Page 1

PowerScan

™

RF

Systems Manual

Page 2

PSC Scanning, Inc.

959 Terry Street

Eugene, Oregon 97402

Telephone: (541) 683-5700

Telefax: (541) 345-7140

PSC, the PSC logo, Quadralogic and PowerScan are registered trademarks of PSC Inc. All

other trademarks and trade names referred to herein are property of their respective owners.

All rights reserved. No part of the contents of this documentation or the procedures described

therein may be reproduced or transmitted in any form or by any means without prior written

permission of PSC Inc. Owners of PSC Inc.'s products are hereby granted non-exclusive,

revocable license to reproduce and transmit this documentation for the purchaser's own internal business purposes. Purchaser shall not remove or alter any proprietary notices, including

copyright notices, contained on this documentation and shall ensure that all notices appear on

any reproductions of the documentation.

Should future revisions of this manual be published, you can acquire printed versions by contacting PSC Customer Administration. Electronic versions will either be downloadable from the

PSC web site (www.pscnet.com) or provided on appropriate media. If you visit our web site

and would like to make comments or suggestions about this or other PSC publications, please

let us know via the “Contact PSC” page.

Disclaimer

Reasonable measures have been taken to ensure that the information included in this

manual is complete and accurate. However, PSC reserves the right to change any

specification at any time without prior notice.

Page 3

TABLE OF CONTENTS

Introduction................................................................................................................................1

About This Manual ..................................................................................................1

References ..............................................................................................................1

Product Description .................................................................................................2

Laser Cautions ..............................................................................................................4

Radio Frequency Interference .......................................................................................5

Quick Start Instructions........................................ ..... .... ...................................... .....................6

Unpacking and Inspecting the Base Station ...........................................................6

Installation Procedures ....................... ..... .... ..... ...................................... ................6

Installing the Battery ......................................................................................................7

Verifying Scanner Operation ..................... ..... .... ...................................... .....................8

Connecting the Base Station to the Host Terminal ........................................................8

Linking the Scanner to a Base Station ........................................................................10

Verifying Scanner-to-Base Station Communications ............................................11

Using the PowerScan RF System ..........................................................................................11

Battery Charging and Maintenance .............................................................................12

Tips for Extending Battery Life ..............................................................................13

Disposing of Batteries .............................. .... ..... ..... ...............................................13

Four Station Charger ............................................................................................ 13

How to Scan ................................................... ..................................... ........................15

Depth of Field ........................................................................................................16

Active Symbologies ...............................................................................................20

Enhanced Scanning for Hard-to-Read Bar Codes ................................................20

LED and Beeper Indications ........................................................................................21

Maximizing Signal Range ............................... .... ...................................... ...................25

Three-Position Lock ..............................................................................................26

Mounting the Base Station .....................................................................................................27

Horizontal (Table or Countertop) Mounting ...........................................................27

Vertical (Wall) Mounting ........................................................................................29

Post or Forklift Mounting .......................................................................................30

RF Programmable Features....................................................................................................31

Programming Overview ................................................................ ........................32

What Is Programming Mode? ...............................................................................33

The Programming Session ...................................................................................34

Programming Sequence ............................................. ..........................................36

Systems Manual

i

Page 4

Scanner vs. Base Station Features ......................................................................38

Interface (I/F) Selection ........................................................................................39

Universal Keyboard Wedge I/F Selection .............................................................42

Terminal/Keyboard Settings .................................................................................43

RF Beeper Settings ..............................................................................................44

RF When to Beep .................................................................................................45

RF When to Beep Options (continued) .................................................................46

Radio Transmit Power ..........................................................................................50

RF Channel Selection ...........................................................................................51

Transmission Retries Before Message Time-out .................................................53

Wait Time for ACK ..................................... ..... ..................................... .................56

Wait Time For Scanner Power Shutdown ............................................................57

Wait Time Between Retries of Failed Transmission .............................................58

HACK Transmit Options .......................................................................................60

Wait Time For HACK From Host ..........................................................................62

Drop Links on Reset Option .................................................................................63

Drop Oldest Links Option .....................................................................................64

Common Configuration .........................................................................................65

Set Maximum Linked Scanners ............................................................................67

Source-Radio Identification (ID) ...........................................................................69

Low Battery LED Indication ..................................................................................71

Maintenance and Troubleshooting........................................................................................72

Scanner Maintenance ...........................................................................................72

Base Station Maintenance .................... ..... ..... ..................................... .................72

Four Station Charger Maintenance ......................................................................72

Troubleshooting ..........................................................................................................73

If the Scanner Fails to Link with the Base Station ................................................74

Standard Warranty..................................................................................................................78

Exclusions ................................................................................................................... 78

Limitations of Liability ..................................................................................................78

Assignment .................................................................................................................78

Risk of Loss .................................................................................................................78

Appendix A: Sample Bar Codes ......................................................................................... A-1

Appendix B: Number Pad ....................................................................................................B-1

ii

PowerScan™ RF

Scanner

Page 5

Introduction

About This

Manual

References

This systems manual provides information and instructions to connect

and configure your PowerScan™ RF system. The following sections are

included in the manual:

• Introduction pr esents gener al inf ormation a bout th e conten ts of

this manual and abou t the system.

• Quick Start Instructions provide easy to follow procedures for

installing your system quickly.

• Using the PowerScan RF System provides details about scanning

basics, system controls and indicators.

• Mounting the Base Station demonstrates ways to securely attach

the Base Station to various work surfaces.

• RF Programmable Features is a set of procedures detailing sys-

tem configuration that is unique to the RF system.

• Maintenance and Troubleshooting provides solutions for prob-

lems that may be encountered during installation and use of

the system.

• Standard Warranty is a statement describing th e warranty pol-

icy covering the system.

Other manuals are available for this product. Printed copies can be

ordered through your distributor. Some manuals can be downloaded

at our website address listed on the back cover of this manual. Read the

terms of use and instructions at the site to download, save, view or

print the most current manual(s) from the internet.

Configurator Express™ On-Screen Programming offers a convenient way

to program your scanner using your PC. Information about ordering a

kit (includes software, adapter and cable) for your RF scanner can also

be accessed from our website (see the back cover of this manual).

Systems Manual

1

Page 6

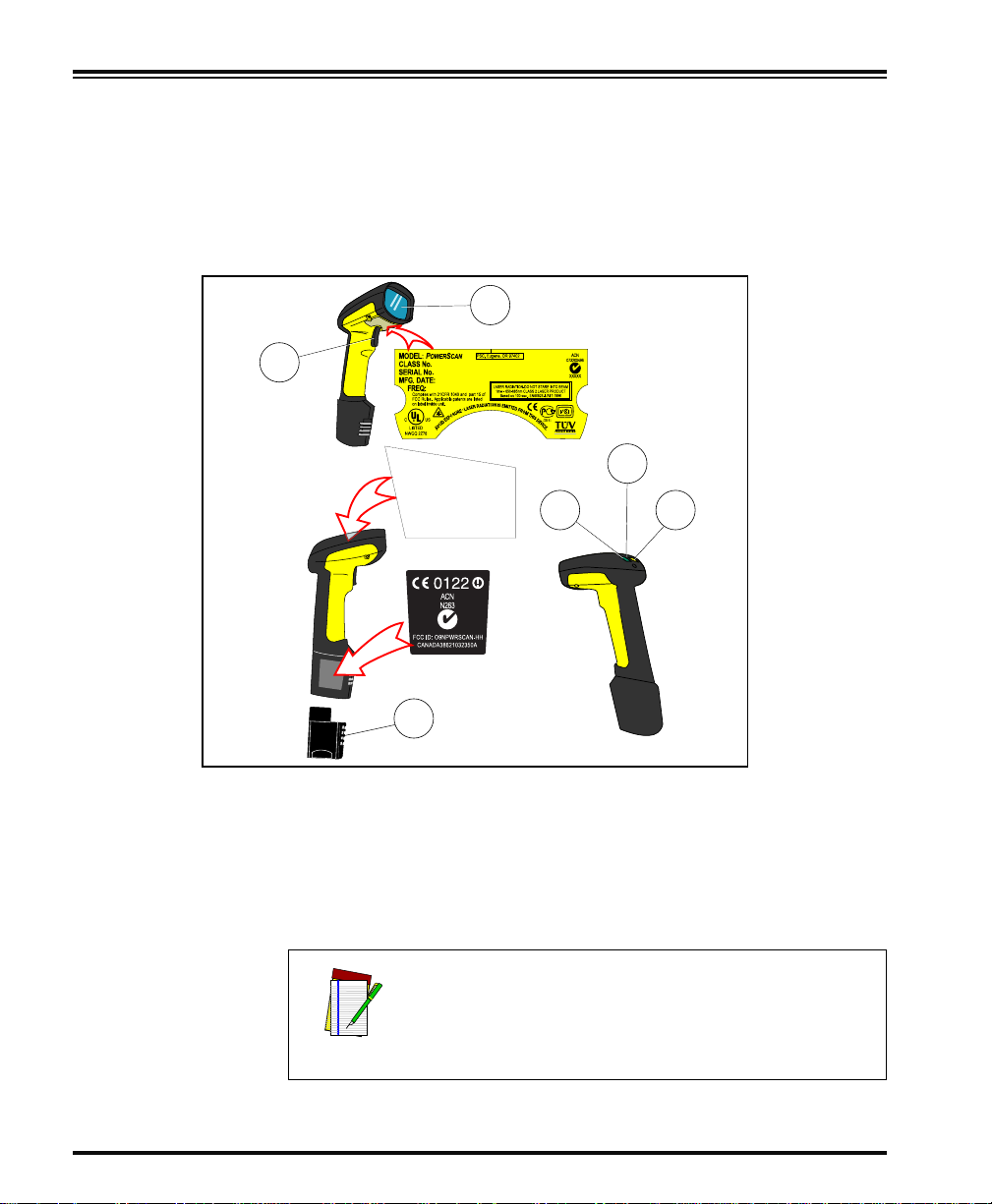

Product

Description

The PowerScan™ RF scanner is designed for durability, with high

impact-resistant material and protective rubber cushioning at every

point of impact, and it also provides the unleashed freedom of Radio

Frequency (RF) communication with your host system. Scanner and

Base Station nomenclature and labeling are shown in Figure 1 and

Figure 2 below .

Figure 1. Scanner Labels and Nomenclature

2

1

COVERED

BY ONE OR MORE OF THE

FOLLOWING PATENTS:

4,387,297 • 4,409,470 • 4,460,120

4,593,186 • 4,652,750 • 4,673,805

4,736,095 • 4,816,660 • 4,845,350

4,861,972 • 4,866,257 • 4,879,456

5,179,270 • 5,180,904 • 5,237,161

5,247,161 • 5,247,162 • 5,258,604

5,260,554 • 5,298,728 • 5,311,000

5,330,370 • 5,468,949 • 5,475,206

5,481,098

RF

CAUTION—LASER RADIATION WHEN OPEN. AVOID EXPOSURE TO BEAM.

Other patents pending

3

6

1. Trigger 4. Tether Hook

2. Scan Window 5. Yellow LED

3. Green LED 6. Battery

4

5

Figure 1 and Figure 2 show label placement ONLY.

For actual regulatory, patent and other applicable

information, view the labels on the product itself, or

NOTE

2

call your nearest sales or service representative.

PowerScan

™ RF

Scanner

Page 7

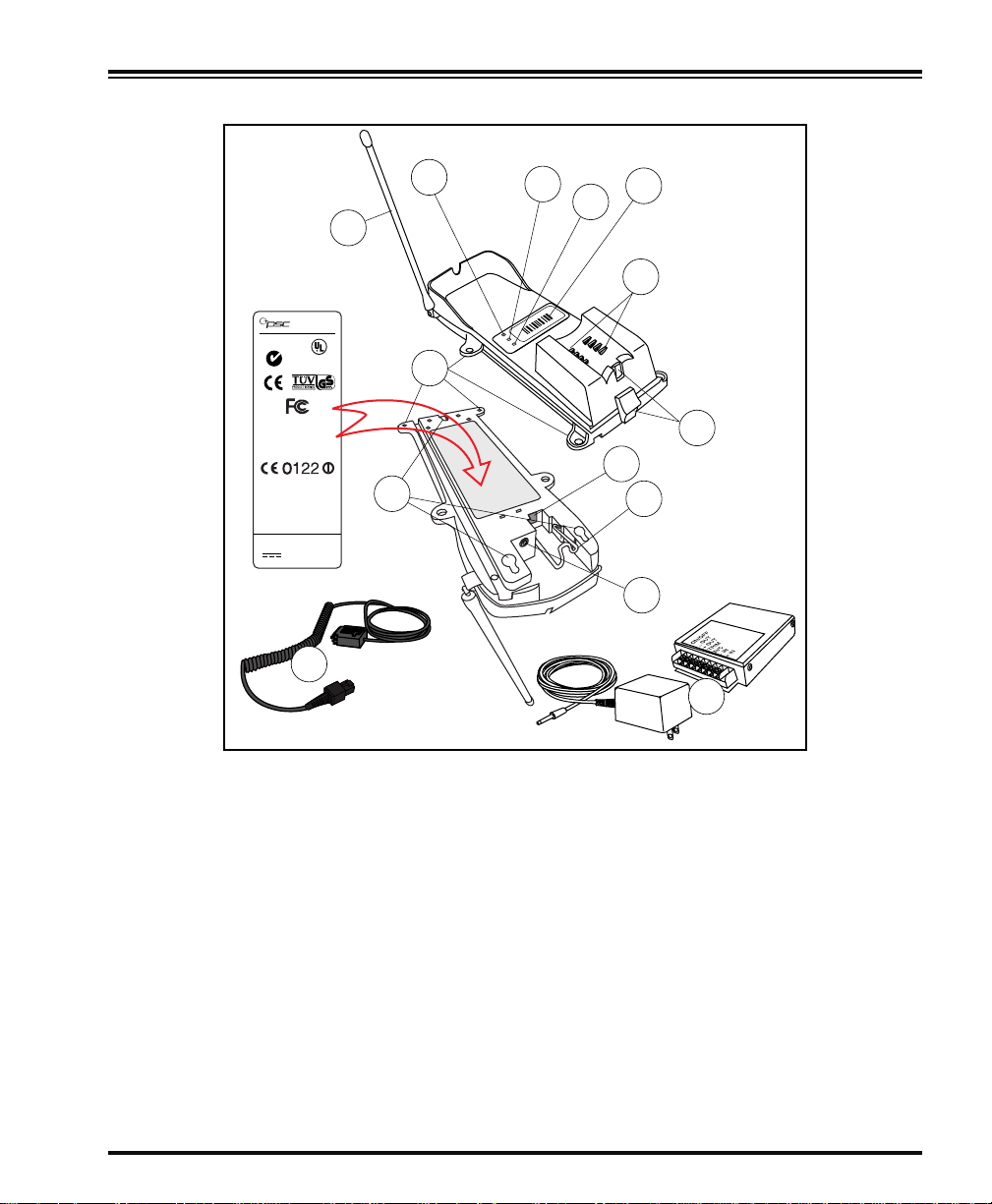

Figure 2. Base Station Labels and Nomenclature

PSC

INC.

