Page 1

®

®

Bowflex® TreadClimber® 1000, 3000 & 5000

Assembly Manual

Nautilus® Bowflex® Schwinn® Fitness StairMaster® Universal® Nautilus Institute

P/N 001-7142 Rev B (01/09)

®

Page 2

Page 3

Table of Contents

Product Specifications ....................................................................................................................................................1

Important Safety Instructions .........................................................................................................................................2

Before You Assemble .......................................................................................................................................................3

Basic Assembly Principles ................................................................................................................................3

Select Your Workout Area .................................................................................................................................3

Machine Mat .......................................................................................................................................................3

Parts................ ....................................................................................................................................................................4

Hardware ...........................................................................................................................................................................6

Assembly ............................................................................................................................................................................7

Put the Treadles on the Base ............................................................................................................................7

Connect the Speed and Step Pickup Wires ...................................................................................................8

Lock the Treadles ................................................................................................................................................9

Attach the Drive Belt ..........................................................................................................................................9

Attach the Uprights ..........................................................................................................................................10

Attach the Upright Junction ...........................................................................................................................11

Attach the Cosmetic Plugs ..............................................................................................................................11

Attach the Console/Handlebar Assembly ....................................................................................................12

Attach the Hydraulic Cylinders ......................................................................................................................13

Inspect the Assembly ......................................................................................................................................13

Attach the Frame Covers .................................................................................................................................14

Adjust Speed Sensor and Attach the Rear Cover .......................................................................................15

Attach the Drive Covers ..................................................................................................................................16

Attach the Side Foot Support Platforms ........................................................................................................16

Apply Decals .....................................................................................................................................................17

Inspect the Assembly ......................................................................................................................................17

Attach the Power Cord ....................................................................................................................................17

Calibration (TC 3000 and TC 5000 only) ..........................................................................................................18

If Calibration Fails .............................................................................................................................................19

Explanation of Calibration Display Messages .............................................................................................19

Troubleshooting ..............................................................................................................................................................20

Exploded Views ..............................................................................................................................................................23

Important Contact Numbers .........................................................................................................................................27

Page 4

Page 5

Product Specifications

Physical Dimensions

Length

Width 28.5 inches (72.5 cm)

Height 55.25 inches (140.5 cm)

Weight 185 pounds (84 kg)

Shipping Weight 220 pounds (100 kg)

System Capacities

Maximum Weight Capacity

Speed

TC1000 0.5 to 3.8 MPH (0.8 to 6.1KPH )

TC3000 and TC5000 0.7 to 4.0 MPH (1.1 to 6.4 KPH)

Workout Resistance Levels 1 to 12

Warranty Length See the Warranty section for full

46 inches (117 cm)

300 lbs (136 kgs)

information per machine type

Component Specifications

Belt

7.75 in x 38.5 in (19.5 cm x 98 cm)

Motor 0.5 hp continuous duty

Treadmill Incline 0% Grade

Frame Powder-coated steel

Operational Voltage 95 to 130 VAC 50 - 60 Hz

Operational Current 12A Max

A short 14 gauge, 3 wire extension cord is permissible.

Regulatory Approvals Marks = c-ETL-US The standard for Safety

for Motor-Operated Massage and Exercise Machines, UL 1647, 3rd Ed. and

Motor-Operated Appliances, CAN/CSA-C22.2 No. 68-92

Patent Information

U.S. and International Patents Pending

TC1000 TC3000 TC5000

Assembly Manual

1

Page 6

Important Safety Instructions

This icon means a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Obey the following warnings:

Read and understand all warnings on this machine.

Carefully read and understand the Assembly Manual.

• Keep bystanders and children away from the product you are assembling at all times.

• Do not connect power supply to the machine until instructed to do so.

• Make sure assembly is done in an appropriate work space away from foot traffic and exposure to

bystanders.

• Some components of the machine can be heavy or awkward. Use a second person when doing

the assembly steps involving these parts. Do not do steps that involve heavy lifting or awkward

movements on your own.

• Set up this machine on a solid, level, horizontal surface.

• Do not try to change the design or functionality of this machine. This could compromise the safety and

can void the warranty.

• If replacement parts are necessary use only genuine Nautilus® replacement parts and hardware.

Failure to use genuine replacement parts can cause a risk to users, keep the machine from operating

correctly or void the warranty.

• Do not use or put the machine into service until the machine has been fully assembled and inspected

for correct performance in accordance with the Owner’s Manual.

• Read and understand the complete Owner’s Manual supplied with this machine before first use.

Keep the Owner’s Manual for future reference.

2

Assembly Manual

Page 7

Before You Assemble

Basic Assembly Principles

Here are a few basic assembly tips that can make assembly of the Bowflex® TreadClimber® exercise machine quick and

easy.

1. Gather the pieces needed for each step prior to starting the step.

2. Turning towards the right tightens all the bolts and locknuts on your

Bowflex®

TreadClimber®. Turning towards the left,

loosens them.

3. All of the tools needed for assembly of your

Bowflex® TreadClimber® exercise machine have been included. These tools

are only designed for one use. If damaged, substitute any commonly available 9/16” wrench and #2 screwdriver.

Note: A utility knife or scissors will be required during the unpacking and assembly process

(not included).

Select Your Workout Area

Select where you are going to put your Bowflex® TreadClimber® exercise machine carefully. The best place for your

TreadClimber

of your TreadClimber

Make sure that the location you choose has a 10A power outlet within reach of the TreadClimber

preferably to the right side of the machine where you will be less likely to step on the cord during dismount.

