Page 1

Flammable Vapor Ignition Resistant

Water Heaters

Ultra Low NOx Gas Water Heaters

SERVICE

MANUAL

Troubleshooting Guide

and Instructions for Service

(To be performed ONLY by

qualified service providers)

Manual 238-51546-00B REV 10/18

Models Covered

by This Manual:

URG230T*N

URG240S*N

URG240T*N

URG250L*N

URG250H*N

URG250T*N

URG250S*N

URG130T*N

URG140T*N

URG150T*N

(*) Denotes Warranty Years

Save this manual for future reference

Page 2

The Bradford White

ECO

DEFENDER

Safety System

®

Ultra Low NOx Gas Water Heaters

Page ED Service Procedure

Introduction.................................................................................................................................4 ---

How to Use This Manual ..........................................................................................................5 ---

Tools Required for Service........................................................................................................5 ---

Troubleshooting.........................................................................................................................6 ---

Burner Operation Inspection, Cleaning & Replacement....................................................... 10 ED-I

Pilot Inspection, Testing & Replacement.................................................................................12 ED-II

Gas Control Testing & Replacement........................................................................................13 ED-III

Chamber Sensor Testing ...........................................................................................................16 ED-IV

Thermopile Testing and Replacement......................................................................................17 ED-V

Igniter, Electrode Testingand Replacement ............................................................................18 ED-VI

Resettable Thermal Switch Testing and Replacement............................................................19 ED-VII

Diptube Inspection and Replacement.......................................................................................21 ED-VIII

Anode Inspection & Replacement............................................................................................22 ED-IX

Inner Door Removal, Inspection & Replacement................................................................... 23

Flue Baffle Inspection & Replacement ....................................................................................26 ED-XI

ScreenLok® ...............................................................................................................................27 ---

Glossary of Terms......................................................................................................................28 ---

Parts List.....................................................................................................................................29 ---

2

ED-X

2

Page 3

ECO Defender Series

WARNING: If the information in these

instructions is not followed exactly, a fire or

explosion may result causing property damage,

personal injury, or death.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable, combustible,

or corrosive vapors and liquids in the vicinity of this or any

other appliance.

WHAT TO DO IF YOU SMELL GAS!

x

Do not try to light any appliance.

Do not touch any electrical switch; do not use any

x

phone in your building.

Immediately call your gas supplier from a neighbor's phone.

x

Follow the gas supplier's instructions.

If you cannot reach your gas supplier, call the fire

x

department.

Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

DANGER

Do not store or use gasoline or other flammable,

combustible, or corrosive vapors and liquids in

the vicinity of this or any other appliance.

IMPORTANT

Before proceeding, please inspect the

water heater and its components for

possible damage. DO NOT install any

water heater with damaged

components. If damage is evident

then please contact the supplier where

the water heater was purchased or the

manufacturer listed on the rating plate

for replacement parts.

WARNING

Water heaters are heat producing appliances. To avoid damage

or injury, do not store materials against the water heater or vent-

air intake system. Use proper care to avoid unnecessary contact

(especially by children) with the water heater and vent-air intake

components. UNDER NO CIRCUMSTANCES MUST

FLAMMABLE MATERIALS, SUCH AS GASOLINE OR PAINT

THINNER BE USED OR STORED IN THE VICINITY OF THIS

WATER HEATER, VENT-AIR INTAKE SYSTEM OR IN ANY

LOCATION FROM WHICH FUMES COULD REACH THE

WATER HEATER OR VENT-AIR INTAKE SYSTEM

CAUTION

If sweat fittings are to be used DO NOT apply heat to the nipples

on top of the water heater. Sweat the tubing to the adapter

before fitting the adapter to the water connections. It is

imperative that heat is not applied to the nipples containing a

plastic liner.

WARNING

Hydrogen gas can be produced in an operating water heater that

has not had water drawn from the tank for a long period of time

(generally two weeks or more). Hydrogen gas is extremely

flammable. To prevent the possibility of injury under these

conditions, we recommend the hot water faucet to be open for

several minutes at the kitchen sink before you use any electrical

appliance which is connected to the hot water system. If

hydrogen is present, there will be an unusual sound such as air

escaping through the pipes as hot water begins to flow. Do not

smoke or have open flame near the faucet at the time it is open.

WARNING

DO NOT ATTEMPT TO LIGHT ANY GAS APPLIANCE IF YOU ARE

NOT CERTAIN OF THE FOLLOWING:

x

Liquefied petroleum gases/propane gas and natural gas

have an odorant added by the gas supplier that aids in the

detection of the gas.

x

Most people recognize this odor as a “sulfur” or “rotten egg”

smell.

x

Other conditions, such as “odorant fade” can cause the

odorant to diminish in intensity, or “fade”, and not be as

readily detectable.

x

If you have a diminished sense of smell, or are in any way

unsure of the presence of gas, immediately contact your gas

supplier from a neighbor’s telephone.

Gas detectors are available. Contact your gas supplier, or plumbing

professional, for more information.

WARNING

FAILURE TO INSTALL AND MAINTAIN A NEW, LISTED ¾” X ¾”

TEMPERATURE AND PRESSURE RELIEF VALVE WILL RELEASE

THE MANUFACTURER FROM ANY CLAIM THAT MIGHT RESULT

FROM EXCESSIVE TEMPERATURE AND PRESSURES.

CAUTION

Turn off or disconnect the electrical power supply to the water heater

before servicing. Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dangerous operation.

Verify proper operation after servicing.

3

3

Page 4

ECO Defender Series

Introduction

The Bradford White ECO-DEFENDER Safety System was designed to resist the ignition of flammable

vapors that can occur outside of the water heater. In addition, the ECO-DEFENDER Safety System is

designed to meet the stringent NOx emissions standards required in the South Coast Air Quality

Management District (SCAQMD) Rule 1121. Use and installation are nearly identical to previous versions of

atmospherically fired and vented water heaters. A number of exclusive design features are incorporated in

the system that will require additional knowledge on the part of the qualified service provider. The following

information will instruct service professionals on the function, proper diagnosis and repair of the water

heaters employing the Bradford White ECO-DEFENDER Safety System

How the Safety System Works

During normal operation, most air for combustion is drawn into the water heater through the openings in the

jacket door. This air travels into the burner venturi, mixing with the gas jet. This air is then mixed with gas

inside the burner and drawn to the burner screen and is efficiently combusted producing Ultra Low NOx

emissions. Additional air is drawn through the openings in the jacket. This air travels down and around the

combustion chamber and enters through holes in the bottom of the corrosion resistant combustion chamber.

