Page 1

OPERATION and MAINTENANCE MANUAL

MANUAL DE OPERACIÓN Y DE MANTENIMIENTO

MANUEL D’INSTRUCTIONS ET D’ENTRETIEN

165356REVB 2/05

STANLEY FASTENING SYSTEMS L.P.

D61ADCSB

COIL-FED PNEUMATIC SIDE STRIKE STAPLER

ENGRAPADORA NEUMÁTICA DE IMPACTO LATERAL

ALIMENTADA CON ROLLO

AGRAFEUSE PNEUMATIQUE À CARTOUCHE

ET À ACTION LATÉRALE

BEFORE OPERATING THIS TOOL, ALL OPERATORS SHOULD STUDY THIS MANUAL TO

UNDERSTAND AND FOLLOW THE SAFETY WARNINGS AND INSTRUCTIONS. KEEP THESE

INSTRUCTIONS WITH THE TOOL FOR FUTURE REFERENCE. IF YOU HAVE ANY QUESTIONS,

CONTACT YOUR BOSTITCH REPRESENTATIVE OR DISTRIBUTOR.

ANTES DE OPERAR ESTAHERRAMIENTA, TODOS LOS OPERADORES DEBERÁN ESTUDIAR

ESTE MANUAL PARA PODER COMPRENDER Y SEGUIR LAS ADVERTENCIAS SOBRE

SEGURIDAD Y LAS INSTRUCCIONES. MANTENGA ESTAS INSTRUCCIONES CON LA

HERRAMIENTAPARA FUTURA REFERENCIA, SI TIENE ALGUNA DUDA, COMUNÍQUESE CON

SU REPRESENTANTE DE BOSTITCH O CON SU DISTRIBUIDOR.

LIRE ATTENTIVEMENT LE PRÉSENT MANUEL AVANT D’UTILISER L’APPAREIL. PRÉTER UNE

ATTENTION TOUTE PARTICULIÈRE AUX CONSIGNES DE SÉCURITÉ ET AUX

AVERTISSEMENTS. GARDER CE MANUEL AVEC L’OUTIL POUR FUTUR RÉFÉRENCE. SI

VOUS AVEZ DES QUESTIONS, CONTACTEZ VOTRE REPRÉSENTANT OU VOTRE

CONCESSIONNAIRE BOSTITCH.

Page 2

-2-

SAFETY INSTRUCTIONS

EYE PROTECTION

which conforms to ANSI specifications and provides protection against

flying particles both from the FRONT and SIDE should ALWA YS be worn by the operator and

others in the work area when connecting to air supply, loading, operating or servicing this

tool. Eye protection is required to guard against flying fasteners and debris, which could

cause severe eye injury.

The employer and/or user must ensure that proper eye protection is worn. Eye protection

equipment must conform to the requirements of the American National Standards Institute,

ANSI Z87.1 and provide both frontal and side protection. NOTE: Non-side shielded

spectacles and face shields alone do not provide adequate protection.

CAUTION:

Additional Safety Protection will be required in some environments. For

example, the working area may include exposure to noise level which can lead to hearing

damage. The employer and user must ensure that any necessary hearing protection is

provided and used by the operator and others in the work area. Some environments will

require the use of head protection equipment. When required, the employer and user must

ensure that head protection conforming to ANSI Z89.1 is used.

Your D61ADCSB Side Strike Stapler is

shipped from factory completely assembled

and ready for use. Before operation, read the

provided Operation and Maintenance Manual

for the D61ADC Carton Closer, which is a part

of this machine. Follow the Operation and Air

Supply instructions carefully – note all the

Warnings and Cautions.

Please also note that the instructions in the

D61ADC manual for loading the magazine do

not apply in this case. The coil of staples are to

be mounted on the short piece of plastic tube

cradled above the tool. All other instructions in

the D61ADC manual apply.

After extensive use of the D61ADCSB, or

when exchanging the D61ADC staples, it may

be necessary to adjust either the trip foot or

the trip cylinder.

To prevent accidental

cycling, always disconnect the air supply

before making adjustments, servicing the

machine, clearing jams and when the

machine is not in use.

