Page 1

User’s Manual Document 1343D

User’s Manual for

THE

FT

Wall-Mounted, Modulating

Gas, Condensing, Heating Only, Boiler

Model FTHW

SERIES

80,000 BTU/hr

100,000 BTU/hr

120,000 BTU/hr

140,000 BTU/hr

199,000 BTU/hr

• Natural Gas (NG) - Factory Conguration

• Propane Gas (LP) - Field-Convertible

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualied in hot water boiler and heater installation and maintenance. Improper installation and/or operation

could create carbon monoxide gas in ue gases which could cause serious injury, property damage, or

death. Improper installation and/or operation will void the warranty.

WARNING

If the information in this manual is not

followed exactly, a re or explosion may

result causing property damage, personal

injury or loss of life.

Do not store or use gasoline or other

ammable vapors and liquids in the vicinity

of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

nearby phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call

the re department.

Installation and service must be performed

by a qualied installer, service agency, or gas

supplier.

AVERTISSEMENT

Assurez-vous de bien suivres les instructions

données dans cette notice pour réduire au

minimum le risque d’incendie ou d’explosion

ou pour éviter tout dommage matériel, toute

blessure ou la mort.

Ne pas entreposer ni utiliser d’essence ni

d’autres vapeurs ou liquides inammables dans

le voisinage de cet appareil ou de tout autre

appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ:

• Ne pas tenter d’allumer d’appareils.

• Ne touchez à aucun interrupteur. Ne pas vous servir

des téléphones dansle bâtiment où vous êtes.

• Appelez immédiatement votre fournisseur de

gaz depuis un voisin. Suivez les instructions

du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de

gaz, appelez le sservice des incendies.

L’installation et l’entretien doivent être assurés par

un installateur ou un service d’entretien qualié ou

par le fournisseur de gaz.