Note: The TreadClimber

circuit breaker is GFI, look for a test and reset button on them. If they have the test and reset button it is a GFI outlet

or circuit breaker.

Further, if you ever perform any repairs on your TreadClimber

at least 60 inches (1.5m) to one side of your workout area.

®

machine is on a hard, level surface. You will need at least 20 inches (0.5 meters) on each side and in front

®

machine, and at least 36 inches (0.75 meters) behind it for dismount.

®

machine power cord,

®

machine is designed to plug into a grounded, non-GFI outlet only. To determine if your outlet or

®

machine that require you to lay it on its side, you will need

Machine Mat

The Bowflex® TreadClimber® Machine Mat is an optional accessory for the TreadClimber® machine that helps keep

your workout area free from debris and dust. The rubber machine floor mat provides a non-slip surface when mounting

and dismounting the TreadClimber

possibility of display or running errors. A rubberized mat will protect your flooring when you are performing repairs or

maintenance. Put your Bowflex

protect your floors and your TreadClimber

®

machine, limits static discharge when you touch the machine, greatly reducing the

®

TreadClimber® Machine Mat in your selected workout area before begining assembly to

®

machine from damage.

Assembly Manual

3

Page 8

Box 1 contains:

Parts

Qty: 1

Descr: Control Panel/Handlebar Assembly

Qty: 2

Descr: Left and Right Side Foot Support Platform

Qty: 1

Descr: Left Side Plastic Frame Cover

Qty: 1

Descr: Rear Cover

Qty: 2

Descr: Plastic Upright Junction Covers

4

Assembly Manual

Qty: 1

Descr: Right Side Plastic Frame Cover

Qty: 1

Descr: Right Side Plastic Drive Cover

Qty: 1

Descr: Left Side Plastic Drive Cover

Qty: 2

Descr: Left & Right

Hydraulic

Cylinder

Qty: 1

Descr: Left

Upright

Support

Qty: 1

Descr: Right

Upright

Support

Page 9

Parts

Box 1 also contains:

Qty:1 Owner’s Manual Bag

Contains the following:

• The Bowflex® TreadClimber® Assembly Guide and Owner’s

Manual

• (1) Drive Belt

• Power Cord

• (2) Treadle Decals

• (2) Drive Cover Decals

• TreadClimber® Safety Key *Note: TC1000 Safety Key plugged

into console for shipping.

• Heart Rate Monitor Chest Strap (TC5000 Only)

• (1) #2 Phillips Screw Driver

Note: Occasionally extra parts are included.

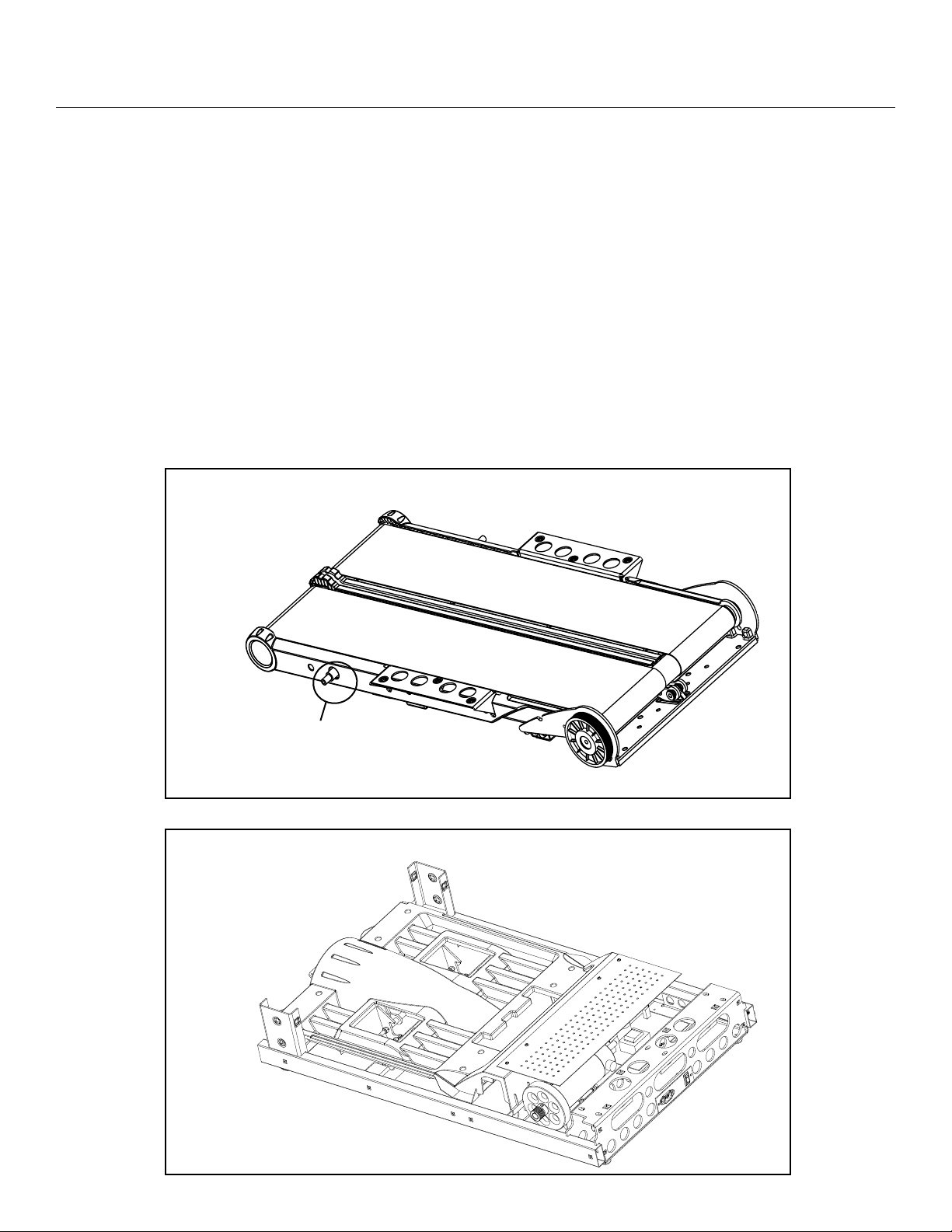

Box 2 contains the TreadClimber® treadles

Qty:1 Assembly Hardware Bag

Contains the following:

• (1) #2 Phillips Screwdriver

• (2) 5/16" x 1 1/2" Button Head Screw

• (1) 3/16" Hex Key

• (12) 5/16" Flat Washers SAE

• (1) 5/32" Hex Key

• ( 2) 5/16" Acorn Nut

• (1) 9/16" Open End Wrench

• (6) 1/4" x 1" Flat Head Screw

• (2) 5/16" Flat Washers

• ( 4) 3/8" Cosmetic Plugs

• (14) 5/16" x 1" Button Head Screw

• (16) #10 Phillips

(smaller O.D.)

Cylinder Stud

Qty: 1

Descr: TreadClimber® Treadle Assembly

Box 3 contains the TreadClimber

Qty: 1

Descr: TreadClimber® Base

®

base

Assembly Manual

5

Page 10

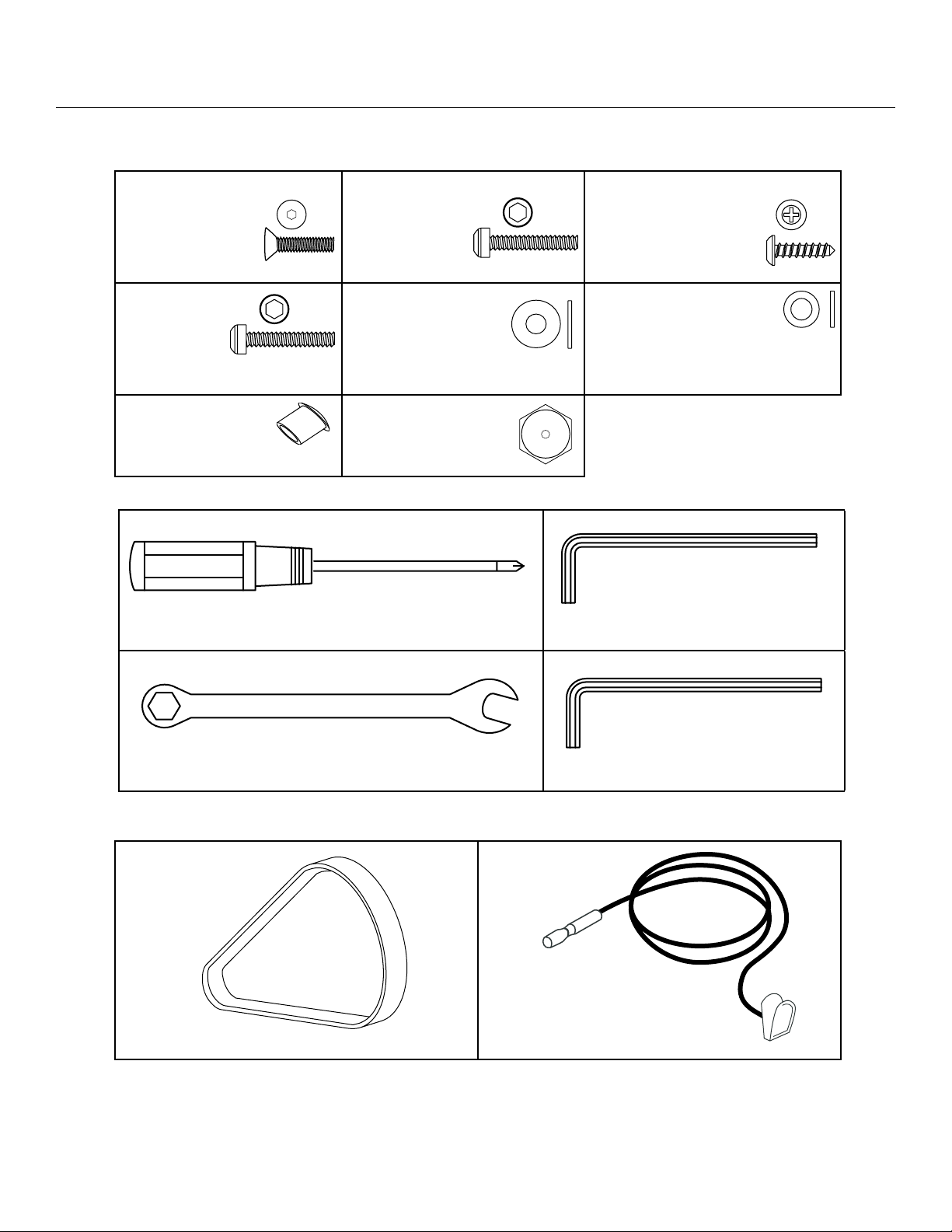

Hardware:

Hardware

Qty: 6

Descr: 1/4” x 1” Flat Head Screw

Qty: 14

Descr: 5/16” x 1” Button Head Screw

Qty: 4

Descr: 3/8” Cosmetic Plugs

Tools:

Qty: 1

Descr: #2 Phillips Screwdriver

Qty: 2

Descr: 5/16” x 1 1/2” Button Head Screw

Qty: 2

Descr: 5/16” Flat Washer

Qty: 2

Descr: 5/16” Acorn Nut

Qty: 16

Descr: #10 Phillips Head Screw

Qty: 12

Descr: 5/16” Flat Washer SAE

Qty: 1

Descr: 3/16” Hex Key

6

Assembly Manual

Qty: 1

Descr: 9/16” Open End Wrench

Parts:

Qty: 1

Descr: Drive Belt

Qty: 1

Descr: 5/32” Hex Key

Qty: 1

Descr: Safety Key with Clip (Models TC3000 & TC5000 only.)

