Page 1

OPERATION and MAINTENANCE MANUAL

MANUAL DE OPERACIÓN Y MANTENIMIENTO

MANUEL DE FONCTIONNEMENT ET D’ENTRETIEN

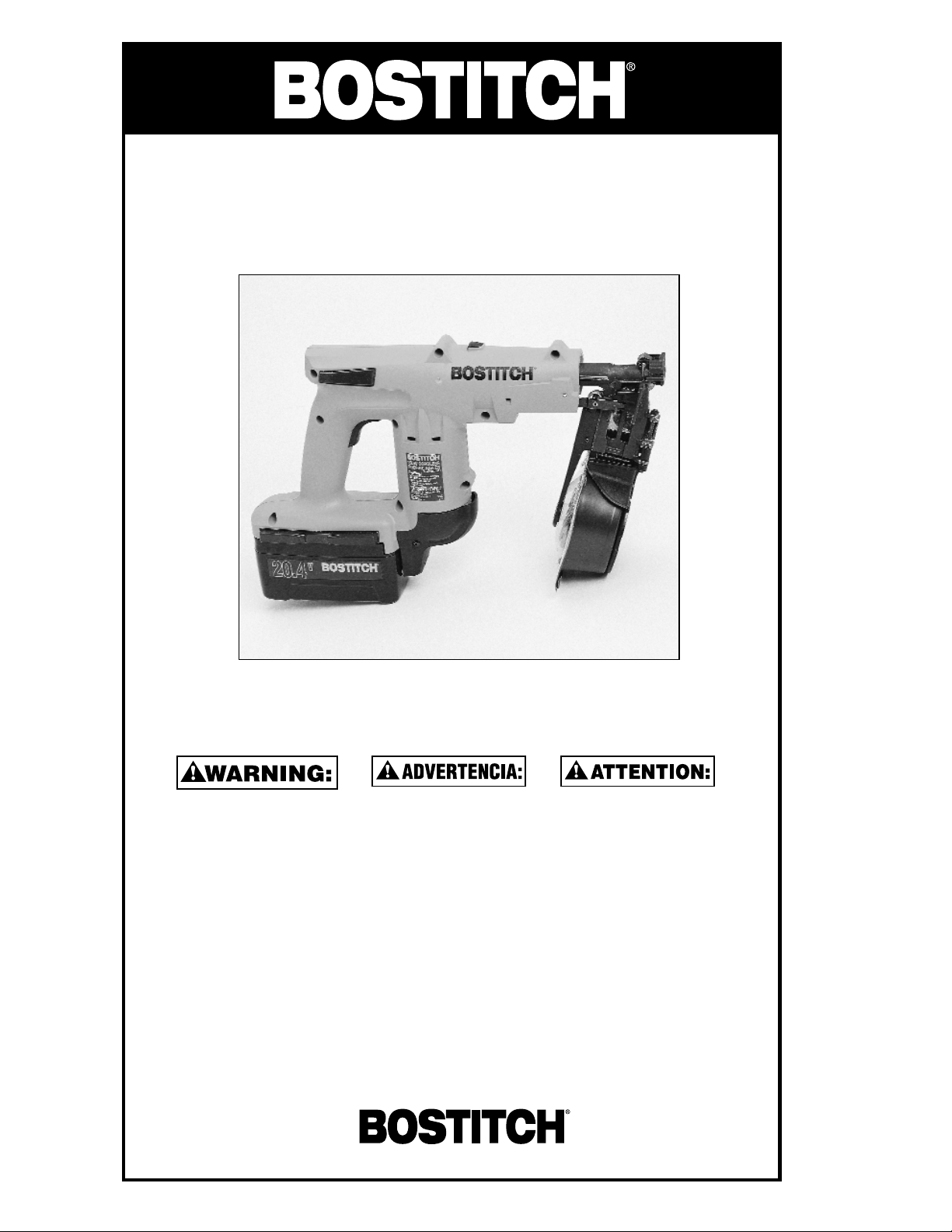

CRN38K

CORDLESS ROOFING NAILER

CLAVADORA DE TECHOS A PILAS

CLOUEUSE DE TOIT SANS FIL

110504 REVB 12/00

Stanley Fastening Systems

BEFORE OPERATING THIS TOOL, ALL OPERATORS SHOULD STUDY THIS MANUAL

TO UNDERSTAND AND FOLLOW THE SAFETY WARNINGS AND INSTRUCTIONS.

