Page 1

P.O. Box 309, Menomonee Falls, WI USA 53052-0309

PHONE 1-800-BRADLEY FAX (262) 251-5817

http://www.bradleycorp.com

Installation

215-1134 Rev. R; EN 06-532G

© 2007 Bradley Corporation

Page 1 of 16 4/27/07

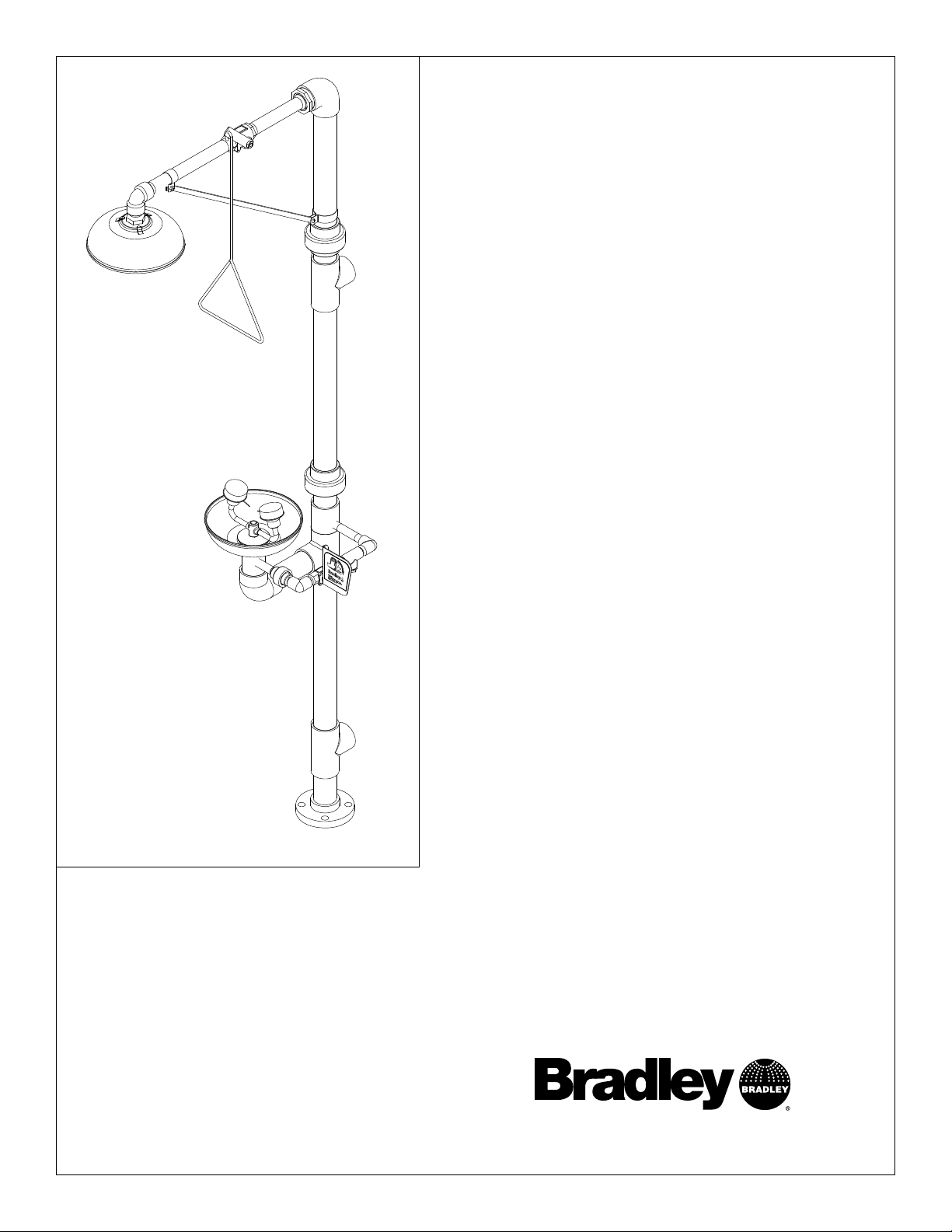

S19-310PVC

Combination Drench Shower and

Eye/Face Wash

Combiné douche oculaire/faciale

Combinación de ducha de

aspersión/lavador de ojos/rostro

Table of Contents

Pre-Installation Information . . . . . . . . . . . . . . . .2–3

Installation Instructions . . . . . . . . . . . . . . . . . . . . . .4

Assembly of Components . . . . . . . . . . . . . . . . . . . .5

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Table des matières

Avant l’installation . . . . . . . . . . . . . . . . . . . . . . .7–8

Instructions d’installation . . . . . . . . . . . . . . . . . . . .9

Montage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Liste des pièces . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Contenido

Información previa a la instalación . . . . . . . . .12–13

Instrucciones de instalación . . . . . . . . . . . . . . . . . .14

Montaje de los componentes . . . . . . . . . . . . . . . . .15

Lista de piezas . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Page 2

2

S19-310PVC Installation

4/27/07 Bradley Corporation • 215-1134 Rev. R; EN 06-532G

WARNING

Read this installation manual completely to ensure proper installation, then file it

with the owner or maintenance department. Compliance and conformity to drain

requirements and other local codes and ordinances is the responsibility of the

installer.

Separate parts from packaging and make sure all parts are accounted for before

discarding any packaging material. If any parts are missing, do not begin

installation until you obtain the missing parts.

Flush the water supply lines before beginning installation and after installation is

complete. Test the unit for leaks and adequate water flow. Main water supply to

the eyewash should be “ON” at all times. Provisions shall be made to prevent

unauthorized shutoff.

The ANSI Z358.1 standard requires an uninterruptible supply of flushing fluid at a

minimum 30 PSI (0.21 MPa) flowing pressure. Flushing fluid should be tepid per

ANSI Z358.1.

The inspection and testing results of this equipment should be recorded weekly

to verify proper operation. This equipment should be inspected annually to

ensure compliance with ANSI Z358.1.

Workers who may come in contact with potentially hazardous materials should be

trained regarding the placement and proper operation of emergency equipment

per ANSI Z358.1.

For questions regarding the operation or installation of this product, visit

www.bradleycorp.com or call 1-800-BRADLEY.

Product warranties may also be found under ”Product Information” on our web

site at www.bradleycorp.com.

Installation

T

H

IS

S

ID

E

U

P

Packing List

!

!

!

!

