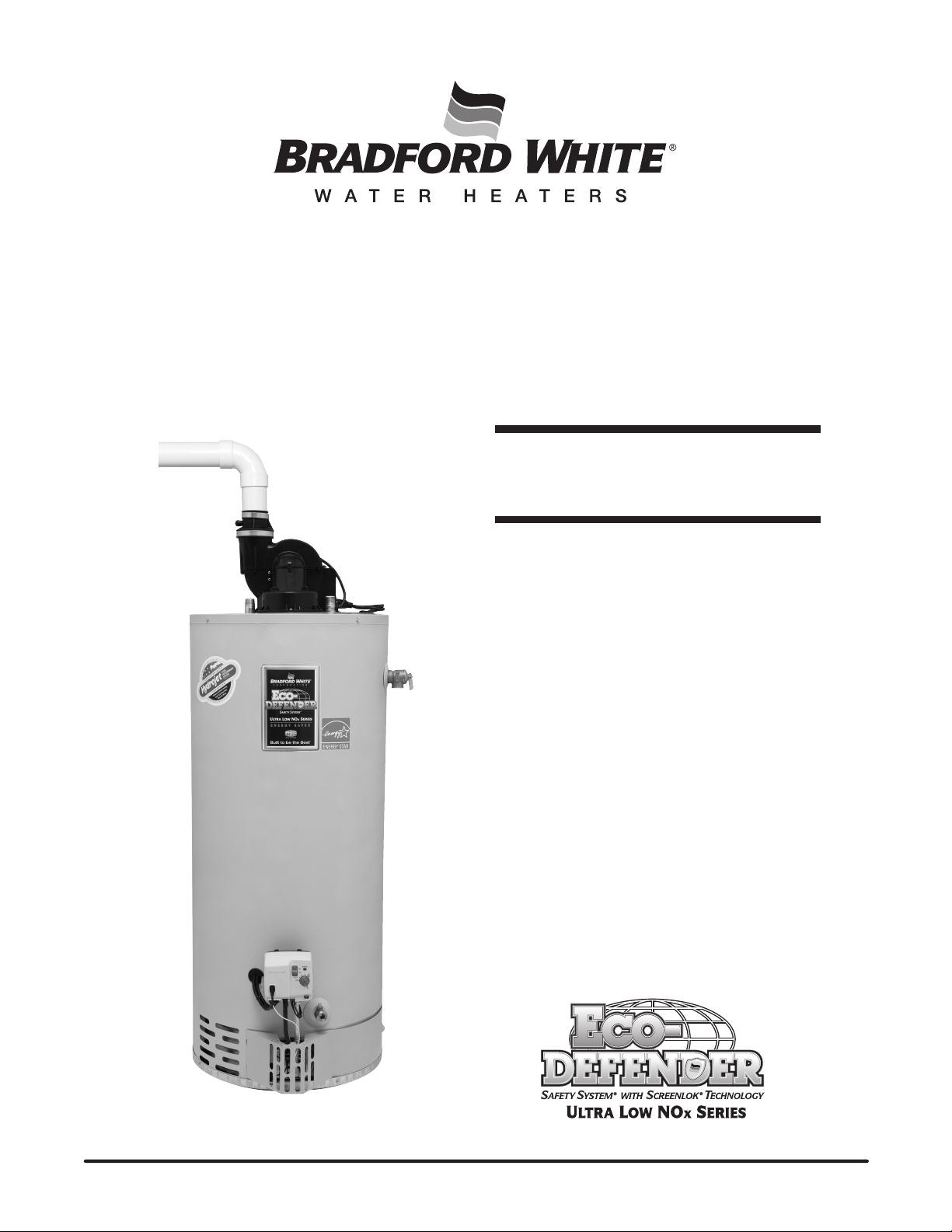

Bradford-White U4TW50T-FRN, U4TW40T-FRN, U4TW60T-FRN User Manual

Save this manual for future reference

Manual 238-48509-00A

SERVICE

MANUAL

Troubleshooting Guide

and Instructions for Service

(To be performed ONLY by

qualified service providers)

Models Covered

by This Manual:

U1TW40S*FRN

U1TW50S*FRN

U1TW60T*FRN

U4TW40T*FRN

U4TW50T*FRN

U4TW60T*FRN

U2TW50T*FRN

U2TW65T*FRN

UTW450S60FR*N

UTW465S60FR*N

(*) Denotes Warranty Years

Residential Ultra Low NOx Gas Water Heaters

TTW Eco-Defender

®

(Model Shown: U-4-TW-40T6FRN)

Table of Contents

2

Section Page

Introduction ______________________________________________5

How to Use this Manual _____________________________________6

Tools Required for Service ___________________________________7

Specifications _____________________________________________8

Sequence of Operation_____________________________________ 12

Power Up Sequence

Normal Heating Sequence

Abnormal Operation

Troubleshooting __________________________________________ 17

Burner Maintenance _______________________________________ 20

Burner Inspection

Burner Cleaning Procedure

Pilot Maintenance _________________________________________ 22

Pilot Inspection Testing and Replacement

Pressure Switch Testing and Replacement _____________________ 25

Blower Testing and Replacement _____________________________ 28

Blower Temperature Switch Testing and Replacement ____________ 31

Thermal Well Testing ______________________________________ 34

Determine Water Temperature Inside Tank_____________________ 35

Gas Control and Thermal Well Testing and Replacement __________ 36

Flammable Vapor Sensor Testing and Replacement ______________ 40

115 VAC Circuit Trace _____________________________________ 40

Safety Circuit Voltage Trace_________________________________ 42

Flue Baffle Inspection and Replacement _______________________ 43

Diptube Inspection and Replacement _________________________ 44

Anode Inspection and Replacement___________________________ 45

Inner Door Removal, Inspection and Replacement _______________ 46

Inner Door Gasket Replacement _____________________________ 47

Inner Door Installation_____________________________________ 48

ScreenLok ® Flame Arrestor Cleaning_________________________ 49

Common Terms __________________________________________ 50

Notes __________________________________________________ 50

Parts List _______________________________________________ 51

Page 2

WARNING

3

If the information in these instructions is not followed exactly, a fire or explosion may result causing property damage, personal injury, or death.