The air then travels up through the oriented flame arrestor plate louvers, where the velocity of the air is

increased and its direction altered. The air then mixes in a normal manner with the combustion products

from the burner.

®

.

In the case where trace amounts of flammable vapors are present in the air flowing into the combustion

chamber and burner venturi, the vapors are harmlessly ignited by the burner pilot flame. If flammable vapors

are in sufficient quantity to prevent normal combustion, the burner and pilot flames are designed to shut

down.

Should the flammable vapors continue to the burner, the flame arrestor plate and burner screen prevent the

flames from traveling backwards and igniting vapors outside of the combustion chamber. This causes the

thermopile to overheat and shuts down the main pilot and burner. The thermopile powers the intelligent

diagnostic control which is capable of recognizing restricted airflow conditions caused by severe lint, dust

and oil accumulation on the burner screen and arrestor plate. The intelligent diagnostic control will

deactivate the burner and pilot in the unlikely event of restricted airflow.

4

4

Page 5

It is intended for this manual to be used by qualified service personnel for the primary purpose of

troubleshooting and repair of the Bradford White ECO-DEFENDER Series water heaters.

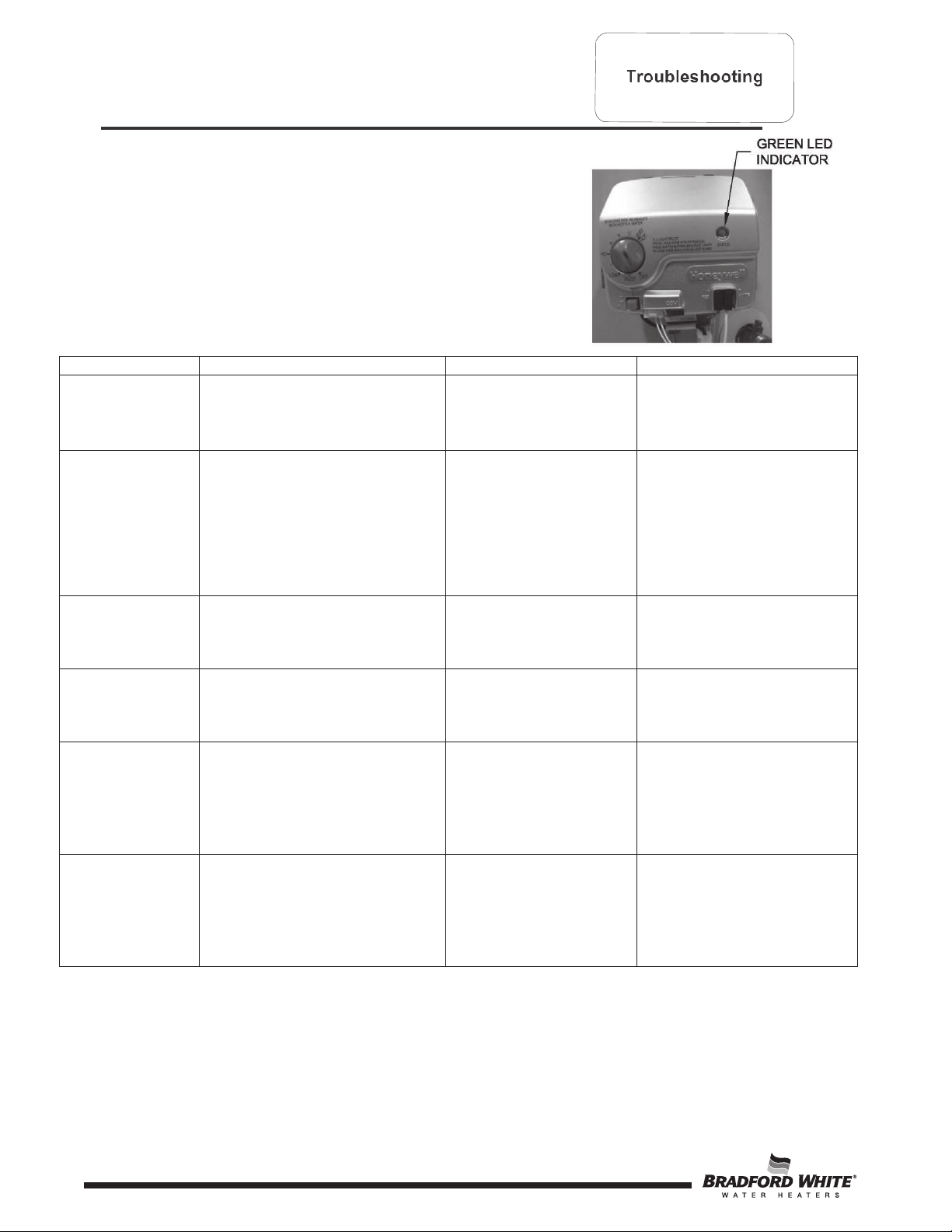

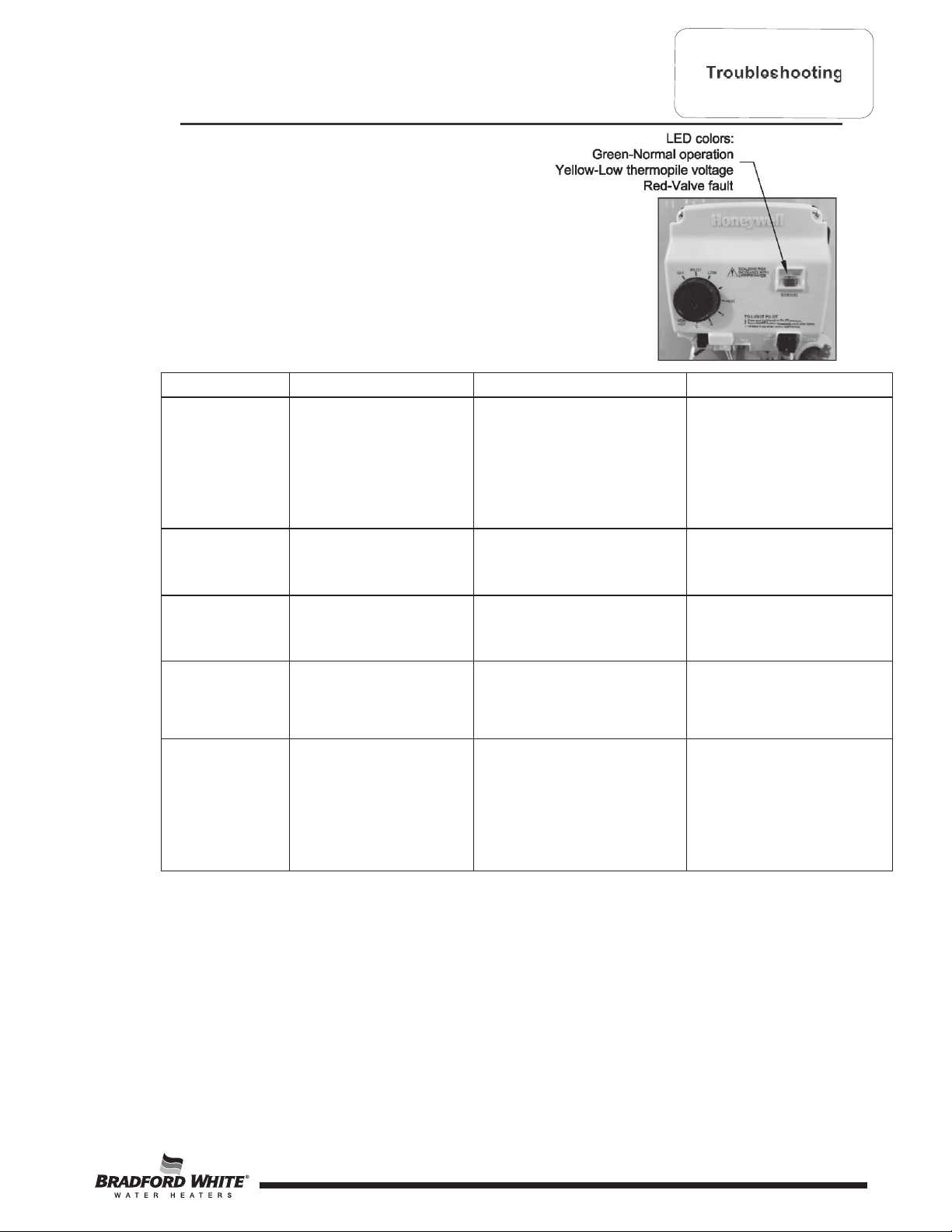

The Honeywell WV8860 Gas Control will display status codes in the event of abnormal operation. Status

codes are listed in the troubleshooting chart beginning on page 6 of this service manual. The troubleshooting

chart will also indicate the probable cause for the status code and direct the service professional to a service

procedure to properly diagnose the abnormal operation.

Contact the Bradford White technical support group immediately if diagnosis cannot be made using the

methods described in this service manual.

Tools Required for Service

ECO Defender Series

Manometer:

Multi-Meter:

Electronic Probes:

Thermometer:

Water Pressure Gage:

Various Hand Tools:

A liquid “U” tube type or a digital (magnahelic) type can be used. This

device is used to measure gas and/or air pressure and vacuum.

A digital type is strongly recommended. This device is used to measure

electrical values. The meter you select must have the capability to

measure volts AC, volts DC, Amps, micro-amps and ohms.

In some cases, standard multi-meter probes will damage or simply not be

