Page 1

70101337 13/06

BOSTITCH AIR TOOL SYSTEMS

BEFORE OPERATING THIS TOOL, ALL OPERATORS SHOULD STUDY THIS

MANUAL TO UNDERSTAND AND FOLLOW THE SAFETY WARNINGS AND

INSTRUCTIONS. KEEP THESE INSTRUCTIONS WITH THE TOOL FOR FUTURE

REFERENCE. IF YOU HAVE ANY QUESTIONS, CONTACT YOUR STANLEYBOSTITCH REPRESENTATIVE OR DISTRIBUTOR.

ANTES DE OPERAR ESTA HERRAMIENTA, TODOS LOS OPERADORES

DEBERÁN ESTUDIAR ESTE MANUAL PARA PODER COMPRENDER Y

SEGUIR LAS ADVERTENCIAS SOBRE SEGURIDAD Y LAS INSTRUCCIONES.

MANTENGA ESTAS INSTRUCCIONES CON LA HERRAMIENTA PARA

FUTURA REFERENCIA, SI TIENE ALGUNA DUDA, COMUNÍQUESE CON SU

REPRESENTANTE DE STANLEY-BOSTITCH O CON SU DISTRIBUIDOR.

LIRE ATTENTIVEMENT LE PRÉSENT MANUEL AVANT D’UTILISER L’APPAREIL.

PRÉTER UNE ATTENTION TOUTE PARTICULIÈRE AUX CONSIGNES DE

SÉCURITÉ ET AUX AVERTISSEMENTS. GARDER CE MANUEL AVEC L’OUTIL

POUR FUTUR RÉFÉRENCE. SI VOUS AVEZ DES QUESTIONS, CONTACTEZ

VOTRE REPRÉSENTANT OU VOTRE CONCESSIONNAIRE STANLEY-BOSTITCH.

OPERATION AND MAINTENANCE MANUAL

MANUAL DE OPERACIÓN Y DE MANTENIMIENTO

MANUEL D’INSTRUCTIONS ET D’ENTRETIEN

BTMT72391

1/2" DRIVE IMPACT WRENCH

CUADRANTE DE 1/2 PUL.LLAVE DE IMPACTO

PRISE ½ PO CLÉ À CHOC

Page 2

INTRODUCTION

• 500 ft-lb of torque for fast removal of stubborn bolts

• Free Speed of 7,200 RPM

• Handle exhaust directs air away from your face and work area

• Forward/reverse control and variable speed trigger

• Suggested applications: For removing wheel lug nuts,nuts, bolts and lag bolts

• Maximum Operating Pressure: 90 psi

INDEX

3 Year limited warranty .............................................................. 2

Tool components, Tool specications ....................................... 3

Denitions: safety guidelines,

Important safety instructions .................................................... 4

Warning: .....................................................................................5-6

Air supply and connections, installation,

safety rules for pneumatic tools ............................................... 7

Preparation for use .................................................................... 8

Operating instructions ............................................................... 9

Maintenance ............................................................................... 10

IMPORTANT

Please make certain that person who is to use this equipment carefully reads and understands these

instructions before operating.

3 YEAR LIMITED WARRANTY — U.S. and Canada Only

Stanley warrants this product to the original purchaser for a period of

THREE (3) YEARS

against

deciencies in material and workmanship.

This LIMITED WARRANTY

does not cover products that are

improperly used, abused, altered or repaired. Decient products will be replaced or repaired at Stanley's

option. Please call 1-800-505-4648 for more information or return instructions.

THIS LIMITED WARRANTY IS GIVEN IN LIEU OF ALL OTHERS INCLUDING THE IMPLIED WARRANTY OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE AND EXCLUDES ALL INCIDENTAL OR

CONSEQUENTIAL DAMAGES.

Some states do not allow limitations on how long an implied warranty

lasts or the exclusion or limitation of incidental or consequential damages, so these limitations may not

apply to you. This

LIMITED WARRANTY

gives you specic legal rights that may vary from state to state.

SAFETY GUIDELINES - DEFINITIONS

This manual contains information that is important for you to know and understand. This information

relates to protecting

YOUR SAFETY

and

PREVENTING EQUIPMENT PROBLEMS

. To help you recognize this

information, we use the symbols below. Please read the manual and pay attention to these sections.

SAFETY

and

PREVENTING EQUIPMENT PROBLEMS

.To help you recognize this information, we

use the symbols below. Please read the manual and pay attention to these sections.

Indicates an imminently

hazardous situation which,

if not avoided,

will

result in

death or serious

injury

.

Indicates a potentially

hazardous situation which,

if not avoided,

may

result in

minor or

moderate injury

.

Indicates a potentially

hazardous situation which,

if not avoided,

could

result in

death or serious injury

.

Used without the

safety alert symbol indicates a

potentially hazardous situation which,

if not avoided,

may

result in

property damage

.

- 2 -

Page 3

- 3 -

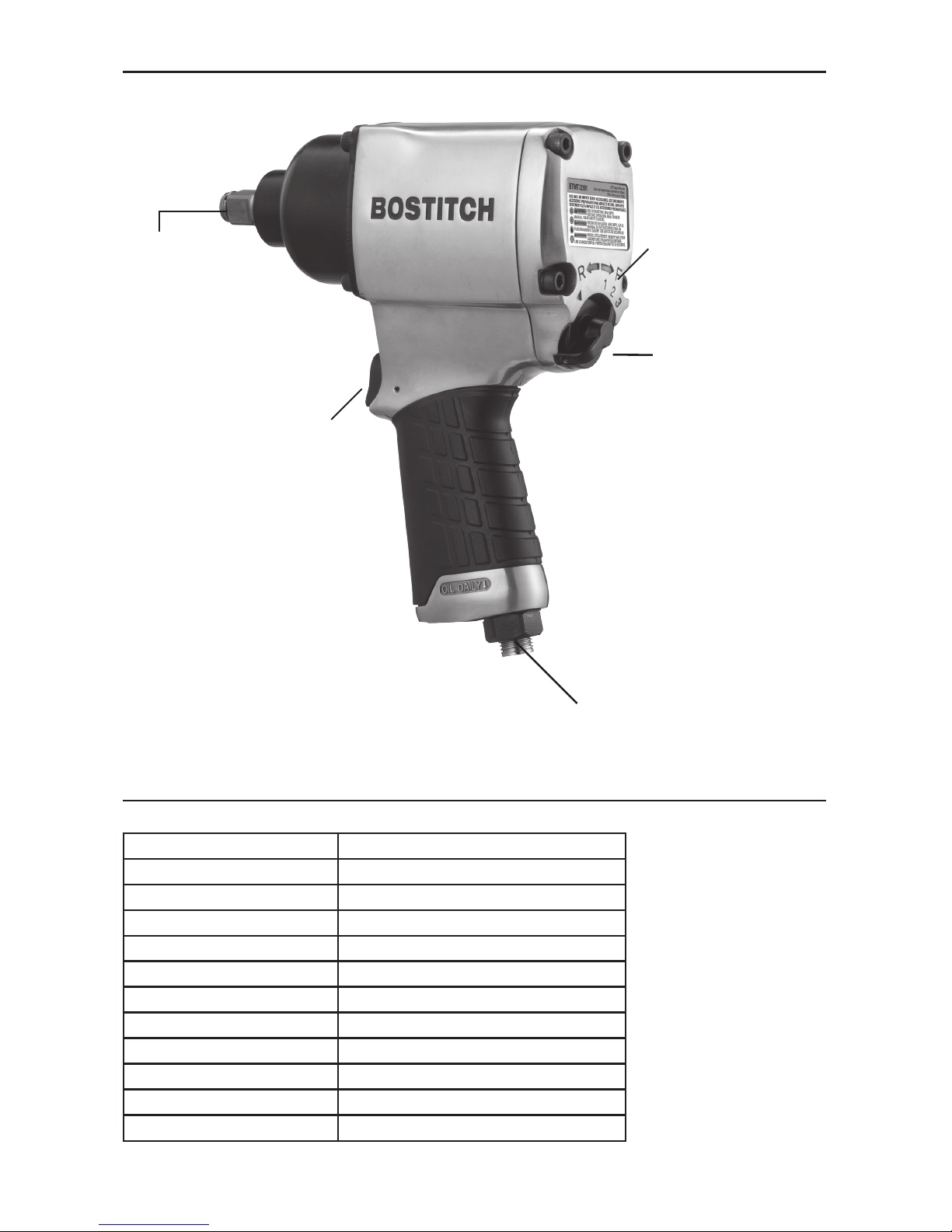

TOOL COMPONENTS

BTMT72391

Description

1/2" Drive Impact Wrench

Average Air Consumption

3.9CFM 100% Usage

Mechanism

Twin Hammer

Free Speed@90 PSI

7,200

Max. Torque

500 ft-lbs

Air Inlet

1/4" NPT (F)

Weight

5.95 lbs.

Recommended Hose Size

3/8"

Square Drive

1/2”

Exhaust

Handle

Air Pressure(PSI)

90

Trigger

Forward/

Reverse

Air inlet

Torque Forward/

Reverse Lever

1/2” Square

Drive

TOOL SPECIFICATIONS

All dimensions in inches unless otherwise specified.

FIG.1

Page 4

- 4 -

Definitions: Safety Guidelines

The definitions below describe the level of severity

for each signal word. Please read the manual and pay

attention to these symbols.

DANGER: Indicates an imminently hazardous

situation which, if not avoided, will result in death or

serious injury.

WARNING: Indicates a potentially hazardous

situation which, if not avoided, could result in death

or serious injury.

CAUTION: Indicates a potentially hazardous

situation which, if not avoided, may result in minor

or moderate injury.

CAUTION: Used without the safety alert symbol indi-

cates a potentially hazardous situation which, if not

avoided, may result in property damage.

