Bradford White UCG-80H-125-3NA, UCG-80H-199-3NA, UCG-80H-270-3NA, UCG-80H-399-3NA, UCG-100H-199-3NA Installation Manual

...

serviced by a plumbing professional.

injury or death.

WARNING

GAS-FIRED COMMERCIAL WATER HEATER

(Ultra Low NOx)

If the information in these

instructions is not followe d exactly,

a fire or explosion may result

causing property damage, personal

- Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch;

do not use any phone in your

building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow

the gas supplier’s instructions.

• If you cannot reach your gas

supplier, call the fire department.

- For your family’s comfort, safety and

convenience, it is recommended this

water heater be installed and

Ambler, PA 19002

Tech Service (800) 334-3393

Service Parts (800) 538-2020

Warranty Service (800) 531-2111

INSTALLATION/OPERATION MANUAL

PLACE THESE INSTRUCTIONS ADJACENT TO W ATER HEATER AND NOTIFY OWNER TO KEEP FOR FUTURE RE FERENCE

WITH TROUBLESHOOTING GUIDE

238-50463-00H REV 5/18

READ CAREFULLY

NOTICE

WARNING

CAUTION

DANGER

NOTICE

TABLE OF CONTENTS

SECTION I: IMPORTANT INFORMATION

This gas-fired water heater is design certified by CSA International under the American National Standard, Z21.10.3 (as

indicated on the rating plate) and CAN/CGA 4.3-M (as indicated on the rating plate) available from CSA Standards

Association, 5060 Spectrum Way, Mississauga, Ontario, CANADA L4W 5N6.

This water heater must be installed in accordance with local codes. In the absence of local codes, it must be installed in

compliance with the National Fuel Gas Code (ANSI Z223.1-Latest Edition), or in Canada CAN/CGA B149.1 Natural Gas

Installation Code (Latest Edition) or CAN/CGA B149.2 Propane Installation Code (Latest Edition).

The following terms are used throughout this manual to bring attention to the presence of hazards at various risk levels,

or to important information concerning product life.

Indicates an imminently hazardous situation, which, if

not avoided, will result in death, serious injury or

substantial property damage.

Indicates a potentially hazardous situation, which, if not

avoided, could result in death, serious injury or

substantial property damage.

This water heater has a limited warranty. The warranty for this water heater is valid only if the water heater has been

installed, maintained and operated in accordance with these instructions.

SECTION I: IMPORTANT INFORMATION................ 2

Indicates potentially hazardous situation, which, if not

avoided, may result in moderate or minor injury or

property damage.

Indicates special instructions on installation, operation

or maintenance, which are important but not related to

personal injury hazards.

SETION VIII: ELECTRICAL CONNECTIONS .......... 25

SECTION II: SPECIFICATIONS ................................ 5

SECTION III: GENERAL INFORMATION ................. 6

SECTION IV: INSTALLATION INSTRUCTIONS ....... 8

SECTION V: VENTING ........................................... 13

SECTION VI: WATER CONNECTIONS .................. 19

SECTION VII: GAS CONNECTIONS ...................... 23

SECTION IX: OPERATING INSTRUCTIONS .......... 26

SECTION X: MAINTENANCE .................................. 35

SECTION XI: DIAGNOSTIC AND

TROUBLESHOOTING GUIDE ................................ 39

SECTION XII: PARTS LIST ..................................... 58

2

DANGER

DO NOT s tore or use gasoline or other f lammable, combustible, or c or ros ive vapors and/or liquids in the vicinity of this or

any other appliance.

This water heater is equipped with an adjustable thermostat to control water temperature. Hot water temperatures

The slower

to draw their own bath water. NEVER leave a child or disabled person unattended in a bathtub or shower.

Toxic chemical, such as those used for boiler treatment, must not be introduced into potable water used for space

heating.

This water heater must not be connected to an existing heating system or component(s) previously used with a nonpotable water heating appliance.

All piping components c onnec ted to this water heater for space heating applications must be suitable for use with potable

WARNING

Improper installation, adjustments, alteration, service or maintenance can cause property damage, personal injury or loss

and service technician.

This water heater requires regular maintenance and service to operate safely. Follow the instructions contained in this

manual.

Installation, maintenance, and service must be performed only by a qualified, skilled and knowledgeable installer or

service provider.

Installation is not complete unless a temperature and pressure relief valve is installed into the proper location at the top of

this water heater.

It is the responsibility of the installing contractor to see that all controls are correctly installed and are properly operating

when the installation is complete.

This water heater is suitable for installation on combustible flooring. Do not install water heater directly on carpeting.

DO NOT operate this water heater without first being certain it is filled with water.

DO NOT tamper with or alter the water heater and/or controls.

DO NOT operate water heater with jumpered or absent controls or safety devices.

DO NOT operate water heater if any external part has been under water. Immediately call a qualified service technician to

inspect the appliance and to replace any part of the control system including gas controls, which has been under water.

DO NOT attempt to use this water heater with any gas other than the type listed on the rating plate. Do not attempt to

company if there are any questions.

Incorrect operation of this appliance may create a hazard to life and property and will nullify the warranty.

DO NOT operate this water heater if the input rate exceeds the rate shown on the water heater rating plate.

This water heater contains very hot water under high pressure. Do not unscrew any pi pe fittings nor attempt to disconnect

not rely on the temperature gauges to determine the temperature. Do not touch any components unless they are cool.

This water heater must be properly vented and connected to an approved vent system in good condition. DO NOT

heater’s efficiency.

required for automatic dishwasher and laundry use can cause scald burns resulting in serious personal injury and/or

death. The temperature at which injury occurs varies with the person’s age and the time of exposure.

response time of disabled pers ons increases the hazards to them. NEVER allow small children to use a hot water tap, or

water.

of life. Failure to follow all instructions in the proper order can cause personal injury or death. Read and understand all

instructions, including all those provided with the appliance before installing, starting-up, operating, maintaining or

servicing this appliance. Keep this manual and literature in legible condition with this water heater for reference by owner

convert this water heater for use with a gas other than the type for which it is equipped. Failure to use the proper gas can

create an unsafe condition resulting in property damage, bodily injury, or death. Consult your local gas supplier or gas

any components of this water heater without positively assuring the water is cool and is not under pressure. Always wear

protective clothing and equipment when installing, starting up or servicing this water heater to prevent scald injuries. Do

operate water heater with the absence of an approved vent system. A clean and unobstructed vent system is necessary

to allow noxious fumes that could cause injury or loss of life to vent safely and will contribute toward maintaining the water

3

WARNING

This water heater needs fresh air for safe operation and must be installed so there are provisions for adequate

cient air supply will cause a recirculation of combustion products resulting in

and flue tubes and creates a risk of asphyxiation.

Water heater materials of construction, pr oducts of combustion and the fuel c ontain carbon monoxide, nitrogen oxides,

Always use proper safety clothing,

respirators and equipment when servicing or working nearby this water heater.

Flammable items, pressurized containers or any other potential fire hazardous articles must never be placed on or

this water heater.

Insulation blankets are not required for this water heater. This water heater meets or exceeds the ASHRAE/IES 90.1b

(latest edition) standards with respect to insulation and standby loss requirements.

Setting the water temperature to the maximum set point can result in scalding hot water delivered to the faucets. It is

the time it is open.

Basements, crawl spaces, c losets and areas below ground level will serve as pockets f or accum ulation of leaking gas.

WARNING

combustion and ventilation air. Insuffi

contamination that m ay be hazardous to life. T his will result in carboning or sooting of the com bustion chamber, burner ,

aldehydes and/or other toxic or harmful substanc es which can cause death or ser ious injury and which are known to the

state of California to cause cancer, birth defects and other reproductive harm.

adjacent to the water heater. O pen containers of f lam m able m aterial should not be stor ed or used in the s am e room with

highly recommended that the maximum setpoint be adjusted to the lowest temperature possible for the needs of the

installation. See following section in this Installation/Operation Manual to change the maximum setpoint limit (max

setpoint). Make sure the water heater control display is not in a public area that can result in the temperature settings

being improperly adjusted.

Hydrogen gas can be produced in an operating water heater that has not had water drawn fr om the tank for a long period

of time (generally two weeks or more). Hydrogen gas is extrem ely flammable. To prevent the possibility of injury under

these conditions, we recomm end the hot water faucet to be open for several m inutes at the kitchen sink before you use

any electrical appliance, which is connect to the hot water system. If hydrogen is present, there will be unusual sounds

such as air esc aping through the pipes as hot water begins to f low. Do not smoke or have open flame near the f aucet at

Before lighting, smell all around the appliance area for gas. Be sure to smell next to the floor.

