Page 1

SINGLE-WALL INDIRECT

WATER HEATER

A Spanish language version of these instructions is available by contacting the

manufacturer listed on the rating plate.

La version espanola de estas instruccions se puede obtener al escribirle a la

fábrica cuyo nombre aparece in la placa de especificaciones.

To avoid damage or injury,

there must be no materials

stored against the indirect

water heater and proper care

shall be taken to avoid

unnecessary contact (especially

by children) with the indirect

water heater.

q Do not store or use

WARNING

gasoline or other

flammable liquids in

the vicinity of this

water heater or any

other appliance.

INTERNET VERSION FOR REFERENCE ONLY

INSTALLATION/OPERATING MANUAL

WITH PARTS LISTING AND TROUBLESHOOTING GUIDE

238-43480-00B REV 12/03

Page 2

For your family’s comfort, safety, and convenience, we

recommend this water heater be installed and serviced by

a plumbing professional.

INTERNET VERSION FOR REFERENCE ONLY

2

Page 3

CONGRATULATIONS!

You have just purchased one of the finest water heaters

on the market today!

This installation, operation, and instruction manual will

explain in detail the installation and maintenance of your

new indirect water heater. We strongly recommend that

you contact a plumbing professional for the installation of

this water heater.

We require that you carefully read this manual, as well as

the enclosed warranty, and refer to it if questions arise. If

you have any specific questions concerning your

warranty, please consult the plumbing professional from

whom your water heater was purchased. For your

records we recommend that you write the model, serial

number and installation date of your water heater in the

back of this manual.

This manual should be kept with the water heater.

We’re committed to providing you with the finest water

heater made.

INTERNET VERSION FOR REFERENCE ONLY

3

Page 4

SECTION I

IMPORTANT INFORMATION

The equipment must be installed in accordance with those

installation regulations required in the area where the installation is

to be made. Thes e regulations must be carefully followed in all

cases. Authorities having jurisdiction shall be consulted before

installations are made.

All wiring on water heaters installed in the USA must be in

accordance with the National Electrical Code and/or local

regulations; or in Canada, installed in accordance with the Canadian

Electrical Code and/or local regulations.

The following terms are used throughout this manual to bring attention

to the presence of hazards of various risk levels, or to important

information concerning product life.

DANGER

Indicates an imminently

hazardous situation,

which, if not avoided, will

result in death, serious

injury, or substantial

property damage.

WARNING

Indicates a potentially

hazardous situation,

which, if not avoided,

INTERNET VERSION FOR REFERENCE ONLY

could result in death,

serious injury, or

substantial property

damage.

-READ CAREFULLY-

Indicates a potentially

hazardous situation,

which, if not avoided, may

result in moderate, or

minor injury or property

damage.

Indicates special

instructions on

installation, operation or

maintenance, which are

important but not related

to personal injury hazards.

CAUTION

NOTICE

4

Page 5

INTERNET VERSION FOR REFERENCE ONLY

5

Page 6

DANGER

DO NOT touch any electric switch; do not use any

DO NOT store or use gasoline or other flammable,

combustible, or corrosive vapors and/or liquids in the

vicinity of this or any other appliance.

IF YOU SMELL GAS:

q DO NOT try to light any appliance.

q

telephone in your building.

q Immediately call your gas supplier from a telephone in

another building. Follow the gas supplier’s

instructions.

q If you cannot reach your gas supplier, call the fire

department

DO NOT OPERATE THE APPLIANCE UNTIL THE

LEAKAGE IS CORRECTED!

Liquefied petroleum gas/propane gas is heavier than air

and will remain at floor level if there is a leak. Basements,

crawl spaces, closets, and areas below ground level will

serve as pockets for accumulation of leaking gas.

This water heater is supplied with an adjustable thermostat

to control water temperature. Hot water temperatures

required for automatic dishwasher and laundry use can

cause scald burns resulting in serious personal injury

and/or death. The temperature at which injury occurs

varies with the person’s age and the time of exposure.

The slo wer response time of disabled persons increases

the hazards to them. NEVER allow small children to use a

INTERNET VERSION FOR REFERENCE ONLY

hot water tap or to draw their own bath water. NEVER

leave a child or disabled person unattended in a bathtub or

shower.

6

Page 7

WARNING

Installation is not complete unless a pressure and

temperature relief valve is installed into the side of the water

heater. See the Water Connections section of this manual

for details.

This water heater contains very hot water under high

pressure. Do not unscrew any pipe fittings or attempt to

disconnect any components of this water heater without

positively assuring the water is cool and has no pressure.

Always wear protective clothing and equipment when

installing, starting up, or servicing this water heater to

prevent scald injuries. Do not rely on the pressure and

temperature gauges to determine the temperature and

pressure of the water heater. This water heater contains

components that become very hot. Do not touch any

components unless they are cool.

Improper installation, adjustments, alteration, service or

maintenance can cause property damage, personal injury or

loss of life. Failure to follow all instructions in the proper

order can cause personal injury or death. Read and

understand all instructions, including all those contained in

component manufacturer’s manuals, which are provided with

the appliance before installing, starting -up, operating,

maintaining, or servicing this appliance. Keep this manual

and literature in legible condition and posted near the

appliance for reference by owner and service technician.

This water heater requires regular maintenance and service

INTERNET VERSION FOR REFERENCE ONLY

to operate safely. Follow the instructions contained in this

manual.

Installation, maintenance, and service must be performed

only by an experienced, skilled, and knowledgeable installer

or service agency.

7

Page 8

INTERNET VERSION FOR REFERENCE ONLY

8

Page 9

INTERNET VERSION FOR REFERENCE ONLY

9

Page 10

WARNING

It is the responsibility of the installing contractor to see that

all controls are correctly installed and are operating properly

when the installation is complete.

DO NOT operate the water heater with jumpered or absent

controls or safety devices.

DO NOT tamper with or alter the water heater and/or

controls.

DO NOT operate the water heater if any external part has

been under water. Immediately call a qualified service

technician to inspect the appliance and to replace any part of

the control system that was under water.

This water heater is suitable for installation on combustible

flooring. DO NOT install this water heater on carpeting.

DO NOT operate this water heater without first being certain

it is filled with water.

Flammable items, pressurized containers, or any other

potential fire hazardous articles must never be placed on or

adjacent to the heater. Containers of flammable gases should

not be stored or used in the same room with this water

heater.