What to do if you smell gas:

x Do not try to light any appliance

x Do not touch any electrical switch; do not use any phone in your build-

ing

x Immediately call your gas supplier from a neighbor’s phone. Follow the

gas supplier’s instructions.

x If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service

agency, or the gas supplier.

DANGER

Do not store or use gasoline or other flammable, combustible, or corrosive

vapors and liquids in the vicinity of this or any other appliance.

CAUTION

Incorrect operation of this water heater may create a hazard to life and

property and will nullify the warranty.

If sweat fittings are to be used, DO NOT apply heat to the nipples on top of

the water heater. Sweat the tubing to the adapter before fitting the

adapter to the water connections. It is imperative that heat is not applied

to the nipples containing a plastic liner.

Turn off or disconnect the electrical power supply to the water heater before servicing. Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous operation. Verify

proper operation after servicing.

NOTICE

Before proceeding, please inspect the water heater and its components for

possible damage. DO NOT install any water heater with damaged components. If damage is evident, then please contact the supplier where the

water heater was purchased or the manufacturer listed on the rating plate

for replacement parts.

Page 3

WARNING

4

Water heaters are heat producing appliances. To avoid damage or injury,

do not store materials against the water heater or any of its components.

Use proper care to avoid unnecessary contact, especially by children, with

the water heater and its components. Under no circumstances must flammable materials, such as gasoline or paint thinner be used or stored in the

vicinity of this water heater or in any location in which the fumes could

reach the water heater.

Hydrogen gas can be produced in an operating water heater that has not

had water drawn from the tank for a long period of time (generally two

weeks or more). Hydrogen gas is extremely flammable. To prevent the

possibility of injury under these conditions, we recommend a hot water faucet to be open for several minutes at the kitchen sink before you use any

electrical appliance which is connected to the hot water system. If hydrogen is present, there will be an unusual sound such as air escaping through

the pipes as hot water begins to flow. Do not smoke or have open flame

near the faucet at the time it is open.

DO NOT ATTEMPT TO LIGHT ANY GAS APPLIANCE IF YOU ARE NOT CERTAIN OF THE FOLLOWING:

Liquefied petroleum gases/propane gas and natural gas have an odorant

added by the gas supplier that aids in the detection of the gas. Most people recognize this odor as a “sulfur” or “rotten egg” smell. Other conditions, such as “odorant fade” can cause the odorant to diminish in intensity,

or ”fade,” and not be as readily detectable. If you have a diminished sense

of smell, or are in any way unsure of the presence of gas, immediately contact your gas supplier from a neighbor's telephone. Gas detectors are

available. Contact your gas supplier, or plumbing professional for more information.

FAILURE TO INSTALL AND MAINTAIN A NEW, LISTED 3/4” X 3/4” TEMPERATURE AND PRESSURE RELIEF VALVE WILL RELEASE THE MANUFACTURER FROM ANY CLAIM THAT MIGHT RESULT FROM EXCESSIVE TEMPERATURE AND PRESSURES.

Page 4

Introduction

5

The Bradford White ECO-DEFENDER Safety System

®

The Bradford White ECO-DEFENDER Safety System was designed to resist

the ignition of flammable vapors that can occur outside of the water heater

and produce Ultra Low NOx emissions. Use and installation are nearly

identical to previous versions of atmospherically fired and vented water

heaters. A number of exclusive design features are incorporated in the

system that will require additional knowledge on the part of the qualified

service provider. The following information will instruct service professionals

on the function, proper diagnosis, and repair of water heaters employing

the Bradford White ECO-DEFENDER Safety System.

Introduction

The new Bradford White TTW ECO-DEFENDER water heaters are designed to provide

reliable performance with enhanced standard features. New design features include reliable

spark to pilot ignition system, enhanced diagnostics, simplified servicing, quiet operation,

additional vent lengths, Bradford White ECO-DEFENDER Safety System ® and Ultra Low

NOx emissions.

Spark-to-Pilot Ignition System - Employing the spark-to-pilot ignition system promotes

reliable and consistent pilot and main burner ignitions to provide hot water on demand.

Integrated Immersion Thermal Well/Gas Control with LED - Was developed for ease of

troubleshooting by providing simple diagnostic codes to pinpoint an installation or component

performance issue.

New Powerful Blower - Will eliminate problems with difficult venting situations.

Quieter and Cooler Blower Operation - Blower noise is significantly reduced for both

interior and exterior environments. Cooler operation increases blower life by reducing bearing

wear and noise.

Rugged Wiring Connections - receptacle type connections promote error free wiring.

Increased Vent Lengths - Increased venting performance is achieved while maintaining

Energy Factor and FHSR performance.