IF YOU SMELL GAS:

• DO NOT try to light any appliance.

• DO NOT touch any electric switch; do not use any telephone in your building.

• Immediately call your gas supplier from a telephone in another building. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

DO NOT OPERATE THE A P PLIAN C E UN TIL THE LEAK A G E IS C O R REC TED !

To comply with NSF requirements this water heater is to be: Sealed to the floor with sealant, in a smooth and easily

cleanable way.

4

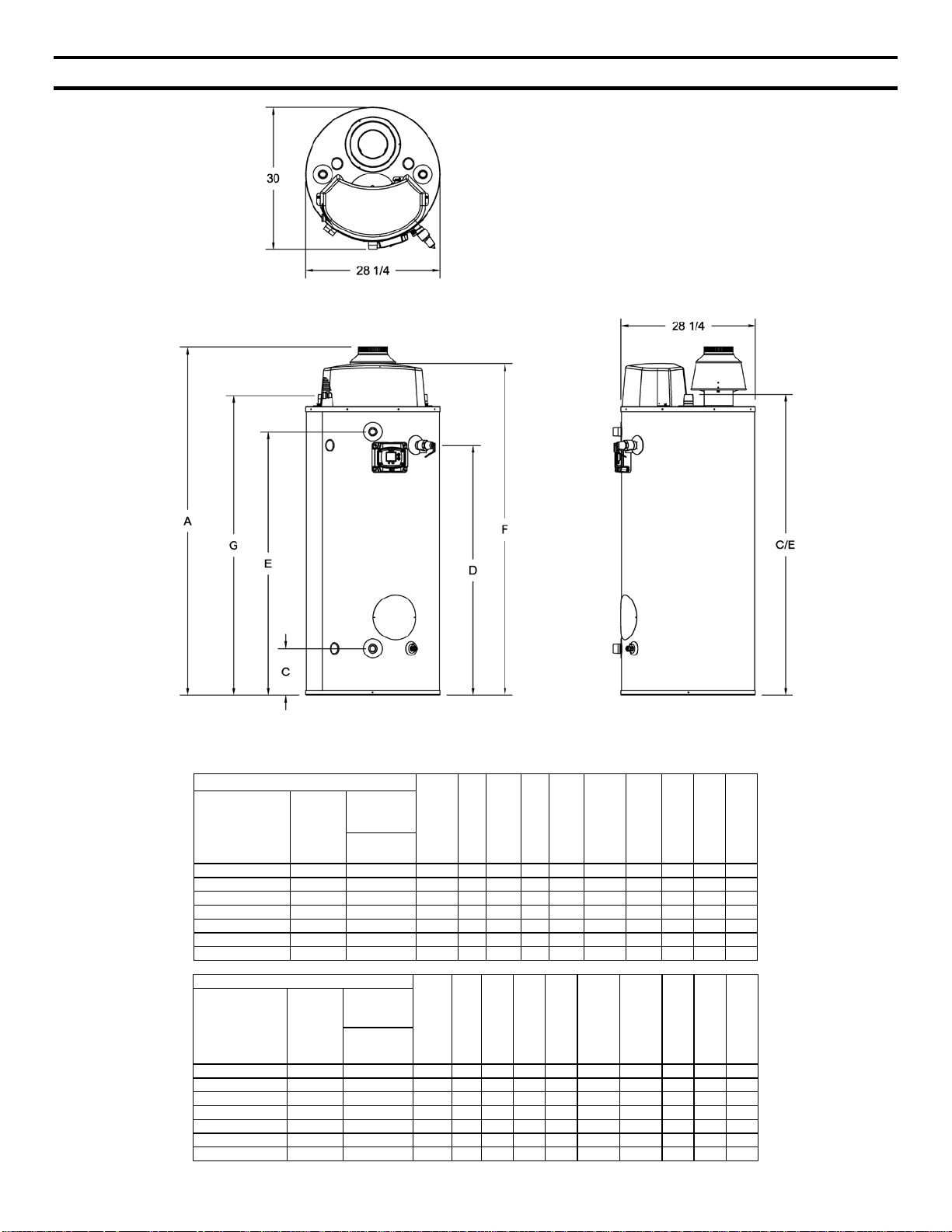

Model Description

A

Floor to

B

Vent

C

Water

(in)

D

Floor

to T&

E

to Hot

Water

F Floor

G

to Gas

Water

Conn.

Gas

Conn.

Relief

Valve

NAT. & L.P.

UCG100H199

100

199,999

73 ¼ 6 10

52 ½

55 ½

69 ¾

63 ¼

1 ½ ¾ ¾

UCG100H270

100

270,000

73 ¼ 6 10

52 ½

55 ½

69 ¾

63 ¼

1 ½ ¾ 1

UCG100H399

98

399,999

77 ¼ 8 10

52 ½

55 ½

69 ¾

63 ¼

1 ½ ¾ 1

UCG80H125

80

125,000

63 5 10

44

47

61 ¼

55 ¾

1 ½ ¾ ¾

UCG80H199

80

199,999

64 ¾ 6 10

44

47

61 ¼

55 ¾

1 ½ ¾ ¾

UCG80H270

80

270,000

64 ¾ 6 10

44

47

61 ¼

55 ¾

1 ½ ¾ 1

UCG80H399

80

399,999

68 ¾ 8 10

44

47

61 ¼

55 ¾

1 ½ ¾ 1

Model Description

A

Floor to

B

Vent

C

Floor

Water

Conn.

(mm)

D

Floor

E

Floor

to Hot

Water

Conn.

F Floor

of Water

G Floor

Water

Conn.

Gas

Conn.

Relief

Valve

NAT. & L.P.

UCG100H199

379

58.6

1861

152

254

1334

1410

1772

1607

38

19

19

UCG100H270

379

79.1

1861

152

254

1334

1410

1772

1607

38

19

25

UCG100H399

371

117.2

1962

203

254

1334

1410

1772

1607

38

19

25

UCG80H125

303

36.6

1600

127

254

1118

1194

1556

1391

38

19

19

UCG80H199

303

58.6

1899

152

254

1118

1194

1556

1391

38

19

19

UCG80H270

303

79.1

1899

152

254

1118

1194

1556

1391

38

19

25

UCG80H399

303

117.2

2000

203

254

1118

1194

1556

1391

38

19

25

SECTION II: SPECIFICATIONS

Figure 1. Dimensional Layout.

Table 1. Specifications.

Model Number

Model Number

Capacity

(Gal.)

Capacity

Liters

Input BTU/Hr.

Input kW/Hr.

Top of

Vent

(in.)

Top of

Vent

(mm)

Dia.

(in)

Dia.

(mm)

Floor

to

Cold

Conn.

P

(in)

Floor

Conn.

(in)

to Top

of

Water

Heater

(in)

Floor

Conn.

(in)

Dia.

(in.)

Dia.

(in.)

(in.)

to Top

to Gas

to

Cold

to

T&P

(mm)

(mm)

Heater

(mm)

Conn.

(mm)

Dia.

(mm)

Dia.

(mm)

(mm)

5

SECTION III: GENERAL INFORMATION

FEATURES

This water heater contains the following features:

MAIN POWER ON/OFF SWITCH

The front panel of this water heater has an ON/OFF switch, which has markings when the main power is turned on to

indicate power to the water heater.

COMBUSTION SYSTEM

This water heater is equipped with a self-compensating negative pressure pre-mix combustion system. As the blower

operates, air is drawn in through the air intak e and into a venturi, which pulls gas from the gas valve. The gas and air is

then mixed in the combus tion blower and sent through t he trans ition tube into the burner. The Direct Spark Ignition System

(DSI) then ignites the gas/air fuel mix ture to produce flue products (combustion). The flam e sensor signals the ignition

control board (described below), that a flame is present.

HONEYWELL INTEGRATED CONTROL

Consists of a control board and a water heater display. An attractive digital water heater display is on the top front of the

water heater for precisely setting and displaying the temperature setpoint and monitoring the status of the water heater.

Pressing the temperature UP and DOWN buttons changes the temperature setpoint. The temperature format may be

displayed in degrees F or degrees C. The water heater display will show diagnostic codes in the event the water heater

needs servicing. The temperature readings of the tank sensor can be monitor ed in Service Mode. Also in Service Mode,

the display can show up to 10 previous error codes to further aid in servicing the water heater.

