Page 1

BEFORE OPERATING THIS COMPRESSOR, THE USER SHOULD STUDY THIS MANUAL TO UNDERSTAND AND

FOLLOW THE SAFETY WARNINGS AND INSTRUCTIONS. KEEP THESE INSTRUCTIONS WITH THE COMPRESSOR

FOR FUTURE REFERENCE. IF YOU HAVE ANY QUESTIONS, CONTACT YOUR BOSTITCH REPRESENTATIVE OR

DISTRIBUTOR.

ANTES DE USAR ESTE COMPRESOR, EL USUARIO DEBE ESTUDIAR ESTE MANUAL PARA ENTENDER Y SEGUIR

LAS ADVERTENCIAS DE SEGURIDAD Y LAS INSTRUCCIONES. CONSERVE ESTAS INSTRUCCIONES CON EL

COMPRESOR PARA REFERENCIA FUTURA. SI TIENE ALGUNA PREGUNTA, DIRÍJASE AL REPRESENTANTE O AL

DISTRIBUIDOR.

AVANT D’UTILISER LE COMPRESSEUR, L’UTILISATEUR DOIT LIRE CE MANUEL AFIN DE COMPRENDRE ET DE

RESPECTER LES AVERTISSEMENTS ET CONSIGNES DE SÉCURITÉ. GARDER CES INSTRUCTIONS AVEC LE

COMPRESSEUR POUR RÉFÉRENCE ULTÉRIEURE. POUR DE PLUS AMPLES INFORMATIONS, COMMUNIQUER

AVEC VOTRE REPRÉSENTANT OU DISTRIBUTEUR BOSTITCH.

158590REVA 6/02

OPERATION and MAINTENANCE MANUAL

MANUAL DE OPERACIÓN Y DE MANTENIMIENTO

MANUEL D’OPÉRATION ET DE MAINTENANCET

D’ENTRETIEN

CAP2045ST-OL

AIR COMPRESSOR

COMPRESOR DE AIRE

COMPRESSEUR D’AIR

Page 2

INTRODUCTION

Congratulations on your purchase of a High Performance BOSTITCH Portable Air Compressor.

This compressor has been designed to provide compressed air to power various pneumatic

tools - including pneumatic fastening tools.

Before assembling, operating or maintaining this air compressor, users must read and

understand the information contained in this owner’s manual. Carefully review the Rules for

Safe Operation section in this owner’s manual and fully understand all warnings.

Danger indicates an imminently hazardous situation which, if not avoided, WILL

result in death or serious injury.

Warnings indicate a potentially hazardous situation which, if not avoided,could

result in death or serious bodily injury.

NOTICE!: Notice indicates important information that if not followed correctly could result in

damage to equipment.

INDEX

Safety Instructions ..........................................................................................................................2

Rules for Safe Operation ..........................................................................................................3, 4

Electrical Grounding Instructions ............................................................................................5, 6

Features...............................................................................................................................................7

Operation Instructions.....................................................................................................................8

General Maintenance .................................................................................................................8, 9

Tr ouble Shooting guide.................................................................................................................10

Warranty ...........................................................................................................................................11

NOTE:

Bostitch compressors have been engineered to provide excellent customer satisfaction and

are designed to achieve maximum performance.

2

Page 3

RULES FOR SAFE OPERATION

Be Educated:

All users must read and fully understand all information contained in this owner’s manual

before assembling, operating, or maintaining this air compressor.

Avoid Moving Parts:

When the compressor is plugged into an electrical source and the pressure switch is in the

ON/AUTO position, this compressor will cycle automatically.

• Never touch any moving parts.

• Keep all body parts, hair, clothing, and jewelry away from moving parts.

• Never operate the air compressor without all guards and shrouds in place.

• Never stand on the compressor.

Attachments and Accessories:

For any attachment or accessory you will be using with this compressor, the maximum

allowable recommended pressure should be clearly marked on the product or should be

clearly noted within the operations manual. Exceeding the pressure rating of these

attachments (including, but not limited to: air tools, air operated accessories, spray guns, air

hose, air hose connections, tires and other inflatables) could cause them to fly apart or

explode and could result in serious injury.

• Never exceed the maximum allowable pressure recommended by the manufacturer of any

attachment or accessory you use with this compressor.

Personal Protection:

The employer and/or user must ensure that proper eye protection is worn. Eye protection

equipment must conform to the requirements of the American National Standards Institute

ANSI Z87.1-1989 and provide both frontal and side protection.

NOTICE!: Non-side shielded spectacles and face shields alone do not provide adequate

protection. Eye protection conforming to ANSI Z87.1-1989 will always be marked “Z87”.

CAUTION: Additional Safety Protection will be required in some environments. For

example, the working area may include exposure to noise level which can lead to hearing

damage. The employer and user must ensure that any necessary hearing protection is

provided and used by the operator and others in the work area. Some environments will

require the use of head protection equipment. When required, the employer and user must

ensure that head protection conforming to ANSI Z89.1-1986.

• Always wear eye protection.

• Wear proper hearing and head protection.

• Compressed air blast must never be aimed at anyone. Compressed air can cause bodily

injury and can propel loose particles and small objects at high speed.

• Keep children away from area of operation.

Transporting:

Use the handle to move the compressor. Do not drag or pull the compressor by the power

cord or air hose. Always disconnect the air compressor before transporting.

3

Page 4

RULES FOR SAFE OPERATION (continued)

Air Tanks:

Due to condensation associated with the process of compressing air, moisture will build up

inside your compressor’s air tank. Drain tanks of moisture daily (See General Maintenance).

Failure to drain moisture from the tanks properly could lead to the formation of rust and

thinning of the steel tank.

WARNING: FAILURE TO REGULARLY DRAIN TANK MAY CAUSE TANK CORROSION AND

RISK OF TANK EXPLOSION, RESULTING IN SERIOUS INJURY. TO AVOID RISK OF TANK

FAILURE DURING USE, DRAIN TANK AFTER EACH USE OR EVERY FOUR HOURS OF

OPERATION TO PREVENT CONDENSATION BUILD-UP AND TANK CORROSION.

WARNING: DO NOT PERFORM WELDING OR REPAIR OPERATIONS ON THE AIR TANK OF

THIS COMPRESSOR. WELDING ON THE AIR COMPRESSOR TANK CAN SEVERELY IMPAIR

TANK STRENGTH AND CAUSE AN EXTREMELY HAZARDOUS CONDITION. WELDING ON

THE TANK IN ANY MANNER WILL VOID THE WARRANTY.

Ventilation:

WARNING: RISK OF FIRE OR EXPLOSION - DO NOT SPRAY FLAMMABLE LIQUID IN A

CONFINED AREA. SPRAY AREA MUST BE WELL VENTILATED. DO NOT SMOKE WHILE

SPRAYING AND DO NOT SPRAY WHERE SPARK OR FLAME IS PRESENT. KEEP

COMPRESSORS AS FAR FROM SPRAYING AREA AS POSSIBLE.

Risk of Burns:

All air compressors generate heat, even operating under normal conditions. Bostitch

compressors have been designed to reduce the risk of burns by limiting access to tubes and

cylinder head parts. In areas where tubes are exposed, a protective sheathing has been

added to the tubes to reduce risk; however, risk of burns does exist.

• To avoid serious burns, never touch the cylinder head parts or tubing during or immediately

after operation.