The TTW1 (U1TW & U4TW), TTW2 (U2TW) & UTW4 water heaters use a combustion

system were flue gases are combined with dilution air to reduce the flue gas temperature in the

blower. The diluted flue gases are evacuated to the exterior through low temperature vent

materials. The gas control maintains water temperature, ignition sequence and regulates gas

flow. A safety circuit consisting of a pressure switch and blower temperature switch verifies

proper conditions exist for safe and reliable operation. If a situation outside of normal

Page 5

How to Use this Manual

6

operating parameters exists, the gas control diagnostic LED will flash a code to positively

identify an operational issue.

This service manual is designed to facilitate problem diagnosis and enhance service efficiency.

To further promote quicker service times the new gas valve can be removed and replaced

without draining the water heater. A special tool is required and will be provided with each gas

valve kit shipped from our Service Parts department.

Please read the service manual completely before attempting service on this new series of

power

How the Safety System Works

During normal operation, most air for combustion is drawn into the water heater through the

openings in the jacket door. This air travels into the burner venturi, mixing with the gas jet.

This air is then mixed with gas inside the burner and drawn to the burner screen and is

efficiently combusted producing Ultra Low NOx emissions. Additional air is drawn through

the openings in the jacket. This air travels down and around the combustion chamber and

enters through holes in the bottom of the corrosion-resistant combustion chamber. The air then

travels up through the oriented flame arrestor plate louvers, where the velocity of the air is

increased and its direction altered. The air then mixes in a normal manner with the combustion

products from the burner.

In the case where trace amounts of flammable vapors are present in the air flowing into the

combustion chamber and burner venturi, the vapors are harmlessly ignited by the burner / pilot

flame. If flammable vapors are in sufficient quantity to prevent normal combustion, the burner

and pilot flames are designed to shut down.

Should the flammable vapors continue to the burner, the flame arrestor plate and burner screen

prevent the flames from traveling backwards and igniting vapors outside of the combustion

chamber. This causes the thermopile to overheat and shuts down the main pilot and burner. The

thermopile powers the intelligent diagnostic control which is capable of recognizing restricted

airflow conditions caused by severe lint, dust and oil accumulation on the burner screen and

arrestor plate. The intelligent diagnostic control will deactivate the burner and pilot in the

unlikely event of restricted airflow.

How to Use this Manual

It is intended for this manual to be used by qualified service personnel for the primary purpose

of troubleshooting and repair of the Bradford White Residential Flue Damper water heaters.

Understanding the sequence of operation section of this manual will contribute greatly to

troubleshooting the water heater.

The Honeywell WV4460E Electronic Gas Control will display error codes in the event of

abnormal operation. Error codes are listed in the troubleshooting chart beginning on page 13 of

this service manual. The troubleshooting chart will also indicate the probable cause for the error

code and direct the service professional to a service procedure to properly diagnose the

abnormal operation.

Page 6

Tools Required

7

Contact the Bradford White technical support group immediately if diagnosis cannot be made

using the methods described in this service manual.

Tools Required for Service

Manometer: A liquid “U” tube type or a digital (magna-helic) type can be used. This device is

used to measure gas and/or air pressure and vacuum.

Multi-Meter: A digital type is strongly recommended. This device is used to measure electrical

values. The meter you select must have the capability to measure volts AC, volts DC, amps,

micro-amps and ohms.

Electronic Probes: In some cases, standard multi-meter probes will damage or simply not be

effective to obtain certain voltage and ohm reading. It will be necessary to have special

electronic “pin” type multi-meter probes. These probes are available at most electronic

wholesale outlets.

Thermometer: Used to measure water temperature. An accurate thermometer is recommended.

Water Pressure Gage: Used to measure water supply pressure. Also used to determine tank

pressure by adapting to the drain valve of the heater.

Gas Control Service Tool: BWC part number 239-45991-00. A specialized tool designed to

remove the gas control from gas control thermal well. Available from your Bradford White

parts supplier.

Various Hand Tools: Pipe wrench, channel locks, open end wrenches (3/8", 7/16", 1/2"), 12"

crescent wrench, Allen wrench set, screw drivers (common & Phillips), 1/4" nut driver, pliers

(common & needle nose), socket set, side cutters, wire cutters, wire strippers, wire crimpers,

torpedo level, small shop vac, step ladder, flashlight, and 5 gallon pail.