959 Terry Street

Eugene, OR 97402 U.S.A.

ACN

N263

CUS

LISTED

NWGQ 2Z78

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference, including

interference that may cause undesired operation.

Applicable patents are listed on label inside handheld unit.

FCC ID: O9NPWRSCAN-BS

CANADA38621032367A

MODEL: PowerScan RF Base Station

CLASS No.

SERIAL No.

FREQ:

Use ONLY PSC

AC/DC Power Supply

Input: +7.5V to +14V

Power: 5.5 Watts (max)

12

2

3

5

4

1

6

BASE ID

TX/RX

CHARGE

POWER

14

7

8

13

9

10

b

a

11

1. Antenna 8. Interface (I/F) Connector

2. Transmit/Receive

9. Cable Retainer

(TX/RX)/ Diagnostics LED

3. Charge LED 10 Power Connector

4. Power LED 11. Po wer Supply - (a) A C Adapter or

(b) Forklift DC Converter

5. Base ID Bar Code 12. Interface (I/F) Cable

6. Charging Pins 13. Mounting Key Slots (3)

7. 3-Position Lock 14. Mounting Flanges (4)

Systems Manual

3

Page 8

Laser Cautions

The PowerScan RF bar code scanner is certified in the U.S. to conform

to the requirements of DHHS/CDRH 21CFR Su bc hapter J f or Cl ass II la ser

products (SR and LR) and Class IIIa (XLR). Class II and IIIa products are

not considered to be hazardous. The scanner contains a Visible Laser

Diode (VLD) at a wavelength of 650-670 nanometers and is designed so

that there can be no human access to harmful levels of laser light during normal operation, user maintenance, or during prescribed service

operations.

In the unlikely event that a bright laser spot is experienced rather than a scan line, do not stare into the

beam or attempt to repair the unit. Discontinue

operation and return the unit to your dealer. Note

CAUTION

CAUTION

that when using Marker Beam Mode, a single aiming

dot is projected momentarily preceding a scan line

and is not considered a malfunction.

Do not open or otherwise service any components

in the optics cavity. Opening or servicing any part

of the optics cavity by unauthorized personnel may

violate laser safety regulations. The optics system

is a factory only repair item.

The PowerScan™ RF scanner is required to be

used in conjunction with the PSC Base Station,

NOTE

4

Model: PowerScan RF Base Station.

PowerScan

™ RF

Scanner

Page 9

Radio Frequency Interference

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two condition s:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including

interference that may cause undesired operation.

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-

003 du Canada.

This equipment has been tested and found to comply with the limits

for a Class B digital device, pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and

used in accordance with these instructions, may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment

does cause harmful interference to radio or television reception, which

can be dertermined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different

from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for

help.

Systems Manual

5

Page 10

Quick Start Instructi ons

Unpacking and

Inspecting the

Base Station

Installation

Procedures

After unpacking your new Base Station, check the contents of the shipping carton to ensure all the items you ordered are included:

• PowerScan

• Interface Cable

• Power Supply (AC Adapter or Forklift DC Converter)

• Systems Manual (this manual)

• Programming Guide

• Optional Accessories that you ordered. (The Base Station can

be purchased with or without accessory kits.)

If your package contains wrong or missing components, contact your

place of purchase. If ther e ar e damaged components, immediately file a

claim with the carrier. You may want to save your packing material in

case you need to ship the scanner at some later time.

NOTE

The basic steps below must be performed to set up the RF scanner.

Each of these steps is detailed in this section.

• Installing the Battery

™ Scanner Base Station

Other manuals for this product are available on our

internet website. See the back cover for our internet

address.

• Verifying Scanner Operation

• Connecting the Base Station to the Host Terminal

• Linking the Scanner to a Base Station

• Ve rifying Scanner-to-Base Stat ion Communications

• Using the PowerScan RF System

6

PowerScan

™ RF

Scanner

Page 11

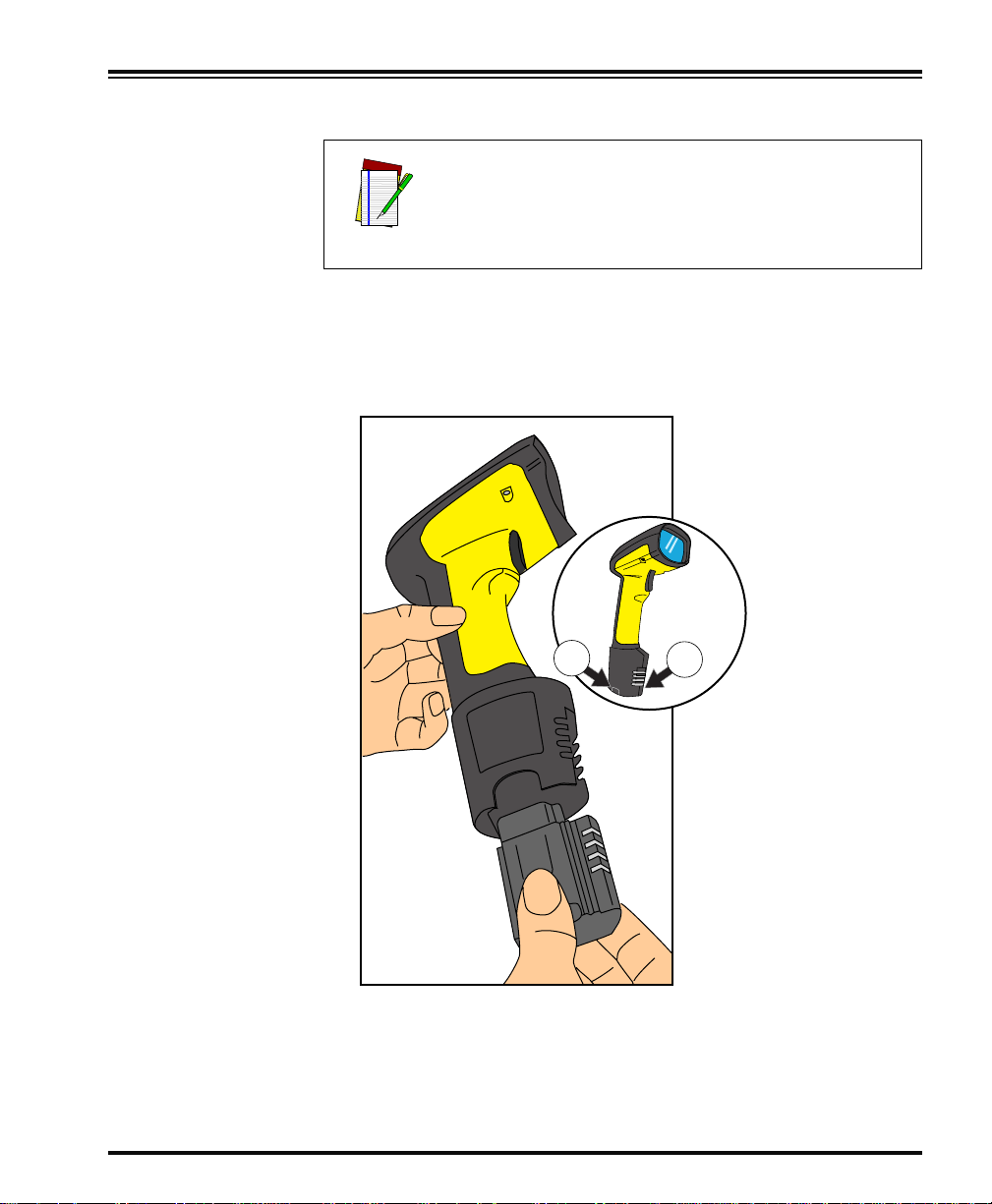

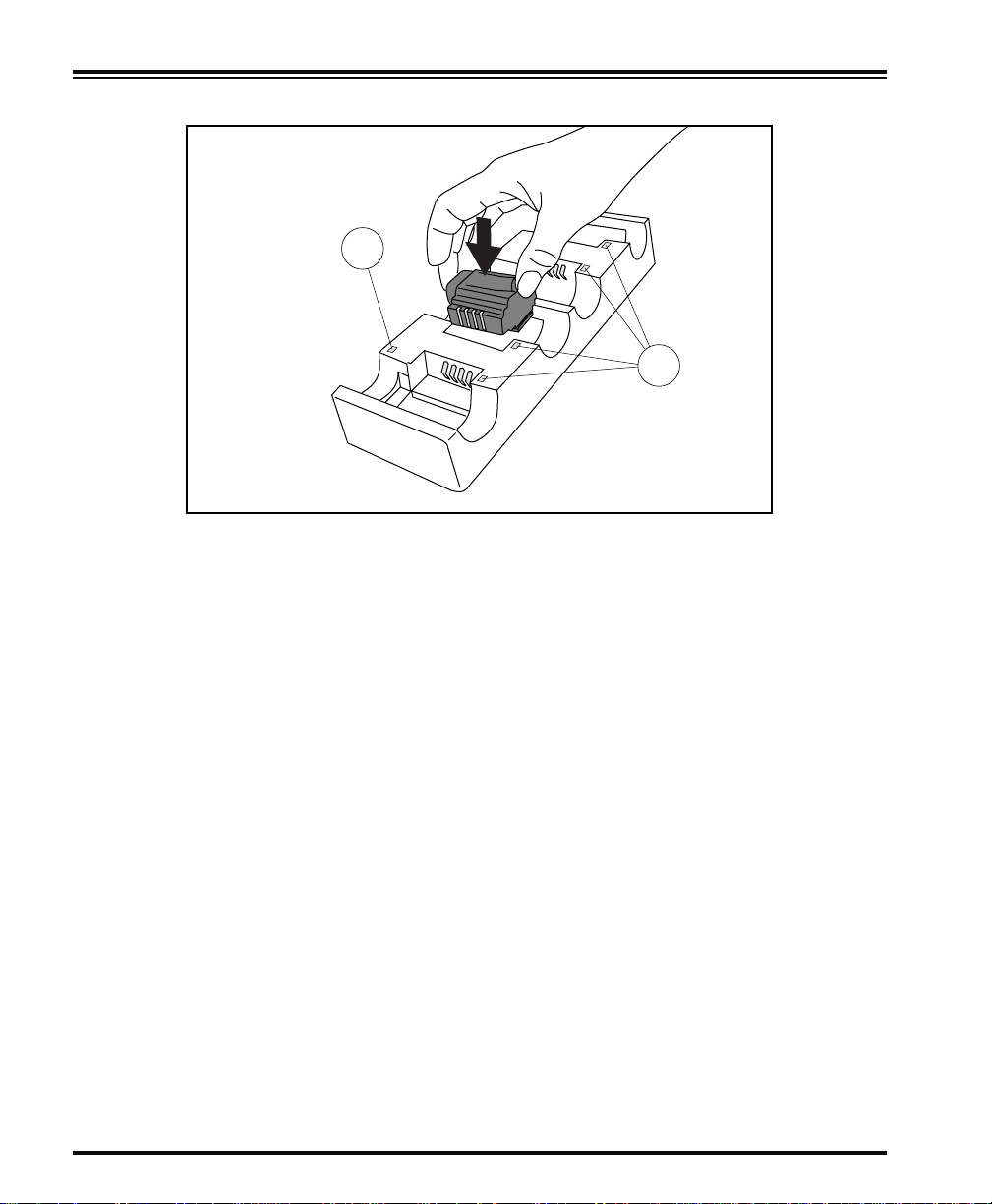

Installing the Battery

Orient the battery as shown in Figure 3, then push it into the scanner

until it snaps in place. T o remove the battery, push in on the release tabs

on both sides of the battery’s base and pull it straight out of the scanner.

To assure maximum usage, batteries should always

be fully charged before their initial use. (See

Charging and Maintenance

NOTE

Figure 3. Installing the Battery

Battery

on page 12.)

1

1. Battery Release Tabs

1

Systems Manual

7

Page 12

Verifying Scanner Operation

Once a charged battery has been installed in the scanner, scan the sample bar codes in Appendix A that correspond to the symbologies your

scanner is programmed to read. If unsure how to do this, see the section on How to Scan in this manual. The system may signal with one or

a combination of indicators depending upon how the scanner and Base

Station a re programme d to respon d (see LED and Beeper Indications for

details). If your scanner fails to read a sample bar code of a symbology

it’s programmed to read, turn to the section titled, Maintenance and

Troubleshooting.

