Page 1

Nautilus owner’s manual

The Nautilus loudspeakers you have invested

in are an exact match of the first production

loudspeakers. Hand-built and tested, serial

marked and packaged individually, the

refusal to compromise at any stage from

concept to reality is a hallmark quality of

Nautilus.

And your guarantee of absolute satisfaction.

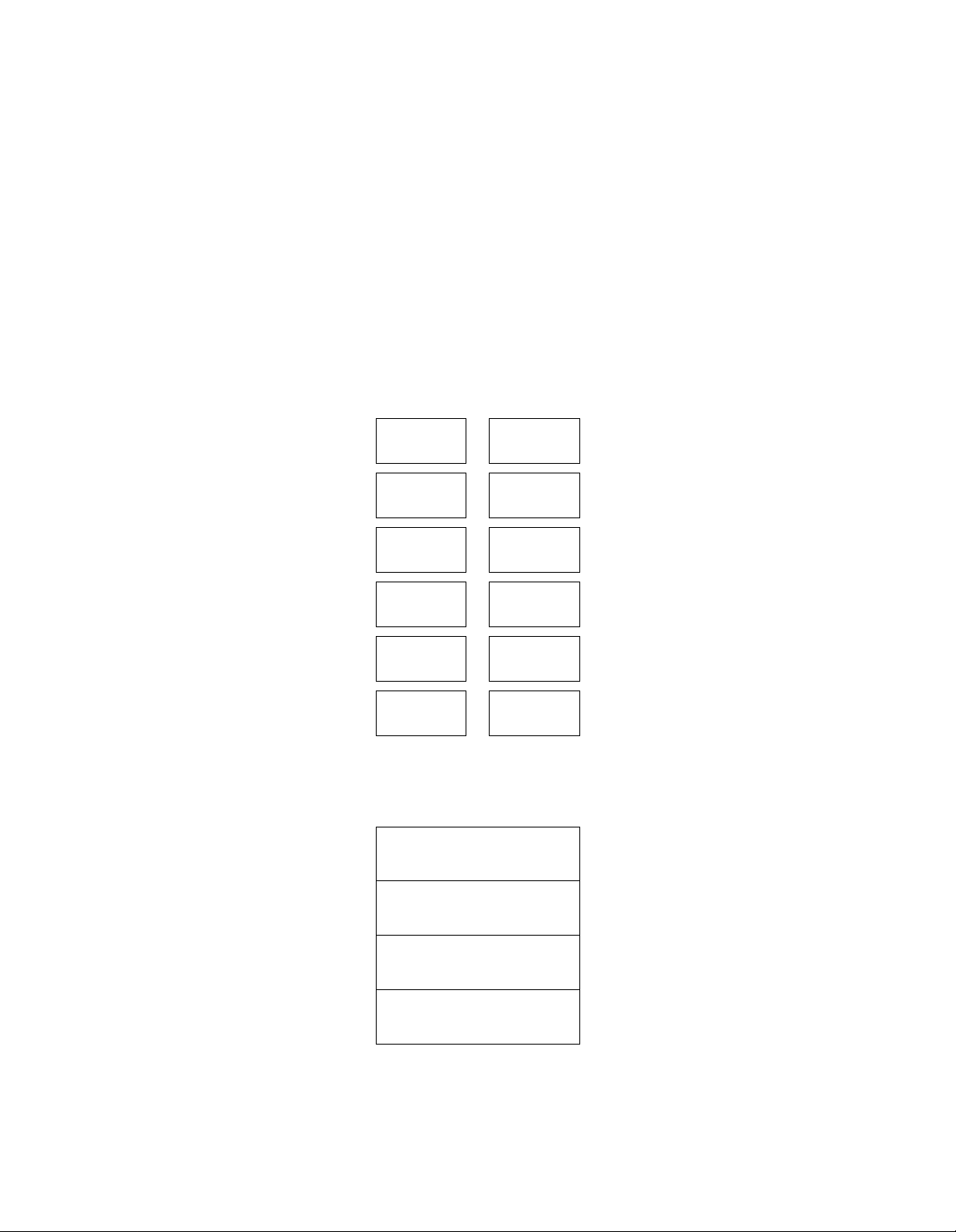

Loudspeaker B

Bass driver

Lower midrange driver

Upper midrange driver

High frequency driver

Crossover B

Loudspeaker A

Bass driver

Lower midrange driver

Upper midrange driver

High frequency driver

Crossover A

Line Insp.

Tester

Packer

Random Insp.

Quality Control

Page 2

Introduction....................................................................5

Enclosure ........................................................................6

Drive units ......................................................................7

Crossover........................................................................7

Unpacking......................................................................8

Positioning......................................................................9

Installation......................................................................9

Cable connection....................................................10

Fine tuning ..................................................................11

Aftercare

......................................................................12

Specification

..............................................................12

Safety instructions ..................................................13

Contents

Page 3

B&W monitors are widely considered to

be the benchmark in music reproduction

by professional musicians and audiophiles

alike. The Matrix #801 has become the

industry standard monitor in recording

studios around the world, and it would be

easy to rest on our development laurels.

However, the team of audio scientists

at B&W’s Research Laboratories at Steyning

are perfectionists. For them, there are

always areas which could be improved

upon or refined.

Company founder, John Bowers, was

an exemplar of the type. For him, the most

glaring compromise in loudspeaker design

lay in the cabinet. The standard rectangular enclosure only partially achieves its

goal of absorbing the rear radiation from

the drive unit.

Worse, it contributes resonances and

reflections from the inside, and diffraction

and reflection from the outside.

The B&W breakthrough of Matrix

cabinet construction offered a significant

improvement to the panel stiffness of the

rectangular box, but ultimately, the

solution, John felt, was to remove the

cabinet completely and create a dipole

source. Sadly, time and ill-health

intervened to prevent John Bowers from

exploring this avenue of research further.

Custody of this work was passed to

Matrix inventor and top acoustic designer,

Laurence Dickie, with an enviable record

of transducer and cabinet problem solving.

Laurence had been experimenting with

drivers mounted in the curved surface

of a cylinder and encountered results

not dissimilar to those of the dipole.

