Page 1

EcoStor™SC Solar Indirect System

Single Coil Electric Backup Models

Photo is of

S-SW2-60R6DS

The EcoStor™Single Coil Models feature:

nternal Single Wall Heat Exchanger—Single Wall 1

■ I

Vitraglas

(

tored water volume of 2.5 gal. Maximum supply temperature from the solar

s

®

steel coil. The coil has a heat transfer area of 14.2 sq. ft. and a

)

1

O.D. glass coated

⁄2"

collector must not exceed 250°F.

-- 1" NPT Front Supply and Return Connections.

■ Sensor Wires for Solar Thermistor Connections—Twisted wires are

provided under the Upper and Lower covers. These wires have been

ovided as a means for connecting thermistors to a solar controller

pr

(Thermistors and Solar Controller are not provided).

■ Integrated Mixing Device—Features an accurate, easy to use hand wheel

for adjusting mixed water temperature, a pre-piped stainless steel flexible

connector for quick installation as well as optional water connections (1/2"

NPT recirculation inlet, 1/2" NPT hot water outlet, 1/4" NPT cold water

outlet). This required system is easily installed and ensures a comfortable

outlet temperature while providing a steady flow of hot water.

■ Backup Element(s)—A dual, or single backup heating element provides

heat only when solar energy does not satisfy demand. Dual element

models allow entire tank to hold hot water during periods where solar

heating is not available.

■ Factory Installed Hydrojet®Total Performance System—Cold water inlet

sediment reducing device helps prevent sediment build up in tank.

Increases first hour delivery of hot water while minimizing temperature build

up in tank.

■ Vitraglas®Lining—Bradford White tanks are lined with an exclusively

engineered enamel formula that provides superior protection from the highly

corrosive effects of hot water. This formula (Vitraglas

®

) is fused to the steel

surface by firing at at temperature of over 1600ºF.

■ Fully Automatic Controls—Fast acting surface-mount thermostat(s) for

automatic temperature control. Factory installed sensitive manual reset

energy cutoff for safety to prevent overheating.

■ 2" Non-CFC Foam Insulation—Covers the sides and top of tank, reducing

the amount of heat loss. This results in less energy consumption, improved

operation efficiencies and jacket rigidity.

■ Potable Water Connections—3⁄4" NPT factory installed true dielectric

fittings extend water heater life and eases installation.

■ Two Protective Anode Rods—Provide added protection against corrosion

for long trouble-free service.

■ Direct Heat Transfer With Immersed Incoloy Element(s)—Transfers heat

directly and efficiently to the water. Screw-in style.

■ T&P Relief Valve—Included.

■ Low Restriction Brass Drain Valve—Durable tamper proof design.

6 or 10-

For more information on warranty, please visit www.bradfordwhite.com

For products installed in USA, Canada and Puerto Rico. Some states do not allow limitations on warranties. See complete

copy of the war

MANUFACTURED UNDER ONE OR MORE OF THE FOLLOWING U.S. PATENTS: 5,954,492; 5,761,379; 5,943,984; 5,081,696; 5,988,117; 6,142,216; 5,199,385; 5,574,822; 5,372,185; 5,485,879; 5,277,171;

(B1)5,341,770; 5,660,165; 5,596,952; 5,682,666; 4,904,428; 5,023,031; 5,000,893; 4,669,448; 4,829,983; 4,808,356; 5,115,767; 5,092,519; 5,052,346; 4,416,222; 4,628,184; 4,861,968; 4,672,919; Re. 34,534;

7,270,087 B2. OTHER U.S. AND FOREIGN PATENT APPLICATIONS PENDING. CURRENT CANADIAN PATENTS: 1,272,914; 1,280,043; 1,289,832; 2,045,862; 2,112,515; 2,108,186; 2,107,012; 2,092,105; 2,409,271.

Vitraglas®and Hydrojet®are registered trademarks of Bradford White®Corporation.

ear Limited Tank Warranties / 6-Year Limited Warranty on Component Parts.

Y

ranty included with the heater

.