IMPORTANT SAFETY INSTRUCTIONS

Some dust created by power

sanding, sawing, grinding, drilling,

and other construction activities contains chemicals

known to the State of California to cause cancer,

birth defects or other reproductive harm. Some

example of these chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks and cement

and other masonry products

• Arsenic and chromium from chemically-treated

lumber

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment,

al ways wear

OSHA/MSHA/NIOSH

approved,

properly fit ting face mask or res pi ra tor when us ing

such tools.When using air tools, basic safety precautions should always be followed to reduce the risk of

personal injury.

This product contains chemicals,

known to the State of California to cause cancer,

and birth defects or other reproductive harm. Wash

hands after handling.

SAVE THESE INSTRUCTIONS

Improper operation or maintenance of

this product could result in serious injury

and property damage. Read and

understand all warnings and operating

instructions before using this equipment.

When using air tools, basic safety precautions

should always be followed to reduce the risk of

personal injury.

Read and understand this instruction manual

and tool labels before installing, operating or

servicing this tool. Keep these instructions in

a safe accessible place.

Operators and others in work area must wear

ANSI Z87.1 CAN/CSA Z94.3 approved safety

glasses with side shields.

Operators and others in work area must wear

ear protection.

Oil daily for optimal performance.

• Avoid prolonged use: repetitive motion or

exposure to vibration may be harmful to your

hands or arms. Use gloves to provide extra

cushion, take frequent rest periods, and limit

daily time of use.

• Do Not Use oxygen or reactive gases;

explosion may occur.

• Do Not Exceed air pressure of 90 PSI.

• Read all manuals included with this product

carefully. Be thoroughly familiar with the

controls and the proper use of the equipment.

• Only persons well acquainted with these rules

of safe operation should be allowed to use the

air tool.

• Do not exceed any pressure rating of any

component in the system.

• Disconnect the air tool from air supply before

changing tools or attachments and during

non-operation.

• Always wear safety glasses and ear protection

during operation. Always wear approved safety

glasses with shields. Always wear approved

hearing protection.

• Do not wear loose fitting clothing or apparel

which contains loose straps or ties, etc. Which

could become entangled in moving parts of the

tool and results in serious personal injury.

• Do not wear jewelry, watches, identifications,

bracelets, necklace, etc. When operating any

tool, they may become caught in moving parts

and result in serious injury.

• Do not depress trigger when connecting the air

supply hose.

• Always use attachments designed for use with

air powered impact tools.

• Do not use damaged or worn attachments.

• DO NOT use hand tool sockets. Use impact

quality sockets only.

• Never trigger the tool when not applied to a

work object Attachments must be securely

attached. Loose attachments can cause serious

injury.

• Protect air lines from damage or puncture.

• Never point an air tool at oneself or any other

person. Serious injury could occur.

• Check air hoses for weak or worn condition

before each use. Make sure all connections are

secure.

• Keep all nuts, bolts and screws tight and

ensure equipment is in safe working condition.

• Do not put hands near or under moving parts.

Page 5

- 5 -

RISK OF EXPLOSION OR FIRE

WHAT CAN HAPPEN HOW TO PREVENT IT

• Abrasive tools such

as sanders and

grinders, rotating

tools such as drills,

and impact tools

such as wrenches,

hammers,and

reciprocating saws

are capable of

generating sparks

which could result

in ignition of flammable materials.

• Never operate tools

near flammable

substances such

as gasoline, naptha,

cleaning solvents,

etc.

• Work in a clean,well

ventilated area free

of combustible

materials.

• Never use oxygen,

carbon dioxide or

other bottled gases

as a power source

for air tools.

• Exceeding the

maximum pressure

rating of tools

accessories could

cause an explosion

resulting in serious

injury.

• Use compressed

air regulated to a

maximum pressure

at or below the

rated pressure of

any attachments.

RISK TO BREATHING

(ASPHYXIATION)

WHAT CAN HAPPEN

HOW TO PREVENT IT

• Abrasive tools,

such as grinders,

sanders, and cut-off

tools generate dust

and abrasive materials which can be

harmful to human

lungs and respiratory system.

• Always wear

MSHA/NIOSH

approved, properly

fitting face mask or

respirator when

using such tools.

• Some materials

such as adhesives

and tar contain

chemicals whose

vapors could cause

serious injury with

prolonged

exposure.

• Always work in a

clean, dry, well

ventilated area.

RISK FROM NOISE

WHAT CAN HAPPEN HOW TO PREVENT IT

• Long term

exposure to noise

produced from the

operation of air

tools can lead to

permanent

hearing loss.

• Always wear ANSI

(S3.19) hearing

protection.

RISK OF INJURY

WHAT CAN HAPPEN HOW TO PREVENT IT

• Tools left

unattended, or

with the air hose

attached can be

activated by unauthorized persons

leading to their

injury or injury to

others.

• Remove air hose

when tool is not in

use and store tool

in a secure location

away from reach

of children and/or

untrained users.

• Air tools can propel

loose objects or

other materials

throughout the

work area.

• Use only parts,

fasteners, and

accessories recommended by the

manufacturer.

• Keep work area

clean and free of

clutter. Keep

children and others

away from work

area during operation of the tool.

• Keep work area

well lit.

• Air tools can

become activated

by accident during

maintenance or tool

changes.

• Remove air hose

to lubricate, add, or

replace sockets.

• Never carry the tool

by the hose.

• Avoid unintentional

starting. Don’t carry

hooked-up tool with

finger on trigger.

• Repair service

should be done

only by an authorized service representative.

• A wrench or a key

that is left attached

to a rotating part of

the tool increases

the risk of personal

injury.

• Remove adjusting

keys and wrench

before turning

the tool on.

• Using inflato

nozzles for duster

applications can

cause serious

injury.

• DO NOT use

inflator nozzles for

duster applications.

• Air tools can cause

the work piece to

move upon contact

leading to injury.

• Use clamps or

other devices

to prevent

movement.

• Loss of control of

the tool can lead to

injury to self or others.

• Never operate tool

while under the

influence of drugs

or alcohol.

• Don’t overreach.

Keep proper footing

and balance at all

times.

• Keep handles dry,

clean, and free from

oil and grease.

• Stay alert. Watch

what you are doing.

Use common

sense. Do not

operate tool when

you are tired.

• Poor quality,

improper, or

damaged tools

such as grinding

wheels, chisels,

sockets, drill, etc.,

can fly apart

during operation,

propelling particles

throughout the

work area causing

serious injury.

• Always use tool

attachments rated

for the speed of

the power tool.

• Never use tools

which have been

dropped, impacted

or damaged by use.

• Use only impact

grade sockets on an

impact wrench.

• Do not apply excessive force to thetool

let the tool perform

the work.

Page 6

- 6 -

RISK OF INJURY (CONTINUED)

WHAT CAN HAPPEN HOW TO PREVENT IT

• Improperly

maintained tool and

accessories can

cause serious

injury.

• Maintain the tool

with care.

• There is a risk of

bursting if the tool

is damaged.

• Check for

misalignment or

binding of moving

parts, breakage of

parts, and any other

condition that

affects the tool’s

operation. If

damaged, have the

tool serviced before

using.

RISK FROM FLYING OBJECTS

WHAT CAN HAPPEN HOW TO PREVENT IT

• Air powered

equipment and

power tools are

capable of propelling materials such

as metal chips, saw

dust, and other

debris at high

speed, which could

result in serious eye

injury.

• Always wear ANSI

Z87.1 CAN/CSA

Z94.3 approved

safety glasses with

side shields.

• Never leave

operating tool

unattended.

Disconnect air hose

when tool is not

in use.

• Compressed air

can be hazardous.

The air stream can

cause injury to soft

tissue areas such

as eyes, ears, etc.

Particles or objects

propelled by the

stream can cause

injury.

• For additional

protection use

an approved face

shield in addition to

safety glasses.

• Tool attachments

can be come loose

or break and fly

apart propelling

particles at the

operator and others

in the work area.

• Make sure that any

attachments are

securely

assembled.

RISK OF ELETRIC SHOCK

WHAT CAN HAPPEN HOW TO PREVENT IT

• This tool is not

provided with an

insulated gripping

surface.Contact

with a “live” wire

will also make

exposed metal

parts of the tool

“live” and can

result in

electrocution or

death.

• Avoid body contact

with grounded

surfaces such as

pipes, radiators,

ranges, and refrigerators. There is

an increased risk

of electric shock

if your body is

grounded.

• Thoroughly investigate the workpiece

for possible hidden

wring before

performing work.

RISK OF CUT OR BURNS

WHAT CAN HAPPEN HOW TO PREVENT IT

• Tools which cut,

shear, drill, punch,

chisel, etc., are

capable of causing

serious injury.

• Keep the working

part of the tool

away from hands

and body.

RISK OF CUT OR BURNS

WHAT CAN HAPPEN HOW TO PREVENT IT

• Tools which contain

moving elements,

or drive other

moving tools such

as grinding wheels,

sockets, sanding

discs,etc., can

become entangled

in hair, clothing,

jewelry and other

loose objects,

resulting in severe

injury.

• Never wear loose

fitting clothes,

or apparel which

contains loose

straps or ties,

etc., which could

become entangled

in moving parts

of the tool.

• Remove any jewelry, watches,

identifications,

bracelets,

necklaces, etc.,

which might

become caught by

the tool.

• Keep hands away

from moving parts.

Tie up or cover

long hair.

• Always wear proper

fitting clothing and

other safety equipment when

using this tool.

Page 7

AIR SUPPLY AND CONNECTIONS

Do not use oxygen, combustible gases, or bottled gases as a power source for this tool as the

tool may explode, possibly causing injury.

Do not use supply sources which can potentially exceed 200 PSI (13.8 bar) as tool may burst, possibly causing

injury.

The connector on the tool must not hold pressure when air supply is disconnected. If a wrong fitting is used,

the tool can remain charged with air after disconnecting and thus will be able to after the air line is disconnected

possibly causing injury.

Always disconnect air supply:

1) Before making adjustments;

2) When servicing the tool;

3) When tool is not in use;

4) When moving to a different work area, as accidental actuation may occur, possibly causing injury.

