Page 1

DIRECT VENT GAS WATER HEATER

A Spanish language version of these instructions is available by contacting the

company listed on the rating plate.

La version espanola de estas instrucciones se puede obtener al escribirle a la

fabrica cuyo nombre aparece en la placa de especificaciones.

DS140S & DS150S

INSTALLATION & OPERATING

INSTRUCTION MANUAL

WARNING: If the information in these instructions is not

followed exactly, a fire or explosion may result causing

property damage, personal injury or death.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable,

combustible, or corrosive vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbor’s

INTERNET VERSION FOR REFERENCE ONLY

phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire

department.

Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

For your family’s comfort, safety and convenience we

recommend Bradford White water heaters to be installed and

serviced by a plumbing professional.

Page 2

You have just purchased one of the finest water heaters

on the market today!

This installation, operation and instruction manual will

explain in detail the installation and maintenance of your

new Direct Vent Gas Water Heater. We at Bradford White

strongly recommend that you contact a plumbing

professional for the installation of this water heater.

We require that you carefully read this manual, as well as

the enclosed warranty, and refer to it when questions

arise. If you have any specific questions concerning your

warranty, please consult the plumbing professional from

whom your water heater was purchased. For your

records we recommend that you write the model, serial

number and installation date of your water heater in the

maintenance section in the back of this manual.

This manual should be kept with the water heater.

INTERNET VERSION FOR REFERENCE ONLY

At Bradford White we’re committed to providing you with

the finest water heater made.

CONGRATULATIONS!

Page 3

TABLE OF CONTENTS

page

GENERAL INFORMATION........................................................ 4

INSTALLATION

Locating The Water Heater...................................................... 6

Minimum Clearances................................................................. 9

Optional Direct Vent-Air Intake Terminal Guard.................... 9

Venting........................................................................................ 12

Horizontal and Vertical Vent-Air Intake Lengths ................... 14

Vent-Air Intake System Installation.......................................... 17

Water Connections.................................................................... 25

Gas Connections....................................................................... 29

GENERAL OPERATION............................................................ 30

Lighting and Shutdown Instructions....................................... 31

Thermostat Adjustment............................................................. 32

Burner Flame Checks ............................................................... 33

MAINTENANCE........................................................................... 34

PARTS LIST................................................................................. 37

PARTS LIST DRAWINGS

Direct Vent Water Hea ter.......................................................... 38

Vent-Air Intake Kits.................................................................... 39

INTERNET VERSION FOR REFERENCE ONLY

INSTALLATIONS FOR POTABLE WATER AND SPACE

HEATING....................................................................................... 40

Page 4

GENERAL INFORMATION

This gas -fired water heater’s design is certified by CSA International under the

American National Standard Z21.10.1 - (as indicated on the rating plate) and

CSA 4.1-M - (as indicated on the rating plate).

This water heater must be installed in accordance with local codes or, in the

absence of local codes, the National Fuel Gas Code, ANSI Z223.1-Latest

Edition) and/or in Canada CAN/CGA B149 Installation Codes (Latest Editions).

The warranty for this water heater is in effect only when the water heater is

installed, adjusted, and operated in accordance with these Installation and

Operating Instructions. The manufacturer will not be held liable for any damage

resulting from alteration and/or failure to comply with these instruc tions.

This water heater is not design certified for installation in a mobile home. Such

an installation may create a hazardous condition and will nullify the warranty.

This water heater has been designed and certified for the purpose of heating

potable water. The installation and use of this water heater for any purpose

other than the heating of potable water may cause damage to the water heater

and create a hazardous condition and nullify the warranty.

CAUTION

Incorrect operation of this appliance may create a hazard to life

and property and will nullify the warranty.

Do not use this appliance if any part has been submerged in water. You should

contact a qualified service technician to inspect the appliance and to replace

any part of the control system including the combination gas control which has

been submerged in water.

DANGER

Do not store or use ga soline or other flammable, combustible, or

INTERNET VERSION FOR REFERENCE ONLY

corrosive vapors and liquids in the vicinity of this or any other

appliance.

Page 5

General Information continued -

IMPORTANT

Before proceeding, please inspect the water heater and its components for

possible damage. DO NOT install any damaged components. If damage is

evident then please contact the supplier where the water heater was

purchased or the manufacturer listed on the rating plate for replacement

parts.

Make sure that you check the rating plate and combination gas control on the

water heater to be certain that the type of gas being supplied corresponds with

the marking on the rating plate and combination gas control.

A sacrificial anode is used to extend tank life. The removal of this anode, for

any reason, will nullify the warranty. In areas where water is unusually active,

an odor may occur at the hot water faucet due to a reaction between the

sacrificial anode and the impurities in the water. If this should happen, an

alternative anode may be purchased from the supplier that installed this water

heater. This will minimize the odor while protecting the tank. Additionally, the

water heater should be flushed with appropriate dissolvers to eliminate any

bacteria.

INTERNET VERSION FOR REFERENCE ONLY

Page 6

INSTALLATION

LOCATING THE WATER HEATER

WARNING

Water heaters are heat producing appliances. To avoid damage or injury, do

not store materials against the water heater or vent -air intake system. Use

proper care to avoid unnecessary contact (especially by children) with the

water heater and vent -air intake components. UNDER NO CIRCUMSTANCES

MUST FLAMMABLE MATERIALS, SUCH AS GASOLINE OR PAINT

THINNER BE USED OR STORED IN THE VICINITY OF THIS WATER

HEATER, VENT-AIR INTAKE SYSTEM OR IN ANY LOCATION FROM

WHICH FUMES COULD REACH THE WATER HEATER OR VENT-AIR

INTAKE SYSTEM.

DO NOT install the water heater in any location where gasoline or

flammable vapors are likely to be present.

Water Heaters in residential garages shall be installed so that all

burner(s) and burner ignition device(s) are located not less than 18

inches (46 cm) above the floor and shall be located, or protected, to

avoid physical damage. For other installations refer to local codes. In

the absence of local codes, the water heater shall be installed in

compliance with the National Fuel Gas Code, ANSI Z223.1 - (Latest

Edition) and/or in Canada, CAN/CGA B149 Installation Codes (Latest

Editions).

The location of this water heater is of the utmost importance. Before installing

this water heater, read the installation section of these instructions. After

reading these installation and operating instructions, select a location for the

water heater where the floor is level and is easily accessible to gas and water

supply lines. DO NOT locate the water heater where water lines could

be subjected to freezing temperatures. Make sure the cold water pipes

are not located directly above the gas control so that condensate

during humid weather does not drip on the controls.