1. T

o Adjust the Trip Foot:

Disconnect the air supply. Loosen the two Trip

Foot mounting holes. The Trip Foot may be

moved on its slotted holes. Adjust so that the

Trip foot comes up flush against the bottom of

the D61ADC when the Valve is fully actuated.

The Trip foot and the Valve should bottom out

together.

2. To Adjust the Air Cylinder:

Make sure air supply is disconnected. With the

D61ADC Trigger held closed, there should be

a minimum clearance between the Trigger and

the Actuating Rod when the Rod is pushed

toward the Trigger to the end of the Air

Cylinder stroke. Adjust the clearance by

loosening the two nuts that hold the Air

Cylinder in the frame, and repositioning the Air

Cylinder and retightening the nuts. If the

Cylinder is being replaced, adjust the Air

Cylinder in the frame.

Note: For best performance, the Depth

Adjustment on the D61ADC should be at a

high setting. At too low of an adjustment,

the driver will push the box away from the

D61ADCSB. The Front Adjustment Plate

of the D61ADC should be set at

approximately the number 3 setting; see

“Depth Adjustment” paragraph in the

D61ADC manual.

To prevent accidental

injury, never place hands or any other part

of the body in contact with the actuating

arm or in the staple clinching area.

Lubrication:

The D61ADCSB Side Strike Stapler should not

require lubrication other than the application of

a light machine oil to the pivot points two to

three times a year.

Refer to the Operation and Maintenance

Manual for the D61ADC for proper lubrication

of the tool.

