Boyertown nrgMax Universal Oil Control User Manual

nrg

nrgMax

nrgnrg

9103i

9103i

9103i9103i

Advanced Universal Oil

Furnace Control

User's Guide

Max

MaxMax

9103i Advanced

Universal

Oil Furnace Control

OVERVIEW

The nrgMAX 9103i is the only oil-furnace control you will ever

need. It is a feature-rich control designed to meet the needs

of modern energy-efficient oil furnaces while still offering

backwards compatibility with legacy products.

Mounting in the industry-standard footprint with familiar layout

and connections this high quality design meets the needs of

an entire industry sector. It eliminates the need for additional

controls to accommodate Euro-style burners, and offers and

array of variable speed options to suit any requirement.

The control is suitable for use with PSC motors and ECM

motors. ECM motors can be controlled in the common

“thermostat-mode”. PSC motors are controlled with

traditional heavy-duty relay outputs.

OPTIONAL ADVANCED FEATURES

•

Enhanced operation of Standard PSC Blowers

•

Alternate Burner Connection (for burners with postpurge capability)

•

Automatic dehumidification

US and Canadian Patents Pending

FEATURES

•

Industry-standard footprint, mounting and

connections

•

compatible with American burners (Beckett, Carlin

etc) as well as Riello Burners with no additional

relays required

•

Industry-standard 9-pin burner connection

•

120VAC Connections for:

◦

Heat speed motor winding

◦

Cool speed Motor winding

◦

EAC

◦

Humidifier

◦

Continuous Fan

•

24VAC Thermostat Connections for:

◦

5-wire (R,C,W,Y,G), plus

◦

W2 (Stage 2 Heating)

◦

Y2 (Stage 2 cooling)

◦

Yx (dummy connection)

◦

O/B (Heat Pump reversing valve)

◦

DH (Dehumidification)

•

16-pin connection to GE/Beloit-style ECM Motors

•

LED Status indicator

•

Solid-State resettable fuse for 50VA Transformer

protection

•

Double-sided Copper-clad PC board, soldered top

and bottom for optimum strength and durability

•

Multipurpose DIP-switch for field settings

nrgMAX

(division of Bob Tonner Applied Research Inc)