P

.O

. B

o

x

3

0

9

, M

e

n

o

m

o

n

e

e

F

a

lls

, W

I 5

3

0

5

1

R

T

E

S

T

T

H

I

S

U

N

I

T

E

A

C

H

W

E

E

K

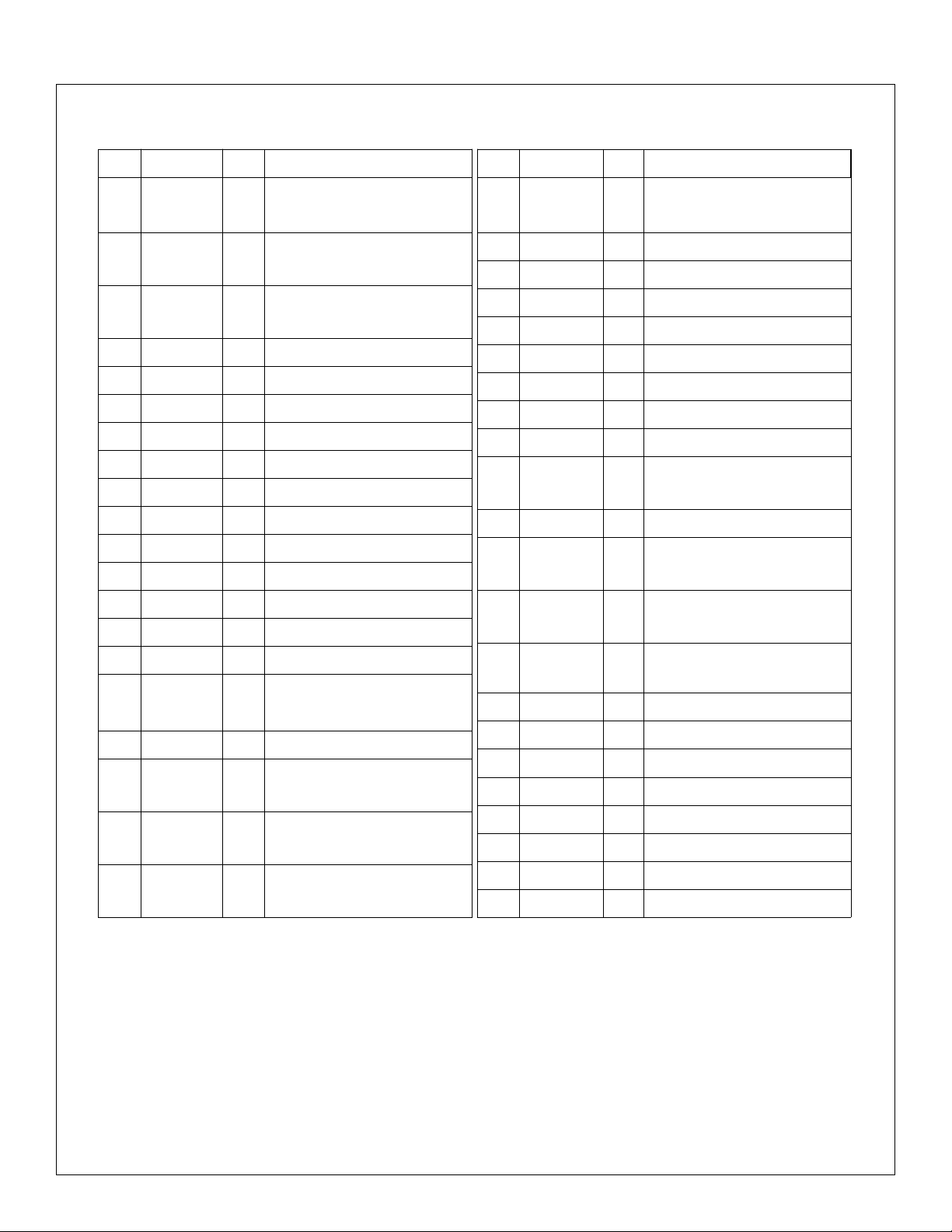

Test-operate valve(s) each week and sign below

.

R

eport any m

alfunctions imm

ediately.

Ven

til(e) w

öche

ntlich im

Testbe

trieb prüfen

, bestätig

t

durch U

ntersch

rift. Jeg

liche Störung sofort m

eld

en.

Date

Datum

Date

Signed

Unterschrift

Signe

Date

Date

Date Signed

Signed

Signed

D

I

E

S

E

S

G

E

R

Ä

T

1

S

T

W

Ö

C

H

E

N

T

L

I

C

H

Z

U

P

R

Ü

F

E

N

.

E

S

S

A

I

H

E

B

D

O

M

A

D

A

I

R

E

Test le fonctionnem

ent des va

lves chaque se

m

ain

e et

signe en bas. S

'il y à quelque chose q

u

i ne va pas fait

un rapport im

médiatem

ent.

