Page 1

Commercial Flue Damper Millivolt-Powered

Gas Water Heater

The Commercial Flue Damper Models feature:

■ Automatic Flue Damper—Reduces stand-by loss, saving gas consumption

and improving overall efficiency.

■ Hand Hole Cleanout—Allows inspection of the tank interior and facilitates

the removal of sediment deposits.

■ Millivolt-Powered Control—No external electrical source is required for

operation. An adjustable thermostat can be set up to 180°F (82°C).

■ Factory Installed Hydrojet

inlet sediment reducing device helps prevent sediment build up in the tank.

■ Vitraglas

®

Lining—An exclusively engineered enamel formula that provides

superior tank protection from the highly corrosive effects of hot water. This

formula (Vitraglas

®

) is fused to the steel surface by firing at a temperature of

over 1600°F (871°C).

■ Water Connections—Factory-installed true dielectric fittings extend water

heater life and simplify water line connections.

■ E.C.O.—An automatic reset Energy Cut Out (E.C.O.) shuts off all gas in event

of an overheat condition. This automatically resets when operation conditions

are back to normal.

■ Insulation System—Non-CFC foam covers the sides and top of the tank,

reducing heat loss. This results in less energy consumption, improved

efficiencies, and jacket rigidity.

■ Protective Magnesium Anode Rods—Provide added protection against

corrosion for long-term, trouble-free service.

■ Sanitizing Capability—Temperature setting up to 180°F (82°C).

■ Low NOx Construction Available.

■ T&P Relief Valve—Installed.

■ Low Restrictive Brass Drain Valve—Durable tamper proof design.

■ NSF construction available.

■ North Carolina Code Compliant.

■ ASME code available on all models above 200,000 BTU/Hr.

®

Sediment Reduction System—Cold water

Photo is of

DM-100T-199-3N

3 or 5-Year Limited Tank Warranties / 1-Year Limited Warranty on Component Parts.

For more information on warranty, please visit www.bradfordwhite.com

For products installed in USA, Canada, and Puerto Rico. Some states do not allow limitations on warranties. See complete

copy of the warranty included with the heater.

MANUFACTURED UNDER ONE OR MORE OF THE FOLLOWING U.S. PATENTS: 5,682,666; 7,634,976; 5,660,165; 5,954,492; 6,056,542; 6,935,280; 5,372,185; 5,485,879; 5,574,822; 7,971,560; 7,992,526; 6,684,821;

7,334,419; 7,866,168; 7,270,087; 7,007,748; 5,596,952; 6,142,216; 7,699,026; 5,341,770; 7,337,517; 7,665,211; 7,665,210; 7,063,132; 7,063,133; 7,559,293; 7,900,589; 5,943,984; 8,082,888; 5,988,117; 7,621,238;

7,650,859; 5,761,379; 7,409,925; 5,277,171; 8,146,772; 7,458,341; 2,262,174. OTHER U.S. AND FOREIGN PATENT APPLICATIONS PENDING. CURRENT CANADIAN PATENTS: 2,314,845; 2,504,824; 2,108,186; 2,143,031;

2,409,271; 2,548,958; 2,112,515; 2,476,685; 2,239,007; 2,092,105; 2,107,012. Vitraglas

®

and Hydrojet® are registered trademarks of Bradford White® Corporation.

