Page 1

WARNING

Read this entire installation manual to ensure proper installation, then file

these instructions with the owner or maintenance department.

Flush all the water supply lines before making connections, then make

sure the water supply is turned off before beginning installation.

Do not use pipe dope on faucet and supply connections. Possible

solenoid contamination could occur and will void any warranty. Teflon

tape is the recommended sealant. Use plumber’s putty only to seal the

faucet to the deck.

The installation site should have access to an electrical box with 120 volt

AC, 60 Hz cycle for input to a transformer. When installing the transformer,

the electrical box should be located within six feet of the sink.

The DC faucets are powered by four “AA” factory-installed alkaline

batteries.

Product warranties may be found under “Product Information” on our web

site at www.bradleycorp.com.

Compliance and conformity to local codes and ordinances is the

responsibility of the installer.

Aerada 1000 Series

Gooseneck Faucet

Installation

Instructions

215-1559 Rev. A; EN 04-216A

© 2004 Bradley Corporation

Page 1 of 8 9/23/04

P.O. Box 309, Menomonee Falls, WI 53052-0309

Phone: 1-800-BRADLEY FAX: (262) 251-5817

http://www.bradleycorp.com

S53-306 DC Gooseneck with Centershank

S53-307 DC Gooseneck with 4" Trimplate

S53-308 AC Gooseneck with Centershank

S53-309 AC Gooseneck with 4" Trimplate

232-007 Plug-In Transformer for AC Gooseneck

Page 2

Table of Contents

Faucet Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Supplies Required for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Installation Information

Installing Single Hole and Cover Plate . . . . . . . . . . . . . . . . . . . . . . . . 3

Installing Solenoid Valves and Electronic Box (AC) . . . . . . . . . . . . . .4

Installing Electronic Battery Box (DC) . . . . . . . . . . . . . . . . . . . . . . . .5

Maintenance Information

Changing Faucet Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Faucet Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7–8

Aerada 1000 Series Gooseneck Faucet Installation Instructions

2 9/23/04 Bradley Corporation • 215-1559 Rev. A; EN 04-216A

Supplies Required for Installation:

• Teflon Tape

• Plumber’s Putty (for securing faucet to deck ONLY)