effective to obtain certain voltage and ohm readings. It will be necessary to

have special electronic “pin” type multi-meter probes. These probes are

available at most electronic wholesale outlets.

Used to measure water temperature. An accurate thermometer is

recommended.

Used to measure water supply pressure. Also used to determine tank

pressure by adapting to the drain valve of the heater.

Pipe wrench, channel locks, open end wrenches (3/8”, 7/16”, 1/2”), 12”

crescent wrench, allen wrench set, screw drivers (common & Phillip’s), 1/4”

nut driver, pliers (common & needle nose), socket set, side cutters, wire

cutters, wire strippers, wire crimpers, torpedo level, small shop vacuum,

step ladder, flashlight and 5-gallon pail.

5

5

Page 6

ECO Defender Series V1

g

Observe green LED indicator on

electronic gas control. Status flash

codes are displayed with a three second

pause before repeating. Check and

repair the system as noted in the

troubleshooting table below.

LED Status Control Status Probable Cause Service Procedure

If the pilot will not stay lit

None (LED not

on or flashing)

One flash and

three second

pause

LED strobe (two

quick flashes)

and three second

pause

LED on

continuously

(solid)

Pilot assembly is not lit

1.

If setpoint knob is in “PILOT”

position then pilot flame is

detected. Turn setpoint knob

to desired setting.

2.

If the setpoint knob is

already at the desired

setting, the water heater is

satisfied.

Thermostat calling for heat (no

faults).

Setpoint knob has been recently

turned to the “OFF” position. Wait

until LED goes out before

attemptin

to relight.

Gas control is not

powered. Light Pilot.

1.

Gas control is

powered and waiting

for setpoint knob to

be turned to a water

temperature setting.

2.

Water heater is

satisfied and

operating normally.

Tank temperature

below setpoint of

thermostat.

Setpoint knob was

turned to “OFF”

position.

replace pilot assembly. If

problem persists, replace

gas control.

Normal operation.

Normal operation.

LED will not go out and the

control will function

normally the is lit.

Two flashes

and three

second pause

Three flashes

and three

second pause

6

Weak pilot signal detected.

System will reset when pilot

flame is sufficient.

Insufficient water heating.

System will reset.

1.

Thermopile failure.

2.

Unstable pilot.

3.

Pilot tube block or

restricted.

1.

Thermal sensor out

of calibration.

2.

Faulty gas control.

1.

See service procedure IV

2.

See service procedure II

3.

See service procedure II

Replace gas control.