4

Page 5

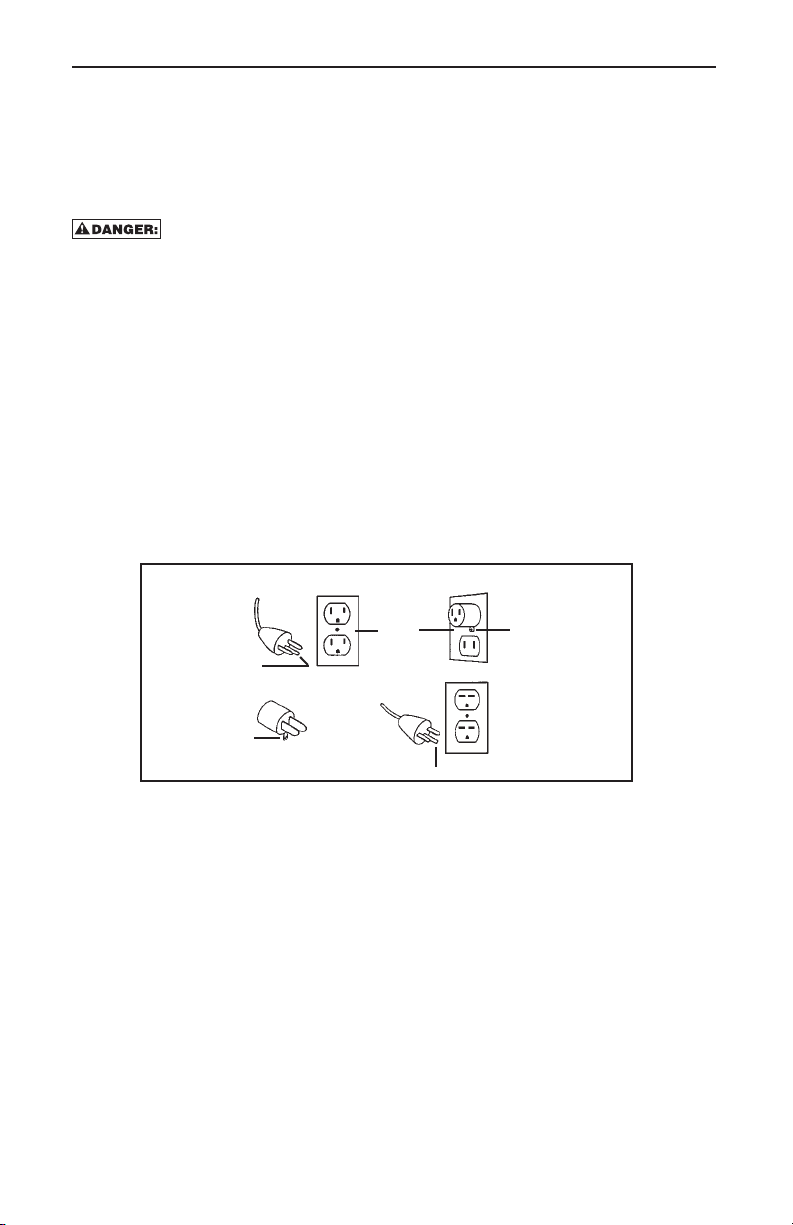

ELECTRICAL GROUNDING INSTRUCTIONS:

This product should be electrically grounded. In the event of an electrical short circuit,

grounding reduces the risk of electrical shock by providing an escape wire for electrical

current. This product is equipped with a cord having a grounding wire with an appropriate

grounding plug. The plug must be plugged into an outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

DANGER: IMPROPER INSTALLATION OF THE GROUNDING PLUG CAN RESULT IN A RISK

OF ELECTRIC SHOCK. If a repair or replacement cord is necessary, do not connect the

grounding wire to either flat blade terminal. Check with a qualified electrician or serviceman,

if the grounding instructions are not completely understood or if there is doubt as to whether

this product is properly grounded. Do not modify the plug provided. If the supplied plug does

not fit the outlet, have the proper outlet installed by a qualified electrician.

This product is shipped for use on a nominal 120-volt circuit, and has a grounding plug that

looks like the plug in sketch A. A temporary adapter that looks like the adapter illustrated in

sketches B and C may be used to connect this plug to a 2-pole receptacle as shown in sketch

B, if a properly grounded outlet is not available. The temporary adapter should be used only

until a properly grounded outlet (sketch A) can be installed by a qualified electrician. The

green colored rigid ear, lug, or like extending from the adapter must be connected to a

permanent ground such as a properly grounded outlet box cover. Whenever the adapter is

used, it must be held in place by a metal screw.

The motor of this compressor has a thermal overload protector in the motor winding. If the

motor should overheat, the overload protector will shut the motor off. When the temperature

returns to normal, the motor will restart automatically.

NOTICE! Do not stop the compressor by pulling out the plug. Use only the Auto/Off switch,

which operates a pressure relief valve on the compressor. If the compressor is plugged in

with the switch in the “Auto” position, the compressor may have trouble restarting against

the high pressure which could cause excessive heat build up and could damage the motor.

Safety Valve:

This compressor is equipped with a safety valve that is set to avoid over-pressurization of the

air tanks. This valve is factory pre-set at 140 PSI and will not function unless tank pressure

reaches this pressure. DO NOT ATTEMPT TO ADJUST OR ELIMINATE THIS SAFETY DEVICE.

ANY ADJUSTMENTS TO THIS VALVE COULD CAUSE SERIOUS INJURY. If this device

requires service or maintenance, see an Authorized BOSTITCH Service Center.

5

Grounding Pin

Metal Screw

Grounding Pin

Grounding Means

Cover of

grounded

outlet box

A

B

C

Page 6

ELECTRICAL GROUNDING INSTRUCTIONS: (continued)

DUTY CYCLE:

To ensure long life of your BOSTITCH air compressor, do not operate on more than a 50% duty

cycle. If this air compressor pumps air more than 50% of one hour, then the compressor’s

capability is less than the air delivery required by the application. Always match the air

volume requirements of the attachment or accessory with the air volume delivery of the

compressor.

Notice!: BOSTITCH does not recommend the use of extension cords with compressors. The

use of an extension cord can result in the loss of voltage supplied to the compressor which

could prevent the compressor from starting. For optimum performance, plug the compressor

directly into an outlet and increase the length of airline as needed.

If an extension cord must be used, use these guidelines:

Distance Needed Recommended Gauge

Less than 25 ft. 12 Gauge

25 - 50 ft. 10 Gauge

Greater than 50 ft. Not Recommended

6

Page 7

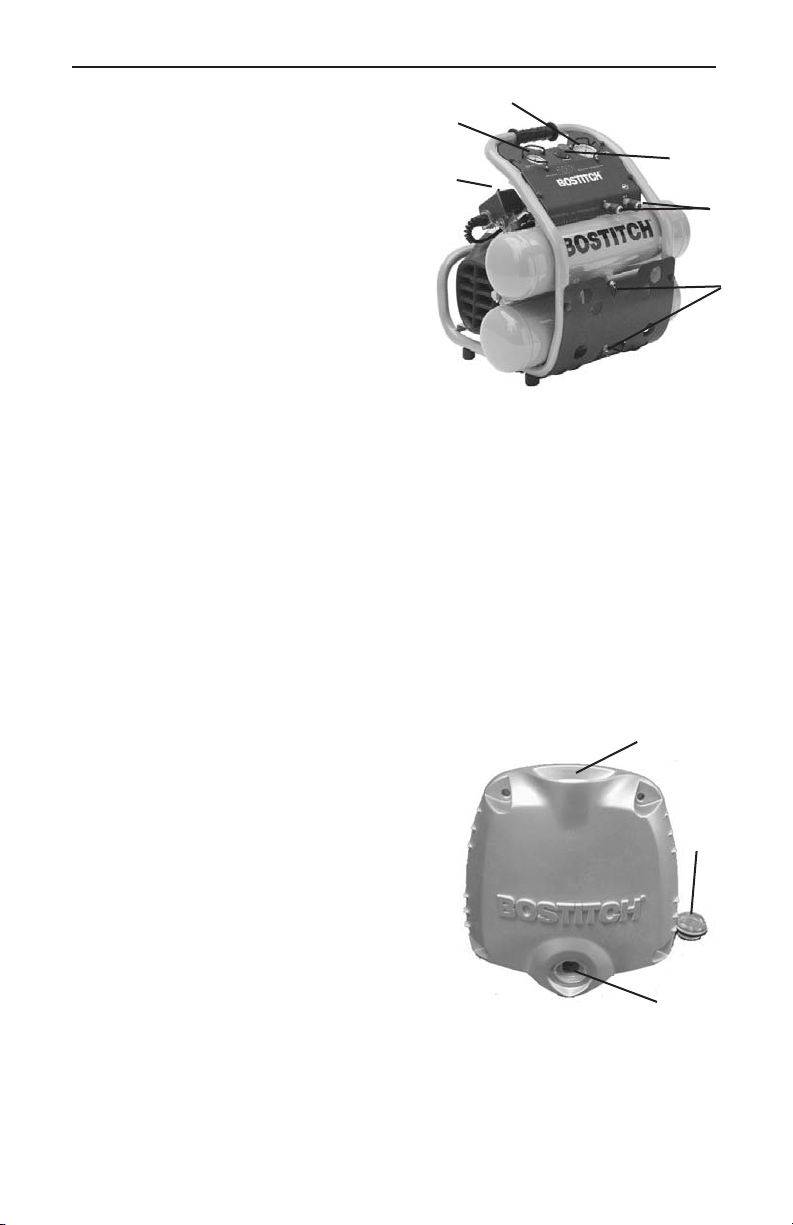

FEATURES OF THE BOSTITCH CAP2045ST-OL

A. Pressure Switch: The pressure switch is

the activation mechanism that is used to start

and stop the compressor. When the switch is

moved to the “AUTO” position, the motor and

pump will compress air until tank pressure

reaches the upper limit of the factory set

operating pressure. When tank pressure falls

below the factory set “cut in” pressure, the

compressor will again automatically start to

compress air.

B. Tank Pressure Gauge: The tank pressure

gauge indicates the air pressure that is

present in the tank in PSI (lbs/sq. in.).

C. Regulated Pressure Gauge: The regulated pressure gauge indicates the amount of

pressure that is allowed into the two discharge lines (E) according to the setting of the

regulator.

D. Regulator Knob: The regulator knob is used to adjust the air pressure that is available at

the two discharge lines. The discharge air pressure is increased by turning the knob

clockwise and decreased by turning the knob counter clockwise.

E. Discharge Lines: This compressor is equipped with two discharge lines. These lines extend

from the control panel as 1/4” female NPT to allow the end user to attach the appropriate size

fitting for the application.

F. Drain Cocks: Pull-style or twist style valves that drain moisture from the tanks when they

are opened.

