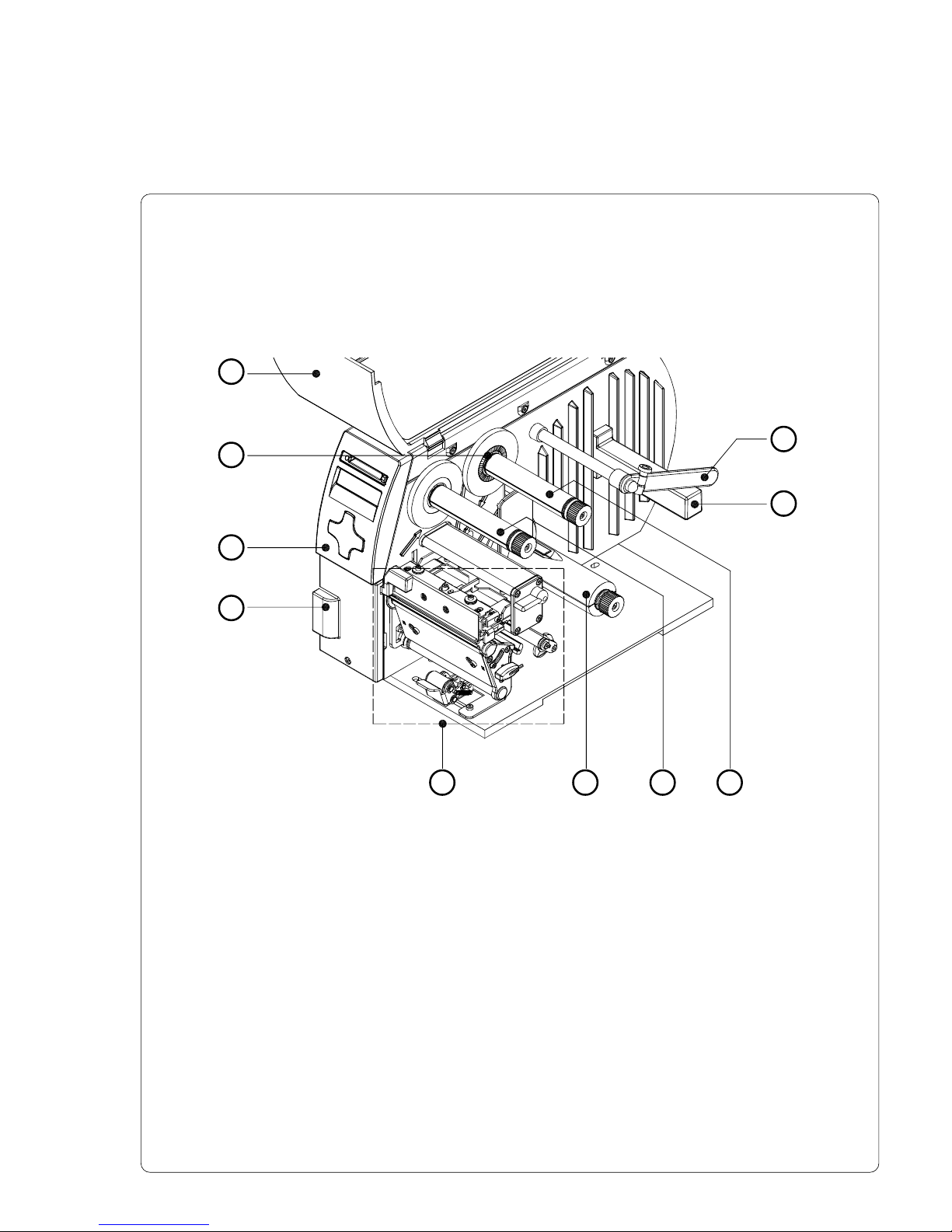

4. Printer Component Location

4. Printer Component Location

Fig. 4a General view

1 - Cover

2 - Warning label ''End of Ribbon''

3 - Control panel

4 - Present sensor (Option for P-Version)

5 - Print mechanism

6 - Internal rewinder (P- Versions only)