Page 11

Assembly

Step 1: Put the Treadles on the Base

Parts:

• TreadClimber® Base Assembly

®

• TreadClimber

Hardware:

• (4) 3/8” X 1 1/4” Hex Bolts (preassembled)

Treadle Assembly

Note: Hardware is only hand tightened. Finish tightening

the hardware in Step 1-5 below.

Tools:

• 9/16” Open End Wrench (included)

• Scissors or other cutting tool

• Ruler

Note: This step requires two people.

1-1 Unlock the latch lever (see Figure 1-1).

1-2 Lower the tower treadle assembly onto base with two

people.

1-3 Align roller casting flush to the base (See Figure 1-2)

1-4 Use a ruler to center the treadles between the upright

bases.

1-5 Tighten the (4) 3/8” x 1 1/4” Hex Bolts on the rear roller

casting and base with the 9/16” open end wrench (See

Figure 1-3).

Figure 1-1

Align roller casting so it lays flush

on base

Figure 1-2

Note: Tighten the outside bolts on the rear roller casting first,

then the inner bolts.

1-6 Cut the treadle zip tie located underneath the treadles.

Figure 1-3

Assembly Manual

7

Page 12

Assembly

Step 2: Connect the Speed and Step Wires

(TC3000 and TC5000 only)

Parts:

• TreadClimber® Base and Treadle assembly from Step 1

2-1 Connect the Speed Wires (See Figure 2-1).

2-2 Connect the Step Wires (See Figure 2-2). Push any excess

wire through holes in frame (See Figure 2-3).

Note: The TC1000 is not equipped with step sensor function. Tuck

unused step sensor wires through hole in frame.

Speed Wire

Figure 2-1

Figure 2-2

8

Assembly Manual

Figure 2-3

Page 13

Assembly

Step 3: Lock the Treadles

Parts:

• TreadClimber® Base and Treadle assembly from Step 2

3-1 Line up the treadles parallel to each other and cut the zip

tie connecting them.

3-2 Move the locking lever down and to the left and then up into

the locked position until it clicks (See Figure 3-1).

3-3 From the front of the machine, press down on each treadle

individually until they lock into the down position.

The treadles might unlock during workout if they are not fully engaged.

Step 4: Attach the Drive Belt

Figure 3-1

Lever in locked position

Parts:

• TreadClimber® Base and Treadle assembly from Step 3

• (1) Drive Belt

Tools:

• 3/16” Hex Key (included)

4-1 Position the drive belt over the roller pulley and the motor

pulley (See Figure 4-1).

4-2 Make sure that the belt is installed correctly into the grooves

of the pulleys (See Figure 4-2).

4-3 Remove the motor shipping bolt from the motor pan with

the 3/16” hex key (See Figure 4-3).

Note: Removing the shipping bolt will make the drive belt tight with

spring-loaded tension. Be sure to keep the bolt in a safe place

in case the machine must be disassembled for shipping or part

replacement.

4-4 Put the unit in the upright position.

Figure 4-1

Figure 4-2

Figure 4-3

Assembly Manual

9

Page 14

Assembly

Step 5: Attach the Uprights

Parts:

• TreadClimber® Base and Treadle assembly from Step 4

• (1) Left Upright Support & Hydraulic Cylinder

• (1) Right Upright Support & Hydraulic Cylinder

Hardware:

• (2) 5/16” x 1” Button Head Screws

Tools:

• 3/16” Hex Key

5-1 Screw a 5/16” x 1” button head screw half way into the

outside of the left and right lower upright brackets of the

base assembly (See Figure 5-1).

5-2 Put the left upright on the left upright bracket (See Figure

5-2) so that it rests on the button head screw (See Figure

5-3). The cylinder bracket will be at the top and face the

rear of the machine.

Note: Make sure the decal on the upright support faces outward from

the machine.

5-3 Repeat on the opposite side.

Figure 5-1

Figure 5-2

10

Assembly Manual

Figure 5-3

Page 15

Assembly

Step 6: Attach the Upright Junction

Parts:

• TreadClimber® Base and Treadle assembly from Step 5

• (2) Plastic Upright Junction Covers

6-1 Put the plastic upright junction cover on the top of the left

upright support (See Figure 6-1).

Note: Make sure the plastic upright junction cover extends to the

rear of the machine.

6-2 Repeat on opposite side.

Figure 6-1

Assembly Manual

11

Page 16

Assembly

Step 7: Attach the Console/

Handlebar Assembly

Parts:

• TreadClimber® Base and Treadle assembly from Step 7

• Console/Handlebar Assembly

Hardware:

• (6) 5/16” x 1” Button Head Screws

• (6) 5/16” Flat Washers SAE

Tools:

• 3/16” Hex Key (included)

Note: This step requires two people.