H2375100D

Page 2

Page 2

CONTENTS Pgs -

1. Familiarizing yourself to the FT ...............................2 - 3

2. Caring For Your FT .......................................................4

3. Start Up and Shut Down. .............................................4

4. Control Setup and Operation .................................5 - 10

MODEL NUMBER

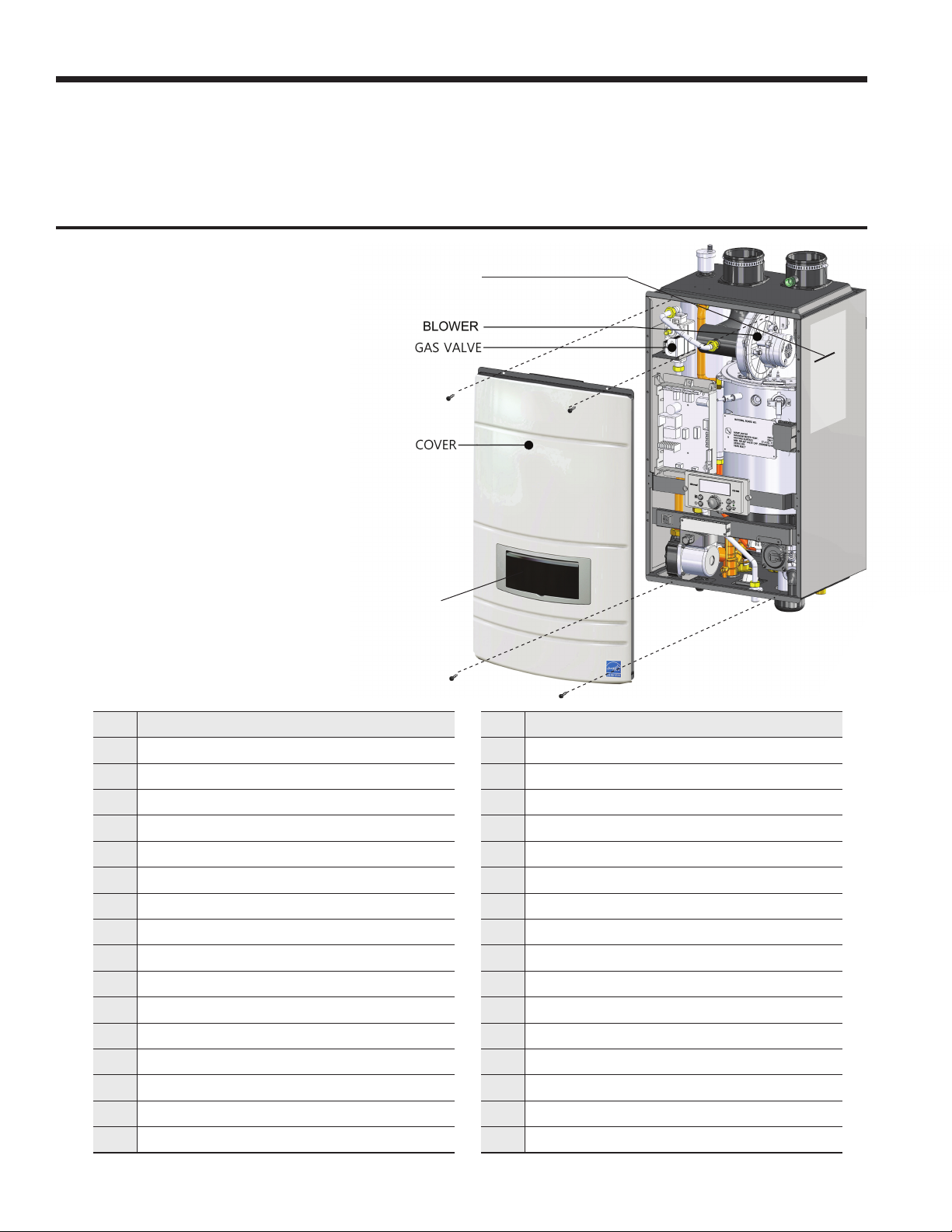

1. Familiarizing yourself to

THE

FT

Heating Only Boiler

4 SCREWS

The FT is a highly efcient, wall mounted,

condensing and fully modulating, residential

boiler. This Users Manual will guide you into the

basics of operating your FT

Please reference the Installation and Operation

Manual for complete details. Doc # 1342

CONTROL DISPLAY COVER

NO Name of Component

1

Air Vent (air eliminator)

2

Air Intake Collar

3

Air / Gas Mixing Pipe

4

Gas Inlet Pipe 2

5

Gas Valve

6

Exhaust Duct

7

Low Water Temperature Sensor

8

OP Sensor

9

Flame Detecting Sensor

10

Main PCB

11

Control Display

12

Manual ON/OFF Power Switch

13

Gas Inlet Pipe 1

14

‘CH’ Internal Pump

15

Gas Inlet Adapter

16

‘CH’ Supply Adapter

(HINGES UPWARD)

NO Name of Component

17

CH Pressure Gauge

18

‘CH’ Return Adapter

19

Condensate Trap

20

Condensate Adapter

21

CH Return Temperature Sensor

22

Condensate Air Pressure Switch

23

Terminal Block

24

Heat Exchanger

25

Ignition Transformer

26

Sight Glass

27

Burner Overheat Switch

28

Igniter

29

BLDC Fan (blower)

