Page 1

WARNING

Installations may be performed at different times of construction by different individuals.

For this reason, this manual should be left on-site with the facility or maintenance manager.

Read this entire installation manual to ensure proper installation, then file these

instructions with the owner or maintenance department.

Flush all the water supply lines before making connections, then make sure the water

supply is turned off before beginning installation.

Do not use pipe dope on faucet and supply connections. Possible solenoid contamination

could occur and will void any warranty. Teflon tape is the recommended sealant.

The installation site should have access to an electrical box with 120 volt AC, 60 Hz cycle

for input to a transformer. When installing the transformer, the electrical box should be

located within six feet of the sink.

The DC faucet is powered by one factory-installed 6-volt lithium battery.

Pressurized plumbing fixtures must be installed in accordance with manufacturer’s

recommendations. The supply piping to these devices must be securely anchored to the

building structure to prevent the installed device from unnecessary movement when

operated by the user. Use extreme caution when installing the device to prevent damage to

the exposed significant surface.

Compliance and conformity to local codes and ordinances is the responsibility of the

installer.

Product warranties may be found under “Product Information” on our web site at

www.bradleycorp.com.

Aerada 1100 Series

High Arc Faucet

Installation

Instructions

215-1558 Rev. A; EN 07-202

© 2007 Bradley Corporation

Page 1 of 8 3/8/07

P.O. Box 309, Menomonee Falls, WI 53052-0309

Phone: 1-800-BRADLEY FAX: (262) 251-5817

http://www.bradleycorp.com

S53-304 DC High Arc Infrared Faucet

S53-305 AC High Arc Infrared Faucet

232-006 115-volt AC Plug-In Adapter

232-005 Multi-use AC Adapter (maximum

8 faucets)

232-007 4" chrome-plated Trimplate

Page 2

Aerada 1100 Series High Arc Faucet Installation Instructions

2 3/8/07 Bradley Corporation • 215-1558 Rev. A; EN 07-202

Table of Contents

Faucet Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Supplies Required for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Faucet Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Installation Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Cleaning and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Changing the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Changing the Sensor Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Faucet Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Transformer Connection Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Supplies Required for Installation:

• Teflon Tape

• 1/2" NPT water inlet supply

• Pipe fittings

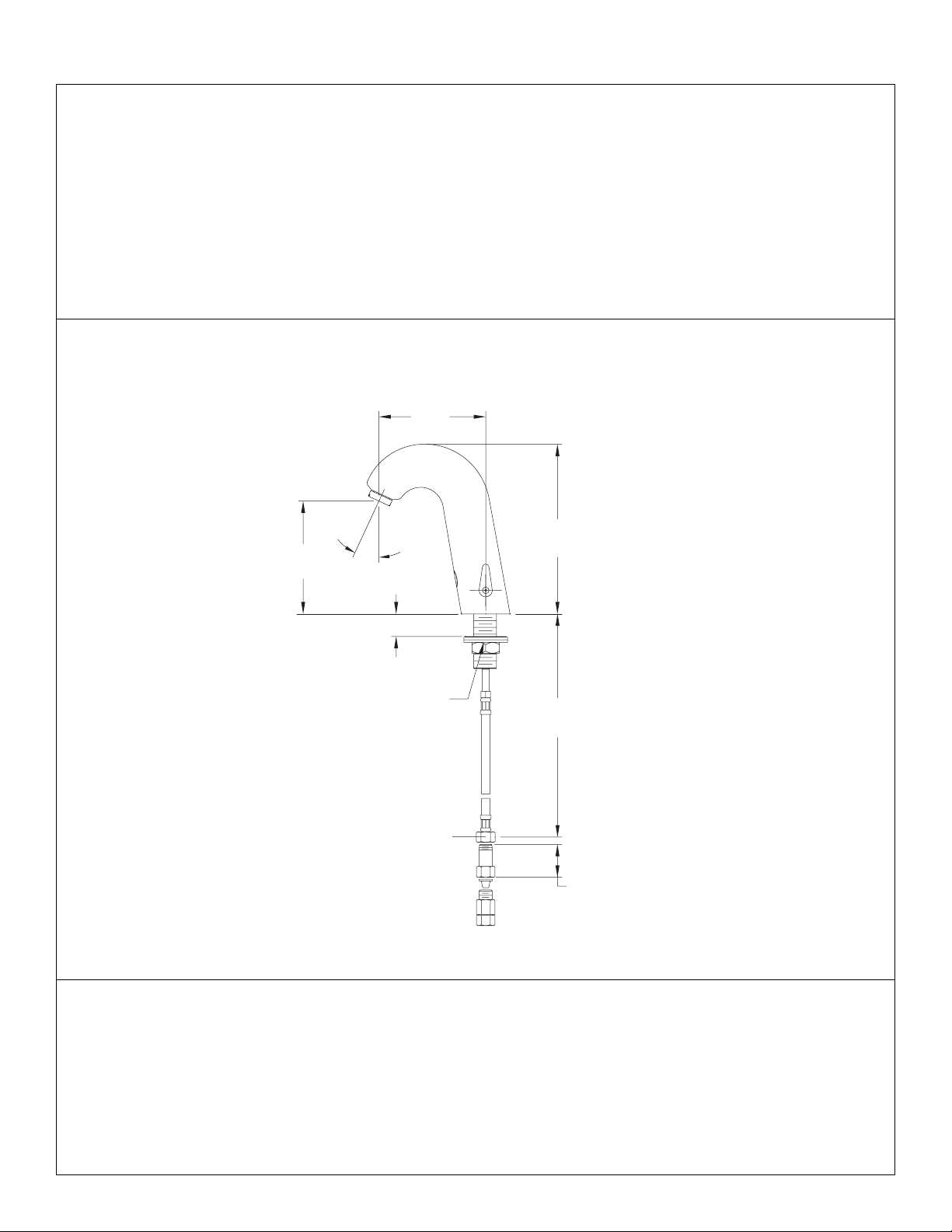

Faucet Dimensions

4.8"

(122mm)

5.3"

(135mm)

25˚

0.2"-1.2"

SW 1.5" (38mm)

SW 0.75" (19mm)

G 3/8" (10mm)

7.6"

(193mm)

14"

(356mm)

0.9"

(23mm)

