Page 1

• Lead-Free Brass Design †

NSF/ANSI 372

• Reliable Liquid-Filled Thermostat with 10-Year Warranty

• Integral Strainer Checkstops on Inlets

• Adjustable Set Point within Temperature Range

• Accurate Temperature Control to within ±3° F

• Positive Shutoff of Flow in the Event of Cold Supply Line Failure

or Thermostat Failure

• Easy Installation and Serviceability

• Dirt and Lime Resistant

• Factory Assembled and Tested

• Universal Mounting Capability

• Dial Thermometer

• Cabinet Features:

— 18 Gauge Body & Door

— Left-Hand Hinge

— Cylinder Lock

— Inlet/Outlet Knock-Out Holes for Mounting Flexibility

— Stainless Steel or Baked White Enamel Finishes

— Surface-Mounted or Recessed Style with Flange

Valve Specifications

Maximum Operating Pressure

125 PSI (860 kPA)

Maximum Inlet Temperature

200° F (93° C)

Temperature Range Set Point

Std.

Low

High

Flow Capacities – GPM (L/Min)

Model

S59-3130

* Recirculation system only (See diagram on Page 2). When properly installed near

the hot water source with a continuously operating recirculation pump, the valve will

maintain set temperature with a .5 GPM (2.0 L/Min) draw from the plumbing system.

90° F (32° C) to 120° F (49° C)

70° F (21° C) to 100° F (38° C)

110° F (43° C) to 140° F (60° C)

Min*

Flow

4.0

(15)

5

(.5)

40.0

(184.5)

Pressure Drop – PSI (Bar)

10

(1.0)

58.0

(265.0)

15

(1.5)

71.0

(327.0)

20

(2.0)

83.0

(380.0)

110° F (43° C)

80° F (27° C)

130° F (54° C)

30

(2.5)

(3.0)

102.0

126.0

(427.0)

(470.0)

45

Code Compliance and Certifications

ASSE 1017 & cUPC certified. Complies with California Lead Plumbing Law.

Certified to

Wetted surface contains less than .25% lead

†

Standard product selections contained within this document are third party

CERTIFIED to NSF/ANSI 372 meeting the Lead-Free content requirement.

Any product configured with custom options will be COMPLIANT with NSF/

ANSI 372 meeting the Lead-Free content requirement.

Engineer's Approval

Page 1 of 4 8/19/2014

This information is subject to change without notice.

Bradley_TMV_HighLow_HL130

60

(4.0)

147.0

(546.0)

HL130

Thermostatic High-Low Valves

HL130 (Part No. S59-3130)

Optional Selections

Finish

¨C

Thermostat

¨L

¨H

Bracket

¨B

Piped Assembly

¨P

¨N

Cabinets

¨SS

¨RS

¨SE

¨RE

¨W

Chrome Plated

Low Range Thermostat

High Range Thermostat

Wall Mounting Bracket

Piped Assembly with Inlet and Outlet Shutoff

Piped Assembly with Outlet Shutoff

Surface Mount Stainless Steel

Recessed Stainless Steel

Surface Mount White Enamel

Recessed White Enamel

Plexi-glass Window in Door

Sample Specification

Thermostatic water mixing valve shall consist of a liquid-filled thermal motor and a piston

control mechanism with positive shutoff of hot water when cold water supply is lost. Valve

allows a restricted cold flow in the event of loss or interruption of the hot water supply. All

flow is shut off in the event of thermostat failure. Construction shall be bronze body and

cap with replaceable corrosion resistant components, including stainless steel piston and

liner. Valve shall come equipped with integral checkstops, thermometer, and removable

strainers. Valve shall control temperature within ±3° F from a low flow to a maximum flow

rate for a given pressure differential per the “Flow Capacity Chart.”