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

114-051

Page 3

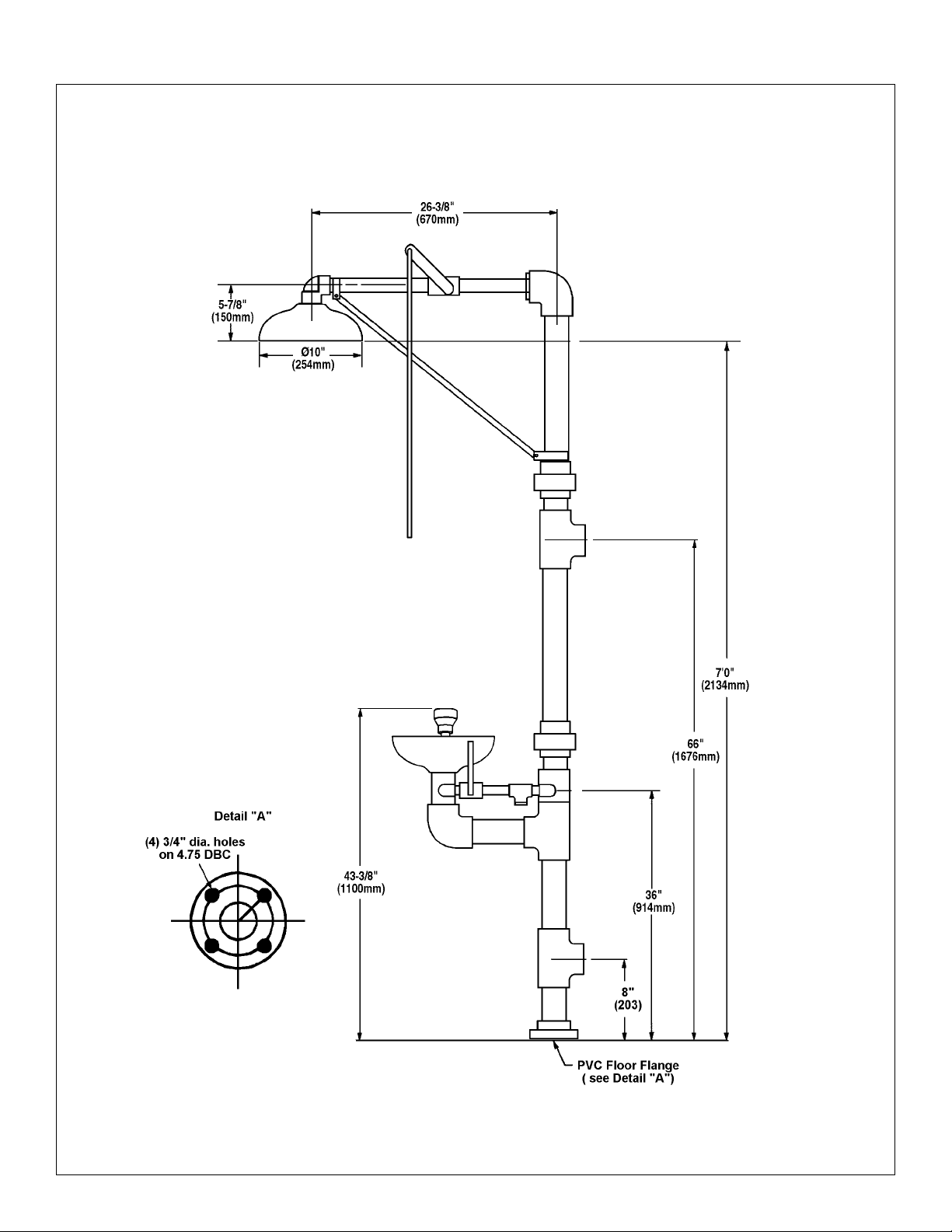

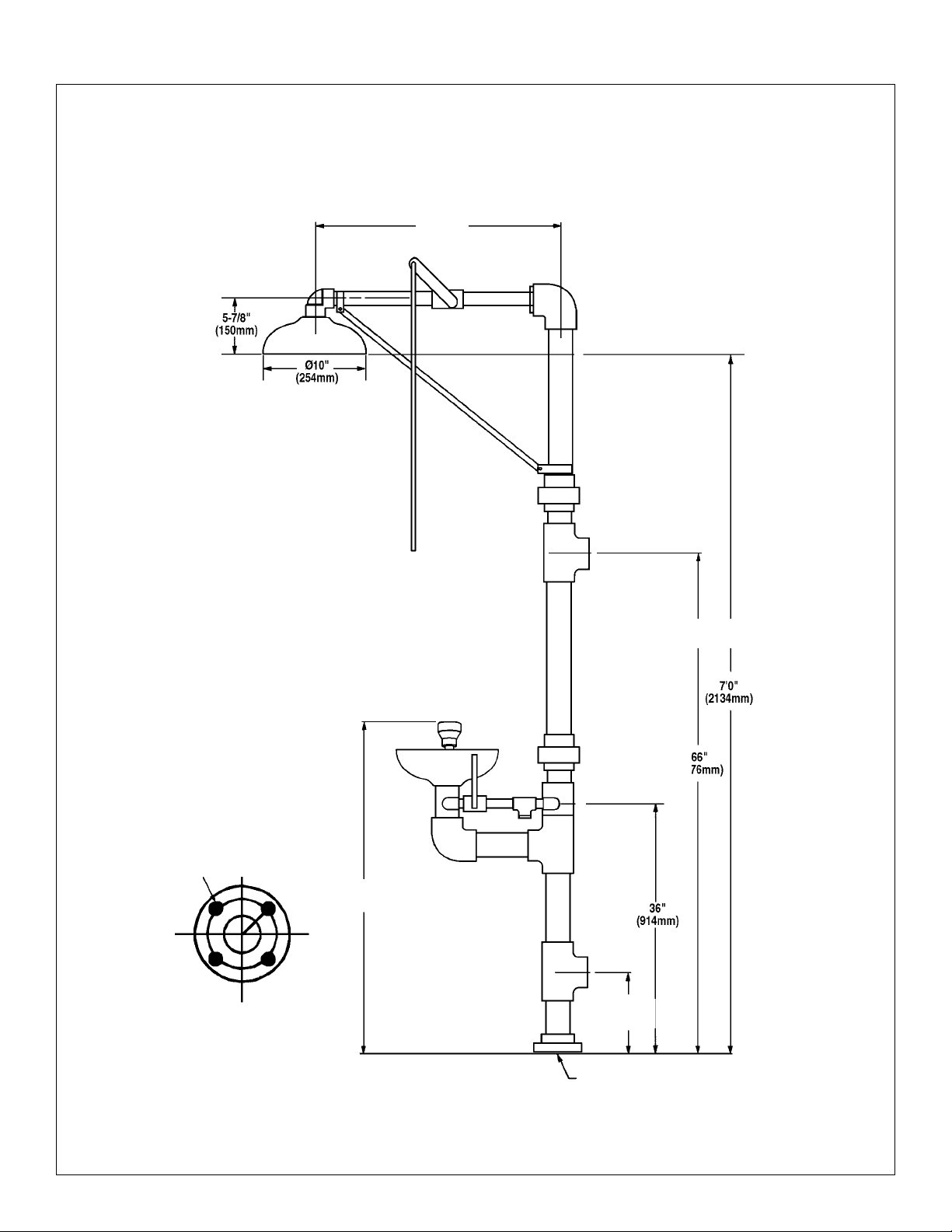

Drench Shower Unit Assembly Dimensions

3

Installation S19-310PVC

Bradley Corporation • 215-1134 Rev. R; EN 06-532G 4/27/07

Figure 1

Page 4

4

S19-310PVC Installation

4/27/07 Bradley Corporation • 215-1134 Rev. R; EN 06-532G

Installation InstructionsInstallation Instructions

Supplies Required:

• (4) 5/8" floor anchors and bolts

• Pipe sealant and teflon tape

• Piping to 2" IPS PVC water supply inlet on unit

• Piping to 2" IPS PVC drain outlet for eye wash on unit

• Adequate supply pipe supports

• Minimum 4" (102mm) drain to accommodate 30 gallons per minute discharge for

drench shower waste

Step 1: Assemble and Install Drench Shower

1. To secure base to floor, install four suitable anchors (supplied by installer) for 5/8" bolts in the

floor (see Figure 1 on page 3).