6

Page 7

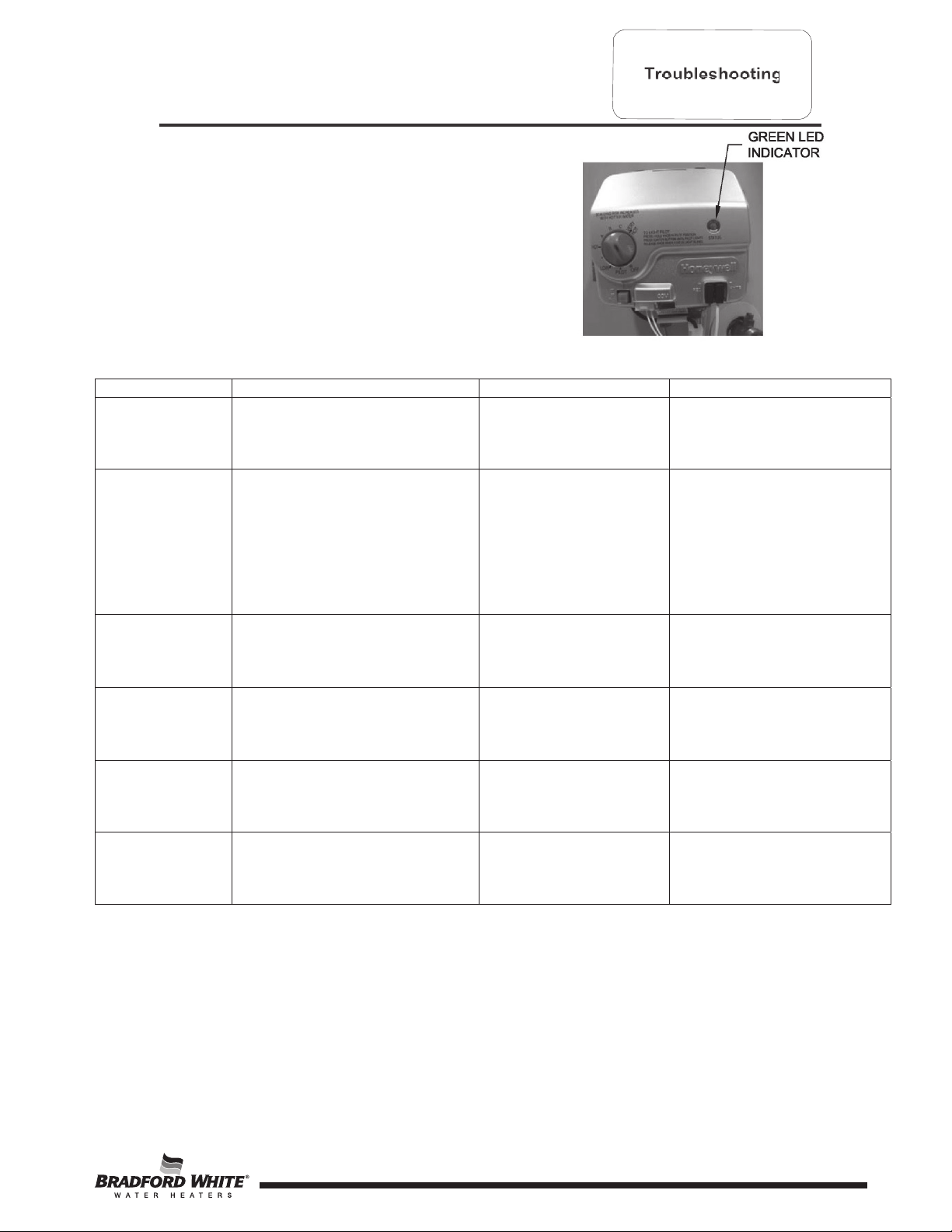

ECO Defender Series V1

Observe green LED indicator on

electronic gas control. Status flash

codes are displayed with a three second

pause before repeating. Check and

repair the system as noted in the

troubleshooting table below.

LED Status Control Status Probable Cause Service Procedure

Four flashes

three second

pause

Five flashes

and three

second pause

Six flashes

and three

second pause

Seven flashes

and three

second pause

Excessive tank temperature.

System must be reset.

Temperature sensor fault.

Chamber temperature sensor out

of specification. Possible short.

Gas valve electronic fault

detected.

1.

Temperature sensor

out of calibration.

2.

Faulty gas control.

1.

Damage to the

temperature sensor.

2.

Temperature sensor

resistance out of

range.

1. Chamber

temperature sensor

out of calibration.

2. Possible short.

1.

Control needs to be

reset.

2.

Control is wet or

physically damaged.

Replace gas control

1.

Verify control is not wet or

physically damaged

2.

Turn set point knob to

“OFF” position. Turn set

point knob to “PILOT”

position and light pilot.

3.

Replace gas valve if five

flash status persists.

1. Reset gas control

2. Replace gas control.

1. Reset gas control

2. Replace gas control.

Eight flashes

and three

second pause

Ten flashes

and three

second pause.

Standing pilot remains on while

setpoint knob is in “OFF”

position.

Insufficient combustion air

detected.

7

Pilot valve stuck in

open position.

Insufficient

combustion air.