• 1/2" NPT water inlet supply

• Pipe fittings

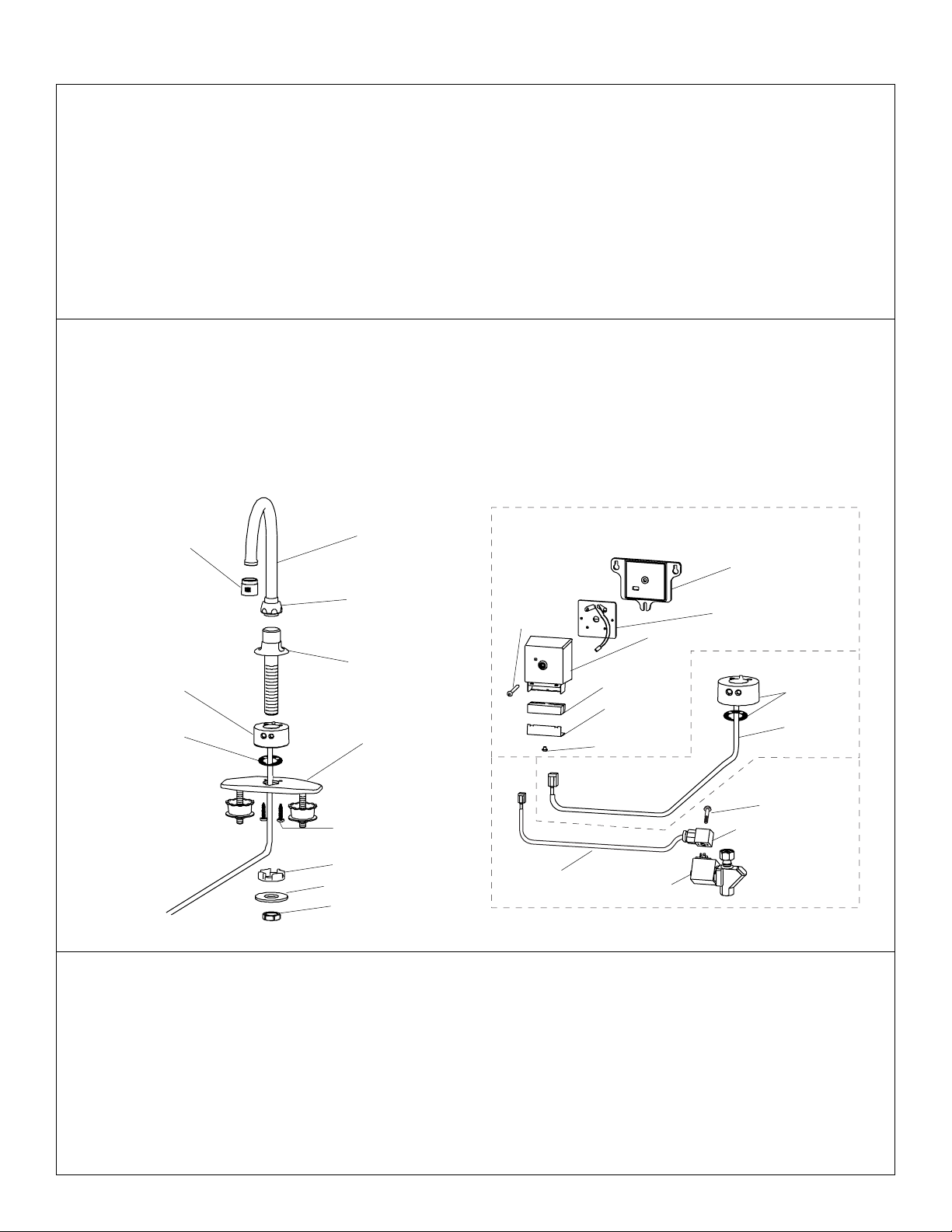

Components for Aerada 1000 Series Faucet

Carefully separate all parts from packaging and check each part with the illustrations below. Make

sure all parts are accounted for before discarding any packaging material. If any parts are missing,

do not attempt to install your Bradley Faucet until you obtain the missing parts.

1000 Series Faucet (shown w/cover plate)

Spout

Vandal-Resistant

Aerator

(269-1817)

Spout Nut

Spout Shank

4" Cover Plate

(optional)

Sensor Collar

Collar Gasket

Screw

Stilt Washer

Shank Washer

Locking Nut

Electronic Box and Solenoid

Baseplate

Partition Assembly

Electronics Cover

Screw

Screw

Screw

Foam Gasket

Collar &

Gasket

Outer Strain

Relief Bracket

Solenoid

DIN Connector

Cable

(Collar Assembly)

Cable

(Solenoid

Assembly)

269-1809-AC (shown), 269-1810-DC (w/Batteries)