Page 7

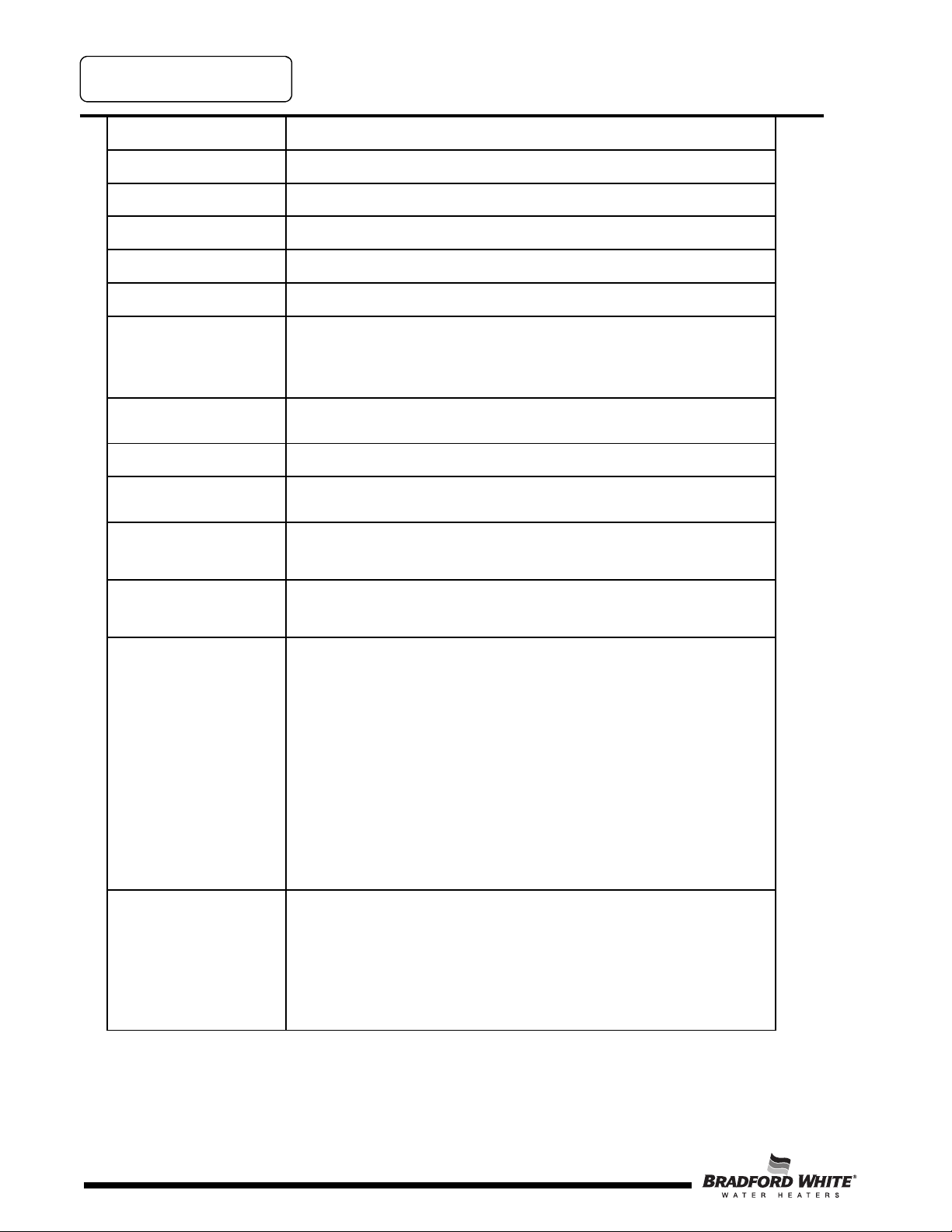

Specifications

8

Power Supply Dedicated 115VAC, 60 Hz, 15A.

Gas Supply Pipe Minimum 1/2” NPT (schedule 40 black iron pipe recommended).

Approved Gas Type Natural Gas.

Gas Pressure 6.0” W.C. minimum, 11.0” W.C. maximum.

Venting System Power vent through the wall or vertical through the roof.

Approved Vent Materials PVC, CPVC or ABS.

Minimum clearance for

Servicing

Water Supply Pressure

TCO Limit Residential 118

Residential Temperature

Set Point Range

Commercial Temperature Set Point Range

Blower Temperature

Switch

Pressure Switch

18” from top, 24” from front, 4” sides and rear.

150 PSI maximum allowable working pressure. Check local codes for

supply pressure.

o

F (16oC) to 160oF (71oC) (approximate temperatures).

60

80oF (27oC) to 180oF (82oC) (approximate temperatures).

Normally closed, opens @ 165oF (74oC), auto reset @130oF (54oC)

UTW1 Models:

Normally open, closes on vacuum increase @ -0.68, opens on vacuum

decrease @ -0.65

U4TW Models:

Normally open, closes on vacuum increase @ -0.83, opens on vacuum

decrease @ -0.80

o

F (87oC), Commercial 199oF (93oC).

U2TW & UTW4 Models:

Normally open, closes on vacuum increase @ -1.28, opens on vacuum

decrease @-1.25

U1TW & U4TW Models:

Blower

115VAC, 60Hz, 3.1 amps, 3000 RPM, 42 CFM @ 1.5” W.C.

U2TW & UTW4 Models:

115VAC, 60Hz, 3.1 amps, 3000 RPM, 68 CFM @ 0.4” W.C.