G. Oil Drain: By removing the sight glass plug, oil can

be drained from the compressor crankcase. The

opening is tapered so that a small receptacle can be

placed under the opening to cleanly catch the oil.

H. Oil Fill: When adding oil to the unit, it is poured into

this opening. The opening is designed to act as a

funnel to make filling easier and cleaner.

I. Sight Glass: This oil drain plug is see-through so that

the user can quickly and easily verify the oil level prior

to operation.

7

A

B

C

D

E

F

G

H

I

Page 8

OPERATION INSTRUCTIONS

Pre-Start Procedures:

1. Inspect the compressor for any damaged components. Do not operate if compressor is

damaged.

2. Check oil level in the compressor pump (See “Checking Oil Level”).

3. Verify that the tanks have been drained and are clear of any moisture or dirt (See

“Draining Tank”).

4. Verify that the air filter is securely in place (See “Air Filter Installation”).

Start-Up Procedures:

1. Verify that the Auto/Off switch is in the Off position.

2. Verify that the tank air pressure is at 0 PSI.

3. Attach the air hose to the discharge line.

4. Plug the unit into a properly grounded outlet.

5. Turn the Auto/Off switch to Auto. The compressor will automatically cycle on and off to

keep the tank pressure maintained .

6. Adjust the pressure regulator to the proper pressure setting required for the air tool.

Shut-Off Procedures:

1. Turn the Auto/Off switch to the Off position.

GENERAL MAINTENANCE

Service and Maintenance:

Prior to performing service and maintenance to the compressor, always disconnect all

accessories and attachments from the unit and disconnect the compressor from the

electrical source. When replacing parts, only use Genuine BOSTITCH replacement parts.

Checking the pump Oil Level - Using the Sight Glass:

1. Verify that the compressor is turned off and on a level surface.

2. Observe the oil level through the clear sight glass that is located at the base

of the crankcase.

3. If oil is visible to the middle of the sight glass, then the oil level is acceptable.

Checking the pump Oil Level - Using the Dipstick:

1. Verify that the compressor is turned off and on a level surface.

2. Remove the dipstick from the oil fill port.

3. Wipe oil off the dipstick.

4. Reinsert dipstick fully into the oil fill port for a few moments.

5. Remove the dipstick and observe the oil level, which should be no

higher than the “MAX” mark and no lower than the “MIN” mark.

8

Page 9

GENERAL MAINTENANCE (continued)

Changing the Oil:

1. Verify the compressor is turned Off.

2. Place a small catch basin under the oil drain port (an 8oz. cup will work fine).

3. Remove the dipstick.

4. Remove the oil drain plug/sight glass.

5. Allow the oil to drain into the catch basin - tilting the compressor toward the

drain plug is beneficial.

6. Insert the oil drain plug/sight glass into the oil drain port.

7. Add 7.5 oz of 30w non detergent oil to the crankcase.

8. Insert dipstick.

Draining Tanks - Pull-Style Drain Cocks:

1. Verify that the compressor is turned Off.

2. Holding the handle, tilt the compressor toward the drain cocks so that they are positioned

at the bottom of the tank.

3. Pull the cord to open the drain valves.

4. Hold until all moisture has been removed.

5. Release when done.

Draining Tanks - Twist-Style Drain Cocks:

1. Verify that the compressor is turned Off.

2. Holding the handle, tilt the compressor toward the drain cocks so that they are positioned

at the bottom of the tank.

3. Turn the drain cocks to open the valve.

4. Keep the compressor tilted until all moisture has been removed.

Air Filter Installation:

1. Remove the plastic plug from the side of the pump head.

2. Remove the air filter from the box.

3. Screw the air filter into the threaded opening on the side of the pump head.

Checking/Cleaning the Air Filter:

WARNING: COOLING FINS, PUMP HEAD, AND SURROUNDING PARTS ARE VERY HOT. DO

NOT TOUCH.

1. Verify that the compressor is turned Off.

2. Remove the cap by turning clockwise.

3. Remove the filter element from the cap.

4. Clean filter pad with soap and water as necessary. If the filter becomes clogged or

damaged, replace it.

WARNING: NEVER CLEAN AIR FILTER WITH A FLAMMABLE LIQUID OR SOLVENT.

EXPLOSIVE VAPORS MAY ACCUMULATE IN THE AIR TANKS AND CAUSE AN EXPLOSION,

RESULTING IN SERIOUS INJURY OR DEATH.

5. Insert filter element into the cap.

6. Place the filter cap onto the filter base and turn counter-clockwise to attach.

ANY OTHER SERVICE SHOULD ONLY BE PERFORMED BY AN AUTHORIZED

BOSTITCH SERVICE CENTER

9

Page 10

TROUBLE SHOOTING GUIDE

NOTE: REMOVE POWER SOURCE AND DRAIN TANK PRESSURE PRIOR TO MAKING ANY REPAIRS OR ADJUSTMENTS.

Problem Probable Cause Correction

Unit will not run Tank pressure exceeds “cut in” pressure Once pressure drops below “cut in” pressure, the unit will start.

Extension cord causing excessive amp draw Check guidelines for proper cord gauge

(use of extension cords is not recommended).

Fuse or circuit tripped Replace fuse or breaker

Unit not turned on or not plugged in Check pressure switch and verify that it is in the Auto position.

Verify that unit is plugged in.

Air filter plug not removed Remove air plug and install Air filter.

Cold weather conditions Place compressor in warmer environment for at least 30 minutes

(typically temperatures below freezing) then try restarting.

Air leaks at fittings Fittings loose Tighten fitting. Check with soapy water. DO NOT OVER TIGHTEN.

Air leak at pressure switch Clogged check valve Remove and clean check valve

Unit will not build pressure Application requires excessive air demand Reduce demand on compressor

Loose head Tighten bolts on head

Blown gasket Remove head and check for

broken or deformed gasket. Replace if needed.

Unit will not build pressure Worn or broken valves Remove head and replace valves.

Air leak at tank or air tank Damaged air tank

welds. WARNING: DO NOT DRILL INTO , WELD OR OTHERWISE MODIFY AIR TANK.

DAMAGED OR MODIFIED TANKS CAN RUPTURE. REPLACE TANK IMMEDIATELY.

10

Page 11

11

LIMITED WARRANTY

Bostitch, Inc., warrants to the original retail purchaser that this product is free from defects in

material and workmanship, and agrees to repair or replace, at Bostitch's option, any defective

product within 1 year from the date of purchase. This warranty is not transferable. It only covers

damage resulting from defects in material or workmanship, and it does not cover conditions or

malfunctions resulting from normal wear, neglect, abuse, accident or repairs attempted or made by

other than our regional repair center or authorized warranty service center.

THIS WARRANTY IS IN LIEU OF ALL OTHER EXPRESS WARRANTIES. ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE IS LIMITED TO THE DURATION OF THIS

WARRANTY. BOSTITCH SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES.

This warranty is limited to sales in the United States and Canada. Some states do not allow

limitations on how long an implied warranty lasts, or the exclusion or limitation of incidental or

consequential damages, so the above limitations or exclusions may not apply to you. This warranty

gives you specific legal rights, and you may also have other rights which vary from state to state.

To obtain warranty service, return the product at your expense together with proof of purchase to a

Bostitch Regional or authorized warranty repair center. You may call us at 1-800-556-6696 for the

location of authorized warranty service centers in your area.

Page 12

INTRODUCCIÓN

Felicitaciones por su compra del compresor de aire portátil BOSTITCH de alto rendimiento. Este

compresor se ha diseñado para dar aire comprimido y operar diversas herramientas neumáticas —

inclusive herramientas neumáticas para instalar clavos, etc.

Antes del ensamblaje, operación o mantenimiento de este compresor de aire, los usuarios deben

leer y entender la información contenida en este manual del propietario. Lea minuciosamente la

sección de reglas para el funcionamiento seguro en este manual del propietario y observe

especialmente todas las advertencias.

Peligro indica una situación peligrosa inminente que, si no se evita, OCASIONARÁ

lesiones graves o fatales.

Las advertencias indican una situación de peligro potencial que, si no se evita,

podría causar la muerte o serias lesiones físicas.

¡AVISO!: El aviso indica información importante que si no se sigue correctamente podría ocasionar

daños al equipo.

ÍNDICE

Instrucciones de seguridad ..................................................................................................................12

Reglas para el funcionamiento seguro ......................................................................................13, 14

Instrucciones para conexión eléctrica a tierra ........................................................................15, 16

Características..........................................................................................................................................17

Instrucciones de uso...............................................................................................................................18

Mantenimiento general.....................................................................................................................18 19

Guía para solucionar problemas..........................................................................................................20

Garantía ......................................................................................................................................................21

NOTA:

Los compresores Bostitch se han diseñado para rendir con un alto grado de satisfacción de los

clientes y lograr un desempeño óptimo.

12

Page 13

REGLAS PARA EL FUNCIONAMIENTO SEGURO

Infórmese:

Antes del ensamblaje, operación o mantenimiento de este compresor de aire, todos los usuarios

deben leer detenidamente toda la información contenida en este manual del propietario.

