Page 1

70101339 13/06

BOSTITCH AIR TOOL SYSTEMS

BEFORE OPERATING THIS TOOL, ALL OPERATORS SHOULD STUDY THIS

MANUAL TO UNDERSTAND AND FOLLOW THE SAFETY WARNINGS AND

INSTRUCTIONS. KEEP THESE INSTRUCTIONS WITH THE TOOL FOR FUTURE

REFERENCE. IF YOU HAVE ANY QUESTIONS, CONTACT YOUR STANLEYBOSTITCH REPRESENTATIVE OR DISTRIBUTOR.

ANTES DE OPERAR ESTA HERRAMIENTA, TODOS LOS OPERADORES

DEBERÁN ESTUDIAR ESTE MANUAL PARA PODER COMPRENDER Y

SEGUIR LAS ADVERTENCIAS SOBRE SEGURIDAD Y LAS INSTRUCCIONES.

MANTENGA ESTAS INSTRUCCIONES CON LA HERRAMIENTA PARA

FUTURA REFERENCIA, SI TIENE ALGUNA DUDA, COMUNÍQUESE CON SU

REPRESENTANTE DE STANLEY-BOSTITCH O CON SU DISTRIBUIDOR.

LIRE ATTENTIVEMENT LE PRÉSENT MANUEL AVANT D’UTILISER L’APPAREIL.

PRÉTER UNE ATTENTION TOUTE PARTICULIÈRE AUX CONSIGNES DE

SÉCURITÉ ET AUX AVERTISSEMENTS. GARDER CE MANUEL AVEC L’OUTIL

POUR FUTUR RÉFÉRENCE. SI VOUS AVEZ DES QUESTIONS, CONTACTEZ

VOTRE REPRÉSENTANT OU VOTRE CONCESSIONNAIRE STANLEY-BOSTITCH.

OPERATION AND MAINTENANCE MANUAL

MANUAL DE OPERACIÓN Y DE MANTENIMIENTO

MANUEL D’INSTRUCTIONS ET D’ENTRETIEN

BTMT72393

GRAVITY FEED HVLP SPRAY GUN

PISTOLA ASPERSORA DE ALIMENTACIÓN POR

GRAVEDAD DE ALTO VOLUMEN Y BAJA PRESIÓN (HVLP)

PISTOLET HVP À GRAVITATION

Page 2

INTRODUCTION

• Fastworking speed and wide fan pattern.

• High transfer efcency means reduced spray mist.

• Stainless steel needle and uid tip allow use with Water borne materials.

• Maximum Operating Pressure: 50 psi

• High efciency design signicantly reduces operating costs.

INDEX

3 Year Limited Warranty .............................................................2

Tool Components, Tool Specications......................................3

Important Safety Instructions ................................................... 4

Warning ...................................................................................... 5

Installation .................................................................................. 6

Operation ....................................................................................7

Maintenance ...............................................................................8

Trouble Shooting Guide ............................................................ 9-10

IMPORTANT

Please make certain that person who is to use this equipment carefully reads and understands these

instructions before operating.

3 YEAR LIMITED WARRANTY — U.S. and Canada Only

Stanley warrants this product to the original purchaser for a period of

THREE (3) YEARS

against

deciencies in material and workmanship.

This LIMITED WARRANTY

does not cover products that are

improperly used, abused, altered or repaired. Decient products will be replaced or repaired at Stanley's

option. Please call 1-800-505-4648 for more information or return instructions.

THIS LIMITED WARRANTY IS GIVEN IN LIEU OF ALL OTHERS INCLUDING THE IMPLIED WARRANTY OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE AND EXCLUDES ALL INCIDENTAL OR

CONSEQUENTIAL DAMAGES.

Some states do not allow limitations on how long an implied warranty

lasts or the exclusion or limitation of incidental or consequential damages, so these limitations may not

apply to you. This

LIMITED WARRANTY

gives you specic legal rights that may vary from state to state.

SAFETY GUIDELINES - DEFINITIONS

This manual contains information that is important for you to know and understand. This information

relates to protecting

YOUR SAFETY

and

PREVENTING EQUIPMENT PROBLEMS

. To help you recognize this

information, we use the symbols below. Please read the manual and pay attention to these sections.

SAFETY

and

PREVENTING EQUIPMENT PROBLEMS

.To help you recognize this information, we

use the symbols below. Please read the manual and pay attention to these sections.

Indicates an imminently

hazardous situation which,

if not avoided,

will

result in

death or serious

injury

.

Indicates a potentially

hazardous situation which,

if not avoided,

may

result in

minor or

moderate injury

.

Indicates a potentially

hazardous situation which,

if not avoided,

could

result in

death or serious injury

.

Used without the

safety alert symbol indicates a

potentially hazardous situation which,

if not avoided,

may

result in

property damage

.

- 2 -

Page 3

- 3 -

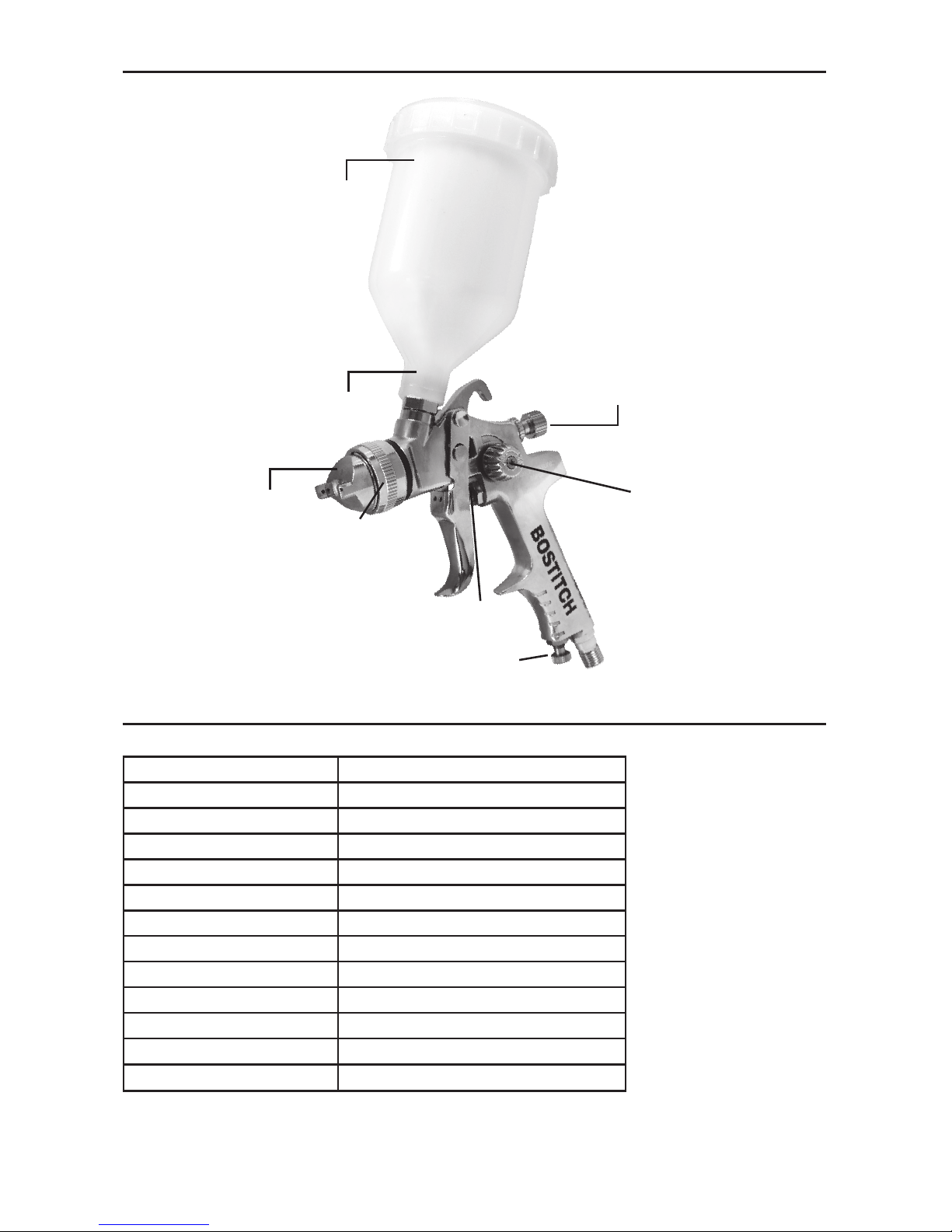

FIG.1

TOOL COMPONENTS

BTMT72393

Description

Gravity Feed Hvlp Spray Gun

Average Air Consumption

5.6CFM 100% Usage

Fluid output

170cc/min

Air Inlet

1/4" NPS (F)

Weight

0.7095KG (1.56lbs)

Min. Hose Size

3/8" ID

Required PSI

30-50 psi

Fluid inlet

3/8" NPS

Inlet Air Pressure

50 psi

Pattern Width

> 180mm

Nozzle Tip

1.5mm

Air connection

1/4'NPT (M)

Air Valve Nut

Fluid Control

Knob

Air Volume Control

Knob

Spray Pattern

Adjustment

Non-Drip Cup

TOOL SPECIFICATIONS

All dimensions in inches unless otherwise specified.

Material Filter

Horns

Air Cap

Page 4

- 4 -

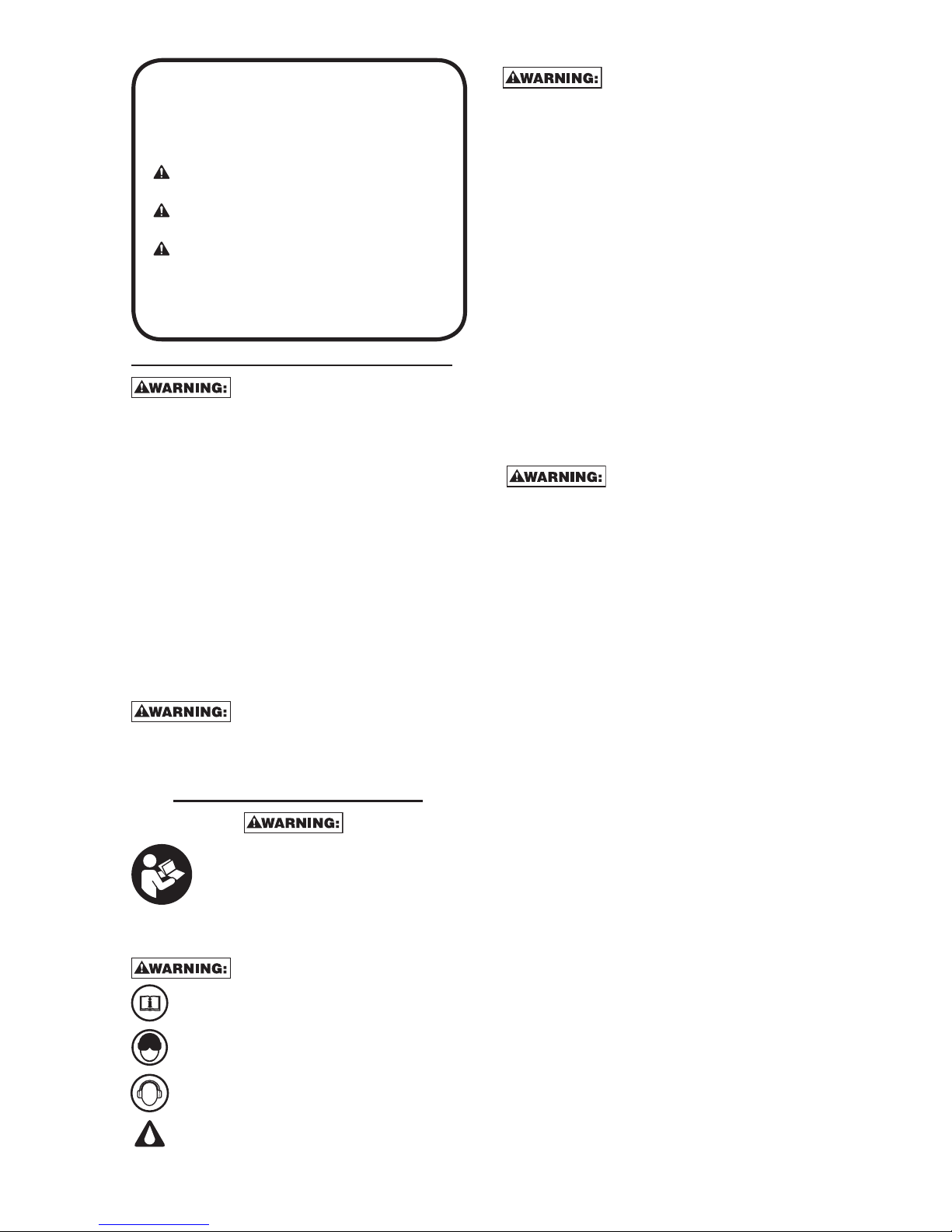

Definitions: Safety Guidelines

The definitions below describe the level of severity

for each signal word. Please read the manual and pay

attention to these symbols.