Page 8

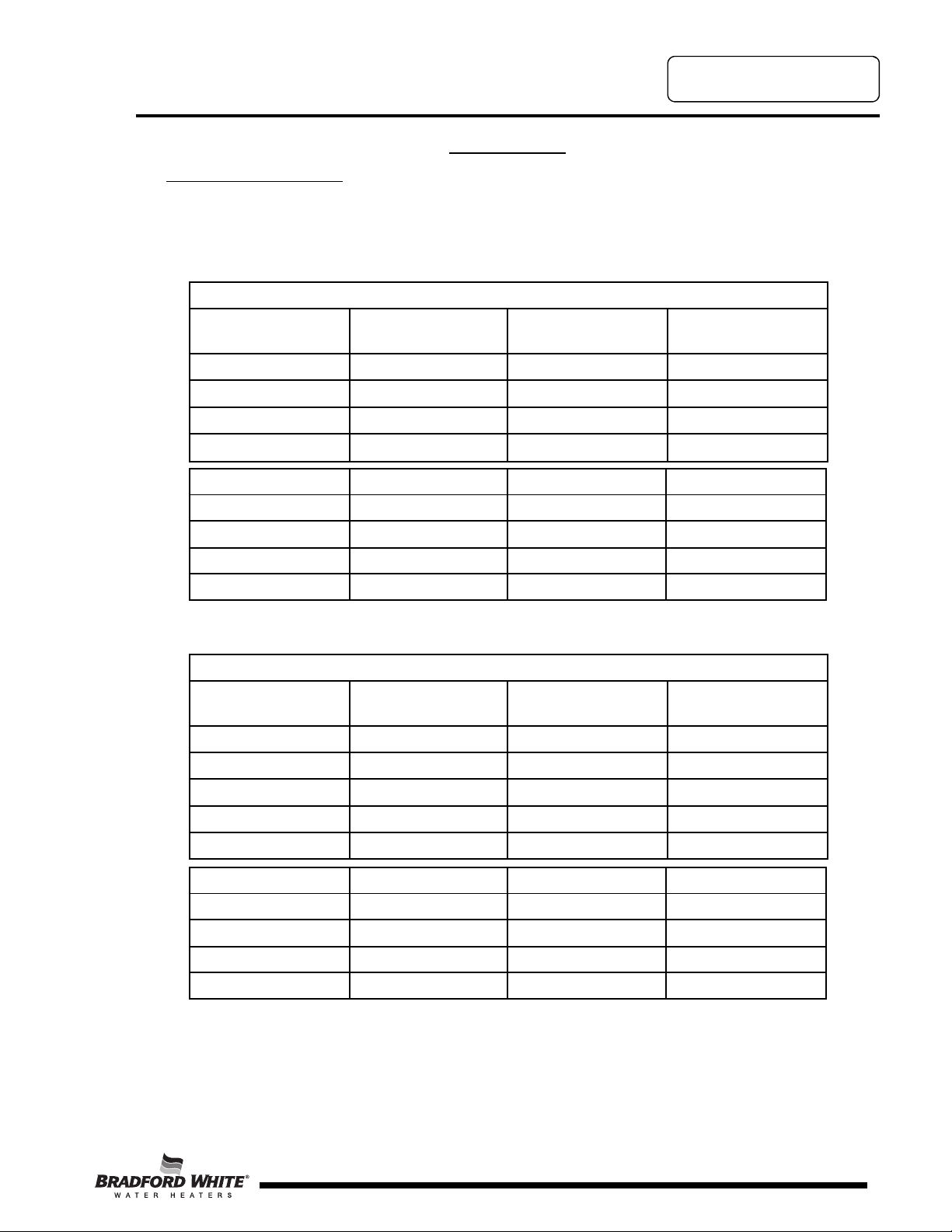

Vent Tables

9

Venting Specifications for:

40 Gallon

50 Gallon

60 Gallon

2” Diameter (5.1 cm) PVC Vent Connector Lengths

Terminating # of Elbows

Through the Wall 1 45 (13.7) 2 (0.6)

Through the Wall 2 40 (12.2) 2 (0.6)

Through the Wall 3 35 (10.7) 2 (0.6)

Through the Wall 4 30 (9.2) 2 (0.6)

Through the Roof 0 50 (15.2) 7 (2.1)

Through the Roof 1 45 (13.7) 7 (2.1)

Through the Roof 2 40 (12.2) 7 (2.1)

Maximum Straight

Length ft (m)

Specifications

Minimum Straight

Length ft (m)

Through the Roof 3 35 (10.7) 7 (2.1)

Through the Roof 4 30 (9.2) 7 (2.1)

3” Diameter (7.6 cm) PVC Vent Connector Lengths

Terminating # of Elbows

Through the Wall 1 115 (35.0) 10 (3.1)

Through the Wall 2 110 (33.5) 10 (3.1)

Through the Wall 3 105 (32.0) 10 (3.1)

Through the Wall 4 100 (30.5) 10 (3.1)

Through the Wall 5 95 (29.0) 10 (3.1)

Through the Roof 0 120 (36.6) 15 (4.6)

Through the Roof 1 115 (35.0) 15 (4.6)

Through the Roof 2 110 (33.5) 15 (4.6)

Through the Roof 3 105 (32.0) 15 (4.6)

Through the Roof 4 100 (30.5) 15 (4.6)

Maximum Straight

Length ft (m)

Minimum Straight

Length ft (m)