Evite las piezas en movimiento:

Cuando el compresor esté enchufado en un tomacorriente y el interruptor de presión esté en la

posición encendido/automático (ON/AUTO), el compresor hace sus ciclos automáticamente.

• Nunca toque piezas en movimiento.

• Mantenga todas las partes del cuerpo, cabello, ropa y joyas alejados de las piezas en movimiento.

• Nunca opere el compresor de aire sin tener en su sitio todas las protecciones y resguardos.

• Nunca se ponga de pie sobre el compresor.

Aditamentos y accesorios:

Para todo aditamento o accesorio que vaya a usar con este compresor, la presión recomendada

permisible máxima debe estar marcada claramente en el producto o debe anotarse claramente

dentro del manual de operaciones. Si se excede la presión nominal de estos aditamenteo

(inclusive, entre otros, herramientas neumáticas, accesorios operados con aire, pistolas

rociadoras, mangueras de aire, conexiones de mangueras de aire, neumáticos y otros artículos

inflables) podría ocasionar que se vuelen o exploten causando lesiones graves. • Nunca exceda la

presión permisible máxima recomendada por el fabricante de ningún aditamente o accesorio que

use con este compresor.

Protección personal:

El empleador y/o el usuario deben asegurar que se protejan debidamente los ojos. El equipo de

protección ocular debe estar en conformidad con los requisitos del Instituto Nacional Americano

de Normas (American National Standards Institute), ANSI Z87.1-1989 y proteger por delante y por el

costado.

¡AVISO!: Las gafas o caretas sin protección lateral por sí solas no dan una protección adecuada.

Los protectores oculares en conformidad con la norma ANSI Z87.1-1989 siempre tienen la marca

“Z87”.

En algunos ambientes se necesitará protección adicional de seguridad. Por

ejemplo, el área de trabajo puede exponer a un nivel de ruido que lesione el oído. El empleador y el

usuario deben comprobar que se cuente con la protección necesaria del oído y que el operador y

los demás presentes en el área la usen. Algunos ambientes exigirán el uso de casco protector.

Cuando sea necesario, el empleado y el usuario deben verificar que se proteja la cabeza en

conformidad con la norma ANSI Z89.1 -1986.

• Protéjase siempre los ojos.

• Protéjase correctamente los oídos y la cabeza.

• Nunca debe apuntarse el aire comprimido hacia una persona. El aire comprimido puede

ocasionar lesiones físicas y puede impulsar partículas sueltas y objetos pequeños a alta

velocidad.

• Mantenga a los niños alejados del área de trabajo.

Transporte:

Use el mango para mover el compresor. No arrastre ni tire del compresor por el cable eléctrico ni

la manguera de aire. Desconecte siempre el compresor de aire antes de transportarlo.

13

Page 14

REGLAS PARA EL FUNCIONAMIENTO SEGURO (continuación)

Tanques de aire:

Debido a la condensación relacionada con el proceso de comprimir aire, se acumulará humedad

dentro del tanque de aire del compresor. Drene la humedad de los tanques todos los días

(Consulte la sección Mantenimiento general). Si no se drena la humedad de los tanques

debidamente, podría formarse óxido y adelgazarse el tanque de acero.

SI NO SE DRENA REGULARMENTE EL TANQUE, PUEDE CORROERSE EL TANQUE

A RIESGO DE EXPLOTAR, OCASIONANDO LESIONES GRAVES. PARA EVITAR EL RIESGO DE QUE

FALLE EL TANQUE DURANTE EL USO, DRÉNELO DESPUÉS DE CADA USO O CADA CUATRO HORAS

DE FUNCIONAMIENTO PARA EVITAR QUE SE ACUMULE CONDENSACIÓN Y SE CORROAN LAS

PAREDES DEL MISMO.

NO SUELDE NI REPARE NADA SOBRE EL TANQUE DE AIRE DE ESTE

COMPRESOR. SI SE SUELDA SOBRE EL TANQUE DEL COMPRESOR DE AIRE PUEDE AFECTAR

GRAVEMENTE LA RESISTENCIA DEL TANQUE Y CAUSAR UNA SITUACIÓN SUMAMENTE

PELIGROSA. EL TRABAJO DE SOLDADURA SOBRE EL TANQUE DE CUALQUIER MANERA

ANULARÁ LA GARANTÍA.

Ventilación:

PELIGRO DE INCENDIO O EXPLOSIÓN — NO ROCÍE NINGÚN LÍQUIDO

INFLAMABLA EN UNA ZONA CERRADA. EL ÁREA DE TRABAJO DEBE ESTAR BIEN VENTILADA.

NO FUME MIENTRAS ROCÍA Y NO TRABAJE DONDE HAYA CHISPAS O LLAMAS. MANTENGA

LOS COMPRESORES LO MÁS ALEJADOS DEL ÁREA DE TRABAJO QUE SEA POSIBLE.

Peligro de quemaduras:

Todos los compresores de aire generan calor, aun cuando funcionen bajo condiciones normales.

Los compresores Bostitch se han diseñado para reducir el riesgo de quemaduras al limitar el

acceso a tubos y piezas de cabezales de cilindros. En áreas donde estén expuestos los tubos, se

ha instalado un blindaje protector a los tubos para reducir el riesgo; sin embargo, igualmente existe

la posibilidad de quemadura.

• Para evitar quemaduras graves, nunca toque las piezas de cabezales de cilindros ni tubos

durante el funcionamiento o inmediatamente después.

14

Page 15

INSTRUCCIONES DE CONEXIÓN ELÉCTRICA A TIERRA:

Este producto debe conectarse eléctricamente a tierra. En caso de un cortocircuito eléctrico, la

conexión a tierra reduce el riesgo de choque eléctrico al aportar un alambre de escape para la

corriente eléctrica. Este producto está equipado con un cable que tiene alambre a tierra con un

enchufe a tierra adecuado. Debe usarse el enchufe para conectar a un receptáculo que esté

debidamente instalado y conectado a tierra en conformidad con los códigos y las ordenanzas

locales.

LA INSTALACIÓN INCORRECTA DEL ENCHUFE A TIERRA PUEDE OCASIONAR

PELIGRO DE CHOQUE ELÉCTRICO. Si es necesario reparar o cambiar el cable, no conecte el cable

a tierra con ninguno de las terminales de hoja plana. Confirme con un electricista o técnico de

servicio capacitado si las instrucciones para la conexión a tierra no se entienden claramente o si

le cabe alguna duda en cuanto a que este producto esté debidamente conectado a tierra. No

modifique el enchufe provisto. Si el enchufe provisto no encaja en el receptáculo, pida a un

electricista capacitado que instale un receptáculo adecuado.

Este producto se envía para usarse en un circuito de 120 voltios nominales, y tiene un enchufe a

tierra que se ve como el que aparece en el dibujo A. Puede usarse un adaptador provisorio como

el que se ilustra en los dibujos B y C para conectar este enchufe en un receptáculo bipolar como

se muestra en el dibujo B, si no se cuenta con un receptáculo debidamente conectado a tierra.

Debe usarse el adaptador provisorio solamente hasta que un electricista capacitado pueda instalar

un receptáculo debidamente conectado a tierra (dibujo A). La oreja rígida de color verde o similar

que se extiende desde el adaptador debe conectarse a tierra permanentemente como, por

ejemplo, a la tapa de una caja de receptáculo debidamente conectada a tierra. Siempre que se use

un adaptador, debe sostenerlo en su lugar un tornillo metálico.

El motor de este compresor tiene un protector de sobrecarga térmica en el devanado del motor. Si

el motor se sobrecalentara, el protector de sobrecarga apaga el motor. Cuando la temperatura

vuelve al nivel normal, el motor se pone en marcha automáticamente.

¡AVISO! No detenga el compresor tirando del enchufe. Use solamente el interruptor de apagado

Auto/Off, el cual funciona como válvula de alivio de presión del compresor. Si el compresor está

enchufado con el interruptor en la posición “Auto”, puede tener dificultades para volver a ponerse en

marcha contra la presión alta que podría causar una acumulación de calor excesiva y dañar el motor.

Válvula de seguridad:

Este compresor está equipado con una válvula de seguridad que está fija de tal modo que evite el

exceso de presión en los tanques de aire. Esta válvula está prefijada de fábrica en 140 PSI y no

funciona a menos que la presión del tanque llegue a esta presión. NO INTENTE AJUSTAR NI

ELIMINAR ESTE MECANISMO DE SEGURIDAD. TODO AJUSTE A ESTA VÁLVULA PODRÍA

CAUSAR LESIONES GRAVES. Si el dispositivo necesita servicio o mantenimiento, consulte a un

Centro de Servicio Autorizado de BOSTITCH.

15

Pata a tierra

Tornillo metálico

Pata a tierra

Medio de conexión

a tierra

Tapa de la caja

de receptáculo

conectada a

tierra

A

B

C

Page 16

INSTRUCCIONES DE CONEXIÓN ELÉCTRICA A TIERRA: (continuación)

CICLO DE TRABAJO:

Para asegurar la larga vida útil del compresor de aire BOSTITCH, no lo haga funcionar a más del

50% del ciclo de trabajo. Si este compresor bombea aire más del 50% de una hora, entonces la

capacidad del compresor es menor que la entrega de aire necesaria para la aplicación. Siempre

haga coincidir los requisitos de volumen de aire del aditamento o accesorio con el volumen de aire

que entrega el compresor.