Page 3

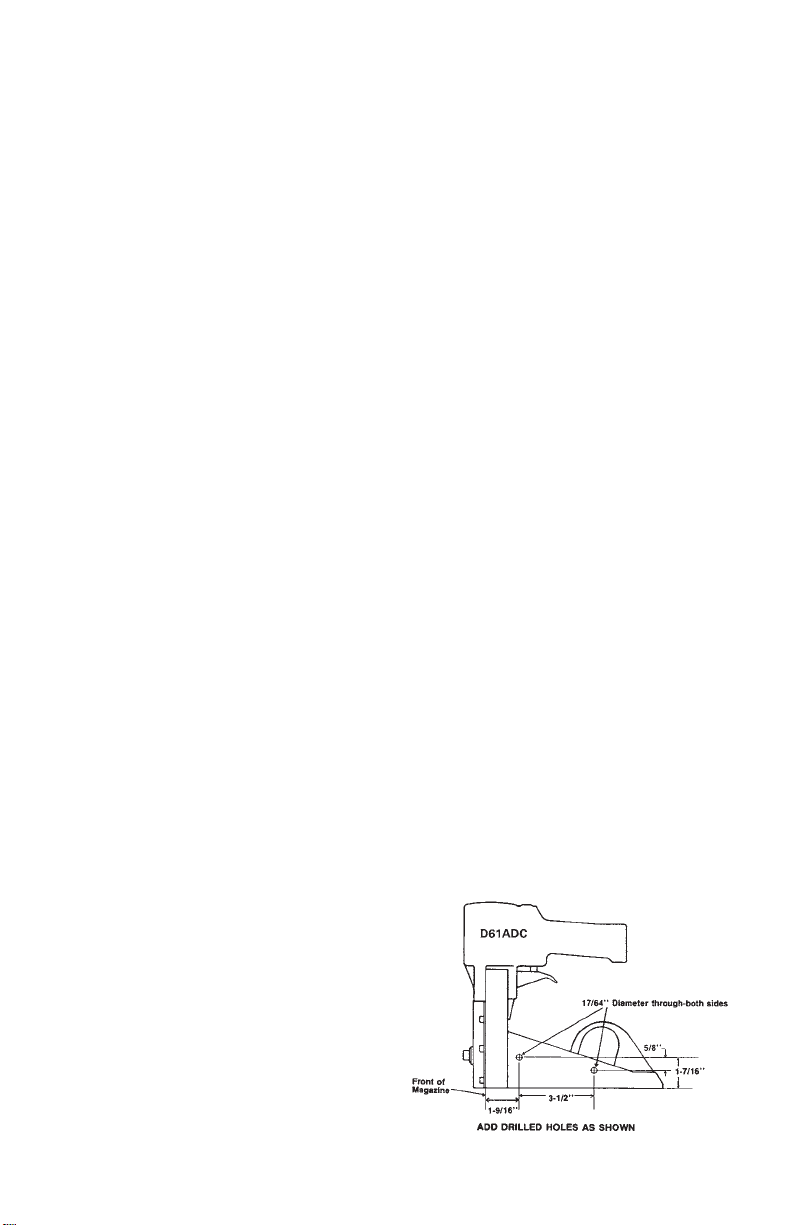

Modification of D61ADC for use on

D61ADCSB

In the event that the D61ADC Carton Closer needs

replacement, it will be necessary to drill two 17/64”

diameter holes through both sides of the frame of the

new tool as shown in the diagram.

NOTE: Use only staples recommended by Bostitch

for use in Bostitch D61ADC Carton Closer or

staples which meet Bostitch specifications.

-3-

Page 4

-4-

LIMITED WARRANTY

Bostitch, Inc., warrants to the original retail purchaser that this product is free from defects in material and

workmanship, and agrees to repair or replace, at Bostitch's option, any defective product within 1 year from the

date of purchase. This warranty is not transferable. It only covers damage resulting from defects in material or

workmanship, and it does not cover conditions or malfunctions resulting from normal wear , neglect, abuse,

accident or repairs attempted or made by other than our regional repair center or authorized warranty service

center. Driver blades, bumpers and o-rings are considered normally wearing parts.

THIS WARRANTY IS IN LIEU OF ALL OTHER EXPRESS W ARRANTIES. ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE IS LIMITED TO THE DURATION OF THIS

WARRANTY. BOSTITCH SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES.

This warranty is limited to sales in the United States and Canada. Some states do not allow limitations on how

long an implied warranty lasts, or the exclusion or limitation of incidental or consequential damages, so the

above limitations or exclusions may not apply to you. This warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

To obtain warranty service, return the product at your expense together with proof of purchase to a Bostitch

Regional or authorized warranty repair center. You may call us at 1-800-556-6696 for the location of authorized

warranty service centers in your area

Page 5

-5-

INSTRUCCIONES DE SEGURIDAD

Al cargar, operar o dar servicio a esta herramienta, el operador y los demás presentes en el área

de trabajo deben usar SIEMPRE PROTECCIÓN DE LOS OJOS

en conformidad con las

especificaciones ANSI y que proteja contra partículas que vuelen por DELANTE y por el LADO,

cuando se haga la conexión al suministro de aire. Se exige protegerse la vista para

resguardarse contra fijaciones o residuos que vuelen, lo cual puede causar lesiones graves a

los ojos.

El empleador o el usuario deben asegurar que se protejan debidamente los ojos. El equipo de

protección ocular debe estar en conformidad con los requisitos del Instituto Nacional

Americano de Normas (American National Standards Institute), ANSI Z87.1 y proteger por

delante y por el costado. NOTA: Los anteojos o máscaras sin protección lateral por sí solos no

dan una protección adecuada.

PRECAUCIÓN:

En algunos ambientes se necesitará protección adicional de seguridad. Por

ejemplo, el área de trabajo puede exponer a un nivel de ruido que lesione el oído. El empleador

y el usuario deben comprobar que se cuente con la protección necesaria del oído y que el

operador y los demás presentes en el área la usen. Algunos ambientes exigirán el uso de casco

protector. Cuando sea necesario, el empleado y el usuario deben verificar que se proteja la

cabeza en conformidad con la norma ANSI Z89.1.

La engrapadora de impacto lateral D61ADCSB se

envía completamente ensamblada de fábrica y lista

para su uso. Antes de la operación, lea el Manual de

operación y de mantenimiento que se incluye para la

cerradora de cajas de cartón D61ADC, el cual forma

parte de esta máquina. Siga cuidadosamente las

instrucciones de operación y suministro de aire,

preste atención a todas las advertencias y

precauciones.