Pickering, ON, 289-800-7131 www.nrgmax.ca

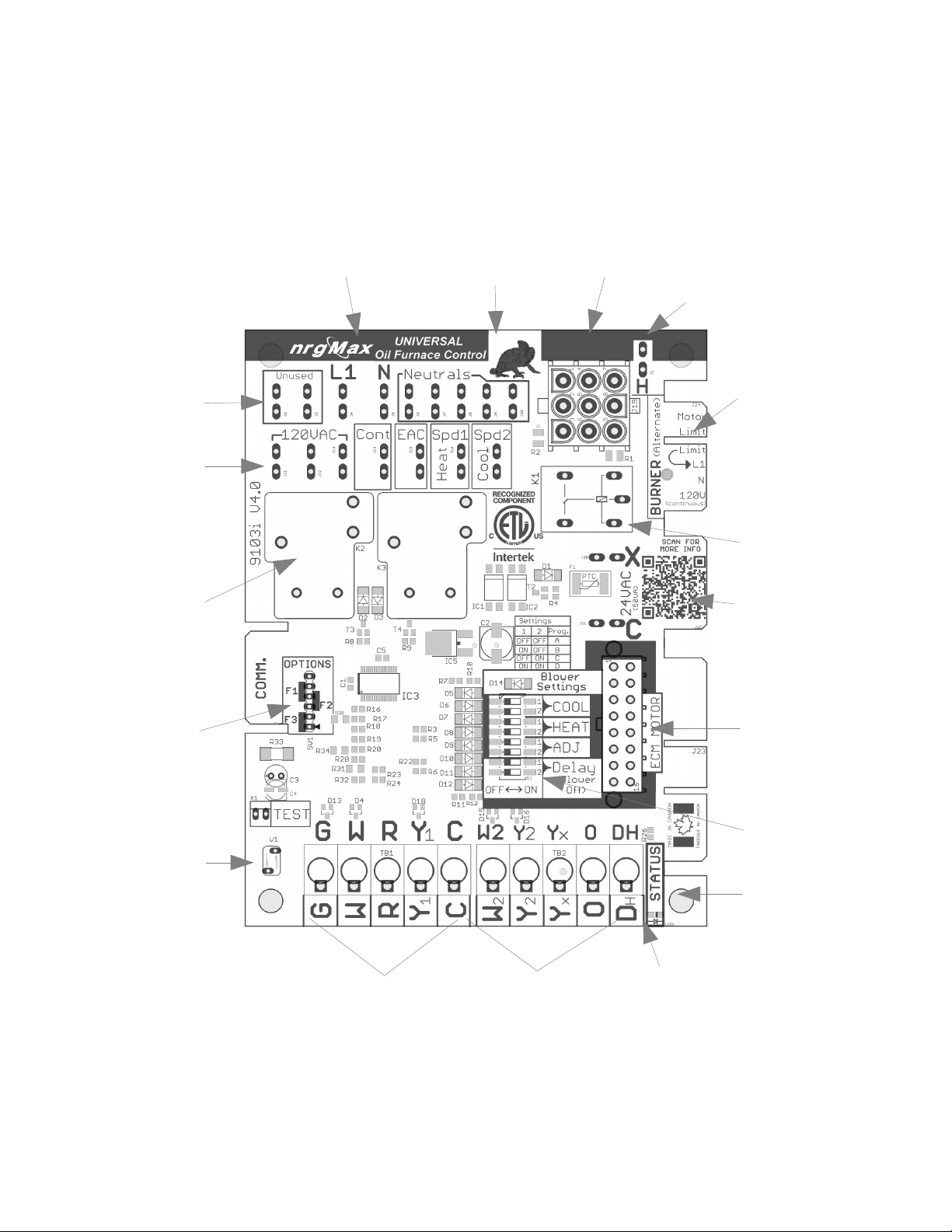

Features and Highlights

Terminals for

unused blower

wires

120VAC outputs

to loads and

accessories

Heavy duty relays

power blowers up

to 15Amps

120VAC Mains

Supply

connections

120VAC

Neutral

Connections

Burner 9-pin

connector

Humidifier

Connection

(120VAC)

Alternate Burner

connection with

continuous

120VAC

Built-in burner

supply relay

(powers limit

string and burner)

24VAC Transformer

input connection.

Protected by Solidstate resettable fuse

Field-selectable

option jumpers:

Extended Blower-

On Delay and/or

Enhanced Mode

Enhanced Low

Voltage Surge

Protection

Standard 5-wire

thermostat

connections

Extended

thermostat

connections

16-pin connector

for ECM Motors

Multipurpose

Dip-switch for

user settings

Industry-Standard

mounting holes

and footprint

Bright LED for

status indication

SPECIFICATIONS

•

Electrical Ratings:

◦

Power Requirements:

▪

Voltage: 24Vac, 50/60 Hz.

▪

Current: 4 VA at 24 Vac.

▪

PTC Fuse (resettable) trips at 4.5A

◦

Contact Ratings:

▪

Circulating Fan: 15A Full Load, 30A Locked

Rotor at 115 Vac (includes optional EAC

load).

▪

Burner: 5.8 A Continuous Load (7.4A with

interrupted ignition)

•

Settings: Standard Configuration

◦

Heating:

▪

Blower On Delay: 30 or 75 seconds, fieldadjustable

▪

Blower Off Delay (BOD): 90, 120, 150, 180

seconds, field-adjustable.

◦

Timing Tolerance: less than 1 second

•

Environmental Ratings:

◦

Temperature: -40 to +150° F [-40° to +66° C].

◦

Humidity: 95% maximum, non-condensing.

Terminals and Connections:

Low Voltage:

•

Thermostat:

◦

G: Blower On

◦

W: Call for heat (0.08A load)

◦

R: 24VAC out to thermostat

◦

Y1: Cooling, Stage 1

◦

C: 24Vac common

◦

W2: Heating, Stage1

◦

Y2: Cooling, Stage2

◦

Yx: Dummy terminal, no connection

◦

O: Heat pump reversing valve

◦

DH: Dehumidification

Line Voltage:

•

Unused: No connection (2 terminals)

•

L1: 120VAC 60Hz, 1ph, 15 A mp (Max) supply

•

N: 120VAC Neutral supply

•

Neutrals: Connection points for loads, tied internally

to N (6 terminals)

•

120VAC : L1 supply to accessories, continuously

powered (3 terminals)

•

Cont. 120VAC to Continuous speed of blower.

Normally energized, it is de-energized whenever

Cool or Heat terminals are energized

•

EAC: 120VAC to Electronic Air Cleaner.

Energized along with Cool or Heat terminals

•

Heat: 120VAC 15A, 1HP blower speed.

•

Cool: 120VAC 15A, 1HP blower speed

•

H: 120VAC 1A to Humidifier. Powered by

burner motor feedback (Pins 7-8 on 9-pin burner

connector).