Hydrogen gas can be produced in an operating water heater

that has not had water drawn from the tank for a long period

of time (generally two weeks or more). Hydrogen gas is

extremely flammable. To prevent the possibility of injury

INTERNET VERSION FOR REFERENCE ONLY

under these conditions, we recommend that the water faucet

be opened for several minutes at the kitchen sink before you

use any electrical appliance that is connected to the hot water

system. If hydrogen is present, there will be unusual sounds

such as air escaping through the pipes as hot water begins to

flow. Do not smoke or have open flame near the faucet at the

time it is open.

10

Page 11

INTERNET VERSION FOR REFERENCE ONLY

11

Page 12

CAUTION

The maximum boiler water supply temperature to the indirect

heat exchanger must not exceed 240°F (116°C).

NOTICE

Insulation blankets are not required for this water heater.

This water heater meets or exceeds the ASHRAE/IES 90.1b

standards with respect to insulation and standby loss

requirements.

I- IMPORTANT

INFORMATION…………….…..

II- SPECIFICATIONS………………………………. 8

III- GENERAL

INFORMATION…………………….

IV- PRE-

INSTALLATION……………………………

V- WATER

CONNECTIONS………………………..

VI- ELECTRICAL

CONNECTIONS………………..

VII- OPERATING

INSTRUCTIONS…………………

INTERNET VERSION FOR REFERENCE ONLY

VIII- MAINTENANCE………………………………

….

IX- TROUBLESHOOTING

GUIDE…………………

X- PARTS

LIST……………………………………….