501-B-0610-A

Page 2

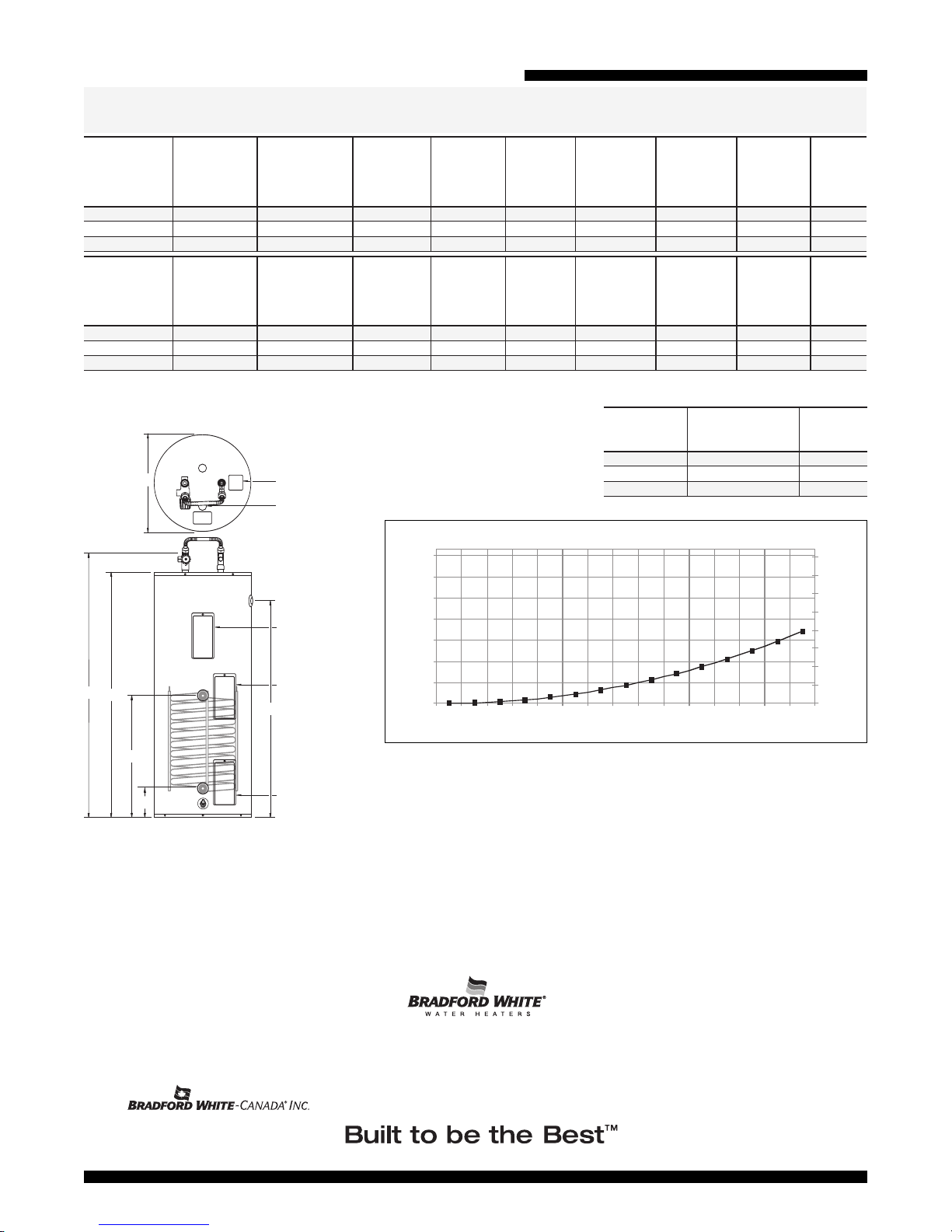

Single Coil Electric Backup Models

Meet or exceed ASHRAE 90.1b (current standard)

Model

N

umber

A

pprox.

Shipping

W

eight

l

bs.

A

Floor to

H

eater

T

op

i

n.

C

Floor to

W

ater

C

onn.

i

n.

B

Jacket

D

ia.

i

n.

C

apacity Recovery at

90°F Rise*

S-SW2-60R6DS

S

-SW2-75R6DS

S

-SW2-115R6DS

U

.S.