Burner Connections:

•

9-PIN AMP Connector:

(MATES WITH TYCO PART #350720)

1) Safety Limit string (return)

2) 120VAC to Oil Burner (high-limit protected)

3) Burner T-T (internally connected to Pin 6)

4) Neutral (internally connected to Pin5 and N)

5) Neutral (internally connected to Pin 4 and N)

6) Burner T-T (internally connected to Pin 3)

7) Burner Motor (internally connected to Pin 8)

8) Burner Motor (internally connected to Pin 7)

9) 120VAC to Safety Limit string. Normally off,

energized on call for heat by Relay K1

•

Edge Connector (Alternate, 6 conductor) mates with

Molex 09-01-6061.

◦

Motor: Burner Motor

◦

Limit: 120VAC to Safety Limit string. Normally

off, energized on call for heat by Relay K1

◦

Limit: Safety Limit string (return)

◦

L1: 120VAC to Oil Burner (high-limit

protected)

◦

120V: 120VAC Continuous (not limit protected)

• CLASS 2 TRANSFORMER 50VA Max (overload

protected)

◦

X: 24VAC

◦

C 24VAC Common

•

16-PIN ECM Connector: Convenient interface

between 10-position thermostat, DIP-switches and

ECM motors.

•

•

Option Jumpers: Selectable Options:

◦

F1 Reserved

◦

F2 Enhanced PSC Mode

◦

F3 Extended Blower On Delay (75 Sec)

nrgMAX

(division of Bob Tonner Applied Research Inc)