Namely, that external cabinet effects

could be virtually eliminated and the

intrinsic sound of the unit heard.

He used a ring magnet outside the coil with

a thin-walled cylindrical pole piece to allow

a smooth transition from dome to enclosure.

Only one type of enclosure will provide

absolute freedom from aberration – the

infinite pipe or waveguide.

Excitingly, it became possible to

imagine that an entirely waveguide-based

system could actually work. Research

showed that the exponentially tapered pipe

was an even better absorber than the cylinder. So complete was its absorbing action

that the pipe could be left open or closed.

This was the breakthrough.

Thereafter,

the usual disciplines of the acoustic

engineer’s art came into play. Juggling the

variables of driver diameter, dispersion,

break-up, excursion, practicality, and of

course, economics.

It was decided that the system should

be four-way with 300mm (12in), 100mm

(4in), 50mm (2in) and 25mm (1in) units

– all mounted in tapered lines within a

diffraction limiting enclosure.

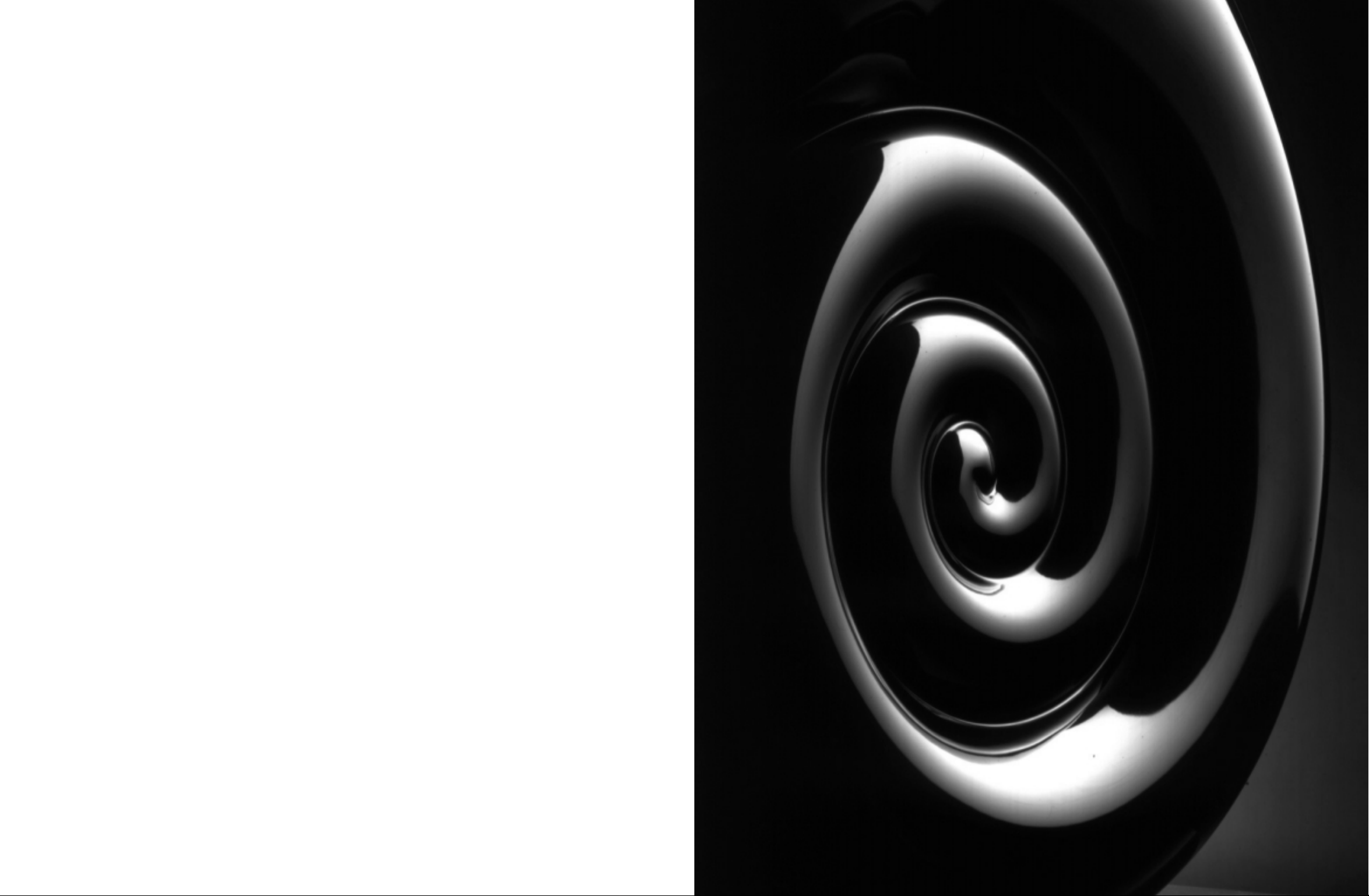

The enclosure evolved from the original

cylinder into the sleek rolling vent design

you have purchased. The massive rolling

vent disposes of rear bass driver radiation,

whilst the exponential line loaded

transmissions effectively deal with internal

reflection and external diffraction at mid

and high frequencies.

The drive for sonic purity is reinforced

by using an active crossover design

allowing separate amplification of each

drive unit, cutting out component crosstalk

and driver inter-reaction. Overall, the

elimination of straight lines defeats

diffraction and helps achieve virtually

transparent music reproduction.

What results is arguably the most

musical loudspeaker ever made.

Introduction

Page 4

Exponential line loading is used for all four

drive units, primarily to achieve freedom from

resonance and reflection, but also for the

damping effect on the fundamental resonance

in the low frequencies.

The two dome units are tightly coupled

to their respective wave guides via a

hollow pole magnet which causes minimal

discontinuity to the advancing wave front.

A

hollow

pole magnet is also to be

found behind the lower mid diaphragm

supported by a chassis which itself forms

the first 50mm of the wave guide. The tube

to which this is attached is shaped to

smooth the transition from the chassis.

The distinctive natural appearance

of Nautilus is derived from the best

compromise of folding a tapered tube to

save space whilst maintaining the highest

curvature-to-width ratio. Traditionally,

folded pipes have involved many 180°

bends which have serious frequency

dependent transmission properties.