DANGER: Indicates an imminently hazardous

situation which, if not avoided, will result in death or

serious injury.

WARNING: Indicates a potentially hazardous

situation which, if not avoided, could result in death

or serious injury.

CAUTION: Indicates a potentially hazardous

situation which, if not avoided, may result in minor

or moderate injury.

CAUTION: Used without the safety alert symbol indi-

cates a potentially hazardous situation which, if not

avoided, may result in property damage.

IMPORTANT SAFETY INSTRUCTIONS

Some dust created by power

sanding, sawing, grinding, drilling,

and other construction activities contains chemicals

known to the State of California to cause cancer,

birth defects or other reproductive harm. Some

example of these chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks and cement

and other masonry products

• Arsenic and chromium from chemically-treated

lumber

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment,

al ways wear

OSHA/MSHA/NIOSH

approved,

properly fit ting face mask or res pi ra tor when us ing

such tools.When using air tools, basic safety precautions should always be followed to reduce the risk of

personal injury.

This product contains chemicals,

known to the State of California to cause cancer,

and birth defects or other reproductive harm. Wash

hands after handling.

SAVE THESE INSTRUCTIONS

Improper operation or maintenance of

this product could result in serious injury

and property damage. Read and

understand all warnings and operating

instructions before using this equipment.

When using air tools, basic safety precautions

should always be followed to reduce the risk of

personal injury.

Read and understand this instruction manual

and tool labels before installing, operating or

servicing this tool. Keep these instructions in

a safe accessible place.

Operators and others in work area must wear

ANSI Z87.1 CAN/CSA Z94.3 approved safety

glasses with side shields.

Operators and others in work area must wear

ear protection.

Oil daily for optimal performance.

• All persons in the work area must always

wear approved eye and hearing protection

and approved respiratory protection when this

spray gun is in operation.

• Never aim spray gun at anyone. Do not spray

near sparks, open flame, lit cigarettes, pilot

lights, space heaters or any other potential

ignition source, DO NOT SMOKE IN WORK

AREA.

• Only persons well acquainted with these rules

of safe operation should be allowed to use the

air tool .

• Follow manufacturers instructions and safety

information to ensure safe handling and proper

use of paints, laquers, thinners, base coats, etc.

Do not use latex or other heavy paints. They are

not recommended for this spray gun.

• Always keep work area free from obstructions

and well ventiilated.

• Always disconnect spray gun from air source

before disassembly.

• To avoid creating an explosive atmosphere,

work only in well ventilated areas.

• Always use respiratory protection to prevent

inhalation of harmful fumes and materials.

• Before disassembly or removal of any part of

gun or attached components, shut off

compressor, release pressure by depressing

trigger, and disconnect power source. NEVER

assume system pressure is zero!

Page 5

- 5 -

RISK OF EXPLOSION OR FIRE

WHAT CAN HAPPEN HOW TO PREVENT IT

• When paints or

materials are

sprayed, they are

broken into very

small particles and

mi xed with air. This

will cause certain

paints and

materials to

become extremely

flammable and

could result in

serious

injury or death.

• Never spray near

open flames or pilot

lights in stoves or

heaters.

• Never smoke while

spraying.

• Provide ample

ventilation when

spraying indoors.

• 1,1,1-Trichloroethane

and Methylene

Chloride can

chemically react

with the aluminum

used in most spray

equipment, and

this gun and cup,

to produce an

explosion hazard

and could result

in serous injury or

death.

• Read the label or

data sheet for the

material you intend

to spray.

• Never use any type

of spray coating

material containing

these solvents.

• Never use these

solvents for

equipment cleaning

or flushing.

• If in doubt as to

whether a material

is compatible,

contact your

material supplier.

RISK TO BREATHING

(ASPHYXIATION)

WHAT CAN HAPPEN HOW TO PREVENT IT

• Some paints,

coatings and

solvents may cause

lung damage, and

burns if inhaled or

allowed to come

into contact with

skin or eyes.

• Use a NIOSH

approved mask

or respirator and

protective clothing designed for

use with your

specific application

and spray materials. Some masks

provide only limited

protection against

toxic materials and

harmful paint solvent. Consult with

a Safety Expert or

Industrial Hygienist

if uncertain about

your equipment or

materials.

RISK OF CUT OR BURNS

WHAT CAN HAPPEN HOW TO PREVENT IT

• Spray guns

operate at

pressures and

velocities high

enough to

penetrate human

and animal flesh,

which could result

in amputation or

other serious injury.

! See a physician

immediately !

• Never place hands

in front of nozzle.

• Direct spray away

from self and

others.

• Seek immediate

medical attention if

direct spray

contacts

exposed body

parts.

RISK FROM FLYING OBJECTS

WHAT CAN HAPPEN HOW TO PREVENT IT

• Certain parts are

under pressure

whenever the gun

is connected to

a pressurized air

line. These parts

may be propelled

if the gun is disassembled.

• Disconnect the

gun from the air

line, or completely

depressurize the

air line whenever

the gun is to

be disassembled.

• Compressed air

may propel dirt,

metal shavings,

etc. and possibly

cause an injury.

• Never point any

nozzle or sprayer

toward a person or

part of the body.

• Always wear ANSI

Z87.1 CAN/CSA

Z94.3 approved

safety glasses with

side shields.

• Prolonged exposure to air spray

can result in

permanent damage to hearing.

• Always wear hearing protection

when operating

spray equipment.

Page 6

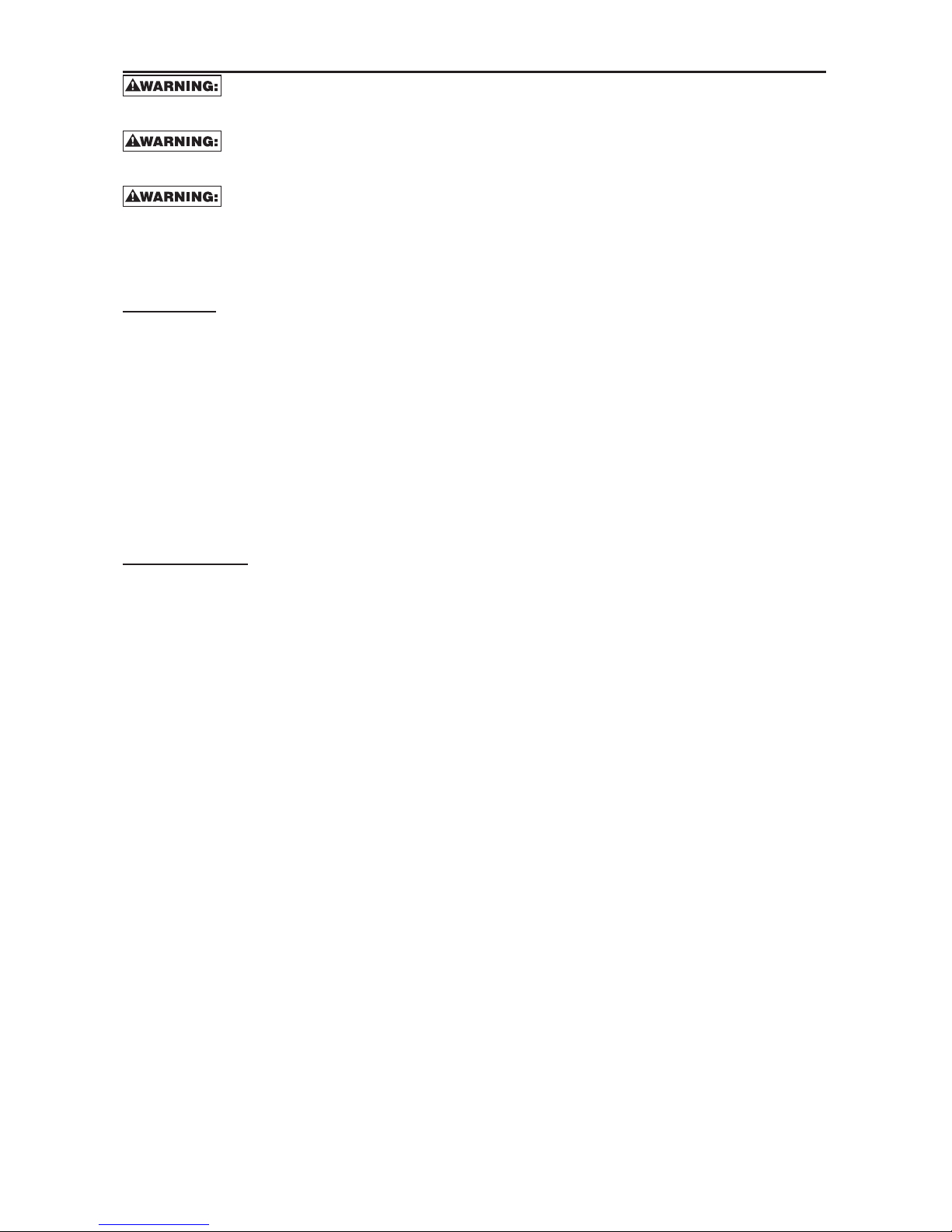

INSTALLATION

AIR SUPPLY

The recommended hook-up is shown in

Figure A.

Pneumatic tools operate on a wide range of air

pressures. For maximum efficiency and longer tool life, the pressure of the air supplied to these tools

MUST

not

exceed the rated PSI at the tool when the tool is running. Using a higher than rated pressure will cause faster

wear and drastically shorten the tool’s life. A higher air pressure can also cause an unsafe condition and explosion. The inside diameter of the hose should be increased to compensate for unusually long air hoses (over 25

feet). Minimum hose diameter should be 3/8” I.D. and fittings should have 1/4” NPT thread. The use of air line

lubricators and air line filters is recommended to prevent water in the line that can damage the tool. Drain the

air tank daily. Clean the air inlet filter screen on at least a weekly schedule to remove accumulated dirt or other

matter that can restrict air flow. The tool’s air inlet used for connecting an air supply has standard 1/4” NPT

American thread.

SAFETY RULES FOR PNEUMATIC TOOLS

1) Inspect the air hose for cracks or other problems. Replace the hose if worn.

2) Never point an air hose at another person.

3) Disconnect the tool when not in use, or before performing service or changing accessories.

4) Use proper hoses and fittings. Never use quick change couplings attached to the tool. Instead, add a hose and

coupling between the tool and the air supply.

FIGURE A

- 6 -

1/2”(or larger)

Pipe and Fittings

Coupler

Air Hose

Leader Hose

Tool

Nipple

Oiler

Filter

Drain Daily

Page 7

OPERATION

DO NOT ATTEMPTTO UNCLOG (BACK

FLUSH) SPRAY GUN BY SQUEEZING

TRIGGER WHILE HOLDING FINGER IN FRONT OF FLUID

NOZZLE.

PRESSURE MAY VARY ACCORDING

TO VISCOSITY OF MATERIAL USED.

MAXIMUM WORKING PRESSURE OF GUN IS 50 PSI.

DO NOT EXCEED PRESSURE LIMIT OF GUN OR ANY

OTHER COMPONENT IN SYSTEM!