2. Bolt the base to the floor anchors using 5/8" bolts (supplied by installer).

3. After the base is secured, assemble the remaining drench shower components as shown in Figure

1. Apply pipe sealant or tape (supplied by installer) to all male threaded pipe joints.

IMPORTANT: Some teflon sealants may cause stress cracks in the plastic

showerhead leading to failure. Use teflon tape when assembling

the showerhead.

4. The plastic showerhead should be assembled to the close nipple with teflon tape. The bottom

edge of the showerhead should be 7' (2134 mm) from the floor.

IMPORTANT: Provide adequate supports (supplied by installer) for supply pipe

using pipe hangers or other means. Do not rely on drench

shower unit to support supply piping.

5. Connect the water supply piping to the 2" PVC IPS inlet on the unit (piping supplied by

installer). Provide adequate supports (supplied by installer) for supply pipe using pipe hangers or

other means.

6. Connect the drain piping to the 2" PVC IPS drain outlet on the unit (piping supplied by

installer).

Step 2: Assemble and Install Eye/Face Wash

NOTE: See Figure 2 on page 5 for part identification.

1. While holding the elbow in the lower assembly piping, thread pipe #113-946 (Item #21) through

the hole in the lower assembly piping, and connect to elbow.

2. Install the reducer on top of the elbow.

3. Center the elbow, then tighten the pipe #113-946 (Item #21) in place.

4. Install the union and pipe nipple on pipe #113-946 (Item #21).

5. Place the gasket, then the strainer, on top of the lower assembly piping.

6. Place the eyewash bowl on top of the strainer.

7. Install the yoke assembly by connecting the stainless steel pipe, at the base of the yoke assembly,

to the reducer on the elbow.

8. Connect the pipe nipple to the valve piping assembly.

9. Open the water supply lines. Test for leaks and adequate water flow on the entire drench

shower/eye wash unit.

Page 5

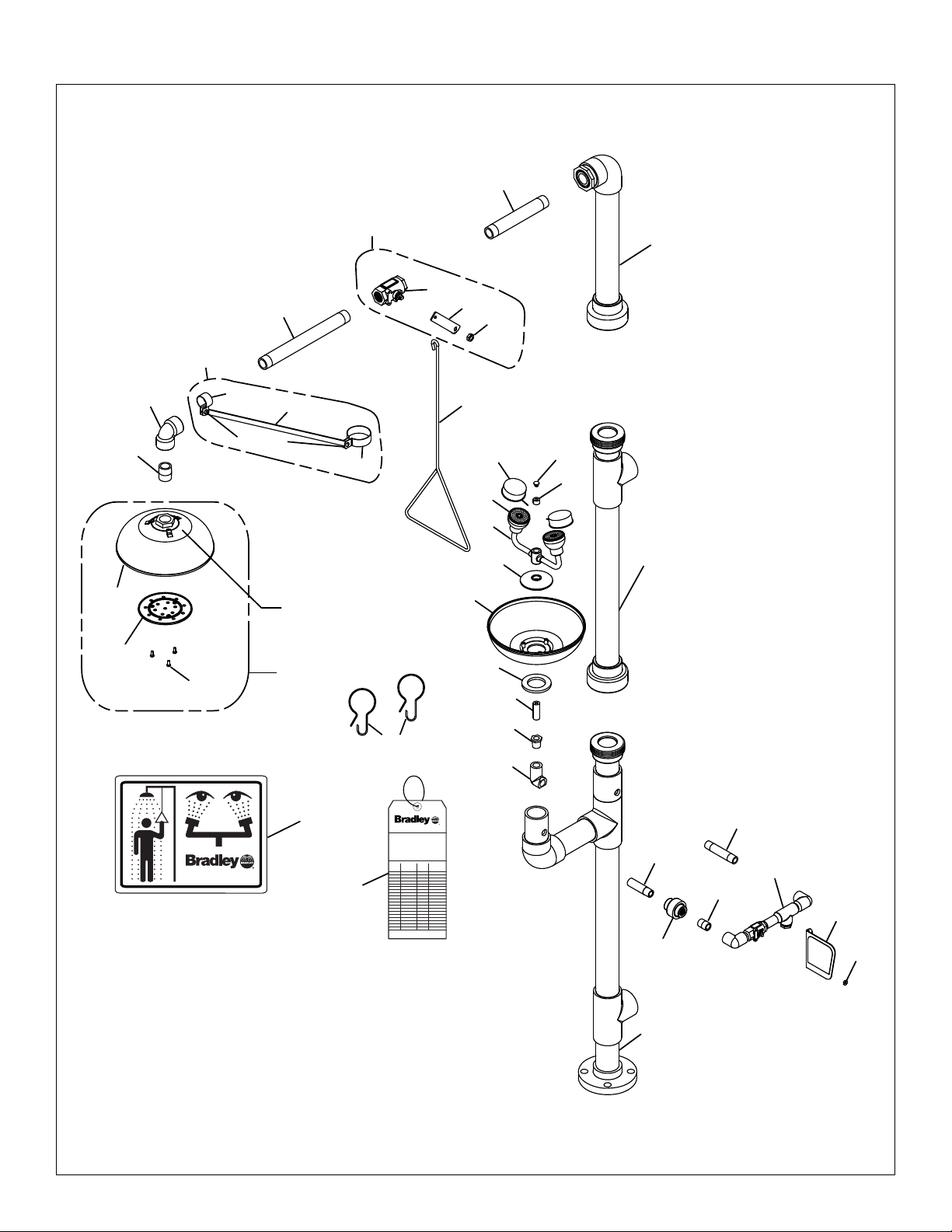

Assembly of Components

1

2

3

4

5

NOTE: Use

teflon tape

only.

5.2

5.3

5.1

7

7.11

7.2

7.1

8

9

11

10

28

21

20

19

15

14.1

14

22

23

26

24

16

25

17

29

27

13

12

6

6.1

6.2

6.3

6.4, 6.5

18

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

114-052

P.O. Box 309, Menomonee Falls, WI 53051

R

TEST THIS UNIT EACH WEEK

Test-operate valve(s) each week and sign below.

Report any malfunctions immediately.