NOTES…………………………………………….. 36

TABLE OF CONTENTS

3

11

14

19

24

26

29

32

34

12

Page 13

SECTION II

SPECIFICATIONS

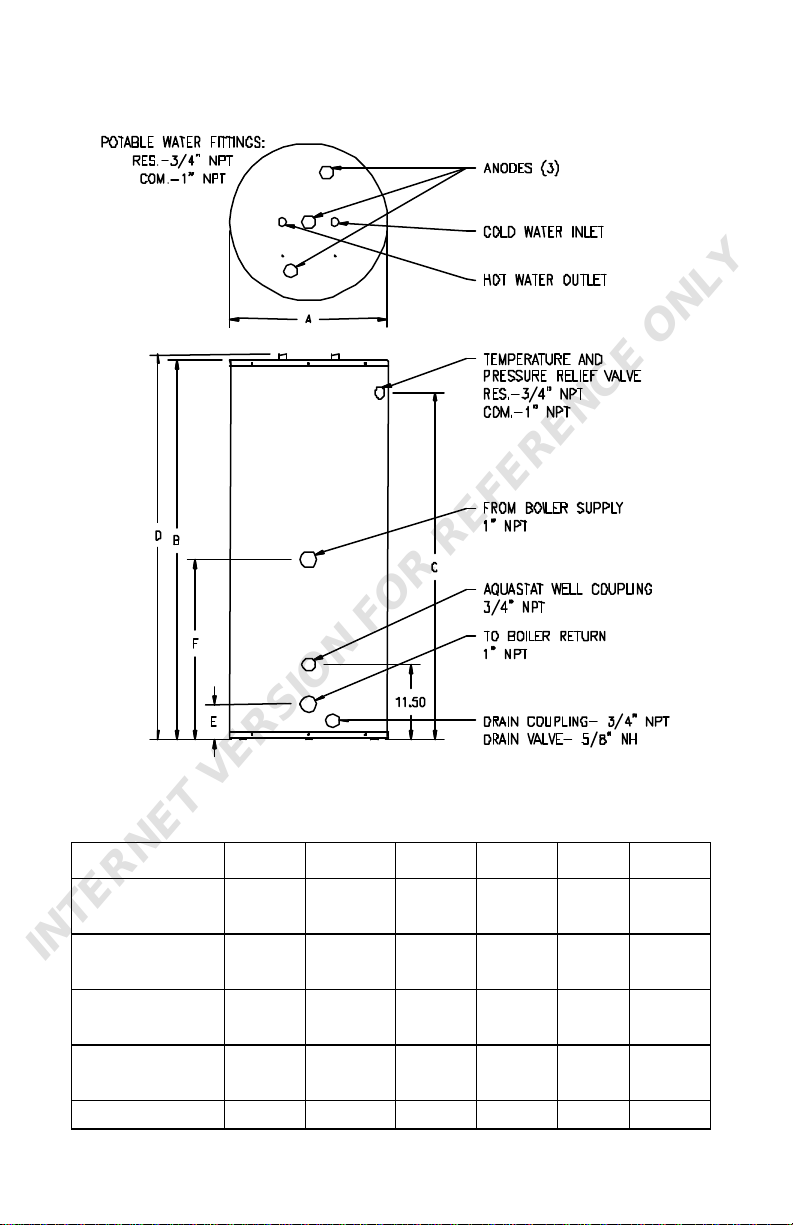

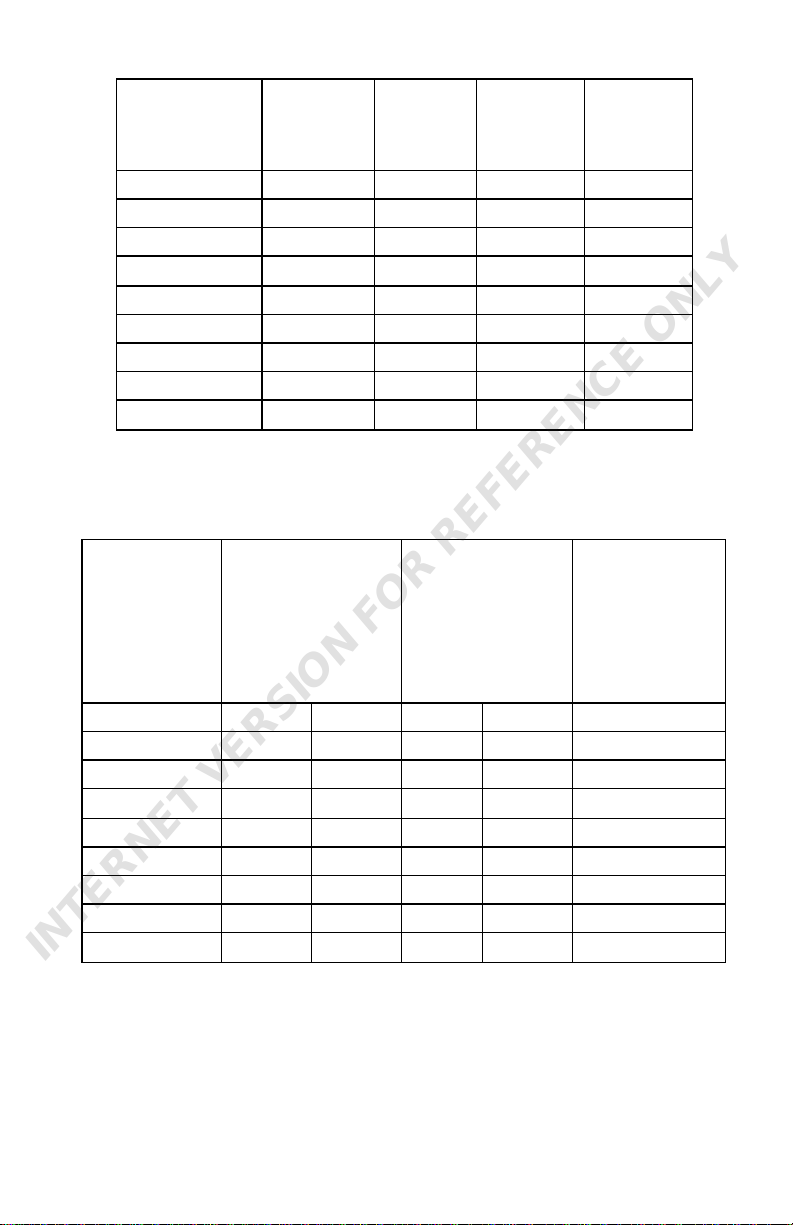

Figure 1 – Tank Layout

Table 1: Water Heater Dimension (Inches)

MODEL

SW -2-30-L 22 33-5/8 28-

SW -2-40-L 24 36 29-

INTERNET VERSION FOR REFERENCE ONLY

SW -2-50-L 26 36 29-

SW -2-65-L 22 59-1/4 53-

SW -65C-5 22 59-1/4 53- 60 5-3/8 47-

A B C D E F

13

1/4

3/4

3/4

1/8

34-

3/8

36-

3/4

36-

3/4

60 5-3/8 27-

5-3/8 27-

1/2

5-3/8 27-

1/2

5-3/8 27-

1/2

1/2

Page 14

1/8 3/4

SW -2-80-L 24 59 52-

7/8

SW -80C-5 24 59 52-

7/8

SW -2-120-L 28-

1/4

SW -120C-5 28-

1/4

62-1/2 55-

3/4

62-1/2 55-

3/4

59-

3/4

59-

3/4

63-

1/4

63-

1/4

5-3/8 27-

1/2

5-3/8 47-

3/4

6-3/8 28-

1/2

6-3/8 48-

3/4

INTERNET VERSION FOR REFERENCE ONLY

14

Page 15

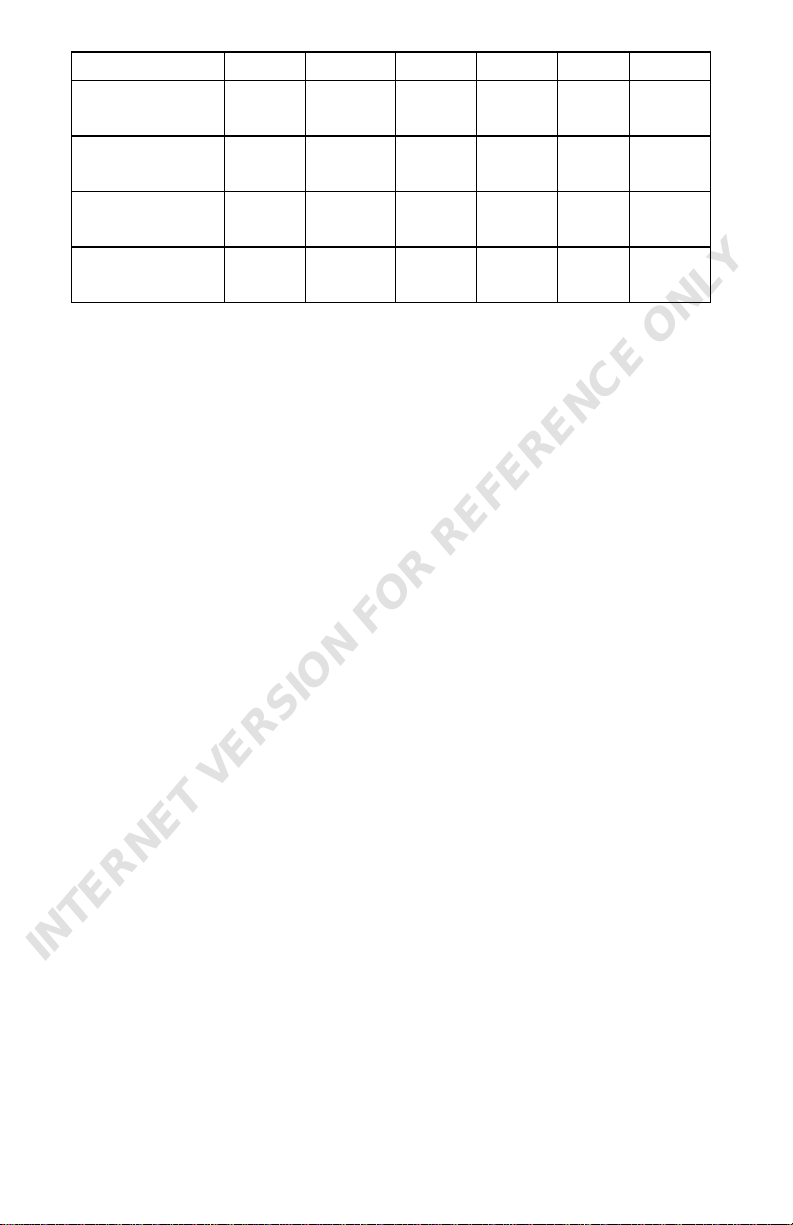

Table 2: Water Heater Capacities

MODEL

SW -2-30-L 30 2.6 140 404

SW -2-40-L 40 2.6 168 514

SW -2-50-L 50 2.6 196 623

SW -2-65-L 60 2.6 196 704

SW -65C-5 58 5.0 265 768

SW -2-80-L 75 2.6 224 861

SW -80C-5 73 5.0 293 920

SW -2-120-L 116 2.6 355 1324

SW -120C-5 114 5.0 415 1370

Table 3: Water Heater Performance

MODEL

SW-2-30-L 279 429 4.2 6.7 220,000

SW-2-40-L 288 438 4.2 6.7 220,000

SW-2-50-L 297 447 4.2 6.7 220,000

SW-2-65-L 306 456 4.2 6.7 220,000

SW-65C-5 534 820 8.0 12.8 420,000

SW-2-80-L 321 470 4.2 6.7 220,000

SW-80C-5 546 834 8.0 12.8 420,000

SW-2-120-L 357 507 4.2 6.7 220,000

SW-120C-5 583 871 8.0 12.8 420,000

INTERNET VERSION FOR REFERENCE ONLY

NOTES: All ratings based on 200 °F boiler water

temperature and 50 °F potable water inlet temperature.