269-1813

269-1808

Page 3

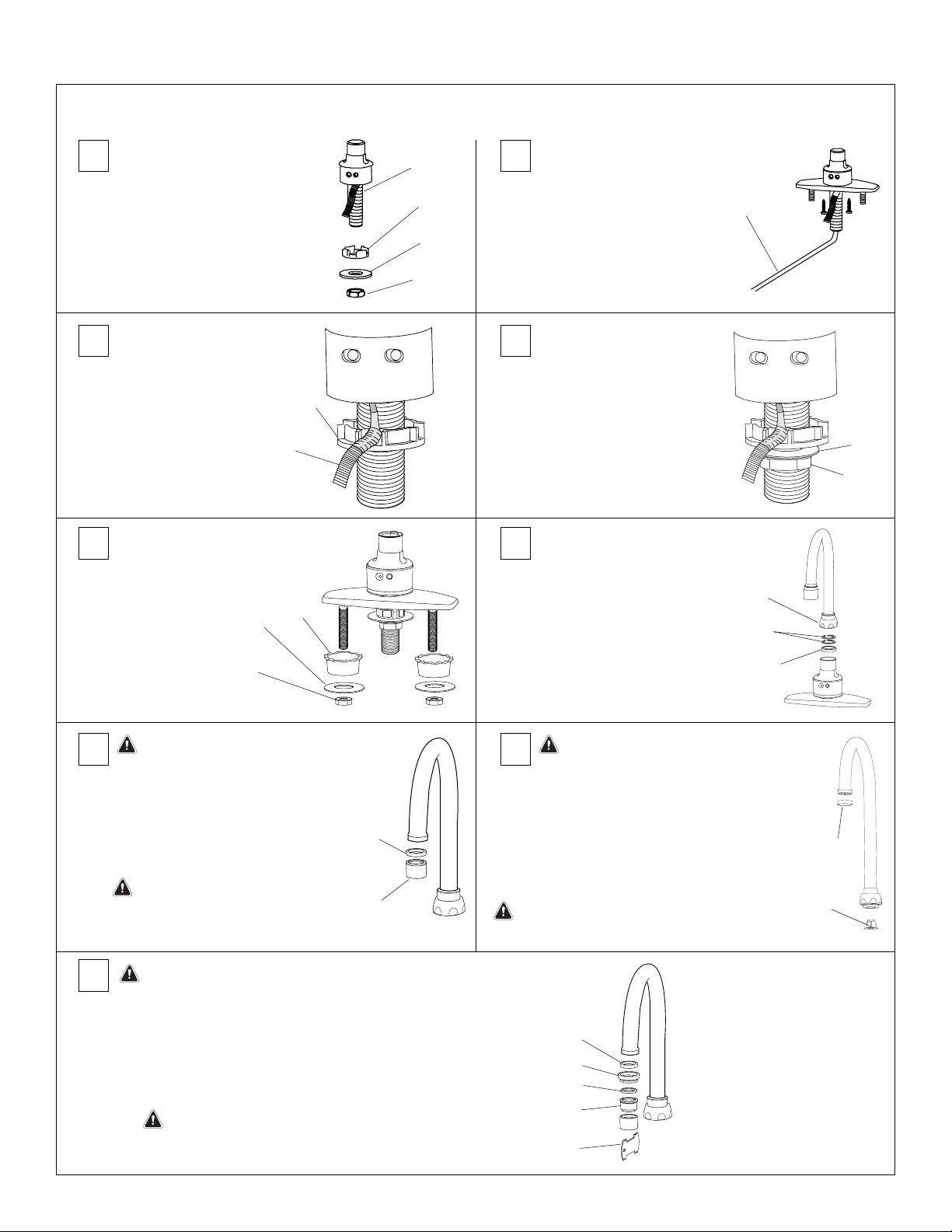

Installation Instructions - Single Hole and Cover Plate

3

Installation Instructions Aerada 1000 Series Gooseneck Faucet

Bradley Corporation • 215-1559 Rev. A; EN 04-216A 9/23/04

1 2

3 4

7a

5 6

8

Remove the locknut (1), washer

(2), stilt washer (3) from the

spout shank (4). Remove shank

from cover plate (if supplied).

Install stilt washer (1) all

the way up onto shank,

crown side up. Position

sensor cable (2) through

one of the rounded slots

in the stilt washer (1).

If faucet was installed with

cover plate, secure cover plate

with basin washers (1), flat

washers (2) and locknuts (3).

Install the shank washer (1)

and locknut (2) onto faucet

shank. Tighten locknut

securely to prevent collar and

spout from rotating. If

necessary, support spout base

from above to prevent twisting.

Install spout nut (1) onto the

spout.

For swivel mount, only install

two plastic split washers (2).

For rigid mount, only install

1/8" thick plastic washer (3).

Mount the spout completely

into the base and securely

tighten the spout nut (1).

Attach the outlet assembly (1) and aerator

gasket (2) to the spout. The outlet assembly

is equipped from the factory with a 0.5 GPM

cartridge (white screen). To configure the

outlet with the 2.2 GPM cartridge (yellow

screen) refer to step 8.

IMPORTANT: If 0.5 GPM spout is to

be used, skip Step 8 and proceed

directly to

Installation - Solenoid

and Optional Valves, page 4.

To convert outlet assembly to 2.2 GPM:

1. Disassemble outlet assembly using key (1).

2. Remove the 0.5 GPM cartridge (white screen) and replace it with the

2.2 GPM cartridge (2).

3. Install the rubber washer (3), adapter (4) and aerator gasket (5).

IMPORTANT: Proceed directly to

Installation - Solenoid and

Optional Valves, page 4.

Install faucet assembly

into deck hole.

Use plumbers putty

to seal faucet to deck.

