B&R ETAL210.1050-1 User Manual

ETAL210.1050-1

User's manual

Version: 1.00 (April 2020)

Order no.: User's manual

Translation of the original documentation

B&R reserves the right to make changes to the content without prior notice. B&R assumes no liability for typographical errors or for any other information in this document as far as legally possible. Liability claims against B&R

regarding the content of delivery and documentation of third-party components used in the product are excluded

in any case. The user is responsible for compliance with all relevant and professionally pertinent safety measures

as well as the intended use. B&R points out that the software and hardware designations and brand names of the

respective companies are subject to the legal protection regulations of intellectual property law.

ETAL210.1050-1 user's manual V1.00 1

Table of contents

Chapter 1 Introduction.................................................................................................3

1 Manual history....................................................................................................................................................3

2 Note regarding additional documentation..........................................................................................................3

3 Organization of notices...................................................................................................................................... 3

Chapter 2 Intended use............................................................................................... 4

1 Protection against electrostatic discharge......................................................................................................... 4

2 Regulations and measures................................................................................................................................ 4

3 Transport and storage....................................................................................................................................... 5

4 Operation............................................................................................................................................................ 5

5 Security concept.................................................................................................................................................5

Chapter 3 Safety notices............................................................................................. 7

1 Safety notices.....................................................................................................................................................7

2 Usage................................................................................................................................................................. 7

3 Electronics.......................................................................................................................................................... 7

4 Responsibilities of the operator......................................................................................................................... 7

Chapter 4 System characteristics.............................................................................. 8

1 General information............................................................................................................................................8

2 Order data..........................................................................................................................................................8

3 Content of delivery.............................................................................................................................................8

Chapter 5 Technical data.......................................................................................... 10

Chapter 6 Commissioning.........................................................................................11

1 Operation..........................................................................................................................................................11

2 Construction..................................................................................................................................................... 11

3 Safety............................................................................................................................................................... 12

4 Power supply....................................................................................................................................................13

5 Memory card.................................................................................................................................................... 13

Chapter 7 Maintenance..............................................................................................14

1 Servicing........................................................................................................................................................... 14

2 Repairing B&R products.................................................................................................................................. 15

Chapter 8 Accessories.............................................................................................. 16

1 Required accessories.......................................................................................................................................16

2 Optional accessories........................................................................................................................................ 19

Chapter 9 International and national certifications................................................ 25

1 Directives and declarations..............................................................................................................................25

Chapter 10 Environmentally friendly disposal........................................................ 26

1 Separation of materials.................................................................................................................................... 26

2 ETAL210.1050-1 user's manual V1.00

Introduction • Organization of notices

Chapter 1 • Introduction

1 Manual history

Version Date Change

0.10 May 2019 First internal version

1.1 INFOBOX: Current user's manual

Information:

B&R makes every effort to keep documents as current possible. The most current versions can be

downloaded from the B&R website (www.br-automation.com).

2 Note regarding additional documentation

This documentation describes the entire product and its intended use in addition to safety guidelines for using

the product.

For information about the components used in the product, see the documentation of the individual components

on our website. For an overview of the components used, see the technical data of this product.

Chapter 1

Introduction

3 Organization of notices

Safety guidelines

Contain only information that warns of dangerous functions or situations.

Signal word Description

Danger! Failure to observe these safety guidelines and notices will result in death, severe injury or substantial damage to property.

Warning! Failure to observe these safety guidelines and notices can result in death, severe injury or substantial damage to property.

Caution! Failure to observe these safety guidelines and notices can result in minor injury or damage to property.

Notice! Failure to observe these safety guidelines and notices can result in damage to property.

Contain useful information for users and instructions for avoiding malfunctions.

Signal word Description

Information: Useful information, application tips and instructions for avoiding malfunctions.

European dimension standards apply to all dimension diagrams.

All dimensions in millimeters.

Unless otherwise specified, the following general tolerances apply:

Nominal dimension range General tolerance per

Up to 6 mm ±0.1 mm

Over 6 to 30 mm ±0.2 mm

Over 30 to 120 mm ±0.3 mm

Over 120 to 400 mm ±0.5 mm

Over 400 to 1000 mm ±0.8 mm

DIN ISO 2768 medium

ETAL210.1050-1 user's manual V1.00 3

Intended use • Regulations and measures

Chapter 2 • Intended use

These products are developed and produced exclusively for training and development in the area of automation.

Any use beyond this is not permitted, in particular the integration of these products or parts thereof in machines,

systems or other devices and processes. B&R does not assume liability for damages of any kind that occur when

using the products outside of training and development or for harm that results from modifying the products. Expansions using products from the ETA system or ETA light system series are permitted.

In addition, the products are only permitted to be used in closed rooms (such as laboratories, offices and classrooms) that do not require separate protective equipment. Trainers shall inform the trainees of the relevant safety

guidelines and precautions before using the product.

