Page 1

S

TANDARD

9001

1

Commercial Gas Light Duty

High Input Direct Vent Water Heater

Features:

Bradford White is ISO registered to the

9001 standard.

■ 1" Non-CFC foam insulation—surrounds the tank surface, saving

energy by retarding loss of heat.

■ Closed combustion—all air for combustion is taken directly from the

outside. The co-axial vent pipe (pipe inside a pipe) draws combustion

air in through the outer pipe (6"), and exhausts the products of

combustion through the inner pipe (4").

■ Co-axial—rotational venting at top of unit.

■ No electrical power necessary.

■ Piezo igniter—for ease of lighting the pilot.

■ Water Connections—3/4" NPT factory installed true dielectric fittings.

Extends water heater life and eases installation.

■ Vitraglas®lined tank—Bradford White water heater tanks are

protected from the corrosive effects of hot water by an exclusive

ceramic porcelain-like coating. The Bradford White high silica Vitraglas

lining provides a tough interior surface for our water heater tanks.

■ Factory installed Hydrojet®Total Performance System—cold inlet

sediment reducing device. Helps prevent sediment build up in tank.

Increases first hour delivery of hot water while minimizing temperature

build up at top of tank.

■ Protective magnesium anode rod—provides added protection

against corrosion for long trouble-free service.

■ Brass drain valve.

■ T&P relief valve—factory installed.

■ Side Tappings—for space heating purposes.

■ Fully automatic controls—automatic temperature selection at your

fingertips. Built-in energy cut-off switch prevents abnormally high water

temperature for extra safety. Built-in gas pressure regulation. Fastacting thermostat starts heat recovery cycle sooner.

■ NSF construction available.

■ Optional vent kits—allow for up to 8 foot max vertical and 8 foot max

horizontal (2.4 meters)). All DH models must be terminated horizontally.

■ Three year limited warranty on steel tank—heavy gauge steel

automatically formed, rolled and welded to assure a continuous seam

for glass lining.

■ One year limited warranty on parts.

■ Design certified by CSA International. (formerly AGA and CGA)

MANUFACTURED UNDER ONE OR MORE OF THE FOLLOWING U.S. PATENTS: 7,063,133 B2; 5,954,492;

5,954,492; 5,761,379; 5,943,984; 5,081,696; 5,988,117; 6,142,216; 5,199,385; 5,574,822; 5,372,185; 5,485,879;

5,277,171; (B1)5,341,770; 5,660,165; 5,596,952; 5,682,666; 4,904,428; 5,023,031; 5,000,893; 4,669,448;

4,829,983; 4,808,356; 5,115,767; 5,092,519; 5,052,346; 4,416,222; 4,628,184; 4,861,968; 4,672,919; Re.

34,534. OTHER U.S. AND FOREIGN PATENT APPLICATIONS PENDING. CURRENT CANADIAN PATENTS:

1,272,914; 1,280,043; 1,289,832; 2,045,862; 2,112,515; 2,108,186; 2,107,012; 2,092,105.5.

®

Page 2

Sales/800-523-2931

Fax/215-641-1670

Technical Support/ 800-334-3393

Fax/269-795-1089

Warranty/800-531-2111

Fax/269-795-1089

International:

Telephone/215-641-9400

Telefax/215-641-9750

Ambler, PA

888-538-7833

Fax on Demand:

bradfordwhite.comwww.

For U.S. and Canada field service,

contact your professional installer or

local Bradford White sales representative.

