Page 1

Internet Version for Reference Only

Installation, Operation and Maintenance Instructions Document 2143

C O R P O R A T I O N

B W

RADFORD HITE

®

Installation, Operation

and Maintenance

Instructions for

Copper Brute

Volume Water Heaters

Model B4

Sizes 175-400

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualied in hot water heater installation and maintenance. Improper installation and/or operation could

create carbon monoxide gas in ue gases which could cause serious injury, property damage, or death.

Improper installation and/or operation will void the warranty.

WARNING

If the information in this manual is not followed exactly, a re or explosion may result

causing property damage, personal injury or loss of life.

Do not store or use gasoline or other ammable vapors and liquids in the vicinity of this or

any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a nearby phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the re department.

Installation and service must be performed by a qualied installer, service agency, or gas

supplier.

H2317000-

Page 2

Internet Version for Reference Only

Page 2

Copper Brute B4 Volume Water Heaters

Page 3

TABLE OF CONTENTS

BRADFORD WHITE

SECTION 1.

General Information

1.1 Introduction..................................................... 3

1.2 Warranty.........................................................3

1.3 Technical Assistance ...................................... 3

SECTION 2.

Installation Instructions

2.1 General Information........................................ 4

2.2 Field Assembly ............................................... 4

2.3 Site Location................................................... 5

2.3.1 Installation Information ...................................5

2.3.2 Outdoor Installation (U.S. only) ......................5

2.3.3 Flooring - Typical Installation .......................... 6

2.4 Combustion and Ventilation Air Supply........... 6

2.4.1 Outdoor Air Supply ......................................... 7

2.4.2 Indoor Air Supply ............................................7

2.4.3 Exhaust Fans or Vents ................................... 7

2.5 Venting of Combustion Products ....................8

2.5.1 General Information........................................ 8

2.5.2 Replacement of Existing Heater.....................8

2.6 Water Flow .....................................................8

2.6.1 Reversible Water Connections.......................8

2.6.2 Water Chemistry........................................... 11

2.6.3 Freeze Protection ......................................... 11

2.6.4 Water Hardness............................................ 11

2.6.5 Pump Requirements..................................... 11

2.6.6 Pressure Buildup in Water System............... 14

2.6.7 Pressure Relief Valve ...................................14

2.6.8 Water Pressure............................................. 14

2.6.9 Pump Installation..........................................14

2.6.10 Storage Tank Installation .............................. 15

2.6.11 Thermal Circulation of Hot Water in

Cold Water Supply Lines..............................15

2.7 Gas Supply and Piping.................................15

2.7.1 General Instructions .....................................15

2.7.2 Special Precautions for Propane Gas ..........16

2.8 Electrical Wiring............................................ 16

2.9 Combined Space Heating/Potable

Water Heating Systems................................ 16

2.9.1 Combined Space Heating............................. 16

SECTION 3.

Operating Instructions

3.1 Normal Operating Sequence........................16

3.2 Start-Up Procedure....................................... 21

3.3 Setting the Temperature Controls................. 21

3.3.1 Remote Water Heater Temperature

Control:.........................................................21

3.3.2 Internal Water Heater Temperature

Control:.........................................................22

3.4 Adjustment for Minimum Input Rate

(models with modulating gas valve) .............22

3.5 Hi-Limit Switch Checkout.............................. 22

3.6 Shut-Down Procedure .................................. 22

SECTION 4.

Maintenance

4.1 General Instructions .....................................23

4.2 Replacement of Gas Controls ......................23

4.3 Heat Exchanger............................................ 25

4.3.1 Inspecting the Heat Exchanger ....................25

4.3.2 Cleaning the Heat Exchanger....................... 25

SECTION 5.

Troubleshooting

5.1 Gas Pressure Tests ...................................... 26

5.1.1 Checking the Main Line Gas Pressure.........26

5.1.2 Checking the Manifold

Regulated Gas Pressure .............................. 26

5.2 Electrical Troubleshooting ............................ 26

5.2.1 Heater Does Not Come On ..........................27

5.2.2 Testing the Transformer................................ 27

5.2.3 Testing the Electrical Power Supply .............28

5.2.4 Testing the Manual Reset

Hi-Limit Switch.............................................. 28

5.2.5 Testing the Flow Switch................................28

5.2.6 Testing the Fusible Link

(Flame roll-out switch) .................................. 28

5.2.7 Testing the Fuse ........................................... 29

5.2.8 Testing the Ignition Control

(for spark ignition)......................................... 29

5.2.9 Testing the High Voltage Ignition Lead.........29

5.2.10 Testing the Safety Shutoff

(for standing pilot)......................................... 30

5.2.11 Testing the Safety Shutoff

(for automatic pilot)....................................... 30

5.2.12 Testing the Igniter Electrode.........................30

5.2.13 Testing the Pilot Thermocouple

(for standing pilot)......................................... 30

5.2.14 Testing for Pilot burner

(for spark ignition)......................................... 30

5.2.15 Testing for Burner Ignition

(for standing pilot)......................................... 31

5.2.16 Heater Will Not Shut Off ............................... 31

5.2.17 On-Off Main Burner Cycling .........................31

5.2.18 Testing the Terminal Strip/External

Controls ........................................................ 31

Page 3

Internet Version for Reference Only

Copper Brute B4 Volume Water Heaters

A

8-1/2 in.

(216mm)

INLET OUTLET

TOP VIEW

C C

OPTIONAL

VENT CAP FOR

OUTDOOR USE

DRAFTHOOD

DRAFTHOOD MUST

BE INSTALLED IN

THE FIELD

HEADER

LOCATION

OUTLET

40-9/16 in. (1030mm)

INLET

5-1/2 in.

(140mm)

26-1/2 in.

SIDE VIEW

V

30-3/16 in. (767mm)

B

Page 3

SECTION 1.

General Information

1.1 Introduction

This manual provides installation, operating, and

maintenance instructions for Copper Brute Volume

Water Heaters, Sizes 175 through 400. Review all

application and installation procedures completely

before proceeding with the installation. Experience

has shown that most operating problems are caused by

improper installation.

1.2 Warranty

The Copper Brute heaters are sold with a limited

factory warranty.

Make all warranty claims to an authorized

Bradford White representative or directly to the

factory. Claims must include the heater serial number

and model (this information can be found on the rating

plate), installation date, and name of the installer.

Shipping costs are not included in the warranty

coverage.

Some accessory items are shipped in separate

packages. Inspect everything for damage immediately

upon delivery, and advise the transporter of any

shortages or damage. Any such claims should be led

with the transporter. The transporter will not accept a

claim from the shipper, Bradford White.

The warranty does not cover damage caused by

improper installation, operation, or eld modication.

1.3 Technical Assistance

Consult Bradford White or your local wholesaler

with any questions or problems involving the

specication, installation and operation of Bradford

White equipment. An experienced technical support

staff is ready to assist in assuring the proper

performance and application of Bradford White

products.

Dimensions shown in inches cm.

Gas Connection

Size Water C C V

Connect. U.S. Only (Indoor) Vent

Nat. Propane Size A B (Outdoor) Dia.

Size in. mm in. mm in. mm in. cm in. cm in. cm in. cm in. mm

175 3/4 19 1/2 13 11/2 38 18 46 261/2 67 141/16 36 23/2 60 6 152

250 3/4 19 1/2 13 11/2 38 221/2 57 31 79 181/16 47 243/4 63 7 178

325 3/4 19 1/2 13 11/2 38 263/4 68 353/4 91 193/16 49 257/8 66 8 203

400 3/4 19 1/2 13 11/2 38 313/4 80 401/4 102 225/8 58 267/8 68 9 229

Note: Dimensions may vary.

Figure 1. General conguration.

Page 4

Internet Version for Reference Only

Page 4

Copper Brute B4 Volume Water Heaters

Page 5

HO

T

HO

T

BRADFORD WHITE

SECTION 2.

Installation Instructions

2.1 General Information

WARNING

Follow local regulations with respect to installation

of carbon monoxide (CO) detectors and

manufacturer's maintenance schedule of the heater.

Install the Copper Brute heaters in accordance

with the procedures in this manual (or the warranty

may be voided), local codes and ordinances. In the

absence of such codes, install the heaters in accordance

with the latest edition of the National Fuel Gas Code,

ANSI Z223.1. In Canada, the installation must be

in accordance with CAN1-B149.1 or .2 and local

codes. The authority having jurisdiction may require

the installation conform to the Standard for Controls

and Safety Devices for Automatically Fired Heaters,

ANSI/ASME CSD-1. Any changes to the heater, gas

controls, gas orices, wiring or draft diverter may void

the warranty. If eld conditions require a change to

any of the above, consult the factory.

All gas-red products require correct installation

to assure safe operation. The requirements for heaters

include the following:

1. Field assembly of drafthood or vent cap (see

Section 2.2).

2. Appropriate site location (clearances) and

ooring.

