Page 1

Save this manual for future reference

Manual 238-49640-00A

SERVICE

MANUAL

Troubleshooting Guide

and Instructions for Service

(To be performed ONLY by

qualified service providers)

Models Covered

by This Manual:

ECO-Defender Safety System® Models

UDS140S*FRN

UDS150S*FRN

UDH1504T*FRN

UDH165T*FRN

UDH175S*FRN

UDH50T45FR*N

UDH65T45FR*N

UDH75T50FR*N

(*) Denotes Warranty Years

Ultra Low NOx Direct Vent Water Heaters

UDS / UDH Series

Page 2

The Bradford White

2

Ultra Low NOx Direct Vent Water Heaters

Table of Contents

Page Service Procedure

Introduction 3 - - -

Trouble shooting Chart 4 - - -

Inner Door Gasket Removal, Inspection, Replacement and Installation 6 I

Thermopile Testing and Replacement 9 II

Pilot Assembly Inspection Cleaning and Replacement 10 III

Igniter, Electrode Testing and Replacement 11 IV

Honeywell Gas Control Testing, Disassembly, and Replacement 20 V

Burner Operation Inspection, Adjustment, Cleaning and Replacement 21 VI

Dip Tube and Anode Inspection and Replacement 23 VII

Generic Parts List 25 - - -

2

Page 3

INTRODUCTION

3

The new Bradford White UDS and UDH water heaters are designed to

provide reliable performance with enhanced standard features. Design

features include reliable standing pilot ignition system, enhanced

diagnostics, simplified servicing, certified FVIR technology and Ultra

Low NOx emissions.

The UDS and UDH water heaters use a combustion system where

combustion air is drawn from the outside of the building. The gas control

maintains water temperature and maintains gas flow. If a situation outside

of normal operating parameters exists, the gas control diagnostic LED wll

flash a code to positively identify an operational issue.

This service manual is designed to facilitate problem diagnosis and

enhance service efficiency. To further promote quicker service times the

gas valve can be removed and replaced without draining the water heater.

Please read the service manual completely before attempting service on

this new series of direct vent water heaters.

How the Safety System Works

During normal operation, air for the combustion chamber is drawn into

the water heater through the vent pipe from outside your building. The air

travels into the closed combustion chamber. The air then mixes in a

normal manner with supplied gas and is efficiently combusted, producing

Ultra Low NOx emissions.

In the unlikely event trace amounts of flammable vapors are present in the

area surrounding the water heater, the sealed combustion system prevents

the flammable vapors from reaching the ignition source.

3

Page 4

4

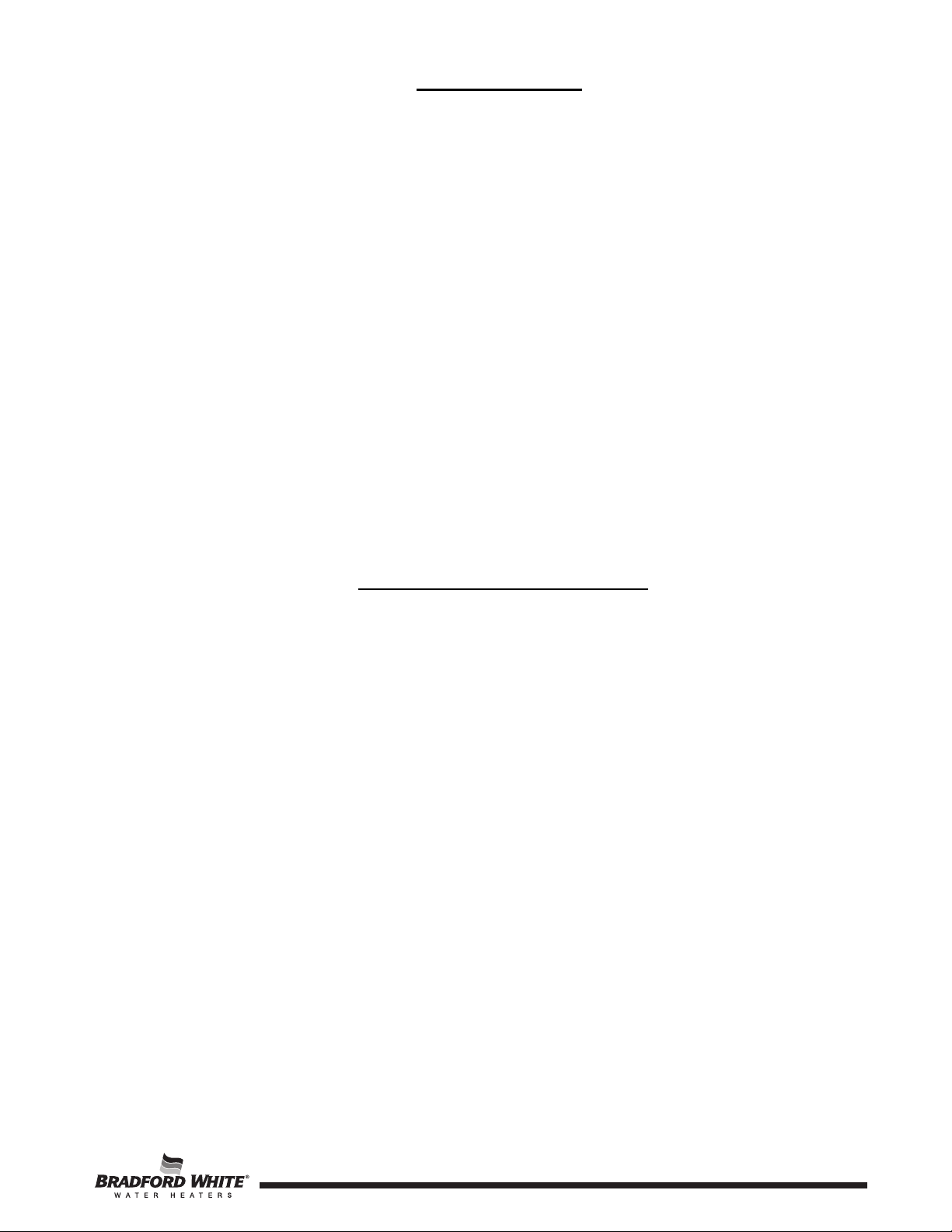

Honeywell Gas Control Troubleshooting Chart

Flammable Vapor Ignition Resistant Water

Heaters

Observe green LED indicator on

Gas Control. Error flash codes are

displayed with a three second pause

before repeating. Check and repair

the system as noted in the

troubleshooting table below.