Tank

Capacity

(Gal)

Maximum First

Hour Rating

(Gal/Hr) @

140 °F 115 °F

Coil

Volume

(Gal)

Continuous

Draw Rating

(Gal/Min) @

140 °F 115

°F

Dry

Weight

(Lbs)

Wet

Weight

(Lbs)

Approximate

Boiler

Output

Needed For

Ratings

(BTU/hr)

15

Page 16

Table 4: Water Heater Performance (continued)

MODEL

SW-2-30-L 5.5

SW-2-40-L 7.5

SW-2-50-L 9.0

SW-2-65-L 11.0

SW-65C-5 10.5

SW-2-80-L 13.5

SW-80C-5 13.2

SW-2-120-L 20.8

SW-120C-5 20.6

Hot Water

Availability

(Minutes)

Coil Heat

Transfer Area

(Sq Ft)

14.2

14.2

14.2

14.2

27.2

14.2

27.2

14.2

27.2

NOTICE

If the boiler takes longer to heat up from a cold start than

the water availability as noted above, hot water shortage

may occur.

Hot water availability is based off drawing 80% of the

heated tank volume at 4 gallons per minute flow rate.

Pressure

Drop at 12

GPM

(Feet of

Head)

1.3

1.3

1.3

1.3

2.6

1.3

2.6

1.3

2.6

The maximum heat transfer through the coil (heat input) of

the water heater at 240°F boiler water supply temperature

and 210°F potable water temperature is 94,100 Btu/hr for

residential models and 180,300 Btu/hr for commercial

INTERNET VERSION FOR REFERENCE ONLY

models. Potable water temperature is limited to below

210 °F and nominal water-containing capacity is below

120 gallons for all single-wall indirect models.

Accordingly, per Part HLW-101.2, Section IV of the

ASME Boiler and Pressure Vessel Code, all Bradford

White Single-wall Indirect products are exempted from

16

Page 17

complian ce with the code.

INTERNET VERSION FOR REFERENCE ONLY

17

Page 18

SECTION III

GENERAL INFORMATION

FEATURES

This water heater contains the following features:

HEAT EXCHANGER -- The heat exchanger (coil) has 1” NPT

female fittings.

These water heaters with single-wall heat exchangers meets the

Uniform Plumbing Code for installation in all potable water systems

provided that:

• The boiler water (including additives) is practically non-toxic,

having toxicity rating of class of 1 as listed in Clinical

Toxicology of Commercial Products.

• The boiler water pressure is limited to maximum 30 psig by

approved relief valve.

• The heat transfer medium is potable water or contains only

substances that are recognized as safe by the U.S. Food and

Drug Administration (FDA).

• The pressure of the heat transfer medium is maintained less

than the normal minimum operating pressure of the potable

water system.

• The equipment is permanently labeled to indicate that only

additives recognized as safe by the FDA shall be used in the

heat transfer medium.

ADJUSTABLE AQUASTAT – The temperature may be adjusted

from 80°F to 160°F. The aquastat (thermostat) was adjusted to

120°F before the heater was shipped from the factory. It is

recommended that lower temperatures be used to avoid the risk of

scalding. Refer to the “Warnings” and the section on SCALDING in

INTERNET VERSION FOR REFERENCE ONLY

“Section VII – Operating Instructions.” It is further recommended,

in all cases, that the water temperature be set for the lowest

temperature that satisfies your hot water needs. This will also

provide the most energy efficient operation of the water heater and

minimizes scale formation.

18

Page 19

Setting the water heater temperature at 120°F will reduce the risk of

scalds. Some states require settings to specific lower temperatures.

INTERNET VERSION FOR REFERENCE ONLY

19

Page 20

TEMPERATURE AND PRESSURE RELIEF VALVE —

WARNING

Keep clear of the combination temperature and pressure

relief valve discharge line outlet. The discharge may be hot

enough to cause scald injury. The water is under pressure and may

splash.

For protection against excessive temperatures and pressure, install

temperature and pressure protective equipment required by local

codes, but not less than a combination temperature and pressure

relief valve certified by a nationally recognized testing laboratory

that maintains periodic inspection of production of listed equipment

or materials as meeting the requirements of the Standard for Relief

Valves and Automatic Gas Shutoff Devices for Hot Water

Supply Systems, ANSI Z21.22 and the Standard CAN1-4.4

Temperature, Pressure, Temperature and Pressure Relief

Valves and Vacuum Relief Valves. The combination temperature

and pressure relief valve must be marked with a maximum set

pressure not to exceed the maximum working pressure of the water

heater. The combination temperature and pressure relief va lve

must also have an hourly rated temperature steam BTU discharge

capacity not less than the hourly rating of the water heater. The

supplied combination temperature and pressure relief valve, when

properly installed and unrestricted, will discharge the ma ximum input

produced by a 240°F (116°C) boiler supply temperature. A lower

boiler supply temperature will reduce the input required to be

discharged in the event of excessive potable water temperatures.

Install the combination temperature and pressure relief valve into

the opening provided and marked for this purpose on the water

heater.

INTERNET VERSION FOR REFERENCE ONLY

Some models may already be equipped or supplied with a

temperature and pressure relief valve. Verify that the combination

temperature and pressure relief valve complies with local codes. If

the temperature and pressure relief valve does not comply with local

codes, replace it with one that does.

20

Page 21

INTERNET VERSION FOR REFERENCE ONLY

21

Page 22

WARNING

Install a discharge line so that water discharged from the

temperature and pressure relief valve will exit within six (6) inches

above, or any distance below, the structural floor and cannot contact

any live electrical part. The discharge line is to be installed to allow

for complete drainage of both the temperature and pressure relief

valve and the discharge line. The discharge opening must not be

subjected to blockage or freezing. DO NOT thread, plug, or cap

the discharge line. It is recommended that a minimum clearance of

four (4) inches be provided on the side of the water heater for

servicing and maintenance of the combination temperature and

pressure relief valve

Do not place a valve between the combination temperature

and pressure relief valve and the tank!

SACRIFICIAL ANODES—Three sacrificial anode rods have

been installed in the tank head to extend tank life. The anode rods

should be inspected annually to determine the amount of sacrificial

decay and replaced when necessary to prolong tank life. Water

conditions in your area will influence the time interval for inspection

and replacement of the anode rod. The use of a water softener may

increase the speed of anode consumption. More frequent inspection

of the anode is needed when using softened (or phosphate treated)

water. Contact the plumbing professional who installed the water

heater or the manufacturer listed on the rating plate for anode

replacement information.