30

Exhaust Temperature Sensor

31

Air Pressure Sensor

32

Vent Pipe Collar

Page 3

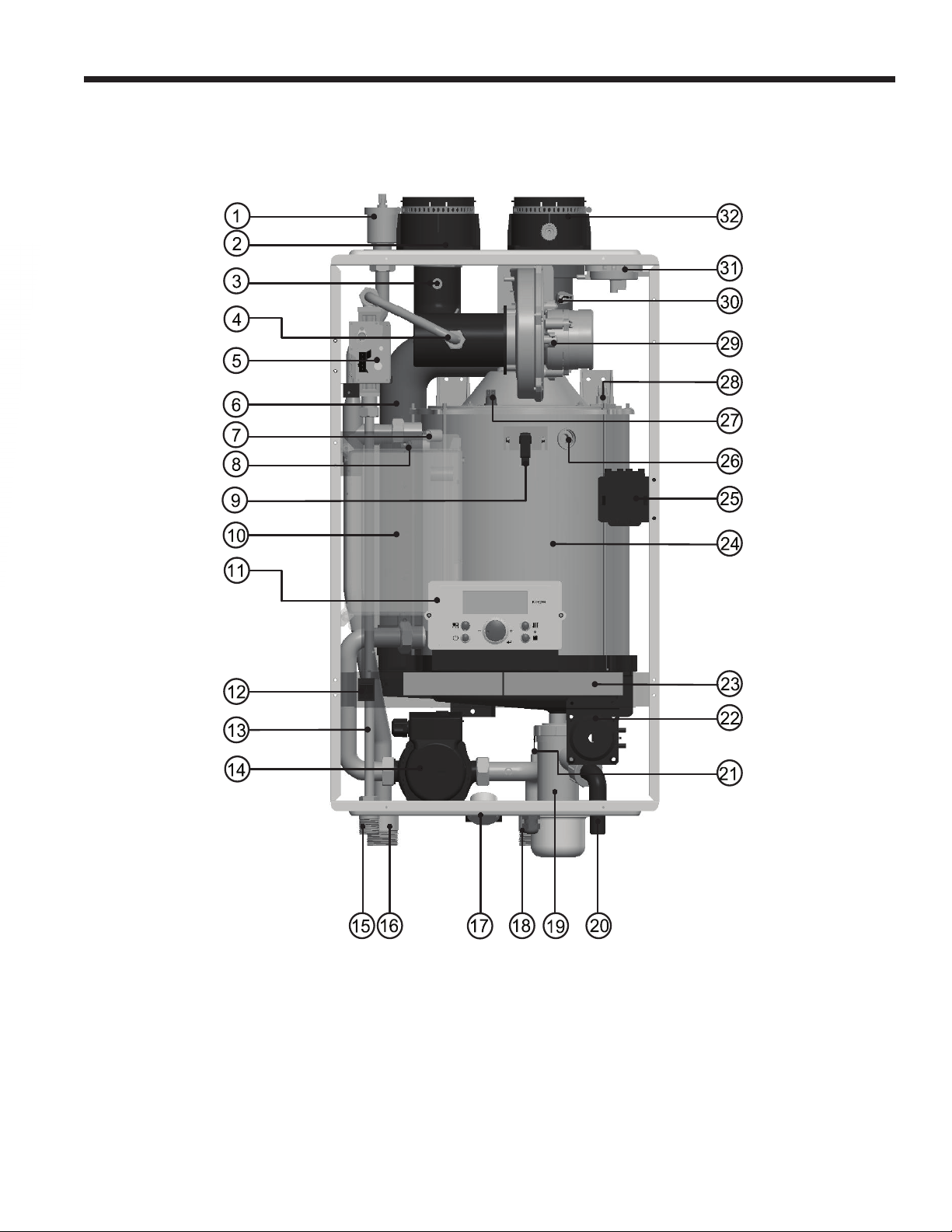

User’s Manual - The FT, Heating Only, Boiler

Page 3

Shown is the FT Heating Only 140 MBH.

All sizes are very similar in component layout.

Page 4

Page 4

2. Caring For Your FT

Your FT will require very little maintenance.

However, as with any ne appliance there are certain

steps that should be taken to ensure continuing

optimum performance.

2.1 General Care

Keep the area around the FT clean and free from

combustible materials, gasoline and other ammable

liquids and vapors.

The FT must be completely isolated and

protected from any source of corrosive chemical fumes

such as trichlorethylene, perchlorethylene, chlorine,

etc.

Keep bottom and top openings on the boiler free

for proper ventilation of interior components.

Do not obstruct or block a free ow of air to the

boiler to ensure proper ventilation.

If desired, clean the jacket surfaces with a

damp cloth and mild detergent. Do not use ammable

cleaning materials.

If sidewall vented, keep the vent terminal clear

of obstructions — do not allow snow to cover the vent

terminal. Clean the intake screen often, and then

develop an appropriate maintenance schedule.

2.2 Annual Inspection of Flue and Vents

Visually inspect the vent pipe once a year. Should

any deterioration exist, have the affected parts replaced

by a qualied service person.

2.3 In the Event of a Power Failure

The FT can not be operated during an electrical

power outage. If there is an extended power outage with

danger from freezing, then the FT (and all other water

systems) should be drained completely. When draining

the boiler, turn off main electrical disconnect switch.

When placing back in service, refer to Section 3 of this

Manual for instruction. All draining and lling must only

be done by a qualied service person.