10mm thick Glass Reinforced Plastic (GRP)

has been used for the exterior surface which,

when coupled with the doubly cur ved shape,

results in an extremely stiff enclosure.

The inner turns of the spiral are bounded by

a foam filled GRP which braces the opposite

faces of the snail in a manner similar to the

Matrix type enclosure perfected by B&W.

The external form of the Nautilus has

been achieved using a blend of hand-built

forming and advanced CAD technology

borrowed from the automotive industry.

This enables B&W to maintain

mathematical accuracy of the wave guide

and to produce the final mould tool to submillimetric accuracy.

The high gloss surface finish is the

result of using a two-part acrylic paint

with a deep lacquer coat for lustre and

durability. A 50kg block of polished

terrazzo type material supports the

complete mollusc.

Enclosure

Each drive unit has been developed to operate

as a piston within its intended frequency band,

with two octaves between the upper roll-off

and the first sign of break-up modes. Extensive

use of aluminium in the diaphragms makes this

possible. All voice coils are wound on polyimide

formers to eliminate eddy-current losses which

are particularly serious at high frequencies.

A 9.5kg (21lbs) magnet with a 100mm

(4in) voice coil acts as the massive motor of

the 300mm(12in) bass unit. This, whenused

in

the exponential line enclosure, results in a

high-pass behaviour so over-damped that

the traditional second-order characteristic is

replaced by two distinct first-order slopes

and no stored energy.

A 250 micron one-piece aluminium

cone/centre dome ensures coherent motion

to beyond 1.5kHz. From 220Hz to 880Hz, a

100mm flat-fronted unit is employed to prevent

the gentle cavity resonance found in conventional cone units at around 2kHz interfering

with the output from the upper midrange unit.

A rare earth magnet assembly with hollow

pole is used to minimise the obstruction to the

rear radiation from the diaphragm.

Two domed units of anodised aluminium

of similar construction, 50mm and 25mm

in diameter, handle the 880Hz-3.5kHz

and 3.5kHz-25kHz ranges respectively.

All drive units are completely mounted on

silicone rubber O-rings to decouple them

from the cabinet.

Drive units

Crossover

IMPORTANT: YOUR DEALER

MUST CHECK THAT THE SERIAL

NUMBER LOCATED AT THE REAR

OF EACH CROSSOVER UNIT

MATCHES THAT OF THE LOUDSPEAKER – AND THAT THE

STATED VOLTAGE IS CORRECT

FOR YOUR MAINS SUPPLY.

The division of the signal into the four

required bandwidths is accomplished in the

Nautilus Active Crossover via totally nonresonant circuitry. Simple 1st Order networks

correct the driver responses. Both inputs and

outputs offer single and balanced operation,

the latter being particularly useful in noisy

electrical environments, although a slight

subjective improvement has been observed

when using balanced signal interconnections

at every stage.

With suitable pre- and power

amplifiers, one unit is required for each

loudspeaker and should be sited close to

the power amplifiers. A power supply

connection for each crossover is required.

Page 5

You should never lift the Nautilus by any

of its tubes.

Lift Nautilus from the crate and position

over the plinth. One person should support

the weight of the speaker holding the

threaded spigot whilst pulling the harness

through the cutout in the plinth.

Gradually, the speaker can be lowered into

the dished plinth, with the spigot fitting in

the slot.

Thread the rubber washer followed by the

metal washer and finally the securing nut

over the harness end and up to the base

of the plinth. Lean the loudspeaker for ward.

Screw the nut over the threaded spigot and

tighten by hand only.

The loudspeaker should now be moved

carefully to the final listening location.

Press the release catch on the buckle of the

strap holding the Nautilus’s front cover in

place. Remove the strap and the front cover.

The front cover performs two important

functions. First, it holds the drive unit

assemblies in the cabinet during transit.

Second, it protects the delicate domes,

diaphragms and cones.

Note: Great care must be taken to ensure

that the detachable tweeter cap is not

removed during this process.

WARNING: Nautilus produces a static

magnetic field that extends outside the

cabinet boundary. As such it should not

be placed within 1m (40in) of equipment

that may be affected by such a field, e.g.

Cathode Ray Tubes in TVs and Personal

Computers.

We suggest you retain the packaging for

future use, in particular the front protective

cover and retaining strap.

A pair of Nautilus is supplied in 3 crates. Each large crate

contains 1 Nautilus loudspeaker, 1 active crossover unit and one of

the crates is marked as and contains the accessory pack. The small

crate contains two stone bases. The bases should be unpacked first

as these are needed to support the Nautilus.

Unpacking

Unscrew all the screws holding the small

crate lid in place. Remove the lid and

the card separator. Insert one hand into

the slot on the plinth and raise one end.

Two people should lift each plinth as

each one weighs approximately 50 Kg.

Lift the plinth from the crate and place

it in or as near as possible to its final

working position. Repeat the operation

for the second plinth.

You should position the Nautilus crate

as near as possible to the plinth.

Unscrew all the screws holding the large

crate’s lid in place. Remove the lid to

reveal the protective foam packaging.

Using the hand holds provided, remove

one side of the foam, followed by the

other side.

You should remove all items of clothing

that may scratch the cabinet’s surface

for example watches, rings.

Remove the loudspeaker’s harness from

its recess in the packaging. Cut the

cable ties off, taking care not to cut

into the harness.

Feed the amplifier end of the harness

through the slot in the plinth, and guide

it into the cutout on the rear of the plinth.

You will need two people to lift the

Nautilus from the crate.

The hand holds for the first person are

the main body of the tweeter enclosure

and underside of the bass enclosure.

For the second person they are the

threaded spigot where the har ness

protrudes from the loudspeaker enclosure

and the top side of the bass enclosure

just below the lower mid assembly.

Page 6

Placement of any loudspeaker can significantly

influence the relative balance of sound in the

listening seat and we recommend a degree of

experimentation.

In general it will be found

that Nautilus gives optimum results when

“toed-in” to a greater extent than in

previous systems, set typically at an angle

of between 60° and 90°. This is due to the

smooth, wide dispersion of Nautilus which

is capable of increasing the relative

significance of the side-wall reflection.

