Page 1

SERVICE MANUAL

ORIGINAL VERSION

REFERENCE NO.SM5110337

BOXLIGHT CP-305t

SERVICE MANUAL

Chassis No. MD8-CP-305t00

NOTE: Match the Chassis No. on the unit’s

back cover with the Chassis No. in the

Service Manual.

If the Original Version Service

Manual Chassis No.does not match

the unit’s, additional Service

Literature is required.You must refer to

“Notices” to the Original Service

Manual prior to servicing the unit.

PRODUCT CODE

(MD8E) 1 122 121 04

Page 2

2

■ Contents

■ Safety instructions ________________________________________________3

■ Specifications __________________________________________________ 4

■ Note on Servicing ______________________________________________ 5

■ Adjustments after parts replacement ________________________________ 5

■ Circuit protections ______________________________________________ 6-7

● Fuse ____________________________________________________ 6

● Thermal switch ____________________________________________ 6

● Interlock switch ____________________________________________ 6

● Warning temperature and power failure protection ________________ 7

■ Mechanical disassemblies ______________________________________ 8-13

■ Optical parts disassemblies ____________________________________ 14-17

■ LCD panel/prism ass’y replacement ________________________________ 19

■ Lamp replacement ______________________________________________ 20

■ Optical adjustments __________________________________________ 21-24

● Contrast adjustment ________________________________________ 21

● Condenser lens adjustment __________________________________ 22

● Condenser lens-Out adjustment ______________________________ 23

● Relay lens-Out adjustment __________________________________ 24

■ Electric adjustments __________________________________________ 25-30

● Service adjustment menu operation____________________________ 23

● Circuit adjustments ______________________________________ 24-29

● Service adjustment data table______________________________ 30-33

● Test points and locations ____________________________________ 34

■ Troubleshooting ______________________________________________ 35-39

● No power______________________________________________ 35-36

● No picture ____________________________________________ 37-38

● No sound ________________________________________________ 39

● Lens motor problems ______________________________________ 39

■ Control port functions ________________________________________ 40-43

■ Waveforms__________________________________________________ 44-45

■ Cleaning ______________________________________________________ 46

■ IC block diagrams ____________________________________________ 47-53

■ Service parts lists ____________________________________________ 54-83

● Electrical parts list ______________________________________ 54-76

● Mechanical parts list ____________________________________ 77-78

● Optical parts list ________________________________________ 79-83

Drawings & Diagrams ______________________________________ A1-A15

■ Parts description and reading in schematic diagram____________________ A2

■ Circuit block diagram ____________________________________________ A3

■ Power supply lines ______________________________________________ A4

■ Schematic diagrams ________________________________________ A5-A11

■ Printed wiring board diagrams ________________________________ A12-A14

■ Pins description of ICs, transistors, diodes __________________________ A15

Page 3

3

■ Safety Instructions

WARNING:

The chassis of this projector is isolated (COLD) from AC line by using the converter transformer.Primary side of

the converter and lamp power supply unit circuit is connected to the AC line and it is hot, which hot circuit is identified with the line ( ) in the schematic diagram. For continued product safety and protection of personnel

injury, servicing should be made with qualified personnel.

The following precautions must be observed.

SAFETY PRECAUTIONS

1: An isolation transformer should be connected in the

power line between the projector and the AC line

before any service is performed on the projector.

2: Comply with all caution and safety-related notes pro-

vided on the cabinet back, cabinet bottom, inside the

cabinet or on the chassis.

3: When replacing a chassis in the cabinet, always be

certain that all the protective devices are installed

properly, such as, control knobs, adjustment covers

or shields, barriers, etc.

DO NOT OPERATE THIS PROJECTOR WITHOUT

THE PROTECTIVE SHIELD IN POSITION AND

PROPERLY SECURED.

4: Before replacing the cabinet cover, thoroughly

inspect the inside of the cabinet to see that no stray

parts or tools have been left inside.

Before returning any projector to the customer, the

service personnel must be sure it is completely safe to

operate without danger of electric shock.

SERVICE PERSONNEL WARNING

Eye damage may result from directly viewing the light produced by the Lamp used in this equipment. Always turn

off Lamp before opening cover.The Ultraviolet radiation eye protection required during this servicing.

Never turn the power on without the lamp to avoid electric-shock or damage of the devices since the stabilizer

generates high voltages(15kV - 25kV) at its starts.

Since the lamp is very high temperature during units operation replacement of the lamp should be done at least

45 minutes after the power has been turned off, to allow the lamp cool-off.

PRODUCT SAFETY NOTICE

Product safety should be considered when a component replacement is made in any area of the projector.

Components indicated by mark in the parts list and the schematic diagram designate components in which

safety can be of special significance.It is, therefore, particularly recommended that the replacement of there parts

must be made by exactly the same parts.

DO NOT ATTEMPT TO SER VICING THE

REMOTE CONTROL UNIT.

Laser Beam may be leaked out when in disassemble

the Unit. As the Laser Beam used in this Remote control unit is harmful to the eyes.

LASER RADIATION

DO NOT STARE INTO BEAM

MAX. OUTPUT: 1mW

WAVE LENGTH: 650±20nm

CLASS

II LASER PRODUCT

This product is complied with 21 CFR

part 1040.10

CAUTION

LASER RADIATION

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

LASER-STRAHLING

NICHT IN DEN STRAHL BLICKEN

LASER KLASSE 2

IEC60825-1, Am. 1 1997

MAX OUTPUT ( ) : 1 mW

WAVE LENGTH ( ) : 650±20nm

Page 4

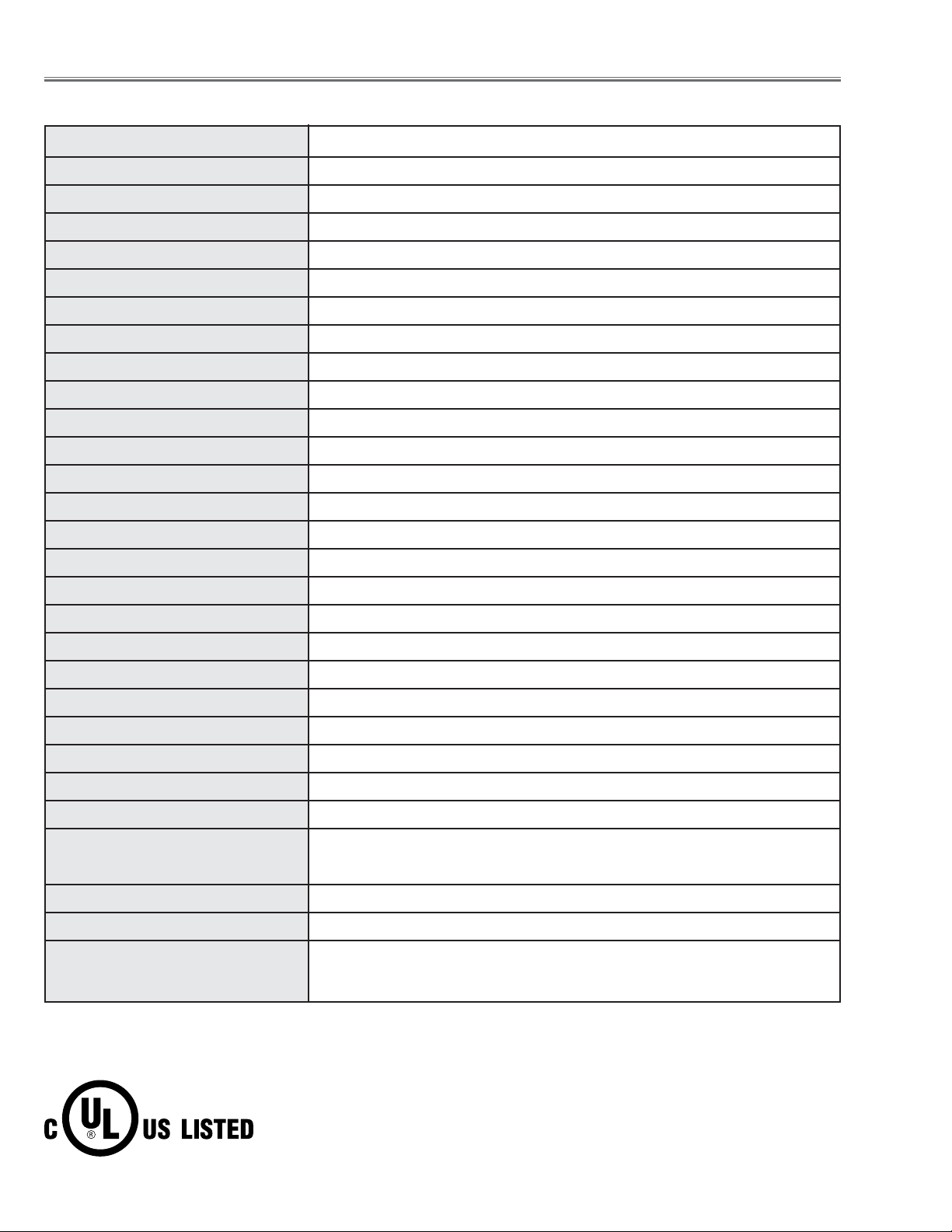

Projector Type Multi-media Projector

Dimensions (W x H x D) 13.11” x 3.52” x 9.96” (333mm x 89.5mm x 253mm)

Net Weight 9.5 lbs (4.3 kg)

LCD Panel System 0.9” TFT Active Matrix type, 3 panels

Panel Resolution 1024 x 768 dots

Number of Pixels 2,359,296 (1024 x 768 x 3 panels)

Color System 6 color system (PAL, SECAM, NTSC, NTSC4.43, PAL-M and PAL-N)

High Definition TV SIgnals 480i, 480p, 575i, 575p, 720p. 1035i and 1080i

Scanning Frequency H-sync. 15 ~ 100kHz, V-sync. 50 ~ 100Hz

Projection Image Size (diagonal) Adjustable from 34” to 300”

Horizontal Resolution 800 TV lines

Projection Lens F 1.9 ~ 2.1 lens with f 21.3mm ~ 25.6mm with motor zoom and focus

Throw Distance 3.0’~ 22.6’(0.9m ~ 6.9m)

Projection Lamp 200watts

AV Input Jacks RCA Type x 3 (Video/Y, Cb/Pb, Cr/Pr) and Mini DIN 4 pin x 1(S-Video)

AV Audio Input Jacks RCA Type x 2

Computer Input Jacks (VGA) HDB15 Ter minal x 1

Monitor Output Jacks (VGA) HDB15 Terminal x 1

Computer Audio Input Jack Mini Jack (stereo)

Control Port Connector Mini DIN 8 pin x 1

USB Connector USB Series B receptance x 1

External Speaker Jack Mini Jack (8Ω 1+1W / stereo)

Internal Audio Amp. 1.0watt RMS (monaural)

Built-in Speaker 1 speaker, 1.18” x 1.57” (30mm x 40mm)

Feet Adjustment 0˚ to 15.6˚

Voltage and AC 100 ~ 120V (3.6A Max. Ampere), 50/60Hz (The U.S.A and Canada)

Power Consumption AC 200 ~ 240V (1.8A Max. Ampere), 50/60Hz (Continental Europe )

Operating Temperature 41˚F ~ 95˚F (5˚C ~ 35˚C)

Storage Temperature 14˚F ~ 140˚F (-10˚C ~ 60˚C)

Remote Control Transmitters Wireless Remote Control, batteries AA, UM3 or R06 Type x 2

4

■ Specifications

● The specifications are subject to change without notice.

This symbol on the nameplate means the product is Listed by Underwriters

Laboratories Inc. It is designed and manufactured to meet rigid U.L. safety standards against risk of fire, casualty and electrical hazards.

Page 5

5

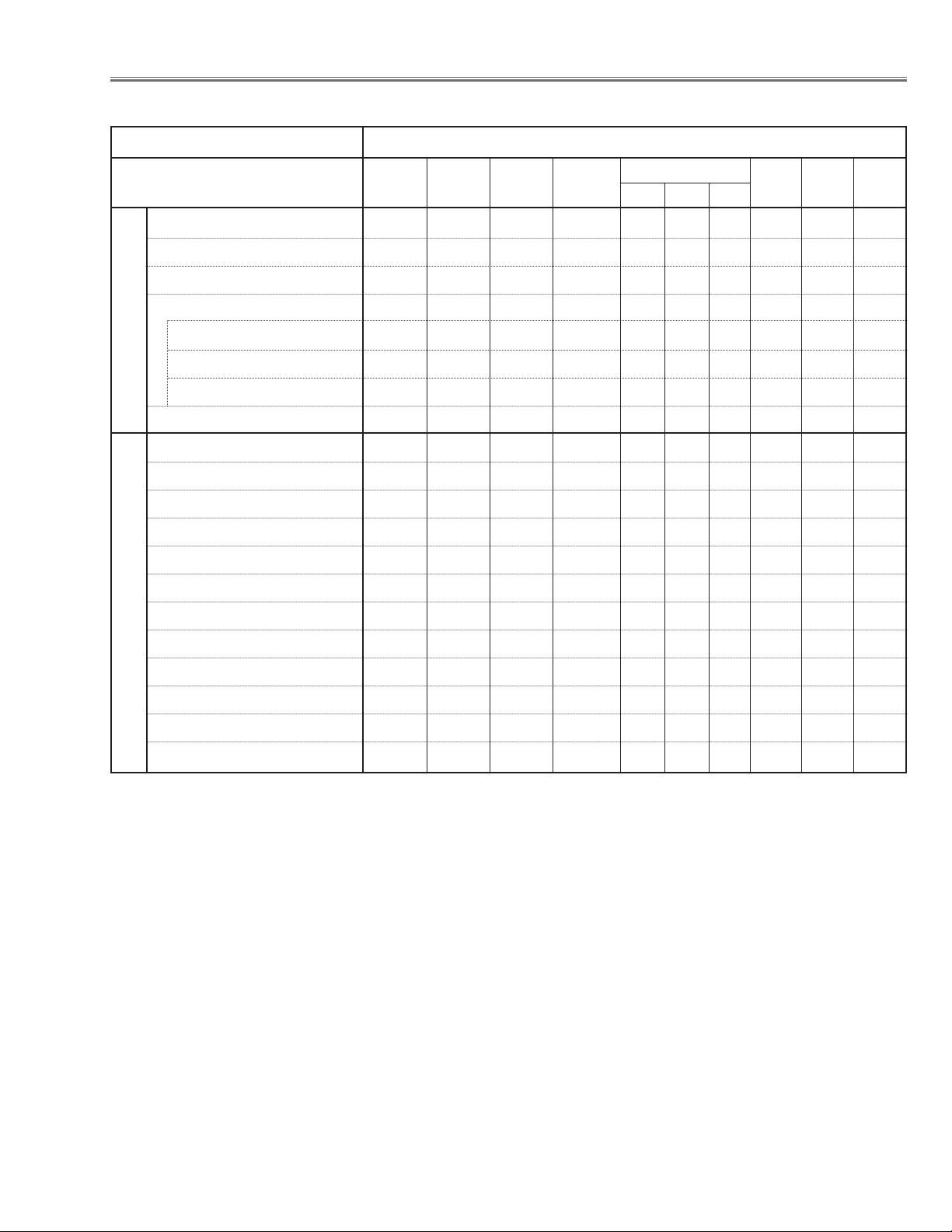

Condenser lens adjustment ❍●

Condenser lens-out adjustment ❍●

Relay lens-out adjustment ❍●

Contrast Adjustment

R-Contrast adjustment ●

G-Contrast adjustment ●

B-Contrast adjustment ●

Output voltage adjustment ●

Fan voltage adjustment ●

Pedestal adjustment ●

NRS adjustment ●

Signal center adjustment ●

Black level adjustment ●

PC offset adjustment ●

PC gain adjustment ●

AV gain adjustment ●

Common center adjustment ● ●

Gamma shift adjustment ❍ ●

White balance adjustment ❍ ❍

Disassembly / Replaced Parts

LCD/

Prism

Ass’y

Condenser

Lens

Polarized glass

RGB

Optical Adjustments

Electrical Adjustments

● : Adjustment necessar y ❍ : Check necessary

P. F.

Board

Main

Board

Condenser

Lens-Out

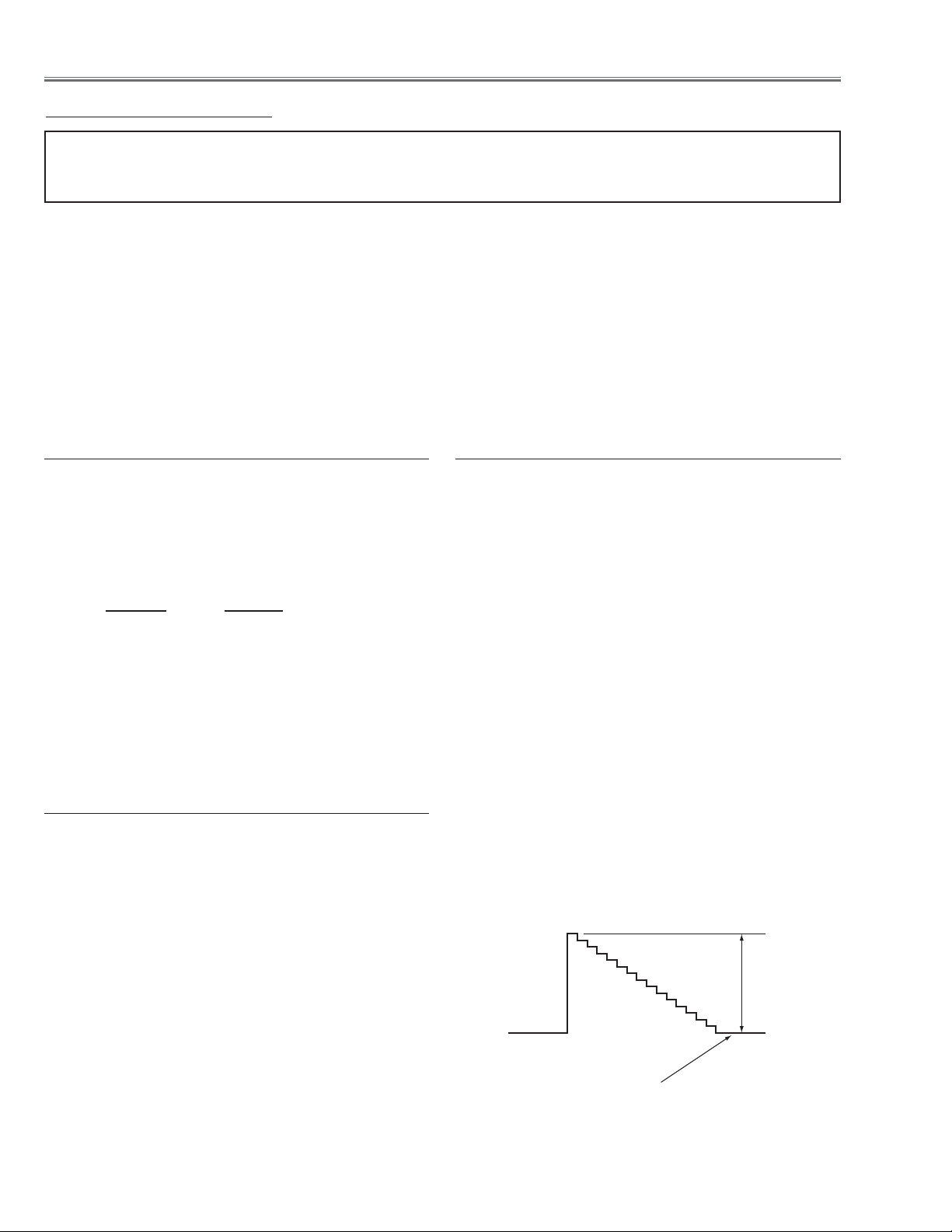

■ Adjustments after Parts Replacement

Relay

Lens-Out

Power

Board

Page 6

-6-

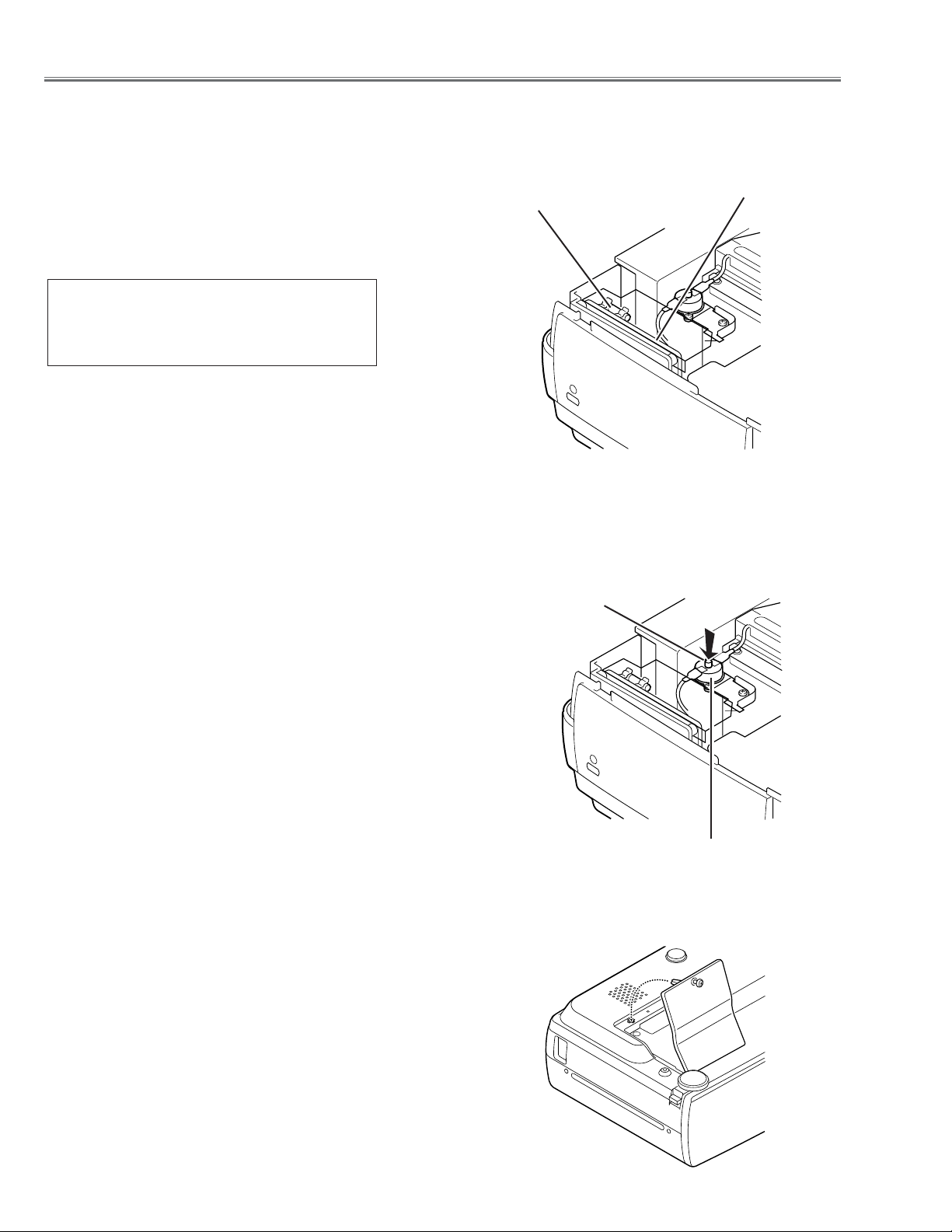

● Interlock switch

The interlock switch (SW904) cuts off the AC mains power supply

when the lamp cover is removed. After opening the lamp cover for

replacing the lamp ass’y, place the lamp cover correctly otherwise

the projector can not turn on.