2.4 Full Service Every Year

In addition to the annual visual inspections, a

qualied service agency should conduct a detailed

inspection of all ue product carrying areas of the boiler

and its venting system.

3. Shut Down and Restart

3.1 To Start the FT

If drained, please refer to the Install and

Operating Manual to ensure that the complete

‘Setup’ procedure has been followed before

starting this boiler. A complete ‘Setup’ must be

performed by a qualied service person.

3.2 Shutting Down the FT

1. Turn off the main electrical disconnect switch.

2. Close all manual gas valves.

3. If freezing is anticipated, drain the FT and be

sure to also protect building piping from freezing.

All water must be removed from heat exchanger

and condensate trap or else damage from

freezing may occur. Please refer to the Install

and Operating Manual.

This step to be performed by a qualied service person.

Page 5

Page 54

SECTION 5. Control Display and Operation

5.1 Control Dial and Buttons

The Control Display

User’s Manual - The FT, Heating Only, Boiler

4. The Control Display and Operation

Page 5

E

The Control Display has a Control Dial (E), 4 buttons (A, B, C, D), and a Liquid

Crystal Display (with 72 back-lit segments). This section of this manual gives

instruction on how to navigate into the many functions of the FT and to change

temperature set points, set system variables and controller parameters.

Buttons

PRESS (Tap) PRESS and HOLD (5 seconds)

Status Light

(constant green

when operating

normally)

Functionality

A

B Modes Tap to return to menu

C

D

E

• Temperature Specifi cations

Operating ambient Temperature Range : -10 to 60°C.

Operating Relative Humidity up to: 90% at 40°C.

Shipping & Storage Temperature Range of : -20 to 80°C.

Display Power

Heating

Water

Time / Date

Set

Scroll / Select

Turns Control Display

CH set-point change mode

(Maxium 82

No Change To SET: Year/Month/Week/Day/Time/Min

Menu select or value

up(+)/down(-) or setting dial.

ON / OFF

°C(180°F))

(If Display Power was On )

(If Display Power was Off )

Status Display Mode

Installer Mode

Page 6

Page 6

The FT Series Heating Only, Boiler

Page 55

5.2 LCD Overview

4. The Control Display and Operation

Symbol Name Description

Service Reminder mode Service Reminder mode indication

Outside Temperature Mode Outside Temp setting indication

(continued)

Anti-freeze mode Anti-freeze mode indication

Storage mode Storage mode indication

Information mode Information mode indication

Communication state Communication state indication

Time setting mode Time /Dispaly/Install mode indication

Fan operating mode Fan operating mode indication

Flame signal Flame Signal indication

CH pump mode CH pump mode indication

Storage pump mode Storage pump mode indication

Internal recirculation mode Internal recirculation mode indication

Celsius mode Indicated as Celsius temperature

Fahrenheit mode Indicated as Fahrenheit temperature

Heat demand mode Heat demand mode indication

DAY mode Current day mode indication

Cascade System connecting

mode

Cascade System operating mode

The LCD will illuminate when a user action is detected (a button is pressed) and will turn back off after 20 seconds.

Cascade System connecting mode

indication

Cascade System operating mode

indication

Page 7

User’s Manual - The FT, Heating Only, Boiler

Page 56

5.3 Operating Mode

Page 7

Operating Mode

After the Power is turned on, and/or the Control Display is turned on , the Control Display

will go through a ‘Start Up’ checklist and briefl y show a sequence of diagnostic codes before

entering into the ‘Operating Mode. It will then display the following information.

B C

A D

E

Indicate Indicator

Current Operating Temperature Set-Point

If the Fan is operating

If a fl ame is detected

Celsius or Fahrenheit

Date and Time indicator

If Outside Temperature Sensor is operating

If there is a Demand for Central Heat (CH)

If CH pump state is

If Internal recirculation pump is operating

If Communication state is activated

The Control Display can operate through user and service modes that have specifi c LCD output

and dedicated controls:

• Set-point change mode • Lock mode • Error mode • Status display mode

• Outside Temperature mode • Installer mode

operating

or

* Control Display will not allow changing of button in case of lock mode activated.

Page 8

Page 8

The FT Series Heating Only, Boiler

Page 57

5.4 Setting the Clock

B C

A D

The P-950EH Control Display does NOT have a daily timer or programmable thermostat.