Another benefit of the dispersion

characteristic is the substantially increased

listening area in which a pleasant and

realistic stereo image may be enjoyed.

Positioning

Installation

Connection to Nautilus is via an 8-core cable

of high purity silver on copper, terminated in

bare ends to allow the most direct connection

to the amplifier terminals.

It is generally accepted that the wires

between power amp and driver should be

as short as possible, so we do not recommend that the captive cable be lengthened

in any way.

In the majority of cases it will be most

convenient to locate the crossover units in

close proximity to the power amplifiers, with

correspondingly short line interconnects.

Each cable should be connected directly

to the respective outputs of each amplifier.

The line from pre-amplifier and

crossover is likely to be comparatively

long and should, therefore, be of high

quality and low capacitance. It is further

recommended that the balanced input

of the crossover be used with two-core

screened cable – even if the pre-amp is

single ended.

In the latter case, the screen and one

core should be joined at the source end.

Detail of twin cored screened lead connecting phono to

xlr plugs (pre-amp to x-over)

Cable connection

1 Meter

From Pre-Amp

X.L.R. & Phono inputs

(X.L.R. to be used for

balanced inputs &

Phono for standard

single ended inputs)

USE ONE TYPE ONLY

To Power Amp

X.L.R. & Phono Outputs

(X.L.R. to be used for

balanced inputs &

Phono for standard

single ended inputs)

USE ONE TYPE ONLY

FOR EACH OUTPUT

Mains A/C in

Listening area

60° 90°

High Frequency Unit

Low Frequency Unit

Upper Mid Range Unit

Lower Mid Range Unit

All connections should be made with the

equipment turned off. Each Nautilus comes

with its own dedicated active crossover network. The serial number on the amplifier end

of the harness should match the serial number

on the rear of the crossover network.

The crossover can be connected to the

amplifiers with Phono leads for unbalanced

operation or XLR types for balanced operation. Each Nautilus will require 1 separate

amplifier channel for each drive unit. The

gain and phase of each must be identical.

Each amplifier (channel) should be

capable of delivering at least 30V RMS

into 6 ohms for realistic levels of reproduction. Most amplifiers capable of delivering

100 watts into 6 ohms should be suitable.

Connect each of the 4 crossover outputs (LF,

LMF, UMF, HF) in turn to each amplifier or

amplifier channel. The loudspeaker harness

should then be connected to the appropriate terminals on the corresponding

amplifier. The input to the crossover should

then be connected to the output of the preamplifier. Connect the power and turn on

the crossover, followed by the amplifiers.

Page 7

Before fine tuning the installation, double

check the polarity and security of the

connections.

If the hand-tightened nut that holds

Nautilus to the plinth is not done up

sufficiently tightly it can occasionally work

loose. This may create a difficult-to-locate

rattle or buzz. The accessory pack includes

a rubber washer and a steel washer that

should be employed between the plinth and

nut to eliminate this problem. The rubber

washer should rest against the plinth.

If it is not possible to position the crate

near the plinth when unpacking, the pieces

of foam covering Nautilus in the crate can

be used to support the loudspeaker close

to the plinth within reach of the loudspeaker harness.

If you need to alter the tilt of the

Nautilus, French chalk is supplied in the

accessory pack to ease movement between

the speaker and its plinth.

If the level of bass is uneven with

frequency, this is usually due to strong

excitation of resonance modes in the

room. Even small changes in the position

of the speakers within the listening room

can have a profound effect on the perceived

sound quality by altering the excitation of

these modes. Try mounting the speakers

along a different wall. Even moving large

pieces of furniture about can have an effect.

If the general level of bass is too high,

try moving the speakers further away from

the walls. Conversely, if you need more

bass, move the speakers closer to the

walls. Space behind the speakers also

improves the impression of perspective

on well recorded material.

If the sound is too harsh, increase the

amount of soft furnishing in the room. For

example, use heavier curtains. Conversely

reduce the amount of soft furnishing if the

sound is dull and lifeless.

Test for flutter echoes by clapping your

hands and listening for rapid repetitions.

These can smear the sound, but may be

reduced by irregular shaped surfaces such

as bookshelves and large pieces of furniture.

As Nautilus is designed in such a way

that the units are de-coupled from the enclosure and the base weighs a substantial

50kg, provision for spikes is unnecessary

and therefore not included.

Fine tuning

The GRP cabinets normally only require

dusting. If you wish to use an aerosol cleaner,

spray onto the cleaning cloth, not directly

onto the cabinet.

If the surface of the speaker suffers

any minor scratches they can be polished

out with fine T-Cut or finishing compound

such as “Finesse It” by 3M.

When making or breaking connections,

ensure all power is switched off otherwise

damage may result.

Avoid touching the drive units, especially the domes, as damage may result.

Aftercare

Specification

(-6dB):10Hz – 25kHz

±0.5dB

10Hz – 220Hz: 305mm

220Hz – 880Hz: 100mm

880Hz – 3.5kHz: 50mm

3.5kHz – 25kHz: 25mm

4 (one per unit) of 30v rms

(100 watts into 6 ohms)

1050mm (H) x 900mm (D) x 420mm (W)

60kg

50kg

Midnight blue, Black and Silver

Bandwidth

Deviation from flat Response (25Hz – 20kHz)

Drive units

Amplifier requirements

Minimum for full satisfaction

Overall dimensions

Loudspeaker weight

Plinth weight

Standard finishes

Matrix is a registered trademark of B&W Loudspeakers Ltd.

Kevlar is a registered trademark of Dupont.

B&W Loudspeakers Ltd reserves the right to amend details of the

specification without notice in line with technical developments.

Copyright © B&W Loudspeakers Ltd.

Design Thomas Manss & Company, London 5/97

Page 8

1. Read Instructions - All the safety and operating

instructions should be read before the appliance is

operated.

2. Retain Instructions - The safety and operating

instructions should be retained for future reference.

3. Heed Warnings - All warnings on the appliance and

in the operating instructions should be adhered to.

4. Follow Instructions - All operating and use

instructions should be followed.