7 - Ribbon take up hub

8 - Ribbon supply hub

9 - Media hub

10 - Media Retainer

1

2

3

4

5 6 7 8

9

10

Page 24

24 Transfer Printer THT-BP Precision

1

2

3

4

5

6

7

8

9

10

11

12

13

4. Printer Component Location

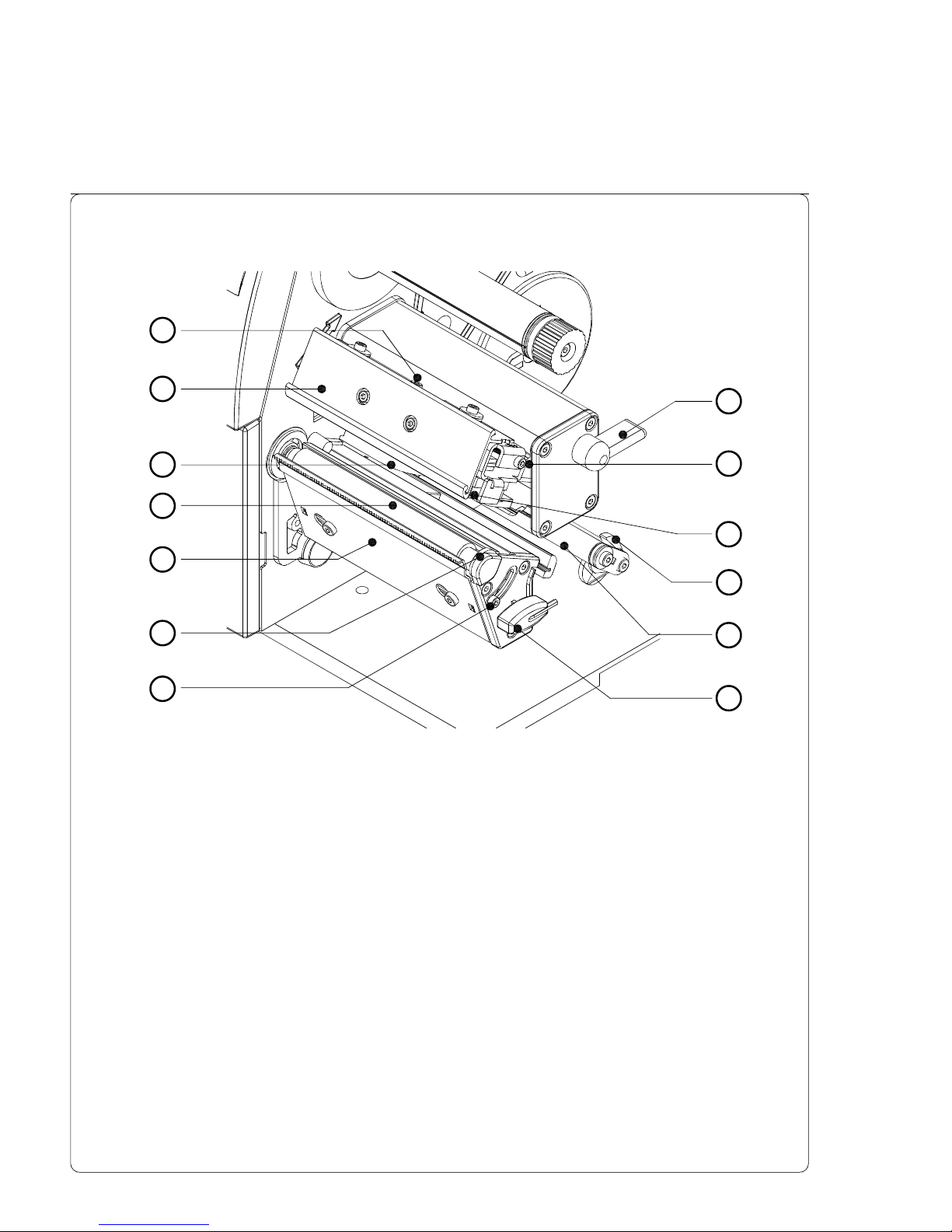

Fig. 4b Print mechanism Basic Devices with printhead open

1 - Printhead locking screw

2 - Ribbon shield

3 - Label edge sensor

4 - Media feed roller

5 - Tear-off plate

6 - Printhead support

7 - Screw to adjust the printhead support

8 - Printhead lever

9 - Screw to adjust the ribbon shield

10 - Thermal printhead

11 - Media guide

12 - Swing (BP Precision 200/300: Guide axle)

13 - Allen Key

Page 25

25Transfer Printer THT-BP Precision

4. Printer Component Location

1

2

3

4

5

7

8

9 10

11

12

13

14

15

16

6

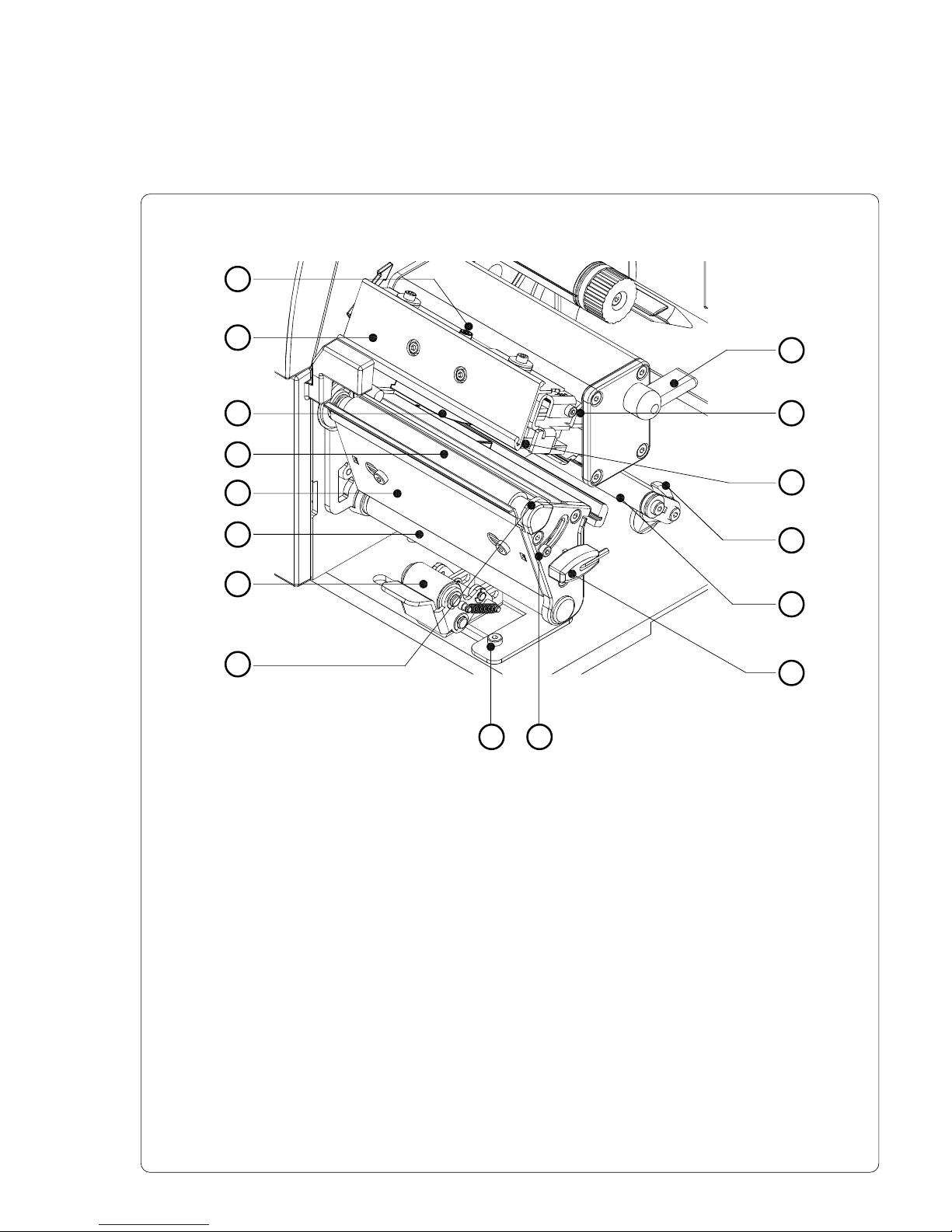

Fig. 4c Print mechanism P-Versions with printhead open

1 - Printhead locking screw

2 - Ribbon shield

3 - Label edge sensor

4 - Media feed roller

5 - Dispense plate

6 - Rewind assist roller

7 - Locking system

8 - Printhead support

9 - Screw for adjusting locking system

10 - Screw for adjusting printhead support

11 - Allen key

12 - Swing (BP Precision 200P/300P: Guide axle)