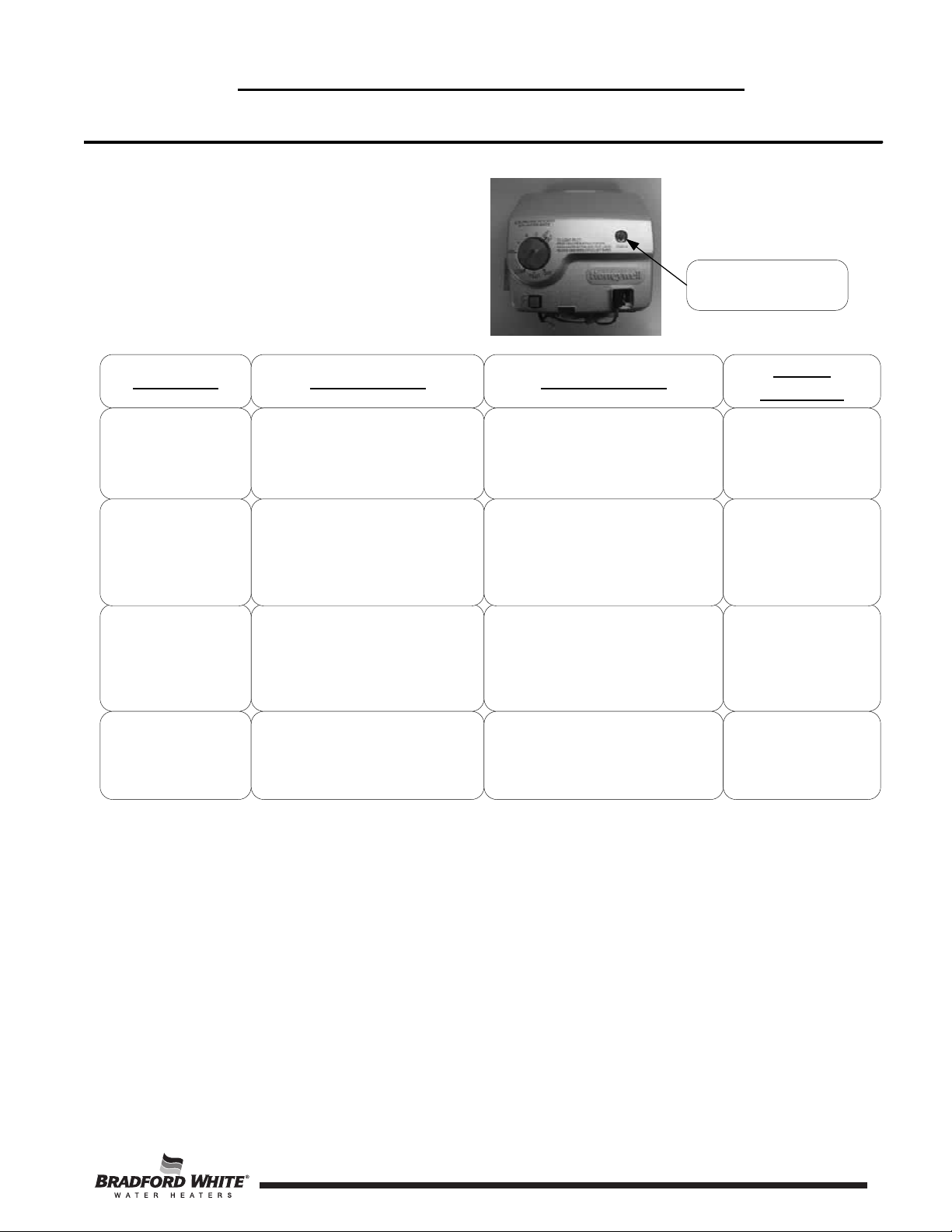

Green LED Indicator

LED Status Control Status Probable Cause

None (LED not on or

flashing

One flash and three

second pause

Two quick flashes

and a three second

pause

LED on continuously

(Solid)

Two flashes and

three second pause

Pilot assembly is not lit

1. If set point knob is in “PILOT”

position then pilot flame is detected.

Turn set point knob to desired setting.

2. If the set point knob is already at

the desired setting, the water heater is

satisfied.

Gas control is calling for heat (no

fault).

Set point knob has been recently

turned to the “OFF” position. Wait

until LED goes out before

attempting to relight

Weak pilot signal detected. System will

reset when pilot flame is sufficient.

.

Gas Control is not powered. Light pilot.

1. Gas Control is powered and waiting

for the set point knob to be turned to a

water temperature setting.

2. Water heater is satisfied and

operating normally.

Tank temperature below set point of

thermostat.

Set point knob was turned to “OFF”

position.

1. Thermopile failure

2. Unstable pilot

3. Pilot tube block or restricted.

Service

Procedure

If the pilot will not stay

lit replace pilot

assembly. If problem

persists replace Gas

Control.

1. Adjust set point knob

to desired setting.

Normal operation.

LED will go out and the

control will function

normally when the pilot

is lit.

1. See service

procedure II

2. See service

procedure III

3. See service

procedure III

Four flashes and

three second pause

Excessive tank temperature. System

must be reset.

1. Temperature sensor out of

calibration

2. Faulty Gas Control

4

1. See service

procedure V

2. See service

procedure V

Page 5

Honeywell Gas Control Troubleshooting Chart

5

Flammable Vapor Ignition Resistant Water

Heaters

Observe green LED indicator on

Gas Control. Error flash codes are

displayed with a three second pause

before repeating. Check and repair

the system as noted in the

troubleshooting table below.

Green LED Indicator

LED Status Control Status Probable Cause

Five flashes and

three second pause

Six flashes and

three second pause

Seven flashes and

three second pause

Eight flashes and

three second pause

Thermostat/well sensor fault.

Water leak detected by accessory

module.

Gas Control electronic fault detected.

Standing pilot remains on while set

point knob is in “OFF” position.

1. Damage to the temperature sensor.

2. Temperature sensor resistance out of

range.

Excessive amount of water in drain

pan/water dam.

1. Control needs to be reset.

2. Control is wet or physically

damaged.

Pilot valve stuck in open position.

Service

Procedure

1. See service

procedure V

1. Check T&P valve

2. Check all water

fittings.

3. Pressurize and leak

test tank.

1. Reset Gas Control

2. Replace Gas

Control.

Replace Gas Control.