INTERNET VERSION FOR REFERENCE ONLY

22

Page 23

SECTION IV

PRE-INSTALLATION

UNPACKING

INSPECT SHIPMENT carefully for any signs of damage. If

damage is noted, do not install the product. Contact the shipper or

manufacturer listed on rating plate. All equipment is carefully

manufactured, inspected, and packed. Our responsibility ceases

upon delivery of the packaged heater to the carrier in good

condition.

NOTE: Any claims for damage or shortage in shipment must

be filed immediately against the carrier by the consignee.

IMPORTANT DECISIONS REQUIRED

BEFORE INSTALLATION

SIZING

1. Boiler DOE Heating Capacity – The Single-wall

Indirect water heater will provide the rated performance

only if used in conjunction with a boiler with a DOE

heating capacity (Boiler Output) at least as much as the

minimum noted in Table 3. If the boiler has less

capacity, the output of the tank will be reduced. To

determine the approximate reduction in output from the

tank use the following formula:

New Rating = (maximum first hour rating) x

Actual Boiler Output Capacity

INTERNET VERSION FOR REFERENCE ONLY

For example, what would the 140°F first hour rating be

if model SW-2-50-L was installed with a boiler having a

DOE heating capacity of 180,000 BTU/h?

Minimum Boiler Output Capacity

23

Page 24

Answer:

New Rating

= 297 gal/hr x (180,000 BTU/h)/(220,000 BTU/h)

= 297 gal/hr x 0.818 = 243 gal/hr

NOTICE

Increasing the boiler DOE heating capacity above the

values listed in Table 3 will not increase the rating of the

water heater.

Ratings are based on 200°F boiler water. If 180°F boiler

water is supplied, First Hour and Continuous Draw ratings

will be reduced by approximately 27%.

2. Circulator Sizing – Refer to Table 4 for the

corresponding pressure drop through the coil for the

given model. Calculate the pressure drop of all straight

pipe and fittings on the supply and return of the water

heater at the selected flow rate. Add the piping/fitting

pressure drop to the pressure drop through the water

heater coil.

Sel ect a circulator that will provide an appropriate flow

rate at the combined pressure drop.

INTERNET VERSION FOR REFERENCE ONLY

SYSTEM ZONE CONTROL

The Single-wall Indirect water heater must be installed as a zone

separate from the space heating system. The domestic hot water

zone’s piping and circulator must be sized for a minimum flow rate

with all zones in use and a maximum flow rate with only the water

24

Page 25

heater in use. For this reason, the preferred method of zone

control is with circulators.

INTERNET VERSION FOR REFERENCE ONLY

25

Page 26

1. Circulators – With space heating zones using circulators,

the Single-wall Indirect should be added as an additional

zone with a circulator.

2. Zone Valves – Select a valve with a low-pressure drop

to assure adequate flow through the water heater.

3. Hybrid – The space heating zone can be zoned using zone

valves and the Single-wall Indirect zoned with a circulator.

DOMESTIC HOT WATER PRIORITY

Two options are available, Priority and Non-Priority.

1. Priority – Demand for space heating is interrupted or

postponed until the domestic hot water demand is

satisfied. This option provides maximum delivery of

domestic hot water. Priority is recommended when:

a) Boiler net output is 100,000 Btu per hour or less, or

b) When boiler output required to satisfy domestic hot

water demand is at least 50% of the boiler output

required to satisfy space heating demand, or

c) When an interruption in space heating can be

tolerated during a long domestic hot water draw.

2. Non-Priority – Boiler output is divided between space

heating and domestic hot water heating. Delivery of

domestic hot water can be reduced during simultaneous

space and domestic hot water heating operations,

depending on such factors as boiler output, boiler oversizing, number of space heating zones calling for heat, and

the ratio of domestic hot water load to space heating load.

INTERNET VERSION FOR REFERENCE ONLY

26

Page 27

Component Location

CAUTION

This water heater must be located in an area where leakage of the

tank, water line connections, or the temperature and pressure relief

valve will not result in damage to the area adjacent to the water

heater or to lower floors of the structure. When such locations

cannot be avoided, a suitable drain pan must be installed under the

water heater. The drain pan depth must be suitable for draining and

collecting water, and have a minimum length and width of at least

four (4) inches measured from the jacket of the water heater. The

drain pan, as described above, can be purchased from your plumbing

professional. The drain pan must be piped to an adequate drain.

The piping must be at least ¾ inc h in diameter and pitched for

proper drainage.

Clearance from Combustible Materials

Top Sides Front Rear

0” 0” 0” 0”

Table 5 – Combustible Material Clearances

Recommended Service Clearances

Non-Piping

Side

4” 16” 0” 4”

Front

(Aquastat)

Table 6 – Service Clearances

Rear

T & P Relief

Valve Side

INTERNET VERSION FOR REFERENCE ONLY

CAUTION

Do not drop water heater. Do not bump water heater jacket against

floor.

27

Page 28

Appliance Location

1. Boiler Location – Locate the Single-wall Indirect as close to

the boiler as practical.

2. Fixture Locations – For fastest delivery of hot water, place

the Single-wall Indirect close to points of use.

Additional Recommended Components

1. Shut-off Valves – Allows isolation of water heater from

domestic water system and/or boiler system during service.

2. Unions – Allows water heater movement during service if

adequate clearance cannot be provided.

3. Thermal Expansion Tank – If the water heater is installed in

a closed water supply system, such as one having a back-flow

preventer in the cold water line, provide thermal expansion

control. Contact the water supplier or local plumbing

inspector for additional information.

WARNING

Do not plug the inlet and outlet tappings of tankless heater left

installed in the boiler.

MOVE THE WATER HEATER TO A PERMANENT

POSITION BY SLIDING OR WALKING.

INTERNET VERSION FOR REFERENCE ONLY

28

Page 29

SECTION V

WATER CONNECTIONS

WARNING

FAILURE TO INSTALL AND MAINTAIN A NEW, LISTED

TEMPERATURE AND PRESSURE RELIEF VALVE WILL

RELEASE THE MANUFACTURER FROM ANY CLAIM

WHICH MIGHT RESULT FROM EXCESSIVE

TEMPERATURE AND PRESSURES.

Hydrogen gas can be produced in an operating water heater that

has not had water drawn from the tank for a long period of time.