Observe también que no se aplican en este caso las

instrucciones en el manual D61ADC para cargar el

depósito. Los rollos de grapas se cargan en el tubo

corto de plástico instalado sobre la herramienta. Se

aplican todas las otras instrucciones del manual

D61ADC.

Después del uso prolongado del D61ADCSB o

cuando se cambien las grapas D61ADC, puede que

sea necesario ajustar ya sea el pedal o el cilindro de

disparo.

Para evitar la operación

accidental, desconecte siempre el suministro de

aire antes de hacer ajustes, dar servicio a la

máquina, despejar atascos y cuando no esté en

uso la máquina.

1. Para ajustar el pedal de disparo:

Desconecte el suministro de aire. Suelte los

agujeros de montaje del pedal de disparo. El pedal

de disparo puede moverse en sus agujeros

ranurados. Ajuste de manera que el pedal de disparo

quede al ras contra la parte inferior del D61ADC

cuando la válvula esté completamente accionada. El

pedal de disparo y la válvula deben llegar juntos a la

parte inferior.

2. Para ajustar el cilindro de aire.

Asegúrese de que esté desconectado el suministro

aire. Con el gatillo del D61ADC mantenido en la

posición cerrada, debe haber un espacio de

separación mínimo entre el gatillo y la vara de

accionamiento cuando la vara está empujada hacia

el gatillo al extremo de la carrera del cilindro de aire.

Ajuste la separación soltando las dos tuercas que

sostienen el cilindro de aire en el armazón y

volviendo a colocar el cilindro de aire y reapretando

las tuercas. Si se está reemplazando el cilindro,

ajuste el cilindro de aire en el armazón.

Nota: Para lograr el óptimo rendimiento, el ajuste

de profundidad del D61ADC debe estar en su

posición más alta. Aun ajuste demasiado bajo, el

impulsor empujará la caja alejándola del

D61ADCSB. La placa de ajuste frontal del

D61ADC debe fijarse aproximadamente en el

número 3; consulte el parrafo “Ajuste de

profundidad” en el manual del D61ADC.

Para evitar lesiones

accidentales, no coloque nunca las manos ni

otras partes del cuerpo en contacto con el brazo

accionador o en el área de apriete de la grapa.

Lubricación:

La engrapadora de impacto lateral D61ADCSB no

necesita lubricación aparte de aplicarle un aceite de

máquina liviano en los puntos pivotales dos a tres

veces al año.

Para ver la lubricación apropiada de la herramienta

consulte el Manual de operación y mantenimiento del

D61ADC.

Page 6

Modificación del D61ADC para usar en

el D61ADCSB

En caso que se necesite reemplazar la cerradora de cajas de

cartón D61ADC, será necesario perforar dos agujeros de 17/64 de

pulgada (6.75 mm) de diámetro a través de ambos lados del

armazón de la nueva herramienta según se ilustra en el diagrama.

NOTA: Use solamente las grapas recomendadas por Bostitch

para usar en las cerradoras de cajas de cartón Bostitch

D61ADC o grapas que cumplan con las especificaciones de

Bostitch.

-6-

Page 7

-7-

GARANTÍA LIMITADA

Bostitch, Inc., garantiza al comprador original al por menor que este producto está exento de defectos de material y

fabricación, además se compromete a reparar o cambiar , a opción de Bostitch, cualquier producto defectuoso dentro

de 1 año de la fecha de compra. Esta garantía no es transferible. Solamente cubre daños resultantes de defectos en

material o fabricación, y no cubre condiciones o desperfectos resultantes del desgaste normal, negligencia, abuso,

accidente o reparaciones intentadas o efectuadas por terceros ajenos a nuestro centro regional de reparaciones o al

centro de servicio bajo garantía. Las aspas del impulsor, los topes y las juntas tóricas se consideran componentes de

desgaste normal.

ESTA GARANTÍA REEMPLAZA TODAS LAS DEMÁS GARANTÍAS EXPRESAS. TODA GARANTÍA DE

COMERCIABILIDAD O IDONEIDAD P ARA UN FIN PARTICULAR SE LIMITA A LA DURACIÓN DE EST A GARANTÍA.