3. Sufcient combustion and ventilation air.

4. Adequate venting of combustion products.

5. Adequate water ow.

6. Properly sized gas meter and piping.

7. Proper electrical wiring.

This manual provides the information needed to

meet these requirements. Review all application and

installation procedures completely before continuing

the installation.

a. Remove the top ller plate, stamped “HOT”, by

slipping a ne-blade screwdriver into the slot at

the rear of the plate and gently prying it up (see

Figure 2).

b. Remove the two screws attaching the adapter

plate to the top assembly and lift it out (see

Figure 3).

c. Remove the vent cap or drafthood from its

package.

d. Disengage the ue transition ring from the stack

extension and place it on top of the collector

assembly as shown in Figure 4.

Figure 2. Top ller plate. Figure 3. Adapter plate.

Figure 4. Flue transition Figure 5. Vent cap with

ring. adapter plate

(outdoor).

2.2 Field Assembly

The Copper Brute heater is shipped from the

factory with the top assembly in the low-prole

conguration for outdoor installations.

The Copper Brute heater is design certied

for indoor installation when equipped with a

special drafthood, which must be installed without

modication. The part number for the drafthood is on

the heater rating plate. Follow this procedure to make

the conversion:

Figure 6. Drafthood with Figure 7. Drafthood switch

adapter plate receptacle.

(indoor).

Page 5

Internet Version for Reference Only

Copper Brute B4 Volume Water Heaters

e. Slide the adapter plate over the bottom of the

stack extension as shown in Figure 5. Fit the

stack extension down over the ue transition

ring. Seat the adapter plate on the top assembly

and secure it with two screws (see Figure 6).

f. Indoor models, size 175 and 250 only, require

an adapter cable (included with product). The

cable connects the blocked vent safety switch

(BVSS) on the bell of the external draft hood to

the 6-position Molex plug on the side of the unit

(see Figure 7). Refer to instruction sheet included

with cable.

2.3 Site Location

2.3.1 Installation Information

Closet Installation

(unacceptable)

A closet is any 4 sided enclosure

which is less than 16* times the

total volume of all the gas red appliances within the enclosure.

Page 5

Room Installation

(acceptable)

A room is any enclosure which is

at least 16* times greater than the

total volume of all the gas red appliances within the enclosure

WARNING

Improper installation or maintenance can cause

nausea or asphyxiation from carbon monoxide

in ue gases which could result in severe injury,

property damage, or death.

Avoid placing the heater in locations where it can

be damaged by water or condensate leakage. If this is

not possible, provide a suitable drain pan to catch and

divert any leakage. The pan must not block natural

ow of air around the heater.

Locate the heater to provide adequate clearance

on all sides for inspection, service and to provide

adequate air circulation for proper operation.

Locate the heater so the clearances from

combustible surfaces shown in Table 1 and Figure 8

are met.

Locate the heater on a waterproof oor with a

oor drain and a 6 inch (152 mm) minimum curb on

all four sides to protect the building if heater repairs

are needed.

Indoors Outdoors

Clearance from: inch mm inch mm

Top 37 940 Unobstructed

Water conn. side 12 305 Unobstructed

Opposite side 6 152 6 152

Front Alcove Unobstructed

Rear 6 152 6 152

Vent* 6 152 —

Flooring Combustible Combustible

Service clearance = 36 inches (914mm) at front of heater,

and 18 inches (457mm) at water connection side.

*1" (25mm) if double wall vent is used.

Table 1. Minimum Boiler Clearances

from Combustible Surfaces.

Alcove Installation

(acceptable)

An alcove suitable for the installation of a heater is a restricted section of a room not separated from

the room by a door or partition and

which meets the minimum clearances specied in this manual.

* When the ceiling height exceeds 8 feet, you are only allowed to consider 8 feet when calculating the total volume of the enclosure.

Figure 8. Alcove installation.

2.3.2 Outdoor Installation

Caution

Outdoor installations are not recommended in areas

where the danger of snow blockage exists. Copper

Brute heaters can be installed in the standard lowprole, grate top conguration as received from the

factory, or with an optional vent cap.

Locate the heater in an open, unroofed area.

Do not locate the heater below or adjacent to any

doors, windows, louvers, grills, etc., which connect

in any way with an inhabited area of a building, even

though the access might be through another structure

such as a garage or utility room (see Figure 9 and

Table 1). There must be a minimum of 4 feet (1.22

m) horizontally and vertically between the heater and

any door, window, or gravity inlet to a building (see

Figure 10).

If the heater is installed close to a structure,

protect it from rain water runoff with rain gutters on

the roof or other measures. Do not locate the heater

near sprinkler systems that could spray water on it.

Avoid locations where wind deection off nearby

structures might cause wind loading and downdraft

conditions. Where downdraft conditions exist, locate

the heater at least 3 feet (0.91 m) from the structure.

Page 6

Internet Version for Reference Only

Copper Brute B4 Volume Water Heaters

Page 7

WINDOW

OR GRILL

INDOOR

ROOM

WRONG

4 ft

(1.2m)

4 ft

(1.2m)

4 ft

(1.2m)

Page 6

Figure 9. Incorrect outdoor installation.

BRADFORD WHITE

Concrete slab must extend out

a minimum of 12 in. (305mm) on

all sides.

Bradford White

UNIT

(Side View)

Base For Combustible Floors

Roof - Wood and Steel Construction

Figure 11. Standard base for combustible oor.

Mounting Platform must extend

out a minimum of 12 in. (305mm)

on all sides.

Figure 10. Outdoor location installation.

2.3.3 Flooring - Typical Installation

Do not install the heater directly on carpeting

without placing a non-combustible platform between

the carpeting and the heater. If the heater is installed in

a carpeted alcove, the entire oor of the alcove must

be covered by a non-combustible panel. The panel

must be strong enough to carry the total weight of the

heater and all piping, pumps, and any other equipment

attached to the heater. For rooftop installation, see

Figure 11 through Figure 13.

Bradford White

20 Gauge

Galvanized

Sheet Metal

Cap

Roong

Figure 12. Typical roof mounting.

Base For Combustible Floors

Bradford White

(Side View)

UNIT

(Side View)

Raised Mounting

Platform (Wood)

UNIT

Base Rail

Flashing

Roof

Base Rail

20 Gauge

Galvanized

Sheet Metal

Cap

2.4 Combustion and Ventilation

Air Supply

All indoor installations must have openings to

outside air for combustion, ventilation and dilution of

ue gases from inside the building (see Figure 14 and

Table 2 ). Bradford White does not recommend indoor

installations that do not provide combustion air from

outside the building.

Base For Combustible Floors

Flashing 4x4 Stringer

Figure 13. Typical roof mounting with standard

combustible mount base.

Roof

Roong

Page 7

Internet Version for Reference Only

Copper Brute B4 Volume Water Heaters

10 ft.

(3.0m)

2 ft. (0.6m)

Listed

Vent

Cap

Storm Collar

Roof Jack

Adequate

Air Supply

To

Room

To

p and

Botom

1/14 in. (6mm)

Minimum Pitch

Per Foot of

Horizontal Pipe

Draf

thood

12 in.

(305mm)

All Sides

Vent terminated at

least 24 in.

(610mm) above

any object within

10 ft. (3.0m)

Page 7

Required Net Free Opening Area

Directly from Outside

At Top At Bottom

2

cm2

Mode in.2 cm2 in.

175 44 284 44 284

250 63 406 63 406

325 82 529 82 529

400 100 645 100 645

Note: For screens or louvers, add 50%.

Table 2. Air Openings to Outside.

Notes:

1. The drafthood must sit directly on top of the heater

as shown and must not be altered in any manner.

2. An Underwriters' Laboratories listed vent cap is re quired to eliminate downdraft and allow the heater

to function properly.

3. Use approved roof tting.

Figure 14. Indoor installation and venting.

requirements specify that the space shall communicate

with the outdoors in accordance with method 1 or 2,

In the United States, the most common

which follow. Where ducts are used, they shall be of

the same cross-sectional area as the free area of the

openings to which they connect.

Method 1:

Two permanent openings, one commencing

within 12" (30 cm) of the top and one commencing

within 12" (30 cm) of the bottom of the enclosure

shall be provided. The openings shall communicate

directly, or by ducts, with the outdoors or spaces that

freely communicate with the outdoors. When directly

communicating with the outdoors directly, or through

vertical ducts, each opening shall have a minimum

free area of 1 square inch per 4000 Btu/hr (550 square

mm/kW) of total input rating of all equipment in the

enclosure. When communicating to the outdoors

through horizontal ducts, each opening shall have a

minimum free area of not less than 1 square inch per

2000 Btu/hr (1100 square mm/kW) of total input rating

of all equipment in the enclosure.

Method 2:

One permanent opening, commencing within

12" (30 cm) of the top of the enclosure shall be

permitted. The opening shall directly communicate

with the outdoors or shall communicate through a

vertical or horizontal duct to the outdoors or spaces

that directly communicate with the outdoors, and shall

have a minimum free area of 1 square inch per 3000

Btu/hr (734 square mm/kW) of the total input rating of

all equipment located in the enclosure. This opening

must not be less than the sum of the areas of all vent

connectors in the conned space.

Other methods of introducing combustion and

ventilation air are acceptable, providing they conform

to the requirements in ANSI Z223.1, or applicable

codes.

In Canada, Table 2 does not apply. Consult

local building and safety codes or, in absence of such

requirements, follow CAN/CGA B149.