● Thermal switch

There is the thermal switch (SW902) inside of the projector to

prevent the internal temperature from rising abnormally.When the

internal temperature reaches near 100˚C, turn off the AC main

power supply automatically.

The thermal switch is not reset to normal automatically even if the

internal temperature becomes normal. Reset the thermal switch

following procedure.

Check the resistance between terminals of thermal switch by

using the tester.If it has high impedance, thermal switch may be

in operative.

How to reset the thermal switch

1.

Remove the cabinet top following to “Mechanical

Disassemblies”.

2. Press the reset button on the thermal switch.

CAUTION:

Before press the reset button, disconnect the AC cord from the

projector.

■ Circuit Protections

This projector is equipped with the following circuit protections to operate in safety. If the abnor mality occurs inside

the projector, it will automatically turn off by operating one of the following protection circuits.

● Fuse

The fuse is located inside of the projector.When either the LAMP

indicator or the READY indicator is not illuminated, fuse may be

opened. Check the fuse as following steps.

It should be used the specified fuse as follows;

How to replace the fuse

1. Remove the cabinet top following to “Mechanical

Disassemblies”.

2. Remove the fuse from fuse holder.

To install the fuse, take reversed step in the above.

Fuse Part No.: 423 022 2102

TYPE T4.0AH 250V FUSE

LITTLE FUSE INC.TYPE 215004

Fuse

Thermal switch (SW902)

Reset Button

Line Filter Board

Page 7

-7-

Circuit Protections

● Warning temperature and power failure protection

The TEMP WARNING indicator flashes red and the projector will automatically turn off when the internal temperature of the projector exceeds the normal temperature or when stopping cooling fans or when the internal power

supply lines are failed.

Check the following possible causes and wait until stopping the TEMP WARNING indicator flashing.

Possible causes

- Air filter is clogged with dust particles. Remove dust from the air filter by following instructions in the “Air filter

care and cleaning” below.

- Ventilation slots of the projector are blocked. In such an event, reposition the projector so that ventilation slots are

not obstructed.

- Check if projector is used at higher temperature place (Normal operating temperature is 5 to 35 ˚C or 41 to 95˚F)

If the TEMP WARNING indicator still continues to flash, there may be defects on cooling fans or power supply circuits. Please check fan operation and power supply lines referring to the “Power Supply Lines Chart”.

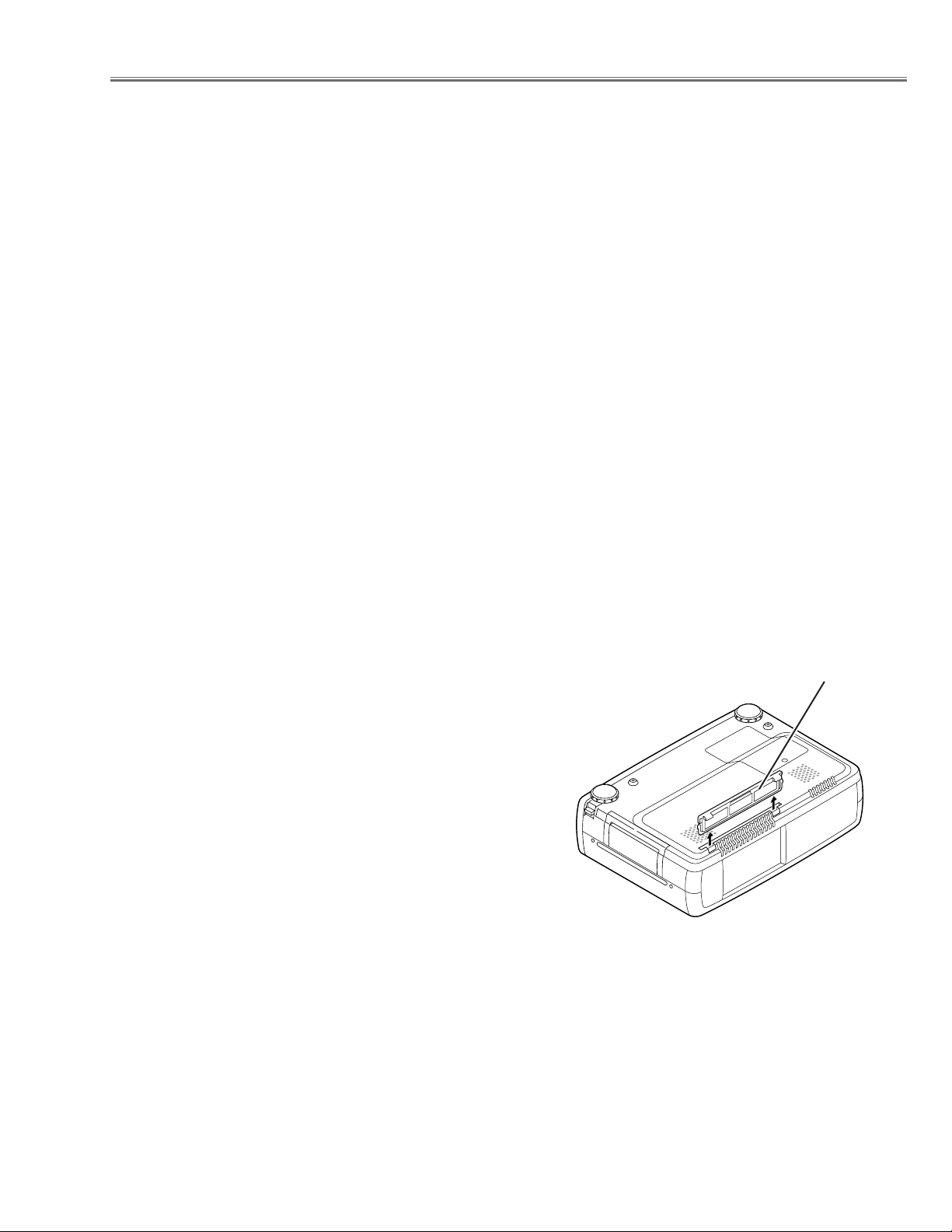

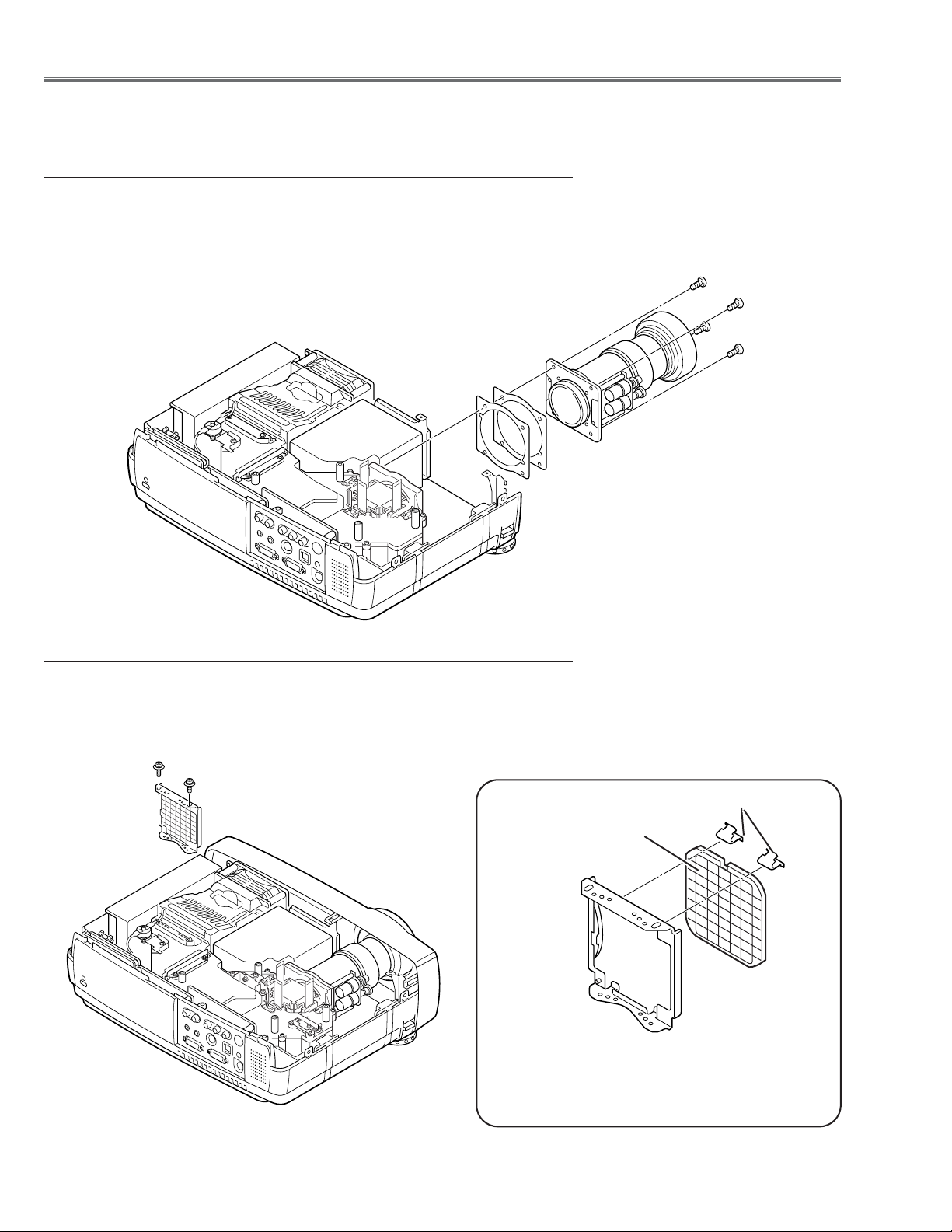

Air filter care and cleaning

The removable air filter prevents dust from accumulation on the surface of the projection lens and projection mirror.

Should the air filter become clogged with dust particles, it will reduce the cooling fan’s effectiveness and may result

in internal heat build up and reduce the life of the projector.

To clean up the air filter, follow the cleaning procedure

below:

1. Turn the power off, and disconnect the AC power cord

from the AC outlet.

2. Turn the projector up side down and remove an air filter

by pulling the latches of them upward.

3. Clean the air filter with brush or wash out the dust and

particles.

4. Replace the air filter properly. Make sure that the air fil-

ter is fully inserted.

CAUTION:

Do not operate the projector with the air filter removed.The

dust is stuck on the LCD panel and the mirror, and it may

spoil the fine picture image.

Do not put the small parts into the air intake vents. It may

result in the malfunction of the projector.The air filter is

small parts. Take care that children don’t eat or swallow it.

RECOMMENDATION

We recommend to avoid dusty, smoky place for operating the projector.Using in dusty place may cause the picture

of poor quality.

When using under the dusty or smoky conditions, dust may accumulate on the LCD panel and lens inside it, and

may resultantly be projected on the screen together with the picture.

When the above symptoms are noticed, please clean up the LCD panel and lens following to the “Cleaning

Method”.