5. Water and Moisture - The appliance should not be

used near water - for example, near a bathtub,

washbowl, kitchen sink, laundry tub, in a wet

basement, or near a swimming pool and the like.

6. Carts and Stands - The appliance should be used

only with a cart or stand that is recommended by

the manufacturer.

7. Wall or Ceiling Mounting - The appliance should be

mounted to a wall or ceiling only as recommended

by the manufacturer.

8. Ventilation - The appliance should be situated so

that its location or position does not interfere with

its proper ventilation. For example, the appliance

should not be situated on a bed, sofa, rug, or

similar surface that may block the ventilation

openings; or placed in a built-in installation, such as

a bookcase or cabinet, that may impede the flow of

air through the ventilation openings.

9. Heat - The appliance should be situated away from

heat sources such as radiators, heat registers,

stoves, or other appliances that produce heat.

10. Power Sources - The appliance should be connected

to a power supply only of the type described in the

operating instructions or as marked on the

appliance.

11. Grounding or Polarisation - The appliance must be

grounded. When using an extension power-supply

cord or a power-supply cord other than that supplied

with the appliance, it should be 3-core, fitted with

the appropriate moulded-on plugs and carry safety

approval appropriate to the country of use.

12. Power Cord Protection - Power-supply cords should

be routed so that they are not likely to be walked on

or pinched by items placed on or against them,

paying particular attention to cords at plugs,

convenience receptacles and the point where they

exit from the appliance.

13. Cleaning - The appliance should be cleaned only as

recommended by the manufacturer.

14. Non-use Periods - The power cord of the appliance

should be unplugged from the outlet when left

unused for a long period of time.

15. Object and Liquid Entry - Care should be taken so

that objects do not fall and liquids are not spilled

into the enclosure through openings.

16. Damage Requiring Service - The appliance should

be serviced by qualified personnel when:

a. The power-supply cord or the plug has been

damaged; or

b. Objects have fallen, or liquid has been spilled

into the appliance; or

c. The appliance has been exposed to rain; or

d. The appliance does not appear to operate

normally, or exhibits a marked change in

performance; or

e. The appliance has been dropped, or the

enclosure damaged.

17. Servicing - The user should not attempt to service

the appliance beyond that described in the

operating instructions. All other servicing should be

referred to qualified service personnel

Safety instructions

WARNINGS

TO PREVENT FIRE OR SHOCK HAZARD, DO NOT EXPOSE

THIS EQUIPMENT TO RAIN OR MOISTURE.

OBSERVE ALL WARNINGS ON THE EQUIPMENT ITSELF. TO

AVOID ELECTRICAL SHOCK, DO NOT OPEN THE

ENCLOSURE. THERE ARE NO USER SERVICEABLE PARTS

INSIDE. REFER ALL SERVICE QUESTIONS TO AN

AUTHORISED B&W DEALER.

TO PREVENT ELECTRIC SHOCK, DO NOT USE THIS

(POLARISED) POWER PLUG WITH AN EXTENSION CORD

RECEPTACLE OR OTHER OUTLET UNLESS THE BLADES CAN

BE FULLY INSERTED TO PREVENT BLADE EXPOSURE.

ENSURE THAT THE VOLTAGE INDICATED ON THE PANEL

MATCHES THAT OF THE POWER SUPPLY.

REPLACE MAINS FUSE ONLY WITH THE SAME TYPE AND

RATING AS SHOWN ON THE VOLTAGE LABEL PLACED

NEAR THE MAINS INPUT SOCKET.

SWITCH OFF THE POWER AND REMOVE THE MAINS

CABLE FROM THE CASE BEFORE CHANGING THE FUSE.

THE EQUIPMENT MUST BE EARTHED (GROUNDED).

TO ENSURE ADEQUATE COOLING DO NOT OBSTRUCT

THE VENTILATION HOLES.

DO NOT INSERT OBJECTS THROUGH THE AMPLIFIER

VENTILATION HOLES.

IMPORTANT FOR UK ONLY:

The wires in this mains lead are coloured in

accordance with the following code:

green-and-yellow: earth

blue: neutral

brown: live

As the colours of the wires in the mains lead of this

apparatus may not correspond with the coloured

markings identifying the terminals in your plug, proceed

as follows:

the wire which is coloured green and yellow must be

connected to the terminal in the plug which is marked

with the letter E, or by the earth symbol or coloured

green or green and yellow.

the wire which is coloured blue must be connected to

the terminal which is marked with the letter N or

coloured black.

the wire which is coloured brown must be connected to

the terminal which is marked with the letter L or

coloured red.

ACHTUNG

UM DIE GEFAHR EINES BRANDES ODER ELEKTRISCHEN

SCHLAGES AUSZUSCHLIESSEN, DARF DAS GERÄT WEDER

NÄSSE NOCH FEUCHTIGKEIT AUSGESETZT WERDEN.

BEACHTEN SIE ALLE WARNHINWEISE AUF DEM GERÄT.

ÖFFNEN SIE NIEMALS DAS GEHÄUSE IM INNERN BEFINDEN

SICH KEINE VOM BEDIENER ZU WARTENDEN TEILE. DER

SERVICE IST AUSSCHLIESSLICH VON EINEM AUTORISIERTEN

B&W-FACHHÄNDLER DURCHZUFÜHREN.

UM EINEM ELEKTRISCHEN SCHLAG VORZUBEUGEN, IST

BEIM ANSCHLIESSEN DES GERÄTES ANS NETZ UNBEDINGT

SICHERZUSTELLEN, DASS DIE POLE DES NETZSTECKERS

EXAKT IN DIE BUCHSEN DER JEWEILIGEN STECKDOSE

PASSEN.

STELLEN SIE SICHER, DASS DIE ANGEGEBENE

BETRIEBSSPANNUNG DER NETZSPANNUNG ENTSPRICHT.

FÜR DEN AUSTAUSCH DER NETZSICHERUNG DÜRFEN NUR

SICHERUNGEN DESSELBEN TYPS VERWENDET WERDEN. DIE

NENNDATEN SIND AUF DEM TYPENSCHILD NEBEN DER

EINGANGSBUCHSE ANGEGEBEN.