P.O. Box 309, Menomonee Falls, WI 53052-0309

800 BRADLEY (800 272 3539) +1 262 251 6000

Lead Free †

© 2015 Bradley

bradleycorp.com

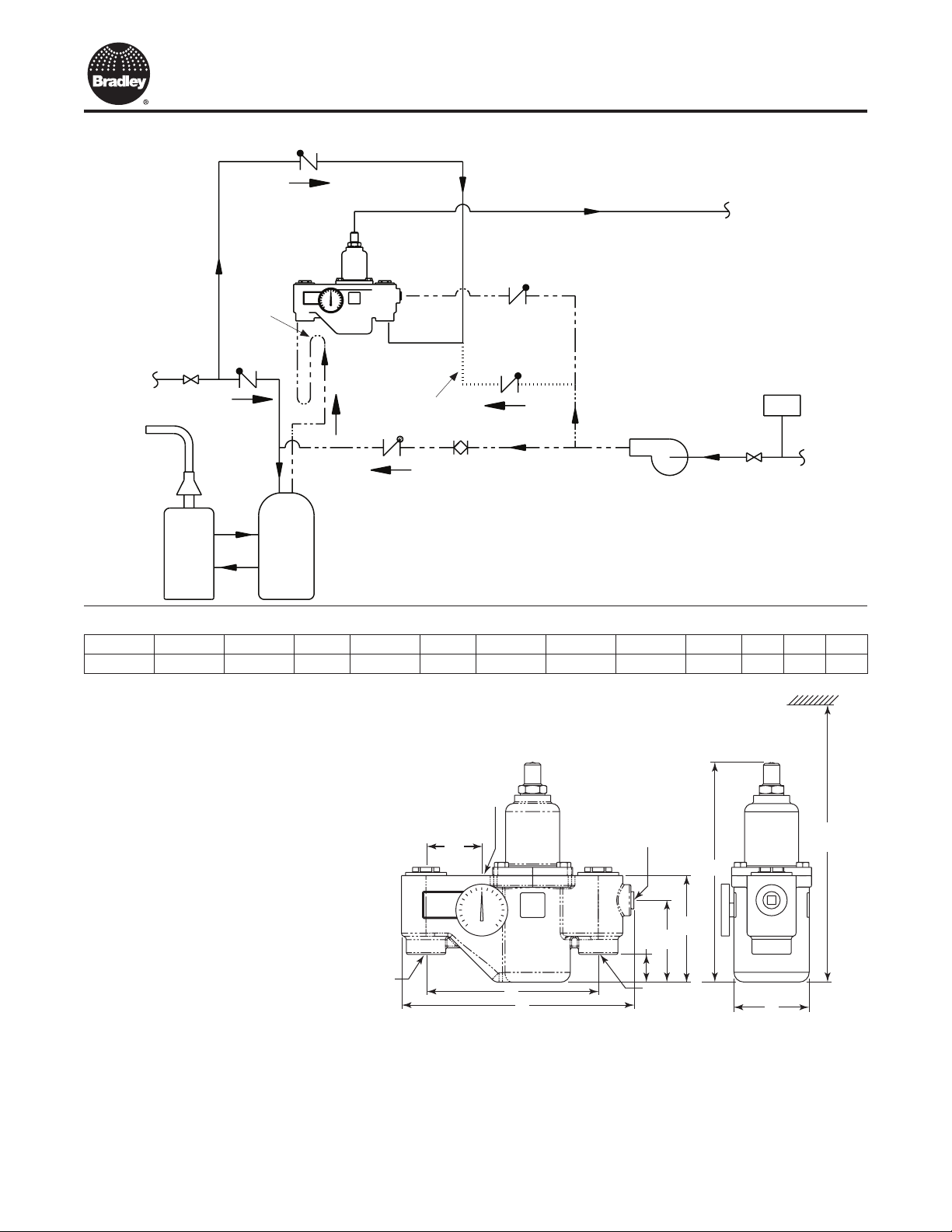

Page 2

HL130

Thermostatic High-Low Valves

Recirculation Diagram (mm)

Check Valve (Typ)

Cold

Tempered Water Flow

Cold

Water

Heat

Trap 28"

Drop

Alternate

Recirculation

(More than

5 GPM)

Balancing

Valve (Typ)

Check Valve

Return

Flow

Recirculating

Pump

Recirculated

Tempered Water

Temperature

Switch

Water

Heater

Storage

Tank

Dimensions

Model A B C D E F G H I X

S59-3130

Page 2 of 4 8/19/2014

This information is subject to change without notice.

Bradley_TMV_HighLow_HL130

2-3/4" (70) 10-1/2" (267) 14" (356) 1-3/4" (45) 5" (127) 6-5/8" (169) 13-1/2" (343) 4-7/8" (124) 22" (559) 1-1/4" 1-1/2" 3/4"

NPT

Y

NPT

A

NPT

X

B

C

Z

F

D

E

NPT

X

P.O. Box 309, Menomonee Falls, WI 53052-0309

800 BRADLEY (800 272 3539) +1 262 251 6000

NPTYNPTZNPT

I

Min.