Air filter

Page 8

-8-

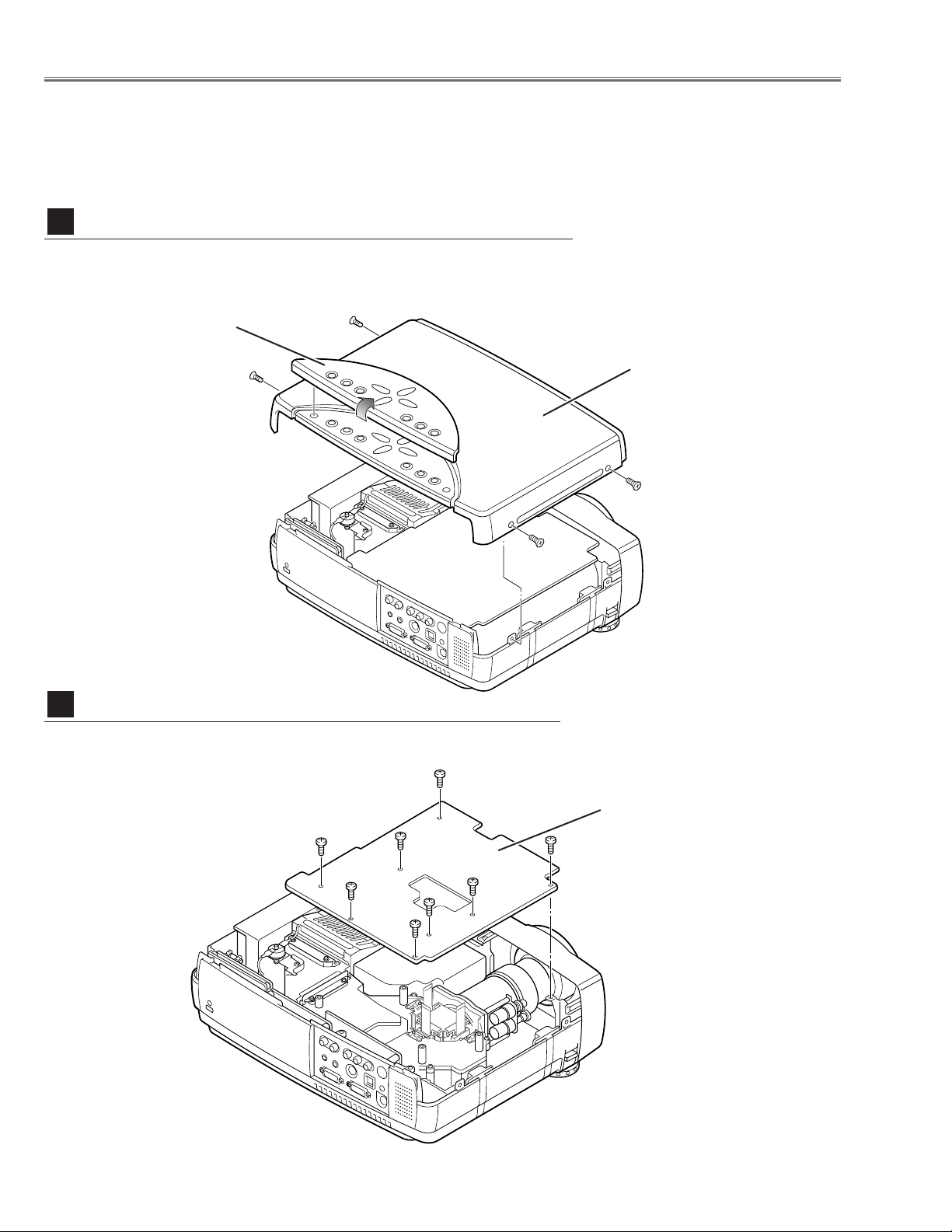

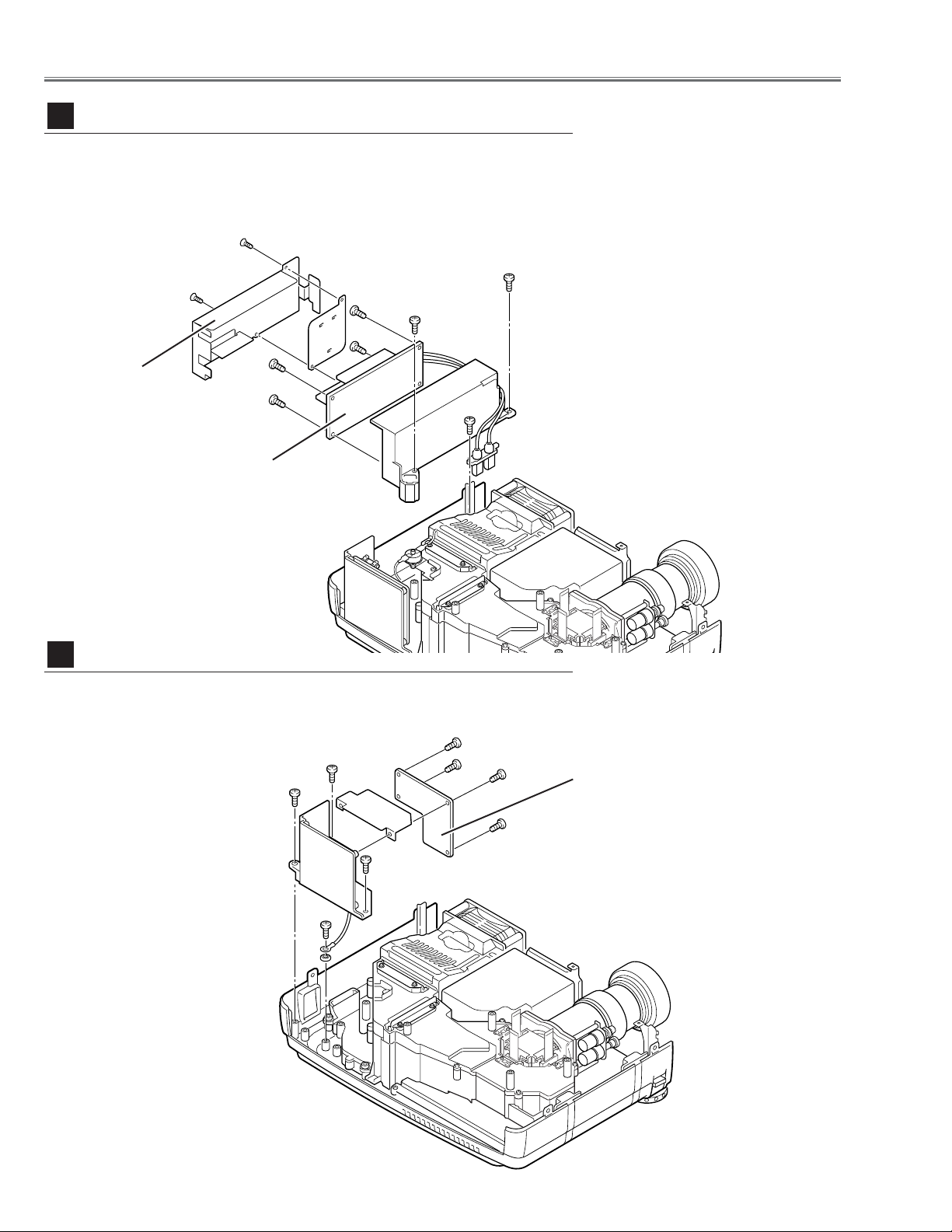

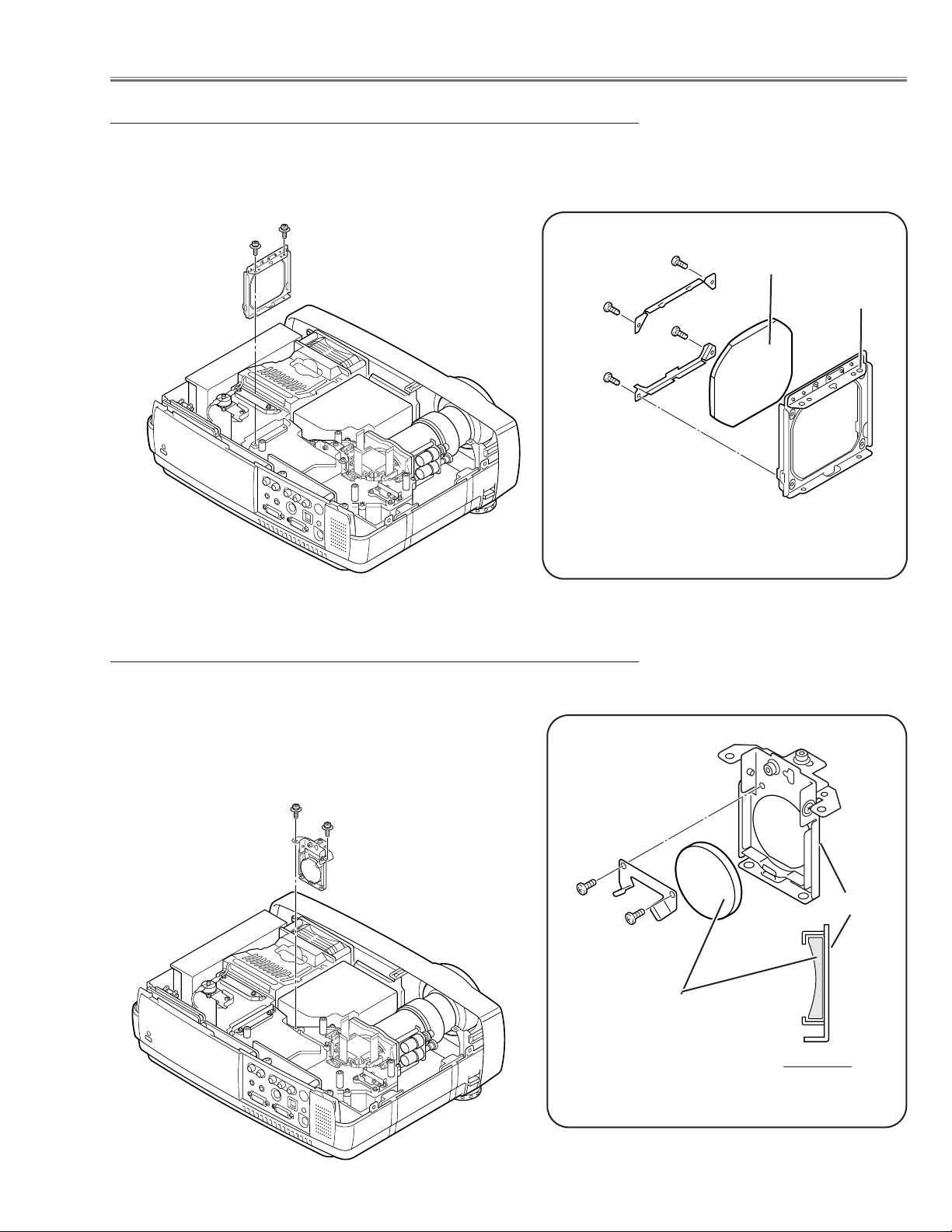

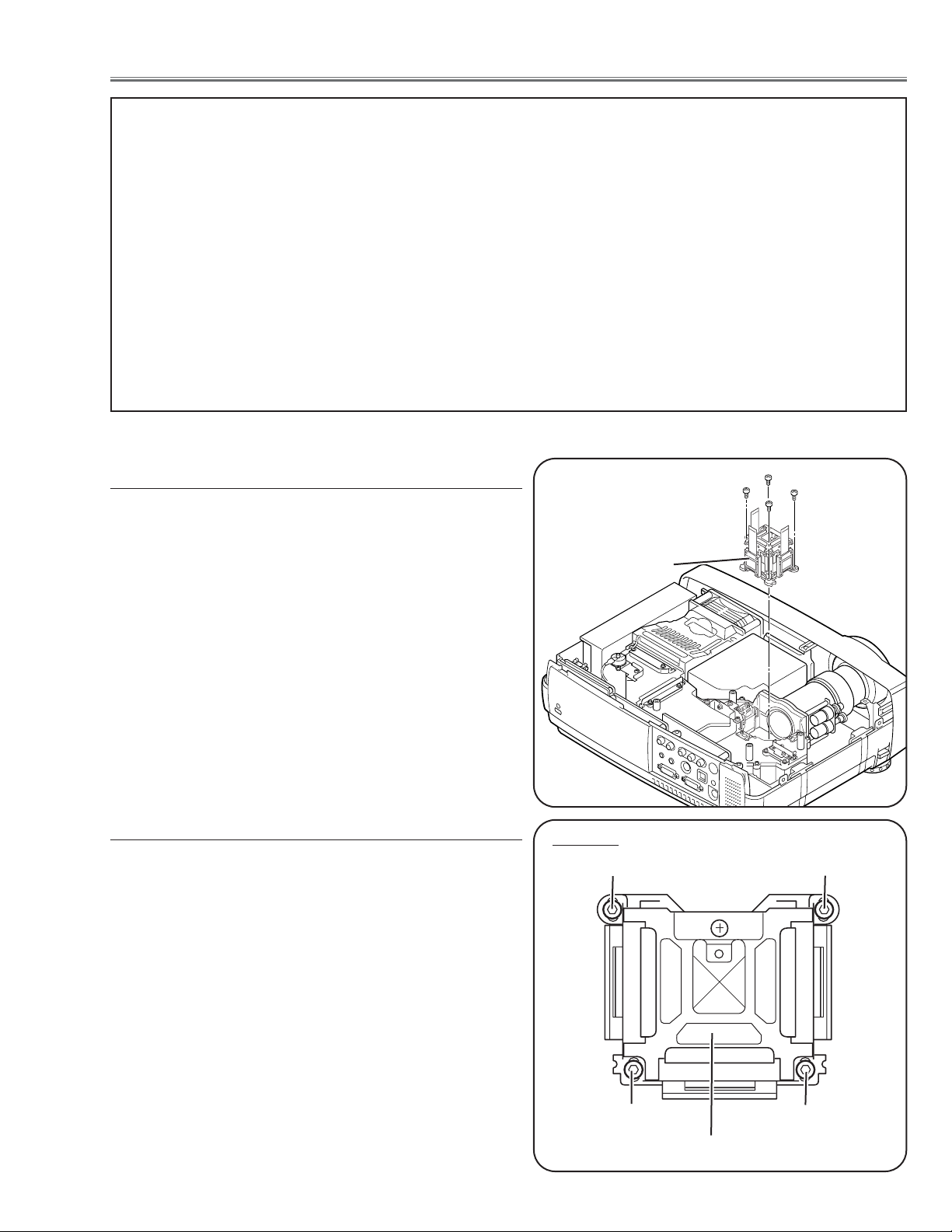

1 Remove 4 screws A to take the Cabinet Top Ass’y upward off.

2 Remove the Control Panel off from the Cabinet Top by lifting the edge of

control panel.

■ Mechanical Disassemblies

Mechanical disassemble should be made following procedures in numerical order.

Following steps show the basic procedures, therefore unnecessary step may be ignored.

Caution:

The parts and screws should be placed exactly the same position as the original otherwise it may cause loss of

performance and product safety.

Fig.1

1 Remove 8 screws to take the Main Board upward off.

Fig.2

Cabinet Top and Control Panel removal

1

Main Board removal

2

A

A

A

A

Main Board

Control panel

Cabinet top

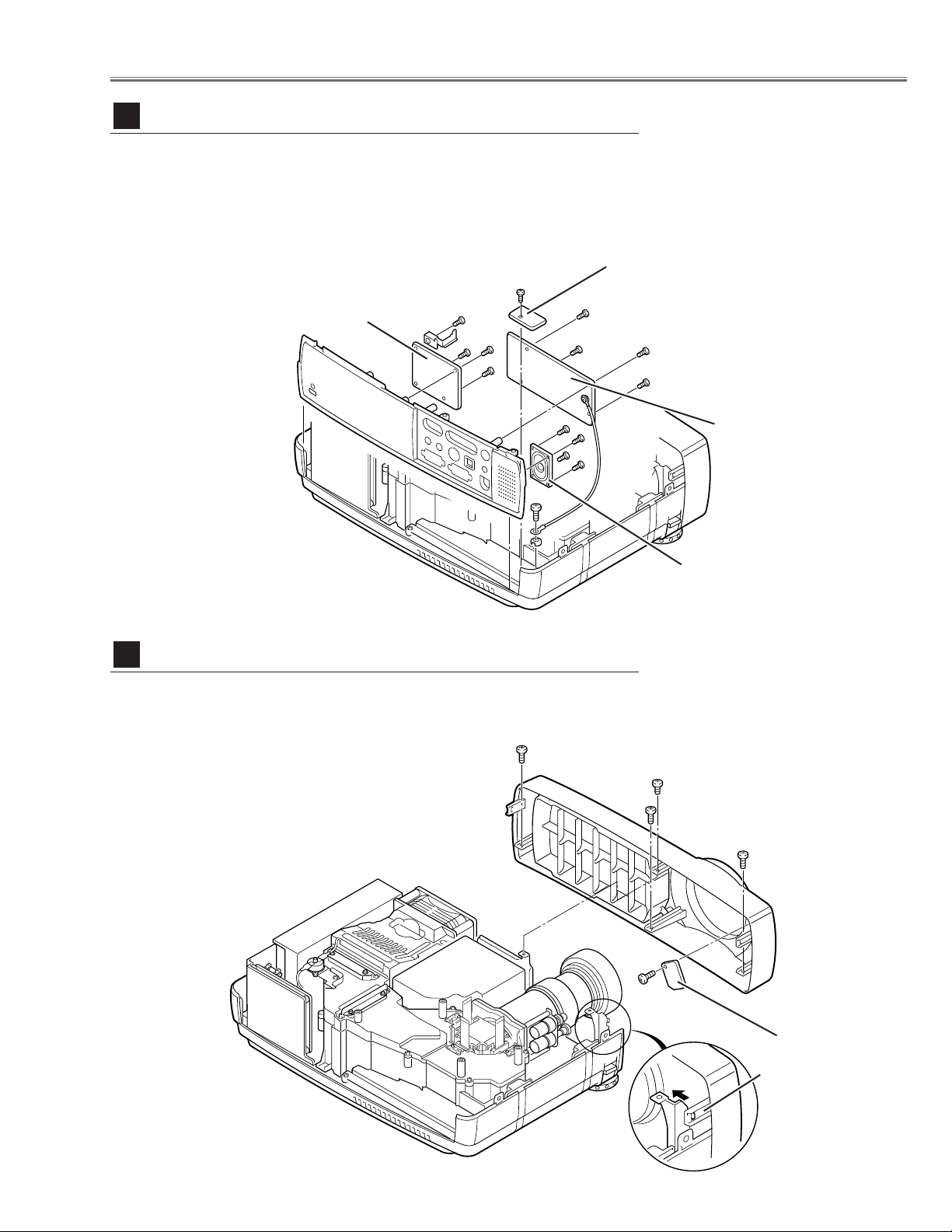

Page 9

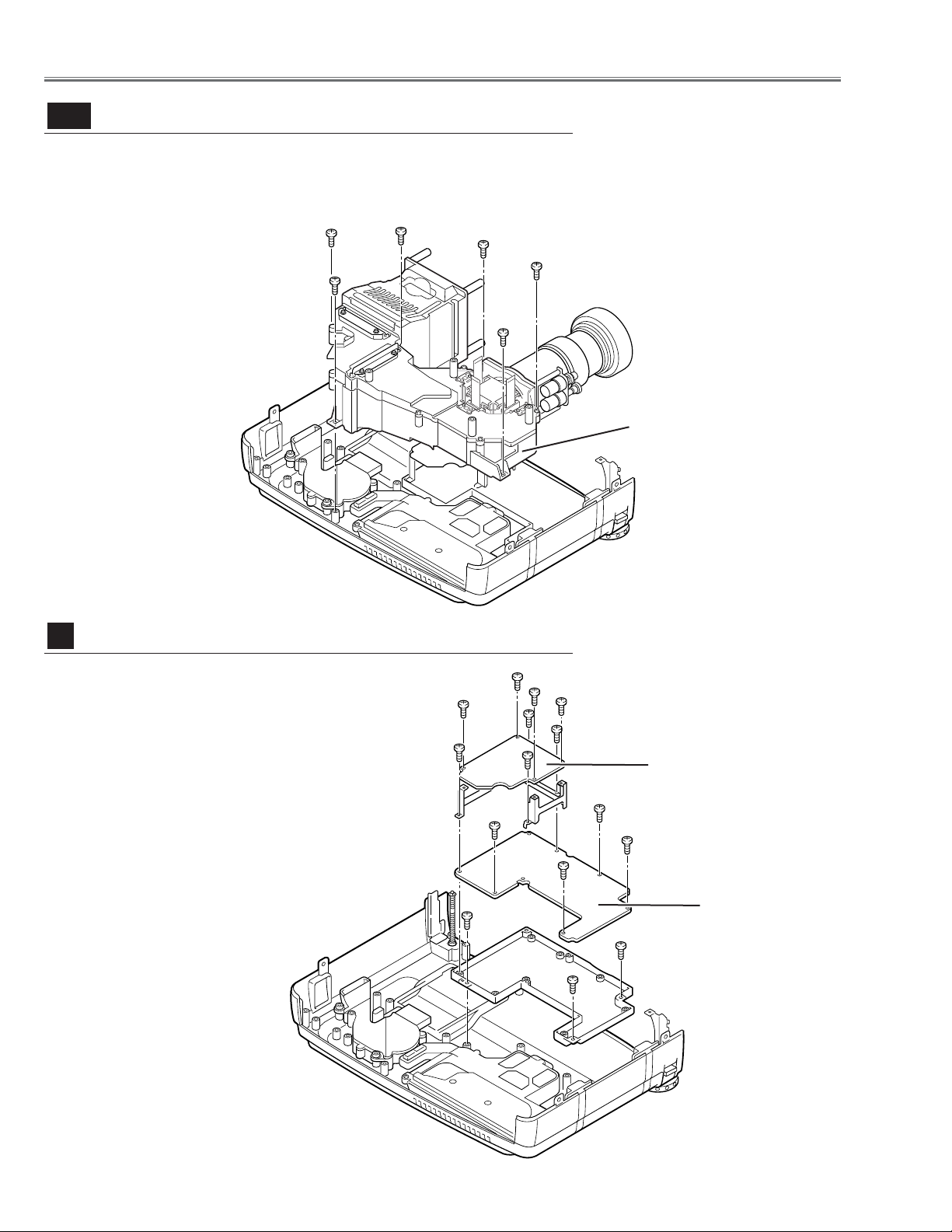

Temp board

-9-

Mechanical Disassemblies

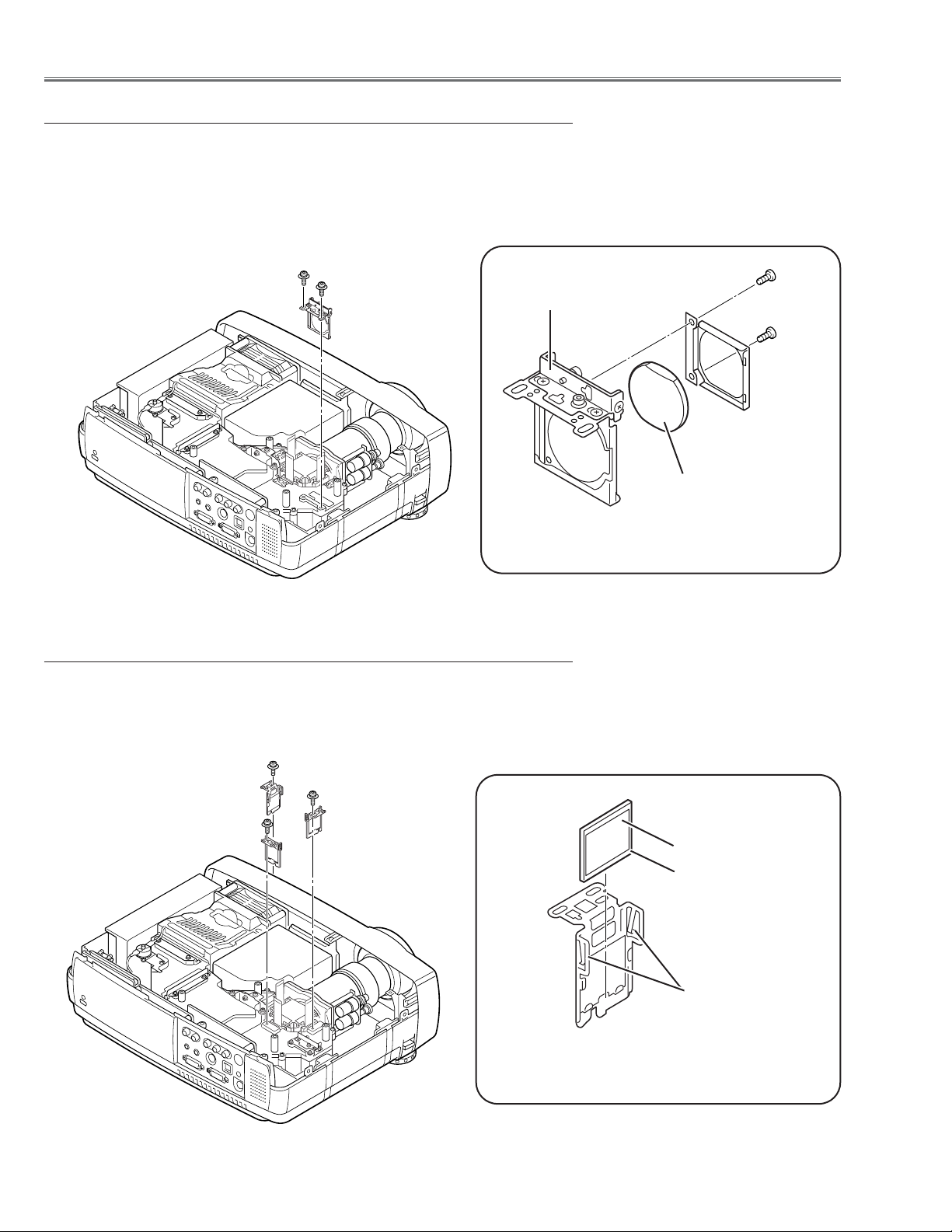

1 Remove 1 screw A to release a grounding wire.

2 Pull the Rear Panel ass’y upward.

3 Remove 4 screws B and remove the AV Board.

4 Remove 4 screws C and remove the AV Sub Board.

5 Remove 4 screws D and remove the speaker.

6 Remove 1 screw E and remove the Temp Board.

Fig.3

Fig.4

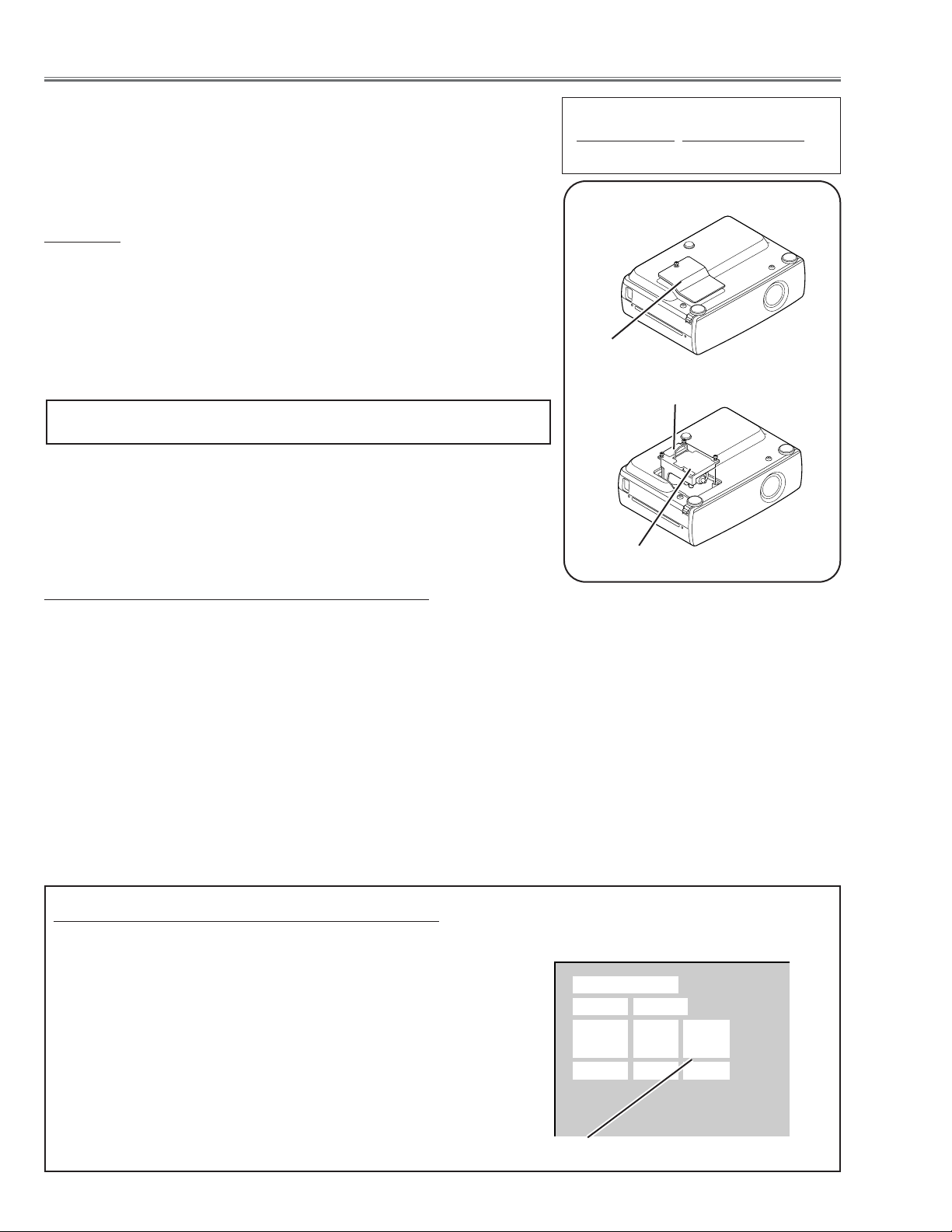

1 Remove 4 screws A and unhook 2 hooks B at the both of left and right

side, and the take the Front Panel ass’y off.