HYDROGEN GAS IS EXTREMELY FLAMMABLE. To

prevent the possibility of injury under these conditions, we

recommend the hot water faucet be opened for several minutes

at the kitchen sink before you use any electrical appliance that is

connected to the hot water system. If hydrogen is present,

there will be an unusual s ound such as air escaping through the

pipes as hot water begins to flow. Do not smoke or have open

flame near the faucet at the time it is open.

Keep clear of the temperature and pressure relief valve

discharge line outlet. The discharge may be hot eno ugh to

cause scald injury. The water is under pressure and may splash.

CAUTION

If sweat fittings are to be used, DO NOT apply heat to the

INTERNET VERSION FOR REFERENCE ONLY

nipples on top of the water heater. Sweat the tubing to the

adapter before fitting the adapter to the water connections. It is

imperative that heat is not applied to the nipples containing a

plastic liner.

29

Page 30

INSTALL TEMPERATURE AND PRESSURE RELIEF

VALVE (if not factory installed)

WARNING

Temperature and pressure relief valve discharge piping must be

piped near the floor to eliminate potential of severe burns. Do

not pipe in any area where freezing could occur. Do not install

any shut-off valves, plugs or caps to the temperature and

pressure relief valve or piping.

INSTRUCTIONS FOR POTABLE CONNECTIONS

1. BEFORE PROCEEDING WITH THE INSTALLATION,

CLOSE THE MAIN WATER SUPPLY VALVE. After

shutting off the main water supply, open a faucet to relieve the

water line pressure to prevent any water from leaking out of

the pipes while making the water connections to the water

heater. After the pressure has been relieved, close the faucet.

The COLD water inlet and HOT water outlet are identified

on the top of the water heater. Make the proper plumbing

connections between the water heater and the plumbing

system to the house. Install a shut-off valve in the cold water

supply line.

2. If this water heater is installed in a closed water supply

system, such as one having a back-flow preventer in the cold

water supply, provisions must be made to control thermal

expansion. DO NOT operate this water heater in a closed

system without provisions for controlling thermal expansion.

Warranties do not cover damages from thermal expansions

such as pressure bulges and/or deformities. A properly sized

expansion tank will alleviate most problems. Your water

supplier or local plumbing inspector should be contacted on

INTERNET VERSION FOR REFERENCE ONLY

how to control this situation.

3. After installation of the water lines, open the main water

supply valve and fill the water heater. While the water heater

is filling, open several hot water faucets to allow air to escape

from the water system. When steady

30

Page 31

streams of water flow through the faucets, close them and

check all water connections for possible leaks.

4. NEVER OPERATE THE WATER HEATER

WITHOUT FIRST BEING CERTAIN THAT IT IS

FILLED WITH WATER.

INSTRUCTIONS FOR BOILER CONNECTIONS

The Single-wall Indirect connection labeled “To Boiler Return”

should be piped to the boiler return piping as close to the boiler as

possible and especially after any flow control or check valves in the

space heating return piping. The use of a union and a shut-off valve

is recommended. The use of a flow control or check valve is

required to prevent back flow through the water heater during

operation of the space heating system. Pipe and fittings between

the boiler and Single-wall Indirect should be ¾” diameter or larger.

CAUTION

Maximum boiler water supply temperature to the indirect

heat exchanger must not exceed 240°F (116°C).

CONNECT WATER BOILER SUPPLY PIPING

1. For a space heating system that utilizes ZONE VALVES, refer

to Figure 2. The Single-wall Indirect connection labeled

“FROM BOILER SUPPLY” should be piped to the boiler

supply piping. Mount the circulator making sure the flow arrow

points toward the water heater. The use of shut-off valves and

INTERNET VERSION FOR REFERENCE ONLY

unions are recommended for future service convenience. The

use of an air separator and vent is recommended to eliminate air

in the system. Pipe and fittings between the boiler and Singlewall Indirect must be ¾” diameter or larger.

31

Page 32

Figure 2 - Water Boiler Piping with Zone Valves

2. For a space heating system that utilizes CIRCULATORS, refer

to Figure 3. The Single-wall Indirect connection labeled

“FROM BOILER SUPPLY” should be piped to the boiler

supply piping. Mount the circulator making sure the flow arrow

points toward the water heater. The use of shut-off valves and

unions are recommended for future service convenience. The

use of an air separator and vent is recommended to eliminate air

in the system. Pipe and fittings between the boiler and Singlewall Indirect must be ¾” diameter or larger.

INTERNET VERSION FOR REFERENCE ONLY

Figure 3 - Water Boiler Piping with Circulators

32

Page 33

CONNECT STEAM BOILER SUPPLY PIPING

hout connections available below the water line is not

F lower than the

Figure 4 represents a typical steam boiler connection diagram.

Refer to the boiler installation manual or contact the boiler

manufacturer for an appropriate piping diagram. The use of a

union, shut-off valves, and a drain valve is recommended for future

service convenience. The use of an in-line “Y”-style strainer is

required to prevent accumulation of sludge in the water heater’s

coil.

Figure 4 – Typical Steam Boiler Connections (connections available

below the water line)

NOTICE

Typical steam boiler wit

recommended due to insufficient water temperature, especially during

warmer months when the space heating system is not operational. Boiler

water temperature at the bottom of a steam boiler can be 50°

boiler’s water temperature limit setting during such periods.

FILL BOILER SYSTEM

1. On new boiler installations, do not purge the boiler or space

INTERNET VERSION FOR REFERENCE ONLY

heating system through the water heater. During any boiler or

space heating system flushing, cleaning, or purging, the water

heater should be isolated to avoid possible attack on the

carbon steel coil by chemical additives.

2. Purge air from boiler/water heater piping.

3. Check system for leaks. Repair as necessary.

33

Page 34

SECTION VI

ELECTRICAL CONNECTIONS

Install electric wiring in accordance with National Electric Code or

the Canadian Electrical Code and local regulations. See the

boiler’s installation manual for wiring diagrams.

DANGER

Positively assure all electrical connections are unpowered before

attempting installation or service of electrical components or

connections of the water heater or building. Lock out all

electrical boxes with padlock once power is turned off.

WARNING

When installed, the water heater must be electrically grounded in

accordance with local codes or, in the absence of local codes,

with the National Electrical Code, ANSI/NFPA 70, and /or the

CSA C22.1 Electric Code.

Failure to properly wire electrical connections to the water heater

may result in serious physical harm.

Electrical power may be from more than one source. Make sure

all power is off before attempting any electrical work.