7-1 Lift and position the console/handlebar assembly above

the upright supports (See Figure 7-1).

Figure 7-1

7-2 Put the console/handlebar assembly cable through the top

of the right upright support (See Figure 7-2). Make sure

that the cable extends throught the bottom of the right

upright.

7-3 Put both sides of the console/handle bar brackets into the

tops of the upright supports at the same time. Do not crimp

the cable.

7-4 Tighten the hardware with the 3/16” hex key (See Figure

7-3).

7-5 Connect the cable from the upright support to the cable on

the right side of the base upright bracket (See Figure 7-4).

Repeat this step on the other side.

7-6 One person will hold the Console/Handlebar assembly

while the second person removes the 5/16” x 1” button

head screw at the base of the support from each side.

7-7 Lower the upright on to the upright bracket base. Do not crimp

the cables. Drop the upright until flush with the base frame.

7-8 Attach the upright with (6) 5/16” x 1” button head screws

and (6) 5/16” flat washers SAE.

Figure 7-2

Figure 7-3

Figure 7-4

Note: Tighten the front (2) screws first (1 per upright) and then

the (4) side screws, two per outer side of upright (See

Figure 7-5).

12

Assembly Manual

Figure 7-5

Page 17

Assembly

Step 8: Attach the Cosmetic Plugs

Hardware:

• (4) Cosmetic Plugs

8-1 Insert the cosmetic plugs into the holes on the top, inside and

outside of the left upright support (See Figure 8-1).

8-2 Repeat on opposite side.

Step 9: Attach the Hydraulic Cylinders

Figure 8-1

Parts:

• TreadClimber® Base and Treadle assembly from Step 8

Hardware:

• (2) 5/16” x 1 1/2” Button Head Screws

• (2) 5/16” Acorn Nuts

• (2) 5/16” x 1” Button Head Screws (preassembled)

• (2) 5/16” Flat Washers (preassembled)

Tools:

• 3/16” Hex Key (included)

• 9/16” Open End Wrench (included)

Note: This step requires two people.

9-1 Attach the hydraulic cylinder to the upright bracket with (1) 5/16”x 1 1/2”

Button Head Screw and (1) 5/16” Acorn Nut (Figure 9-1).

Note: Make sure that the single white arrow, located on the Workout Level

Setting Dials at the top of the hydraulic cylinders, is pointing up and to

the rear of the machine.

9-2 Remove the pre-installed (1) 5/16” x 1” Button Head Screw and (1) 5/16”

Flat Washer from treadle. Lift treadle and slide the lower shock eyelet

onto the treadle stud.

Figure 9-1

Figure 9-2

9-3 Attach the hydraulic cylinder with the (1) 5/16” x 1” button head screw

and (1) 5/16” flat washer (Figure 9-2).

9-4 Tighten the hardware with the Hex Key and Open End Wrench.

Assembly Manual

13

Page 18

Assembly

Step 10: Inspect the Assembly

10-1 Remove the plastic film from the console face.

10-2 Inspect all of the attachments and securely tighten all of

the bolts before proceeding to Step 11.

Step 11: Attach the Frame Covers

Parts:

• TreadClimber® Base and Treadle assembly from Step 10

• (1) Left Plastic Frame Cover

• (1) Right Plastic Frame Cover

Hardware:

• (6) #10 Phillips Head Screws

Tools:

• #2 Phillips Head Screwdriver (included)

11-1 Attach the left and right Plastic Frame Covers to the sides

of the base frame with (6) #10 Phillips Head Screws (3 per

side) and the provided #2 Phillips screwdriver (See Figures

11-1 and 11-2).

Figure 11-1

Figure 11-2

14

Assembly Manual

Page 19

Assembly

Step 12: Adjust Speed Sensor and Attach

the Rear Cover

Parts:

• TreadClimber® Base and Treadle assembly from Step 11

• (1) Rear Cover

Hardware:

• (4) #10 Phillips Head Screws

Tools:

• #2 Phillips Head Screwdriver (included)

12-1 Hold a stiff business card, ID card, or similar object onto

the inside of the drive pulley. Adjust the speed sensor

towards the card until it just makes contact.

12-2 Remove object.

12-3 Attach the rear cover to the back of the frame with the (4)

#10 Phillips Head Screws (2 per side) and the provided #2

Phillips Head Screwdriver (See Figure 12-1 and 12-2).

Figure 12-1

Figure 12-2

Assembly Manual

15

Page 20

Assembly

Step 13: Attach the Drive Covers

Parts:

• TreadClimber® Base and Treadle assembly from Step 12

• (1) Left Plastic Drive Cover

• (1) Right Plastic Drive Cover

Hardware:

• (6) #10 Phillips Head Screws

Tools:

• #2 Phillips Head Screwdriver (included)

13-1 Attach the left and right Plastic Drive Covers to the sides of the

base with (6) #10 Phillips Head Screws (3 per side) and the provided

#2 Phillips screwdriver (See Figures 13-1). Install upper screw first.

Note: Do not tighten hardware until all screws have been installed.

Figure 13-1

Step 14: Attach the Side Foot

Support Platforms

Parts:

• TreadClimber® Base and Treadle assembly from Step 13

• (1) Left Foot Support Platform

• (1) Right Foot Support Platform

Hardware:

• (6) 1/4” x 1” Flat Head Screws

Tools:

• 5/16” Hex Key (included)

14-1 Attach the right and left side foot support platforms to each treadle

with (6) 1/4” x 1” Flat Head Screws (3 per side) (See Figures 14-1

and 14-2).