Ventil(e) wöchentlich im Testbetrieb prüfen, bestätigt

durch Unterschrift. Jegliche Störung sofort melden.

Date

Datum

Date

Signed

Unterschrift

Signe

Date

Date

Date Signed

Signed

Signed

DIESES GERÄT 1ST WÖCHENTLICH ZU PRÜFEN.

ESSAI HEBDOMADAIRE

Test le fonctionnement des valves chaque semaine et

signe en bas. S'il y à quelque chose qui ne va pas fait

un rapport immédiatement.

30

31

5

Installation S19-310PVC

Bradley Corporation • 215-1134 Rev. R; EN 06-532G 4/27/07

Figure 2

NOTE: Seal all male threads with plastic

pipe sealant. Assemble couplings hand-tight;

then tighten one full turn with a wrench.

Page 6

6

S19-310PVC Installation

4/27/07 Bradley Corporation • 215-1134 Rev. R; EN 06-532G

Parts List

1 S90-337 1 PVC Lower Assembly

2 S90-338 1 PVC Middle Assembly

3 S90-339 1 PVC Upper Assembly

4 128-156A 1 Pull Rod - 24" Long

5 S24-070 1 Plastic Showerhead Assy.

5.1 154-057 1 Showerhead Shell

5.2 155-005 1 Diffuser

5.3 160-245 3 Screw

6 S90-341 1 2” x 1” Pipe Hanger Assembly

6.1 269-1121 1 1/2” Support Rod

6.2 269-1123 1 1” Pipe Hanger

6.3 269-1124 1 2” Pipe Hanger

6.4 160-069 2 Screw

6.5 161-047 2 Hex Nut

7 S30-061 1 1” Ball Valve Assembly

7.1 S27-276 1 1" Ball Valve with Nut

7.11 161-079 1 Jam Nut only

7.2 128-142 1 Handle

8 269-1109 1 1" PVC 90° Elbow

9 113-942 1 1” PVC Pipe x Closed Nipple

10 113-944 1 1” PVC Pipe x 8” Long

11 113-945 1 1” PVC Pipe x 12” Long

12 153-333 1 Pipe Plug

13 269-874 1 Cap Plug - Eye/Face Wash

14 S90-008 1 Valve Piping Assembly with Nut

14.1 110-215 1 Jam Nut only

15 S08-338 1 Handle

16 154-058 1 Plastic Eyewash Receptor

17 S05-131 1 Eye Wash Yoke Sub-Assembly

18 151-001 2 Curtain Hook

19 113-936 1 PVC Pipe Nipple

20 269-1114 1 PVC Union

21 113-946 1 PVC Pipe Nipple Modified

22 269-1120 1 PVC 90° Elbow

23 269-1119 1 PVC Reducer

24 124-028 1 Gasket

25 173-025 1 Cup Strainer

26 113-1151 1 Supply Pipe

27 S53-063 2 Tethered Dust Cover

28 113-940 1 1/2” Pipe Nipple

29 S05-135 2 EFW Assembly

30 114-052 1 Safety Sign

31 204-421 1 Emergency Tag

Item Part No. Qty Description

Item Part No. Qty Description

Item 6.2 includes items 6.4, 6.5

Item 6.3 includes items 6.4, 6.5

Page 7

7

Installation S19-310PVC

Bradley Corporation • 215-1134 Rev. R; EN 06-532G 4/27/07

AVERTISSEMENT

Lire ce manuel d'installation dans son intégralité pour garantir une installation

appropriée. Une fois celle-ci terminée, classer ce manuel auprès du service à la

clientèle ou d'entretien. L'installateur est responsable de la conformité de

l'installation aux codes pour des drain et codes et règlements en vigueur.

Assurez-vous que toutes les pièces sont incluses dans l’emballage et qu’il n’en

manque aucune avant de jeter l’emballage. Ne commencez pas l’assemblage

avant de recevoir les pièces manquantes.

Rincez la conduite d’alimentation avant et apres l’installation. Assurez-vous que

le débit d’eau est adéquat et qu’il n’y a pas de fuites. L’alimentation principale en

eau doit être toujours OUVERTE. On devra prévoir des dispositions pour

empêcher tout arrêt non autorisé.

La norme ANSI Z358.1 requiert une alimentation sans coupure du liquide de

rinçage à une pression minimum de 30 psi (0.21 MPa). Le liquide de rinçage doit

être tiède conformément à la norme ANSI Z358.1.

Inspectez et testez cet équipement une fois par semaine pour en assurer le bon

fonctionement. Notez les dates d’inspection. Ce matériel doit être inspecté une

fois par an pour assurer sa conformité à la norme ANSI Z358.1.

Les ouvriers susceptibles d'entrer en contact avec des matières potentiellement

dangereuses doivent recevoir une formation sur la mise en place et le bon

fonctionnement du matériel d'urgence conformément à la norme ANSI Z358.1.

Pour toute question concernant le fonctionnement ou l'installation de ce produit,

consulter le site www.bradleycorp.com ou appeler le 1-800-BRADLEY.

Les garanties de produits figurent sous la rubrique « Informations techniques »

sur notre site Internet à www.bradleycorp.com.

Installation

T

H

IS

S

I

D

E

U

P

Packing List

!

!

!

!

P

.O

. B

o

x

3

0

9

, M

e

n

o

m

o

n

e

e

F

a

lls

, W

I 5

3

0

5

1

R

T

E

S

T

T

H

I

S

U

N

I

T

E

A

C

H

W

E

E

K

Test-operate valve(s) each week and sign below

.

R

eport an

y m

alfunctions imm

ediately.

V

entil(e) w

öchentlich im T

estbetrieb prüfen, bestätigt

durc

h U

nterschrift. Jegliche Störung so

fort m

eld

en.

Date

Datum

Date

Signed

Unterschrift

Signe

Date

Date

Date Signed

Signed

Signed

D

I

E

S

E

S

G

E

R

Ä

T

1

S

T

W

Ö

C

H

E

N

T

L

I

C

H

Z

U

P

R

Ü

F

E

N

.

E

S

S

A

I

H

E

B

D

O

M

A

D

A

I

R

E

Test le fonctionnem

ent des valves ch

aque sem

aine et

signe en bas. S'il y à quelque chose q

ui n

e va pas fait

un rapport im

médiatement.

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

114-051

Page 8

8

S19-310PVC Installation

4/27/07 Bradley Corporation • 215-1134 Rev. R; EN 06-532G

Cotes de montage du combiné douche/lave-yeux

Figure 1

Bride PVC

(voir Détail « A »)

24 in.