NOTE: Check with louver manufacturers for net

free area of louvers. If screens or louvers are installed,

add 50 percent for each screen/louver to the net free

area Check all local codes applicable to combustion

air.

2.4.1 Outdoor Air Supply

When combustion air comes directly through an

outside wall, each opening must have a minimum free

area of at least one square inch for each 4,000 BTU/h

input of the total input rating of all appliances in the

enclosed area. (In Canada, refer to CGAB149.1 and .2.)

2.4.2 Indoor Air Supply

Conned and non-conned areas have different

requirements for installation. Consult the latest edition

of the National Gas Code for installation requirements.

2.4.3 Exhaust Fans or Vents

Any equipment which uses air or removes air

from the heater room can use up the combustion air

supply or reverse the natural draft action of the venting

system. This could cause ue products to build up in

the heater room. More air must be supplied to make up

for the decrease.

Page 8

Internet Version for Reference Only

Page 8

Copper Brute B4 Volume Water Heaters

Page 9

BRADFORD WHITE

2.5 Venting of Combustion Products

2.5.1 General Information

When installed indoors, the drafthood must be

connected to a venting system. The venting system

must be installed by a qualied installer and in

accordance with the latest edition of ANSI Z223.1. In

Canada, the installation must be in accordance with

CAN1-B149.1 or .2, and any local codes that apply.

The vent pipe must have a listed vent cap, and

extend at least 2 feet (0.6 m) above any object within a

10 foot (3.0 m) radius.

NOTE: Do not use sheet metal screws at the

snap lock joints of Type B double-wall gas vents.

Do not weld or bolt the vent pipe to the heater

drafthood. The weight of the stack must not rest on the

heater. The drafthood and heater top must be easily

removable for normal heater service and inspection.

WARNING

Avoid ending heater vents near air conditioning or

air supply fans. The fans can pick up exhaust ue

products from the heater and return them inside the

building, creating a possible health hazard.

Avoid horizontal runs of the vent pipe and 90

degree elbows, reductions, and restrictions. Horizontal

runs should have at least a 1/4 inch (6.3 mm) rise per

foot in the direction of ow. Support a vent connector

for the design and weight of the material used to

maintain clearances and physical damage and separate

of joints.

Always use double-wall or insulated vent pipe

(Type B or equivalent).

WARNING

In cold weather, uninsulated outside vents can

chill the rising ue products, blocking the natural

draft action of the venting system. This can create

a health hazard by spilling ue products into the

heater room.

Avoid oversize vent piping or extremely long

runs of the pipe which may cause too much cooling

and condensation of ue gasses.

When the installation of a power vent or draft

fan in the venting system is necessary, qualied

personnel should design the installation following

good engineering practices and all applicable codes.

A suitable draft switch must be wired into the heater

control circuit at the terminal designated Field

Interlock to keep the heater from ring unless there is

a positive draft.

2.5.2 Replacement of Existing Heater

When a heater is removed from a common

venting system, the venting system may be too large

for proper venting of the other appliances connected

to it.

If replacing an existing heater with a Copper

Brute heater and the existing heater was connected

to a common venting system, the common venting

system must comply with ANSI Z223.1/National Fire

Protection Association (NFPA) 54. When resizing any

portion of the common venting system, the common

venting system should be resized to approach the

minimum size as determined using the tables in

ANSI Z223.1/NFPA 54, Appendix G. In Canada, the

common venting system should be resized so the

installation will be in accordance with CAN/CGA

B149.1 or .2.

2.6 Water Flow

2.6.1 Reversible Water Connections

Bradford White ships the heater with the

water connections on the right side. The heater can

be installed with the water connections on either

side. It could be necessary, or helpful, to switch the

connections to the left side to improve access for

installation service. Have a professional service

technician perform this modication before installing

the heater using the following procedures:

1. Remove the front cover.

2. If there is a vent cap or drafthood installed, they

must be removed before removing the grate top

assembly. On indoor installations (sizes 175-

250), the drafthood switch must be disconnected

at the left side of the heater.

3. If the unit is in the low-prole outdoor

conguration, remove the hex-head screws

(see Figure 15) and lift the grate top assembly

straight up.

4. Remove the screws that fastens the ue collector

holddown clamps and remove the clamps (see

Figure 16).

5. Remove the ue collector assembly by lifting it

out of the chassis.

6. Remove the screws that fastens the gap closures

and put them aside.

7. Remove the three grommets.

8. Remove the drain valves and plug. There is one

hex plug on the left side, near the rear of the

jacket. The drain valves are located on the left

side and right side of the heater (see Figure 15).

9. Remove the four screws that fastens the metal

channels covering the capillary tube on the right

side of the jacket, and lay the channels aside.

Page 9

Internet Version for Reference Only

Copper Brute B4 Volume Water Heaters

Clamp

Bracket

Heat

Exchanger

Bracket

In/Out Header

Clamp

Flue Collector

REAR TILE COVER

FLOW SWITCH

CONDUIT

GAP CLOSURE

GROMMET

DRAIN

VALV

E

METAL CHANNEL

(FOR CAPILLAR

Y TUBE)

TERMINAL STRIP

HEAT EXCHANGER

ASSEMBLY

GAP CLOSURE

DRAIN PLUG

DRAIN VALV

E

REAR TILE

COVER

HEX HEAD

SCREWS

MANUAL RESET

HIGH LIMIT

SWITCH BOX

Page 9

Figure 15. Heat exchanger reversal.

Figure 16. Flue collector Holddown Clamps.

Page 10

Internet Version for Reference Only

Page 10

Copper Brute B4 Volume Water Heaters

Page 11

3.1 in.

(79mm)

2.4

in.

(61mm)

2.4

in.

(61mm)

Attach Capillary

Covers

on

Left Side

LEFT

0.9 in.

dia

(23mm)

(Two holes)

FRONT

1.9 in.

(48mm)

Retaining

Clip

2-Stage/

Operating

Controller

Header

Modulating (if

installed)

Inlet Oulet

High Limit

BRADFORD WHITE

10. In the control compartment, nd the manual reset

high-limit switch box (see Figure 15) and loosen

the screw on the top to remove the cover.

11. Loosen the screw that fastens the white wire and

remove it from the terminal. Pull it out through

the top of the case and separate the other white

wire from the red wire coming from the fuse

Figure 17. Sensory bulb locations.

Figure 18. Retaining clip removal.

Figure 19. Hole location, left side.

holder. Gently pull the two white wires out of the

control compartment and coil them on top of the

heat exchanger.

12. A temperature control sensing bulb is located

in the front of the header on the inlet side and a

manual reset hi-limit sensing bulb is located on

the back side of the header on the outlet side (see

Figure 17). Remove these sensing bulbs from the

header. The following steps for removal apply to

all sensing bulbs:

a. If there is more than one capillary tube coming

out of the header, label the capillary tubes.

b. Loosen the screw on the capillary tube

retaining clip, then gently pry the clip apart

until it comes free from the temperature

control (see Figure 18).

c. Pull the sensing bulbs out of the temperature

control.

d. Gently pull the capillary tubes into the control

compartment.

e. Pull the temperature sensing bulb out of the

header, and temporarily route it to the front of

the heater.

13. Use a pair of diagonal cutters to cut the plastic

tie around the wire bundle in the control

compartment.

14. On the terminal strip, disconnect the two brown

wires from No. 5 and No. 6 terminals.

15. Remove the ow switch conduit retaining clip

and the elbow leading into the jacket.

16. Reach inside the control compartment and

release the retaining nut in the upper right corner.

The nut should only be nger-tight.

17. When the conduit is pulled away from the jacket,

pull the two brown wires out of the control

compartment. Coil the conduit and wires on top

of the heat exchanger.

18. Use a chassis punch to put two 7/8 inch (22

mm) holes in the front left side of the jacket (see

Figure 19).

19. Remove the front and rear tile covers (see

Figure 15).

20. Lift out the heat exchanger assembly, turn it 180

degrees, and reseat the unit in the heater with the

water connections on the left side.

21. Reinstall the front and rear tile covers.

22. Push the capillary tube(s) out through the lower

hole in the left side of the jacket.

23. Install the sensing bulb(s) into the appropriate

temperature control (keep in mind that the

positions of the inlet and outlet have been

reversed. The inlet is now behind the outlet).

Page 11

Internet Version for Reference Only

Copper Brute B4 Volume Water Heaters

Page 11

24. Fasten the capillary tube(s) by squeezing the

retaining clip together, then tighten the screw.

25. Feed the two brown wires through the top hole

on the left side until the conduit elbow is against

the jacket.

26. Fasten the conduit by sliding the retaining nut

over the two brown wires (inside the control

compartment) then screwing it down nger-tight

on the conduit elbow.

27. Straighten the capillary tubing and fasten it to the

side of the heater under the channel. Use the selftapping screws to fasten the channel to the jacket.

28. Feed the two white wires into the control

compartment. Attach one wire to the terminal

in the manual reset hi-limit switch. If one is not

installed, attach it to terminal No. 1. Connect the

other wire to the red wire attached to the fuse

holder.

29. Attach the two brown wires to terminals No. 5

and 6 on the terminal strip. Keep all wiring away

from surfaces that will get hot during heater

operation.