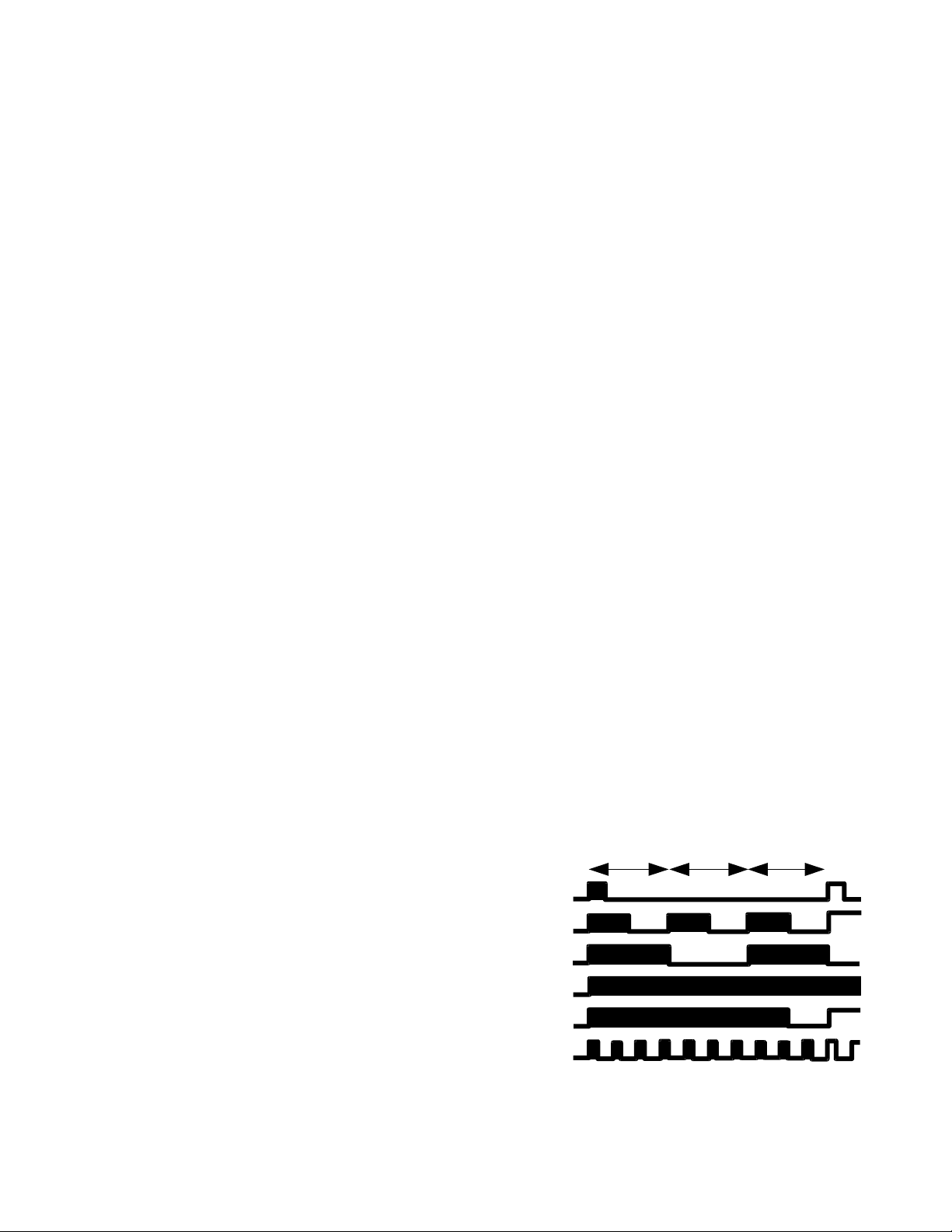

Status LED Flashing Patterns

1

Standby

Heating

Cooling

Limit

Limit reset

No Burner

Pickering, ON, 289-800-7131 www.nrgmax.ca

sec

1

sec

1

sec

OPERATIONAL MODES:

All operational modes are simultaneously active on

the 9103i, and the user needs only to make the

appropriate connections to make use of them. The

DIP-Switch is interpreted by the on-board software

differently for each mode of operation.

•

Standard PSC: Blower motor is driven by on-board

heavy duty relays. Heat, Cool and Continuous

speeds are available from 0.250” male spade

terminals clearly marked on board. Compatible with

all 5+ wire thermostats and responds to:

◦

W: heating

◦

Y1: cooling

◦

Y2: cooling

◦

G: Blower On

◦

DIP-Switch:

▪

Blower Off Delay (BOD):

•

A: 90 Seconds

•

B: 120 Seconds

•

C: 150 Seconds

•

D: 180 Seconds

▪

Heat: no function

▪

Cool: no function

▪

Adj: no function

OPTION:

Enhanced PSC Mode is selected by placing the

option jumper across position #3 and #4 on the

Option Select pins (See “Setting Options”). All wiring

and connections remain the same as the Standard

PSC mode, however the operation is enhanced.

ENABLE THIS OPTION ONLY WHEN THE COOL

TERMINAL IS CONNECTED TO A HIGHER

BLOWER SPEED THAN HEAT OUTPUT.

EXAMPLE:

“HEAT” CONNECTED TO MED-HIGH

“COOL” CONNECTED TO HIGH

speed

◦

DH (NO 24V signal): immediately

drops from Cool speed to Heat speed

to dehumidify.

◦

DH (24V signal returns): Blower

stepped up to Cool speed

◦

Y2 (24V signal) overrides DH and Y1

keeping Cool terminal on as long as

signal on Y2 is present

◦

G (24V signal alone without Y1, Y2, or

W): energizes Heat terminal

Note: for 2-stage cooling in Enhanced mode use Yx

and Y2. Yx is a dummy terminal and is ignored by

the control logic but provides a convenient

connection point for the AC compressor. When the

thermostat calls for stage 1 cooling (a Y1 signal from

the thermostat) it is terminated at Yx, but the

thermostat also activates G simultaneously. The

9103i then energizes the lower speed Heat terminal

as long as the condition exists. If Y2 is energized

(together with Y1/G, or separately) the control will

switch to Cool speed. This allows for 2 different

blower speeds for 2-stage cooling

• ECM Mode: ECM Motor handles all blower speed

logic in factory-set “thermostat mode” and it monitors

all ten thermostat inputs. The 9103i control

energizes the EAC and H terminals normally. While

the DIP-Switch settings are now directed to the ECM

motor through the 16-pin connector the 9103i will

continue to interpret the BOD settings to establish

the delay period before de-energizing EAC terminal.

Please note that the OEM factory -settings for the

ECM blower-off delay may not co-ordinate with the

EAC delay. The 9103i Controller has no influence

over the ECM motor as all signals are “passthrough” only.

• Heating:

◦

W (24V signal) activates Heat Speed

output

◦

W+W2 (24V signals) activate Cool

Speed.

• Cooling: Blower is initially started on Heat

Speed for 4 minutes to allow for

dehumidification, after which the blower

switches to Cool Speed. If the the 24VAC

signal to the DH terminal opens this signals

a call to dehumidify and the blower drops

down to heat speed to encourage greater

condensation across the cooling coil. When

the 24VAC signal reappears on DH the

blower is switched back up to Cool speed.

◦

Y1 (24V signal): 4 minutes at Heat

speed to dehumidify, then to Cool

Loading...

Loading...