SAVE THESE INSTRUCTIONS FOR FUTURE USE

INSTALLATION

AIR SUPPLY

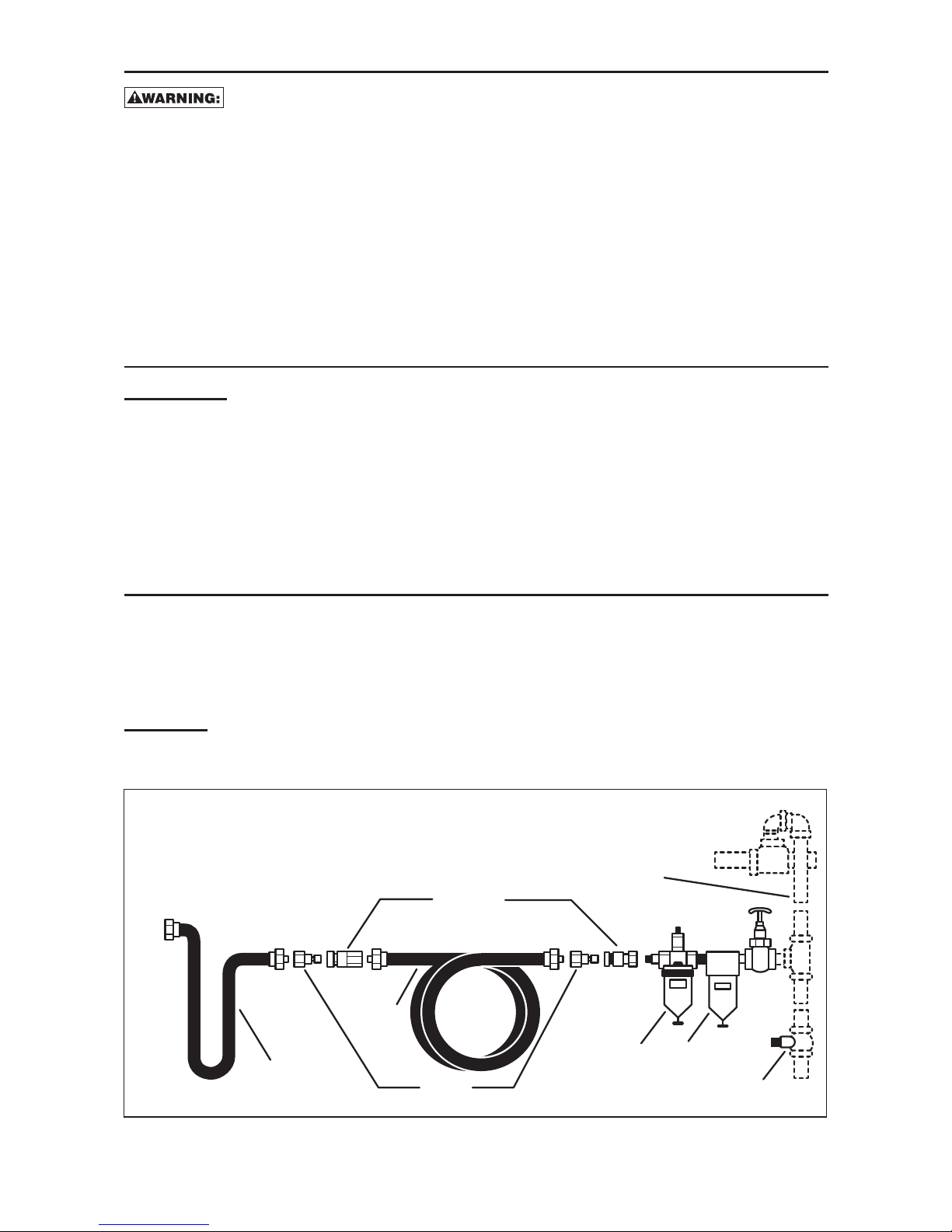

The recommended hook-up is shown in

Figure A.

Pneumatic tools operate on a wide range of air

pressures. For maximum efficiency and longer tool life, the pressure of the air supplied to these tools MUST not

exceed the rated PSI at the tool when the tool is running. Using a higher than rated pressure will cause faster

wear and drastically shorten the tool’s life. A higher air pressure can also cause an unsafe condition and explosion. The inside diameter of the hose should be increased to compensate for unusually long air hoses (over 25

feet). Minimum hose diameter should be 3/8” I.D. and fittings should have 1/4” NPT thread. The use of air line

lubricators and air line filters is recommended to prevent water in the line that can damage the tool. Drain the

air tank daily. Clean the air inlet filter screen on at least a weekly schedule to remove accumulated dirt or other

matter that can restrict air flow. The tool’s air inlet used for connecting an air supply has standard 1/4” NPT

American thread.

SAFETY RULES FOR PNEUMATIC TOOLS

1) Inspect the air hose for cracks or other problems. Replace the hose if worn.

2) Never point an air hose at another person.

3) Disconnect the tool when not in use, or before performing service or changing accessories.

4) Use proper hoses and fittings. Never use quick change couplings attached to the tool. Instead, add a hose and

coupling between the tool and the air supply.

FIGURE A

- 7 -

1/2”(or larger)

Pipe and Fittings

Coupler

Air Hose

Leader Hose

Tool

Nipple

Oiler

Filter

Drain Daily

Page 8

- 8 -

PREPARATION FOR USE

PROPER USE OF THE TOOL

Your new 1/2” Drive Impact Wrench is designed for driving,

tightening and loosening threaded fasteners, usually nuts and

bolts, when tted with a suitable impact socket.

Always use impact-rated extension bars,

universal joints and socket adapters between the

square output drive of the impact wrench and the female square

drive of the socket. Do not use the tool for any other purpose than

that specied without consulting the manufacturer or the

manufacturer’s authorized supplier. To do so may be dangerous.

Never use the impact wrench as a hammer to dislodge or

straighten cross threaded fasteners. Never attempt to modify the

tool for other uses.

WORK STATIONS

Your impact wrench should only be used as a hand operated tool. It is always recommended that the tool

is used when standing with solid footing. It can be used in other positions but before any such use, the

operator must be in a secure position having a rm grip and footing and be aware that when loosening

fasteners the tool can move quite quickly away from the fastener being undone. An allowance must

always be made for this rearward movement so as to avoid the possibility of hand/arm/body entrapment.

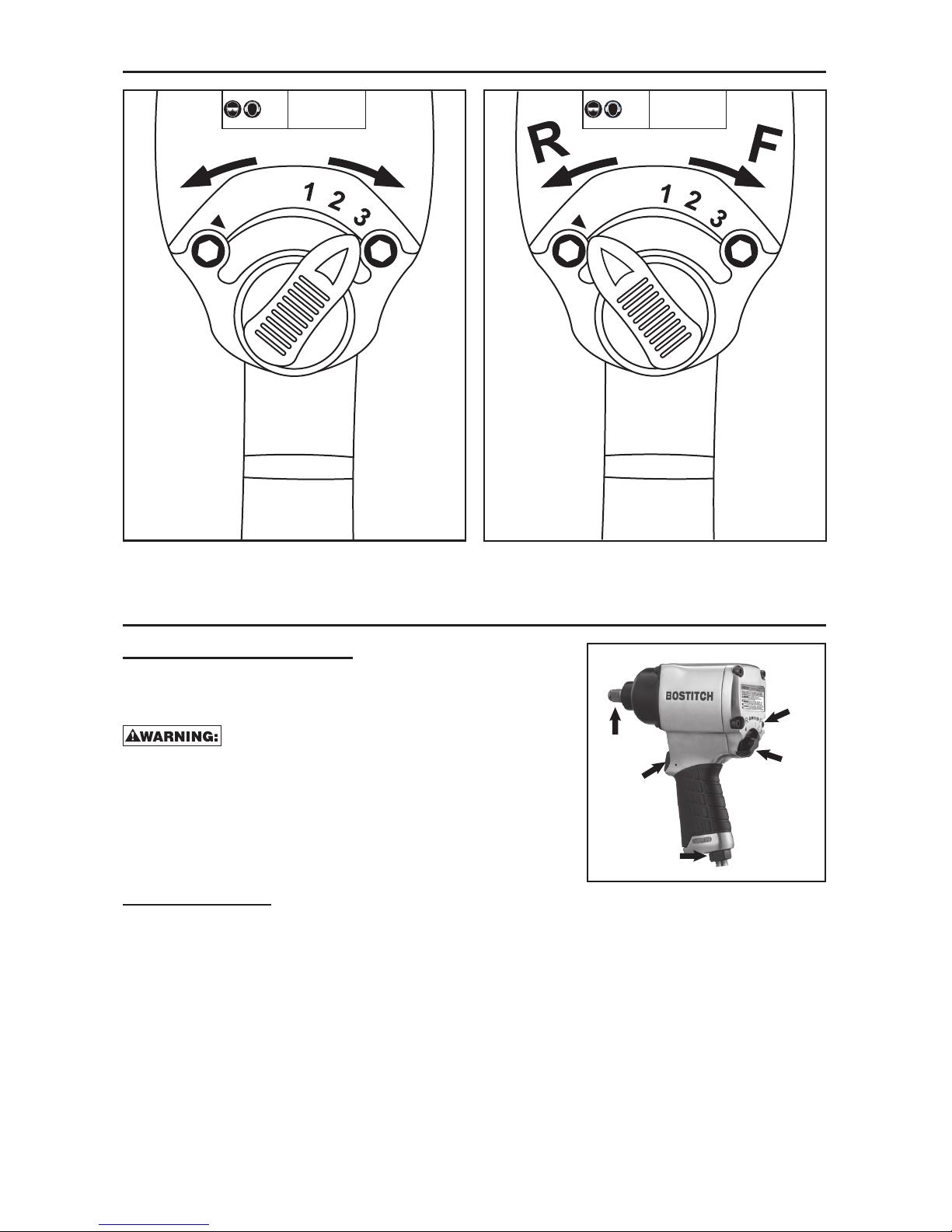

FORWARD / REVERSE SWITCH

Switch position for driving fasteners.Tool power

increases with higher numbered setting.