30. Replace the gap closures and tighten the screws

securely.

31. Replace the three grommets and the cap.

32. Reinstall the drain plug and drain valves.

33. Slip the ue collector assembly back down inside

the enclosure.

34. Carefully slip a hand inside to make sure there

are no gaps between the heat exchanger and the

ue collector.

35. Check to make sure the wiring is not pinched

against sharp edges, or resting on the collector

assembly.

36. Replace the two ue collector holddown clamps.

37. Replace the top assembly and fasten it with the

hex-head screws.

38. Replace the front cover.

39. Reinstall the vent cap or drafthood if one was

removed.

40. On indoor installations (sizes 175-250), insert the

draft hood switch plug into the receptacle on the

left side of the heater.

2.6.2 Water Chemistry

Bradford White equipment is designed to be used

in a variety of water conditions. With the proper pump,

the water velocity in the heat exchanger tubes is kept

high enough to prevent scaling from hard water, yet

low enough to avoid erosion by soft water.

NOTE: It is possible to have hard and soft

water in the same city. Check with the local water

companies.

If an installer sees damage to any water handling

equipment at the installation site, it should be repaired

as soon as possible to help reduce maintenance costs.

If there is erosion, resize the pump to reduce water

velocity before the tube ruptures. If scaling is bad,

set up a heat exchanger tube-cleaning maintenance

schedule to prevent heat exchanger tube cracking

and wear. Not xing the condition will mean serious

damage to the heater and the water system.

NOTES:

• In areas where the water supply is soft or

corrosive, the heater must have cupronickel tubes

in the heat exchanger.

• Bradford White does not warrant heat exchangers

damaged by scaling, corrosion, or erosion.

2.6.3 Freeze Protection

Although Copper Brute heaters are design

certied for outdoor installations, such installations

are not recommended in areas subject to freezing

temperatures unless proper precautions are taken.

Consult the local factory representative or Bradford

White for additional information.

2.6.4 Water Hardness

Consider the water hardness when selecting a

pump for the heater (see Table 3). Hard water needs a

pump which can provide high ow to prevent scaling,

while soft water needs low ow to prevent erosion.

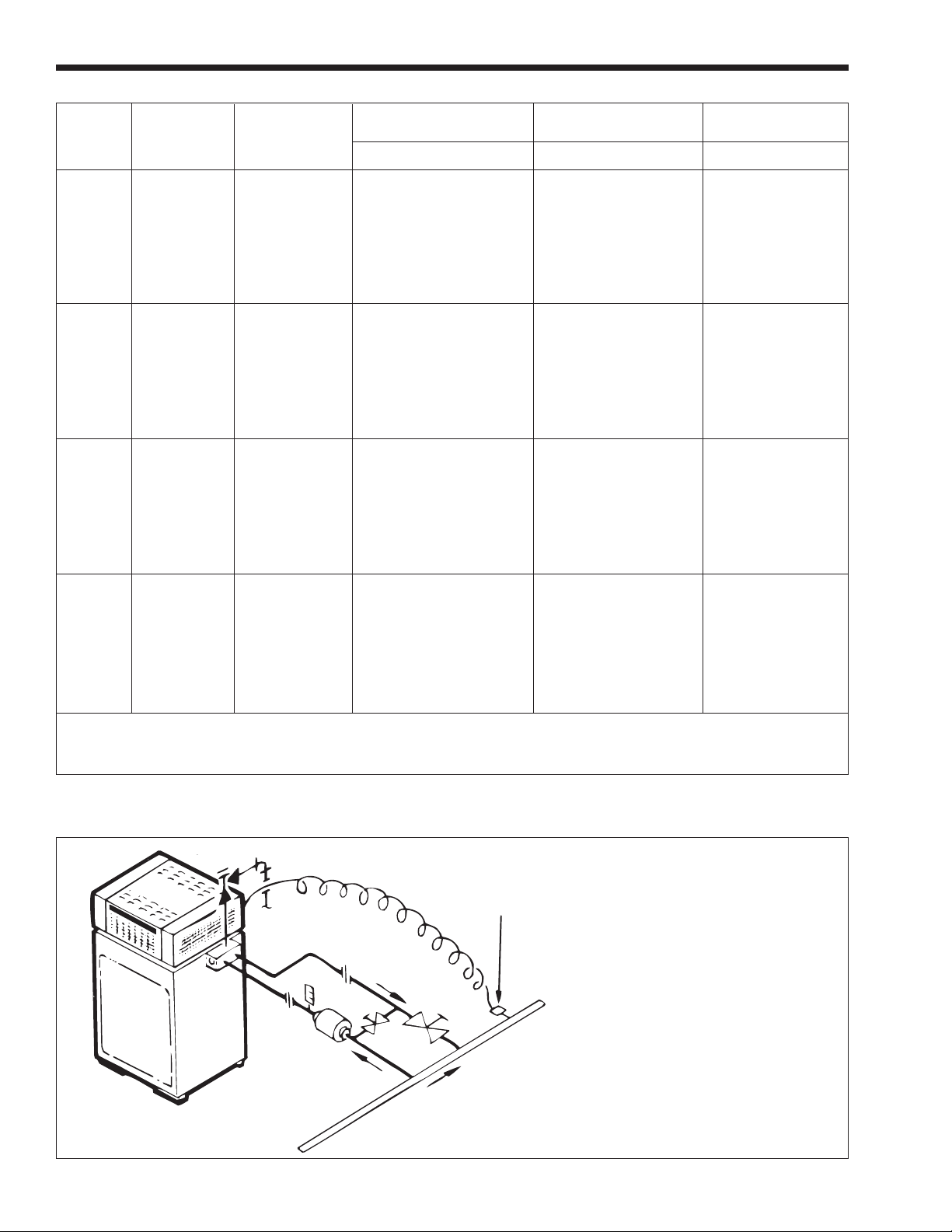

2.6.5 Pump Requirements

The Copper Brute heater has a factory installed

pump which is for heater-to-tank circulation only.

Pump performance is shown in Table 4.

The pump that is mounted on the heater is sized

for the heat exchanger and 30 feet (9.1m) of 1-1/2"

pipe, including six (6) 90° elbows. If more piping is

needed, contact Bradford White for options.

The water temperature entering the Copper Brute

must be at least 110°F (43°C).

Figures 20, 21 and 22 show typical piping

arrangements. For assistance with other piping

methods, contact Bradford White.

Hardness Grains per Parts

Category Gallon per Million

Soft 1 through 7.5 17 through 128

Normal 7.6 through 17 129 through 291

Hard Over 17 Over 291

Table 3. Water Hardness.

Page 12

Internet Version for Reference Only

Copper Brute B4 Volume Water Heaters

Page 13

To

Drain

Heater

T1

A

B

Remote

Temperature

Control for Heater

Page 12

Heat Flow Pressure* Water Temp

Exch. Water Rate Drop Rise

Model Passes Category

175 2 Soft 22 1.4 5.8 1.8 13 7

Normal 34 2.1 11.2 3.4 8 4

Hard 46 2.9 19.1 5.8 6 3

4 Soft 11 0.7 4.9 1.5 25 14

Normal 17 1.1 9.3 2.8 16 9

Hard 23 1.5 15.9 4.8 12 7

250 2 Soft 22 1.4 5.8 1.8 18 10

Normal 34 2.1 11.2 3.4 12 7

Hard 46 2.9 19.1 5.8 9 5

4 Soft 11 0.7 4.9 1.5 35 19

Normal 17 1.1 9.3 2.8 33 18

Hard 23 1.5 15.9 4.8 17 9

325 2 Soft 34 2.1 12.5 3.8 18 10

Normal 34 2.1 12.5 3.8 18 10

Hard 46 2.9 21.7 6.6 11 6

4 Soft 17 0.7 10.4 3.2 36 20

Normal 17 0.7 10.4 3.2 30 17

Hard 23 1.5 18.1 5.5 22 12

BRADFORD WHITE

gpm L/s ft. m °F °C

400 2 Soft 34 2.1 13.3 4.1 19 11

Normal 34 2.1 13.3 4.1 19 11

Hard 46 2.9 23.4 7.1 14 8

4 Soft 17 0.7 11.1 3.4 37 21

Normal 17 0.7 11.1 3.4 37 21

Hard 23 1.5 19.5 5.9 27 15

*Pressure drop includes head loss of heat exchanger and through 30 feet (9.1 m) of pipe and normal ttings when heater

is installed with storage tank. Pipe and ttings are assumed to be 1-1/2 inch (38 mm).

Table 4. Pump Performance Requirements.

Adjustment Procedure

1. Turn on heater and open gate

valves A and B.

2. After 15 minutes, read T1.

3. If T1 is less than 110°F (43°C),

slowly close valve B until T1

climbs to 110°F (43°C).

4. If T1 is greater than 110°F (43°C),

slowly close valve A until T1

drops to 110°F (43°C).

5. Check after 5 minutes

operation and make nal

adjustments.

Main Circulating Loop

(With Own Pump)

Water Maintained

Less Than 110°F (43°C)

Figure 20. Cold water application.