The single control boar d has plug in wiring harnesses to reduce the chance of mis-wiring. The control board contr ols all

ignition, temperature, and combus tion blower f unctions . The control board controls the combustion blower, ignition timings,

and gas valve to control the combustion system in order to maintain the desired tank temperature. The sequence of

operation is described in detail in the Diagnostic Section at the back of this Installation and Operating Instruction Manual.

ADJUSTABLE THERMOSTAT

This water heater is equipped with an adjustable thermostat as part of the Integrated Control System to control water

temperature. Hot water temperatures required for automatic dishwasher and laundry use can cause scald burns r esulting

in serious personal injury and/or death.

The temperature m ay be adjusted from about 70°F (21°C) to about 180°F (82°C). The thermostat was adjusted to 70°F

(21°C) before the water heater was s hipped from the factory. It is recomm ended that lower tem perat ures be us ed to avoid

the risk of scalding. Refer to the “War nings” and the sec tion on SCALDING in “Sec tion V: Water Connections”. It is further

recommended, in all cases, that the water temperature be set f or the lowest temperature, which satisfies your hot water

requirements for the installation. This will also provide the most energy efficient operation of the water heater and

minimizes scale formation.

Setting the water heater temperature at 120°F (49°C) will reduce the risk of scalds. Some states require setting lower

temperatures for specific installations.

The top immersion well of the single sens or c ontr ol also c ontains a r edundant s ensor f or the high lim it ( energy cutoff ). The

high limit circuit interrupts the m ain burner gas flow should the water temperature exceed approx imately 200°F (93°C).

Error code “65” will be shown on the water heater control display if the high limit temperature has been exceeded.

Should the high limit switch activate, it must be m anually reset. T his should only be done by a service technician after the

cause of overheating has been corrected. Refer to the section on “Accessing Service Mode on the Display” in the

Diagnostic section of this Installation and Instruction Manual.

Contact your qualified installing contractor, service provider or manufacturer listed on the rating plate if continued high limit

operation occurs.

LATCHES

The latches allow easy access for servicing the water heater from the top. Simply remove the two latches for s er vicing and

re-latch upon completion. No tools are required to obtain access to the top of the water heater.

6

WARNING

This product contains one or more chemicals known to the State of

California to cause c ancer, birth defects, or reproductive harm.

Keep clear of combination temperature and pressure relief valve discharge line outlet. The discharge may be

WARNING

hot enough to cause scald injury. The water is under pressure and may splash.

For protection against excessive temperatures and pressure, install temperature and pressure protective equipment

required by local codes, but not less than a combination temperature and pressure relief valve certified by a

nationally recognized testing laboratory that maintains periodic inspection of production of listed equipment or

materials as meeting the requirements of the Standard for Relief Valves and Automatic Gas Shutoff Devices for Hot

Water Supply Systems, ANS Z21.22 and the Standard CAN1-4.4 Temperature, Pressure, Temperature and

Pressure Relief Valves and Vacuum Relief Valves. The combination temperature and pressure relief valve must be

marked with a maximum set pressure not to exceed the maximum working pressure of the water heater. The

combination temperature and pressure relief valve must also have an hourly rated temperature steam BTU

discharge capacity not less than the hourly rating of the water heater.

Install the combination temperature and pressure relief valve into the opening provided and marked for this purpose

on the water heater.

Note: Some models may already be equipped or supplied with a combination temperature and pressure relief valve.

Verify that the combination temperature and pressure relief valve complies with local codes. If the combination

temperature and pressure relief valve does not comply with local codes, replace it with one that does. Follow the

installation instructions above on this page.

Install a discharge line so that water discharged from the combination temperature and pressure relief valve will exit

within six (6) inches (15.2 cm) above, or any distance below the structural floor and cannot contact any live electrical

part. The discharge line is to be installed to allow for complete drainage of both the combination temperature and

pressure relief valve and the discharge line. The discharge opening must not be subjected to blockage or freezing.

DO NOT thread, plug or cap the discharge line. It is recommended that a minimum clearance of four (4) inches (10.2

cm) be provided on the side of the water heater for servicing and maintenance of the combination temperature and

pressure relief valve.

Do not place a valve between the combination temperature and pressure relief valve and the tank.

DISHWASHING MACHINE REQUIREMENTS

All dishwashing machines meeting the National Sanitation Foundation requirem ents are designed to operate with water

flow pressures between 15 and 25 pounds per square inch. Flow pressures above 25 pounds per square inch, or below 15

pounds per square inch, will result in improperly sanitized dishes.

The National Sanitation Foundation also recommends circulation of 180°F water. Where this is done, the circulation should

be very gentle so that it does not cause any unnecessary turbulence inside the water heater. The circulation should be just

enough to provide 180°F water at the point of take-off to the dishwashing machine. Adj ust flow by means of the valve in

the circulation line.

SACRIFICIAL ANODES – Three sacrificial anode rods have been installed in the tank head to extend tank life. The

anode rods should be inspected periodically for corrosion and replaced when necessary to prolong tank life. Water

conditions in your area will influence the time interval for inspection and replacement of the anode rods. The use of a

water softener may increase the speed of anode cons umption. More frequent inspection of the anodes is needed when

using softened (or phosphate treated) water. Cont act the installing contrac tor, or s ervice provider that ins talled the water

heater or the manufacturer listed on the rating plate for anode replacement information.

7

INSTALLATION OF THIS WATER HEATER REQUIRES ABILITY EQUIVALENT TO THAT OF A LICENSED

Y AND

UNDER NO CIRCUMSTANCES SHALL FLAM MABLE MATERIALS, SUCH AS GASOLINE OR PAINT

SECTION IV: INSTALLATION INSTRUCTIONS

WARNING

TRADESPERSON IN THE FIELD INVOLVED. PLUMBING, AIR SUPPLY, VENTING, GAS SUPPL

ELECTRICAL WORK ARE REQUIRED.

DO NOT ATTEMPT TO LIGHT ANY GAS APPLIANCE IF YOU ARE NOT CERTAIN OF THE FOLLOWING:

• Liquefied petroleum gases /propane gas and natural gas have an odorant added by the gas supplier that aids in

detection of the gas.

• Most people recognize this odor as a “sulfur” or “rotten egg” smell.

• Other conditions, such as “odorant f ade” c an cause the odor ant to dim inish in intensity, or “fade”, and not be as

readily detectable.

• If you have a diminished sense of sm ell, or are in any way unsure of the presence of gas, imm ediately contact

your gas supplier from a telephone in another building.

• Gas detectors are available. Contact your gas supplier or plumbing professional for more information.

Liquefied petroleum gases/pr opane gas is heavier than air and will remain at floor level if there is a leak. Basements,

crawl spaces, closets and areas below ground level will serve as pockets for accumulation of leaking gas. Before

lighting, smell all around the appliance area for gas. Be sure to smell next to the floor.

IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any telephone in your building.

• Immediately call your gas supplier from a telephone in another building. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

DO NOT OPERATE THE APPLIANCE UNTIL THE LEAKAGE IS CORRECTED!

This water heater m ust be located in an area where leakage of the tank, water line connections, or the com bination

temperature and pressur e relief valve will not result in damage to the ar ea adjacent to the water heater or to lower floors

of the structure. When such locations cannot be avoided, a suitable drain pan m ust be ins talled under the water heater.

The drain pan depth must be suitable f or dr aining and collecting water, and have a minimum length and width of at least

four (4) inches (10.0 cm ) measured from the jac ket of the water heater. The drain pan, as described above, can be

purchased from your plumbing prof essional. The water heater m ight need to be placed on bloc ks inside dr ain pan to fit

in standard size pan. The drain pan m us t be piped to an adequate drain. The piping must be at least ¾ inch (2.0 cm ) in

diameter and pitched for proper drainage.

Water heater s are heat produc ing appliances. To avoid dam age or injury there mus t be no materials st ored against the

water heater and proper care m ust be tak en to avoid unnecess ary contact (espec ially by children) with the water heater

components.

THINNER BE USED OR STORED IN THE VICINIT Y O F T HIS W ATER HEATER, VENT-AIR INTAKE SYSTEM OR IN

ANY LOCATION FROM WHICH FUMES COULD REACH THE WATER HEATER OR VENT-AIR INTAKE SYSTEM.

Failure to adhere to these installation and operating instructions may create a hazard to life and property and will nullify

the warranty.

Sacrificial anode rods have been installed in the tank head of the water heater to extend tank life. The r emoval of these

anodes, except for inspection and/or r eplacement, will nullify the warranty. In areas where water is unusually active, an odor

may occur at the hot water faucet due to a react ion between the sacrificial anode and the impurities in the water. If this

should happen, alternative anodes may be purchased from the supplier that installed this water heater. This will minimize

the odor while protecting the tank. Additionally, the water heater should be flushed with appropriate dissolvers to eliminate

any bacteria.