5

Page 6

The Bradford White

6

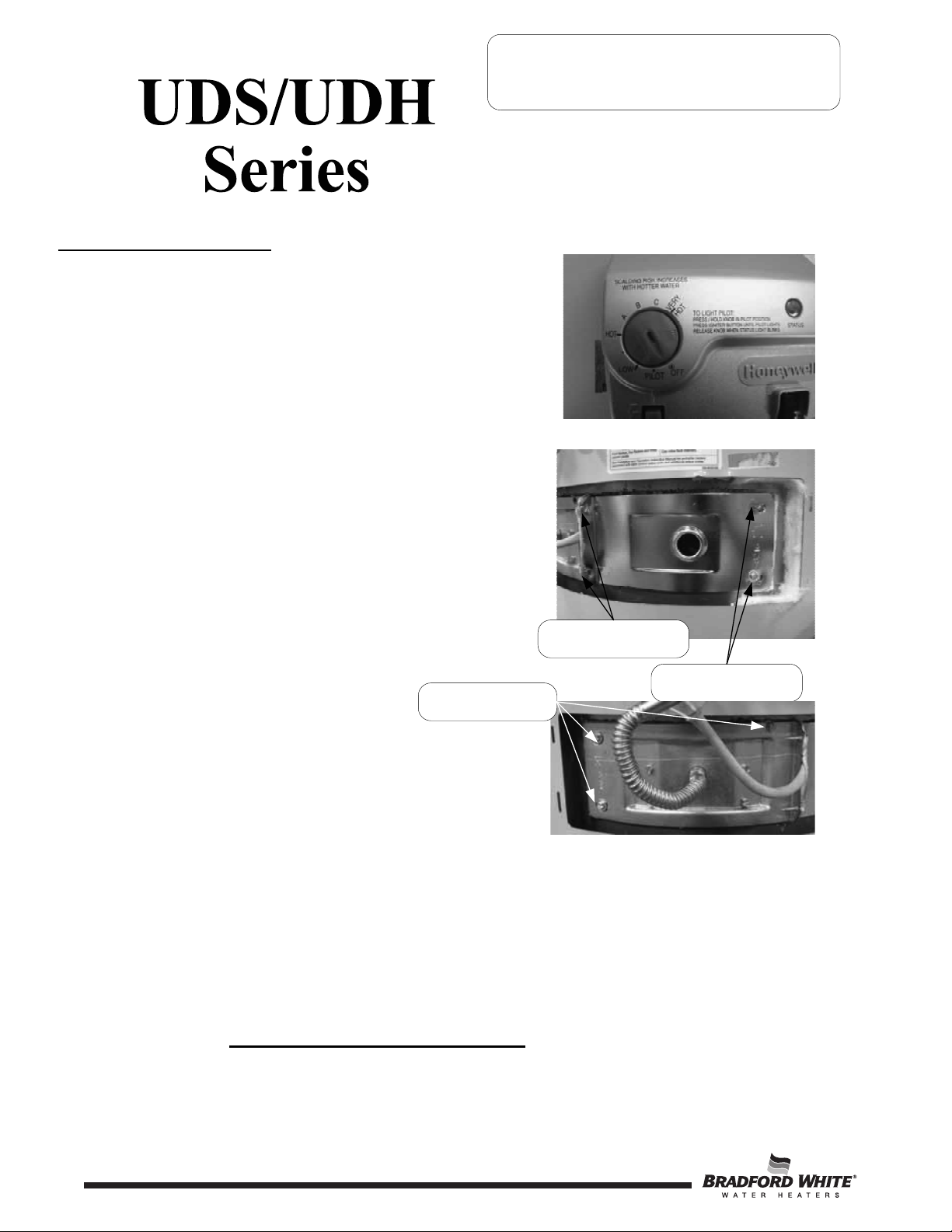

Inner Door Removal Procedure

Step 1. Rotate set point knob of the gas control to the “OFF” position.

Step 2. Turn off the gas supply to the water heater

Step 3. Remove the outer door.

Step 4. Remove the four (4) ¼” hex drive screws holding the

right side inner door in place

SERVICE PROCEDURE I

Inner Door/Gasket Removal, Inspection

Replacement and Reinstallation

Step 5. Remove the three (3) ¼” hex drive screws holding the

left side burner door in place.

¼” Hex Drive Screws at Flange

Area of Inner Door

¼” Hex Drive Screws on Left

Side Inner Door

Step 6. Disconnect the pilot tube from the gas control using a

7/16" wrench. Remove the main burner feedline from

the gas control with a ¾” wrench.

Step 7. Disconnect the spark igniter wire from

the gas control.

Step 8. Remove the burner assembly from the combustion chamber.

tep 9. Fully inspect burner and inner door gaskets for the following:

>Tears >Other imperfections that will inhibit proper seal

>Missing Material >Gasket adhesion to inner door

>Cracks >Material left on combustion chamber (around opening)

>Dirt or debris

If the gasket is not affected by any of the above, gasket replacement is not required. If replacement is

required, proceed to Inner Door Gasket Replacement Procedure.

¼” Hex Drive Screws Right

Side Inner Door

6

Page 7

The Bradford White

7

Inner Door/Gasket Removal, Inspection

SERVICE PROCEDURE I

Replacement and Reinstallation

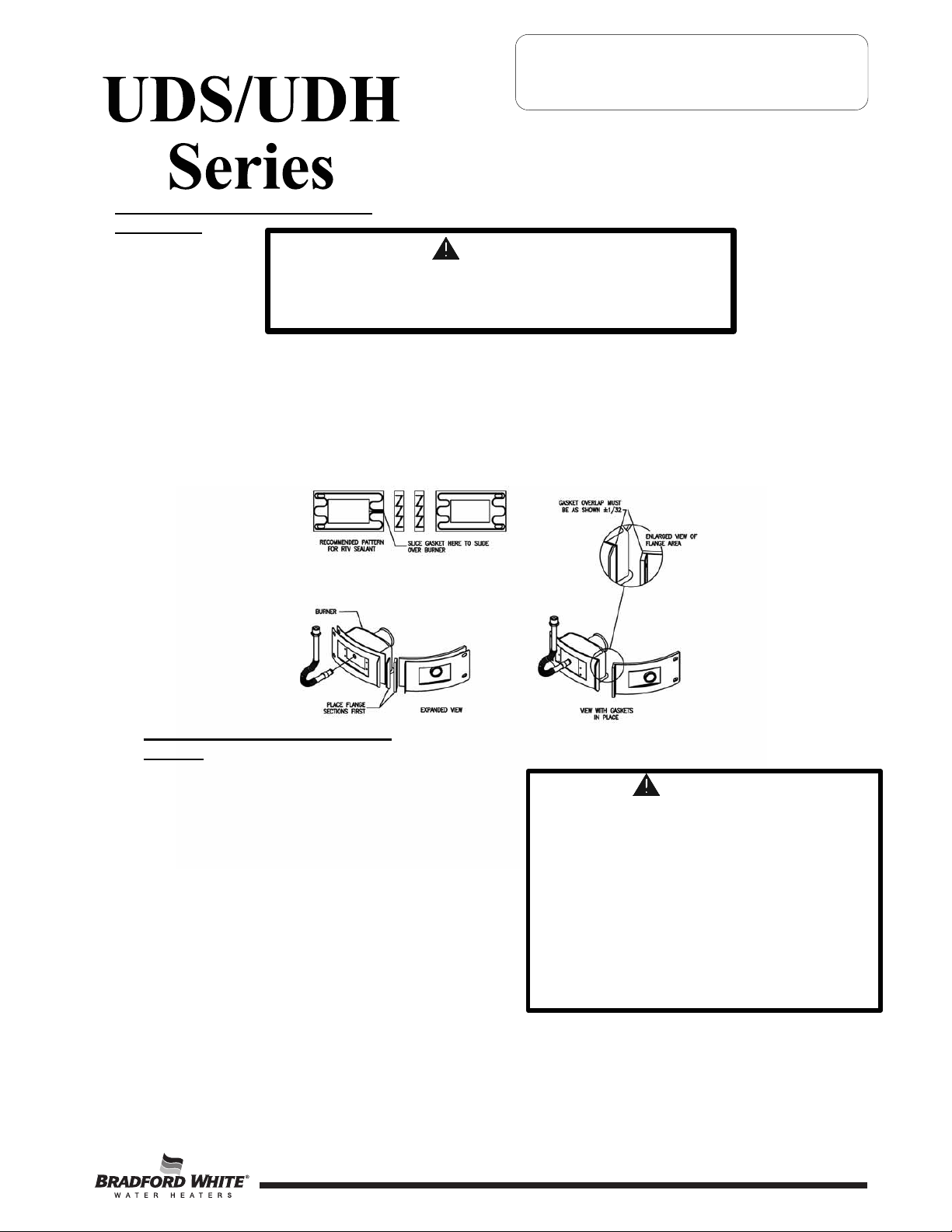

Inner Door Gasket Replacement

Procedure.