R

F

use: Repetitive motions or

exposure to vibration may be

harmful to your hands or arms.

90psig (6.2bar) Maximum

Air Pressure.

Instruction Manual

.

Wear eye and ear protection.

use: Repetitive motions or

exposure to vibration may be

harmful to your hands or arms.

90psig (6.2bar) Maximum

Air Pressure.

Instruction Manual

.

Wear eye and ear protection.

Switch position for removing fasteners.

1/2”

Square

Drive

Trigger

Air inlet

Torque

Forward/

Reverse

Lever

Forward/

Reverse

Page 9

- 9 -

PUTTING INTO SERVICE

AIR SUPPLY

Use a clean lubricated air supply that will give a measured air pressure at the tool of

90 psi/6.2 bar when the tool is running with the trigger fully depressed.

Use recommended hose size. It is recommended that the tool is connected to the air supply as shown

in

figure A

on page 7 . Do not connect the tool to the air line system without incorporating an easy to

reach and operate air shut off valve. The air supply should be lubricated. It is strongly recommended

that an air lter, regulator,

lubricator (FRL)

is used as shown in

figure A

on page 7 as this will supply

clean, lubricated air at the correct pressure to the tool. Details of such equipment can be obtained

from your supplier. If such equipment is not used then the tool should be lubricated by shutting off the

air supply to the tool and then depressurizing the line by pressing the trigger on the tool. Disconnect

the air line and pour into the air inlet 1 teaspoon (5cc.) of a suitable pneumatic motor lubricating oil,

preferably incorporating a rust inhibitor. Reconnect tool to air supply and run tool slowly for a few

seconds to allow air to circulate the oil.

Lubricate tool daily if used frequently, or when it starts to slow or lose power.

USING AN IMPACT WRENCH

1) Read all instructions before using this tool. All operators must be fully trained in its use and aware

of these safety rules.

2) Do not exceed the maximum working air pressure of 90 psi/6.2 bar.

3) Use personal safety equipment.

4) Use only compressed air at the recommended conditions.

5) If the tool appears to malfunction, remove from use immediately and arrange for service and repair.

6) If the tool is used with a balancer or other support device, ensure that it is xed securely.

7) Always keep hands away from the working attachment tted to the tool.

8) The tool is not electrically insulated. Never use the tool if there is any chance of it coming into

contact with live electricity.

9) When using the tool, always adopt a firm footing and/or position and grip the tool firmly to

counteract any forces or reaction forces that may be generated while using the tool.

10) Use only correct spare parts. Do not improvise or make temporary repairs.

11) Do not lock, tape, wire, etc. the on/off trigger in the run position. The trigger must always be free

to return to the “off” position when it is released.

12) Always shut off the air supply to the tool and depress the trigger to release air from the feed hose

before tting, adjusting or removing the working attachment.

13) Check hoses and fittings regularly for wear. Replace if necessary. Do not carry the tool by its

hose. Ensure the hand is removed from the on/off trigger when carrying the tool with the air supply

connected.

14) Take care against entanglement of moving tool parts with clothing, ties, hair, cleaning rags, etc.

This will cause the body to be drawn towards the tool and can be very dangerous.

15) It is expected that users will adopt safe working practices and observe all relevant legal

requirements when installing, using or maintaining the tool.

16) Only install the tool when an easily accessible and easily operable on/off switch is incorporated

in the air supply.

17) Take care that the tool exhaust air does not cause problems or blow onto another person.

18) Never lay a tool down unless the working attachment has stopped moving.

19) Always ensure that the forward/reverse switch is in the desired position before starting the tool.

20) Do not use sockets with excessive wear to the input or output drives. Periodically check the squae

drive on the impact wrench. Make surer the socket, extension bar, or other attachment is securely

tted before operating tool.

21) When loosening fasteners rst ensure that there is sufcient clearance behind the tool to avoid

hand entrapment. The tool will move away from the threaded joint as the nut/bolt is loosened and

rides up the thread, moving the tool with it.

Page 10

PRE-START CHECKLIST

• Drain water from air compressor tank and condensation from air lines. (Please refer to air compressor’s

operation manual.)

• Lubricate the tool. (Please refer to the “Maintenance” section in the manual.)

• Select the necessary impact sockets. The sockets have to match with the size of the drive on the air

impact wrench.

• Connect air impact wrench to air source with the hose of recommended size.

Risk of unsafe operation. Firmly grasp air hose with hand when installing or

disconnenting to prevent hose whip.

Risk of bursting. Too much air pressure causes a hazardous risk of bursting. Check the

manufacturer’s maximum pressure rating for air tools and accessories. The regulator

output pressure must never exceed the maximum pressure rating.

OPERATING PROCEDURES

START-UP (FIG. 1, PG.3)

• Turn on the air compressor and allow the air tank to be lled.

• Set the air compressor regulator to 90 PSI. This air tool operates at a maximum of 90 PSI air pressure.

• Adjust power dial (if it is available) to desired torque.

• Adjust tool either in forward or reverse position. See Features on page 8 for diagram.

• Depress the trigger to start operating the tool.

SHUT-DOWN (FIG. 1, PG. 3)

• Release the trigger in order to stop the tool.

• When changing sockets, always disconnect air supply to avoid injury.

• When job is completed, turn off the air compressor and store the air tool after lubrication.

OPERATING INSTRUCTIONS

• Securely t the socket or attachment to the impact wrench.

• Ensure that the forward/reverse switch is in the correct position for tightening or loosening the fastener.

• The nut/bolt can then run down the thread using the power drive of the tool. For loosening a joint the

tool can be used in the reverse sequence.

MAINTENANCE

LUBRICATION

Air tools require lubrication throughout the lifetime of the tools. The air motor and bearing uses

compressed air to power the tool. The compressed air contains moisture that will rust the air motor and

other parts in side of the tools, therefore lubrication is required daily. Failure to lubricate the air tool

properly will dramatically shorten the life of the tool and will void the warranty

This air tool requires lubrication BEFORE initial use, also before and after each additional

use.

TO LUBRICATE THE AIR TOOL MANUALLY:

1. Remove any attachment on the drive of air tools, such as: sockets, chisels and etc.

2. Disconnect the tool from the air supply source, place the air inlet face up.

3. Depress the trigger and place about 1 teaspoon (5cc.) of air tool oil into the air inlet. (Depressing the

trigger will help circulate oil in the motor.)

NOTE:Use SAE #10 weight oil if air tool oil is not available.

4. Connect the tool to an air source, cover the exhaust end with a towel and run for about 20 to 30

seconds.

Keep out of the reach of children. If taken internally, do not induce vomiting, call a doctor immediately.

- 10 -

Page 11

- 11 -

GLOSSARY

CFM:

Cubic feet per minute.

SCFM:

Standard cubic feet per minute; a unit of measure of air delivery.

PSI:

Pounds per square inch; a unit of measure of pressure.

Code Certification:

Products that bear one or more of the following marks:

UL, CUL, ETL, CETL

, have

been evaluated by

OSHA

certied independent safety laboratories and meet the applicable Underwriters

Laboratories Standards for Safety.

RPM:

Revolutions per minute; is a measure of the frequency of a rotation

BPM:

Beats per minute.

NPT:

National pipe thread (tapered thread); is a U.S. standard for tapered threads used on threaded

pipes and ttings.

ID:

Inner diameter

MAINTENANCE

Any excess oil in the motor is immediately expelled from the exhaust port. Always direct exhaust port

away from people or objects.

STORAGE:

The air tool must be lubricated before storing.

Follow the “Lubrication” instruction with exception of step 4.

Page 12

- 12 -

INTRODUCCIÓN

• 500 lbs. pie de torsión para remover rápidamente tornillos pegados

• Velocidad libre de 7.200 RPM

• El escape por el mango dirige el aire lejos de su cara y del área de trabajo

• Control de marcha adelante/atrás y gatillo de velocidad variable

• Usos sugeridos: Para remover pernos de ruedas, tuercas, tornillos y tirafondos

• Máxima presión de operación 90 lbs./ pul ².” (PSI)

ÍNDICE

Garantía Limitada De 3 Años ....................................................12

Componentes De La Herramienta,

Especicaciones De La Herramienta ........................................ 13

Deniciones: Normas de seguridad,

Instrucciones de seguridad importantes.................................. 14

Advertencia................................................................................. 15-16

Alimentación de aire y conexiones, instalación,

Reglas de seguridad para herramientas neumáticas .............. 17

Preparación para el uso ............................................................. 18-19

Notice d’emploi .......................................................................... 20

Mantenimiento ........................................................................... 21

IMPORTANT

Por favor asegúrese de que la persona que va a usar este equipo lea cuidadosamente y comprenda estas

instrucciones antes de operarlo.

GARANTÍA LIMITADA DE 3 AÑOS

Stanley garantiza este producto al comprador original durante un período de

TRES (3) AÑOS

contra

deficiencias en material y mano de obra. Esta

GARANTÍA LIMITADA

no cubre productos que sean

usados impropiamente, abusados, alterados o reparados. Los productos decientes serán reemplazados

o reparados a la opción de Stanley. Por favor llame al teléfono 1-800-505-4648 para obtener mayor

información o instrucciones de retorno.

ESTA GARANTÍA LIMITADA ES OTORGADA EN LUGAR DE TODAS LAS DEMÁS, INCLUYENDO GARANTÍA

IMPLÍCITA DE COMERCIABILIDAD O APTITUD PARA UN PROPÓSITO EN PARTICULAR Y EXCLUYE TODOS

LOS DAÑOS INCIDENTALES O CONSECUENTES.

Algunos estados no permiten limitaciones con relación

a cuanto dura una garantía implícita, o la exclusión o la limitación de daños incidentales o consecuentes,

de modo que estas limitaciones pueda que no le apliquen a usted. Esta

GARANTÍA LIMITADA

le otorga

derechos legales especícos los cuales pueden variar de estado a estado.