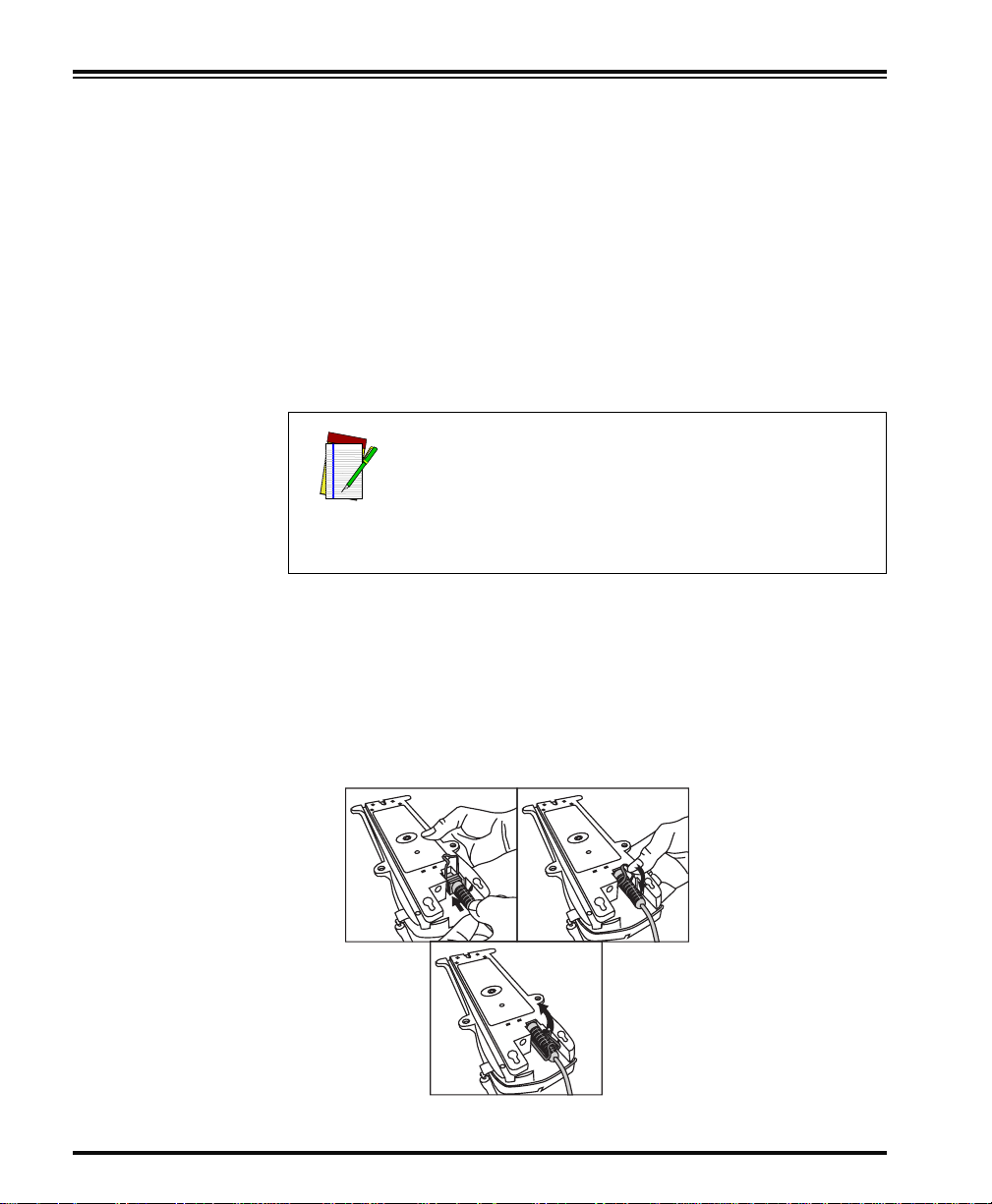

Connecting the Base Station to the Host Terminal

It is important that the interface (I/F) cable be connected to the Base Station prior to applying power

to the system. This is because the interface type

(RS-232, IBM, Keyboard Wedge, etc.) is selected by

NOTE

1. Connect the I/F cable to the Base Station (see Figure 4A). The

I/F cable is inserted into the connector and the cable retainer

clip is rotated over the cable overmold until the retainer snaps

in place (see Figure 4B). T o disconnect the cable, push in on the

retainer (away from the catch on the plastic wall) to release it

and enable it to swing upward, allowing the cable to be pulled

free (see Figure 4C).

the Base Station subject to the I/F cable it is connected to at the time of power-up.

Figure 4. Connecting/Disconnecting the Interface (I/F) Cable

ab

c

8

PowerScan

™ RF

Scanner

Page 13

2. Consult your Host Terminal manual to determine the required

communication parameters for the Host Te rminal (e.g., baud

rate, parity, etc.) and, if necessary, modify the programmed

parameters to be compatible with those requirements. Scanner

and Base Station programming is performed using one of the

following:

- Configurator Express™ Programming Software

- PowerScan

NOTE

CAUTION

3. Connect the I/F cable to the proper port on the Host Terminal

(check your Host Terminal manual to determine hardware

requirements).

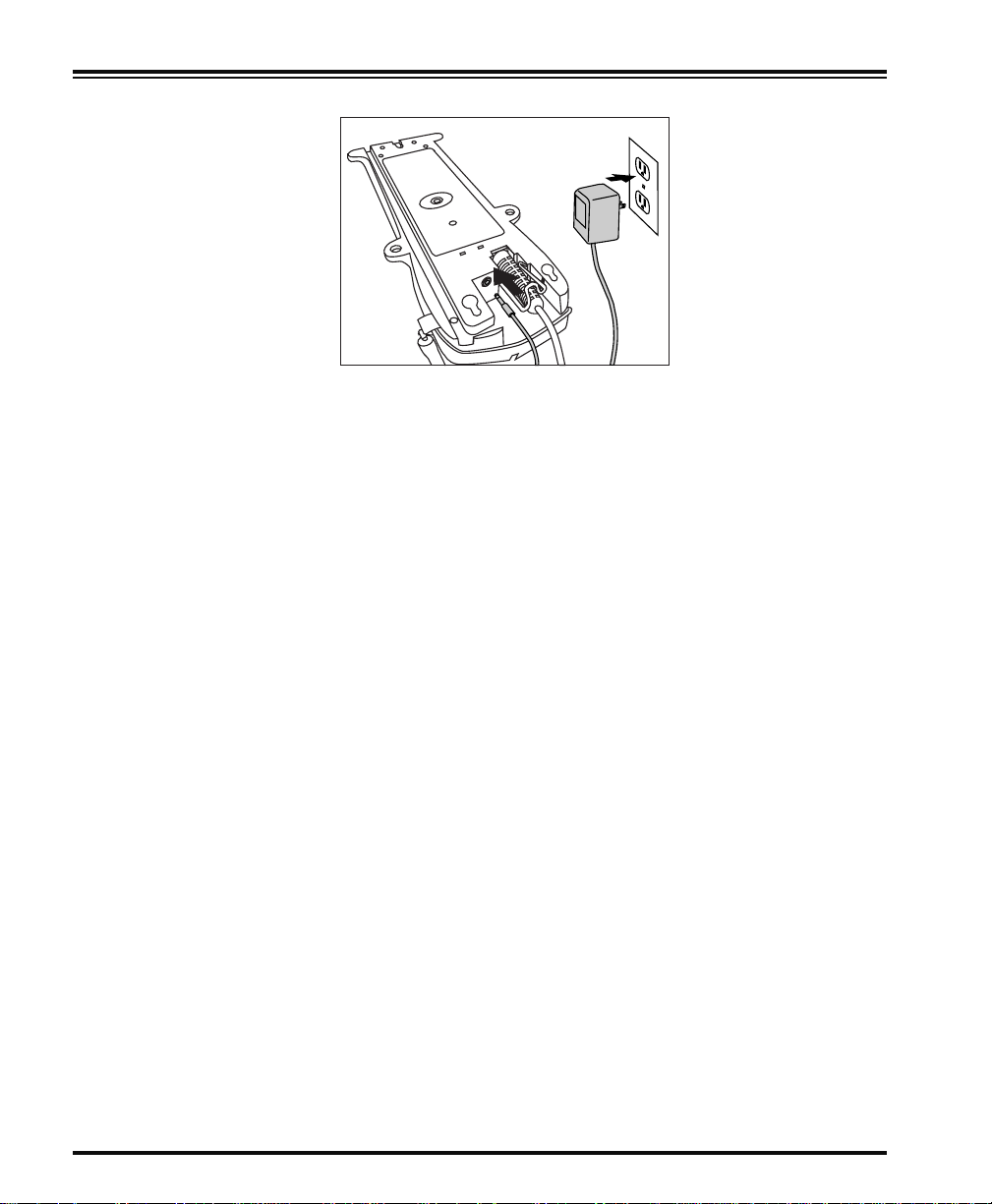

4. Connect the AC Adapter's power cord at the Base Station and

plug the AC/DC adapter in at the wall outlet (see Figure 5).

The Base Station’s POWER LED should be illumin at ed when

the unit is properly connected to power.

™ Bar Code Scanner Programming Guide

References

See

obtain software and manuals for this product.

The Host T erminal man ual sho uld also be consu lted

as to whether power must be turned off before connecting peripheral devices. Ensure that the correct

procedure is followed to avoid damage to equipment or interruption of system functions.

for more information about how to

Systems Manual

9

Page 14

Figure 5. Connecting Power to the Base Station

5. Apply power to the Host Terminal.

6. Verify communication with the Host Terminal by aiming the

linked scanner at a sample bar code from Appendix A, and

pulling the trigger (see How to Scan for tips about scanning bar

codes). Confirm that the scanner/Base Station sent the data to

the host terminal. If not, see the section, Maintenance and Trou-

bleshooting. Once all communications are verified, the system is

ready for use.

Linking the Scanner to a Base Station

To link a scanner to a Base Station, simply scan the Base Station ID bar

code located on the top of the desired Base Station (see Figure 2). As the

scanner searches for the Base Station, a short beep is heard as it seeks

for the correct channel. When the Base Station responds to the request,

the scanner’s beeper will either sound a "Link Granted," or "Link

Denied" signal (see the section, LED and Beeper Indications for more

information).

10

PowerScan

™ RF

Scanner

Page 15

The existing Base Station system configuration can be automatically

downloaded to the scanner. This automatic download feature is configurable and can be disabled. See the section, Common Configuration for

more information about this feature. If downloading occurs, a slight

delay with link verification anno uncement will occur.

Since a new/replacement scanner may have been

shipped with a custom configuration or may have

been modified with other special programming, it

may not be desirable to download a potentially

older configuration from an existing Base Station.

CAUTION

In this case, reference the

tures

section of this manual, or the

™

Express

consider uploading the scanner’s newer configuration to the Base Station prior to linking.

On Screen Programming Software and

RF Programmable Fea-

Configurator

Verifying

Scanner-to-Base

Station

Communications

Point the linked scanner at a sample bar code from Appendix A, and

pull the trigger (see How to Scan for tips on scanning bar codes). Watch

the TX/RX (transmit/receive) indicator LED on the Base Station and/

or scanner green LED while scanning the bar code. The LEDs should

flash momentarily as the two devices communicate. If no communication is indicated, see the section titled, If the Scanner Fails to Link with the

Base Station.

When the scanner is programmed to do so, communication can also be

indicated by a second "acknowledgement" ton e

"good read" tone. If a transmission error beep (warble) is heard following a "good read" tone instead of the single acknowledgement tone,

communication between the devices may have failed

tions Using the PowerSc a n RF System, and Maintenance and Troubleshoot-

ing for possible remedies, should this occur.

Using the PowerScan RF System

This section covers the following topics:

• Battery Charging and Maintenance

• How to Scan

1. See

LED and Beeper Indications

2. Other reasons for a "warble" are that the Base Station may be configured differently than the scan-

ner, or that the system’s interface doesn’t support the symbology (bar code type) you’re trying to

scan.

1

that is sounded after a

for more details about beeper signals.

2

. Refer to the sec-

Systems Manual

11

Page 16

• LED and Beeper Indications

• Maximizing Signal Range

• Three-Position Lock

Battery Charging and Maintenance

When the scanner is in use, a low battery condition

is indicated by a repeated two-flash signal from the

scanner’s green LED every time the trigger is pulled

before the laser is enabled. This indicator may have

NOTE

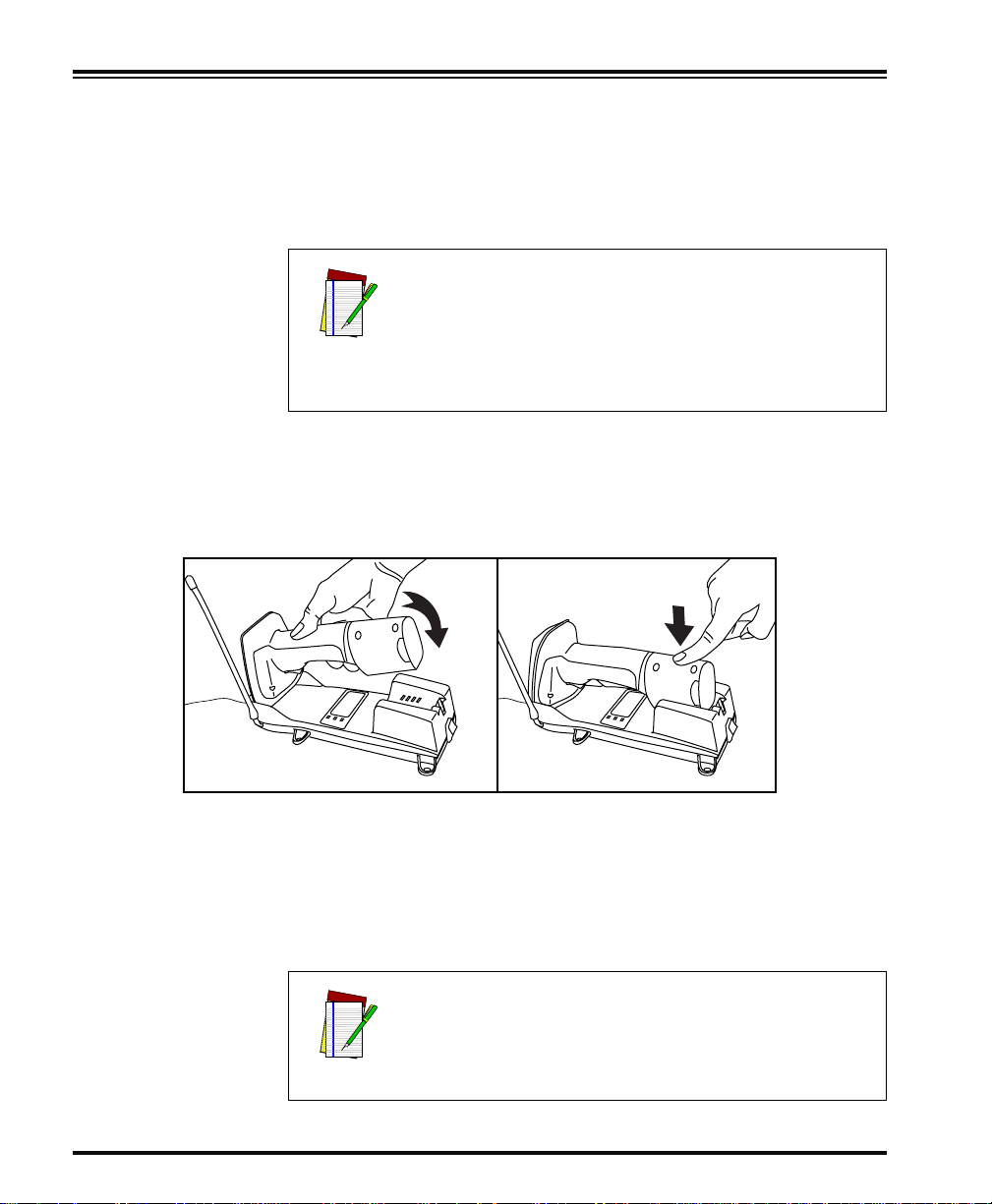

Seat the scanner in the Base Station as shown in Figure 6, ensuring that

the battery fully engages the station’s metal con tacts. The CHARGE

LED on the Base Station should flash, indicating the battery is charging.