SCHALTEN SIE DAS GERÄT AUS UND ENTFERNEN SIE DAS

NETZKABEL VOM GERÄT, BEVOR SIE DIE SICHERUNG

WECHSELN.

DAS GERÄT DARF NUR MIT EINER ORDNUNGSGEMÄSSEN

SCHUTZKONTAKT-STECKDOSE BETRIEBEN WERDEN.

UM EINE AUSREICHENDE KÜHLUNG ZU GEWÄHRLEISTEN,

SOLLTEN DIE LÜFTUNGSLÖCHER NIEMALS VERDECKT UND

AUCH KEINE GEGENSTÄNDE HINEINGESTECKT WERDEN.

AVVERTENZE

PER EVITARE INCENDI O FOLGORAZIONI NON ESPORRE

L’APPARECCHIATURA A PIOGGIA O UMIDITUÀ

RISPETTARE TUTTE LE AVVERTENZE SULLE APPARECCHIATURE

STESSE. PER EVITARE SCOSSE NON APRIRE IL CABINET.

NON CONTIENE PARTI AD USO DELL’UTENTE. PER

QUALSIASI PROBLEMA RIVOLGERSI AL RIVENDITORE

AUTORIZZATO B&W.

PER EVITARE FOLGORAZIONI, NON UTILIZZARE QUESTA

SPINA DI CORRENTE (POLARIZZATA) CON UNA PROLUNGA

O ALTRO A MENO CHE LE LAMELLE NON SIANO

ACCURATAMENTE INSERITE PER EVITARE L’ESPOSIZIONE

DELLA LAMELLA STESSA.

CONTROLLARE CHE IL VOLTAGGIO DELL’APPARECCHIATURA

SIA QUELLO DELLA RETE.

SOSTITUITE IL FUSIBILE DI RETE SOLO CON LO STESSO TIPO

E LA STESSA POTENZA COME INDICATO SULL’ETICHETTA DI

VOLTAGGIO POSTA VICINO ALL’INGRESSO DEL CAVO DI

ALIMENTAZIONE.

TOGLIETE L’ALIMENTAZIONE PRIMA DI CAMBIARE IL

FUSIBILE.

QUESTA APPARECCHIATURA RICHIEDE LA MESSA A TERRA.

PER GARANTIRE UN RAFFREDDAMENTO ADEGUATO

DELL’APPARECCHIATURA, NON OSTRUITE I FORI DI

VENTILAZIONE.

NON INFILATE OGGETTI ATTRAVERSO I FORI DI

VENTILAZIONE.

ADVERTENCIAS

PARA EVITAR INCENDIOS O ACCIDENTES ELECTRICOS, NO

EXPONGA ESTE EQUIPO A LA LLUVIA O A LA HUMEDAD.

TENGA EN CUENTA TODAS LAS ADVERTENCIAS QUE

FIGURAN EN EL EQUIPO. PARA EVITAR UN SHOCK

ELECTRICO, NO ABRA LA CAJA. DENTRO DEL EQUIPO NO

EXISTEN PARTES MANIPULABLES POR EL USUARIO. TODAS

LAS CUESTIONES REFERENTES A REPARACIONES DIRIJALAS

A UN VENDEDOR AUTORIZADO DE B&W.

PARA EVITAR UN SHOCK ELECTRICO, NO USE ESTE

ENCHUFE DE ALIMENTACION (POLARIZADO) CON UN

RECEPTACULO DE UN CABLE DE EXTENSION NI CON OTRA

SALIDA, A MENOS QUE LAS CLAVIJAS QUEDEN

TOTALMENTE INSERTADAS, Y SE EVITE LA EXPOSICION DE

LAS MISMAS.

COMPRUEBE QUE EL VOLTAJE QUE SE INDICA EN EL PANEL,

ES EL QUE CORRESPONDE AL SUMINISTRO DE POTENCIA.

EL FUSIBLE ESTA DENTRO DEL MODULO, DEBE SER

REEMPLAZADO POR UNO DEL MISMO TIPO Y VALOR

NOMINAL QUE EL SUMINISTRADO, Y DEBE SER COLOCADO

POR UN SERVICIO TÉCNICO AUTORIZADO DE B&W.

EL EQUIPO NO DEBE TENER TOMA A TIERRA.

PARA ASEGURARSE QUE ESTA ADECUADAMETNE

REFRIGERADO Y NO OBSTRUYA LOS ORIFICIOS DE

VENTILACIÓN.

ADVARSLER

FOR AT UNDGÅ FARE FOR ILD OG RISIKO FOR ELEKTRISK

STØD MÅ UDSTYRET IKKE UDSÆTTES FOR VAND ELLER

FUGT.

VÆR OPMÆRKSOM PÅ DE ADVARSLER SOM ANGIVES PÅ

UDSTYRET. LAD VÆRE MED AT ÅBNE UDSTYRET. DER FINDES

INGEN BETJENINGSDELE INDE I APPARATET. ALLE SERVICE

SPØRGSMÅL BEDES RETTET TIL AUTORISERET B&W

FORHANDLER.

AF SIKKERHEDSHENSYN ER DETTE APPARATET FORSYNET

MED JORDSTIK. FOR AT UNDGÅ RISIKO FOR ELEKTRISK

STØD BØR DE DERFOR IKKE ANVENDE

FORLÆNGERLEDNING, MED MINDRE DENNE OGSÅ ER

JORDFORBUNDET.

APPARATET SKAL JORDFORBINDES!

CHECK AT SPÆNDINGSVÆLGEREN STÅR I KORREKT

POSITION.

SLUK FOR FORSTÆRKEREN OG AFBRYD NETLEDNINGEN

INDEN EVT. UDSKIFTNING AF SIKRINGEN.

UDSKIFTNING AF SIKRINGEN MÅ KUN SKE MED EN

TILSVARENDE SIKRING. SE DEN PÅKLISTREDE LABEL VED

SIDEN AF NEDSTIKKET.

FOR AT SIKRE BEDST MULIG AFKØLING VENLIGST UNDGÅ

AT PUTTE GENSTANDE GENNEM AFKØLINGSHULLERNE TIL

FORSTÆRKEREN.