KEEP THESE INSTRUCTIONS WITH THE TOOL FOR FUTURE REFERENCE. IF YOU

HAVE ANY QUESTIONS, CONTACT YOUR STANLEY-BOSTITCH REPRESENTATIVE

OR DISTRIBUTOR.

ANTES DE OPERAR ESTA HERRAMIENTA, TODOS LOS OPERADORES DEBERÁN

ESTUDIAR ESTE MANUAL CON EL FIN DE COMPRENDER Y SEGUIR LAS ADVERTENCIAS DE SEGURIDAD Y LAS INSTRUCCIONES. MANTENGA ESTAS INSTRUCCIONES CON LA HERRAMIENTA PARA REFERENCIA FUTURA. SI USTED TIENE

ALGUNA PREGUNTA, PÓNGASE EN CONTACTO CON SU REPRESENTANTE O DISTRIBUIDOR DE STANLEY-BOSTITCH.

AVANT D’UTILISER CET OUTIL,TOUS LES UTILISATEURS DEVRAIENT ÉTUDIER CE

MANUEL POUR COMPRENDRE ET SUIVRE LES INSTRUCTIONS ET LES AVERTISSEMENTS DE SÉCURITÉ. GARDEZ CES INSTRUCTIONS AVEC L’OUTIL POUR

VOUS Y RÉFÉRER À L’AVENIR. POUR TOUTE QUESTION, PRENEZ CONTACT AVEC

VOTRE REPRÉSENTANT OU DISTRIBUTEUR STANLEY-BOSTITCH.

Page 2

INTRODUCTION

The Stanley-Bostitch CRN38 is a precision-built tool, designed for high speed, high volume

nailing. These tools will deliver efficient, dependable service when used correctly and with

care. As with any fine power tool, for best performance the manufacturer’s instructions must

be followed. Please study this manual before operating the tool and understand the safety

warnings and cautions. The instructions on installation, operation and maintenance should be

read carefully, and the manual kept for reference. NOTE: Additional safety measures may be

required because of your particular application of the tool. Contact your Stanley-Bostitch

representative or distributor with any questions concerning the tool and its use.

Stanley-Bostitch, Inc., East Greenwich, Rhode Island 02818.

INDEX

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3,4

Loading the Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4,5

Tool Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cleaning Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Maintaining the Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

NOTE:

Stanley-Bostitch tools have been engineered to provide excellent customer satisfaction and are

designed to achieve maximum performance when used with precision Stanley-Bostitch fasteners

engineered to the same exacting standards.

Stanley-Bostitch cannot assume responsibility for product performance if our tools are

used with fasteners or accessories not meeting the specific requirements established for

genuine Stanley-Bostitch nails, staples and accessories.

LIMITED WARRANTY

Stanley-Bostitch, Inc., warrants to the original retail purchaser that this product is free from

defects in material and workmanship, and agrees to repair or replace, at Stanley-Bostitch's

option, any defective product within 1 year from the date of purchase. This warranty is not

transferable. It only covers damage resulting from defects in material or workmanship, and it

does not cover conditions or malfunctions resulting from normal wear, neglect, abuse, accident or

repairs attempted or made by other than our regional repair center or authorized warranty

service center. Driver blades, bumpers and o-rings are considered normally wearing parts.

THIS WARRANTY IS IN LIEU OF ALL OTHER EXPRESS WARRANTIES. ANY WARRANTY

OF MERCHANTABILITY OR FITNESS FOR APARTICULAR PURPOSE IS LIMITED TO THE

DURATION OF THIS WARRANTY. STANLEY-BOSTITCH SHALL NOT BE LIABLE FOR ANY

INCIDENTAL OR CONSEQUENTIAL DAMAGES.

This warranty is limited to sales in the United States and Canada. Some states do not allow

limitations on how long an implied warranty lasts, or the exclusion or limitation of incidental or

consequential damages, so the above limitations or exclusions may not apply to you. This

warranty gives you specific legal rights, and you may also have other rights which vary from

state to state.