PRIOR TO DAILY OPERATION, MAKE

CERTAIN THAT ALL CONNECTIONS

AND FITTINGS ARE SECURE. CHECK HOSE AND ALL

CONNECTIONS FOR A WEAK OR WORN CONDITION

THAT COULD RENDER SYSTEM UNSAFE. ALL

REPLACEMENT COMPONENTS SUCH AS HOSE

OR FITTINGS MUST HAVE A WORKING PRESSURE

EQUAL TO OR GREATER THAN SYSTEM PRESSURE.

Prior to shipment, this gun was treated with an

anticorrosive agent. Before using this gun make sure

that it is carefully ushed with thinner.

1. The position of the air cap

(H) horns

will determine

the spray pattern. Loosen

(G) air cap

and rotate horns

to achieve desired pattern. Tighten air cap.

2. Attach paint cup to the gun.

NOTE:

The

(F) filter

supplied is optional to protect

against contaminants and small particles. See parts

list for lter orientation.

3. Attach air supply line to 1/4 NPS air inlet.

NEVER point spray gun at self or any other person.

Accidental discharge of material may result in serious injury.

4. Adjust air pressure at air compressor.

DO NOT exceed 50 psi.

5. Depress spray gun trigger fully to spray material.

NOTE:

Depressing trigger partially will cause only air to be released.

ADJUST SPRAY GUN:

a. Amount of material released (density of “fan spray”) is controlled

by

(D) fluid

control knob . Turn knob counterclockwise to increase, or

clockwise to decrease, the uid ow.

b. Width of “fan spray” is governed by

(B) spray pattern control knob

. Turn knob counter-clockwise to

increase, or clockwise to decrease, air ow.

c. Air quantity is controlled by

(C) air-volume control knob

. Turn knob counterclockwise to increase, or

clockwise to decrease, the air ow.

NOTE:

Care should be exercised when handling spray gun to avoid damage to the orice of the air cap

and tip of uid nozzle. Damage to these parts results in irregular spray patterns.

- 7 -

(A) Air

Valve Nut

(E) Non-Drip Cup

(G) Air Cap

(C) Air

Volume

Control Knob

(D) Fluid

Control

Knob

(B) Spray

Pattern

Adjustment

(H) Horns

(F) Material

Filter

Horizontal position

Vertical position

Page 8

- 8 -

MAINTENANCE

SHUT OFF AIR COMPRESSOR, RELEASE ALL PRESSURE BY DEPRESSING TRIGGER, AND

DISCONNECT POWER SOURCE BEFORE DISASSEMBLY OR REMOVAL OF ANY PART OF THE GUN OR

ATTACHED COMPONENTS.

ALWAYS EXERCISE EXTREME CARE WHEN USING ANY SOLVENT OR THINNER. NEVER

CLEAN THE GUN NEAR FIRE, FLAME, OR ANY SOURCE OF HEAT OR SPARKS. PROPERLY DISPOSE OF

USED CLEANING MATERIALS.

DO NOT SOAK THE ENTIRE SPRAY GUN IN SOLVENT OR THINNER FOR A LONG PERIOD

OF TIME AS THIS WILL DESTROY LUBRICANTS AND POSSIBLY IMPAIR OPERATION. NEVER USE LYE OR

CAUSTIC ALKALINE SOLUTION FOR CLEANING. SUCH SOLUTIONS WILL ATTACK ALUMINUM ALLOY

PARTS OF THE GUN.

It is important that the spray gun be cleaned after each use.

CLEANING

1. Empty material from gravity feed cup and replace with a suitable solvent or thinner.

2. Operate trigger until all material traces have disappeared and gun is thoroughly clean.

3. Clean air cap with a brush.

4. Wipe the exterior of the spray gun with a solvent soaked cloth or use cleaning brush(es) provided to

remove any accumulated material.

IMPORTANT:

Make certain that the air cap and uid nozzle are kept clean at all times. If necessary, remove

these two components and soak them in solvent. DO NOT use hard objects to clean clogged holes. The

smallest amount of damage may cause

irregular spray pattern.

NOTE:

If the uid nozzle is to be removed for thorough cleaning, squeeze the trigger to prevent damage of

the uid needle tip when unscrewing the nozzle.

LUBRICATION

Lubrication procedures must be observed after thoroughly cleaning the gun to ensure effective, high

quality performance of spray gun.

1. Lubricate working points with straight mineral oil, or castor oil.

2. Periodically, place a few drops of oil on tapered sections of the uid nozzle to ensure easy operation

of the air cap. When spraying water base materials, coat the uid nozzle inside and outside with straight

mineral oil after each use.

3. Outer diameter of the needle sleeve in the uid needle assembly must be lubricated occasionally with

straight mineral oil.

Page 9

- 9 -

TROUBLESHOOTING GUIDE

This section provides a list of the more frequently encountered malfunctions, their cause and corrective

actions. The operator or maintenance personnel can perform some corrective actions, and others may

require the assistance of a qualied Bostitch technician or your dealer.

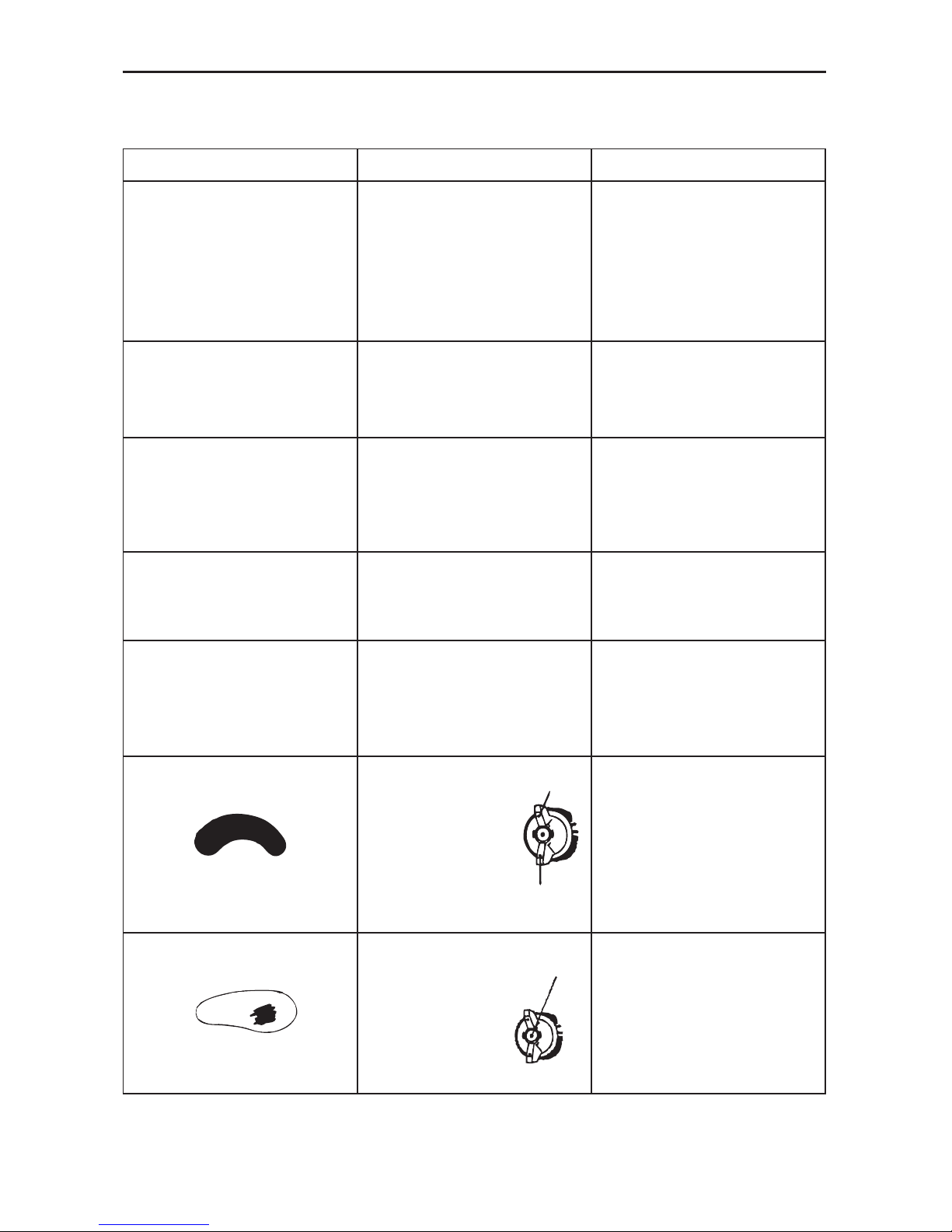

DEFECTIVE PATTERN LIKELY CAUSE SUGGESTED REMEDY

HEAVY TOP OR

BOTTOM PATTERN

1. Dirty or damaged

air cap

2. Dirty or damaged

uid tip

1. Rotate air cap 180°. If the

pattern follows the air cap,

the problem is in the air cap.

Clean and inspect the air cap.

If the pattern is not corrected,

replacement is necessary.

2. If pattern doesn’t follow the

air cap, the problem is with

the uid tip. Clean and

inspect the tip for dried paint,

dirt or damage. If the pattern

is not corrected, replacement

is necessary.

SPLIT PATTERN Air pressure too high for

material viscosity being sprayed.

1. Reduce air pressure.

2. Turn pattern control knob

clockwise to decrease fan

width. Turn uid needle

adjusting nut counterclockwise

to increase uid ow.

1. Dirty or distorted air horn

holes.

2. One of the air horn holes

completely obstructed.

1. Rotate air cap 180°. If the

pattern follows the air cap,

the problem is in the air cap.

2. Clean and inspect the horn

holes. If the horn holes are

distorted, replacement is

necessary.

GUN SPLITTING Air getting into paint stream

somewhere.

Example: Same symptoms as a

cup running out paint.

1. Check and tighten uid needle

packing nut.

2. Tighten uid tip.

3. Check uid tip seat for

damage.

4. Check for poor gun to cup

seating.

5. Check that cup is correctly

fastened on the gun.

SPITTING, IRREQULAR

OR FLUTTERING SPRAY

1. Fluid nozzle

cracked or worn

2. Leak at thread

of uid nozzle

3. Leak at uid needle

4. Needle packing

worn out

5. Insufcient uid in cup

6. Vent hole in

container cover clogged

1. Tighten or replace

2. Tighten uid nozzle

3. Tighten compression nut

assembly or replace needle

packing

4. Replace packing

5. Fill cup with uid

6. Clean out

AIR BACK

PRESSURING

INTO CUP.

Excessive air blowing back into

cup.

1. Tighten uid tip.

2. Check uid tip seat.

3. Check for damaged uid seat

on tip or seat on gun head.

Page 10

- 10 -

TROUBLESHOOTING GUIDE:

This section provides a list of the more frequently encountered malfunctions, their cause and corrective

actions. The operator or maintenance personnel can perform some corrective actions, and others may

require the assistance of a qualied Bostitch technician or your dealer.

DEFECTIVE PATTERN LIKELY CAUSE SUGGESTED REMEDY

UNATOMIZED

OR SPATTERED

SPRAY

1. Material too heavy

2. Insufcient air

pressure

3. Fluid pressure

too high

4. Dried material on tip

of uid nozzle or

air jets of air cap

1. Thin material or use larger

orice uid nozzle set

2. Increase pressure to within

limit

3. Reduce pressure

4. Clean

INADEQUATE

AIR DELIVERY

1. Air needle partially

closed

2. Dried material in air

jets or air cap

3. Obstruction in air line.

1. Open control knob

2. Clean

3. Remove obstruction

EXCESSIVE FOG 1. Air pressure too high

for viscosity of uid

1. Reduce air pressure and/or

open uid control knob

MATERIAL LEAKING

FROM FLUID INLET

OF CUP

1. Loose cup or foreign

substances on/between cup

thread and uid inlet

1. Tighten and clean or replace it

MATERIAL LEAKING

FROM NOZZLE WHEN

TRIGGER IS RELEASED

1. Worn uid neddle

2. Dried material in tip of nozzle

3. Loose packing nut

1. Replace

2. Clean

3. Tighten needle packing nut by

turning counterclockwise

A. Dried material is

clogging side-port “A”

and causing

side-port “B” to blow

spray towards the

clogged side

Soak side-ports in

thinner to clean clog.

DO NOT poke any

opening with hard objects.