(610)

84 in.

(2134)

90 in.

(2286)

66 in.

(1676)

42 in.

(1007)

8 in.

(203)

Detail « A »

Trous de 3/4 in. sur

un cercle de Ø 120

mm (4.75 in.).

Page 9

9

Installation S19-310PVC

Bradley Corporation • 215-1134 Rev. R; EN 06-532G 4/27/07

Instructions d’installation

Fournitures:

• (4) Chevilles d’ancrage au sol de 5/8 in. et vis

• Produit d’étanchéité pour tuyauterie, ruban au téflon

• Tuyau d’alimentation PVC de 2 in. IPS PVC pour l’alimentation en eau à raccorder sur l’orifice

d’admission

• Tuyau PCV de 2 in. IPS pour l’évacuation (douche oculaire/faciale)

• Un nombre suffisant de supports de tuyau

• Tuyau d’évacuation d’au moins 100 mm (4 in.) pour évacuer les 30 GPM d’eau de la douche

Étape 1: Montage et installation de la douche

1. Pour fixer la base au sol, poser les trois chevilles (à fournir) pour les trois vis de 5/8 in. dans le

sol (Figure 1, p. 8).

2. Visser la base dans les chevilles avec trois vis de 5/8 in. (à fournir).

3. Une fois la base fixée monter le reste des éléments de la douche comme sur la Figure 1, page 10.

Mettre du ruban de téflon ou un produit d’étanchéité (à fournir) sur tous les filetages mâles des

raccords.

IMPORTANT: Certaines pâtes d’étanchéité au Téflon sont susceptibles de

provoquer des fissures dans le pommeau de douche en plastique, en

raison de la fatigue mécanique, et d’entraîner sa rupture. Utiliser du

ruban de téflon pour la pose du pommeau de douche en plastique.

4. Poser le pommeau de douche en plastique sur son raccord avec du ruban de téflon. Le bord

inférieur du pommeau de la douche d’urgence doit se trouver à 2,10 m (7 ft.) du sol.

IMPORTANT: Prévoir des supports adéquats (à fournir) pour la tuyauterie

d’alimentation. Ne pas utiliser la douche comme support de la

tuyauterie.

5. Raccorder le tuyau d’alimentation PVC 2 in. IPS (à fournir) sur l’orifice d’alimentation de

l’appareil. Prévoir des supports adéquats (non fournis) pour la tuyauterie d’alimentation.

6. Brancher le tuyau d’évacuation PVC de 2 in. (à fournir) sur l’orifice d’évacuation de la douche

d’urgence.

Étape 2: Assemblage des composantes de la douche oculaire/faciale

REMARQUE: Voir Figure 2, p. 10 pour identifier les pièces.

1. Tout en maintenant le coude dans la section inférieure de la tuyauterie, visser le tuyau fileté réf.

113-946 (pièce 21) dans le trou de la tuyauterie inférieure et y visser le coude.

2. Visser le réducteur sur le coude.

3. Centrer le coude et serrer le tuyau réf. 113-946 (pièce 21) en place.

4. Poser le joint et le raccord sur le tuyau réf. 113-946 (pièce 21).

5. Placer le joint et la crépine au sommet de la tuyauterie inférieure.

6. Poser la vasque sur la crépine.

7. Pour poser le guidon, raccorder le tube en acier inox sur la base du guidon au réducteur posé sur

le coude.

8. Raccorder le raccord sur la vanne.

9. Ouvrir l’alimentation en eau. S’assurer que le débit d’eau est convenable et qu’il n’y a pas de

fuites.

Page 10

10

S19-310PVC Installation

4/27/07 Bradley Corporation • 215-1134 Rev. R; EN 06-532G

Assemblage des composantes

1

2

3

4

5

NOTE: Use

teflon tape

only.

5.2

5.3

5.1

7

7.11

7.2

7.1

8

9

11

10

28

21

20

19

15

14.1

14

22

23

26

24

16

25

17

29

27

13

12

6

6.1

6.2

6.3

6.4, 6.5

18

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

114-052

P.O. Box 309, Menomonee Falls, WI 53051

R

TEST THIS UNIT EACH WEEK

Test-operate valve(s) each week and sign below.

Report any malfunctions immediately.

Ventil(e) wöchentlich im Testbetrieb prüfen, bestätigt

durch Unterschrift. Jegliche Störung sofort melden.

Date

Datum

Date

Signed

Unterschrift

Signe

Date

Date

Date Signed

Signed

Signed

DIESES GERÄT 1ST WÖCHENTLICH ZU PRÜFEN.

ESSAI HEBDOMADAIRE

Test le fonctionnement des valves chaque semaine et

signe en bas. S'il y à quelque chose qui ne va pas fait

un rapport immédiatement.

30

31

Figure 2

REMARQUE: Mettre du produit d’étanchéité

pour plastique sur les filetages mâles. Serrer

tous les raccordements à la main puis les

serrer d’un tour complet avec une clé.

NOTE: Utiliser

uniquement du

ruban de téflon

Page 11

11

Installation S19-310PVC

Bradley Corporation • 215-1134 Rev. R; EN 06-532G 4/27/07

Liste des pièces

1 S90-337 1 Base PVC

2 S90-338 1

Portion centrale PVC

3 S90-339 1

Portion supérieure PVC

4 128-156A 1

Tige de commande long. 24 in.

5 S24-070 1

Pommeau de douche plastique

5.1 154-057 1

Pommeau

5.2 155-005 1

Diffuseur plastique

5.3 160-245 3 Vis

6 S90-341 1

Support 2 x 1 in.

6.1 269-1121 1

Tige 1/2 in.

6.2 269-1123 1

Support 1 in.

6.3 269-1124 1

Support 2 in.

6.4 160-069 2 Vis

6.5 161-047 2

Écrou

7 S30-061 1

Vanne 1 in.

7.1 S27-276 1

Vanne avec écrou

7.11 161-079 1

Écrou (seulement)

7.2 128-142 1

Levier de la vanne

8 269-1109 1

Coude PVC 1 in. 90°

9 113-942 1

Tuyau PVC 1 in. raccord fermé

10 113-944 1

Tuyau PVC 1 in. long. 8

11 113-945 1

Tuyau PVC 1 in. long. 12 in.

