Page 1

User's Information 1262X

User's Information for

Brute Mini

Residential

Gas-Fired

Hydronic Boilers

Model BJVS

Vent damper is optional in some provinces of Canada..

WARNING: If this Users Information

Manual not followed exactly, a re or explosion

may result causing property damage, personal

injury or death.

Do not store or use gasoline or other ammable

vapors and liquids in the vicinity of this or any

other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the re

department.

Installation and service must be performed by

a qualied installer, service agency, or the gas

supplier.

Sizes 50-225

U.S. Patent No. 1,609,692

Canada Patent No. 383,318

AVERTISSEMENT: Si cette informa-

tion utilisateurs manuel n'a pas suivi exactement,

un incendie ou une explosion peut entraîner des

dommages matériels, des blessures ou la mort

Ne pas entreposer ni utiliser d’essence ni d'autres

vapeurs ou liquides inammables dans le voisinage

de cet appareil ou de tout autre appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ:

• Ne pas tenter d’allumer d’appareils.

• Ne touchez à aucun interrupteur. Ne pas vous servir

des téléphones dans le bâtiment où vous vous

trouvez.

• Appelez immédiatement votre fournisseur de

gaz depuis un voisin. Suivez les instructions du

fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de gaz,

appelez le service des incendies.

L’installation et l’entretien doivent être assurés par un

installateur ou un service d’entretien qualié ou par le

fournisseur de gaz.

A. System Start Up

1. Verify that the pump system is operating

properly.

a. Shut off the manual gas valve.

b. Set the wall thermostat to a setting high

enough to call for heat.

c. The pump should come on immediately. If

it doesn’t, have a service technician test the

electrical circuits.

H2360400B

2. Light the pilot.

a. The BJVS boiler does not require manual

lighting. The pilot is controlled by the

automatic ignition system.