INTERNET VERSION FOR REFERENCE ONLY

Page 7

Installation (Locating The Water Heater) co ntinued-

Water heater corrosion and component failure can be caused by the heating

and breakdown of airborne chemical vapors. Examples of some typical

compounds that are potentially corrosive are: spray can propellants, cleaning

solvents, refrigerator and air conditioning refrigerants, swimming pool

chemicals, calcium and sodium chloride, waxes and process chemicals.

These materials are corrosive at very low concentration levels with little or no

odor to reveal their presence. NOTE: DAMAGE TO THE WATER HEATER

CAUSED BY EXPOSURE TO CORROSIVE VAPORS IS NOT COVERED BY

THE WARRANTY. DO NOT OPERATE THE WATER HEATER IF

EXPOSURE HAS OR WILL OCCUR. DO NOT STORE ANY POTENTIALLY

CORROSIVE COMPOUNDS IN THE VICINITY OF THE WATER HEATER.

WARNING

Liquefied petroleum gases/propane gas are heavier than air

and will remain at floor level if there is a leak. Basements,

crawl spaces, closets and areas below ground level will

serve as pockets for accumulation of leaking gas. Before

lighting, smell all around the appliance area for gas. Be sure

to smell next to the floor.

IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any

telephone in your building.

• Immediately call your gas supplier from a neighbor’s

telephone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

DO NOT OPERATE APPLIANCE UNTIL THE LEAKAGE IS

CORRECTED!

INTERNET VERSION FOR REFERENCE ONLY

Page 8

Installation (Locating The Water Heater) continued -

WARNING

DO NOT ATTEMPT TO LIGHT ANY GAS APPLIANCE IF YOU ARE

NOT CERTAIN OF THE FOLLOWING:

• Liquefied petroleum gases/propane gas and natural gas have

an odorant added by the gas supplier that aids in the detection

of the gas.

• Most people recognize this odor as a “sulfur” or “rotten egg”

smell.

• Other conditions, such as “odorant fade” can cause the odorant

to diminish in intensity, or ”fade”, and not be as readily

detectable.

• If you have a diminished sense of smell, or are in any way unsure

of the presence of gas, immediately contact your gas supplier

from a neighbor’s telephone.

• Gas detectors are available. Contact your gas supplier, or

plumbing professional, for more information.

The water heater must be located close enough to the outside wall to keep the

venting distance within the maximum distance described in the installation

instructions. Note: The direct vent -air intake terminal must be installed on a

vertical wall. Read the venting section in this installation instruction manual

before locating the water heater.

This water heater must be located in an area where leakage of the tank or

water line connections and the combination temperature and pressure relief

valve will not result in damage to the area adjacent to the water heater or to

lower floors of the structure. When such locations cannot be avoided, a

suitable drain pan, adequately drained, be installed under the water heater.

The pan must not restrict combustion airflow. The drain pan must be no

greater than 1-½ inches (3.8 cm) deep and have a minimum length and width

of at least four (4) inches (10.2 cm) measured from the jacket of the water

INTERNET VERSION FOR REFERENCE ONLY

heater. The drain pan, as described above, can be purchased from your

plumbing professional. The drain pan must be piped to an adequate drain.

The piping must be at least 3/4 inch (1.9 cm) in diameter and pitched for

proper drainage.

It is recommended that a minimum clearance of four (4) inches (10.2 cm) be

provided on the side of the water heater for servicing and maintenance of the

combination temperature and pressure relief valve.

Page 9

Installation continued -

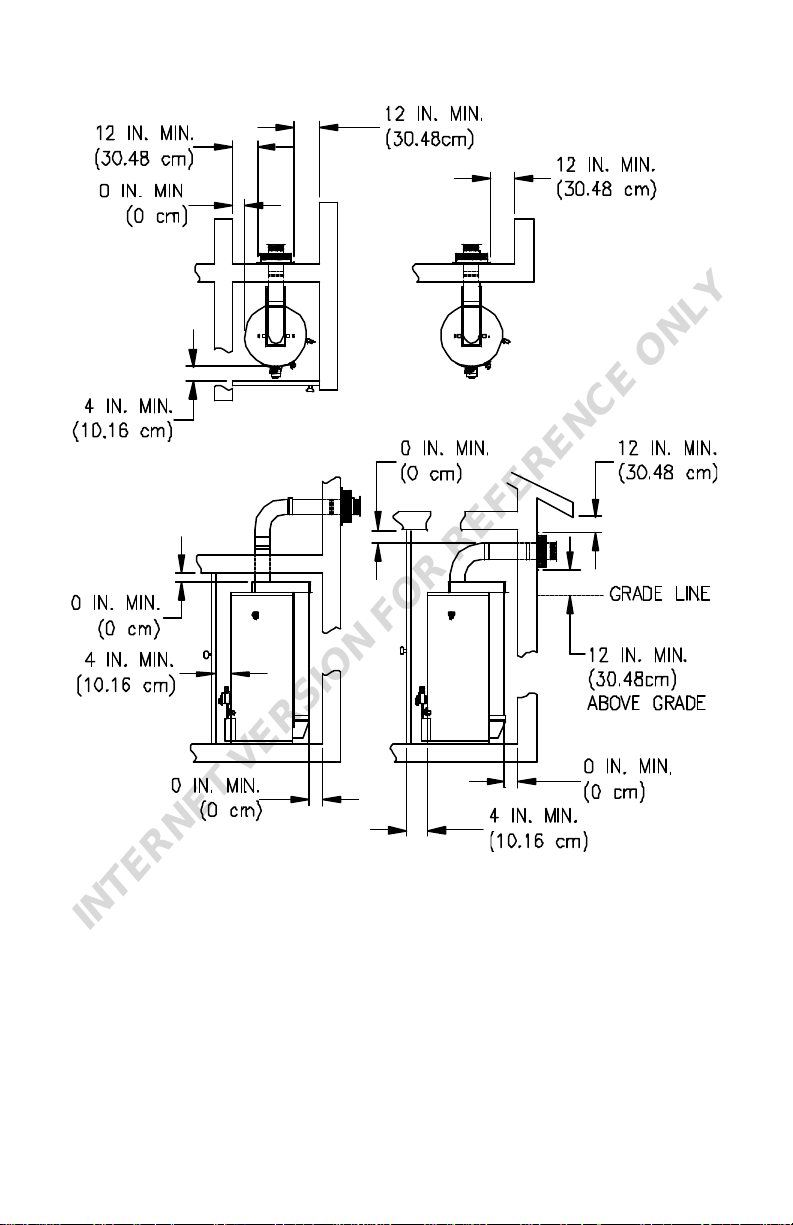

MINIMUM CLEARANCES

WARNING

Failure to adhere to these installation and operating instructions

may create a hazard to life and property and will nullify the

warranty.