G

H

© 2015 Bradley

bradleycorp.com

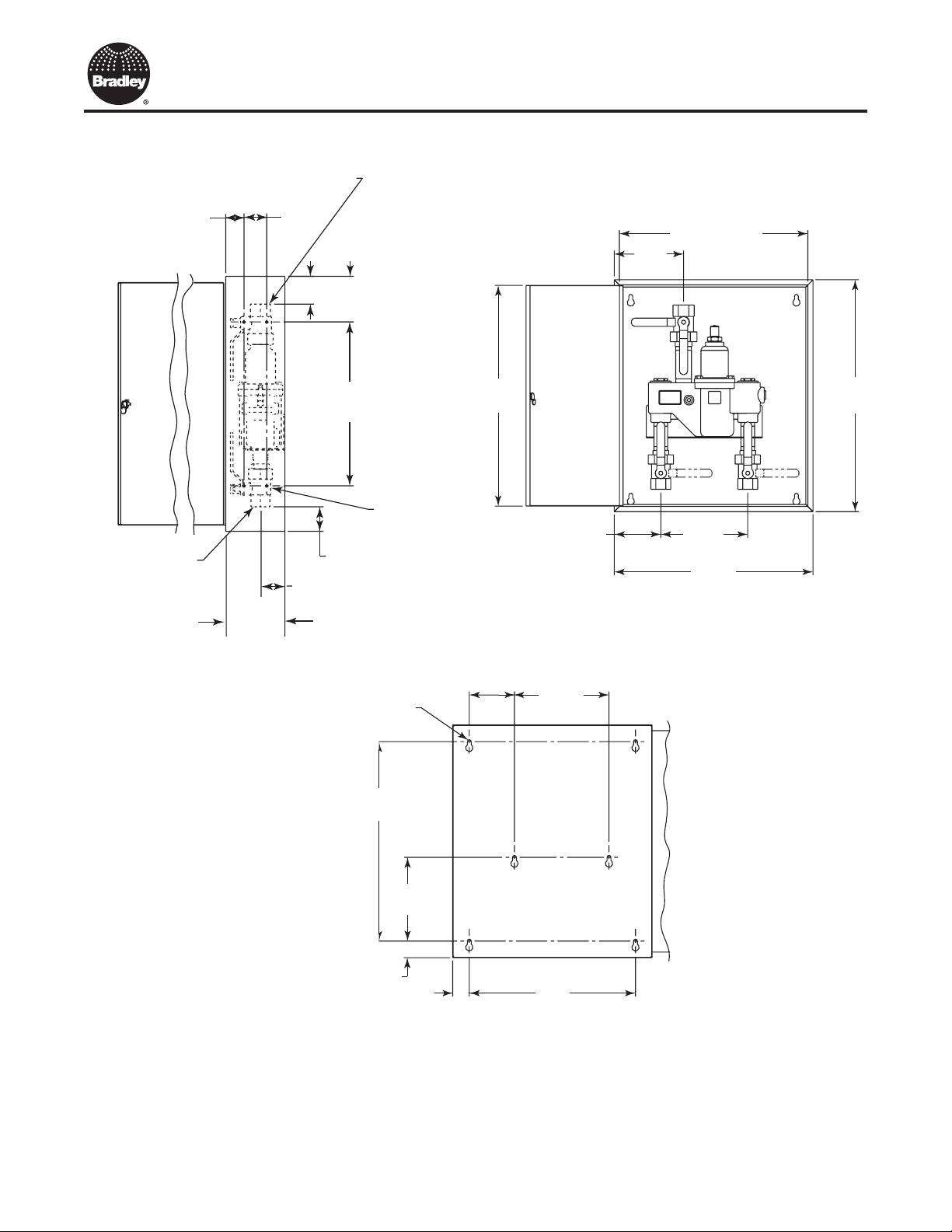

Page 3

Dimensions — HL130 Surface-Mounted Cabinet

HL130

Thermostatic High-Low Valves

(mm)

Side

View

1-1/4"

NPT

Inlets

(51)

2"

6-1/2"

(165)

1-1/2" NPT Outlet

2-1/2"

(64)

3"

(76)

2-3/4" (70)

2-3/4" (70)

5"

(127)

18"

(457)

.28" Dia. Holes

4 Each Side

8 Total

Front

View

26-5/8"

(677)

5-5/8"

(143)

8-3/8"

(213)

22-3/4" (578)

10-1/2"

(267)

24"

(610)

28"

(711)

Back

View

Page 3 of 4 8/19/2014

This information is subject to change without notice.