1 Protection against electrostatic discharge

Electrical assemblies that can be damaged by electrostatic discharge (ESD) must be handled accordingly.

1.1 Packaging

•

Electrical assemblies with housing:

Do not require special ESD packaging but must be handled properly (see "Electrical assemblies with housing").

•

Electrical assemblies without housing:

Are protected by ESD-suitable packaging.

1.2 Regulations for proper ESD handling

Electrical assemblies with housing

•

Do not touch the connector contacts of connected cables.

•

Do not touch the contact tips on circuit boards.

Electrical assemblies without housing

The following applies in addition to "Electrical assemblies with housing":

•

All persons handling electrical assemblies and devices in which electrical assemblies are installed must

be grounded.

•

Assemblies are only permitted to be touched on the narrow sides or front plate.

•

Always place assemblies on suitable surfaces (ESD packaging, conductive foam, etc.). Metallic surfaces

are not suitable surfaces!

•

Assemblies must not be subjected to electrostatic discharges (e.g. due to charged plastics).

•

A minimum distance of 10 cm from monitors or television sets must be maintained.

•

Measuring instruments and devices must be grounded.

•

Test probes of floating potential measuring instruments must be discharged briefly on suitable grounded

surfaces before measurement.

Individual components

•

ESD protective measures for individual components are implemented throughout B&R (conductive floors,

shoes, wrist straps, etc.).

•

The increased ESD protective measures for individual components are not required for handling B&R

products at customer locations.

2 Regulations and measures

Electronic devices are generally not failsafe. If the programmable logic controller, operating or control device or

uninterruptible power supply fails, the user is responsible for ensuring that connected devices (such as motors)

are brought to a safe state.

4 ETAL210.1050-1 user's manual V1.00

Intended use • Security concept

When using programmable logic controllers as well as when using operating and monitoring devices as control

systems in conjunction with a Soft PLC (e.g. B&R Automation Runtime or similar product) or Slot PLC (e.g. B&R

LS251 or similar product), the safety measures that apply to industrial controllers (protection by protective equipment such as emergency stops) must be observed in accordance with applicable national and international regulations. This also applies to all other connected devices, such as drives.

3 Transport and storage

During transport and storage, devices must be protected against undue stress (mechanical stress, temperature,

humidity, aggressive atmosphere, etc.).

Devices contain components sensitive to electrostatic charges that can be damaged by improper handling. It is

therefore necessary to provide the required protective measures against electrostatic discharge when installing

or removing these devices.

4 Operation

4.1 Protection against contact with electrical parts

Before switching on programmable logic controllers, operating and monitoring devices and uninterruptible power

supplies, it must be ensured that the housing is properly connected to ground potential (PE rail). The ground

connection must also be made if the operating and monitoring device and uninterruptible power supply are only

connected for testing purposes or only operated for a short time!

Chapter 2

Intended use

4.2 Ambient conditions - Dust, moisture, aggressive gases

The use of operating and monitoring devices (e.g. industrial PCs, Power Panels, Mobile Panels) and uninterruptible

power supplies in dusty environments must be avoided. This can otherwise result in dust deposits that affect the

functionality of the device, especially in systems with active cooling (fans), which may no longer ensure sufficient

cooling.

The presence of aggressive gases in the environment can also result in malfunctions. In combination with high

temperature and relative humidity, aggressive gases – for example with sulfur, nitrogen and chlorine components

– trigger chemical processes that can very quickly impair or damage electronic components. Blackened copper

surfaces and cable ends in existing installations are indicators of aggressive gases.

When operated in rooms with dust and condensation that can endanger functionality, operating and monitoring

devices such as Automation Panels or Power Panels are protected on the front against the ingress of dust and

moisture when installed correctly (e.g. cutout installation). The back of all devices must be protected against the

ingress of dust and moisture, however, or the dust deposits must be removed at suitable intervals.

4.3 Programs, viruses and malicious programs

Any data exchange or installation of software using data storage media (e.g. floppy disk, CD-ROM, USB flash

drive) or via networks or the Internet poses a potential threat to the system. It is the direct responsibility of the user

to avert these dangers and to take appropriate measures such as virus protection programs and firewalls to protect

against them and to use only software from trustworthy sources.

5 Security concept

B&R products communicate via a network interface and were developed for integration into a secure network. The

network and B&R products are affected by the following hazards (not a complete list):

•

Unauthorized access

•

Digital intrusion

•

Data leakage

•

Data theft

•

A variety of other types of IT security breaches

It is the responsibility of the operator to provide and maintain a secure connection between B&R products and the

internal network as well as other networks, such as the Internet, if necessary. The following measures and security

solutions are suitable for this purpose:

•

Segmentation of the network (e.g. separation of the IT and OT networks)

•

Firewalls for the secure connection of network segments

ETAL210.1050-1 user's manual V1.00 5

Intended use • Security concept

•

Implementation of a security-optimized user account and password concept

•

Intrusion prevention and authentication systems

•

Endpoint security solutions with modules for anti-malware, data leakage prevention, etc.