2 Remove 1 screw C to take the R/C Board off.

AV , AV Sub, Temp Board and Speaker removal

3

Front Panel and R/C Board removal

4

A

B

B

B

C

A

A

A

A

B

C

AV Sub board

AV board

Speaker

R/C board

B

C

C

D

D

E

Page 10

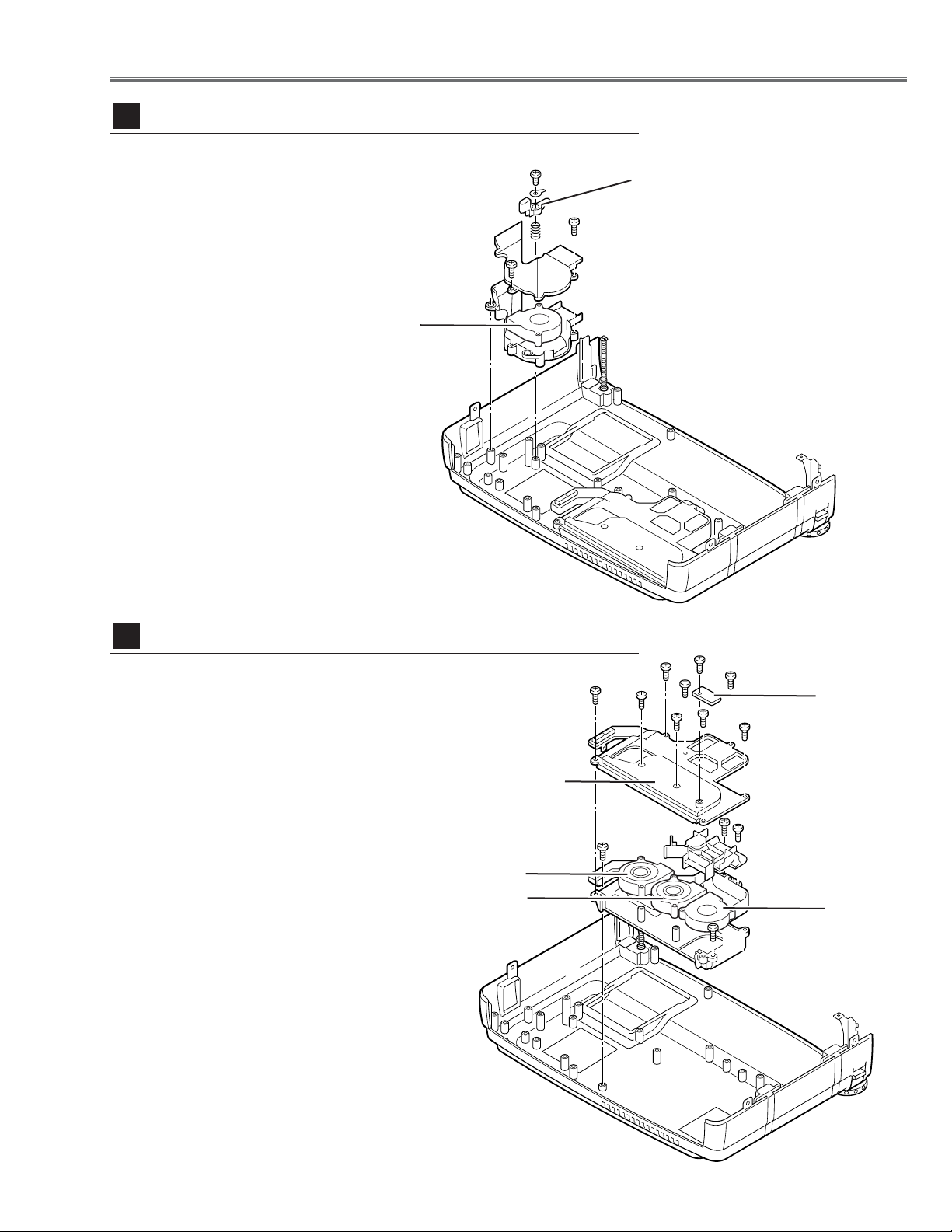

-10-

Mechanical Disassemblies

1 Remove 1 screw A and disconnect the Lamp Socket.

2 Remove 2 screws B to take the Lamp Ballast ass’y upward off.

3 Remove 2 screws C to take the isolation sheet off.

4 Remove 4 screws D to take the lamp ballast board off.

Fig.5

1

Remove 3 screws A and pull the Filter Board ass’y upward.

2 Remove 1 screw B to take the grounding lead from the cabinet bottom.

3 Remove 4 screws C to take the Filter Board off.

Fig.6

Lamp Ballast Unit removal

5

Filter Board removal

6

A

Lamp ballast board

B

B

D

D

D

D

A

A

A

B

C

C

C

C

Filter board

C

C

Isolation sheet

Page 11

-11-

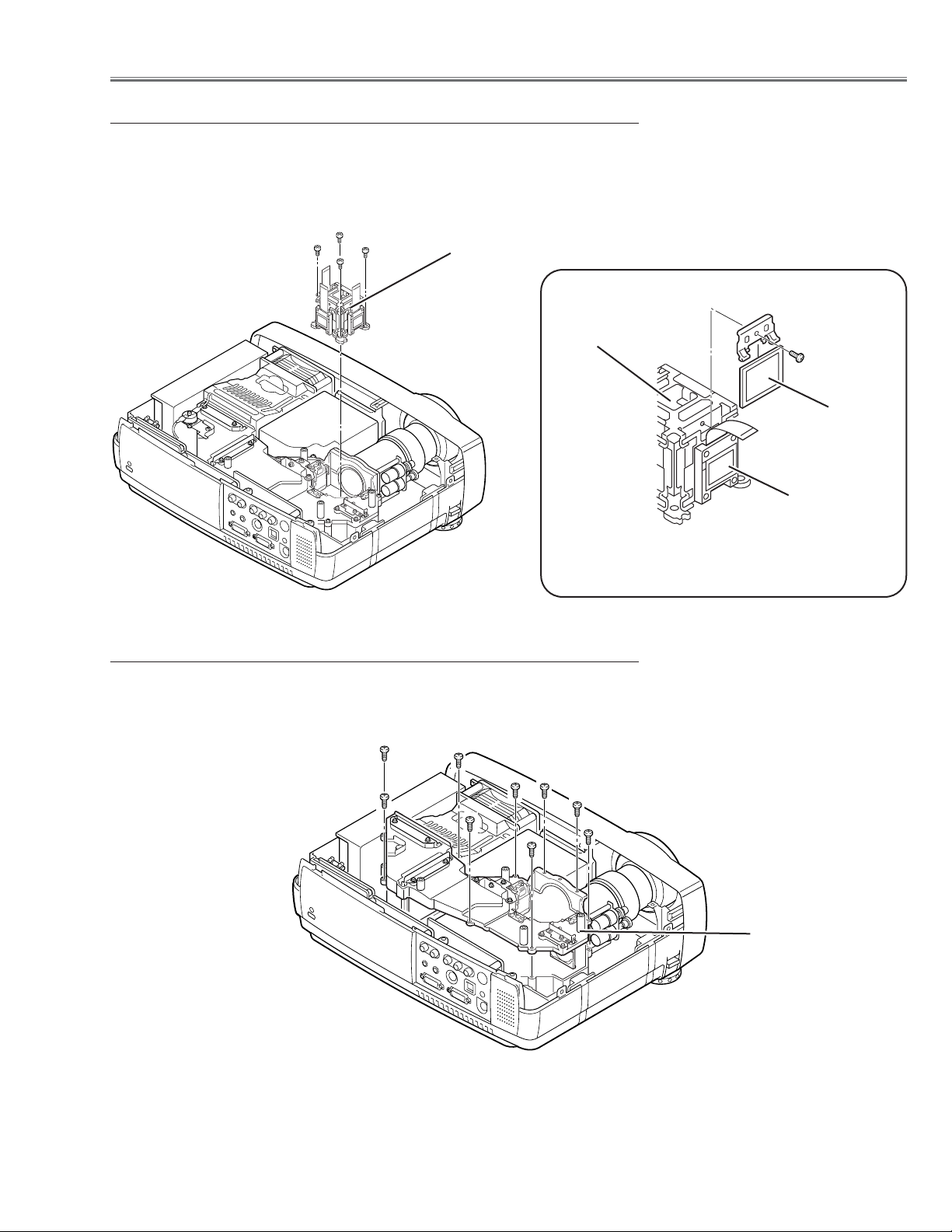

1 Remove 4 screws A to take the Fan(FN901) off.

2 Remove 4 screws B to take the Fan(FN905) off.

3 Remove 3 screws C to take the Power Box Cover upward off.

Mechanical Disassemblies

1 Remove 1 screw A to take the Lamp Cover off.

2 Loosen 3 screws B to take the Lamp assembly by

pulling the handle.

Step to next procedure.

Fig.8-1

Fig.7

Power Box Cover and Fans(FN901, FN906) removal

7

Optical Unit removal

8

-1

A

A

A

A

B

BB

B

C

C

C

FN901

FN906

Power box cover

Lamp cover

Lamp ass’y

A

B

B

B

Page 12

Step from previous procedure.

3 Remove 6 screws C to take the Optical Unit upward upward off.

To mount optical unit, mount optical unit first then mount the Lamp assembly

and Lamp Cover.

-12-

Mechanical Disassemblies

1 Remove 8 screws A to take the Power Board ass’y

upward off.

2 Remove 4 screws B to take the P.F. Board from the

Power Board.

3 Remove 3 screws C to take the Power Board holder

from the Cabinet Bottom.

Fig.9

Power and P.F. Board removal

9

A

Power board

A

A

A

A

A

A

A

B

B

B

B

C

C

C

P. F. board

Fig.8-2

Optical Unit removal

8

-2

Optical unit

C

C

C

C

C

C

Page 13

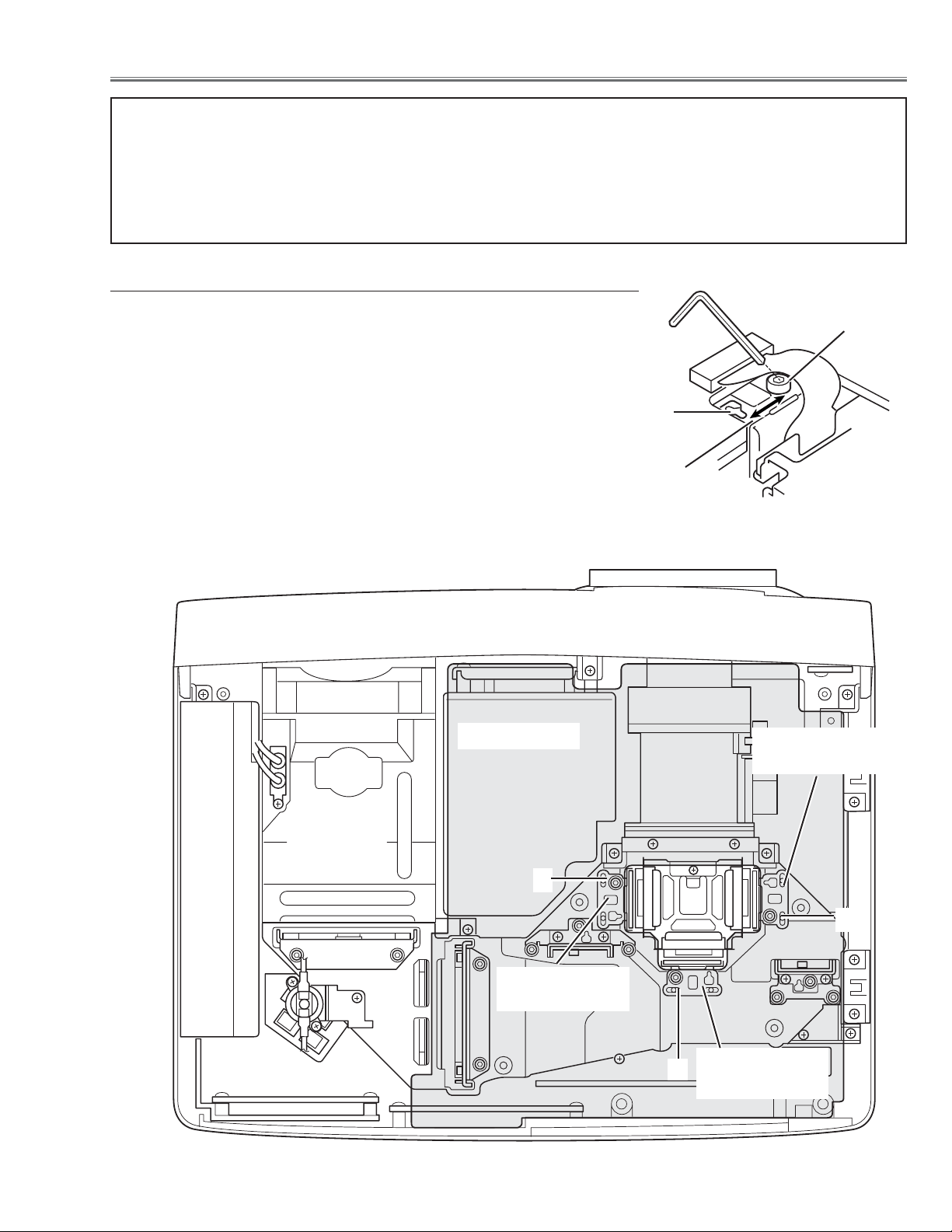

1 Remove 1 screw A and take a Washer, Spring and

Interlock Switch lever.

2 Pull the Fan and duct ass’y upward, then remove the

2 screws B to take the Fan (FN906) off.

-13-

Mechanical Disassemblies

Fig.10

1 Remove 1 screw A to take the Temp. Board off.

2 Remove 8 screws B and to take the Fan Duct

Top off and remove the Fans (FN902, FN903,

FN904).

3 Remov e 4 screws Cto take the F an Duct Bottom

off from the Cabinet Bottom.

Fig.11

Fan (FN905) removal

10

Temp Board and Fans (FN902, FN903, FN904) removal

11

Interlock switch lever

A

B

B

FN905

A

B

B

B

B

B

B

B

C

C

C

C

FN904

FN903

FN902

Temp board

Fan duct top

Page 14

-14-

1 Remov e the Front Panel f ollowing to “Front P anel Remo v al”on “Mechanical

Disassemblies”.

2 Remove 4 screws to take the Projection Lens ass’y off.

1 Remove 2 screws A and pull the Integrator Lens-In ass’y upward.

2 Remove 1 stoppers B and then take the Lens off from the holder.

Fig.1

■ Optical Parts Disassemblies

Before taking this procedure, remove Cabinet Top and Main Board following to the “Mechanical Disassemblies”.

Disassembly requires a 2.0mm hex wrench and a screwdriver.

Integrator Lens

* Lens should be placed as the

rugged surface side comes to

the holder side.

Fig.2-

1

Fig.2-2

Projection Lens removal

Integrator Lens-In disassembly

Stopper B

A

A

Page 15

-15-

1 Remove 2 screws A and pull the Condenser Lens ass’y upward.

2 Remove 4 screws B to take the Lens off from the holder.

1 Remove 2 screws A and pull the Condenser Lens-Out ass’y upward.

2 Remove 2 screws B to take the Lens off from the holder.

Note:

Should be place the lens as shown in the figure.

A

Optical Pats Disassemblies

B

Condenser Lens

Fig.3-2

Fig.3-1

* Lens should be placed as the flat

surface side comes to the holder

side.

Holder

A

A

Fig.4-2

Fig.4-1

B

B

Holder

Condenser Lens-Out

A

Condenser lens disassembly

Condenser Lens-Out disassembly

B

B

B

Side View

Page 16

-16-

Optical Parts Disassemblies

1 Remove 2 screws A and pull the Relay Lens-Out ass’y upward.

2 Remove 2 screws B to take the Lens off from the holder.

Note:

There is no mounting direction of the lens.

1 Remove each screw and pull the Polarized Glass-In ass’y upward.

2 Unhook the stoppers and take the glass off upward.

Hooks

Polarized Glass-In

Fig.6-2

Fig.6-1

* Should be places the glass as the

film attached side comes to the

prism side.

Phase Sheet

A

Fig.5-2

Fig.5-1

B

B

Holder

Relay Lens-Out

A

Relay Lens-Out disassembly

Polarized Glass-In removal

Page 17

-17-

1 Remove 4 screws A and take the LCD/Prism ass’y off upward from the

optical unit.

2 Remove each screw B and take the glass off upward.

Polarized

Glass-Out

LCD Panel/Prism

Ass’y

LCD Panel/Prism Ass’y

Fig.7-

2

* Glass should be placed as the film

attached side comes to the LCD

panel side.

LCD Panel

Note:

Do not replace the LCD panel

separately otherwise it can

not obtain proper picture.

1 Remove 9 screws to take the Optical Unit Top off upward.

Fig.7-1

Fig.8

Polarized Glass-Out removal

Optical Unit Top removal

Optical Parts Disassemblies

B

A

A

A

Optical Unit Top

Page 18

-18-

Optical Parts Disassemblies

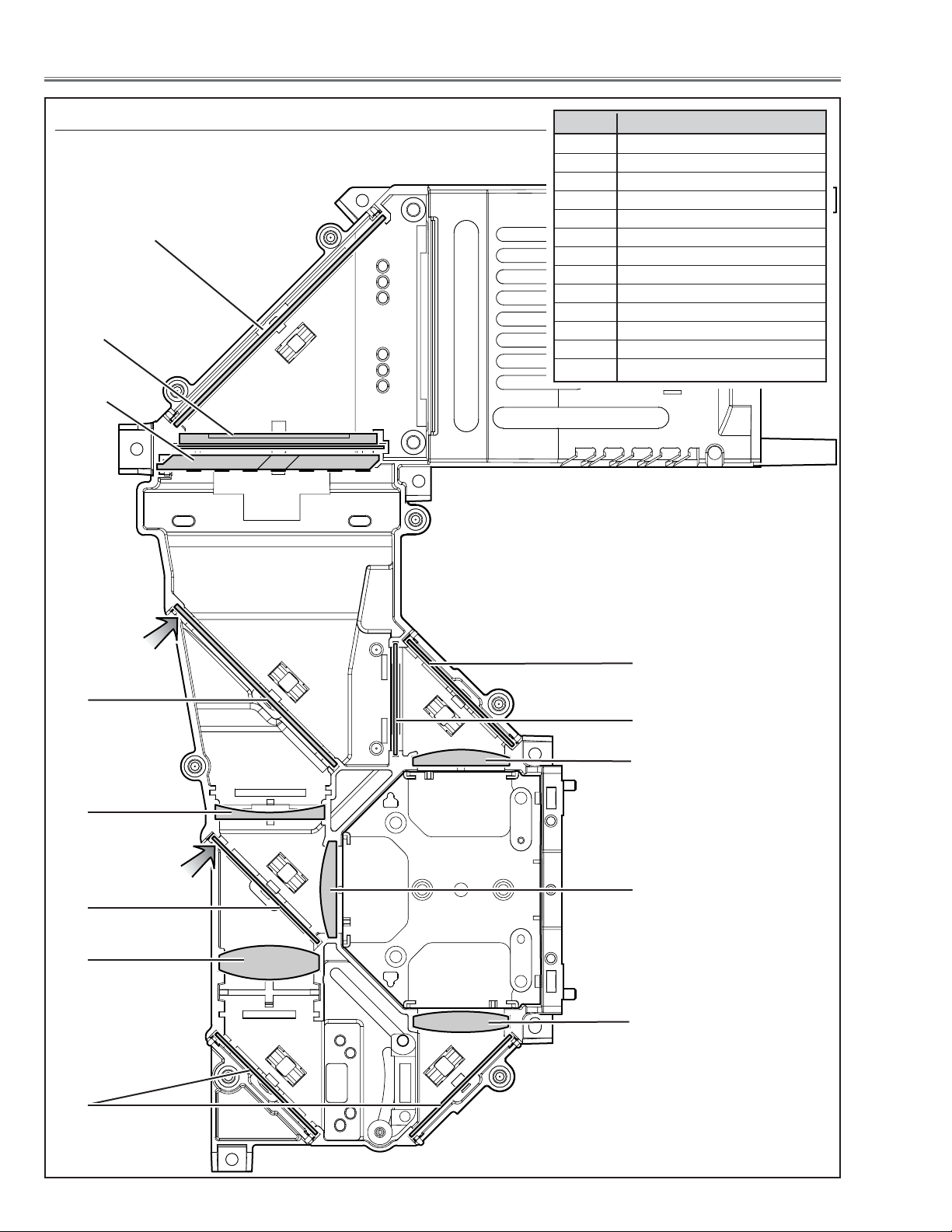

When mounting or assembling the optical parts in the optical unit, the

parts must be mounted in the specified location and direction as

shown in figure below.

5

8

9

Fig.9

2

4

1

The printed marker

comes this side.

13

3

7

10

Locations and Directions

6

12

1 Mirror (W)

2 Integrator lens (OUT)

3Prism beam splitter (PBS)

4 Dichroic mirror (B)

5 Condenser lens (OUT)

6 Dichroic mirror (G)

7Relay lens (IN)

8 Mirror (R)

9 Condenser lens (R)

10 Condenser lens

11 Condenser lens (B)

12 Optical filter (UV cut)

13 Mirror (B)

Key No. Description

The printed marker

comes this side.

11

Page 19

-19-

■ LCD Panel/Prism Ass’y Replacement

1 Remove the cabinet top and main board following to

“Mechanical Disassemblies”.

2 Remove 4 screws by using the 2.0 mm hex driver and

take the LCD Panel/Prism ass’y off upward from the

optical unit.

LCD Panel/Prism

Ass’y

After replacing or installing the LCD Panel/Prism ass'y,

please make sure to obtain the best focus in both TELE

and WIDE zoom.If the focus adjustment is required,

please adjust the positioning of LCD Panel/Prism Ass’y by

following below procedure.

Mounting Procedure:

1 Loosen 4 screws A on the LCD Panel/Prism ass'y with

2.0 mm hex driver.