B. 1. Dried material at

uid nozzle “C”

restricts air ow

2. Loose air nozzle

3. Air pressure

set too high

1. Remove air nozzle.

Wipe off uid tip using a

cloth soaked in thinner

or by soft brush

2. Fasten nozzle securely

3. Reduce air pressure

A

B

C

Page 11

- 11 -

GLOSSARY

CFM:

Cubic feet per minute.

SCFM:

Standard cubic feet per minute; a unit of measure of air delivery.

PSI:

Pounds per square inch; a unit of measure of pressure.

Code Certification:

Products that bear one or more of the following marks:

UL, CUL, ETL, CETL

, have

been evaluated by

OSHA

certied independent safety laboratories and meet the applicable Underwriters

Laboratories Standards for Safety.

RPM:

Revolutions per minute; is a measure of the frequency of a rotation

BPM:

Beats per minute.

NPT:

National pipe thread (tapered thread); is a U.S. standard for tapered threads used on threaded

pipes and ttings.

ID:

Inner diameter

LAS CAÍDAS PUEDEN CAUSAR

LESIONES GRAVES. NO PISAR NI

PARARSE EN ESTA ÁREA.

ADVERTENCIA

LES CHUTES PEUVENT CAUSER DE GRAVES

BLESSURES. NE MARCHEZ PAS ET NE VOUS

TENEZ PAS SUR CET EMPLACEMENT.

AVERTISSEMENT

FALLS CAN CAUSE SERIOUS

INJURIES. DO NOT STEP OR STAND

ON THIS AREA.

WARNING

SEE OWNER’S MANUAL FOR

BREAK-IN PROCEDURES.

CAUTION

PARA EL PROCEDIMIENTO DE

ASENTADO DE LA MAQUINA, VER

MANUAL DEL OPERARIO.

ATENCIÓN

CONSULTEZ LE MANUEL DE

L’UTILISATEUR POUR LES

PROCEDURES DE RODAGE.

ATTENTION

ADVERTENCIA

EL USO INDEBIDO PUEDE GENERAR RIESGOS. SEGUIR ESTAS INSTRUCCIONES: RIESGO DE ESTALLIDO. ASEGÚRESE QUE LA VÁLVULA DE SALIDA DEL

COMPRESOR ESTE REGULADA POR DEBAJO DEL MÁXIMO DE LA PRESIÓN DE OPERACIÓN DE LA PISTOLA ROCIADORA O HERRAMIENTA. ANTES DE ARRANCAR

EL COMPRESOR, TIRAR DEL ANILLO EN LA VÁLBULA DE SEGURIDAD PARA ASEGURARSE QUE LA VÁLVULA SE MUEVE LIBREMENTE. DRENAR EL AGUA DEL TANQUE DESPUÉS DE CADA USO.

RIESGO DE FUEGO O EXPLOSIÓN. NO ROCIAR LÍQUIDO NI PINTURAS INFLAMABLES O COMBUSTIBLES CERCA DE CHISPAS, LLAMAS, LLAMAS DE PILOTO O EN ÁREAS CERRADAS. EL ÂREA DE

TRABAJO DEBE ESTAR BIEN VENTILADA. MANTENER EL COMPRESOR ALEJADO POR LO MENOS 20 PIES DEL AREA DE PINTURA. NO LLEVAR NI OPERAR EL COMPRESOR NI DISPOSITIVO ELÉCTRICO

ALGUNO CERCA DEL AREA DEL ROCIADO. NUNCA FUME EN EL ÁREA DEL ROCIADO. USAR UNA MANGUERE DE UN MÍNIMO DE 25 PIES PARA CONECTAR LA PISTOLA AL COMPRESOR. RIESGO DE

DAÑOS PERSONALES. USAR GAFAS DE SEGURIDAD ANSI Z87. NUNCA APUNTAR EL CHORRO DE AIRE COMPRIMIDO O DE MATERIAL QUE SE ESTÉ ROCIANDO A SÍ MISMO NI A OTRAS PERSONAS.

NE RESPIRAR EL AIRE COMPRIMIDO. REDUCIR LA PRESIÓN A CERO ANTES DE DESMONTAR LA MANGUERA. RIESGO DE CHOQUE ELÉCTRICO. ALTO VOLTAJE. DESCONECTAR LA UNIDAD ANTES DE

QUITAR LA CUBIERTA. NO EXPONER A LLUVIA. ALMACENAR EN INTERIORES. PARA SEGURIDAD COMPLETA, OPERACIÓN E INSTRUCCIONES PARA REPARAR, LEER EL MANUAL DEL OPERADOR.

AVERTISSEMENT

UNE UTILISATION INCORRECTE PEUT ÊTRE DANGEREUSE. SUIVEZ LES INSTRUCTIONS CI-DESSOUS: RISQUE D'ECLATEMENT. ASSUREZ-VOUS QUE LA

PRESSION DE SORTIE DU COMPRESSEUR EST RÉGLÉE À UN NIVEAU INFÉRIEUR À LA PRESSION D'UTILISATION MAXIMUM DU PISTOLET VAPORISATEUR OU DE

L'ACCESSOIRE. AVANT DE DÉMARRER LE COMPRESSEUR, TIREZ SUR L'ANNEAU DE LA SOUPAPE DE SÛRETÉ POUR VOUS ASSURER QU'ELLE FONCTIONNE LIBREMENT. VIDANGEZ L'EAU DU RÉSERVOIR

À AIR APRÈS CHAQUE UTILISATION. RISQUE D'INCENDIE OU D'EXPLOSION. NE PAS VAPORISER UN LIQUIDE OU UN PEINTURE INFLAMMABLE OU COMBUSTIBLE PRÈS D'ÉTINCELLES, DE FLAMMES, DE

VEILLEUSES NI DANS UN ENDROIT RESTREINT OU RENFERMÉ. L'AIRE DE VAPORISATION DOIT ÊTRE BIEN AÉRÉE. GARDEZ LE COMPRESSEUR À UNE DISTANCE D'AU MOINS 20 PIEDS DE LA SURFACE À

VAPORISER. NE PORTEZ PAS LE COMPRESSEUR ET NE L'UTILISEZ PAS NI AUCUN AUTRE APPAREIL ÉLECTRIQUE À PROXIMITÉ DE L'AIRE DE VAPORISATION. NE FUMEZ JAMAIS QUAND VOUS

VAPORISEZ. UTILISEZ UN FLEXIBLE D'AIR D'UNE LONGUEUR MINIMUM DE 25 PIEDS POUR RELIER LE PISTOLET VAPORISATEUR AU COMPRESSEUR. RISQUE DE BLESSURES CORPORELLES. PORTEZ DES

LUNETTES DE PROTECTION ANSI Z87. NE DIRIGEZ JAMAIS L'AIR COMPRIME OU DES MATÉRIAUX VERS SOI OU VERS AUTRUI. NE JAMAIS UTILISER DE L'AIR COMPRIMÉ POUR LA RESPIRATION. RÉGLEZ

LA PRESSION À ZÉRO AVANT DE RETIRER LE BOYAU. RISQUE DE CHOC ÉLECTRIQUE. VOLTAGE DANGEREUX. DEBRANCHEZ LA MACHINE AVANT D'ENLEVER BOITIER. N'EXPOSEZ PAS LE COMPRESSEUR

À LA PLUIE. REMISEZ-LE À L'INTÉRIEUR. LISEZ LE MANUEL DE L'UTILISATEUR POUR DES INSTRUCTIONS COMPLÈTES CONCERNANT LA SÉCURITÉ, L'UTILISATION ET LES RÉPARATIONS.

INCORRECT USE CAN CAUSE HAZARDS. FOLLOW THESE INSTRUCTIONS: RISK OF BURSTING. MAKE SURE THE COMPRESSOR OUTLET PRESSURE IS SET

LOWER THAN THE MAXIMUM OPERATING PRESSURE OF THE SPRAY GUN OR TOOL. BEFORE STARTING THE COMPRESSOR, PULL THE RING ON THE SAFETY

VALVE TO MAKE SURE THE VALVE MOVES FREELY. DRAIN WATER FROM TANK AFTER EACH USE. RISK OF FIRE OR EXPLOSION. DO NOT SPRAY A FLAMMABLE OR COMBUSTIBLE

LIQUID OR PAINT NEAR SPARKS, FLAMES, PILOT LIGHTS, OR IN A CONFINED AREA. THE SPRAY AREA MUST BE WELL VENTILATED. KEEP COMPRESSOR AT LEAST 20 FEET AWAY FROM

SPRAY AREA. DO NOT CARRY AND OPERATE THE COMPRESSOR, OR ANY OTHER ELECTRICAL DEVICE NEAR THE SPRAY AREA. NEVER SMOKE WHEN SPRAYING. USE A MINIMUM OF

25 FEET OF HOSE TO CONNECT A SPRAY GUN TO THE COMPRESSOR. RISK OF PERSONAL INJURY. WEAR ANSI Z87 SAFETY GLASSES. NEVER SPRAY COMPRESSED AIR OR MATERIAL

AT SELF OR OTHERS. DO NOT USE COMPRESSED AIR FOR BREATHING. REGULATE PRESSURE TO ZERO BEFORE REMOVING HOSE. RISK OF ELECTRICAL SHOCK. HAZARDOUS VOLTAGE.

UNPLUG UNIT BEFORE REMOVING COVER. DO NOT EXPOSE TO RAIN, STORE INDOORS. READ OWNER'S MANUAL FOR COMPLETE SAFETY, OPERATION, AND REPAIR INSTRUCTIONS.

WARNING

HOLD HOSE FIRMLY TO

PREVENT HOSE WHIP.

CAUTION

SOSTENGA LA MANGUERA

CON FIRMEZA PARA EVITAR EL.

ATENCIÓN

BIEN TENIR LE TUYAU POUR

ÉVITER UN À-COUP.

ATTENTION

DRAIN TANK DAILY OR AFTER EACH USE. CONDENSATION BUILD-UP MAY CAUSE CORROSION

INSIDE TANK RESULTING IN TANK FAILURE. SEE MANUAL FOR INSPECTION PROCEDURES. TO DRAIN

TANK OPEN VALVE SLOWLY AND TILT COMPRESSOR TO EMPTY ACCUMULATED WATER.

WARNING

DRENE EL TANQUE A DIARIO O DESPUÉS DE CADA USO. LA ACUMULACIÓN DE CONDENSACIÓN

PUEDE OCASIONAR CORROSIÓN DENTRO DEL TANQUE Y PROVOCAR FALLA DEL TANQUE.

CONSULTE EL MANUAL PARA CONOCER LOS PROCEDIMIENTOS DE INSPECCIÓN. PARA DRENAR EL TANQUE, ABRA LA

VÁLVULA LENTAMENTE E INCLINE EL COMPRESOR PARAELIMINAR EL AGUA ACUMULADA.

ADVERTENCIA

RÉSERVOIR DE VIDANGE QUOTIDIEN

OU APRÈS CHAQUE UTILISATION. L'HABILLAGE

DE

CONDENSATION PEUT CAUSER LA CORROSION À L'INTÉRIEUR DU RÉSERVOIR AYANT POUR

RÉSULTAT L'ÉCHEC DE RÉSERVOIR. VOIR LE MANUEL POUR DES PROCÉDURES D'INSPECTION. À LA VALVE

OUVERTE

DE RÉSERVOIR DE VIDANGE LENTEMENT ET AU COMPRESSEUR D'INCLINAISON À L'EAU ACCUMULÉE VIDE.

AVERTISSEMENT

Page 12

- 12 -

INTRODUCCIÓN

• Velocidad de rápido funcionamiento y modelo de ventilador ancho

• VEcacia de transferencia elevada signica pulverización reducida

• Aguja de acero inoxidable y tapa de uido que permite usar con materiales transportados por agua

• Presión máxima de funcionamiento: 50 psi

• Diseño de ecacia elevada que reduce signicativamente los costos de funcionamiento

ÍNDICE

Garantía Limitada De 3 Años .................................................... 12

Componentes De La Herramienta, Especicaciones De La

Herramienta ................................................................................ 13

Instrucciones De Seguridad ...................................................... 14

Advertencia.................................................................................15

Instalación ..................................................................................16

Operación ................................................................................... 17

Instrucciones De Mantenimiento .............................................. 18

Solución De Problemas ............................................................. 19-20

IMPORTANT

Por favor asegúrese de que la persona que va a usar este equipo lea cuidadosamente y comprenda estas

instrucciones antes de operarlo.