Page 13

Internet Version for Reference Only

Copper Brute B4 Volume Water Heaters

Conventional

Tank

Heater

To

Drain

Drain

24-inch

Min.

Service

Valves

Cold

Water

Hot Water

to Building

Hot Water

Return from

Building

Check

Valve

Bldg.

Loop

Circ.

Pump

Hot Water

Return from

Building

Throttling

Valve

Check

Valve

Bldg.

Loop

Circ.

Pump

Cold

Water

Conventional

Tank

To

Drain

Hot Water

to Building

Optional Cold

Water Supply

When Adequate

Tank Opening

Not Available

Heater

Pump

To

Drain

Service

Valves

Page 13

Figure 21. Hot water supply with vertical tank.

Note:

Heavy line indicates heater-to-tank circulation loop.

Figure 22. Hot water supply with horizontal tank.

Page 14

Internet Version for Reference Only

Copper Brute B4 Volume Water Heaters

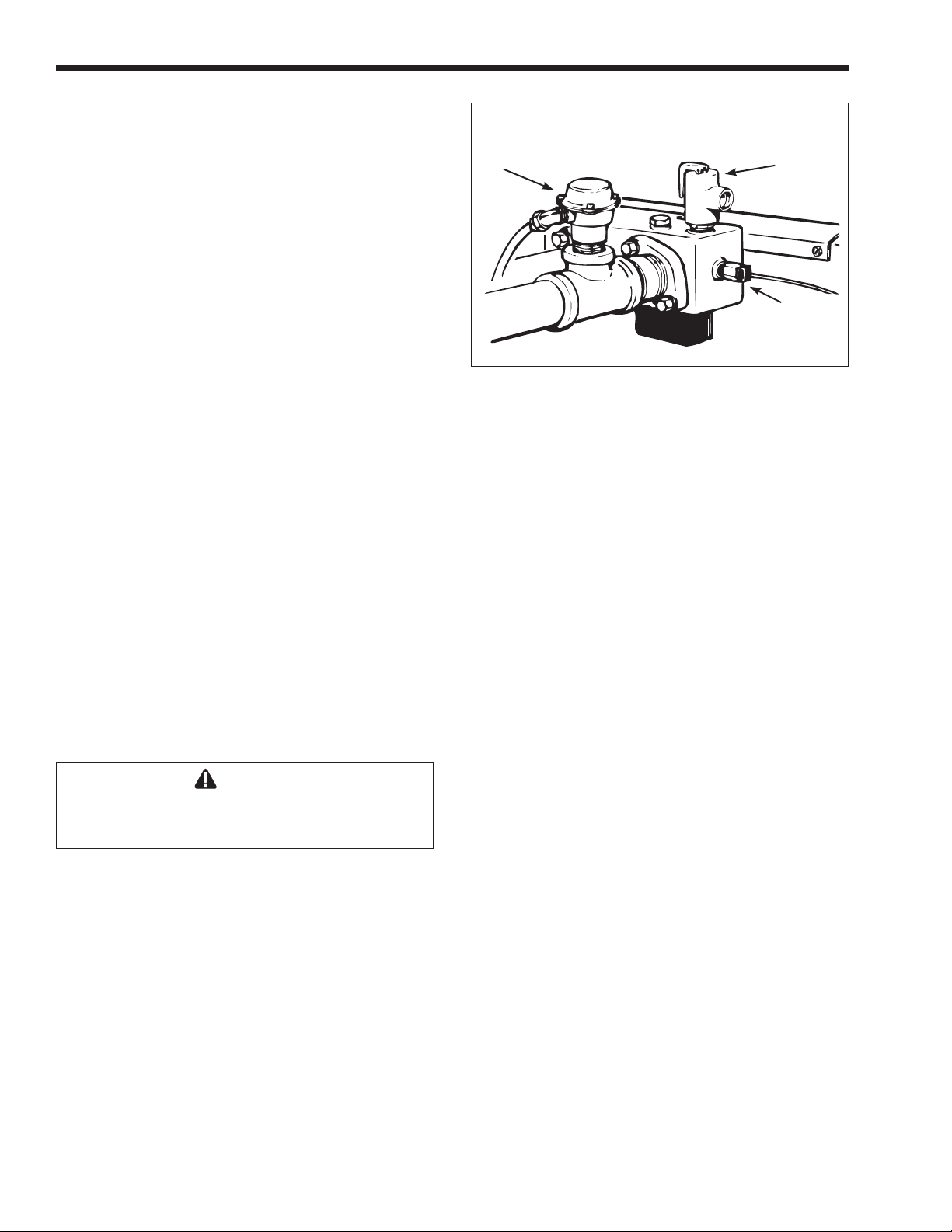

Page 15

Flow

Switch

Pressure

Relief

Valve

High-Limit

Dry

Well

Page 14

2.6.6 Pressure Buildup in Water System

The water utility supply meter may contain a

check valve, back ow preventer, or water pressure

reducing valve that will create a closed water supply

system. Contact the water supplier or local plumbing

inspector on how to control this situation.

During the heating cycle of the heater, the water

expands creating a pressure buildup in the water

system. The pressure relief valve may discharge hot

water under these conditions, causing a loss/waste of

energy and a buildup of lime on the relief valve seat.

NOTE: Do not plug the relief valve.

There are two methods to prevent the relief valve

from discharging hot water in a closed water system:

1. Install a pressure relief valve on the cold water

supply line. Make sure that the discharge of this

valve is directed to an open drain and protected

from freezing.

2. Install a properly sized thermal expansion tank

on the cold water supply line.

2.6.7 Pressure Relief Valve

The pressure relief valve must be installed in the

tapped opening provided in the boiler header with its

outlet piped to a drain or oor sink. Special attention

must be given to relief valve settings in installations

where the boiler is located on the ground oor of a

tall building, or where the operating temperature of

the boiler is above 210°F. In both instances, the static

pressure of the system is elevated, and could cause

the relief valve to leak. Where no special setting of

the relief valve is ordered, the factory will furnish a

125 psi setting.

WARNING

Hot water can scald! Hot water can produce

third degree burns in 6 seconds at 140°F (60°C)

and in 30 seconds at 130°F (54°C).

2.6.8 Water Pressure

Keep the water pressure in the system above

30 psi (207 kPa). If the system pressure drops below

30 psi (207 kPa), it could damage the heater through

lack of circulation. If for any reason, the water is

turned off temporarily, to service the equipment for

example, airlock could be a problem when the heater

is turned back on. To eliminate the airlock, open the

pressure relief valve (see Figure 23) and allow the air

to bleed out until water starts to ow. As soon as full

circulation is restored, the trapped air will be released

through the hot water faucets.

BRADFORD WHITE

Figure 23. Pressure relief valve.

2.6.9 Storage Tank Installation

1. Be sure the oor is structurally capable of

supporting the tank when it is lled with water,

and is waterproof.

2. Place the tank so that manholes, inspection

covers, nameplates and drain valves are

accessible.

3. Be sure the tank is suitable for the water in the

system. Some water is corrosive and requires

a protected tank. Most tanks are available with

glass, plastic, or galvanized linings.

4. If the tank is glass-lined, it should be equipped

with a suitable magnesium anode. It is a

good practice to replace the anode when it is

approximately 50 percent used. The factory

warranty on a glass-lined tank may be void if a

satisfactory anode is not in place at the time of a

failure or if it is consumed by cathodic action.

5. The tank must be lined if a water softener is

installed in the system.

6. Make sure the tank connections in the heatertank circulating loop are the proper size (see

Section 2.6.5). If tappings are smaller than the

recommended pipe size, a larger pump may be

required. Consult the factory if in doubt.

7. Install a pipe in the tank drain tting that goes to

a oor sink, and install a drain valve. If a oor

sink is not available, install a hose bib.

8. Hot water tanks in an existing installation

are likely to have silt deposits on the bottom.

Therefore, it is important to extend the pump

suction pipe in the tank to a position near the top.

Pipe the return from the heater to the bottom of

the tank.

Incorrect installation can cause rapid failure

of water tanks due to electrolysis. Tanks must

be installed with dialectric connections to

electrically isolate the tank from stray current.

Note that use of brass or bronze connectors does

not replace the need for dialectric connections.

Page 15

Internet Version for Reference Only

Copper Brute B4 Volume Water Heaters

MANUAL SHUT-OFF

VALV

E

GAS

SUPPLY

INLET

T-FITTING

3" (76 mm)

MIN.

UNION

NIPPLE

CAP

TO

BOILER

INLET

Page 15

2.6.10 Thermal Circulation of Hot Water

in Cold Water Supply Lines

Under certain circumstances, thermal circulation

will occur in the cold water pipe supplying the water

to the heating system. This happens in a multi-story

building when the cold water pipe rises from its

connection to the system. To correct the problem, a

check valve in the cold water line supplying the heater

will prevent thermal circulation, and a small expansion

tank will permit heated water to expand without

popping off the relief valve.

2.7 Gas Supply and Piping

2.7.1 General Instructions

Review the following instructions before

continuing the installation.

1. Gas piping installation must be in accordance

with the latest edition of ANSI Z223.1. In

Canada, the installation must be in accordance

with CAN1-B149.1 or .2 and all local codes that

apply.