•

Data encryption

It is the responsibility of the operator to take appropriate measures and to implement effective security solutions.

B&R Industrial Automation GmbH and its subsidiaries are not liable for damages and/or losses resulting from, for

example, IT security breaches, unauthorized access, digital intrusion, data leakage and/or data theft.

Before B&R releases products or updates, they are subjected to appropriate functional testing. Independently of

this, the development of customized test processes is recommended in order to be able to check the effects of

changes in advance. Such changes include, for example:

•

Installation of product updates

•

Notable system modifications such as configuration changes

•

Deployment of updates or patches for third-party software (non-B&R software)

•

Hardware replacement

These tests should ensure that implemented security measures remain effective and that systems behave as

expected.

6 ETAL210.1050-1 user's manual V1.00

Safety notices • Responsibilities of the operator

Chapter 3 • Safety notices

1 Safety notices

Warning!

Observe safety notices

Disregarding safety notices can result in serious damage to property and personal injury.

The safety notices on the product and in the documentation must be observed.

Products that cannot be ensured as safe due to damage, for example, are not permitted to be started

up under any circumstance. Disturbances that impair general safety must be eliminated immediately.

2 Usage

This product is designed and manufactured for training and development. General safety guidelines must be observed at all times.

Chapter 3

Safety notices

Caution!

Risk of injury

Disregarding safety notices can result in serious damage to property and personal injury.

The data sheets of components and the safety notices contained therein must be observed.

For a list of the components used, see the technical data of this product.

3 Electronics

The product is prewired and prepared for use. No additional wiring examples are required.

The power supply and communication, e.g. Ethernet, are implemented via cables with standard connector systems

such as RJ45.

Caution!

Electric shock

Incorrect or faulty supply elements can result in damage to property and personal injury.

Only power supply unit 0TP650.07, which is available as an accessory, is permitted to be used for the

power supply.

Connecting or disconnecting connectors and elements is only permitted in a voltage-free state.

4 Responsibilities of the operator

The operator is the person who operates the product or who provides it for use/application by a 3rd party while

carrying legal product responsibility for the protection of the user, personnel or other 3rd parties.

•

The operator is obliged to know and implement the applicable industrial safety regulations.

•

The operator is obliged to know and implement national, local and plant-specific regulations.

•

The operator is obliged to clearly define and manage responsibilities for installation, operation, fault correction, maintenance and cleaning.

•

The operator is obliged to ensure that responsible personnel have read and understood this user's manual.

ETAL210.1050-1 user's manual V1.00 7

System characteristics • Content of delivery

Chapter 4 • System characteristics

1 General information

System ETAL210.1050-1 offers you a wide range of options from entry-level programming to more complex programming processes and even includes HMI. With other products from the ETA light system portfolio, the range

of functions can be easily adapted and expanded to meet training needs.