12 153-333 1

Bouchon

13 269-874 1

Bouchons des érogateurs

14 S90-008 1

Vanne avec écrou

14.1 110-215 1

Écrou (seulement)

15 S08-338 1

Poignée

16 154-058 1

Vasque plastique

17 S05-131 1

Eléments du guidon EFW

18 151-001 2 Crochet

19 113-936 1

Raccord PVC

20 269-1114 1

Joint PVC

21 113-946 1

Raccord PVC modifié

22 269-1120 1

Coude PVC 90°

23 269-1119 1

Réducteur PVC

24 124-028 1

Joint

25 173-025 1

Crépine

26 113-1151 1

Tuyau d’ alimentation

27 S53-063 2

Cache-poussière attaché

28 113-940 1

Raccord 1/2 in.

29 S05-135 2

Gliceur “EFW”

30 114-052 1

Panneau de sécurité

31 204-421 1

Etiquette d’urgence

Pièce Réf. Qté

Description

Pièce Réf. Qté

Description

Pièce 6.2 comprend les éléments 6.4, 6.5

Pièce 6.3 comprend les éléments 6.4, 6.5

Page 12

12

S19-310PVC Installation

4/27/07 Bradley Corporation • 215-1134 Rev. R; EN 06-532G

ADVERTENCIA

Lea en su totalidad este manual de instalación para garantizar una instalación

adecuada. Una vez que termine la instalación, entregue este manual al propietario o

al Departamento de Mantenimiento. Es responsabilidad de quien instale el equipo

cumplir con los códigos para desagüe y otra códigos y ordenanzas locales.

Separar todas las piezas del material de embalaje y asegurarse que todas las piezas

estén incluídas antes de desechar cualquier material de embalaje. Si faltase alguna

pieza, no intentar instalar la unidad combinada Bradley hasta obtener las piezas

faltantes.

Aclarar el conducto del suministro de agua antes y después de la instalación.

Verificar que no haya fugas y que el flujo de agua sea adecuado. El suministro

principal de agua a la unidad debe estar siempre en posición “ON” (abierto). Se

deben tomar medidas a fin de evitar el corte no autorizado del suministro.

La norma ANSI Z358.1 exige un suministro ininterrumpido del líquido de enjuague a

una presión mínima de 30 psi

(0.21 MPa). El líquido de limpieza debe estar tibio en

conformidad con la norma ANSI Z358.1.

Este equipo se debe inspeccionar, probar y anotar semanalmente para mantener un

funcionamiento adecuado

. Se debe revisar este equipo anualmente para asegurarse

de que cumpla con la norma ANSI Z358.1.

Los trabajadores que puedan tener contacto con materiales potencialmente

peligrosos deben recibir capacitación sobre la ubicación y operación adecuada de

los equipos de emergencia en conformidad con la norma ANSI Z358.1.

Para consultas sobre la operación o instalación de este producto, visite

www.bradleycorp.com o llame al 1-800-BRADLEY.

Las garantías del producto se pueden encontrar en "Información del producto" o en

nuestro sitio Web, www.bradleycorp.com.

Installation

T

H

IS

S

I

D

E

U

P

Packing List

!

!

!

!

P

.O

.

B

o

x

3

0

9

, M

e

n

o

m

o

n

e

e

F

a

ll

s

, W

I 5

3

0

5

1

R

T

E

S

T

T

H

I

S

U

N

I

T

E

A

C

H

W

E

E

K

Test-operate

valve(s) ea

c

h w

eek an

d sign b

elo

w.

R

epo

rt any

m

alfu

ncti

ons im

m

ediately.

V

en

til(e) wöc

hentlic

h im

T

estbetrieb

p

rü

fen, be

stätig

t

durch Un

tersc

hrift. Jegliche S

törun

g sofo

rt m

elden

.

Date

Datum

Date

Signed

Unterschrift

Signe

Date

Date

Date Signed

Signed

Signed

D

I

E

S

E

S

G

E

R

Ä

T

1

S

T

W

Ö

C

H

E

N

T

L

I

C

H

Z

U

P

R

Ü

F

E

N

.

E

S

S

A

I

H

E

B

D

O

M

A

D

A

I

R

E

Test le fonc

tio

nnem

ent des valve

s ch

aqu

e sem

aine

et

s

ig

ne en b

as. S

'il y

à quelque cho

se qu

i n

e va pas fait

un rap

port im

mé

diatem

en

t.

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

114-051

Page 13

13

Installation S19-310PVC

Bradley Corporation • 215-1134 Rev. R; EN 06-532G 4/27/07

Dimensiones del conjunto de la unidad de ducha de aspersión

Figura 1

Agujeros de 3/4" de

diámetro en DBC de 4,75

Brida de suelo de cloruro de

polivinilo (PVC) (ver detalle “A”)

Detalle “A”

24"

(610)

84"

(2134)

90"

(2286)

66"

(1676)

8"

(203)

42"

(1007)

Page 14

14

S19-310PVC Installation

4/27/07 Bradley Corporation • 215-1134 Rev. R; EN 06-532G

Instrucciones de instalación

Materiales que se requieren:

• (4) Pernos y anclajes de suelo de 5/8"

• Obturador de tubo y cinta de teflón

• Tubo a tubo de entrada de cloruro de polivinilo (PVC) IPS de 2" de abastecimiento de agua

• Tubo a salida de drenaje de cloruro de polivinilo (PVC) IPS de 2" para el lavador de ojos/rostro

• Soportes adecuados para los tubos de abastecimiento

• Un drenaje de 102 mm (4 in.) mínimo para acomodar una descarga de 30 galones por minuto para

el consumo de la ducha de aspersión

Paso 1: Montar e instalar la ducha de aspersión

1. Para afianzar la base al suelo, instalar los cuatro anclajes apropiados (suministrados por el

instalador) para los pernos de 5/8" en el suelo (ver la figura 1 en la página 16).

2. Empernar la base a los anclajes de suelo utilizando pernos de 5/8" (suministrados por el

instalador).

3. Una vez que la base está afianzada, montar los componentes restantes de la ducha de aspersión

como se muestra en la figura 1 de la página 13. Aplicar obturador para tubos o cinta

(suministrado por el instalador) a todas las conexiones de tubo con rosca macho.

IMPORTANTE: Algunos obturadores de teflón pueden ocasionar grietas de tensión en el

cabezal de ducha de plástico, lo que a su vez puede ocasio-nar fallos.

Utilizar cinta de teflón al montar el cabezal de la ducha.

4. El cabezal de ducha de plástico debe montarse al tubo de empalme cerrado con cinta de teflón.

El borde inferior del cabezal de ducha debe estar a 2.134 mm (7 ft.) del suelo.