13 - Media guide

14 - Thermal printhead

15 - Screw to adjust the ribbon shield

16 - Printhead lever

Page 26

26 Transfer Printer THT-BP Precision

1

2

3

4

5

Fig. 4d Control panel

1 - Display

2 - Navigator pad with keys

3 - Memory card LED

4 - Memory card slot

5 - Memory card ejection lever

4. Printer Component Location

1

2

3

4

5

6

Fig. 4e Back view

1 - Slot for the additional interface

card (Ethernet or USB-slave)

2 - Bi-directional parallel interface

3 - USB master interface for

keyboard or scanner

4 - RS-232-interface

5 - Power switch

6 - Power supply connector

Page 27

27Transfer Printer THT-BP Precision

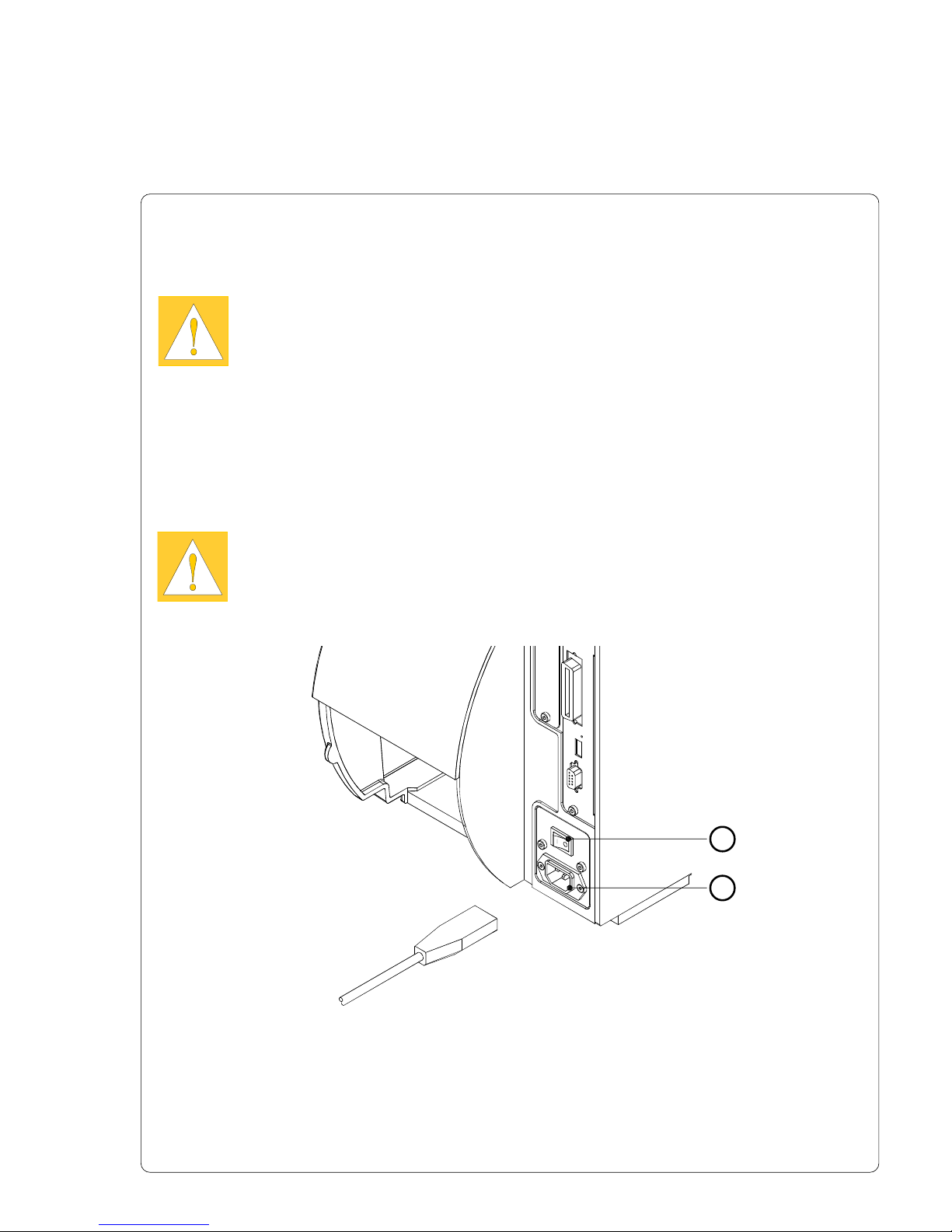

1

2

5. Connecting the Printer

5. Connecting the Printer

CAUTION !

Make sure the printer is located where the unit or the operator cannot

come in contact with water. Otherwise it could cause damage to the

printer.

Connection to Power Supply

The printer is equipped with a wide range power unit (100-240V~), so it is

possible to use the printer both with a voltage of 230V~/50 Hz and with a

voltage of 115V~/60 Hz without making changes to the printer.

CAUTION !

Make sure the power switch (1) is in position "O" (OFF) before

connecting the printer to a power supply !

Fig. 5a Power supply

Insert the power cable supplied in the accessories carton into the power supply

connector (2) and contact the cable to a grounded outlet.