NORMAS DE SEGURIDAD – DEFINICIONES

Este manual contiene información que es importante que usted la sepa y la comprenda. Esta información

está relacionada con

SU SEGURIDAD

y

EVITAR PROBLEMAS CON EL EQUIPO

. Para ayudarle a reconocer

esta información, use los símbolos mostrados abajo. Por favor lea el manual y préstele atención a esas

secciones.

SEGURIDAD y EVITAR PROBLEMAS CON EL EQUIPO.

Para ayudarle a reconocer esta información, use

los símbolos mostrados abajo. Por favor lea el manual y préstele atención a esas secciones.

Indica una situación

inminentemente

peligrosa que, si no es evitada,

podrá

dar como

resultado la

muerte o lesiones graves

.

Indica una situación

potencialmente

peligrosa que, si no es evitada,

podrá

resultar en

heridas corporales menores o moderadas

.

Indica una situación

potencialmente peligrosa que,

si no es evitada,

podrá

resultar en la

muerte o en

lesiones graves

.

Usada sin el símbolo

de alerta de seguridad

indica una situación potencialmente peligrosa

que, si no es evitada,

podrá

resultar en

daños

a la propiedad

.

Page 13

- 13 -

COMPONENTES DE LA HERRAMIENTA

BTMT72391

Descripción

Cuadrante de 1/2 pul.Llave de impacto

Promedio de consumo de aire

3.9 CFM Uso al 100%

Mecanismo

Martillo Doble

Velocidad libre @ 90 lbs./pul/² (PSI)

7.200

Torsión máxima

500 lbs. pie

Entrada de aire

Rosca de 1/4 pul.NPT (Hembra)

Peso

5,95 lbs.

Tamaño de manguera

recomendado

3/8 pul.

Cuadrante

1/2 pul.

Escape

Mango

Presión de aire lbs./pul.² (PSI)

90

Gatillo

Marcha/

Reverso

Entrada de aire

Palanca de

marcha/ reverso

de torsión

Cuadrante de

1/2 pul.

ESPECIFICACIONES DE LA HERRAMIENTA

Todas las dimensiones están en pulgadas a menos que se especifique lo contrario.

FIG.1

Page 14

- 14 -- 14 -

Definiciones: Normas de seguridad

Las siguientes definiciones describen el nivel de

gravedad de cada advertencia. Lea el manual y preste

atención a estos símbolos.

PELIGRO: indica una situación de peligro

inminente que, si no se evita, provocará la muerte o

lesiones graves.

ADVERTENCIA: Indica una situación de peligro

potencial que, si no se evita, podría provocar la

muerte o lesiones graves.

ATENCIÓN: Indica una situación de peligro

potencial que, si no se evita, puede provocar lesiones leves o moderadas.

ATENCIÓN: Utilizado sin el símbolo de alerta de

seguridad indica una situación de peligro potencial

que, si no se evita, puede provocar daños en la

propiedad.

INSTRUCCIONES DE SEGURIDAD

IMPORTANTES

Algunas partículas originadas al lijar,

aserrar, amolar, taladrar y realizar otras actividades de

construcción contienen productos químicos reconocidos por

el Estado de California como causantes de cáncer, defectos

de nacimiento u otros problemas reproductivos. Algunos

ejemplos de estos productos químicos son:

• el plomo de las pinturas de base plomo

• la sílice cristalina de ladrillos, cemento y otros productos de mampostería,

• el arsénico y cromo de madera con tratamiento

químico.

El riesgo derivado de estas exposiciones varía según la

frecuencia con la que se realice este tipo de trabajo. Para

reducir la exposición a estos productos químicos: trabaje en

áreas bien ventiladas y con equipos de seguridad aprobados,

use siempre mascarilla facial o de respiración adecuada y

aprobada por OSHA/MSHA/NIOSH cuando use este tipo de

herramientas.

Cuando se utilizan herramientas neumáticas, siempre se

deben respetar las precauciones de seguridad para reducir el

riesgo de lesiones personales.

Este producto contiene sustancias químicas, incluido el

plomo, reconocidas por el Estado de California como causantes de cáncer, defectos de nacimiento u otros problemas

reproductivos. Lávese las manos después de utilizarlo.

GUARDE ESTAS INSTRUCCIONES

Laoperación o el mantenimiento inapropiados de

este producto podrán resultar en Lesiones graves

y daños a la propiedad. Lea y comprenda todas

las advertencias e Instrucciones de operación

antes de usar este equipo. Cuando use herramientas

neumáticas,Se deberán seguir las precauciones de seguridad

básicas para reducir el riesgo de heridas Personales.

Lea y comprenda este manual de instrucciones y los

rótulos en la herramienta antes de instalarla, operarla

o darle servicio a esta herramienta. Mantenga estas

instrucciones en un lugar seguro y accesible.

Tanto el operador como las demás personas deben

llevar puestas gafas de seguridad con protectores

laterales que cumplan con la norma ANSI Z87.1 CAN/

CSA Z94.3.

Los operadores y otros en el área deberán usar

protección para los oídos.

Graissez tous les jours pour un rendement optimal.

• Evite el uso prolongado: el movimiento repetitivo o la

exposición a la vibración podrán ser dañinos para sus

manos o brazos. Utilice guantes para proporcionar protección adicional, tome descansos frecuentes y limite el

el tiempo de uso diario.

• No use oxígeno o gases reactivos; podrá ocurrir una

explosión.

• No exceda una presión de aire de 90 lbs./pul.² (PSI).

• Lea cuidadosamente todos los manuales incluidos con

este producto. Familiarícese completamente con los

controles y con el uso apropiado del equipo.

• Sólo personas bien familiarizadas con estas reglas de

operación seguras se les deberá permitir el uso de la

herramienta neumática.

• No exceda ninguna capacidad de presión de ningún

componente en el sistema.

• Desconecte la herramienta neumática de la fuente de

aire antes de cambiar de herramienta o aditamento y

mientras no está operando.

• Siempre use gafas de seguridad y protección para los

oídos durante la operación. Siempre use gafas de

seguridad aprobadas con protector de cara. Siempre

use protección para los oídos aprobada.

• No use ropas sueltas o atavío que contengas cintas o

corbatas sueltas, etc. los cuales se podrán enredar con

las piezas en movimiento de la herramienta y resultar

en heridas corporales serias.

• No use joyas, relojes, identificaciones, brazaletes,

collares, etc. cuando opere esta herramienta, ellos se

podrán enredar con las piezas en movimiento de la

herramienta y resultar en lesiones graves.

• No oprima el gatillo cuando esté conectando la

manguera de alimentación de aire.

• Utilice siempre accesorios diseñados para ser utilizados

con herramientas de impacto neumáticas.

• No use accesorios dañados o desgastados.

• NO USE dados de herramientas manuales.

• IL NE FAUT JAMAIS utiliser les douilles des outils à

main.

• Il ne faut jamais déclencher l’outil lorsqu’il n’est pas

appliqué contre un objet. Les accessoires doivent êtrebien ancrés. Les accessoires lâches peuvent causer des

blessures graves.

• Protégez les conduits d’air des dommages et des pe

forations.

• Il ne faut jamais pointer l’outil pneumatique vers soi ou

autrui. Des blessures graves peuvent survenir.

• Vérifiez les boyaux d’air en cas d’usure ou de détério

tion avant chaque emploi. S’assurer que tous les ra

cords sont bien branchés.

• S’assurer que les boulons, écrous et vis sont bien se

rés et que l’équipement est en bon état.

• Ne jamais placer ses mains près d’une pièce mobile ou

en dessous.

Page 15

- 15 -- 15 -

RIESGO DE INCENDIO O

EXPLOSIÓN

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• Herramientas abrasivas

tales como lijadoras y

esmeriles,herramientas

rotativas como taladros, y herramientas de

impacto como llaves,

martillos y sierras

recíprocas son capaces

de generar chispas las

cuales pueden resultar

en la ignición de

materiales inflamables.

• Nunca operes herramientas cerca de

sustancias inflamables

como gasolina,

nafta, disolventes de

limpieza, etc.

• Trabaje en una área

limpia y bien ventilada

libre de materiales combustibles.

• Nunca use oxígeno,

dióxido de carbono u

otro gas embotellado

como fuente deenergía

para las herramientas

neumáticas.

• Exceder la presión

nominal máxima de los

accesorios de las herramientas puede causar

una explosión y ocasionar serias lesiones.

• Use aire comprimido

regulado a la presión

máxima o por debajo

de la clasificación de

presión de cualquier

accesorio.

RIESGO RESPIRATORIO

(asfixia)

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• Herramientas abrasivas,

tales como esmeriles,

lijadoras y herramientas

de corte, generan polvo

y materiales abrasivos

los cuales pueden ser

dañinos para los pulmones humanos y el

sistema respiratorio.

• Cuando use tales herramientas, siempre use

una máscara o respirador que le quede justo y

que sea aprobado por la

MSHA/NIOSH.

• Algunos materiales

tales como adhesivos

y brea, contienen

químicos cuyos vapores

pueden causar lesiones

graves bajo exposición

prolongada.

• Siempre trabaje en una

área limpia, seca y bien

ventilada.

RIESGO DE PERDIDA

AUDITIVA

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• La exposición prolongada al ruido producido

por el funcionamiento

de las herramientas

neumáticas puede causar una pérdida permanente de la audición.

• Utilice siempre protección auditiva de

acuerdo con la norma

ANSI (S3.19).

RIESGO DE LESIONES

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• Las herramientas

desatendidas, o con la

manguera conectada

pueden ser activadas

por personas no autorizadas conduciendo a

lesiones o a lesionar

a otros.

• Extraiga la manguera de

aire cuando no se utilice

la herramienta y guarde

la herramienta en un

lugar seguro lejos del

alcance de los niños o

usuarios no capacitados

para utilizarla.

• Las herramientas

neumáticas pueden

despedir objetos flojos

u otros materiales en el

área de trabajo.

• Use sólo las piezas,

los sujetadores y los

accesorios

recomendados por el

fabricante.

• Mantenga el área de

trabajo limpia y sin.

• obstrucciones.

Mantenga a los niños y

otros alejados del área

de trabajo mientras

opera la herramienta.