¡Aviso!: BOSTITCH no recomienda el uso de cables de extensión con los compresores. El uso de

un cable de extensión puede ocasionar la pérdida de voltaje suministrado al compresor, lo cual

podría impedir la puesta en marcha del mismo. Para lograr un rendimiento óptimo, enchufe el

compresor directamente en un receptáculo y aumente la longitud de la línea de aire según sea

necesario.

Si debe usar un cable de extensión, use estas directrices:

Distancia necesaria Calibre recomendado

menos de 25 pies Calibre 12

25 — 50 pies Calibre 10

Mayor que 50 pies No se recomienda

16

Page 17

CARACTERÍSTICAS DEL BOSTITCH CAP2045ST-OL

A. Interruptor de presión: El interruptor de

presión es el mecanismo de activación que se

usa para poner en marcha y detener el

compresor. Cuando se mueve el interruptor a la

posición “AUTO”, el motor y la bomba comprime

el aire hasta que la presión del tanque llega al

límite superior de la presión operativa fijada en la

fábrica. Cuando la presión del tanque baja de la

presión de “entrada” fijada en la fábrica, el

compresor nuevamente comienza

automáticamente a comprimir el aire.

B. Medidor de presión del tanque: El medidor de

presión del tanque indica la presión existente en

el tanque en PSI (lbs/pulg. cuad.).

C. Medidor de presión regulada: El medidor de presión regulada indica la cantidad de presión que

se permite entrar a las dos líneas de descarga (E) según la selección del regulador.

D. Perilla del regulador: La perilla de regulador se usa para ajustar la presión de aire que está

disponible en las dos líneas de descarga. La presión de aire de descarga aumenta al girar la

perilla hacia la derecha y disminuye al girarla hacia la izquierda.

E. Líneas de descarga: Este compresor está equipado con dos líneas de descarga. Estas líneas se

extienden desde el panel de control tipo 1/4” hembra NPT para permitir al usuario final conectar el

accesorio del tamaño adecuado para la aplicación.

F. Grifos de drenaje: Válvulas de giro o extracción que drenan la humedad de los tanques cuando

se abren.

G. Drenaje de aceite: Al quitar el tapón de la mirilla, el

aceite puede drenarse del cigüeñal del compresor. La

abertura es aguzada para que pueda colocarse un

recipiente pequeño bajo la abertura para recoger

limpiamente el aceite.

H. Llenado de aceite: Al poner aceite en la unidad, se

vierte dentro de esta abertura. La abertura está diseñada

para actuar como embudo para facilitar un llenado más

limpio.

I. Mirilla: Este tapón de drenaje de aceite es transparente

para que el usuario uede verificar rápida y fácilmente el

nivel de aceite antes del funcionamiento.

17

A

B

C

D

E

F

G

H

I

Page 18

INSTRUCCIONES DE OPERACIÓN

Procedimientos previos a la puesta en marcha:

1. Inspeccione el compresor en busca de componentes dañados. No lo haga funcionar si el

compresor está dañado.

2. Revise el nivel de aceite en la bomba del compresor (Consulte la sección “Verificación del nivel

de aceite”).

3. Revise que los tanques se hayan drenado y que estén despejados de toda humedad y suciedad

(Consulte la sección “Drenaje del tanque”).

4. Compruebe que el filtro de aire esté firme en su sitio (Consulte la sección “Instalación del filtro

de aire”).

Procedimientos de puesta en marcha:

1. Revise que el interruptor de apagado Auto/Off esté en la posición apagada Off.

2. Compruebe que la presión de aire del tanque esté en 0 PSI.

3. Conecte la manguera de aire a la línea de descarga.

4. Enchufe la unidad en un receptáculo debidamente conectado a tierra.

5. Ponga el interruptor Auto/Off en Auto. El compresor pasará automáticamente por sus ciclos de

encendido y apagado para mantener la presión del tanque.

6. Ajuste el regulador de presión a la selección correcta de presión necesaria para la herramienta

neumática.

Procedimientos de apagado:

1. Ponga el interruptor Auto/Off en la posición apagada Off.

MANTENIMIENTO GENERAL

Servicio y mantenimiento:

Antes de dar servicio o mantenimiento al compresor, desconecte siempre todos los accesorios y

aditamentos de la unidad, además desconecte el compresor del tomacorriente. Al cambiar piezas,

solamente use repuestos genuinos BOSTITCH.

Verificación del nivel de aceite de la bomba — Uso de la mirilla:

1. Revise que el compresor esté apagado y sobre una superficie nivelada.

2. Observe el nivel de aceite a través de la mirilla que está en la base

del cigüeñal.

3. Si se ve aceite hasta la mitad de la mirilla, el nivel de aceite es aceptable.

Verificación del nivel de aceite de la bomba — Uso de la varilla medidora:

1. Revise que el compresor esté apagado y sobre una superficie nivelada.

2. Retire la varilla del orificio de llenado de aceite.

3. Limpie el aceite de la varilla.

4. Reinsértela totalmente dentro del orificio de llenado de aceite unos momentos.

5. Retire la varilla y observe el nivel de aceite, el cual no

debe estar más arriba de la marca “MAX” ni más bajo de la marca “MIN”.

18

Page 19

MANTENIMIENTO GENERAL (continuación)

Cambio de aceite:

1. Revise que el compresor esté apagado.

2. Ponga un recipiente pequeño bajo el orificio de drenaje del aceite (una taza común sirve).

3. Quite la varilla.

4. Retire el tapón de drenaje de aceite y mirilla.

5. Deje que el aceite drene dentro del recipiente — inclinando el compresor hacia

el tapón de drenaje para facilitar la tarea.

6. Inserte el tapón de drenaje de aceite y mirilla dentro del orificio de drenaje.

7. Ponga 7.5 oz de aceite no detergente 30w en el cigüeñal.

8. Inserte la varilla medidora.

Drenaje de los tanques — Grifos de drenaje tipo extracción:

1. Revise que el compresor esté apagado.

2. Sosteniendo el mango, incline el compresor hacia los grifos de drenaje de tal modo que queden

en la parte inferior del tanque.

3. Tire de la cuerda para abrir las válvulas de drenaje.

4. Sostenga hasta que se haya eliminado toda la humedad.

5. Suelte cuando termine.

Drenaje de los tanques — Grifos de drenaje tipo giro:

1. Revise que el compresor esté apagado.

2. Sosteniendo el mango, incline el compresor hacia los grifos de drenaje de tal modo que queden

en la parte inferior del tanque.

3. Gire los grifos de drenaje para abrir la válvula.

4. Mantenga el compresor inclinado hasta que se haya eliminado toda la humedad.

Instalación del filtro de aire:

1. Retire el tapón de plástico del costado del cabezal de la bomba.

2. Desmonte el elemento del filtro de aire de la caja.

3. Atornille el filtro de aire dentro de la abertura roscada en el costado del cabezal de la bomba.

Verificación y limpieza del filtro de aire:

LAS ALETAS DE ENFRIAMIENTO, EL CABEZAL DE LA BOMBA Y LAS PIEZAS

CIRCUNDANTES SE CALIENTAN MUCHO. NO LOS TOQUE.

1. Revise que el compresor esté apagado.

2. Retire la tapa girando hacia la derecha.

3. Desmonte el elemento del filtro de la tapa.

4. Limpie la almohadilla del filtro con agua y jabón según se necesite. Si el filtro se obstruye o

se daña, cámbielo.

NUNCA LIMPIE EL FILTRO DE AIRE CON UN LÍQUIDO O SOLVENTE INFLAMABLE.

SE PUEDEN ACUMULAR VAPORES EXPLOSIVOS EN LOS TANQUES DE AIRE Y CAUSAR UNA

EXPLOSIÓN, PRODUCIENDO LESIONES GRAVES O FATALES.

5. Inserte el elemento del filtro en la tapa.

6. Ponga la tapa del filtro en la base del mismo y gire hacia la izquierda para instalarla.

UN CENTRO DE SERVICIO AUTORIZADO DE BOSTITCH DEBE REALIZAR TODO OTRO SERVICIO

19

Page 20

GUÍA PARA SOLUCIONAR PROBLEMAS

NOTA: DESCONECTE DE LA RED ELÉCTRICA Y DRENE LA PRESIÓN DEL TANQUE ANTES DE HACER REPARACIONES O AJUSTES.

Problema Causa probable Corrección

La unidad no funciona La presión del tanque excede la presión de “entrada” La unidad se pone en marcha una vez que baje la presión bajo la presión de “entrada”.

El cable de extensión causa excesivo consumo de amperaje Revise las pautas para ver el calibre correcto del cable

(no se recomienda usar cables de extensión).

Se disparó un fusible o circuito Cambie el fusible o disyuntor

La unidad no está encendida o no está enchufada Revise el interruptor de presión y verifique que esté en la posición Auto.

Compruebe que la unidad esté enchufada.