Note: For California installation this water heater must be braced, anchored, or strapped to avoid falling or moving

during an earthquake. See instructions for correct installation procedures. Instructions may be obtained from DSA

Headquarters Office, 1102 Q Street, Suite 5100, Sacramento, California 95811.

This water heater MUST be installed indoors out of the wind and weather.

8

The National Fuel Gas Code (ANSI Z233.1- latest edition) or in Canada The Natural Gas Installation Code

CAUTION

DAMAGE TO THE WATER HEATER CAUSED BY EXPOSURE TO CORROSIVE VAPORS IS NOT COVERED BY

STORE ANY POTENTIALLY CORROSIVE COMPOUNDS IN THE VICINITY OF THE WATER HEATER.

NOTICE

This water heater MUST NOT be installed in any location where gasoline or flammable vapors are likely to be

present, unless the installation is such to elimina te the probable ignition of gasoline or flammable vapors.

CAN/CGA (B149.1 - latest edition), expressly prohibits the following:

a. Installation of a water heater in a bathroom, bedroom, or any occupied room normally kept closed.

b. Installation of a water heater in a garage, unless the unit is installed so that the burner and ignition devices are at

least eighteen (18) inches (45.8 cm) above floor level and protected to avoid damage by a moving vehicle.

If the buildings cold water supply has a back-flow preventer, check valve or water meter with check valve, provisions for

thermal expansion of water in the hot water system must be provided.

The location of this water heater is of the utmost importance. Before installing this water heater, you should read the

Installation section of these instructions . After r eading these Installation and Oper ating Instruc tions, select a loc ation for the

water heater where the floor is level and is easily accessible to water lines, gas supply (type identified on the rating plate),

an adequate open drain, and a chimney or exhaust gas vent. DO NOT locate the water heat er where water lines could

be subjected to freezing temperatures. Make sure the cold water pipes are not located directly above the gas

control box or any other electrical control so that condensate during humid weather does not drip on the controls.

This installation must allow access to the front of the water heater and adequate clear ance must be provided for servicing

and operating this water heater. The water heater m ay be installed on either a combustible or non-com bustible floor. If the

water heater is to be installed directly on carpeting, it must be ins talled on top of a metal or wood panel (or equivalent)

extending beyond the full width and depth of the appliance by at least three (3) inches (7.6 cm) in any direction or, if the

appliance is to be installed in an alcove or closet, the entire floor must be covered by the panel. The minimum clearances to

combustibles for this water heater are given in the following pages. A minimum of 24 inches front clearance must be

provided for inspection and servicing. Adequate clearances must be provided for easy access to controls by service

personnel to enable proper cleaning, servicing, and operation of the water heater.

Water heater corrosion and com ponent failure can be caused by the heating and breakdown of airborne chem ical vapors.

Examples of some typical compounds that are potentially corrosive are: spray can propellants, cleaning solvents,

refrigerator and air conditioning refrigerant s, swimming pool chem icals, calcium and sodium chloride, waxes and process

chemicals. These materials are corrosive at very low concentration levels with little or no odor to reveal their presence.

THE WARRANTY. DO NOT OPERATE THE WATER HEATER IF EXPOSURE HAS OR WILL OCCUR. DO NOT

UNPACKING

1. Inspect carefully for any signs of damage

2. All equipment is carefully manufactured, inspected and packed.

3. Any claims for damage or shor tage in shipment must be filed immediately with the manufacturer noted on the

rating plate label.

LOCATE WATER HEATER

1. Locate water heater in front of final position before removing crate.

2. LOCATE so that venting connections will be short and direct.

3. THIS WATER HEATER IS SUITABLE FOR INSTALLATION ON COMBUSTIBLE FLOOR.

4. Proper venting practices must be considered when selecting a location for this water heater. For exact venting

specifications, please consult the Venting section of these Installation and Operating Instructions.

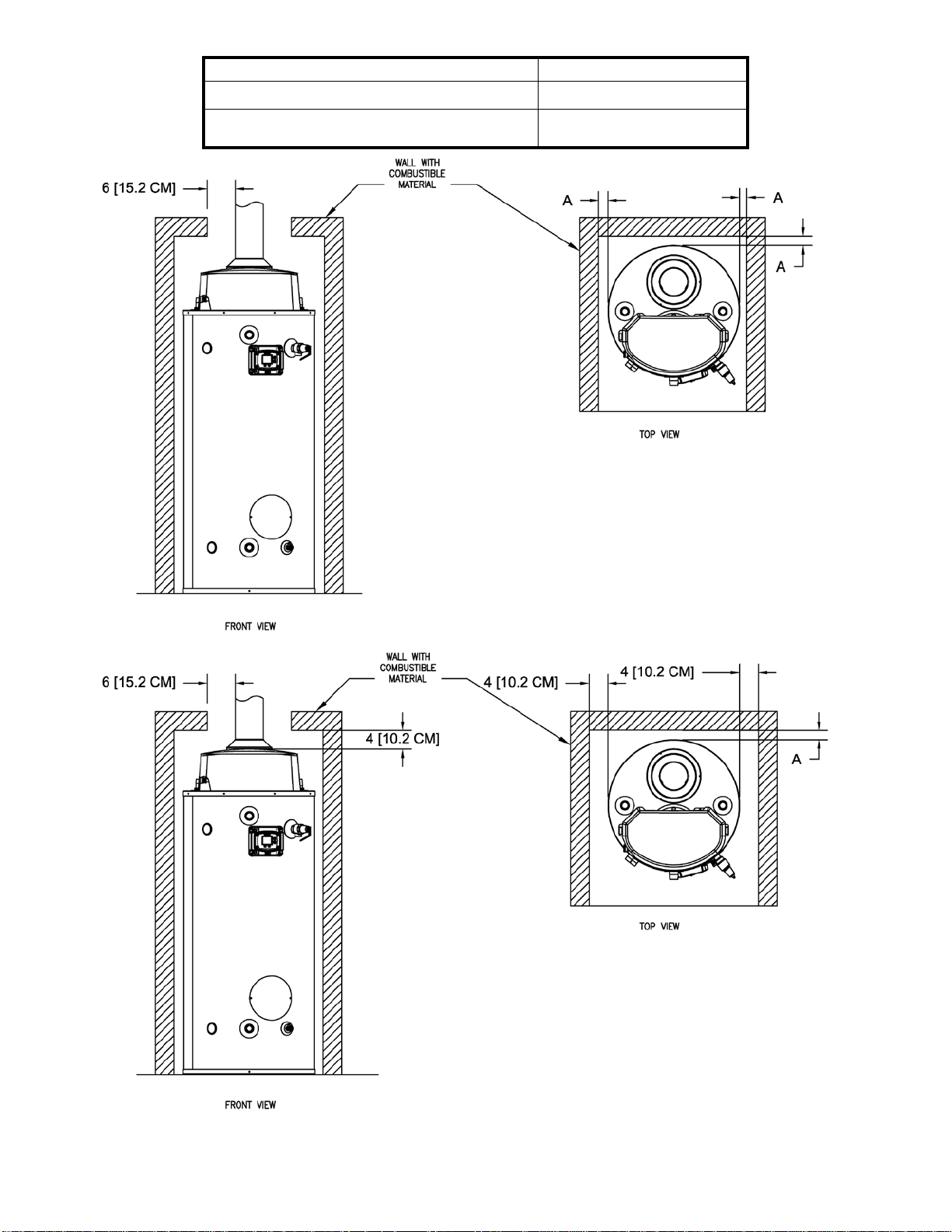

5. It is recommended that minimum clearances shown in figure 2b be provided on the sides and top of the water

heater for servicing and maintenance of the water heater.

6. Increase distances to provide clearance for servicing.

9

Input

Front, sides and Rear “A”

399,999 BTUH

0 in. (0.0 CM) (2 in. Rear

ONLY)

Less than or equal to 270,000 BTUH 0 in. (0.0 CM)

Figure 2a. Minimum Clearance To Combustible Material.

Figure 2b. Recommended Minimum Clearances For Service Access.

10

CAUTION

Do not drop water heater. Do not bump water heater jacket against floor.

DANGER

Temperature setting should not exceed safe temperature at fixtures. See water temperature control warning in Section

approved mixing device for hot water supplied to fixtures.

WARNING

Temperature and pressure relief valve discharge piping must be piped near floor to eliminate potential of severe burns.