This installation shall allow access to the front of the water heater and

adequate clearance shall be provided for servicing and operating this

water heater. The water heater may be installed on either a combustible or

non-combustible floor. If the water heater is to be installed directly on

carpeting, it shall be installed on top of a metal or wood panel extending

beyond the full width and depth of the appliance by at least three (3) inches

(7.6 cm) in any direction or, if the appliance is to be installed in an alcove or

closet, the entire floor shall be covered by the panel. The minimum clearances

to combustibles for this water heater is: zero (0) inch (0 cm) from the sides

and rear, four (4) inches (10.2 cm) from the front of the jacket, zero (0) inch (0

cm) from the plenum, zero (0) inch (0 cm) from the air intake elbow and

telescopic tubes and twelve (12) inches (30.5 cm) from the direct vent -air

intake terminal. (See Figure 1).

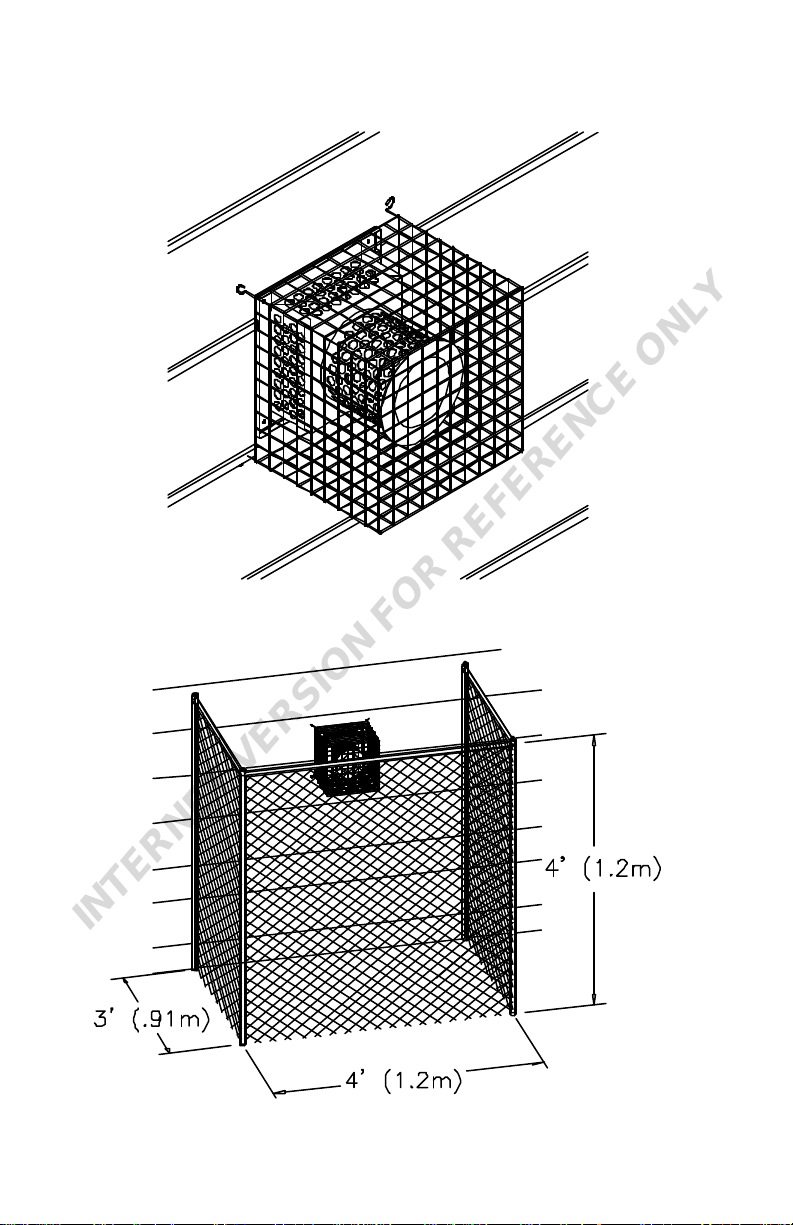

OPTIONAL DIRECT VENT-AIR INTAKE TERMINAL GUARD

WARNING

The direct vent-air intake terminal is HOT while the water heater is

in operation. Do not touch. Keep children, combustibles, gasoline

and other liquids having flammable vapors away.

It is recommended that a vent -air intake terminal guard be installed when the

vent-air intake terminal is located where it can be touched accidentally, or

accessed by children. (See Figure 2).

INTERNET VERSION FOR REFERENCE ONLY

A chain link or louvered fence may be used instead of the vent -air intake

terminal guard. Maintain proper clearances as specified in this instruction

manual to the vent -air intake terminal. (See Figure 3).

Page 10

Installation (Minimum Clearances) continued -

Figure 1

INTERNET VERSION FOR REFERENCE ONLY

Page 11

Installation continued -

Figure 2

INTERNET VERSION FOR REFERENCE ONLY

Figure 3

Page 12

Installation continued -

VENTING

This is a Direct Vent Gas Water Heater where all air for combustion is

obtained from the outside atmosphere and all flue gases are discharged to the

outside atmosphere.

WARNING

The vent-air intake system must be properly installed. Failure to

properly install the vent-air intake system properly could result in

property damage, personal injury or death.

DO NOT install any damaged vent-air intake system components.

Contact the manufacturer of the water heater for replacement parts.

Direct Vent-Air Intake Terminal (See Figure 4)

• Shall be installed with at least a 9 in. (22.9 cm) vent termination

clearance from any air opening into a building.

• The bottom of the direct vent -air intake terminal shall be located at

least 12 in. (30.5 cm) above grade.

• Installed at least 3 ft. (91.4 m) from any gas meter, gas valve or

other gas regulating equipment.

• Must be installed in a location where it will not be blocked by snow.

Note: Provide protection of the building materials from degradation by flue

gases from the direct vent -air intake terminal.