The Single-wall Indirect is supplied with an aquastat temperature

control. This aquastat must be installed in the aquastat well

location of the water heater. Refer to Figure 5. Remove the cover

INTERNET VERSION FOR REFERENCE ONLY

and loosen the clamping screws. Insert the aquastat capillary bulb

to the well bottom as shown and screw the aquastat clamp securely

in the well groove. The aquastat acts as a thermostat for zone

control and should be wired accordingly. Refer to the boiler or

zone control manufacturer’s instructions if any additional wiring is

required. The control is factory set at 120°F and care should be

34

Page 35

made to not rotate this dial while wiring the control. Once electrical

connections are

INTERNET VERSION FOR REFERENCE ONLY

35

Page 36

complete, secure the aquastat cover back in place. AT NO TIME

SHOULD WATER HEATER OPERATION TAKE PLACE

WITHOUT THE COVER ON THE CONTROL.

Figure 5 - Aquastat Control

INTERNET VERSION FOR REFERENCE ONLY

36

Page 37

SECTION VII

OPERATING INSTRUCTIONS

WARNING

Water heaters are heat-producing appliances. To avoid damage

or injury there must be no materials stored against the water

heater, and proper care must be taken to avoid unnecessary

contact (especially by children) with the water heater.

UNDER NO CIRCUMSTANCES SHALL FLAMMABLE

MATERIALS, SUCH AS GASOLINE OR PAINT THINNER

BE USED OR STORED IN THE VICINITY OF THE

WATER HEATER OR IN ANY LOCATION FROM WHICH

FUMES COULD REACH THE WATER HEATER.

Installation or service of this water heater requires ability

equivalent to that of a licensed tradesman in the field

involved. Plumbing and electrical work are required.

SYSTEM START-UP

Follow boiler installation instructions to place boiler in operation.

SEQUENCE OF OPERATIONS

1. Aquastat senses stored water temperature drops below

desired setting.

a. Domestic hot water priority only: Normally closed

contacts open to interrupt space heating.

2. Aquastat satisfied.

a. Aquastat contacts open, turning off domestic hot water

INTERNET VERSION FOR REFERENCE ONLY

circulator and de-energizing relay.

b. Normally open contacts open, stopping boiler operation.

c. Domestic hot water priority only: Normally closed

contacts close, returning boiler control to space

heating.

37

Page 38

WATER TEMPERATURE ADJUSTMENT

ure water at any

heater to obtain an increased water temperature, you may create

Such valves are available from the manufacturer of

1. The aquastat controls the maximum water temperature in the

tank. The differential is a fixed 5°F with a 160°F maximum

setting, set at the factory to 120°F.

WARNING

SCALDING

This water heater can deliver scalding temperat

faucet in the system. Be careful whenever using hot water to

avoid scalding injury. By setting the aquastat on this water

the potential for scald injury. To protect against inju ry, you

should install an ASSE approved mixing valve (a device to limit

the temperature of water to protect against scald injury via

mixing hot and cold water supply) in the water system. This

valve will reduce point of discharge temperature in branch

supply lines.

this water heater or a local plumbing supplier. Please consult

with a plumbing professional.

Table 7 details the approximate relationship of water temperature and

time with regard to scald injury and may be used as a guide in

determining the safest water temperature for your applications.

RELATIONSHIPS IN SCALDS

INTERNET VERSION FOR REFERENCE ONLY

Figure 6 - Scald Warning

38

APPROXIMATE

TIME/TEMPERATURE

120°F More than 5 minutes

125°F 1 ½ to 2 minutes

130°F About 30 seconds

135°F About 10 seconds

140°F Less than 5 seconds

145°F Less than 3 seconds

150°F About 1 ½ seconds

155°F About 1 second

Table 7 – Scald Relationships

Page 39

INTERNET VERSION FOR REFERENCE ONLY

39

Page 40

2. For the most energy efficient operation, adjust the aquastat for

the minimum water temperature necessary to meet domestic

hot water needs. Refer to Figure 7. Use a small flat

screwdriver to rotate the temperature dial through the hole

directly below the temperature indication window. The

temperature setting is aligned with the notch in this window.

IT IS NOT NECESSARY TO REMOVE THE COVER

TO ADJUST THE TEMPERATURE SETTING. THE

AQUASTAT COVER SHOULD NEVER BE

REMOVED WITHOUT ELECTRICITY BEING

FIRST DISCONNECTED.

3. After the water heater completes a heat-up cycle, check the

water temperature at a faucet. Allow enough water to flow to

ensure that the water temperature reflects the tank

temperature. Adjust the water heater’s temperature setting as

necessary.

a. Adjusting to a lower temperature setting will not

immediately affect water temperature. Draw sufficient

INTERNET VERSION FOR REFERENCE ONLY

water or allow the water heater to sit until a heat-up cycle

is initiated. Repeat step 3.

b. Adjusting to a higher temperature may not immediately

affect water temperature. If a heat-up cycle begins,

return to step 3. If a heat-up cycle does not begin, draw

Figure 7 - Aquastat Control

40

Page 41

sufficient water or allow the water heater to sit until a

heat-up cycle is initiated. Repeat step 3.

INTERNET VERSION FOR REFERENCE ONLY

41

Page 42

SECTION VIII

MAINTENANCE

The Single-wall Indirect is intended to provide a service life of many

years. Components that require service, however, may be subject

to failure. Failure to use the correct procedures or parts in these

circumstances may make the water heater unsafe.

The owner should arrange to have the following inspections and

simple maintenance procedure performed by qualified service

personnel at the frequencies suggested.

1. Boiler and Domestic Water Piping (Annual) – Check all

piping for signs of leakage at joints, unions, and shut-off

valves. Repair as needed.

2. Temperature-Pressure Relief Valve (Annual)- The

temperature-pressure relief valve should be checked to ensure

that it is in operating condition. To check the relief valve, lift

the lever at the end of the valve several times. The valve

should seat properly and operate freely. If water does not

flow, remove and inspect for obstructions or corrosion.

Replace with a new valve of the recommended size as

necessary. Do not attempt to repair the valve, as this could

result in improper operation and a tank explosion. In areas

with poor water conditions, it may be necessary to inspect the

temperature-relief valve more often than once a year.

CAUTION

Before manually operating the valve, make sure that a

drain line has been attached to the valve to direct the

INTERNET VERSION FOR REFERENCE ONLY

discharge to an open drain. Failure to take this

precaution could mean contact with extremely hot water

discharging from the valve during this checking

operation.

42

Page 43

If the temperature–pressure relief valve on the heater discharges

periodically or continuously, it may be due to thermal expansion of

water in a closed water supply system, or it may be due to a faulty

relief valve.