Figure 6. Charging the Battery

been disabled via custom programming. See

and Beeper Indications

LED

for more information.

12

Rapid flashing indicates that charging is ta king place. Rapid charging

occurs when the battery temperature is between 10°C (50°F) and 46°C

(115°F), and/or voltage of the battery is between 2.0 and 3.2V. Charge

time is less than 4.2 hours. Rapid charge ends with the battery at

approximately 90 to 95% capacity. The CHARGE LED remains on

steady when trickle charging or after the charge cycle is complete.

A scanner may be charged simultaneously while

other scanners are in use with the Base Station.

NOTE

PowerScan

™ RF

Scanner

Page 17

NOTE

Batteries will not charge if their temperature is

below 0°C (30°F). If a battery that is too cold is

inserted into the Base Station, the Charge LED will

not illuminate.

Tips for

Extending

Battery Life

Disposing of

Batteries

Four Station

Charger

Nickel Metal Hydride (NiMH) batteries will better hold a charge if

allowed to discharge at least once a week. The chemical reactions that

correspond to charge and discharge in a rechargeab le battery should

occur to obtain the maximum number of charge/discharge cycles in

the battery. If a battery is removed from the scanner and stored, it

should be fully charged when stored. Batteries will lose the ability to

hold a charge when stored for long periods of time (weeks, months, or

longer).

Batteries will typically have about 30% charge capacity when shipped.

To assure maximum usage, the battery should be fully charged before

use.

Store your battery in a cool dry place. Do not leave your battery

exposed to direct sunlight or temperatures below 0°C (30°F) and above

38°C (100°F).

There presently are no US, North America or World disposal requirements for NiMH batteries, so when they won't hold a charge anymore,

the batteries can be disposed of, preferably through a recycling center.

If you have a Four Station Charger, batteries are inserted for charging

as shown in Figure 7. A 90% rapid charge can be achieved in only two

hours when using this optional accessory; half the time than when a

Base Station is used for charging. The LEDs at each battery station

operate the same as the CHARGE LED on the Base Station, with rapid

flashing indicating that rapid charging is taking place and on steady

during trickle charging or when the rapid charge cycle is finished.

If you insert a battery into the Four Station Charger

and no LEDs illuminate, the battery may be too

cold. Batteries must be at 0°C or higher to charge.

Do not attempt to charge cold batteries, since plac-

NOTE

ing them in the charger will curtail the charging of

other batteries already present in the unit.

Systems Manual

13

Page 18

Figure 7. Using the Four Station Charger Accessory

1

2

1. Device Power LED 2. Station Charge LEDs

14

PowerScan

™ RF

Scanner

Page 19

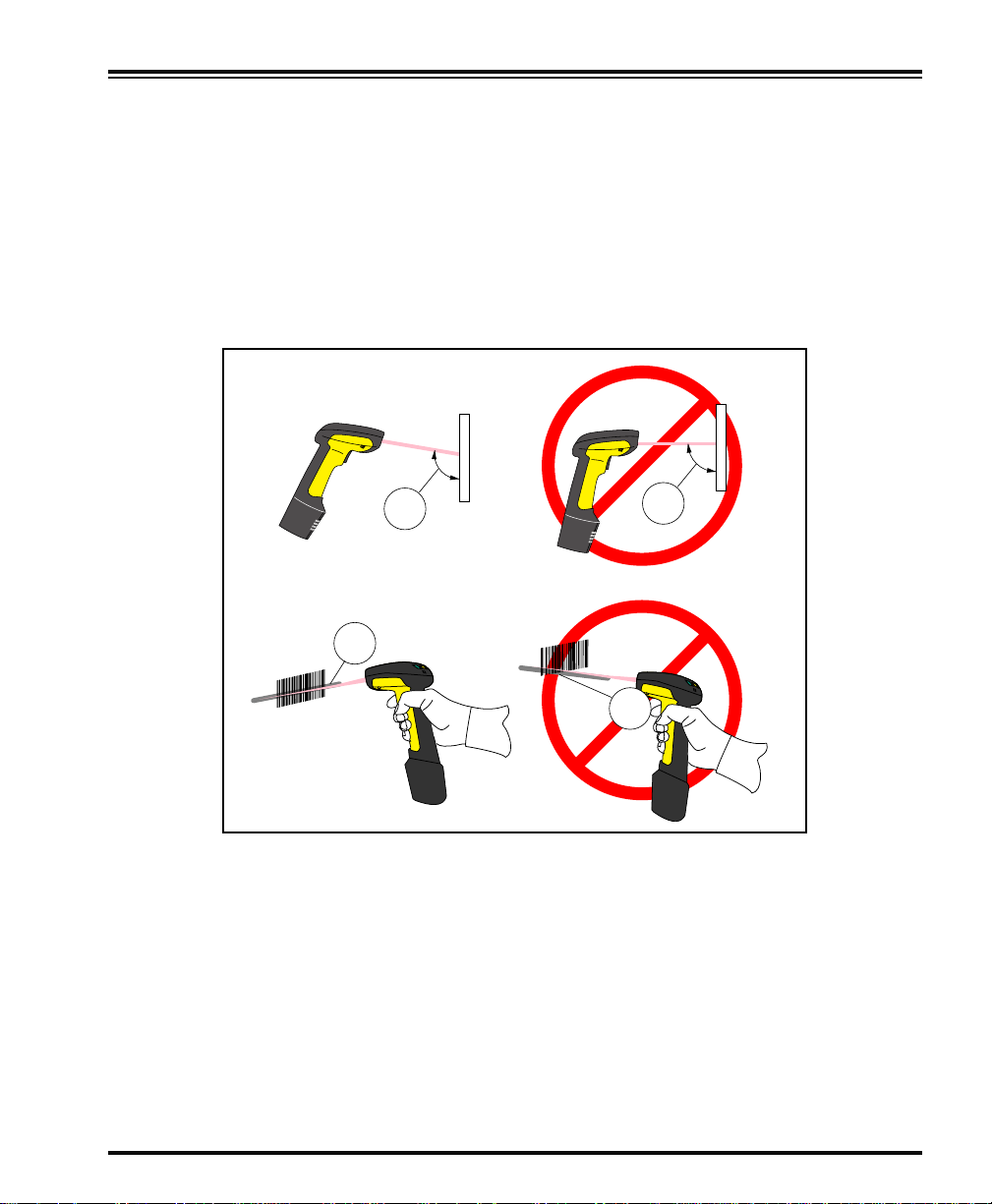

How to Scan

Figure 8 illustrates some tips to help get the best scanning results:

1. The scanner must be pointed at a slight angle to the bar code.

Do not hold the scanner perpendicular to the bar code.

2. The laser beam must cross the entire bar code. The scanner

cannot correctly read if the entire bar code is not scanned.

Figure 8. Scanning Tips

1

2

1

2

Systems Manual

15

Page 20

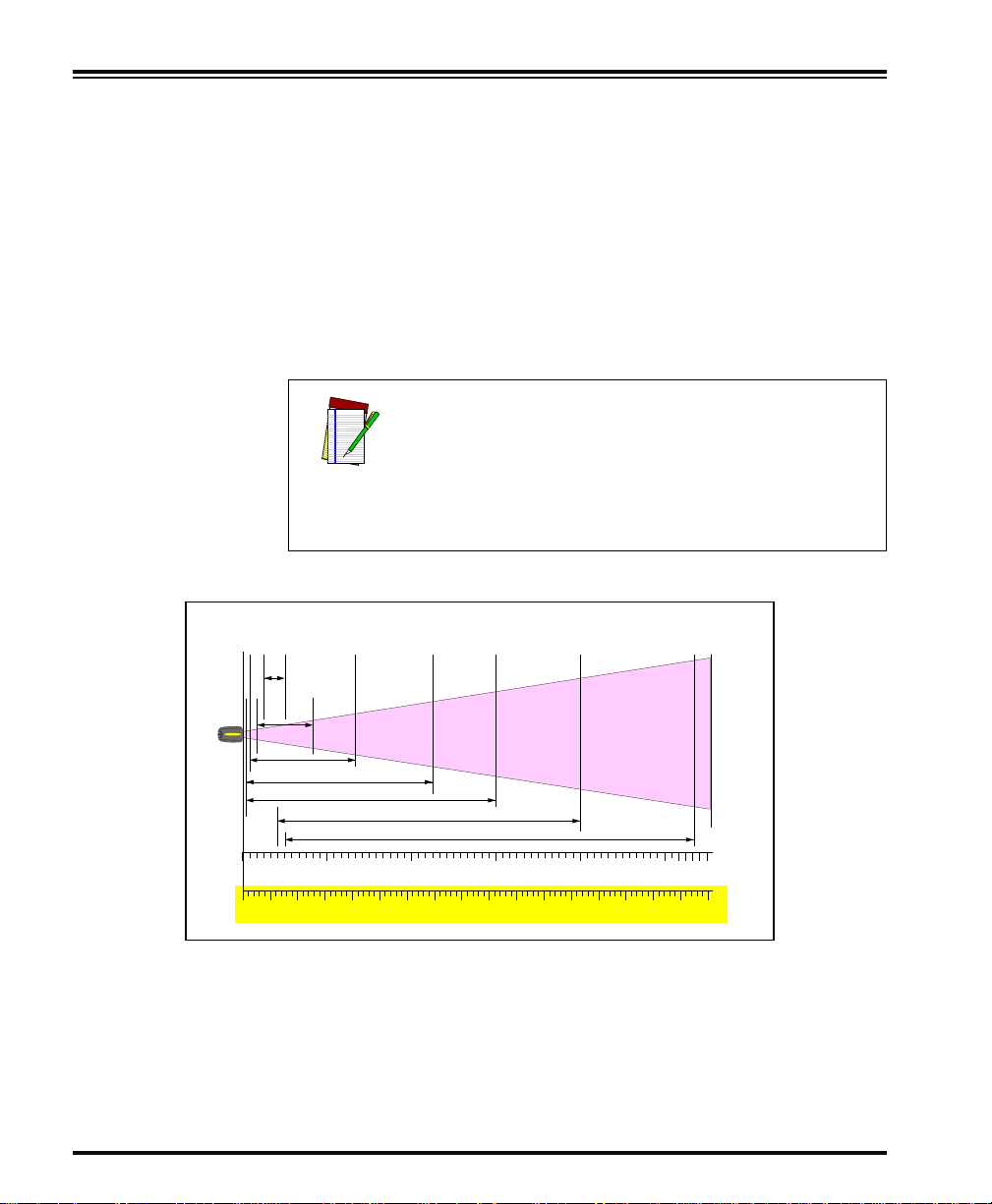

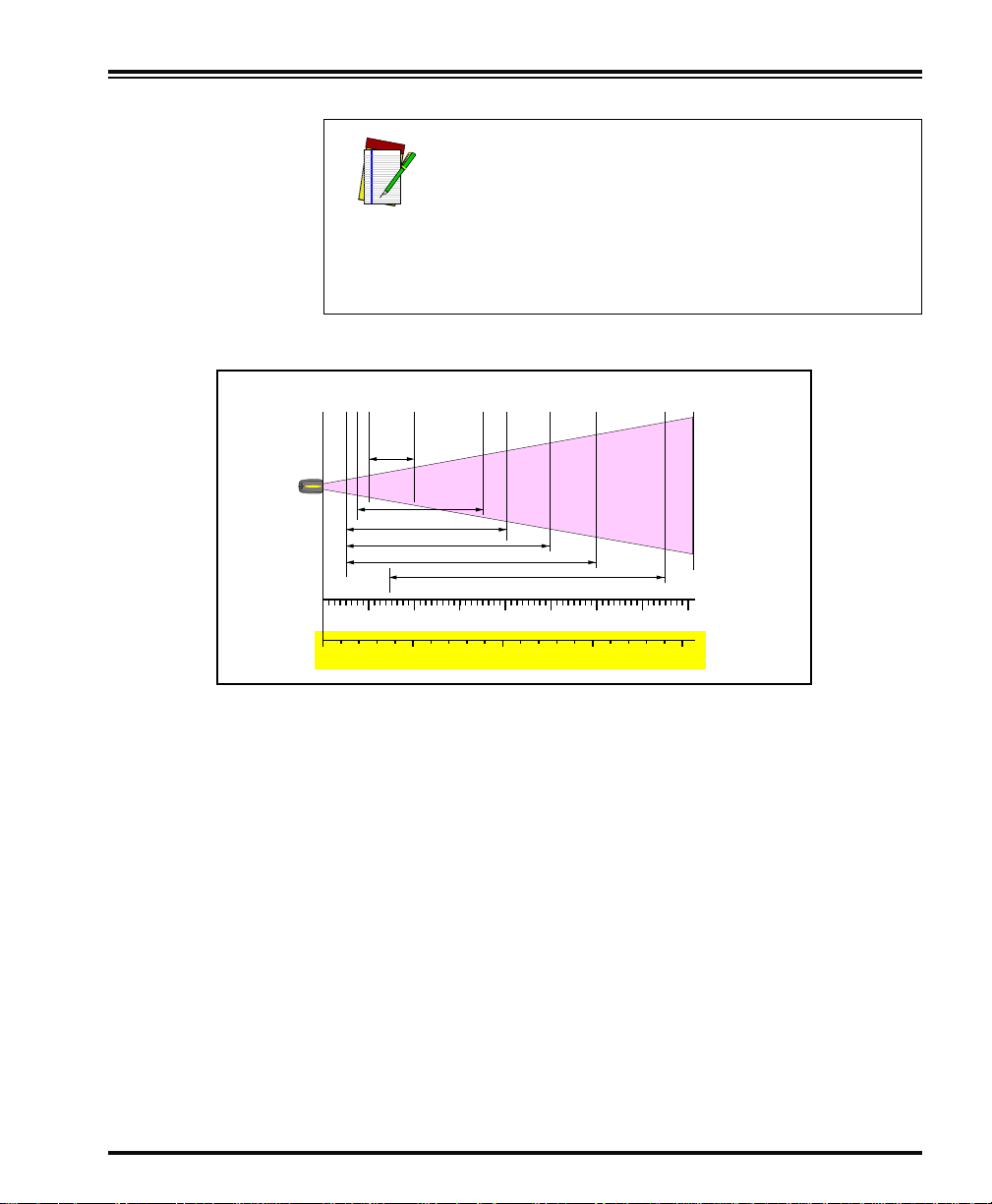

Depth of Field

Definition of

a "mil"

Depth of Field

Paper Labels (SR decoded model, Code 39)

There are currently four different range models for the RF scanner.