Page 28

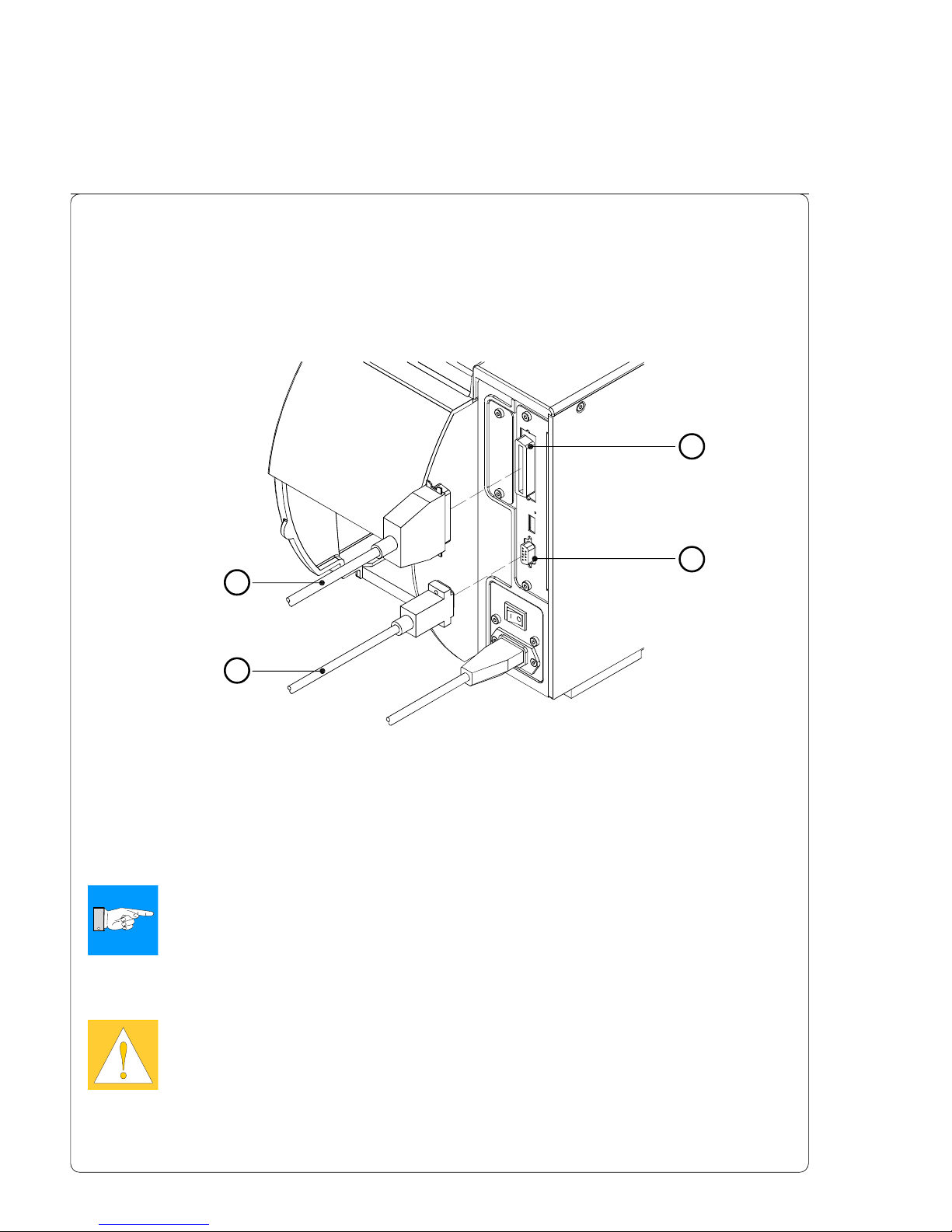

28 Transfer Printer THT-BP Precision

1

2

3

4

5. Connecting the Printer

Connection to a Computer

As standard, the printer is equipped with a bi-directional parallel interface (3)

and a serial RS-232-interface with a 9 pin connector (4).

For connection to the parallel interface use a suitable parallel interface cable

(1).

Cables for the serial connection (2) are described in appendix B. You can also

find descriptions of the pin assignments for the interface connectors

NOTICE !

For serial connection, make sure the serial interface RS-232 of the printer

is correctly configured to the settings of your computer (see printer

configuration section).

Connect the computer and the printer with a suitable cable and secure the

cable connections with screws provided on the connectors.

CAUTION !

Make sure that all connected computers and their connecting cables are

correctly grounded.

Information for the optional interfaces (Ethernet, USB) can be found in the

documentation for the respective interface.