2 Turn the projector on and project the image with WIDE

zoom, and adjust the FOCUS control to obtain the best

focus.

3 Turn the ZOOM control to the TELE position.

4 Move the LCD Panel/Prism Ass’y backward or forward

(about 0mm ~ 0.8mm) to obtain the proper focus.

Confirm the focus at TELE and WIDE zoom.

5 Tighten 4 screws A to fix the LCD Panel/Prism ass'y.

T

op View

A

A

A

A

LCD Panel/Prism Ass’y

Note:

Do not replace the LCD

panel separately otherwise

it can not obtain proper picture.

IMPORTANT NOTICE on LCD Panel/Prism Ass'y Replacement

LCD panels used for this model can not be replaced separately. Do not disassemble the LCD Panel/Prism Ass’y.

These LCD panels are installed with precision at the factory.When replacing the LCD panel, should be replaced

whole of the LCD panels and prism ass’y at once.

After replacing LCD Panel/Prism ass’y, please check the following adjustments.

- Check the “Condenser Lens Adjustment” , “Condenser Lens-Out Adjustment” and “Relay Lens-Out

Adjustment” following to chapter “Optical Adjustment”.

- Check the “White Balance Adjustment” , “Common Center Adjustment” and “Gamma Shift Adjustment”

following to chapter “Electrical Adjustment”.

- Check the white uniformity on the screen.

If you find the color shading, please adjust the white uniformity by using the proper computer and

“Color Shading Correction” software supplied separately.

LCD Panel/Prism Ass’y removal

Note on LCD Panel/Prism Ass’y Mounting

Page 20

-20-

WARNING:

- For continued safety, replace with a lamp assembly of the same type.

- Allow the projector to cool for at least 45 minutes before you open the

lamp cover.The inside of the projector can become very hot.

- Do not drop the lamp module or touch the glass bulb! The glass can

shatter and cause injury.

Procedure

1 Turn off the projector and disconnect the AC cord. Allow the projector to

cool for at least 45 minutes.

2 Remove a screw with a screwdriver and remove the lamp cover.

3 Remove 2 screws and pull out the lamp assembly by grasping the han-

dle.

4 Replace the lamp assembly securely and tighten 3 screws.

5 Place the lamp cover and tighten a screw.

6 Connect the AC cord to the projector and turn on.

Note:

- Do not reset the Lamp Replace Counter, except after lamp is replaced.

- The projector can not be turned-on with lamp cover removed, because

when the lamp cover is removed, the interlock switch is also released to

switch off the mains power for safety.

7 Reset the Lamp Replace Counter, see below explanation.

■ Lamp Replacement

1 Turn the projector on, and press the MENU button

and the on-screen menu will appear.Press the POINT

LEFT/RIGHT buttons to move a red frame pointer to

SETTING menu icon.

2 Press the POINT DOWN button to move a red frame

pointer to “Lamp counter reset” and then press the

SELECT button.The message “Lamp replace counter

reset?” is displayed. Move the pointer to [Yes] and the

press the SELECT button.

3 Another confirmation dialog box appears and select

[Yes] to reset Lamp Replace Counter .

Please refer to the owners manual for further information.

Recommendation

Should the air filter become clogged with dust particles,

it will reduce the cooling fan’s effectiveness and may

result in internal heat build up and short lamp life. We

recommend cleaning the air filter after the projection

lamp is replaced.

Refer to “Air Filter Cleaning”.

The LAMP REPLACEMENT indicator will illuminate

when the Lamp Replace Counter reaches 1000

hours.This is to indicate that lamp replacement is

required.

You can check the lamp replace counter following to

below procedure.

1 Press and hold the pointer UP on the projector for

more than 20 seconds.

2 The Lamp replace Counter service menu appears on

the screen. For example, when the value of data indicates “123”, the accumulated operation time is 123

hours. To make this menu disappear, press Power

button on the projector.

Lamp cover

Lamp Assembly

Handle

Lamp replace counter data

ORDER REPLACEMENT LAMP

T

ype No.

Service Parts No.

POA-LMP35 610 293 2751

How to reset Lamp Replace Counter

How to check Lamp Replace Counter

Service Mode

Input Video

Group No. Data

10 0 123

Ver. 1 .00

Page 21

-21-

[Before Adjustment]

- Input a 100% of black raster signal.

[R/G/B-CONTRAST ADJUSTMENT]

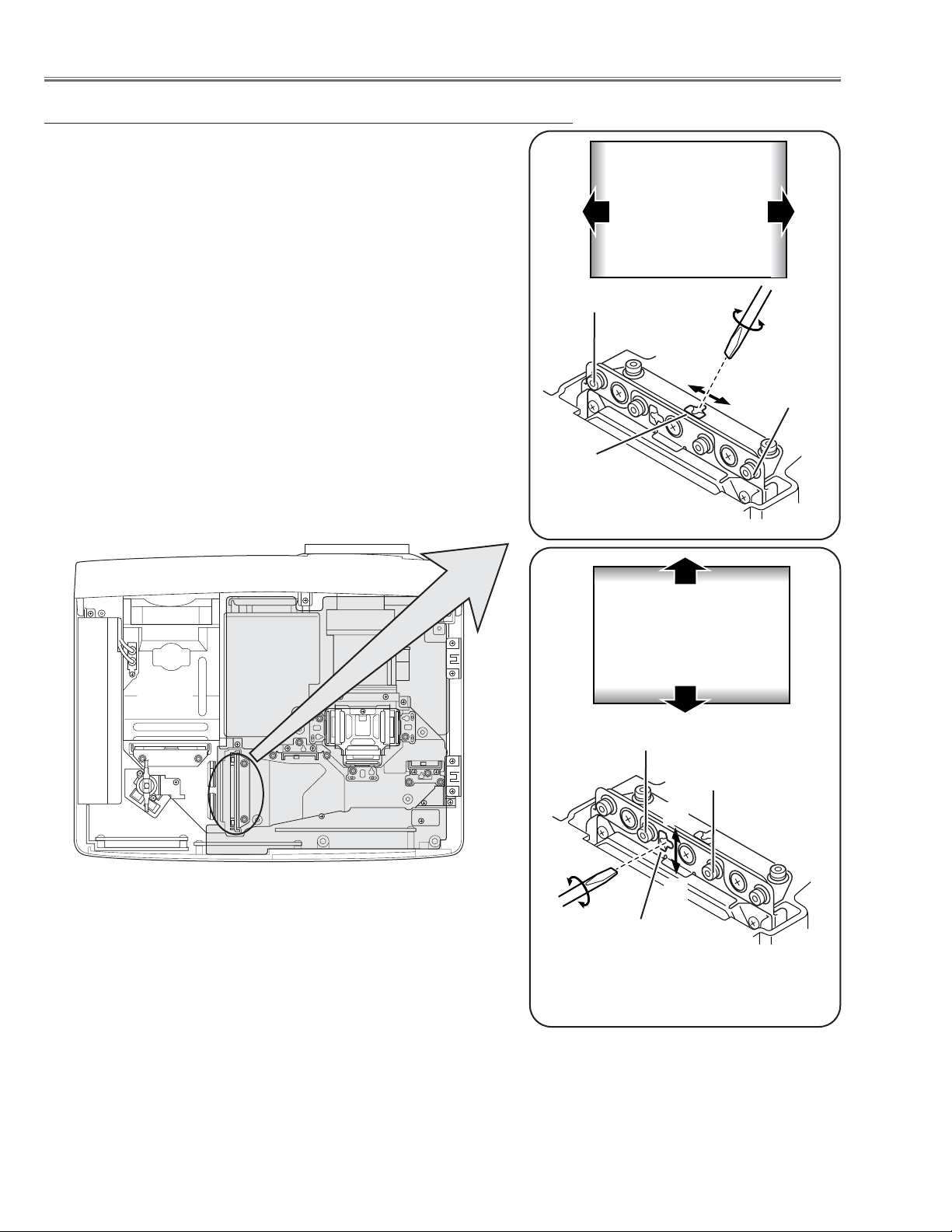

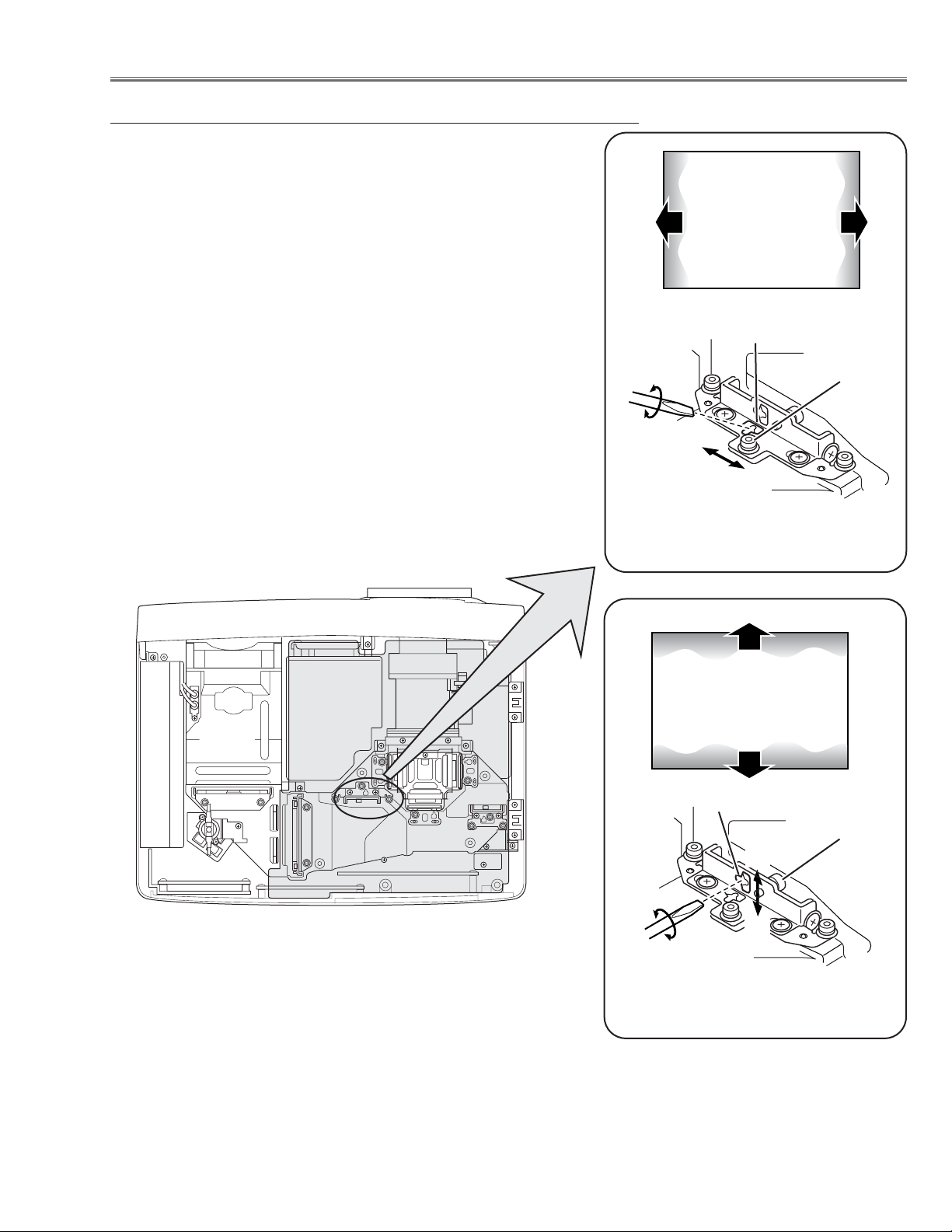

1 Loosen a screw A (Fig.1-1/1-2) on the polarized glass mounting

base which you intend to adjust.

2 Turn the polarized glass mounting base as shown in Fig.1-1 to

obtain the darkest brightness on the screen.

3 Tighten the screw A to fix the polarized glass mounting base.

Repeat steps 1 to 3 for remaining polarized glasses.

B-Polarized Glass

Mounting Base

R-Polarized Glass

Mounting Base

G-Polarized Glass

Mounting Base

A

A

A

Slot B

Fig.1-2

Fig.1-1

Polarized glass

mounting base

■ Optical Adjustments

Main Board

A

Contrast adjustment

Before taking optical adjustments below, remove the Cabinet Top and Main Board following to the “Mechanical

Disassemblies”

Adjustments require a 2.0mm hex wrench and a slot screwdriver. When you adjust Condenser lens, Condenser

lens-out or Relay lens adjustment, you need to disconnect some connectors and FPC cab les of LCD panels on the

main board.

Note: Do not disconnect connectors K8N, K8P, K8H, K8R and K8S on the main board, because the projector can

not turn on due to operate the power failure protection.

Page 22

-22-

Optical Adjustments

Fig.2-2

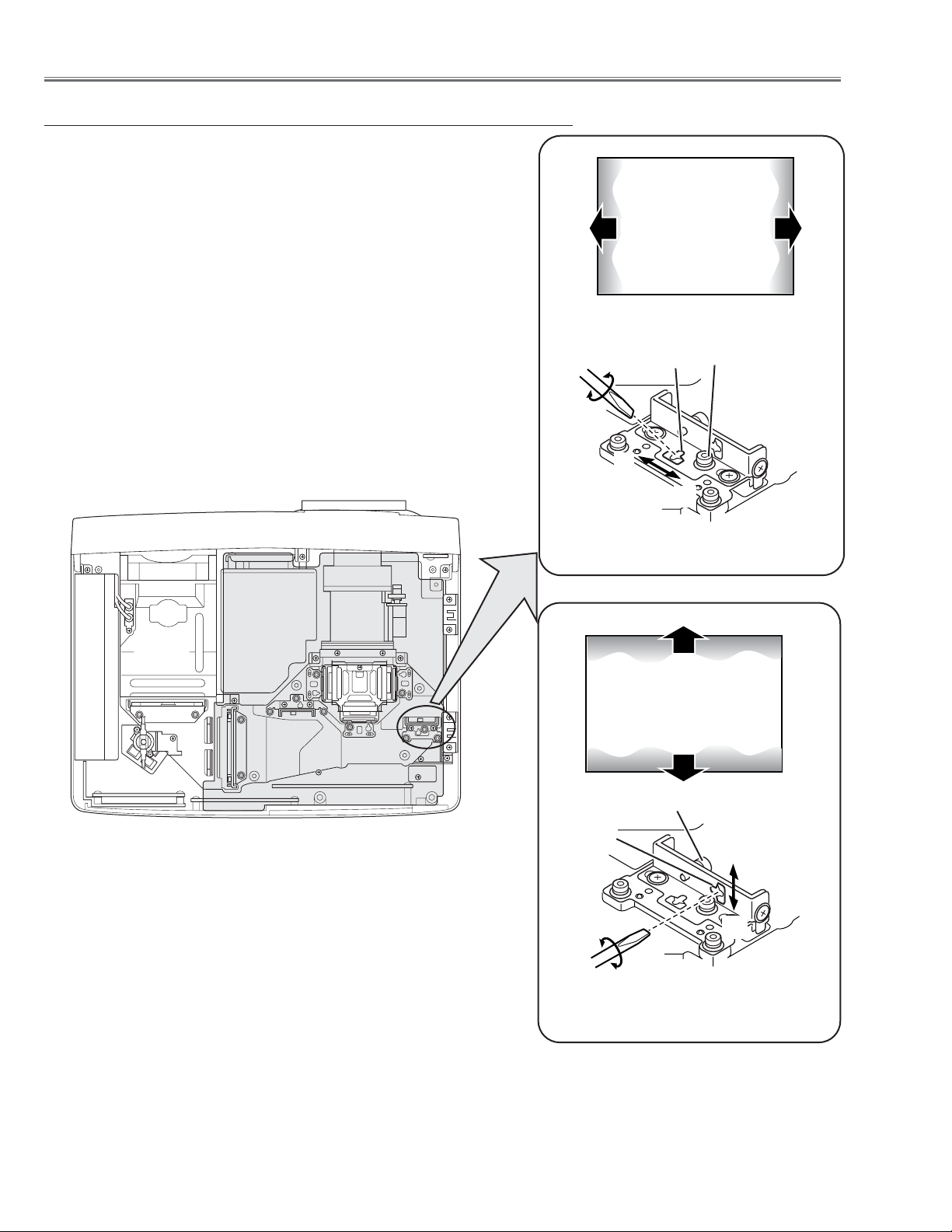

1 Turn the projector on by a state of without FPC cables.

2 Project only green light on the screen.

3 Adjust the adjustment base of condenser lens assy to make color

uniformity in green.

1) If the shading appears on the left or right of the screen as

shown in Fig.2-1, loosen 2 screws A with the 2.0mm hex driver, and adjust the slot B to make color uniformity in green by

using a slot screwdriver.

2) If the shading appears on the top or bottom of the screen as

shown in Fig.2-2, loosen 2 screw C with the 2.0mm hex driver,

and adjust the slot D to make color uniformity in green by using

a slot screwdriver

4 Tighten screws A and C to fix the Condenser lens unit.

Note:

The relay lens adjustment must be carried out after completing this

adjustment.

y

x

Moving of Slot D

Slot D

C

a

b

a

b

Moving of slot B

Fig.2-1

Slot B

A

C

y

x

Green

Green

Condenser Lens adjustment

A

Page 23

-23-

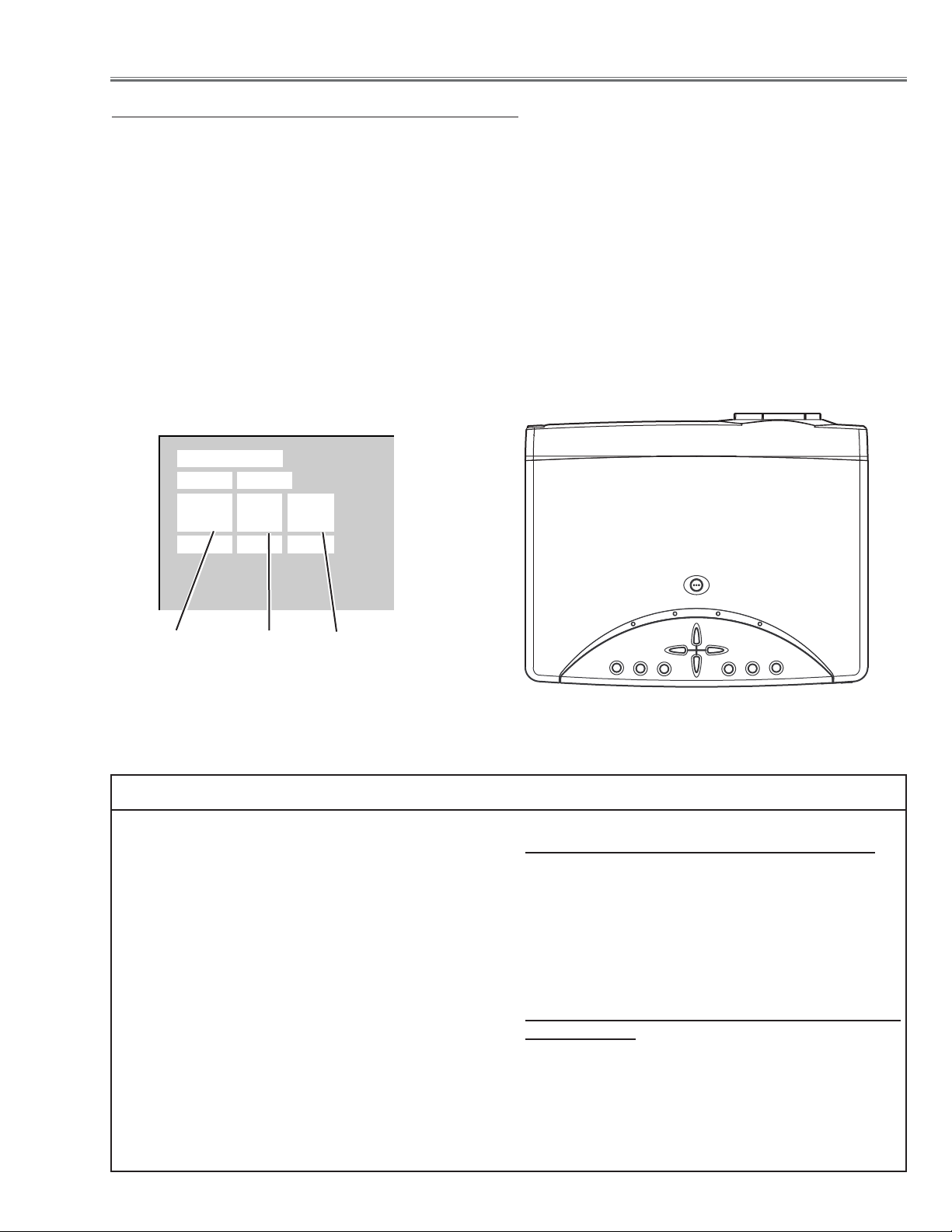

1 Turn the projector on by a state of without FPC cables.

2 Project green and blue lights on the screen.

3 Adjust the adjustment base of condenser lens-out assy to make

color uniformity in cyan.

1) If the shading appears on the left or right of the screen as shown

in Fig.3-1, loosen 1 screw A with the 2.0mm hex driver, and

adjust the slot B to make color uniformity in cyan by using a slot

screwdriver.

2) If the shading appears on the top or bottom of the screen as

shown in Fig.3-2, loosen 1 screw C with the 2.0mm hex driver,

and adjust the slot D to make color uniformity in cyan by using a

slot screw driver.