IMPORTANT-The flow of combustion and ventilating air must not be obstructed.

WARNING

REMOVE CRATE

1. Remove all banding and pry off crate sides carefully so as not to damage the water heater.

2. Carefully roll/lift the water heater from the crate base.

Do not bump exhaust vent pipe against crate or other objects. This will damage the heater and cause it to be inoperable

or create nuisance problems.

MOVE WATER HEATER TO PERMANENT POSITION by sliding or walking.

INSTALL TEMPERATURE AND PRESSURE RELIEF VALVE (if not already installed).

VI, “Water Connections”. If higher preheat temperatures are necessary to obtain adequate booster output, add an ASSE

Do not pipe in any area where freezing could occur. Do not install any shut-off valves, plugs or caps to the temperature

and pressure relief valve or piping.

This water heater must be located in an area where the general public does not have access to set temperatures.

AIR REQUIREMENTS

1. Do not obstruct the flow of ventilating air.

2. For safe operation, adequate air is needed for c ombustion and ventilation. Sooting may result in serious dam age

to the water heater and risk of fir e or ex plosion. It can also create a risk of asphyxiation. Such a condition often will

result in a yellow, luminous burner flame, causing carboning or sooting of the combustion chamber, burner and

flue tubes.

MECHANICAL EXHAUS TING OF ROOM AIR - Where an exhaust fan is installed in the same room with this water

heater and combustion air is drawn from inside the room, sufficient openings for air must be provided in the walls.

UNDERSIZED OPENINGS WILL CAUSE AIR TO BE DRAWN INTO THE ROOM THROUGH THE WATER HEATER’S

VENTING SYSTEM, CAUSING POOR COMBUSTION THAT MAY BE HAZARDOUS TO LIFE. SOOTING MAY

RESULT IN SERIOUS DAMAGE TO THE WATER HEATER AND RISK OF FIRE OR EXPLOSION, WHICH CAN

ALSO CREATE A RISK OF ASPHYXIATION. Refer to local codes and /or National Fuel Gas Code (ANSI Z223.1-Latest

Edition), or in Canada CAN/CGA B149.1 Natural Gas Installation Code (Latest Edition) or CAN/CGA B149.2 Propane

Installation Code (Latest Edition) for proper air opening sizing.

CONFINED SPACES

If the water heater is installed in a confined space (volume is less than 50 ft.3/1000 BTU (15 m3/0.29 kW) per hour of the

total input rating of all gas appliances in that space), air must be supplied through two permanent openings. One opening

must be within 12 inches (30.5 cm) from the top of the enclosure and one within 12 inches (30.5 cm) of the bottom. The

openings must be protected by metal louvers or 1/4” (6.4 mm) min. mesh metal screen. The size of the openings are as

follows:

11

The draft hood relief opening of the water heater and combustion air inlet must be in the same atmospheric pressure

CAUTION

zone. Large exhaust fans in kitchens and other locations can lower the air pressure inside an enclosure and interfere

with the proper operation and venting of the water heater. In these cases, the water heater should be installed in a

separate room with the combustion and ventilation air supplied directly from outdoors as previously described.

1. If the openings communicate directly with an additional room(s) of sufficient volume, each opening must have a

2

minimum free area opening of 1 in.

appliances in the confined space, but not less than 100 in.

/1000 BTU (2.54cm2/0.29kW) per hour of the total input rating of all gas

2

(254 cm2).

2. If the openings communicate with the outdoors through horizontal ducts, each opening must have a minimum free

2

area of 1 in.

/2000 BTU (2.54cm2/0.59kW) per hour of the total rating of all gas appliances in the enclosure.

3. If the openings communicate directly with the outdoors or through vertical ducts with the outdoors, each opening must

2

have a minimum free area of 1 in.

/4000 BTU (2.54cm2/1.18kW) per hour of the total rating of all gas appliances in

the enclosure.

ALL AIR FROM INSIDE THE BUILDING

The confined space must be provided with two permanent openings com municating directly with an additional room(s) of

sufficient volume so that the c ombined volume of all spaces meets the criteria for an unconf ined space. T he total input of

all gas utilization equipment installed in the combined space must be considered in making this determination. Each

2

opening must have a minim um free ar ea of 1 in.

utilization equipment in the confined space, but not less than 100 squar e inches ( 254cm

/1000 BTU (2.54cm2/0.29kW) per hour of the total input rating of all gas

2

). One opening must be within 12

inches (30.5 cm) of the top and one within 12 inches (30.5 cm) of the bottom of the enclosure.

UNCONFINED SPACES

In unconfined spaces in buildings, infiltration m ay be adequate to provide air for com bustion, ventilation and dilution of flue

gases. However, in buildings of tight construction ( f or example, weather stripping, heavily insulated, caulked, vapor barrier,

etc.), additional air may need to be provided using the methods described above under CONFINED SPACES: All Air F ro m

Outdoors or SPECIALLY ENGINEERED INSTALLATIONS.

SPECIALLY ENGINEERED INSTALLATIONS

The requirements noted under CONFINED SPACES above must not necessarily govern when special engineering,

approved by the authority having jurisdiction, provides an adequate supply of air for combustion, ventilation, and dilution of

flue gases.

CHEMICAL VAPOR CORROSION

Corrosion of the flue ways and vent system will occur if air for combustion contains certain chemical vapors. Such

corrosion may result in poor combustion and create a risk of asphyxiation, as well as reducing the life of the water

heater. Spray can propellants, cleaning solvents, refr igerator and air c onditioning ref riger ants, swim ming pool chemicals,

calcium and sodium c hloride, waxes and process chemicals are corrosive. Produc ts of this sort should not be stored

near the water heater or outside by the air intake (if applicable).

12

WARNING

The intake vent system must be properly installed. Failure to properly install the vent system could result in property

damage, personal injury, or death.

Use only the vent terminals provided or factory authorized terminals for venting this water heater.

The water heater requires its own separate intake venting system.

Do not terminate the venting where noise from intake venting will be objectionable. This includes locations close to or

rubber isolation pipe hangers are used. This prevents any vibrations from being transmitted into the living spaces.

Do not exceed the venting distances or the number of elbows listed in this manual. Exceeding the maximum venting

distances may cause the water heater to malfunction or cause an unsafe condition.

DO NOT operate this water heater until the venting installation is complete and the piping completed. Failure to complete

installation before operation can result in property damage, personal injury, or death.

The venting system must be installed properly follow ing all local codes or in the absence of local codes, the

WARNING

SECTION V: VENTING

latest edition of the National Fuel Gas Code (ANSI Z223.1- latest edition), or in Canada, The Natural Gas

Installation Code (B14 9 .1 -00 l atest ed iti on ) or CAN/CGA B149 . 2 Propane Inst allation Code (Latest Edition).

Failure to properly install t he venting syst em could result in property damage, personal injury, or death.

Caref ully inspect t he venting syst em of a replacement w at er heat er installation before connect ing to t he vent ing

system. A ll joints in t he vent connect or must be securely f astened w ith screw s and f it t ightly together. Inspect

t he venting syst em for signs of det eriorat ion (rust and perforat ion) and replace any sections t hat are not in good

condition.

The chimney must be lined and in good condit ion. Check t o make sure the venting sy st em is properly sized f or

t he w at er h eater . I f t he v ent in g sys tem w as previously sized f or anot her gas appliance that has been removed,

the venting system may now be too large. Refer to the latest edition of the National Fuel Gas Code (ANSI

Z223.1-latest edition), or in Canada, the Natural Gas and Propane Installation Code (B149.1-0 0 lat est edit ion)

for the correct sizing of venting systems and common venting with another gas appliance. Do not vent this

w at er heat er into t he vent ing syst em of anot her gas appliance designed t o v ent under positiv e pressure.

The w at er heat er sh ould be installed as c lose as prac tic al to t he venting syst em to minimize the vent connector

length required. Ref er to local codes for t he distance limitat ions on vent connect or lengths. At t he completion of

t he wat er heat er i nst al lat i on, t h e bur ner an d v ent ing system must be checked for proper operation wit h all other

commonly vented appliances in operation. Check f or spillage of flue product s around t he outside relief opening

of t he draf t hood aft er several minutes of operation. The f lame from a mat ch should be drawn int o t he draft hood.

Do not use the w at er heater or connect ed equipm ent if spillage is detect ed until t he problem is correc ted. Refer

t o the lat est edit ion of t he Nat ional Fuel Gas Code, or in Canada, t he Natural Gas and Propane Inst allat ion Code

f or complet e details on the ‘‘Procedure to Be Follow ed t o Place Equipment in Operation’’.