Exceptions for Installations in Canada

The direct vent -air intake terminal shall not terminate:

(a) directly above a paved sidewalk or paved driveway which is located

between two single-family dwellings and serves both dwellings;

(b) less than 7 ft. (2.1 m) above a paved sidewalk or a paved driveway

located on public property;

INTERNET VERSION FOR REFERENCE ONLY

(c) within 6 ft. (1.8 m) of a mechanical air supply inlet to any building;

(d) above a gas meter/ regulator assembly within 3 ft. (91.4 cm) horizontally

of the vertical centerline of the regulator;

(e) within 6 ft. (1.8 m) of any gas service regulator vent outlet;

(f) less than 12 in. (30.5 cm) above grade level;

(g) within 12 in. (30.5 cm) of a window or door which can be opened in any

building, any non-mechanical air supply inlet to any building or the

combustion air inlet of any other appliance:

Page 13

Installation (Venting) continued -

(h) underneath a verandah, porch or deck, unless:

(i) the verandah, porch or deck is fully open on a minimum of two

sides beneath the floor, and

(ii) the distance between the top of the vent-air intake termination and

the underside of the verandah, porch or deck is greater than 12 in.

(30.5 cm).

Figure 4

INTERNET VERSION FOR REFERENCE ONLY

Page 14

Installation (Venting) continued -

The co-axial vent -air intake tubes of this water heater can be installed in any

360° configuration as long as the proper clearances for installation, plumbing,

operation and servicing are maintained. (See Figure 5).

Figure 5

Note: Maintain proper clearances for installation, plumbing, operation

and service.

INTERNET VERSION FOR REFERENCE ONLY

HORIZONTAL AND VERTICAL VENT-AIR INTAKE LENGTHS

This Direct Vent Gas Water Heater comes with one (1) vent -air intake “Kit C”.

Optional vent -air intake kits are available that can extend the horizontal length

and/or vertical height of the vent -air intake system. Table A lists the various

vertical and horizontal vent -air intake system configurations.

Page 15

Installation (Horizontal and Vertical Vent-Air Intake Lengths) continued -

13 1/4

15

22 1/4

36

58 5/16

order

order

add'l

order

order

14 3/4

*order

order

order

order

order

16 1/2

order

*order

order

order

order

23 3/4

order

order

order

*order

order

37 1/2

order

order

*order

*order

order

59 13/16

order

order

order

order

*order

The water heater is shipped with the following standard vent and air intake

system: 239-41097-00. The components of this vent and air intake systems is

as follows:

3” Vent Tube* Vent Terminal Hardware

5” Air Intake Tube* RTV Silicone Sealant

Vent Terminal 3” Vent Elbow

Inner Wall Term. Mounting Flange 5” Vent Elbow

Outer Wall Term. Mounting Flange

*The vent and air intake telescopes from 13 3/4" to 23 11/16”.

Table A

Horizontal "X"

Vertical "Y"

10

15 11/16

19 3/16

33 11/16

57 3/8

105 13/16

14 3/16

kit A

kit A (2)

kit A & B

kit A

kit A & C

kit D & A

17 11/16

kit B

kit A & B

kit B (2)

kit B

kit C & B

kit D & B

32 3/16

no

kit req'd

kit A

kit B

kit C

kit C (2)

kit D

55 7/8

kit C

kit A & C

kit B & C

kit C (2)

kit C (3)

kit D & C

104 5/16

kit D

kit A & D

kit B & D

kit D

kit C & D

kit D (2)

* (2) = Order two of the kits referenced.

INTERNET VERSION FOR REFERENCE ONLY

* (3) = Order three of the kits referenced.

The bold text above show what kit(s) are needed in addition to the standard

vent and air intake tubes. If the standard vent and air intake tubes are not

used in the venting system (those that do not have bold text) they can be

discarded or saved.

Page 16

Installation (Horizontal and Vertical Vent-Air Intake Lengths) continued -

Figure 6

INTERNET VERSION FOR REFERENCE ONLY

Page 17

Installation continued -

VENT-AIR INTAKE SYSTEM INSTALLATION

WARNING

The vent-air intake system must be properly installed. Failure to

properly install the vent-air intake system could result in property

damage, personal injury or death.

Do not install any damaged vent-air intake system components.

Contact the manufacturer of the water heater for replacement parts.

IMPORTANT

When the following instructions specify, to seal a vent-air intake joint,

use only Loctite Ultra Blue 587 RTV Silicone sealant. A tube of Loctite

Ultra Blue 587 RTV Silicone sealant is supplied with every direct vent

water heater and each optional vent-air intake kit. Make sure that all

joints are completely sealed.

When drilling pilot holes for the #8 sheet metal screws through the

five (5) inch (12.7 cm) diameter components, be careful not to drill into

the inner three (3) inch (7.6 cm) diameter components.

Tools Required For Vent-Air Intake Installation

The following minimum tools are required to properly install the ventair intake system. Note: Wall construction will determine tool usage.

Tape Measure

Drill

3/16 inch Diameter Drill Bit(s)

1/8 inch Diameter Drill Bit(s)

Masonry Drill Bit(s) (For Poured Concrete, Concrete Block and Brick Wall

Construction)

Reciprocating Saw w/appropriate Blade(s) (Dependent on Wall

INTERNET VERSION FOR REFERENCE ONLY

Construction)

Chisel (For Poured Concrete, Concrete Block and Brick Wall Construction)

Hammer (For Poured Concrete, Concrete Block and Brick Wall

Construction)

1/4 & 5/16 inch Nut Drivers (Preferred) or Slotted Head Screwdriver

Phillips Head Screwdriver

Page 18

Installation (Vent-Air Intake System Installation) continued-

Figure 7

1. Measure the vertical height “Y” required in your installation. (See Figure

6). Reference the appropriate Table A to determine number of vent -air

intake kits required in your installation.

2. Measure the horizontal length “X” required in your installation (See Figure

6). Reference Table A to determine number of vent -air intake kits required

in your installation.

3. Cut a 5-1/2 inch (14 cm) diameter minimum clearance hole in the wall at

the point where the vent -air intake tubes will pass through the outside wall

and connect with the direct vent -air intake terminal

(See Figure 6).

4. From outside the building, position the outer wall mount plate and direct

vent-air intake terminal over the center of the opening. Mark the mounting

screw hole locations. With a 3/16 inch diameter drill bit (not supplied), drill

holes for the wall anchors (supplied). Install the wall anchors but DO NOT

affix the outer wall mount plate and direct vent -air intake terminal to the

wall at this time (See Figure 7). Note: Certain construction of walls may

require the use of a different type of wall anchoring means than supplied.