4 Tighten the screw A and C to fix the relay lens unit.

Fig.3-1

A

Slot B

Optical Adjustments

a

b

b

Moving of slot B

a

Cyan

Fig.3-2

D

Moving of slot D

y

x

C

Condenser Lens-Out adjustment

y

x

Cyan

Page 24

-24-

1 Turn the projector on by a state of without FPC cables.

2 Project all of lights on the screen.

3 Adjust the adjustment base of relay lens assy to make color unifor-

mity in white.

1) If the shading appears on the left or right of the screen as shown

in Fig.4-1, loosen 1 screw A with the 2.0mm hex driver, and

adjust the slot B to make color uniformity in white by using a slot

screwdriver.

2) If the shading appears on the top or bottom of the screen as

shown in Fig.4-2, loosen 1 screw C with the 2.0mm hex driver,

and adjust the slot D to make color uniformity in white by using

a slot screwdriver.

4 Tighten the screws A and C to fix the relay lens unit.

Fig.4-1

A

Slot B

a

b

b

Moving of slot B

a

White

Fig.4-2

Slot D

Moving of slot D

y

x

C

Optical Adjustments

y

x

Relay lens-Out adjustment

White

Page 25

-25-

■ Electrical Adjustments

To enter the service mode

To enter the “Service Mode”, press and hold the MENU and IMAGE button on the projector at the same time for

more than 3 seconds.The service menu appears on the screen as follows.

To adjust service data

Select the adjustment group no.by pressing the MENU button, and select the adjustment item no. by pressing the

pointer UP or DOWN button, and change the data value by pressing the VOLUME – or VOLUME + button. Refer

to the “Service Adjustment Data Table” for further descr iption of adjustment group no., item no.and data value.

To exit the service mode

To exit the ser vice mode, press the POWER ON-OFF button on the projector or remote control unit.

● Service Adjustment Menu Operation

IC1801 on the main board stores the data for the service adjustments, and should not be replaced except for

the case of defective device.

If replaced, it should be performed the re-adjustments

following to the “Electrical Adjustments”.

The data of lamp replacement monitor timer is stored

in the IC1801.

Please note that the lamp replace counter is reset

when the memory IC (IC1801) is replaced.

(Lamp replace counter can not be set to the previous

value.)

● Caution to memory IC replacement

When IC1801 is replaced with new one, the CPU

writes down the default data of the service adjustments

to the replaced IC, refer to the service adjustment

table. As these data are not the same data as factory

shipped data, it should be required to perform the re-

adjustments following to the “Electrical Adjustments”.

Please note that the lamp replace counter is reset.

● Caution of Main Board replacement (in the case

IC1801 is not defective)

When the main board is replaced, IC1801 should be

replaced with the one on previous main board. After

replacement, it should be required to perform the readjustments following to the “Electrical Adjustments”.

In this case, the lamp replace counter can be kept the

v

alue as before.

● Memory IC Replacement

Group No.

Data value

Item No.

Service Mode

Input Video

Group No. Data

0032

Ver. 1 .00

Page 26

-26-

After replacing the Power Board, PF.C. Board, readjust

the Output voltage adjustment as follows.

1. Connect a digital voltmeter to pins 1 (+) and 3 (-) of

K6D.

2. Adjust the voltage by using VR611 as following.

A

C Input Reading

230V 370V ±2V

or 120V 340V ±2V

Caution:

Be sure to connect the lamp when taking this adjustment.

● Circuit Adjustments

CAUTION:The each circuit has been made by the fine adjustment at factory. Do not attempt to adjust the follow-

ing adjustments except requiring the readjustments in servicing otherwise it may cause loss of performance and product safety.

[Adjustment Condition]

● Input signal

Video signal .......................... 1.0Vp-p/75Ω terminated, 16 steps gray scale (Composite video signal)

Computer signal ...................... 0.7Vp-p/75Ω terminated, 16 steps gray scale pattern (XGA)

● Picture control mode ...................... “STANDARD” mode unless otherwise noted.

Note:

* Please refer to “Service Adjustment Menu Operation” for entering to the service mode and adjusting the service

data.

Electrical Adjustments

Output Voltage adjustment

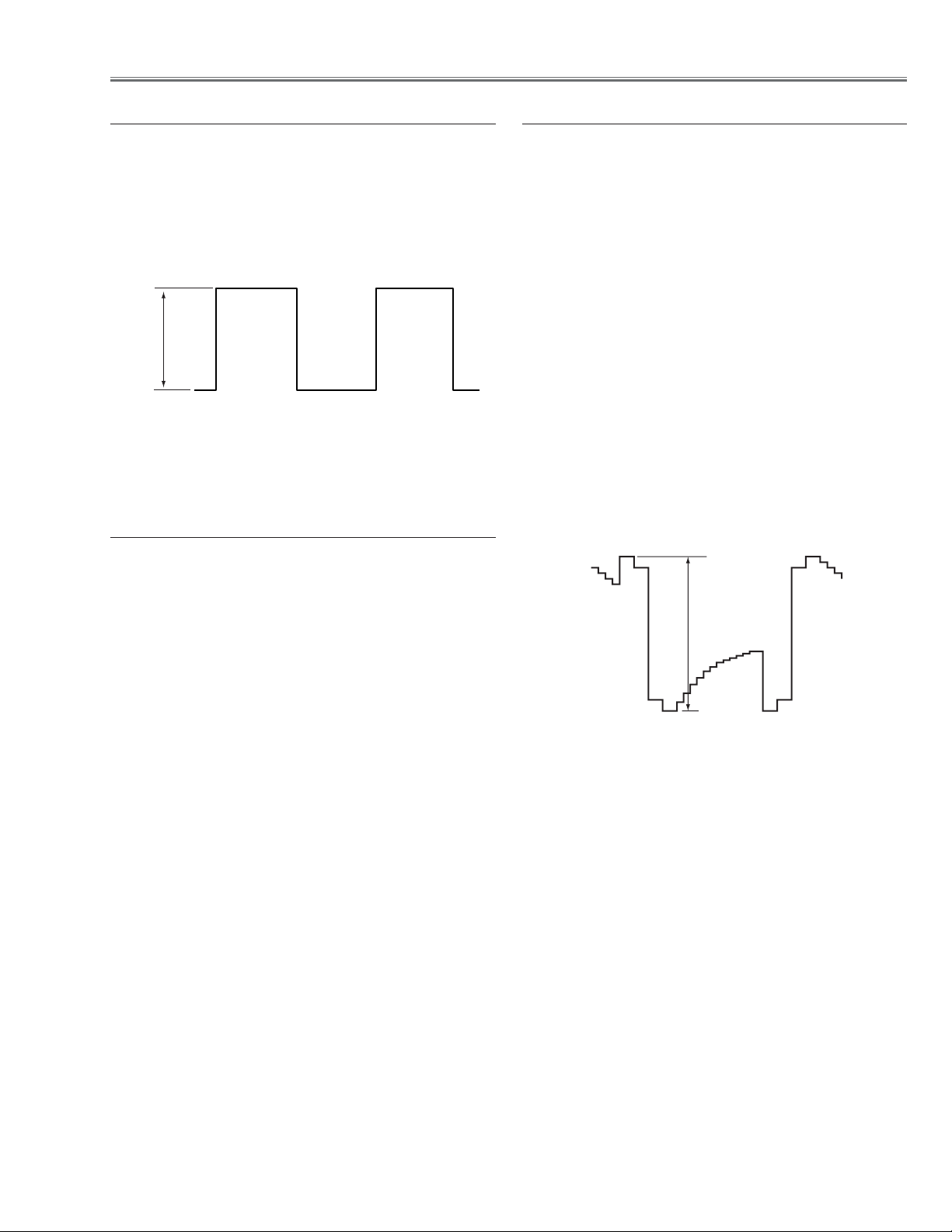

1. Receive the 16-step grey scale video signal.

2. Set to VIDEO mode.

3. Enter the ser vice mode.

[R-PEDESTAL ADJUSTMENT]

4. Connect an oscilloscope to test point “TP201R”(+)

and chassis ground (-).

5. Select group no. “3”, item no. “14” and change data

value to adjust the pedestal lev el and b lack level to be

the same level.

[G-PEDESTAL ADJUSTMENT]

6. Connect an oscilloscope to test point “TP201G”(+)

and chassis ground (-).

7. Select group no. “3”, item no. “15” and change data

value to adjust the pedestal lev el and b lack level to be

the same level.

[B-PEDESTAL ADJUSTMENT]

8. Connect an oscilloscope to test point “

TP201B”(+)

and chassis ground (-).

9. Select group no. “3”, item no. “16” and change data

value to adjust the pedestal lev el and b lack level to be

the same level.

Pedestal adjustment

1. Enter the service mode and select group no. “11” and

item no.“0”. Set data value to “1”.

2. Connect a digital voltmeter to test point “TP12V1” (+)

and chassis ground (-).Select item no .“1” and change

data value to adjust voltage to be 8.0 ±0.1V.

3. Connect a digital voltmeter to test point “TP12V2” (+)

and chassis ground (-). Select item no.“2” and

change data value to adjust voltage to be 9.0 ±0.1V.

4. Select group no. “11” and item no. “0” and set data

value to “3”.

5. Connect a digital voltmeter to test point “TP12V1” (+)

and chassis ground (-).Select item no .“3” and change

data value to adjust voltage to be 13.0 ±0.1V.

6. Connect a digital voltmeter to test point “TP12V2” (+)

and chassis ground (-).Select item no .“4” and change

data value to adjust voltage to be 13.5 ±0.1V.

Fan Voltage adjustment

Pedestal level = Black level

(a)

Page 27

-27-

Electrical Adjustments

1. Receive the 16-step grey scale computer signal.

2. Set to COMPUTER mode.

3. Enter the ser vice mode.

[R-SIGNAL CENTER ADJUSTMENT]

4. Connect a digital voltmeter to test point “TP25R1”(+)

and chassis ground (-).

5. Select group no. “3”, item no. “0” and change data

value to adjust the voltage to be 7.30 ±0.05V.

[G-SIGNAL CENTER ADJUSTMENT]

6. Connect a digital voltmeter to test point “TP25G1”(+)

and chassis ground (-).

7. Select group no. “

3”, item no. “1” and change data

value to adjust the voltage to be 7.30 ±0.05V.

[B-SIGNAL CENTER ADJUSTMENT]

8. Connect a digital voltmeter to test point “TP25B1”(+)

and chassis ground (-).

9. Select group no. “3”, item no. “2” and change data

value to adjust the voltage to be 7.30 ±0.05V.

1. Receive the 16-step grey scale computer signal.

2. Set to COMPUTER mode.

3. Connect an oscilloscope to test point “TP3551” (+)

and chassis ground (-).

4. Enter the ser vice mode, select group no.“3”, item no.

“7” and change data value to adjust amplitude “a” to

be 5.5 ±0.1V.

Signal Center adjustment

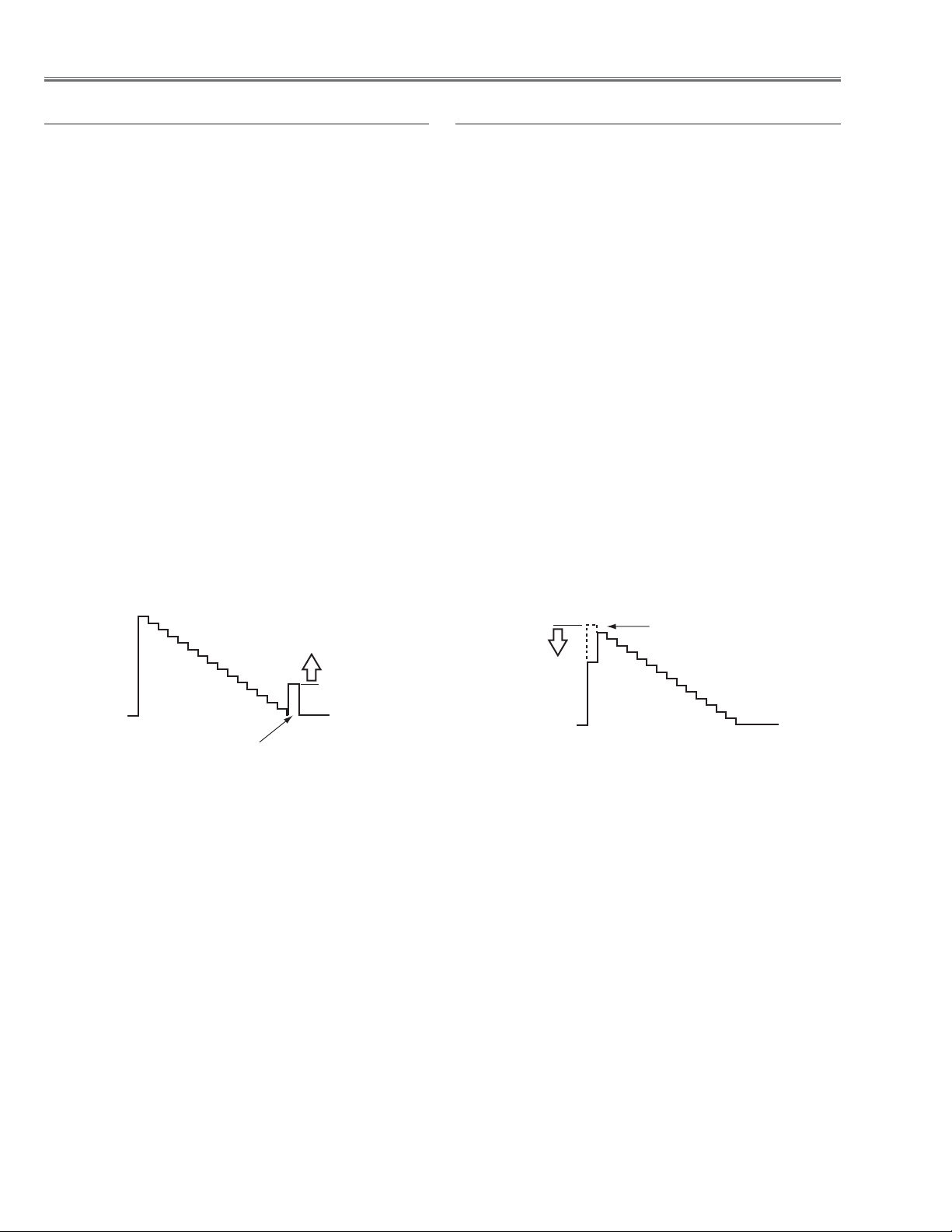

NRS adjustment

1. Receive the 16-step grey scale computer signal.

2. Set to COMPUTER mode.

3. Enter the ser vice mode.

[R-BLACK ADJUSTMENT]

4. Connect an oscilloscope to test point “TP25R1” (+)

and chassis ground (-).

5. Select group no.“3”, item no.“3” and change data

value to adjust amplitude “a”to be 10.0 ±0.1V.

[R-BLACK ADJUSTMENT-]

6. Connect an oscilloscope to test point “TP25G1” (+)

and chassis ground (-).

7. Select group no.“3”, item no.“4” and change data

value to adjust amplitude “a”to be 10.0 ±0.1V.

[R-BLACK ADJUSTMENT-]

8. Connect an oscilloscope to test point “TP25B1” (+)

and chassis ground (-).

9. Select group no.“3”, item no.“5” and change data

value to adjust amplitude “a”to be 10.0 ±0.1V.

Black Level adjustment

(a)

black level

(a)

black level

Page 28

-28-

Electrical Adjustments

1. Receive the 16-step gray scale computer signal.

2. Set to COMPUTER mode.

3. Enter the ser vice mode.

[R-GAIN ADJUSTMENT]

4. Connect an oscilloscope to test point “TP25R1”(+)

and chassis ground (-).

5. Select group no.“2”, item no.“3” and change data

value to adjust waveform “a”to be minimum amplitude.

[G-GAIN ADJUSTMENT]

6. Connect an oscilloscope to test point “TP25G1”(+)

and chassis ground (-).

7. Select group no.“2”, item no.“4” and change data

value to adjust waveform “a”to be minimum amplitude.

[B-GAIN ADJUSTMENT]

8. Connect an oscilloscope to test point “TP25B1”(+)

and chassis ground (-).

9. Select group no.“2”, item no.“5” and change data

value to adjust waveform “a”to be minimum amplitude.

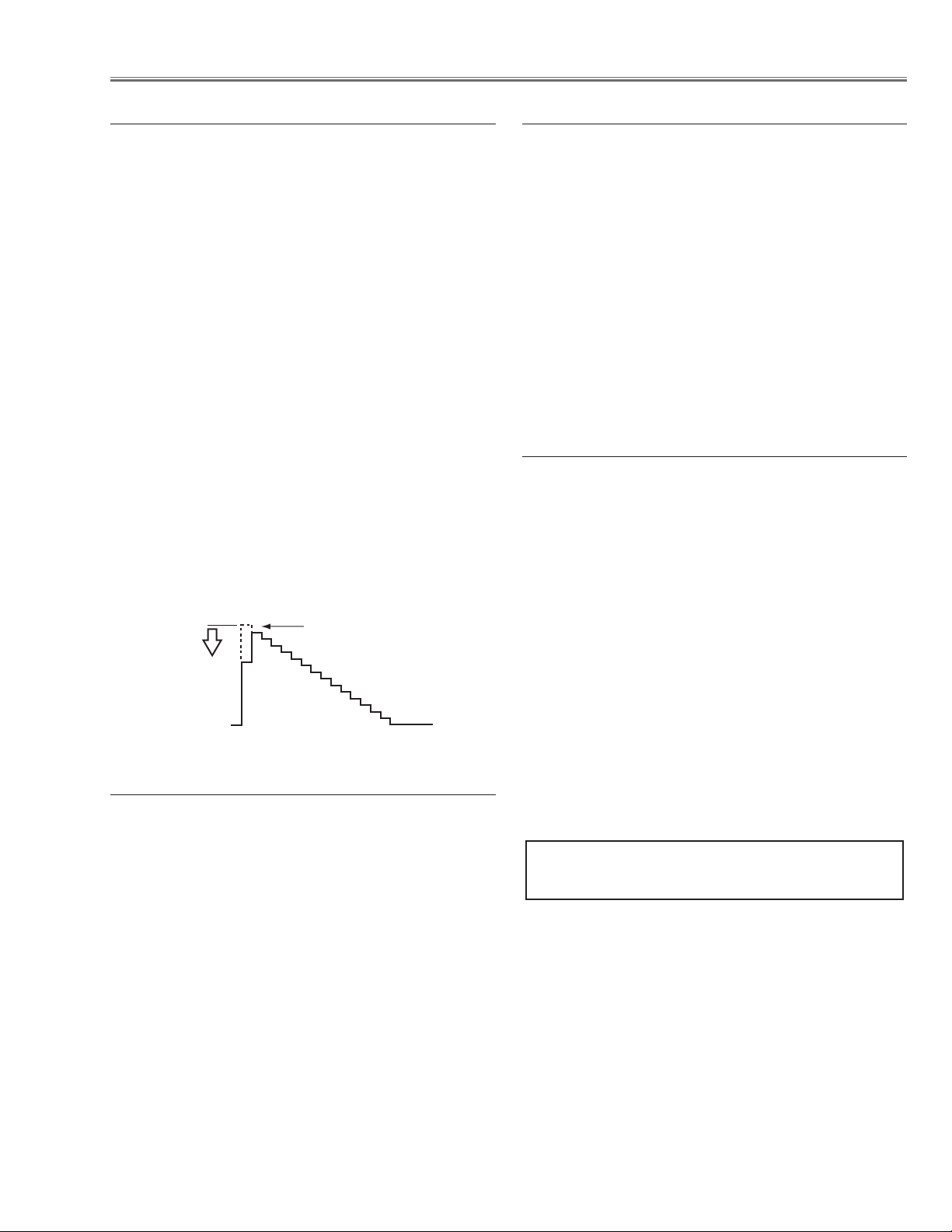

PC Gain adjustment

1. Receive the 16-step gray scale computer signal.

2. Set to COMPUTER mode.

3. Enter the ser vice mode.

[R-OFFSET ADJUSTMENT]

4. Connect an oscilloscope to test point “TP25R1”(+)

and chassis ground (-).

5. Select group no.“3”, item no.“11” and change data

value to adjust the waveform “a” (black portion ) to

be maximum amplitude.

[G-OFFSET ADJUSTMENT]

6. Connect an oscilloscope to test point “TP25G1”(+)

and chassis ground (-).

7. Select group no.“3”, item no.“12” and change data

value to adjust the waveform “a” (black portion ) to

be maximum amplitude.

[B-OFFSET ADJUSTMENT]

8. Connect an oscilloscope to test point “TP25B1”(+)

and chassis ground (-).

9. Select group no.“3”, item no.“13” and change data

value to adjust the waveform “a” (black portion ) to

be maximum amplitude.

PC Offset adjustment

Black Level

(a)

White Level

(a)

Page 29

-29-

Electrical Adjustments

[PC-GAMMA OFF ADJUSTMENT]

1. Receive the 16-step gray scale computer signal.

2. Set to COMPUTER mode.

3. Enter the service mode, select group no. “2”, item

no.“6”and change data value to reproduce the proper gray scale picture on the screen.

[AV-GAMMA OFF ADJUSTMENT]

4. Receive the 16-step gray scale video signal.

5. Set to VIDEO mode.

6. Enter the service mode, select group no. “2”, item

no.“6”and change data value to reproduce the proper gray scale picture on the screen.

1.Receive the 1 dot black & white pattern computer signal.

2. Set to COMPUTER mode.

3. Enter the service mode.

[G-COMMON CENTER ADJUSTMENT]

4. Project only green light component to the screen.

5. Select group no.“3”, item no.“8” and change data

value to obtain the minimum flicker on the screen.

[B-COMMON CENTER ADJUSTMENT]

6. Project only blue light component to the screen.

7. Select group no.“3”, item no.“9” and change data

value to obtain the minimum flicker on the screen.