2. Check the rating plate to make sure the heater

is tted for the type of gas being used. Bradford

White heaters are normally equipped to operate

below a 2000 foot (609 m) altitude. Heaters

equipped to operate at higher altitudes have

appropriate stickers or tags attached.

3. If a gas pressure regulator is required, the

installation must be in accordance with the latest

edition of ANSI Z223. In Canada, the installation

must be in accordance with CAN1-B149.1 or .2

and all local codes that apply.

4. The gures in Table 5 should be used to size the

gas piping from the gas meter to the heater.

5. Install a sediment trap (drip leg) ahead of the

gas controls (see Figure 24 ). Fit the trap with a

threaded cap which can be removed for cleaning.

6. Install a manual gas shutoff valve for service and

safety. Check the local codes.

7. Disconnect the heater and its individual shutoff

valve from the supply gas system during pressure

test of the system at pressures higher than 1/2 psi

(3.4 kPa).

8. Gas supply pressures to the heater are listed in

Table 6.

NOTE: The heater and all other gas appliances

sharing the heater gas supply line must be ring at

maximum capacity to properly measure the inlet

supply pressure. Low gas pressure could indicate

an under-sized gas meter and/or obstructed gas

supply line.

Distance from Gas Meter or Last Stage Regulator

0-100 feet 100-200 feet 200-300 feet

0-30 m 30-60 m 60-90 m

Boiler Nat. Nat. Nat.

Size in. mm in. mm in. mm

175 1 25 1 32 1 32

250 1 32 1 32 1 38

325 1 32 1 38 1 38

400 1 32 1 38 2 51

Notes:

1. These numbers are for natural gas (0.65 Sp. Gr.) and

are based on inch (13mm) water column pressure

drop. Check supply pressure with a manometer, and

local code requirements for variations. For liqueed

petroleum gas, reduce pipe diameter one size, but

maintain a inch (13mm) minimum diameter.

2. Check supply pressure and local code requirements

before preceding with work.

3. Pipe ttings must be considered when determining gas

pipe sizing.

4. For propane gas: Reduce pipe diameter one size, but

maintain a inch (19mm) minimum diameter.

Table 5. Natural Gas and Propane,

Pipe Size Requirements.

Figure 24. T-Fitting and sediment trap.

Supply Pressure Natural Gas Propane Gas

Water Column in. mm in. mm

Minimum 6.5 165 11 279

See Rating Plate

Maximum 9 229 14 356

Table 6. Gas Supply Pressure Requirements.

9. Do not exceed the maximum inlet gas pressures

specied. Excessive pressure will result in

damage to the heater's gas controls. The

minimum pressures specied is for gas input

adjustment.

10. The correct burner manifold gas pressure is

stamped on the rating plate. The regulator on the

gas valve is preset at the factory, and does not

normally need adjustment.

Page 16

Internet Version for Reference Only

Page 16

Copper Brute B4 Volume Water Heaters

Page 17

Mixing Valve

Out —

Mixed

Water

For Potable Use

Hot

Water

From

Water Heater

or Storage Tank

Cold

Water

Supply

BRADFORD WHITE

11. Before operating the heater, test the complete gas

supply system and all connections for leaks using

a soap solution.

Caution

Since some leak test solutions (including soap and

water) may cause corrosion or stress cracking, rinse

the piping with water after testing.

2.7.2 Special Precautions

for Propane Gas

Liqueed petroleum (LP) gas is heavier than

air. Therefore, do not install heaters using LP gas in

a pit or locations where gas might collect. Locate

heaters a safe distance from LP gas storage and lling

equipment. Consult local codes and re protection

authorities about specic installation restrictions.

2.8 Electrical Wiring

WARNING

Electrically ground the heater in accordance with

the latest edition of the National Electrical Code,

ANSI/NFPA 70. In Canada, use C22.1. Do not rely

on the gas or water piping to ground the metal

parts of the heater. Often, plastic pipe or dielectric

unions isolate the heater electrically. Service and

maintenance personnel who work on or around the

heater may be standing on wet oors and could be

electrocuted by an underground heater.

1. Check heater wiring and pump for correct

voltage, frequency, and phase. Check to make

sure heater is wired for 120 volts alternating

current (VAC). If 240 VAC, contact local factory

representative or Bradford White.

2. Wire the heater and pump exactly as shown in

the wiring diagram supplied with the heater.

See Figure 26 and 27 for a typical example of a

wiring diagram.

3. Electrically interlock the pump and heater so

the heater cannot come on unless the pump is

running.

4. Connect all eld-installed devices (draft

switches, relays, timers, outdoor temperature

reset devices, etc.) to the heater wiring at points

labeled Field Interlock (see Figures 26, 27, 28

and 29).

2.9 Combined Space Heating/Potable

Water Heating Systems

2.9.1 Combined Space Heating

NOTE: These systems are not allowed in the

Commonwealth of Massachusetts.

Piping and components connected to this water

heater for the space heating application shall be

suitable for use with potable water.

Toxic chemicals, such as used for boiler

treatment, shall not be introduced into the potable

water used for space heating. Do not use solder

containing lead in the potable water lines.

This water heater when used to supply potable

water shall not be connected to any heating system

or components(s) previously used with a non-potable

water heating appliance.

When the system requires water for heating

at temperatures higher than required for other

uses, an anti-scald mixing or tempering valve (see

Figure 25) shall be installed to temper the water

for those uses in order to reduce scald hazard

potential. Some jurisdictions may require a backow

preventer in the cold water line. In such cases, the

temperature and pressure relief valve may discharge

water due to expansion. A diaphragm type expansion

tank will normally eliminate this condition. Follow

the manufacturer's instructions for installation of the

expansion tank.

SECTION 3.

Operating Instructions

3.1 Normal Operating Sequence

NOTE: Safe lighting and other performance

criteria were met with the gas manifold and control

assembly installed on the heater during tests specied

in ANSI Z21.13.

Figure 25. Installation of tempering valve.

Page 17

Internet Version for Reference Only

Copper Brute B4 Volume Water Heaters

IGNITION SYSTEM NO. 1 (SIZES 175-250)

W

3

W

6

2

1

R

O

P

4

5

Y

R

10

11

12

Y

TR

Y

TH

8

9

6

7

4

5

2

3

BR

BR

BR

R

R

R

115V

1

Y

R

24V

ON/OFF WITH EM2

R

4

6

5

3 2

G

1

W

BK

BK

BK

R

1

3

P

BK

BK

W

BL

1

3

2

BR

54

BR BK

BR

W

BK

BR

Y

T

A

B

O

FLOW

SWITCH

GAS VALV

E

ALTERNATE WIRING FOR INDOOR INSTALLATION ONLY

PLUG

VENT DAMPER

VENT DAMPER

JUMPER

VENT DAMPER

RECEPT

ACLE

FUSIBLE

LINK

FIELD INTERLOCK

(REMOVE JUMPER

WHEN USED)

2 AMP

FUSE

HI-LIMIT

CONTROL

TEMP

RESET

MANUAL

STRIP

TERMINAL

TRANSFORMER

VENT DAMPER

ACTUATOR

M

VENT DAMPER

AND DRAFTHOOD

SWITCH, M. RESET

PILOT BURNER WITH

THERMOCOUPLE

SWITCH

POWER

LOW WATER

CUT-OFF (OPTIONAL)

GROUNDING

CONDUCTOR

PUMP

HOT

NEUTRAL

POWER SUPPL

Y

115/60HZ

PUMP

RELA

Y

BK

G

BK - BLACK

W - WHITE

R - RED

Y - YELLOW

BL

- BLUE

BR

- BROWN

O - ORANGE

G - GREEN

P - PURPLE

FACTORY WIRING

24V

115V

FIELD WIRING

24V

115V

Page 17

IF ANY OF THE ORIGI NAL WIRE AS SUPPLIED

WITH T HE HEATER MUST BE REPLACED, IT

MUST BE REPLACED WITH APPLIAN CE WIRING

MATERIAL 10 5°C (220°F ) OR ITS EQUIVALENT.

WHITE WIRES TO FUSIBLE LINK MUST BE

REPLAC ED WITH WIRE HAVING INSULATIO N

RATED AT 200°C (390°F). (AVAILABL E FROM

FACTORY).

Figure 26. Typical example of wiring schematic, System 1, Sizes 175-250.