To obtain warranty service, return the product at your expense together with proof of purchase

to a Stanley-Bostitch Regional or authorized warranty repair center. You may call us at

1-800-556-6696 for the location of authorized warranty service centers in your area.

-2-

Page 3

SAFETY INSTRUCTIONS

EYE PROTECTION which conf orms to ANSI specifications and pro vides protection

against flying particles both from the FRONT and SIDE should ALWAYS be worn

by the operator and others in the work area when loading, operating or servicing

this tool. Eye protection is required to guard against flying fasteners and debris,

which could cause severe eye injury.

The employer and/or user must ensure that proper eye protection is worn. Eye

protection equipment must conform to the requirements of the American National

Standards Institute, ANSI Z87.1-1989 and provide both frontal and side protection.

NOTE: Non-side shielded spectacles and face shields alone do not provide adequate protection.

CAUTION:

Additional Safety Protection will be required in some en vironments.For

example, the working area may include exposure to noise level which can lead to

hearing damage. The employer and user must ensure that any necessary hearing

protection is provided and used by the operator and others in the work area. Some

environments will require the use of head protection equipment. When required, the

employer and user must ensure that head protection conf orming to ANSI Z89.1 1986

is used.

Always disconnect battery: 1.) Before making adjustments; 2.) When servicing the

tool; 3.) When clearing a jam; 4.) When tool is not in use; 5.) When moving to a different work area, as accidental actuation may occur, possibly causing injury.

OPERATION

Always handle the tool with care: 1.) Never engage in horseplay; 2.) Never pull

the trigger unless nose is directed toward the work; 3.) Keep others a safe distance from the tool while tool is in operation as accidental actuation may occur,

possibly causing injury.

The operator must not hold the trigger pulled except during fastening operation

as injury could result if the trip accidentally contacted someone or something,

causing the tool to cycle .

Keep hands and body away from the discharge area of the tool.

Do not drive fasteners close to the edge of the work piece as the wood may split,

allowing the fastener to be deflected possibly causing injury.

Do not operate tool in explosive atmospheres such as in the presence of flammable

gases, liquids or dust. This tool creates sparks which can ignite fumes or dust.

MAINTAINING THE TOOL

When working on cordless tool note the warnings in this manual and use extra

care when evaluating problem tools.

BATTERY/CHARGER

• To reduce risk of injury, only charge Model BP20419 nickel cadmium batteries

with the Model BC20419 Charger. Other types of batteries may burst causing

personal injury and damage.

• Do not expose Charger to rain, snow or frost.

• Do not abuse the Charger line cord. Disconnect from receptacle by pulling the

plug rather than cord. Locate cord so that it will not be stepped on, tripped

over, or otherwise subjected to damage or stress.

• Do not use an extension cord unless absolutely necessary. Use of improper

extension cord could result in a risk of fire and electric shock. If an extension

cord must be used, make sure:

a) that blades on plug of extension cord are the same number, size and

shape as those of plug on charger

b) that extension cord is properly wired and in good electrical condition

c) that wire size is at least 16 gauge (AWG)

If the charger is used outdoors with an extension cord, the cord should be suitable for outdoor use. Suitable cords are marked with "W" or "WA" on the jacket

and it is recommended that they be listed by the Underwriters Laboratories Inc.

(UL).

• Do not operate the Charger with a damaged line cord or plug – have these

replaced immediately.

-3-

Page 4

• Do not operate the Charger if it has received a sharp blow, been dropped or

otherwise been damaged in any way. Do not disassemble the charger; refer to

the Bostitch Service Center or a qualified service technician for service or

repair. Incorrect re-assembly may result in a risk of electric shock or fire.

• Unplug the Charger from outlet to reduce the risk of electric shock while

cleaning or attempting any maintenance.

• Unplug the Charger from outlet when it is not being used.

• When batteries are not installed in the CRN38, keep them away from nails or

other metal objects that may short circuit the terminals. Do not place

batteries in pockets or toolboxes with nails, screws or other metal objects.

This may cause fire or injury.

• To reduce risk of explosion and injury, do not place battery packs in a fire or

incinerator.