742-C-0818

Page 2

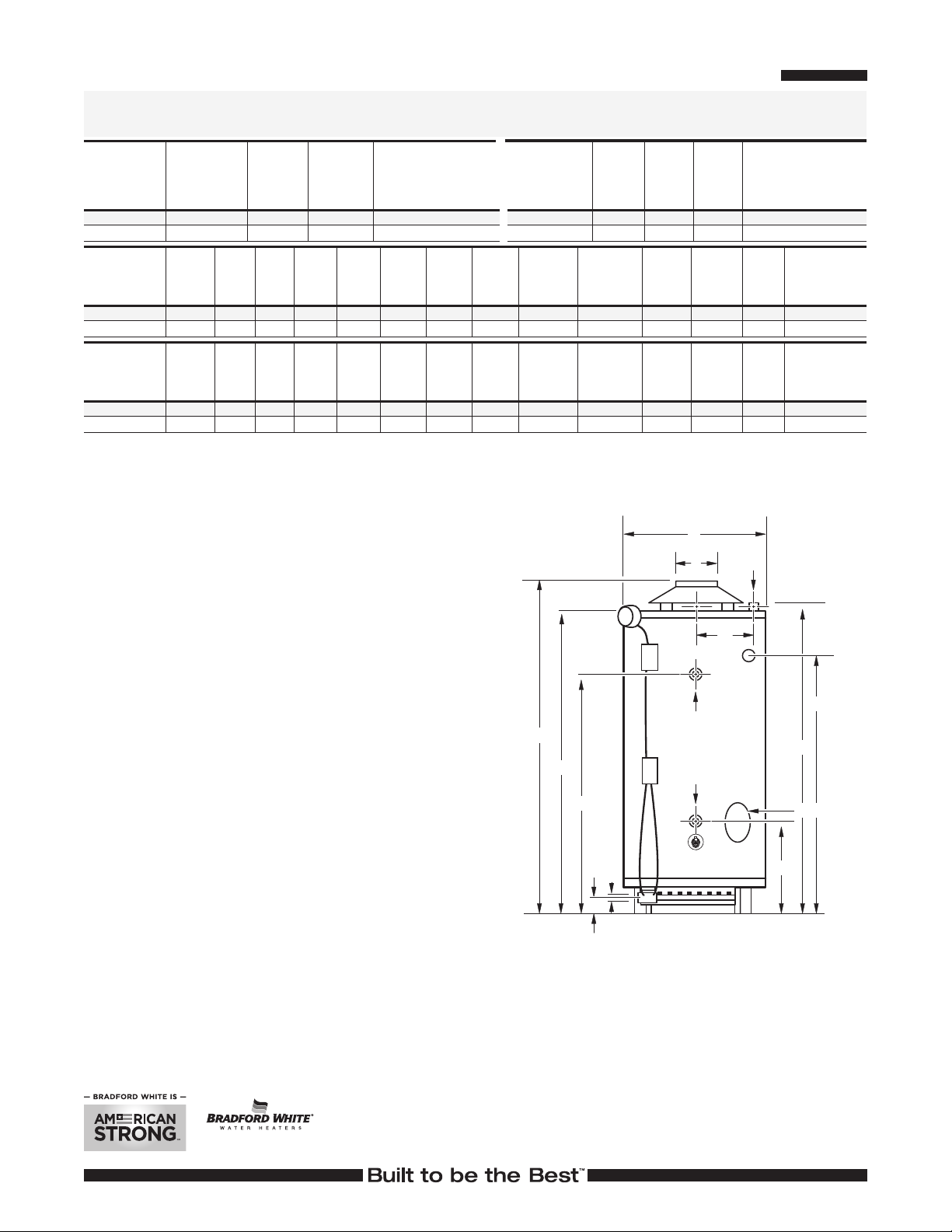

C

R

R

B

F

L

A

K

CLEANOUT

D

HOT

COLD

E

S

Commercial Flue Damper Millivolt-Powered Gas Water Heater

Millivolt Powered Models

NATURAL GAS AND LIQUID PROPANE GAS

Model

Number

DM-80T-199-3N

DM-100T-199-3N

Model

Number

DM-80T-199-3N

DM-100T-199-3N

Model

Number

DM-80T-199-3N

DM-100T-199-3N

Nominal

Capacity

U.S.

Gal.

809867

A

Floor to

Vent

Conn.

in.

3

/

8

76

15

88

/

16

A

Floor to

Vent

Conn.

mm.

1940

2259

Gal.

Imp.

Gal.

82

Jacket

28

28

Jacket

mm.

B

Dia.

in.

B

Dia.

718

718

D

Floor to

T&P

Conn.

in.

15

59

/

16

15

70

/

16

D

Floor to

T&P

Conn.

mm.

1522

1802

LP

BTU/Hr.

Input

190,000

199,999

E

Floor to

Gas

Conn.

in.

5

8

/

8

5

8

/

8

E

Floor to

Gas

Conn.

mm.

219

219

BTU/Hr.

Input

199,999

199,999

C

Vent

Size

in.

1

6

/

4

1

6

/

4

C

Vent

Size

mm.

152

152

*Recoveries based on Thermal Efficiencies of 80%.

(A) = ASME Code Available

For Propane Gas (LP) models change suffix “N” to “X”.