GARANTÍA LIMITADA DE 3 AÑOS

Stanley garantiza este producto al comprador original durante un período de

TRES (3) AÑOS

contra

deficiencias en material y mano de obra. Esta

GARANTÍA LIMITADA

no cubre productos que sean

usados impropiamente, abusados, alterados o reparados. Los productos decientes serán reemplazados

o reparados a la opción de Stanley. Por favor llame al teléfono 1-800-505-4648 para obtener mayor

información o instrucciones de retorno.

ESTA GARANTÍA LIMITADA ES OTORGADA EN LUGAR DE TODAS LAS DEMÁS, INCLUYENDO GARANTÍA

IMPLÍCITA DE COMERCIABILIDAD O APTITUD PARA UN PROPÓSITO EN PARTICULAR Y EXCLUYE TODOS

LOS DAÑOS INCIDENTALES O CONSECUENTES.

Algunos estados no permiten limitaciones con relación

a cuanto dura una garantía implícita, o la exclusión o la limitación de daños incidentales o consecuentes,

de modo que estas limitaciones pueda que no le apliquen a usted. Esta

GARANTÍA LIMITADA

le otorga

derechos legales especícos los cuales pueden variar de estado a estado.

NORMAS DE SEGURIDAD – DEFINICIONES

Este manual contiene información que es importante que usted la sepa y la comprenda. Esta información

está relacionada con

SU SEGURIDAD

y

EVITAR PROBLEMAS CON EL EQUIPO

. Para ayudarle a reconocer

esta información, use los símbolos mostrados abajo. Por favor lea el manual y préstele atención a esas

secciones.

SEGURIDAD y EVITAR PROBLEMAS CON EL EQUIPO.

Para ayudarle a reconocer esta información, use

los símbolos mostrados abajo. Por favor lea el manual y préstele atención a esas secciones.

Indica una situación

inminentemente

peligrosa que, si no es evitada,

podrá

dar como

resultado la

muerte o lesiones graves

.

Indica una situación

potencialmente

peligrosa que, si no es evitada,

podrá

resultar en

heridas corporales menores o moderadas

.

Indica una situación

potencialmente peligrosa que,

si no es evitada,

podrá

resultar en la

muerte o en

lesiones graves

.

Usada sin el símbolo

de alerta de seguridad

indica una situación potencialmente peligrosa

que, si no es evitada,

podrá

resultar en

daños

a la propiedad

.

Page 13

- 13 -

FIG.1

COMPONENTES DE LA HERRAMIENTA

BTMT72393

Descripción

Pistola aspersora de alimentación por gravedad de

alto volumen y baja presión (HVLP)

Promedio de consumo de aire

5.6 CFM Uso al 100%

Salida de fluido

170 cc/min.

Entrada de aire

Rosca de 1/4 pul. NPS (Hembra)

Peso

0,7095KG (1,56lb)

Tamaño mínimo de la manguera

3/8 pul. de D.I.

Presión requerida en lbs./pul.² (PSI)

30-50 lbs./pul.² (PSI)

Entrada de fluido

Rosca de 3/8 pul. NPS (Hembra)

Presión de entrada de aire

50 psi

Ancho del patrón

> 180 mm

Punta de la boquilla

1,5 mm

Conexión de aire

1/4 pul. NPT (Macho)

ESPECIFICACIONES DE LA HERRAMIENTA

Todas las dimensiones están en pulgadas a menos que se especifique lo contrario.

Tuerca de la válvula

de aire

Botón de

control de

uido

Botón de control

de volumen de aire

Ajuste del

patrón de

atomización

Taza anti goteo

Filtro de

material

Cuernos

Tapa de aire

Page 14

- 14 -- 14 -

Definiciones: Normas de seguridad

Las siguientes definiciones describen el nivel de

gravedad de cada advertencia. Lea el manual y preste

atención a estos símbolos.

PELIGRO: indica una situación de peligro

inminente que, si no se evita, provocará la muerte o

lesiones graves.

ADVERTENCIA: Indica una situación de peligro

potencial que, si no se evita, podría provocar la

muerte o lesiones graves.

ATENCIÓN: Indica una situación de peligro

potencial que, si no se evita, puede provocar lesiones leves o moderadas.

ATENCIÓN: Utilizado sin el símbolo de alerta de

seguridad indica una situación de peligro potencial

que, si no se evita, puede provocar daños en la

propiedad.

INSTRUCCIONES DE SEGURIDAD

IMPORTANTES

Algunas partículas originadas al lijar,

aserrar, amolar, taladrar y realizar otras actividades de

construcción contienen productos químicos reconocidos por

el Estado de California como causantes de cáncer, defectos

de nacimiento u otros problemas reproductivos. Algunos

ejemplos de estos productos químicos son:

• el plomo de las pinturas de base plomo

• la sílice cristalina de ladrillos, cemento y otros productos de mampostería,

• el arsénico y cromo de madera con tratamiento

químico.

El riesgo derivado de estas exposiciones varía según la

frecuencia con la que se realice este tipo de trabajo. Para

reducir la exposición a estos productos químicos: trabaje en

áreas bien ventiladas y con equipos de seguridad aprobados,

use siempre mascarilla facial o de respiración adecuada y

aprobada por OSHA/MSHA/NIOSH cuando use este tipo de

herramientas.

Cuando se utilizan herramientas neumáticas, siempre se

deben respetar las precauciones de seguridad para reducir el

riesgo de lesiones personales.

Este producto contiene sustancias químicas, incluido el

plomo, reconocidas por el Estado de California como causantes de cáncer, defectos de nacimiento u otros problemas

reproductivos. Lávese las manos después de utilizarlo.

GUARDE ESTAS INSTRUCCIONES

Laoperación o el mantenimiento inapropiados de

este producto podrán resultar en Lesiones graves

y daños a la propiedad. Lea y comprenda todas

las advertencias e Instrucciones de operación

antes de usar este equipo. Cuando use herramientas

neumáticas,Se deberán seguir las precauciones de seguridad

básicas para reducir el riesgo de heridas Personales.

Lea y comprenda este manual de instrucciones y los

rótulos en la herramienta antes de instalarla, operarla

o darle servicio a esta herramienta. Mantenga estas

instrucciones en un lugar seguro y accesible.

Tanto el operador como las demás personas deben

llevar puestas gafas de seguridad con protectores

laterales que cumplan con la norma ANSI Z87.1 CAN/

CSA Z94.3.

Los operadores y otros en el área deberán usar

protección para los oídos.

Graissez tous les jours pour un rendement optimal.

• Todas las personas en el área de trabajo deben utilizar

protección ocular, auditiva y respiratoria aprobada

cuando se utiliza la pistola pulverizadora.

• Nunca apunte la pistola pulverizadora a una persona.

No pulverice cerca de chispas, llamas, cigarrillos

encendidos, luces piloto, calefactores de espacios u

otras fuentes potenciales de incendio. NO FUME EN EL

ÁREA DE TRABAJO.

• El uso de esta herramienta neumática se debe permitir

solo a aquellas personas que estén bien familiarizadas

con estas reglas o el funcionamiento seguro de la

máquina.

• Siga las instrucciones del fabricante y la información

de seguridad para garantizar la manipulación segura y

el uso de pinturas, lacas, diluyentes, bases de fondo,

etc. No utilice látex u otras pinturas espesas. Estas no

se recomiendan para la pistola pulverizadora.

• Mantenga siempre el área de trabajo libre de obstrucciones y bien ventilada.

• Desconecte siempre la pistola pulverizadora de la

fuente de aire antes de desarmarla.

• Para evitar la creación de una atmósfera explosiva,

trabaje solo en áreas ventiladas.

• Utilice siempre protección respiratoria para evitar la

inhalación de de gases y materiales nocivos.

• Antes de desarmar o extraer alguna de las piezas

de la pistola o componentes acoplados, apague el

compresor, presione el gatillo para liberar la presión y

desconecte la fuente de alimentación. ¡NUNCA asuma

que la presión es cero!

Page 15

- 15 -- 15 -

RIESGO DE EXPLOSIÓN O

INCENDIO

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• Cuando se pulverizan

las pinturas o materiales, estos se dividen en

partículas muy pequeñas y se mezclan con

el aire. Esto causa que

ciertas pinturas y

materiales sean extremadamente inflamables

y puedan ocasionar

lesiones o la

muerte.

• Nunca pulverice cerca

de llamas abiertas o

luces piloto en hornos o

calefactores.

• Nunca fume mientras

pulveriza.

• Asegúrese de suministrar una amplia ventilación cuando pulverice

en lugares cerrados.

• Los solventes 1,1,1tricloroetano y cloruro

de metileno pueden

reaccionar químicamente con el

aluminio utilizado en la

mayoría de los equipos

de pulverización, y esta

pistola y recipiente,

para generar riesgos de

explosión y puede ocasionar serias lesiones o

la muerte.

• Lea la etiqueta o la hoja

de datos para el material que desea pulverizar.

• Nunca utilice ningún

tipo de material de recubrimiento pulverizado

que contenga estos

solventes.

• Nunca utilice estos

solventes para la limpieza del equipo o el

enjuague.

• Si está en duda sobre si

un material es compatible, contáctese con su

proveedor de materiales.

RIESGO RESPIRATORIO

(ASFIXIA)

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• Algunas pinturas,

recubrimientos y solventes pueden causar

daños en los pulmones

y quemaduras si se las

inhala o permite que

entren en contacto con

la piel y con los ojos.

• Use una máscara o

respirador aprobado por

NIOSH e indumentaria

protectora diseñada

para utilizar con

su aplicación específica

y materiales de pulverización. Algunas máscaras solo proporcionan

protección limitada

contra materiales

tóxicos y solventes de

pintura nocivos.

Consulte un experto de

seguridad o higienista

industrial si posee

dudas acerca de su

equipo o materiales.

RIESGO DE INYECCIÓN

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• Las pistolas funcionan

a presiones y velocidades lo suficientemente

elevadas como para

penetrar la piel de los

humanos y de los

animales, lo que puede

resultar en la

amputación u otras

lesiones serias. ! ¡Vea a

un médico

inmediatamente!

• Nunca coloque las

manos en frente de la

boquilla.

• Dirija el material pulverizado lejos de usted y

otras personas.

• Busque atención médica

de inmediato si la pulverización entra en contacto

directo con partes expuestas del cuerpo.

RIESGO DE OBJETOS

EXPULSADOS

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• Algunas piezas están

bajo presión siempre

que la pistola esté

conectada a una

tubería de aire presurizada. Es posible que

estas piezas salgan

expulsadas si se

desarma la pistola.

• Desconecte la pistola

de la tubería de aire,

despresurice

completamente la

tubería de aire siempre que esté por

desarmar la pistola.

• Es posible que el aire

comprimido expulse

suciedad, limaduras

metálicas, etc.,

y posiblemente cause

lesiones.

• Nunca apunte ninguna boquilla

o pulverizador hacia

una persona o parte

del cuerpo.

• Utilice siempre gafas

de seguridad con protectores laterales que

cumplan con

la norma ANSI Z87.1

CAN/CSA Z94.3.

• La exposición prolongada

a la pulverización por

aire puede causar

daños

permanentes en la

audición.

• Utilice siempre

protección auditiva

cuando emplee

equipos de pulverización.

Page 16

- 16 -

INSTALACIÓN

SUMINISTRO DE AIRE

La conexión recomendada se muestra en la

figura A

Las herramientas neumáticas operan sobre un amplio

margen depresiones de aire. Para obtener la máxima eficiencia y mayor vida útil de la herramienta, la presión

del aire suministrado a estas herramientas NO debe exceder la PSI de servicio especificada en la herramienta

durante su funcionamiento. El uso de una presión más alta de la capacidad nominal de la herramienta causará

un desgaste más rápido reduciendo drásticamente la vida de la herramienta. Una presión de aire más alta también causará una condición insegura y una explosión.