CAUTION

RISK OF ELECTRIC

SHOCK DO NOT

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE THE BACK PANEL.

NO USER-SERVICEABLE PARTS INSIDE. REFER SERVICING

TO QUALIFIED PERSONNEL.

Explanation of Graphical Symbols

The lightning flash within an equilateral triangle is

intended to alert you to the presence of uninsulated

“dangerous voltage” within the product’s enclosure

that may be of sufficient magnitude to constitute an

electric shock to persons. The exclamation point

within an equilateral triangle is intended to alert you

to the presence of important operating and

maintenance (servicing) instructions in the literature

accompanying the appliance.

GB

I

N

D E

Page 9

A LIRE IMPÉRATIVEMENT

POUR ÉVITER TOUT RISQUE D’INCENDIE OU

D’ÉLECTROCUTION, NE PAS EXPOSER CET APPAREIL À LA

PLUIE OU À L’HUMIDITÉ.

RESPECTEZ LES CONDITIONS NORMALES D’UTILISATION DE

L’APPAREIL. POUR ÉVITER TOUTE ÉLECTROCUTION, NE PAS

OUVRIR LE CAPOT. IL N’EXISTE AUCUNE PIÉCE SUSCEPTIBLE

D’ÊTRE CHANGÉE PAR L’UTILISATEUR À L’INTÉRIEUR DE

L’APPAREIL. EN CAS DE PROBLÉME, ADRESSEZ-VOUS

EXCLUSIVEMENT Ë UN REVENDEUR AGRÉÉ B&W.

POUR ÉVITER TOUT RISQUE D’ÉLECTROCUTION, N’UTILISEZ

PAS CET APPAREIL AVEC UN CABLE DE PROLONGATION

D’ALIMENTATION SECTEUR OU UNE AUTRE PRISE QUE CELLE

FOURNIE, À MOINS QUE SES BROCHES SOIENT BIEN

INSÉRÉES À FOND DANS LA PRISE MURALE.

ASSUREZ-VOUS QUE LA TENSION SECTEUR INDIQUÉE SUR

LE PANNEAU CORRESPOND BIEN À CELLE DE VOTRE

ALIMENTATION.

NE REMPLACER LE FUSIBLE QU’AVEC UN FUSIBLE DE MÊME

TYPE COMME INDIQUÉ SUR L’ETIQUETTE D’INDICATION DE

TENSION SITUÉE PRÉS DE LA PRISE D’ENTRÉE SECTEUR.

ETEIGNER L’APPAREIL ET RETIRER LA PRISE AVANT DE

CHANGER LE FUSIBLE

CET APPAREIL DOIT ÊTRE MIS A LA MASSE ( PRISE TERRE ).

POUR GARANTIR UN BON REFROIDISSEMENT N’OBSTRUER

PAS LES PRISES D’AIR

N’INSÉRER PAS D’OBJETS DANS LES PRISES AIR

WAARSCHUWINGEN

OM BRAND- EN SCHOKGEVAAR TE VOORKOMEN MAG U

DIT APPARAAT NIET BLOOTSTELLEN AAN REGEN OF VOCHT.

VOLG ALLE WAARSCHUWINGEN DIE OP HET APPARAAT

STAAN ALTIJD OP.

OM EEN ELEKTRISCHE SCHOK TE VOORKOMEN: OPEN DE

BEHUIZING NIET.

ONDERDELEN KUNNEN NIET DOOR GEBRUIKER WORDEN

GEREPAREERD.

REPARATIE EN ONDERHOUD UITSLUITEND DOOR EEN

GEKWALIFICEERDE B&W-DEALER.

VOORKOM EEN ELEKTRISCHE SCHOK EN GEBRUIK DE

NETSPANNINGSKABEL UITSLUITEND MET KONTAKTDOZEN

WAAR DE STEKERPENNEN VOLLEDIG KUNNEN WORDEN

INGESTOKEN.

OVERTUIG U ERVAN OF DE NETSPANNING VAN HET

APPARAAT OVEREENKOMT MET DIE VAN HET LICHTNET.

VERVANG DE NETZEKERING UITSLUITEND DOOR EEN VAN

HETZELFDE TYPE EN WAARDE ZOALS WORDT AANGEGEVEN

DOOR HET TYPE-INDICATIEPLAATJE NAAST DE

LICHTSPANNINGSAANSLUITING.

HET APPARAAT MAG UITSLUITEND WORDEN AANGESLOTEN

OP EEN WANDKONTAKTDOOS MET RANDAARDE.

VOOR EEN OPTIMALE KOELING MOETEN DE VENTILATIEOPENINGEN ALTIJD VOLLEDIG VRIJ BLIJVEN.

VOORKOM DAT VOORWERPEN EN VLOEISTOF VIA DE

VENTILATIE-OPENINGEN IN HET APPARAAT KUNNEN VALLEN.

VARNINGAR

FÖR ATT UNDVIKA ELDSVÅDA OCH ELEKTRISKA STÖTAR,

FÅR APPARATEN INTE UTSÄTTAS FÖR REGN ELLER FUKT.

LÄGG MÄRKE TILL ALL VARNINGSTEXT PÄ APPARATEN.

AVLÄGSNA EJ HÖLJET. APPARATEN INNEHÅLLER INGA

DELAR SOM KAN REPARERAS AV LEKMAN. ALL SERVICE

SKALL UTFÖRAS PÅ AV B&W AUKTORISERAD VERKSTAD.

UNDVIK ELEKTRISKA STÖTAR GENOM ATT ALLTID TILLSE ATT

STICKKONTAKTEN SITTER KORREKT I VÄGGUTTAGET ELLER

FÖRLÄNGNINGSSLADDEN.

KONTROLLERA ATT APPARATENS MÄRKSPÄNNING

ÖVERENSSTÄMMER MED SPÄNNINGEN I VÄGGUTTAGET.

ERSÄTT HUVUDSÄKRINGEN MED ENDAST SAMMA TYP OCH

VÄRDE SOM ANGES PÅ ETIKETTEN VID UTTAGET FÖR

STRÖMKABELN.