[R-COMMON CENTER ADJUSTMENT]

8. Project only red light component to the screen.

9. Select group no.“3”, item no.“10” and change data

value to obtain the minimum flicker on the screen.

Gamma Shift adjustment

Common Center adjustment

1. Receive the 16-step gray scale video signal.

2. Set to VIDEO mode.

3. Enter the ser vice mode.

[R-GAIN ADJUSTMENT]

4. Connect an oscilloscope to test point “TP25R1”(+)

and chassis ground (-).

5. Select group no.“2”, item no.“3” and change data

value to adjust waveform “a”to be minimum amplitude.

[G-GAIN ADJUSTMENT]

6. Connect an oscilloscope to test point “TP25G1”(+)

and chassis ground (-).

7. Select group no.“2”, item no.“4” and change data

value to adjust waveform “a”to be minimum amplitude.

[B-GAIN ADJUSTMENT]

8. Connect an oscilloscope to test point “TP25B1”(+)

and chassis ground (-).

9. Select group no.“2”, item no.“5” and change data

value to adjust waveform “a”to be minimum amplitude.

AV Gain adjustment

[PC WHITE BALANCE ADJUSTMENT]

1. Receive the 16-step gray scale computer signal.

2. Set to COMPUTER mode.

3. Enter the service mode, select group no.“2”, item no.

“7” (Red) or “8” (Blue), and change data values

respectively to make a proper white balance.

[A V WHITE BALANCE ADJUSTMENT]

4. Receive the 16-step grey scale video signal.

5. Set to VIDEO mode.

6. Enter the service mode, select group no.“2”, item no.

“7” (Red) or “8” (Blue), and change data values

respectively to make a proper white balance.

Confirm that the same white balance is obtained in

video and computer input.

White Balance adjustment

If you find the color shading on the screen, please

adjust the white uniformity by using the proper computer and “Color Shading Correction” software supplied

separately.

NOTE ON WHITE UNIFORMITY

ADJUSTMENT

(a)

White Level

Page 30

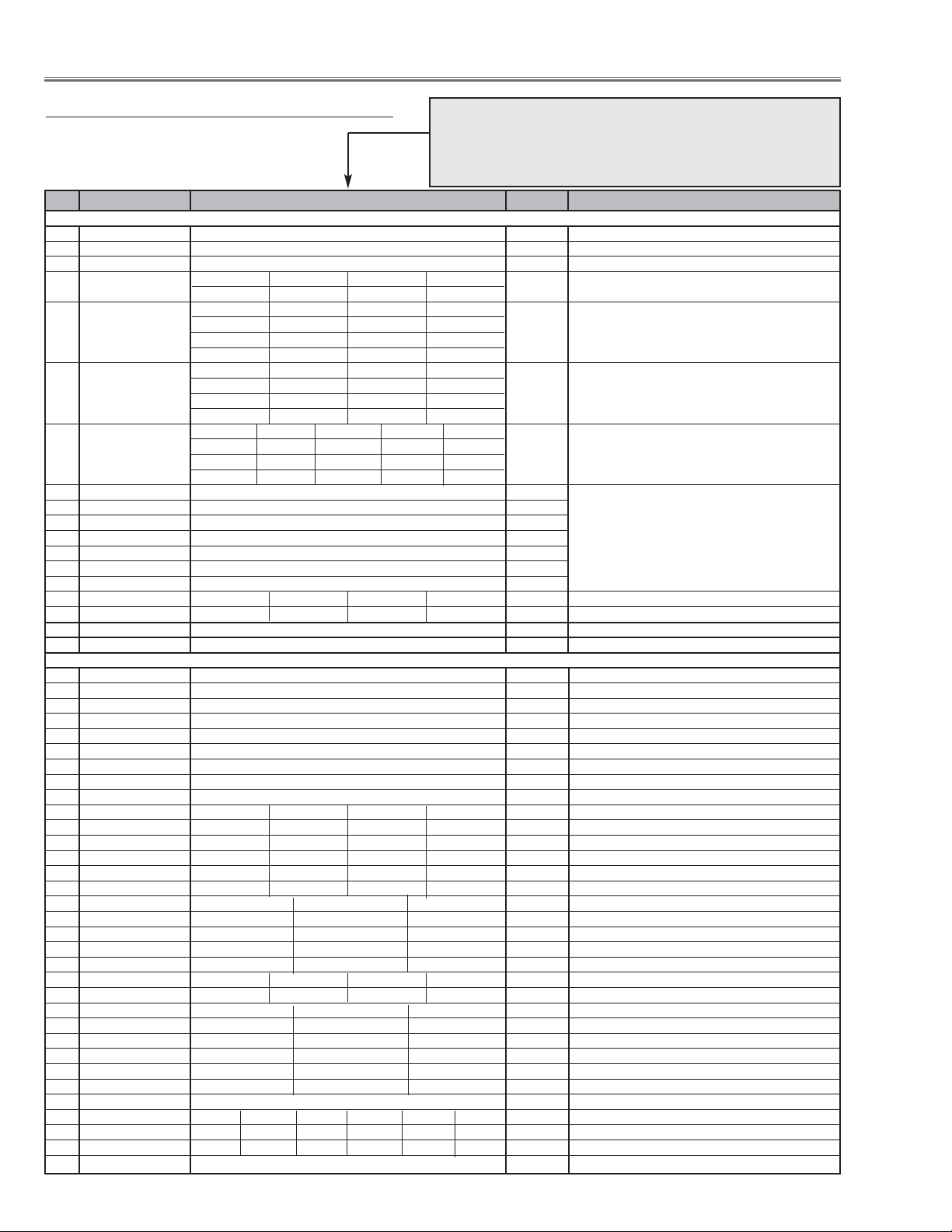

Group: 0 TB1274

0 TINT 32 0 ~ 63

1 SHP_EQ 2 0 ~ 3

2 SHP_FO 1 0 ~ 3

NTSC,PAL SECAM,NT4.43 S-Video Y,Cb,Cr

3 SHP_GAIN 10 10 10 10 0 ~ 15

NTSC NT4.43 PAL SECAM

4 Y_OUT_LEVEL 30 30 31 31 0 ~ 63

S-Video NTSC S-Video PAL S-Video SECAM Y,Cb,Cr

30 31 31 31

NTSC NT4.43 PAL SECAM

5 C_OUT_LEVEL 32 32 32 32 0 ~ 63

S-Video NTSC S-Video PAL S-Video SECAM Y,Cb,Cr

32 32 32 32

NTSC PAL SECAM NT4.43 PAL 60

6 Y_DELAY 6 6 6 4 4 0 ~ 15

S-Video NTSC S-Video PAL S-Video SECAM S-Video NT4.43 S-Video PAL60

443 34

7 COL_SYS - -

8X’TAL - -

9 NOISE_DET - -

10 V_FREQ - - Read only

11 Vert. Std - -

12 CID - -

13 V_SIG - -

NTSC,PAL SECAM,NT4.43 S-Video YCbCr

14 Cinema SHP_GAIN 8 8 8 8 0 ~ 15 For cinema mode

Group: 1 CXA2101

0 PICTURE 30 0 ~ 63

1 BRIGHT 31 0 ~ 63

2 R_DRIVE 31 0 ~ 63

3 G_DRIVE 31 0 ~ 63

4 B_DRIVE 31 0 ~ 63

5 HSEP_SEL 1 0 ~ 1

6 CR_OFFSET1 15kHz: 7 Others: 10 0 ~ 15

7 CB_OFFSET1 15kHz: 7 Others: 10 0 ~ 15

8 BLK_BOTTOM 15 0 ~ 15

NTSC PAL, SECAM 1035i Y,Cb,Cr *1 *1 Y, Cb, Cr and Y, Pb, Pr except 1035i

9 R-Y/R 6 13 6 6 0 ~ 15

10 R-Y/B 5 15 5 5 0 ~ 15

11 G-Y/R 8 8 8 8 0 ~ 15

12 G-Y/B 10 4 10 10 0 ~ 15

13 MAT_OUT 0 0 0 1 0 ~ 3

15kHz 480i, 575i 480p, 575p 1080i, 1035i, 720p

14 SYSTEM 0 1 2 0 ~ 3

15 V_TC 3 3 3 0 ~ 3

16 H_WIDTH 3 2 0 0 ~ 3

17 HS_MASK 0 1 1 0 ~ 1

Video, S-Video 480i, 575i 480p, 575p 1080i, 1035i, 720p

18 CTI_LEVEL 2 2 2 2 0 ~ 3

15kHz 480i, 575i 480p, 575p 1080i, 1035i, 720p

19 SUB_SHP 3 3 3 0 ~ 3

20 SHP_FO 0 2 3 0 ~ 3

21 PRE_OVER 2 2 3 0 ~ 3

22 LTI_LEVEL 0 1 1 0 ~ 3

23 D_PIC 0 0 0 0 ~ 3

24 HUE 31 0 ~ 63 Only adjustable for PAL,SECAM

NTSC PAL,SECAM 525i,480p 625i,575p 1035i Others

25 SUB_COL 5 5 12 12 6 9 0 ~ 15

26 SUB_HUE 7 7 8 7 9 6 0 ~ 15

27 Cinema CTI_LEVEL 2 0 ~ 3 Set this value at Cinema Mode

-30-

Electrical Adjustments

● Service Adjustment Data Table

These initial values are the reference data written from the CPU

ROM to memory IC when replaced new memory IC.The adjustment items indicated with “✻” are required to readjust following

to the “Electrical adjustments”. Other items should be used with

the initial data value.

No. Adjustment Item Initial Value Range Description

Page 31

28 Cinema LTI_LEVEL 0 0 ~ 3 Set this value at Cinema Mode

Group: 2 L3E07050 (Digital Gamma, Color Shading & Timing Controller)

PC DVI,AV

0 R_SUB_BRT 0 0 0 ~ 1023

1 G_SUB_BRT 0 0 0 ~ 1023

2 B_SUB_BRT 0 0 0 ~ 1023

PC AV DVI

3R_SUB_GAIN 573 573 492 0 ~ 1023 ✻ Red PC/AV gain adjustment

4 G_SUB_GAIN 573 573 492 0 ~ 1023 ✻ Green PC/AV gain adjustment

5 B_SUB_GAIN 573 573 492 0 ~ 1023 ✻ Blue PC/AV gain adjustment

PC, DVI Standard AV Standard

6 Standard G GAMMA SHIFT 415 415 Note1 ✻ Gamma shift adjustment

7 Standard R GAMMA SHIFT 415 415 Note1 ✻ White balance adjustment

8

Standard B GAMMA SHIFT 415 415 Note1

✻ White balance adjustment

9 Standard GAMMA 0 0 0 0 ~ 1023

10 Standard GAMMA 1 210 166 0 ~ 1023

11 Standard GAMMA 2 340 290 0 ~ 1023

12 Standard GAMMA 3 436 406 0 ~ 1023

13 Standard GAMMA 4 511 496 0 ~ 1023

14 Standard GAMMA 5 574 560 0 ~ 1023

15 Standard GAMMA 6 633 626 0 ~ 1023

16 Standard GAMMA 7 674 672 0 ~ 1023

17 Standard GAMMA 8 709 709 0 ~ 1023

18 Standard GAMMA 9 740 740 0 ~ 1023

19 Standard GAMMA 10 770 770 0 ~ 1023

20 Standard GAMMA 11 800 800 0 ~ 1023

21 Standard GAMMA 12 832 838 0 ~ 1023

22 Standard GAMMA 13 884 877 0 ~ 1023

23 Standard GAMMA 14 950 940 0 ~ 1023

24 Standard GAMMA 15 1023 1023 0 ~ 1023

PC, DVI Real AV Cinema (Different value to Standard)

25

Real/Cinema G GAMMA SHIFT 506 507 Note1 Note1:

26

Real/Cinema R GAMMA SHIFT 512 512 Note1

27 Real/Cinema B GAMMA SHIFT 504 504 Note1

28 Real/Cinema GAMMA 0 512 512 0 ~ 1023

29 Real/Cinema GAMMA 1 492 538 0 ~ 1023

30 Real/Cinema GAMMA 2 497 524 0 ~ 1023

31 Real/Cinema GAMMA 3 502 519 0 ~ 1023

32 Real/Cinema GAMMA 4 507 516 0 ~ 1023

33 Real/Cinema GAMMA 5 509 515 0 ~ 1023

34 Real/Cinema GAMMA 6 510 512 0 ~ 1023

35 Real/Cinema GAMMA 7 510 511 0 ~ 1023

36 Real/Cinema GAMMA 8 510 510 0 ~ 1023

37 Real/Cinema GAMMA 9 510 510 0 ~ 1023

38 Real/Cinema GAMMA 10 510 510 0 ~ 1023

39 Real/Cinema GAMMA 11 509 510 0 ~ 1023

40 Real/Cinema GAMMA 12 508 510 0 ~ 1023

41 Real/Cinema GAMMA 13 506 509 0 ~ 1023

42 Real/Cinema GAMMA 14 502 502 0 ~ 1023

43 Real/Cinema GAMMA 15 512 512 0 ~ 1023

44 R 2 127 0 ~ 255 R Correction value of vertical line

45 G 2 127 0 ~ 255 G Correction value of vertical line

46 B 2 127 0 ~ 255 B Correction value of vertical line

47 Red MID2 Level 453 0 ~ 1023

48 Red MID1 Level 500 0 ~ 1023

49 Red MAX Level 576 0 ~ 1023

50 Green MID2 Level 453 0 ~ 1023 Gray scale level adjustment

51 Green MID1 Level 500 0 ~ 1023

52 Green MAX Level 575 0 ~ 1023

53 Blue MID2 Level 418 0 ~ 1023

54 Blue MID1 Level 465 0 ~ 1023

55 Blue MAX Level 541 0 ~ 1023

56 DVI std G GAMMA SHIFT 512 0 ~ 1023

57 DVI std R GAMMA SHIFT 512 0 ~ 1023

58 DVI std B GAMMA SHIFT 512 0 ~ 1023

Group: 3 DAC

0R_VIDEO_CENTER 74 0 ~ 255 ✻ Red Signal center adjustment

1 G_VIDEO_CENTER 74 0 ~ 255 ✻ Green Signal center adjustment

2 B_VIDEO_CENTER 74 0 ~ 255

✻ Blue Signal center adjustment

-31-

Electrical Adjustments

No. Adjustment Item Initial Value Range Description

Page 32

3 REF_R 136 0 ~ 255 ✻ Red white-black level adjustment

4 REF_G 136 0 ~ 255 ✻ Green white-black level adjustment

5 REF_B 136 0 ~ 255 ✻ Blue white-black level adjustment

6 NRS_B 128 0 ~ 255

7 NRS_A 190 0 ~ 255 ✻ NRS adjustment

8 G_V_COM 140 0 ~ 255 ✻ Green common center adjustment

9 B_V_COM 140 0 ~ 255 ✻ Blue common center adjustment

10 R_V_COM 140 0 ~ 255 ✻ Red common center adjustment

11 R_CLMP 63 0 ~ 255 ✻ Red PC offset adjustment

12 G_CLMP 63 0 ~ 255 ✻ Green PC offset adjustment

13 B_CLMP 63 0 ~ 255 ✻ blue PC offset adjustment

14 R_BLK_DC 76 0 ~ 255 ✻ Red pedestal adjustment

15 G_BLK_DC 76 0 ~ 255 ✻ Green pedestal adjustment

16 B_BLK_DC 76 0 ~ 255 ✻ blue pedestal adjustment

Group: 4 TA1318

15kHz 31kHz 33kHz 45kHz

0 SEP_LEV 0 0 0 0 0 ~ 3

1080i 720p 480p 575i,PAL,SECAM 480i,NTSC

1 HD_PHASE 36 38 36 32 32 0 ~ 63

2 V_FREQ - - Read only

3H_FREQ - -

4 HD_IN - -

Group: 5 LP05 (Turbo)

0 LP05_R_GAIN 128 0 ~ 255

1 LP05_G_GAIN 128 0 ~ 255

2 LP05_B_GAIN 128 0 ~ 255

3 TURBO_GAIN 19 0 ~ 255

Group: 10 Option

0 Lamp Time Monitor - - Read only

1 RS232C Baudrate 0 0 ~ 1 0: 19200bps 1: 9600bps

2 Shootout Mode 0 0 ~ 2

1:Mode-1(Change when no signal input) 2:Mode-2(Priority of AV) 0: Disable

3 Cooling Time 3 0 ~ 15 Set cooling time period 1:30 sec. 3:90 sec. 15:450 sec. 0:On conti.

4High-Land SW 0 0 ~ 1 0: Normal mode(Normal operation) 1:Highland mode(max speed in nor mal)

5V-Sync SW 0 0 ~ 1 0:Vertical-synchronized 1:No vertical-synchronized

6 Color Shading SW 1 0 ~ 1 Color correction 0: No 1:Yes, adjustable but does no store the value

7MCI Output Auto 1 0 ~ 1 Auto: 1, Fixed: 0

6Keystone Option 0 0 ~ 1 Fixed limitation :0, Change limitation to the input: 1

Group: 11 Fan Control ✻ Fan voltage adjustment

0Fan Speed Mode 0 0 ~ 3 0: Fan control 1: Min., 2:Mid., 3: Max. it can not be memorized.

1Fan-1 Min Data 44 0 ~ 127 Minimum output data when controlling Fans ✻

2Fan-2 Min Data 63 0 ~ 127 Minimum output data when controlling Fans ✻

3Fan-1 Max Data 217 128 ~ 255 Maximum output data when controlling Fans ✻

4Fan-2 Max Data 236 128 ~ 255 Maximum output data when controlling Fans ✻

5Temp Low 37 10 ~ 80 Decides output data of DAC for temperature

6Temp High 45 30 ~ 80 Decides output data of DAC for temperature

7Fan-1 Temp Error 61 30 ~ 80 Temperature which CPU judges the abnormal temperature

(optical unit temperature, on Main board)

8Fan-2 Temp Error 51 30 ~ 80 Temperature which CPU judges the abnormal temperature

(outside temperature, on Temp board)

9Fan-1 Speed Monitor - 0 ~ 255 Read only, displays DAC output data

10 Fan-2 Speed Monitor - 0 ~ 255 Read only, displays DAC output data

11 Temp Monitor - 0 ~ 9999 Read only ( Upper 2 byte indicates for Fan-1.

Lower 2 byte indicates Fan-2)

12 Eco mode Fan-1 Min Data 44 0 ~ 127 decides minimum output data at Eco mode.

13 Eco mode Fan-2 Min Data 63 0 ~ 127 decides minimum output data at Eco mode.

14

Eco mode Fan-1 Max Data 217 128 ~ 255 decides maximum output data at Eco mode.

15 Eco mode Fan-2 Max Data 236 128 ~ 255 decides maximum output data at Eco mode.

Group: 12 PC Real / AV Cinema

0 PC Real Contrast 32 0 ~ 63

1 PC Real Br ightness 32 0 ~ 63

2 PC Real Red 32 0 ~ 63

3 PC Real Green 32 0 ~ 63

4PC Real Blue 32 0 ~ 63

5 PC Real Gamma 8 0 ~ 15

6AV Cinema Contrast 32 0 ~ 63

7AV Cinema Brightness 32 0 ~ 63

8AV Cinema Color 32 0 ~ 63

9AV Cinema Tint 32 0 ~ 63

10 AV Cinema Red 32 0 ~ 63

-32-

Electrical Adjustments

No. Adjustment Item Initial Value Range Description

Page 33

11 AV Cinema Green 32 0 ~ 63

12 AV Cinema Blue 32 0 ~ 63

13 AV Cinema Sharpness 15 0 ~ 31

14 AV Cinema Gamma 8 0 ~ 15

Group: 500 ADC

0 ADC R-OFFSET 64 0 ~ 255

1 ADC G-OFFSET 64 0 ~ 255

2 ADC B-OFFSET 64 0 ~ 255

3 ADC R-GAIN 254 0 ~ 255

4ADC G-GAIN 254 0 ~ 255

5 ADC B-GAIN 254 0 ~ 255

Group: 510 NTSC Gakaku

0 NTSC TOTAL DOTS 2626 0 ~ 2047

1 NTSC DISP DOTS 1024 0 ~ 2047

2 NTSC H BACK PORCH 230 0 ~ 2047

3 NTSC V BACK PORCH 46 0 ~ 2047

4 NTSC DISP LINE 456 0 ~ 2047

5 NTSC CLAMP 4 0 ~ 2047

Group: 511 PAL Gakaku

0PAL TOTAL DOTS 2690 0 ~ 2047

1PAL DISP DOTS 1024 0 ~ 2047

2PAL H BACK PORCH 266 0 ~ 2047

3PAL V BACK PORCH 62 0 ~ 2047

4PAL DISP LINE 533 0 ~ 2047

5PAL CLAMP 4 0 ~ 2047

Group: 512 HDTV 1080i-60 Gakaku

0TOTAL DOTS 1206 0 ~ 2047

1 DISP DOTS 1024 0 ~ 2047

2H BACK PORCH 145 0 ~ 2047

3V BACK PORCH 52 0 ~ 2047

4 DISP LINE 1048 0 ~ 2047

5 CLAMP 5 0 ~ 2047

Group: 513 HDTV 1080i-50 Gakaku

0TOTAL DOTS 1448 0 ~ 2047

1 DISP DOTS 1024 0 ~ 2047

2H BACK PORCH 144 0 ~ 2047

3V BACK PORCH 64 0 ~ 2047

4 DISP LINE 1044 0 ~ 2047

5 CLAMP 5 0 ~ 2047

Group: 514 HDTV 1035i Gakaku

0TOTAL DOTS 1206 0 ~ 2047

1 DISP DOTS 1024 0 ~ 2047

2H BACK PORCH 145 0 ~ 2047

3V BACK PORCH 90 0 ~ 2047

4 DISP LINE 1006 0 ~ 2047

5 CLAMP 5 0 ~ 2047

Group: 515 HDTV 720p Gakaku

0TOTAL DOTS 1354 0 ~ 2047

1 DISP DOTS 1024 0 ~ 2047

2H BACK PORCH 260 0 ~ 2047

3V BACK PORCH 36 0 ~ 2047

4 DISP LINE 698 0 ~ 2047

5 CLAMP 5 0 ~ 2047

Group: 516 HDTV 575p Gakaku

0TOTAL DOTS 1348 0 ~ 2047

1 DISP DOTS 1024 0 ~ 2047

2H BACK PORCH 240 0 ~ 2047

3V BACK PORCH 60 0 ~ 2047

4 DISP LINE 524 0 ~ 2047

5 CLAMP 0 0 ~ 2047

Group: 517 HDTV 480p Gakaku

0TOTAL DOTS 1288 0 ~ 2047

1 DISP DOTS 1024 0 ~ 2047

2H BACK PORCH 212 0 ~ 2047

3V BACK PORCH 46 0 ~ 2047

4 DISP LINE 451 0 ~ 2047

5 CLAMP 0 0 ~ 2047

No. Adjustment Item Initial Value Range Description

-33-

Electrical Adjustments

Page 34

-34-

Electrical Adjustments

● MAIN BOARD

Test Points and Locations

TP3551

TP25R1

TP11SC

K25R

TP25R2

TP11SY

TP25G1

TP25G2

TP11CV

K25G

TP11PB

TP11PR

TP62V

IC4101

TP25B1

TP62H

K25B

TP52R

TP201G

TP25B2

TP52G

TP52B

TP201B

TP201R

TP205

IC301

TP12V2

TP12V1

TPDCLK

TPDVS

TPDHS

TP3581

IC401

IC801

K8P

Page 35

-35-

■ Troubleshooting

No Power

The possible causes of No Power are listed below.Please

check following and refer to power supply and protection circuits diagram in the figure opposite.