Gal.

60

7

5

1

15

I

mp.

Gal.

50

6

2

9

6

U

.S.

GPH

20

2

0

2

0

I

mp.

GPH

18

1

8

1

8

59

1

/

4

5

9

1

/

4

6

2

3

/

4

631/

4

6

3

1

/

4

6

6

3

/

4

210

2

36

3

40

22

2

4

2

8

1

/

4

E

Floor to

S

olar

C

ollector

Supply

i

n.

29

1

/

2

2

9

1

/

2

2

9

1

/

2

73/

8

73/

8

73/

8

53

5

3

5

5

3

/

4

D

Floor to

T

&P

C

onn.

i

n.

M

odel

N

umber

Approx.

S

hipping

W

eight

k

g.

A

F

loor to

H

eater

Top

m

m.

C

F

loor to

W

ater

Conn.

m

m.

B

J

acket

D

ia.

m

m.

Capacity Recovery at

5

0°C Rise*

S-SW2-60R6DS

S-SW2-75R6DS

S-SW2-115R6DS

Liters

227

283

435

L

iters/

Hour

76

76

76

1504

1504

1593

1607

1607

1695

95

107

154

559

609

717

E

F

loor to

S

olar

Collector

S

upply

m

m.

749

749

749

F

Floor to

S

olar

C

ollector

Return

i

n.

F

F

loor to

S

olar

Collector

R

eturn

m

m.

187

187

187

1346

1346

1416

D

F

loor to

T

&P

Conn.

m

m.

EcoStor™Indirect Water Heater System

C

D

F

E

A

B

S

olar Sensor Wiring

Junction Box

Optional Outlet

f

or Recirculation

(S-SW2-60R & S-SW2-75R)

Solar Thermistor Wires

Upper Heating Element

w

ith Thermostat

Thermostat

(controls lower element

on dual element models)

Solar Thermistor Wires

Lower Heating Element

(on dual element models)

M

odel

Number

Electric Backup Water Heater Ratings

First Hour Supply (Gal.)

Single

Element

Dual

Element

Standby Heat

L

oss Rating

(°F/Hr.)

S

-SW2-60R6DS

S

-SW2-75R6DS

S

-SW2-115R6DS

8

4

9

7

1

24

4

6

5

3

8

3

1

.1

0

.9

0

.7

Heat Exchanger Pressure Drop Curve

Flow Rate (GPM)

Pressure Drop (PSID)

Head Loss (ft. w.c.)

16.00

14.00

12.00

10.00

8.00

6.00

4.00

2.00

0.00

7.00

6.00

5.00

4.00

3.00

2.00

1.00

0.00

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14

*Based on 4500W/4500W, Non-Simultaneous operation.

Optional 5500W/5500W, Non-Simultaneous operation.

For single element models change suffix "D" to "S".

General

All electric water heaters are certified at 300 PSI test pressure (2068 kPa) and 150 PSI working pressure (1034 kPa). All potable water and electrical

connections are 3⁄4" NPT (19mm) on 8" (203mm) centers. All models UL listed.

Dimensions and specifications subject to change without notice in accordance with our policy of continuous product improvement.

Suitable for W

Toxic chemicals, such as those used for boiler treatment, shall NEVER be introduced into the potable side of this system. The potable side may NEVER be

connected to any existing heating system or component(s) previously used with a non-potable water heating appliance.

ater (Potable) Heating and Space Heating.

Sales 800-523-2931 ●Fax 215-641-1670 / T

501-B-0610-A

For U.S. and Canada field ser

International:

vice, contact your pr

echnical Suppor

Telephone 215-641-9400 ●Telefax 215-641-9750 / www.bradfordwhite.com

Sales / T

echnical Suppor

©2010, Bradford White Corporation. All rights reserved.

, PA

Ambler

ofessional installer or local Bradfor

t

800-334-3393 ●Fax 269-795-1089 ●W

t

866-690-0961 / 905-238-0100 ●Fax 905-238-0105 / www

d White sales r

ranty

ar

800-531-2111 ●Fax 269-795-1089

epresentative.

.bradfor

dwhite.com

Printed in U.S.A.

Loading...

Loading...