4

3

2

3

1

1

1

2

3

4

5

2

2

2

2

1

3

1

1

1

2

Be careful not to

nick or cut the

sensor cable during

installation.

CAUTION: Flush water lines

before beginning this step.

7b

Attach the plain spray ring (1) to the spout. Insert

the laminar flow control insert (2) into the spout.

IMPORTANT: If laminar flow is to be used,

skip Step 8 and proceed directly to

Solenoid and Optional Valves, page 4.

1

(269-1814)

IMPORTANT: Flow rates exceeding the

0.5 GPM maximum limit for public

lavatories set by ASME A112.18.1

negate the UPC certification of this

faucet for public use applications.

For applications requiring laminar

flow without an aerator, refer to the

instructions below.

2

(269-1815)

IMPORTANT: Flow rates exceeding the 0.5 GPM maximum limit

for public lavatories set by ASME A112.18.1 negate the UPC

certification of this faucet for public use applications.

Page 4

Aerada 1000 Series Gooseneck Faucet Installation Instructions

4 9/23/04 Bradley Corporation • 215-1559 Rev. A; EN 04-216A

Installation Instructions - Solenoid Valves and Electronic Box (AC)

Models S53-308 and S53-309

1

Thread the union nut (1) of the solenoid assembly to the

faucet shank (2). Use Teflon tape on the threads to

ensure a leak-free joint. Make sure the solenoid is

positioned for easy access. Tighten the union nut.

1

2

CAUTION:

Do not use pipe

dope on threads.

The solenoid could

become

contaminated and

will void any

warranty.

2

When installing the transformer, make sure the electrical box

is located within 6' of the sink. Install the baseplate and mount

the electronic box to the desired wall location. The baseplate

must be mounted either level with or above the solenoid

valve, and within 12" of the solenoid valve. Make sure the

transformer wires (1) are positioned in the baseplate channel

(2) before mounting the unit.

1

2

NOTE: When

positioning baseplate,

make sure there is

enough room for drip

loops in final

installation. See Note in

step 7.

3

Remove the strain relief

cover and screw (1)

using hex key provided

(2). Remove both foam

gaskets (3). Separate

the foam gaskets at the

perforation.

1

3

2

CAUTION:

Do not attempt to operate multiple

faucets using a single transformer.

4

Insert smaller foam gasket (3) into strain relief. Install

solenoid cable plug (1) into the smaller, telephone-style

jack in the electronic box. Install faucet sensor cable plug

(2) into the larger RJ-45 jack.

1

3

2

5

Insert larger foam gasket (1). Attach strain relief cover (2)

with screw (3) using hex key provided (4).

1

2

4

3

6

CAUTION:

Faucet will automatically calibrate when sensor

cable is connected and power is supplied. DO

NOT place objects in front of collar sensor for

first 30 seconds after power-up.

Feed the wires from the transformer through the baseplate.

Connect the 1/4" spade terminal to the positive (+) terminal

and connect the 3/16" spade terminal to the negative (-)

terminal. Terminals are two different sizes and match

corresponding terminal clips from transformer.

NOTE: The faucet will

automatically calibrate when

sensor cable is connected

and power is supplied.

Refer to step 8.

7

NOTE: To ensure the

electronic box is level

with or above the

solenoid valve, the

cables should create a

drip loop. The

electronic box is

designed with the wire

connectors facing

downward to ensure

proper drip loops.

2

1

Re-attach the electronic box to the baseplate location

using screw(1) and hex key provided (2).

8

CAUTION: DO NOT turn on water supply

until all electrical connections

are made.

Plug the transformer into the applicable electrical receptacle.

Wait at least 30 seconds, then turn on the water supply.

NOTE: When power is initially supplied, the LED on the electronic

box will blink and an audible indicator chirps twice per second

whenever hand presence is detected. This will continue for 8

minutes and then stop.

Proceed to Faucet Operation, page 6.

Page 5

Installation Instructions - Electronic Battery Box (DC)

Models S53-306 and S53-307

CAUTION: Faucet will automatically calibrate when

sensor cable is connected. DO NOT place

objects in front of collar sensor for first 30

seconds after power-up.