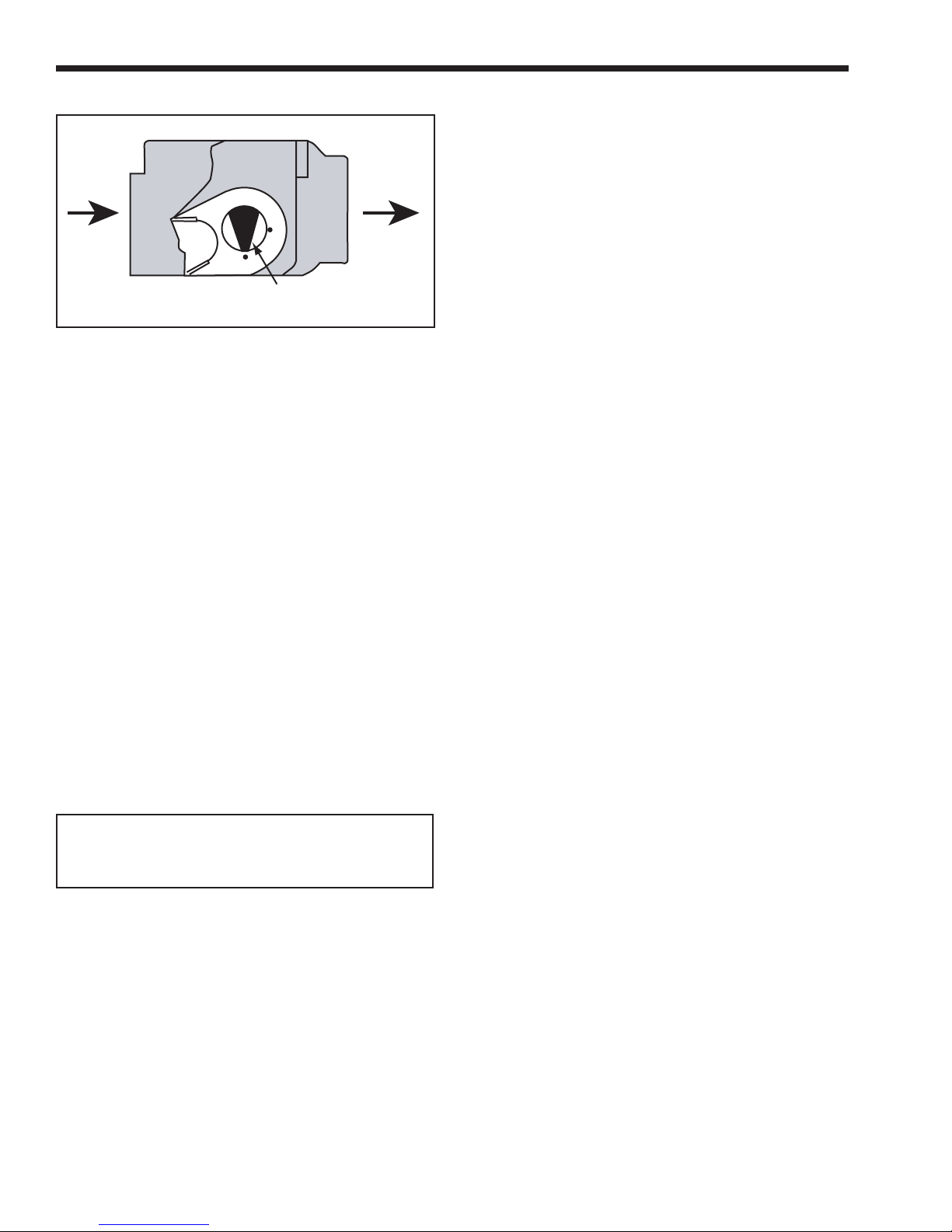

b. Different models of the JV boiler utilize

various gas valves. Although the gas valves

may have different control knobs, they are

all similar in operation. The gas valve has a

two-position knob - On and Off.

Page 2

Page 2

ON

OFF

Gas Control Knob

Figure 1 - Gas Control for Automatic Ignition System

B

RADFORD WHITE

Important: When lighting or relighting, wait the

full 5 minutes specied in the lighting instructions.

Unburned gases can accumulate in the re box and

may ash back. Allow ample time for natural air

movement to clear the gases from the chamber before

lighting or relighting.

Relighting - All Models:

1. Turn off electrical power to the boiler.

2. Turn the gas valve knob clockwise to Off.

3. Wait ve minutes.

4. Turn the gas valve knob counterclockwise to On.

5. Restore power to the boiler, and set the

thermostat to the desired temperature. The

pilot will automatically ignite when there is

a call for heat.

Circulator Pump:

In normal operation, the pump is energized by the wall

thermostat via the pump relay supplied with the boiler.

Caution: Hazard of electrical shock!

Disconnect power to the boiler before

servicing the relay or transformer.

B. System Shut Down

1. Turn off power to the boiler and set the

thermostat to the lowest setting.

2. Turn the gas valve knob (clockwise for JVS) or

switch to the Off position.

3. Whenever danger of freezing exists, shut off the

water supply, remove the drain plugs in the left

side of the heater and open the drain valve on the

right side. Drain every part of the system which

might be subject to freezing temperatures.

Should overheating occur or the gas supply fail

to shut off, do not turn off or disconnect the electrical

supply to the pump. Instead, shut off the gas supply at

a location external to the appliance.

En cas de surchauffe ou si l'admission de gas

ne peut être coupée, ne pas couper ni débrancher

l'alimentation électrique de la pompe. Fermer plutôt le

robinet d'admission de gas à l'extérieur de l'appareil.

C. Maintenance

1. Lubricate the water circulating pump according

to the instructions found on the pump.

2. If a strainer is employed in a pressure reducing

valve or in the piping, clean it every six months.

3. At start-up and periodically thereafter, the ame

should be observed for proper performance. If

the ame has “sooting” tips, check for debris

near the orices. If this continues, call a service

technician.

4. Ensure proper operation of the mechanical

damper, mounted in the ue collar, by observing

the damper handle. Be sure the handle swings

when the draft inducer starts. Depending on the

boiler size, the swing may be as little as 30°.

Remove any obstructions and clean around the

pivot rod (handle) holes.

5. Inspect the venting system for obstructions,

leakage and corrosion at least once each year.

6. Keep the boiler area clear and free from

combustible material, gasoline and other

ammable vapors and liquids.

7. Be certain all combustion air and ventilation

openings are unobstructed.

8. Check for fouling on the external surfaces of the

heat exchanger every six months.

Fouling on the external surfaces of the heat

exchanger is caused by incomplete combustion

and is a sign of combustion air and/or venting

problems. As soon as any fouling is observed, the

cause of the fouling should be corrected.

The heat exchanger can be checked using a

ashlight by locating a mirror under the burners.

An alternate method is to remove the venting and

top panel as necessary to inspect from above.

Also, check the vent system for defects at this

time.

Page 3

Brute Mini

Page 3

NOTE: After installation and rst start-up, check

the heat exchanger for fouling after the following

periods of operation:

24 hours 30 days

7 days 90 days+

Then once every six months thereafter.