El diámetro interior de la manguera deberá ser aumentado para compensar por una manguera inusualmente

larga (más de 7,62 m o sea 25 pies). El diámetro mínimo de lamanguera deberá ser de 3/8” de D. I. y los conectores deben tener el mismo diámetro interno.

El uso de lubricadores de manguera de aire y de filtros de aire en línea es recomendado para evitar que agua

en la manguera dañe la herramienta. Drene diariamente el tanque de aire.

Limpie el cedazo del filtro de entrada de aire por lo menos una vez por semana para remover la mugre acumulada u otras cosas que puedan restringir el flujo de aire. La entrada de aire de la herramienta usada para

conectar una fuente de aire tiene una rosca estándar americana de 1/4” NPT.

REGLAS DE SEGURIDAD PARA HERRAMIENTAS

NEUMáTICAS

1) Inspeccione las mangueras de aire para ver si están rajadas o tienen otros problemas. Reemplace la

manguera si está desgastada.

2) Nunca apunte una manguera de aire hacia otra persona.

3) Desconecte la herramienta cuando no esté siendo usada, antes de prestarle servicio o cambiar de accesorio.

4) Use las mangueras y conectores apropiados. Nunca use acopladores de cambio rápido en la herramienta. En

cambio, adicione una manguera y un acoplador entre la herramienta y la fuente de aire.

FIGURE A

Herramienta

Manguera líder

Acoples

1/2 pul. (o mayor)

Tubos y

conectores

Manguera

de aire

Aceitera

Conector

Filtro

Drene a diario

Page 17

OPERACIÓN

NO INTENTE DESATASCAR

(RETRO ENJUAGAR) LA PISTOLA

OPRIMIENDO EL GATILLO MIENTRAS SOSTIENE

SU DEDO ENFRENTE DE LA BOQUILLA DE

FLUIDO.

LA PRESIÓN PUEDE VARIAR DE

ACUERDO CON LA VISCOSIDAD

DEL MATERIAL USADO. LA PRESIÓN DE

TRABAJO MÁXIMA DE LA PISTOLA ES DE 50

LBS./PUL.²(PSI). ¡NO EXCEDA EL LÍMITE DE

PRESIÓN DE LA PISTOLA O DE CUALQUIER

COMPONENTE EN EL SISTEMA!

ANTES DE LA OPERACIÓN

DIARIA, ASEGÚRESE DE QUE.

TODAS LAS CONEXIONES Y CONECTORES

ESTÉN SEGUROS. REVISE LA MANGUERA Y

TODAS LAS CONEXIONES PARA VER SI ESTÁN

DÉBILES O DESGASTADAS LO CUAL PUDIERA

TIENEN INSEGURO EL SISTEMA. TODOS LOS

COMPONENTES DE REEMPLAZO TALES COMO

MANGUERAS Y CONECTORES TIENE N QUE

TENER UNA PRESIÓN DE TRABAJO IGUAL O

MAYOR QUE LA PRESIÓN DEL SISTEMA.

Antes del despacho, esta pistola fue tratada

con un agente anticorrosivo. Antes de usar esta

pistola asegúrese de enjuagarla cuidadosamente

con disolvente.

1. La posición de los

cuernos (H)

de la tapa de

aire determinan el patrón de atomizado. Aoje la

tapa

de aire (G)

y gire los cuernos para obtener el patrón

deseado. Apriete la tapa de aire.

2. Sujete la taza de pintura en la pistola.

NOTA :

El

filtro (F)

es opcional para proteger contra contaminantes y

partículas pequeñas. Vea la lista de piezas para obtener la orientación

del ltro.

3. Sujete la manguera de suministro de aire a una entrada de aire de

1/4 pul. NPS.

NUNCA

apunte la pistola atomizadora hacia usted

o cualquier otra persona. La descarga accidental de material podrá

resultar en lesiones graves.

4. Ajuste la presión en el compresor de aire.

NO EXCEDA las 50 lbs./pul.²

5. Oprima completamente el gatillo de la pistola para atomizar el material.

NOTA:

El oprimir el gatillo parcialmente causará que salga sólo aire.

AJUSTE DE LA PISTOLA:

a. La cantidad de material atomizado (densidad del “abanico”) es controlada por el botón de control de

fluido (D)

. Gire el botón en el sentido contra horario para aumentar o en el sentido horario para disminuir

el ujo de uido.

b. El ancho del “abanico” es gobernado por el

botón de control de patrón de atomización (B)

. Gire el

botón en el sentido contra horario para aumentar o en el sentido horario para disminuir el ujo de aire.

c. La cantidad de aire es controlada por el

botón de control de volumen de aire (C)

. Gire el botón en el

sentido contra horario para aumentar o en el sentido horario para disminuir el ujo de aire.

NOTA:

Se deberá tener cuidado al manipular la pistola atomizadora para evitar dañar el oricio de la tapa

de aire y la punta de la boquilla de uido. Los daños en estas piezas resultarán en patrones de atomizado

irregulares.

- 17 -

Posici n horizontal

Posicin vertical

(A) Tuerca

de la

vl vula de

aire

(E) Taza anti goteo

(G) Tapa

de aire

(C) Botn de

control de

volumen de aire

(D) Botn de

control de

fluido

(B) Ajuste del

patrn de

atomizaci n

(H) Cuernos

(F) Filtro de

material

Page 18

- 18 -- 18 -

MANTENIMIENTO

APAGUE EL COMPRESOR DE AIRE, PRESIONE EL

GATILLO PARA LIBERAR LA PRESIÓN Y DESCONECTE LA FUENTE DE ALIMENTACIÓN

ANTES DE DESARMAR O EXTRAER ALGUNA DE LAS PIEZAS DE LA PISTOLA O COMPONENTES

COLOCADOS.

PROCEDA SIEMPRE CON EXTREMA PRECAUCIÓN AL

UTILIZAR CUALQUIER TIPO DE SOLVENTE O DILUYENTE. NUNCA LIMPIE LA PISTOLA CERCA DEL

FUEGO, LLAMA O CUALQUIER FUENTE DE CALOR O CHISPAS. ELIMINE ADECUADAMENTE LOS

MATERIALES DE LIMPIEZA UTILIZADOS.

NO MOJE LA TOTALIDAD DE LA PISTOLA PULVERIZADORA

EN SOLVENTE O DILUYENTE DURANTE UN PERÍODO DE TIEMPO PROLONGADO YAQUE ESTO PUEDE

DESTRUIR LOS LUBRICANTES Y POSIBLEMENTE PERJUDIQUE SU FUNCIONAMIENTO. NUNCA UTILICE

LEJÍA O SOLUCIÓN ALCALINA CÁUSTICA PARA LA LIMPIEZA. TALES SOLUCIONES AFECTARÁN LAS

PARTES MOLDEADAS DE ALUMINIO DE LA PISTOLA.

ES IMPORTANTE QUE LIMPIE LA PISTOLA PULVERIZADORA DESPUÉS DE

CADA USO.

LIMPIEZA

1. Vacíe el material del recipiente de alimentación por gravedad y coloque un solvente o diluyente

adecuado.

2. Accione el gatillo hasta que se hayan eliminado los rastros de material y la pistola quede

completamente limpia.

3. Limpie la tapa de aire con un cepillo.

4. Limpie el exterior de la pistola pulverizadora con un paño embebido en solvente o utilice los cepillos

de limpieza provistos para eliminar cualquier material acumulado.

IMPORTANTE:

Mantenga la tapa de aire y la boquilla de uido limpias en todo momento. Si es necesario,

quite estos dos componentes y remójelos en solvente. NO utilice objetos duros para limpiar los agujeros

obstruidos. El más mínimo daño puede causar un patrón de pulverización irregular.

NOTA:

Si se debe quitar la boquilla de uido para limpiarla en detalle, presione el disparador para

prevenir daños en la punta de la aguja de uido cuando desatornilla la boquilla.

LUBRICACIÓN

Después de una limpieza profunda, se deben realizar los procedimientos de lubricación, a n de garantizar

un rendimiento efectivo y de alta calidad de la pistola pulverizadora.

1. Lubrique los puntos de trabajo con aceite mineral o aceite de ricino.

2. Coloque periódicamente varias gotas de aceite en las secciones cónicas de la boquilla de uido para

garantizar el funcionamiento fácil y correcto de la tapa de aire. Cuando pulverice materiales a base de

agua, recubra la boquilla de uido por dentro y por fuera con aceite mineral puro después de cada uso.

3. El diámetro exterior de la manga de la aguja en el conjunto de la aguja de uido debe ser lubricado

ocasionalmente con aceite mineral puro.

Page 19

- 19 -- 19 -

GUÍA DE SOLUCIÓN DE PROBLEMAS

Esta sección proporciona una lista de las averías encontradas con mayor frecuencia, sus causas y

sus acciones correctivas. El operador o personal de mantenimiento pueden realizar algunas acciones

correctivas y es posible que otras requieran la asistencia de un técnico calicado de Bostitch o de su

distribuidor.

PATRÓN

DEFECTUOSO

POSIBLE CAUSA REPARACIÓN RECOMENDADA

PATRÓN SUPERIOR

O INFERIO VISCOSO

1. Tapa de aire sucia

o dañada

2. Punta de salida del

uido sucia o dañada

1. Gire la tapa de aire 180°. Si el

patrón sigue el patrón de la tapa

de aire, el problema se encuentra

en la tapa de aire. Limpie e

inspeccione la tapa de aire. Si esto

no corrige el patrón, es necesario

realizar un reemplazo de las

piezas.

2. Si el patrón no sigue el patrón

de la tapa de aire, el problema se

encuentra en la punta de salida

del uido. Limpie e inspeccione

la punta de salida en busca de

pintura seca, suciedad o daños.

Si esto no corrige el patrón, es

necesario realizar un reemplazo

de las piezas.

PATRÓN

DIVIDIDO

La presión de aire es muy alta

para la viscosidad del material

que se está pulverizando.

1. Reduzca la presión de aire.

2. Mueva la perilla de control del

patrón en el sentido de las

agujas del reloj para reducir

el ancho del abanico. Gire la

tuerca de ajuste de la aguja

de uido en el sentido

contrario a las agujas del reloj

para aumentar la circulación

del uido.

1. Los oricios de las horquillas

de aire están sucios o

deformados.

2. Uno de los oricios de las

horquillas de aire está

completamente obstruido.

1. Gire la tapa de aire 180°. Si el

patrón sigue el patrón de la

tapa de aire, el problema se

encuentra en la tapa de aire.

2. Limpie e inspeccione los

oricios de las horquillas. Si

los oricios de las horquillas

están deformados, es

necesarioreemplazarlos.

ASTILLAMIENTO

DE LA PISTOLA

El aire entra al ujo de pintura

por algún lugar. Ejemplo: Los

mismos síntomas que en un

recipiente que se está quedando

sin pintura

1. Revise y ajuste la tuerca del

envase de la aguja de uido.

2. Ajuste la punta de uido.

3. Revise el asiento de la punta

de uido en busca de daños.

4. Revise si el asiento del

recipiente está deteriorado.

5. Compruebe que el recipiente

esté sujetado correctamente a

la pistola.

PULVERIZACIÓN

SALPICADA,

IRREGULAR O CON

ONDAS

1. Boquilla de uido rota o

desgastada

2. Pérdida en la rosca de la

boquilla de uido

3. Pérdida en la aguja de uido

4. Envase de la aguja desgastada

5. Fluido insuciente en el

recipiente

6. El agujero de ventilación en la

cubierta del envase está

atascado

1. Ajuste o reemplace

2. Ajuste la boquilla de uido

3. Ajuste el ensamblaje de

la tuerca de compresión o

reemplace el envase de la

aguja

4. Reemplace el envase

5. Llene el recipiente con uido

6. Limpie a fondo

Page 20

- 20 -

- 20 -

GUÍA DE SOLUCIÓN DE PROBLEMAS

Esta sección proporciona una lista de las averías encontradas con mayor frecuencia, sus causas y

sus acciones correctivas. El operador o personal de mantenimiento pueden realizar algunas acciones

correctivas y es posible que otras requieran la asistencia de un técnico calicado de Bostitch o de su

distribuidor.