• Do not disassemble or mutilate the battery pack, the cells contain chemicals

that can cause burns.

SAFETY

SAVE THESE INSTRUCTIONS

• This manual contains important safety and operating instructions for using the

Bostitch Model BC20419 Battery Charger and the Bostitch Model BP20419

Battery Pack.

• Before Using Tool, Battery, and Charger, read all instructions and cautionary

markings on Battery Charger, Battery Pack, and CRN38 Roofing Nailer.

LOADING THE CRN38

EYE PROTECTION which conforms to ANSI specifications and provides protection against flying particles both from the FRONT and SIDE should ALWAYS be

worn by the operator and others in the work area when loading, operating or servicing this tool. Eye protection is required to guard against flying fasteners and

debris, which could cause severe eye injury.

The employer and/or user must ensure that proper eye protection is worn. Eye

protection equipment must conform to the requirements of the American

National Standards Institute, ANSI Z87.1-1989 and provide both frontal and side

protection.

NOTE: Non-side shielded spectacles and face shields alone do not provide adequate protection.

TO PREVENT ACCIDENTAL INJURIES:

• Never place a hand or any other part of the body in nail discharge area of the

tool while the battery is connected.

• Never point the tool at anyone else.

• Never engage in horseplay.

• Never pull the trigger unless nose is directed at the work.

• Always handle the tool with care.

• Do not pull the trigger or depress the trip mechanism while loading the tool.

READ AND UNDERSTAND BEFORE OPERATING

Nail Loading / unloading

Loading:

To load the tool, unlatch the door and rotate.

Open the door and canister holder.

Pull about 3" of fasteners out of the canister,

and load the canister into the holder.

Rotate the holder to the operating position.

Place the lead fastener into the drive channel

of the nose. Close the door and check that it

is latched.

Unloading is the reverse of loading.

-4-

Page 5

BATTERY PACK OPERATION

CHARGING THE BA TTER Y PA CK

• IMPORTANT – Charge the battery packs before using for the first time since they are shipped in a partially charged condition. Two or three additional charges will be required before the battery packs are

fully conditioned and operating at full capacity.

• For best results charge the batteries in an ambient temperature between 40°F and 105°F.

• Batteries that have been used in the CRN38 for extended periods of time will become hot. If they are

hot when placed on the charger, the red charge indicator flashes until the battery cools to a temperature that is safe for charging. This cool off time will depend on the battery and ambient temperatures

and can range from a few minutes to over 30 minutes. When the battery has cooled, the charger will

automatically switch to the Rapid Charge mode.

• Use care when installing and removing the battery from the tool, do not press the trigger or the tool

may activate. Be sure to first remove the battery from the CRN38 before cleaning the nose or removing it for service.

STORAGE

• To get the longest battery life, ensure that the battery packs are discharged before being stored for

long periods (more than one month). Batteries can be stored in a dry location at any temperature

between –20°F and 120°F. They should be recharged before being used again.

BATTERY DISPOSAL

• Nickel cadmium batteries are recyclable and should be disposed of properly. Many state and local

laws make it illegal to dispose of these battery packs in normal trash or land fill

facilities. Recycle the batteries by dropping them off at local battery replacement

retailers or recycling centers. Look for the RBRC emblem.

Call 1-800-8-BATTERY for information about nickel cadmium battery recycling

and disposal.

Installation and Removal

• The battery is installed on the CRN38 Roofing Nailer by placing it on

the rails and sliding it forward until the latch engages.

• To remove, release the latch and at the same time slide the battery off

the rails.

TOOL OPERATION

EYE PROTECTION which conforms to ANSI specifications and provides protection

against flying particles both from the FRONT and SIDE should ALWAYS be worn by the

operator and others in the work area when loading, operating or servicing this tool. Eye

protection is required to guard against flying fasteners and debris, which could cause

severe eye injury.

The employer and/or user must ensure that proper eye protection is worn. Eye protection equipment must conform to the requirements of the American National Standards

Institute, ANSI Z87.1-1989 and provide both frontal and side protection. NOTE: Nonside shielded spectacles and face shields alone do not provide adequate protection.