Replace gas control

1. Reset gas control

2. Replace gas control.

7

Page 8

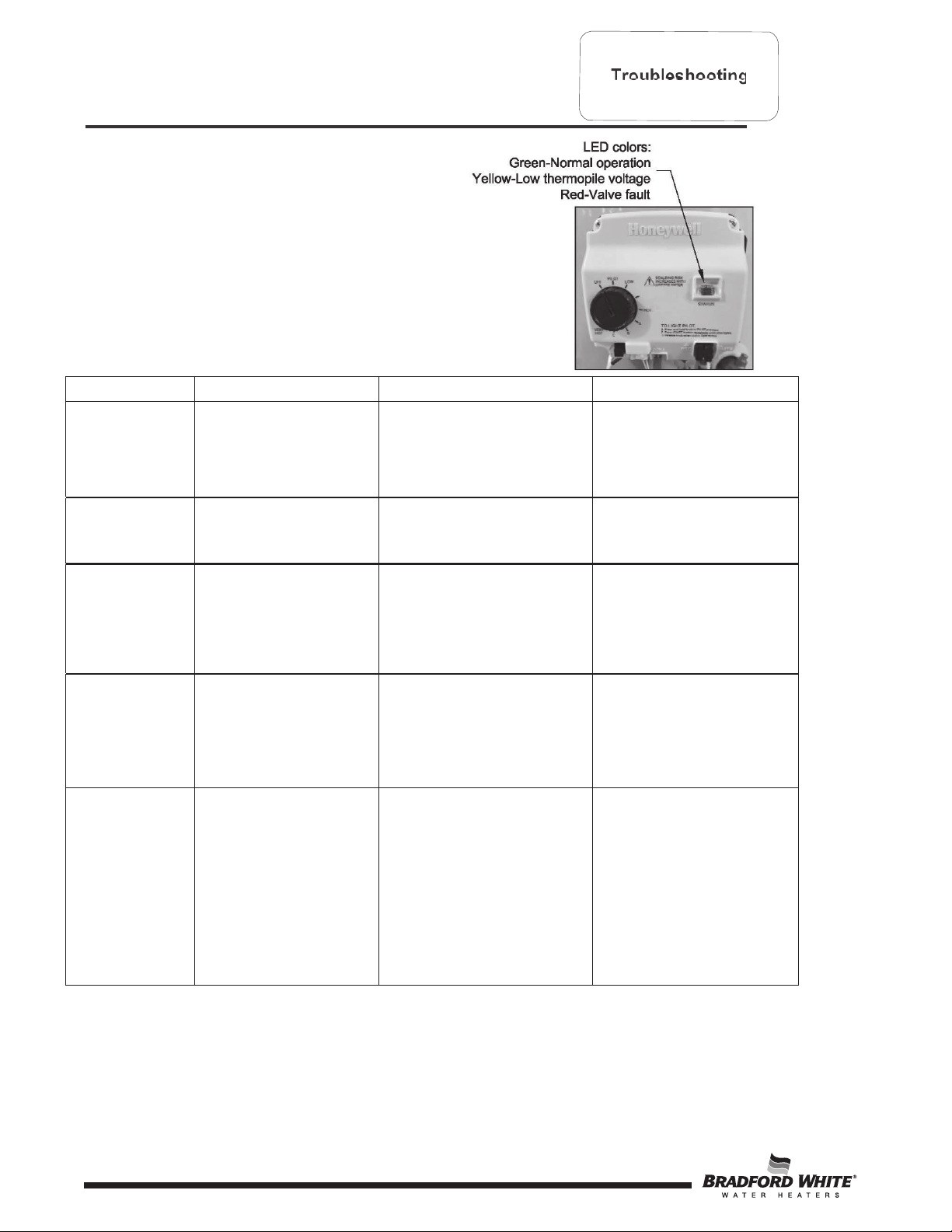

ECO Defender Series V2

Observe colored LED indicator on

electronic gas control. Status flash

codes are displayed with a three second

pause before repeating. Check and

repair the system as noted in the

troubleshooting table below.

LED Status Control Status Probable Cause Service Procedure

If the pilot will not stay

None (LED not

on or flashing)

One flash every

four seconds

(LED green)

One flash every

second

(LED green)

Two flashes

(LED yellow)

Four flashes

(LED red)

Millivolt power is not

present. Light pilot.

Not an error. Indicates

pilot is lit and main

burner is off.

Not an error. Indicates

main valve is open and

main burner is lit.

Low thermopile voltage;

main valve not turned

ON.

Temperature cut-out

limit reached.

Gas valve is functioning

normally. Gas valve is not

powered. Light pilot.

You can now turn the know

to a desired setpoint

temperature

None. Control will

automatically shut main

burner off when water

temperature reaches the

setpoint temperature.

Check thermopile and its

connections. Check pilot

flame.

Check the valves and the

water temperature sensor.

Reduce the water

temperature setpoint.

Thoroughly check

out main valve operation

and water temperature

control before walking

away.

lit replace pilot

assembly. If problem

persists, replace gas

control.

Normal operation.

Normal operation.

1. See service procedure

IV.

2. See service procedure

II.

3. See service procedure

II.

Replace gas control

8

8

Page 9

ECO Defender Series V2

Observe colored LED indicator on

electronic gas control. Status flash

codes are displayed with a three second

pause before repeating. Check and

repair the system as noted in the

troubleshooting table below.

LED Status Control Status Probable Cause Service Procedure

Check water temperature

sensor and its connection

Five flashes

(LED red)

Six flashes

(LED red)

Solid ON

(LED red)

Nine flashes

(LED red)

Ten flashes

(LED red)

Water temperature

sensor failure.

Door temperature

sensor failure.

Not an error-indicates

that the control is in

OFF mode.

Tank leakage detected

by accessory module.

Abnormal combustion

chamber temperature

profile during heating

cycle.

for open circuits, shorts, or

differences in resistance

between the two sensor

elements.

Check door temperature

sensor and its connection

for open circuits or shorts.

None; wait until LED turns

off if you want to restart

system.

Control recovers after

receiving message from

accessory module.

Clean all combustion air

intakes to the appliance.

Clean the burner. Remove

all obstacles that may

restrict air flow to the

burner.

Replace gas control

See service procedure X.

LED will go out and the

control will function

normally the pilot is lit.

1. Check T&P valve.

2. Check all water fittings.

3. Pressurize and leak test

tank.

Replace gas control

9

9

Page 10

ECO Defender Series

Burner Inspection

At periodic intervals (every 6 months) a visual

inspection should be made of the pilot and main

burner for proper operation and to assure no

debris is accumulating.

Pilot flame should be stable, some causes for an unstable

pilot flame are:

a)

b)

c)

Main burner should light smoothly from

pilot and burn with a blue flame with a

minimum of yellow tips.

Main burner must be free from any

debris accumulation that may affect

burner operation (see burner cleaning

procedure below).

Water heater vent is less than the allowable

vent length.

Gas pressure is out of specification.

Pilot flame not fully

engulfing spark/flame

sensor.

Burner Cleaning

Step 1.

Step 2.

Step 3.

Step 4.

Step 5.

Step 6.

Step 7.

Position gas control knob to the

“OFF” position.

Turn off gas supply to water

heater.

Remove outer jacket door and inner door per

service procedure ED-X on page 21.

Disconnect pilot tube (7/16” wrench) and

feedline (3/4” wrench) from gas control.

Disconnect chamber door temperature sensor

from gas control.

Disconnect resettable thermal switch’s white

and red wire leads from gas control.

Remove burner assembly from combustion

chamber.

10

10

Page 11

ECO Defender Series

Burner Cleaning (cont.)

Step 8.

Step 9.

Remove manifold mount from burner

inner door by removing (2) ¼” hex

drive screws.

Thoroughly inspect burner surface

area and burner port area. Remove

any loose debris using a stiff brush,

compressed air and/or a shop

vacuum.

Step 10.

Step 11.

Step 12.

Unscrew main burner orifice and feedline

from manifold mount. Remove main burner

orifice from feedline (1/2” wrench) inspect

orifice, clean or replace if necessary.

Reassemble burner and reinstall into

water heater. Restore gas supply and

check for gas leaks.

To resume operation, follow the

instructions located on the lighting

instruction label or the lighting instructions

located in the installation and operation

manual.

11

11

Page 12

ECO Defender Series

Pilot Inspection, Testing and

Replacement

Step 1.

Step 2.

Step 3.

Step 4.

Step 5.

Step 6.

Step 7.

Step 8.

Step 9.

Step 10.

Step 11.

Step 12.

Step 13.

Step 14.

Step 15.

Step 16.

Step 17.

Step 18.

Step 19.

Position gas control knob “OFF” position.

Turn off gas supply to water heater.

Remove outer jacket door and inner door per

service procedure ED-X on page 21.