DO NOT modify the direct vent -air intake terminal or outer wall mount

plate.

INTERNET VERSION FOR REFERENCE ONLY

Page 19

Installation (Vent-Air Intake System Installation) continued -

IMPORTANT

The following instructions detail the installation of the standard

horizontal vent-air intake kit supplied with the water heater.

5. Insert the straight end of the three (3) inch (7.6 cm) diameter elbow into

the flue reducer until firmly seated and oriented in the correct direction.

With a 1/8 inch diameter drill bit (not supplied), drill three (3) holes, 120o

apart, through the flue reducer into the three (3) inch (7.6 cm) diameter

elbow. Fasten with three (3) #8 sheet metal screws (supplied). Using the

supplied special RTV silicone sealant, apply a sufficient amount to seal

the joint (See Figure 8).

INTERNET VERSION FOR REFERENCE ONLY

6. Place the straight end of the five (5) inch (12.7 cm) diameter elbow over the

three (3) inch (7.6 cm) diameter elbow and plenum collar until seated on

top of the plenum box. Make certain that the five (5) inch (12.7 cm)

diameter elbow is oriented in the same direction as the three (3) inch (7.6

cm) diameter elbow and both are oriented in the correct direction. Drill

three (3) 1/8 inch diameter holes, 120o apart, through the five (5) inch (12.7

cm) diameter elbow into the plenum collar. Fasten with three (3) #8 sheet

metal screws (supplied) (See Figure 9).

Figure 8

Page 20

Installation (Vent-Air Intake System Installation) continued -

Figure 9

7. Extend the three (3) inch (7.6 cm) diameter telescopic tube to its

maximum length and slide the backing plate over it. Place the large end of

the three (3) inch (7.6 cm) diameter telescopic tube through the hole in the

outside wall. Insert the smaller end of the three (3) inch diameter (7.6 cm)

telescopic tube into the flared end of the three (3) inch (7.6 cm) diameter

elbow, one (1) inch (2.5 cm) (or until seated). Drill three (3) 1/8 inch

diameter holes, 120o apart, through the three (3) inch (7.6 cm) diameter

elbow into the three (3) inch (7.6 cm) diameter telescopic tube. Fasten

with three (3) #8 sheet metal screws (supplied). Adjust the overall length

of the three (3) inch (7.6 cm) diameter telescopic tube so that 2-1/2 inches

INTERNET VERSION FOR REFERENCE ONLY

(6.4 cm) extends beyond the outside wall. Drill three (3) 1/8 inch diameter

holes, 120o apart, through the three (3) inch (7.6 cm) diameter telescopic

tubes where the small and large sections overlap. Fasten with three (3) #8

sheet metal screws (supplied). Using the supplied special RTV silicone

sealant, apply a sufficient amount to seal the joints (See Figure 10).

Page 21

Installation (Vent-Air Intake System Installation) continued -

Figure 10

8. Extend the five (5) inch (12.7 cm) diameter telescopic tube to its maximum

length. Place the large end of the five (5) inch (12.7 cm) diameter

telescopic tube over the collar on the outer wall mount plate. Drill three (3)

1/8 inch diameter holes, 120o apart, through the five (5) inch (12.7 cm)

diameter telescopic tube into the collar on the outer wall mount plate.

Fasten with three (3) #8 sheet metal screws (supplied). Using the

supplied special RTV silicone sealant, apply a sufficient amount to seal

the joint (See Figure 11).

INTERNET VERSION FOR REFERENCE ONLY

Figure 11

Page 22

Installation (Vent-Air Intake System Installation) continued -

9. From outside the building, slide the five (5) inch (12.7 cm) diameter

telescopic tube through the opening in the wall until the outer wall mount

plate is flush with the wall (See Figure 12).

Figure 12

10. Using the supplied special RTV silicone sealant, apply a bead one (1)

inch (2.5 cm) from the end of the three (3) inch (7.6 cm) diameter tube

that is part of the vent -air intake terminal. Slide the direct vent-air intake

terminal into the three (3) inch (7.6 cm) diameter telescopic tube that

INTERNET VERSION FOR REFERENCE ONLY

extends through the wall and position it so it is flush with the outer wall

mount plate. Make sure that the rain guard and the word “HOT” on the

end of the direct vent -air intake terminal are oriented properly. Secure the

direct vent -air intake terminal to the outer wall mount plate and wall with

four (4) #10 x 1 inch screws (supplied) (See Figure 13). Note: Certain

construction of walls may require the use of different type of anchoring

means than supplied. DO NOT modify the direct vent -air intake terminal

or outer wall mount plate.

Page 23

Installation (Vent-Air Intake System Installation) continued -

Figure 13

11. From inside the building, slide the backing plate over the five (5) inch

(12.7 cm) diameter telescopic tube until it is flush with the wall. Adjust

the length of the five (5) inch (12.7 cm) diameter telescopic tube and

insert the end into the flared end of the five (5) inch (12.7 cm) diameter

elbow one (1) inch (2.5 cm) (or until seated). Drill three (3) 1/8 inch

diameter holes, 120o apart, through the five (5) inch (12.7 cm) diameter

elbow into the five (5) inch (12.7 cm) diameter telescopic tube and

through the tubes where the small and large sections overlap. Fasten

with three (3) #8 sheet metal screws (supplied). Using the supplied

special RTV silicone sealant, apply a sufficient amount to seal all joints

(See Figure 14).

INTERNET VERSION FOR REFERENCE ONLY

Figure 14

Page 24

Installation (Vent-Air Intake System Installation) continued -

12. Mark the mounting screw hole locations for the backing plate. Rotate the

backing plate in order to gain access to the markings. With a 3/16 inch

diameter drill bit (not supplied), drill holes for the supplied wall anchors.

Install the wall anchors and secure the backing plate to the wall with

four (4) #10 x 1 inch screws (supplied) (See Figure 15). Note: Certain

construction of walls may require the use of a different type of anchoring

means than supplied.

Figure 15

IMPORTANT

INTERNET VERSION FOR REFERENCE ONLY

When the installation is complete, visually inspect the air intake

system to insure that all joints are completely sealed.

Page 25

Installation continued -

WATER CONNECTIONS

Note: BEFORE PROCEEDING WITH THE INSTALLATION, CLOSE THE

MAIN WATER SUPPLY VALVE.