-5-

Battery Latch

• The CRN38 is a contact trip operated tool.

• For best operation hold the trigger in and press the tool against the work surface. Make sure to

push down until the tool stops against the work surface and turns off.

• The tool should be held perpendicular to the work surface or leaned back slightly.

Page 6

• For best operation hold the tool as you would a screwdriver or drill driver as shown.

• It is not necessary to push the tool hard, simply follow the nail down.

NOTE: Head damage and incomplete drives will result if the tool is

pushed hard.

• The tool will drive the nail quickly (less than .25 seconds). For optimum battery life push the tool down quickly.

The operator must not hold the trigger pulled except during fastening operation,

as serious injury could result if the trip accidentally contacted someone or

something, causing the tool to cycle.

Keep hands and body away from the discharge area of the tool.

COLD WEA THER OPERATION:

For cold weather operation, near and below freezing, the tool may slow down in operation and battery capacity

will be reduced.

Do not store tools in a cold weather environment to prevent frost or ice formation on

the tools operating mechanisms that could cause tool failure.

ENERGY ADJUSTMENT/FASTENER DEPTH CONTROL

• Fastener drive depth adjustment is accomplished by rotating the

adjustment wheel of the Energy Management System.

• Rotate the wheel counterclockwise for deeper drives, clockwise for

less depth.

• Thicker layers of shingles generally require more depth of drive.

• Unless the shingles are hot the tool can typically be used at the

maximum setting without overdriving and damaging the shingles.

• To optimize the number of fasteners per charge, adjust the energy

management system so the driven nails are flush with the shingle surface on the lowest setting possible.

TOOL OPERATION CHECK

Remove all fasteners from tool before performing tool operation check.

Contact T rip OPERA TED T OOL:

With finger off the trigger, press the contact trip against the work surface.

THE TOOL MUST NOT CYCLE.

Hold the tool off the work surface, and pull the trigger.

THE TOOL MUST NOT CYCLE.

With the tool off the work surface, pull the trigger.

Press the contact trip against the work surface.

THE TOOL MUST TURN ON.

Without touching the trigger, press the contact trip against the work surface,

then pull the trigger.

THE TOOL MUST TURN ON.

THE TOOL WILL CYCLE EACH TIME THE TRIGGER IS PULLED!

-6-

Adjusting Wheel

Page 7

CHARGER OPERATION

NORMAL CHARGING:

• Plug the charger into a 120V AC outlet. Insert the battery pack onto

the charger ramp; press firmly to seat completely. The red indicator will

begin to flash and after a few seconds will light continuously. When the

charge is complete, the red indicator will go off and the green indicator

will come on. The battery pack can now be removed and installed in the

tool.

• Charge battery packs in a well-ventilated area. The charger housing has several ventilation openings.

These must remain open for proper charger operation. Do not obstruct these openings or place

charger on any surface that will block air from flowing through the charger housing. Do not cover the

charger or battery with a cloth or other cover while charging.

• The battery can be left on the charger after full charge has been reached. The battery will continue to

be charged at a low, trickle rate.

• If the CRN38 and battery packs are not going to be used within a week, battery life will be extended by

taking them off the charger. Recharge the battery packs before using again.

• Normal charging time is between 10 and 60 minutes. This will vary depending on the charge that is

needed. If the battery has only been partially discharged, the full 60-minute charge will not be

required.

• It is normal for the charger to hum and become warm to the touch during charging, this does not indicate a problem.

FUNCTION OF CHARGER INDICATORS

• Flashing Red Indicator – when the battery pack is first placed on charger, it is being analyzed before

starting the Rapid Charge mode. Normally the indicator will change to steady red after a few seconds, showing that rapid charging has begun. However, if the indicator continues flashing, the battery

pack may be too hot or may have been over discharged. Battery pack condition will be monitored and

the charger will switch to the Rapid Charge mode when ready. At that time, the steady red indicator

will be seen.

• Steady Red Indicator – the battery pack is in the Rapid Charge mode. Depending on the battery

pack condition, the charge mode will normally last up to one hour.

• Steady Green Indicator – the Rapid Charge mode has ended and the battery pack can be removed

for use in the tool. The battery pack can also be left in the charger and a small Trickle Charge current

will keep the battery pack fully charged.