Page 3

3

Installation Instructions Aerada 1100 Series High Arc Faucet

Bradley Corporation • 215-1558 Rev. A; EN 07-202 3/8/07

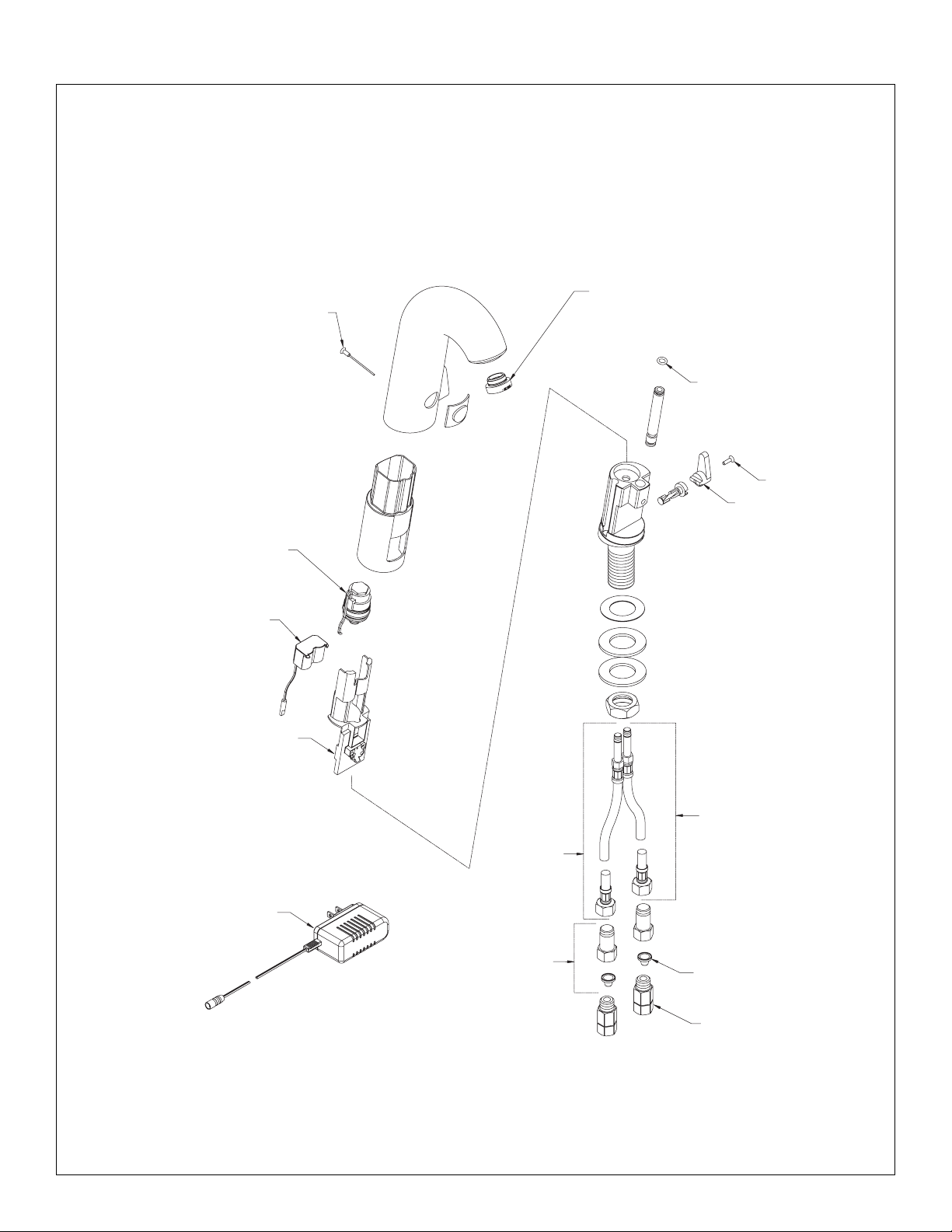

Components for Aerada 1100 Series Faucet

Model S53-305 shown, model S53-304 is similar

Carefully separate all parts from packaging and check each part with the illustrations below. Make sure

all parts are accounted for before discarding any packaging material. If any parts are missing, do not

attempt to install your Bradley Faucet until you obtain the missing parts.

VANDAL-RESISTANT

FIXING SCREW

WITH WIRE

SOLENOID VALVE

(269-1806)

AERATOR

(S05-176)

O-RING

SETSCREW

EXTERNAL

TEMPERATURE

CONTROL KNOB

AC ADAPTER

MODULE

(AC model

only)

ELECTRONIC MODULE

(269-1807)

115V AC PLUG-IN

ADAPTER

(232-006)

BRAIDED

SUPPLY

HOSE

BACKFLOW

PREVENTER

AND FILTER

BRAIDED

SUPPLY

HOSE

SCREEN FILTER

ADAPTER FOR

ANGLE STOP VALVE

Page 4

Aerada 1100 Series High Arc Faucet Installation Instructions

4 3/8/07 Bradley Corporation • 215-1558 Rev. A; EN 07-202

Installation Instructions

1. Turn off water supply to the existing faucet and

remove the faucet.

2. Mount the spout and rubber washer to top of base

as shown in the illustration. Install the second

rubber washer, steel washer and spout nut

underneath the base. Securely tighten the spout

nut.

3. Tighten the spout nut securely to prevent the spout

from rotating. If necessary, support the spout from

above to prevent twisting. Do not overtighten.

IMPORTANT: Do not use a wrench on

spout or inlet tubes.

4. AC Only: Plug the power supply into the

appropriate 110/115V wall outlet. Connect the

power supply female plug into the faucet male

plug.

NOTE: Power supply is equipped with an 11.8"

(30cm) cord. For multiple faucet installation, an

additional extension cord is provided. Refer to the

wiring diagram packaged with the faucet.

5. Connect the hot and cold water lines to the supply

pipes. Use Teflon tape on the threads to ensure a

leak-free joint. Tighten connections securely.

6. Turn the water supply on.

7. Remove the protective covering from the sensor.

8. Place a hand in front of the sensor for 15 seconds

to activate for the first time.

AC High Arc Faucet shown; DC model is similar.

SPOUT

RUBBER

WASHER

RUBBER WASHER,

STEEL WASHER,

SPOUT NUT

HOT AND COLD

WATER SUPPLY

Page 5

5

Installation Instructions Aerada 1100 Series High Arc Faucet

Bradley Corporation • 215-1558 Rev. A; EN 07-202 3/8/07

Cleaning the Aerator

Cleaning the Inline Filter

Cleaning and Maintenance

1. Shut off the hot and cold water supply.

2. Disconnect the hot and cold water lines from the

supply lines.

3. Remove the filters from the connections and clean

them thoroughly of any debris.

4. Reinstall filters and connect the hot and cold water

lines to the supply pipes. Use Teflon tape on the

threads to ensure a leak-free joint. Tighten

connections securely.

5. Turn water supply on.

1. Shut off the hot and cold water supply.

2. Remove the aerator with the spanner wrench and

thoroughly clean out any debris.

3. Reinstall the aerator using the spanner wrench

supplied with the faucet.

4. Turn the water supply on.

It is not necessary to shut off water supply to

clean the sink.