After shutting off the main water supply, open a faucet to relieve the water line

pressure to prevent any water from leaking out of the pipes while making the

water connections to the water heater. After the pressure has been relieved,

close the faucet. Th e COLD water inlet and HOT water outlet are identified on

the top of the water heater. The fittings at the cold water inlet and hot water

outlet are dielectric waterway fittings with 3/4” NPT male thread. Make the

proper plumbing connections between the water heater and the plumbing

system to the house. Install a shut -off valve in the cold water supply line.

CAUTION

If sweat fittings are to be used, DO NOT apply heat to the nipples on top of

the water heater. Sweat the tubing to the adapter before fitting the adapter

to the water connections. It is imperative that heat is not applied to the

nipples containing a plastic liner.

INTERNET VERSION FOR REFERENCE ONLY

Page 26

WARNING

For protection against excessive temperatures and pressure, install

temperature and pressure protective equipment required by local codes,

but not less than a combination temperature and pressure relief valve

certified by a nationally recognized testing laboratory that maintains

periodic inspec tion of production of listed equipment or materials as

meeting the requirements of the Standard for Relief Valves and Automatic

Gas Shutoff Devices for Hot Water Supply Systems, ANSI Z21.22 and the

Standard CAN1-4.4 Temperature, Pressure, Temperature and Pressure

Relief Valves and Vacuum Relief Valves . The combination temperature

and pressure relief valve shall be marked with a maximum set pressure not

to exceed the maximum working pressure of the water heater. The hourly

BTU discharge capacity or the rat ed steam relief capacity of the

combination temperature and pressure relief valve shall not be less than

the input rating of the water heater.

Install the combination temperature and pressure relief valve into the

opening provided and marked for this purpose on the water heater.

Note: Some models may already be equipped or supplied with a

combination temperature and pressure relief valve. Verify that the

combination temperature and pressure relief valve complies with local

codes. If the combination temperature and pressure relief valve does not

comply with local codes, replace it with one that does. Follow the

installation instructions above on this page.

Install a discharge line which terminates six (6) inches (15 cm) above the

floor, or any distance below the structural floor, to the outlet of the

combination temperature and pressure relief valve. DO NOT allow water

from the discharge line to contact any live electrical part. The discharge

line is to be installed to allow for complete drainage of bot h the

combination temperature and pressure relief valve and the discharge line.

The water from the discharge line must be directed to a suitable drain or

area that will not be damaged by water (Refer to page 6 “LOCATING THE

WATER HEATER.” The discharge opening must not be subjected to

blockage or freezing. DO NOT thread, plug or cap the discharge line.

It is recommended that a minimum clearance of four (4) inches (10.2 cm)

INTERNET VERSION FOR REFERENCE ONLY

be provided on the side of the water heater for servicing and maintenance

of the combination temperature and pressure relief valve.

Do not place a shutoff valve between the combination temperature and

pressure relief valve and the water heater, or on discharge pipes between

such valves or the atmosphere.

Page 27

Installation (Water Connections) continued -

WARNING

FAILURE TO INSTALL AND MAINTAIN A NEW, LISTED 3/4” X 3/4”

TEMPERATURE AND PRESSURE RELIEF VALVE WILL RELEASE THE

MANUFACTURER FROM ANY CLAIM WHICH MIGHT RESULT FROM

EXCESSIVE TEMPERATURES AND PRESSURES.

If this water heater is installed in a closed water supply system, such as the

one having a back-flow preventer in the cold water supply, provisions shall be

made to control thermal expansion. DO NOT operate

this water heater in a closed system without provisions for controlling thermal

expansion. Your water supplier or local plumbing inspector should be

contacted on how to control this situation

After installation of the water lines, open the main water supply valve and fill

the water heater. While the water heater is filling, open several hot water

faucets to allow air to escape from the water system. When a steady stream

of water flows through the faucets, close them and check all water connections

for possible leaks. NEVER OPERATE THE WATER HEATER WITHOUT

FIRST BEING CERTAIN IT IS FILLED WITH WATER.

WARNING

Hydrogen gas can be produced in an operating water heater that

has not had water drawn from the tank for a long period of time

(generally two weeks or more). Hydrogen gas is extremely

flammable. To prevent the possibility of injury under these

conditions, we recommend the hot water faucet to be open for

several minutes at the kitchen sink before you use any electrical

appliance which is connected to the hot water system. If hydrogen

is present, there will be an unusual sound such as air escaping

through the pipes as hot water begins to flow. Do not smoke or

have open flame near the faucet at the time it is open.

INTERNET VERSION FOR REFERENCE ONLY

This water heater can deliver scalding temperature water at any faucet in the

system. Be careful whenever using hot water to avoid scalding injury. Certain

appliances such as dishwashers and automatic clothing washers may require

increased temperature water. By setting the thermostat on this water heater

to obtain the increased temperature water required by these appliances, you

may create the potential for scald injury. To protect against injury, you should

install an ASSE approved mixing valve in the water system. This valve will

reduce point of discharge temperature by mixing cold

Page 28

Installation (Water Connections) continued -

and hot water in branch supply lines. Such valves are available from the

manufacturer of this water heater or a local plumbing supplier. Please consult

with a plumbing professional.

INTERNET VERSION FOR REFERENCE ONLY

Page 29

GAS CONNECTIONS

The gas supply lines must meet all requirements of the National Fuel Gas

Code, ANSI Z223.1 - (Latest Edition) and/or in Canada, CAN/CGA B149

Installation Codes - (Latest Editions).

The minimum permissible gas supply pressure for the purpose of input

adjustment is one (1.0) inch (.25kPa) water column above the operating

manifold pressure. See the rating plate and combination gas control for the

manifold pressure and gas type. The maximum permissible gas supply

pressure is fourteen (14.0) inches (3.5kPa) water column for natural gas and

liquefied petroleum gases/propane gas.

1. Connect this water heater only to the type of gas (natural or propane

gas) as shown on the rating plate. Use clean 1/2 inch black iron

pipe. (Dirt and scale from the pipe can enter the combination control and

cause it to malfunction). The inlet gas line must have a drip leg (sediment

trap) installed as close as possible to the water heater’s combination gas

control having a minimum length of three (3) inches (7.6 cm). A ground

joint union must be installed in the gas supply line feeding the water heater

to permit servicing of the water heater. Compounds used on the threaded

joints of the gas piping must be resistant to the action of liquefied

petroleum gases/propane gas.