WARNING

If the information in these instructions is not

followed exactly, a fire or explosion may result causing

property damage, personal injury or death.

Step 10. After inspection of inner door as noted in step 9, completely remove gasket and adhesive residue from

burner and left side inner doors as needed.

Step 11. Use RTV sealant (recommended bead size 1/8") to secure the inner door gasket to the inner door sections

(right & burner). The burner door gasket must be sliced in the location shown on the illustration below in

order to slide the gasket over the burner venturi. Refer to illustration below for proper RTV sealant

application. Note the overlap configuration in the flange area of the inner door. Set the flange section first, this

will help to achieve the proper over lap position.

Installation of Inner Door With

Gasket.

Step 12. Clean any residual gasket residue or other

debris from combustion chamber surface

before installing the inner door/gasket

assembly.

Step 13. Place the burner door into position first. Tighten

the pilot line nut to the gas control. Tighten the

main burner feedline to the gas control. Use the

¼” hex drive screw without the built-in washer

to secure the right side of the burner door to the

chamber. Use the ¼” hex drive screws with the

built-in washer to secure the left side of the

burner door in place. DO NOT OVER

TIGHTEN SCREWS.

Step 14. Position the fiberglass sock containing the igniter

wire, the pilot tube and the armored thermopile

cable against the inner door flange.

7

WARNING

Stripped fastener connections may allow

for seal breach of inner door. A seal

breach may result in a fire or explosion

causing property damage, personal injury

or death. Do not over tighten screws in

steps 13, 15 and 16.

If a fastener connection is stripped,

contact the manufacturer listed on the

water heater rating plate.

Page 37

Page 8

The Bradford White

8

Inner Door/Gasket Removal, Inspection

SERVICE PROCEDURE I

Replacement and Reinstallation

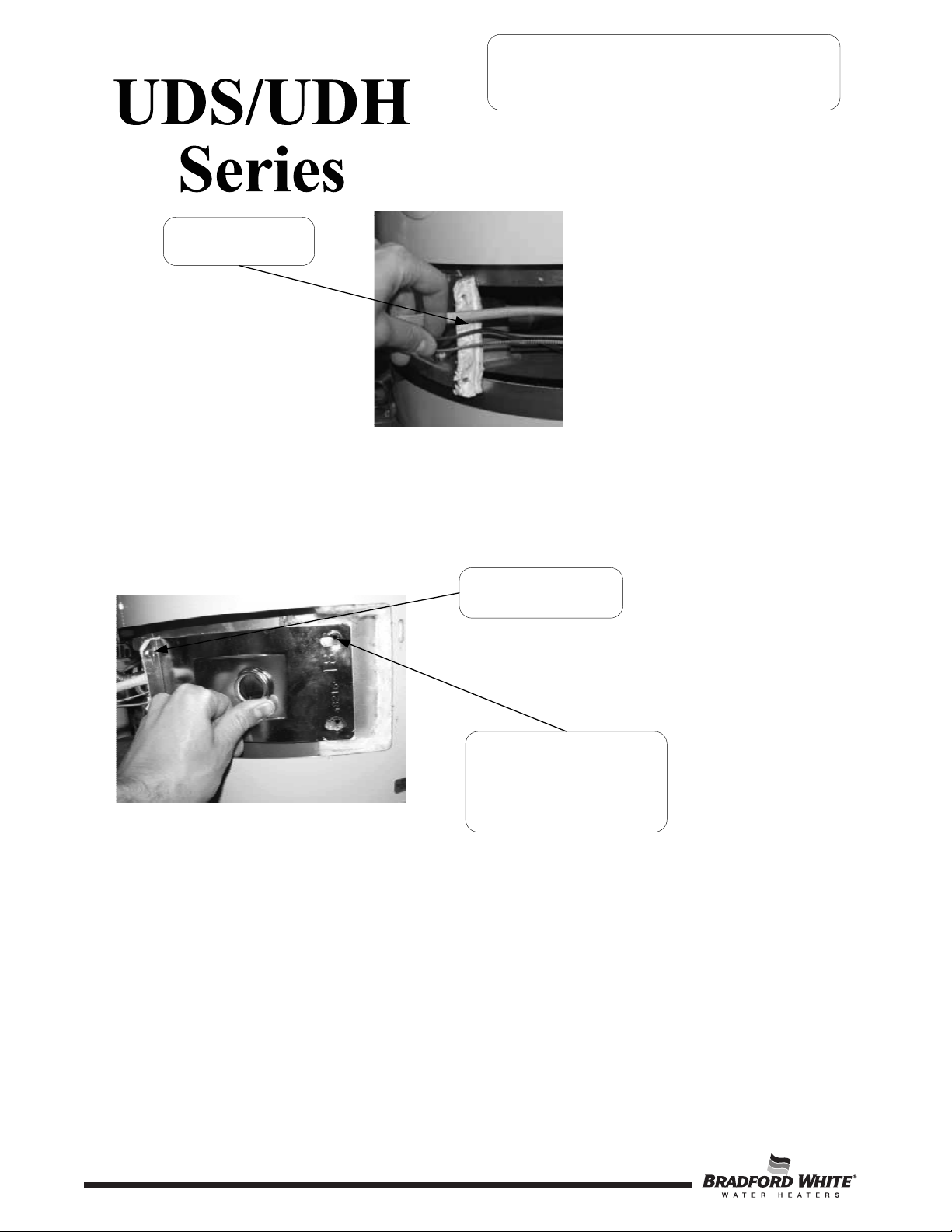

Position fiberglass sock, pilot

tube and armored thermopile

cable against flange.

Step 15. Firmly place right side inner door flange against the burner door flange and secure with two ¼” drive

screws from step 5. DO NOT OVER TIGHTEN SCREWS.

Step 16. Align right side inner door to combustion chamber and verify the fastener holes of the combustion

chamber are aligned with the right side inner door slotted opening. Verify seal integrity around combustion

opening. Secure right side inner door using 1/4” hex drive screws from step 5. DO NOT OVER TIGHTEN

SCREWS. Verify both burner and right sides of the inner door are properly positioned and sealed against

the combustion chamber.

Secure flange with

¼" drive screws.

Verify threaded hole

alignment with slotted

openings in inner door.

Step 17. Reconnect the igniter wire to the gas control

Step 18. Replace outer jacket burner access door.

Step 19. To resume operation follow the instructions located on the lighting instruction label or the lighting instructions

located in the installation and operation manual.