SHINGLE GUIDE

SHINGLE GUIDE ADJUSTMENT

• Loosen locking screw using the 3mm wrench.

• Slide the guide to set the desired exposure 5" - 6 1/2"

• For longer exposure, remove the guide and reverse it.

• Tighten the locking screw.

IN ADDITION TO THE OTHER WARNINGS CONTAINED IN THIS MANUAL

OBSERVE THE FOLLOWING FOR SAFE OPERATION

• Use the STANLEY-BOSTITCH cordless tool only for the purpose for which it was designed.

• Never use this tool in a manner that could cause a fastener to be directed toward the user or

others in the work area.

• Do not use the tool as a hammer.

• Always carry the tool by the handle.

• Do not alter or modify this tool from the original design or function without approval from

STANLEY-BOSTITCH, INC.

• Always be aware that misuse and improper handling of this tool can cause injury to yourself

and others.

• Never clamp or tape the trigger in an actuated position.

• Never leave a tool unattended with the battery pack attached.

• Do not operate this tool if it does not contain a legible WARNING LABEL.

• Do not continue to use a tool that does not function properly. Notify your nearest StanleyBostitch representative if your tool continues to experience functional problems.

-7-

Page 8

TROUBLE SHOOTING

PROBLEM CAUSE CORRECTION

CHARGER

No lights turn on Not plugged in properly . . . . . . . . . . . . . . . . . . .Plug in the charger

Battery is not fully inserted into charger . . . . . .Make sure battery is pushed all the way into charger

Charger has failed . . . . . . . . . . . . . . . . . . . . . .Replace

Red lights stay flashing Battery is too hot, or cold . . . . . . . . . . . . . . . . .Warm or cool as needed, or allow battery to stay on

charger until temperature normalized

Battery is completely drained . . . . . . . . . . . . . .Leave battery in charger, charger will start when trickle

charge has brought battery voltage up enough to allow

charging to begin

TOOL

Tool won't drive fastener Tool is not being fully pressed to work . . . . . . . .Depress tool fully while driving a nail (tool does not

surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .bump fire)

Fasteners won't feed Fastener coil damaged in canister . . . . . . . . . . .Check if fasteners exit smoothly, if not then replace coil

Tool is not being fully cycled . . . . . . . . . . . . . . .Make sure tool is depressed completely during drive

Fastener is caught in the nose . . . . . . . . . . . . .Open door and clear jam, and straighten any distorted

collation

Feed torsion spring has failed . . . . . . . . . . . . . .Replace spring

Feed delay lever or spring has failed . . . . . . . . .Replace lever or spring (See parts list)

Tool won't turn off Energy management system failed . . . . . . . . . .Service tool, replace energy management system

Tool won't turn on Battery installed incorrectly . . . . . . . . . . . . . . . .Make sure battery is fully inserted onto tool

Battery is completely drained . . . . . . . . . . . . . .Charge battery

Nose switch is out of position . . . . . . . . . . . . . .Service tool, replace wire harness

Trigger or nose switch has failed . . . . . . . . . . . .Service tool, replace wire harness

Energy management system failed . . . . . . . . . .Service tool, replace energy management system

Tool seems slow or Battery is drained . . . . . . . . . . . . . . . . . . . . . . .Charge battery

under powered Driver or driver guide is full of tar . . . . . . . . . . . .Remove nose and driver guide and clean with solvent

O-rings are worn out . . . . . . . . . . . . . . . . . . . . .Replace o-rings

Driver is binding in nose . . . . . . . . . . . . . . . . . .Service tool

Tar build up . . . . . . . . . . . . . . . . . . . . . . . . . . . .Clean nose and driver guide

Battery is too cold . . . . . . . . . . . . . . . . . . . . . . .Warm as needed, or allow battery to stay on

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .charger until temperature is normalized

Battery goes dead Battery has not been charged in a long time . . .Charge battery

quickly Battery charger shuts off early . . . . . . . . . . . . . .Repeat, if problem continues replace charger

Battery won't hold charge . . . . . . . . . . . . . . . . .Replace battery

Tool power setting is too high . . . . . . . . . . . . . .Reduce power until depth of drive is just being achieved