Fig. 5b Computer connection

Page 29

29Transfer Printer THT-BP Precision

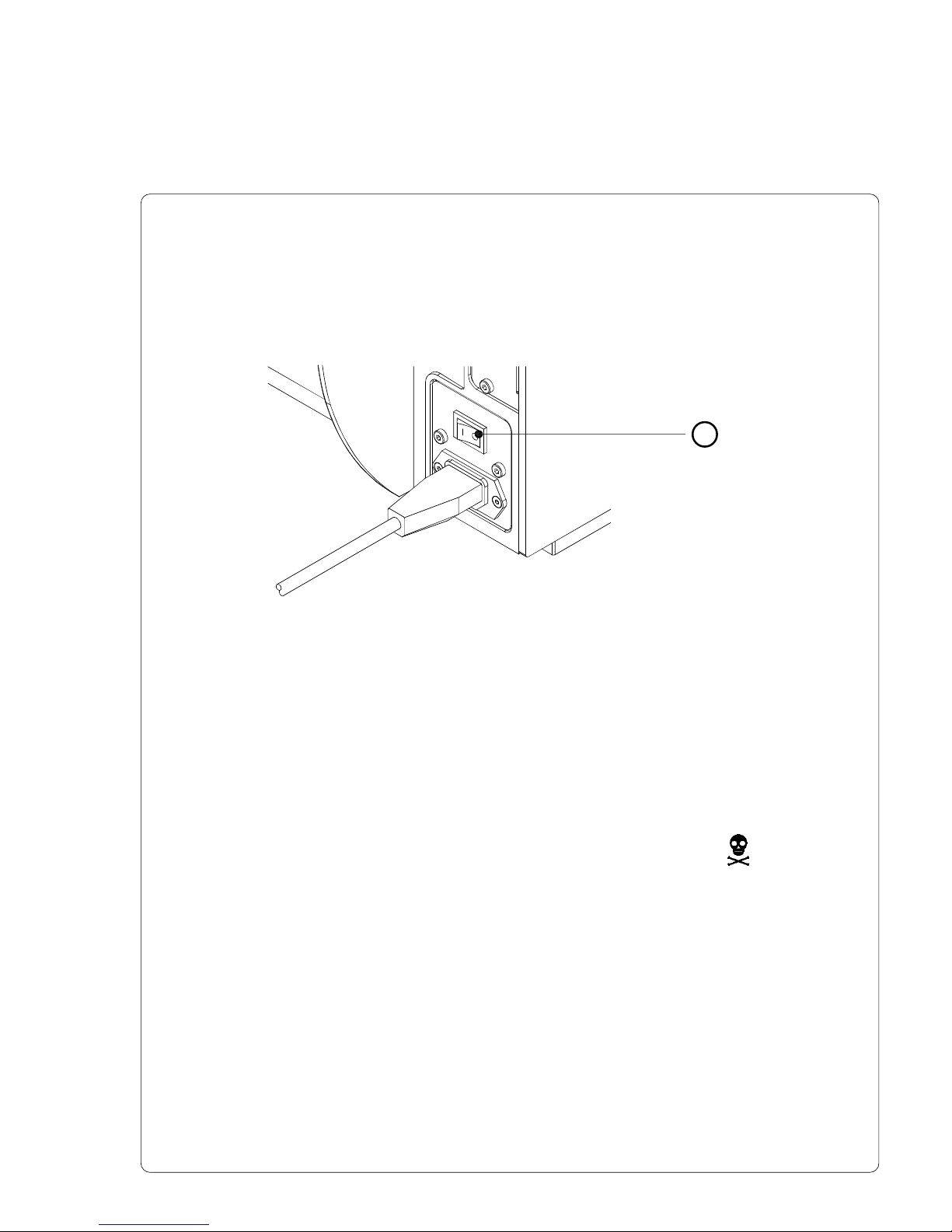

1

Switch on the Printer

Fig. 5c Switch on the printer

After making all connections, power on the printer using the power switch (1).

The printer will perform a short system test, then display "ONLINE" on the front

panel LCD.

If a hardware failure occurs during the system test, the symbol and a

description of the failure will be displayed on the LCD. In this case the printer

should be powered off and on again. If the failure re-occurs, call for service.

5. Connecting the Printer

Page 30

30 Transfer Printer THT-BP Precision

6. Control Panel

Use of the Control Panel

The control panel allows the operator the ability to control the operation of the

printer in various ways.

Uses of the control panel :

- to control the current print job, e.g. to pause and continue or to cancel print

jobs on demand.

- to set print parameters, for example the heat level, the print speed, the baud

rate of the serial interface, the language or the time.

- to execute self test functions of the printer.

- to operate the printer using a memory card without having a computer

connected.

- to carry out an update of the printer's firmware.

Several functions and settings can also be configured by sending printer

commands from software or through direct programming.

The settings configured by the control panel are basic settings.

Parameters can be set on/off for all print jobs, for example "Transfer print on/

off" or the setting can be set by software for single print jobs.

Parameters such as "Printhead position", which determines the position of the

print image, can be set for all print jobs. Any setting that has both a front panel

setting and software command, the values are totaled together for printing.

In the case of On/Off settings, the software commands will override the front

panel setting.

The section "Printer Configuration" will indicate whether it is possible to change

the settings of the front panel via software.

NOTICE !

Whenever possible, use the software command during print jobs to

control the printer's settings.

6. Control Panel

Page 31

31Transfer Printer THT-BP Precision

Structure of the Control Panel

The control panel consists of a graphic display (1) and the Navigator Pad (2)

with four integrated keys.

The control panel display constantly provides the operator with realtime

information concerning the current printer mode and label processing.

The function and operation of the keys depends on the current mode.

The available functions are marked by illuminating the valid symbols and text in

the keys.

Fig. 6a Control Panel

6. Control Panel

Online

1

2

Page 32

32 Transfer Printer THT-BP Precision

Functions of the Control Panel during Printing

System Mode ONLINE

The printer is switched ON and ready to receive data.

The display shows the time and the word "Online".

During the transfer of data a rotating symbol appears on the display.

When saving data on the PC card the symbol appears on the display.

Key Description Function

on Switches to OFFLINE mode.

on Performs a label feed.

(on) Repeats the print of the last label, after the previous

print job has been completed.

(Only when setup parameter "Pause reprint" is on.)

(on) Clears internal memory of the previous print job.

"Pause reprint" is no longer available.

Fig. 6b Navigator Pad during Printing

During printing the keys on the Navigator Pad are illuminated to indicate what

functions control the print jobs. The exact key functions in the different system

modes are described below.

The text is not illuminated when the keys have no function in the current mode.

6. Control Panel

Page 33

33Transfer Printer THT-BP Precision

System Mode PRINT

The printer is currently processing an active print job.

In this mode, the transfer of data is possible. New print jobs will be carried out

immediately following the completion of the previous job. The display shows

the message "Printing label" and the current number of printed labels.

Key Description Function

on Interrupts the current print job

on Short press - cancels the current print job

Long press - cancels the current print job

and deletes all jobs contained in the

internal memory

System Mode PAUSE

The printing process is temporarily interrupted by the operator.

The display shows "Pause" and the symbol appears.

Key Description Function

on Continues the print job

on Short press - cancels the current print job

Long press - cancels the current print job

and deletes all jobs contained in the

internal memory

System Mode POWERSAVE

If the printer does not receive a print job or the front panel has not been

accessed for a period of time, the printer will switch into a powersave mode.