Figure 4 - Pilot Arrangements

1) Pilot

2) Main burner ame pattern

If cleaning is required:

a. Shut off all power to the boiler.

b. Expose the heat exchanger by removing the

draft hood (when equipped), and venting, top

assembly, ue collector, and heat exchanger

bafes.

c. Remove the burners by lifting them off the

orices and pulling them out of the boiler.

d. Use a hand-operated spray bottle lled with

water and a wire brush to clean any soot and

loose scale from the underside of the heat

exchanger. Do not use compressed air, high

pressure water or a garden hose.

e. Clean any fallen debris from the bottom of the

unit.

f. Check to make sure that the burner ports

and pilot assembly are free of debris before

returning the burners to their original

positions.

g. Reassemble the boiler in reverse order, making

sure to replace the heat exchanger bafes.

9. The gas and electric controls installed on the

boiler are engineered for both dependable

operation and long life, but the safety of this

equipment completely depends on their proper

functioning. For this reason, it is strongly

recommended that the basic items be checked by

a competent service technician every year and

replaced when necessary.

in Section 8D of the Installation and Operating

Instructions (Document number 1254) to ensure

that all possible causes have been investigated

and corrected. If the problem continues and the

boiler cannot be restored to normal operation call

a qualied service agency.

11. The ame rollout safety switch provides

additional safety, and will shut down the boiler

should the ame from the main burners rollout

(ashback) towards the main gas valve. Before

resetting the ame rollout switch, see Section 8D

of the Installation and Operating Instructions,

(Document H2355800) to ensure that all possible

causes have been investigated and corrected.

If the problem continues and the boiler cannot

be restored to normal operation call a qualied

service agency. Never attempt to bypass the

ame roll-out safety switch for the purpose of

operating the boiler.

Do not use this boiler if any part has been under

water. Immediately call a qualied service

technician to inspect the boiler and to replace any

part of the control system and any gas control

which has been under water.

12. Check all heat exchanger water connections,

ange or header gaskets for water tight integrity

24 hours after commissioning. If there are any

signs of water leakage, re-torque fasteners or reseat threaded connections as necessary

The basic controls are:

a. Water temperature controls

b. Pilot safety system

c. Automatic electric gas valve(s)

d. Flue or vent damper

10. The blocked vent safety switch is used to shut

the boiler down in the case of insufcient draft

due to venting system problems. Before resetting

the blocked vent safety switch see the Appendix

Note: The warranty does not cover any damage

caused by lack of required maintenance or

improper operating procedures.

Page 4

Page 4

Boiler Type of Valve

Model Size Sufx* Gas Part No. Mfr. No. Manufacturer

BJVS 50-75 D NAT V0077400 VR8304H HONEYWELL

BJVS 100-225 K NAT V0079000 VR8304H HONEYWELL

BJVS 50-75 D LP V0077500 VR8304H HONEYWELL

BJVS 100-225 K LP V0079100 VR8304H HONEYWELL

BJVH 50-160 C NAT V2001800 SV9501H HONEYWELL

BJVH 225 C NAT V2001900 SV9601H HONEYWELL

BJVH 50-225 C LP V2002300 SV9501H HONEYWELL

*Sufx Denitions C = On/Off Firing

D = On/Off Firing

K = Two-Stage Firing

Table 1 - Gas Control Valves

B

RADFORD WHITE

D. Air Shutter Adjustment (when required)

1. STOP! Read the safety information on the last page.

2. Perform a System Start-Up in accordance with

Section A of this manual.

3. Remove the burner cover by loosening the two

thumbscrews.

4. Observe the ame pattern on all burners. If the

ame on any burner is pulsing, unstable or lifting

continue with this procedure. Otherwise skip to

step 10.

5. On all burners exhibiting an abnormal ame, loosen

but do not remove the air shutter locking screw

LOCKING SCREW

(5/16" HEAD)

AIR SHUTTER

BURNER

using a 5/16 inch wrench. (See Fig. 5 below.)

6. On each affected burner, slowly close the air

shutter until a normal ame is observed, then re-

tighten its associated locking screw.

7. Turn the boiler off.

8. Perform a System Start-Up in accordance with

Section A of this manual.

9. Observe the ame pattern on all burners. If

the ame on any burner is pulsing, unstable or

lifting, repeat steps 5 and 6 until all burners are

exhibiting a normal ame.

10. Re-install the burner cover and tighten it in place.

Figure 5 - Removing the Air Shutter Locking Screw

200 Lafayette St.

Middleville, MI 49333

Warranty: (800) 531-2111

H2360400B

www.BradfordWhite.com

Litho in U.S.A. © Bradford White 1509 Document 1262X-BW

Loading...

Loading...