Disconnect pilot tubing nut (7/16” wrench) and

feedline nut (3/4” wrench) from gas control.

Disconnect igniter/flame sense wire from gas control.

Disconnect wire connections to the resettable thermal switch.

Disconnect chamber door thermal sensor from gas control.

Remove burner assembly from combustion chamber.

Remove pilot assembly from burner (1/4” nut driver).

Visually inspect igniter/flame sense wire for damage.

Replace pilot if damage is found.

With a multi-meter set to ohms setting,

check continuity through igniter/flame

sense wire. Replace pilot if no continuity.

Visually inspect igniter/flame sense

electrode for deterioration. Replace

pilot as necessary. Electrode should

not be in contact with pilot hood.

Visually inspect igniter/flame sense

electrode for oxidation build up.

Carefully clean any oxidation using very

fine emery cloth.

Visually inspect pilot tubing for kinks or

cracks. If damage is found, replace

pilot.

Inspect pilot tubing and pilot orifice for

blockage:

a.

Remove ferrule nut from bottom of pilot

assembly (7/16” wrench).

b.

Remove pilot tube and pilot orifice.

c.

Inspect pilot tubing and pilot orifice for blockage.

replace as necessary.

Reassemble pilot and install onto burner.

Reinstall burner assembly to water heater.

Restore gas supply and check for gas leaks.

To resume operation, follow the instructions located on the lighting

instruction label or the lighting instructions located in the installation and

operation manual.

Clean or

12

12

Page 13

ECO Defender Series

Line Pressure

The gas control is designed for a maximum

line pressure of 14.0” w.c. and a minimum

line pressure of 1.0” w.c. over the water

heater’s rated manifold pressure (check

rating plate). Line pressure must be

checked with the main burner on and off to

assure proper readings.

Manifold Pressure Testing

(this procedure presumes a maximum

line pressure of 14.0” w.c.)

Step 1.

Step 2.

Step 3.

Step 4.

Step 5.

Step 6.

Step 7.

Set the gas control knob to the “OFF”

position.

Remove pressure tap plug and install

1/8” NPT pipe, coupling & pressure

tap.

Connect manometer to pressure tap.

Follow instructions located on the

lighting instructions label and proceed

to light the main burner and observe

manometer reading.

Proper manifold pressure operating

range for Natural Gas is 5.0” ±0.5” w.c.

If pressure is within the range specified

in the previous step, set Gas

Control knob to the “OFF” position,

remove manometer and pressure tap,

and replace pressure tap plug. Check

for gas leaks prior to placing water

heater back into operation by following

the instructions located on the lighting

label, or the lighting instructions

located in the installation and operation

manual.

If gas pressure is outside the

specification noted above, refer to

page 16 to replace gas control.

13

13

Page 14

ECO Defender Series

Determine Water Temperature Inside Tank

WARNING

Stored water may be HOT WHEN PERFORMING THE FOLLOWING STEPS IN

THIS PROCEDURE. Take necessary precaution to prevent personal injury.

Step 1.

Step 2.

Position gas control knob to the “OFF” position.

Draw approximately 4 gallons of water from the drain valve into a container

and discard. Draw an additional gallon and immediately measure water

temperature using an accurate thermometer (It may be necessary to open

a hot water faucet to allow heater to drain).

Compare the measured water temperature with the setting on the gasStep 3.

control.

10°F.

In most instances, they should not differ by more than approx.

14

14

Page 15

ECO Defender Series

Gas Control Removal from Water Heater

Step 1.

Step 2.

Step 3.

Step 4.

Step 5.

Step 6.

Step 7.

Step 8.

Step 9.

Step 10. Reattach main burner feedline, pilot tube and all wire harnesses.

Step 11. Reconnect gas supply piping to inlet of gas control.

Rotate the gas control knob to the

“OFF” position.

Drain the heater to a point below the

gas control level.

Turn off the gas supply to the water

heater and disconnect gas piping from

the gas control.

Disconnect wire harnesses from the

gas control.

Remove the outer jacket burner

access door.

Disconnect main burner feedline, swing counter-clockwise away from gas control.

Disconnect pilot tube from gas control and move away from gas control.

Removal gas control from water heater by rotating counter clockwise. DO NOT

use a wrench on the gas control body, damage to the gas control may occur. If

necessary, use a length of ½” NPT pipe threaded into gas inlet of gas control.

Install new gas control into water heater by rotating clockwise. DO NOT use a

wrench on the gas control body, damage to the gas control may occur. If

necessary, use a length of ½” NPT pipe threaded into gas inlet of gas control.

15

15

Page 16

ECO Defender Series

Chamber Sensor Testing

Step 1. Rotate the gas control knob to

the “OFF” position.

Step 2. Disconnect the chamber sensor wire

harness from the gas control.

Step 3. Remove the chamber door temperature

sensor from the right side inner door

(Phillips screw driver).

Step 4. Make sure that the ring terminal of the chamber door

temperature sensor is not touching any surface. Using a multi-meter set to the

ohms setting, insert one-meter probe (see caution) into each of the wire

positions (see photo).

Step 5. Measure the ambient air temperature near the sensor. Compare the ambient

temperature range to the expected resistance range on the chart below.

that resistance increases as temperature decreases.

Note

16

CAUTION

DO NOT use standard multimeter

probes for this test. Doing so will

damage connector. Use special

pin type electronic probes or

small diameter wire pins inserted

into connector.

Sensor Resistance at Various Temperatures

Temperature Range (°F)

41-50

50-59

59-68

68-77

77-86

86-104

104-113

113-122

122-131

Resistance Range (kOhms)

279-175

219-139

173-112

137-90

110-72

89-59

73-48

60-39

49-32

16

Page 17

ECO Defender Series

Closed Circuit Thermopile Testing

WARNING

115 volt potential exposure. Use

caution to avoid personal injury.

Step 1.

Step 2.

Step 3. If reading is

Closed circuit testing is the

preferred method for testing the

thermopile. Following the lighting

instruction label on the heater,

proceed to light the pilot and allow

to operate for three minutes. If the

pilot will not stay lit, hold the pilot

button (rotate the gas control knob

to the pilot position, push and hold

in) during this test.

Using a multimeter capable of measuring millivolts, place

on lead of the multi meter on the left side of the wire

harness and place the second lead of the multi meter on

the right side of the wire harness.

If meter reads 300 millivolts or higher, the thermopile is OK.

below 300 millivolts, replace the pilot assembly per service procedure ED-II

on page 10.