2. This water heater and its gas connection must be leak tested before

placing the water heater in operation. Check for gas leaks with a

soap and water solution and a brush or a commercial leak detector

fluid. NEVER USE A MATCH OR OPEN FLAME FOR TESTING!

CAUTION

The water heater and its individual shutoff valve must be disconnected from

the gas supply piping system during any pressure testing of the system at

test pressures in excess of 1/2 psi (3.5 kPa). The water heater must be

isolated from the gas supply piping system by closing its manual shutoff

valve during any pressure testing of the gas supply system at test

pressures equal to or less than 1/2 psi (3.5 kPa). The supply line must be

INTERNET VERSION FOR REFERENCE ONLY

capped when not connected to the water heater.

Page 30

GENERAL OPERATION

WARNING

Water heaters are heat producing appliances. To avoid damage or injury,

do not store materials against the water heater or vent -air intake system.

Use proper care to avoid unnecessary contact (especially by children) with

the water heater and vent -air intake system. UNDER NO

CIRCUMSTANCES MUST FLAMMABLE MATERIALS, SUCH AS

GASOLINE OR PAINT THINNER BE USED OR STORED IN THE

VICINITY OF THIS WATER HEATER, VENT-AIR INTAKE SYSTEM OR

IN ANY LOCATION FROM WHICH FUMES COULD REACH THE WATER

HEATER OR VENT-AIR INTAKE SYSTEM.

TO FILL THE WATER HEATER

1. Close the water heater drain valve by turning the knob clockwise.

2. Open the cold water supply shut -off valve.

3. Open several hot water faucets to allow air to escape from the system.

4. When a steady stream of water flows from the faucets, the water heater is

filled. Close the faucets and check for water leaks at the water heater

drain valve, combination temperature and pressure relief valve and the hot

and cold water connections.

TO DRAIN THE WATER HEATER

Should it become necessary to completely drain the water heater, make sure

you follow the steps below:

1. Rotate the thermostat dial clockwise to the “PILOT LIGHTING” position.

2. Rotate and partially depress gas control knob clockwise to the “OFF”

position.

3. Shut off the gas supply to the water heater.

4. Close the cold water supply shut -off valve.

5. Open the drain valve on the water heater by turning the knob counter-

clockwise. The drain valve has threads on the end that will allow the

connection of a standard hose coupling.

6. Open a hot water faucet to allow air to enter the system.

INTERNET VERSION FOR REFERENCE ONLY

To refill the water heater, refer to “To Fill the Water Heater.”

Page 31

INTERNET VERSION FOR REFERENCE ONLY

Page 32

General Operation continued -

THERMOSTAT ADJUSTMENT

The thermostat dial is set to its lowest temperature setting when shipped from

the factory. Remember that lower temperature settings are more energy

efficient. Adjust the temperature by turning the thermostat dial. It is

suggested that the starting point setting not be greater than the “ ” mark on

the thermostat dial (approximately 120°F [49°C]) as indicated below. Rotate

the thermostat dial clockwise

Rotate the thermostat dial counterclockwise

temperature setting. Adjust the dial until the minimum acceptable temperature

is achieved (See figure below for approximate temperature settings).

to increase the temperature setting.

to decrease the

Figure 16

Hotter water increases the risk of scald injury. Scalding may occur within

five (5) seconds at a temperature setting of 135° F (57° C). To protect

against hot water injury, install an ASSE approved mixing valve in the

water system. This valve will reduce point of discharge temperature by

mixing cold and hot water in branch water lines. A licensed plumbing

professional or local plumbing authority should be consulted.

Note: This water heater is equipped with an energy cut out device to

prevent overheating. Should overheating occur or the gas supply fail to

INTERNET VERSION FOR REFERENCE ONLY

shut off, turn off the manual gas control valve to the appliance and call a

qualified service technician.

Note: Whenever the water heater is filled with cold water, condensate will

form on the cool tank surface and drops of water will fall on the hot burner

and combustion chamber surfaces producing a “sizzling” noise.

Condensation is normal and does not indicate a leak. It will disappear

when the tank becomes heated.

DANGER

Page 33

General Operation continued -

BURNER FLAME CHECKS

At the time of installation and at periodic intervals (not more than six (6)

months), a visual check of the pilot and main burner flames should be

conducted. The flames should be similar to those pictured below. The main

burner should light smoothly from the pilot. (See Figure 17).

INTERNET VERSION FOR REFERENCE ONLY

Figure 17

Page 34

MAINTENANCE

WARNING

Water heaters are heat producing appliances. To avoid damage or injury,

do not store materials against the water heater or vent -air intake system.

Use proper care to avoid unnecessary contact (especially by children) with

the wat er heater and vent-air intake system. UNDER NO

CIRCUMSTANCES MUST FLAMMABLE MATERIALS, SUCH AS

GASOLINE OR PAINT THINNER BE USED OR STORED IN THE

VICINITY OF THIS WATER HEATER, VENT-AIR INTAKE SYSTEM OR

IN ANY LOCATION FROM WHICH FUMES COULD REACH THE WATER

HEATER OR VENT-AIR INTAKE SYSTEM.

IMPORTANT

The water heater should be inspected at a minimum annually by a

qualified service technician for damaged components and/or joints

not sealed. DO NOT operate this water heater if any part is found

damaged or if any joint is found not sealed.

The following maintenance should be performed by a qualified service

technician at the minimum periodic intervals suggested below. In some

installations the maintenance interval may be more frequent depending on

upon the amount of use and the operating conditions of the water heater.

Regular inspection and maintenance of the water heater and vent -air intake

system will help to insure safe and reliable operation.

1. Annually check the operation of the thermostat.

2. The flow of combustion and ventilation air MUST NOT be restricted.

Annually inspect the direct vent -air intake terminal to insure it is not

blocked or damaged. Clear the direct vent -air intake terminal openings of

any dirt, dust, or other restrictions. WARNING! Certain areas of the

direct vent -air intake terminal are HOT.

INTERNET VERSION FOR REFERENCE ONLY

3. Annually inspect the vent -air intake system to insure that all components

are securely fastened and all joints and seams are properly sealed.

4. At all times keep the water heater area clear and free from combustible

materials, gasoline and other flammable vapors and liquids.

5. Bi-annually conduct a visual check of the main and pilot burner flames to

determine that they are burning properly. See information on page 33

“BURNER FLA ME CHECKS.”