Depending upon the model type of your scanner, you’ll need to hold

the unit at a given distance from the bar code to achieve optimum scanning results. The following diagrams provide depth of field information for each of the models when scanning grade A, Code 39 bar codes:

Standard Range (SR), High Density (HD), Long Range (LR) and Extra

Long Range (XLR).

A "mil" is equal to 0.001 inches. In the context of the illustrations in this

section, a mil represents the minimum bar code element width. Thus a

5 mil bar code would have a minimum element width of 5 mils (or

0.005 inches).

Measurements are based on SR models set with the

standard 28° scan width (as opposed to the Half

Angle setting of 14°). Reference the Programming

Manual for more information about the Half Angle

NOTE

feature.

Specifications are subject to change without notice.

Figure 9. Depth of Field (SR)

16

5 mil

7.5 mil

10 mil

FRONT OF SCANNER

0

15 mil

20 mil

40 mil

12345

10

20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170

55 mil

FEET

CENTIMETERS

PowerScan

™ RF

Scanner

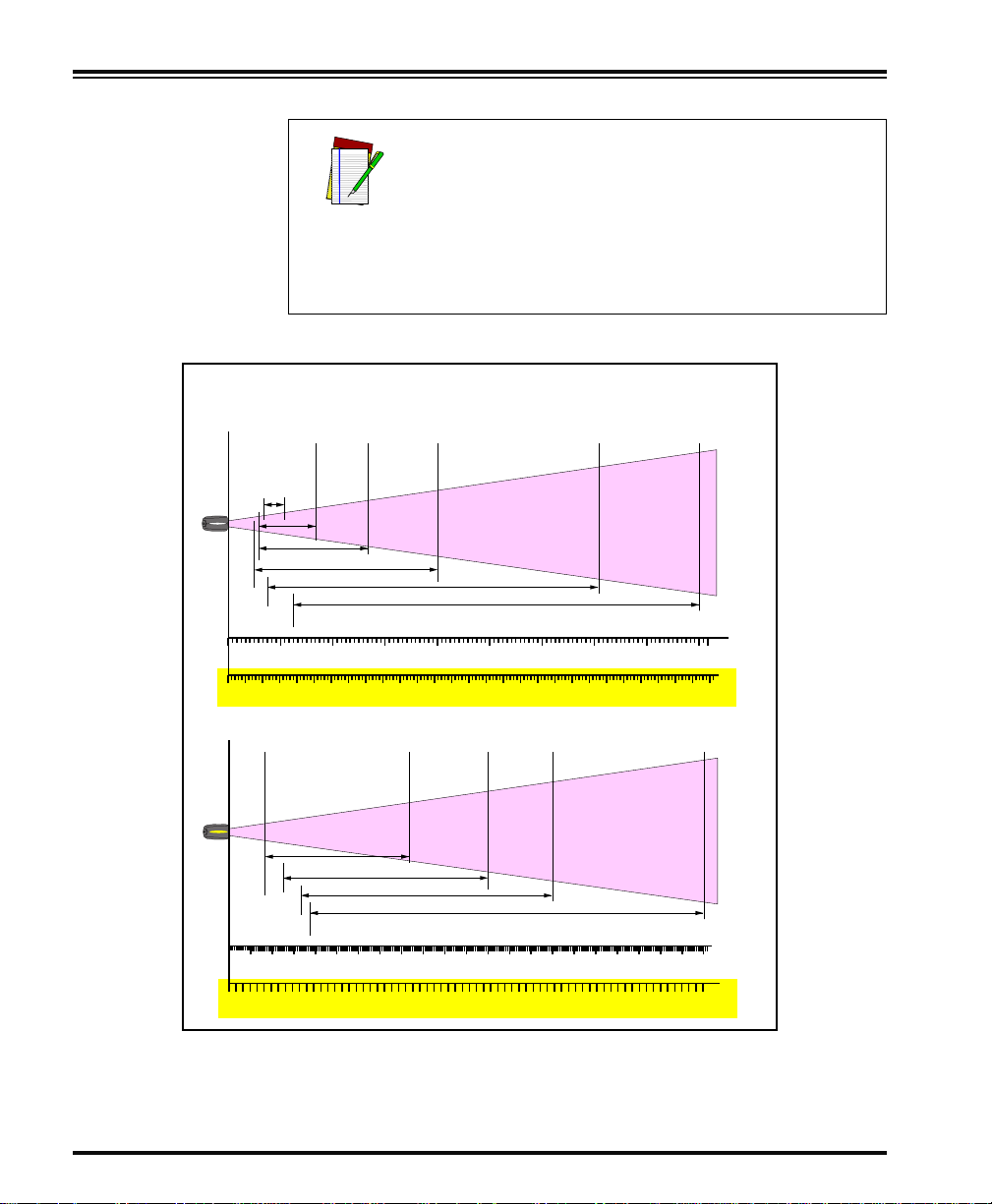

Page 21

See the section titled,

information about reading this chart. Measurements

are based on HD models set with the standard 28°

scan width (as opposed to the Half Angle setting of

14°). Reference the Programming Manual for more

NOTE

information about the Half Angle feature.

Specifications are subject to change without notice.

Figure 10. Depth of Field (HD)

Depth of Field

Paper Labels (HD decoded model, Code 39)

3 mil

4 mil

FRONT OF SCANNER

5 mil

7.5 mil

10 mil

20 mil

Definition of a "mil"

for more

12345678

0

5

INCHES

10 15 20

CENTIMETERS

Systems Manual

17

Page 22

See the section titled,

information about reading this chart. Measurements

are based on LR models set with the a 14° scan

width (as opposed to the alternate Full Angle setting of 28°). Reference the Programming Manual for

NOTE

more information about the Half Angle feature.

Specifications are subject to change without notice.

Figure 11. Depth of Field (LR)

Depth of Field

Paper Labels (LR decoded model, Code 39)

7.5 mil

10 mil

15 mil

FRONT OF SCANNER

20 mil

40 mil

55 mil

Definition of a "mil"

for more

18

12345

0

10

20 30 40 50 60 70 80 90 100 110 120 130 140 150 160

FEET

CENTIMETERS

6789

170 180 190 200 210 220 230 240 250 260 270 280

Reflective Labels (LR decoded model, Code 39)

40 mil

FRONT OF SCANNER

102345678910 11 12 13 14 15 16 17 18 19 20 21 22

55 mil

70 mil

100 mil

FEET

CENTIMETERS

6706506306105905705505305104904704504304103903703503303102902702502302101901701501301109070503010

PowerScan

™ RF

Scanner

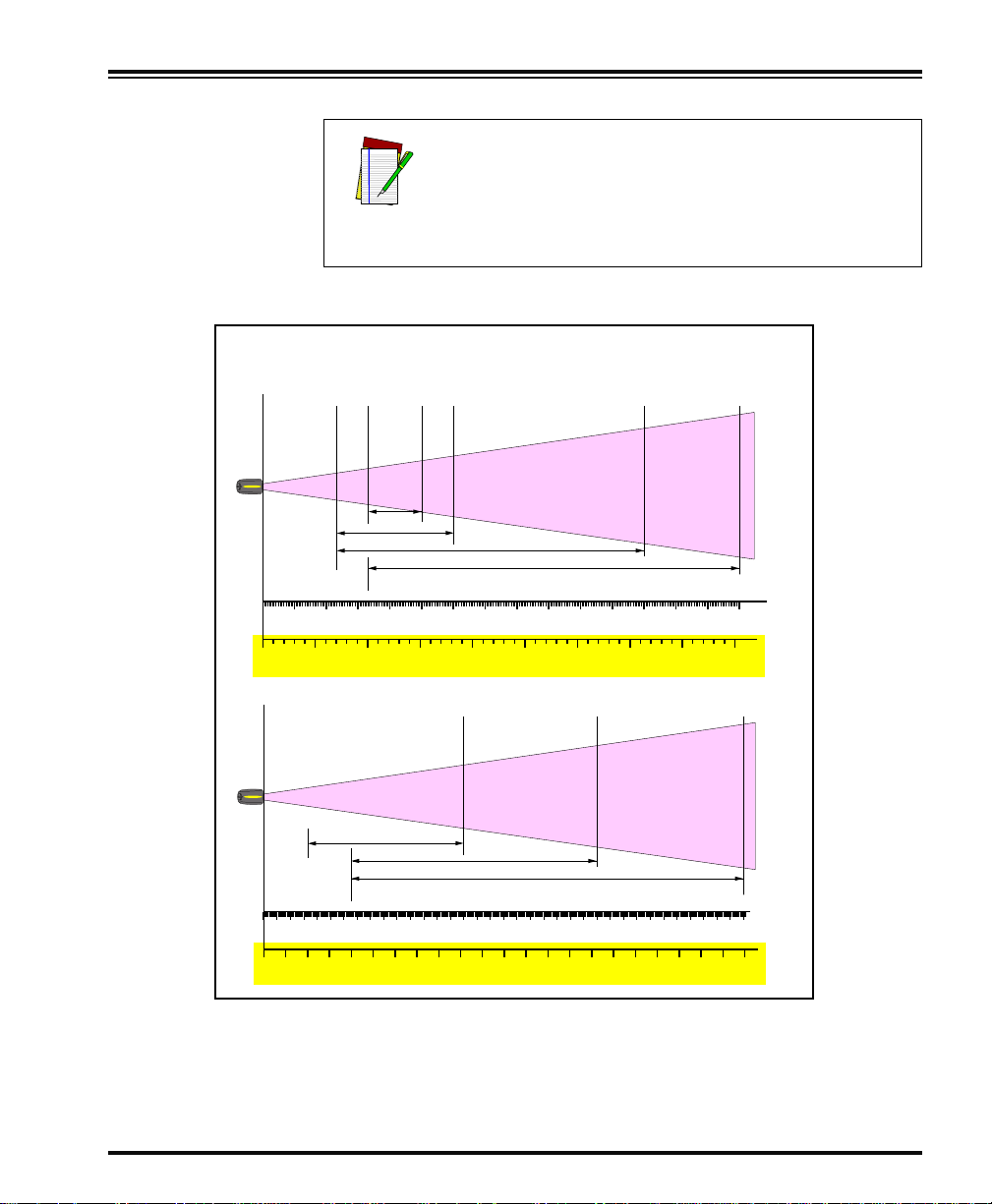

Page 23

See the section titled,

information about reading this chart. Measurements

are based on XLR models set with a 10° scan angle

width.

NOTE

Specifications are subject to change without notice.

Figure 12. Depth of Field (XLR)

Depth of Field

Paper Labels (XLR decoded model, Code 39)

15 mil

FRONT OF SCANNER

20 mil

40 mil

55 mil

Definition of a "mil"

for more

12345678910 11 12 13 14 15

0

FEET

CENTIMETERS

45040035030025020015010050

Reflective Labels (XLR decoded model, Code 39)

FRONT OF SCANNER

2345678910 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

40 mil

70 mil

100 mil

FEET

CENTIMETERS

1100105010009509008508007507006506005505004504003503002502001501005010

Systems Manual

19

Page 24

Active

Symbologies

The active (enabled) bar code symbologies in the standard factory

defaults are:

• Code 39 (C39)

• Code 128 (C128)

• Interleaved 2 of 5 (I 2 of 5)

Your scanner should be pre-programmed with these standard factory

default settings, unless...

...it was shipped to you programmed with unique, customer con-

figuration settings.

...you or another user have made changes to scanner program-

ming.

Enhanced

Scanning for

Hard-to-Read

Bar Codes

Decoded scanners can be programmed to decode extremely poor quality bar codes by activating advanced Quadralogic

select this feature, see the Programming Guide.

Scanner programming can also be performed using your PC and the

Configurator Express

NOTE

™ On-Screen Programming Kit.

Information about manuals, kits and programming

software for this product are available at our website. See the back cover for our web address.

™ Decoding. To

20

PowerScan

™ RF

Scanner

Page 25

LED and Beeper Indications

The Base Station LED indicators and the scanner’s LEDs and beeper are

used to announce system status and perform other useful signals. The

tables below list the default function of each of the various indicators.

NOTE

Some LED and beeper indications can be disabled

or modified via scanner programming. The tables

indicate the default behavior of the indicators, with

shaded rows representing features that are programmable.