Figure 14-1

Figure 14-2

16

Assembly Manual

Page 21

Assembly

Step 15: Apply Decals

Parts:

• TreadClimber® Base and Treadle assembly from Step 14

• (2) Treadle Decals

• (2) Drive Cover Decals

Tools:

• #2 Phillips Head Screwdriver (included)

15-1 Clean the application surface with a wet cloth and dry

thoroughly with a towel.

15-2 Remove the relase backing on the decal.

15-3 Center the decal on the appropriate application surfaces

(See Figure 15-1) for locations.

15-4 Rub the decal onto the surface to force out the air bubbles.

Drive decal

1 per side

Treadle decal

1 per side

Figure 15-1

Step 16: Inspect the Assembly

16-1 Inspect your machine to make sure that all of it has been

assembled correctly, there are no loose or missing parts

and that all of the hardware has been tightened.

Step 17: Attach the Power Cord

17-1 Make sure that the Main Power Switch is in the “Off”

postition.

17-2 Carefully insert the power cord into the Incoming Power Plug

at the rear of the base unit (See Figure 17-1).

Note: Always plug cord into the base before plugging into the

wall outlet.

®

Note: The TreadClimber

grounded (three-prong) wall outlet.

machine plugs into any standard,

Illustration 15-A:

TreadClimber® Drive and

Treadle Decals

Failure to visually check and test assembly

before use can cause damage to the

®

TreadClimber

machine and serious injury

to users and bystanders and can also

compromise the effectiveness of your exercise

program.

Figure 17-1

NEVER remove the grounding prong from the power plug

and never use a two-prong adapter without a grounding

wire.

Incoming Power Plug Main Power Switch

Assembly Manual

17

Page 22

Assembly

É

0/7%2 -/$5,%

4/34!24

0RESS*"7,

--

Step 18: Calibration (TC3000

and TC5000 only)

Note: During calibration, observe the walking belt alignment.

Belts do not need to be perfectly centered, but if they

are far enough from center to cause a scraping sound,

follow the belt alignment instructions in the Owner’s

Manual.

Failure to calibrate your machine prior to use could result in

machine failure and could cause injury.

During the entire calibration process, stand on the side

foot support platforms or rubber mat only. Do not stand on

the walking belts during this entire process.

Note: Re-calibration is also neccessary in the event of a

power outage or if a component like a belt or motor

has been replaced.

Figure 18-1

Main Power Switch “On”

18-1 Plug the power cord into the the wall outlet.

18-2 Turn on the Main Power Switch (See Figure 18-1).

18-3 Stand on the side foot support platforms or rubber floor

mat. Do NOT stand on the belts.

18-4 Hold down the POWER and SLOWER buttons. Insert the

Safety Key.

Note: If the Safety Key is not fully inserted into the safety

®

keyhole, the TreadClimber

will not operate.

18-5 Release the POWER and SLOWER buttons. The TIME

display will read “CAL”, PrSS”,”Strt”.

18-6 Press the START/STOP button to start calibration.

Note: The belts will start and stop and the displays will show

various numbers that relate to the calibration process.

Do NOT interrupt calibration.

18-7 Calibration will take about 3 minutes. When calibration

has finished “CAL” “PASS” will show in the TIME

display.

18-8 Remove and re-insert the Safety Key to clear the display.

®

When the Bowflex

TreadClimber® exercise machine has

completed calibration, you may begin your workout.

Figure 18-2

TC5000 Power & Slower Buttons

Figure 18-3

TC3000 Power & Slower Buttons

Note: During calibration the 30 meter LED on the TC5000

signifies the belt speed sensor, 305 meters LED is the

step sensor. Some models of the TC 3000 will show the

step sensor in the DISTANCE window as a heart and the

speed sensor in the SPEED window as a heart.

18

Assembly Manual

Page 23

Assembly

If Calibration Fails (Screen Displays “Cal Fail” Message):

This error usually indicates that the console is unable to determine the speed of the belts. Take the following steps:

1. Unplug the unit and remove the three back covers.

2. Hold a stiff business card, ID card, or other similar onto the inside of the drive pulley. Adjust the speed sensor towards the card until it just makes contact.

3. Remove the card.

4. Plug unit in and recalibrate.

If calibration is successful:

• Replace the three back covers.

If calibration is not successful:

• Leave plastic covers off and contact customer care for assistance. ( See Important Contact Numbers page at the

back of this manual).

Explanation of Calibration Display Messages (for information only):

During calibration, the TIME display will show you text messages updating you as to the status of calibration. When there

is no text message in the TIME display window, the other displays will show the following:

HEART RATE (TC5000 Only) – will show the status of the motor control relay.

• “ON” signifies the power relay is on and energizing the motor.

• “OFF” signifies the motor control relay is off and not energizing the motor.

CALORIES/CAL PER MIN – will show the version number of the software.

TIME – will show either a text message regarding auto-calibration (“d0nE”, “Strt”, etc.) or the actual Pulse Width

Modulation (PWM) number (a number that provides digital information about base unit functions to the console) if

START/STOP, FASTER or SLOWER is pressed during calibration.

MILES/TOTAL STEPS (DISTANCE/MILES for TC3000) – will show the calibration of the total step count.

SPEED – will display the actual belt speed during the calibration function.

Assembly Manual

19

Page 24

Troubleshooting

Condition / Problem Things to Check Solution

Unit will not power up/turn on/

start

Outlet Make sure outlet is functioning correctly. Verify

this by plugging another object (ex: lamp) into

the outlet. If outlet is connected to a light

switch, check to make sure it is on. If outlet is

not functioning find a working outlet.