Page 18

Internet Version for Reference Only

Page 18

Copper Brute B4 Volume Water Heaters

Page 19

115V

24V

TRANSFORMER

1

2

3

4

5

6

7

8

9

10

11

12

RR

FUSE

2 AMP

FIELD INTERLOCK

(REMOVE JUMPER

WHEN USED)

Y

FLOW

SWITCH

STRIP

TERMINAL

Y

BR

BR

1

23

6

4

5

W

W

O

P

Y

R

VENT DAMPER

JUMPER

HI-LIMIT

RESET

MANUAL

RECEPTACLE

VENT DAMPER

1

23

6

4

5

R

G

W

M

BK

ACTUATOR

VENT DAMPER

BK

BK

VENT DAMPER

PLUG

ALTERNATE WIRING FOR INDOOR INSTALLATION ONLY

VENT DAMPER

AND DRAFTHOOD

SWITCH, M. RESET

ON/OFF WITH EM2

IGNITION SYSTEM NO. 12 (SIZES 175-250)

BR

R

R

CONTROL

TEMP

LOW WATER

CUT-OFF (OPTIONAL)

BK

P 1

3BR2 4 5

Y

SENSOR

PILOT BURNER

WITH SPARK

ELECTRODE

SPARK

O

BR

Y

GAS VALVE

PV

MV/PV

MV

Y

O

LINK

FUSIBLE

W W

TR

TH-TR

GAS VALVE

ALTERNATE

TH

O

Y

BR

POWER

SWITCH

T

B

3

RELAY

PUMP

A

1

R

W

BK

BL

GROUNDING

BK

PUMP

BR

BR

CONDUCTOR

POWER SUPPLY

115/60HZ

W

BK

NEUTRAL

HOT

W

W

BK

IGNITION

CONTROL

1 M

V

2 MV/PV

3 P

V

4 GND

5 24V (GND)

6 24V

7 TH-W

8 M

V

9 S

PARK

BK

- BLACK

W - WHITE

R - RED

Y - YELLOW

BL

- BLUE

BR

- BROWN

O - ORANGE

G - GREEN

P - PURPLE

FACTORY WIRING

24V

115V

FIELD WIRING

24V

115V

BRADFORD WHITE

IF ANY OF THE ORIGI NAL WIRE AS SUPPLIED

WITH T HE HEATER MUST BE REPLACED, IT

MUST BE REPLACED WITH APPLIAN CE WIRING

MATERIAL 10 5°C (220°F ) OR ITS EQUIVALENT.

WHITE WIRES TO FUSIBLE LINK MUST BE

REPLAC ED WITH WIRE HAVING INSULATIO N

RATED AT 200°C (390°F). (AVAILABL E FROM

FACTORY).

Figure 27. Typical example of wiring schematic, System 12, Sizes 175-250.

Page 19

Internet Version for Reference Only

Copper Brute B4 Volume Water Heaters

2 AMP

FUSE

TRANSFORMER

MANUAL

RESET

HI-LIMIT

LOW WATER

CUT-OFF (OPTIONAL)

POWER

SWITCH

HOT

115/60 HZ

POWER SUPPL

Y

PUMP

GROUNDING

CONDUCTOR

NEUTRAL

TEMP

CONTROL

TERMINAL

STRIP

PUMP

RELA

Y

FIELD INTERLOCK

(REMOVE JUMPER

WHEN USED)

FLOW

SWITCH

BK

- BLACK

W - WHITE

R - RED

Y - YELLOW

BL

- BLUE

BR

- BROWN

O - ORANGE

G - GREEN

P - PURPLE

FACTORY WIRING

24V

115V

FIELD WIRING

24V

115V

GAS VALVE

PILOT BURNER WITH

THERMOCOUPLE

1

2

3

4

5

6

7

8

9

10

11

12

R

R

R

R

R

R

Y

Y

Y

Y

BK

BK

BK

BK

BR

BR

BR

BR

BR

BR

BR

O

W

W

W

W

BL

BK

P

1 2

3

4

5

G

A

T

B

1

3

24V 115V

TH

TR

IGNITION SYSTEM NO. 1 (SIZES 325-400)

ON/OFF WITH Em2

Page 19

Figure 28. Typical example of wiring schematic, System 1, Sizes 325-400

IF ANY OF THE ORIGI NAL WIRE AS SUPPLIED

WITH T HE HEATER MUST BE REPLACED, IT

MUST BE REPLACED WITH APPLIAN CE WIRING

MATERIAL 10 5°C (220°F ) OR ITS EQUIVALENT.

WHITE WIRES TO FUSIBLE LINK MUST BE

REPLAC ED WITH WIRE HAVING INSULATIO N

RATED AT 200°C (390°F). (AVAILABL E FROM

FACTORY).

Page 20

Internet Version for Reference Only

Page 20

Copper Brute B4 Volume Water Heaters

Page 21

IGNITION SYSTEM NO. 12 (SIZES 325-400)

ON/OFF WITH EM2

2 AMP

FUSE

TRANSFORMER

LOW WATER

CUT-OFF (OPTIONAL)

POWER

SWITCH

HOT

PUMP

RELA

Y

TERMINAL

STRIP

MANUAL

RESET

HI-LIMIT

TEMP

CONTROL

200°F MAX

FIELD INTERLOCK

(REMOVE JUMPER

WHEN USED)

PILOT BURNER

WITH SP

ARK

ELECTRODE

SENSOR

GAS VALV

E

SPARK

FLOW

SWITCH

115V/60HZ

POWER SUPPL

Y

PUMP

NEUTRAL

GROUNDING

CONDUCTOR

1

2

3

4

5

6

7

8

9

10

11

12

BK - BLACK

W -

WHITE

R -

RED

Y -

YELLOW

BL - BLUE

BR - BROWN

O -

ORANGE

G -

GREEN

P -

PURPLE

FACTORY WIRING

24V

115V

FIELD WIRING

24V

115V

R

R

24V

115V

BK

BR

W

Y

Y

W

R

R

R

BR

O

Y

BK

BL

W

R

R

BR

BR

BR

Y

O

BR

BR

BK

W

BK

BK

W

G

Y

BR

O

Y

Y

P

1 2

3

4

5

A

T

B

1

3

IGNITION

CONTROL

1 M

V

2 MV/PV

3 P

V

4 GND

5 24V (GND)

6 24V

7 TH-W

8 M

V

9 S

PARK

TH-TR

TR

TH

BRADFORD WHITE

IF ANY OF THE ORIGI NAL WIRE AS SUPPLIED

WITH T HE HEATER MUST BE REPLACED, IT

MUST BE REPLACED WITH APPLIAN CE WIRING

MATERIAL 10 5°C (220°F ) OR ITS EQUIVALENT.

WHITE WIRES TO FUSIBLE LINK MUST BE

REPLAC ED WITH WIRE HAVING INSULATIO N

RATED AT 200°C (390°F). (AVAILABL E FROM

FACTORY).

Figure 29. Typical example of wiring schematic, System 12, Sizes 325-400.

Page 21

Internet Version for Reference Only

Copper Brute B4 Volume Water Heaters

Manual Reset Temp. Control

Temperature Controller

WARNINGS

Vent pipes, drafthoods, and heater tops get

hot! These surfaces can cause serious burns.

Do not touch these surfaces while the heater

is in operation. Adding a vent cap reduces the

temperature on the top.

For your safety, when starting the heater, keep your

head and face well away from the lower rebox

opening to prevent any risk of personal injury.

LP GAS: To avoid possible injury, re and

explosion, read and follow these precautions and

all instructions on this heater before lighting. This

heater uses LP gas which is heavier than air and

will remain at ground level if there is a leak. Before

lighting, sniff at ground level.

If you smell gas, follow these rules:

1. DO NOT light matches. DO NOT turn electric

lights or switches on or off in area. DO NOT use

an electric fan to remove the gas from area.

2. Shut off gas at LP tank.

3. Telephone gas company and re department

for instructions. Give your name, address and

phone number.

If your LP tank runs out of fuel, turn off gas at the

heater. After the tank is relled, the heater must be

relit in accordance with the instructions found on the

inside of the heater. DO NOT attempt repairs on the

gas control or heater. Tampering is dangerous and

voids all warranties.

Page 21

7. Turn manual gas valve on.

8. Reset all safety devices (some units have manual

resets on hi-limit switch, low water cutoff, etc.).

9. Set temperature control to desired setting.

10. Replace control access panel.

11. Turn electric power to the heater on.

12. If the heater will not operate:

a. Turn gas to heater off following the

instructions found on the inside of the heater

and call a qualied service technician or gas

supplier.

b. Turn main electrical switch off.

c. Close all manual gas valves.

3.3 Setting the Temperature Controls

The hi-limit switch is factory set, and should not

be adjusted above the factory setting.

WARNING

Adjusting the temperature control past the

recommended setting can result in a scalding

injury. Hot water can produce third degree burns

in 6 seconds at 140°F (60°C) and in 30 seconds at

130°F (54°C).

3.2 Start-Up Procedure

Lighting instructions can be found on the inside

of the heater. To start up the heater:

1. Make sure the system pump is running and there

is water ow.

2. Remove the control access panel.

3. Set the temperature control (see Figure 30) to its

4. Turn electric power to the appliance to off.

5. Turn manual gas valve off.

6. Wait 5 minutes to clear out any gas, then smell

lowest setting.

for gas, including near the oor. Be sure to smell

next to the oor because some types of gas are

heavier than air and will settle on the oor.

Caution

This heater is equipped with an ignition device

which automatically lights the burner. Do not try to

light the burner by hand.

Figure 30. Temperature controls.

3.3.1. Remote Water Heater Temperature

Control:

The water heater can be used with a eldsupplied tank aquastat, sequencing control, or other

temperature control device, which will call the unit for

heat when the temperature goes below the controller’s

setpoint. For the most efcient setting, set the tank

temperature at the lowest possible setting for adequate

hot water in the application.