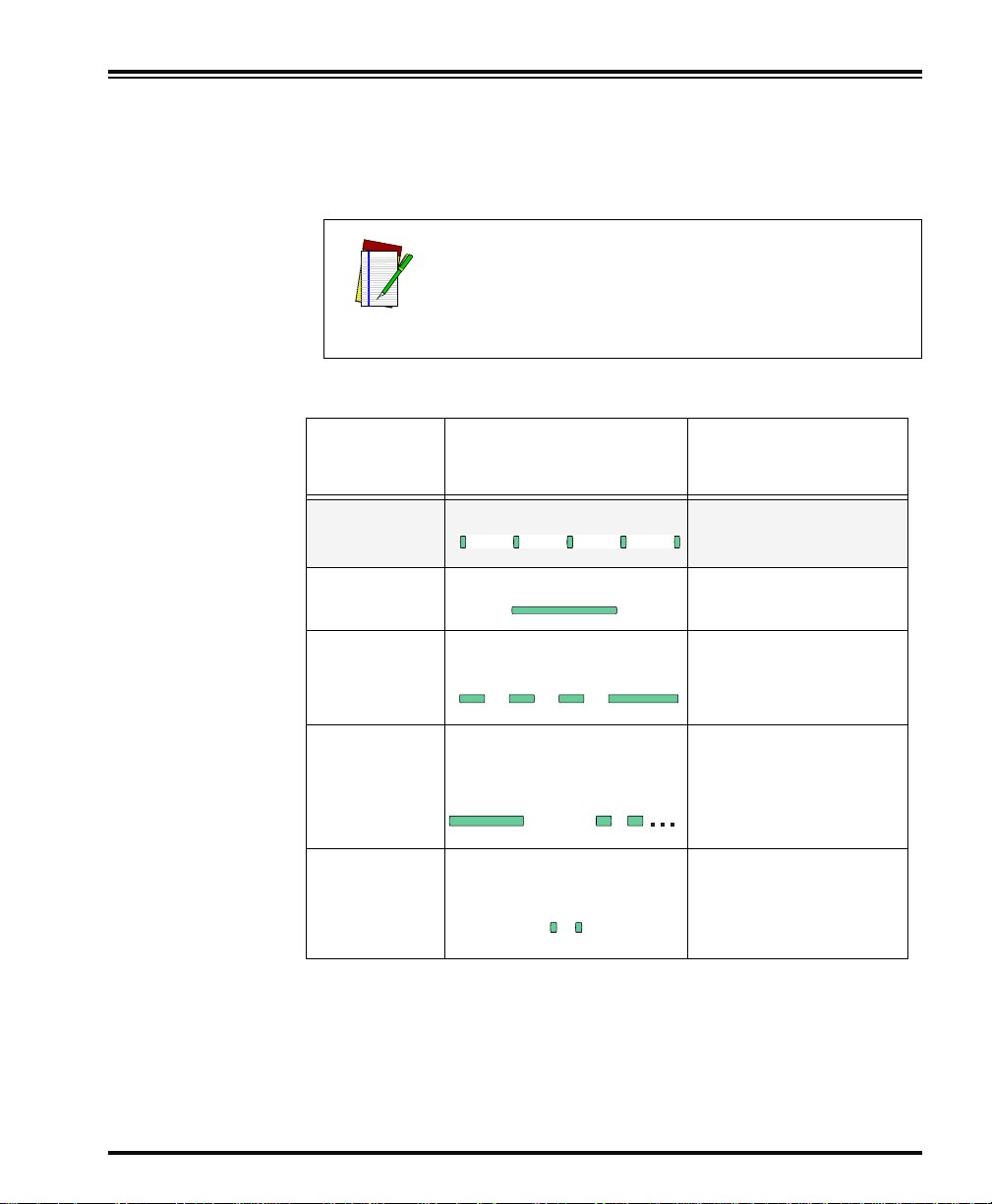

Table 1. Scanner GREEN LED Functions

LED

INDICATION

Disable

Indication

Good Read

Indication

Program Mode

Indication

Field Replaceable Unit (FRU)

Indications

Low Battery

Indication

DURATION COMMENT

100ms on, 900 ms off

500 ms on

500 ms on, 500 ms off

Continuous flashing

Varies. Consists of a long

flash followed by multiple short

flashes.

Two flashes at 100 ms on, 350

ms off.

Indicates the scanner has

been disabled.

Indicates a bar code has

been read and decoded.

Indicates the scanner is in

Programming Mode.

Enables service technicians to identify Field

Replaceable Unit (FRU)

errors.

Occurs at trigger pull

before the laser is enabled.

Indicates the battery is in

need of recharging.

Systems Manual

21

Page 26

Table 2. Scanner YELLOW LED Functions

LED

INDICATION

Laser on indication

SPEAKER

INDICATION

Scanner Not

Currently

Linked

Good Read

Beep

DURATION COMMENT

On Steady

The yellow LED illuminates

whenever the laser is on.

Ta ble 3. Scanner BEEPER Functions

DURATION COMMENT

Six beeps consisting of 20 ms

on, 20 ms off

100 ms on (short)

250 ms on (medium)

500 ms on (long)

Indicates a bar code was

read before the scanner

was linked to a Base Station.

Three programmable functions are available. This

indicates a bar code has

been read and decoded.

22

Partial Read

Bip

Base Station

Acknowledgement Beep

20 ms on

100 ms on (short)

250 ms on (medium)

500 ms on (long)

A very short beep ("bip") is

sounded when one bar

code of a two-bar code pair

has been successfully

decoded.

Indicates a successful bar

code transmission to the

host (configurable), a successful change of channel,

or a successful transmission of a new configuration

to the host.

PowerScan

™ RF

Scanner

Page 27

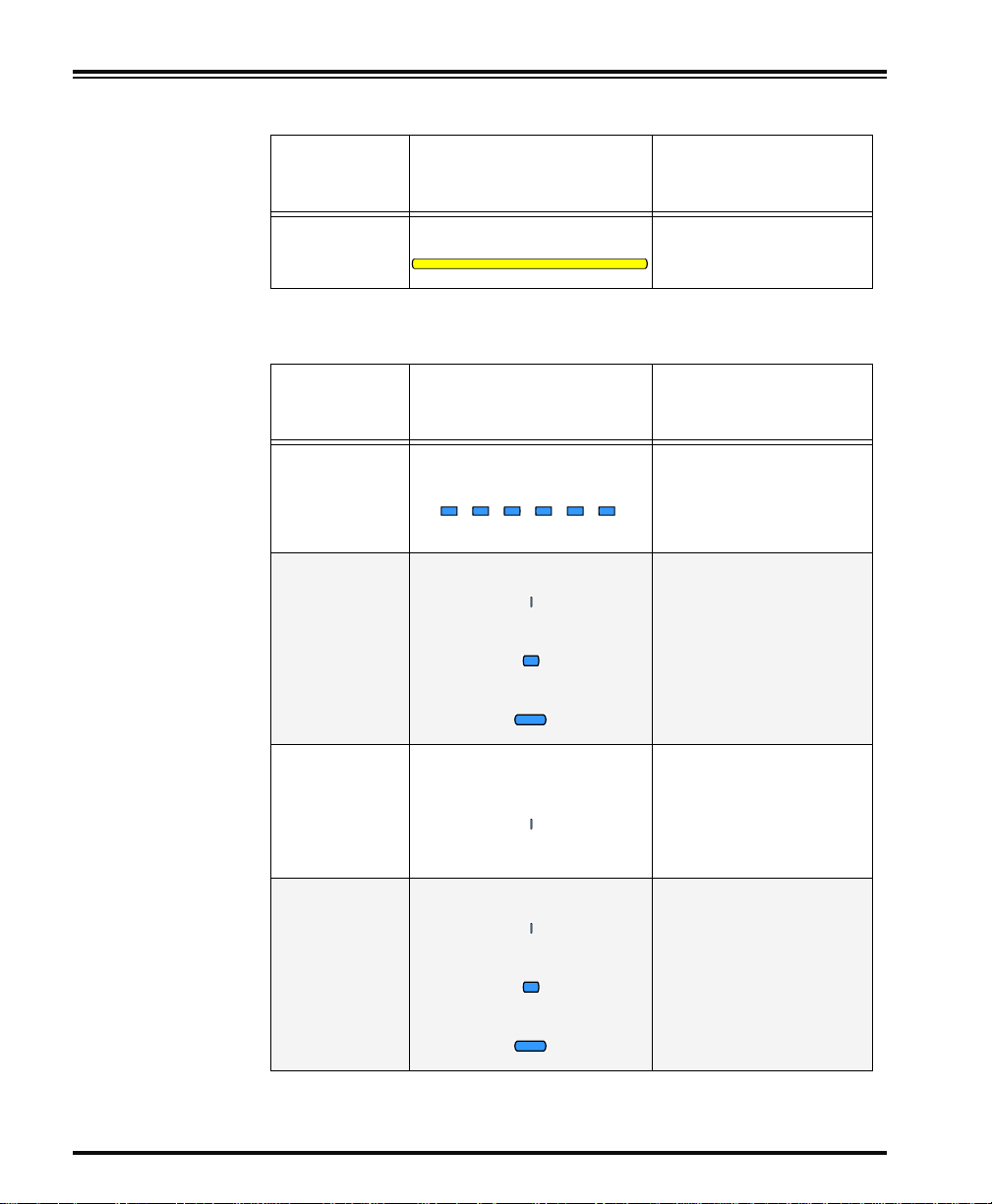

SPEAKER

INDICATION

Transmission

Error Beep

DURATION COMMENT

High, then low , then high, then

low.

Indicates unsuccessful

transmission to the host.

Link Beep

Unlink Beep

Field Replaceable Unit (FRU)

Indications

Low, then medium, then high.

High, then medium, then low.

Varies. Consists of a long tone

followed by multiple short

tones.

Indicates a scanner has

been successfully linked to

a base station.

Indicates a scanner has

been successfully unlinked

from a base station.

Enables service technicians to identify Field

Replaceable Unit (FRU)

errors.

Systems Manual

23

Page 28

Table 4. Base Station LED Functions

LED

INDICATION

TX/RX (Transmit/Receive)

Charge

(Battery)

DURATION COMMENT

Lit for variable time

Continuous rapid

flashing at power-up

Varies. Consists of a long

flash followed by multiple short

flashes.

Continuous flashing

Lit Constantly

a

Indicates communications

activity to or from the Base

Station.

Indicates a broken radio.

Enables service technicians to identify Field

Replaceable Unit (FRU)

errors.

When a scanner is nested

in the station, this indicates

its battery is being quick

charged.

When a scanner is nested

in the station, this indicates

its battery is at or near full

charge.

24

A scanner is not present or

incorrectly inserted into the

Not Lit

Power

a. The LED remains on while the unit is actively processing code which

requires a TX/RX to occur. The duration of the LED is dependent upon

the length of the message.

Lit Constantly

station. It can also mean

the battery is below 0°C

(too cold for charge)

Indicates that power is on.

PowerScan

™ RF

Scanner

Page 29

Maximizing Signal Range

Here are a few tips about how you can optimize your system installation to allow the scanner greater roving distance from its linked Base

Station while maintaining clear communication between the devices.

• Minimize obstructions between the scanner and its Base Sta-

• Never place or install the Base Station in a metal-lined area or

• Position the Base Station and experiment at various elevations ,

• Ensure that programmable features are set to maximize radio

• Consider using a Four Station Charger accessory to charge bat-

tion. While the system is capable of communicating through

walls, a clean line of sight will alwa ys increase the scanner’s

signal range from the Base Station.

enclosure, or near large metal objects.

orientations, etc. to achieve better communications between

devices. The system usually works best at heights of one meter

or more off the ground. Usually the scanner and Base Station

work optimally when operating at about the same height.

transmission. For example, if the feature Radio Transmit Power

is set to low, set it to high. Selectin g a different channel using

the options under RF Channel Selection might also help. See the

section titled, RF Programmable Features, for more information

about these features.

teries as opposed to using the Base Station for this function. It

offers faster charging (about half the time to a 90% charge as

Base Station charging).

Systems Manual

25

Page 30

Three-Position

Lock

The Base Station is equipped with a three-position lock to allow a scanner to be secured in the Base Station in horizontal, vertical, and forklift

installations.

Figure 13. Using the Three-Position Lock

1

2

3

26

1. Top position:

Vertical Forklift Mount Lock

2. Middle position:

Vertical (Wall) Mount Lock

3. Bottom position:

Unlocked

PowerScan

™ RF

Scanner

Page 31

Mounting the Base Station

The Base Station can be secured to varying surfaces to ensure a permanent, stable installation. Several options are available.

Horizontal

(Table or

Countertop)

Mounting

Using Key

Slots

Refer to Figure 14 and follow these steps:

1. Once you have identified the desired area for permanent Base

Station installation, use the mounting template included with

this manual to mark the position of its "key slot" mounting

screws.

2. Install three #8 x 1" (4.1mm x 25.4mm) pan head, self-tapping

screws in the marked positions until completely threaded into

the mounting surface, then back the screws off two to three full

turns.

3. Ensure that power and interface cables are securely connected

and routed in the channels provided in the bottom of the Base

Station.

4. Align the Base Station key slots (wide end) with the screws,

then slide the Base Station to position the screws in the smaller

ends of the key slots. Adjust the height of the mounting screws

if needed for a secure fit. The Base Station is now secured to

the table or countertop.

Systems Manual

27

Page 32

Figure 14. Mounting Using Key Slots

2

1

BASE ID

TX/RX

CHARGE

POWER

1. Key Slots 2.

Using

Mounting

Flanges

Refer to Figure 15a and follow these steps:

1. Once you have identified the desired area for permanent Base

Station installation, hold the unit in place and mark the position of screws using the "mounting flanges."

2. Start and remove four screws (provided) at the marked posi-

tions in the mounting surface.

3. Ensure that power and interface cables are securely connected

and routed in the channels provided in the bottom of the Base

Station.

4. Secure the Base Station to the surface by installing the four

screws into the mounting flanges. Base Station attachment is

now complete.

#8 x 1" (4.1mm x 25.4mm) Pan

Head Screw

28

PowerScan

™ RF

Scanner

Page 33

Figure 15. Mounting Using Flanges or Two-sided Tape

2

3

BASE ID

TX/RX

CHARGE

POWER

1

ab

1. Mounting Flanges (4) 3. Two-sided Tape Strips

2. 4 Screws (provided) 4. Backing

4

Mounting

Using TwoSided Tape

Vertical (Wall)

Mounting

You can also affix the Base Station to a surface using the two-sided tape

strips provided with the unit. Simply remove the backing from one

side of the strips and apply them to the bottom of the Base Station as

shown in Figure 15b. Remove the remaining backing from the tape,

then position and firmly press the unit against a smooth, clean surface

in the orientation desired.

The Base Station can be mounted vertically using the same methods as

horizontal mounting (see previous section):

• Using Key Slots

• Using Mounting Flanges

• Mounting Using Two-Sided Tape

1. Since mounting using this method offers less secure attachment, verify that your tape installation

is robust enough for your application.

1

Systems Manual

29

Page 34

Post or Forklift

Mounting

To secure the Base Station to a post or forklift f r ame, refer to Figure 16

and follow these steps:

1. Verify that the desired mounting area offers sufficient space

for safe forklift operation and will not present a hazard for

operators or potentially damage the mounted device(s).