8

Page 9

The Bradford White

9

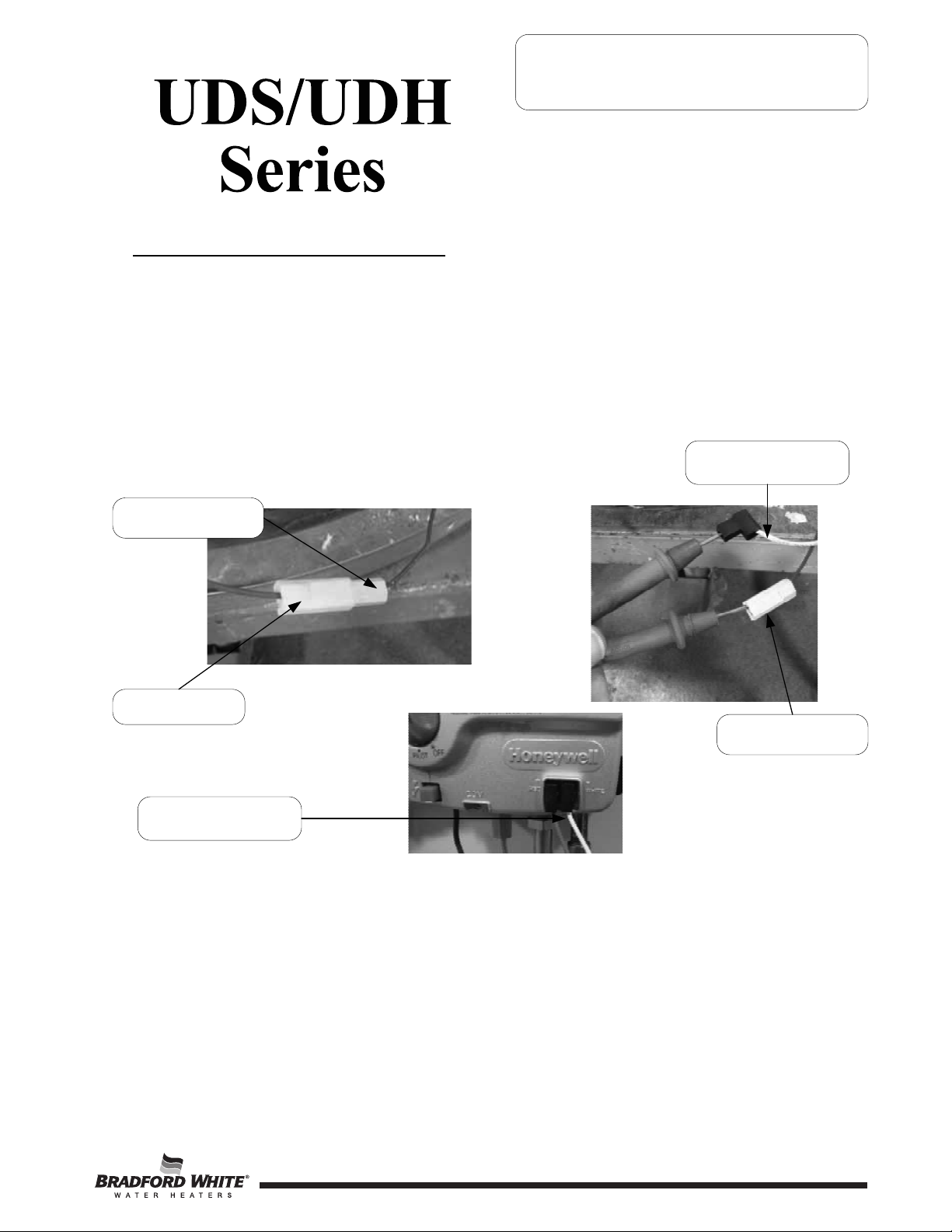

SERVICE PROCEDURE II

Thermopile Testing and Replacement

OPEN CIRCUIT THERMOPILE TESTING

The following test should be performed while the pilot flame is on.

Step 1. Turn knob to pilot position and depress.

Step 2. Continue pressing knob and remove red (+) thermopile wire from the red wire leading from the gas control.

Also remove white (-) thermopile wire from the gas control.

Step 3. Using a multimeter capable of measuring millivolts, connect the positive side of the multimeter to the

red (+) thermopile wire connector. Connect the negative side of the multimeter to the white thermopile

connector.

White (-) thermopile wire

Red (+) thermopile wire

Red gas control wire

Red (+) thermopile wire

White (-) thermopile wire

Normal thermopile operation will be between 350mV - 850mV. If reading is less than 350mV, replacement of pilot

assembly is recommended following SERVICE PROCEDURE III.

Step 4. If thermopile reading is between 350mV - 850mV, remove multimeter and reconnect red (+) thermopile wire

to red wire leading from the gas control. Reconnect white (-) thermopile wire negative (-) terminal on gas

control.

Step 5. Release Gas Control knob and turn to desired setting to resume normal operation.

9

Page 10

s

The Bradford White

10

PILOT/ELECTRODE ASSEMBLY INSPECTION,

CLEANING AND REPLACEMENT

SERVICE PROCEDURE III

Pilot Assembly Inspection, Cleaning

and Replacement

For Honeywell Control, rotate knob

counter-clockwise to the “OFF”

position.

Step 1. Turn off gas supply to water heater. Rotate knob

of gas control/gas valve

to “OFF” position.

Step 2. Remove outer jacket door.

Step 3. Remove burner and right side inner door per

SERVICE PROCEDURE I, steps 1 through 8.

Step 4 Disconnect thermopile, pilot tube,

and feedline from gas control.

Step 5 Disconnect igniter wire from gas control.

Step 6. Remove pilot/electrode assembly from burner (¼”

drive tool).

Step 7. Inspect pilot for the following:

a) Primary air openings for blockage. Must be free from any

debris (dirt, lint, etc).

b) Kinks or cracks in the pilot tube. If found,

the pilot must be replaced.

Step 8. Inspect pilot orifice:

a) Remove ½" nut from bottom of pilot assembly.

Pilot tube

Igniter wire

Primary air

opening

Thermopile

connections

Feedline nut

b) Remove pilot tube and pilot orifice.

c) Inspect pilot orifice for blockage, must be cleaned or replaced.

(Honeywell pilot orifice not replaceable, replace pilot assembly)

Step 9. Install pilot/electrode assembly to feedline, secure with screw from step 6.

Step 10. Re-Install burner assembly and right side inner door per SERVICE

Pilot orifice

PROCEDURE I, steps 9 through 19.

Step 11. To resume operation follow the instructions located on the lighting instruction label or the lighting instruction

located in the installation and operation manual.

10

Page 11

The Bradford White

11

IGNITER, ELECTRODE TESTING AND REPLACEMENT

With the pilot not in operation (no pilot flame) you can check the igniter and electrode circuit by viewing pilot

thru the sight glass located on the inner door and observing the spark action.

Step 1. Remove outer jacket door.

Step 2. Repeatedly depress the igniter while viewing the pilot thru the sight glass. If a spark is

present, the circuit is OK. If there is no spark, proceed to step 3.

SERVICE PROCEDURE IV

Igniter, Electrode Testing

and Replacement

View spark

Action through

Sight glass

Repeatedly

Depress Piezo

Igniter

Step 3. Remove white wire from igniter and install a jumper wire in its place. Hold the other end of the

jumper by the wire insulation or using an insulated tool, next to an unpainted surface such as the

feedline and depress the igniter. If there is a spark, the igniter is OK, the pilot is not functioning and

must be replaced, see SERVICE PROCEDURE III for pilot replacement. If no spark is present the

igniter is not functioning and must be replaced. See SERVICE PROCEDURE V for gas control

disassembly/reassembly.