STÄNG AV APPARATEN OCH DRA UT STICKKONTAKTEN UR

VÄGGUTTAGET VID SÄKRINGSBYTE.

APPARATEN MÄSTE ANSLUTAS TILL JORDAT VÄGGUTTAG.

TILLSE ATT APPARATEN FÅR ORDENTLIG LUFTVÄXLING

GENOM ATT EJ TÄPPA TILL VENTILATIONSHÅLEN.

STICK EJ IN FRÄMMANDE FÖREMÅL I VENTILATIONSHÅLEN.

TURVAOHJEET

TULIPALON TAI SÄHKÖISKUN VAARAN VÄLTTÄMISEKSI

SUOJAA LAITE SATEELTA TAI KOSTEUDELTA.

OTA HUOMIOON KAIKKI LAITTEESSA OLEVAT

VAROITUKSTEKSIT. SÄHKÖISKUNVAARAAN VUOKSI ÄLÄ

AVAA LAITETTA. LAITE EI SISÄLLÄ KÄYTTÄJÄN

HUOLLETTAVISSA OLEVIA HUOLTOKOHTEITA. KÄÄNNY

HOULTOASIOISSA SUOMEN HI-FI KLUBIN PUOLEEN.

KÄYTÄ VAIN MAADOITETTUA JATKOJOHTOA.

VARMISTU, ETTÄ LAITTEEN TYYPPIKILVESSÄ OLEVA JÄNNITE

VASTAA SULAKETAULUSSA MAINITTUA.

VAIHTAESSASI SULAKETTA KÄYTÄ VAIN

ALKUPERÄISTYYPPISTÄ SULAKETTA; SULAKKEEN TYYPPI KÄY

ILMI VERKKOLIITÄNNÄN VÄLITTÖMÄSSÄ LÄHEISYYDESSÄ

OLEVASTA JÄNNITEKILVESTÄ.

KATKAISE VIRTA JA IRROITA LAITE SÄHKÖVERKOSTA ENNEN

SULAKKEEN VAIHTAMISTA.

RIITTÄVÄN JÄÄHTYMISEN VARMISTAMISEKSI LAITETTA SAA

KÄYTTÄÄVAIN SITEN ASENNETTUNA ETTÄ LAITTEEN

TUULETUSREIÄT OVAT VAPAAT ESTEISTÄ.

ÄLÄ TYÖNNÄ MITÄÄN ESINEITÄ LAITTEEN TUULETUSREISTÄ

SISÄÄN.

AVISOS

PARA EVITAR O RISCO DE CHOQUE ELÉCTRICO, NÄO

EXPONHA ESTE EQUIPAMENTO À CHUVA OU HUMIDADE.

RESPEITE TODOS OS AVISOS PRESENTES NO PRÓPRIO

EQUIPAMENTO. PARA EVITAR CHOQUES ELÉCTRICOS, NÄO

ABRA A TAMPA DO EQUIPAMENTO. NÄO EXISTEM PARTES

SUBSTITUÍVEIS PELO UTILIZADOR NO INTERIOR, DEVENDO

TODAS AS QUESTÖES RELATIVAS A ASSISTÊNCIA SER

APRESENTADAS A UM REVENDEDOR AUTORIZADO B&W.

PARA EVITAR O RISCO DE CHOQUE ELÉCTRICO, NÄO UTILIZE

UMA EXTENSÄO PARA O CABO DE ALIMENTAÇÄO, A NÄO

SER QUE OS PINOS DA FICHA FIQUEM COMPLETAMENTE

COBERTOS.

ASSEGURE-SE QUE A TENSÄO DE ALIMENTAÇÄO

ESPECIFICADA PARA O EQUIPAMENTO É IGUAL À DA SUA

INSTALAÇÄO.

O FUSÌVEL DE ALIMENTAÇÄO ESTÁ COLOCADO JUNTO DA

TOMADA DE ENTRADA DE CORRENTE EM CASO DE DEFEITO,

O SUBSTITUTO DEVE SER DO MESMO TIPO E CALIBRE DO

INICIALMENTE FORNECIDO E A SUBSTITUIÇÄO LEVADA A

CABO POR UM REVENDEDOR AUTORIZADO B&W.

ESTE EQUIPAMENTO DEVE SER LIGADO COM CONTACTO À

TERRA.

DEPOIS DE LIGADO NÄO DESLOQUE O EQUIPAMENTO, POIS

PODEM SOLTAR-SE OS CABOS DE LIGAÇÄO E CAUSAR

DANOS.

ADVARSEL

FOR Å UNNGÅ BRANN OG ELEKTRISKE STØT, MÅ DETTE

UTSTYR IKKE UTSETTES FOR VANN ELLER FUKTIGE

OMGIVELSER.

FØLG ANVISNINGEN PÅ PRODUKTET. SKAL IKKE ÅPNES.

BRUKER VIL IKKE FINNE NOEN DELER FOR UTSKIFTING

INNVENDIG. ALLE FORESPØRSLER OM REPARASJON SKAL

RETTES TIL AUTORISERT B&W FORHANDLER.

MÅ IKKE BRUKES I IMPROVISERTE KONTAKTER SOM

BLOTTLEGGER NETTSTIKKETS METALLDELER.

PASS PÅ AT UTLESNINGEN PÅ BAKSIDEN AV APPARATET

KORRESPONDERER MED DEN LOKALE NETTSPENNING.

HOVEDSIKRING SKAL KUN ERSTATTES MED DEN TYPE OG

VERDI SOM KORRESPONDERER MED ANGIVELSEN VED

SIDEN AV NETTKABELKONTAKTEN.

SKRU AV FORSTERKEREN OG FJERN NETTKABELEN F¯R

BYTTING AV HOVEDSIKRING.

DETTE APPARATET MÅ JORDES.

VENTILASJONSHULLENE MÅ IKKE BLOKKERES. DETTE ER

NØDVENDIG FOR Å SIKRE TILSTREKKELIG KJØLING.

INGEN OBJEKTER MÅ PUTTES ELLER STIKKES INN GJENNOM

VENTILASJONSHULLENE.

F

P

S

NL

N

SF

Loading...

Loading...