Thermal expansion is the normal response of water when it is

heated. In a closed system, thermal expansion will cause the

system pressure to build until the relief valve actuation pressure is

equaled. Then the relief valve will open, allowing some water to

escape, slightly lowering the pressure. Contact your water supplier

or local plumbing inspector on how to control this situation.

ABOVE ALL, DO NOT PLUG THE TEMPERATURE AND

PRESSURE RELIEF VALVE. THIS IS NOT A SOLUTION

AND CAN CREATE A HAZARDOUS SITUATION.

3. Anode Inspection and Replacement - This water heater is

equipped with multiple sacrificial anodes. Anodes protect the

glass-lined tank from corrosion by sacrificing themselves

through electrolysis. When the anode material is consumed,

there is no more protection and corrosion of the tank

accelerates.

Inspection of the anode every year allows you to identify a

spent anode and replace. Replace the anode when its

diameter is 3/8 of an inch, or every other year, which ever is

first. Aggressive, very hot and softened water causes rapid

consumption of the anode, requiring frequent inspections.

Anodes are available from your distributor or from the

manufacturer listed on the rating plate.

To inspect or replace an anode:

The anodes on this water heater are easily accessible from the

top of the heater making replacement simple and quick.

INTERNET VERSION FOR REFERENCE ONLY

a. Turn the water heater electricity off for the zone

containing the Single-wall Indirect. Flow water until

the discharge is cool or allow enough time for the

potable water to cool naturally. Connect a hose to the

drain valve. Locate the hose’s

43

Page 44

discharge in an area where any remaining hot water

will not cause any damage or injury.

b. Open the drain valve to flush any sediment out of the

bottom to the heater.

c. Shut off the cold water supply. Make sure all hot

water fixtures and circulating pumps are turned off.

d. Wait for water flow from the hose to stop. Remove

the anode using a socket of the appropriate size. Do

not use an impact wrench.

e. Inspect and replace the anode as required. Use pipe

tape or sealant when reinstalling the anode.

f. Close the drain valve. Open a hot water fixture to

allow air to escape. Open the cold water supply to

the heater and allow the tank to fill.

g. Check your anode and drain valve for leaks.

h. Turn the water heater electricity on for the zone

containing the Single-wall Indirect.

4. Sediment (Annual, but harsh water quality may

dictate more frequent service)- Depending on water

conditions, a varying amount of sediment may collect in the

tank. Levels requiring service are indicated by a small

temperature difference in the supply and return lines (See

also “Scale” below). Repeated flushing usually clears such

material. As a preventive measure, water should be drawn

from the tank at the drain valve until it runs clear.

5. Scale (Annual)- Hard water may cause scale to build-up

on the outside of the heat exchanger coil. A water softener

will prevent this problem (See also “Sediment” above).

Symptoms would be reduced recovery capacity or reduced

INTERNET VERSION FOR REFERENCE ONLY

temperature differential between boiler supply and return

lines. Repeated flushing should resolve the problem.

44

Page 45

SECTION IX

TROUBLE SHOOTING GUIDE

PROBLEM

No hot water at

faucet

Water at faucet

too hot

INTERNET VERSION FOR REFERENCE ONLY

CAUSE SOLUTION

Boiler does not

operate

operate

Improper aquastat

setting or calibration

open (if used)

Electrical problem

(relay, wiring, etc.)

Scale build-up If boiler, circulator, and tank

Clogged cold water

filter or boiler

supply strainer (if

used)

Aquastat set too

high

Improper system

plumbing

Improper system

wiring

Refer to boiler installation

instructions

Check main service switch

Check fused disconnect

Check power supply Circulator does not

Replace as necessary

Turn tank aquastat to

appropriate setting

Check power supply Zone valve does not

Replace as necessary

Check fuse and replace

Check circuit breaker and

reset (if applicable)

Check power supply

are operating satisfactorily,

coil may have scale coating.

See Section VIII:

Maintenance

Clean or replace filter or

strainer

Lower aquastat setting. See

Section VII

Compare plumbing to

Section V: Water

Connections

Compare wiring to Section

VI: Electrical Connections

45

Page 46

TROUBLE SHOOTING GUIDE (CONT.)

PROBLEM

Insufficient hot

water

Boiler cycles

more than 5

times per day in

summer Boiler high limit set

CAUSE SOLUTION

Aquastat setting too

low

Undersized boiler

with no priority to

domestic hot water

Peak use of hot

water is greater than

tank storage

capacity

Faulty tank aquastat Replace aquastat

Excessive demand Reduce demand or

Faulty aquastat Replace aquastat

too low

Adjust aquastat to higher

setting. See Section VII

Rewire for priority

Determine peak usage and

compare to tank capacity

consider larger tank

Increase boiler high limit

setting

INTERNET VERSION FOR REFERENCE ONLY

46

Page 47

SECTION X

PARTS LIST

PART NAME & DESCRIPTION

1. Aquastat Control 7. Drain Valve

2. Aquastat Well 8. Jacket Head Pan

3. Anode 9. Hole Closure

4. Diptube 10. Heat Exchanger Escutcheon

5. Outlet Nipple 11. Escutcheon

INTERNET VERSION FOR REFERENCE ONLY

6. T & P Relief Valve 12. Finish Flange

47

Page 48

Contact your supplier or plumbing professional for replacement

parts or contact the company at the address given on the rating

plate of the water heater.

Provide the part name, model, and serial numbers of the water

heater when ordering parts.

READ THE WARRANTY FOR A FULL EXPLANATION OF THE

LENGTH OF TIME THAT PARTS AND THE WATER HEATER ARE

WARRANTED.

Manufactured under one or more of the following U.S. Patents: 4,416,222;

4,628,184; 4,669,448; 4,672,919; 4,808,356; 4,829,983; 4,861,968; 4,867,106;

4,904,428; 5,000,893; 5,023,031; 5,052,346; 5,081,696; 5,092,519; 5,115,767;

5,199,385; 5,277,171; 5,341,770; 5,372,185; 5,485,879; 5,660,165; 5,574,822;

5,596,652; 5,682,666; 5,943,984. Other U.S. and Foreign patents applications

pending. Current Canadian Patents: 1,272,914; 1,280,043; 1,289,832; 2,045,862;

2,107,012; 2,108,186; 2,112,525.

Complete the following information and retain for future reference:

Model No:

Serial No:

Service Phone

Days: Nights:

Address:

Supplier:

Supplier Phone No:

INTERNET VERSION FOR REFERENCE ONLY

48

Page 49

Notes

INTERNET VERSION FOR REFERENCE ONLY

49

Loading...

Loading...