Insulated jumper

wire

Feedline

11

Page 12

The Bradford White

12

SERVICE PROCEDURE V

Gas Control

Testing, Disassembly & Replacement

Honeywell Gas Control Testing, Disassembly, and Replacement

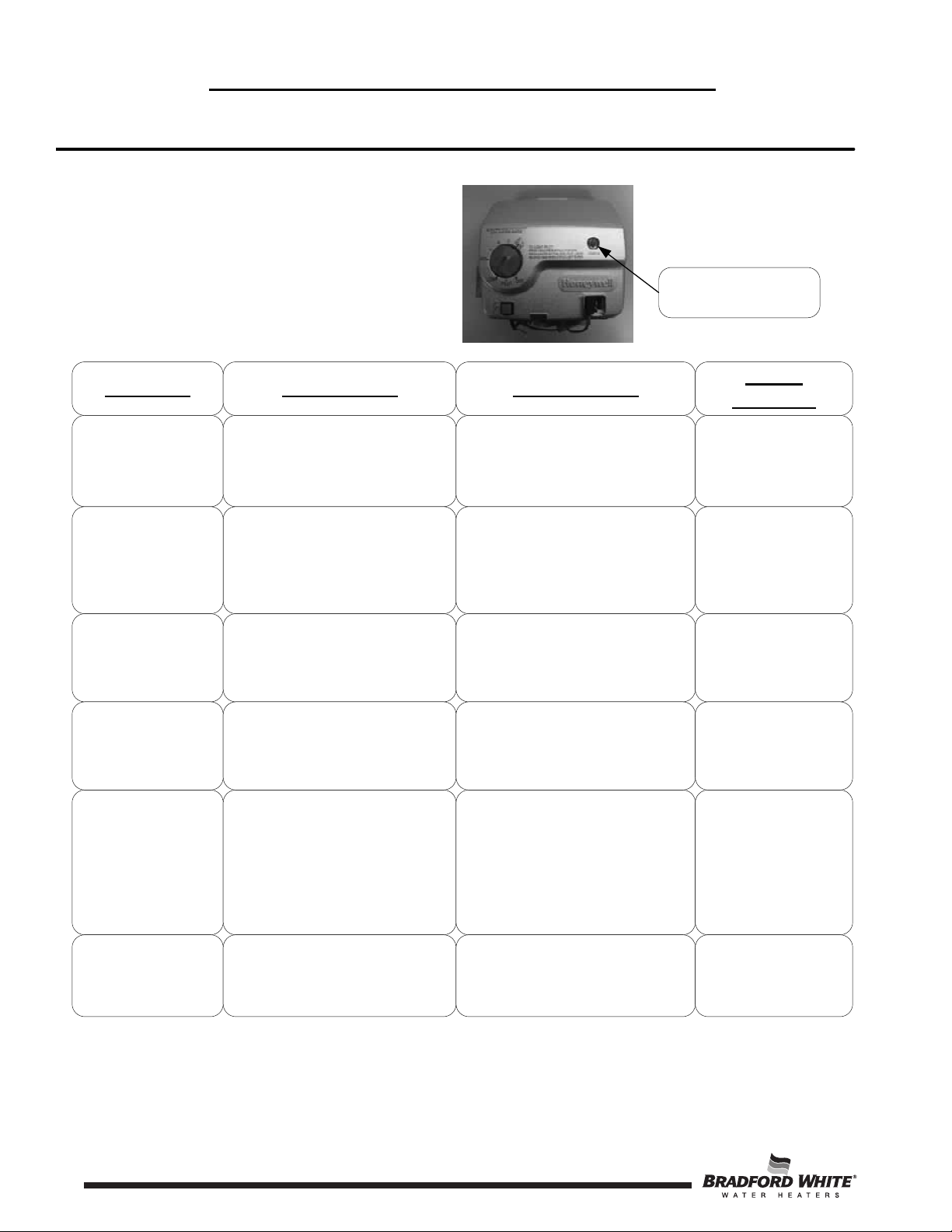

The Gas Control is made up of (5) major components; the control cover, the piezo igniter, the valve body, the temperature

sensor, and the back plate. The Gas Control is designed so that any of these components may be replaced without

replacing the entire Gas Control.

Gas Control

Gas Control

Cover Screw

Piezo Igniter

Cover

Valve Body Backplate

Temperature

Sensor

Valve Body

Screw

Insertion Stick

LINE PRESSURE

The Gas Control is designed for a maximum line pressure of 14.0" w.c. and a minimum line pressure of 1.0" w.c. over the

water heater’s rated manifold pressure (check rating plate). Line pressure must be checked with the main burner on and

off to assure proper readings.

12

Page 13

The Bradford White

13

SERVICE PROCEDURE V

Gas Control

Testing, Disassembly & Replacement

MANIFOLD PRESSURE TESTING (this procedure presumes a maximum line pressure of 14.0" w.c.)

Step 1. Set the Gas Control to the “OFF” position.

Step 2. Remove pressure tap plug and install

1/8" NPT pipe, coupling, & pressure tap.

Gas Control shown in the “OFF” position

Step 3. Connect manometer to pressure tap.

Step 4. Follow instructions located on the lighting

instructions label and proceed to light the main

burner and observe manometer reading.

Step 5. Proper operating range for natural gas is: 4.0" ±0.5" w.c.

Proper operating range for LP gas is: 10.0" ±0.5" w.c.

Step 6. If pressure is within the range specified in the previous

step, set Gas Control knob to the “OFF” position,

remove manometer and pressure tap, and replace

pressure tap plug. Check for gas leaks prior to placing

water heater back into operation by following the

instructions located on the lighting instruction label or the

lighting instructions located in the installation and

operation manual.

Step 7. If gas pressure is outside the specification noted above,

refer to “Honeywell Gas Control Testing, Disassembly,

and Replacement” to replace Gas Control or valve body.

Pressure Tap

Shown Installed

THERMOPILE TESTING

See SERVICE PROCEDURE II

ECO (Energy Cut Off) TESTING

The Honeywell Gas Control is designed with an ECO device that will reset.

To reset the Gas Control after an error code (4), turn the Gas Control knob to the “OFF” position and wait a minimum

of (5) minutes before relighting following the instructions located on the lighting instruction label or the lighting

instructions located in the installation and operation manual.

13

Page 14

The Bradford White

14

TEMPERATURE SENSOR TESTING

SERVICE PROCEDURE V

Gas Control

Testing, Disassembly & Replacement

If Control has gone into lockout due to excessive tank

temperature (four flash, three second pause) reset

control by rotating gas control knob to “OFF” position

and wait a minimum of (5) minutes. Then follow lighting

instructions and return gas control knob to desired

Observe Green LED indicator.

Does error code 4 (four flash, three

second pause) continue?

Temperature Sensor Testing

Following “Gas Control

Disassembly/Reassembly”

instructions, disassemble Gas

Control to access temperature

With the temperature sensor still

in the back plate, use a multi-

meter set to the Ohms setting,

determine the resistance of

temperature sensor

(see caution and photos above)

setpoint.

N

Y

sensor.

DO NOT use standard multimeter probes for this test.

CAUTION

Doing so will damage connector. Use special pin type

electronic probes or small diameter wire pins inserted

into connector.

Using a multi-meter set to the ohms setting, insert one meter probe (see caution)

into center wire position of thermal well connector, insert the second probe (see

caution) into either of the outside wire positions (see photo on left).