Nail heads are damaged Tool is being pushed down too hard . . . . . . . . .Use light push force to follow the nail in

during drive Tool is being held improperly . . . . . . . . . . . . . . .For best operation hold tool at top of handle, see figure

in operation section

Nails are incompletely Depth of drive setting is inadequate . . . . . . . . .Adjust control for increased energy

driven Tool is being pushed down too hard . . . . . . . . .Use light pressure to follow the nail in

O-rings are worn out . . . . . . . . . . . . . . . . . . . . .Replace o-rings

Driver or guide is full of tar . . . . . . . . . . . . . . . .Remove nose and driver guide and clean with solvent

Nails are being over Depth of drive setting is incorrect . . . . . . . . . . .Adjust for decreased depth of drive

driven Nail is being driven over a void in wood . . . . . . .Drive in different area wood or shingles

Roof shingles are too soft . . . . . . . . . . . . . . . . .Use lowest energy setting and low push force

Nails are going in at an Tool is being pushed down too hard . . . . . . . . .Use light push force to follow the nail in

angle Nose is not appropriately against work . . . . . . .Hold tool perpendicular to work surface or slightly

surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .back from perpendicular

Tool turns on or off Loose or broken nose switch wiring . . . . . . . . . .Service tool, replace switch wire harness assembly

-8-

Page 9

-9-

CLEANING THE CORDLESS NAILER

Do not use gasoline or similar highly flammable liquids to clean

the nailer. Vapor could be ignited by a spark causing an explosion.

For best operation clean system as follows:

Tar and dirt may build up on the nose, driver, and feed system. This

can prevent correct operation. Remove any buildup with kerosene,

#2 fuel oil or diesel fuel. Do not dunk the nailer into these solvents

beyond the height of the nail heads. Dry off the nailer before use.

Any oil film left after cleanup will accelerate the tar buildup, and the

nailer will require more frequent re-cleaning.

NOTE: Solvents sprayed on the nose driver and feed system

may have the opposite effect! The solvent may soften the tar on

the shingles and cause tar buildup to be accelerated. Dry

operation is better, as noted above.

Cleaning of tar from nose assembly and driver

Depress nose release button, and pull nose from tool.

Nose can be wiped down, or immersed in cleaning solvent. Clean the end

of the driver as well as the nose assembly. The driver guide may need

to be removed from the nose in order to clean it properly. Do not immerse

tool in cleaning solvents. Instead, apply a light coat of oil to the nail feed

roller. Tool exterior can be wiped down with cleaning solvents. Once clean

insert nose assembly into tool. Make sure D shaped driver is properly

aligned to nose. Push nose into tool until it locks in place. Review

the nose control switch and verify that it cycles correctly.

MAINTAINING THE CORDLESS TOOL

When working on cordless tools, note the warnings in this manual

and use extra care evaluating problem tools.

Replacing motor brushes:

Remove screws from either side of brush cover and pull brush cover down

to remove it from the motor area of the tool. Remove the brush retaining

springs from the motor. Remove the quick disconnects from the control

module, remove the brush retaining springs, and remove the brushes.

Be careful when removing brush springs as they may fly off and become

lost or stuck in motor.

Installation is the reverse of removal.

REPLACEMENT PARTS:

STANLEY-BOSTITCH replacement parts are recommended. Do not use modified parts or parts which

will not give equivalent performance to the original equipment.

PROCEDURE FOR SEALS:

When repairing a tool, make sure the internal parts are clean and lubricated. Use Parker “O”-LUBE or

equivalent on all o-rings. Coat each o-ring with “O”-LUBE before assembling.

Lubricating the o-rings is recommended on a yearly basis for a normally used tool. Heavy usage may

warrant more frequent greasing intervals. See your authorized Bostitch dealer or service center for

o-ring service information.

clean here

nose release button

Cover removal direction

Page 10

ACCESSORIES AVAILABLE

110679 O-ring lube 1lb. can

851325 Locktite® 271 packet

BP20419 High energy 20.4V nickle cadmium battery pack

BC20419 1 hour fast charger

www.stanleyworks.com

-10-

Loading...

Loading...