Page 22

Internet Version for Reference Only

Page 22

Copper Brute B4 Volume Water Heaters

Page 23

BRADFORD WHITE

After a setting has been chosen for the tank

temperature control, set the heater temperature control

10°F (6°C) higher. The heater’s temperature control

senses the inlet water temperature to the heater. The

heater’s manual reset high limit (and automatic

reset high limit, if applicable) senses heater outlet

temperature.

If the unit is equipped with an automatic reset

high limit, set the automatic reset high limit 20°F

(11°C) above the outlet temperature to avoid nuisance

lockouts. Set the manual reset high limit 5°F (3°C)

above the automatic reset high limit.

For units that only have a manual reset high limit

(no automatic reset high limit), set the manual reset

high limit 20°F (11°C) above the outlet temperature to

avoid nuisance lockouts.

Example, Imperial units: If the tank temperature

is set to 140°F, set the heater’s temperature control to

150°F (140°F + 10°F). Further, if the temperature rise

through the heater is 25°F, the outlet temperature will

be 175°F (150°F + 25°F). Therefore, set the automatic

reset high limit to 195°F (170°F + 20°F), and the

manual reset high limit to 200°F (195°F + 5°F).

Example, Metric units: If the tank temperature

is set to 60°C, set the heater’s temperature control to

66°C (60°C + 6°C). Further, if the temperature rise

through the heater is 15°C, the outlet temperature will

be 81°C (66°C + 15°C). Therefore, set the automatic

reset high limit to 92°C (81°C + 11°C), and the

manual reset high limit to 95°C (92°C + 3°C).

Example, Metric units: If the heater’s

temperature control is set to 55°C, and the

temperature rise through the heater is 14°C, the outlet

temperature will be 69°C (55°C + 14°C). Set the

automatic reset high limit to 80°C (69°C + 11°C) and

set the manual reset high limit to 83°C (80°C + 3°C).

3.4 Adjustment for Minimum Input Rate

(models with modulating gas valve)

Adjust the red knob on the modulating gas valve

to the dial number for the desired water temperature

(see Table 7). Adjusting the red knob to number

"1" sets the gas ow rate to minimum. The control

is factory set at "2" which is satisfactory for most

installations.

Temp.

Dial No. °F °C

1 120 49

2 127 53

3 135 57

4 142 61

5 150 66

6 157 69

7 165 74

8 172 78

9 180 82

Table 7. Water Temperature Setting.

3.3.2. Internal Water Heater Temperature

Control:

When an external control is not used, the

circulator between the heater and the storage tank

must run continuously, so that the heater’s temperature

control can detect and control the water temperature

in the storage tank. The water heater’s temperature

control is adjusted to its lowest temperature position

(130°F, 54°C) when shipped from the factory. This is

the preferred starting point for setting the temperature

control.

If the unit is equipped with an automatic reset

high limit, set the automatic reset high limit 20°F

(11°C) above the outlet temperature to avoid nuisance

lockouts. Set the manual reset high limit 5°F (3°C)

above the automatic reset high limit.

For units that only have a manual reset high limit

(no automatic reset high limit), set the manual reset

high limit 20°F (11°C) above the outlet temperature to

avoid nuisance lockouts.

Example, Imperial units: If the heater’s

temperature control is set to 130°F, and the

temperature rise through the heater is 25°F, the outlet

temperature will be 155°F (130°F + 25°F). Set the

automatic reset high limit to 175°F (155°F + 20°F) and

set the manual reset high limit to 180°F (175°F + 5°F).

3.5 Hi-Limit Switch Checkout

After running the heater for a long enough

period, bring the water temperature within the range of

the hi-limit switch and slowly back off the high limit

setting until the heater shuts off. The main burners

should reignite when the hi-limit switch is reset and

turned back up to its original setting. The heater should

now run until it shuts off automatically on operating

control.

Should overheating occur or the gas supply fail

to shut off, turn off the manual gas control valve to the

heater.

3.6 Shut-Down Procedure

Shut down the heater following the instructions

found on the inside of the heater.

Where there is a danger of freezing, shut off the

water supply and remove the drain plugs on both sides

of the heater jacket. Drain every part of the system

subject to damage from freezing temperatures.

Page 23

Internet Version for Reference Only

Copper Brute B4 Volume Water Heaters

Page 23

SECTION 4.

Maintenance

4.1 General Instructions

1. Oil the water circulating pump in accordance

with the manufacturer's instructions.

2. If a strainer is used in a pressure reducing valve

or in the piping, clean it every 6 months in

accordance with the manufacturer's instructions.

3. At startup and every 6 months after, look at

the pilot and main burner ame (see Figure

31). If the ame has the appearance of sooting

tips, check for debris near orices. Call service

technician.

4. Inspect the venting system for blockage, leakage,

and corrosion at least once a year.

5. Keep the heater area clear of combustible

material, gasoline, and other ammable liquids

and vapors.

6. Be sure all combustion air and ventilation

openings are not blocked.

7. Check for black carbon soot buildup on the

external surfaces of the heat exchanger every 6

months.

8. Do not use the heater if any part has been under

water. Replace any part of the control system and

any gas control which has been under water.

NOTE: After installation and rst startup, check

the heat exchanger for black carbon soot buildup after

the following periods of operation: 24 hours, 7 days,

30 days, 90 days, and once every 6 months thereafter.

4.2 Replacement of Gas Controls

The gas and electric controls installed on the

heaters are designed for both dependable operation and

long life. Safe operation of the heater depends on their

proper functioning.

NOTE: The warranty does not cover damage

caused by lack of required maintenance or improper

operating practices.

WARNING

Never attempt to repair the gas valve. Such

attempts will void the warranty, and could lead to

dangerous results.

If the gas valve is found to be defective, replace

it by following these instructions.

1. Turn off electrical power to the heater.

2. Turn off the main gas supply at the manual gas

cock outside the heater jacket or at the meter.

Electronic Pilot Standing Pilot

Figure 31. Flame patterns.

3. Remove the front access door on the heater.

4. Disconnect the service union in the gas line, and

unscrew the main gas pipe from the gas valve

(see Figure 32).

5. Remove the two screws that fastens the antirotation bracket on the left side of the gas valve

(see Figure 32), and the three screws attached to

heater.

6. Remove the pilot gas tube and copper

thermocouple shield, if present, from the gas

valve.

Caution

Label all wires prior to disconnection. Wiring errors

can cause improper and dangerous operation.

7. Tag and remove all wires from the gas valve

terminals.

8. Pull the burner tray out of the heater (see

Figure 32).

9. Screw the new gas valve onto the manifold pipe.

Make sure the arrow on the bottom of the gas

valve that indicates the direction of gas ow is

in the proper direction. Also make sure the brass

tting is on the right side.

10. Connect the pilot gas tube to the pilot assembly

and thermocouple to the gas valve.

Page 24

Internet Version for Reference Only

Page 24

Copper Brute B4 Volume Water Heaters

Page 25

Gas Line

Gas Line

NOTE:

Gas line is connected

to pilot igniter

, not pilot burner.

Anti-Rotation

Bracket

BRADFORD WHITE

Figure 32. Gas valve/burner replacement.

NOTE: Due to sharp edges on the metal burners, wear

protective gloves for the next steps.

11. Hold the gas burner or pilot burner rmly, and

push it away from the manifold until it is clear of

the orice. Slide the burner to be replaced out of

the burner tray (see Figure 33).

12. To replace the gas burner, insert the burner into

the slot at the rear of the burner tray, line it up

with the proper orice and snap it into position.

13. To replace the pilot burner, install the pilot

assembly on the new pilot burner and install it in

the burner tray.

14. Slide the burner tray back into the heater and

fasten it with two screws.

15. Install the anti-rotation bracket to the inner panel

and fasten with two screws (see Figure 32), and

the three screws to heater.

16. Connect the service union in the gas line, and

screw the main gas pipe to the gas valve (see

Figure 32).

17. Turn on gas valve following the lighting

instructions found on the inside of the heater.

18. Turn on the main gas supply at the manual gas

cock or the meter.

19. Check the system for leaks using a soap solution.

Figure 33. Burner removal.

Caution

Since some leak test solutions (including soap and

water) may cause corrosion or stress cracking, rinse

the piping with water after testing.

20. Reconnect the electrical wires to the gas valve in

accordance with the wiring diagram found on the

inside of the heater.

Page 25

Internet Version for Reference Only

Copper Brute B4 Volume Water Heaters

Page 25

21. Install the front access door on the heater.

22. Turn all electrical power to the heater on.

4.3 HEAT EXCHANGER

4.3.1 Inspecting the Heat Exchanger

To check the scale buildup, periodically inspect

the tube having the highest temperature as follows:

1. Open the drain valve on the left side of the

heater.

2. Remove the hex-head plug located on the right

side of the heater under the in/out header (see

Figure 34). Perform this inspection after 60 days

of and after 120 days of operation. This will

establish a regular inspection routine.

4.3.2 Cleaning the Heat Exchanger

An inspection and cleaning of the complete heat

exchanger can only be done by removing it from the

heater.

1. To remove the heat exchanger, refer to Section

2.6.1.

Caution

Black carbon soot buildup on a dirty heat exchanger

can be ignited by a random spark or ame. To