Open Circuit Thermopile Testing

17

Step 1.

Step 2.

Step 3.

Disconnect red thermopile wire from wire harness leading to the gas control.

Disconnect the white thermopile wire from the resettable thermal switch.

Using a multi meter capable of measuring millivolts, connect one lead to

the red thermopile wire and one lead to the white thermopile wire.

Following the lighting instruction label on the heater,

proceed to light the pilot

and allow the heater to

operate for three minutes.

It will be necessary to hold

the gas control knob down

in the “PILOT”

position continuously

throughout this test. A

reading over 400 millivolts

indicates a good thermopile

output. A reading under 400 millivolts indicates a bad thermopile,

replace the pilot assembly per service procedure ED-II on page 10.

17

Page 18

ECO Defender Series

Igniter, Electrode Testing and Replacement

Step 1.

Step 2.

Step 3.

Remove outer jacket door.

Repeatedly depress the igniter button while

viewing the pilot through the sight glass. If a

spark is present, the circuit is OK. If there is

no spark, proceed to step 3.

Remove white wire from igniter. Hold the

igniter lead from the gas control to an

unpainted surface such as the feedline or gas

control and depress the igniter. If there is a

spark, the igniter is OK, the pilot is not

functioning and must be replaced, see service

procedure ED-II on page 10.

18

18

Page 19

ECO Defender Series

Resettable Thermal Switch Testing and Replacement

Step 1.

Step 2.

Step 3.

Step 4.

Step 5.

Remove outer jacket door.

Disconnect white wire leads from the

resettable thermal switch.

Using a multimeter capable of

measuring continuity (Ohms), place one

probe of the meter on one of the brass

connection tabs of the resettable

thermal switch, and the remaining probe

on the other connection tab.

If continuity is indicated, the switch is

closed, allowing millivolt current to pass.

If continuity is not indicated, the switch

is open, possibly due to an overheating

condition. The switch is designed to

open at predetermined temperatures.

An open switch can be reset by

depressing the red colored button

located at the center of the switch. The

overheating condition must be

determined prior to putting the water

heater back into service.

19

PROBABLE CAUSE FOR RESETTABLE THERMAL SWITCH

PROBABLE CAUSE CORRECTIVE ACTION

Inspect burner per service

-

Burner failure

Weak switch or switch out of

Flammable vapor incident Replace water heater

procedure ED

replace burner if

Replace resettable thermal switch

I on page 8 and

19

Page 20

ECO Defender Series

Resettable Thermal Switch Testing and Replacement (cont.)

Step 1.

Step 2.

Step 3.

Step 4.

Step 5.

Step 6.

Step 7.

Step 8.

Step 9.

Rotate gas control knob to the

“OFF” position.

Remove outer jacket door.

Disconnect wire leads from

resettable thermal switch.

Remove (2) ¼” hex drive screws

from the manifold mount.

Remove resettable thermal switch from

manifold mount (Phillips screw driver).

Place new resettable thermal switch in place. Be sure contact surface

of resettable thermal switch and manifold mount are free of any debris.

Secure resettable thermal switch into place using screws from step 6.

DO NOT OVER TIGHTEN SCREWS.

Reconnect wire leads from gas valve and thermopile to resettable

thermal switch.

Note: Wire terminations are interchangeable with either resettable

thermal switch connection.

Replace outer jacket door.

To resume operation, follow the instructions located on the lighting

instruction label or the lighting instruction located in the installation and

operation manual.

20

20

Page 21

ECO Defender Series

Diptube Inspection & Replacement

WARNING

Water Heater components and stored water may be HOT when performing the

following steps in this procedure. Take necessary precaution to prevent

personal injury.

Step 1.

Step 2.

Step 3.

Step 4.

Step 5.

Step 6.

Step 7.

Rotate gas control knob to the “OFF”.

Turn off the cold-water supply to the water heater. Connect the hose to the

drain valve of the water heater and route it to an open drain. Open a nearby hot

water faucet to vent the water heater for draining. Open the drain valve of the

water heater and allow the water heater to drain to a point below the inlet

connection nipple.

Disconnect the inlet nipple from the plumbing system.

With an appropriate tool such as a pipe wrench, remove the inlet nipple/diptube

from the water heater. Use caution not to damage the pipe threads.

Visually inspect the inlet nipple/diptube. The Inlet nipple/diptube should be free

of cracks and any blockages. The Hydrojet slots should be open and free of any

blockages. Any damage such as cracks, restriction due to deformation or

unintentional holes, are not field repairable and the inlet nipple/diptube must be

replaced.

Upon completion of an inspection or subsequent replacement, reinstall the inlet

nipple/diptube into the water heater. Ensure pipe dope is used on the nipple’s

threads. Connect the nipple to the plumbing system, resume the water supply

and refill with water.

To resume operation, follow the instructions located on the lighting instruction

label or the lighting instructions located in the installation and operation manual.

21

21

Page 22

ECO Defender Series

Anode Inspection & Replacement

WARNING

Water Heater components and stored water may be HOT when performing the

following steps in this procedure. Take necessary precaution to prevent

personal injury.

Step 1.

Step 2.

Step 3.

Step 4.

Step 5.

Step6.

Step 7.

Rotate the gas control knob to the “OFF” position.

Turn off the cold-water supply to the water heater. Connect a hose to the drain

valve of the water heater and route it to an open drain. Open a nearby hot

water faucet to vent the water heater for draining. Open the drain valve of the

water heater and allow the water heater to drain to a point below the outlet

connection nipple.

Disconnect outlet nipple from the plumbing system.

With an appropriate tool such as a pipe wrench, remove the outlet

nipple/anode from the water heater. Use caution not to damage the pipe

threads.

Visually inspect the outlet nipple/anode. The outlet nipple/anode should show

signs of depletion, this is normal. If depletion is ½ of the original anode

diameter (approximately ¾” diameter), replacement is recommended. If any of

the steel core of the anode is exposed, replacement is recommended.

Upon completion of an inspection or subsequent replacement, reinstall the

outlet nipple/anode into the water heater. Ensure pipe dope is used on the

nipple’s threads. Connect the nipple to the plumbing system, resume the

water supply and refill with water.

To resume operation, follow the instructions located on the lighting instruction

label or the lighting instructions located in the installation and operation

manual.

22

22

Page 23

ECO Defender Series

Inner Door Removal Procedure

Step 1.

Step 2.

Step 3.

Step 4.

Step 5.

Step 6.

Step 7.

Rotate the gas control knob to the “OFF” position.