For LowNOx compliance to meet SCAQMD requirements,

place an “E” following the BTU Input identifier of the

model number.

Example: DM-80T-199E-3N

GPH Recovery

at Degree Rise*

40°F

485

485

F

Floor to

Top of

Heater

in.

3

/

8

68

5

79

/

16

F

Floor to

Top of

Heater

mm.

1737

2015

100°F

194

194

Floor to

Floor to

G

Water

Conn.

in.

70

7

81

G

Water

Conn.

mm.

1778

2069

/

16

140°F

139

139

DM-80T-199-3N

DM-100T-199-3N

J

C/L of

Water

Conn.

in.

19

19

J

C/L of

Water

Conn.

mm.

483

483

Model

Number

K

Floor to

Space

Heating Inlet

in.

1

/

2

23

1

23

/

2

K

Floor to

Space

Heating Inlet

mm.

597

597

Meet or exceed ASHRAE 90.1b (current standard) C.E.C. Listed

Nominal

Liter

Capacity

303

371

L

Floor to

Space

Heating Outlet

in.

15

/

16

59

15

70

/

16

L

Floor to

Space

Heating Outlet

mm.

1522

1802

kW

Input

58.6

58.6

M

Water

Conn.

NPT

in.

1

1

/

2

1

1

/

2

M

Water

Conn.

NPT

mm.

38

38

LP

kW

Input

55.7

58.6

R

Space

Heating

Conn. Size

in.

1

1

/

2

1

1

/

2

R

Space

Heating

Conn. Size

mm.

38

38

LPH Recovery

at Degree Rise*

22°C

1836

1836

S

Gas

Conn.

Size

in.

1

/2

1

/2

S

Gas

Conn.

Size

mm.

13

13

56°C

78°C

734

526

734

526

Approx.

Shipping Weight

(lbs.)

Std.

ASME

N/A

540

N/A

610

Approx.

Shipping Weight

(kg.)

Std.

ASME

N/A

245

N/A

277

Water Connections

Top and Front

B

C

M

J

HOT

Sample Specification

The water heater shall be a Bradford White model with a rated storage

capacity of not less than_______gallons (_______liters), a minimum gas input of

A

R

_______BTU/Hr. (_______ kW), a minimum recovery of _______GPH (_______

LPH). The tank shall be Vitraglas® lined and have a bolted hand hole cleanout.

A millivolt-powered control shall be an adjustable electronic thermostat to

any temperature up to 180ºF (82°C) must have an automatic re-set Energy

Cut-off (E.C.O), which shuts off all gas in an event of a overheat condition.

The tank shall have _______magnesium anode rods installed in separate tank

head couplings. The heater shall have Non-CFC foam insulation, standing

pilot, and come equipped with an ASME rated T&P relief valve, a cold water

inlet Hydrojet® Sediment Reduction System, and a automatic flue damper (no

F

L

R

COLD

E

S

electricity required). It shall be design certified by CSA International for 180ºF

(82ºC) application, either with or without a separate storage tank, and comply

with state and local codes and ordinances.

General

All gas water heaters are certified at 300 PSI test pressure (2068 kPa) and 150 PSI working pressure (1034 kPa). All models are design certified by CSA

International (formerly AGA/CGA), ANSI standard Z21.10.3, for up to 180°F (82°C) application as an Automatic Storage Heater, and an Automatic Circulating

Tank Heater. As an Automatic Storage Heater, all models are complete, self-contained water heating systems. It needs no separate storage tank, pump,

wiring or elaborate piping network. When equipped with a mixing valve, it will supply 180°F (82°C) sanitizing and lower temperature general purpose hot water

simultaneously. These models can be used either as a single unit or in multiples connected in series or parallel (recommended).

Dimensions and specifications subject to change without notice in accordance with our policy of continuous product improvement.

For field service, contact your professional installer or local Bradford White sales representative.

Sales 800-523-2931 n Fax 215-641-1612

Technical Support 800-334-3393

Ambler, PA

Warranty 800-531-2111

International: Telephone 1-215-641-9400 n Email international@bradfordwhite.com / www.bradfordwhite.com

©2018, Bradford White Corporation. All rights reserved.

n

n

Email techserv@bradfordwhite.com

Email warranty@bradfordwhite.com

D

G

CLEANOUT

K

Printed in U.S.A.742-C-0818

Loading...

Loading...