BOSTITCH NO SERÁ RESPONSABLE DE DAÑOS FORTUITOS O CONSECUENCIALES.

Esta garantía se limita a ventas dentro de los Estados Unidos y Canadá. Algunos estados no permiten limitaciones a

la duración de una garantía implícita ni la exclusión o limitación de daños fortuitos o consecuenciales, de modo que

las limitaciones o exclusiones anteriores pueden no corresponder a su caso. Esta garantía le concede derechos

legales específicos, y usted puede tener también otros derechos que varían de un estado a otro.

Para obtener servicio bajo la garantía, devuelva el producto con cargo a nosotros junto con su comprobante de compra

dirigido al centro regional o al centro de reparaciones bajo garantía de Bostitch. Puede llamarnos al 1-800-556-6696

para obtener la dirección de los centros autorizados de servicio bajo garantía en su área.

Page 8

-8-

INSTRUCTIONS DE SÉCURITÉ

Une PROTECTION DES YEUX, conforme aux normes ANSI et fournissant une protection contre

les projectiles en provenance de l’AVANT et des CÔTÉS, doit TOUJOURS être portée par

l’opérateur et les personnes présentes dans la zone de travail, lors du raccordement à une

source d’air, du chargement, du fonctionnement et de la maintenance de l’outil. Une telle

protection est indispensable pour vous protéger contre les attaches et débris projetés,

susceptibles d’entraîner des blessures sérieuses.

L’employeur et/ou l’utilisateur doivent s’assurer de porter une bonne protection oculaire.

L’équipement de protection doit être conforme à la norme ANSI Z87.1 et doit fournir une

protection frontale et latérale. REMARQUE : Des lunettes sans protection latérale et des

masques faciaux ne fournissent pas la protection nécessaire.

MISE EN GARDE

: Des mesures de sécurité supplémentaire sont requises dans certains

environnements. Par exemple, la zone de travail peut favoriser l’exposition à un niveau de bruit

susceptible d’entraîner une surdité. L’employeur et l’utilisateur doivent s’assurer qu’une

protection de l’ouïe sera utilisée par l’opérateur et les personnes présentes dans la zone de

travail. Certains environnements exigeront l’utilisation d’un équipement de protection de la tête.

Lorsque cela s’avère nécessaire, l’employeur et l’utilisateur doivent s’assurer que la protection

de la tête est conforme à la norme ANSI Z89.1.

Votre agrafeuse D61ADCSB à action latérale est

livrée de l’usine complètement assemblée et prête à

l’utilisation. Toutefois, avant de vous en servir, lisez le

manuel d’utilisation et d’entretien pour le ferme-boîte

D61ADC, lequel fait partie de cet appareil. Suivez

attentivement les instructions d’utilisation et

d’alimentation en air , et prenez note des

avertissements et des mises en garde.

Veuillez aussi noter que les instructions dans le

manuel du D61ADC pour le chargement du magasin

ne s’appliquent pas ici. La cartouche d’agrafes doit

être installée sur la petite section de tube de

plastique cloisonnée au-dessus de l’outil. Toutes les

autres instructions dans le manuel du D61ADC sont

applicables.

Après une longue utilisation du D61ADCSB, ou lors

du changement des agrafes du D61ADC, il peut être

nécessaire de régler soit le pied de la butée, soit le

cylindre de la butée.

Afin d’éviter un cycle

accidentel de l’outil, coupez toujours

l’alimentation en air lorsque l’appareil n’est pas

utilisé et avant d’effectuer tout réglage ou

entretien ou de débloquer une attache coincée.

1. Réglage du pied de butée :

Déconnectez l’alimentation d’air. Desserrez les deux

trous de montage du pied de butée. Le pied peut être

déplacé à l’intérieur de ses trous allongés. Réglez-le

de façon qu’il arrive à égalité contre le bas du

D61ADC lorsque la valve est complètement activée.

Le pied et la valve doivent atteindre ensemble leur

point le plus bas.