This w ater heater has been shipped w it h a draft divert er for whic h it w as designed w it h reference to t he horizont al

and vert ic al pl anes, i t s cert if ied cat egor y I, per l ates t A NSI Z 2 1 .1 0. 3 -2015.CSA 4.3-2 0 15 rev isi on. Ref er t o t h e

latest edition of the National Fuel Gas Code (ANSI Z223.1-latest edition), or in Canada, the Natural Gas and

Propane installation Code (B1 49.1-0 0 latest edit ion). If rem oved, t he draf t divert er must be replaced in t he same

position and secured to t he jacket t op by t he screw s w it h which it was installed.

This water heater must be connected to a lined masonry chimney or venting system approved by local codes or

ordinances. T he vent connector us ed to attach the draft hood outlet to the chimney or approved vent must be of the sam e

diameter as the draft diverter outlet or larger. For proper venting in certain installations, a larger vent connector may be

needed. Consult venting tables in ANSI standard ( Z223.1- latest edition), National Fuel Gas Code and CAN/CGA (B149.1

or B149.2-latest editions) Natural Gas and Propane Installation Code, or loc al code off icials for proper application for your

area.

Optional Intake Venting

The venting instructions mus t be f ollowed to avoid restric ted combustion or recirculation of flue gases. Such conditions

cause sooting or risks of fire and asphyxiation.

across from windows and doors. Avoid anchoring the intake vent pipes directly to framed walls, floors, or ceilings unless

13

For installations in Canada, field supplied vent piping must comply with CAN/CGA B149.1 (latest edition) and be certified to the

time limitations.

Approved Venting Materials

For installations in the US only

ABS Sch. 40 DWV (ASTM D2661)

For installations in CANADA

Approved Primers and Cements

For installations in the US only

• ABS Primer and Ceme nt (ASTM D-2235)

For installations in CANADA

NOTICE

Use of cellular core PVC (ASTM F891). Cellular core CPVC, or Radel® (polyphenosulfone) in non-metallic venting systems is

prohibitied, and covering non-metallic venting with thermal insulation is prohibited.

NOTICE

Before beginning installation of any vent pipe, read the vent pipe manufacturer’s installation instructions.

Do not install the water heater in any location where the ambient temperature may fall below freezing. Water heater must be

protected from freezing downdrafts during shutdown periods.

CAUTION

The vent shall terminate a minimum of 12 inches above expected snowfall level to prevent blockage of vent termination.

The horizontal centerline of the exhaust vent terminal (if applicable) must not be located lower than the horizontal centerline of the

air intake terminal if vented through the same wall.

A service drain loop must be installed in the drain tubing to serve as a condensate trap to prevent flue gases from escaping into the

room.

NEVER locate the air intake where exhaust gases from other appliances can be introduced into the intake.

CAUTION

Check to make sure flue gases do not recirculate into the air intake terminal when using direct venting. If the water heater is having

during periods of below freezing weather.

NOTICE

Standard For Type BH, Class II, 65°C, Gas Venting Systems, ULC S636. Components of this listed system shall not be interchanged

with other vent systems or unlisted pipe/fittings. All components and specified primers and cements of the certified vent system must

be from a single system manufacturer and not intermixed with other system manufacturer’s vent system parts. The supplied vent

connector and vent termination are certified under ULC S636 and are also certified as part of the water heater. Refer to the following

tables for approved venting materials, primers, and cements. All approved primers and cem ents are to be used within their marked

• PVC Sch. 40, 80 (ASTM D-1785)

• PVC DWV (ASTM-D2665)

• CPVC Sch. 40, 80 (ASTM-F441)

• CPVC (ASTM D2846)

•

• PVC and CPVC Primer (ASTM F-656)

• PVC Cement (ASTM D-2564)

• CPVC Cement (ASTM F493)

• ULC S636 approved CAN-COM VENTING SYSTEM

schedule 40 PVC for flue gas venting rated Class II,

65°C (components provided with water heater)

• IPEX ULC S636 approved schedule 40 PVC (all other

vent pipe/ fittings)

• IPEX ULC S636 approved PVC Primer and Cement for

flue gas venting rated Class II, 65°C

service issues, flue recirculation may be a contributing factor. Even when the minimum vent terminal separation distances are

followed, recirculation may still occur depending upon the location outside the building, the distance from other buildings, proximity to

corners, weather conditions, wind patterns, and snow depth. Periodically check to make sure that flue recirculation is not occurring.

Signs of flue gas recirculation include frosted or frozen intake terminals, condensate in the intake terminal and venting system,

oxidation or white chalk material on the flame sensor or igniter shield. Correction to flue recirculation may involve relocating the air

intake to another side of the building, or using inside air for combustion. Check to be sure the intake is not obstructed, especially

High levels of dust and debris such as road and construction dust, insects, and tree pollen may clog the burner resulting in poor

performance and damage to the water heater. Avoid air intake locations where debris can be created such as exhaust ventilation

hoods, gravel parking lots, and near outdoor spotlights that attract bugs. For these installations, an air intake filter kit, part number

239-47330-00A, is available as an accessory service part from the installer of this water heater. The air intake filter kit is not designed

to filter out airborne contaminants or chemicals that may damage the water heater.

14

Canadian

US Installations2

Canadian

US Installations2

A=

Clearance above

12 inches (30

12 inches

H=

Clearance to each side

3 feet (91 cm) within a

assembly

*b

B=

Clearance to window

36 inches (91

4 feet (1.2 m)

opening

I=

Clearance to service

36 inches

*b

C=

Clearance to

*b

*b

J=

Clearance to non-

any other appliance

36 inches

4 feet (1.2m)

above opening.

D=

Vertical clearance to

of the terminal

*b

*b

K=

Clearance to a

6 feet

3 feet (91 cm)

E=

Clearance to

*b

*b

L=

Clearance above paved

public property

7 feet

7 feet

F=

Clearance to outside

*b

*b

M=

Clearance under a

balcony

12 inches (30 cm) ‡

*b

G=

Clearance to inside

corner

36 inches

(91 cm)*a

36 inches

(91 cm)*a

Figure 3. Intake Vent Terminal Clearances (Referencing Other Appliance Venting Locations).

grade, veranda,

porch, deck or

balcony

or door that may be

opened

permanently closed

window

ventilated soffit

located above the

terminal within a

horizontal distance

of 2 feet (61 cm)

from the center line

unventilated soffit

corner

Installations1

cm)

cm)

(30 cm)

below or to the

side of opening;

12 inches (30

cm) above

of center line extended

above meter/regulator

assembly

regulator vent outlet or

oil tank vent

mechanical air supply

inlet to building or the

combustion air inlet to

mechanical air supply

inlet

sidewalk or paved

driveway located on

veranda, porch, deck, or

Installations1

height 15 feet (4.6 m)

above the

meter/regulator

(91 cm)

(91 cm)

(1.83 m)

(2.13 m)†

below or to side

of opening; 12

inches (30 cm)

above if within

10 feet

horizontally

(2.13 m)†

In accordance with the current CAN/ CGA-B149 Installation Codes.

2

In accordance with the current ANS I Z223.1-(Latest Edition)/NFPA 54 National F uel Gas Code.

† A vent shall not termi nate directly above a sidewalk or paved driveway that is located between two single-family dwellings and serves both

dwellings.

‡ Permitted only if a veranda, porch, deck or balcony is fully open on a minimum of two sides beneath the floor.

*a) A minimum clearance value determined by testing in accordanc e with section 2.20.

*b) “Clearance in accordance with local i nstallation codes and the requirements of the gas supplier”.

15

CAUTION

Failure to properly support the vent piping with hangers and clamps may result in damage to the water heater or venting

Clearance to combustibles for all venting pipes and terminals

For installations in the CANADA

instructions for clearances to combustibles

WARNING! DO NOT USE 2”

MODELS

Vent pipes serving power vented appliances are classified by building codes as “vent connectors”. Required clearances

from com bus tible materials must be provided in accordance with inform ation in this manual under LOCATION OF WAT ER

HEATER and CLEARANCES, and with National Fuel Gas Code and local codes.

For installations in the US

0” minimum

DO NOT place insulation or other materials in the required clearance spaces between the venting to combustible material unless

otherwise specified.