No se sacó el tapón del filtro de aire Retire el tapón de aire e instale el filtro de aire.

Condiciones climáticas frías Ponga el compresor en un ambiente más cálido al menos 30 minutos

(generalmente temperaturas bajo cero) luego pruebe volver a ponerlo en marcha.

Fugas de aire en los conectores Conectores sueltos Apriete los conectores. Revise con agua jabonosa. NO APRIETE EN EXCESO.

Fuga de aire en el interruptor Válvula de retención obstruida Retire y limpie la válvula de retención

de presión

La unidad no acumula presión La aplicación exige un consumo excesivo de aire Reduzca la demanda del compresor

Cabezal suelto Apriete los pernos del cabezal

Empaquetadura rota Retire el cabezal y revise si la empaquetadura está rota o deformada. Cámbiela si

es necesario.

La unidad no acumula presión Válvulas desgastadas o rotas Retire el cabezal y cambie las válvulas.

Fuga de aire en el tanque o Soldadoras dañadas del tanque de aire

tanque de aire. NO TALADRE, SUELDE NI MODIFIQUE EL TANQUE DE AIRE DE NINGUNA

MANERA. LOS TANQUES DAÑADOS O MODIFICADOS PUEDEN ROMPERSE. CAMBIE EL

TANQUE INMEDIATAMENTE.

20

Page 21

21

GARANTÍA LIMITADA

Bostitch, Inc., garantiza al comprador original al por menor que este producto está exento de

defectos de material y fabricación, además se compromete a reparar o cambiar, a opción de

Bostitch, cualquier producto defectuoso dentro de 1 año de la fecha de compra. Esta garantía no

es transferible. Solamente cubre daños resultantes de defectos en material o fabricación, y no

cubre condiciones o desperfectos resultantes del desgaste normal, negligencia, abuso, accidente o

reparaciones intentadas o efectuadas por terceros ajenos a nuestro centro regional de

reparaciones o al centro de servicio bajo garantía.

ESTA GARANTÍA REEMPLAZA TODAS LAS DEMÁS GARANTÍAS EXPRESAS. TODA GARANTÍA DE

COMERCIABILIDAD O IDONEIDAD PARA UN FIN PARTICULAR SE LIMITA A LA DURACIÓN DE ESTA

GARANTÍA. BOSTITCH NO SERÁ RESPONSABLE DE DAÑOS FORTUITOS O CONSECUENCIALES.

Esta garantía se limita a ventas dentro de los Estados Unidos y Canadá. Algunos estados no

permiten limitaciones a la duración de una garantía implícita ni la exclusión o limitación de daños

fortuitos o consecuenciales, de modo que las limitaciones o exclusiones anteriores pueden no

corresponder a su caso. Esta garantía le concede derechos legales específicos, y usted puede

tener también otros derechos que varían de un estado a otro.

Para obtener servicio bajo la garantía, devuelva el producto con cargo a nosotros junto con su

comprobante de compra dirigido al centro regional o al centro de reparaciones bajo garantía de

Bostitch. Puede llamarnos al 1-800-556-6696 para obtener la dirección de los centros autorizados

de servicio bajo garantía en su área.

Page 22

INTRODUCTION

Nous vous félicitons pour l’achat du compresseur d’air portatif haute performance BOSTITCH.

Ce compresseur a été conçu pour alimenter différents outils pneumatiques — y compris les

outils pneumatiques d’assemblage — en air comprimé.

Avant d’assembler, d’utiliser ou de faire l’entretien de ce compresseur, les utilisateurs doivent

lire et comprendre les renseignements contenus dans le présent manuel du propriétaire. Lire

attentivement la section « Règles pour une utilisation sécuritaire » du manuel puis s’assurer

de bien comprendre tous les avertissements.

Le signe de danger indique une situation dangereuse imminente qui, si elle n’est

pas évitée, causera À COUP SÛR la mort ou des blessures graves.

Les avertissements indiquent une situation potentiellement dangereuse qui, si

elle n’est pas évitée, pourrait causer des blessures graves, voire la mort.

AVIS! : Les avis indiquent des renseignements importants qui doivent être respectés, sinon

l’équipement pourrait être endommagé.

INDEX

Instructions de sécurité ...............................................................................................................22

Règles pour une utilisation sécuritaire ..............................................................................23,24

Instructions pour mise à la terre ..........................................................................................25,26

Caractéristiques..............................................................................................................................27

Instructions d’utilisation................................................................................................................28

Entretien général......................................................................................................................28, 29

Dépannage.......................................................................................................................................30

Garantie.............................................................................................................................................31

REMARQUE :

Les compresseurs Bostitch ont été conçus pour donner une excellente satisfaction à leurs

utilisateurs et donner une performance maximale.

22

Page 23

RÈGLES POUR UNE UTILISATION SÉCURITAIRE

Renseignez-vous :

Tous les utilisateurs doivent lire et bien comprendre l’ensemble des renseignements que

contient le présent manuel avant d’assembler, d’utiliser ou de faire l’entretien du compresseur

d’air.

Évitez les pièces mobiles :

Lorsque le compresseur est raccordé à une source électrique et que l’interrupteur à pression

est à la position ON/AUTO, il commence automatiquement son cycle.

• Ne jamais toucher aux pièces mobiles, quelles qu’elles soient.

• Garder toute partie du corps, cheveux et bijoux loin des pièces mobiles.

• Ne jamais utiliser le compresseur si tous les gardes et carénages ne sont pas en place.

• Ne jamais se tenir debout sur le compresseur.

Embouts et accessoires :

Pour tout embout ou accessoire que vous utiliserez avec ce compresseur, la pression

maximale admissible recommandée devrait être clairement indiquée sur le produit même ou

dans son manuel d’utilisation. Dépasser la pression nominale de ces accessoires (incluant,

entre autres : outils pneumatiques, accessoires à air comprimé, pistolets à peinture, tuyaux à

air, accouplements des tuyaux à air, pneus et autres produits gonflables) pourrait provoquer

un fonctionnement incontrôlé ou une explosion et causer de graves blessures.

• Ne jamais dépasser la pression maximale recommandée par le fabricant de tout embout ou

accessoire que vous utiliserez avec ce compresseur.

Protection personnelle :

L’employeur et/ou l’utilisateur doivent s’assurer qu’une protection des yeux est portée.

L’équipement de protection doit être conforme à la norme ANSI Z87.1-1989 et fournir une

protection frontale et latérale.

AVIS!:Des lunettes sans protection latérale et des masques faciaux ne fournissent pas la

protection nécessaire. Les accessoires de protection des yeux conformes à la norme ANSI

Z87.1-1989 porteront toujours l’inscription « Z87 ».

Des mesures de sécurité supplémentaires

sont requises dans certains

environnements. Par exemple, la zone de travail peut favoriser l’exposition à un niveau de

bruit susceptible d’entraîner une diminution de l’acuité auditive. L’employeur et l’utilisateur

doivent s’assurer qu’une protection de l’ouïe sera utilisée par l’opérateur et les personnes

présentes dans la zone de travail. Certains environnements exigeront l’utilisation d’un

équipement de protection de la tête. Lorsque cela s’avère nécessaire, l’employeur et

l’utilisateur doivent s’assurer que la protection de la tête est conforme à la norme

ANSI Z89.1-1986.

• Toujours utiliser une protection adéquate pour les yeux.

• Porter une protection appropriée des oreilles et de la tête.

• Ne jamais diriger le jet d’air comprimé vers une autre personne. L’air comprimé peut

causer des blessures et projeter des particules lâches et de petits objets à des vitesses

élevées.

• Garder les enfants loin de la zone de travail.

TRANSPORT :

Utiliser la poignée pour déplacer le compresseur. Ne pas traîner ou tirer l’appareil par

son cordon d’alimentation ou son tuyau à air. Toujours débrancher le compresseur avant

son transport.

23

Page 24

RÈGLES POUR UNE UTILISATION SÉCURITAIRE (suite)

Réservoirs d’air :

Étant donné la condensation provoquée par la compression de l’air, il y aura

accumulation d’humidité à l’intérieur du réservoir du compresseur. Évacuer l’humidité

du réservoir sur une base quotidienne (voir la section Entretien général). Le défaut

d’évacuer correctement l’humidité du réservoir pourrait mener à la formation de rouille

et à l’amincissement du réservoir d’acier.

LE DÉFAUT D’EFFECTUER UNE VIDANGE RÉGULIÈRE DU RÉSERVOIR

PEUT CAUSER LA CORROSION DE CE DERNIER ET CONSTITUER UN RISQUE

D’EXPLOSION, LAQUELLE POURRAIT CAUSER DE GRAVES BLESSURES. POUR ÉVITER

LE RISQUE D’UNE DÉFECTUOSITÉ DU RÉSERVOIR PENDANT L’USAGE, LE VIDANGER

APRÈS CHAQUE UTILISATION OU À TOUTES LES QUATRE HEURES AFIN D’ÉVITER

L’ ACCUMULATION DE CONDENSATION ET LA CORROSION.