• Mantenga el área bien

alumbrada.

• Las herramientas

neumáticas pueden activarse accidentalmente

durante operaciones de

mantenimiento o cambios en la herramienta.

• Extraiga la manguera

de aire para lubricar,

añadir o reemplazar los

casquillos.

• Nunca transporte la

herramienta por la

manguera.

• Evite una arrancada

accidental. No transporte una herramienta

conectada con el dedo

en el gatillo.

• El servicio de reparación

deberá ser efectuado

sólo por un representante de servicio autorizado.

• Una llave o llave de

ajuste abandonada en

una pieza giratoria de la

herramienta incrementa

el riesgo de lesiones

personales.

• Extraiga la llave y las

llaves de ajuste antes

de encender la herramienta.

• Usar las boquillas de

inflado para eliminar

el polvo puede causar

serias lesiones.

• NO utilice las boquillas

de inflado para eliminar

el polvo.

• Las herramientas

mecanizadas pueden

causar que la pieza de

trabajo se mueva al

hacer contacto

causando lesiones.

• Use abrazaderas u otros

dispositivos para evitar

el movimiento.

• La pérdida del control

de la herramienta podrá

conducir a lesiones personales o de otros.

• No opere la herramienta

mientras esté bajo la

influencia de drogas o

alcohol.

• No se estire demasiado.

Mantenga los pies

sobre el piso y el balance en todo momento.

• Mantenga los mangos

secos, limpios y libres

de aceite y grasa.

• Manténgase alerta.

Vigile lo que está haciendo. Use el sentido

común. No opere la

herramienta cuando

esté cansado.

Page 16

- 16 -

RIESGO DE LESIONES (continuación)

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• Una herramienta o los

accesorios que no reciban un mantenimiento

adecuado pueden causar

serias lesiones.

• Mantenga la herr mienta

bien cuidada.

• Existen riesgos de que

la herramienta estalle si

está dañada.

• Revise la desalineación

o el atoramiento de

piezas en movimiento,

ruptura de piezas y

cualquier otra condición

que pueda afectar el funcionamiento de la herramienta. Si la herramienta

está dañada, envíela a

reparación antes de utilizarla.

RIESGO DE HERIDAS

EN LOS OJOS O CABEZA

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• Los equipos motorizados

neumáticos y las

herramientas motorizadas son capaces de propulsar materiales como

astillas, |viruta de sierra,

y otros desperdicios a

alta velocidad, lo que

puede resultar en heridas serias en los ojos.

• Utilice siempre gafas

de seguridad con

protectores laterales

que cumplan con la

norma ANSI Z87.1 CAN/

CSA Z94.3.

• Nunca deje desatendida una herramienta en

operación. Desconecte

la manguera de aire

cuando la herramienta

no esté siendo usada.

• El aire comprimido

puede ser peligroso. El

chorro de aire puede

causar heridas a los tejidos blandos tales

como los ojos, oídos,

etc. Las partículas u

objetos propulsados por

un chorro de aire pueden

causar

heridas.

• Para protección adicional

use un protector de cara

además de las gafas de

seguridad.

• Los accesorios de la

herramienta se pueden

aflojar o romper y volar

en pedazos impulsando

partículas al operador

u otros en el área de

trabajo.

• Compruebe que los

accesorios estén firmemente ensamblados.

RIESGO DE DESCARGA ELÉCTRICA

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• Esta herramienta no

incluye una superficie de

agarre aislada. El contacto con un cable cargado

también cargará las piezas metálicas expuestas

de la herramienta, lo

que puede ocasionar

una electrocución o la

muerte.

• Evite el contacto del

cuerpo con superficies

conectadas a tierra, tales

como caños, radiadores

y refrigeradores. Existe

un riesgo de descarga

eléctrica mayor si su

cuerpo está en contacto

con tierra.

• nvestigue exhaustivamente la pieza de trabajo

en busca de cableados

ocultos antes de realizar

el trabajo.

RIESGO DE CORTADAS O

QUEMADURAS

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• Las herramientas que

corta, cizallan, perforan, cincelan, etc., son

capaces de causar

lesiones graves.

• Mantenga la pieza de

trabajode la herramienta

alejada de las manos y

del cuerpo.

RIESGO DE ENREDO

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• Las herramientas que

contienen elementos

móviles, o propulsan

otras herramientas

móviles, tales como discos de esmeril,

discos de lijado, etc., se

pueden enredar en el

pelo, la ropa, las joyas

y otros objetos sueltos,

resultando en lesiones

severas.

• Nunca use ropas sueltas,

o atavíos que contengas

cintas

o corbatas sueltas, etc.

los cuales se podrán

enredar con las piezas en

movimiento de la

herramienta.

• Quítese cualquier joya,

reloj, identificación,

brazalete, collar, etc., que

se pueda enredar con la

herramienta.

• Mantenga las manos

alejadas de las piezas en

movimiento.

Amárrese o cúbrase el

pelo suelto.

• Siempre use ropa que

ajuste apropiadamente y

otros equipos de seguridad cuando

use esta herramienta.

Page 17

- 17 -

ALIMENTACIÓN DE AIRE Y CONEXIONES

• No use oxígeno, gases combustibles o gases embotellados como fuente de potencia para

esta herramienta ya que la herramienta puede explotar, posiblemente causando lesiones.

• No utilice fuentes de suministro que puedan exceder potencialmente 200 PSI (13,8 bar) ya que esto puede

ocasionar que la herramienta estalle y cause lesiones.

• El conector de la herramienta no deberá mantener la presión cuando el suministro de aire es desconectado. Si

se usa un acople equivocado, la herramienta podrá quedarse cargada

con aire después de desconectar y así será capaz de operar después de que la manguera de aire ha sido desconectada causando posiblemente lesiones.

• Siempre desconecte el suministro de aire:

1) Antes de efectuar ajustes,

2) Cuando le preste servicio a la herramienta,

3) Cuando la herramienta no esté siendo usada,

4) Cuando se mueva hacia otra área de trabajo, ya que puede

ocurrir activación accidental, posiblemente causando heridas.

CONSERVE ESTAS INSTRUCCIONES

PARA FUTURAS CONSULTAS

INSTALACIÓN

SUMINISTRO DE AIRE

La conexión recomendada se muestra en la

figura A

Las herramientas neumáticas operan sobre un amplio

margen depresiones de aire. Para obtener la máxima eficiencia y mayor vida útil de la herramienta, la presión

del aire suministrado a estas herramientas NO debe exceder la PSI de servicio especificada en la herramienta

durante su funcionamiento. El uso de una presión más alta de la capacidad nominal de la herramienta causará

un desgaste más rápido reduciendo drásticamente la vida de la herramienta. Una presión de aire más alta también causará una condición insegura y una explosión.

El diámetro interior de la manguera deberá ser aumentado para compensar por una manguera inusualmente

larga (más de 7,62 m o sea 25 pies). El diámetro mínimo de lamanguera deberá ser de 3/8” de D. I. y los conectores deben tener el mismo diámetro interno.

El uso de lubricadores de manguera de aire y de filtros de aire en línea es recomendado para evitar que agua

en la manguera dañe la herramienta. Drene diariamente el tanque de aire.

Limpie el cedazo del filtro de entrada de aire por lo menos una vez por semana para remover la mugre acumulada u otras cosas que puedan restringir el flujo de aire. La entrada de aire de la herramienta usada para

conectar una fuente de aire tiene una rosca estándar americana de 1/4” NPT.

REGLAS DE SEGURIDAD PARA HERRAMIENTAS

NEUMÁTICAS

1) Inspeccione las mangueras de aire para ver si están rajadas o tienen otros problemas. Reemplace la

manguera si está desgastada.

2) Nunca apunte una manguera de aire hacia otra persona.

3) Desconecte la herramienta cuando no esté siendo usada, antes de prestarle servicio o cambiar de accesorio.

4) Use las mangueras y conectores apropiados. Nunca use acopladores de cambio rápido en la herramienta. En

cambio, adicione una manguera y un acoplador entre la herramienta y la fuente de aire.

FIGURE A

Herramienta

Manguera líder

Acoples

1/2 pul. (o mayor)

Tubos y

conectores

Manguera

de aire

Aceitera

Conector

Filtro

Drene a diario

Page 18

- 18 -- 18 -

PREPARACIÓN PARA EL USO

USO APROPIADO DE LA HERRAMIENTA

Su llave de impacto de 1/2 pul. fue diseñada para enroscar,

apretar y desapretar sujetadores roscados, usualmente

tuercas y tornillos, cuando tiene instalado un dado de impacto

apropiado.

Siempre use barras de extensión, acoples

universales y dados clasicados para llaves de

impacto entre el cuadrante de salida de la llave de impacto y el

cuadrante hembra del dado. No use la herramienta para ningún

otro propósito diferente al especicado sin consultar al

fabricante o al distribuidor autorizado del fabricante. El hacer

esto podrá ser peligroso.

Nunca utilice la llave de impacto como un martillo para quitar

o enderezar sujetadores con las roscas cruzadas. Nunca intente

modicar la herramienta para otros usos.

ESTACIONES DE TRABAJO

Su llave de impacto debe ser utilizada solo como una herramienta manual. Se recomienda que utilice

la herramienta cuando esté parado de manera rme y equilibrada. Se puede utilizar en otras posiciones

pero antes de darle tal uso, el operador debe estar en una posición segura y tener buen equilibrio y agarre

rme, y tener siempre presente que al aojar sujetadores la herramienta puede moverse rápidamente

fuera del sujetador que se está aojando. Se debe permitir siempre una tolerancia para este movimiento

hacia atrás para evitar que la mano, el brazo o el cuerpo quedan atrapados.

INTERRUPTOR DE MARCHA/REVERSO

Posición del interruptor para apretar sujetadores.

La potencia de la herramienta aumenta en los

números más altos.

R

F

use: Repetitive motions or

exposure to vibration may be

harmful to your hands or arms.

90psig (6.2bar) Maximum

Air Pressure.

Instruction Manual

.