IMPORTANTE: Proveer soportes adecuados (suministrados por el instalador) para los

tubos de abastecimiento utilizando cuelgatubos u otros medios. No

depender de la unidad para soportar el tubo de abastecimiento.

5. Conectar el tubo de abastecimiento de agua al tubo de entrada de cloruro de polivinilo (PVC)

IPS de 2" en la unidad (tubo suministrado por el instalador). Proveer soportes adecuados

(suministrados por el instalador) para los tubos de abastecimiento

utilizando cuelgatubos u otros medios.

6. Conectar el tubo de drenaje a la salida de drenaje de cloruro de polivinilo (PVC) IPS de

2" en la unidad (tubo suministrado por el instalador).

Paso 2: Montar e instalar el lavador de ojos/rostro

NOTA: Ver la figura 2 de la página 15 para obtener información sobre la identificación de las piezas

1. Mientras se sujeta el codo en el tubo del conjunto inferior, enroscar el tubo nº 113-946 (artículo

nº 21) a través del agujero en el tubo del conjunto inferior, y conectar al codo

2. Instalar el reductor sobre el codo.

3. Centrar el codo, luego apretar el tubo nº 113-946 (artículo nº 21) en su lugar

4. Instalar la unión y el empalme de tubo en el tubo nº 113-946 (artículo nº 21).

5. Colocar la junta y luego el depurador sobre los tubos del conjunto inferior.

6. Colocar la pila del lavador de ojos/rostro sobre el depurador.

7. Instalar el conjunto de horquilla conectando la tubería de acero inoxidable en la base del

conjunto de horquilla al reductor en el codo.

8. Conectar el empalme del tubo al conjunto de tubos de la válvula.

9. Abrir los tubos de abastecimiento de agua. Comprobar que no haya fugas y que el caudal de

agua sea adecuado en toda la unidad de ducha de aspersión/lavador de ojos/rostro.

Page 15

Armado de los componentes

1

2

3

4

5

NOTE: Use

teflon tape

only.

5.2

5.3

5.1

7

7.11

7.2

7.1

8

9

11

10

28

21

20

19

15

14.1

14

22

23

26

24

16

25

17

29

27

13

12

6

6.1

6.2

6.3

6.4, 6.5

18

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

114-052

P.O. Box 309, Menomonee Falls, WI 53051

R

TEST THIS UNIT EACH WEEK

Test-operate valve(s) each week and sign below.

Report any malfunctions immediately.

Ventil(e) wöchentlich im Testbetrieb prüfen, bestätigt

durch Unterschrift. Jegliche Störung sofort melden.

Date

Datum

Date

Signed

Unterschrift

Signe

Date

Date

Date Signed

Signed

Signed

DIESES GERÄT 1ST WÖCHENTLICH ZU PRÜFEN.

ESSAI HEBDOMADAIRE

Test le fonctionnement des valves chaque semaine et

signe en bas. S'il y à quelque chose qui ne va pas fait

un rapport immédiatement.

30

31

15

Installation S19-310PVC

Bradley Corporation • 215-1134 Rev. R; EN 06-532G 4/27/07

Figura 2

NOTA: Sellar todas las roscas macho con

obturador de tubo de plástico. Montar los

acoplamientos apretándolos a mano; luego,

apretar una vuelta completa más con una

llave para tuercas.

NOTA: Usar

cinta de

teflon

solamente

Page 16

16

S19-310PVC Installation

4/27/07 Bradley Corporation • 215-1134 Rev. R; EN 06-532G

Lista de piezas

1 S90-337 1

Conjunto de cloruro de

polivinilo (PVC) inferior

2 S90-338 1

Conjunto de cloruro de

polivinilo (PVC) intermedio

3 S90-339 1

Conjunto de cloruro de

polivinilo (PVC) superior

4 128-156A 1

Barra de tiro de 24"

5 S24-070 1

Conjunto de cabezal de ducha

5.1 154-057 1

Cabezal de ducha de plástico

5.2 155-005 1

Difusor de plástico

5.3 160-245 3

Tornillo

6 S90-341 1

Conjunto de cuelgatubos de 2" x 1"

6.1 269-1121 1

Barra de soporte de 1/2"

6.2 269-1123 1

Cuelgatubos de 1"

6.3 269-1124 1

Cuelgatubos de 2"

6.4 160-069 2

Tornillo

6.5 161-047 2

Tuerca hexagonal

7 S30-061 1

Conjunto de válvula esférica de 1"

7.1 S27-276 1

Válvula esférica 1" con tuerca

7.11 161-079 1 T

uerca (solamente)

7.2 128-142 1

Manilla

8 269-1109 1

Codo de 90° de cloruro de

polivinilo (PVC) de 1"

9 113-942 1

Tubo de cloruro de polivinilo (PVC)

de 1" x empalme cerrado

10 113-944 1

Tubo de cloruro de polivinilo (PVC)

de 1" x 8"

11 113-945 1

Tubo de cloruro de polivinilo (PVC)

de 1" x 12"

12 153-333 1

Tapón de tubería

13 269-874 1

Tapón - Lavaojos

14 S90-008 1

Conjunto de tubos de la válvula

14.1 110-215 1

Contratuerca (servicio)

15 S08-338 1

Manilla

16 154-058 1

Receptor de plástico EFW

17 S05-131 1

Conjunto de horquilla EFW

18 151-001 2

Gancho

19 113-936 1

Empalme para tubo de cloruro

de polivinilo (PVC)

20 269-1114 1

Unión de cloruro de polivinilo (PVC)

21 113-946 1

Empalme para tubo de cloruro de

polivinilo (PVC) modificado

22 269-1120 1

Codo de 90° de cloruro de

polivinilo (PVC)

23 269-1119 1

Reductor de cloruro de polivinilo

(PVC)

24 124-028 1

Junta

25 173-025 1

Depurador

26 113-1151 1

Tubería de suministro

27 S53-063 2

Cubierta para polvo

28 113-940 1

Empalme para tubo de 1/2 pulg.

29 S05-135 2

Conjunto EFW

30 114-052 1

Señal de seguridad

31 204-421 1

Etiqueta de emergencia

Art. Nº de Pieza Cant.

Descripción

Art. Nº de Pieza Cant.

Descripción

Art. 6.2 incluye art. 6.4, 6.5

Art. 6.3 incluye art. 6.4, 6.5

Loading...

Loading...