Power cord not plugged in Make sure the power cord is firmly secured to

A/C inlet on the unit and firmly inserted into a

non-GFI wall socket.

Power switch turned off Make sure the power switch at the rear of the

unit is in the “ON” position.

Safety key not plugged in Plug Safety Key into console (See Emergency

Stop Procedure within the Important Safety

Precautions section).

LED Diagnostic needed Remove rear plastic covers and contact cus-

tomer service for assistance.

Speed displayed is not accurate Display set to wrong unit of mea-

sure. (English/Metric)

Out of calibration Re-calibrate machine (See Calibration procedure

Heart rate not displayed while

using chest strap

Walking belt misalignment Rear belt guides Belts should ride on top of triangular black belt

Speed dependent grinding or

scraping noise in all modes

Transmitter not making good contact with skin

Electromagnetic interference Turn off any television, AM radio, microwave, or

Chest strap transmitter Test chest strap with another HR monitoring

HR receiver If chest strap is known to work with other

Tracking adjustment Belts are not required to be perfectly centered

Belt alignment Check walking belt alignment. Belt contact with

Rollers or motor Contact customer service for further assistance.

Change display units (See Owner’s Manual).

in Owner’s or Service Manual).

Moisten skin contact area on the chest strap.

computer within 6 feet (2 meters) of the TreadClimber® fitness machine.

device such as HR watch or a machine at a gym.

If transmitter has good skin contact and still is

not found to be emitting HR signal, replace chest

strap transmitter.

devices and no sources of interference are

present, or console has been tested with a Pulse

Simulator and is not receiving the signal, replace

the HR receiver.

guides at rear of treadles.

and are typically farther out in the rear than they

are in the front. This may vary depending on

user’s stride. If belt is tracking to one side far

enough to cause rubbing of belt follow belt alignment procedure in Owner’s Manual.

metal guides under treadle can make loud grinding sound. If belts are misaligned follow belt

alignment procedure in Owner’s Manual.

20

Assembly Manual

Page 25

Troubleshooting

Condition / Problem Things to Check Solution

Hesitation or belt slipping

when walking on unit

“Tick” sound once per revolution or scraping noise from

under treadle

Floors Climbed Display not

updating

Belt tension If belt hesitates or slips when walking on unit

it may be caused by either a loose walking belt

or a loose drive belt. To determine the cause

perform the following test: Stand beside TreadClimber® fitness machine and set speed to 2

MPH. Step on one treadle and attempt to stop

movement. If one belt stops but roller at rear

and other belt continue to turn walking belt tension should be adjusted. If both belts stop but

motor is still turning the drive belt tension should

be adjusted.

Walking belt tension Adjust walking belt tension at the front of the unit

using the provided hex wrench on the exposed

adjustment bolts located on each side of each

front roller. Be sure to adjust both bolts on each

roller the same amount as to not disrupt belt

alignment. Tighten (turn clockwise) each adjustment bolt in full turn increments. After each

adjustment, restart unit and check to see if belt

slippage has been eliminated. Repeat if necessary. If slipping feel persists after several adjustments, stop and refer to drive belt checklist.

Drive belt Unplug power from unit. Wait 5-minutes to

ensure no residual power remains. Turn unit on

its side to expose its underside. Verify shipping

bolt has been removed. If bolt is not present,

return machine to upright posiition. Remove

left rear plastic cover to expose “v” belt drive

line and motor. Tighten nut on the motor tension

bolt located on front side of motor in 1/2 turn

increments until drive belt slippage is eliminated

- DO NOT OVER TIGHTEN. Replace cover when

finished.

Belt alignment Belt seam may be contacting metal belt guide

under treadle. Slight adjustment of belt should

alleviate noise. Follow belt alignment procedure

in Owner’s Manual.

Size of steps taken In order for a step to register, the pedals must

pass each other completely. This ensures that

the magnet on the treadle passes the step sensor. Make sure treadles are not locked in treadmill mode and that they are moving enough to

register a step.

Step sensor Be sure step sensor wire is connected at rear of

machine.

Assembly Manual

21

Page 26

Troubleshooting

Condition / Problem Things to Check Solution

Knocking noises when unit is

operating in TreadClimber or

stepper mode, but not in treadmill mode

Belts stop turning and “err LS”

or “err OS” is displayed

Treadle alignment Make sure treadles are centered between

uprights and treadle is not contacting upright

during use. If not centered remove rear plastic

covers to access rear baseplate bolts. Loosen

bolts slightly to allow treadles to be centered.

Once centered tighten outer two bolts securely

then tighten inner bolts securely.

Drive pulley and flywheel

pulley

Igus bushing If knocking sound seems to be coming directly

Hydraulic cylinder bolts Check and tighten both upper and lower bolts

Calibration Re-calibrate machine using Owner’s Manual

Speed sensor 1. Cycle power off and on.

I/O cables If LED D is flashing when the belts are turning

Unplug power from Unit. Wait at least 5 minutes.

Remove left side plastic drive cover to expose

“v” belt drive line. Using a ½” wrench, tighten

the bolt that attaches the 4 ½” drive pulley to

the drive shaft while holding the drive rollers

still. Also, using a 5/32” hex wrench, tighten the

setscrew on the flywheel motor pulley. Reinstall

plastic drive cover.

from the rear roller, check igus bushings and

replace if cracked.

that connect the hydraulic cylinders to the unit.

calibration procedure.

2. Put the machine in calibration mode (see Calibration procedure in Owner’s Manual) but do not

start the calibration routine.