Alternate the probe on the outside position to the opposite outside wire position

(see photo on right).

Resume normal operation.

Once the temperature sensor resistance values are known, the

water temperature must also be known to determine if the

resistance values are correct. See next page to obtain water

temperature.

Are temperature sensor resistance values correct?

Y

Replace Gas Control

N

Replace temperature

sensor

14

Page 15

The Bradford White

15

SERVICE PROCEDURE V

Gas Control

Testing, Disassembly & Replacement

WARNING

Stored water may be HOT when performing the following steps in this procedure.

Take necessary precaution to prevent personal injury.

DETERMINE WATER TEMPERATURE INSIDE TANK

Note: It is important to understand once the resistance for the temperature sensor is determined from the

previous page, water flow through the water heater should not occur. Prior to drawing water from drain

valve, turn off the cold water supply to the water heater. This will prevent cold water flow into the tank

affecting the resistance value of the temperature sensor.

Step 1. Set the Gas Control knob to the “OFF” position.

Step 2. Turn off inlet water supply to water heater.

Step 3. Draw approximately 4 gallons of water from drain valve into a container, or suitable drain, and discard.

Draw an additional gallon and immediately measure water temperature using an accurate thermometer.

It may be necessary to open a hot water faucet to allow water heater to drain.

Step 4. Using the chart below, determine correct resistance value for the water temperature from step 3.

Example: If temperature of water is 84°F, then the resistance through the sensor would be

8449 (see shaded area). NOTE: Sensor resistance increases as the temperature

decreases.

Sensor Resistance at Various Temperatures

In Degrees F

°F012345678 9

40 26109 25400 24712 24045 23399 22771 22163 21573 21000 20445

50 19906 19383 18876 18383 17905 17440 16990 16553 16128 15715

60 15314 14925 14548 14180 13823 13477 13140 12812 12494 12185

70 11884 11592 11308 11032 10763 10502 10248 10000 9760 9526

80 9299 9078 8862 8653 8449 8250 8057 7869 7685 7507

90 7333 7165 7000 6839 6683 6531 6383 6238 6098 5961

100 5827 5697 5570 5446 5326 5208 5094 4982 4873 4767

110 4663 4562 4464 4368 4274 4183 4094 4006 3922 3839

120 3758 3679 3602 3527 3453 3382 3312 3244 3177 3112

130 3048 2986 2925 2866 2808 2752 2697 2643 2590 2538

140 2488 2439 2391 2344 2298 2253 2209 2166 2124 2083

150 2043 2004 1966 1928 1891 1856 1820 1786 1753 1720

160 1688 1656 1625 1595 1566 1537 1509 1481 1454 1427

170 1402 1376 1351 1327 1303 1280 1257 1235 1213 1191

180 1170 1150 1129 1110 1090 1071 1953 1035 1017 999

190 982 965 949 933 917 901 886 871 857 842

200 828 814 801 788 775 762 749 737 725 713

15

Page 16

The Bradford White

16

GAS CONTROL DISASSEMBLY/REASSEMBLY

Step 1. Rotate knob of the Gas Control to the “OFF” position.

Step 2. Turn off gas supply to water heater.

SERVICE PROCEDURE V

Gas Control

Testing, Disassembly & Replacement

Step 3. Disconnect gas supply line from Gas Control.

Step 4. Disconnect igniter wire.

Rotate knob counter-clockwise to

the “OFF” posistion.

Step 5. Disconnect main burner feedline, pilot tube and thermopile wires from gas control.

Step 6. Remove Gas Control cover screw.

Gas Control cover

screw

Step 7. Depress both tabs on the top of the Gas Control cover and pull to remove.

Use caution not to bend or damage valve body pins

when removing or installing Gas Control cover.

CAUTION

Valve body pins

16

Page 17

The Bradford White

17

SERVICE PROCEDURE V

Gas Control

Testing, Disassembly & Replacement

GAS CONTROL DISASSEMBLY/REASSEMBLY

Step 8. Disconnect temperature sensor from control board and remove wire from the temperature sensor wire routing clip.

Temperature sensor

wire routing clip

Disconnect

temperature sensor

Step 9. Remove the piezo igniter from the control cover by releasing the lock tab on the control cover.

Release lock tab

17

Page 18

The Bradford White

18

SERVICE PROCEDURE V

Gas Control

Testing, Disassembly & Replacement

GAS CONTROL DISASSEMBLY/REASSEMBLY

Step 10. Remove the valve body by removing screw located at the lower left corner then unclipping the lower right side

from the backplate first followed by the lower left side using a flat head screwdriver.

Use caution not to bend or

damage valve body pins.

Unclip lower right

side first

Unclip lower left side

second

Valve body screw

Step 11. Remove temperature sensor and insertion stick from backplate by first removing wire from the temperature sensor

wire routing clips located on the backplate. Note the orientation of insertion stick, insertion stick can only be

installed in one way.

CAUTION

Insertion stick fully

inserted into backplate

Temperature sensor

wire routing clips

CAUTION

When reinstalling temperature sensor and insertion stick,

make sure the assembly is inserted FULLY into the

backplate and the wires are routed through the wire

routing clips. Failure to do so will not allow valve body to

be reinstalled properly and may damage temperature

sensor wires.

18

Page 19

SERVICE PROCEDURE V

The Bradford White

19

Testing, Disassembly & Replacement

GAS CONTROL DISASSEMBLY/REASSEMBLY

Step 12. Remove temperature sensor from insertion stick by pulling apart as illustrated below.

Gas Control

Pull in this direction

Pull in this direction

Temperature sensor

Insertion stick

Step 13. To reassemble Gas Control, follow the previous steps in reverse order. Once Gas Control is reassembled, burner

assembly is reinstalled, and the gas supply line is reconnected, resume water supply to water heater. Be sure tank

is full of water before relighting.

Step 14. To resume operation, follow the instructions located on the lighting instruction label or the lighting instructions

located in the installation and operation manual.

19

Page 20

The Bradford White

20

GAS CONTROL REPLACEMENT

SERVICE PROCEDURE V

Gas Control

Testing, Disassembly & Replacement

Step 1. Rotate knob of the gas control

to the “OFF” position.

Rotate knob counter-clockwise to

the “OFF” position.

Step 2. Turn off gas supply to water heater.

Step 3. Disconnect gas supply line from gas control.

Step 4. Turn off water supply and drain water heater completely.

Step 5. Remove the wire clip from the feedline.

Step 6. Disconnect main burner feedline, pilot tube, white thermopile wire and igniter wire from gas control and bend

the main burner feedline and pilot tube out of the way. Also disconnect the red wire leading from the thermopile

from the red wire leading from the gas control.

Step 7. Remove the gas control from the water heater by rotating counter-clockwise. It may be necessary to use a length

of ½” NPT pipe threaded into the inlet of the gas control.

Pilot tube

Igniter wire

White thermopile

Main burner

feedline

wire

Red gas control

wire

Red thermopile

wire

Step 8. Install new gas control into the water heater.

a) Install gas control into water heater by rotating clockwise. DO NOT use a wrench on the gas control

body or damage to the gas control may occur. If necessary, use a length of ½” NPT pipe threaded into

gas inlet of gas control.

b) Bend the main burner feedline and pilot tube back to the gas control and attach to the gas control.