PATRÓN

DEFECTUOSO

POSIBLE CAUSA REPARACIÓN RECOMENDADA

EL AIRE RETROCEDE

E INTRODUCE PRESIÓN EN EL

RECIPIENTE.

Exceso de aire que sopla hacia

el interior del recipiente.

1. Ajuste la punta de uido.

2. Revise el asiento de la punta

de uido.

3. Compruebe si el asiento de

uido está dañado en la

punta, en el asiento o en el

cabezal de la pistola.

PULVERIZACIÓN

SALPICADA O SIN

ATOMIZADO

1. El material es muy viscoso

2. Presión de aire insuciente

3. Presión del uido muy alta

4. Material seco en la punta de la

boquilla de uido o chorros de

aire de la tapa de aire

1. Diluya el material o utilice un

conjunto de boquillas de uido

más grandes.

2. Aumente la presión dentro del

límite

3. Reduzca la presión

4. Limpie

ENTREGA DE AIRE

INADECUADA

1. La aguja de aire está

parcialmente cerrada

2. Material seco en los

chorros de aire o en

la tapa de aire

3. Obstrucción en la

línea de aire

1. Abra la perilla de control.

2. Limpie

3. Quite las obstrucciones

NIEBLA EXCESIVA 1. Presión de aire muy

alta para la

viscosidad del uido.

1. Reduzca la presión de aire y/o

abra la perilla de control de

uido.

PÉRDIDA DE MATERIAL

DESDE LA ENTRADA DE

FLUIDO DEL RECIPIENTE

1. Recipiente ojo o

sustancias extrañas sobre/

entre la rosca de la tapa

y la entrada de uido

1. Ajústela y límpiela o

reemplácela.

PÉRDIDA DE MATERIAL

DESDE LA BOQUILLA

CUANDO SE SUELTA

EL GATILLO

1. Aguja de uido desgastada

2. Material seco en la punta

de la boquilla

3. Tuerca del envase oja

1. Reemplace.

2. Limpie

3. Ajuste la tuerca del envase de

la aguja moviéndola en el

sentido contrario a las agujas

del reloj

A.

El material seco

atasca el puerto

lateral “A” y causa

que el puerto

lateral “B” dispare

pulverización

a través del lado

atascado.

Remoje los puertos

laterales en diluyente para limpiar

la obstrucción. NO intente hacer

una apertura con objetos duros.

B.

1. El material seco

en la boquilla del

uido “C” restringe

el ujo de aire.

2. Boquilla de aire

oja

3. Conguración d

e presión de aire

muy alta

1. Quite la boquilla de aire.

Limpie la punta del uido

con un trapo remojado en

diluyente o un cepillo suave

2. Ajuste la boquilla de

manera segura

3. Reduzca la presión de aire

A

B

C

Page 21

- 21 -- 21 -

GLOSARIO

CFM:

Pies cúbicos por minuto.

PSI:

Libras por pulgada cuadrada; una unidad de medida de presión.

SCFM:

pies cúbicos estándar por minuto; unidad de medida de suministro de aire.

Certificación de código:

Los productos que tienen una o más de las indicaciones siguientes:

UL, CUL,

ETL, CETL,

han sido evaluados por los laboratorios de seguridad independientes certicados de

OSHA

y

cumplen los estándares de seguridad de Underwriters Laboratories cuya aplicación corresponda.

RPM:

Revoluciones por minuto; es una medida de la frecuencia de rotación.

BPM:

Golpes por minuto (del inglés, Beats Per Minute).

NPT:

Rosca de tubería nacional (del inglés, National Pipe Thread) (rosca cónica); es un estándar de

EE. UU.

para roscas cónicas utilizadas en caños y accesorios roscados.

ID:

Diámetro interno

LAS CAÍDAS PUEDEN CAUSAR

LESIONES GRAVES. NO PISAR NI

PARARSE EN ESTA ÁREA.

ADVERTENCIA

LES CHUTES PEUVENT CAUSER DE GRAVES

BLESSURES. NE MARCHEZ PAS ET NE VOUS

TENEZ PAS SUR CET EMPLACEMENT.

AVERTISSEMENT

FALLS CAN CAUSE SERIOUS

INJURIES. DO NOT STEP OR STAND

ON THIS AREA.

WARNING

SEE OWNER’S MANUAL FOR

BREAK-IN PROCEDURES.

CAUTION

PARA EL PROCEDIMIENTO DE

ASENTADO DE LA MAQUINA, VER

MANUAL DEL OPERARIO.

ATENCIÓN

CONSULTEZ LE MANUEL DE

L’UTILISATEUR POUR LES

PROCEDURES DE RODAGE.

ATTENTION

ADVERTENCIA

EL USO INDEBIDO PUEDE GENERAR RIESGOS. SEGUIR ESTAS INSTRUCCIONES: RIESGO DE ESTALLIDO. ASEGÚRESE QUE LA VÁLVULA DE SALIDA DEL

COMPRESOR ESTE REGULADA POR DEBAJO DEL MÁXIMO DE LA PRESIÓN DE OPERACIÓN DE LA PISTOLA ROCIADORA O HERRAMIENTA. ANTES DE ARRANCAR

EL COMPRESOR, TIRAR DEL ANILLO EN LA VÁLBULA DE SEGURIDAD PARA ASEGURARSE QUE LA VÁLVULA SE MUEVE LIBREMENTE. DRENAR EL AGUA DEL TANQUE DESPUÉS DE CADA USO.

RIESGO DE FUEGO O EXPLOSIÓN. NO ROCIAR LÍQUIDO NI PINTURAS INFLAMABLES O COMBUSTIBLES CERCA DE CHISPAS, LLAMAS, LLAMAS DE PILOTO O EN ÁREAS CERRADAS. EL ÂREA DE

TRABAJO DEBE ESTAR BIEN VENTILADA. MANTENER EL COMPRESOR ALEJADO POR LO MENOS 20 PIES DEL AREA DE PINTURA. NO LLEVAR NI OPERAR EL COMPRESOR NI DISPOSITIVO ELÉCTRICO

ALGUNO CERCA DEL AREA DEL ROCIADO. NUNCA FUME EN EL ÁREA DEL ROCIADO. USAR UNA MANGUERE DE UN MÍNIMO DE 25 PIES PARA CONECTAR LA PISTOLA AL COMPRESOR. RIESGO DE

DAÑOS PERSONALES. USAR GAFAS DE SEGURIDAD ANSI Z87. NUNCA APUNTAR EL CHORRO DE AIRE COMPRIMIDO O DE MATERIAL QUE SE ESTÉ ROCIANDO A SÍ MISMO NI A OTRAS PERSONAS.

NE RESPIRAR EL AIRE COMPRIMIDO. REDUCIR LA PRESIÓN A CERO ANTES DE DESMONTAR LA MANGUERA. RIESGO DE CHOQUE ELÉCTRICO. ALTO VOLTAJE. DESCONECTAR LA UNIDAD ANTES DE

QUITAR LA CUBIERTA. NO EXPONER A LLUVIA. ALMACENAR EN INTERIORES. PARA SEGURIDAD COMPLETA, OPERACIÓN E INSTRUCCIONES PARA REPARAR, LEER EL MANUAL DEL OPERADOR.

AVERTISSEMENT

UNE UTILISATION INCORRECTE PEUT ÊTRE DANGEREUSE. SUIVEZ LES INSTRUCTIONS CI-DESSOUS: RISQUE D'ECLATEMENT. ASSUREZ-VOUS QUE LA

PRESSION DE SORTIE DU COMPRESSEUR EST RÉGLÉE À UN NIVEAU INFÉRIEUR À LA PRESSION D'UTILISATION MAXIMUM DU PISTOLET VAPORISATEUR OU DE

L'ACCESSOIRE. AVANT DE DÉMARRER LE COMPRESSEUR, TIREZ SUR L'ANNEAU DE LA SOUPAPE DE SÛRETÉ POUR VOUS ASSURER QU'ELLE FONCTIONNE LIBREMENT. VIDANGEZ L'EAU DU RÉSERVOIR

À AIR APRÈS CHAQUE UTILISATION. RISQUE D'INCENDIE OU D'EXPLOSION. NE PAS VAPORISER UN LIQUIDE OU UN PEINTURE INFLAMMABLE OU COMBUSTIBLE PRÈS D'ÉTINCELLES, DE FLAMMES, DE

VEILLEUSES NI DANS UN ENDROIT RESTREINT OU RENFERMÉ. L'AIRE DE VAPORISATION DOIT ÊTRE BIEN AÉRÉE. GARDEZ LE COMPRESSEUR À UNE DISTANCE D'AU MOINS 20 PIEDS DE LA SURFACE À

VAPORISER. NE PORTEZ PAS LE COMPRESSEUR ET NE L'UTILISEZ PAS NI AUCUN AUTRE APPAREIL ÉLECTRIQUE À PROXIMITÉ DE L'AIRE DE VAPORISATION. NE FUMEZ JAMAIS QUAND VOUS

VAPORISEZ. UTILISEZ UN FLEXIBLE D'AIR D'UNE LONGUEUR MINIMUM DE 25 PIEDS POUR RELIER LE PISTOLET VAPORISATEUR AU COMPRESSEUR. RISQUE DE BLESSURES CORPORELLES. PORTEZ DES

LUNETTES DE PROTECTION ANSI Z87. NE DIRIGEZ JAMAIS L'AIR COMPRIME OU DES MATÉRIAUX VERS SOI OU VERS AUTRUI. NE JAMAIS UTILISER DE L'AIR COMPRIMÉ POUR LA RESPIRATION. RÉGLEZ

LA PRESSION À ZÉRO AVANT DE RETIRER LE BOYAU. RISQUE DE CHOC ÉLECTRIQUE. VOLTAGE DANGEREUX. DEBRANCHEZ LA MACHINE AVANT D'ENLEVER BOITIER. N'EXPOSEZ PAS LE COMPRESSEUR

À LA PLUIE. REMISEZ-LE À L'INTÉRIEUR. LISEZ LE MANUEL DE L'UTILISATEUR POUR DES INSTRUCTIONS COMPLÈTES CONCERNANT LA SÉCURITÉ, L'UTILISATION ET LES RÉPARATIONS.

INCORRECT USE CAN CAUSE HAZARDS. FOLLOW THESE INSTRUCTIONS: RISK OF BURSTING. MAKE SURE THE COMPRESSOR OUTLET PRESSURE IS SET

LOWER THAN THE MAXIMUM OPERATING PRESSURE OF THE SPRAY GUN OR TOOL. BEFORE STARTING THE COMPRESSOR, PULL THE RING ON THE SAFETY

VALVE TO MAKE SURE THE VALVE MOVES FREELY. DRAIN WATER FROM TANK AFTER EACH USE. RISK OF FIRE OR EXPLOSION. DO NOT SPRAY A FLAMMABLE OR COMBUSTIBLE

LIQUID OR PAINT NEAR SPARKS, FLAMES, PILOT LIGHTS, OR IN A CONFINED AREA. THE SPRAY AREA MUST BE WELL VENTILATED. KEEP COMPRESSOR AT LEAST 20 FEET AWAY FROM

SPRAY AREA. DO NOT CARRY AND OPERATE THE COMPRESSOR, OR ANY OTHER ELECTRICAL DEVICE NEAR THE SPRAY AREA. NEVER SMOKE WHEN SPRAYING. USE A MINIMUM OF

25 FEET OF HOSE TO CONNECT A SPRAY GUN TO THE COMPRESSOR. RISK OF PERSONAL INJURY. WEAR ANSI Z87 SAFETY GLASSES. NEVER SPRAY COMPRESSED AIR OR MATERIAL

AT SELF OR OTHERS. DO NOT USE COMPRESSED AIR FOR BREATHING. REGULATE PRESSURE TO ZERO BEFORE REMOVING HOSE. RISK OF ELECTRICAL SHOCK. HAZARDOUS VOLTAGE.

UNPLUG UNIT BEFORE REMOVING COVER. DO NOT EXPOSE TO RAIN, STORE INDOORS. READ OWNER'S MANUAL FOR COMPLETE SAFETY, OPERATION, AND REPAIR INSTRUCTIONS.