Bradley_TMV_HighLow_HL130

.47" Dia. Holes

12 Places

24"

(610)

10-1/8"

(257)

2"

(51)

(51)

2"

5-1/2"

(140)

11-3/8"

(289)

20"

(508)

P.O. Box 309, Menomonee Falls, WI 53052-0309

© 2015 Bradley

800 BRADLEY (800 272 3539) +1 262 251 6000

bradleycorp.com

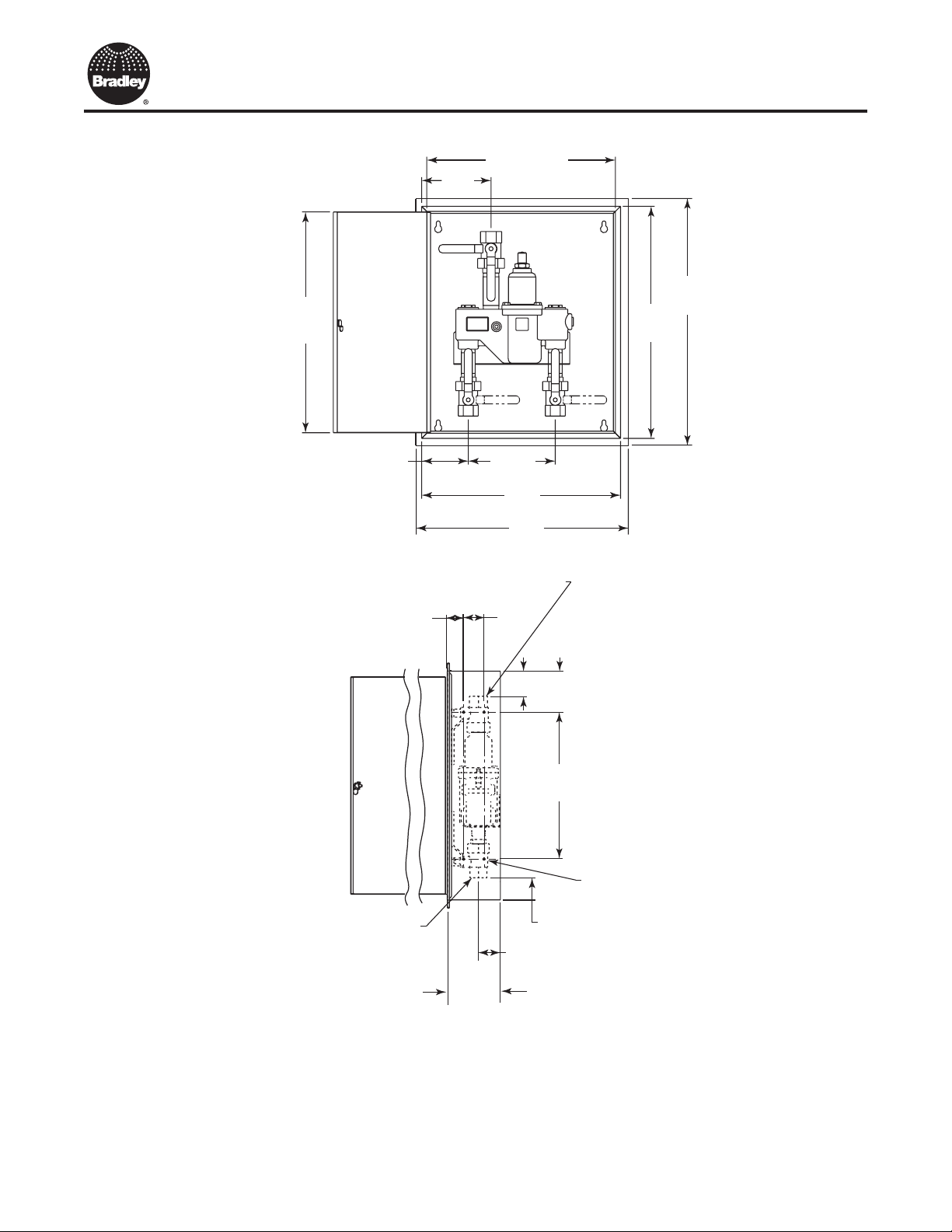

Page 4

Dimensions — HL130 Recessed Cabinet

HL130

Thermostatic High-Low Valves

(mm)

Front

View

Side

View

26-5/8"

(677)

Door

5-5/8"

(143)

(51)

2"

8-3/8"

(213)

22-3/4" (578)

10-1/2"

(267)

24"

(610)

26"

(660)

1-1/2" NPT Outlet

2-1/2"

(64)

28"

(711)

30"

(762)

Page 4 of 4 8/19/2014

This information is subject to change without notice.

Bradley_TMV_HighLow_HL130

1-1/4" NPT

Inlets

6-1/2"

(165)

18"

(457)

.28" Dia. Holes 2

Each Side

4 Total

2-3/4"

(70)

2-3/4"

(70)

P.O. Box 309, Menomonee Falls, WI 53052-0309

800 BRADLEY (800 272 3539) +1 262 251 6000

© 2015 Bradley

bradleycorp.com

Loading...

Loading...