Page 9

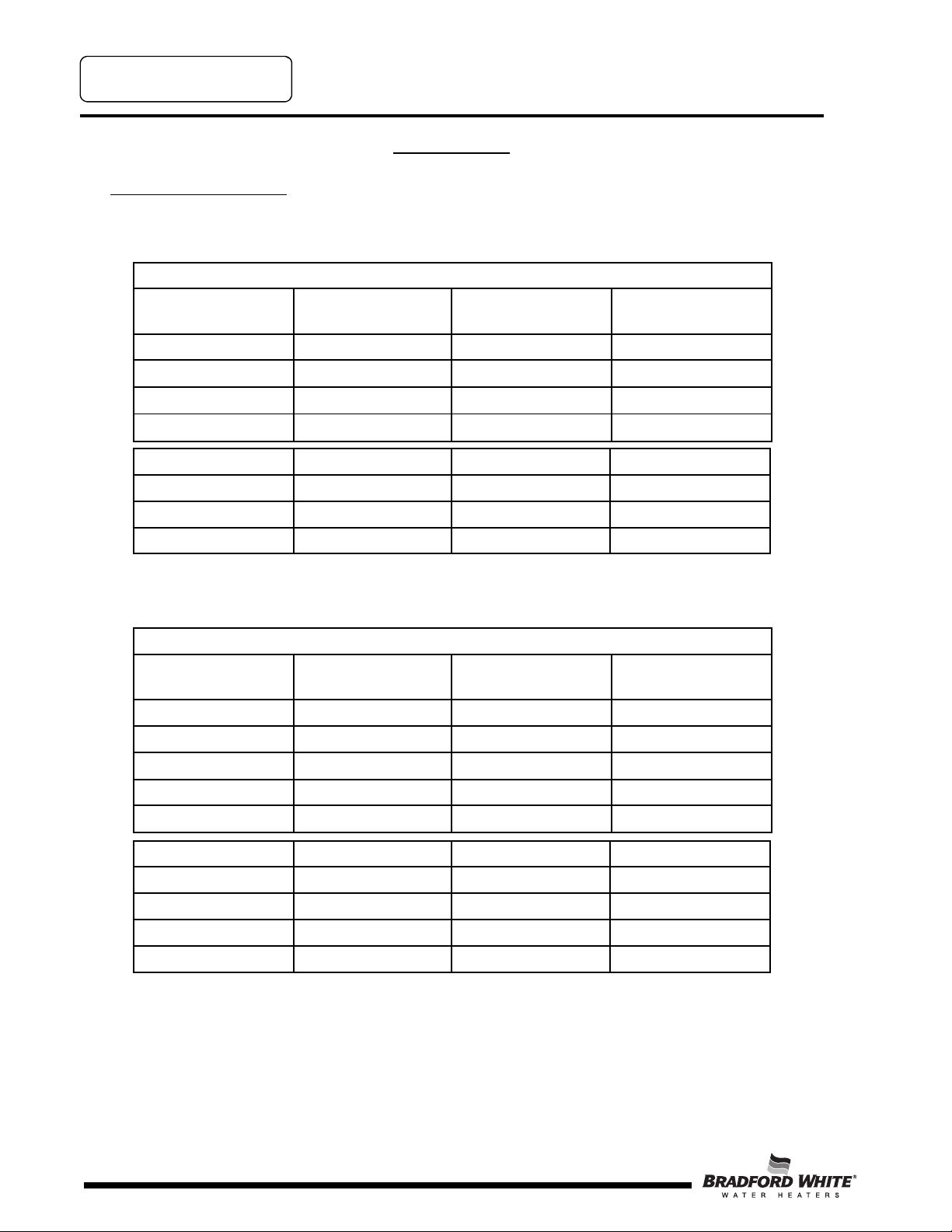

Specifications

10

Venting Specifications for:

48 Gallon

65 Gallon

Terminating # of Elbows

Through the Wall 1 55 (16.8) 2 (0.6)

Through the Wall 2 50 (15.2) 2 (0.6)

Through the Wall 3 45 (13.7) 2 (0.6)

Through the Wall 4 40 (12.2) 2 (0.6)

Through the Roof 0 60 (18.3) 7 (2.1)

Through the Roof 1 55 (16.8) 7 (2.1)

Through the Roof 2 50 (15.2) 7 (2.1)

Through the Roof 3 45 (13.7) 7 (2.1)

Vent Tables

3” Diameter (7.6 cm) PVC Vent Connector Lengths

Maximum Straight

Length ft (m)

Minimum Straight

Length ft (m)

4” Diameter (10.2 cm) PVC Vent Connector Lengths

Terminating # of Elbows

Through the Wall 1 175 (53.3) 10 (3.1)

Through the Wall 2 170 (51.8) 10 (3.1)

Through the Wall 3 165 (50.3) 10 (3.1)

Through the Wall 4 160 (48.8) 10 (3.1)

Through the Wall 5 155 (47.2) 10 (3.1)

Through the Roof 0 180 (54.9) 15 (4.6)

Through the Roof 1 175 (53.3) 15 (4.6)

Through the Roof 2 170 (51.8) 15 (4.6)

Through the Roof 3 165 (50.3) 15 (4.6)

Through the Roof 4 160 (48.8) 15 (4.6)

Maximum Straight

Length ft (m)

Minimum Straight

Length ft (m)