5

Installation Instructions Aerada 1000 Series Gooseneck Faucet

Bradley Corporation • 215-1559 Rev. A; EN 04-216A 9/23/04

1

Install the baseplate and mount the electronic box to the

desired wall location. The baseplate must be mounted either

level with or above solenoid valve, and within 12" of the

solenoid valve.

NOTE: When positioning

the baseplate, make sure

there is enough room for

drip loops in the final

installation. Refer to Note

in step 6.

2

Remove the strain relief cover and screw (1) using hex

key provided (2) . Remove foam gasket (3). Separate the

foam gasket at the perforation.

1

3

2

4

Insert larger foam gasket (1). Attach strain relief cover (2)

and screw (3) using hex key provided (4).

1

2

3

4

5

Mount the electronic box to the wall location using

screw(1) and hex key provided (2).

NOTE: To ensure the

electronic box is level

with or above the

solenoid valve, the cables

should create a drip loop

The electronic box is

designed with the wire

connectors facing

downward to ensure

proper drip loops.

1

2

3

Insert smaller foam gasket (3) into the strain relief. Install

solenoid cable plug (1) into the smaller, telephone-style

jack in the transformer. Install faucet sensor cable plug (2)

into the larger RJ-45 jack.

1

2

3

CAUTION: DO NOT turn on water supply until all

electrical connections are made.

6

Turn on the water supply.

NOTE: When power is initially supplied, the LED on the

electronic box will blink and an audible indicator chirps twice per

second whenever hand presence is detected. This will continue

for 8 minutes and then stop.

Proceed to Faucet Operation, page 6.

Page 6

Faucet Operation

Aerada 1000 Series Gooseneck Faucet Installation Instructions

6 9/23/04 Bradley Corporation • 215-1559 Rev. A; EN 04-216A

Changing Faucet Operation

In order to change any faucet option, the DIPswitch must be

used (located inside the electronics cover assembly, see

illustration this page).

Checking/Changing DIPswitch Settings

1. Remove the electronics cover (1) from the baseplate

(2).

2. Lift the partition (3) out to expose the circuit board and

DIPswitch.

3. To change a DIPswitch setting, use a small pointed

object to move the appropriate DIPswitch to ON or

OFF.

Faucet range and mode settings along with their

corresponding DIPswitch settings are outlined in Table 1 and

Table 2

Resetting Faucet Electronics

In order to reset the faucet electronics, a reset button located

inside the electronics cover assembly must be pushed in

(see illustration this page).

To reset faucet electronics:

1. Remove hex screw holding the electronics cover to the

baseplate and remove cover.

2. Lift the partition out to expose the circuit board and

reset button.

3. Make sure there are no objects in front of the collar

sensor, then push the button to reset.

4. Wait 30 seconds for faucet to automatically calibrate to

the environment.

5. Activate water flow by placing your hand in front of the

sensor.

6. Place partition into the electronics cover.

7. Place the electronics cover onto the baseplate and

secure with the hex screw.

NOTE: Resetting the faucet electronics causes loss of virtual

settings and time in use, and will also start the 8-minute

timer where the LED on the electronics box will blink and an

audible indicator chirps twice per second whenever hand

presence is detected.

ON

ON

OFF

OFF

1 2 3 4 5

1 2 3 4 5

MANUAL

RESET

BUTTON

DIPSWITCHES

Electronics Cover Assembly & DIPswitch

Range Short Normal Far Maximum

Switch 1 off on on off

Switch 2 off off on on

Table 1 - Faucet Range

Normal Scrub Meter Water Saver

Modes Mode Mode Mode Mode

Switch 3 off on off off

Switch 4 off off on off

Switch 5 off off off on

Table 2 - Faucet Mode

Operating Modes

• Normal Motion Detecting Mode: water flows within 1/4

second after activating sensor (i.e., putting hands in

front of collar) and continues to stay on as long as

motion is detected. Maximum time is 45 seconds

(factory default setting).

• Scrub Mode: water continues to flow for 60 seconds

(default) after deactivating the sensor (removing

hands).

• Metered Mode: water flows for 10 seconds (default)

from first hand detection.

• Water Saver Mode: water flows for a maximum of

5 seconds starting from first hand detection and

immediately turns off when hands are removed.

Additional Operating Features

• 12-second, no-motion turn off in normal mode

• “Low battery” indication

• Battery life up to one year depending on frequency

of use.