2. Ensure that power and interface cables are securely connected

and routed in the channels provided in the back of the Base

Station.

3. Using tie-wraps or a similar strapping material, secure the

Base Station (through the mounting flanges) to a post or frame.

Tighten and adjust as needed to assure a secure installation.

Figure 16. Post or Forklift Mounting

1

30

1. Tie Wraps

PowerScan

™ RF

Scanner

Page 35

RF Programmable Features

Use the special programming bar codes contained in this section to set

features that are unique to RF models of PowerScan™ bar code scanners. To program other features that a re common to a ll models, use on e

of the following:

- Configurator Express™ On-Screen Programming Kit

- PowerScan

NOTE

Programming features included in this manual are:

• Interface (I/F) Selection

• RF Beeper Settings

• Radio Transmit Power

• RF Channel Selection

• Transmission Retries Before Message Time-out

• Wait Time for ACK

• Wait Time For Scanner Power Shutdown

• Wait Time Between Retries of Failed Transmission

• HACK Transmit Opt ions

• Wait Time For HACK From Host

• Drop Links on Reset Option

™ Programming Guide

References

See

about how to obtain kits, software and manuals for

this product.

on page 1 for more information

• Drop Oldest Links Option

• Common Configuration

• Set Maximum Linked Scanners

• Source-Radio Identification (ID)

• Low Battery LED Indication

Systems Manual

31

Page 36

Programming

Overview

The RF system's programmable feature settings can be modified to

accommodate your unique requirements. Listed below are the various

methods to configure scanner and Base Station units:

Base Stations and the scanners linked to them m ust

possess compatible configuration files.

NOTE

Scanner

1. The Base Station’s configuration files can be automatically

downloaded to the scanner at the time of linking. See the sections, Linking the Scanner to a Base Station and Commo n Configu-

ration for more details.

2. The easiest, most comprehensive way to program the scanner

is to use the Configurator Express™ On-Screen Programming

Kit. See References for more information about this product.

3. The scanner can be configured using special programming bar

codes like those contained in this section. For the most part, the

programming instructions and bar codes on the following

pages address this method of scanner configuration.

32

NOTE

If you program the scanner using any of the

methods above, the scanner will store the changes

until reprogrammed or returned to factory defaults.

PowerScan

™ RF

Scanner

Page 37

Base Station

Base Station configuration is primarily performed by first programming a scanner with the desired options, then downloading the configuration to the Base Station from that scanner.

Verify that the scanner and Base Station host interface types (RS-232, Keyboard Wedge, etc.) are

matched before attempting to download any configuration files or perform any custom programming

CAUTION

Use the bar code below to overwrite a Base Station’s configuration file.

CAUTION

sessions. Go to Interface (I/F) selection on page x

and set the scanner to the Base Station’s I/F type.

After the Base Station receives the entire configuration, it will drop all links to scanners other than the

scanner transmitting the new configuration. This

will require the user to relink all other scanners (see

Linking the Scanner to a Base Station

time of relinking, it is advisable to consider

enabling the feature,

ensuring that the Base Station will attempt to share

the new configuration with scanners as they are

linked.

Common Configuration

). Prior to th e

,

Transmit Scanner

Configuration to Base

Station ---------

What Is

Programming

Mode?

The scanner must be placed into the Program ming Mode state in o r d er

to accept programming commands. When programming using the bar

code labels in this manual, the scanner is placed in Programming Mode

by scanning the "SET" label at the top of most programming feature

pages.

While in Programming Mode, the scanner only recogn izes special programming bar codes. See the section, LED and Beeper Indications for

information about scanner in di cations while in Programming Mode.

Systems Manual

33

Page 38

The

Programming

Session

Scanner programming allows you to customize the scanner’s configuration to match your specific needs. A typical programming session is

conducted as follows:

1. Scan the SET bar code at the top of the page. The scanner will

emit one beep, indicating it has r ead the bar code and the green

LED will flash on and off slowly while the scanner remains in

Programming Mode. Normal scanning functions are disabled.

2. Scan the programming bar codes(s) to make the desired

changes. With few exceptions, the scanner will emit a triple

beep each time you scan a valid programming bar code..

Not all features are available for all interfaces. The

scanner will sound an error tone when scanning

programming bar codes for features that cannot be

used with the currently active interface. Only fea-

NOTE

NOTE

tures supported by the currently active interface

will be implemented.

If you are enabling a differ ent in terface (I/F), we suggest/recommend that you change the I/F designation first and then proceed with other changes.

Once a bar code is scanned that changes the scanner's I/F, all previous I/F configuration items

scanned in the programming session are lost.

34

3. Scan the END label at the bottom of the page to save any new

settings and exit Programming Mode. The scanner will sound

a beep and reset upon exiting Programming Mode, and the

green LED will return to its usual state (on steady or off).

The scanner will not exit Programming Mode unless the END

bar code is scanned or the scanner’s battery is removed.

Removing power during Programming Mode, before scanning

the END label, will cause all new settings to be ignored. On

power-up, the scanner will return to previous settings.

PowerScan

™ RF

Scanner

Page 39

4. Maintain a record of all changes made to ensure that you

know if the original factory settings have been changed. Use

the following table to log your custom configuration changes.

RF

Programmable

Feature

RF When to Beep Option 7

RF Beeper Volume Vol 3

RF Beeper Frequency High

RF Beep Duration 50ms

Radio Transmit Power High

RF Channel Selection Channel 1

Transmission Retries

Before Message Time-

out

Wait Time for ACK 200ms

Wait Time for Scanner

Power Shutdown

Wait Time Between

Retries of Failed Trans-

mission

Factory

Default

Setting

3 Retries

1 Second

90ms

Your

Setting

Comment

HACK upon

HACK Transmit Options

Wait Time for HACK

From Host

Drop Links on Reset

Option

Drop Oldest Links

Option

Base Station

transmission to

host

1 Second

Disable

Enable

Systems Manual

35

Page 40

Common Configuration Disable

Programming

Sequence

Set Maximum Linked

Scanners

Source-Radio Identifi-

cation (ID)

Low Battery LED Indi-

cation

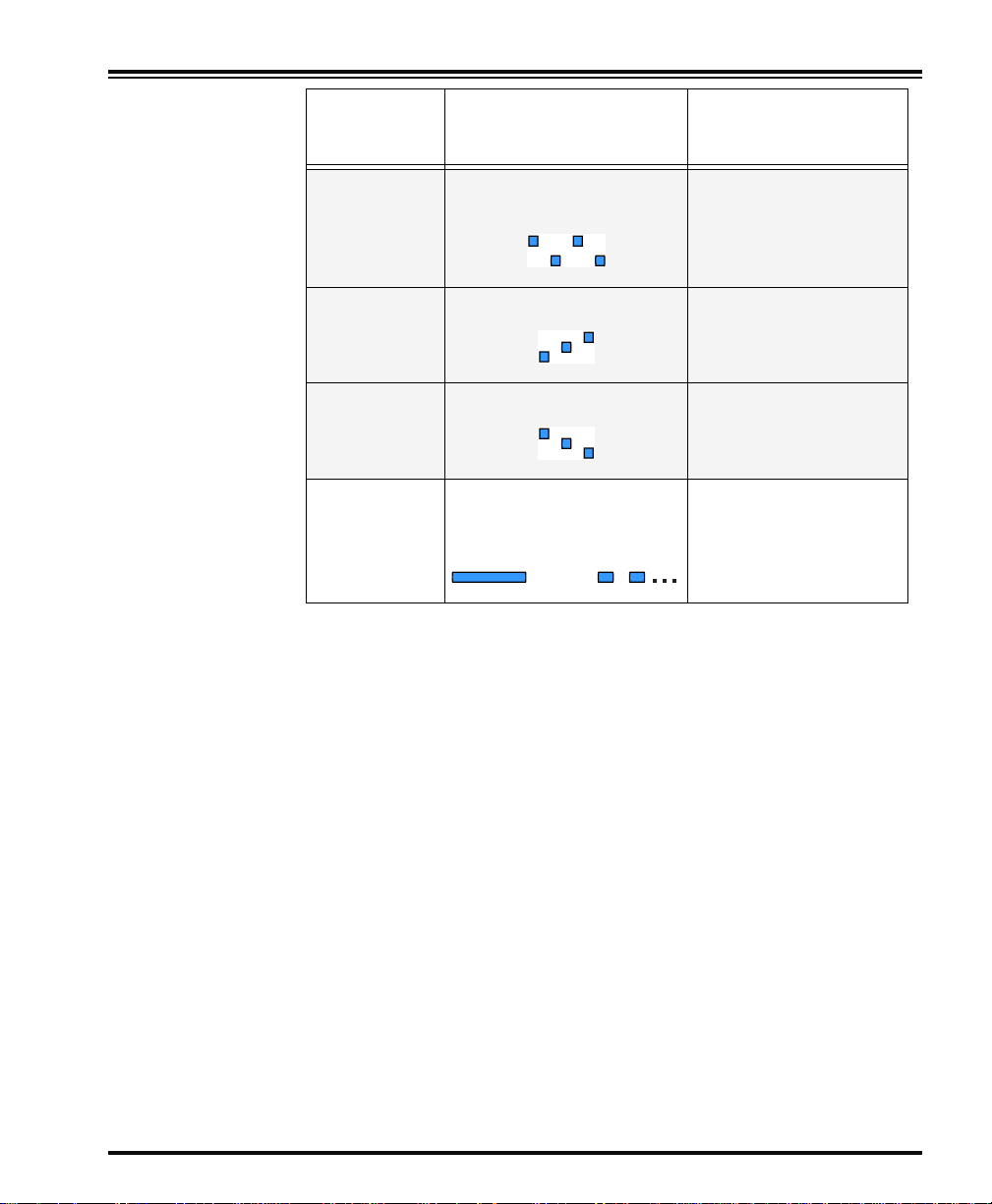

To modify a scanner feature (item), the programming bar codes contained in this manual must be scanned in a given sequence depending

upon the feature being programmed (as shown in Table 5). There are

three possible programming sequences:

A. Programming sa mple A (the most commonly used format)

demonstrates how three bar codes are scanned in sequence to

do the following:

1. Place the scanner in Programming Mode (SET bar code).

2. Scan the Item Tag

3. End the programming session and reset the scanner (END

bar code).

B. Sample B provides an example of a programming feature

requiring the entry of a range value. Like sample A, the scanner is placed in Programming Mode and an Item Tag

scanned. Then, a value must be entered before ending the programming session. In the example, three digits must be

scanned from the number pad in Appendix B. This type of format, requiring a total of as many as six programming bar

codes, is necessary to allow flexible programming with larger

item value numeric ranges.

8

Don’t Include

Enable

1

that will enable the new feature.

1

is

36

C. The programming sequence shown in example C requires

scanning of a single, extended length bar code. This special

programming bar code contains all the data necessary to enter

Programming Mode, set the Item T ag

Programming Mode (all in one step).

1. An “Item Tag” is a term used to describe an assigned number, which is encoded in a programming

bar code, that toggles (selects, enables, disables, etc.) a specific programming feature.

1

and Item V alue, and exit

PowerScan

™ RF

Scanner

Page 41

Table 5. Programming Sequence

A

B

C

SET

1

SET

ITEM T AG ITEM VALUE END/RESET

23

ENABLE

NEW FEATURE

END

123456

0

ENABLE NEW

FEATURE

USING THE

FOLLOWING

SET END

SETTINGS...

0

8

1

ONE BAR CODE CONTAINS SET + ITEM TAG + ITEM VALUE + END

Systems Manual

37

Page 42

Scanner vs .

Base Station

Features

Some programming features are specific to either the scanner (handheld unit) or the Base Station, while others are applicable to both. Each

feature in this manual is marked with an indicator as to which unit(s) it

is applicable.

Feature is specific to scanner ONLY

Feature is specific to Base Station ONLY

NOTE

Feature is applicable to scanner

When programming using bar codes via the scanner, it is important to remember that features affecting the Base Station WILL NOT be enabled until the

new configuration is downloaded to the Base Station using the feature

tion to Base Station

and

Base Station.

Transmit Scanner Configura-

on page 33.

38

PowerScan

™ RF

Scanner

Page 43

Interface (I/F)

Selection

It is very important that the scanner and Base Station are each configured to operate with the same interface (I/F) type as the host terminal.

The Base Station uses a “smart” cable, which automatically sets the Base Station to the correct I/F

upon power-up and connection to the appropriate

NOTE

SET ------------ ----------------------- --------

Enable Wand Emulation ---------

Enable Standard

RS-232 ---------

Enable Wincor Nixdorf

RS-232 ---------

host.

Enable IBM Port 5B ---------

Enable IBM Port 9B ---------

Enable IBM Port 17 ---------

Enable IBM Port E ---------

Systems Manual

39

Page 44

Enable Keyboard Wedge

a

Type A

Enable Keyboard Wedge

Type B ---------

Enable Keyboard Wedge

Type C ---------

Enable Keyboard Wedge

Type D ---------

Enable Keyboard Wedge

Type E ---------

Enable Keyboard Wedge

Type F ---------

Enable Keyboard Wedge

Type G ---------

---------

40

Enable Keyboard Wedge

Type H ---------

Enable Keyboard Wedge

Type I ---------

Enable Keyboard Wedge

Type J ---------

END ------------------------------------------

a. See Table 6 for the specific interfaces supported by each of the keyboard

types listed above. See the following section Universal Wedge Terminal

Selection to enable that interface type.

PowerScan

™ RF

Scanner

Page 45

Ta ble 6. Keyboard Wedge I/F Selection

I/F Type PCs Supported

A PC/XT w/Alternate Key Encoding

B

C PS/2 25 and 30 w/Alternate Key Encoding

D PC/XT w/Standard Key Encoding

E

F PS/2 25 and 30 w/Standard Key Encoding

G IBM 3xxx w/122 keyboard

H IBM 3xxx w/102 keyboard

I PS/55 5530T w/104 keyboard

J NEC 9801

AT, PS/2 25-286, 30-286, 50, 50Z, 60, 70, 80, 90 & 95

w/Alternate Key Encoding

AT, PS/2 25-286, 30-286, 50, 50Z, 60, 70, 80, 90 & 95

w/Standard Key Encoding

Systems Manual

41

Page 46

Universal

Wedge

T ermi nal

Selection

To activate the Universal Wedg e interface, follow these instructions:

1. Scan the START bar code.

2. Determine the I.D. of the terminal/keyboard. Refer to the Ter-

minal/Keyboard Settings section below for more information

plus a listing of the most common keyboard I.D.s.