ETAL210.1050-1 - ETA light system control technology X20CP1586

•

Enables extensive control tasks

•

High processing power thanks to Intel® Atom™ CPU

•

Integrated HMI with VNC server and web server

•

Integrated FTP and web server

•

Closed-loop control and mathematical functions

•

Data recording on mass storage device

•

Web-based system diagnostics

•

Modular with other ETA light systems via POWERLINK

•

Compact dimensions

2 Order data

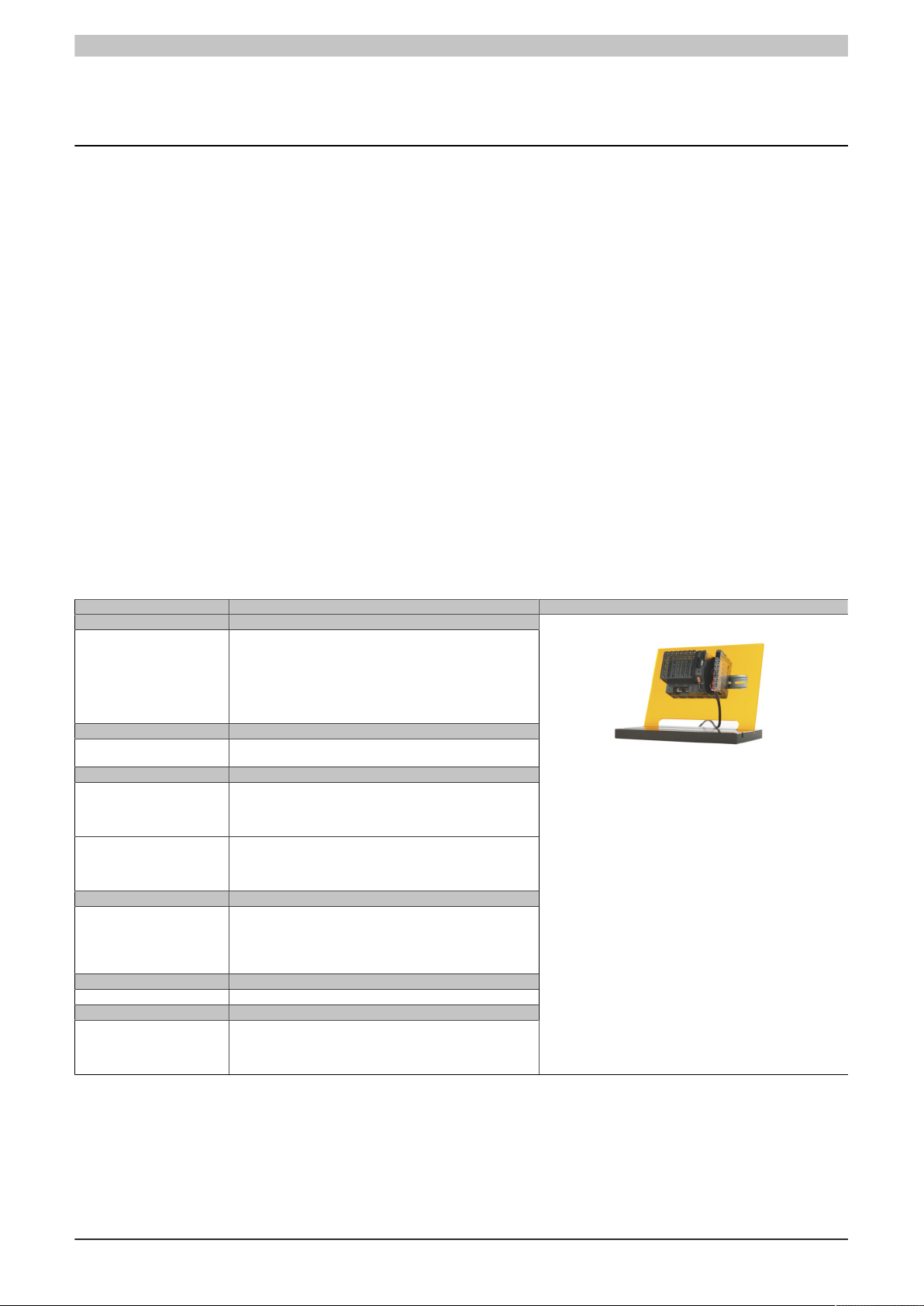

Model number Short description Figure

ETAL210.1050-1 ETA light system for control technology, enables extensive con-

ETAL100.0000-2 Black-coated wooden plate with B&R logo, two milled grooves

0TP370.76 Attachment cable to wide-range desktop power supply unit for

0TP650.07 Wide-range desktop power supply unit for office and laboratory

ETAL100.1Y05-0 ETA light system Y-current distributor, for connecting two ETA

X20CA0E61.00100 POWERLINK/Ethernet connection cable, RJ45 to RJ45, 1 m

ETAL120.1050-1 Keypad module with RAFI built-in elements, 1 selector switch,

Control technology

trol tasks, high computing power thanks to Intel® Atom™ CPU,

integrated HMI with VNC server, integrated FTP and web server,

control engineering and mathematical functions, data recording

to mass storage device, web-based system diagnostics, modularly expandable with other ETA light systems via POWERLINK,

compact dimensions

Required accessories

for holding ETA light systems, groove distance: 8 cm.

Accessories

office and laboratory use, CEE 7/7 to IEC C13 connector typical

application: power supply for ETA light evaluation and training

systems

use, output parameters: 24 VDC, 2.5 A, connection: low voltage

connector 5.5 mm / 2.1 mm (+ pin inside), typical application:

power supply for ETA light evaluation and training systems

Optional accessories

light systems to a desktop power supply unit, 1x DC 5.5 x 2.1 mm

female connector, 2x DC 5.5 x 2.1 mm male connector, max.

current 5 A, max. voltage 24 VDC, length including connections:

45 cm

POWERLINK/Ethernet cables

Simulation and input devices

2 illuminated keys, 1 illuminated actuator, 1 potentiometer drive, prewired on X20TB12 for ETAL210.1050-1, I/O modules required!

Table 1: ETAL210.1050-1 - Order data

3 Content of delivery

This product contains the following materials:

ETAL100.0200-1

8 ETAL210.1050-1 user's manual V1.00

System characteristics • Content of delivery

X20CP1586

5CFCRD.0512-06

ETAL100.3200-12

For details and additional technical data, see the data sheets for the individual products.

Chapter 4

System characteristics

ETAL210.1050-1 user's manual V1.00 9

Loading...

Loading...