Wear eye and ear protection.

use: Repetitive motions or

exposure to vibration may be

harmful to your hands or arms.

90psig (6.2bar) Maximum

Air Pressure.

Instruction Manual

.

Wear eye and ear protection.

Posición del interruptor para desapretar

sujetadores.

Cuadrante

de

1/2 pul.

Gatillo

Entrada de aire

torsió

n

marcha/

reverso

Palanca

de

marcha/

reverso

de

Page 19

- 19 -- 19 -

PUESTA EN SERVICIO

SUMINISTRO DE AIRE

Use una fuente de aire limpio y lubricado que proporcione una presión de aire

medida en la herramienta de 90 lbs./pul.² (6,2 bar) cuando la herramienta esté

funcionando con el gatillo completamente oprimido.

Utilice el tamaño de manguera recomendado. Se recomienda conectar la manguera al suministro de

aire como se muestra en la

figura A

en la página 17. No conecte la herramienta al sistema de la tubería

de aire sin incorporar una válvula de cierre de aire de fácil alcance y operación. Se debe lubricar el

suministro de aire. Se recomienda encarecidamente que utilice un lubricador y regulador de ltro de

aire, como se muestra en la

figura A

en la página 17, ya que este permitirá proporcionar aire limpio y

lubricado a la presión correcta en la herramienta. Se recomienda enérgicamente que se use un ltro

de aire, regulador,

lubricador (FRL)

tal como se muestra en la

Figura A

, ya que esto le suministrará a

la herramienta aire limpio y lubricado a la presión correcta. Los detalles de este equipo pueden ser

obtenidos donde su proveedor. Si no se usa tal equipo, entonces la herramienta deberá ser lubricada

desconectando la fuente de aire de la herramienta y despresurizando el conducto oprimiendo el gatillo

de la herramienta. Desconecte la tubería de aire y vierta 1 cucharadita (5 cc.) de aceite lubricante para

motor neumático adecuado en la entrada de aire, que incorpore preferentemente un inhibidor de

óxido. Conecte la fuente de aire en la herramienta y opérela lentamente por unos segundospara que

el aceite circule. Lubrique la herramienta diariamente si es usada frecuentemente, o cuando comience

a perder velocidad o potencia.

USO DE UNA HERRAMIENTA DE IMPACTO

1) Lea todas las instrucciones antes de usar esta herramienta. Todos los operadores deberán ser

entrenados completamente en su uso y estar informados sobre estas reglas de seguridad.

2) No exceda la máxima presión de aire de trabajo de 90 lbs./pul.² (6,2 bar).

3) Use equipos de seguridad personales.

4) Use únicamente aire comprimido en las condiciones recomendadas.

5) Si parece que la herramienta funciona mal, retírela de servicio y haga los arreglos necesarios para

repararla.

6) Si la herramienta es usada con un balanceador u otro dispositivo de soporte, asegúrese de que

esté seguramente sujetado.

7) Mantenga siempre sus manos alejadas del accesorio de trabajo instalado en la herramienta.

8) Esta herramienta no está aislada eléctricamente. Nunca use la herramienta si hay alguna

probabilidad de que entre en contacto con laelectricidad.

9) Cuando use la herramienta, siempre adopte una posición de pies rmes y agarre rmemente la

herramienta para contrarrestar cualquier fuerza o fuerzas de reacción que puedan ser generadas al

usar la herramienta.

10) Utilice solo piezas de repuesto Dewalt o piezas que presten un servicio equivalente. No realice

arreglos temporales o permanentes con partes no autorizadas.

11) No trabe, pegue con cinta adhesiva, amarre con alambre el gatillo en la posición de marcha. El

gatillo siempre deberá estar libre para regresar a la posición de “apagado” al ser soltado.

12) Siempre cierre la fuente de aire de la herramienta y oprima el gatillo para aliviar el aire de la

manguera de alimentación antes de ajustar o remover el accesorio de trabajo.

13) Revise regularmente las mangueras y conectores para ver si están desgastados. Reemplácelos

si es necesario. No transporte la herramienta agarrándola por la manguera.Asegúrese de retirar su

mano del gatillo cuando transporte la herramienta con la fuente de aire conectada.

14) Tenga cuidado de no enredar ninguna pieza de la herramienta en la ropa, corbata, cabello, trapos

de limpieza, etc. Esto causará que el cuerpo sea atraído hacia la herramienta lo cual puede ser muy

peligroso.

15) Se espera que los usuarios adopten prácticas de trabajo seguras y observen todos los requisitos

egales relevantes al instalar, usar o darle mantenimiento a la herramienta.

16) Sólo instale la herramienta cuando tenga un interruptor de encendido/apagado fácilmente

accesible y operable en la fuente de aire.

17) Tenga cuidado para que el escape de aire de la herramienta no cause problemas o sople en

dirección a otra persona.

18) Nunca recueste la herramienta a menos que el accesorios de trabajo haya dejado de moverse.

19) Asegúrese siempre de que el interruptor de marcha adelante/reverso esté en la posición deseada

antes de arrancar la herramienta.

20) No use dados con desgaste excesivo en la cabeza motriz de entrada o de salida. Revise

periódicamente el cuadrante de la llave de impacto. Asegúrese de que el dado, barra de extensión u

otro aditamento quede asegurado rmemente antes de operar la herramienta.

21) Al aflojar sujetadores asegúrese primero que haya suficiente espacio libre detrás de la

herramienta para evitar que le atrape la mano. La herramienta se alejará de la junta roscada a medida

que la tuerca o tornillo es aojado ysale de la rosca, moviendo la herramienta con el sujetador.

Page 20

- 20 -

- 20 -

LISTA DE CONTROL PREVIA A LA PUESTA EN MARCHA

• Drene el agua del tanque del compresor de aire y la condensación de las mangueras de aire. (Por favor

consulte el manual de operación del compresor).

• Lubrique la herramienta.

• Seleccione los tubos de impacto necesarios. Los tubos deben coincidir con el tamaño del impulsor en la

llave neumática de impacto.

• Conecte la llave de impacto neumática a la fuente de aire con la manguera del tamaño recomendado.

Riesgo de operación insegura. Sostenga la manguera firmemente con las manos al

instalarla o desconectarla para evitar la desconexión repentina de la manguera.

Riesgo de rotura. Una presión de aire excesiva puede causar un riesgo de estallido

peligroso. Controle el valor nominal máximo de presión del fabricante para las

herramientas y los accesorios neumáticos. La presión de salida del regulador nunca debe exceder la

presión de servicio máxima.

PROCEDIMIENTOS OPERATIVOS

PUESTA EN MARCHA (FIG. 1, PG.13)

• Encienda el compresor de aire y permita que el tanque de aire se llene.

• Ajuste el regulador del compresor de aire a 90 PSI. Esta herramienta neumática funciona a una presión

de servicio máxima de 90 PSI.

• Ajuste el cuadrante de potencia (si está disponible) al par de apriete deseado.

• Ajuste la herramienta en la posición de avance o retroceso.

Consulte Características en la página 18 para

ver el diagrama.

• Presione el gatillo para comenzar a utilizar la herramienta.

APAGADO (FIG. 1, PG.13)

• Libere el gatillo para dejar de utilizar la herramienta.

• Al cambiar los casquillos, desconecte siempre el suministro de aire para evitar lesiones.

• Una vez que haya completado el trabajo, apague el compresor y almacene la herramienta neumática

después de haberla lubricado.

NOTICE D’EMPLOI

• Ajuste rmemente el casquillo o el accesorio a la llave de impacto.

• Compruebe que el interruptor de avance/retroceso esté en la posición correcta para apretar o aojar el

sujetador.

• La tuerca/El perno puede enroscar utilizando el encastre impulsor de la herramienta. Para aojar una

unión, la herramienta se puede utilizar en la secuencia inversa.

MANTENIMIENTO

GRAISSAGE

Les outils pneumatiques doivent être graissés pendant toute la vie des outils. Le moteur pneumatique

et les coussinets utilisent l’air comprimé pour actionner l’outil et comme l’humidité de l’air comprimé

entraîne la formation de rouille sur le moteur et les pièces intérieures de l’outil, il faut graisser l’outil

tous les jours. Tout manquement à graisser les outils correctement réduira fortement la vie de l’outil et

annulera la garantie.

Il faut graisser l’outil AVANT l’emploi initial, avant et après chaque usage additionnel.

POUR GRAISSER L’OUTIL PNEUMATIQUE À LA MAIN :

1. Débrancher l’outil de la source d’alimentation d’air, placer les entrées d’air vers le haut.

2. Retirer l’accessoire de la prise de l’outil pneumatique, comme les douilles, les ciseaux, etc.

3. Presione el gatillo y coloque alrededor de 1 cucharadita (5 cc.) de aceite para herramienta neumática en

la entrada de aire. (Presionar el gatillo ayudará a hacer circular el aceite en el motor.)

Remarque: Utiliser l’huile SAE n˚10 si l’huile à outil pneumatique n’est pas disponible.

4. Conecte la herramienta en una fuente de aire, cubra el extremo de escape con una toalla y hágalo

funcionar entre 20 y 30 segundos.

Page 21

- 21 -- 21 -

GLOSARIO

CFM:

Pies cúbicos por minuto.

PSI:

Libras por pulgada cuadrada; una unidad de medida de presión.

SCFM:

pies cúbicos estándar por minuto; unidad de medida de suministro de aire.

Certificación de código:

Los productos que tienen una o más de las indicaciones siguientes:

UL, CUL,

ETL, CETL,

han sido evaluados por los laboratorios de seguridad independientes certicados de

OSHA

y

cumplen los estándares de seguridad de Underwriters Laboratories cuya aplicación corresponda.

RPM:

Revoluciones por minuto; es una medida de la frecuencia de rotación.

BPM:

Golpes por minuto (del inglés, Beats Per Minute).

NPT:

Rosca de tubería nacional (del inglés, National Pipe Thread) (rosca cónica); es un estándar de

EE. UU.

para roscas cónicas utilizadas en caños y accesorios roscados.