To shut off water flow, cover the infrared window

with your hand (as shown) for 5 seconds.

Remove your hand. Water flow will be halted for

90 seconds.

FILTER

AERATOR

Page 6

Aerada 1100 Series High Arc Faucet Installation Instructions

6 3/8/07 Bradley Corporation • 215-1558 Rev. A; EN 07-202

Changing the Sensor Detection Range

Changing the Battery

NOTE: The detection distance setting can be used to change

the detection distance.

1. Cover the infrared window as shown below. Water will

switch off after 5 seconds. Keep the window covered and

the water will come back on after another 5 seconds.

Uncover the window. The detection distance function is now

active.

NOTE: When the battery is low, the sensor will display a

continuous signal until the battery is completely dead.

1. Remove the fixing screw with wire from the back of the

spout and the setscrew from the side of the spout. Remove

the external temperature control knob and the spout.

2. Remove the old battery and replace with a new 6volt lithium battery.

3. Reinstall the spout, fixing screw with wire,

temperature control knob and setscrew.

2. Hold your hand in the current detection area (under

the water flow) until the LED flashes.

3. Move your hand to the desired detection range.

When the LED stays lit for 2 seconds, detection

range is set.

Page 7

7

Installation Instructions Aerada 1100 Series High Arc Faucet

Bradley Corporation • 215-1558 Rev. A; EN 07-202 3/8/07

Open supply valves.

Wait for cleaning mode to end.

- Clean inlet line filter

- Eliminate braided supply hose kink.

- Eliminate problem at BFP.

- Check water pressure.

Clean aerator, replace if necessary.

Check sensor detection distance adjustment.

(see Changing the Sensor Detection Range, page 6)

- Replace fixing screw with wire.

- Replace fixing screw with wire.

- Contact local Bradley representative

Replace solenoid valve.

- Replace battery.

- Clean contacts.

- Clean window, replace if necessary.

- Check external water supply.

- Replace solenoid valve.

.

Change sensor detection distance

Clean LED.

Install appropriate line pressure regulators.

- Tighten gently to prevent damage.

- Check for rubber washers, tighten securely.

- Ensure that solenoid O-rings are not damaged.

Carefully reinstall solenoid and tighten. Do not

overtighten.

Clean or replace solenoid valve.

Open supply valves fully.

- Clean inlet line filter

- Eliminate braided supply hose kink.

- Eliminate problem at BFP.

- Check water pressure.

Inspect boiler.

Correct the connections.

Supply valves are closed.

Faucet is in cleaning mode (approx. 90 secs).

Water inlet lines are interrupted or are

not in order.

- Inlet water line filter is dirty or blocked.

- Braided supply hose is kinked.

- Backflow preventer (BFP) is blocked.

- No external water pressure.

Aerator is blocked or dirty.

Sensor distance (detection) is not

adjusted properly.

Solenoid valve does not open.

- Fixing screw with wire is missing.

- Wire on fixing screw too short or broken off

- Electronics inoperable.

Solenoid valve does not open (is inoperable).

No electric power from battery to electronics.

- Battery is drained.

- Battery contacts are corroded.

- Connecting cable is kinked or broken.

Infrared does not detect any object.

- IR window is not transparent (scratched or

water condensation)

- Interfering reflections from the room

Solenoid valve does not close or closes late.

- External water pressure is high.

- Solenoid valve is inoperable.

Sensor detection is not adjusted properly.

LED is dirty or has water condensation.

Input line pressure fluctuates.

Faucet is not leak tight.

- Connections between housing and

braided supply hose.

- Braided supply hose to inlet supply.

- Connection between valve block and

solenoid valve.

Faucet drips, solenoid valve does not close.

Not enough hot or cold water. Supply valves

are closed or not open fully.

Individual inlet lines (hot and cold) are

blocked or kinked.

- Inlet water line filter is dirty or blocked.

- Braided supply hose is kinked.

- Backflow preventer (BFP) is blocked.

- No external water pressure.

Temperature of hot water is too low.

Braided supply hoses are connected

improperly (hot water braided supply hose on

cold water connection or vice versa).

No water flow.

Water runs continuously.

Faucet turns on by itself.

Faucet is leaking water.

Temperature cannot be

adjusted.

Troubleshooting

Problem Possible Cause Possible Solution

Page 8

Transformer Connection Detail (232-005)

Aerada 1100 Series High Arc Faucet Installation Instructions

8 3/8/07 Bradley Corporation • 215-1558 Rev. A; EN 07-202

NOTE: For bank installation only.

Loading...

Loading...