Connect the igniter wire and the white thermopile wire to the gas control. Connect the red wire from

the gas control to the red wire from the thermopile.

c) Gather the igniter wire, white thermopile wire and red thermopile wire near the side of the feedline.

Use the clip that was removed in Step 5 to secure the wires to the feedline.

d) Connect gas supply to inlet of gas control.

Step 9. Resume the water supply to the water heater. Be sure that the tank is full before operation is resumed.

Step 10. To resume operation follow the instructions located on the lighting instruction label or the lighting

instructions located in the installation and operation manual.

20

Page 21

The Bradford White

21

SERVICE PROCEDURE VI

Burner Operation Inspection, Adjustment

Cleaning and Replacement

MAIN BURNER: Inspection,

Cleaning and Replacement

At periodic intervals (not more then 6 months) a visual inspection should be made of the main burner for proper operation

and to insure no debris is accumulating.

Main burner should light smoothly from pilot and burn with a blue flame with a minimum of yellow tips. After 5 minutes

of operation the burner screen will become radiant and the flame will soften and turn orange. If the burner screen does not

become radiant after 5 minutes of operation it must be cleaned (see burner cleaning procedure below).

Main burner must be free from any debris accumulation that may effect burner operation (see burner cleaning procedure

below).

DANGER

Under no circumstances shall flammable materials be used or stored in the vicinity of the water heater. With

the inner door removed the Bradford White Defender Safety System will be inactivated. If flammable vapors

are present, a fire or explosion may result causing property damage, personal injury or death.

WARNING

Inner door and burner components may be HOT when performing this operation. Take

necessary precaution to prevent personal injury.

BURNER CLEANING

Step 1. Remove burner and inner door assembly per SERVICE PROCEDURE I, steps 1 through 9.

Step 2. Thoroughly inspect burner screen and burner venturi and remove any loose debris accumulation. Inspect

burner screen for any openings larger than the normal screen openings.

Step 3. Use compressed air and/or a vacuum to remove any scale or other debris accumulation from the burner screen

and venturi.

Burner Venturi

Burner Screen

21

Page 22

The Bradford White

22

SERVICE PROCEDURE VI

Burner Operation Inspection, Adjustment

Cleaning and Replacement

Step 4. Disconnect (unscrew) feedline from the main burner door.

Feedline

Step 5. Remove main burner orifice from feed line (3/8" wrench). Inspect and

clean if necessary

Main Burner Orifice

Step 6. Remove pilot assembly, refer to SERVICE PROCEDURE III

for cleaning and inspection.

Step 7. Reassemble burner.

Step 8. Reinstall burner and inner door per SERVICE PROCEDURE I,

steps 9 through 19.

Step 9. To resume operation, follow the instructions located on the lighting instruction label or the lighting

instructions located in the installation and operation manual.

22

Page 23

The Bradford White

23

SERVICE PROCEDURE VII

Dip Tube and Anode

Inspection and Replacement

DIP TUBE INSPECTION AND REPLACEMENT

WARNING

Heater components and stored water may be HOT when performing the following steps in

this procedure. Take necessary precaution to prevent personal injury.

Step 1. Rotate knob of gas control to “OFF” position.

For Honeywell Control, rotate knob

counter-clockwise to the “OFF”

position.

Step 2. Turn off cold water supply to heater. Connect hose to drain spigot of water heater and route to an open drain.

Open a nearby hot water faucet to vent heater for draining. Open drain spigot of hot water heater and allow

heater to drain to a point below the inlet connection nipple.

Step 3. Disconnect inlet nipple from plumbing system.

Step 4 With an appropriate wrench, remove inlet nipple/dip tube from the water heater. Use caution not to damage

pipe threads.

Step 5. Visually Inspect inlet nipple/dip tube. Inlet nipple/dip tube should be free of cracks and any blockage.

Hydro-jets located near the bottom of the dip tube should be open and free of any blockage.

Anti-siphon hole located approximately 6" from the bottom of nipple, should be free of any blockage.

Any damage such as cracks, restriction due to deformation or unintentional holes are not field repairable

and the inlet nipple/dip tube must be replaced.

Step 6. Upon completion of inspection or subsequent replacement, reinstall inlet nipple/dip tube into heater. Connect

nipple to plumbing system, resume water supply and refill heater with water.

Step 7. To resume operation follow the instructions located on the lighting instruction label or the lighting instructions

located in the installation and operation manual.

23

Page 24

The Bradford White

24

SERVICE PROCEDURE VII

Dip Tube and Anode

Inspection and Replacement

ANODE INSPECTION AND REPLACEMENT

WARNING

Heater components and stored water may be HOT when performing the following steps in

this procedure. Take necessary precaution to prevent personal injury.

Step 1. Turn off water supply to water heater. Rotate knob of gas control to “OFF” position.

For Honeywell Control, rotate knob

counter-clockwise to the “OFF”

position.

Step 2. Turn off cold water supply to heater. Connect hose to drain spigot of water heater and route to an open drain.

Open a nearby hot water faucet to vent heater for draining. Open drain spigot of hot water heater and allow

heater to drain to a point below the outlet connection nipple.

Step 3. Disconnect outlet nipple from plumbing system.

Step 4 With an appropriate wrench, remove outlet nipple/anode from the water heater. Use caution not to damage

pipe threads.

Step 5. Visually Inspect outlet nipple/anode. Outlet nipple/anode should show signs of depletion, this is normal.

If depletion is ½ of the original anode diameter (approximately 5/8” diameter), replacement is recommended.

If any of the steel core of the anode is exposed, replacement is recommended.

Step 6. Upon completion of inspection or subsequent replacement, reinstall outlet nipple/anode into heater. Connect

nipple to plumbing system, resume water supply and refill heater with water.

Step 7. To resume operation, follow the instructions located on the lighting instruction label or the lighting

instructions located in the installation and operation manual.

24

Page 25

The Bradford White

25

Generic Parts List

1 Vent Package

2 Air Intake Terminal

3 Outer Wall Mounting Plate

4 Backing Plate

5 Telescopic Air Intake Tube

6 Telescopic Vent Tube

7 Intake Elbow

8 Exhaust Elbow

9 Plenum

10 Flue Reducer

11 Plenum Gasket

12 Air Intake Tube

13 Air Intake Terminal Guard (Optional)

14 Flue Baffle

15 Heat Trap (Inlet)

16 Cold Water Inlet Tube

17 Hot Water Outlet/Anode

18 Heat Trap (Outlet)

19 T&P Relief Valve

20 ¾” NPT Tank Plug (UDH Models)

21 Feedline Spring Clip

22 Air Intake Boot

23 Air Intake Boot Gasket

24 Complete Right Side Inner Door

25 Screw-#10-12 x ¾ Hex Washer Head

26 Screw-#8-18 x ¾ Hex Washer Head

27 Brass Drain Valve

28 Outer Door

29 Gas Control

30 Inner Door Gasket Kit

31 Heat Trap Kit

32 ASSE Approved Mixing Valve (Optional)

33 Ultra Low NOx Burner Assembly

34 Pilot Assembly

35 Ultra Low NOx Burner

36 Main Burner Feedline

37 Main Burner Orifice

25

Page 26

Page 27

Page 28

Loading...

Loading...