Refer to vent pipe and terminal manufacturer’s installation

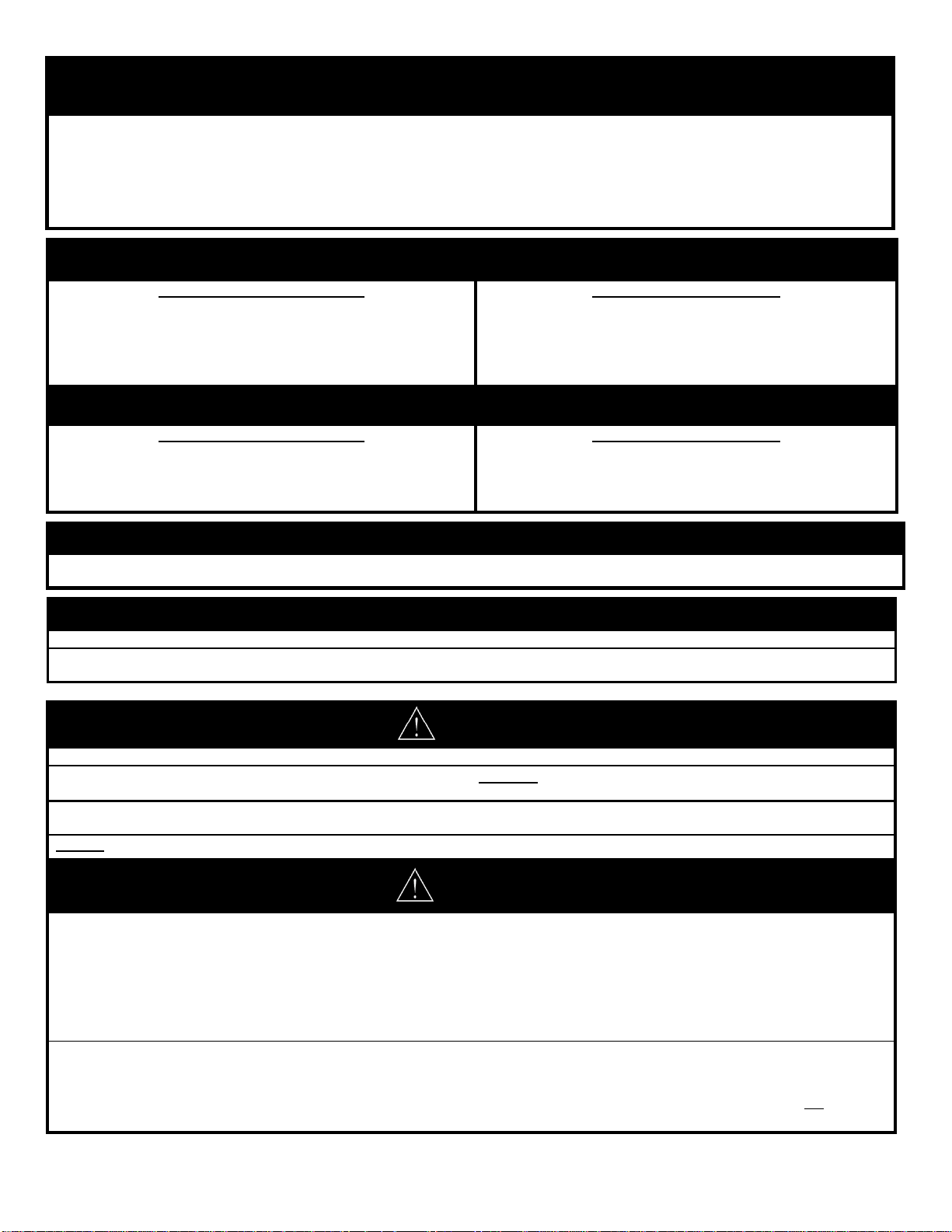

Horizontal Installation

In a horizontal application, it is important that moisture is not to be allowed to buildup in the intake vent pipe. To prevent

this from happening, the pipe should be installed with a slight downward slope so the moisture will run back away from the

water heater. The vent system must be supported every 5 feet of vertical run and every 3 feet of horizontal run of vent

pipe length.

system.

VENT WITH UCG100H399

Figure 4. Typical Horizontal Intake Vent System.

16

CAUTION

Failure to properly support the vent piping with hangers and clamps may result in damage to the water heater or venting

WARNING! DO NOT USE 2”

MODELS

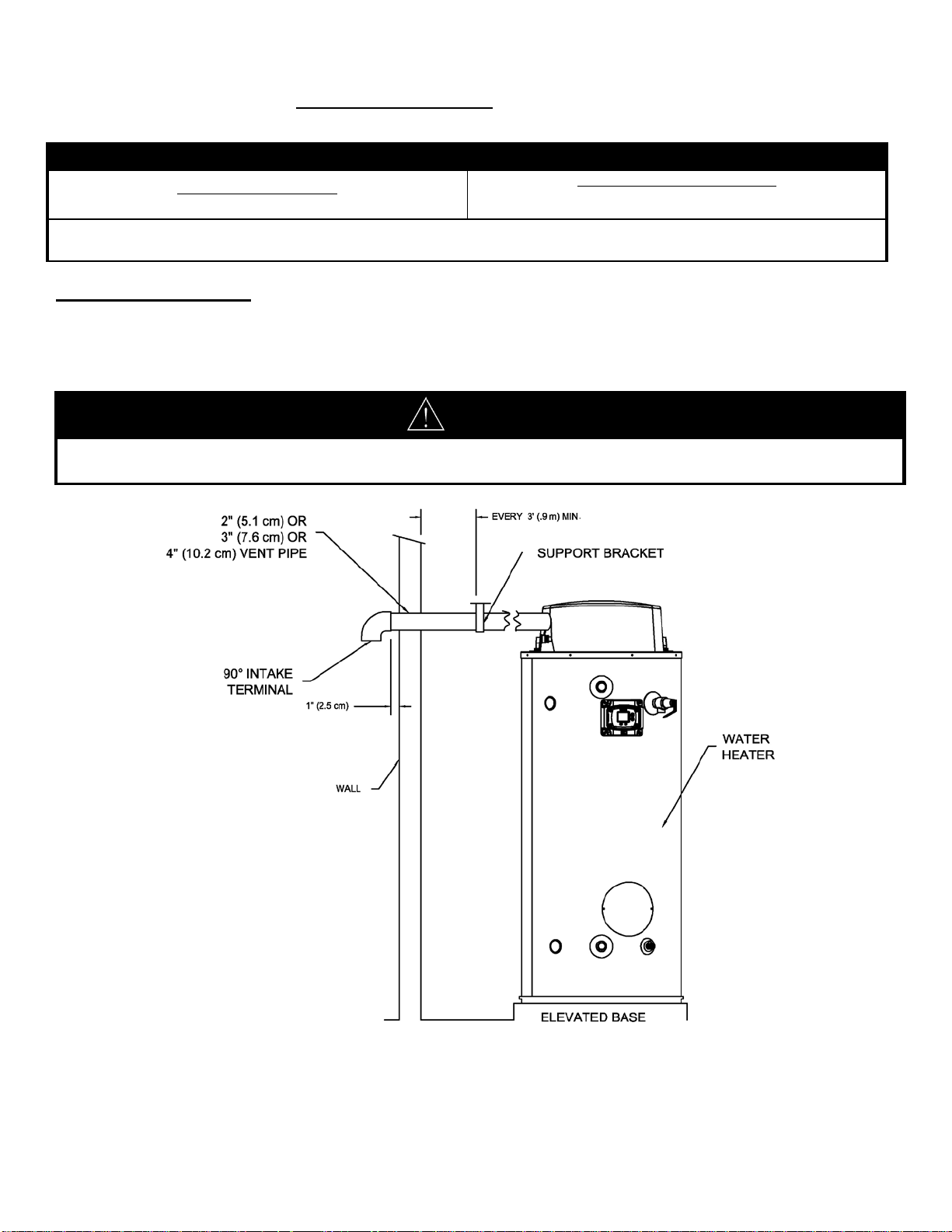

Vertical Installation

Vertical venting system must be supported every 5 feet of vertical run and every 3 feet of horizontal run of vent pipe

length.

system.

VENT WITH UCG100H399

Figure 5. Typical Vertical Intake Vent System Installation.