Sales/Technical Support

866-690-0961

905-238-0100

Fax/905-238-0105

Mississauga, ON

www.bradfordwhitecanada.com

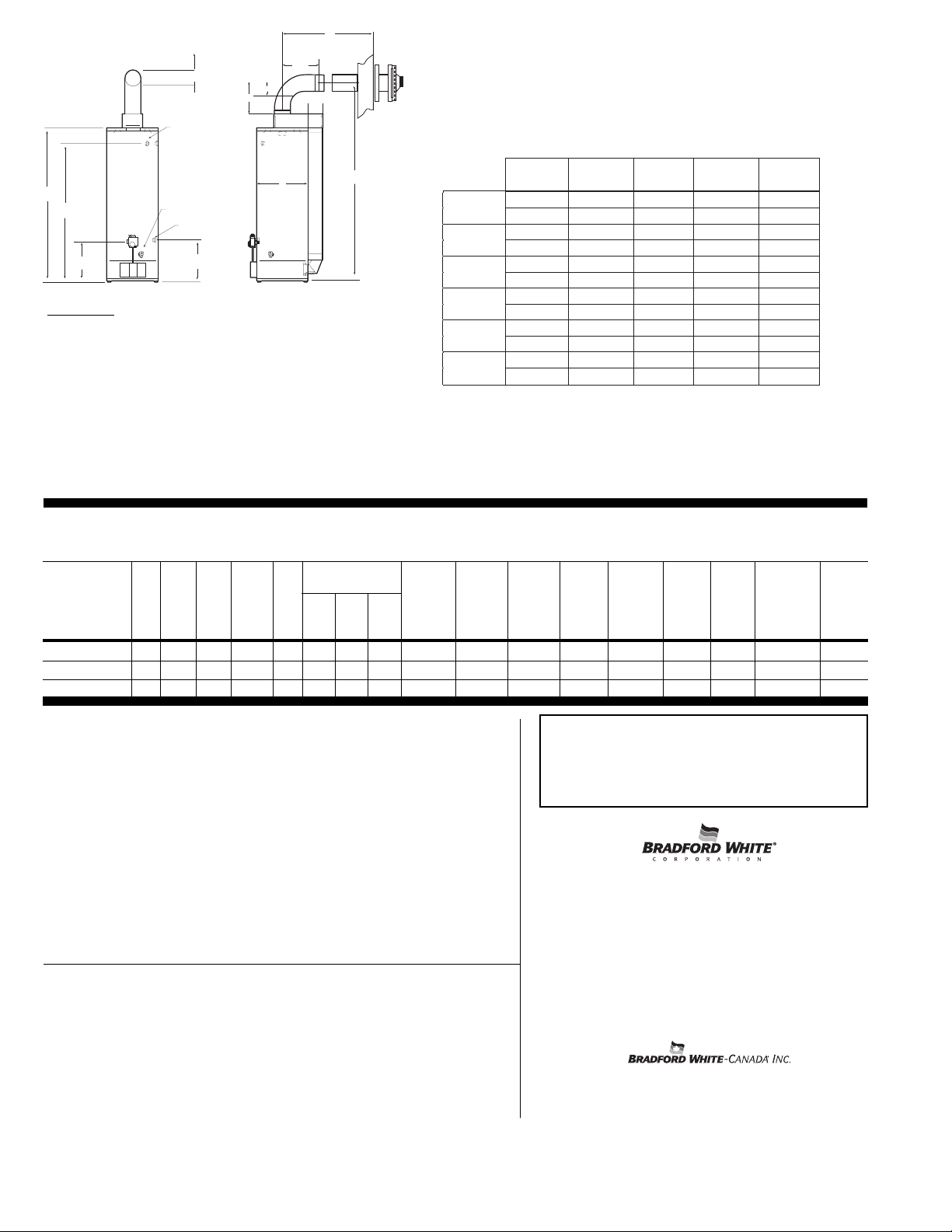

Horizontal "X"

16 1/4 18 25 1/4 37 3/4 61 5/16

17 3/16 20 11/16 35 3/16 57 7/8 107 5/16

order order

n

o add'l order

order

11 9/16

kit F kit G

kit req'd kit H

kit I

16 5/16 *order order

order order

order

1

7 1/4 kit F (2) kit G & F

kit F kit H & F

k

it F & I

1

8 1/16 order order

order order

o

rder

2

0 3/4 kit F & G kit G (2)

kit G kit G & H

k

it G & I

25 5/16

order order order order order

35 1/4

kit F kit G kit H kit H (2) kit I

38 1/16

order order order order order

57 15/16

kit H & F kit H & G kit H (2) kit H (3) kit H & I

61 3/8 order order

order order

order

Vertical "Y"

107 3/8 kit I & F kit I & G

kit I kit I & H

kit I (2)

ptional Kits

C

E & F

D

1/2” GAS

CONNECTION

SIDE WATER OUTLET

DRAIN VALV E

SIDE WATER INLET

G

A

B

6.5 inch (16.5 cm)

Min. Diameter Hole in Wall

Y

11 9/16

X

11 1/2

7 3/16”

B

oot Extension

H

O

Part Number Description

243-42516-00

243-42517-00 Kit G – Telescopes from 61⁄2" to 93⁄16"

243-42514-00 Kit H – Telescopes from 133⁄4" to 2311⁄16"

243-42512-00 Kit I – Telescopes from 4913⁄16" to 9513⁄16"

For more details on the vent kits above, please reference the

upplemental venting instructions.

s

:

Kit F – Telescopes from 43⁄4" to 511⁄16"

Horizontal Installation Only

The standard vent kit (239-42979-00) is ordered and shipped separately. The components

re as follows: 4" vent tube*, 6" Air Intake Tube, Vent Terminal, Inner Wall Term Mounting

a

Flange, Outer Wall Term. Mounting Flange, Vent Terminal Hardware, RTV Silicone Sealant,

" Vent Elbow and a 6" Air Intake Elbow.