Page 10

Specifications

11

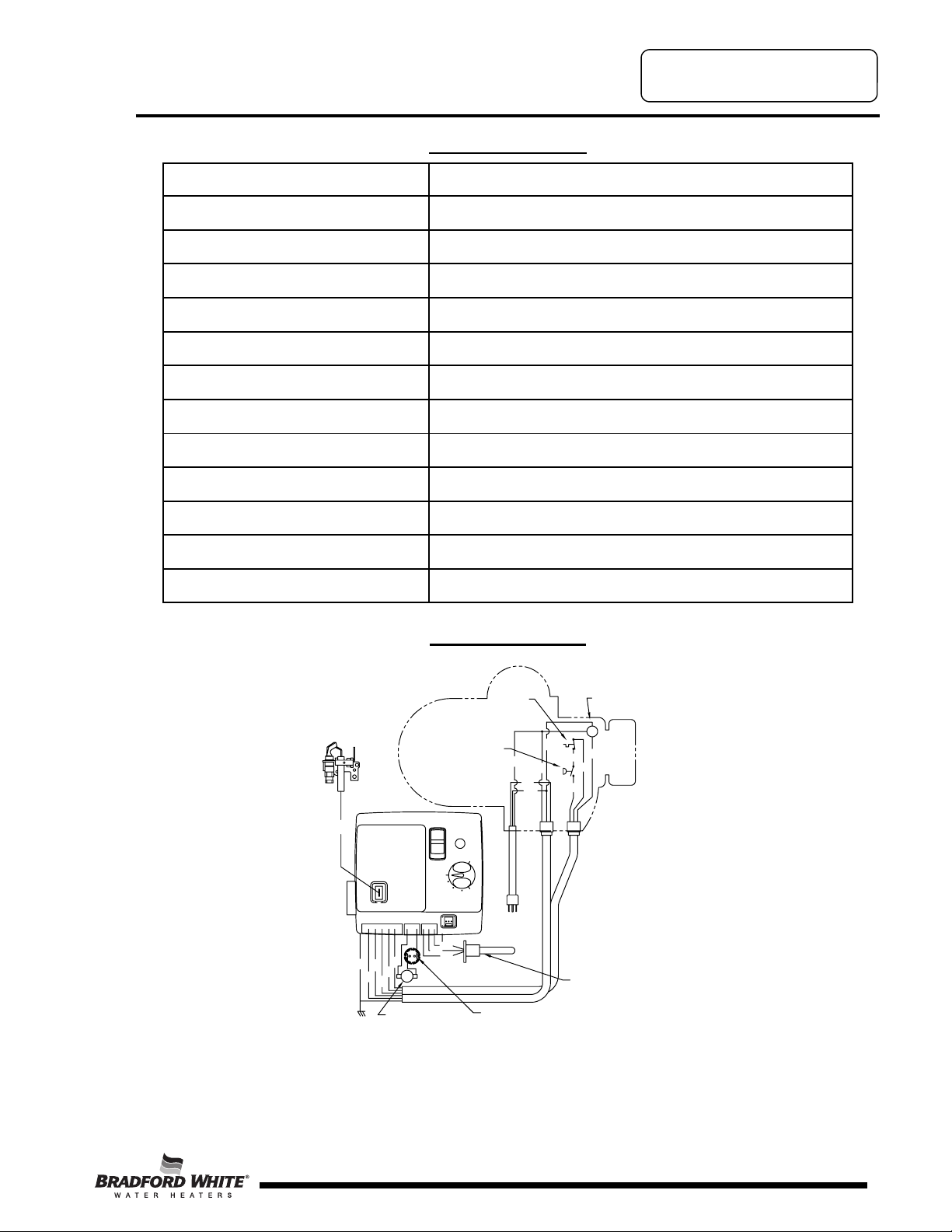

Control Timings

Ignition State Timing

Pre-purge 15 seconds

Trial for Ignition 90 seconds

Flame Stabilization Period 3 seconds

Inter-purge 15 seconds

Flame Failure Response Time 1.5 seconds (2 second maximum, 1 second minimum)

Post-purge 15 seconds

PS Fault Delay (failed open/close) Retry after 2 minutes

Soft Lockout Retry after 5 minutes

TCO Limit Lockout Indefinite (see page 34 to reset)

Verify Resistive Delay Retry after 2 minutes (repeats 5 times)

Simulated Resistive Load Lockout Indefinite (cycle power to reset)

Hardware Error Lockout Indefinite (self clears if fault clears for at least 15 seconds)

Wiring Diagram

PILOT

W

G

Honeywell

Y

W

R

BK

BL

RESETTABLE

THERMAL

BLOWER

BK

BK

BK

BLOWER

TEMPERATURE

SWITCH

PRESSURE

SWITCH

FLAMMABLE

VAPOR SENSOR

W

PLUG

G

W

BK

G

BLOWER

MOTOR

M

BL

Y

R

Y

WATER TEMPERATURE

SENSOR

Page 11

Sequence of Operation

12

Power Up Sequence

1. Start-up: Upon power up, the gas control runs a safe start check with a

typical delay of 5 seconds.

2. Flammable Vapor Verification: The gas control verifies that the Flamma-

ble Vapor Sensor is in the proper operating range prior to energizing any

components. If the sensor is within the proper range, the gas control

resumes normal operation. If the Flammable Vapor Sensor is out of

range, the gas control LED immediately flashes 7 times with a 3 second

pause.

Normal Heating Sequence

1. Thermostat Calls for Heat: Prior to energizing the blower, the gas control

checks the safety circuit to insure the circuit is open. In the safety circuit

the pressure switch is normally open and the blower temperature switch

is normally closed.

2. If the safety circuit is closed, the gas control waits 4 seconds, the gas

control LED flashes 2 times with a 3 second pause. The gas control

waits 2 minutes. Then, the blower runs for 30 seconds. This cycle repeats until the safety circuit opens.

3. Blower energizes.

4. Pressure switch proves blower/vent system operation: If the pressure

switch does not close within 30 seconds, the gas control LED flashes 3

times with 3 second pause. The blower runs for 30 seconds every 2 minutes trying to get the pressure switch or blower temperature switch to

close. This cycle repeats as long as there is a call for heat.

5. Blower pre-purge period (15 seconds).

6. Trial for Pilot Ignition (90 seconds): The gas control lights the pilot by

activating the spark igniter and gas flow to the pilot burner. If flame is

not sensed within 90 seconds, the spark igniter and gas flow are deactivated. The blower will post-purge, and the gas control LED flashes 6

times with a 3 second pause.

Page 12

Sequence of Operation

13

Normal Heating Sequence (cont’d)

7. Main Burner Ignition: After pilot flame is sensed, the gas control activates the main valve for main burner ignition. The gas control will ignore flame and pressure switch signals for 3 seconds to allow for the

main burner to stabilize.