NE PAS EFFECTUER DE SOUDURE NI DE RÉPARATIONS SUR LE

RÉSERVOIR DE CE COMPRESSEUR. TOUT SOUDAGE SUR LE RÉSERVOIR POURRAIT

L’AFFAIBLIR GRANDEMENT ET REPRÉSENTER UN DANGER EXTRÊME. TOUTE

OPÉRATION DE SOUDURE SUR LE RÉSERVOIR, QUELLE QU’ELLE SOIT, ANNULERA LA

GARANTIE.

Ventilation :

RISQUE DE FEU OU D’EXPLOSION — NE PAS VAPORISER DE LIQUIDE

INFLAMMABLE DANS UN ESPACE CLOS. LA ZONE DE VAPORISATION DOIT ÊTRE BIEN

VENTILÉE. NE PAS FUMER DURANT LA VAPORISATION ET NE PAS VAPORISER LA OÙ

DES ÉTINCELLES OU DES FLAMMES SONT PRÉSENTES. GARDER LE COMPRESSEUR

AUSSI LOIN QUE POSSIBLE DE LA ZONE DE VAPORISATION.

Risque de brûlures :

Tous les compresseurs d’air génèrent de la chaleur, même dans des conditions

d’utilisation normales. Les compresseurs Bostitch ont été conçus pour réduire le risque

de brûlures en limitant l’accès aux tuyaux et aux pièces de la culasse. Dans les endroits

où les tuyaux sont à découvert, une chemise protectrice leur a été ajoutée afin de

réduire les risques de brûlures; ces risques restent toutefois présents.

• Pour éviter les brûlures sérieuses, ne jamais toucher les pièces de la culasse ou les

tuyaux pendant l’utilisation ou immédiatement après celle-ci.

24

Page 25

INSTRUCTIONS DE MISE À LA TERRE :

Ce produit doit être mis à la terre. En cas de court-circuit, la mise à la terre réduit le

risque de choc électrique en donnant au courant électrique un chemin de sortie. Ce

produit est muni d’un cordon d’alimentation avec fil de terre et fiche de mise à la terre

appropriée. Cette fiche doit être insérée dans une prise installée et mise à la terre

conformément à tous les codes et règlements locaux.

UNE MAUVAISE INSTALLATION DE LA FICHE DE MISE À LA TERRE PEUT

REPRÉSENTER UN RISQUE DE CHOC ÉLECTRIQUE. Si la réparation ou le remplacement

du cordon est nécessaire, ne pas raccorder le fil de terre à l’une des bornes à lame

plate. Consulter un électricien ou un technicien qualifié si les instructions de mise à la

terre sont difficiles à comprendre ou s’il y a des doutes quant à la bonne mise à la terre

de ce produit. Ne pas modifier la fiche fournie. Si la fiche fournie n’entre pas dans la

prise de courant, faire remplacer la prise par un électricien qualifié.

Ce produit, tel qu’il est livré, est conçu pour un circuit 120 volts et comporte une fiche de

mise à la terre semblable à celle illustrée à la Figure A. Un adaptateur temporaire (voir

Figures B et C) peut être utilisé pour brancher cette fiche dans une prise à 2 trous

(Figure B) si une prise correctement mise à la terre n’est pas disponible. Cet adaptateur

temporaire ne doit être utilisé qu’en attendant qu’une prise correctement mise à la terre

(Figure A) ne soit installée par un électricien qualifié. L’oreille ou la patte verte qui sort

de l’adaptateur doit être raccordée à une terre permanente, par exemple un couvercle

de boîte électrique correctement mis à la terre. Si l’adaptateur est utilisé, il doit être

maintenu en place par une vis de métal.

Le moteur de ce compresseur est muni d’un dispositif contre les surcharges thermiques,

placé dans l’enroulement du moteur. Si celui-ci surchauffe, le dispositif coupera son

fonctionnement. Une fois la température revenue à la normale, le moteur redémarrera

automatiquement.

AVIS! Ne pas arrêter le compresseur en tirant sur la fiche. U. Si ce dernier est branché

pendant que l’interrupteur est à la position « Auto », il pourrait avoir de la difficulté à

redémarrer contre la pression élevée, ce qui pourrait causer une accumulation

excessive de chaleur et endommager le moteur.

Soupape de sûreté :

Ce compresseur est pourvu d’une soupape de sûreté réglée de façon à prévenir toute

surpression des réservoirs d’air. La soupape est préréglée en usine à 140 lb/po et ne

s’activera pas tant que la pression du réservoir n’atteindra pas ce seuil. NE PAS

ESSAYER DE RÉGLER NI D’ÉLIMINER CE DISPOSITIF DE SÉCURITÉ. TOUT AJUSTEMENT

DE CETTE SOUPAPE PEUT CAUSER DE GRAVES BLESSURES. Si ce dispositif requiert de

l’entretien ou une réparation, consulter un Centre de service BOSTITCH autorisé.

25

Branche de

mise à la terre

Vis métallique

Branche de mise à la terre

Pièces pour mise

à la terre

Face de la

prise mise

à la terre

A

B

C

Page 26

INSTRUCTIONS DE MISE À LA TERRE : (suite)

CYCLE DE SERVICE :

Afin d’assurer la longue durée de vie de votre compresseur d’air BOSTITCH, éviter de

l’utiliser à un cycle de service dépassant 50 %. Si le compresseur pompe de l’air durant

plus de 50 % d’une heure, sa capacité devient alors inférieure à la quantité d’air requise

par l’ouvrage en cours. Toujours faire correspondre les exigences de l’embout ou de

l’accessoire avec la capacité de sortie d’air du compresseur.

Avis! : BOSTITCH déconseille l’utilisation de rallonges avec un compresseur. La rallonge

peut créer une perte de tension fournie au compresseur, ce qui pourrait l’empêcher de

démarrer. Pour une performance optimale, brancher le compresseur directement dans

une prise de courant et augmenter la longueur du tuyau d’air au besoin.

Si une rallonge doit être utilisée, consulter le tableau suivant en guise de référence :

Distance requise Calibre recommandé

Moins de 25 pi Calibre 12

25 - 50 pi Calibre 10

Plus de 50 pi Non recommandé

26

Page 27

CARACTÉRISTIQUES DU BOSTITCH CAP2045ST-OL

A. Interrupteur à pression : L’interrupteur à

pression est le mécanisme d’activation

utilisé pour démarrer et arrêter le

compresseur. Lorsque l’interrupteur est

placé à la position « AUTO », le moteur et

la pompe compriment de l’air jusqu’à ce que

la pression du réservoir atteigne la limite

supérieure de la pression de

fonctionnement réglée en usine. Lorsque la

pression tombe sous le point

d’enclenchement, le compresseur se remet

automatiquement à comprimer l’air.

B. Manomètre du réservoir : Le manomètre

du réservoir indique la pression de l’air

présent dans le réservoir, en PSI (lb/po).

C. Manomètre — pression régulée : Le manomètre (pression régulée) indique la

quantité de pression permise dans les deux conduites de sortie (E), selon l’ajustement du

régulateur.

D. Bouton du régulateur : Le bouton du régulateur sert à régler la pression d’air

disponible aux deux conduites de sortie. On augmente la pression de sortie en faisant

tourner le bouton dans le sens horaire; on tourne le bouton dans le sens antihoraire pour

la diminuer.

E. Conduites de sortie : Ce compresseur est pourvu de deux conduites de sortie. Ces

conduites sortent du panneau de commande et comportent un filetage femelle 1/4 po

NPT, permettant à l’utilisateur d’y fixer le raccord approprié pour l’application.

F. Robinets de vidange : Ces robinets qu’on tourne

ou sur lesquels on tire permettent, à leur ouverture,

d’évacuer l’humidité des réservoirs.

G. Trou de vidange d’huile : Si on enlève le bouchon

du hublot de regard, l’huile peut être vidée du carter

du compresseur. L’ouverture est conique, permettant

ainsi de placer un petit réceptacle sous l’ouverture

pour amasser l’huile proprement.

H. Orifice de remplissage d’huile : Ajouter de l’huile

à l’appareil par cette ouverture. Elle a été conçue

en forme d’entonnoir afin de faciliter et d’accélérer

le remplissage.

I. Hublot de regard : Ce bouchon de remplissage d’huile est transparent; on peut donc

vérifier facilement et rapidement le niveau d’huile avant l’utilisation.

27

A

B

C

D

E

F

G

H

I

Page 28

INSTRUCTIONS D’UTILISATION

Procédure avant le démarrage :

1. Inspecter le compresseur afin de déceler toute composante endommagée. Ne pas

utiliser le compresseur s’il est endommagé.

2. Vérifier le niveau d’huile dans la pompe du compresseur (voir la section « Vérification

du niveau d’huile »).

3. Vérifier que les réservoirs ont été vidangés et sont exempts de toute saleté ou

humidité (voir « Vidange du réservoir »).

4. S’assurer que le filtre à air est bien fixé en place (voir « Pose du filtre à air »).

Procédure de démarrage :

1. Vérifier que l’interrupteur Auto/Off est à la position Off.

2. S’assurer que la pression du réservoir est à 0 lb/po.

3. Fixer le tuyau d’air à la conduite de sortie.

4. Brancher l’appareil dans une prise correctement mise à la terre.

5. Placer l’interrupteur Auto/Off à la position Auto. Le compresseur démarrera et

s’arrêtera automatiquemen pour maintenir la pression du réservoir.