2. Réglage du cylindre à air :

Assurez-vous que l’alimentation d’air est coupée. La

gâchette du D61ADC maintenue enfoncée, il doit y

avoir un espace minimal entre celle-ci et la bielle de

commande lorsque cette bielle est poussée vers la

gâchette à la fin de la course du cylindre à air. Ajustez

l’espace en desserrant les deux écrous qui retiennent

le cylindre à air dans le cadre; repositionnez le

cylindre au besoin et resserrez les écrous. Si le

cylindre doit être remplacé, ajustez le nouveau

cylindre à l’intérieur du cadre de l’appareil.

Remarque : Pour obtenir de meilleurs résultats,

ajustez le réglage de la profondeur du D61ADC à

un niveau élevé. Si le réglage est trop bas, le

mandrin poussera la boîte et l’éloignera du

D61ADCSB. La plaque de réglage avant

du D61ADC doit être aux environs du réglage 3;

référez-vous au paragraphe « Réglage de la

profondeur » dans le manuel du D61ADC.

Afin de prévenir toute

blessure, ne placez jamais les mains ni autre

partie du corps en contact avec le bras de

déclenchement ni dans la zone de pincement des

agrafes.

Lubrification :

L’agrafeuse pneumatique à cartouche et à action

latérale D61ADCSB ne devrait pas nécessiter de

lubrification autre que l’application d’une huile à

machine légère sur les points de pivot deux ou trois

fois par année.

Consultez le manuel d’utilisation et d’entretien du

D61ADC pour connaître la bonne procédure de

lubrification de l’outil.

Page 9

Modification du D61ADC pour

l’utilisation sur le D61ADCSB

Dans l’éventualité ou le ferme-boîte D61ADC doive être remplacé,

il faudra percer deux trous de 17/64 po (6,75 mm) dans les deux

côtés du cadre du nouvel outil, tel qu’illustré.

REMARQUE : Utilisez uniquement les agrafes recommandées

par Bostitch pour le ferme-boîte D61ADC de Bostitch ou des

agrafes répondant aux spécifications de Bostitch.

-9-

Page 10

GARANTIE LIMITÉE

Bostitch, Inc., garantit à l’utilisateur final que ce produit est exempt de tout défaut de matériau et de fabrication, et

accepte le cas échéant de réparer ou de remplacer, à l’option de Bostitch, tout produit défectueux pendant une période

de 1 an à partir de la date d’achat. Cette garantie n’est pas cessible. Elle couvre uniquement les dommages résultant

de défauts de matériau et de fabrication, et ne couvre pas les conditions ou défauts de fonctionnement résultant d’une

usure normale, d’une négligence, d’un usage abusif, d’un accident ou de tentatives de réparation par une entité autre

que notre Centre de réparation local ou un Centre de service de garantie autorisé. Les lames du mandrin, les

amortisseurs et les joints toriques sont considérés comme des pièces normales d’usure.

CETTE GARANTIE REMPLACE TOUTE AUTRE GARANTIE EXPRESSE. TOUTE GARANTIE DE V ALEUR

MARCHANDE, DE QUALITÉ COMMERCIALE OU D’ADÉQUA TION À UN USAGE P ARTICULIER SE LIMITE À LA

DURÉE DE CETTE GARANTIE. BOSTITCH NE SERA PAS TENUE RESPONSABLE DES DOMMAGES INDIRECTS

OU ACCESSOIRES.

Cette garantie se limite aux ventes effectuées aux États-Unis et au Canada. Les limitations imposées par la durée d’une

garantie implicite ou l’exclusion des dommages accessoires ou indirects n’étant pas reconnues dans certains États, les

limitations ou exclusions précitées peuvent ne pas vous être adressées. Cette garantie vous confère des droits

juridiques spécifiques qui s’ajoutent aux autres droits éventuels qui peuvent varier d’une province ou d’une juridiction

à l’autre.

Pour obtenir des services liés à la garantie, retournez le produit à vos frais accompagné de la preuve d’achat à votre

Centre de réparation local ou à un Centre de service de garantie autorisé. Pour obtenir l’adresse d’un Centre de service

de garantie autorisé dans votre localité, composez le 1-800-556-6696.

Loading...

Loading...