17

Max Vent

Length (feet) 2”

Max Vent

Length (feet) 3"

Max Vent

Length (feet) 4"

UCG100H199

20

50

75

UCG100H270

20

50

75

UCG100H399

N/A

25

50

UCG80H125

20

50

75

UCG80H199

20

50

75

UCG80H270

20

50

75

UCG80H399

N/A

25

50

WARNING! DO NOT USE 2”

MODELS

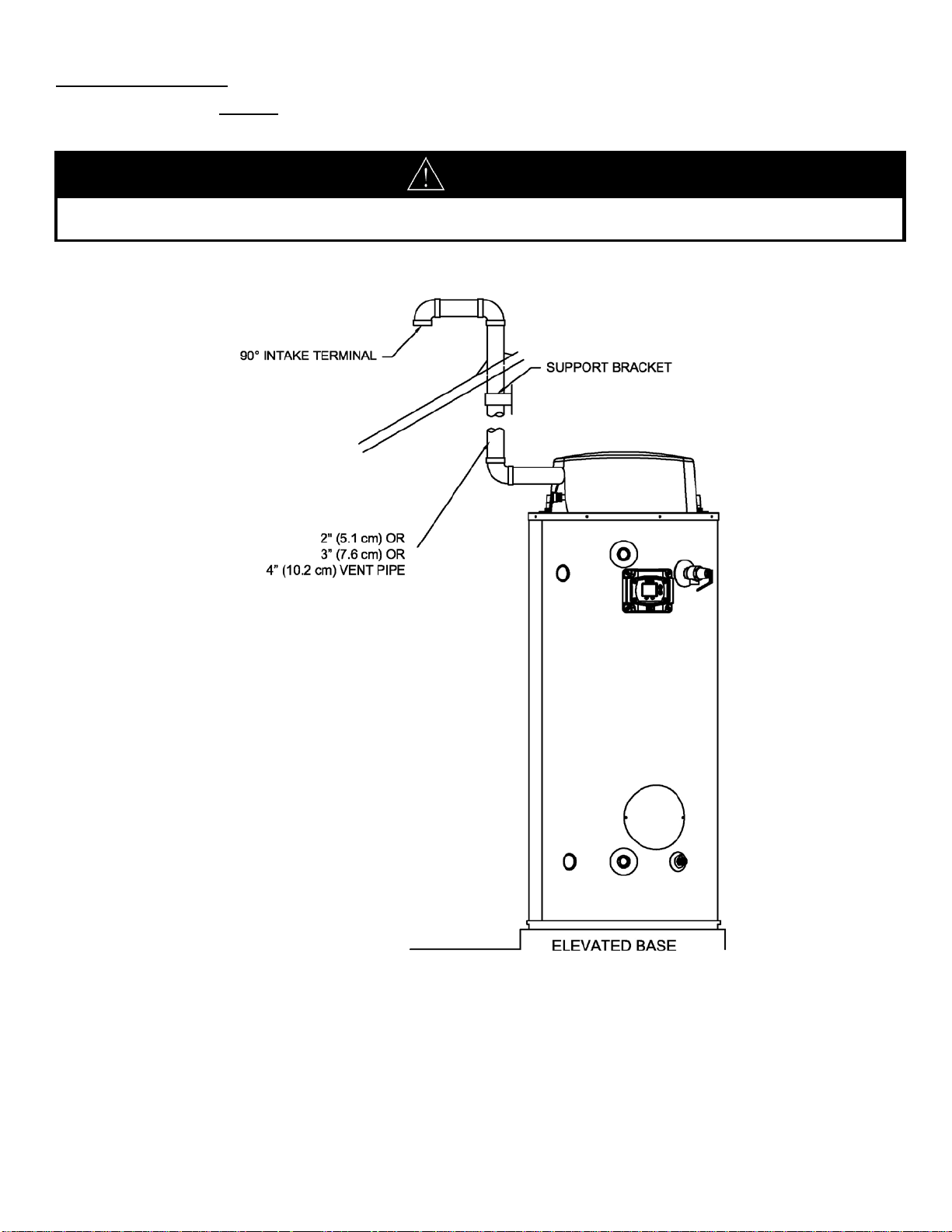

Through The Wall Venting With Low Ground Clearance:

When venting cannot ex it through the wall at a height greater than or equal to 12” (30.5 cm) (and above expected snow

level) from the ground, then the installation must be modified as shown below (see Figure 6).

VENT WITH UCG100H399

Figure 6. Vent Terminal (Low Ground Clearance

).

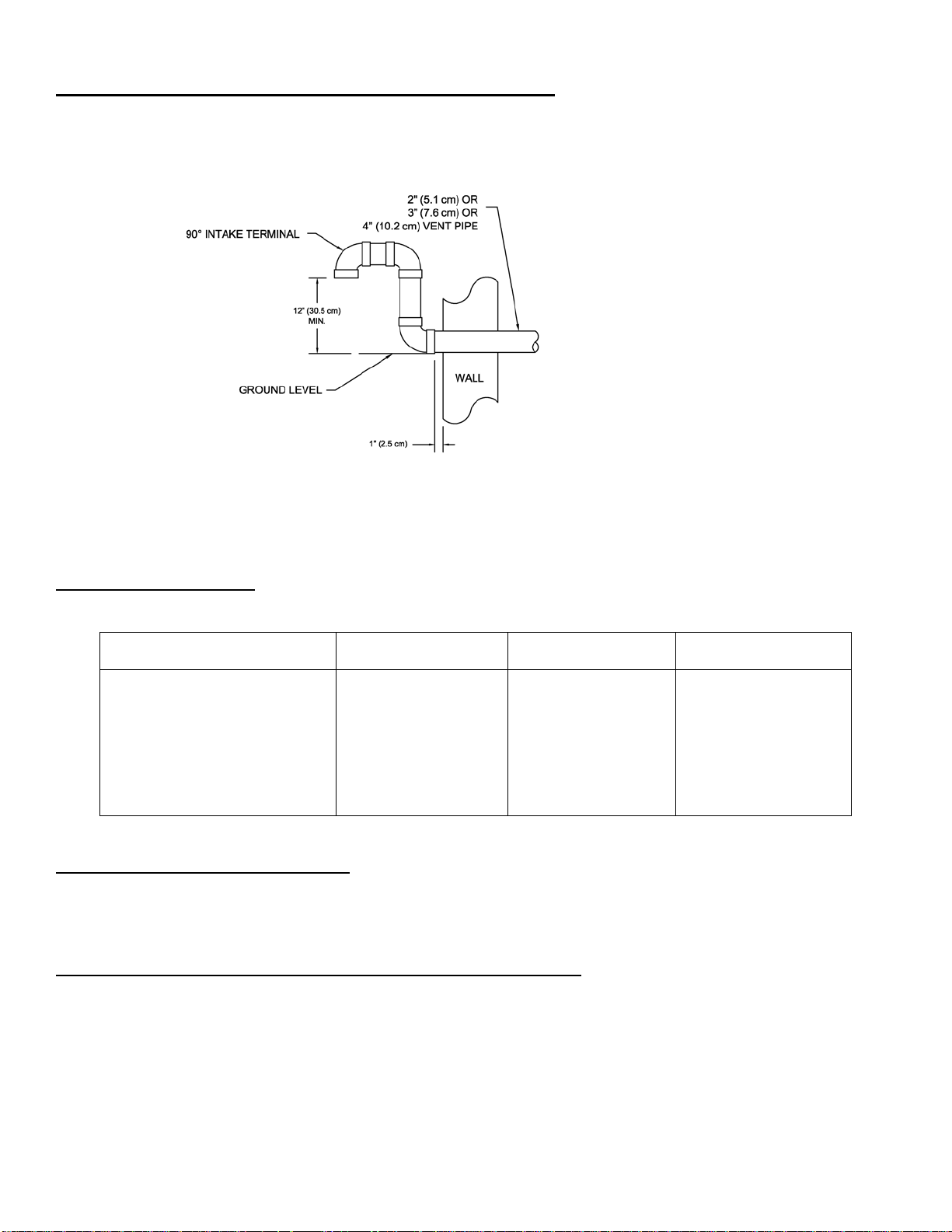

Maximum Vent Length

Table 2. Maximum Intake Vent Length.

Model Number

Determining required vent length

1. Determine the total length of straight vent pipe (in feet) required for the intake.

2. Add 5 feet of venting for every 90° elbow.

3. Add 2 ½ feet of venting for every 45° elbow.

4. Total vent length cannot exceed “Max Vent Length” on the venting table shown above.

Example of Total Vent Length for UCG100H199 installation:

A 3” venting system has a total of t hr ee 90-degree elbows and a total straight pipe length of 30 feet.

Equivalent vent length for elbows: 3 x 5 f eet = 15 feet.

Total equivalent vent distance = 30 feet + 15 feet = 45 feet total equivalent vent length. This is below

the maximum allowed distance of 50 feet for this model using 3” vent.

18

Loading...

Loading...