ID:

Diámetro interno

MANTENIMIENTO

Gardez hors de la portée des enfants. En cas d’ingestion, ne pas provoquer de

vomissement, appelez un médecin immédiatement.

L’excédent d’huile dans le moteur est immédiatement expulsé par l’orifice

d’échappement. Toujours éloigner l’orifice d’échappement des gens ou objets.

RANGEMENT

Il faut graisser l’outil pneumatique avant de le ranger. Se reporter aux instructions sur le« Graissage » en

omettant l’étape 4.

Page 22

- 22 -

INTRODUCTION

• 500 pi-lb de couple pour retrait rapide des boulons tenaces

• Vitesse en régime libre de 7 200 rpm

• Échappement dans le manche pour éloigner l’air du visage et de la zone de travail

• Commande réversible et gâchette de vitesse variable

• Applications suggérées : Pour le retrait des écrous de roue, des écrous, des boulons et des tire-fond.

• Pression de fonctionnement maximale : 90 psi

TABLE DES MATIÈRES

Garantie limitée de 3 ans .......................................................... 22

Composants de l'outil,

Especicacispécications de l’outil .......................................... 23

Dénitions : lignes directrices en matière de sécurité,

Directives de sécurité importantes ........................................... 24

Avertissement ...........................................................................25-26

Arrivée d’air et raccords, installation,

règles de sécurité pour les outils pneumatiques .................... 27

Emploi correct de l’outil ............................................................ 28-29

Notice d’emploi .......................................................................... 30

Entretien ..................................................................................... 31

IMPORTANT

S’assurer que l’utilisateur de l’outil lit attentivement et comprend ces instructions avant d’utiliser l’outil.

GARANTIE LIMITÉE DE 3 ANS

Stanley garantit ce produit à l’acheteur d’origine pendant une période de

TROIS (3) ANS

contre les défauts

de matériaux et de main d’œuvre. Cette

GARANTIE LIMITÉE

ne couvre pas les produits qui ont été mal

utilisés, abusés, modiés ou réparés. Les produits défectueux seront remplacés ou réparés au choix de

Stanley. Veuillez appeler le

1-800-505-4648

pour plus de renseignements ou au sujet desinstructions de

renvoi.

CETTE GARANTIE LIMITÉE EST DONNÉE EN LIEU DE TOUTES AUTRES, Y COMPRIS LES

GARANTIESTACITES D’APTITUDE À ÊTRE VENDU ET UTILISÉ À UN BUT PARTICULIER, ET EXCLUT TOUS

LES DÉGÂTS SECONDAIRES OU CONSÉQUENTS.

Quelques états ne permettent pas de limites sur la

durée de garanties tacites ou sur l’exclusion ou la limitation des dégâts secondaires ou conséquents,

donc il se peut que ces limitations ne s’appliquent pas à vous.

Cette GARANTIE LIMITÉE

vous procure des

droits spéciques qui peuvent varier d’un état à l’autre.

DIRECTIVES DE SÉCURITÉ – DÉFINITIONS

Ce manuel contient des informations qu’il est important de connaître et de comprendre. Cette

information porte sur

VOTRE SÉCURITÉ

et sur la

PRÉVENTION DES PROBLÈMES D’OUTIL

. Pour vous

aider à reconnaître cette information, nous utilisons les symboles ci-dessous. Veuillez lire ce manuel

attentivement et accorder une attention particulière à ces paragraphes.

SÉCURITÉ et PRÉVENTION DES PROBLÈMES D’OUTIL

Pour vous aider à reconnaître cette information,

nous utilisons les symboles ci-dessous. Veuillez lire ce manuel attentivement et accorder une attention

particulière à ces paragraphes.

Indique une situation

dangereuse imminente

qui, si elle n’est pas évitée,

causera

le

décès ou une blessure grave

.

Indique une situation

dangereuse potentielle qui,

si elle n’est pas évitée,

peut

causer une

blessure

mineure ou modérée

.

Indique une situation

dangereuse potentielle qui, si elle

n’est pas évitée,

pourrait

causer le

décès ou

une blessure grave

.

Utilisé sans le symbole d’alerte de

sécurité indique une situation dangereuse

potentielle si, si elle n’est pas évitée,

peut

causer

des

dommages aux biens

.

Page 23

- 23 -

COMPOSANTS DE L'OUTIL

BTMT72391

Description

Prise ½ po Clé à choc

Consommation moyenne d’air

3,9 pi3/min Usage à 100 %

Mécanisme

Marteau jumelé

Régime en tr/min maximum

7 200

Torsion maximale

500 pi-lb

Entrée d’air

Taraudage de 6,35mm NPT (F)

Poids

5,95 lb

Taille minimale du tuyau

9,5 mm (3/8 po)

Carré d’entraînement

12,7 mm (1/2 po)

Échappement

Poignée

Pression requise en lb/po2 (PSI)

90

Gâchette

Réversible

Entrée d’air

Levier

réversible du

couple

Carréd’

entraînement

½ po

ESPECIFICACISPÉCIFICATIONS DE L’OUTIL

Les mesures sont métriques suivies de mesures impériales entre parenthèses.

FIG.1

Page 24

- 24 -

Définitions : lignes directrices

en matière de sécurité

Les définitions ci-dessous décrivent le niveau de

gravité pour chaque symbole. Veuillez lire le mode

d’emploi et porter une attention particulière à ces

symboles.

DANGER : Indique une situation dangereuse

imminente qui, si elle n’est pas évitée, causera la

mort ou des blessures graves.

AVERTISSEMENT : Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée,

pourrait se solder par un décès ou des blessures

graves.

ATTENTION : Indique une situation potentielle-

ment dangereuse qui, si elle n’est pas évitée pourrait

se solder par des blessures mineures ou modérées.

ATTENTION : Utilisé sans le symbole d’alerte à la

sécurité, indique une situation potentiellement dangereuse qui, si elle n’est pas évitée pourrait se solder

par des dommages à la propriété.

DIRECTIVES DE SÉCURITÉ

IMPORTANTES

Nertaines poussières produites par les

travaux de ponçage, sciage, meulage, perçage et autres

peuvent contenir des produits chimiques pouvant selon l’état

de Californie causer le cancer, des anomalies congénitales ou

d’autres problèmes liés aux fonctions reproductrices. Voici

quelques exemples de ces produits chimiques :

• le plomb contenu dans les peintures à base de plomb;

• la silice cristalline provenant de la brique, du ciment et

d’autres produits de maçonnerie;

• l’arsenic et chrome provenant de bois traité chimiquement.

Les risques reliés à l’exposition à ces poussières varient

selon la fréquence à laquelle l’utilisateur travaille avec ce type

de matériaux. Pour réduire votre exposition à ces produits

chimiques : travailler dans un endroit bien ventilé et porter un

équipement de sécurité approuvé par

l’OSHA/MSHA/NIOSH

comme un masque anti-poussières spécialement adapté ou

un respirateur lors de l’utilisation de ces outils.

Lors de l’utilisation d’outils pneumatiques, des précautions

de base en matière de sécurité doivent être suivies afin de

réduire le risque de blessure personnelle.

Ce produit contient des produits chimiques, notamment le

plomb, reconnus par l’État de Californie comme étant cancérigènes et pouvant entraîner des anomalies congénitales et

d’autres dangers relatifs à la reproduction. Se laver les mains

après toute manipulation.

CONSERVER CES INSTRUCTIONS

a mauvaise utilisation ou maintenance de ce

produit peut causer des blessures graves Et des

dommages sérieux aux biens. Il faut lire et

comprendre tous les avertissements et la. Notice

d’emploi avant d’utiliser cet équipement. Lorsque vous

utilisez des outils pneumatiques, il faut respecter les mesures

de sécurité fondamentales pour réduire leRisque de

blessures.

l faut lire et comprendre ce guide d’instructions et les

étiquettes de l’outil avant d’installer, d’utiliser cet outil

ou d’en faire l’entretien. Gardez ces instructions dans

un lieu sûr à portée de la main.

Les opérateurs et autres personnes dans la zone de

travail doivent porter des lunettes de sécurité avec

écrans latéraux approuvées

ANSI Z87.1 CAN/CSA

Z94.3

.

Les utilisateurs et les gens dans la zone de travail

doivent porter une protection auditive.

Graissez tous les jours pour un rendement optimal.

• Évitez l’utilisation prolongée : le mouvement répétitif

ou l’exposition aux vibrations peuvent être nocifs pour

vos mains ou vos bras. Utiliser des gants pour offrir un

maximum de protection, prendre des pauses fréquentes et limiter le temps d’utilisation quotidien.

• N’utilisez pas de gaz oxygène ou réactif; une explosion

peut survenir.

• Ne pas excéder une pression d’air de 90 psi.

• Il faut lire attentivement tous les livrets inclus avec ce

produit. Il faut bien se familiariser avec les commandes

et l’emploi correct de l’équipement.

• Seules les personnes qui connaissent bien ces règles

de sécurité devraient utiliser l’outil pneumatique.

• Il ne faut pas excéder la pression limite des composantes du système.

• Débrancher l’outil pneumatique de l’arrivée d’air avant

de changer les outils ou les accessoires et lorsqu’il

n’est pas utilisé.

• Il faut toujours porter des lunettes de protection et une

protection auditive durant l’emploi.Il faut toujours

porter des lunettes de protection avec écrans latéraux.Il

faut toujours porter une protection auditive.

• Il ne faut jamais porter des vêtements amples ou un

habillement comportant des attaches ou bretelles

lâches, etc. qui pourraient être happées par les pièces

mobiles de l’outil et causer des blessures graves.

• Il ne faut pas porter de bijou, montre, identification,

bracelet, collier, etc. lorsque vous utilisez l’outil, car ils

pourraient être happés par les pièces mobiles de l’outil

et causer des blessures graves.

• Il ne faut pas abaisser la gâchette lorsque vous raccordez l’outil au boyau d’air d’arrivée.

• Toujours utiliser un accessoire conçu pour les outils

percuteurs pneumatique.

• Il ne faut jamais utiliser des accessoires endommagés