3

1

2

Page 7

7

Installation Instructions Aerada 1000 Series Gooseneck Faucet

Bradley Corporation • 215-1559 Rev. A; EN 04-216A 9/23/04

Troubleshooting

Whenever new batteries are installed, AC power is applied,

or a manual reset button is pressed, the LED on the

electronics cover will blink and an audible indicator chirps

twice per second whenever hand presence is detected.

After 8 minutes, the LED and buzzer function stops.

If an error occurs, the LED will blink and the buzzer will

sound every 30 seconds to assist in diagnosing the

problem. When corrective action is taken the LED and

buzzer will stop.

The following chart provides details concerning the number

of beeps and possible errors associated with them .

1 Beep: Indicates low battery.

2 Beeps: Calibration out of range (environment too

reflective).

3 Beeps: Room infrared level out of range; too much

sunlight, heat lamp present, etc.

4 Beeps: Solenoid short circuit.

5 Beeps: Solenoid unplugged or loose/broken solenoid

connection.

Refer to Troubleshooting Chart below and on page 8 for

further troubleshooting information.

Disassemble solenoid and inspect/clean parts.

Reduce pressure to under 80 PSI.

Change range setting using DIPswitch (page 6).

Turn on water supply.

Check connection.

Replace electronics cover.

Check connection.

Inspect collar wiring for signs of damage or corrosion.

Replace if necessary.

Replace cover assembly.

Reduce pressure to under 80 PSI.

Replace batteries (DC only).

Use correctly sized terminal clips (page 4).

Faucets must be wired in parallel from transformer

(transformer to each individual unit), not connected in

a series.

Remove interference; reset electronics using reset

button (page 6). Allow 30 seconds for faucet to

automatically re-calibrate.

Change range setting using DIPswitch (page 6).

Change range setting using DIPswitch (page 6).

Water runs continuously.

Faucet turns on by itself

(ghosting).

No water flow.

Debris in solenoid (no beeps).

Water pressure too high (no beeps).

Incorrect range setting for spout type and

sink used (2 beeps).

Water not turned on (no beeps).

Solenoid cable not connected to

electronics cover (5 beeps).

Solenoid short circuit (4 beeps).

Sensor cable not connected to electronics

cover (no beeps).

Inoperative sensor (no beeps).

Inoperative electronics cover assembly

(no beeps).

Water pressure too high (no beeps).

Low battery voltage (DC only) (1 beep).

6VDC transformer not properly connected

to partition assembly (no beeps).

Wiring of multiple unit 6VDC transformer

(no beeps).

Interference during automatic calibration

(no beeps).

Incorrect range setting for type of spout

and sink used.

Lighting environment affecting sensor

(3 beeps).

Problem Check Possible Solution

Range too short or too long.

Page 8

Aerada 1000 Series Gooseneck Faucet Installation Instructions

8 9/23/04 Bradley Corporation • 215-1559 Rev. A; EN 04-216A

Replace solenoid.

Change mode or range setting using DIPswitch (page 6).

Clean internal parts or replace solenoid valve.

Clean outlet.

Change mode setting using DIPswitch (page 6).

Electronics cover must be mounted to allow for drip loops

for the sensor and solenoid cables (pages 4 & 5).

Clean connector.

Reset electronics using reset button (page 6).

Clogged strainer. Clean if necessary.

Clean faucet outlet.

Replace batteries if below 4.2 volts.

Change range setting using DIPswitch (page 6).

Faucet works in reverse.

Faucet turns off too soon.

Faucet stays on longer than

normal.

Faucet stopped working.

Solenoid wiring on DIN connector

(no beeps).

Faucet operating mode (no beeps) or

faucet range setting.

Dirty solenoid valve (no beeps).

Clogged spout outlet.

Faucet in wrong mode (no beeps).

Mounting of electronics cover (no beeps).

Sensor cable connector.

No clicking sound from solenoid during

hand presence (no beeps).

Solenoid valve strainer.

Check if faucet outlet is clogged

(no beeps).

Battery voltage (battery operated only).

Incorrect range setting for spout type and

sink used (no beeps).

Problem Check Possible Solution

Troubleshooting

continued . . .

Loading...

Loading...