During powersave mode, certain functions such as the background lighting of

the display are powered off. The display shows . The illumination of

the keys is switched off.

To leave this mode press any key or send a print job.

6. Control Panel

Page 34

34 Transfer Printer THT-BP Precision

System Mode FAULT-CORRECTABLE

The printer has encountered a fault during printing which is easily corrected by

the operator (e.g. "Out of paper"). Once the fault has been corrected, the

printing process may be continued.

The symbol appears on the display. Additionally, the type of fault and the

total of the remaining labels is also displayed.

Key Description Function

flashes Continues current print job after fault correction

on Short press - cancels the current print job

Long press - cancels the current print job

and deletes all jobs contained in the

internal memory

System Mode FAULT-IRRECOVERABLE

During printing, a fault has occured which cannot be cleared by the operator

without canceling the current print job.

The symbol appears on the display and the type of the fault is displayed.

Key Description Function

flashes Short press - cancels the current print job

Long press - cancels the current print job

and deletes all jobs contained in the

internal memory

6. Control Panel

Page 35

35Transfer Printer THT-BP Precision

Functions of the Control Panel in the Offline Menu

The Offline Menu contains options to set machine and print parameters, to

enter test and service functions as well to operate with the memory card.

To enter this mode press the key while in the ONLINE mode. If a

memory card is installed the display shows "Memory card". Otherwise "Test"

will be displayed.

Table 6 Structure of the Offline Menu

Online [Memory card] Label from card

Print directory

Copy memory card *

Format card *

ASCII dump (Card)

Test Short status

Status print

Font list

Device list

Printhead profile

ASCII Dump Mode

Test grid

Label profile

Setup * Local settings

Machine parameter

Print parameter

Interfaces

Security

Service Firmware upd. *

Menus and options marked with * can be protected by a PIN from unauthorized

access.

Functions marked with [...] are only accessible, if an optional device has been

installed.

6. Control Panel

Page 36

36 Transfer Printer THT-BP Precision

6. Control Panel

Fig. 6c Navigator Pad in the Offline Menu

After switching from the "Online" mode into the Offline Menu the function of the

keys are changed. Now the keys of the Navigator Pad have the function of

cursor keys.

Key Function

- Move up in the menu

- Increase numeric values

- Move down in the menu

- Decrease numeric values

- Switch to a secondary menu

- Move the cursor to the right during numeric settings

- Finish a setting with confirmation of the selected settings

- Start of a selected test or service function

- Return from a secondary menu

- Move the cursor to the left during numeric settings

- Finish a setting with rejecting the selected settings

- At the start of the menu, return to the system mode

"Online"

Page 37

37Transfer Printer THT-BP Precision

6. Control Panel

Fig. 6d Display during selection of a function

During selection of the test and service functions the display shows the

selected menu. A graphic symbol accompanies the text.

In the "Setup" menu, the display shows the selected parameter and the current

setting of the parameter.

If the symbol appears in the upper line, the symbol indicates that it is

possible to switch between several parameters by pressing the key and the

key.

Fig. 6e Display during selection of a parameter

Fig. 6f Display during change of a parameter

To change the current setting press the key. Then the symbol is shown in

the bottom line of the display indicating that it is possible to change the setting

of the parameter by pressing the key and the key.

Page 38

38 Transfer Printer THT-BP Precision

1

7. Media Loading

General Information

1. Pay attention to the specifications of the material indicated in chapter 1 .

2. When using the printer for the first time or using label media with a different

width, make sure to adjust the printhead support as well as the position of

the label edge sensor.

3. There is a warning label (1) on the ribbon supply hub which will be visible if

the material is getting low. When that warning label is visible, prepare to

replace the ribbon material soon.

4. If you do not use the printer for an extended period of time, lift the printhead

to avoid possible flattening of the print roller.

5. If you want to move or ship the printer to another location, remove the

media and the ribbon from the printer.

Fig. 7a Warning label

7. Media Loading

Page 39

39Transfer Printer THT-BP Precision

Preparation for Rewind Mode

The P-version printers are prepared for the dispense mode an the tear-off

mode. After mounting the optional rewind guide plate (1) the printers also may

be operated in rewind mode.

7. Media Loading

Fig. 7b Exchange Dispense Plate / Rewind Guide Plate

1. Open the cover.

2. Loosen the two screws (2).

3. Slide the dispense plate (3) to the right as far as possible to remove the

plate from the printer.

4. Place the slotted holes on the rewind guide plate (1) over the screws (2) on

the front of the printer and slide the plate to the left until it stops.

5. Tighten the two screws (2).

2

2

3

1

Page 40

40 Transfer Printer THT-BP Precision

1

2

3

4

8

9

10

11

12

7. Media Loading

Loading Labels

Fig. 7c Label Loading in Tear-off Mode

1. Open the cover (1).

2. Loosen the knurled screw (10), swing the media retainer (11) upwards and

slide it out as far as possible.

If you are using material with the same width as the previous material, just

swing the media retainer (11) upwards.

3. Place the media roll (8) onto the media hub (9) and unwind a strip of

media (4) from the roll. When operating in the rewind or peel-off mode

make sure that the strip is long enough to reach the internal rewinder by

guiding the strip through the whole print mechanism and underneath of it.

Make sure that the labels between the media hub and the print

mechanism are facing up. Slide the roll onto the media hub (9) until its

stops.

Loading Labels from Roll

567

Page 41

41Transfer Printer THT-BP Precision

13

Fig. 7d Feed path in Tear-off Mode

8. Slide the media guide ring (6) inward until it lightly touches the side of the

media strip.

7. Media Loading

4. Swing the media retainer (11) downwards until it touches the media hub

(9). Push the media retainer against the supply role until it rests against

the label media. Tighten the knurled screw (10).

5. Raise the printhead assembly (2) by rotating the lever (7) clockwise until it

stops.

6. Slide the media guide ring (6) outward, allowing enough clearance for the

label stock's width when loaded.