8. Steady State Operation: During steady state operation, the gas control

monitors:

Thermostat Temperature Sensor: When the setpoint temperature is satisfied, the gas control is shutdown, and the blower will post-purge for 15

seconds. The gas control LED flashes a short flash once every 4 seconds

(Idle status code).

Pressure switch/blower temperature switch: If either switch opens, the

pilot valve and the main valve are shut down. The blower continues to

run for 30 seconds attempting to close the circuit. The gas control LED

flashes 3 times with 3 second pause.

Flame Sensor: If flame is lost, the pilot and main valves are shutdown.

The blower runs for 15 seconds. The gas control attempts to re-light the

pilot 4 times. If unsuccessful, the blower is shutdown, and the gas control proceeds to a 5 minute lockout. The gas control re-attempts to light

the pilot starting at Normal Heating Sequence #2.

9. Thermostat Satisfies: Gas control LED flashes once every 4 seconds.

10.Burner Off.

11.Blower post-purge (15 seconds).

Abnormal Operation

1. Flammable Vapor Sensor Fault:

A) If the resistance is greater than 70,000 ohms: The gas control immediately turns off all outputs. The gas control waits and monitors resistance for 30 seconds. If the resistance is greater than 65,000 ohms after 30 seconds, the gas control proceeds to verify resistive delay for 2

minutes and flashes 7 times then 1 time with a three second pause. This

process is repeated 5 times until the control either returns to normal operation or proceeds to flammable vapor lockout.

Page 13

Sequence of Operation

14

Abnormal Operation (cont’d)

B) If the resistance is below 3000 ohms: The gas control immediately

turns off all outputs and proceeds to flash 8 times then 1 time with a

three second pause. The error self clears if the resistance returns to normal range for at least 15 seconds.

2. Temperature Sensor Fault:

A) Temperature Sensor Open Circuit: The gas control immediately turns

off all outputs and proceeds to flash 8 times then 3 times with a three

second pause. The error self clears if the fault clears for at least 15 seconds.

B) Thermal well sensors not reading the same temperature within

±5.5°F: The gas control immediately turns off all outputs and proceeds

to flash 8 times then 3 times with three second pause. The error self

clears if the fault clears for at least 15 seconds.

C) Water Temperature in excess of ECO (Energy Cut Off) Limit: The gas

control immediately turns off the pilot and main valves. The gas control

LED proceeds to flash 4 times with a 3 second pause.

To reset the gas control, rotate the setpoint knob to the minimum setting for at least 6 seconds before returning to desired temperature setting.

3. Pressure Switch/Blower Temperature Fault:

A) Pressure switch closed at start of call for heat: The gas control waits 4

seconds then, proceeds to flash 2 times with a 3 second pause. The

gas control waits 2 minutes and then turns on the blower for 30 seconds. The blower turns off after 30 seconds and the control waits for

the pressure switch to open. Any time the pressure switch opens, the

blower turns on (or stays on) and the control proceeds to wait for the

pressure switch to close.

Page 14

Sequence of Operation

15

Abnormal Operation (cont’d)

B) Pressure switch or blower temperature switch failed to close: The gas

control runs the blower for 30 seconds waiting for the pressure switch

and/or the blower temperature switch to close. If either switch does

not close in 30 seconds, the blower turns off and the control flashes 3

times with a 3 second pause. The gas control waits 2 minutes before

turning on the blower for another 30 seconds to see the circuit close.

This cycle repeats as long as there is a call for heat or until the circuit

closes.

C) Pressure switch or blower temperature switch opens during operation:

The gas control turns off the pilot and main valve, runs the blower for

15 seconds (inter-purge) waiting for the pressure switch and/or the

blower temperature switch to close. If either switch fails to close, the

gas control proceeds as described in 3b above. If the circuit closes

again by the end of the inter-purge, the recycle counter is incremented, if the recycle count has not reached its limit (4), another trial

for ignition begins. If the recycle count has been reached, the gas

control turns off the blower and flashes 6 times, then 2 times with a

3 second pause. The gas control waits 5 minutes before repeating ignition sequence.

4. Trial for Ignition Fault:

A) Pressure switch opens during trial: The gas control turns off the ig-

niter and pilot valve. The gas control proceeds as described in 3b

above. If the pressure switch closes within 30 seconds the gas control

will continue with a trial for ignition starting at blower pre-purge.

B) Flame Not Sensed: The gas control energizes the spark igniter at-

tempting to light the pilot and prove flame. If flame is not sensed

within 90 seconds, the spark igniter turns off, the pilot valve is

closed. The gas control LED flashes 6 times then 1 time with 3 second pause. The control waits 5 minutes before repeating the ignition

sequence.

Page 15

Sequence of Operation

16

Abnormal Operation (cont’d)

5. Flame Sensing Fault:

A) Flame Lost During Run: The gas control turns off the pilot and main

valves and runs the blower for 15 seconds (inter-purge) The gas control

increments the recycle count, if the recycle count has not reached its

limit (4), another trial for ignition begins. If the recycle count has been

reached, the gas control LED flashes 6 times then 3 times with a 3 second pause. The gas control waits 5 minutes before repeating the ignition sequence.

B) Flame Sensed Out of Sequence: The gas control only looks for pilot

flame when the blower is running. If flame is present when the pilot

valve is not open, the gas control proceeds to wait for flame loss and

flashes 5 times with 3 second pause. This continues until flame is lost,

once the flame signal is lost, the control flashes 6 times then 4 times

with a 3 second pause. The control waits 5 minutes before repeating the

ignition sequence.

Page 16

Loading...

Loading...