4

* (2) = Order two of the kits referenced.

* (3) = Order three of the kits referenced.

he bold text above show what kit(s) are needed in addition to the standard vent and air

T

intake tubes. If the standard vent and air intake tubes are not used in the venting system

(those that do not have bold text) they can be discarded or saved.

or vent distances not found in the selection chart above, please contact the Product

F

anagement Department for sizing recommendations.

M

EC listed. 78% Recovery Efficiency for all models.

Energy Saver Direct Vent Models

NATURAL GAS

GPH Rec.

56°C/100°F. Rise

Model

Number

Imp. US

Gal. Gal. Input

Cap. Cap. Liters BTU KW in. mm in mm in mm in mm in mm in mm in mm in mm Lbs. kg

Imp.

Gal.USGPH

LPH

DH-50T-50B-3N 40 48 182 50,000 14.7 39 47 178 751⁄4 1411 20 508 583⁄4 1492 151⁄4 387 521⁄4 1327 521⁄4

DH-65T-55B-3N 54 65 246 55,000 16.1 43 51 193 781⁄4 1988 22 559 62 1575 151⁄4 387 56 1422 56

DH-75T-60B-3N 62 75 284 60,000 17.6 47 56 212 751⁄2 1918 241⁄2 622 59 1499 151⁄4 387 52 1321 52

All propane gas heaters are equipped with Cast Iron Burner. Change suffix “BN”

to “CX”.

Suitable for Water (Potable) Heating and Space Heating

Toxic chemicals, such as those used for boiler treatment, shall NEVER be introduced

into this system. This unit may NEVER be connected to any existing heating system

or component(s) previously used with a non-potable water heating appliance.

ABCDEFG

Ht. to

Center

Line of

Vent

C

Jacket

Dia.

Ht. to

Top of

Heater

Ht. to

Gas

Conn.

(LP)

Propane Gas Inputs

DH-50T-50-3CX 48,000 BTU/H 14.1 KW 38 45 170

DH-75T-60-3CX 57,000 BTU/H 16.7 KW

Ht. to

T&P

Conn.

Space

Htg.

Outlet

1327

1422

1320

Space

Htg.

Inlet

4/6 102/152 197/89.4

153⁄4 400

4/6 102/152 243/110

153⁄4 400

4/6 102/152 281/127

161⁄2 419

Recovery at

50°C Rise and 100°F Rise

Imp. U.S. Liters/

GPH GPH Hr.

44 53 200

General

All gas water heaters are certified at 300 PSI (2068 kPa) test pressure and 150 PSI

(1034 kPa) working pressure. All water connections are 3⁄4" (19mm) NPT on

8" (703mm) centers on top of unit, all gas connections 1⁄2" (13mm). All models design

certified by CSA International (formerly AGA and CGA). Recovery based on rated

efficiency.

Meets NAECA requirements. All natural gas models meet SCAQMD

requirements.

Dimensions and specifications subject to change without notice in accordance

with our policy of continuous product improvement.

Sample Specification

The water heater shall be a Bradford White model with a rated storage capacity of not less

than _______ gallons (liters), a minimum gas input of _______ BTUH (KWH), and a

minimum recovery of _______ GPH (LPH) at 100

design certified by CSA International (formerly AGA and CGA). The tank shall be lined with

Vitraglas®vitreous enamel. The tank shall have one extruded magnesium anode rod. The

heater shall be insulated with Non-CFC foam insulation. This water heater shall be

equipped with an ASME rated T&P relief valve. The entire installation shall be in

compliance with state and local codes and ordinances.

Vitraglas®and Hydrojet®are registered trademarks of Bradford White®Corporation.

©2006, Bradford White Corporation. All rights reserved.

705-B-HIDV-1106-A Printed in U.S.A.

°F (56°C) temperature rise. It shall be

PRODUCTS ONL Y FOR PROFESSIONALS

Vent

Dia.

Approx.

Shipping

Weight

Loading...

Loading...