7. Slide the media strip underneath the swing (5 /BP Precision 200/300:

axle) and through the adjustable photocell assembly (3) until it comes out

of the front of the printer. If you are using labels that are wound-in, please

make sure that you slide the media strip over the internal rewind hub (13).

In figure 7d the feed path for labels wound-out is represented by a solid

line, and the feed path for wound-in labels is represented by a broken line.

Page 42

42 Transfer Printer THT-BP Precision

3

14

15

7

9. To accommodate a variety of print jobs, the position of the label edge

sensor (3) can be adjusted until it is at the proper sensing position.

It is important to ensure that the sensor (14) itself (the position of which is

indicated by a notch in the sensor housing) is positioned so that the space

between the labels can be recognized by the photocell. In the case of

labels which have an unconventional shape (ie. not square or rectangular),

the photo cell should be positioned at the leading edge of the label.

Adjustment of the sensor is performed by sliding the handle (15) in and

out.

10. Lower the printhead by rotating the lever (7) counter-clockwise until it

locks.

11. When the printer is operated in peel-off mode continue with point 12.

When the printer is operated in rewind mode continue with point 17.

Fig. 7e Adjustment of the Label Edge Sensor

7. Media Loading

Page 43

43Transfer Printer THT-BP Precision

7. Media Loading

22 23 13 2419 20 21

18

17

16

Fig. 7f Loading Labels from Roll in Peel-off mode

12. For peel-off mode swing the locking system (18) away from the rewind

assist roller (20).

13. Remove all labels from the media strip hangig out of the printer. Then,

slide the strip (22) around the dispense plate (16) to the internal rewind

hub (13) as shown in figure 7f. Slide the strip under the clamps (23) that

are located on the internal rewind hub (13). Hold the internal rewind hub

(13) and rotate the nut (24) counter-clockwise until it is tight. The media

strip will now be fastened to the internal rewind hub (13). Rotate the

internal rewind hub (13) counter-clockwise to tighten the media strip.

14. Loosen the screw (19) using the Allen key (21).

Align the locking system (18) including the pinch roller (17) by sliding it

sidewards. The alignment is correct if the pinch roller (17) is placed in the

middle of the label strip.

15. Swing the locking system (18) to the rewind assist roller (20) and tighten

the screw (19).

16. For further informationen about operating in the peel-off mode see

appendix A.

Page 44

44 Transfer Printer THT-BP Precision

7. Media Loading

25 26 23 13 24

Fig. 7g Loading Labels from Roll in Rewind Mode

17. For rewind mode, the rewind guide plate (25) must be mounted.

18. Open the locking system (18)

19. Remove the labels from the first 4 in (100mm) of the label strip.

Then, slide the media strip (26) around the rewind guide plate (25) to the

internal rewind hub (13) as shown in figure 7g.

20. Slide the strip under the clamps (23) that are located on the internal

rewind hub (13). Hold the internal rewind hub (13) and rotate the nut (24)

counter-clockwise until it is tight. The media strip will now be fastened to

the internal rewind hub (13).

21. Rotate the internal rewind hub (13) counter-clockwise to tighten the media

strip.

18

Page 45

45Transfer Printer THT-BP Precision

1

2

3

4

5

When printing narrow label stock (width less than 60% of the maximum print

width), it is possible that the printhead will come into direct contact with the

printing roller in the area where there is no media.

CAUTION !

The printhead touching the printing roller could lead to premature failure

on the printhead or the print roller!

This can also cause the printhead to be at a slight angle to the media, leading

to a variation in the darkness of the print across the label.

This fault can be corrected by adjusting the printhead support :

Adjustment of the Printhead Support

7. Media Loading

1. The current position of the printhead support (2) is shown by the position

of the screw (3) in the elongated hole (4).

2. For wide media the screw position shown in figure 7h is recommended. In

this position the printhead support (2) is not used.

3. For narrow media, it is necessary to adjust the printhead support. In this

case insert a second strip of a label at the outer side of the print roller and

close the printhead. Loosen the screw (3) using the Allen key (5) and slide

it slowly in the arrow direction until the printhead support (2) touches the

printhead mounting (1).

4. Tighten the screw (3).

5. Remove the second label strip.

NOTICE !

Incorrect adjustments of the printhead support may cause wrinkles in the

transfer ribbon.

Fig. 7h Adjustment of the Printhead Support

Page 46

46 Transfer Printer THT-BP Precision

1

2

3

7

6

5

4

Loading Fanfold Labels

1. Open the cover.

2. Loosen the knurled screw (7) and slide the media guide (6) to its

outermost position. Rotate the media guide (6) downwards past the media

retainer (5).

3. Place the stack of media (4) behind the printer. Make sure the labels on

the media strip are facing up.

4. To raise the printhead assembly (2), rotate the lever (1) clockwise until it

stops.

5. Slide the media guide ring (3) outward, allowing enough clearance for the

media's width when loaded.

6. Slide the media strip through the printer as shown in figure 7i.

7. Adjust the label edge sensor so, that the sensor can recognize the space

between the labels respectively the reflective or the perforation mark.

8. Slide the media guide (6) inward until it lightly touches the side of the

media strip. Rotate the media guide (6) upwards against the media

retainer (5) and tighten the knurled screw (7).

Fig. 7i Loading Fanfold Labels

7. Media Loading

Page 47

47Transfer Printer THT-BP Precision

7. Media Loading

9. Slide the media guide ring (3) inward until it lightly touches the side of the

media strip.

10. Lower the printhead by rotating the lever (1) counter-clockwise until it

stops.

NOTICE !

When printing narrow label stock please activate the printhead support as

described in the previous chapter !

Page 48

48 Transfer Printer THT-BP Precision

3

4

5

6

1

2

7

7. Media Loading

NOTICE !

For direct thermal printing no transfer ribbon is needed !

1. Rotate the printhead lever (7) clockwise until it stops to raise the

printhead.

2. Slide the roll of transfer ribbon (4) as far as possible onto the ribbon

supply hub (5).

NOTICE !