6. Ajuster le régulateur de pression à la valeur appropriée pour l’outil pneumatique.

Procédure de fermeture :

1. Placer l’interrupteur Auto/Off à la position Off.

ENTRETIEN GÉNÉRAL

Réparation et entretien :

Avant d’effectuer toute réparation ou opération d’entretien sur le compresseur, toujours

débrancher tous les embouts et accessoires de l’appareil et débrancher celui-ci de la

source électrique. Au moment de remplacer des pièces, n’utiliser que les pièces

originales de rechange BOSTITCH.

Vérifier le niveau d’huile de la pompe — Utilisation du hublot de regard :

1. Vérifier que le compresseur est éteint et repose sur une surface plate.

2. Observer le niveau d’huile à travers le hublot de regard, situé à la base

du carter.

3. Si l’huile est visible au milieu du hublot, son niveau est acceptable.

Vérification du niveau d’huile de la pompe — Utilisation de la jauge graduée :

1. Vérifier que le compresseur est éteint et repose sur une surface plate.

2. Retirer la jauge graduée de l’orifice de remplissage d’huile.

3. Essuyer l’huile de la jauge.

4. Réinsérer la jauge complètement dans l’orifice pendant quelques instants.

5. Retirer la jauge puis observer le niveau d’huile; il ne devrait pas être plus haut

que l’indication « MAX » et pas plus bas que « MIN ».

28

Page 29

ENTRETIEN GÉNÉRAL (suite)

Vidange de l’huile :

1. S’assurer que le compresseur est éteint (Off).

2. Placer un petit récipient collecteur sous l’orifice de remplissage d’huile (une tasse de

8 oz fera l’affaire).

3. Retirer la jauge graduée.

4. Retirer le hublot de regard/bouchon de remplissage d’huile.

5. Laisser l’huile s’écouler dans le récipient; incliner le compresseur vers le

bouchon de remplissage est recommandé.

6. Insérer le hublot de regard/bouchon de remplissage dans l’orifice.

7. Ajouter 7,5 oz d’huile non-détergente dans le carter.

8. Insérer la jauge graduée.

Vidange des réservoirs — Robinets de vidange à traction :

1. Vérifier que le compresseur est éteint (Off).

2. Tout en tenant la poignée, incliner le compresseur vers les robinets de vidange de

façon qu’ils soient placés au fond du réservoir.

3. Tirer sur la corde pour ouvrir les vannes de purge.

4. Maintenir la position jusqu’à ce que toute l’humidité soit évacuée.

5. Relâcher une fois l’opération terminée.

Vidange des réservoirs — Robinets de vidange rotatifs :

1. Vérifier que le compresseur est éteint (Off).

2. Tout en tenant la poignée, incliner le compresseur vers les robinets de vidange de

façon qu’ils soient placés au fond du réservoir.

3. Tourner les robinets pour ouvrir la vanne.

4. Garder le compresseur incliné jusqu’à ce que toute l’humidité soit évacuée.

Pose du filtre à air :

1. Retirer le bouchon de plastique du côté de la tête de la pompe.

2. Retirer le filtre à air de la boîte.

3. Enfiler le filtre dans l’ouverture filetée sur le côté de la tête de la pompe.

Vérification/nettoyage du filtre à air :

LES AILETTES DE REFROIDISSEMENT, LA TÊTE DE LA POMPE ET LES

PIÈCES VOISINES SONT TRÈS CHAUDES. NE PAS LES TOUCHER.

1. Vérifier que le compresseur est éteint (Off).

2. Retirer le capuchon en le faisant tourner dans le sens des aiguilles d’une montre.

3. Enlever l’élément filtrant du capuchon.

4. Nettoyer le tampon filtrant à l’eau savonneuse, au besoin. Si le filtre est obstrué

ou endommagé, le remplacer.

NE JAMAIS UTILISER DE LIQUIDES OU DE SOLVANTS INFLAMMABLES

POUR NETTOYER LE FILTRE À AIR. DES VAPEURS EXPLOSIVES POURRAIENT

S’ACCUMULER DANS LES RÉSERVOIRS ET PROVOQUER UNE EXPLOSION, LAQUELLE

POURRAIT CAUSER DES BLESSURES SÉRIEUSES VOIRE LA MORT.

5. Insérer l’élément filtrant dans le capuchon.

6. Placer le capuchon du filtre dans sa base puis tourner dans le sens contraire des

aiguilles d’une montre pour fixer en place.

TOUTE AUTRE OPÉRATION D’ENTRETIEN NE DOIT ÊTRE EFFECTUÉE QUE PAR UN

CENTRE DE SERVICE AUTORISÉ BOSTITCH

29

Page 30

GUIDE DE DÉPANNAGE

REMARQUE : COUPER LA SOURCE D’ALIMENTATION ET VIDANGER LE RÉSERVOIR AVANT D’EFFECTUER TOUT RÉGLAGE OU RÉPARATION.

Problème Cause probable Solution

L’appareil refuse de fonctionner La pression du réservoir dépasse le niveau d’enclenchement Une fois la pression descendue sous ce niveau, l’appareil se mettra en marche.

La rallonge cause un appel de courant excessif Vérifier les recommandations pour un calibre approprié de la rallonge

(l’utilisation de rallonges n’est pas recommandée).

Fusible grillé ou disjoncteur déclenché Remplacer le fusible ou réarmer le disjoncteur

L’appareil n’est pas sous tension ou en marche Vérifier l’interrupteur à pression et s’assurer qu’il est à la position Auto.

S’assurer que l’appareil est branché.

Bouchon du filtre à air toujours en place Retirer le bouchon et installer le filtre à air.

Température froide Placer le compresseur dans un environnement plus chaud durant au moins 30 minutes,

(généralement sous le point de congélation) puis redémarrer.

Fuites d’air aux raccords Raccords desserrés Serrer les raccords. Vérifier avec de l’eau savonneuse. NE PAS TROP SERRER.

Fuite d’air à l’interrupteur sous pression Clapet anti-retour obstrué Retirer le clapet et le nettoyer

L’appareil n’accumule aucune pression L’application exige une demande en air excessive Réduire la demande sur le compresseur

Tête desserrée Serrer les boulons de la tête

Joint statique défectueux Retirer la tête puis vérifier

si le joint est défectueux ou déformé. Remplacer au besoin.

L’appareil n’accumule aucune pression Vannes usées ou défectueuses Retirer la tête puis remplacer les vannes.

Fuite d’air au réservoir ou aux Réservoir d’air endommagé

soudures du réservoir. NE PAS PERCER, SOUDER NI MODIFIER LE RÉSERVOIR DE QUELQUE FAÇON

QUE CE SOIT. DES RÉSERVOIRS ENDOMMAGÉS OU MODIFIÉS PEUVENT SE ROMPRE.

REMPLACER IMMÉDIATEMENT LE RÉSERVOIR.

30

Page 31

31

GARANTIE LIMITÉE

Bostitch, Inc. garantit à l’utilisateur final que ce produit est exempt de tout défaut de matériaux et

de fabrication, et accepte le cas échéant de réparer ou remplacer, à la discrétion de Bostitch, tout

produit défectueux pendant une période de 1 an à partir de la date d’achat. Cette garantie n’est pas

transférable. Elle couvre uniquement les dommages résultant de défaut de matériaux et de

fabrication, et ne couvre pas les conditions ou défauts de fonctionnement résultant d’une usure

normale, d’une négligence, d’un abus d’usage, d’un accident ou de tentatives de réparation par une

entité autre que notre Centre de réparation local ou un Centre de service de garantie autorisé.

CETTE GARANTIE REMPLACE TOUTE AUTRE GARANTIE EXPRESSE. TOUTE GARANTIE DE VALEUR

MARCHANDE, DE QUALITÉ SATISFAISANTE, OU D’ADÉQUATION À UN USAGE PARTICULIER SE LIMITE

À LA DURÉE DE CETTE GARANTIE EXPRESSE. BOSTITCH NE SERA PAS TENUE RESPONSABLE DES

DOMMAGES INDIRECTS OU ACCESSOIRES.

Cette garantie se limite aux ventes effectuées aux États-Unis et au Canada. Les limitations imposées

par la durée d’une garantie implicite, ou l’exclusion des dommages occasionnels ou indirects n’étant

pas reconnue dans certains États, les limitations ou exclusions précitées peuvent ne pas vous être

adressées. La présente garantie vous donne des droits légaux spécifiques en complément des droits

particuliers dont vous pouvez bénéficier et qui varient d’un état à l’autre.

Pour obtenir des services liés à la garantie, retournez le produit à vos frais accompagné de la

preuve d’achat à votre Centre de réparation local ou à un Centre de service de garantie autorisé.

Pour obtenir l’adresse d’un Centre de service de garantie autorisé dans votre localité, composez le

1-800-556-6696.

Page 32

32

Loading...

Loading...