Remove outer jacket burner access door.

Disconnect chamber door temperature sensor wire harness from gas control.

Remove (2) ¼” hex drive screws from right side inner door.

Remove (2) ¼” drive screws from flange section of inner door.

Remove (2) ¼” drive screws from left side inner door.

Remove inner door and inspect per step 8.

23

Step 8.

If the gasket is not affected by any of the above, gasket replacement is not required.

replacement is required, proceed to Inner Door Gasket Replacement Procedure.

Fully inspect inner door gaskets for the following:

-Tears

-Missing Material

-Cracks

-Dirt or debris

-Other imperfections that will inhibit proper seal

-Gasket adhesion to inner door

-Material left on combustion chamber (around opening)

If

23

Page 24

ECO Defender Series

Inner Door Gasket Replacement Procedure

WARNING

If the information in these instructions is not followed exactly, a

fire or explosion may result causing property damage, personal

injury or death.

Step 9. After inspection of inner door as noted in step 8, completely remove gasket

and adhesive residue from right and left side inner doors as needed.

Step 10. Use RTV sealant (recommended bead size 1/8”) to secure the inner door

gasket to the inner door sections (right & left). Refer to illustration on next

page for proper application. Note the overlap configuration in the flange area

of the inner door. Set the flange section first, this will help to achieve the

proper overlap position.

Installation of Inner Door with Gasket

Step 11.

Step 12.

Step 13.

Clean any residual gasket residue or other debris

from the combustion chamber surface before

installing the inner door/gasket assembly.

Place the left side inner door into position first.

Using the ¼” hex drive screws from step 6,

secure left side inner door in place. DO NOT

OVER TIGHTEN SCREWS

Position pilot tube and igniter/sensor wire against

left side inner door flange gasket.

WARNING

Stripped fastener connections

may allow for seal breach of

inner door. A seal breach may

result in a fire or explosion

causing property damage,

personal injury or death. Do

not over tighten screws in

steps 12, 14 and 15.

24

24

Page 25

ECO Defender Series

Installation of Inner Door with Gasket (cont.)

Step 14.

Step 15.

Firmly place right side inner door flange against the left side inner door flange

and secure with (2) ¼” hex drive screws from step 5. DO NOT OVER

TIGHTEN SCREWS.

Align right side inner door to combustion chamber and verify the fastener

holes of the combustion chamber are aligned with right side inner door slotted

opening. Verify seal integrity around combustion opening. Secure right side

inner door using ¼” hex drive screws from step 4. DO NOT OVER TIGHTEN

SCREWS. Verify both left and right sides of inner door are properly

positioned and sealed against the combustion chamber.

Step 16. Replace outer jacket burner access door.

Step 17. To resume operation, follow the instructions located on the lighting instruction label

or the lighting instructions located in the installation and operation manual.

25

25

Page 26

ECO Defender Series

Flue Baffle Inspection and Replacement

ED SERVICE PROCEDURE

XI

Flue Baffle Inspection &

Step 1.

Step 2.

Step 3.

Step 4.

Step 5.

Step 6.

Rotate the gas control knob to the “OFF”

position.

Disconnect vent system from the exhaust

adapter on top of the water heater.

Remove the draft diverter on top of the water

heater.

Remove the flue baffle from the heater (see

photo A below).

Inspect baffle for deterioration, missing

restrictors. Clean any scale or debris build

up. Replace with a new baffle as necessary.

Reinstall baffle into the flue tube. Be sure

hanger tabs are inserted into the notch

locations at the top of the flue tube (see

photos B & C).

Step 7.

Step 8.

Step 9.

26

Check burner to ensure no scale has accumulated during this operation.

See burner cleaning procedure on page 8.

Reinstall the draft diverter on top of the water heater. Re-connect the

vent system.

To resume operation, follow the lighting instructions located on

the lighting instruction label or the lighting instructions located in

the installation operation manual.

26

Page 27

ECO Defender Series

ScreenLok®Flame Arrestor Cleaning

NOTICE

Some models are not equipped with the

ScreenLok

®

Flame Arrestor.

Step 1.

Step 2.

Step 3.

Step 4.

Step 5.

Step 6.

Step 7.

Step 8.

Step 9.

Rotate the gas control knob to the “OFF” position.

Remove outer door.

Remove outer jacket door and inner door per service procedure ED-X on page

24.

Disconnect main burner feedline (3/4” wrench), pilot tube (7/16” wrench) and

igniter/flame sensor wire from gas control and remove burner assembly from

combustion chamber.

Clean ScreenLok®Flame Arrestor using a stiff brush, compressed air and/or

shop vacuum to remove any scale or other debris accumulation. Using a soft

brush, clear jacket openings from any dirt, dust, restrictions or other obstructions.

Remove any debris from burner assembly per procedure ED-I and reinstall

burner assembly into combustion chamber.

Reconnect feedline, pilot tube and igniter/flame sensor wire to the gas control

Reinstall outer jacket door and inner door per service procedure ED-X on page

24.

To resume operation, follow the instructions located on the lighting instruction

label or the lighting instructions located in the installation and operation manual.

27

27

Page 28

ECO Defender Series

Glossary of Terms

BTU

GPM

Hz

kWh

LED

NPT

Homs

PSI

RPM

ECO

VAC

“w.c.

ºC

ºF

British Thermal Units

Gallons per Minute

Hertz

Kilowatt hour Light

Emitting Diode National

Pipe Thread Ohm

s of resistance Pounds

per Square Inch

Revolutions per minute

Energy Cut Out

Volts Alternating Current

Inches of Water Column

Degrees Centigrade

Degrees Fahrenheit

28

28

Page 29

ECO Defender Series

Heat Trap Outlet

1.

Hot Water Outlet Anode

2.

T&P Valve

3.

4.

Draft Diverter

5.

Heat Trap Inlet

6.

Flue Baffle

7.

Inlet Diptube

8.

¾ NPT Plug (“H” Models

only)

9.

Burner Ass’y complete

29

10.

Main Burner Feedline

11.

Resettable Thermal

Switch

12.

Main Burner

13.

Pilot Assembly

14.

Pilot Orifice

15.

Right Side Inner Door

Ass’y

16.

Thermal Switch Harness

17.

Manifold Mount

18.

Main Burner Orifice

19.

Drain Valve

20.

Polymer Gas Control

21.

Outer Jacket Door

22.

Inner Door Gasket Kit

23.

Kit-Heat Trap Insert

24.

ASSE Approved Mixing

Valve

29

Page 30

Loading...

Loading...