Note which side of the transfer ribbon is coated with ink! The inked side

is generally the dull side of the transfer ribbon. When the ribbon is

inserted, the inked side must not be placed in contact with the printhead!

In figure 7l the solid line represents ribbon with ink on the inner side, and

the broken line represents ribbon with ink on the outer side.

3. Rotate the knurled knob (6) counter-clockwise to clamp the roll of transfer

ribbon (4) onto the ribbon supply hub (5).

Loading Transfer Ribbon

Fig. 7k Loading Transfer Ribbon

Page 49

49Transfer Printer THT-BP Precision

1 27

4. Slide a cardboard core (1) onto the ribbon take up hub (2). Clamp the

core by rotating the knurled knob (3) counter-clockwise.

5. Feed the transfer ribbon along the path as shown in figure 7l and attach it

to the cardboard core (1) using a piece of tape or a label.

6. Turn the ribbon take up hub (2) counter-clockwise until the ribbon is taut

and without any wrinkles.

7. Rotate the printhead lever (7) counter-clockwise until it stops, thereby

locking the printhead into position.

Fig. 7l Path of Transfer Ribbon

7. Media Loading

Page 50

50 Transfer Printer THT-BP Precision

1

2

4

3

5

Fig. 7m Adjustment of the Transfer Ribbon

In the event that wrinkles appear in the transfer ribbon (1), which cause an

inconsistent print image, the transfer ribbon shield (2) can be adjusted to

remove the wrinkles. The adjustment should be done during the printing

process.

1. The current position is visible on the scale (3).

2. To change the position, rotate the screw (4) using the Allen key (5).

Rotating it in the direction of "+" will tighten the transfer ribbon the inner

edge of the transfer ribbon. Rotating it in the direction of "-" will tighten the

outer edge of the tranfer ribbon.

To eliminate the wrinkles, tighten the side where the wrinkles are

originating.

Adjustment of the Transfer Ribbon

7. Media Loading

Page 51

51Transfer Printer THT-BP Precision

This page is intentionally left blank

7. Media Loading

Page 52

52 Transfer Printer THT-BP Precision

8. Printer Configuration

8. Printer Configuration

Overview

There are a variety of parameters that can be set to configure the printer to

specific requirements in the "Setup" menu of the Offline Menu.

The setup should be performed when operating the printer for the first time and

also when basic changes need to be carried out. In most cases however,

simple changes such as heat setting adjustments, using different media will be

made with software settings.

The "Setup" menu can be protected from unauthorized access by using a code

number (PIN).

1. Switch to the Offline Menu by pressing the key.

2. Continue to press the key or the key until you reach the "Setup"

menu. Press the key.

3. If the "Setup" menu is protected by a PIN the display will show "PIN: 0000".

You will need to enter the correct PIN before you can continue. The

numbers of the PIN can be changed by using the key and the key.

The position to be changed will be flashing on the display. Press the key

to move to the next number. If the correct number is entered, the "Setup"

menu is displayed.

4. The parameters are arranged in a tree like structure. Pressing the key

as well as the key will scroll between the secondary menus. By pressing

the key, the selected secondary menu will be chosen.

5. If a parameter is selected, the display shows the actual value underneath

the parameter. On the top line the symbol is shown. This symbol

indicates that it is possible to switch between the parameter choices by

pressing the key and the key.

6. To change the current setting press the key.

Then the symbol is shown in the lower line of the display and it indicates

that it is possible to change the setting of the parameter by pressing the

key and the key.

7. Press the key to confirm the change. To cancel the change press the

key. In both cases the symbol appears on the top line again.

Page 53

53Transfer Printer THT-BP Precision

Online

[Memory card]

Test

Setup Local settings Country

Timezone

Daylight saving

Set date

Set time

Machine param. Printhead pos. X

Printhead pos. Y

Tear-off pos.

[Demand sensor]

[Cutter]

[Applicator]

Brightness LCD

Contrast LCD

Time Powersave

Debug mode

Print parameters Heat level

Print speed

Transfer print

Warn level ribbon

Label sensor

Tear-off mode

Backfeed

Pause-Reprint

Error-Reprint

Barcode error

Width ASCII dump

Interfaces Character set

IEEE 1284

RS-232

[RS-422/485]

[Ethernet]

[Keyboard]

Security PIN

Service

The "Setup" menu can be protected from unauthorized access by using a PIN.

[...] The parameters in the brackets are only accessible after installing an

optional device

8. Printer Configuration

8. Press the key several times if necessary to return to the "Setup"

menu or to "Online" mode.

Table 8a Structure of the "Setup" Menu under the Offline-Menu

Page 54

54 Transfer Printer THT-BP Precision

Parameter Meaning

Country Set the display language and the

date and time format for the

country

Default Setting: USA

Time zone Set the Time zone using UTC

(Universal Time Coordinated)

Default : UTC +1

Daylight saving Select the method of daylight

savings adjustment

Default : USA

Set date Set the printer's date

Default : current

Set time Set the printer's time

Default : current

Setup

Local settings

Selection

Belgie, België,

QB;8G@V,

Ceska republika,

Danmark,

Deutschland, Ελλας,

Espana, Farsi,

France, Italia,

Lietuva,

$8A=<ED@j8,

Magyarország,

Nederlands, Norge,

Polska, Portugal,

(EHH@V, Schweiz,

South Africa,

Suisse, Suomi,

Sverige, Türkiye,

United Kingdom,

USA

UTC +12

...

UTC -10

EU

USA

Off

31.12.2069

...

01.01.1970

23:59:59

...

00:00:00

8. Printer Configuration

Local Settings

1. Switch from the "Online" mode to the offline-menu by pressing the

key.

2. Select the "Setup" menu.

3. Select the "Local settings" menu.

Table 8b Overview of the "Local settings" Menu

Page 55

55Transfer Printer THT-BP Precision

8. Printer Configuration

Country

The "Country" parameter allows the setting of the LCD display language, which

also defines the date and time format used for the printer display as well as for

printing. The formats for time and date can be configured with software, but