Page 35

Maintenance continued -

6. Annually remove the inner door and main burner assembly to clean orifices

and related parts of any dirt or other foreign material. Inspect the burner

ports for obstructions or debris and clean with a wire brush as needed.

Wire brush and/or vacuum clean the combustion chamber as needed to

remove scale deposits and debris. Inspect the inner door gasket for wear

and tear and replace if necessary. NOTE: It is imperative for proper

operation of the water heater that the inner door be properly sealed.

7. At least once a year, check the combination temperature and pressure

relief valve to insure that the valve has not become encrusted with lime.

Lift the lever at the lever at the top of the valve several times until the valve

seats properly without leaking and operates freely.

WARNING

When lifting lever of the combination temperature and pressure

relief valve, hot water will be released under pressure. Be careful

that any released water doe s not result in bodily injury or property

damage.

8. Monthly, drain off a gallon of water to remove silt and sediment by using

the water heater’s drain valve.

WARNING! THIS WATER MAY BE HOT.

9. If the combination temperature and pressure relief valve on the appliance

discharges periodically, this may be due to thermal expansion in a closed

water supply system. Contact the water supplier or local plumbing

inspector on how to correct this situation. Do not plug the combination

temperature and pressure relief valve outlet.

10. A combination sacrificial anode rod/hot water outlet nipple has been

installed to extend tank life. The anode rod should be inspected

periodically (every two years) and replaced when necessary to prolong

tank life. Contact the plumbing professional who installed the water heater

INTERNET VERSION FOR REFERENCE ONLY

or the manufacturer listed on the rating plate for anode replacement

information. The use of a water softener may increase the speed of anode

consumption. More frequent inspection of the anode is needed when

using softened (or phosphate treated) water.

Maintenance (continued)-

Page 36

CAUTION

FOR YOUR SAFETY. DO NOT ATTEMPT REPAIR OF COMBINATION

GAS CONTROL, BURNERS OR GAS PIPING. REFER REPAIRS TO A

QUALIFIED SERVICE TECHNICIAN.

Contact your supplier or plumbing professional for replacement parts or contact

the company at the address given on the rating plate of the water heater.

Provide the part name, model and serial numbers of the water heater when

ordering parts.

READ THE WARRANTY FOR A FULL EXPLANATION OF THE LENGTH OF

TIME THAT PARTS AND THE WATER HEATER ARE WARRANTED.

Manufactured under one or more of the following U.S. Patents:

4,416,222; 4,628,184; 4,669,448; 4,672,919; 4,808,356; 4,829,983;

4,861,968; 4,867,106; 4,904,428; 5,000,893; 5,023,031; 5,052,346;

5,081,696; 5,092,519; 5,115,767; 5,199,385; 5,277,171; 5,341,770;

5,372,185; 5,485,879; 5,574,822; 5,596,952; 5,660,165; 5,682,666;

5,943,984. Other U.S. and Foreign patent applications pending. Current

Canadian Patents: 1,272,914; 1,280,043; 1,289,832; 2,045,862;

2,107,012; 2,108,186; 2,112,515.

Complete the following information and retain for future reference:

Model No:

Serial No :

Installation Date:

Service Phone No.

Days: Nights:

INTERNET VERSION FOR REFERENCE ONLY

Address:

Supplier:

Supplier’s Phone No:

PART NAME & DESCRIPTION

Page 37

1. Direct Vent-Air Intake Terminal 21. Piezo Ignitor Assembly

2. Outer Wall Mount Plate 22. Drain Valve

3. Backing Plate 23. Outer Door

4. Five (5) inch (12.7 cm)

Diameter Telescopic Air Intake

Tube

5. Three (3) inch (7.6 cm)

Diameter Telescopic Vent

Tube

6. Five (5) inch (12.7 cm)

Diameter Elbow

7. Three (3) inch (7.6 cm)

Diameter Elbow

8. Plenum 28. Pilot Assembly w/Electrode

9. Plenum Gasket 29. Gas Feed Line (Burner)

10. Flue Reducer 30. Main Burner Orifice

11. Jacket Top 31A. 42 Port Steel Burner

12. Insulation 31B. 65 Port Cast Iron Burner

13. Glass Lined Tank 32. Radiation Shield

14. Flue Baffle Assembly 33A. Direct Vent -Air Intake Kit A

15. Dip Tube & Nipple 33B. Direct Vent -Air Intake Kit B

16. Anode Rod & Nipple 33C. Direct Vent -Air Intake Kit C

17. Temperature-Pressure Relief

Valve (Certain Models)

18. Air Intake Tube 33E. Direct Vent -Air Intake Kit E

19. Combustion Chamber

Assembly

20. Combination Gas Control

w/E.C.O.

INTERNET VERSION FOR REFERENCE ONLY

Note: Provide the part name, model and serial numbers of the water heater when

ordering parts.

24. Jacket

25. Inner Door Assembly

26. Air Intake Boot

27. Air Intak e Boot Gasket

(Certain Models)

(Optional)

(Optional)

(Supplied & Optional)

33D. Direct Vent -Air Intake Kit D

(Optional)

(Optional)

34. Loctite Ultra Blue 587 RTV

Silicone Sealant

35. Direct Vent -Air Intake Terminal

Guard (Optional)

THIS MANUAL SHOULD BE KEPT WITH THE WATER HEATER

Page 38

DIRECT VENT WATER HEATER

INTERNET VERSION FOR REFERENCE ONLY

Page 39

VENT-AIR INTAKE KITS

INTERNET VERSION FOR REFERENCE ONLY

Page 40

THE FOLLOWING INSTRUCTIONS ARE FOR INSTALLATION OF:

GAS WATER HEATERS

SUITABLE FOR WATER (POTABLE) HEATING AND SPACE

HEATING

1. All piping components connected to this water heater for space heating

applications must be suitable for use with potable water. In

Massachusetts, space heating piping must not exceed 50 feet.

2. Toxic chemicals, such as those used for boiler treatment, must not

be introduced into potable water used for space heating;

3. This water heater must not be connected to an existing heating system

or component(s) previously used with a non-potable water heating

appliance;

4. When the system requires water for space heating at temperatures higher

than required for other means, such as an ASSE approved mixing valve

must be installed to temper the water for those uses in order to reduce the

scald hazard potential.

Please refer to the illustration for suggested piping arrangements.

INTERNET VERSION FOR REFERENCE ONLY

Loading...

Loading...