WARNING

HOLD HOSE FIRMLY TO

PREVENT HOSE WHIP.

CAUTION

SOSTENGA LA MANGUERA

CON FIRMEZA PARA EVITAR EL.

ATENCIÓN

BIEN TENIR LE TUYAU POUR

ÉVITER UN À-COUP.

ATTENTION

DRAIN TANK DAILY OR AFTER EACH USE. CONDENSATION BUILD-UP MAY CAUSE CORROSION

INSIDE TANK RESULTING IN TANK FAILURE. SEE MANUAL FOR INSPECTION PROCEDURES. TO DRAIN

TANK OPEN VALVE SLOWLY AND TILT COMPRESSOR TO EMPTY ACCUMULATED WATER.

WARNING

DRENE EL TANQUE A DIARIO O DESPUÉS DE CADA USO. LA ACUMULACIÓN DE CONDENSACIÓN

PUEDE OCASIONAR CORROSIÓN DENTRO DEL TANQUE Y PROVOCAR FALLA DEL TANQUE.

CONSULTE EL MANUAL PARA CONOCER LOS PROCEDIMIENTOS DE INSPECCIÓN. PARA DRENAR EL TANQUE, ABRA LA

VÁLVULA LENTAMENTE E INCLINE EL COMPRESOR PARAELIMINAR EL AGUA ACUMULADA.

ADVERTENCIA

RÉSERVOIR DE VIDANGE QUOTIDIEN

OU APRÈS CHAQUE UTILISATION. L'HABILLAGE

DE

CONDENSATION PEUT CAUSER LA CORROSION À L'INTÉRIEUR DU RÉSERVOIR AYANT POUR

RÉSULTAT L'ÉCHEC DE RÉSERVOIR. VOIR LE MANUEL POUR DES PROCÉDURES D'INSPECTION. À LA VALVE

OUVERTE

DE RÉSERVOIR DE VIDANGE LENTEMENT ET AU COMPRESSEUR D'INCLINAISON À L'EAU ACCUMULÉE VIDE.

AVERTISSEMENT

Page 22

- 22 -

INTRODUCTION

• Vitesse de travail rapide et large jet en éventail

• Grande efcacité de transfert pour une diffusion réduite

• Pointeau de réglage du mélange en acier inoxydable et embout pour utiliser avec les matériaux en phase

aqueuse

• Pression de fonctionnement maximale : 50 psi

• Modèle de grande efcacité pour réduire fortement les coûts d'exploitation

TABLE DES MATIÈRES

Garantie Limitée De 3 Ans

..........................................................22

Composants de l’outil, Spécications de l’outil

........................ 23

Consignes de sécurité

................................................................24

Avertissement ................................................................................25

Installation .....................................................................................26

Mode d’emploi

............................................................................ 27

Instruction d'entretien du mécanisme ..................................... 28

Dépannage

.................................................................................. 29-30

IMPORTANT

S’assurer que l’utilisateur de l’outil lit attentivement et comprend ces instructions avant d’utiliser l’outil.

GARANTIE LIMITÉE DE 3 ANS

Stanley garantit ce produit à l’acheteur d’origine pendant une période de

TROIS (3) ANS

contre les défauts

de matériaux et de main d’œuvre. Cette

GARANTIE LIMITÉE

ne couvre pas les produits qui ont été mal

utilisés, abusés, modiés ou réparés. Les produits défectueux seront remplacés ou réparés au choix de

Stanley. Veuillez appeler le

1-800-505-4648

pour plus de renseignements ou au sujet desinstructions de

renvoi.

CETTE GARANTIE LIMITÉE EST DONNÉE EN LIEU DE TOUTES AUTRES, Y COMPRIS LES

GARANTIESTACITES D’APTITUDE À ÊTRE VENDU ET UTILISÉ À UN BUT PARTICULIER, ET EXCLUT TOUS

LES DÉGÂTS SECONDAIRES OU CONSÉQUENTS.

Quelques états ne permettent pas de limites sur la

durée de garanties tacites ou sur l’exclusion ou la limitation des dégâts secondaires ou conséquents,

donc il se peut que ces limitations ne s’appliquent pas à vous.

Cette GARANTIE LIMITÉE

vous procure des

droits spéciques qui peuvent varier d’un état à l’autre.

DIRECTIVES DE SÉCURITÉ – DÉFINITIONS

Ce manuel contient des informations qu’il est important de connaître et de comprendre. Cette

information porte sur

VOTRE SÉCURITÉ

et sur la

PRÉVENTION DES PROBLÈMES D’OUTIL

. Pour vous

aider à reconnaître cette information, nous utilisons les symboles ci-dessous. Veuillez lire ce manuel

attentivement et accorder une attention particulière à ces paragraphes.

SÉCURITÉ et PRÉVENTION DES PROBLÈMES D’OUTIL

Pour vous aider à reconnaître cette information,

nous utilisons les symboles ci-dessous. Veuillez lire ce manuel attentivement et accorder une attention

particulière à ces paragraphes.

Indique une situation

dangereuse imminente

qui, si elle n’est pas évitée,

causera

le

décès ou une blessure grave

.

Indique une situation

dangereuse potentielle qui,

si elle n’est pas évitée,

peut

causer une

blessure

mineure ou modérée

.

Indique une situation

dangereuse potentielle qui, si elle

n’est pas évitée,

pourrait

causer le

décès ou

une blessure grave

.

Utilisé sans le symbole d’alerte de

sécurité indique une situation dangereuse

potentielle si, si elle n’est pas évitée,

peut

causer

des

dommages aux biens

.

Page 23

- 23 -

COMPOSANTS DE L'OUTIL

BTMT72393

Description

Pistolet Hvp À Gravitation

Consommation moyenne d’air

5,6 pi

3

/min Usage à 100 %

Débit du mélange

170 cc/min

Entrée d’air

Taraudage de 6,35 mm NPS (F)

Poids

0,7095KG (1,56lb)

Taille minimale du tuyau

9,53 mm (3/8 po) D.I.

Pression requise en lb/po²

30 – 50 psi

Entrée de liquide

Taraudage de 9,53mm (3/8 po) DN (F)

Pression d’air d’entrée

345 kPa (50 psi)

Largeur du jet

> 180 mm

Embout de buse

1,5 mm

Raccord à air comprimé

Taraudage de 6,35mm (1/4 po) DN (F)

ESPECIFICACISPÉCIFICATIONS DE L’OUTIL

Les mesures sont métriques suivies de mesures impériales entre parenthèses.

Écrou De Soupape

Anti-Vide

Bouton

Régulateur De

Liquide

Bouton Régulateur

De Volume D’air

Réglage De La

Forme De Jet

Godet AntiGoutte

Filtre

Cornes

Anneau

Déecteur

FIG.1

Page 24

- 24 -

Définitions : lignes directrices

en matière de sécurité

Les définitions ci-dessous décrivent le niveau de

gravité pour chaque symbole. Veuillez lire le mode

d’emploi et porter une attention particulière à ces

symboles.

DANGER : Indique une situation dangereuse

imminente qui, si elle n’est pas évitée, causera la

mort ou des blessures graves.

AVERTISSEMENT : Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée,

pourrait se solder par un décès ou des blessures

graves.

ATTENTION : Indique une situation potentielle-

ment dangereuse qui, si elle n’est pas évitée pourrait

se solder par des blessures mineures ou modérées.

ATTENTION : Utilisé sans le symbole d’alerte à la

sécurité, indique une situation potentiellement dangereuse qui, si elle n’est pas évitée pourrait se solder

par des dommages à la propriété.

DIRECTIVES DE SÉCURITÉ

IMPORTANTES

Nertaines poussières produites par les

travaux de ponçage, sciage, meulage, perçage et autres

peuvent contenir des produits chimiques pouvant selon l’état

de Californie causer le cancer, des anomalies congénitales ou

d’autres problèmes liés aux fonctions reproductrices. Voici

quelques exemples de ces produits chimiques :

• le plomb contenu dans les peintures à base de plomb;

• la silice cristalline provenant de la brique, du ciment et

d’autres produits de maçonnerie;

• l’arsenic et chrome provenant de bois traité chimiquement.

Les risques reliés à l’exposition à ces poussières varient

selon la fréquence à laquelle l’utilisateur travaille avec ce type

de matériaux. Pour réduire votre exposition à ces produits

chimiques : travailler dans un endroit bien ventilé et porter un

équipement de sécurité approuvé par

l’OSHA/MSHA/NIOSH

comme un masque anti-poussières spécialement adapté ou

un respirateur lors de l’utilisation de ces outils.

Lors de l’utilisation d’outils pneumatiques, des précautions

de base en matière de sécurité doivent être suivies afin de

réduire le risque de blessure personnelle.

Ce produit contient des produits chimiques, notamment le

plomb, reconnus par l’État de Californie comme étant cancérigènes et pouvant entraîner des anomalies congénitales et

d’autres dangers relatifs à la reproduction. Se laver les mains

après toute manipulation.

CONSERVER CES INSTRUCTIONS

a mauvaise utilisation ou maintenance de ce

produit peut causer des blessures graves Et des

dommages sérieux aux biens. Il faut lire et

comprendre tous les avertissements et la. Notice

d’emploi avant d’utiliser cet équipement. Lorsque vous

utilisez des outils pneumatiques, il faut respecter les mesures

de sécurité fondamentales pour réduire leRisque de

blessures.

l faut lire et comprendre ce guide d’instructions et les

étiquettes de l’outil avant d’installer, d’utiliser cet outil

ou d’en faire l’entretien. Gardez ces instructions dans

un lieu sûr à portée de la main.

Les opérateurs et autres personnes dans la zone de

travail doivent porter des lunettes de sécurité avec

écrans latéraux approuvées

ANSI Z87.1 CAN/CSA

Z94.3

.

Les utilisateurs et les gens dans la zone de travail

doivent porter une protection auditive.

Graissez tous les jours pour un rendement optimal.

• Toute personne se trouvant dans la zone de travail doit

porter, en tout temps, une protection pour les yeux et

auditive appropriées, ainsi qu’un masque de protection

approuvé lorsque le pistolet de pulvérisation est utilisé.

• Ne jamais pointer le pistolet de pulvérisation vers

quelqu’un. Ne pas pulvériser à proximité d’étincelles,

de flammes nues, de cigarettes allumées, de veilleuses, d’appareils de chauffage ni de toute autre source

d’allumage potentielle, NE PAS FUMER

DANS LA ZONE DE TRAVAIL.

• Seules les personnes connaissant parfaitement ces

règles de fonctionnement sécuritaire doivent utiliser cet

outil pneumatique.

• Suivre les instructions et les informations de sécurité

du fabricant afin de s’assurer de bien manipuler les

peintures, les laques, les diluants, les couches de fond,

etc. Ne pas utiliser de peinture au latex ou à texture

plus épaisse Elles ne sont pas recommandées pour ce

pistolet de pulvérisation.

• Toujours garder la zone de travail libre d’obstructions et

bien ventilée.

• Toujours séparer le pistolet de pulvérisation de la

source d’air avant de le démonter.

• Pour éviter de créer une atmosphère explosive, maintenir la zone de travail bien ventilée en tout temps.

• Toujours utiliser un masque de protection afin de ne

pas inhaler

de vapeurs et de substances nocives.

• Avant de démonter ou de retirer toute pièce du pistolet

ou tout composant fixé sur celui-ci, arrêter le compresseur, décharger la pression en maintenant la gâchette

enfoncée et séparer la source d’alimentation. Ne

JAMAIS présumer que la pression du système est à

zéro!

Page 25

- 25 -

RISQUE D’EXPLOSION OU

D’INCENDIE

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Lorsque des peintures

ou des matériaux sont

pulvéris és, ils sont

fracturés en de très

petites particules

et mélangés à de l’air.

Cela rend certaines

peintures et certains

matériaux

extrêmement inflammables et peut causer

des blessures graves

ou la mort.

• Ne jamais pulvériser

près de flammes nues

ni de veilleuses

de cuisinières ou

d’appareils de

chauffage.

• Ne jamais fumer lors

d’une pulvérisation.

• Fournir une ventilation abondante lors

d’une pulvérisation à

l’intérieur.