1. Stop the operation of power supply circuit due

to detection of abnormality

.

- Detected the abnormality on the secondary power supply

lines.

Power failure detection diodes detect an abnormal voltage on the power supply. Check the shortage of secondary circuits, ICs, condensers, etc.

- Detected the operation stop of cooling fans.

Power failure detection diodes detect the fan operation

stop.Check Fans FN901, FN902, FN903, FN904, FN905

and FN906

Check fan's power supply lines and detection diodes and

transistors D69A, D69B, D69C and Q69A

- Detected the abnormal temperature rise inside the projec-

tor.

Temperature sensor ICs detect abnormal temperature.

Check peripheral circuits and sensor ICs IC4881 and

IC2881.

Thermal switch (TSW611) detects abnormal temperature.

Check peripheral circuits and TSW611.

TSW611.................... open in normal

TSW611 shorts when the peripheral temperature is over

90°C.

Thermal switch (SW902) detects abnormal temperature.

Check peripheral circuits and SW902.

SW902...................... short in normal

SW902 opens when peripheral temperature is over

100°C.

- Detected the abnormality on the lamp ballast unit.

The lamp ballast unit outputs error signal (LAMP_ERR)

to pin 47 of IC801.

LAMP_ERR .............. High in abnormal

- Detected the over load/over voltage on power supply circuit.

Feedback circuits detect over load or over voltages.

Check PC641, PC642 and peripheral circuits.

- Operated the mechanical protect on the Interlock switch

(SW904). Check lamp cover fixed correctly.

- Fuse (F601) open.

2. Abnormality occurs on drive signals for power

or lamp circuit.

- Abnormality on power starter signals (POWER, 5V_SW).

POWER signal is output from pin 1 of IC801 and sent to

pin 17 of IC1881, and output from pin 3 by the name of

5V_SW signal. 5V_SW signal drives 15.5V and 9VMCI

power supply circuits on the power board.

POWER/5V_SW ............ High in power on

Check POWER and 5V_SW signals, 9V regulator circuit

Q65A, Q65B, Q65C, IC65A and peripheral circuit, 15.5V

switch circuit Q661, Q662 and peripheral circuit on the

Power Board.

- Abnormality on lamp ballast drive signal (BALLAST_AC).

BALLAST_AC signal is output from pin 39 of IC801 and

sent to pin 11 of IC1881, and output from pin 9 by the

name of BALLAST_AC1 signal. BALLAST_SW1 signal

drives the lamp ballast unit.

Check BALLAST_AC and BALLAST_AC1 signals and

lamp ballast unit.

- Abnormality on fan drive signal (FAN DRIVE).

FAN DRIVE signal is output from pin 41 of IC801 and

sent to pin 15 of IC1881, and output from pin 5 by the

name of FAN DRIVE1 signal. FAN DRIVE1 signal drives

fan supply voltages (12V/12V1) on the power board.

FAN DRIVE/

FAN DRIVE1 .............. High in power on

Check FAN DRIVE/FAN DRIVE1 signals, 12V regulator

circuits IC681, Q681, Q682, Q66A, IC671, Q671, Q672

and peripheral circuits.

- Abnormality on power drive signal (LAMP_BST_SW).

LAMP_BST_SW signal is output from pin 82 of IC801

and sent to pin 2 of IC1871, and output from pin 18 by

the name of LAMP_BST_SW1 signal. LAMP_BST_SW1

signal drives the power factor control IC on the P.F. board

through the Power board.

LAMP_BST_SW/

LAMP_BST_SW1............ High in power on

Check LAMP_BST_SW and LAMP_BST_SW1 signal,

photo-coupler PC643, transistors Q651, Q641 and

peripheral circuits.

3. Abnormality occurs on the power circuit.

- Abnormality on power primary circuit

Check Line filters, L601, L602, D614, L611, IC631, D632,

etc.

- Abnormality on power secondary circuit

Check D651, D652, D653, IC651, etc.

Page 36

-36-

Troubleshooting

Power supply drive and protection diagrams and locations

SW902

F601

SW904

IC2881

IC4881

AC IN

FN901FN902

FN903

Power

Oscillator

Circuit

15.5V

P.F BOARD

K6D

K6E

147

4

1

TSW611

7

K6F

K6S K8S

LAMP_BST_SW1

On: High

K6S K8S

On: High

On: High

37-38

13-14

9-10

15-16

11-12

IC611

P.F.CONTROL

Failure: Low Failure: Low

1

2

1

2

FN904

F601

Fuse

K6J

K6K

K6M

K6L

SW902

Thermal sw.

Fan Control

IC681IC671

Interlock sw.

15.5V

6V

-6V

Q661

SW904

POWER BOARD MAIN BOARD

LAMP BALLAST UNIT

11

CB1

3

3

CB2

1 3

1

K8B

LAMP_BST_SW1

LAMP

LAMP_SW1

BALAST_AC1

5V_SW5V_SW

FAN DRIVE1FAN DRIVE1

3

LAMP_ERR

FN905

FN906

1 2

K8N

K8P

P-FAILP-FAIL

BUFFER

BUFFER

IC1871

18 2

IC1881

12

9

3

LAMP Ass'y

Failure: High

On: High

On: Low

8

11

On: High

17

On: High

15

47 80 81

48

82

3

39

1

415

TEMP. SENS.

3

5

K48E

TEMP. SENSOR

53

K8E

SCL

SDA

TEMP.SENSOR

IC801

SUB CPU

IC4881

1

2

BOARD

IC2881

1

2

Page 37

-37-

The possible causes of No Picture are listed below. Please

check following and refer to video signal processing diagrams in the figure opposite.

1. No picture from Video source

Composite Video Input

Check composite video signal at pins 45 and 46 of K10U

on AV Board and K3U on Main Board.

Check Y, C signals at pins 7 and 9 of IC2101.

Check Y, C signals at pins 5 and 7 of IC1101

S-Video Input

Check S-video signals at pins 39, 40 (Y), 41, 42 (C) of

K10U and K3U.

Check Y, C signals at test points TP11SC and TP11SY.

Check Y, C signals at pins 43 and 44 of IC1101.

Component Input

Check component signals at pins 49, 50(Pb), 51, 52 (Pr)

of K10U and K3U.

Check component signals (Y, Pr, Pb) at test points

TP11CV, TP11PB and TP11PR.

All of video signals

Check component signals (Y, Cr, Cb) at pins 21, 22 and

23 of IC1101.

Check component signals (Y, Cr, Cb) at pins 67, 68 and

69 of IC4101.

Check component signals (Y, Pr, Pb) at pins 73, 74 and

75 of IC4101.

Check Sync signals (AV_HSYNC, AV_VSYNC) at pins 4

and 9 of IC1101.

Check Sync signals (AV_HSYNC, AV_VSYNC) at pins 65

and 66 of IC4101.

Check RGB signals at pin 35, 37 and 39 of IC4101.

Check RGB signals at pins 14, 4 and 15 of IC3101.

Check blanking signal at pin 9, 10, 11 of IC3101.

Check RGB signals at pins 1, 3 and 5 of IC5241.

Check Sync signals (AV_HSYNC, AV_VSYNC) at pins 2

and 12 of IC6261.

Check AV/PC switching signal at pin 22 of IC5241 and

pins 10 and 11 of IC6261.

AV :Low, PC : High

2.

No picture from Computer source

Check RGB signals at pins 3-4, 7-8 and 11-12 of K10T on

AV Board and K3T on Main Board.

Check Sync signals (PC_HSYNC, PC_VSYNC) at pins

15-16 and 19-20) of K10T on AV Board and K3T on Main

Board.

Check RGB signals at pins 12, 10 and 8 of IC5241.

Check Sync signals at pins 1 and 13 of IC6261.

Check AV/PC switching signal at pin 22 of IC5241 and

pins 10 and 11 of IC6261.

AV :Low, PC : High

3.

No picture from both of Video and Computer

sources.

Check RGB signals at test points TP52R, TP52G and

TP52B.

Check RGB signals at test points TP201R, TP5201G and

TP201B.

Check HSYNC signal at test point TP205.

Check Sync signals at test points at TP62H and TP62V.

4. No picture from all of sources

Check RGB S&H signals at test points TP25B1, TP25B2,

TP25G1, TP25G2, TP25R1 and TP25R2.

Check NRS signals at test points TP3551 and TP3581.

Check power supply circuit 15.5V and 15VL and peripheral circuit.

Check ICs IC501, IC531, IC561, IC1501, IC1531, IC1561,

IC3501, IC3531, IC3561, IC801, IC301, IC401and peripheral circuits.

Troubleshooting

No Picture

SIGNAL K10T/K3T

V-Sync 19-20

H-Sync 15-16

B 11-12

G 7-8

R 3-4

SIGNAL K10U/K3U

Video 45-46

S-C 41-42

S-Y 39-40

PB 49-50

PR 51-52

Page 38

-38-

Troubleshooting

Video Signal processing diagrams

TP25B1

TP25B2

K25B

IC501

B-LCD

IC1501

S&H_B

B

IC5241

IC5211

PANEL

TP25G1

DBB0-9

IC401

7

TP201R

TP201G

R

G

IC5281

IC5271

TP52R

TP52G

20

8

12

10

AV/PC-RGB

B

R

G

RGB

151210

257

RGB-AMP.

3

7

11

RGB

ANALOG

K25G

TP25G2

DIGITAL

DGB0-9

IC1401

DB0-9

GB00-7

GBE0-7

15

TP201B

B

IC5291

TP52B

18

R

IC531

DGB0-9

COLOR

DGA0-9

DIGITAL

DG0-9

GG00-7

GGE0-7

IC201

22

16

315

G

G-LCD

PANEL

TP3551

22

SHIFT

IC3531

G_LEVEL

NRS

IC3551

IC1531

S&H_G

DRB0-9

G

6,7 13

TIMING

CONTROL

UNIFORMITY

CORRECTION

DRA0-9

5,4 9,1

CONTROL

BRIGHTER

DR0-9

IC301

SCAN

GR00-7

GRE0-7

SYSTEM

CONVERTER

TPDHS

CONTROL

A/D

40

IC6271

HSYNC

TP205

AV/PC

IC251

IC5251

HAFC

13

2

1

DET

AFC

IC6171

16 17

PC: H

AV : L

22

AV/ PC

B

IC6241

6

3

TP25R1

TP25R2

IC561

DHS/DVS

TPCLK

TPDVS

244

323

34

H

HS

TP62H

TP62V

3

2

BUFFER

15

2

1

SYNC-SW

H

12

1

IC6251

INVERTER

V

H

13

235

SYNC DET.

IC6211

19

15

16

V-SYNC

H-SYNC

IC1561

R

TURBO_1

240

133

V

VS

6

5

14

13

12

V

8

5

11

IC6221

K3T

20

K10T

R-LCD

PANEL

K25R

IC3561

R/B_LEVEL

S&H_R

IC1581

DCLK

10 11

22

SHIFT

RGT

DWN

14

2

D/A

PC: H

AV/ PC

AV BOARD MAIN BOARD

|

3

AV : L

19

H

TP3581

7

3

V

IC3581

NRS

VCOM

5

7

|

2

D/A

IC2571

AV-RGB

NRS

12

3

13

IC6101

IC801

79,78

SCL2_5

BLANK_SW

15

13

D/A

7

4,5,6

7

Pr

515249

Pr/Cr

Pb

IC2161

Y

C

Y

50

Pb/Cb

AV/PC

PC: H

AV : L

7

9

Cb_SW

Cr_SW

INVERTER

AV_HSYNC

AV_VSYNC

TP11SC

IC3101

55 56

HD_HSYNC

8

13

9

13 14

TP11SY

K3U

RGB

IC3121

15

1

BLANKING

R

G

393735

RGB

IC4101

66

6529286968

HD_VSYNC

HS_OUT

4

12

10

1

5

11

4

IC1101

4344171819

Cr

Y/C

TP11PR

39

41

K10U

Y/C

S_SW

S-VIDEO

IC2131

IC3141

4

3

13

2512

B

MATRIX

VS_OUT

Y

Cb

212223

VIDEO

DECODER

Cb

TP11CV

TP11PB

14

9,10

73 74 75

67

Cr

75

CV/Y

SUB

CPU

SDA2_5

8

8

SYNC_SW

IC2101

COMB

DIGITAL

2

CV

45

46

VIDEO/Y

9,18,19

BLKC_DC

FILTER

IC5161

11

C_SWIN

Component-In: H

C_SWIN

353633

2

3

IC2181

12

S_SW

S-In: H

34

I/O

Page 39

-39-

1. No drive signals supplied at motors

Check drive signals at pins 1 to 4 of K6U on Power Board.

Check ICs IC5501, IC5551 and peripheral circuits. Check

motor drive power supply (9VMCI).

2. No drive signals supplied at motor drive ICs.

Check drive signals at pins 3-4 (ZOOM), 5-6 (FOCUS) of

k6S. Check IC801.

3. No drive signals output from CPU.

Check drive signals at pins 29,30, 33, 34 of IC801(SUB

CPU). Check IC801.

4. No key switch signals input to CPU.

Check signals at pins 50 to 52 of IC801 when pressing the

key buttons.Check key buttons.

Troubleshooting

Logic Table of IC5501/IC5551

Input Output Operation

4571

HL LHForward drive

LHHLReverse drive

HH LLBraking

LL --Stand by

Lens Motor Problems

No Sound

1. No audio signals at A

V input circuit.

Check audio signals at pins14 and 15 of IC5011 on AV

Board. Check IC5011 and peripheral circuits.

2.

Incorrect operation of VIDEO/COMPUTER mode

switching.

Check AV/PC switching signal at pins 10 and 11 of

IC5011. Check IC5011, IC801 and switching signal.

AV :Low, PC : High

3. No audio output signal at speaker

.

Check audio signal at pins 1 and 3 of K8F on Main Board.

Check MUTE signal at pin 4 of IC031.

Mute On : High

Check MUTE signal at pin 7 of IC1831, pins 7 and 13 of

IC1881, and peripheral circuit.

Mute On : High

Check sound volume signal at pins 27, 28 of K10U, and

pin 14 of IC1831.Check IC IC001, IC031 and peripheral

circuit.

Volume Min.: Low

4. No power supply at audio circuit.

Check 6V(6V AUDIO) power supply line.

AV BOARD

COMPUTER

AUDIO IN

VIDEO

AUDIO IN

EXTERNAL

SPEAKER

SPEAKER

PC_L/R

AV_L/R

Q2051

IC5011

AUDIO-SW

10

11

1

13

15

14

2

12

9

Q5072 Q5071

Q5031

Q5042

AV/PC

K10Y

AV/PC

10

11

K10X

3

4

7

6

8

Q011

Q021

K10U

VOLUME

MUTE On: H

AV SUB BOARD

IC001

AUDIO

PRE-AMP.

1, 7

242, 6

IC031

AUDIO

CONTROL

5

17

3

14

K3U

29

30

27

28

MUTE

31

32

21

|

24

K8F

1,3

18

13

MUTE

7

IC1881

BUFFER

L

R

13

AUDIO MUTE

MUTE On: H

IC2161

D/A

7

7

8

AV/PC

PC: H

AV : L

IC1831

D/A

14

7

SCL2_5

13

SDA2_5

2

SCL1_5

3

SDA1_5

MAIN BOARD

Q1817

Q1817

Q1818

Q1819

79,78

80,81

IC801

SUB

CPU

Power

Supply

Circuit

ON: H

5V_SW

4 52

5

4

5

FOCUS

MOTOR

M

ZOOM

MOTOR

M

15V

Q65A

Q65B Q65C

9V MCI

K6U K6S K8S

1

2

3

4

IC5551

FOCUS

MOTOR DRIVE

3

1

7

IC5501

ZOOM

MOTOR DRIVE

3

1

7

POWER BOARD

LEVEL +

IC801

SUB CPU

LEVEL -

345

345

51

50

KEY SW BOARD

IC1881

BUFFER

15

3

16

FOCUS +

6

FOCUS -

5

ZOOM +

4

ZOOM -

3

POWER

ON: H

1

33

34

29

30

17

FOCUS

ZOOM

K68A

K8A

MAIN BOARD

Page 40

-40-

● System Control & I/O Port Table (IC801)

■ Control Port Functions

1PE5/D5 POWER_SW Power_SW O H: On

2PE6/D6 SYS SW Peripheral IC power supply SW O L: on

3PE7/D7 LAMP_SW Lamp LED O H: On

4 PD0/D8 DATA0 Data Bus 0 I/O 5 PD1/D9 DATA1 Data Bus 1 I/O 6 PD2/D10 DATA2 Data Bus 2 I/O 7 PD3/D11 DATA3 Data Bus 3 I/O 8 PD4/D12 DATA4 Data Bus 4 I/O 9 PD5/D13 DATA5 Data Bus 5 I/O -

10 PD6/D14 DATA6 Data Bus 6 I/O -

11 PD7/D15 DATA7 Data Bus 7 I/O 12 CVCC CVCC Power supply - 13 PC0/A0 ADDRESS0 Address Bus 0 O 14 VSS VSS Vss - 15 PC1/A1 ADDRESS1 Address Bus 1 O 16 PC2/A2 ADDRESS2 Address Bus 2 O 17 PC3/A3 ADDRESS3 Address Bus 3 O 18 PC4/A4 ADDRESS4 Address Bus 4 O 19 PC5/A5 ADDRESS5 Address Bus 5 O 20 PC6/A6 ADDRESS6 Address Bus 6 O 21 PC7/A7 ADDRESS7 Address Bus 7 O 22 PB0/A8/TIOCA3 ADDRESS8 Address Bus 8 O 23 PB1/A9/TIOCB3 ADDRESS9 Address Bus 9 O 24 PB2/A10/TIOCC3 ADDRESS10 Address Bus 10 O 25 PB3/A11/TIOCD3 ADDRESS11 Address Bus 11 O 26 PB4/A12/TIOCA4 ADDRESS12 Address Bus 12 O 27 PB5/A13/TIOCB4 ADDRESS13 Address Bus 13 O 28 PB6/A14/TIOCA5 ADDRESS14 Address Bus 14 O 29 PB7/A15/TIOCB5 ZOOM + Zoom + O L: Zoom +

30 PA0/A16 ZOOM - Zoom - O L: Zoom 31 PA1/A17/TxD2 Tx RS232C TxD O L: active

32 PA2/A18/RxD2 Rx RS232C RxD I L: active

33 PA3/A19/SCK2 FOCUS + Focus + O L: Focus +

34 P10/TIOCA0/A20 FOCUS - Focus - O L: Focus 35 P11/TIOCB0/A21 R/C Remote control signal input I L: active

36 P12/TIOCC0/TCLKA/A22 USB_RESET USB Reset signal output O L: active

37 P13/TIOCD0/TCLKB/A23 USB_BRST USB_BRST O L: On”

38 P14/TIOCA1/IRQ0 SCLK Serial clock output O H: active

39 P15/TIOCB1/TCLKC BLAST_AC Lamp Ballast control signal O H: on

40 P16/TIOCA2/IRQ1 TXD_SW TXD_SW O H: PW-Main CPU

41 P17/TIOCB2/TCLKD FAN ON/OFF Fan Drive output O H: on

42 AVSS Avss A/D ground - 43 P97/DA1 PIXEL WRITE PIXEL write I L: PW write

44 P96/DA0 TEMP_DET TEMP DET I L: Temperature abnormal

45 P47/AN7 OPT2 Option input I L: XGA H: SVGA

46 P46/AN6 Not used I

47 P45/AN5 LAMP_ERR Lamp Error I H: Lamp not lit

48 P44/AN4 POWER_FAIL Power Fail (Abnormal less than 2V) I Abnormal less that 1V

49 P43/AN3 OPT1 Destination option I

50 P42/AN2 KEY3 Key Input3 (A/D Input) I