3. Remove right rear plastic cover to view LED

diagnostics on control board.

Caution: Machine is on. Current is active!!

4. Locate LED D on the motor controller board.

LED may be lit or unlit.

5. Manually advance the treadle with your foot,

and check if LED D is blinking.

6. If LED D is not blinking, then the speed sensor

is not supplying a signal. Check that the speed

sensor wire is plugged into the motor controller

board, to the connection labeled “P1”. Check

connection of speed sensor to jumper wire.

Check speed sensor adjustment (use business

card to set gap between sensor and pulley). If

LED D still does not flash replace sensor.

but err LS or OS persists check connections and

for signs of visible damage to any of the three I/O

cables. If no damage, check continuity using a

multi-meter. If a multi-meter is not available contact customer service for replacement cables

and further assistance.

22

Assembly Manual

Page 27

Exploded Views

Ordering Replacement Parts

Call a Bowflex® TreadClimber® Representative at 1-800-NAUTILUS (1-800-628-8458) to order replacement parts and

get assistance with your specific replacement or service requirements.

TC1000

Console Assembly

(Not illustrated)

Electronics

Tether Housing

Assembly

Upright Junction

Covers

Overlay

Console Top

Limit Switch

Tether Housing

Console Bottom

TC Handlebar

Upright

Plugs

Cylinders/Shocks

Round Plug

Upright

Assembly Manual

23

Page 28

Front Roller

Keeper

Exploded Views

Walking Belts

Deck

R. Outer

Treadle Skin

R. Rear

Belt Guide

(L. Rear Belt Guide

Not Shown)

Foot Platform

L. Outer

Treadle Skin

Foot Platform

Front Roller

Bracket

Belt Guide

Treadle Stop

Bracket

Front Roller

Inner Treadle

Skin (L & R)

Rear Roller

Bracket

Drive Pulley

Front Roller

Bracket

Left Drive

Bracket

Treadle

Friction

Block

Single

Roller

Bearing

Speed Sensor

Drive Base

Center

Inner Roller

Bracket

Shaft Spacer

Rear Roller Bracket

Right Drive

Bracket

Bearing

M. Pivot Bushing

Washer Kit*

24

Assembly Manual

Treadle Stop

Blocks

Rear Drive

Base

*Middle Pivot Bushing/Washer Kit:

(4) TC Igus® Bearing

(8) TC Igus® Washer

(4) TC Treadle Pivot Bushing

Page 29

Exploded Views

Motor

Latch Arm

Latch Offset Bracket

Locking Latches

Right Drive Cover

Motor Controller

Lever Latch

Bracket

Right Frame Cover

Plugs

TC Foot

Plugs

Wheels

Motor Tension Kit

Motor Base

Rear Cover

Cord Bracket

Red Cap

Safety Plate

Base Cover

Main Frame

Left Frame Cover

Left Drive Cover

Assembly Manual

25

Page 30

Page 31

Important Contact Numbers

UNITED STATES OFFICES

TECHNICAL/CUSTOMER SERVICE

Phone: 800-NAUTILUS (800-628-8458)

E-mail: tcinquiry@nautilus.com

CORPORATE HEADQUARTERS

Nautilus, Inc.

World Headquarters

16400 SE Nautilus Drive

Vancouver, Washington, USA 98683

Phone: (800) NAUTILUS (800) 628-8458

INTERNATIONAL OFFICES

INTERNATIONAL CUSTOMER SERVICE

Nautilus International S.A.

Rue Jean Prouvé

1762 Givisiez / Switzerland

Tel: + 41 26 460 77 77

Fax: + 41 26 460 77 70

E-mail: technics@nautilus.com

GERMANY and AUSTRIA

Nautilus International GmbH

Albin-Köbis-Str. 4

51147 Köln

Tel: + 49 02203 2020 0

Fax: + 49 02203 2020 45 45

ITALY

Nautilus Italy S.r.l., Via della Mercanzia, 103

40050 Funo di Argelato - Bologna

Tel: + 39 051 664 6201

Fax: + 39 051 664 7461

SWITZERLAND

Nautilus Switzerland SA

Rue Jean-Prouvé 6

CH-1762 Givisiez

Tel: + 41 26 460 77 66

Fax: + 41 26 460 77 60

Please supply the serial number of your machine and the date of

purchase when you call Nautilus. Use the space in the boxes below

to write down this information. Dial the number of the office close

to you.

Serial Number

Date of Purchase

UNITED KINGDOM

Nautilus UK Ltd

4 Vincent Avenue

Crownhill, Milton Keynes, Bucks, MK8 0AB

Tel: + 44 1908 267 345

Fax: + 44 1908 267 345

CHINA

Nautilus (Shanghai) Fitness Co., Ltd.

7A No.728, Yan’an Road (West)

200050 Shanghai, China

Tel: + 86 21 523 707 00

Fax: + 86 21 523 707 099

Assembly Manual

27

Page 32

®

®

Printed in China

©2008. Nautilus, Inc. All rights reserved. Nautilus, the Nautilus Logo, TreadClimber, the TreadClimber Logo, Bowflex, Bowflex Logo, StairMaster and Nautilus Institute are either registered trademarks or trademarks of Nautilus, Inc. Schwinn is a registered trademark. All other trademarks are owned by their respective companies. Nautilus, Inc., World Headquarters, 16400 SE Nautilus

Drive, Vancouver, WA 98683 1-800-NAUTILUS www.nautilus.com

Nautilus® Bowflex® Schwinn® Fitness StairMaster® Universal® Nautilus Institute

®

Loading...

Loading...