3. Scan the Activate Universal Wedge Interface bar code.

4. Use the Universal W edge Nu mber P ad to scan in the digits for the

keyboard I.D. number you determined in step 2.

5. Scan the END bar code.

START----------------------------------------

Activate Universal Wedge

Interface ---------

Scan the digit(s) representing the desired key board I/F type using

the

Universal Wedge Number Pad

, then scan the END bar code.

42

Terminal/

Keyboard

Settings

END ------------------------------------------

The list below contains the most common terminal/keyboard types. If

your specific system is not listed below, consult the Universal Keyboard Wedge Connectivity Guide for a detailed listing of terminal/

keyboard types. A copy of the guide can be obtained from the internet

at www.pscnet.com, or call your dealer for customer support informa-

tion.

Keyboar d T er minal I.D.

High Speed PC/AT, PS2 591

PC AT, PS2 11

MAC 25

PowerScan

™ RF

Scanner

Page 47

Universal

Wedge Number

Pad

The default communication mode (factory settings) is Keyboard Wedge

of PC AT (keyboard I.D. 11). Use the codes on this page to select the

I. D. corresponding to your computer or terminal (reference the Universal Keyboard Wedge Connectivity Guide for this product or call

PSC Customer Support).

0

→

1

→

2

→

3

→

4

→

5

→

6

→

7

→

8

→

9

→

Systems Manual

43

Page 48

RF Beeper

Settings

The RF version of the scanner exhibits different beeper behavior than

standard (non-RF) models. For more information about RF beeper indications, see the section, LED and Beeper Indications.

The following descriptions highlight configurable

beeper functions that are unique to RF handheld

scanners. All other beeper functions supported by

NOTE

Good Read Beep — When good read beep is enabled, this beep sounds

at the time the scanner successfully reads a bar code. Selectable settings

for the good read beep include:

• RF When to Beep

• Beeper Volume

• Good Read Beep Frequency

• Beep Duration

ACK Beep — The scanner can sound an acknowledgement (ACK)

beep to indicate when the Base Station has acknowledged to the scanner that is has received a successful data transmission from the scanner.

This beep is also sounded upon a successful channel change sequence

or a successful configuration transmission.

the standard version of the scanner are supported

by RF models.

44

Transmission Error Beep — Another selectable indicator beep is the

transmission error beep. This beep sounds to indicate an error in transmission between the RF devices.

Link Beep — The handheld scanner will sound a special link beep

upon successfully linking with a Base Station. This indication cannot be

disabled and is not programmable, other than that it shares the same

Beeper Volume setting as other beeper indications set using that feature.

Unlink Beep — When a scanner is successfully unlinked from a Base

Station, a unique unlink beep is sounded. This beep is not programmable, and also sounds at the same volume set for Beeper Volume.

PowerScan

™ RF

Scanner

Page 49

RF When to

Beep

Feature is specific to scanner ONLY

Several options are available to specify how the RF handheld scanner

will beep to indicate a good read. Settings are based on the enable/disable status desired for three selectable beep indications:

• Good Read Beep

• Acknowledgement (ACK) Beep

• Transmission Error Beep

The available options are described and numbered in Table 7 to correspond with the programming bar codes provided for this feature.

These settings supersede any settings made using

the generic "When to Beep" feature listed in the

PowerScan Programming Manual.

NOTE

Table 7. RF When to Beep Options

#

0 Disabled Disabled Disabled

1

2

3

4

5

6

7

Good Read

Beep

Disabled Disabled Enabled

Disabled Enabled Disabled

Disabled Enabled Enabled

Enabled Disabled Disabled

Enabled Disabled Enabled

Enabled Enabled Disabled

Enabled Enabled Enabled

ACK Beep

Transmission Erro r

Systems Manual

Beep

45

Page 50

RF When to

Beep Options

(continued)

SET ------------ ----------------------- --------

When to Beep

Option #0 ---------

When to Beep

Option #1 ---------

When to Beep

Option #2 ---------

When to Beep

Option #3 ---------

When to Beep

Option #4 ---------

46

When to Beep

Option #5 ---------

When to Beep

Option #6 ---------

When to Beep

Option #7 ---------

END ------------------------------------------

PowerScan

™ RF

Scanner

Page 51

RF Beeper

Volume

Feature is specific to scanner ONLY

The volume at which the beeper sounds for ACK, transmission error,

link, or unlink beeps (but not the good read beep

1

) are all affected by

this setting. Select volume #1 (25% duty cycle), volume #2 (35% duty

cycle), or volume #3 (50% duty cycle).

SET ------------ ----------------------- --------

RF Beeper Volume #1 ---------

RF Beeper Volume #2 ---------

RF Beeper Volume #3 ---------

END ------------------------------------------

1. Good read beep volume is selectable via the features available in the PowerScan Programming

Manual (P/N R44-1840). See

References

for information about acquiring other manuals.

Systems Manual

47

Page 52

RF Beeper Frequency

Feature is specific to scanner ONLY

This setting affects the frequency at which the ACK beep is sounded,

and is independent of the frequency setting for the good read beep.

When the ACK beep is sounded at a different frequency than the good

read beep, this can provide a clearer distinction between the tones.

Select low frequency (760Hz), medium fr equency (1250Hz), o r high fr equency (2400Hz).

SET ------------ ----------------------- --------

RF Beeper Low

Frequency ---------

RF Beeper Medium

Frequency ---------

48

RF Beeper High

Frequency ---------

END ------------------------------------------

PowerScan

™ RF

Scanner

Page 53

RF Beep Duration

Feature is specific to scanner ONLY

The duration of time that an ACK beep is sounded is selectable using

this setting. RF beep duration can be set in increments of 10 ms (tolerance of +/- 10%) from 0 to 2.55 seconds.

SET ------------ ----------------------- --------

Set RF Beep Duration ---------

Scan three digits representing the desired duration using the

Number Pad in Appendix B, padded with leading zeros (example:

008 = 80ms, 025 = 250ms, 100 = 1 second, etc.), then scan the

END bar code.

END ------------------------------------------

Systems Manual

49

Page 54

Radio Transmit

Power

Feature is applicable to scanner

Remember, programming changes to the Base Station have no effect until the new configuration is

downloaded via the feature

NOTE

The power level at which the radio signal is transmitted between the

devices is selectable to be either low or high. This setting allows adjustment to a low setting to minimize potential radio interference caused

by communication between the devices, or provides a high setting to

increase the signal power which would enable clearer communication

over longer distances.

SET ------------ ----------------------- --------

Radio Transmit Power

= Low ---------

figuration to Base Station

and

Base Station.

Transmit Scanner Con-

on page 33.

50

Radio Transmit Power

= High ---------

END ------------------------------------------

PowerScan

™ RF

Scanner

Page 55

RF Chann e l

Selection

Feature is applicable to scanner

Channel selection bar codes are of the type C programming sequence category (see

Sequence

NOTE

Radio communications between the handheld scann er an d its linked

Base Station can be carried over one of ten different allowable frequencies (channels). Select alternate channels to improve communications

between devices in noisy RF environments.

NOTE

When a new channel is selected, the scanner sends a change-o f-channel

message to the Base Station. After the Base Station has acknowledged

receipt of the message, both the scanner and the Base Station switch

their radio channels to the new channel (reference LED and Beeper Indi -

cations for information regarding scanner and Base Station acknowledgement signals at this point). All further communication is done on

the new channel.

scan accompanying SET or END bar codes.

Available channel frequencies will vary according

to the country/model of the scanner.

on page 36), and do not require you to

and

Base Station.

Programming

Any other scanner that happens to be linked to that

Base Station will be unable to communicate with

the Base Station until it has switched to the new

channel. To accomplish this, scan the Base ID label

NOTE

with each scanner you desire to be linked to the

Base Station. This action will automatically set each

scanner to the correct new channel.

Systems Manual

51

Page 56

Select Radio Channel

0 ---------

Select Radio Channel

1 ---------

Select Radio Channel

2 ---------

Select Radio Channel

3 ---------

Select Radio Channel

4 ---------

Select Radio Channel

5 ---------

52

Select Radio Channel

6 ---------

Select Radio Channel

7 ---------

Select Radio Channel

8 ---------

Select Radio Channel

9 ---------

PowerScan

™ RF

Scanner

Page 57

Transmission

Retries Before

Message Ti me-

out

Feature is applicable to scanner

Remember, programming changes to the Base Station have no effect until the new configuration is

downloaded via the feature

NOTE

When the scanner attempts to transmit data to the Base Station, communication may not always occur on the first try due to interference,

signals from other scanners in the queue, etc.. This setting defines the

number of transmission retries the scanner/Base Station will attempt

before the message gives up tryng to successfully resend/transmit the

message (times out). If the specified retry count is exceeded, the scanner will sound a transmission error beep (when transmission error

beep is enabled).

In a noisy RF environment, a large number of retries may allow a transmission to get through to the Base Station, but at the cost o f increased

time-out (should the transmissi on fail). To maximize battery life, set

this feature to the lowest optimal number of retries.

figuration to Base Station

and

Base Station.

Transmit Scanner Con-

on page 33.

Selectable range for this setting is 0-15 retries.

SET ------------ ----------------------- --------

0 Retries ---------

1 Retry ---------

Systems Manual

53

Page 58

2 Retries ---------

3 Retries

(recommended) ---------

4 Retries ---------

5 Retries ---------

6 Retries ---------

54

7 Retries ---------

8 Retries ---------

9 Retries ---------

PowerScan

™ RF

Scanner

Page 59

10 Retries ---------

11 Retries ---------

12 Retries ---------

13 Retries ---------

14 Retries ---------

15 Retries ---------

END ------------------------------------------

Systems Manual

55

Page 60

Wait Time for

ACK

Feature is applicable to scanner

Remember, programming changes to the Base Station have no effect until the new configuration is

downloaded via the feature

NOTE

This setting defines a time period allowed once the scanner has sent

data to the Base Station for that Base Station to send an acknowledgement (ACK) back to the scanner, signalling receipt of the data. This feature is used to streamline the scanning speed of your system.

The range for this delay is 0.08 - 2.55 seconds in 10ms increments.

NOTE

SET ------------ ----------------------- --------

figuration to Base Station

Selecting longer values for this feature will

decrease the battery life between charges.

and

Base Station.

Transmit Scanner Con-

on page 33.

56

Set Wai t Time for ACK ---------

Scan three digits representing the desired delay using the Number Pad in Appendix B. Be sure the number is padded with leading zeros (example: 008 = 80ms, 025 = 250ms, 100 = 1 second,

etc.), then scan the END bar code.

END ------------------------------------------

PowerScan

™ RF

Scanner

Page 61

Wait Time For

Scanner Power

Shutdown

Feature is specific to scanner ONLY

To conserve battery life, the handheld scanner can be automatically

shut down when it has not been in use for a given period. A trigger

pull or other stimulus will then be required to reactivate the scanner.

The idle duration determines how long the scanner stays on/active

after each use. Range for this feature is a setting of 1 to 120 seconds in

one-second increments. A setting of one second is recommended.

Selecting higher values for this feature will effect

the length of battery life.

NOTE

SET ------------ ----------------------- --------

Set Wait Time for Scanner

Power Shutdown ---------

Scan three digits representing the desired delay using the Number Pad in Appendix B. Be sure the number is padded with leading zeros (example: 001 = 1 second, 025 = 25 seconds, 100 = 100

seconds, etc.), then scan the END bar code.

END ------------------------------------------

Systems Manual

57

Page 62

Wait Time

Between

Retries of

Failed

Transmission

Feature is applicable to scanner

Remember, programming changes to the Base Station have no effect until the new configuration is

downloaded via the feature

NOTE

In conjunction with the previous feature, TRANSMISSION RETRIES

BEFORE MESSAGE TIME-OUT, this feature defines the duration of

time the system must wait before re-trying a transmission of data

between the scanner and the Base Station. Consideration for this setting would be to ensure that enough time elapses between tries to

avoid encountering the source of the origin al transmission conflict,

while being short enough to avoid causing a substantial increase in the

time required to successfully transmit the message.

Wait range can be set from 5ms to 255ms in one-millisecond in crements, and is multiplied by the amount of retries selected via the feature, TRANSMISSION RETRIES BEFORE MESSAGE TIME-OUT

(TRBMTO) to determine the total duration. For example if this feature

(WAIT TIME BETWEEN RETRIES OF FAILED TRANSMISSION) is

selected to be 80 ms, and TRBMTO feature is selected to be 3, the r esulting total duration between retries would be 80 x 3, or 240ms total.

figuration to Base Station

and

Base Station.

Transmit Scanner Con-

on page 33.

58

PowerScan

™ RF

Scanner

Page 63

SET ------------ ----------------------- --------

Set Wait Time Between Retries

of Failed Transmission ---------

Scan three digits representing the desired delay using the Number Pad in Appendix B. Be sure the number is padded with leading zeros (example: 005 = 5ms, 065 = 65ms, 250 = 250ms, etc.),

then scan the END bar code.

END ------------------------------------------

Systems Manual

59

Page 64

HACK Transmit

Options

Feature is applicable to scanner

Remember, programming changes to the Base Station have no effect until the new configuration is

downloaded via the feature

NOTE

A Host Acknowledgement (HACK) message is a signal sent to the

scanner via the Base Station indicating the host has received bar code

data previously transmitted by that scanner. This feature determines

when the Base Station should send the HACK to the scanner. Choices

are:

• Send HACK as soon as the Base Station receives the scanner’s

transmission. This option is recommended for in stallations

where multiple scanners are linked to one Base Station.

• Send HACK as soon as the Base Station completes trans mis-

sion to the host. This option is recommended for installations

where only a single scanner is linked to one Base Station.

• Send HACK after the host transitions the CTS line from inac-

tive to activate (using CTS scan control). RS-232 ONLY.

• Send HACK after host returns ACK to Base Station. RS-232

with ACK/NAK turned on ONLY.

figuration to Base Station

and

Base Station.

Transmit Scanner Con-

on page 33.

60

PowerScan

™ RF

Scanner

Page 65

SET ------------ ----------------------- --------

HACK upon receipt of scanner

transmission ---------

HACK upon Base Station