Setting the Clock

a. Press and hold the

then, press the dial

‘Clock button’ for about 5 seconds. Set the ‘Year’ by turning the dial E. And

E to Save.

E

b. Set the ‘MON’ (Month) by turning the dial

c. Set the ‘DATE’ (1-31, Day of the Month) by turning the dial

d. Set the ‘HOUR’ (1-24, Hour of the Day) by turning the dial

e. Set the ‘MIN’ (1-60, Minute of the Hour) by turning the dial

f. Set the ‘Day’ (Sun - Sat) by turning the dial

To Exit at any time, press and hold the

E to the desired month number. Then press the dial E to Save.

E. Then press the dial E to Save.

‘Clock button’ for about 5 seconds.

E. Then press the dial E to Save.

E. Then press the dial E to Save.

E. Then press the dial E to Save.

Page 9

Page 58

User’s Manual - The FT, Heating Only, Boiler

5.5 CH Set Point Change Mode

CH Set point Change Mode

B C

Page 9

A D

To change CH Setpoint, press the C

CH Setpoint will fl ash.

Turn the E dial clockwise to increase, and counterclockwise to decrease CH setpoint, until

desired temperature is reached.

Press E dial to save changes and to Exit.

Indicate Indicator

Current CH Temperature Set-Point

Celsius or Fahrenheit

If Communication state is activated

If fl ame is detected

Date and Time indicator

If CH pump is operating

E

button. The CH Icon and current

or

If there currently a Demand for Central Heat (CH)

Default CH set-point is 180°F (82°C)

CH set-point range is 86°F ~180°F (30.0°C ~ 82.0°C)

Page 10

Page 10

The FT Series Heating Only, Boiler

Page 59

5.6 Status Display Mode

Status display mode

To change any Status Parameter,

Press and Hold Button B to get into the Status Display Mode.

Rotate Dial E until you fi nd the Parameter that you wish to change. Tap Dial E to enter that Parameter.

Adjust to the setting that you require and then press (tap) Dial E to save and to Exit.

B C

A D

Digital Display

O: ot Outdoor temperature Current outdoor sensor temperature

A: In 0-10 V display Current voltage of (0-10V input)

b: tt CH target temperature in cascade system

C: It CH return water temperature Current CH return water temperature

d: Fr FAN speed ( rpm) Current FAN speed ( RPM)

E: oP

F: Eh Exhaust gas temperature Current exhaust gas temperature

Status Display Parameter

CH supply temperature (Operating temperature)

E

Description

Current CH target temperature or Current

System target temperature in a cascade system

Current heating temperature

Indirect DHW tank temperature

H: dH

I: oH Overheat water temperature Current Overheat water temperature

1: PH

2: rh

L: rt

M:

CC

N: St

3: rH

4: It Cycle for ignition

5: IH

SELF Percentage of self units running. Percentage of self units running.

ALL

F1 – F

19

* If temperature sensor is not connected

then it will display with 0°F (0°C).

Time for supply power

Time for burner

operation

Burner Operation

Time

Capacity for all operating

cascade units

Capacity for individual boilers

System Temperature (cascade

mode) * If system temperature

sensor is not connected then it will

display with 0°F (0°C).

Time for burner

operation

Cycle for ignition

Percentage of all cascade units running.

This screen shows the overal cascade power output. The

range of this value of boilers communicating with theMaster

x 100. For example, if 8 boilers are connected and

communicating, the maximum cascade power is 800%.

Range: 0 -100%

Percentage of each cascade units running.

Ex. F1, F2, ….

Current System Temperature (cascade mode)

Current DHW tank temperature

Unit : 1000hour

Unit : 1hour

L: rt on display

on sub menu

Unit : 1,000hour

Cycle : 10 times the

displayed unit

Cycle : 10,000 times the

displayed unit

Page 11

User’s Manual - The FT, Heating Only, Boiler

Notes:

Page 11

Page 12

Notes:

Dimensions and specications subject to change without notice in accordance with our policy of continuous product improvement.

H2375100D

Customer Service and Product Support: 800.900.9276 • Fax 800.559.1583

20 Industrial Way, Rochester, NH, USA 03867

1706 Document 1343D

Loading...

Loading...